Page 1

Service Manual

[Field Service]

CF5001

Page 2

Dual references may be used on the following:

Official Options name : Popular Options name

AFR-20 : RADF, DF

C-208 : LT

FN-120 : FNS

FN-9 : FNS

Cover Inserter D : PI

PK-5 : PU

TMG-3 TU

In-System Writer : ISW

Page 3

CF5001 Field Service Ver.1.0 Sep 2003 CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-1

IMPORTANT NOTICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-1

DESCRIPTION ITEMS FOR DANGER, WARNING AND CAUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-1

SAFETY WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-2

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-10

IMPORTANT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-10

SAFETY CIRCUITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-11

INDICATION OF WARNING ON THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-13

I DISASSEMBLY/ASSEMBLY

1. EXTERIOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

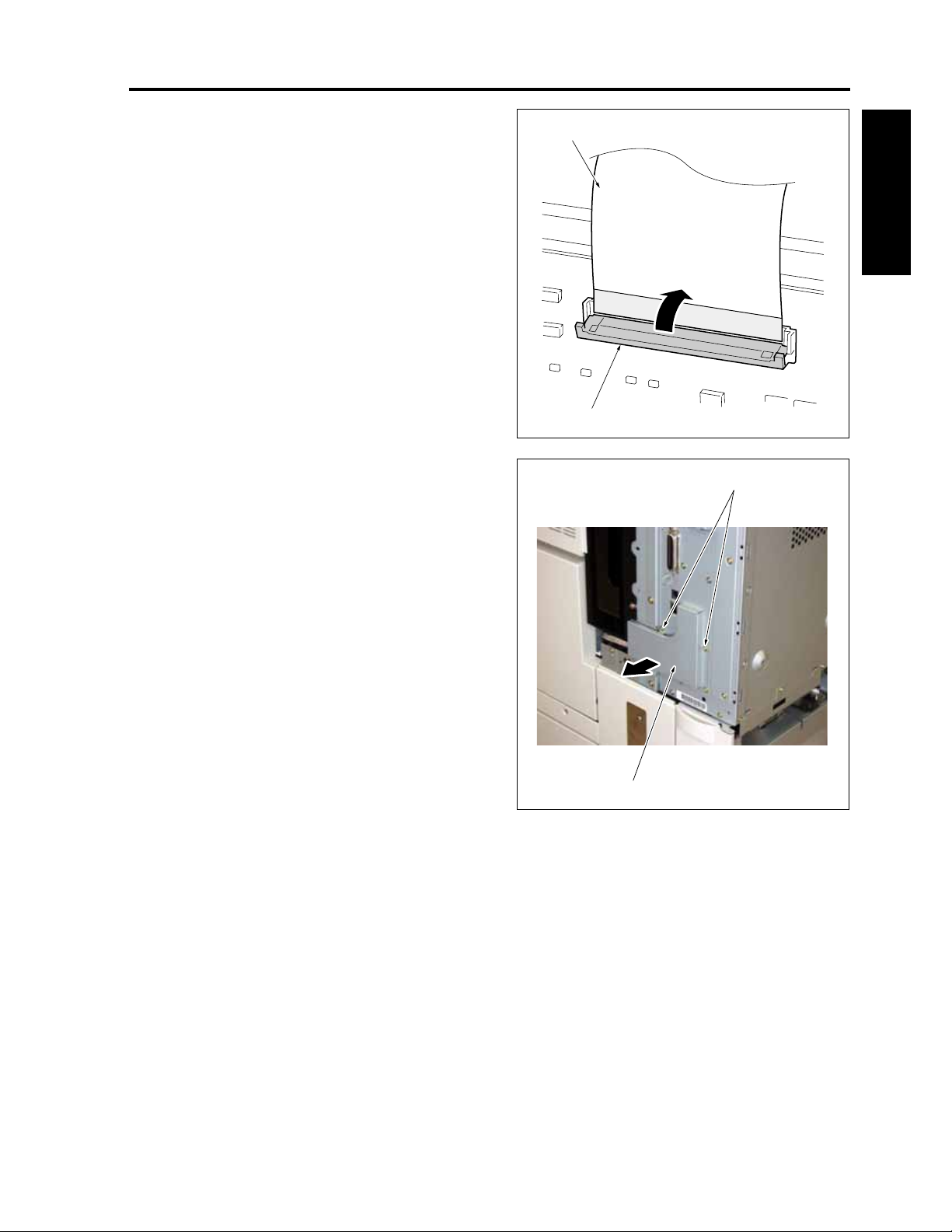

1.1 Replacing the dust filter /2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Replacing the dust filter /1 and the ozone filter /1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Replacing the toner collection box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4 Angle adjustment of the operation board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

