Page 1

SPECTRORADIOMETER

CS-2000/CS-2000A

Instruction Manual

Page 2

Safety Symbols

The following symbols are used in this manual to prevent accidents which may occur as a

result of incorrect use of the instrument.

Denotes a sentence regarding a safety warning or note.

Read the sentence carefully to ensure safe and correct use.

Denotes a prohibited operation.

The operation must never been performed.

Denotes an instruction.

The instruction must be strictly adhered to.

Denotes an instruction.

Disconnect the AC adapter from the AC outlet.

Denotes a prohibited operation.

Never disassemble the instrument.

Notes on This Manual

Copying or reproduction of all or any part of the contents of this manual without

KONICA MINOLTA's permission is strictly prohibited.

The contents of this manual are subject to change without prior notice.

Every effort has been made in the preparation of this manual to ensure the accuracy of

its contents. However, should you have any questions or find any errors, please contact

the nearest KONICA MINOLTA-authorized service facility.

KONICA MINOLTA will not accept any responsibility for consequences arising from the

use of the instrument.

Page 3

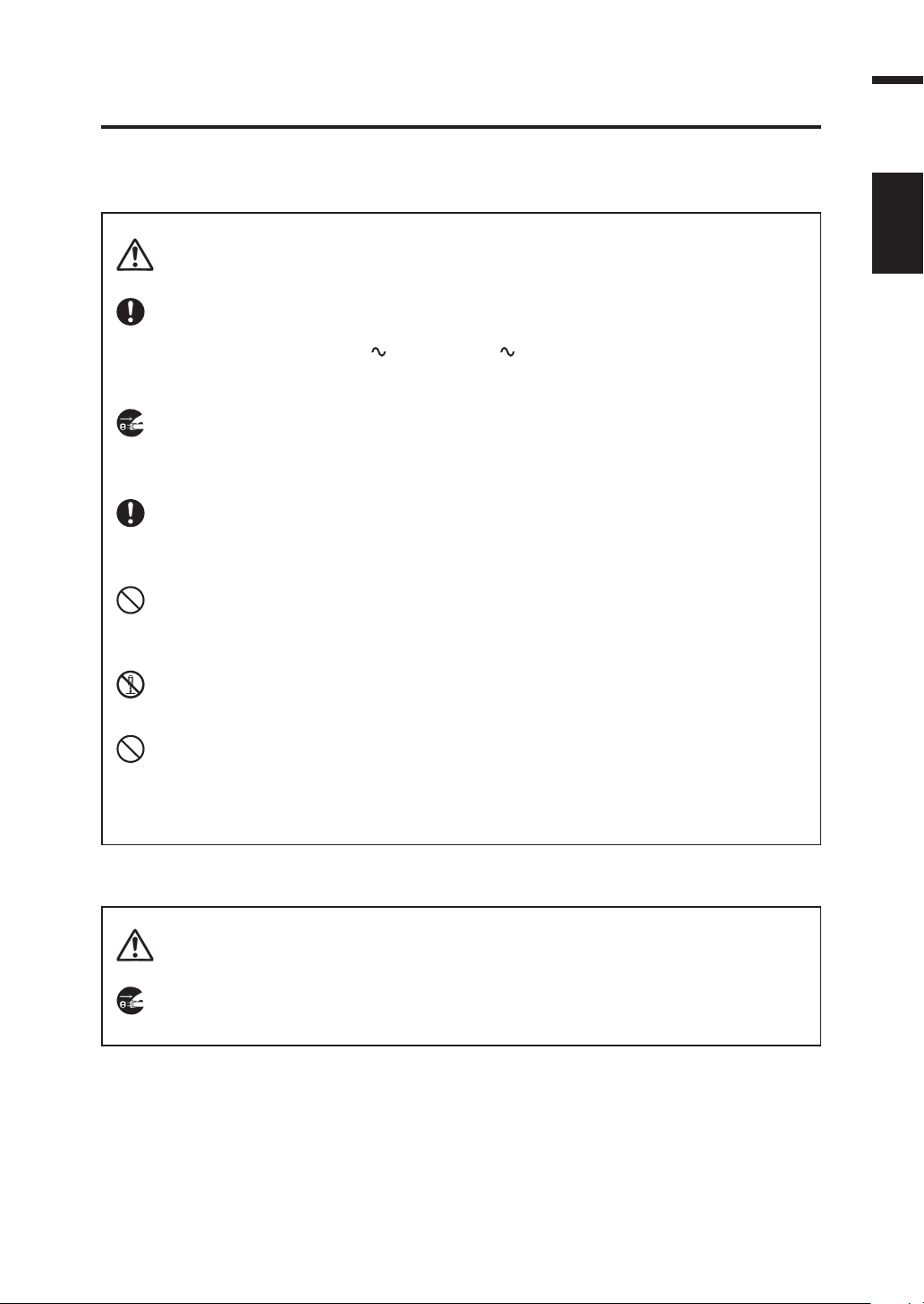

Safety Precautions

To ensure correct use of this instrument, read the following points carefully and adhere to

them. After you have read this manual, keep it in a safe place where it can be referred to

anytime a question arises.

(Failure to adhere to the following points may result in

Warning

Do not use this instrument in places where flammable or combustible gases

(gasoline etc.) are present.

Doing so may cause fire.

Always use the AC adapter and power cord supplied as a standard accessory

or optional (AC-A312), and connect it to indoor AC outlet of rated voltage and

frequency (100 - 120 V or 200 - 240 V , 50/60Hz). Failure to follow either of

these may result in damage to unit, fire or electric shock.

If this instrument is not used for a long time, disconnect AC adapter from AC

outlet. Accumulated dirt or water on prongs of AC adapter plug may cause fire

and should be removed.

Do not forcibly pull any part on power cord when unplugging since this may

cause fire or electric shock. Gently disconnect by holding plug. Also, do not

handle power cord with wet hands. Doing so may cause electric shock.

death or serious injury.)

Do not forcibly bend, twist or pull power cord. Also, do not place heavy object

on power cord, or damage or modify one. Any of these may cause fire or

electric shock due to damage to power cord.

Do not disassemble or modify this instrument or AC adapter. Doing so may

cause fire or electric shock.

Do not spill liquid on this instrument or drop metal into this instrument. Should

either of these happen, switch power off, unplug AC adapter immediately and

contact the nearest KONICA MINOLTA authorized service facility.

Should this instrument or AC adapter be damaged or smoke or odd smell be

generated, do not keep using such instrument or AC adapter without correction.

Doing so may cause fire. In such situations, switch power off immediately,

unplug AC adapter and contact the nearest KONICA MINOLTA authorized

service facility.

Do not look at sun or intense light through finder of this instrument. This may

lose your sight.

1

Page 4

(Failure to adhere to following points may result in injury or

Caution

Use this instrument near AC outlet for easy plugging or unplugging in using AC

adapter.

Do not place this instrument on unstable or sloping surface which may drop or

overturn it. Dropping or overturning may injure someone around. Take care not

to drop this instrument when carrying it.

Do not move while looking inside finder since this would fall or injure user.

Take special care in handling the ND filter or closeup lens included in the

optional accessories. Breakage of the ND filter or closeup lens may injure

someone around.

damage to this instrument or other property.)

2

Page 5

Introduction

This instrument is a high-accuracy spectroradiometer designed to measure luminance and

chromaticity up to super-low luminance regions. Carefully read this manual before using one.

Packaging material

Be sure to save all packaging materials (corrugated cardboard boxes, pads and plastic

bags) supplied with the purchase. This is delicate measurement instrument. Use packaging

materials supplied in purchasing in case this instrument needs to be transferred for such

purpose as maintenance in KONICA MINOLTA's factories. These packaging materials are

useful for minimizing shock or vibration to this instrument in such situation.

Should any of these packaging materials be lost or broken, please contact the nearest

KONICA MINOLTA authorized service facility.

Note on Use

Operating Environment

The standard AC adapter (AC-A312) of this instrument is designed specifically for use

indoors. Do not use it outdoors.

Do not disassemble this instrument for being composed of delicate electronic components.

Use this instrument at rated voltage of 100 V - 120 V or 200 V - 240 V (50/60Hz).

Connect AC power cord to AC outlet with rated voltage and frequency. Connected

voltage should not be outside the range of ±10% of nominal.

This instrument is classified into a Pollution Degree 2 as instrument used in mainly in

manufacturing plant, laboratory, warehouse or equivalents. Use this instrument in metal

dust free and non condensing potential environment.

This instrument is categorized into Installation Category II as equipment connected to

commercially available power source.

Connect PC for controlling this instrument to the outlet with protective grounding.

Failure to follow this may result in electric shock due to short circuit.

Take care not to enter foreign substance like water or metal in this instrument.

Operating in such state cause serious danger.

Do not use this instrument under direct sunlight or near heater. The internal temperature of this

instrument to becomes much higher than ambient temperature which may break this instrument.

Also, use this instrument in a well-ventilated place. To ensure proper heat dissipation,

keep the ventilation holes free from obstructions.

Avoid rapid change in ambient temperature which may form dew condensation.

Avoid using this instrument in extremely dusty or humid place.

Use the CS-2000 at ambient temperature between 5 and 35ºC and relative humidity

80% or less (at 35ºC) with no condensation. Use the CS-2000A at ambient

temperature between 5 and 30ºC and relative humidity 80% or less (at 30ºC) with no

condensation. Operating this instrument outside specified temperature and humidity

range may not satisfy its original performance.

3

Page 6

This Instrument

Do not subject this instrument to strong impact or vibration.

Do not forcibly pull, bend, or apply strong force to power cord for attached AC adapter

or USB cable. This may result in snapping.

Connect this unit to power source with minimal noise.

Do not measure a high-luminance light source (including sunlight) beyond the

measurement range. The failure to observe this warning could result in damage to the

optical system.

Should breakage or abnormality be found during operation, switch power off

immediately and unplug. Then refer to “Error Check” on page 82.

Should this instrument break down, do not try to disassemble and repair it by yourself.

Please contact the nearest KONICA MINOLTA authorized service facility.

Warm this instrument up for 20 minutes at least after switching power on when the

object luminance is 2 cd/m2 or lower (measuring angle 1º).

Objective lens, ND filter and Closeup lens (Optional Accessories)

Make sure that surfaces of objective lens, ND filter or closeup lens are clear. Correct

measurement may not be performed if there is dirt, dust, hand soil or part left unclean.

Do not touch surface of objective lens, ND filter or closeup lens with hand.

Do not change ambient temperature rapidly under high humidity. This may mist

objective lens, ND filter or closeup lens, resulting in incorrect measurement.

Note on Storage

Body

Do not store this instrument under direct sunlight or near heater. The internal

temperature of this instrument becomes much higher than ambient temperature which

may break this instrument.

Store this instrument at ambient temperature between 0 and 35ºC and relative humidity

80% or less (at 30ºC) with no condensation. Storage under high temperature and

humidity may deteriorate performance of this instrument. For added safety, we

recommend storage with such drying agent at room temperature.

Take care not to form condensation. Avoid rapid change in ambient temperature when

transferring body for storage.

Put the body in a packaging box supplied when purchased or the storage case (CS-

A30) in the optional accessories to store in safe place.

Objective lens

For storage, cover the objective lens with standard accessory lens cap.

4

Page 7

Cleaning

Body

If this unit becomes dirty, wipe with dry and soft cloth. Do not use organic solvent like

benzine or thinner and other chemical agent for cleaning. Should none of these

methods be helpful, please contact the nearest KONICA MINOLTA authorized service

facility.

Objective lens

Should it be gotten dirt or dust, wipe off with dry and soft cloth or lens cleaning paper. Do not

use organic solvent like benzine or thinner and other chemical agent for cleaning. Should

none of these methods be helpful, please contact the nearest KONICA MINOLTA authorized

service facility.

Notes on Transfer

Use packaging material supplied when purchased to minimize vibration or shock

generated during transfer.

Put all material including unit and accessories in original packaging material when

returning this instrument for service.

Maintenance

Periodical checkup is recommended annually to maintain measurement accuracy of

instrument. For details on checkup, please contact the nearest KONICA MINOLTA

authorized service facility.

Disposal Method

Make sure that the CS-2000/CS-2000A, its accessories and the packing materials are

either disposed of or recycled correctly in accordance with local laws and regulations.

