Page 1

User Manual

CF5001

Page 2

Recycled paper is used for the inside pages of this manual.

Thank you very much for your purchase of the CF5001.

This Manual deals with making copies, correct handling of the machine, and

precautions for safety. Please read before copying.

In order to maintain a satisfactory copying performance, please keep this

Manual readily available for reference in the rear pocket of the machine.

ENERGY STAR

The ENERGY STAR Program has been established

to encourage the widespread and voluntary use of

energy-efficient technologies that reduce energy

consumption and prevent pollution. As an

®

Program

ENERGY

STAR Partner, we have determined that this product

meets the

efficiency grounding it on the following features.

Auto Low Power

This function conserves energy by lowering the set temperature of the fixing

unit. In the standard setting, Auto Low Power operates automatically when 15

minutes have elapsed after completion of the last copy, with the copier remaining

in the ready to copy state during that time.

The time period for the Auto Low Power function can be set for 5 minutes, 10

minutes, 15 minutes, 30 minutes, 60 minutes, 90 minutes, 120 minutes, or 240

minutes. See p. 2-19 for details.

Automatic Shut-Off

This function achieves further energy conservation by partially turning OFF the

power supply, thereby reducing energy consumption to 20 W or less. In the

standard setting, Automatic Shut-Off follows Auto Low Power, operating

automatically when 90 minutes have elapsed after completion of the last copy,

with the copier remaining in the ready to copy state during that time.

The time period for the Automatic Shut-Off function can be set for 30 minutes,

60 minutes, 90 minutes, 120 minutes or 240 minutes. See p. 2-19 for details.

Automatic Duplex Copying

To reduce paper consumption, use this function to make double-sided (duplex)

copies, automatically.

ENERGY STAR guidelines for energy

We recommend that you utilize the Auto Low Power function, the Automatic

Shut-Off function, and the Automatic Duplex Copying function.

Copyright © 2000 GoAhead Software, Inc. All rights Reserved.

Page 3

Contents

Contents

Features of the CF5001

Legal Restrictions on Copying

Basic

Section 1: Safety Information

Caution Labels and Indicators ....................................................... 1-2

Requirements for Safe Use............................................................ 1-6

Power Source .................................................................................... 1-6

Environment....................................................................................... 1-7

Precautions for Routine Handling .................................................... 1-10

Regulations.................................................................................. 1-13

CE Marking (Declaration of Conformity) .......................................... 1-13

Laser Safety..................................................................................... 1-13

Internal Laser Radiation................................................................... 1-14

Laser Safety Label ........................................................................... 1-17

Ozone Release ................................................................................ 1-18

Section 2: Machine Information

Machine Configuration ................................................................... 2-2

External Machine Items ..................................................................... 2-2

Internal Machine Items....................................................................... 2-4

Standard/Optional Equipment............................................................ 2-5

Control Panel Layout ......................................................................... 2-6

Basic Screen...................................................................................... 2-8

FN-120/FN-9 Finisher (with PK-5 Punch Kit) ................................... 2-10

Cover Inserter D............................................................................... 2-12

C-208 Large Capacity Cassette....................................................... 2-13

TMG-3 Trimming Unit ...................................................................... 2-14

Turning On the Power Switch ...................................................... 2-16

To Turn On the Power ..................................................................... 2-16

To Turn Off the Power ..................................................................... 2-18

Reducing the Power in Standby Mode (Auto Low Power) ............... 2-19

Shutting Off Automatically (Auto Shut-Off) ...................................... 2-19

Shutting Off / Reducing the Power Manually ................................... 2-20

Entering an EKC Password (EKC)................................................... 2-21

i

Page 4

Contents (continued)

Section 2: Machine Information (continued)

Loading Paper..............................................................................2-22

Loading Paper in Tray 1 ,2, and 3....................................................2-23

Loading Paper in Multi-Sheet Bypass Tray...................................... 2-26

Loading Paper in LCT (C-208).........................................................2-27

Loading Tabbed Sheets in Tray 1, 2, or 3........................................2-30

Loading Tabbed Sheets in LCT (C-208) .......................................... 2-31

Loading Tabbed Sheets in Multi-Sheet Bypass Tray .......................2-32

Section 3: Copying Operations

Selecting Colour Mode ................................................................... 3-2

Positioning Originals ...................................................................... 3-4

Positioning Originals in RADF............................................................3-4

Positioning Original on Platen Glass..................................................3-8

Setting Print Quantity ...................................................................3-10

To Set Print Quantity........................................................................3-10

To Change Print Quantity................................................................. 3-10

Setting Job During Warm-up........................................................ 3-11

To Stop Scanning/Printing ........................................................... 3-13

Selecting Paper Size.................................................................... 3-14

To Select Paper Size Automatically (APS) ......................................3-14

To Specify Desired Paper Size (AMS) .............................................3-16

Copying Using Special Paper (Multi-Sheet Bypass Tray) ..................3-18

Selecting Magnification Ratio (Lens Mode).................................. 3-22

To Copy in 1.000 Magnification Mode.............................................. 3-22

To Change Magnification Ratio (Fixed Magnification / Zoom Mode)3-23

Making Double-Sided Copies (1a2, 2a2) ................................... 3-25

Using RADF .....................................................................................3-25

Using Platen Glass........................................................................... 3-28

Making Single-Sided Copies from Double-Sided Originals (2a1) .................. 3-31

To Scan Originals into Memory (Store Mode).............................. 3-33

To Set Next Copying Job (Reserve) ............................................ 3-35

To Check/Control Jobs in Progress (Job Status Screen) ...................3-38

Output Mode for Machine without Finisher ..................................3-41

Output Mode for Machine with Finisher ....................................... 3-45

Selecting Binding Mode ...............................................................3-52

ii

Page 5

Contents (continued)

Section 4: Helpful Functions

Making Sample Copy (Proof Copy) ............................................... 4-2

Checking Feature Selections / Proof Copying (Check Mode) ....................4-4

Interrupt Copying ........................................................................... 4-8

Storing Job Conditions (Job Memory: Job Store)........................ 4-11

Recalling Stored Job Settings (Job Memory: Job Recall).................. 4-14

Recalling Previous Job Settings .................................................. 4-15

Displaying Screen for Operation Guide (Help Mode)................... 4-16

To Display Help Screen from Basic Screen..................................... 4-16

To Display Help Screen from Other Screens................................... 4-18

Section 5: Troubleshooting

When “Call for Service” Message Is Displayed.............................. 5-2

Limited Use of the Copier in Trouble ................................................. 5-3

Clearing Mishandled Paper............................................................ 5-4

When “JAM” Appears on Folder Key (Or Arrow Key Flashes) .......................... 5-6

When “ADD PAPER” Appears on Folder Key (Or Arrow Key Flashes) .....................5-8

When “Memory Full” Message Is Displayed (Memory Overflow) ...................... 5-9

Memory Overflow in Current Job ....................................................... 5-9

Memory Overflow in Reserve Job.................................................... 5-10

When Power OFF/ON Screen Is Displayed................................. 5-11

Troubleshooting Tips ................................................................... 5-12

Section 6: Machine Specifications

Main Body Specifications ............................................................... 6-2

Main Body .......................................................................................... 6-2

Option Specifications ..................................................................... 6-4

AFR-20 Duplexing Document Feeder................................................ 6-4

FN-120/FN-9 Finisher ........................................................................ 6-4

Cover Inserter D................................................................................. 6-5

TMG-3 Trimming Unit ........................................................................ 6-5

PK-5 Punch Kit................................................................................... 6-6

C-208 Large Capacity Cassette......................................................... 6-6

Others ................................................................................................ 6-6

iii

Page 6

Contents (continued)

Advanced

Section 7: Colour Image Adjustment

About Colours ................................................................................ 7-2

RGB and CMYK Models ....................................................................7-2

HSB Model .........................................................................................7-3

Colour Copy Quality ....................................................................... 7-4

Modifying Colours ..............................................................................7-4

Reproducing Images ........................................................................7-11

What Is Image Detection? ................................................................7-12

Applying Filters................................................................................. 7-13

Improving Colour Copy Quality ........................................................ 7-14

Selecting Density Level and Whitening the Background(Copy Density)...........................7-15

To Adjust Copy Density / Background Whiteness............................ 7-15

Setting Density Shift .........................................................................7-17

Changing Colours Using RGB and HSB Values (Colour Adjustment)..................... 7-19

Modifying RGB Value .......................................................................7-19

Modifying HSB Value .......................................................................7-21

Changing Colours Using CMYK Value (Colour Balance Adjustment) ..................... 7-24

Selecting Line Screen, Dot Screen, or High Compression (Screen Setting) ....................7-26

Adjusting Sharpness and Contrast / Selecting Gloss Mode......................7-29

Making Fine Adjustment in Image Detection (Image Judge) ....................7-32

Specifying Original Type (Original Image/Type in Special Original)........................7-34

Section 8: Advanced Information

Programmed Shut-Off (Weekly Timer)........................................... 8-2

Rotation.......................................................................................... 8-4

Vertical/Horizontal Zoom Mode......................................................8-5

Making Folded Booklet (Fold / Stitch & Fold)................................. 8-8

Punching File Holes in Copies (Punch)........................................ 8-11

Output Three-Folded Copies (Three-Fold)................................... 8-14

Making Trimmed Booklets (Trimming) ......................................... 8-16

Cover Sheet Feeding ...................................................................8-19

Off-Line Finishing ......................................................................... 8-22

iv

Page 7

Contents (continued)

Section 9: Special Original

Specifying Original Direction.......................................................... 9-2

Copying Non-Standard Size Originals (Original Form) ........................ 9-4

Copying Mixed Size Originals (Mixed Original).............................. 9-6

Copying Z-Folded Originals (Z-Folded Original) ............................ 9-8

Scanning Thin/Thick Originals in RADF (Original Thickness) ..................9-10

Section 10: Applications

To Display Application Selection Screen ..................................... 10-2

Inserting Sheets and Covers (Sheet/Cover Insertion) ....................... 10-3

Locating Title Pages on the Right Side (Chapter)........................ 10-7

Lay Out Several Pages onto One Sheet (Combination) .................. 10-10

Making a Multiple Page Signature Booklet (Booklet)....................... 10-13

Inserting Images into Printed Sets (Image Insert)...................... 10-17

Dividing an Image into Right and Left Pages (Dual Page) .....................10-20

Programming Different Settings for an Output Job (Program Job) ........................10-24

Dividing an Image for Enlarged Copy (Multi-Page Enlargement)...........................10-27

Erasing Outside of the Original (Non-Image Area Erase)................ 10-30

Reversing Colour in Image (Reverse Image).........................................................10-32

Repeating Selected Image Area (Repeat: Vert./Horiz. Mode)................10-34

Repeating Automatically or Selecting RepeatingTimes (Repeat: AUTO/ Repeat Mode).................................... 10-37

Eliminating Copy Marks Along Borders (Frame/Fold Erasure)...................... 10-40