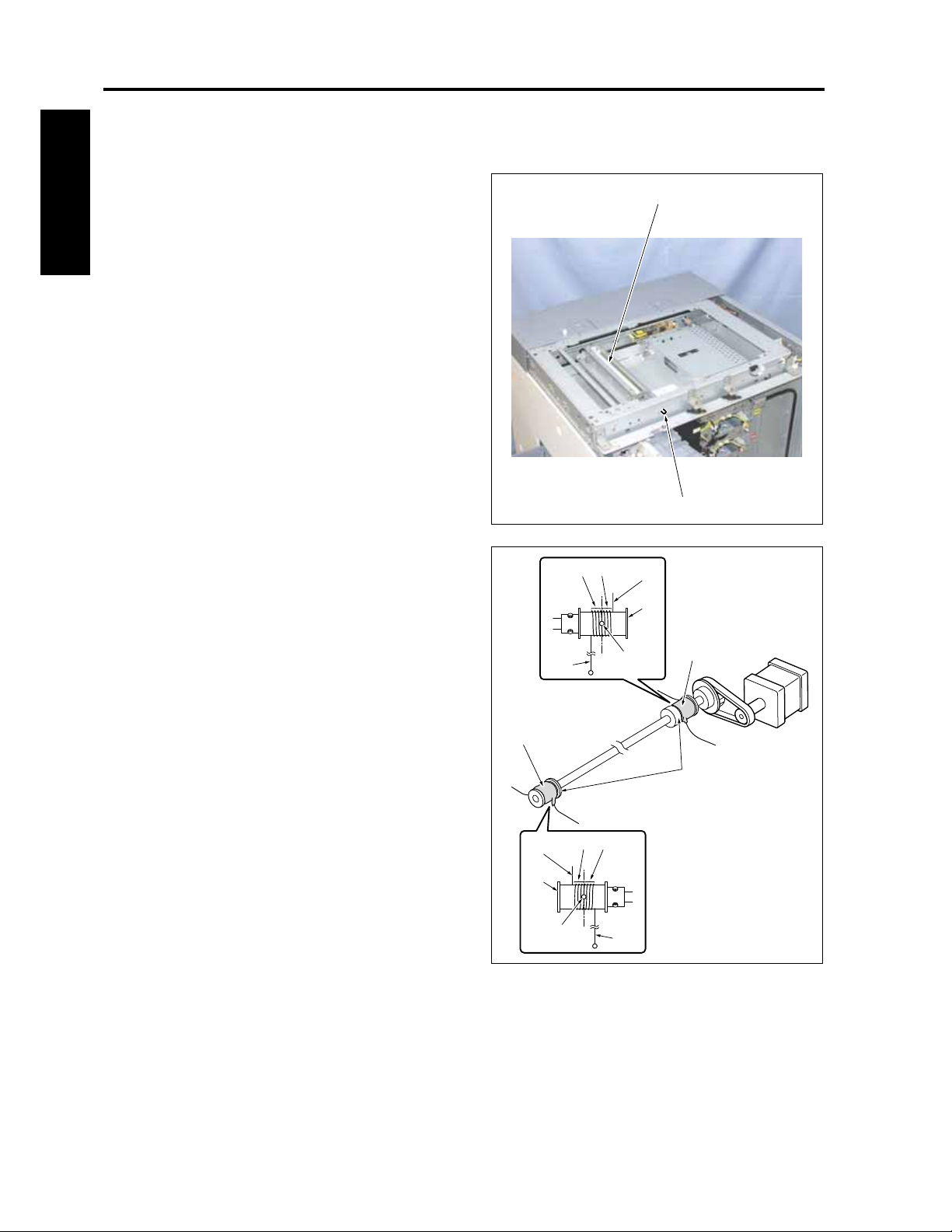

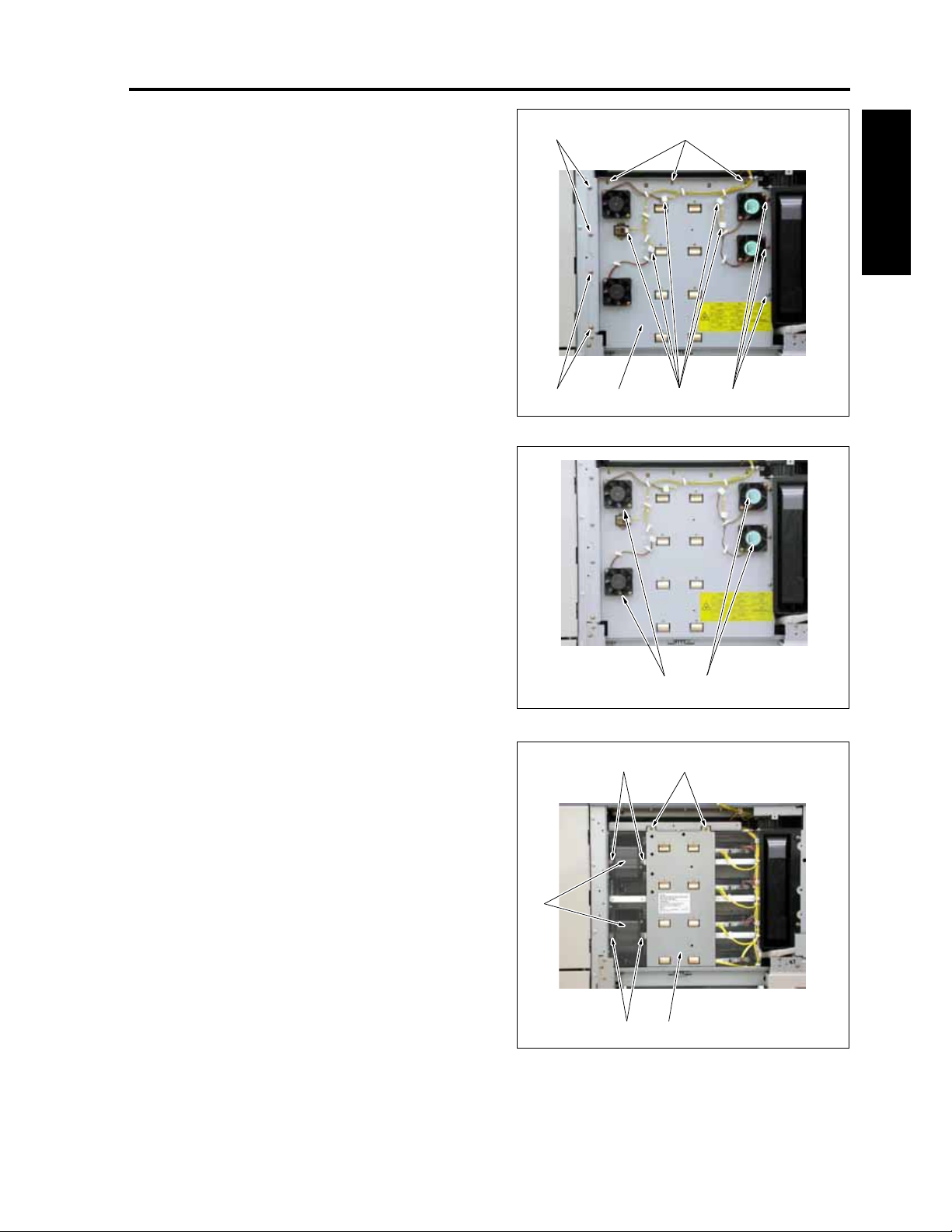

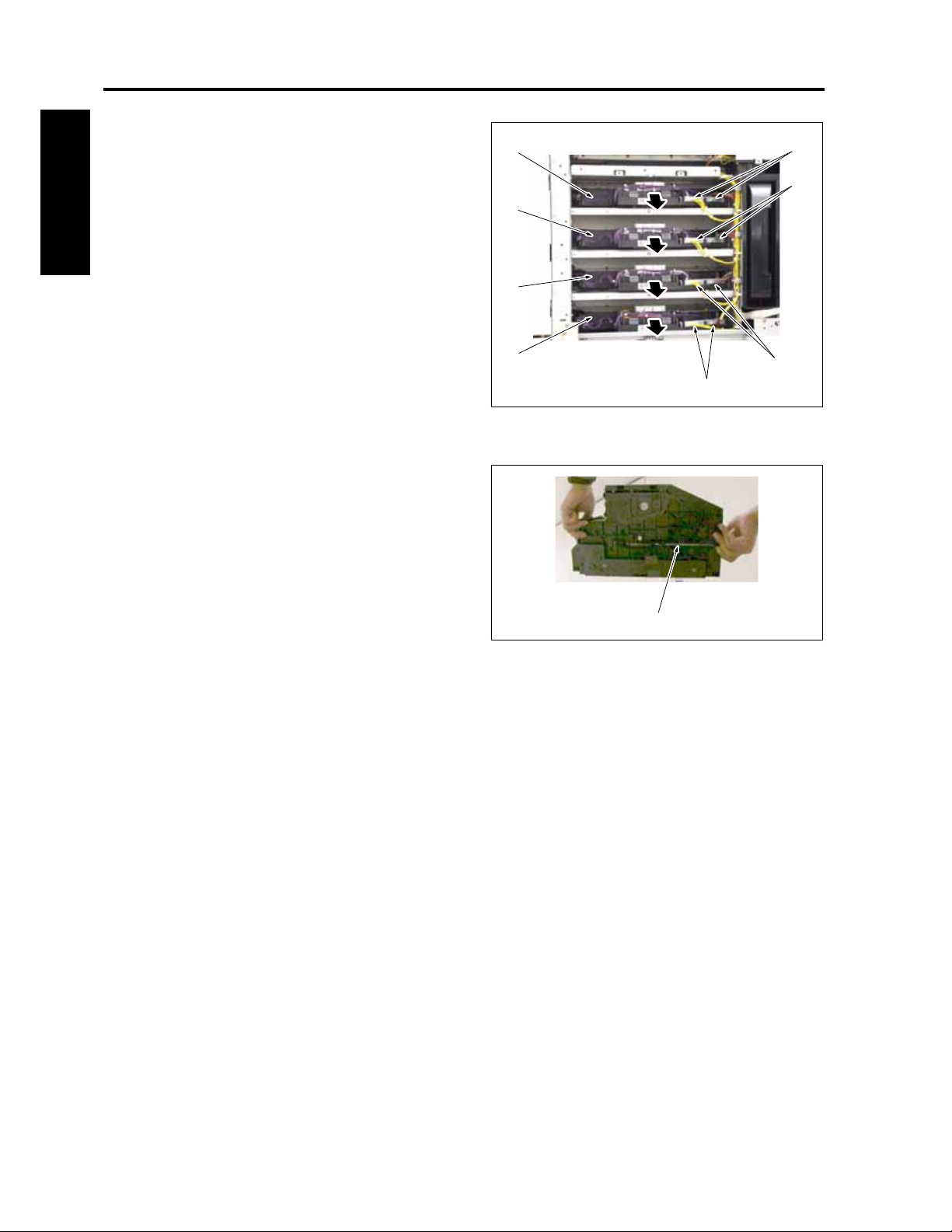

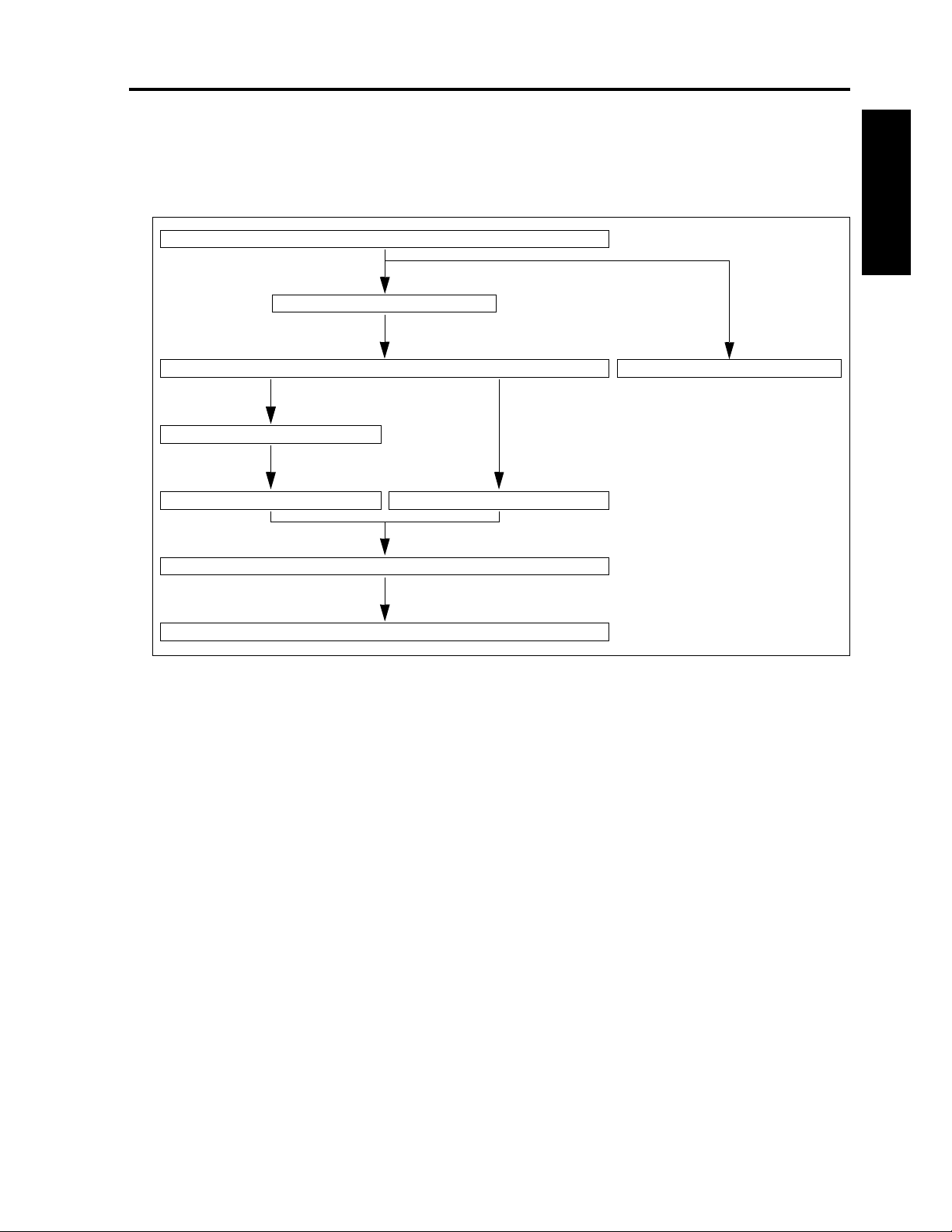

