Konica Minolta DF-217 User Manual

SERVICE MANUAL

Model

DF-217

Used on models 7115/7118

DECEMBER 2001

CSM-DF217

KONICA BUSINESS TECHNOLOGIES, INC.

DF-217

SERVICE MANUAL

DECEMBER 2001

Used on Konica Models

7115/7118

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced

person servicing this equipment, as well as the risk of

damage to the equipment, Konica Business Technologies strongly recommends that all servicing be performed by Konica-trained service technicians only.

Changes may have been made to this equipment to

improve its performance after this service manual was

printed. Accordingly, Konica Business Technologies,

Inc., makes no representations or warranties, either

expressed or implied, that the information contained in

this service manual is complete or accurate. It is understood that the user of this manual must assume all risks

or personal injury and/or damage to the equipment while

servicing the equipment for which this service manual

is intended.

Corporate Publications Department

© 2001, KONICA BUSINESS TECHNOLOGIES, INC.

All rights reserved.

Printed in U.S.A.

CONTENTS

GENERAL, MECHANICAL/ELECTRICAL

1. SPECIFICATIO NS .............. ........... ................ ............... ............... ............... ..... M-1

2. EXTERIOR VIEW ................................................. ...........................................M-2

3. CROSS-SEC TION AL VIEW .............. ............... ................ ............... ............... .M-3

4. DRIVE SYSTEM ..............................................................................................M-4

5. ELECTRICAL COMPONENT LAYOUT ...........................................................M-5

6. MODES ........ .... ....... ........ ........ ....... ........ .... ....... ........ ........ ....... ........ ........ ... .....M-6

6-1. Standard M od e ........... ............... ............... ................ ............... ............... .M-6

6-2. Mixed Origin al D et ection Mode ..................... ................ ... ................ ........M -6

7. TAKE-UP SECTION ........................................................................................M-7

7-1. Document Take-U p and Fee d Mec ha ni sm ........... .... .... ............... .... ........M- 7

7-2. Document Separating Mechanism ...........................................................M-8

8. TRANSPORT/EXIT MECHANISM ...................................................................M-9

8-1. Document Transport Mechanism .............................................................M-9

8-2. Document Exit Mechanism ......................................................................M-10

9. OTHER FEATURES ........................................................................................M-11

9-1. Document Size Det ectio n M echa ni sm ... ............... .... ............... ............... .M-11

9-2. Raised/Lowered Position Detection Mechanism .....................................M-11

DIS/REASSEMBLY, ADJUSTMENT

1. MAINTENANCE SCHEDULE ..........................................................................D-1

2. DISASSEMBLY ...............................................................................................D-2

2-1. Removal of the Exterior Covers ...............................................................D-2

2-2. Removal of the Pi ck -U p Rol ler/Take-Up R o lle r ........ ............... ................D-3

2-3. Removal of the Separator Roller .............................................................D-4

2-4. Cleaning of the Registration R o lle r /Rolls .......... ............... ................ ........D-4

2-5. Cleaning of the Exit Roller/Rolls ..............................................................D-5

3. ADJUSTMENT ............ .... ............... .... .... ............... .... ............... .... ............... .... .D-6

3-1. Adjust Mode Se tti ng Pr o c ed ure .................... ................ ............... ............D-6

3-2. Height Adjustment ...................................................................................D-6

3-3. Leading Edge Skew Adjustment ..............................................................D-7

3-4. Zoom Adju st me nt an d R eg is tra tion Adjustm e nt ........... ............... ............D-8

(1) FD Zoom Ratio Adjus tm e nt ....... .... ... ................ .... ............... .... ........D-8

(2) CD Registration Adjustment ............................................................D-9

(3) FD Registration Adjustme nt .......................... ...................................D - 10

TECH. REP. MODE

1. TECH. REP. M OD E .... .... ............... .... ............... .... ................ ... ................ ... .....S-1

1-1. Tech. Rep. Mode Setting Procedure .......................................................S-1

1-2. ADF Document Passage Test .................................................................S-1

1-3. ADF Original Glass Check .......................................................................S-1

TROUBLESHOOTING

1. MISFEED DETECTION TIMING AND MISFEED TROUBLESHOOTING

PROCEDURES ...............................................................................................T-1

1-1. Misfeed Dete ctio n Tim in g ...................... ............... .... ............... ............... .T-1

1-2. Misfeed Troub les h ootin g Proc e du res ............... .... .... .... ... ................ ... .....T-2

iii

iv

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

Installation Environment

Safety considerations usually are directed toward

machine design and the possibility of human error. In

addition, the environment in which a machine is operated must not be overlooked as a potential safety

hazard.

Most electrical equipment is safe when installed in a

normal environment. However, if the environment is

different from what most people consider to be normal, it is conceivable that the combination of the

machine and the room air could present a hazardous

combination. This is because heat (such as from

fusing units) and electrical arcs (which can occur

inside switches) have the ability to ignite flammable

substances, including air.