5

Page 8

Contents

Safety Precautions ………………… 1

Introduction

Note on Use …………………………… 3

Operating Environment ……………………… 3

This Instrument

Objective lens, ND filter and Closeup lens

(Optional Accessories)

Note on Storage ……………………… 4

Body …………………………………………… 4

Objective lens

Cleaning ………………………………… 5

Body …………………………………………… 5

Objective lens

Notes on Transfer ……………………… 5

Maintenance

Disposal Method

…………………………… 3

……………………………… 4

……………………… 4

………………………………… 4

………………………………… 5

…………………………… 5

……………………… 5

Standard Accessories ……………… 8

Optional Accessories

System Configuration

Names and Functions of Parts

Names of Each Part …………………… 12

Functions of Each Part

Key Panel

Main Functions of Each Key

Diopter Adjustment

LCD Screen

MEAS (Measurement value) screen …… 16

MENU screen

……………………………… 14

…………………………… 16

……………………………… 17

……………… 9

……………… 11

…… 12

……………… 13

………… 14

…………………… 15

Installation

Installing ……………………………… 20

Connecting AC Adapter

Connection Method …………………… 22

…………… 21

Power Switch ON( | )/OFF(O) ……… 23

Turning power switch ON …………… 23

Turning power switch OFF

…………… 23

Setting

Setting of Synchronization ………… 26

Selecting Measurement Time

Setting Observer

…………………… 35

Selecting Display Format

Selecting Color Space

……………… 39

Selecting Absolute Value (ABS)/

Difference (DIFF) Display

When Using Closeup Lens

When Using ND Filter

Calibration

Calibration Channel …………………… 47

…………………………… 47

……………… 45

Backlight ON/OFF During

Measurement ………………………… 49

……… 29

………… 37

………… 41

………… 43

6

Page 9

Measurement

Measurement ………………………… 52

Saving the Measurement Value

Deleting the Memory Data

Registering Target Color

Target color …………………………… 61

…………… 61

…… 55

………… 58

Selecting Target Color ……………… 65

Deleting Target Color

……………… 67

Communication

Connecting to PC …………………… 72

Remote Mode

………………………… 73

Explanation

Measurement Principle …………… 76

Sensor Section …………………………… 76

Dark Measurement ………………… 76

TΔuv ………………………………… 77

L

v

Dominant wavelength /Excitation purity

Measurement of Object Color

Necessary Setting for Object Color Measurement

White Calibration

Measurement of Object

…………………………… 79

…………………… 79

… 78

…… 79

… 79

Dimensions …………………………… 80

Error Message

Error Check

Setting Initialization

Switching Luminance Unit

Main Specifications

……………………… 81

…………………………… 82

………………… 85

………… 86

………………… 87

7

Page 10

Standard Accessories

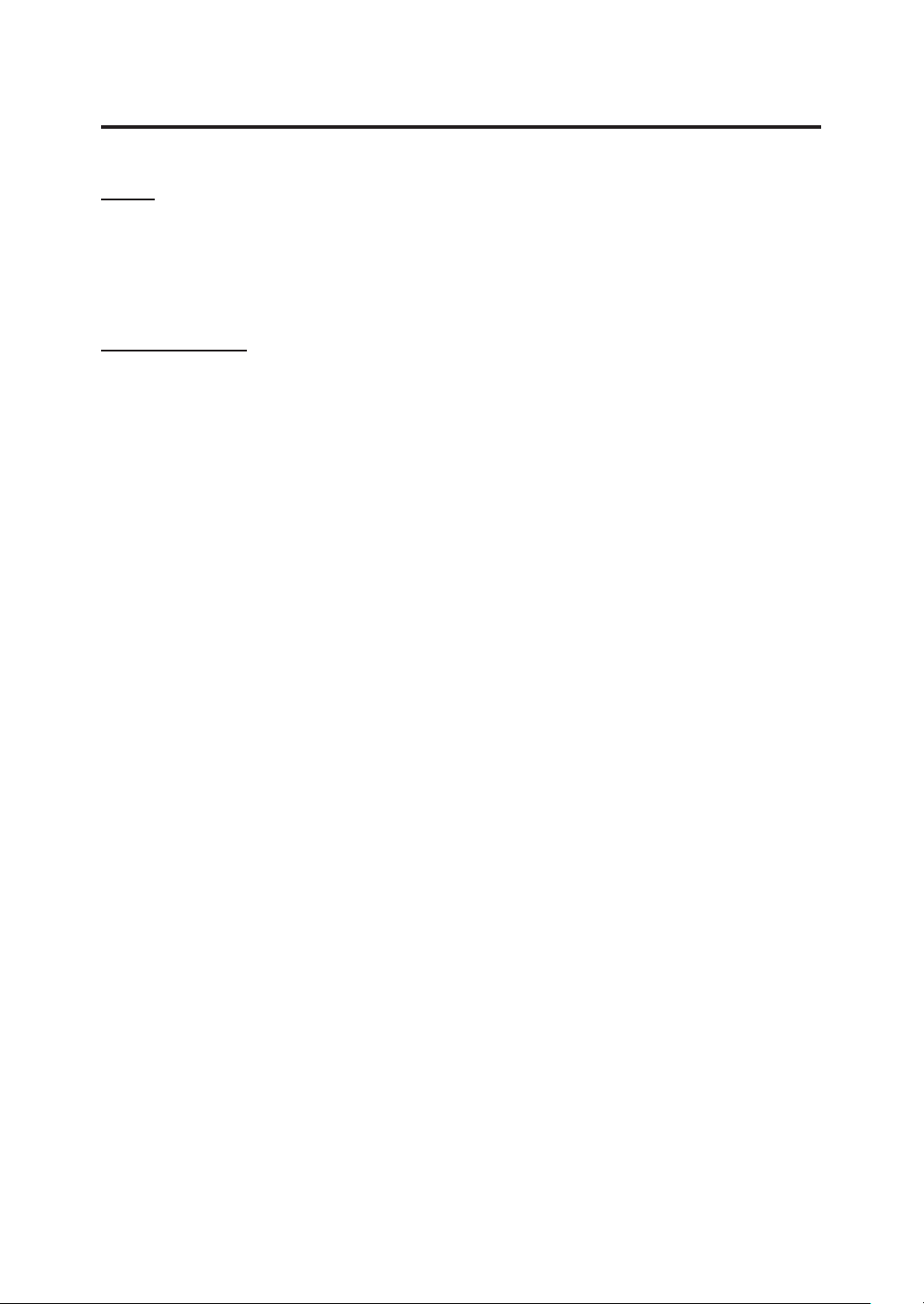

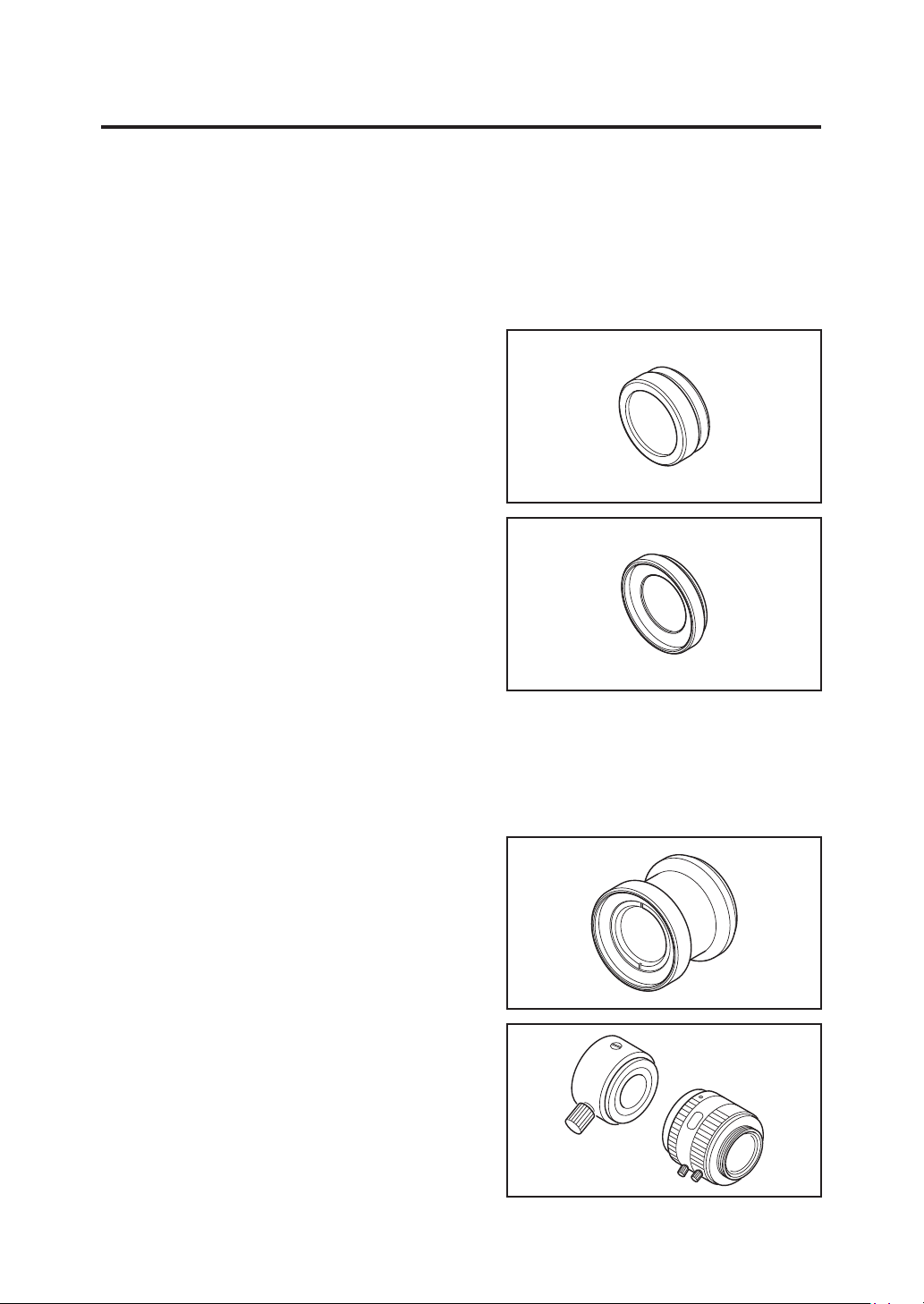

Lens Cap CS-A31

Attached to objective lens for protecting it

when not using this instrument.

USB Cable (2 m) CS-A32

Used for communication between this

instrument and PC.

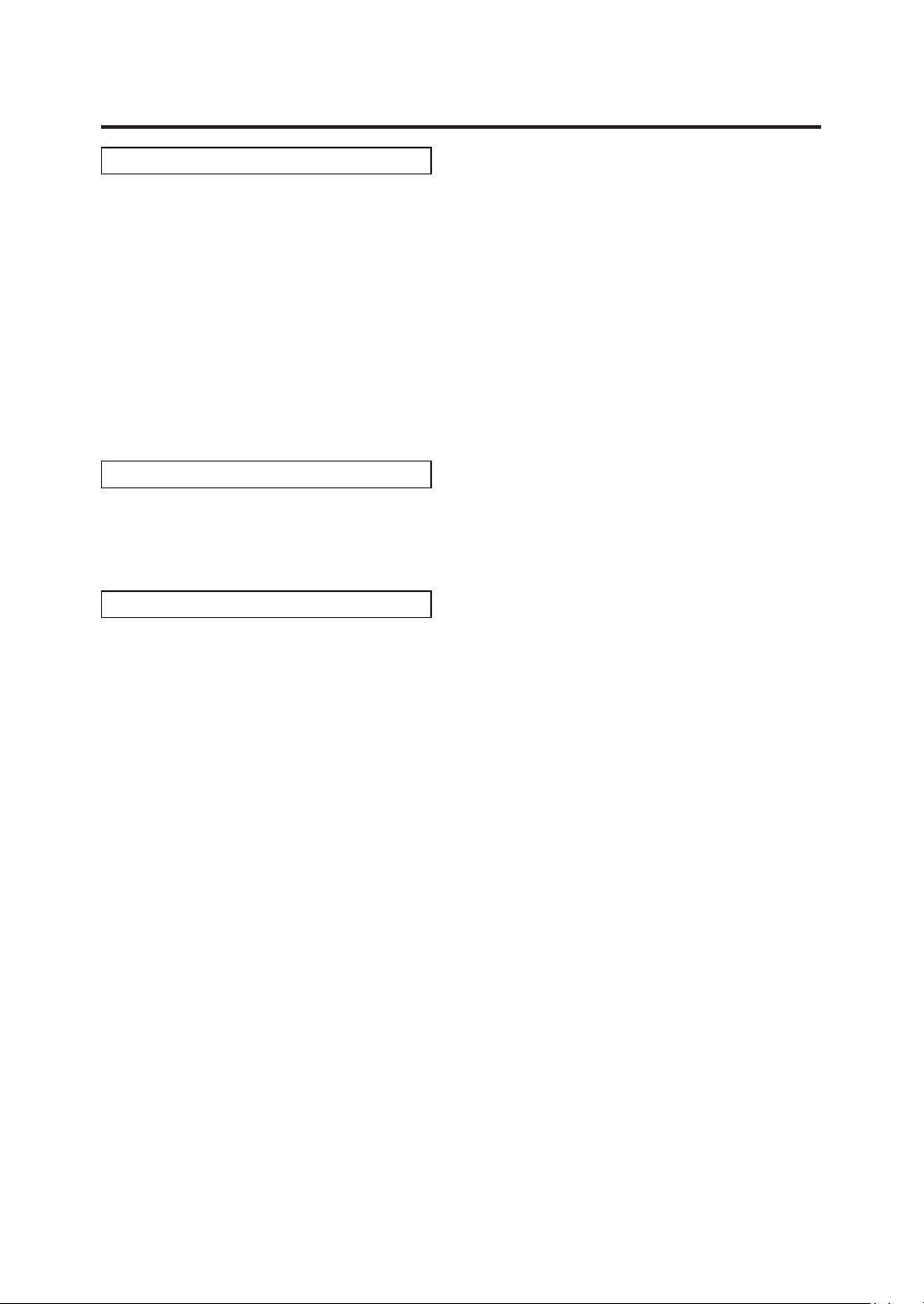

AC Adapter AC-A312

Supplies power from AC outlet.

Input: 100 - 120 V or 200 - 240 V

0.75 - 0.42 A

50/60 Hz

Output: 12 V 3 A

Data Management Software

CS-S10w Professional

Software to control this instrument from PC

for various data management.

The protect key is attached.

Screw for focus ring lock CS-A38

Locks the focus adjustment ring of the CS-

2000/CS-2000A so that it does not move

unintentionally and change the focus.

· Do not use any screw except for the

attached screw. Should it be lost or

damaged, purchase a new CS-A38.

· When storing the CS-2000/CS-2000A in the Storage Case (optional accessory),

remove the screw.

· When storing the CS-2000/CS-2000A in the packing box for transfer, remove the

screw.

8

Page 11

Optional Accessories

Calibration Certificate

ND Eyepiece Filter CS-A1

Reduces glare during observation through

the finder when a high-luminance object is

measured. Be sure to place this filter in front

of the finder when measuring highluminance objects.

ND Filter (1/10) CS-A33

ND Filter (1/100) CS-A34

Placed in front of objective lens for

measurement of high luminance object.

Calibration Certificate (for ND filter)

Calibration certificates can be attached to

the ND filters (1/10) CS-A33 and (1/100) CSA34.

Closeup Lens CS-A35

Placed in front of objective lens for

measurement of small object.

Adapter for CCD camera CS-A36

Placed between the finder and the body

when a C-mount industrial camera is used.

9

Page 12

White Calibration Plate CS-A5 (without data)

White Calibration Plate CS-A5 (with data)

White Calibration Plate CS-A5 (with data

and calibration certificate)

Used for measurement of object colors.

Three types (named, not-named, named

with calibration certificate) are prepared.

Tripod CS-A3

Pan Head CS-A4

Used when installing this instrument.

Storage Case CS-A30

Used to house the instrument and

accessories or to carry them by hand. Never

use this as a transport case.