Copying Image in the Centre of Copy Paper (AUTO Layout).................10-43

Adjusting Position of Copy Image (Image Shift) ........................ 10-45

Reducing Images to Create Binding Margin (Reduce&Shift)..................10-48

Printing Stamp, Page, Date/Time onto Copies (Stamp) .................. 10-51

Printing Watermark onto Copies (Stamp) .................................. 10-58

Overlaying an Image onto Each Page Copied in the Job (Overlay).......................10-62

Storing an Overlay Image in HDD / Overlaying Image Stored in HDD (Overlay Memory).................................. 10-65

v

Page 8

Contents (continued)

Section 11: Network Function

To Use Web Utilities..................................................................... 11-2

To Display Information on Machine.............................................. 11-4

To Display Current Machine Status (Job Status) ......................... 11-5

Setting E-Mail Transmission Function..........................................11-7

Setting E.K.C. Function................................................................ 11-9

Setting Scan Transmission Function.......................................... 11-19

Transmitting/Editing Machine Setting File.................................. 11-23

Section 12: Paper and Original Information

Paper Information......................................................................... 12-2

Paper Weight ...................................................................................12-2

Tray/ Exit Tray Capacity...................................................................12-4

Paper Size........................................................................................ 12-6

Special Paper in Multi-Sheet Bypass Tray....................................... 12-8

To Store Copy Paper .......................................................................12-8

Original Information...................................................................... 12-9

Platen Glass Originals......................................................................12-9

RADF Originals ..............................................................................12-10

Section 13: Maintenance & Supplies

Adding Toner................................................................................13-2

Inserting a New Staple Cartridge into FN-120/FN-9 Finisher....................13-7

Empty Waste Basket of PK-5 Punch Kit .................................... 13-10

Empty Waste Basket of TMG-3 Trimming Unit .......................... 13-12

Exchanging Toner Recovery Box...............................................13-14

Cleaning Image Scanning Section............................................. 13-16

Cleaning the Platen Glass.............................................................. 13-16

Cleaning the RADF Platen Guide Cover........................................13-16

Cleaning the Platen Cover ............................................................. 13-17

Checking Copy Count ................................................................ 13-18

To Display the Counter List Screen ............................................... 13-18

To Print the Counter List ................................................................ 13-19

Periodic Maintenance................................................................. 13-20

To Check the PM Counter.............................................................. 13-20

vi

Page 9

Contents (continued)

Section 14: Key Operator Mode

An Outline of the Key Operator Mode.......................................... 14-2

How to Access the Key Operator Mode........................................... 14-2

[1] System Initial Setting .............................................................. 14-4

[1] Date & Time Setting.................................................................... 14-4

[2] Language Select Setting............................................................. 14-6

[3] IP Address Setting ...................................................................... 14-7

[4] E-Mail Transmission Setting ....................................................... 14-8

[2] Copier Initial Setting.............................................................. 14-10

[3] User Setting Mode ................................................................ 14-11

[1] User Lens Mode Ratio Setting.................................................. 14-11

[4] EKC (Electronic Key Counter) Function Setting ................... 14-12

How to Access the EKC Setting Mode........................................... 14-13

[1] E.K.C. Data Edit........................................................................ 14-14

[2] E.K.C. All Count Reset.............................................................. 14-17

[3] E.K.C. Function Setting............................................................. 14-18

[4] Scanner Function Setting.......................................................... 14-19

[5] Lock/Delete Job Memory ...................................................... 14-20

[6] Paper Type / Special Size Set .............................................. 14-21

[1] Paper Type / Special Size Set .................................................. 14-21

[2] Paper Type Set (Bypass).......................................................... 14-23

[7] Panel Contrast / Key Sound Adjustment............................... 14-24

[8] Key Operator Data Setting.................................................... 14-25

[9] Weekly Timer ........................................................................ 14-26

How to Access the Weekly Timer Setting Mode ............................ 14-27

[1] Weekly Timer On/Off Setting .................................................... 14-28

[2] Timer Setting............................................................................. 14-29

[3] Timer Action On/Off Setting...................................................... 14-31

[4] Lunch Hour Off Setting ............................................................. 14-32

[5] Timer Interrupt Password Setting ............................................. 14-33

[10] Control Panel Adjustment ................................................... 14-34

[11] Tray Auto Select Setting ..................................................... 14-35

[12] Power Save Setting ............................................................ 14-36

[13] Memory Switch Setting ....................................................... 14-37

[14] Machine Management List Print ......................................... 14-43

[15] Call Remote Centre ............................................................ 14-44

[16] Finisher Adjustment ............................................................ 14-45

vii

Page 10

Contents (continued)

Section 14: Key Operator Mode (continued)

[17] Front & Back Density Setting .............................................. 14-47

[18] Scan Transmission Setting ................................................. 14-48

[19] Non-Image Area Erase Setting ...........................................14-50

[20] AE Adjustment .................................................................... 14-51

[21] Execute Adjustment Operation ........................................... 14-52

[22] Magnification Adjustment.................................................... 14-53

[23] Timing Adjustment .............................................................. 14-54

[24] Centring Adjustment............................................................ 14-56

[25] Printer Gamma Sensor Adjustment .................................... 14-57

Index

viii

Page 11

Features of the CF5001

AE - Automatic Exposure

Automatically adjusts exposure to compensate for quality of the original.

AMS - Automatic Magnification Selection

Automatically selects an appropriate magnification ratio when Paper Size is selected

manually. Automatically selected when the AMS key is touched.

APS - Automatic Paper Selection

Automatically selects copy paper size to match the original documents.

ATS - Automatic Tray Switching

Automatically switches tray to allow copying to continue without interruption if the

selected tray empties while copying is in progress.

Auto Layout

The original image on the platen glass or in the document feeder is copied and

centred on a sheet.

Auto Low Power

Automatically lowers the power after a specified period of copier inactivity.

Auto Reset

Automatically resets to auto mode defaults after a specified period of copier

inactivity.

Auto Shut-Off

Automatically shuts off the main power after a specified period of copier inactivity.

Booklet

Creates a multiple page signature booklet copied on both sides of paper in 1a2 or

2a2 copy mode.

Chapter

Starts chapter pages on the right side (front pages) of the finished document. Only

duplex mode (1a2) is compatible with this feature.

Colour Mode

Copies full-coloured originals or makes single-coloured copies, and also adjusts

image quality of the copies.

Combination

Copies a fixed number (2, 4, or 8) of pages onto one sheet of copy paper to create a

draft copy of a multi-page report at the same time as saving paper.

Copy Density

Manually selects up to 9 density levels.

Copy Mode

Selects the desired simplex mode (1a1 or 2a1); or duplex mode (1a2 or 2a2).

Counter List

Displays on the screen and prints the following data: total counter of the machine,

copier counter, print counter and the date when the counter started.

ix

Page 12

Features of the CF5001 (continued)

Density Shift

Shifts each of nine density levels in four density modes (Auto, Text, Photo, Map) to

three levels lighter or three levels darker.

Dual Page

Copies both pages of an open book or A3/B4 size sheet separately onto two A4/B5

size sheets in 1a1 mode or separately onto each side of one A4/B5 size sheet in

1a2 mode. You can use the Dual Page mode with the Front or Front/Back cover

mode. The cover page(s) will be scanned and copied normally before image division

is performed on the other pages.

Frame/Fold Erasure

Erases border and/or fold image area using Frame (1 - 300 mm), Fold (1 - 99 mm), or

Frame & Fold.

Image Insert

Stores pages in memory from the platen glass, and inserts the pages into a

document copied from the document feeder.

Image Shift

Creates or removes a binding margin at the top, bottom, right and left edges (shift

amount from 0 ~ 250 mm, in 1 mm increments); reduces image to prevent image

loss (reduce & shift amount from 0 ~ 250 mm, in 1 mm increments).

Interrupt Copying

Interrupts copying-in-progress to perform an urgent copy, using any of the copier

features for the interrupt job.

Job Memory

Programs up to 30 jobs and recalls each job by job number, as needed. All

compatible platen glass functions can be programmed into Job Memory directly after

they are selected.

Job Status

Displays the Job Status Screen to view the current machine status, changes the

operation order of reserve jobs, deletes the unused reserve job, or displays the

previous job list.

Lens Mode (Fixed, Zoom)

Selects fixed ratios, four reduction, four enlargement, and three user-set ratios.

Zoom ratios can be selected from 25.0% ~ 400.0% in 0.1% increments.

Machine Status Confirmation

Displays the current machine status on LCD for confirmation.

Manual Shut-off

Shuts off the machine power when pressing [POWER SAVER ON/OFF] on the

control panel.

Mixed Original

Copies mixed size originals from the document feeder in APS or AMS mode. APS

automatically selects the paper size of each original. AMS mode allows you to select

one paper size for all originals.

x

Page 13

Features of the CF5001 (continued)

Multi-Page Enlargement

Makes an enlarged copy, made up of several copied pages divided and enlarged

from an original image.

Network Function by Web Browser

When the machine is connected to a PC over a network, uses a web browser on the

PC to check the machine or job information, and to perform the Key Operator

settings concerning the network environment.

Non-Image Area Erase

When copying from the platen glass when the document cover is open, copies only

the image area and not the exposed area of glass, which would otherwise copy as

black.

Non STD Size for Multi-Sheet Bypass Tray

Enters the special paper size to be loaded on the Multi-sheet bypass tray using the

touch screen keypad in order to avoid paper misfeed.

Non STD Size for Original

Identifies the special original size which the CF5001 cannot detect, in order to select

the optimal paper size for copying or printing.

Original Image

Enhances photo image in PHOTO mode, regular image in TEXT/PHOTO mode, text

image in TEXT mode, coloured image with small text in MAP mode.

Original Type

Improves the image quality by specifying the printed original type.

Output Mode for Machine with FN-120/FN-9 Finisher Installed:

Non-Sort, Sort, Staple-Sort, and Group modes using the primary (main) tray

Non-Sort Face Down exit, Non-Sort Face Up exit, Group Face Down exit, and

Group Face Up exit modes using the secondary (sub) tray

Fold and Stitch & Fold modes using the booklet tray (FN-9 only)

Selects an output tray and output mode on the Output Mode popup menu.

Output for Machine with no Finisher Installed:

Non-sort, Rotation sort, Group, and Rotation group modes are available in

combination with Face down or Face up exit.

Selects an output mode on the Output Mode popup menu.

Output for FN-120/FN-9 Finisher with Cover Inserter D Installed:

Cover Sheet mode

Off-Line Finishing mode

For details, see Section 8: Advanced Information.

Overlay

Scans an original image and overlays it on the pages of another document. For

example, you may want to incorporate a page heading, graphic design or logo into

the pages of your document.

Overlay Memory

Same as for Overlay except the overlay image is stored in memory.

xi

Page 14

Features of the CF5001 (continued)

Paper Capacity

Total 1,750 sheets, including three 500-sheet trays and a 250-sheet Multi-sheet

bypass tray.

Total 4,250 sheets, including 2,500-sheet optional large capacity tray.