When installing a machine, check to see if there

is anything nearby which suggests that a potential hazard might exist. For example, a laboratory

might use organic compounds which, when they

evaporate, make the room air volatile. Potentially dangerous conditions might be seen or smelled. The

presence of substances such as cleaners, paint thinners, gasoline, alcohol, solvents, explosives, or similar items should be cause for concern.

If conditions such as these exist, take appropriate

action, such as one of the following suggestions.

know what effect may be caused by altering any

aspect of the machine’s design. Such changes have

the potential of degrading product performance and

reducing safety margins.

For these reasons, installation of any modification not

specifically authorized by Konica Business Machines

U.S.A., Inc., is strictly prohibited.

The following list of prohibited actions is not all-inclusive, but demonstrates the intent of this policy.

• Using an extension cord or any unauthorized

power cord adapter.

• Installing any fuse whose rating and physical size

differs from that originally installed.

• Using wire, paper clips, solder, etc., to replace or

eliminate any fuse (including temperature fuses).

• Removing (except for replacement) any air filter.

• Defeating the operation of relays by any means

(such as wedging paper between contacts).

• Causing the machine to operate in a fashion other

than as it was designed.

• Making any change which might have a chance

of defeating built-in safety features.

• Using any unspecified replacement parts.

• Determine that the environment is controlled

(such as through the use of an exhaust hood) so

that an offending substance or its fumes cannot

reach the machine.

• Remove the offending substance.

• Install the machine in a different location.

The specific remedy will vary from site to site, but the

principles remain the same. To avoid the risk of injury

or damage, be alert for changes in the environment

when performing subsequent service on any machine, and take appropriate action.

Unauthorized Modifications

Konica equipment has gained a reputation for being

reliable products. This has been attained by a combination of outstanding design and a knowledgeable

service force.

The design of the equipment is extremely important.

It is the design process that determines tolerances

and safety margins for mechanical, electrical, and

electronic aspects. It is not reasonable to expect

individuals not involved in product engineering to

General Safety Guidelines

This equipment has been examined in accordance

with the laws pertaining to various product safety

regulations prior to leaving the manufacturing facility

to protect the operators and service personnel from

injury. However, as with any operating device, components will break down through the wear-and-tear of

everyday use, as will additional safety discrepancies

be discovered. For this reason, it is important that the

technician periodically performs safety checks on the

equipment to maintain optimum reliability and safety.

The following checks, not all-inclusive, should be

made during each service call:

CAUTION: Avoid injury. Ensure that the equipment is

disconnected from its power source before continuing.

• Look for sharp edges, burrs, and damage on all

external covers and copier frame.

• Inspect all cover hinges for wear (loose or bro-

ken).

• Inspect cables for wear, frays, or pinched areas.

v

SAFETY PRECAUTIONS

• Ensure that the power cord insulation is not dam-

aged (no exposed electrical conductors).

• Ensure that the power cord is properly mounted

to the frame by cord clamps.

• Check the continuity from the round lug (GND) of

the power cord to the frame of the copier -- ensure

continuity. An improperly grounded machine can

cause an electrically-charged machine frame.

Safeguards During Service Calls

Confirm that all screws, parts, and wiring which are

removed during maintenance are installed in their

original positions.

• When disconnecting connectors, do not pull the

wiring, particularly on AC line wiring and high

voltage parts.

• Do not route the power cord where it is likely to

be stepped on or crushed.

• Carefully remove all toner and dirt adhering to any

electrical units or electrodes.

• After part replacement or repair work, route the

wiring in such a way that it does not contact any

burrs or sharp edges.

• Do not make any adjustments outside of the

specified range.

Applying Isopropyl Alcohol

Care should be exercised when using isopropyl alcohol, due to its flammability. When using alcohol to

clean parts, observe the following precautions:

• Remove power from the equipment.

• Use alcohol in small quantities to avoid spillage

or puddling. Any spillage should be cleaned up

with rags and disposed of properly.

• Be sure that there is adequate ventilation.

• Allow a surface which has been in contact with

alcohol to dry for a few minutes to ensure that the

alcohol has evaporated completely before applying power or installing covers.

Summary

It is the responsibility of every technician to use professional skills when servicing Konica products. There

are no short cuts to high-quality service. Each piece

of equipment must be thoroughly inspected with respect to safety considerations as part of every routine

service call. The operability of the copier, and more

importantly, the safety of those who operate or service

the equipment, are directly dependent upon the conscientious effort of each and every technician.