10

Page 13

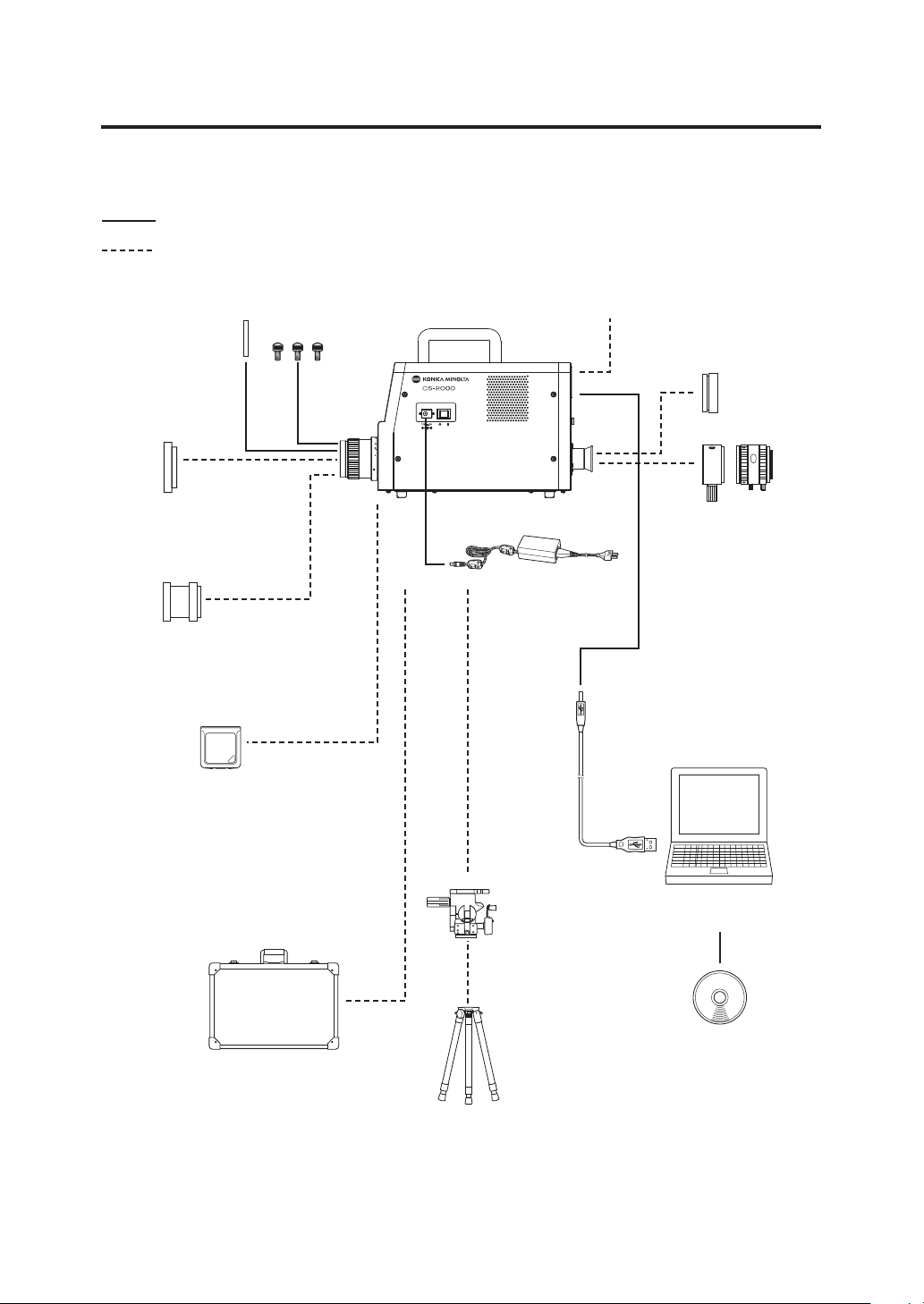

System Configuration

Pan Head

CS-A4

Tripod

CS-A3

AC Adapter

AC-A312

ND Eyepiece Filter

CS-A1

Adapter

for CCD camera

CS-A36

CS-2000 Main Unit

USB Cable (2 m)

CS-A32

PC

(on the market)

Standard Accessories

Optional Accessories

ND Filter

(1/10) CS-A33

(1/100) CS-A34

Calibration Certificate

(for ND filter)

Calibration CertificateLens Cap

Screw for

focus ring lock

CS-A38

Data Management

Software

CS-S10w Professional

Closeup Lens

CS-A35

White Calibration Plate

CS-A5 (w/o data)

CS-A5 (w/ data)

CS-A5 (

w/ data and calibration certificate

)

Storage Case

CS-A30

11

Page 14

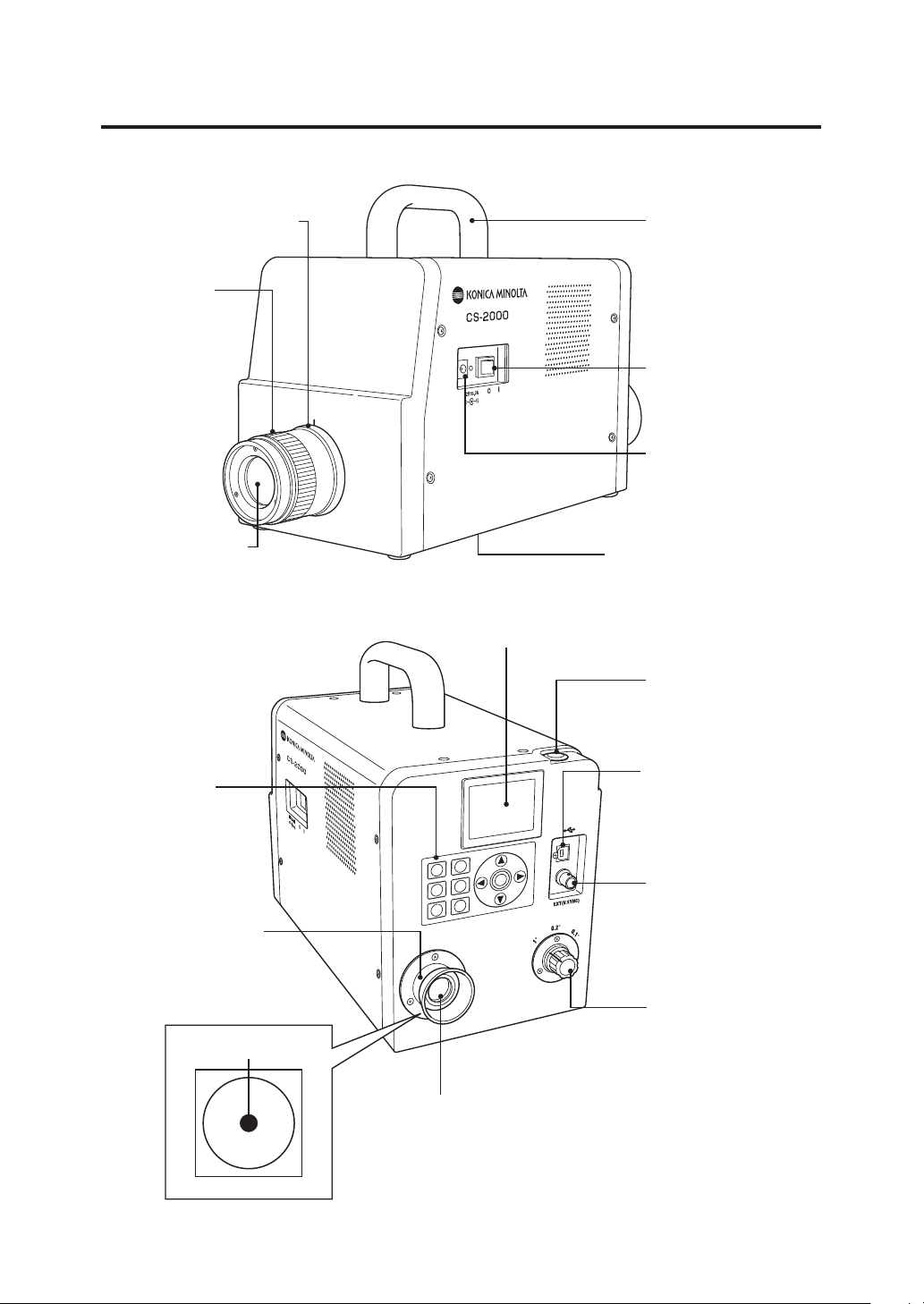

Names and Functions of Parts

Names of Each Part

(7) Focus distance scale

(6) Focus

adjustment ring

(5) Objective lens

Handle

(1) Power switch

(2) AC adapter

input terminal

(14) Screw holes for fixing

(8) LCD screen

(10) Measurement

button

(9) Key panel

(12) Diopter

adjustment ring

Inside finder

(13) Aperture

(3) USB connector

(15) Vertically

synchronized

signal input

terminal

(4) Measuring

angle selector

(11) Finder

12

Page 15

Functions of Each Part

(1) Power switch

AC adapter input terminal

(2)

(3) USB connector Connects the USB cable when connecting to PC. ………(p.72)

Measuring angle selector Selects measurement angle among 1º, 0.2º and 0.1º.

(4)

(5) Objective lens

Focus adjustment ring

(6)

Focus distance scale

(7)

(8) LCD Screen

(9) Key Panel Offers several keys for operation of this instrument. …… (p.14)

(10)

Measurement button

(11) Finder

(12)

Diopter adjustment ring

Used to observe object for measurement. ………… (p.15, 53)

Directed to object for measurement. ………………………(p.53)

Switches this instrument on/off. ( | ) for ON; (O) for OFF.

Connects the attached AC adapter. ……………………… (p.21)

Adjusts focus of objective lens before measurement. ……(p.53)

Helps adjusting focus. ………………………………………(p.53)

Displays various screens like measurement and menu.

For measurement. ……………………………………………(p.53)

Adjusts diopter. ………………………………………… (p.15, 53)

…(p.23)

………(p.52)

… (p.16)

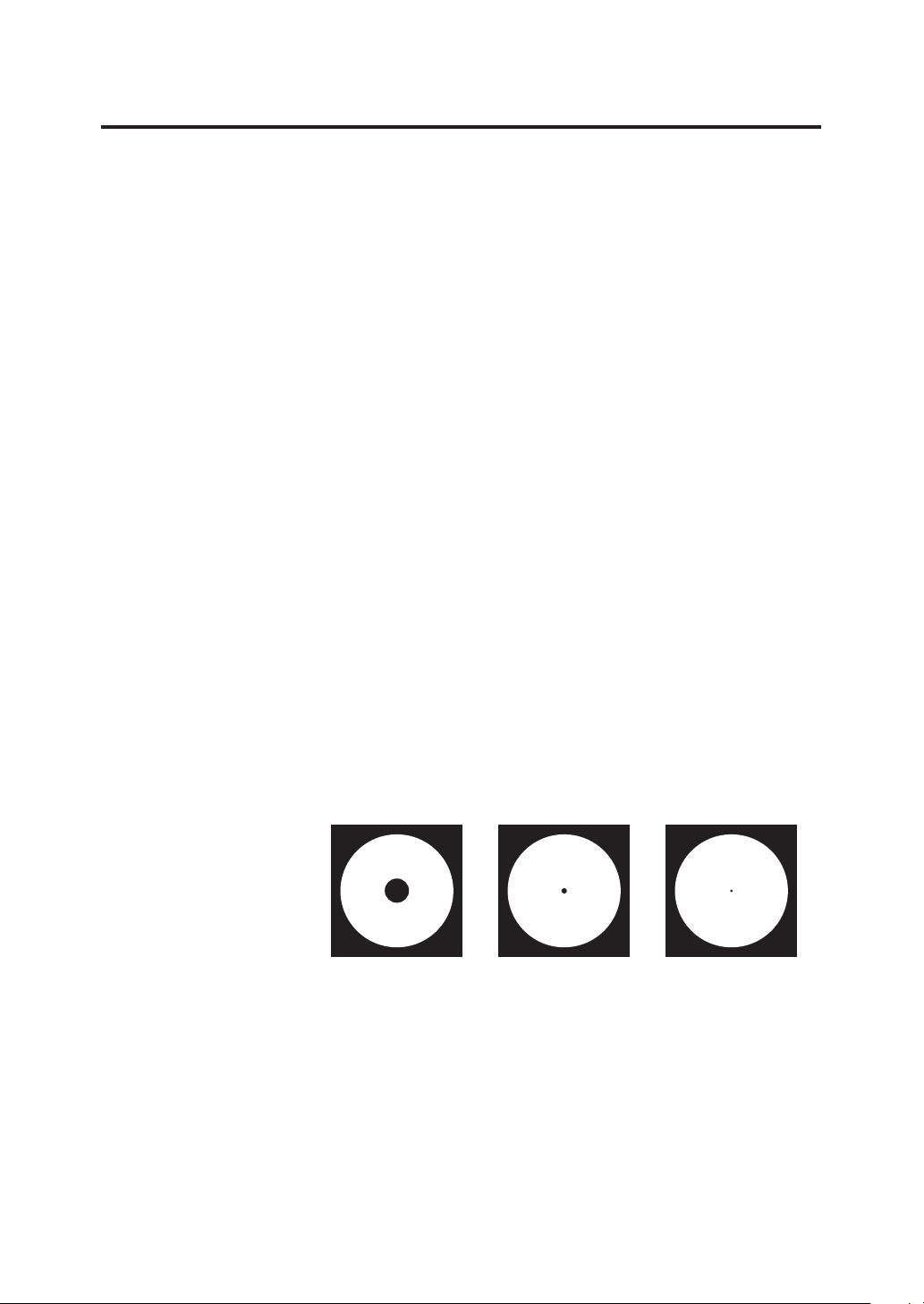

(13)Aperture Indicates measuring area. …………………………………(p.53)

Size of black circle will change depending on measuring angle.

1º Aperture 0.2º Aperture 0.1º Aperture

Screw holes for fixing

(14)

Vertically synchronized

(15)

signal input terminal

Used to fix this instrument with tripod or jig.

Connects the cable to input the vertically synchronized

signal or the external sync measurement.