Platen Memory

Scans documents into memory from the platen glass and/or the document feeder

and inserts the pages into another document copied from the document feeder. If an

incompatible function is selected in this mode, the latter function will not be selected,

and an Error message will be displayed.

Power Saver

Automatically turns off all but nominal power supply after a specified period of copier

inactivity, for optimal efficiency. Power is returned after a brief warm up period by

pressing [POWER SAVER ON/OFF] on the control panel.

Program Job

Scans documents into memory while designating different copy conditions for each

original, then prints all the documents collectively.

Proof Copy

To ensure correct output before running multiple copies, run a proof copy by pressing

[PROOF COPY] on the control panel or touching PROOF COPY on the Check

Screen.

Punch Mode for FN-120/FN-9 Finisher with PK-5 Punch Kit Installed:

Punches four holes in output copies.

Repeat

Selects the horizontal image area across the page, and repeats it down the page as

many times as the repeat width setting (10 ~ 150 mm) permits in manual or auto.

Reserve

Scans in subsequent copy jobs while the CF5001 is busy printing or copying.

Reverse Image

Reverses the positive image to negative image or vice versa in the selected colour

mode.

Rotation

Rotates the image before copying when the portrait/landscape orientation of the

original is different from the orientation of the copy paper.

Rotation Exit (Rotation Sort / Rotation Group)

When no Finisher is installed, Rotation Exit alternately switches the horizontal and

vertical orientation of each sorted set as it outputs to the exit tray. Be sure to load

both A4 and A4R in separate trays (including the Multi-sheet bypass tray) before

selecting this feature.

Sheet/Cover Insertion

Insert up to 30 blank or copied sheets from any tray including the Multi-sheet bypass

tray, or inserts blank or copied front and back covers from any tray including the

Multi-sheet bypass tray to enhance the presentation of multi-page documents.

xii

Page 15

Features of the CF5001 (continued)

Stamp

Prints watermark, regular stamp, date/time, page number, and numbering onto the

output copies to enhance the presentation and usefulness of the copies.

Staple

Selects the stapling position and number of staples.

STD Size (Special)

Detects the standard paper sizes which cannot normally be detected when loaded in

a main body tray or Multi-sheet bypass tray.

Tab Paper

Copies onto tabbed sheets from tabbed originals, allowing the image on the tab part

of the original to be printed on the same part of the tabbed copy paper.

Three-Fold Mode for Machine with FN-9 Finisher Installed:

Folds A4 or 8.5”x11”R output copies in three.

Trimming Mode for FN-9 Finisher with TMG-3 Trimming Unit Installed:

Trim the end of folded or stitched & folded booklets.

Weekly Timer

Can be set according to the needs of each work environment. Turns main body

power Off/On daily or weekly, during lunch time, on holidays, and also enables the

Timer Interrupt mode, which allows temporary use of the machine even when the

machine is in the daily, weekly, or holiday Off mode.

Wide Size Paper

Copies onto paper slightly larger than the specified regular size.

Z-Folded Original

This feature sets the RADF to accept Z-folded originals.

xiii

Page 16

Legal Restrictions on Copying

Certain types of documents must never be copied with the purpose or intent to pass

copies of such documents off as the originals.

The following is not a complete list, but is meant to be used as a guide to responsible

copying.

<Financial Instruments>

• Personal checks

•Travelers checks

• Money orders

• Certificates of deposit

• Bonds or other certificates of indebtedness

• Stock certificates

<Legal Documents>

• Food stamps

• Postage stamps (canceled or uncanceled)

• Checks or drafts drawn by government agencies

• Internal revenue stamps (canceled or uncanceled)

• Passports

• Immigration papers

• Motor vehicle licenses and titles

• House and property titles and deeds

<General>

• Identification cards, badges, or insignias

• Copyrighted works without permission of the copyright owner

You are prohibited under any circumstances to copy domestic or foreign currencies,

or works of art without permission of the copyright owner.

When in doubt about the nature of a document, consult with legal counsel.

xiv

Page 17

Basic

Page 18

Page 19

Section 1:

Safety Information

1

Caution Labels and Indicators .......................................... 1-2

Requirements for Safe Use .............................................. 1-6

Regulations..................................................................... 1-13

Precautions for Installation and Use

Page 20

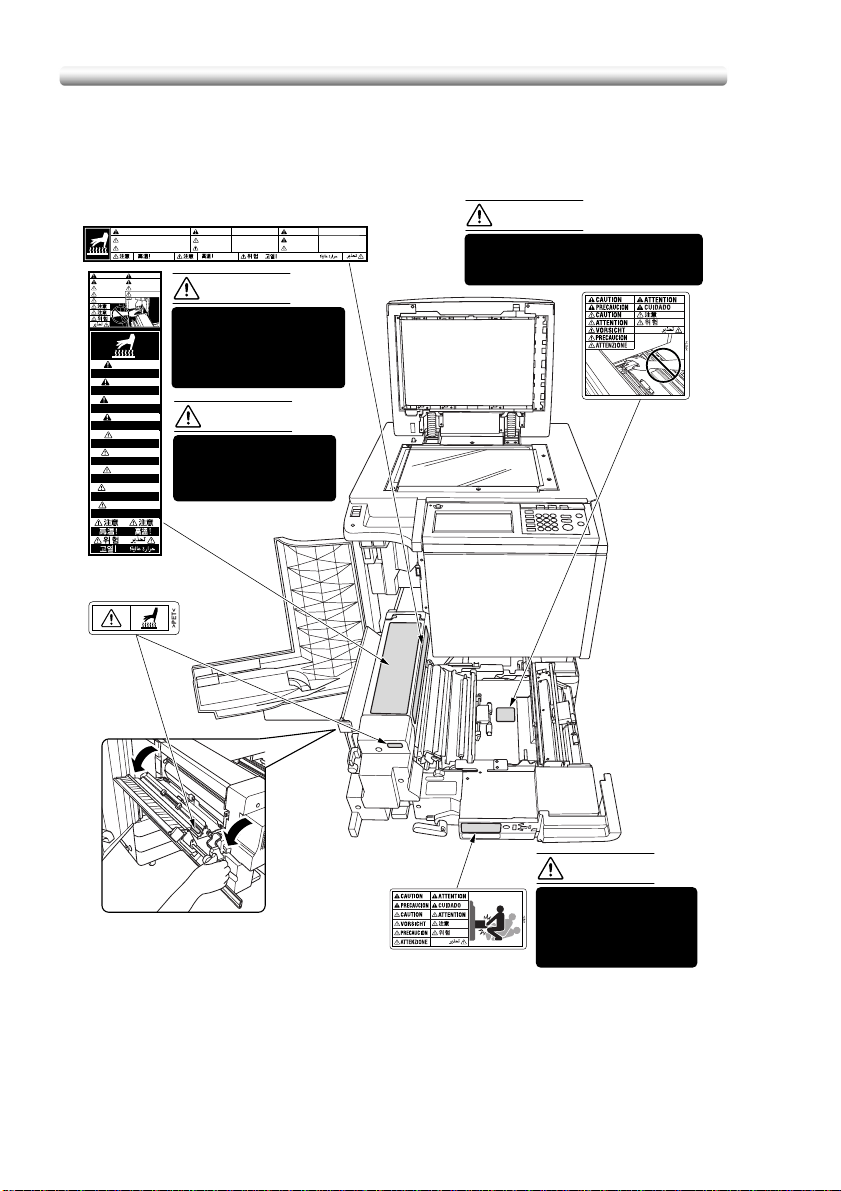

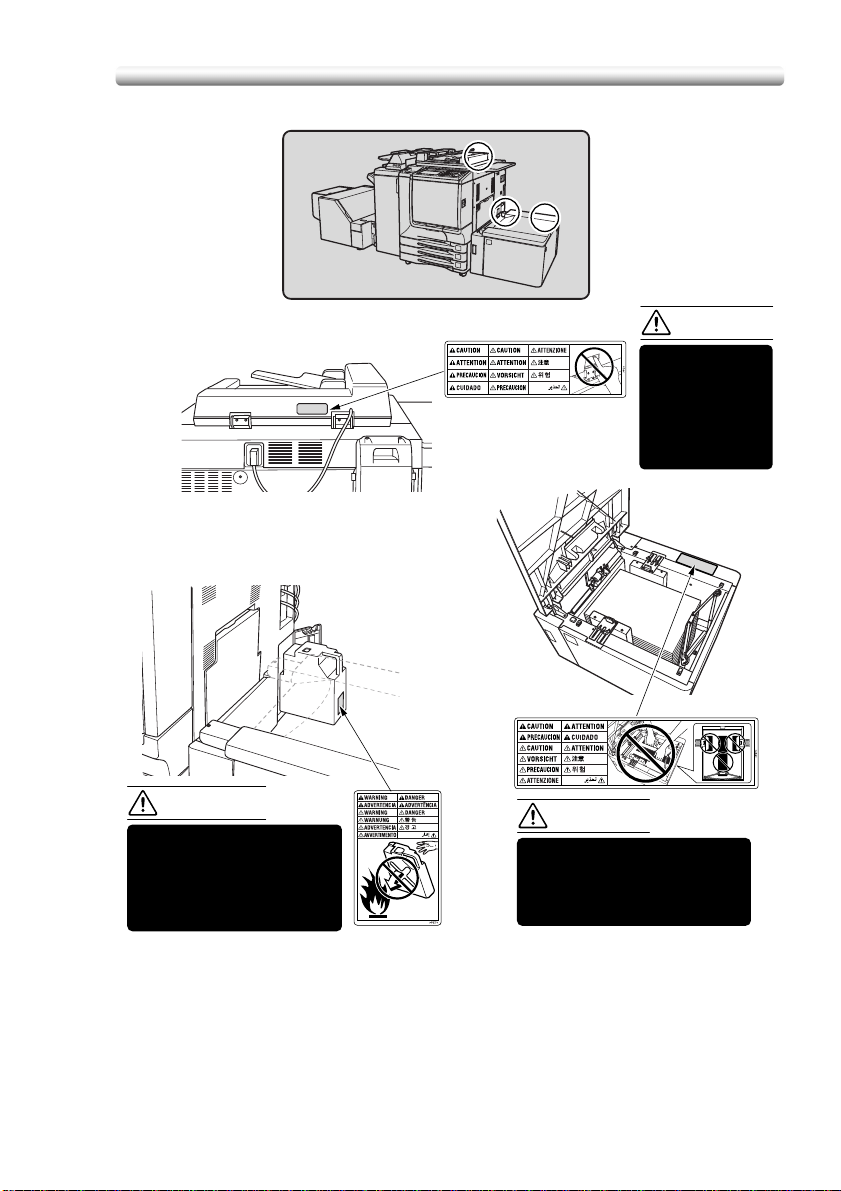

Caution Labels and Indicators

The caution labels and indicators are attached to the machine areas, as shown

below, where you are advised to pay special attention to avoid any dangerous

situations or serious injury.