Remember...when performing service calls, use good

judgment (have a watchful eye) to identify safety

hazards or potential safety hazards that may be present, and correct these problem areas as they are

identified -- the safety of those who operate the equipment as well as those who service the copier depend

on it!

vi

GENERAL,

MECHAN ICAL/ELECTRICAL

1. SPECIFICATIONS

Name : Automatic Document Feeder

Installation : Inserted in top portion in the rear of copier

Type of Do cume n t :

Detectable Document

Size

Capacity :

Document Alignment : Center

Document Loading : Face up

Document Exchan ge

Speed

Modes : Standard

Power Require m en ts : DC24 V, DC5 V (suppl ie d f rom t he c op ier)

Max. Power Consumption : 36 W or less

Dimensions : Width: 602 mm or 23-3/4

Weight : 5.5 kg or 12-1/4 lbs.

Operati n g E nv ir o nment : Same as copier

Type of Originals Not

Guaran teed for Reliable

Feeding

Plain pa pe r (Sta ndar d : 50 to 11 0g/m

Mixed Original: 60 to 90 g/m

: Metric Areas:A5R, B5/B5R, A4/A4R, B4R, A3R, 11 × 8-1/2,

Inch Areas:5-1/2 × 8-1/2R, 11 × 8-1/2, 8-1/2 × 11R,

50 sheets max. (80 g/m

: 15 sheets/min. (A4)

18 sheets/min. (A4)

Mixed Original (only for originals with the same width)

Depth: 502 mm or 19-3/4

Height: 101 mm or 4

8-1/2 × 11R, F4

8-1/2 × 14R, 11 × 15, 11 × 17

2

)

2

or 13-1 / 4 to 29 - 1/4 l bs . ,

2

or 16 to 24 lbs.)

Type of Original Possible Trouble

Sheets stapled or clipped together Take-up failure, damaged sheet, defective

drive mechanism due to jammed staples or

clips.