13

……………

………………

(p.20)

(p.26)

Page 16

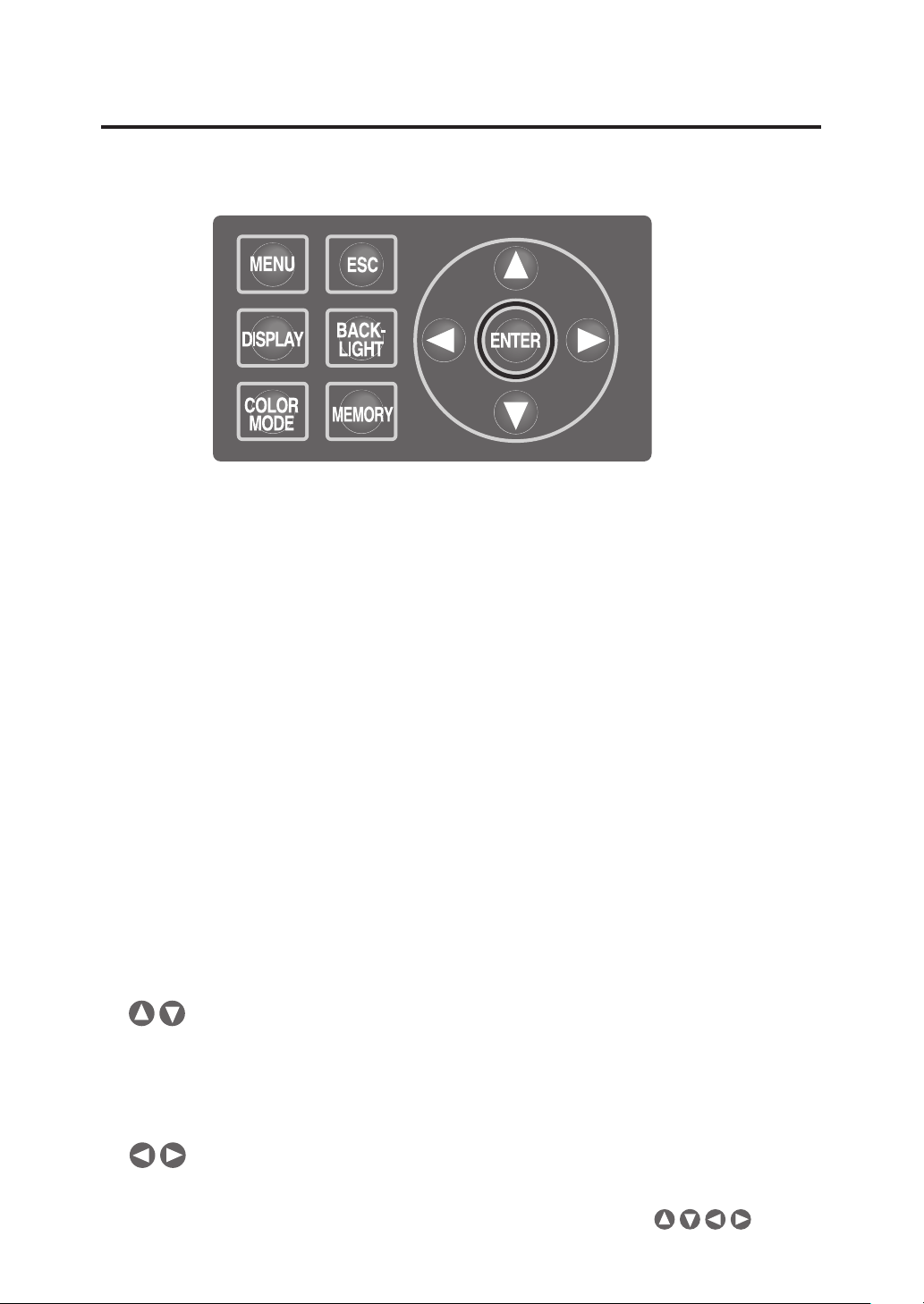

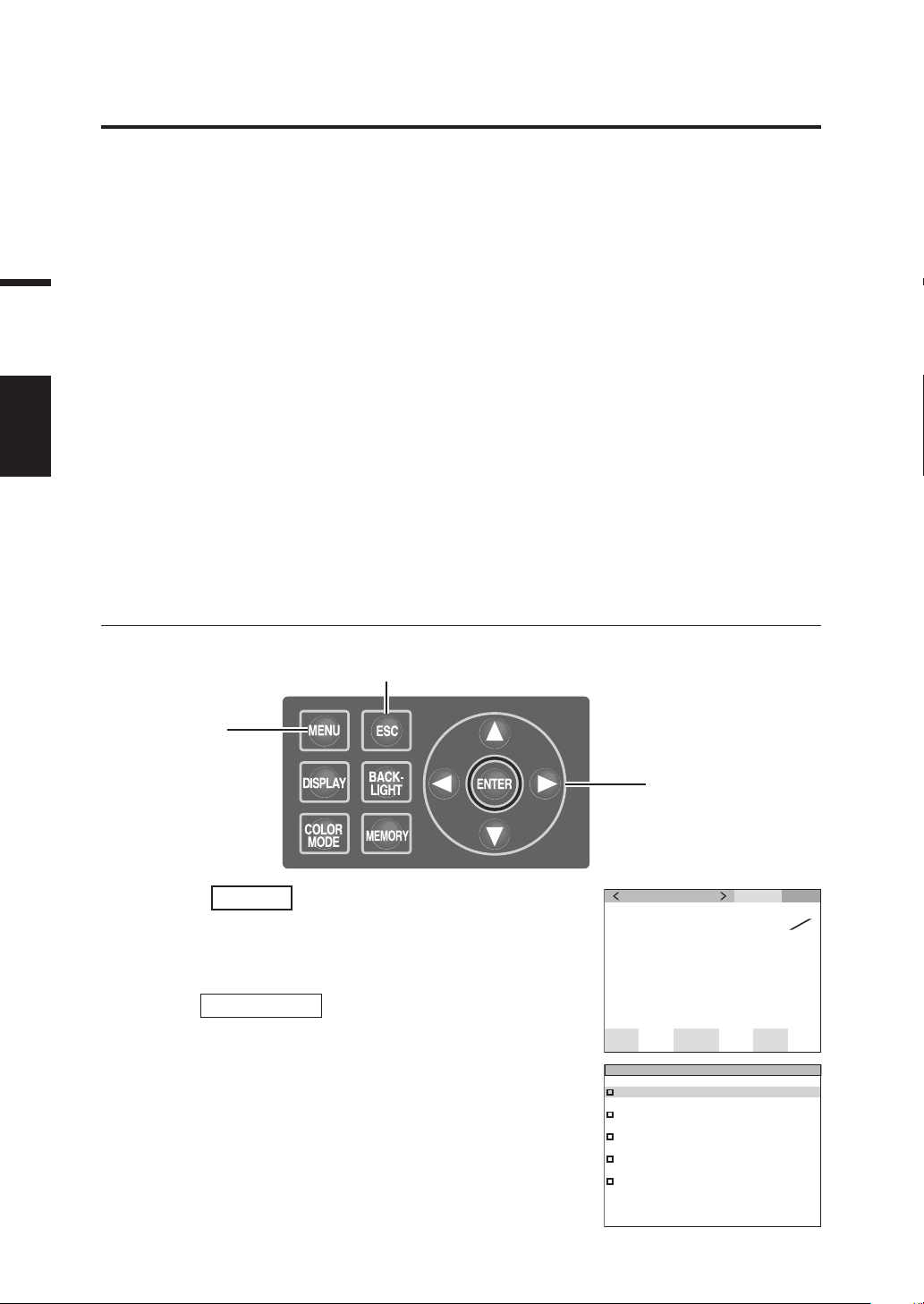

Key Panel

(1)

(2)

(3)

(4)

(5)

(6 )

(7)

Main Functions of Each Key

(1) MENU key The MENU screen appears if this key pressed when the

measurement value screen appears. (p.17)

(2) DISPLAY key

(3) COLOR MODE key Color space modes are switched in turn as follows, by pressing

Selects whether chromaticity is displayed in absolute value (ABS) or difference

(DIFF) if this key pressed when the measurement value screen appears. (p.41)

the key when the measurement value screen appears: Lvxy

Lvu’v’ LvTΔuv XYZ Dominant wavelength/Excitation purity

Spectral graph Lvxy. (p.39)

(4) ESC key

(5) BACKLIGHT key

(6) MEMORY key Measured data is stored in memory by pressing this key when the

(7)

ENTER key Press the key to fix the contents selected in

If this key is pressed when the MENU screen is displayed, the

settings are canceled and the measurement value screen

appears again. If pressed during numerical input or when making

each setting, the settings are canceled. If pressed during

continuous measurement, the measurement ends.

Selects backlight ON/OFF on LCD screen. (p.49)

measurement value screen appears. (p.55)

keys Memory data, target color channels, calibration channels, etc.,

are changed by pressing the key when the screen for display of

various data appears. The cursor position is moved up and

down, or the values and set items are changed, by pressing the

key during numerical input or when making each setting.

keys The cursor position moves right and left by pressing the key for

numerical input or when making each setting.

14

.

Page 17

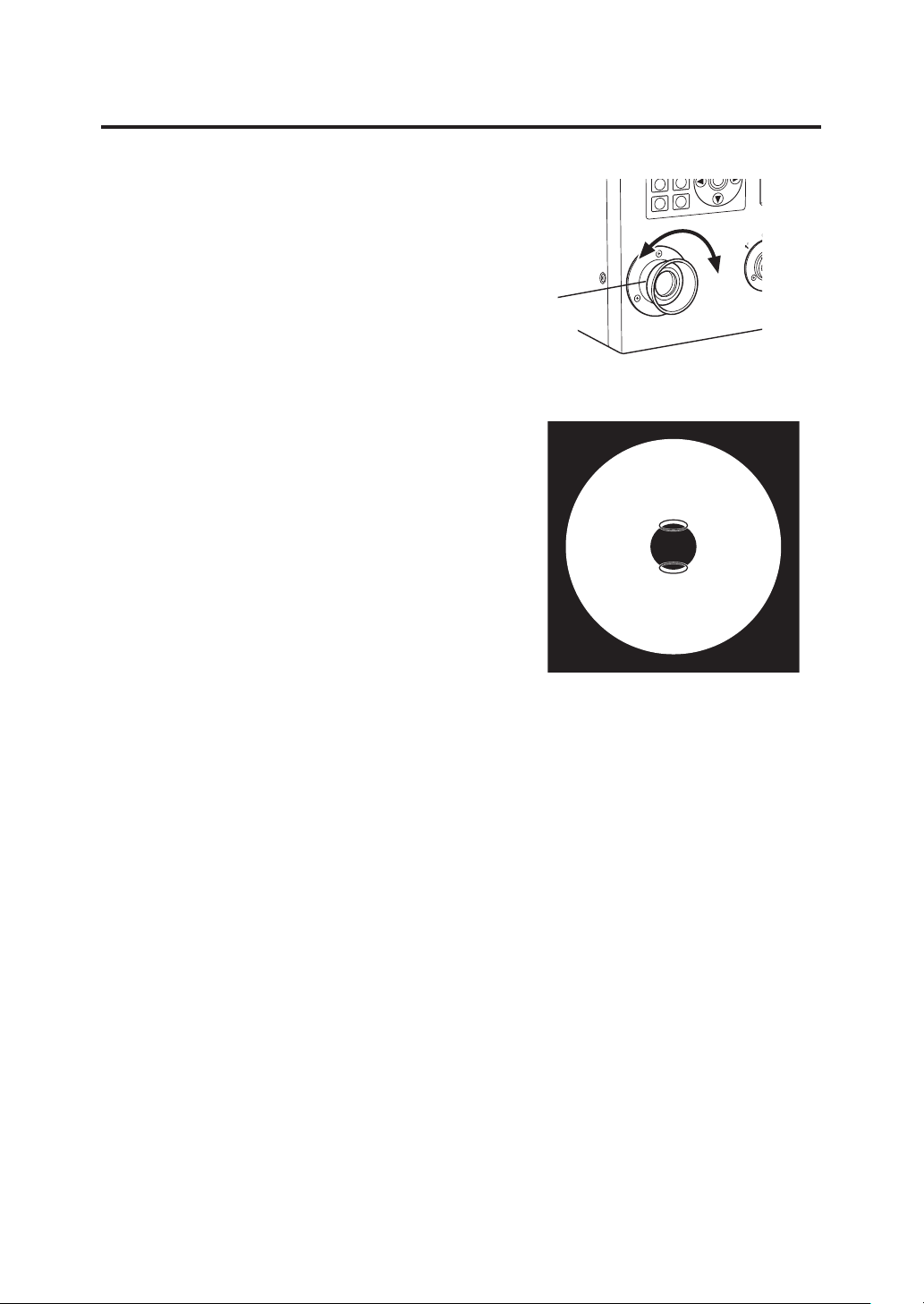

Diopter Adjustment

A

B

Rotate the diopter adjustment ring for adjustment

of diopter.

Diopter

adjustment ring

Adjust so that A or B on aperture or black circle

indicating measuring area looks clear when

observing object through finder.

Adjustment would be easy starting with 1º

aperture where object near aperture looks blur.

Make sure to adjust diopter before

measurement. Diopter should be adjusted for

the eyesight of the person who will be taking

measurement. If diopter is not adjusted before

focus measurement, correct measurement value

may not be expected. This is because the focus

is actually off even if you think it is correctly in

focus. In addition, if diopter is not correctly

adjusted, you may see the aperture moving

depending on viewing angle.

* You sometimes see small black dots or stripes

in internal finder. It gives no effect on

measuring performance.