1.5 Removing and reinstalling the main board unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

2. SCANNER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

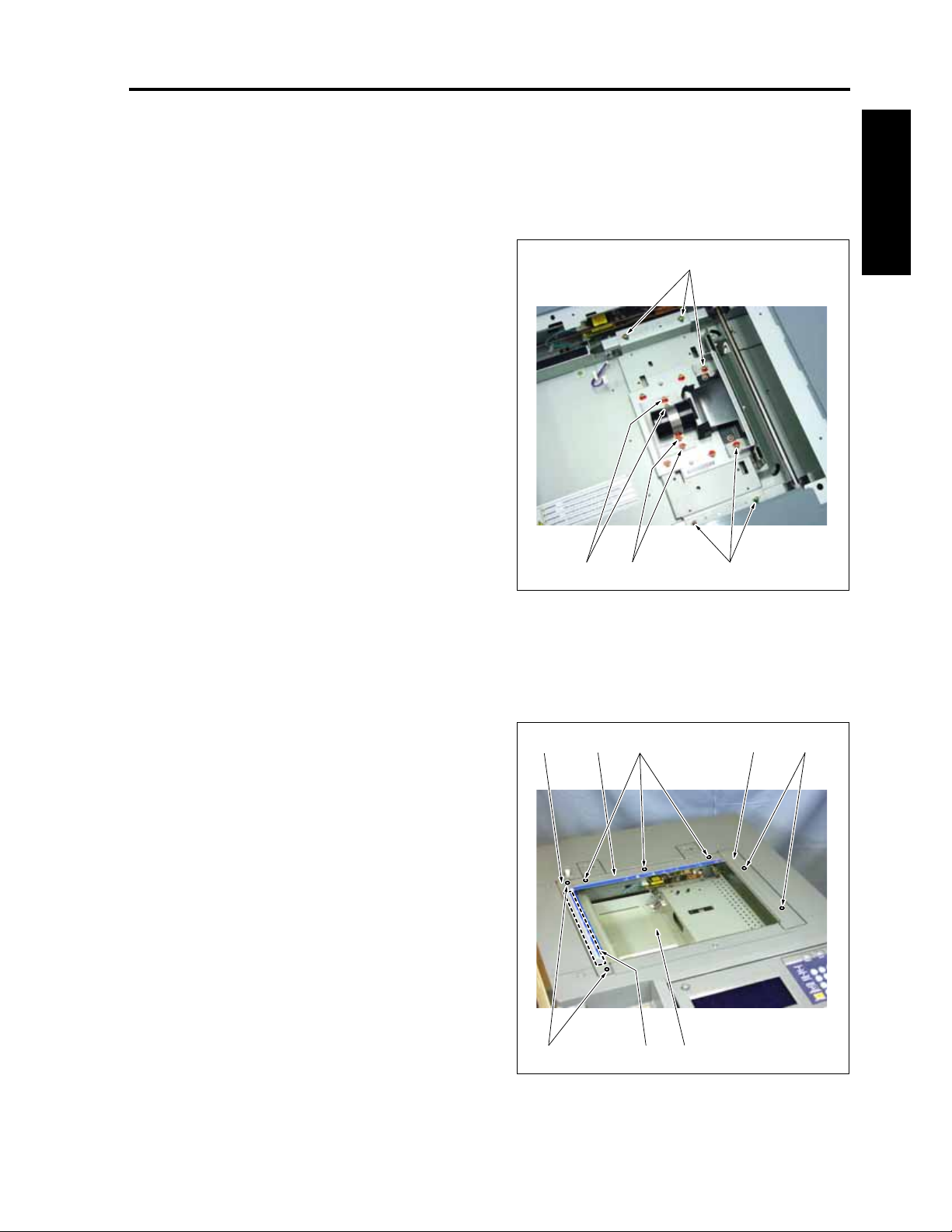

2.1 Screws that must not be removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