Sheets glued toget her Ta ke-up f ailure, dama ged sheet

Sheets folded, torn, or wrinkled Ta ke-up failure, damaged sheet

Sheets severely curled Sheets misfeed due to being dog-eared or

fed in askew

M-1

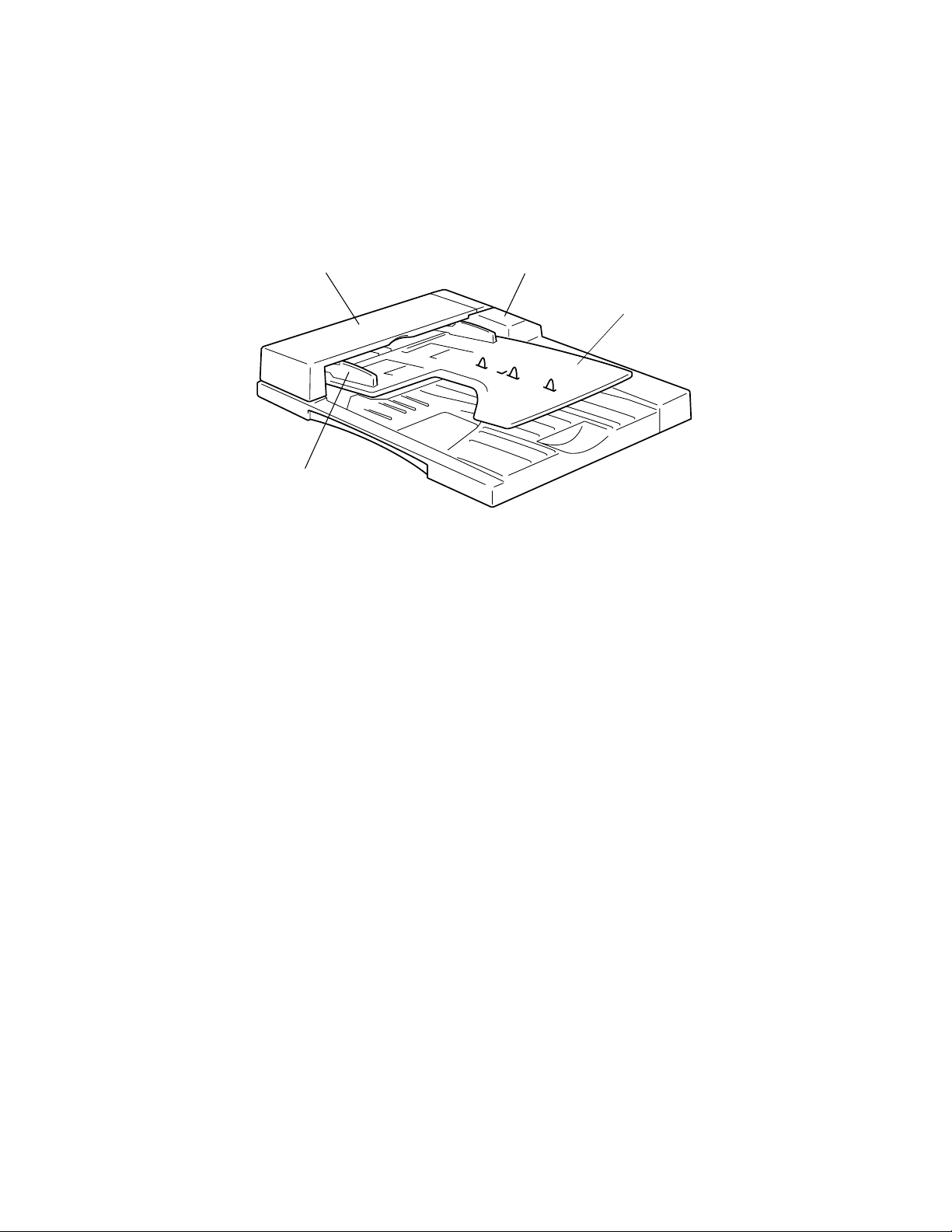

2. EXTERIOR VIEW

12

4

1. Take-Up C ove r 3. Doc um e nt Loading Tray

2. Rear Cover 4. Document Edge Guide

3

4688M507CA

M-2

3. CROSS-SECTIONAL VIEW

12 3

8

7

456

1. Take-Up Roller 5. Registration Rollers

2. Pick-Up Roller 6. Registration Rolls

3. Exit Rollers 7. Transport Rolls

4. Exit Ro lls 8. Separat or Roller

4688M504CA

M-3

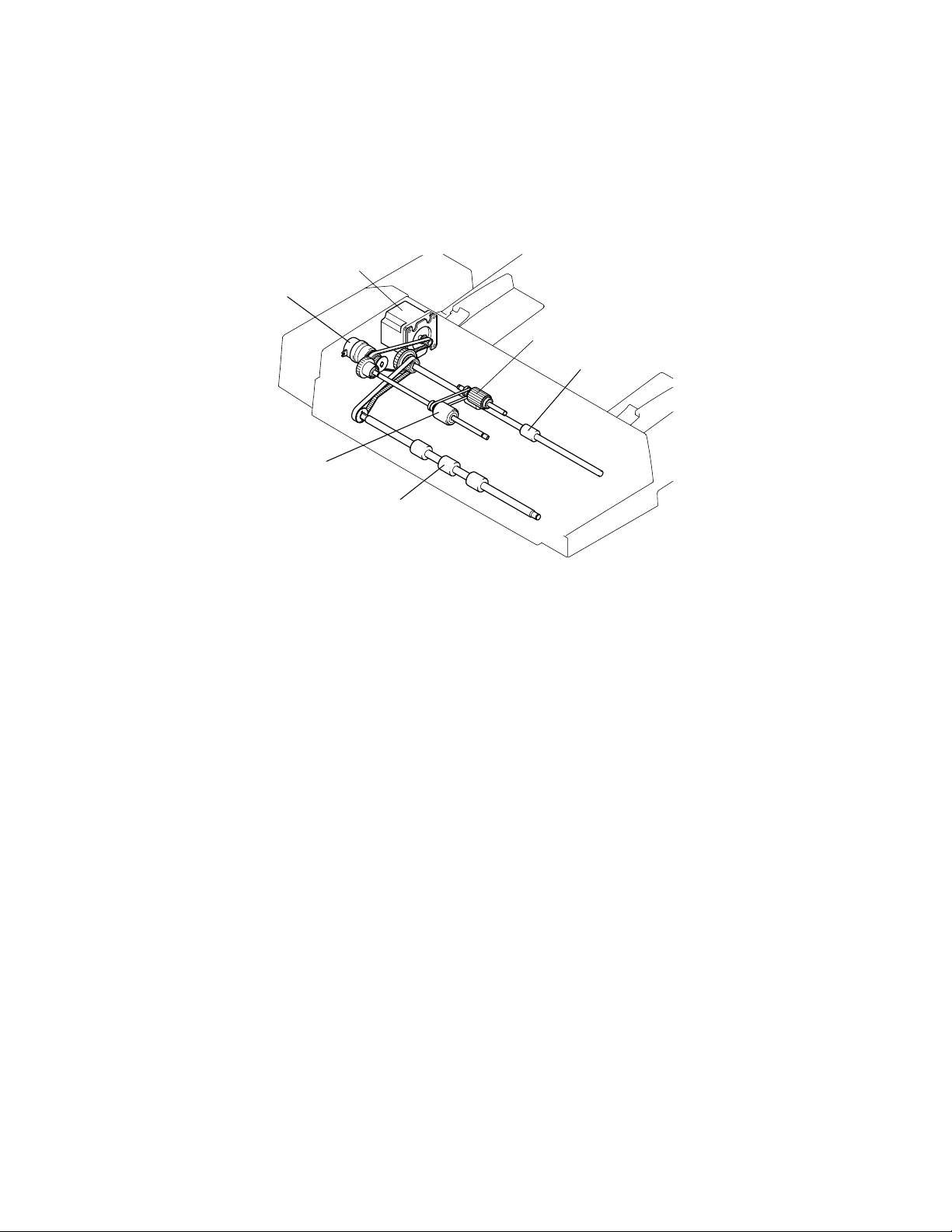

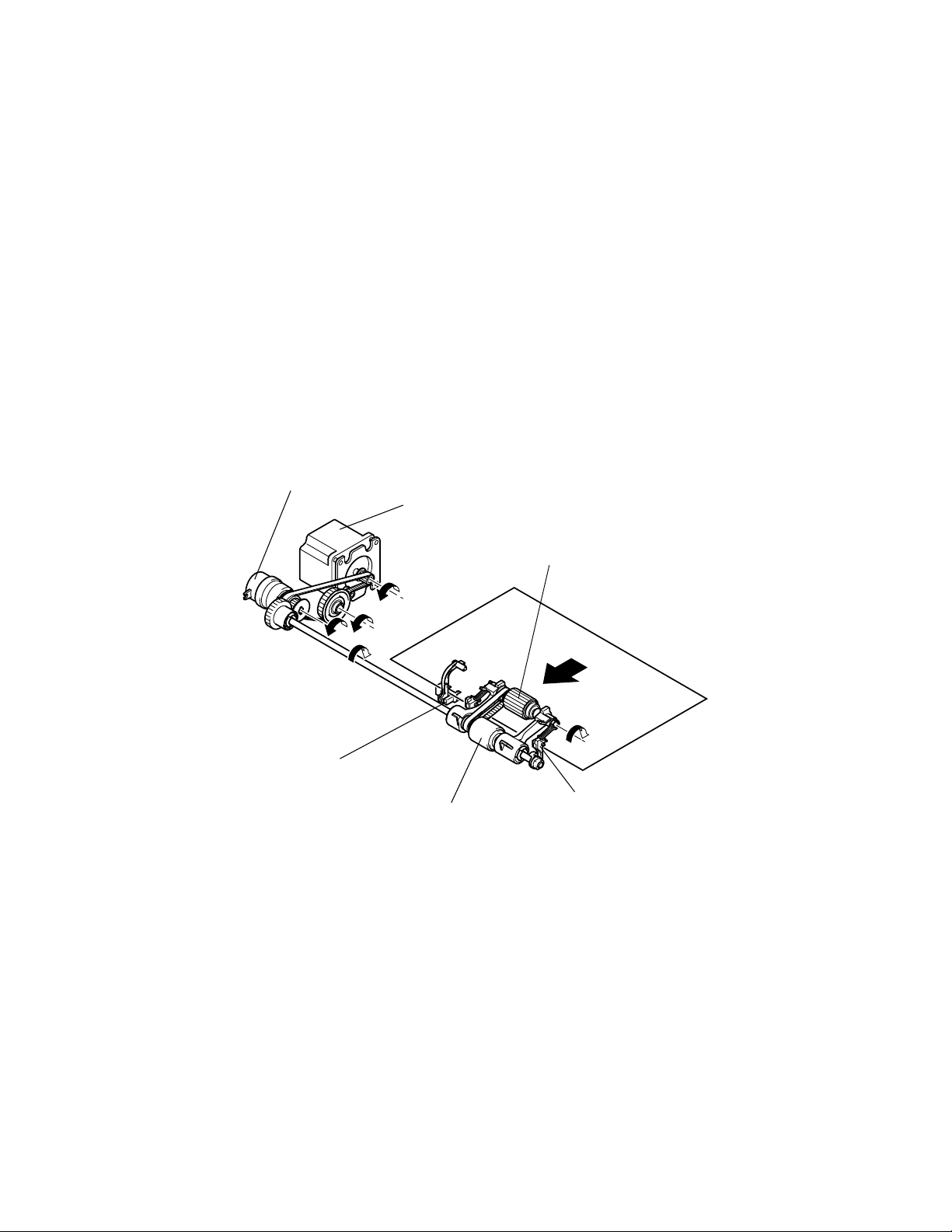

4. DRIVE SYSTEM

1

6

5

4

1. Main M o t or 4. Reg is tr ati on Roll ers

2. Pick-Up Roller 5. Take-Up Roller