15

Page 18

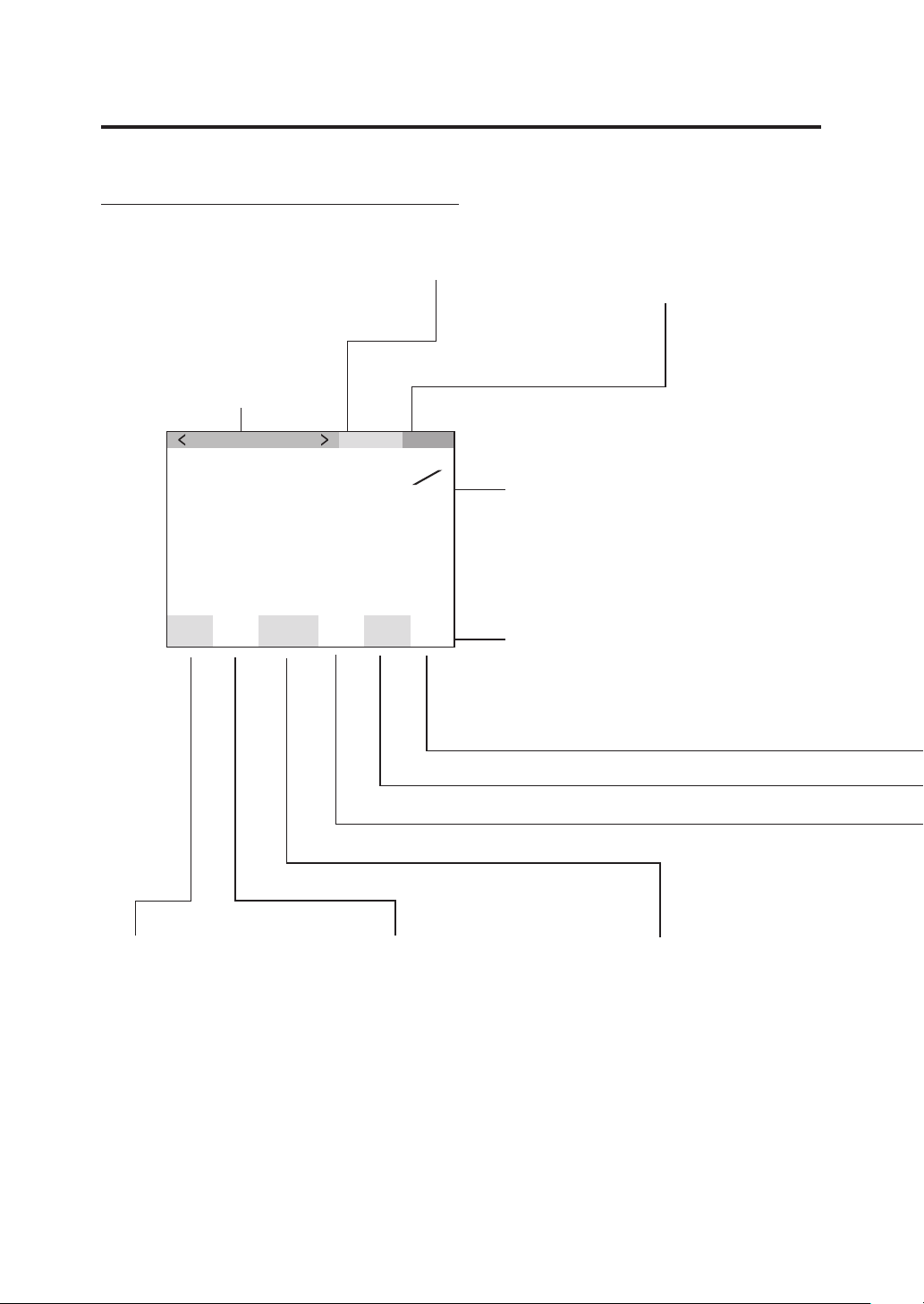

LCD Screen

ME A S SNG L

UC 0 0

SPD

M-N

Ob

s

10

˚

SYNC

Non

ND

100BLon

LE N

C-U

cd

m

2

Lv

80. 00

0 . 0000

0 . 0000

x

y

T0 1

MEAS (Measurement value) screen

“SNGL” is displayed for the

values obtained during single

measurement, while “CONT”

is displayed for the values

obtained during continuous

measurement. (p.53)

Calibration channel (p.47) Target color channel

(p.61, 65, 67)

Measurement result is displayed in the

currently selected color space.

(Lvxy, Lvu’v’, LvTΔuv, XYZ, Dominant

wavelength/Excitation purity, Spectral

graph) (p.39)

Display format can be changed. (p.37)

Setting status in this instrument is

displayed.

<Obs>

Currently selected

observer angle is

displayed.

(2°,10°) (p.35)

<SPD>

Currently selected

measuring time is

displayed.

(Nrm, Fst, M-N, M-F,

Mnl) (p.29)

<SYNC>

“Int” is displayed when

the internal sync

measurement mode is

set. “Ext” is displayed

when the external sync

measurement mode.

“Non” is displayed when

the sync measurement

mode is not set. (p.26)

16

Page 19

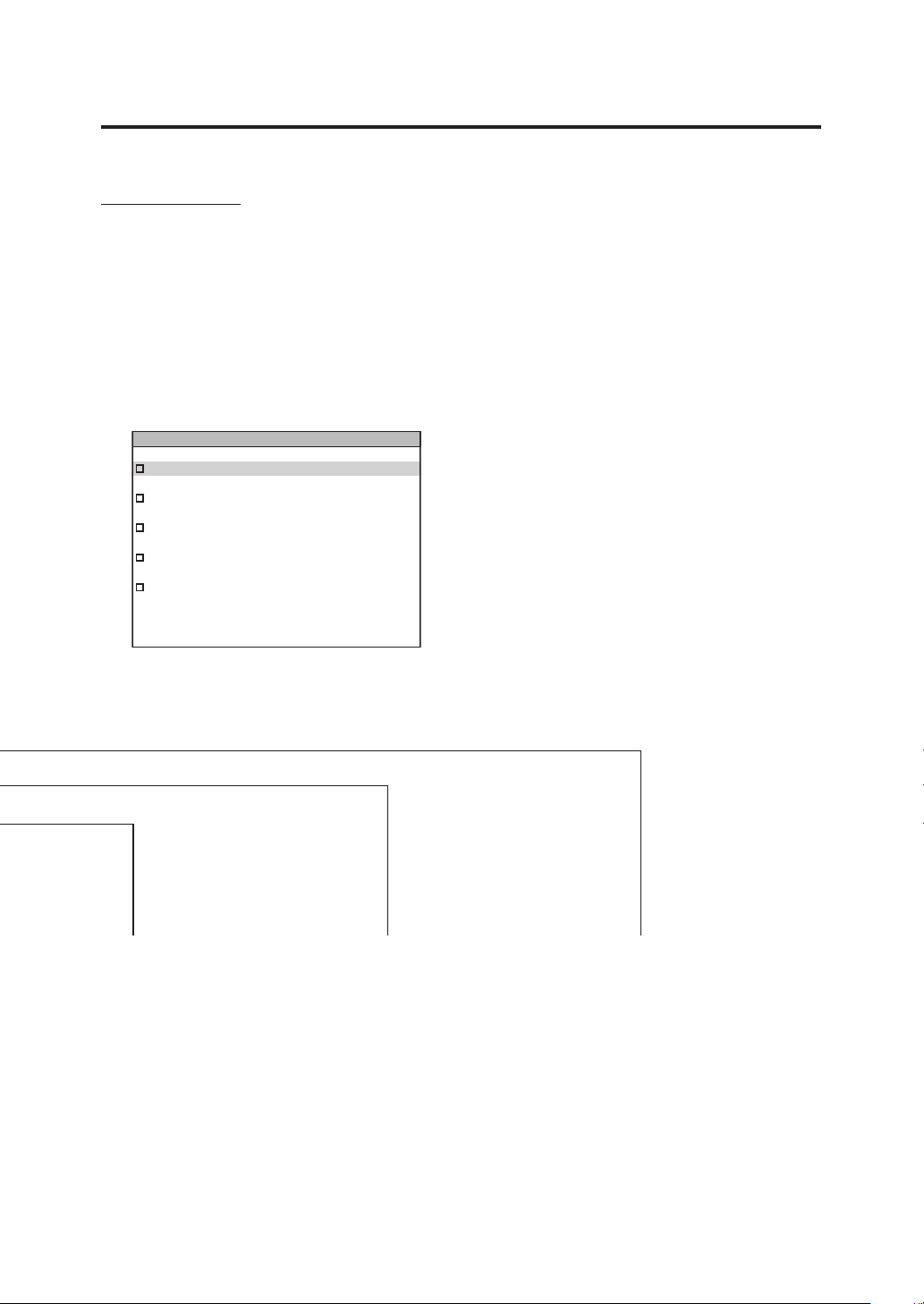

MENU screen

MEAS

MEMORY

TA R GET

OPTION

SETUP

ME N U

The MENU screen appears if MENU key is pressed when the measurement value screen

is displayed.

MEAS

Used to set measurement time or

synchronizing method. (p.26, 29)

MEMORY

Used to read or delete the measurement

memory data. (p.56, 58)

TARGET

Used to register, select or delete the

target color. (p.61, 65, 67)

OPTION

Used to set the closeup lens, ND filter or

calibration channel. (p.43, 45, 47)

SETUP

Used to set the observer, backlight or

display format. (p.35, 49, 37)

<LENS>

“C-U” is displayed, if the

closeup lens is attached.

If not, “Std” is displayed

(p.43).

<ND>

The current ND filter type

is displayed.

(Non, 10, 100) (p.45)

17

<BL>

“On” is displayed, if the

backlight is set to be

turned on during the

measurement. “Off” is

displayed, if the backlight

is set to be turned off

during that time. (p.49)

Page 20

18

Page 21

Installation

19

Page 22

Installing

70

Measurement distance

reference

Optical

axis

ISO screw ISO screwTripod screw

190.4

170

Installation

Use screw holes for fixing at the bottom of this instrument if utilized with the tripod or jig.

2-type holes are available.

Tripod screw hole: To set on the tripod. Use a tripod screw with top diameter of 3/8 inches

and depth of 10.5 mm.

[Note] The tripod screw holes correspond with the 3/8-inch screws of a

large camera tripod. 1/4-inch screws cannot be used for fixing

this instrument.

ISO screw hole: To set on the jig. Use ISO screws with top diameter of 5 mm and depth

of 6.5 mm.

For other detailed dimensions, see p.80.

20

Page 23

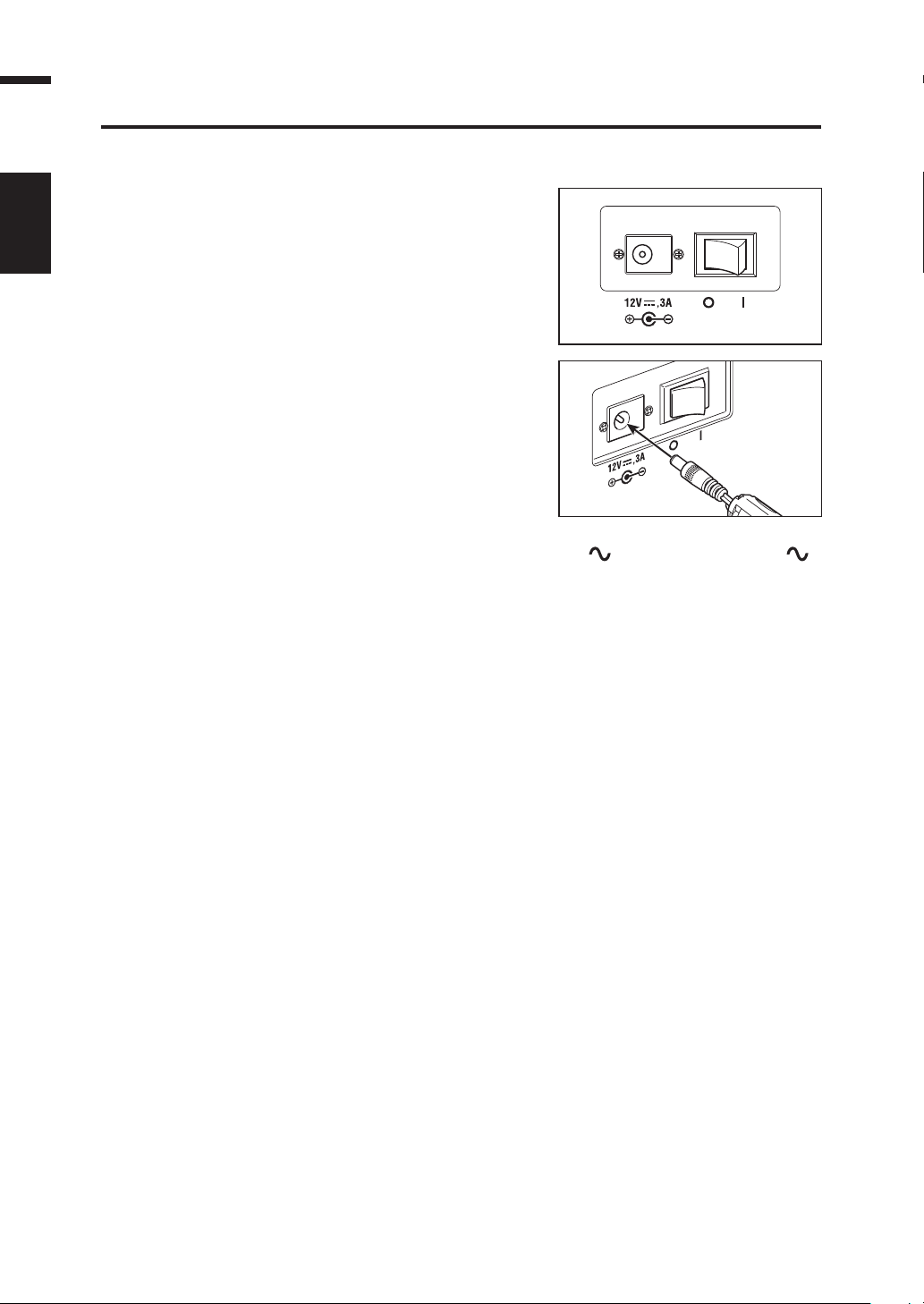

Connecting AC Adapter

The AC adapter supplied with this instrument is used for the corresponding power

source.

Warning

Always use the AC adapter and power cord supplied as a standard accessory or

optional accessory (AC-A312), and connect it to indoor AC outlet of rated voltage

and frequency (100 - 120 V

these may result in damage to unit, fire or electric shock.

If this instrument is not used for a long time, disconnect AC adapter from AC

outlet. Accumulated dirt or water on prongs of AC adapter plug may cause fire and

should be removed before use.

Do not forcibly pull any part on power cord when unplugging since this may cause

fire or electric shock. Gently disconnect by holding plug. Also, do not handle

power cord with wet hands. Doing so may cause electric shock.

Do not forcibly bend, twist or pull power cord. Also, do not place heavy object on

power cord, or damage or modify one. Any of these may cause fire or electric

shock due to damage to power cord.

(Failure to adhere to the following points may result in death or serious injury.)

or 200 - 240 V , 50/60Hz). Failure to follow either of

Installation

Do not disassemble or modify this instrument or AC adapter. Doing so may cause

fire or electric shock.

Should this instrument or AC adapter be damaged or smoke or odd smell be

generated, do not keep using such instrument or AC adapter without correction.

Doing so may cause fire. In such situations, switch power off immediately, unplug

AC adapter and contact the nearest KONICA MINOLTA authorized service facility.