2.2 Removing and reinstalling the platen glass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

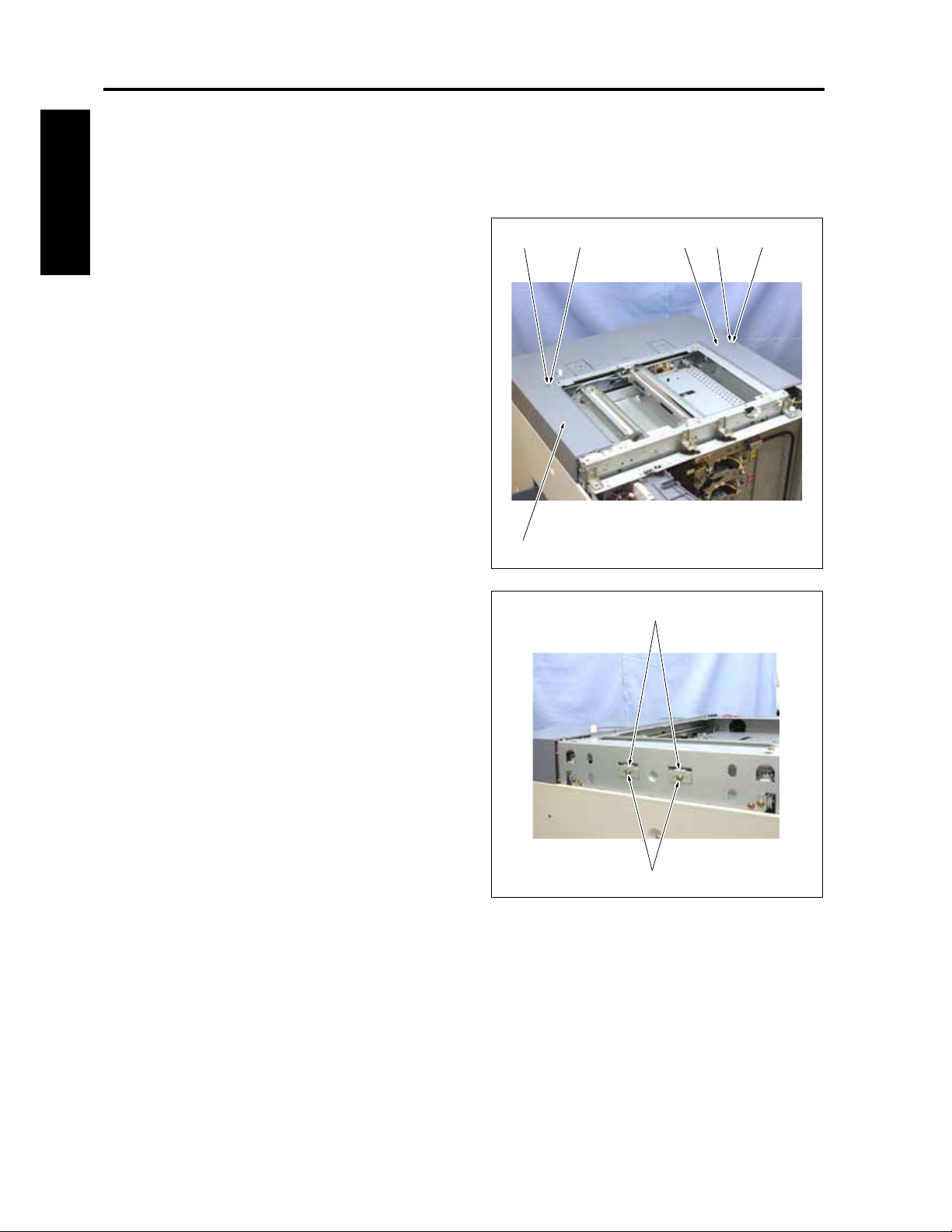