3. Exit Rollers 6. Take-Up Clutch

2

3

4688M502AA

M-4

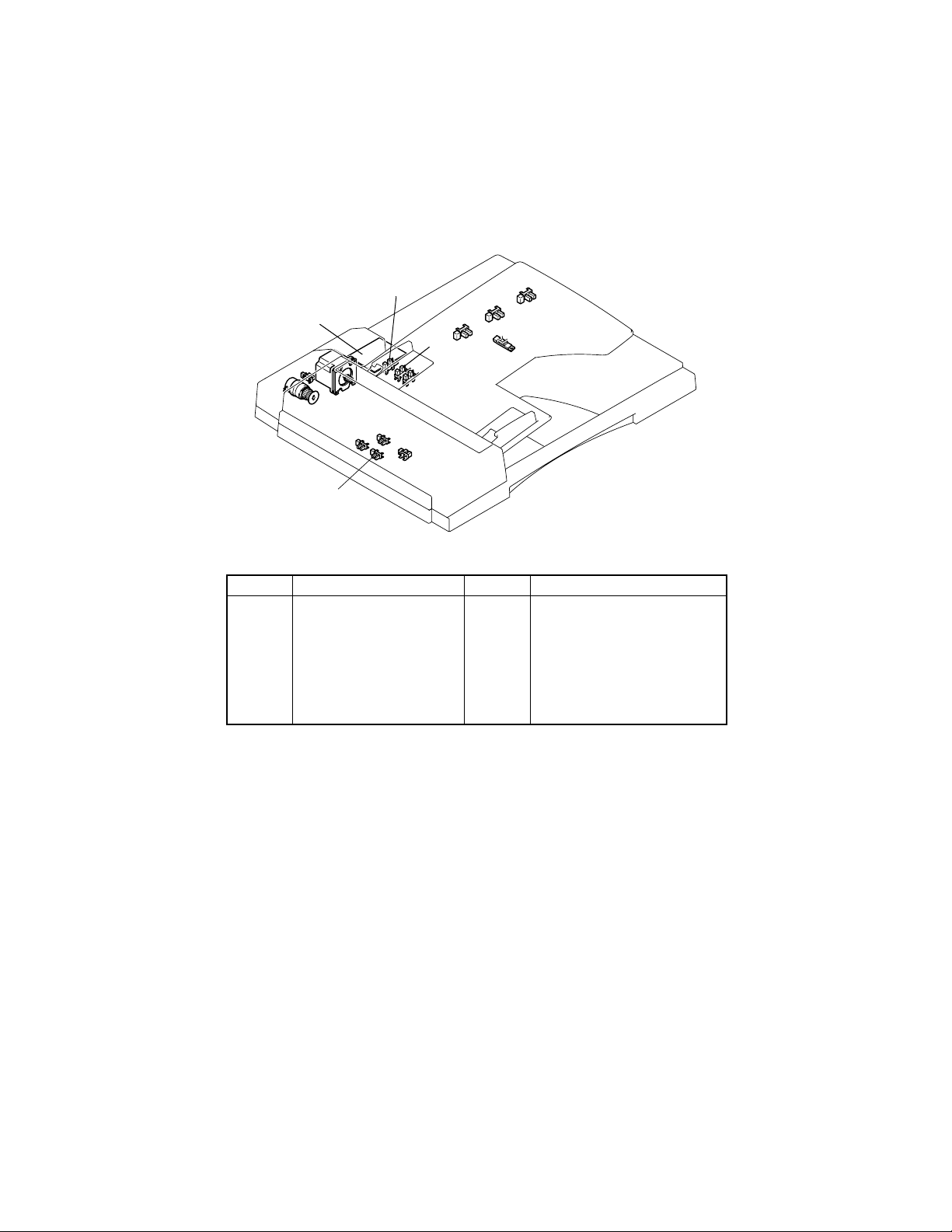

5. ELECTRICAL COMPONENT LAYOUT

PC12

PWB

PC1

CL1

PC2

PC4

PC3

Symbol Name Symbol Name

PWB

CL1

PC1

PC2

PC3

PC4

✽ PC9: In ch area only

✽ PC10: Metric area only

Interface Board

Main Motor

M1

Paper Take-Up Clutch

Take-Up Cover Open/Close

Detecting Sensor

Paper Empty Sensor

Registration S ensor

Separator Sensor

PC6

PC11

PC10

PC5

PC8

PC5

PC6

PC7

PC8

PC9

PC10

PC11

PC12

PC9

PC7

Paper Exit Sensor

Length Si ze D etection Se n s or 1

Length Si ze D etection Se n s or 2

Length Si ze D etection Se n s or 3

Length Si ze D etection Se n s or 4

Width S ize D etection Sensor 1

Width S ize D etection Sensor 2

Width S ize D etection Sensor 3

4688M505CA

M-5

6. MODES

6-1. Standard Mode

• When a multi-page document is being copied, the copier detects the size of only the first

page of the document and copies the subsequent pages based on that size detection.

• This saves the copier th e t ime required for detecting the sizes of the subsequent pages

of the document, making for faster paper feed timing.

6-2. Mixed Original Detection Mode

• The copier detec t s t he si ze of each pag e of the docu ment and, according to th e size

detected, feeds the paper of the corresp onding s ize selec ted from a m ong the avai labl e

paper sources for making copies.

• This mode is used when making copies from a document set consistin g of pages of varying leng th, but of th e sa me width.