(Right side of the fixing unit)

High temperature!

CAUTION

CAUTION

VORSICHT

ATTENTION

CAUTION

PRECAUCION

CUIDADO

ATTENTION

CAUTION

VORSICHT

PRECAUCION

ATTENZIONE

CAUTION

High temperature!

ATTENTION

Température élevée!

PRECAUCION

¡Temperatura alta!

CUIDADO

Alta temperatura!

CAUTION

High temperature!

ATTENTION

Température élevée!

VORSICHT

Heisse Oberfläche!

PRECAUCION

¡Temperatura alta!

ATTENZIONE

Alta temperatura!

(Top surface of

the fixing unit)

ATTENTION

High temperature!

ATTENTION

Heisse Oberfläche!

PRECAUCION

CAUTION

DO NOT put your hand

between the main body

and developing fixing unit;

otherwise you may be

injured.

CAUTION

The fixing unit is very

hot.

To avoid getting burned

DO NOT TOUCH.

Température élevée!

Température élevée!

¡Temperatura alta!

PRECAUCION

CUIDADO

ATTENZIONE

¡Temperatura alta!

Alta temperatura!

Alta temperatura!

CAUTION

DO NOT put your hand between the

main body and developing fixing

unit; otherwise you may be injured.

(Inside of the fixing unit)

1-2

CAUTION

The conveyance fixing

unit is heavy.

Use care and draw it out

gently; otherwise you

may be injured.

Page 21

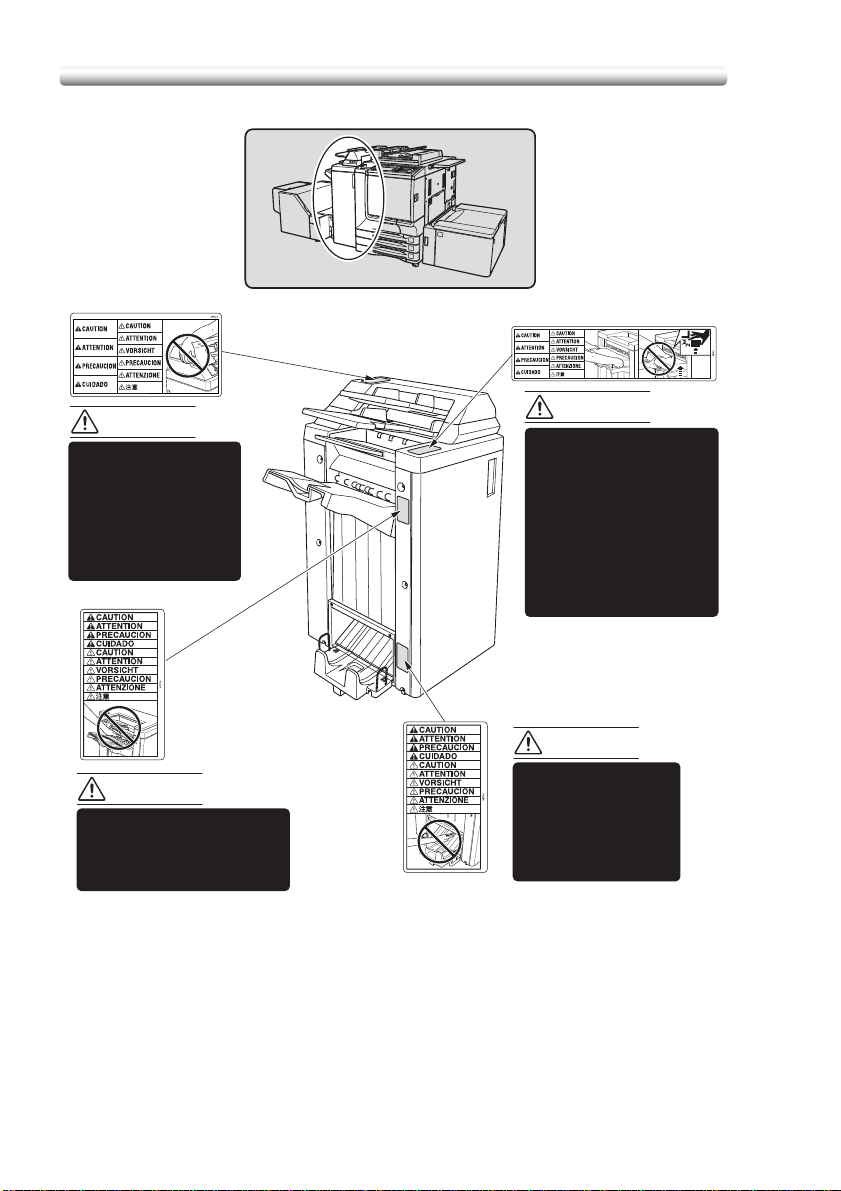

(Rear side of the RADF)

(Right rear side

of the Main body)

Caution Labels and Indicators (continued)

CAUTION

DO NOT INSERT

your finger into

the two RADF

hinge portions;

otherwise you

may be injured.

WARNING

DO NOT throw the toner

recovery box into a fire. If it

is thrown into a fire, the

toner may ignite and cause

a dangerous situation.

(Inside of the LCT)

CAUTION

To avoid any unexpected

injury, DO NOT put your hand

into the holes (3 places) on

the bottom plate of the LCT.

1-3

Page 22

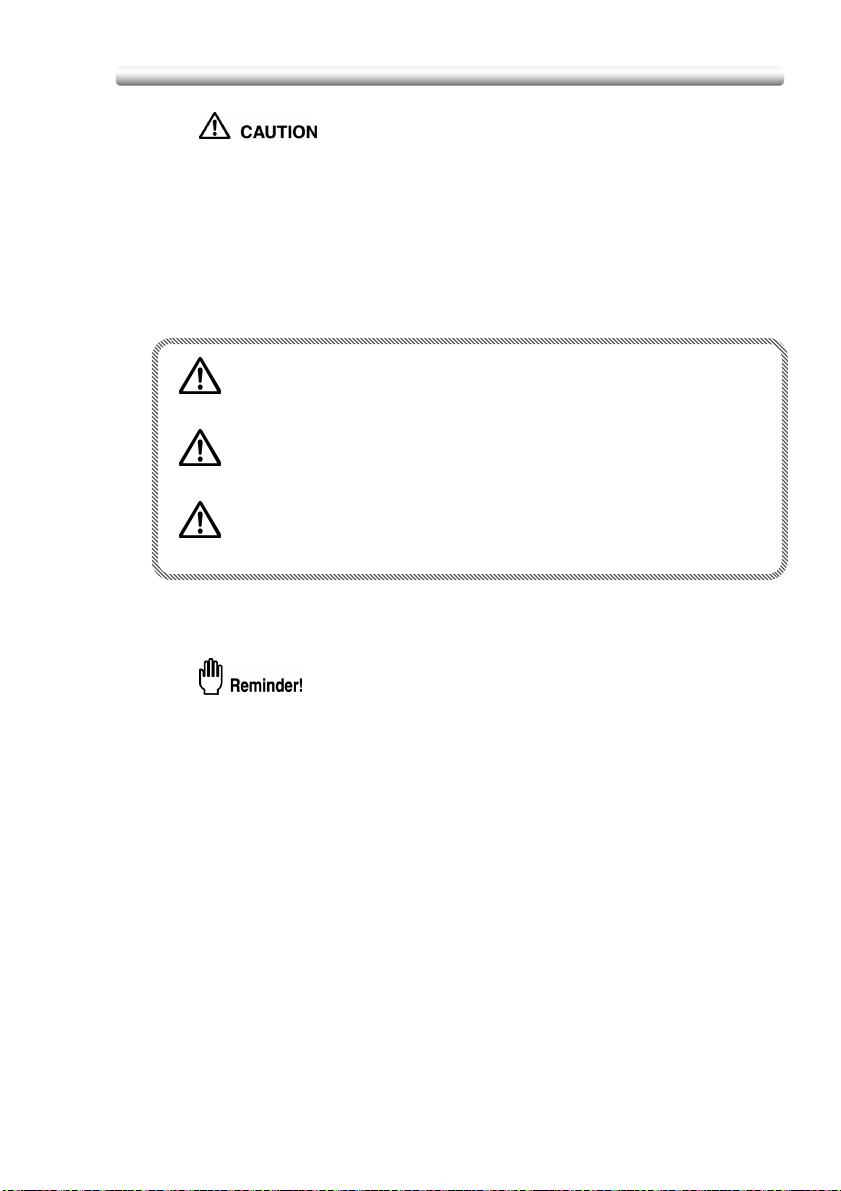

(Finisher with Cover inserter)

Caution Labels and Indicators (continued)

CAUTION

DO NOT insert your

finger into the bottom

of the upper part of the

feeder when returning

to its original position;

otherwise you may be

injured.

CAUTION

Use care after opening the

paper exit outlet. DO NOT put

your hand into it; otherwise

you may be injured.

CAUTION

To avoid injury, DO NOT

put your hand on top of

the printed sheets.

Be sure to hold both sides

of the printed sheets when

removing them, and DO

NOT leave your hand on

the printed sheets while

the primary (main) tray

goes up.

CAUTION

Inside the lower paper

exit outlet is the roller

drive unit. DO NOT put

your hand into it;

otherwise you may be

injured.

1-4

Page 23

Caution Labels and Indicators (continued)

Burns or injury may occur from touching the areas detailed in the

caution labels and caution indicators. Do not remove caution labels

or indicators. If any caution label or caution indicator is soiled,

please clean to make legible. If you cannot make them legible, or if

the caution label or indicator is damaged, please contact your

service representative for replacement labels.

The following indicators are used on the caution labels or in this manual to

categorize the level of safety cautions.

DANGER:

Action highly liable to cause death or serious injury.

WARNING:

Action liable to cause death or serious injury.

CAUTION:

Action liable to cause minor injury, machine trouble or physical damage.

If you find any of these indicators when removing jammed paper, adding toner, or

reading the manual, be sure to follow the information.

If the safety cautions in the manual become illegible due to soilage, etc.,

please procure a new copy from your service representative.

1-5

Page 24

Requirements for Safe Use

To ensure your safe use of the machine, the following describes the precautions you

are required to observe without fail for the power source of the machine and during

installation and routine handling. Be sure to read and observe them.

Power Source

CAUTION: Plug Socket

• A plug socket is limited in capacity. Use only a power source with the correct rating

for the machine; otherwise, hazardous situations such as smoking or overheating

may occur.

• Avoid multiple connections in the same outlet. Do not use multiple outlet adaptors.

CAUTION: Power Plug and Cord

• Be sure to insert the power plug firmly into the power socket. Otherwise an

accident may occur as a result of smoking or overheating. If the inserted power

plug is loose in the socket, even after it has been positively inserted, disconnect

the plug and contact your electrical contractor.

• For plug cable equipment, the socket-outlet shall be installed near the equipment

and shall be easily accessible.