2.3 Removing and reinstalling the CCD unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

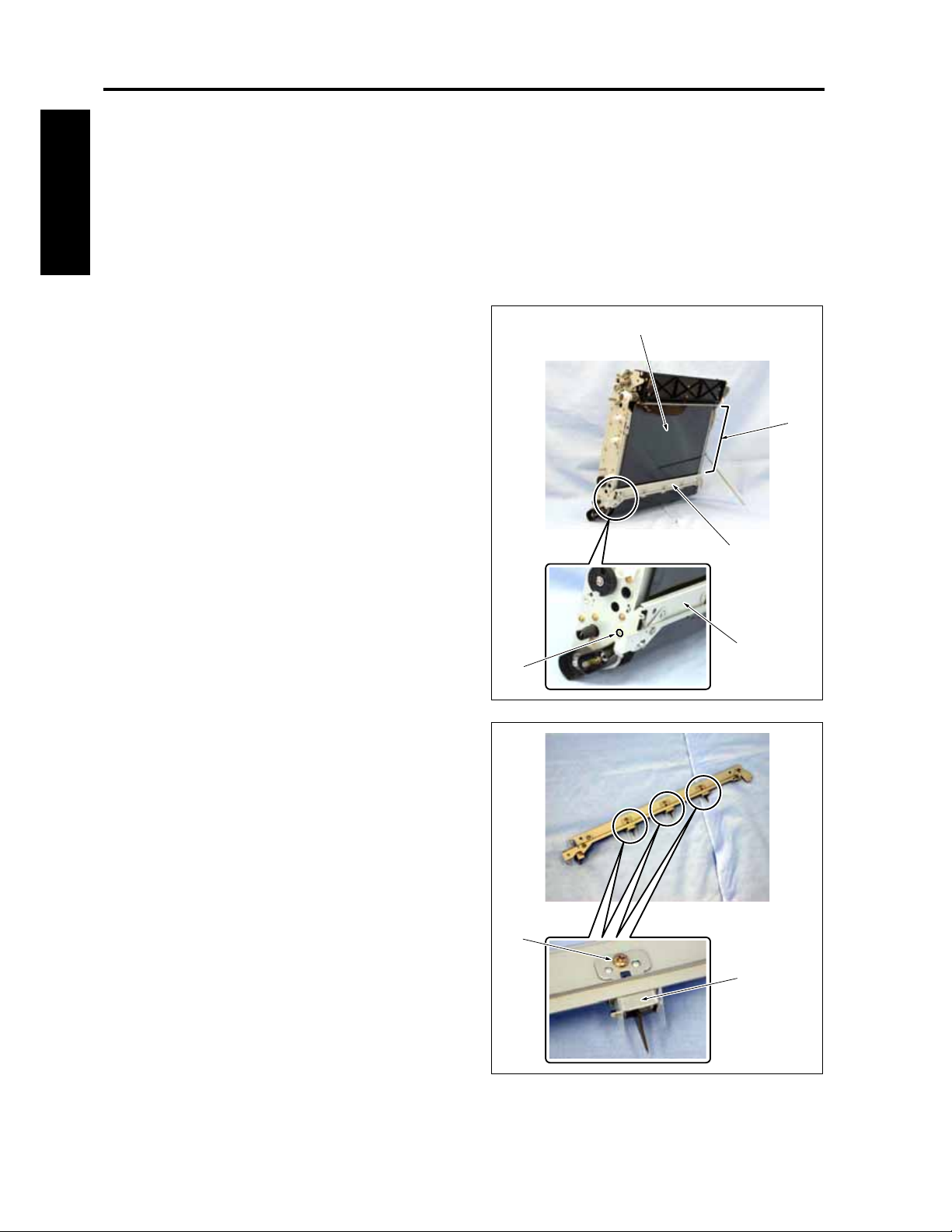