M-6

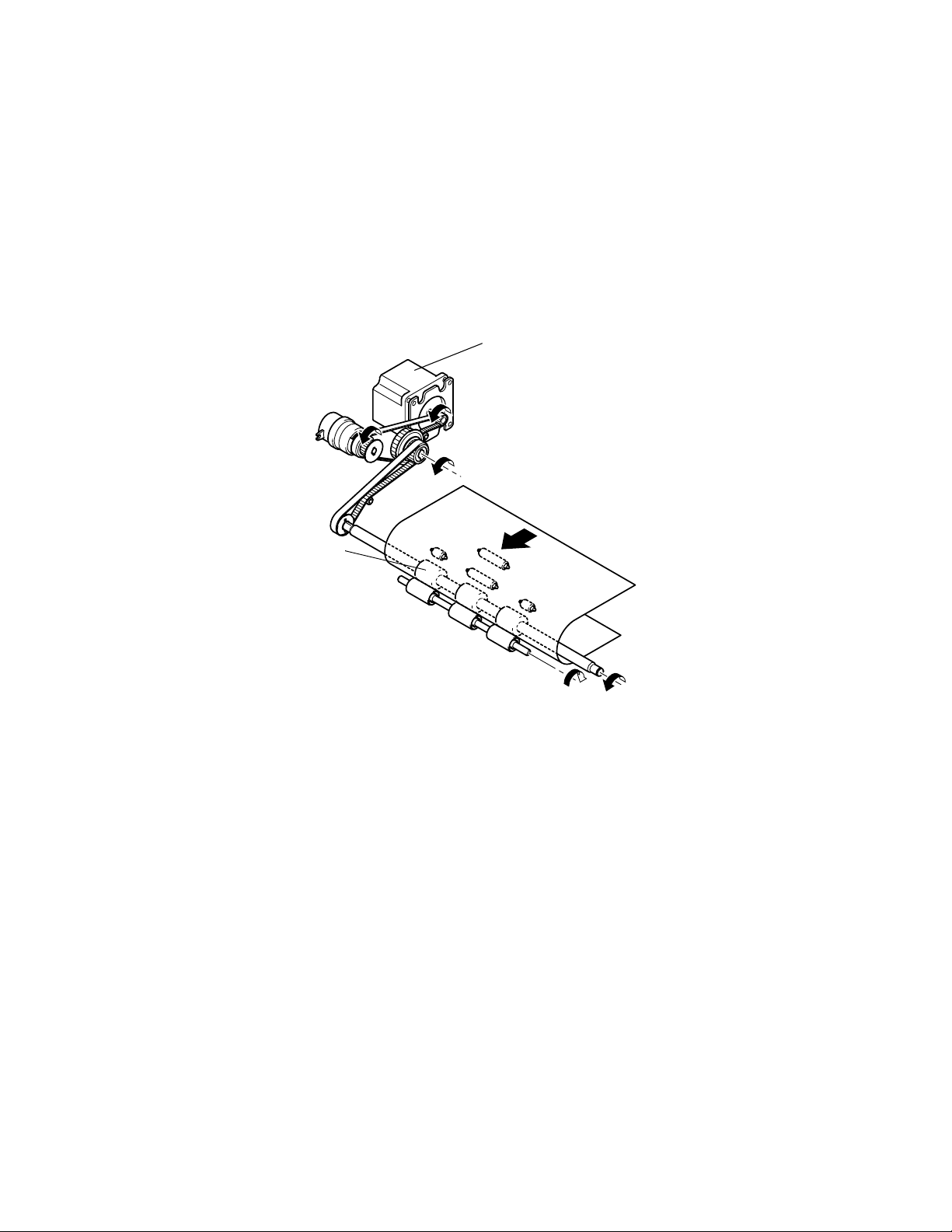

7. TAKE-UP SECTION

7-1. Document Take-Up and Feed Mechanism

• The document is taken up as the Pick-Up Roller and Take-Up Roller turn.

• The Pick-Up R oller tran s port s the docu ment up to the Take-Up Roller.

• After a scan is completed, the Main Motor is turned backward to raise the Pick-Up Roller.

• The Pick-U p Roller an d the Take-Up R olle r are tu rned thro ug h th e P ap er Take-U p Clu t ch

and by a gear train and a belt driven by the Main Motor.

• The Paper Empty Sensor is used to detect a document loaded on the Document Loading

Tray.

• The Document Stoppers determine the leading edge position of the document loaded on

the Document Loading Tray. They are in the lowered, swung-down position in the standby

state and swing upward w he n the docu m en t is to be taken up.

• The swing-up and swing-down motion of the Document Stoppers is operatively connected to the r ai si ng and lowering of the Pic k- Up Roller.

Paper Take-Up Clutch CL1

Main Motor M1

Pick-Up Roller

Paper Empty Sensor PC2

Ta ke-Up Roller

M-7

Document Stoppers

4688M005AA

7-2. Document Separating Mechanism

• The coeffic ie nt of fr ic tion betw ee n the Take-Up Roller and S ep arator Rol le r i s effec tive ly

used to prevent double feed of paper.