• Do not bend or crush the power cord. If your copier power cord is bent or damaged

in any way, contact your service representative immediately. Do not attempt to

repair it yourself, and do not continue to operate the copier. A damaged power cord

may result in overheating, a short circuit, or fire.

• Do not bundle or coil the power cord of the copier. Otherwise an accident may

occur as a result of overheating or fire.

CAUTION: Connecting Multiple Loads to One Socket Outlet Prohibited

Never connect multiple loads to one socket outlet using a multi-outlet extension cord

or branched socket. Otherwise an accident may occur as a result of overheating or

fire.

CAUTION: Extension Cord

An extension cord must never be used with this machine.

1-6

Page 25

Requirements for Safe Use (continued)

Environment

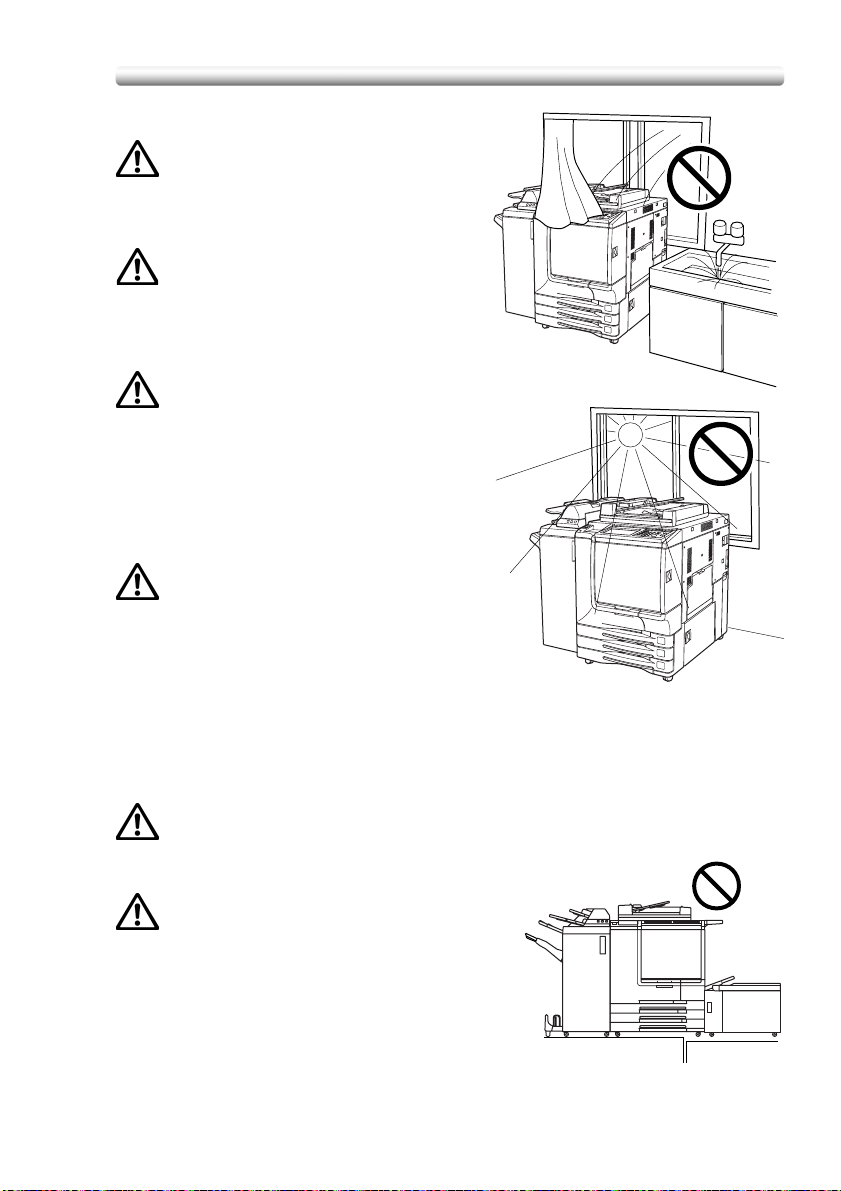

CAUTION: Prevention of Fire

Do not install near flammable materials,

curtains and volatile combustibles, that can

catch or cause fire.

CAUTION: Prevention of Short Circuit

Do not install the copier where it could be

splashed with rain water, or water from a tap,

to avoid a short circuit.

CAUTION: Temperature and Humidity

• Keep away from direct sunlight, heat

sources such as stoves, cool air from an air

conditioner and hot air from a heater.

• Avoid any environment that is outside the

range shown below:

10 to 30°C in temperature

10 to 80% in humidity

CAUTION: Ventilation

• Keep the installation place well-ventilated.

• Keep away from dust or corrosive gases.

These materials may cause poor image

quality.

• During the use of machine, the machine

generates ozone in an insufficient amount to cause any hazard to the human body.

However, if the machine is used in a poorly ventilated room, many copies are

made, or more than one copier is used at the same time, an odor may be detected.

Ensure adequate ventilation for a comfortable working environment.

CAUTION: Vibration

Do not install on a floor which is subject to

vibration or is not level.

CAUTION: Transportation

Be sure to contact your service representative

when moving or transporting the machine. If you

move the machine with the Hard disk drive or

Memory unit installed, machine trouble may be

caused by vibration.

1-7

Page 26

Requirements for Safe Use (continued)

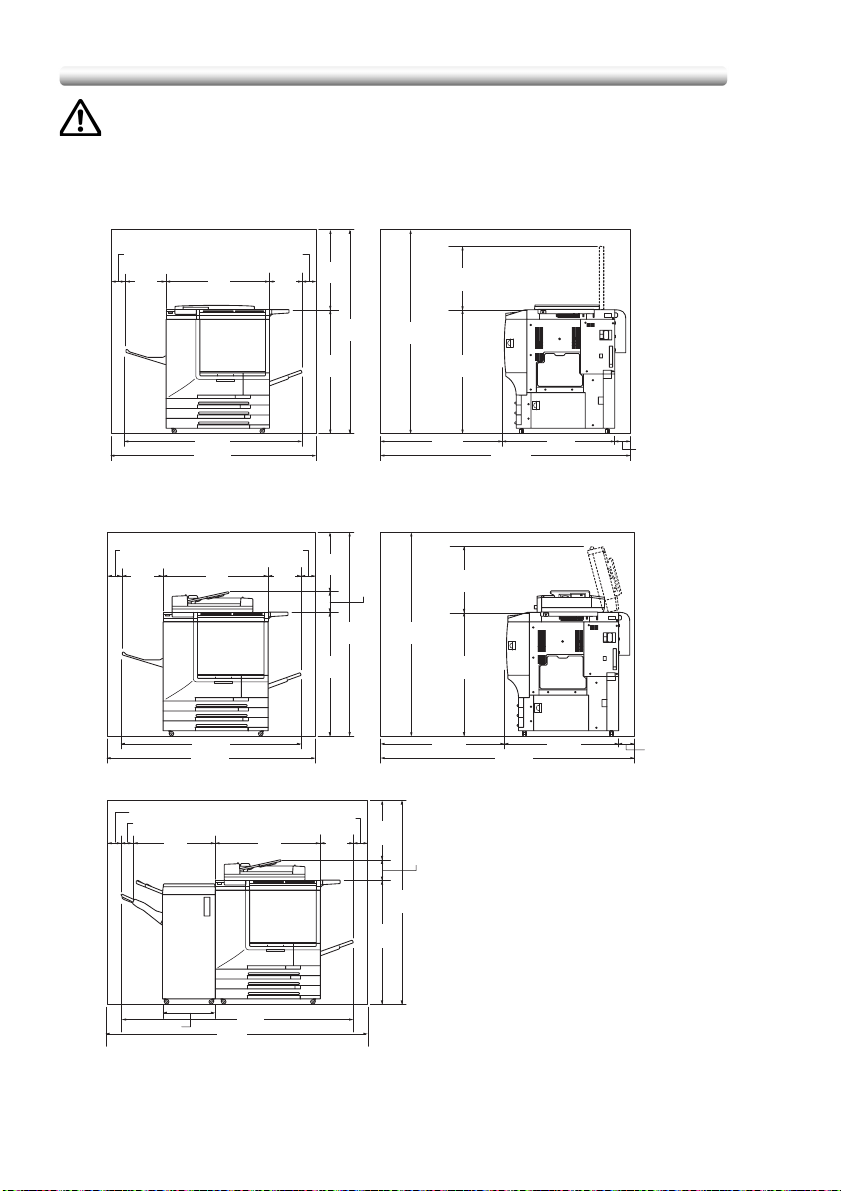

CAUTION: Installation Space

Allow sufficient space for facilitating copy operation, changing parts, and periodic

inspection. Leave an adequate space behind the machine to let hot air out from the

rear fan.

Unit: mm Unit: mm

100 100

315

760

200

570

470

1275

1475

1591

1021 1021

1591

950

1959

CF5001 + OC-2 (Front) CF5001 + OC-2 (Right side)

Unit: mm Unit: mm

200

100

440

1021

1619

158

499

1619

1021

950

CF5001 + AFR-20 (Right side)

1959

100

315

1275

1475

760

CF5001 + AFR-20 (Front)

Unit: mm

100

85

760656

200

100

440

158

1619

889

889

120

120

1-8

410

1901

1701

CF5001 + AFR-20 + FN-120 (Front)

1021

Page 27

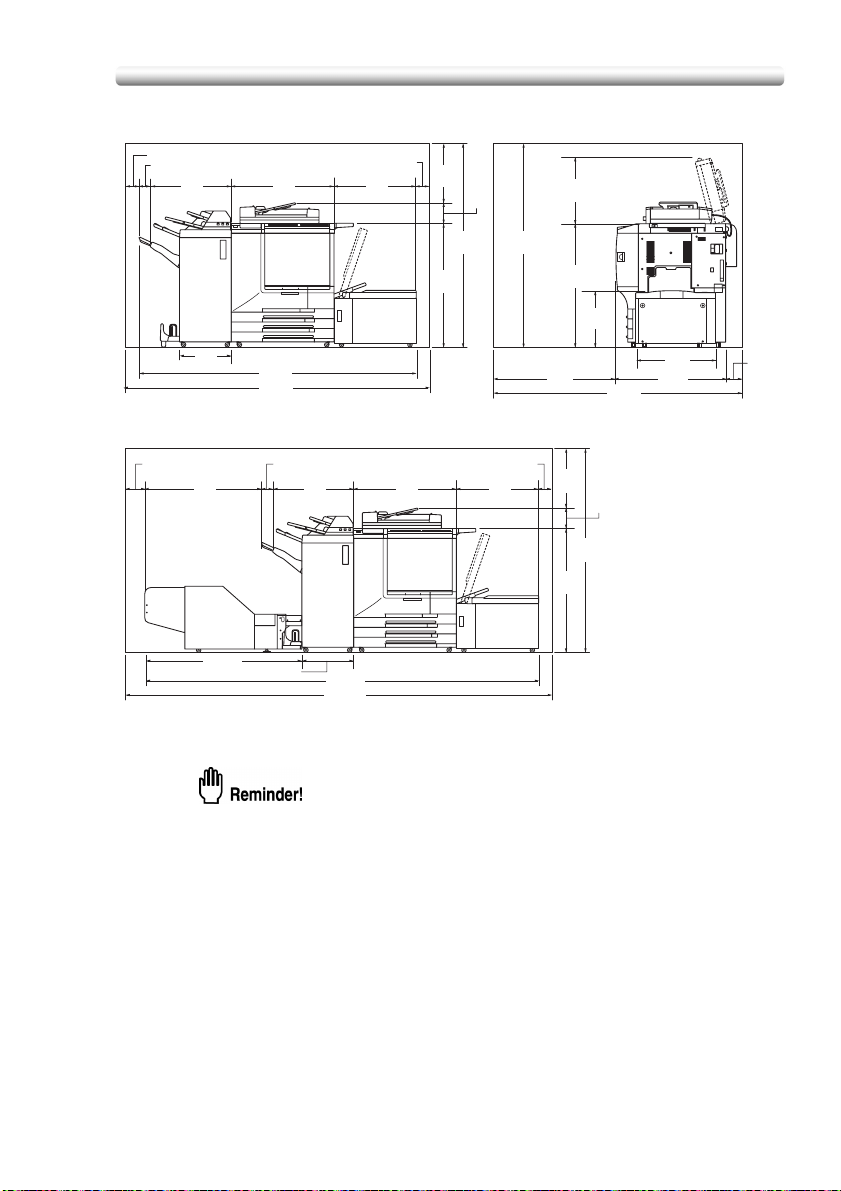

Requirements for Safe Use (continued)