2.4 Removing and reinstalling the exposure unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

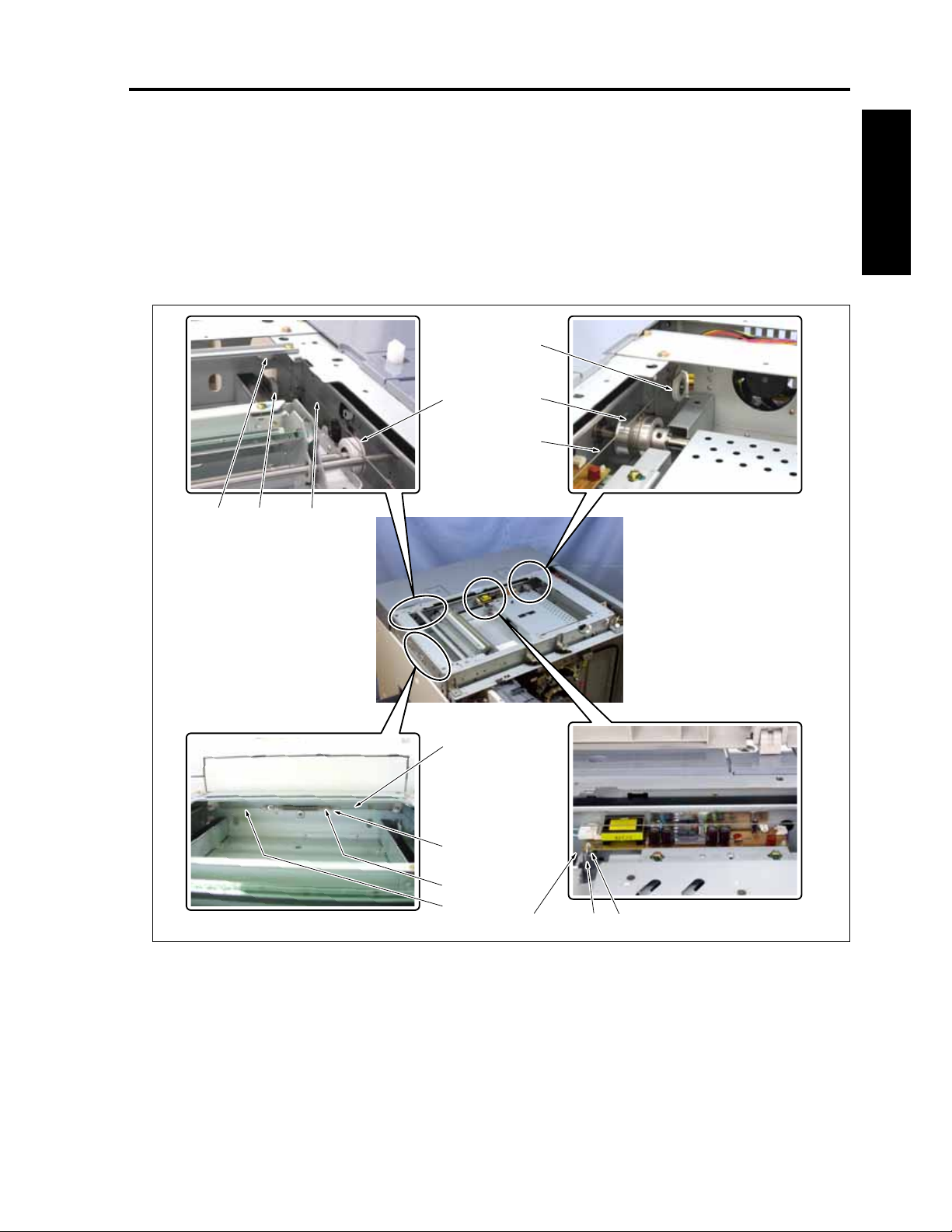