When on e sh ee t

of paper is take n

up

When tw o or mor e

shee ts of paper

are taken up

Ta ke-Up Roller

: The coefficient of f riction on the front sid e of the shee t of paper

taken up and fed through the space between the Take-Up Roller

and Separator Rolle r is th e sa me as that on th e backside of t h e

sheet of paper, allowing the paper to be properly fed into the

copier.

: The coefficient of friction between the paper and the Separator

Roller is greater than that betwe en the shee ts of paper, which

allows only the top sheet of paper to be fed into the copier.

Separator Roller

4688M006AA

M-8

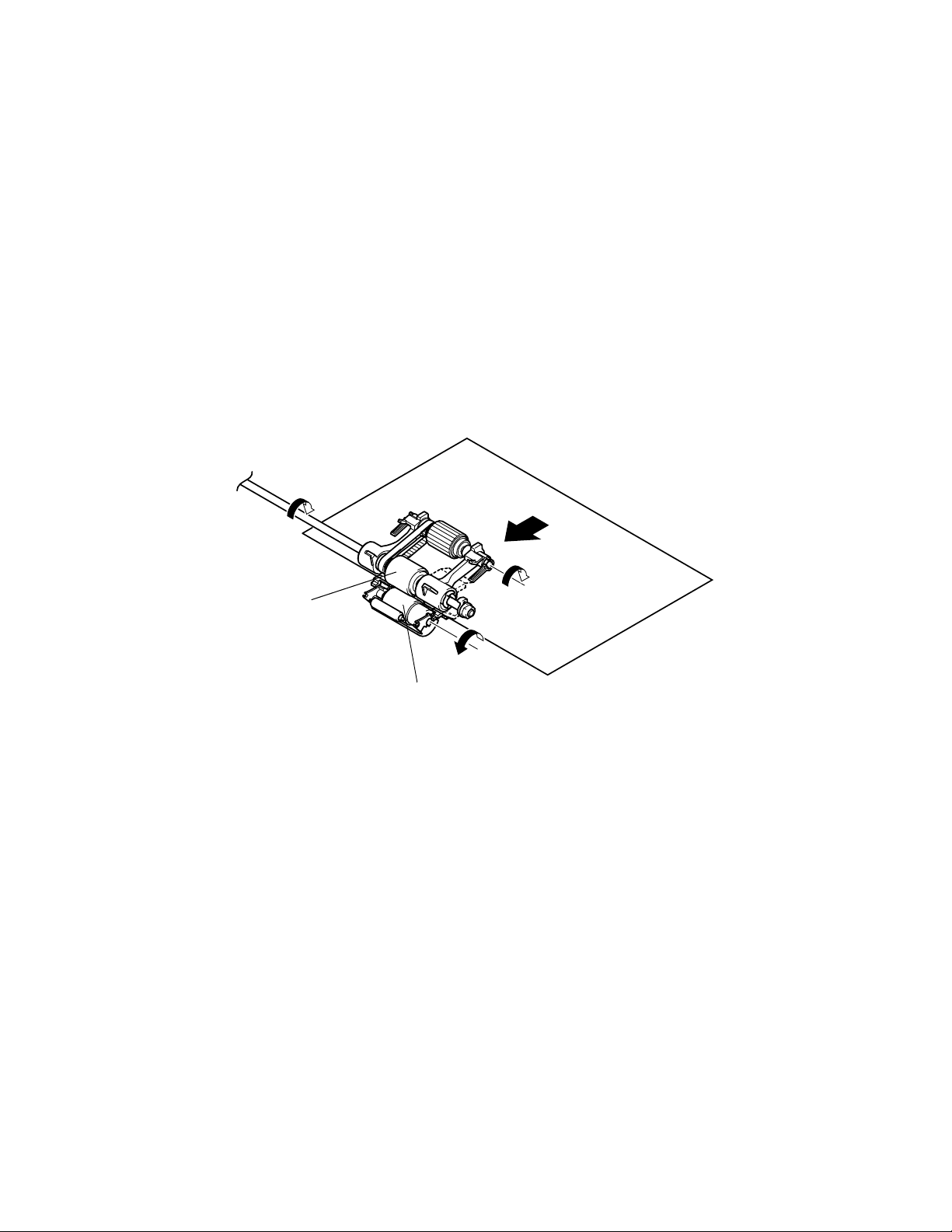

8. TRANSPORT/EXIT MECHANISM

8-1. Document Transport Mechanis m

• The document taken up is tran sported to the do cument scanning position of the copier by

the Reg is trat i on R o ll er s.

• The Registration Ro ll ers a r e tur ned by a ge ar trai n and be lt s which are drive n by the

Main Motor.

Main Motor M1

Registration Rollers

M-9

4688M007AA

Loading...

Loading...