Unit: mm

100

85

656

410

2213

2413

760

CF5001 + AFR-20 + FN-9

+ Cover Inserter D + C-208 (Front)

712

100

440

1021

158

1619

1619

CF5001 + AFR-20 + C-208 (Right Side)

Unit: mm

150 150

949

1280

85

410

656

3162

3462

760

712

CF5001 + AFR-20 + FN-9 + Cover Inserter D

+ C-208 + FN-120/FN-9 + TMG Kit A + TMG-3 (Front)

950

1021

440

1021

499

1619

450

158

1959

600

889

Unit: mm

120

Finisher primary (main) tray of FN-120/FN-9 Finisher gradually goes down

while printed materials output. DO NOT allow any object to interfere with the

operation of the tray on the left side of the finisher, as any interference may

cause damage to the finisher.

1-9

Page 28

Requirements for Safe Use (continued)

Precautions for Routine Handling

WARNING: Toner Recovery Box

DO NOT THROW the toner recovery box into a fire. If it is thrown into a fire, the toner

may ignite and cause a dangerous situation.

CAUTION: Actions in Response to Troubles

• If the Service Call screen is displayed and copier operations cannot be continued

anymore, stop the operation to prevent any unexpected accident. Write down the

report code as stated on the 2nd line of the message, then switch off the copier

and disconnect from the power socket. Contact your service representative and

inform them of the report code.

• Do not touch the high temperature parts indicated with CAUTION labels or

described in the manual.

• Do not touch the inside of the machine for any other purpose than removing

jammed paper or adding toner.

• If machine repair is necessary, be sure to contact your service representative.

Never attempt to repair it by yourself.

• If any abnormal sound, smell or smoke comes from the machine, immediately stop

using it, turn off the power switch, disconnect the power plug and contact your

service representative.

• If the breaker trips or the fuse blows, turn off the power switch, reset the breaker or

the fuse, and turn on the machine. If the same situation occurs again, contact your

service representative.

• Ensure the replacement fuse conforms with the rating of the power source. Never

use a fuse with an incorrect rating.

CAUTION: Prevention of Fire

Do not use volatile combustibles, such as thinner or alcohol, near the machine.

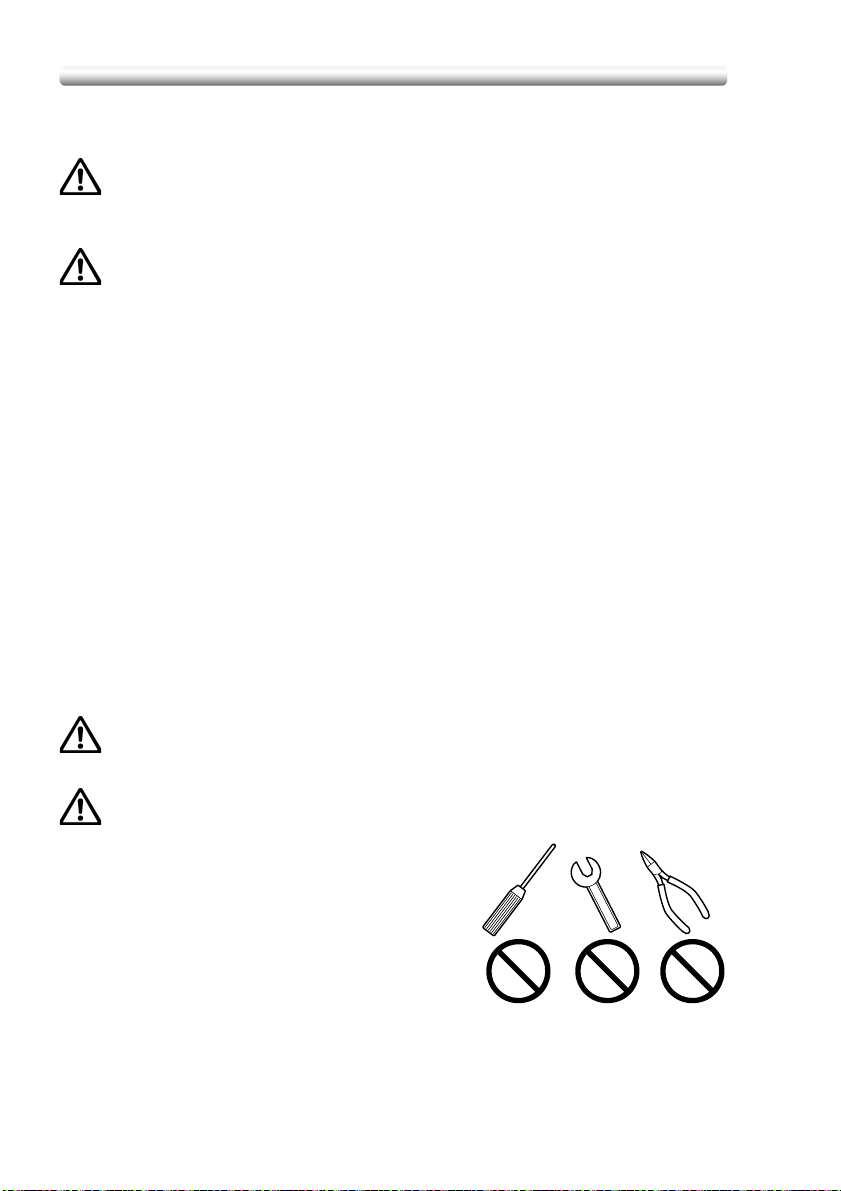

CAUTION: Prohibition of Machine

Modification

Do not modify or remove any parts by yourself.

1-10

Page 29

Requirements for Safe Use (continued)

CAUTION: Prevention of Machine Troubles

• Do not drop small metallic objects, such as paper

clips or staples, inside the machine.

• Do not place any heavy or hard objects such as a

vase, books or ornaments on the machine.

CAUTION: Recommendation of Periodic

Check

Be sure to periodically check the following points:

(1) The main cord or the power plug does not generate abnormal heat.

(2) The power plug is not inserted loosely or the cord is not cut or scratched.

(3) The grounding wire is correctly connected.

(4) The power plug or the power outlet is not covered with dust.

If you find anything abnormal in the above items, stop using the machine and contact

your service representative.

CAUTION: Toner

• Keep the toner cartridge away from children. The toner is nontoxic; however if you

inhale or contact with eyes by accident, flush with water and seek medical advice.

• Do not throw the empty toner cartridge into a fire. If it is thrown into a fire the toner

may ignite and cause a dangerous situation.

CAUTION: Paper

Check paper to be sure it conforms to the specifications outlined in Section 12.

• Do not use paper with staples or paper that conducts electricity (silver, carbon,

etc.), otherwise an accident may occur as a result of fire.

• To avoid machine trouble, do not use heat-sensitive paper, coloured transparency,

or paper specifically designed for ink-jet printers, such as photo-paper.

CAUTION: Power Saver and Weekly Timer

• In Power Saver mode the copier is still connected to the main power supply and

power is still applied to certain areas of the machine. To avoid any unexpected

troubles turn the power OFF when not using the copier for long periods of time.

• When the Weekly Timer function is operating, turning power OFF will disable the

function.

CAUTION: Inside the Booklet Mode Outlet

Inside the Booklet mode outlet is the roller drive unit. DO NOT put your hand into it,

when removing the folded or stitched & folded sheet; otherwise you may be injured.

CAUTION: Finisher Paper Exit Outlet

To avoid injury when stapling large size copies, DO NOT put your hand into the open

Paper Exit Outlet.

1-11

Page 30

Requirements for Safe Use (continued)

CAUTION: Fixing Unit

The internal fixing unit is very hot. To avoid getting burned, DO NOT TOUCH. Be

careful when withdrawing the fixing unit.

WARNING: Drum Unit

The internal drum unit generates a high voltage.

To avoid an electrical shock, DO NOT TOUCH.

CAUTION: LCT Bottom Plate

To avoid any unexpected injury, DO NOT put your hand into the holes (3 places) on

the bottom plate of the LCT.

CAUTION: Disposal of Copier

Do not dispose of this copier yourself. Contact your service representative, who can

arrange for its safe disposal.

If you change the place of installation, please contact your service representative.

CAUTION: Paper Capacity for the Exit Tray

The exit tray capacity is max. 150 sheets (90 g/m2 paper). If a copy run of more than

150 is required, be sure to remove the copies from the exit tray before the maximum

capacity is reached. Failure to do so will cause the copier to jam.

CAUTION: FN-120/FN-9 Finisher Paper Capacity

The FN-120 Finisher is equipped with two exit trays, and FN-9 Finisher is equipped

with three exit trays.

Select an exit tray and output mode on the Output Mode popup menu.

To prevent paper misfeed, do not exceed the paper capacity of the Finisher.

When the total number of copies in the copy run exceeds the capacity stated in

Section 12, be sure to unload the exit tray while the copier is still copying. Failure to

do so will cause the copier to jam.

CAUTION: FN-120/FN-9 Finisher Primary (Main) Tray

When printed materials are removed from the primary (main) tray of the Finisher, the

tray goes up automatically. To avoid injury, DO NOT put your hand on top of the

printed sheets. Be sure to hold both sides of the printed sheets when removing them,

and DO NOT leave your hand on the printed sheets while the primary tray goes up.

1-12

Page 31

Regulations

CE Marking (Declaration of Conformity)

This product complies with the following EU directives:

89/336/EEC, 73/23/EEC and 93/68/EEC directives.