Caution

Use this instrument near AC outlet for easy plugging or unplugging in using AC

adapter.

(Failure to adhere to following points may result in injury or damage to this instrument or other property.)

21

Page 24

Installation

Connection Method

1. Make sure that power switch is OFF

(slided to [O] side).

2. Connect the AC adapter plug to the

AC adapter input terminal of the body.

3. Plug the AC adapter to outlet (100 - 120 VAC or 200 - 240 VAC ,

50 Hz/60 Hz).

Insert the AC adapter plug all the way seated in AC outlet.

22

Page 25

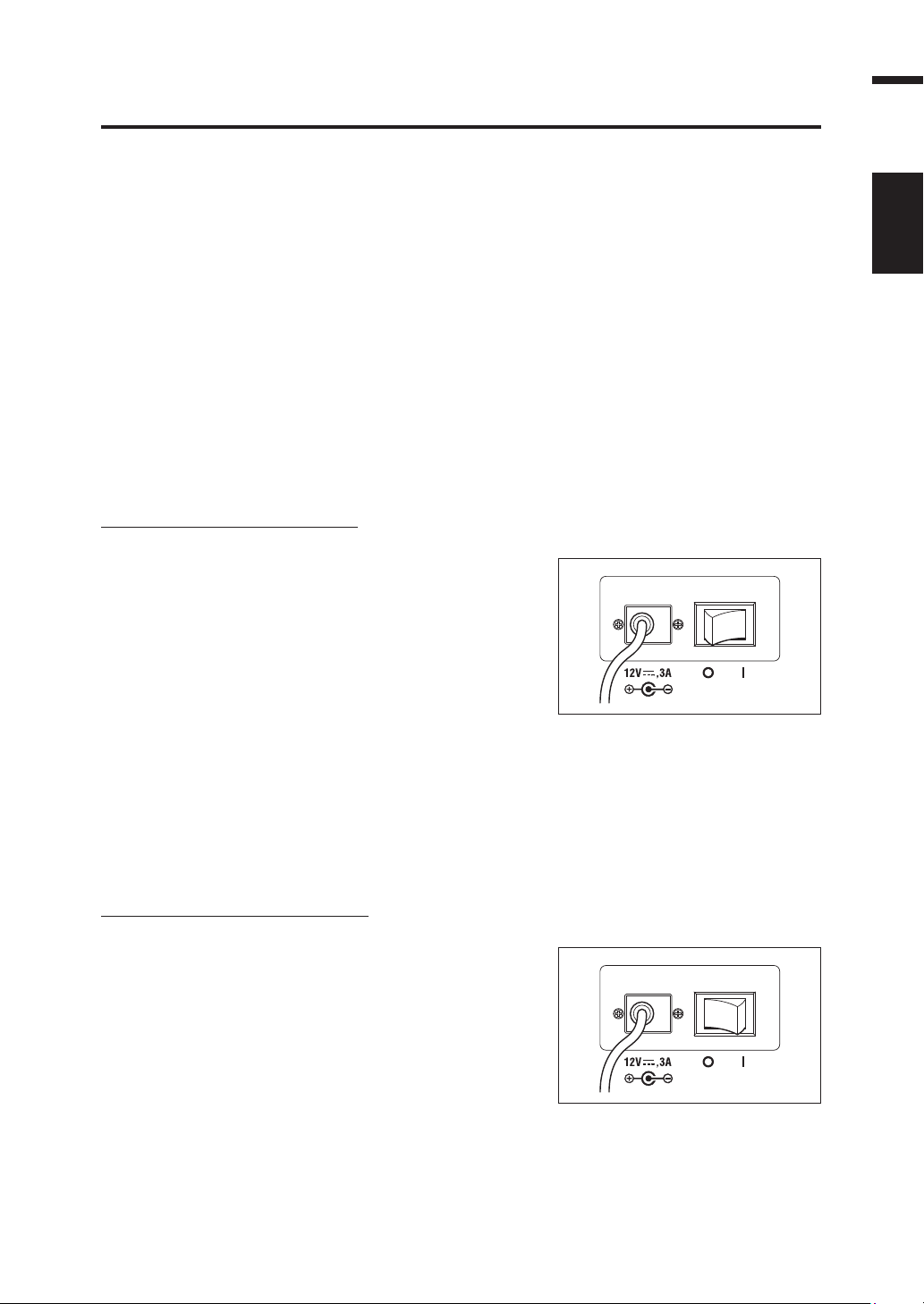

Power Switch ON( | )/OFF(O)

The warm-up time needed is a minimum of 20 minutes in order to measure the objects

with excellent accuracy under the conditions described below. Warm up this instrument for

20 or more minutes when the power source is turned off even for a short period, and

turned on again.

(1) The object is a low-luminance light source, using 2856 K (standard light source A) as a

guide: 2 cd/m2 or lower (1° Aperture)

50 cd/m2 or lower (0.2° Aperture)

200 cd/m2 or lower (0.1° Aperture)

(2) Outside room temperature and normal humidity ranges

Turning power switch ON

1. Slide power switch to ON ( | )

side.

The measurement screen appears 5

seconds after the initial screen on the

LCD.

The model type (CS-2000 or CS-

2000A), body version and product

serial numbers are displayed on the

initial screen. The model type can be

also confirmed on the nameplate.

Installation

Turning power switch OFF

2. Slide power switch to OFF (O

side) after measurement.

23

Page 26

24

Page 27

Setting

25

Page 28

Setting of Synchronization

ME AS S NG L

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

cd

m

2

Lv

35. 93

0 . 3968

0 . 4060

x

y

T0 1

MEA S

MEMORY

TA RG ET

OP T I ON

SE T U P

ME NU

The synchronized measurement refers to measurement mode where measurement is

made in the same timing as periodical light source pulse frequency, such as vertically

synchronized frequency for the display device.

[INT SYNC]

The internal sync measurement mode is used to measure the display equipment without

the input of vertically synchronized signals to the body, or to measure flicker light from a

light source such as a fluorescent light. Input the frequency of vertically synchronized

signals for the display equipment, or the commercial frequency (50 or 60 Hz) for flicker

light from a light source such as a luminescent light. The optimal integration time is

automatically set based on the input value and the brightness of the object. For this

Setting

reason, enter the correct frequency value to two places of decimals.

However, if the vertically synchronized frequency of the display equipment is not clear, accurate

measurement will not be possible with an inaccurate frequency setting. In this case it is

recommended to select [NO SYNC] mode without sync measurement (at 60 Hz of frequency), but to

select [MULTI-NORMAL] mode or [MULTI-FAST] mode for the measurement time (refer to p. 29).

[EXT SYNC]

The external sync measurement mode is used to measure the display equipment after the

line input of a vertically synchronized signal through the input terminal for vertically

synchronized signals to the body. The optimal integration time is set automatically, based

on the frequency of vertically synchronized signals and the brightness of the object.Input

CMOS (5V) Level of the input signals.

* Range of synchronized frequencies : 20.00 to 200.00 Hz

* Factory default setting : NO SYNC

Operation Procedure

1

1. Press

screen is displayed.

The MENU screen appears.

When the backlight of the LCD has been turned

off via

the backlight is turned on.

MENU

BACKLIGHT

6, 7

2, 3, 4, 5

key when the MEAS

key on the MEAS screen,

26

Page 29

2. Press either or key to select

SP EED NORMAL

SY NC NO SYNC

ME NU

ME AS

ME NU

ME AS

SYNC MODE

NO SYNC

I N T SYNC

E X T SYNC

ME NU

ME AS

SYNC MODE

NO SYNC

I N T SYNC

E X T SYNC

ME NU

ME AS

SYNC MODE

I N T SYNC

0 5 0. 0 0 H z

ME NU

ME AS

SYNC MODE

I N T SYNC

0 6 0. 0 0 H z

[MEAS] and then press

ENTER

The MENU – MEAS screen appears.

The current set contents are displayed in the

SYNC item.

key.

3. Press either or key to select

[SYNC] and then press

ENTER

The MENU - MEAS - SYNC MODE (sync

method selection) screen appears.

key.

4. Press either or key to select the

sync method.

4-a-1. INT SYNC setting:

Select [INT SYNC] and press

ENTER

The MENU - MEAS - SYNC MODE – INT

SYNC screen appears. This screen is used

for the input of an internal synchronized

frequency.

key.

Setting

4-a-2. Press either or key to set a

4-a-3. Press either or key to move

value.

key for larger number.

key for smaller number.

The range of the internal synchronized

frequency is from 20 Hz to 200 Hz.

the cursor.

27

Page 30

4-a-4. Repeat the same procedures 4-a-

ME AS S NG L

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

I nt

ND

No nBLon

LE N

S td

cd

m

2

Lv

x

y

T0 1

35. 93

0 . 3968

0 . 4060

2. and -3. as necessary.

Setting

4-a-5. Press

ENTER

key.

After the setting is entered, the MENU MEAS - SYNC MODE screen appears

again on the LCD.

5. Press

ENTER

key.

When the synchronizing method is set, the

MENU - MEAS screen appears again on the

LCD.

ESC

By pressing

key, after the setting is

canceled the MENU - MEAS screen appears

again on the LCD.

The setting of the synchronizing method is

saved even after the power switch is turned off

(O).

6. Press

ENTER

key.

The MENU screen appears again on the LCD.

7. Press

ESC

key.

The MEAS screen appears again on the LCD.

28

Page 31

Selecting Measurement Time

Select measurement time according to the purpose. Five modes are available for

measurement time.

Measurement

time mode

NORMAL

FAST

MULTI

INTEGNORMAL

MULTI

INTEGFAST

MANUAL

*1 Time for sensor to measure light indicating “exposure time”. On the other hand, measurement time shows time for

integration × 2 +Time to open/close shutter + Time for calculation), indicating time needed for actual measurement.

* Factory default setting : MULTI INTEG-NORMAL, IN-ND : AUTO

Operation explanation Feature Cautions

In this mode, integration time*1 is adjusted

between 0.005s and 120s according to the

brightness of the measurement subject.

This mode emphasizes performance

when measuring low luminances.

In this mode, integration time is adjusted

between 0.005s and 16s according to the

brightness of the measurement subject.

This mode emphasizes measurement

time when measuring low luminances.

In this mode, several cycles of the

integration time for NORMAL mode are

taken and averaged. Under luminance

conditions which require an integration

time longer than the set luminance, the

integration time will be the same as for

normal measurement.

This mode can be used when the

synchronization time for measurement is

unknown or when the synchronization

time is known but the frequency is

unstable. In such case, the sync mode

should be set to NO SYNC.

In this mode, several cycles of the

integration time for FAST mode are taken

and averaged. Under luminance

conditions which require an integration

time longer than the set luminance, the

integration time will be the same as for

FAST measurement.

This mode can be used when the

synchronization time for measurement is

unknown or when the synchronization

time is known but the frequency is

unstable. In such case, the sync mode

should be set to NO SYNC.

This mode can be used when you want to set a

fixed integration time for measurements.

Integration time: 0.005s to 120s

Improved accuracy

and repeatability for

luminances below

approx. 4 cd /m2

(measurement angle: 1°)

Shorter measuring

times for luminances

below approx. 4 cd/m2

(measurement angle: 1°)

Measurements which do

not depend on the

synchronization

frequency of the

measurement subject

can be taken.

Improved accuracy and

repeatability for

luminances below

approx. 4 cd /m2

(measurement angle: 1°)

Measurements which do

not depend on the

synchronization

frequency of the

measurement subject

can be taken.

Shorter measuring times

for luminances below

approx. 4 cd /m2

(measurement angle: 1°)

The desired fixed integration

time can be set.

When measuring low luminances,

since the total measurement

time can be as long as 4

minutes, if the brightness of the

measurement subject changes,

the measurement results will

be the average luminance.

In addition, be careful to not

move the instrument during

measurement. When measuring

periodic light sources, MULTI

INTEG-NORMAL mode or

MULTI INTEG-FAST mode may

be more suitable, for example,

when the synchronization

frequency is unknown.

When higher accuracy and

repeatability are required

at low luminances, the

NORMAL mode should

be used if necessary.

Even for high luminances,

the set integration time (1s or

longer) will be used.

Even for high luminances,

the set integration time (1s or

longer) will be used

Be careful that the “OVER” error

message does not occur and that the

measurement accuracy is not reduced.

Examples of

measurement subjects

Constant light

sources (halogen

lamps, etc.)

Periodic light

sources (whose are

stable and whose

synchronization

frequency is

known)

Same as above

Periodic light

sources (whose

synchronization

frequency is

unknown or

unstable)

Periodic light

sources (whose

synchronization

frequency is

unknown or

unstable)

All light sources

Setting

29

Page 32

Operation Procedure

ME AS S NG L

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

cd

m

2

Lv

35. 85

0 . 3964

0 . 4059

x

y

T0 1

MEA S

MEMORY

TA RG ET

OP T I ON

SE T U P

ME NU

SP EED NORMAL

SY NC NO SYNC

ME NU

ME AS

ME NU

ME AS

SP EED MODE

NORMAL

F A S T

MU LT I- NO RM A L

MU LT I- FA ST

MANUA L

6, 7

1

2, 3, 4, 5

Setting

1. Press

MENU

key when the MEAS

screen is displayed.

The MENU screen appears.

When the backlight of the LCD has been turned

off via

BACKLIGHT

key on the MEAS screen,

the backlight is turned on.

2. Press either or key to select

[MEAS] and then press

ENTER

The MENU – MEAS screen appears.

The current set contents are displayed in the

SPEED item.

key.

3. Press either or key to select

[SPEED] and then press

The MENU - MEAS - SPEED MODE

(measurement speed setting) screen

appears.

ENTER

30

key.

Page 33

4. Press either or key to select

ME NU

ME AS

SP EED MODE

NORMAL

F A S T

MU LT I- NO RM A L

MU LT I- FA ST

MANUA L

ME NU

ME AS

IN ND

AU TO

ON

O F F

SP EED MODE

ME NU

ME AS

IN ND

AU TO

ON

O F F

SP EED MODE

ME NU

ME AS

SP E ED MODE

NORMAL

F A S T

MU LT I- N O R M A L

MU LT I- F A S T

MANUA L

ME NU

ME AS

MU LTI IN TEG

IN TE G TI M E

0 1

I N -N D A U TO

SP EED MODE

measurement speed.