This declaration is valid for the area of the European Union.

Laser Safety

This is a digital machine which operates by means of a laser. There is no possibility

of danger from the laser, provided the machine is operated according to the

instructions in this manual.

Since radiation emitted by the laser is completely confined within protective housing,

the laser beam cannot escape from the machine during any phase of user operation.

This machine is certified as a Class 1 laser product. This means the machine does

not produce hazardous laser radiation.

1-13

Page 32

Regulations (continued)

Internal Laser Radiation

Maximum radiation power: 2.02 mW

Wavelength: 645-660 nm

This product employs a Class IIIb Laser Diode that emits an invisible laser beam.

The Laser Diode and Scanning Polygon Mirror are incorporated in the print head

unit.

The print head unit is NOT A FIELD SERVICE ITEM.

Therefore, the print head unit should not be opened under any circumstances.

1-14

x 4

Page 33

Regulations (continued)

For the United States

CDRH regulation

This machine is certified as a Class 1 Laser product under the Radiation

Performance Standard according to the Food, Drug and Cosmetic Act of 1990.

Compliance is mandatory for Laser products marketed in the United States and is

reported to the Center for Devices and Radiological Health (CDRH) of the U.S. Food

and Drug Administration of the U.S. Department of Health and Human Services

(DHHS). This means that the device does not produces hazardous laser radiation.

The label shown on page 2-16 indicates compliance with the CDRH regulations and

must be attached to laser products marketed in the United States.

CAUTION:

Use of controls, adjustments or performance of procedures other than

thosespecified in this manual may result in hazardous radiation exposure.

This is a semiconductor laser. The maximum power of the laser diode is 7 mW and

the wavelength is 645-660 nm.

For European Users

CAUTION:

Use of controls, adjustments or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure.

This is a semiconductor laser. The maximum power of the laser diode is 7 mW and

the wavelength is 645-660 nm.

For Denmark Users

ADVARSEL

Usynlig laserstråling ved åbning, når sikkerhedsafbrydere er ude af

funktion. Undgå udsættelse for stråling. Klasse 1 laser produkt der opfylder

IEC60825 sikkerheds kravene.

Dansk: Dette er en halvlederlaser. Laserdiodens højeste styrke er 7 mW og bølgelængden

er 645-660 nm

.

1-15

Page 34

Regulations (continued)

For Finland, Sweden Users

LOUKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

VARO ITUS!

Laitteen Käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa

altistaa käyttäjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

Tämä on puolijohdelaser. Laserdiodin suurin teho on 7 mW ja aallonpituus on 645660 nm.

VARNING!

Om apparaten används på annat sätt än i denna bruksanvisning specificerats,

kan användaren utsättas för osynlig laserstrålning, som överskrider gränsen för

laserklass 1.

Det här är en halvledarlaser. Den maximala effekten för laserdioden är 7 mW och

våglängden är 645-660 nm.

VARO !

Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättömälle

lasersäteilylle. Älä katso säteeseen.

VARNING!

Osynlig laserstrålning när denna del är öppnad och spärren är urkopplad.

Betrakta ej strålen.

For Norway Users

ADVERSEL

Dersom apparatet brukes på annen måte enn spesifisert i denne

bruksanvisning, kan brukeren utsettes for unsynlig laserstråling som

overskrider grensen for laser klass 1.

Dette en halvleder laser. Maksimal effekt till laserdiode er 7 mW og bølgelengde er

645-660 nm.

1-16

Page 35

Regulations (continued)

Laser Safety Label

A laser safety label is attached to the outside of the machine as shown below.

KONICA MINOLTA BUSINESS TECHNOLOGIES, INC.

1-6-1, Marunouchi, Chiyoda-ku, Tokyo, Japan

MANUFACTURED: KHK

THIS PRODUCT COMPLIES WITH 21 CFR

CHAPTER I, SUBCHAPTER J

CLASS 1 LASER PRODUCT

APPAREIL A RAYONNEMENT

LASER DE CLASSE 1

LASER KLASSE 1 PRODUKT

1-17

Page 36

Regulations (continued)

Ozone Release

NOTE

= Locate the Machine in a Well Ventilated Room =

A negligible amount of ozone is generated during normal operation of this machine.

An unpleasant odor may, however, be created in poorly ventilated rooms during

extensive machine operations. For a comfortable, healthy, and safe operating

environment, it is recommended that the room well ventilated.

REMARQUE

= Placer l’appareil dans une pièce largement ventilée =

Une quantité d’ozone négligable est dégagée pendant le fonctionnement de

l’appareil quand celui-ci est utilisé normalement. Cependant, une odeur désagréable

peut être ressentie dans les pièces dont l’aération est insuffisante et lorsque une

utilisation prolongée de l’appareil est effectuée. Pour avoir la certitude de travailler

dans un environnement réunissant des conditions de confort, santé et de sécurité, il

est préférable de bien aérer la pièce ou se trouve l’appareil.

1-18

Page 37

Section 2:

Machine Information

2

Machine Configuration...................................................... 2-2

Turning On the Power Switch ......................................... 2-16

Loading Paper ................................................................ 2-22

Machine Configuration, Turning On

the Power and Loading Paper

Page 38

Machine Configuration

External Machine Items

1 AFR-20 Duplexing

document feeder (option)

20 LCD Touch screen

19 Power switch

14 FN-120 Finisher

17 TMG-3 Trimming unit

(option)

(option)

13 Front door

18 Cover inserter D

(option)

21 Control panel

12 Tray 1

11 Tray 2

10 Tray 3

2 OC-2 Original cover

4 Key counter

5 Toner access door

6 Toner recovery box

7 Multi-sheet

9 Right side door

3 Work table

8 Tray 4 (C-208 Large

capacity cassette) (option)

(option)

(option)

bypass tray

2-2

16 Trimming kit A (option)

15 FN-9 Finisher (option)

Page 39

Machine Configuration (continued)

1 RADF (AFR-20 Duplexing Document Feeder) (option) automatically feeds

multiple originals one at a time to the platen glass for copying. AFR-20 appears

as RADF in the screen message.

2 OC-2 Original cover (option) covers documents to be copied and holds them in

place.

3Work table provides a convenient workspace for documents both before and

after copying.

4 Key counter (option) manages the number of copies made on the machine.

5 Toner access door opens to replenish the black toner or colour toner.

6 Toner recovery box opens to replace the filled toner box with new one.

7 Multi-sheet bypass tray opens to use copy paper of the other size or type than

those loaded in the main body trays or LCT.

8 Tray 4 (C-208 Large capacity cassette) (option) holds 2,500 sheets (90 g/m

paper) from 13”x19” to B5. C-208 appears as LCT in the screen message.

9 Right side door opens to allow removal of mishandled paper.

10 Tray 3 (universal tray) is user-adjustable and holds 500 sheets (90 g/m

from 13”x19” to A5R.

11 Tray 2 (universal tray) is user-adjustable and holds 500 sheets (90 g/m

from 13”x19” to A5R.

12 Tray 1 (universal tray) is user-adjustable and holds 500 sheets (90 g/m

from 13”x19” to A5R.

13 Front door opens to allow removal of mishandled paper.

14 FN-120 Finisher (option) sorts, staple-sorts, or groups copies into finished

sets.

15 FN-9 Finisher (option) sorts, staple-sorts, or groups copies into finished sets.

FN-9 also folds or staples & folds copies into booklet-styled sets, or folds max. 3

copies in three.

16 Trimming kit A (option) connects the finisher and trimming unit.

17 TMG-3 Trimming unit (option) trims the end of booklet.

18 Cover inserter D (option) loads cover sheet paper and feeds the sheet as

cover to the sorted sets, used in combination with FN-120/FN-9 Finisher.

19 Power switch turns copier power On/Off when pressed.

20 LCD Touch screen displays interactive operation screens.

21 Control panel controls copier operations and displays messages as required.

2

paper)

2

paper)

2

paper)

2

2-3

Page 40

Internal Machine Items

5 Black print counter

4 Total counter

3 Main power

switch

Machine Configuration (continued)

2 Fixing unit

1 Lever A can be moved to withdraw the conveyance fixing unit for removal of

mishandled paper.

2 Fixing unit fuses the toner onto the copy paper.

3 Main power switch used only by service representative turns machine power

on/off when pressed.

4 Total counter indicates the total number of prints made.

5 Black print counter indicates the total number of the black prints made.

1 Lever A

2-4

Page 41

Machine Configuration (continued)

Standard/Optional Equipment

PK-5 Punch kit

Cover inserter D

OC-2 Original cover

FN-120 Finisher

AFR-20 Duplexing document feeder

Work table

Key counter

FN-9 Finisher

TMG-3 Trimming unit

CF5001

main body

256MB Memory unit

HDD-7 Hard disk drive

Printer controller

(Fiery S300 50C-K)

TMG kit A

C-208 Large

capacity cassette

2-5

Page 42

Machine Configuration (continued)

Control Panel Layout

12 45671110983

121319 18 14151617

1 CONTRAST ADJUSTMENT DIAL can be turned to adjust the touch panel

contrast.

2 LCD TOUCH SCREEN displays machine and copying status, help information,

interactive screens, and touch keys for selecting all functions.

3 CHECK displays a screen showing all settings that are selected for the current

job.

4HELP displays a screen with help for the currently selected function, or to

access the Key Operator Mode Screen.

5 KEYPAD enters numeric values.

6 PRINTER switches the machine operation mode to printer. (This key does not

function at present.)

7 SCANNER switches the machine operation mode to scanner.

8COPY switches the machine operation mode to copy.

9TIMER lights when the timer function is set.

10 INTERRUPT stops copying in progress to allow copying from the platen glass.

11 POWER SAVER ON/OFF activates power-saving mode for times when the

copier is inactive, or activates Timer Interrupt mode when Weekly Timer

function is active.

12 STOP stops the copying sequence; deletes the stored memory.

13 PROOF COPY outputs a single set of copies to confirm whether the current

settings are selected properly.

14 START activates copying or scanning.

15 [C] (CLEAR QTY.) allows resetting of print quantity.

16 [P] (COUNTER) displays the Counter Screen or accesses programming modes

for setting special functions.

17 AUTO RESET restores copier to automatic mode settings or to Key Operator

settings.

2-6

Page 43

Machine Configuration (continued)

18 JOB MEMORY displays screens for selecting job store/job recall functions.

19 ACCESS sets the machine to allow copying only when the EKC password is

entered.

The touch screen of the control panel is covered with glass. Do not

drop heavy objects on the glass or put excess weight or pressure on

it, otherwise the glass may be scratched or break to cause injury.

When the Call for Service Screen (p. 5-2) is displayed, be sure to

contact your service representative immediately.

The control panel of this machine can be slightly lowered to three angled positions

to ensure easy access by anyone, regardless of the physical or positional status of

the operator. Your authorized service representative can make this setting for you.