4-a-1. NORMAL or FAST setting: Select

[NORMAL] or [FAST] and press

ENTER

The MENU - MEAS - SPEED MODE - INND screen appears.

This screen is used to determine whether the

ND filter built into the body is used or not.

key.

4-a-2. Press either or key to select

[AUTO], [OFF] or [ON].

Select [ON] when the error message “OVER” appears.

When measuring objects having a wide range of luminance

under the adjusted measurement conditions (ex. γ

measurement), set IN-ND to [OFF] or [ON]. For [OFF] or [ON]

selection, select [OFF] when the upper limit luminance is 100cd/

m2 or less, and [ON] when it is 100cd/m2 or more as a guide.

Setting

4-a-3. Press

After the setting is entered, the MENU

4-b-1. MULTI-NORMAL or MULTI-FAST

ENTER

key.

- MEAS - SPEED MODE screen

appears again on the LCD.

setting:

Select [MULTI-NORMAL] or [MULTIFAST] and press

ENTER

The MENU - MEAS - SPEED MODE MULTI INTEG screen appears.

This screen is used for input of the integration

time in the MULTI INTEG-NORMAL mode or

MULTI INTEG-FAST mode.

key.

31

Page 34

4-b-2. Press either or key to set a

ME NU

ME AS

SP EED MODE

NORMAL

F A S T

MU LT I- NO RM A L

MU LT I- FA ST

MANUA L

ME NU

ME AS

MU LTI IN TEG

IN TE G TI M E

1 0

SP EED MODE

I N -N D A U TO

ME NU

ME AS

MAN UAL

IN TE G TI M E

IN-N

D O

FF

0 0 0 0 3 3 . 3 3 3

m

s

SP EED MODE

ME NU

ME AS

SP EED MODE

NORMAL

F A S T

MU LT I- NO RM A L

MU LT I- FA ST

MANUA L

ME NU

ME AS

MU LTI IN TEG

IN TE G TI M E

1 0

SP EED MODE

I N -N D A U TO

ME NU

ME AS

MU LTI IN TEG

IN TE G TI M E

1 0

SP EED MODE

I N -N D O N

value.

key for larger number.

key for smaller number.

The setting range of integration time is from 1 to 16 s.

Setting

4-b-3. Press

The cursor moves to the IN-ND item.

This screen is used to determine whether

the ND filter built into the body is used or

not.

ENTER

key.

4-b-4. Press either or key to

select [AUTO], [OFF] or [ON].

Select [ON] when the error message “OVER” appears.

When measuring objects having a wide range of luminance

under the adjusted measurement conditions (ex. γ

measurement), set IN-ND to [OFF] or [ON]. For [OFF] or [ON]

selection, select [OFF] when the upper limit luminance is 100cd/

m2 or less, and [ON] when it is 100cd/m2 or more as a guide.

4-b-5. Press

After the setting is entered, the MENU MEAS - SPEED MODE screen appears

again on the LCD.

ENTER

key.

4-c-1. MANUAL setting:

Select [MANUAL] and press

ENTER

The MENU - MEAS – SPEED MODE MANUAL screen appears. This screen is

used for input of the integration time in the

manual mode.

key.

32

Page 35

4-c-2. Press either or key to set a

ME NU

ME AS

MAN UAL

IN TE G TI M E

IN-N

D O

FF

0 0 0 5 0 0 . 0 0 0

m

s

SP EED MODE

ME NU

ME AS

SP EED MODE

NORMAL

F A S T

MU LT I- NORMAL

MU LT I- FAST

MA NU AL

ME NU

ME AS

MAN UAL

IN TE G TI M E

IN-N

D O

N

0 0 0 5 0 0 . 0 0 0

m

s

SP EED MODE

ME NU

ME AS

MAN UAL

IN TE G TI M E

IN-N

D O

FF

0 0 0 0 3 3 . 3 3 0

m

s

SP EED MODE

ME NU

ME AS

MAN UAL

IN TE G TI M E

IN-N

D O

FF

0 0 0 5 0 0 . 0 0 0

m

s

SP EED MODE

value.

key for larger number.

key for smaller number.

The setting range of integration time is from

5 to 120,000 ms.

4-c-3. Press either or key to move

the cursor.

4-c-4. Repeat the same procedures 4-a-

2. and -3. as necessary.

Setting

4-c-5. Press

4-c-6. Press either or key to select

4-c-7. Press

ENTER

key.

The cursor moves to the IN-ND item.

This screen is used to determine whether

the ND filter built into the body is used or

not.

[ON] or [OFF].

Select [ON] when the error message

“OVER” appears.

ENTER

When the setting is entered, the MENU MEAS - SPEED MODE screen appears

again on the LCD.

key.

33

Page 36

5. Press

ME AS S NG L

UC 00

SPD

Mn

l

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

cd

m

2

Lv

35. 85

0 . 3964

0 . 4059

x

y

T0 1

ENTER

key.

When the measurement time is set, the MENU MEAS screen appears again on the LCD.

ESC

By pressing

key, after the setting is

canceled the MENU - MEAS screen appears

again on the LCD.

Setting

Measurement time setting is saved even after

switching OFF (O).

6. Press

ESC

key.

The MENU screen appears again on the LCD.

7. Press

ESC

key.

The MEAS screen appears again on the LCD.

34

Page 37

Setting Observer

ME AS S NG L

UC 00

SPD

Mn

l

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

cd

m

2

Lv

35. 85

0 . 3964

0 . 4059

x

y

T0 1

MEA S

MEMORY

TA RG ET

OP T I ON

SE T U P

ME NU

OB SER V ER

2

°

DA TA

FO RM F

BA CKL I GH T@MEA S

O

N

ME NU

SE TU P

SE TU P

ME NU

OB S ER V ER

2°O

BS

10

°

O

BS

Color matching function for chromaticity calculation is selectable between 2°OBS and

10°OBS.

* Observer setting : 2°OBS, 10°OBS

* Factory default setting : 2°OBS

Operation Procedure

8, 9

1

1. Press

MENU

screen is displayed.

The MENU screen appears.

When the backlight of the LCD has been turned

off via

the backlight is turned on.

BACKLIGHT

key when the MEAS

key on the MEAS screen,

Setting

2, 3, 4,

5, 6, 7

2. Press either or key to select

3. Press either or key to select

[SETUP] and then press

ENTER

The MENU – SETUP screen appears.

The current set contents are displayed in

the [OBSERVER] item.

[OBSERVER] and then press

ENTER

key.

The MENU - SETUP – OBSERVER (Observer

selection) screen appears.

35

key.

Page 38

4. Press either or key to select [2º

SE TU P

ME NU

OB S ER V ER

2°O

BS

10

°

O

BS

SE TU P

ME NU

OB SER V ER

CHA NG E

OK C AN CEL

SE TU P

ME NU

OB SER V ER

CHA NG E

OK C AN CEL

ME AS S NG L

UC 00

SPD

Mn

l

Ob

s

10

˚

SYN C

No n

ND

No nBLon

LE N

S td

cd

m

2

Lv

35. 85

0 . 3964

0 . 4059

x

y

T0 1

OBS] or [10º OBS].

Setting

5. Press

ENTER

key.

The confirmation screen appears. [CANCEL] is

selected.

6. Press key to move the cursor to

[OK].

7. Press

ENTER

When the observer angle is set, the MENU MEAS screen appears again on the LCD.

By pressing

canceled the MENU - SETUP screen appears

again on the LCD.

Observer setting is saved even after switching

OFF (O).

key.

ESC

key, after the setting is

8. Press

9. Press

ESC

key.

The MENU screen appears again on the LCD.

ESC

key.

The MEAS screen appears again on the LCD.

When observer angle is set to 10°, Lv display

changes to Y display.

36

Page 39

Selecting Display Format

OB SER V ER

2

°

DA TA

FO RM F

BA CKL I GH T@MEA S

O

N

ME NU

SE TU P

MEA S

MEMORY

TA RG ET

OP T I ON

SE T U P

ME NU

ME AS S NG L

UC 00

SPD

Mn

l

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

cd

m

2

Lv

35. 85

0 . 3964

0 . 4059

x

y

T0 1

SE TU P

ME NU

DATA F

O

RM

** * * . ** * *

* . ** * *

E

+

*

The formats of indicating the luminance and excitation values X, Y and Z can be selected as either

normal indication to display the values to four places of decimals, or as index number indication. If

the measurement values on the LCD are unreadable, use the index number indication.

* Display format setting : Normal, Index

* Factory default setting : ****.**** [F]

* When the number of displayed digits is six (luminance and X/Y/Z are 100000 or more) in

the normal indication, “******.*****” will be displayed. In this case, the value will be

displayed if you set to the index number indication.

Operation Procedure

6, 7

1

1. Press

MENU

screen is displayed.

The MENU screen appears.

When the backlight of the LCD has been turned

off via

the backlight is turned on.

BACKLIGHT

key when the MEAS

key on the MEAS screen,

Setting

2, 3, 4, 5

2. Press either or key to select

3. Press either or key to select

[SETUP] and then press

ENTER

The MENU – SETUP screen appears.

The current set contents are displayed in the

[DATA FORM] item.

[DATA FORM] and then press

ENTER

The MENU - SETUP - DATA FORM (Display

format selection) screen appears.

key.

key.

37

Page 40

4. Press either or key to select

OB SER V ER

2

°

DA TA

FO RM E

BA CKL I GH T@MEA S

O

N

ME NU

SE TU P

SE TU P

ME NU

DATA F

O

RM

** * * . ** * *

* . ** * *

E

+

*

ME AS S NG L

UC 00

SYN C

No n

ND

No nBLon

LE N

S td

cd

m

2

Lv

3. 5846E+1

0. 3964

0. 4059

x

y

T0 1

SPD

Mn

l

Ob

s

2

˚

[****.**** [F]] or [*.****E+* [E]].

Setting

5. Press

ENTER

key.

When the display format is set, the MENU SETUP screen appears again on the LCD.

By pressing

ESC

key, after the setting is

canceled the MENU - SETUP screen appears

again on the LCD.

Display format setting is saved even after

switching OFF (O).

6. Press

ESC

key.

The MENU screen appears again on the LCD.

7. Press

ESC

key.

The MEAS screen appears again on the LCD.

38

Page 41

Selecting Color Space

Color Space

LCD Screen

Display Description

(When Normal is selected for display format)

(When Index is selected for display format)

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

cd

m

2

Lv

34 . 22

0 . 3958

0 . 4060

x

y

T0 1

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

cd

m

2

Lv

3 . 4221E+1

0 . 3958

0 . 4060

x

y

T0 1

Displays and outputs in

luminance Lv and

chromaticity coordinates

x,y.

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

cd

m

2

Lv

34 . 22

0 . 2236

0 . 5161

u’

v’

T0 1

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

Lv

0 . 2236

0 . 5161

u’

v’

T0 1

cd

m

2

3 . 4221E+1

Displays and outputs in

luminance Lv and u’v’

chromaticity diagram

(CIE 1976 UCS

chromaticity diagram)

coordinates u’, v’.

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

cd

m

2

Lv

34 . 22

3829K

+0. 009

T

duv

T0 1

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

Lv

3829K

+0. 009

T

duv

T0 1

cd

m

2

3 . 4221E+1

Displays and outputs in

luminance Lv, correlated

color temperature T and

color difference from

blackbody locus ∆uv.

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

X

33 . 36

34 . 22

16 . 71

Y

Z

T0 1

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

X

3 . 3365E+1

3 . 4221E+1

1 . 6709E+1

Y

Z

T0 1

Displays and outputs in

tristimulus values X, Y,

Z.

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

λ

d

+576 . 220 n

m

0 . 407%

Pe

T0 1

Displays and outputs in

dominant wavelength λd

and excitation purity Pe.

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

38 0

38 0n

m

1. 3 118 E-5

78 0

T0 1

Displays or outputs

spectral radiance Le(λ)

in the spectral waveform

See below table for available color space.

* Factory default setting :L

Lvxy *1

Lvu’v’ *1

Lv T ∆uv

xy

v

Setting

XYZ

Dominant

wavelength/

Excitation purity

*2

Spectral graph

39

Page 42

*1 Y is displayed instead of Lv when observer angle is 10°.

ME AS S NG L

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

cd

m

2

Lv

34 . 22

0 . 2236

0 . 5161

u’

v’

T0 1

ME AS S NG L

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

cd

m

2

Lv

34 . 22

0 . 3958

0 . 4060

x

y

T0 1

*2 For non-spectral colors, the complementary wavelength will be displayed. The display

indication will remain λd.

* If the calculated value does not establish a proper combination with the value in the

color space mode, “_ _ _ _ _ _ _ _” will be displayed.

Operation Procedure

Setting

1

2

1. When the MENU or MEMORY screen

is displayed, press

ESC

switch to the MEAS screen.

2. Press

COLOR MODE

the desired color space.

Measurement screen switches in order of Lvxy

Lvu’v’ LvT∆uv XYZ λd/Pe Spectral

graph Lvxy while

pressed.

It switches in order of Yxy Yu’v’ XYZ λd/

Pe Spectral graph Yxy when observer

angle is 10°.

Color space setting is saved even after

switching OFF (O).

COLOR MODE

key to

key to display

key is

40

Page 43

Selecting Absolute Value (ABS)/Difference (DIFF) Display

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

cd

m

2

Lv

34 . 22

0 . 3958

0 . 4060

x

y

T0 1

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYNC

No n

ND

No nBLon

LE N

S td

cd

m

2

T0 1

cd

m

2

Lv 34.

34

x

0 .39 58

y

0 .40 59

Lv +0.118 8

%

Lv

10 0.35

%

x .-0.

00 00

y .-0.

00 01

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

cd

m

2

Lv

34 . 22

0 . 2236

0 . 5161

u’

v’

T0 1

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYNC

No n

ND

No nBLon

LE N

S td

cd

m

2

T0 1

cd

m

2

Lv 34.

34

u’

0 .22 36

v’

0 .51 60

Lv +0.118 8

%

Lv

10 0.35

%

u ’+0.00 00

v ’-0.00 00

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

cd

m

2

Lv

34 . 22

3829K

+0. 009

T

duv

T0 1

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYNC

No n

ND

No nBLon

LE N

S td

cd

m

2

T0 1

cd

m

2

Lv 34.

34

T

3830K

duv

+0.