2-7

Page 44

Basic Screen

Machine Configuration (continued)

1 Folder keys 9 Memory indicator

2 Word icons 8 Count/Set indicator

3 Graphic icons

21 Output icon area

4 Message area

5 Reserve job

18 Copy mode area20 Output mode keys

6 Original count

7 TYPE/SIZE key

17 Paper size area19 Colour mode area

16 Lens mode area

14 ROTATION OFF key

12 SPECIAL ORIGINAL key

10 STATUS key

15 STORE key

13 APPLICATION key

11 IMAGE ADJUST key

1 Folder keys:

FREE JOB is selected to specify a copy job conditions.

When scanning starts, FREE JOB changes to SCAN JOB, then changes to

PRINT JOB when the machine starts printing.

FREE JOB at the right side of SCAN JOB or PRINT JOB can be touched to

specify a reserve job conditions. Up to 9 reserve jobs can be set. The arrow

keys at the right side of folder keys are used to scroll.

2 Word icons:

ADD TONER icon is displayed when toner supply becomes low. The toner

colour to be supplied is indicated by a letter; C (cyan), M (magenta), Y (yellow),

or K (black).

Printer icon indicates the machine status when operating as a printer.

3 Graphic icons:

Original direction icon indicates the original direction specified on the Special

Original popup menu.

Image adjust icon indicates the enhance mode specified on the Special

Original popup menu.

Rotation icon is displayed when Rotation automatically functions.

Toner recovery box icon is displayed when replacement of the toner recovery

box is due.

PM icon is displayed when preventive maintenance is due.

4 Message area displays the machine status and procedure required at that

time.

2-8

Page 45

Machine Configuration (continued)

5 Reserve job counts the reserve jobs already specified.

6 Original count counts the original pages placed in the document feeder as

they are scanned.

7 TYPE/SIZE key appears when the Bypass key is selected, and is touched to

specify the type and size of the paper loaded in the Multi-sheet bypass tray.

8 Count/Set indicator indicates the print quantity entered from the control panel

keypad, and also indicates the print count on the left of the set count while

printing.

9 Memory indicator indicates the remaining memory available for the next

operation.

10 STATUS key is touched to view the current job status, to change the printing

order of reserve jobs, or to cancel printing a reserve job.

11 IMAGE ADJUST key is touched to display five sorts of the Image Adjustment

Setting Screens to adjust the image quality.

12 SPECIAL ORIGINAL key is touched to specify the condition of originals to be

scanned.

13 APPLICATION key is touched to select various application functions.

14 ROTATION OFF key is touched to release the Rotation function.

15 STORE key is touched to store scanned images into memory.

16 Lens mode area is used to select the desired magnification ratio.

17 Paper size area is used to select the desired paper size or APS.

18 Copy mode area is used to select the copy mode (1a1, 1a2, 2a1, or 2a2).

19 Colour mode area is used to specify the desired colour mode (single colour,

black, full colour, or auto).

20 Output mode keys are used to specify the desired output mode.

21 Output icon area displays the appropriate output icon according to the

selected output mode.

2-9

Page 46

Machine Configuration (continued)

FN-120/FN-9 Finisher (with PK-5 Punch Kit)

4 Secondary

(Sub) tray

3 Primary

(Main) tray

FN-120 Finisher

4 Secondary

(Sub) tray

3 Primary

(Main) tray

2 Booklet tray

(FN-9 Finisher only)

1 Finisher door1 Finisher door

FN-9 Finisher

1 Finisher door opens to the internal Finisher to allow clearing mishandled paper,

replenishing staples, and emptying waste basket of Punch kit.

2Booklet tray (FN-9 Finisher only) holds sets output in Fold mode, Stapling &

Fold mode, or Three-fold mode.

3 Primary (Main) tray holds sets output in Non-sort mode, Sort mode (offset),

Staple-sort mode, or Group mode (offset).

4 Secondary (Sub) tray holds sets output in Sort mode or Group mode with face

down/up mode.

2-10

Page 47

FN-120 Finisher

11 Cartridge housing

10 Stacker unit handle

4 Sub tray

conveyance lever

3 Cover sheet

conveyance

lever

1 Entrance lever

5 Stacker

conveyance

lever

Machine Configuration (continued)

4 Sub tray

conveyance lever

3 Cover sheet

conveyance

lever

2 PK-5

Punch kit

(option)

1 Entrance lever

9 Trash basket

(option)

8 Stacker unit

7 Stacker unit

knob

6 Lower lever

FN-9 Finisher

with PK-5 Punch kit

1 Entrance lever opens downward to remove mishandled paper.

2 PK-5 Punch kit (option) punches file holes in the output copies.

3 Cover sheet conveyance lever opens to remove mishandled paper.

4 Sub tray conveyance lever opens to remove mishandled paper.

5 Stacker conveyance lever opens to remove mishandled paper.

6 Lower lever opens to remove mishandled paper.

7 Stacker unit knob can be turned to ease removal of mishandled paper from

the Stacker unit.

8 Stacker unit folds or stitches & folds copies into booklet-styled sets, and also

folds max. 3 copies in three.

9 Waste basket (option) holds waste paper punched out.

10 Stacker unit handle withdraws unit to allow removal of mishandled paper and

replacement of staple cartridge.

11 Cartridge housing holds staple cartridge to be replaced when supplying

staples.

2-11

Page 48

Cover Inserter D

Machine Configuration (continued)

4 Upper tray

5 Lower tray

6 Lower tray

guide plates

3 Upper tray guide plates

2 Upper unit release lever

1 Cover inserter

control panel

1 Cover inserter control panel controls cover inserter operations.

2 Upper unit release lever can be moved to slide the upper unit of cover inserter

for removal of mishandled paper.

3 Upper tray guide plates hold cover sheets to fix the position.

4Upper tray holds cover sheets for use in cover sheet output mode.

5Lower tray holds cover sheets for use in cover sheet output mode or a copied

set in manual stapling/punching/three-fold mode.

6 Lower tray guide plates hold cover sheets to fix the position.

2-12

Page 49

Machine Configuration (continued)

C-208 Large Capacity Cassette

5 Paper feed roller

4 Paper loading button

2 LCT top door

1 LCT lever

10 LCT bottom plate

3 LCT left side door

6 LCT paper guides

7 LCT paper guide knobs

8 Rear stopper

9 Rear stopper

knob

1 LCT lever can be moved downward to ease removal of mishandled paper.

2 LCT top door opens to allow paper loading or removal of mishandled paper.

3 LCT left side door opens to allow removal of mishandled paper.

4 Paper loading button is pressed to lower the bottom plate to allow loading

paper.

5 Paper feed roller conveys the copy paper to the main body.

6 LCT paper guides hold copy paper to fix the position.

7 LCT paper guide knobs can be turned to move or fix the LCT paper guide.

8 Rear stopper fixes the rear end of copy paper.

9 Rear stopper knobs can be turned to move or fix the rear stopper.

10 LCT bottom plate goes up automatically when paper supply becomes low, and

goes down when the paper loading button is pressed.

2-13

Page 50

TMG-3 Trimming Unit

7 FN-9 Finisher

5 Trimmer stacker cover

4 Trimmer unit tray

Machine Configuration (continued)

6 TMG kit A

1 Front-right cover

2 Front door

3 Trimmer stacker

1 Front-right cover opens to allow removal of mishandled paper.

2 Front door opens to allow removal of mishandled paper or waste paper.

3 Trimmer stacker holds sets output in Trimming mode.

4 Trimmer unit tray slides to the left side each time a trimmed booklet is delivered.

5 Trimmer stacker cover opens to allow you to take out the finished sets.

6TMG kit A connects the Finisher and Trimming unit.

7 FN-9 Finisher allows the Trimming unit to be installed.

DO NOT place heavy objects on the trimmer stacker or apply any weight on it,

and DO NOT use it for storage.

Excessive weight applied to the inside or outside of the trimmer stacker will

damage the equipment.

2-14

Page 51

Machine Configuration (continued)

1 Trimmer unit knob

3 Trimmer pressure

release lever

1 Trimmer unit knob can be turned to ease removal of mishandled paper.

2 Waste basket holds waste paper cut off from the booklets.

3 Trimmer pressure release lever opens to allow removal of mishandled paper.

2 Wast basket

2-15

Page 52

Turning On the Power Switch

To Turn On the Power

1. Turn ON the power switch.

The power switch is located on the left side of the control panel.

The main power switch is located on the upper-left side of the internal main

body. Be sure not to use the main power switch in usual operation.

2. The Wake-up Screen and Warm-up Screens will be displayed.

A few seconds after the Wake-up Screen appears in the LCD touch screen,

seven types of Warm-up Screens will be displayed in succession for

approx. 7.0 minutes.

2-16

Page 53

Turning On the Power Switch (continued)

You can set reserve jobs while the machine is warming up. Touch the LCD

screen to change the Warm-up Screen to the Basic Screen, then check that

the message “Ready to copy reserve” is displayed on the Basic Screen. See

p. 3-11 to p. 3-12.

3. The Basic Screen will be displayed.

The message on the Basic Screen will inform you that copying job is now

available.

• When the initial settings are changed by the Key Operator, the modified

conditions will be displayed on the Basic Screen.

• When “Enter E.K.C. password” is displayed, enter your password to use the

machine.

• When “Set the key counter” is displayed, insert the key counter to its inlet

on the right side of the main body.

2-17

Page 54

Turning On the Power Switch (continued)

To Turn Off the Power

1. Turn OFF the power switch.

The power switch is located on the left side of the control panel.

The touch screen and all the LEDs on the control panel will go out.

Be sure not to use the main power switch in usual operation.

When the machine is under control of the Weekly Timer function, turning off

the power switch will deactivate the function.

2-18

Page 55

Turning On the Power Switch (continued)

Reducing the Power in Standby Mode (Auto Low Power)

This function automatically lowers the power after a specified period (initially 15

minutes) of copier inactivity. The LCD screen will go off.

The Auto Low Power function can be set to 5 minutes/ 10 minutes/ 15 minutes/

30 minutes/ 60 minutes/ 90 minutes/ 120 minutes/ 240 minutes in the Key

Operator mode. For information about the Key Operator setting, see p. 14-36.

To start a copying job, press any key on the control panel.

The Auto low power will be released and the LCD screen recovers usual brightness.

• If the Auto Shut-Off function activates at the same time, the power will be

turned off without the LCD screen becoming dark.

• The LCD screen will not go off during a duplex copying job or when the

Jam Position Screen is displayed.

Shutting Off Automatically (Auto Shut-Off)

This function automatically shuts off the power after a specified period (initially 90

minutes) of copier inactivity.

To start a copying job, press [POWER SAVER ON/OFF].

The copying operation will become available.

• The Auto shut-off can be set for 30 minutes/ 60 minutes/ 90 minutes/ 120

minutes/ 240 minutes in the Key Operator mode. For information about the

Key Operator setting, see p. 14-36.

• When “Timer interrupt mode / Enter password” is displayed after pressing

[POWER SAVER ON/OFF], see p. 8-2 and follow the procedure to