00 9

Lv +0.118 8

%

Lv

10 0.35

%

T

O

K

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

X

33 . 36

34 . 22

16 . 71

Y

Z

T0 1

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYNC

No n

ND

No nBLon

LE N

S td

T0 1

X

33.

49

Y

34.

34

Z

16.

78

X

+0.

120 4

Y

+0.

118 8

Z

+0.

074 79

X

%

100.36

%

Y

%

100.35

%

Z

%

100.45

%

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

λ

d

+576 . 220 n

m

0 . 407%

Pe

T0 1

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYNC

No n

ND

No nBLon

LE N

S td

T0 1

d

+

576. 220 n

m

Fe

0.40 6

d

0 .00 0n

m

Pe-0 .0 00

%

λ

λ

Whether chromaticity value is shown in absolute (ABS) or difference (DIFF) is selectable.

See below table for each case.

* Factory default setting: Absolute value (ABS)

Color Space Absolute value (ABS) Difference (DIFF)

xy *1 Lv, x , y

L

v

Lv, x, y

∆Lv, %LV, ∆x, ∆y

Setting

Lvu’v’ *1 Lv, u’, v’

Lv T ∆uv Lv, T, duv

XYZ X, Y, Z

Lv, u’, v’

%Lv, ∆Lv, ∆u’, ∆v’

Lv, T, duv

∆Lv, %Lv, ∆T

X, Y, Z

∆X, ∆Y, ∆Z

%X, %Y, %Z

Dominant wavelength

λ d, P

e

λd P

e

∆λd, ∆Pe *2

41

Page 44

Color Space Absolute value (ABS) Difference (DIFF)

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYNC

No n

ND

No nBLon

LE N

S td

38 0

38 0n

m

1. 3 118 E-5

78 0

T0 1

ME AS S NGL

UC 00

SPD

N

r

m

Ob

s

2

˚

SYNC

No n

ND

No nBLon

LE N

S td

38 0

38 0n

m

+

1. 870 4E-7

78 0

T0 1

ME AS S NG L

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

cd

m

2

T0 1

cd

m

2

Lv

34.34

x

0 .39 58

y

0 .40 59

Lv +0.118 8

%

Lv

10 0.35

%

x

.

-0.

00 00

y

.

-0.

00 01

ME AS S NG L

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No n

ND

No nBLon

LE N

S td

cd

m

2

Lv

34 . 22

0 . 3958

0 . 4060

x

y

T0 1

Spectral graph

Le (λ) spectral waveform

Wavelength at the cursor position

and Le (λ) in the wavelength

Measurement value and Le (λ)

spectral waveform of target color

Wavelength of the cursor position

and Le (λ) of the measurement value

in the wavelength

Setting

*1 Y is displayed instead of Lv when observer angle is 10°.

*2 Even if either the measured value, target color, or both are the complementary

wavelength, the difference between the two values will be displayed. The display

indication will remain ∆λd.

* If the calculated value or the registered target color does not establish a proper

combination with the value in the color space mode, “_ _ _ _ _ _ _ _” will be displayed.

Operation Procedure

1. When the MENU or MEMORY screen

2. Press

1

2

is displayed, press

switch to the MEAS screen.

DISPLAY

absolute value (ABS) or color

difference (DIFF) to select.

Measurement value switches between that for

absolute value (ABS) and difference (DIFF)

DISPLAY

while

The setting of absolute value (ABS) and difference

(DIFF) is saved even after switching OFF (O).

key is pressed.

ESC

key to

key to show

42

Page 45

When Using Closeup Lens

US ER. CAL NON

LE NS ST D

ME NU

OP TI ON

ND-F I L TE R NON

MEA S

MEMORY

TA RG ET

OP T I ON

SE T U P

ME NU

ME AS S NG L

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

I nt

ND

No nBLon

LE N

S td

cd

m

2

Lv

x

y

T0 1

35. 93

0 . 3968

0 . 4060

Use the closeup lens in the optional accessories to measure a fine surface. For the

attachment of the closeup lens, refer to the instruction manual for the closeup lens.

If the closeup lens is attached, the measurement value must be compensated for the lens

transmittance. This compensation coefficient is attached to the closeup lens. Use the data

management software CS-S10w Professional supplied with the CS-2000 as standard to

set the coefficient in this instrument. After that, when the closeup lens is selected as lens

type, the measurement value compensated with the compensation coefficient can be

obtained. See instruction manual of CS-S10w for details.

The wrong setting of lens type leads to inaccurate measurement.

Do not use the closeup lens with the ND filter. It leads to inaccurate measurement.

* Lens type : STANDARD, CLOSE-UP

* Factory default setting : STANDARD

Setting

Operation Procedure

6, 7

1

1. Press

screen is displayed.

The MENU screen appears.

When the backlight of the LCD has been turned

off via

the backlight is turned on.

MENU

key when the MEAS

BACKLIGHT

key on the MEAS screen,

2, 3, 4, 5

2. Press either or key to select

[OPTION] and then press

key.

The MENU – OPTION screen appears.

ENTER

The current set contents are displayed in the

[LENS] item.

43

Page 46

3. Press either or key to select

OP T I ON

ME NU

LE N S

S TA N D A RD

CL O SE-UP

US ER. CAL NON

LE NS C

-

UP

ME NU

OP TI ON

ND-F I L TE R NON

ME AS S NG L

UC 00

SPD

N

r

m

Ob

s

2

˚

ND

No nBLon

LE N

C-U

cd

m

2

Lv

x

y

T0 1

SYN C

I nt

35. 93

0 . 3968

0 . 4060

OP T I ON

ME NU

LE N S

S TA N D A RD

CL O SE-UP

[LENS] and then press

ENTER

The MENU - SETUP – LENS (Lens type

selection) screen appears.

Setting

key.

4. Press either or key to select

[CLOSE-UP].

When you removed the closeup lens, select

[STANDARD].

5. Press

ENTER

key.

When the lens type is set, the MENU - OPTION

screen appears again on the LCD.

ESC

By pressing

key, after the setting is

canceled the MENU - OPTION screen appears

again on the LCD.

Lens type setting is saved even after switching

OFF (O).

6. Press

ESC

key.

The MENU screen appears again on the LCD.

7. Press

ESC

key.

The MEAS screen appears again on the LCD.

44

Page 47

When Using ND Filter

US ER. CAL NON

LE NS ST D

ME NU

OP TI ON

ND-F I L TE R NON

MEA S

MEMORY

TA RG ET

OP T I ON

SE T U P

ME NU

ME AS S NG L

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

I nt

ND

No nBLon

LE N

S td

cd

m

2

Lv

x

y

T0 1

35. 93

0 . 3968

0 . 4060

Use the ND filter in the optional accessories when measuring a high-luminance object.

If the ND filter is attached, the measurement value must be compensated for the filter

transmittance. This compensation coefficient is attached to the ND filter. Use the data management

software CS-S10w Professional supplied with the CS-2000 as standard to set the coefficient in this

instrument. After that, when the ND filter is selected, the measurement value compensated with the

compensation coefficient can be obtained. See instruction manual of CS-S10w for details.

The wrong setting of ND filter leads to inaccurate measurement.

Do not use the ND filter with the closeup lens. It leads to inaccurate measurement.

Note that an extra ND filter is built into this instrument. There are three setting options for use or

non-use of this built-in ND filter: [AUTO] for switching automatically depending on the luminance of

the object, [OFF] for constant non-use, and [ON] for constant use (See p.31 to p.33).

* ND-FILTER : NONE, ND10, ND100

* Factory default setting : NONE

Setting

Operation Procedure

6, 7

1

1. Press

screen is displayed.

The MENU screen appears.

When the backlight of the LCD has been turned

off via

the backlight is turned on.

MENU

key when the MEAS

BACKLIGHT

key on the MEAS screen,

2, 3, 4, 5

2. Press either or key to select

[OPTION] and then press

ENTER

key.

The MENU – OPTION screen appears.

The current set contents are displayed in the

[ND-FILTER] item.

45

Page 48

3. Press either or key to select

US ER. CAL NON

LE NS ST D

ME NU

OP TI ON

ND-F I L TE R 10

OP TI ON

N

D-F I LT ER

NON E

ND 10

N

D

1 00

ME NU

ME AS S NG L

UC 00

SPD

N

r

m

Ob

s

2

˚

ND10BL

on

LE N

S td

cd

m

2

Lv

x

y

T0 1

SYN C

I nt

35. 93

0 . 3968

0 . 4060

OP TI ON

N

D-F I LT ER

NON E

ND 10

N

D

1 00

ME NU

[ND-FILTER] and then press

key.

The MENU - SETUP – ND-FILTER (ND filter

selection) screen appears.

ENTER

Setting

4. Press either or key to select

[NONE], [ND 10] or [ND 100].

5. Press

ENTER

When the ND filter is set, the MENU - OPTION

screen appears again on the LCD.

By pressing

canceled the MENU - OPTION screen appears

again on the LCD.

ND filter setting is saved even after switching

OFF (O).

6. Press

ESC

The MENU screen appears again on the LCD.

key.

ESC

key, after the setting is

key.

7. Press

ESC

key.

The MEAS screen appears again on the LCD.

46

Page 49

Calibration

ME AS S NG L

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No

n

ND10BL

on

LE N

S td

cd

m

2

Lv

x

y

T0 1

35. 93

0 . 3968

0 . 4060

MEA S

MEMORY

TA RG ET

OP T I ON

SE T U P

ME NU

US ER. CAL NON

LE NS ST D

ME NU

OP TI ON

ND-F I L TE R 10

Calibration Channel

This instrument includes 11 calibration channels from Ch00 to Ch10.

Ch00 is for measurement based upon KONICA MINOLTA’s calibration standard. Its

calibration correction coefficient has been set and is unchangeable.

The following contents can be set to Ch01 to Ch10 respectively using data management

software CS-S10w Professional supplied with the CS-2000 as standard. See instruction

manual of CS-S10w for details.

Correction coefficient of user calibration

Correction coefficient ID

They are commonly used among each color space of Lvxy, Lvu’v’, LvT∆uv, XYZ, dominant

wavelength/excitation purity and spectral graph in one channel.

Calibration channels can be changed using the following procedure.

Setting

Operation Procedure

6, 7

1

1. Press

screen is displayed.

The MENU screen appears.

When the backlight of the LCD has been turned

off via

the backlight is turned on.

MENU

key when the MEAS

BACKLIGHT

key on the MEAS screen,

2, 3, 4, 5

2. Press either or key to select

[OPTION] and then press

key.

The MENU – OPTION screen appears.

The current set contents are displayed in the

ENTER

[USER.CAL] item.

47

Page 50

3. Press either or key to select

OP TI ON

US ER. CAL

CAL NO,

NON

ME NU

US ER. CAL 03

LE NS ST D

ME NU

OP TI ON

ND-F I L TE R 10

ME AS S NG L

UC 03

SPD

N

r

m

Ob

s

2

˚

SYN C

No

n

ND10BL

on

LE N

S td

cd

m

2

Lv

x

y

T0 1

35. 93

0 . 3968

0 . 4060

OP TI ON

US ER. CAL

CAL NO,

03

ME NU

[USER.CAL] and then press

ENTER

key.

The MENU - SETUP – USER.CAL (Calibration

channel selection) screen appears.

The calibration channel number and

Setting

compensation coefficient ID (with a maximum of

10 letters) are displayed. In case of Ch00,

“NON” is displayed. See instruction manual of

CS-S10w for details.

4. Press either or key to select the

channel.

key for larger number.

key for smaller number.

The calibration channel numbers can be

selected among NON, and 01 to 10.

5. Press

6. Press

7. Press

ENTER

key.

When the calibration channel is set, the MENU OPTION screen appears again on the LCD.

If the calibration channel without compensation

coefficient setting is selected, the setting will not

be possible.

ESC

By pressing

key, after the setting is

canceled the MENU - OPTION screen appears

again on the LCD.

ESC

key.

The MENU screen appears again on the LCD.

ESC

key.

The MEAS screen appears again on the LCD.

48

Page 51

Backlight ON/OFF During Measurement

OB SER V ER

2

°

DA TA

FO RM F

BA CKL I GH T@MEA S

O

N

ME NU

SE TU P

MEA S

MEMORY

TA RG ET

OP T I ON

SE T U P

ME NU

ME AS S NG L

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No

n

ND10BL

on

LE N

S td

cd

m

2

Lv

x

y

T0 1

35. 93

0 . 3968

0 . 4060

The LCD backlight can be selectively turned on or off during measurement.

If the backlight is turned off, LCD backlight reflection on the surrounding area

affecting the measurement value during measurement can be avoided.

If pressing the BACKLIGHT key to turn off the backlight, while the MEAS screen is

displayed, the backlight is forcibly turned off independently of the following setting.

* Factory default setting : ON

Operation Procedure

6, 7

1

1. Press

screen is displayed.

The MENU screen appears.

When the backlight of the LCD has been turned

off via

the backlight is turned on.

MENU

key when the MEAS

BACKLIGHT

key on the MEAS screen,

Setting

2, 3, 4, 5

2. Press either or key to select

[SETUP] and then press

ENTER

The MENU – SETUP screen appears.

The current set contents are displayed in the

[BACKLIGHT@MEAS] item.

key.

49

Page 52

3. Press either or key to select

OB SER V ER

2

°

DA TA

FO RM F

BA CKL I GH T@MEA S

O

FF

ME NU

SE TU P

SE TU P

ME NU

BAC KL I G HT

@

MEA S

O

FF

O

N

ME AS S NG L

UC 00

SPD

N

r

m

Ob

s

2

˚

SYN C

No

n

BL

o f f

LE N

S td

cd

m

2

Lv

x

y

T0 1

ND

10

35. 93

0 . 3968

0 . 4060

[BACKLIGHT@MEAS] and then press

ENTER

The MENU - SETUP - BACKLIGHT@MEAS

(Turning ON/OFF backlight during

measurement) screen appears on the LCD.

Setting

key.

4. Press either or key to select

[ON] or [OFF].

5. Press

ENTER

key.

When the setting is made to turn the backlight

on or off during measurement, the MENU -

SETUP screen appears again on the LCD.

ESC

By pressing

key, after the setting is

canceled the MENU - SETUP screen appears

again on the LCD.

Setting of backlight ON/OFF during

measurement is saved even after switching OFF

(O).

6. Press

ENTER

key.

The MENU screen appears again on the LCD.

7. Press

ESC

key.

The MEAS screen appears again on the LCD.

50

Page 53

Measurement

51

Page 54