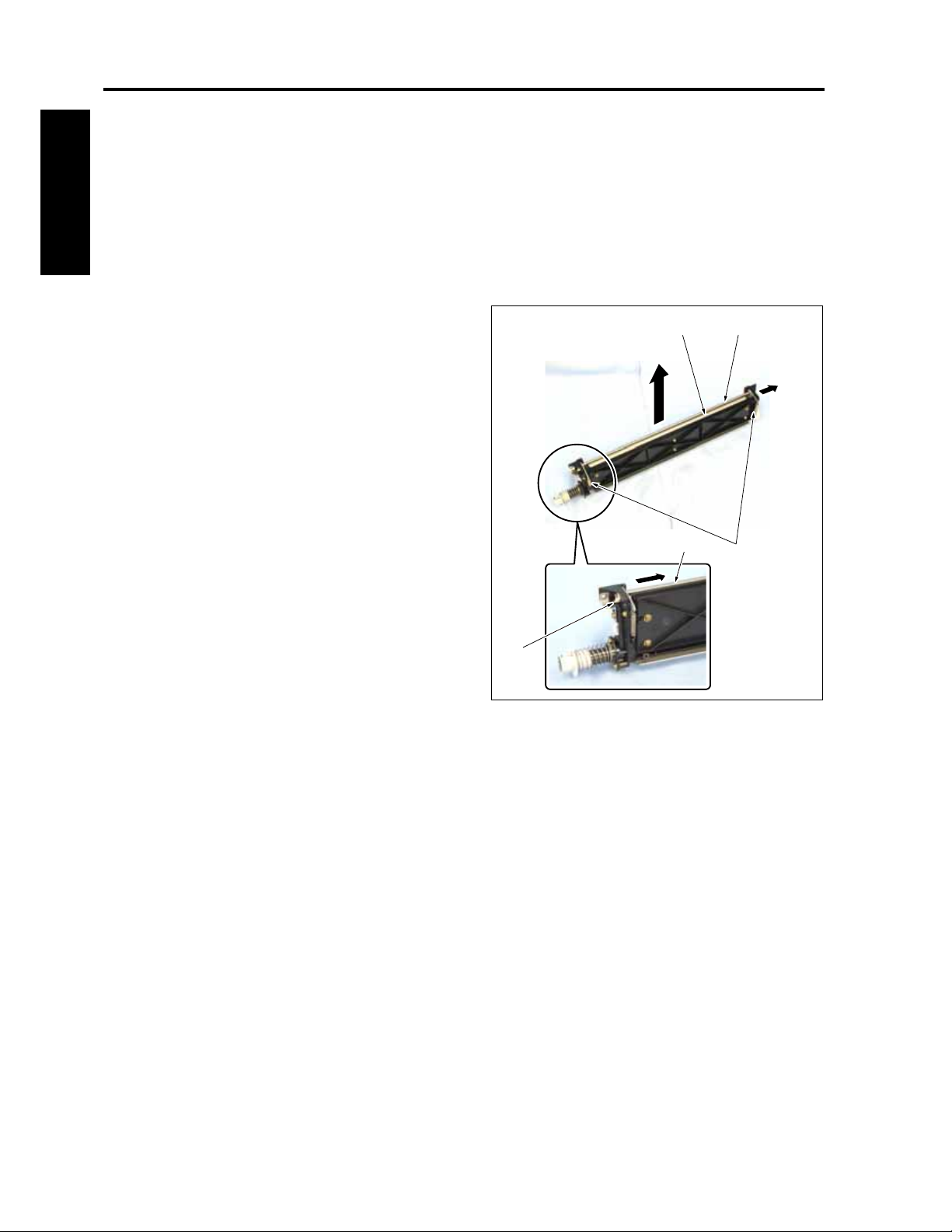

2.5 Removing and reinstalling the exposure lamp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

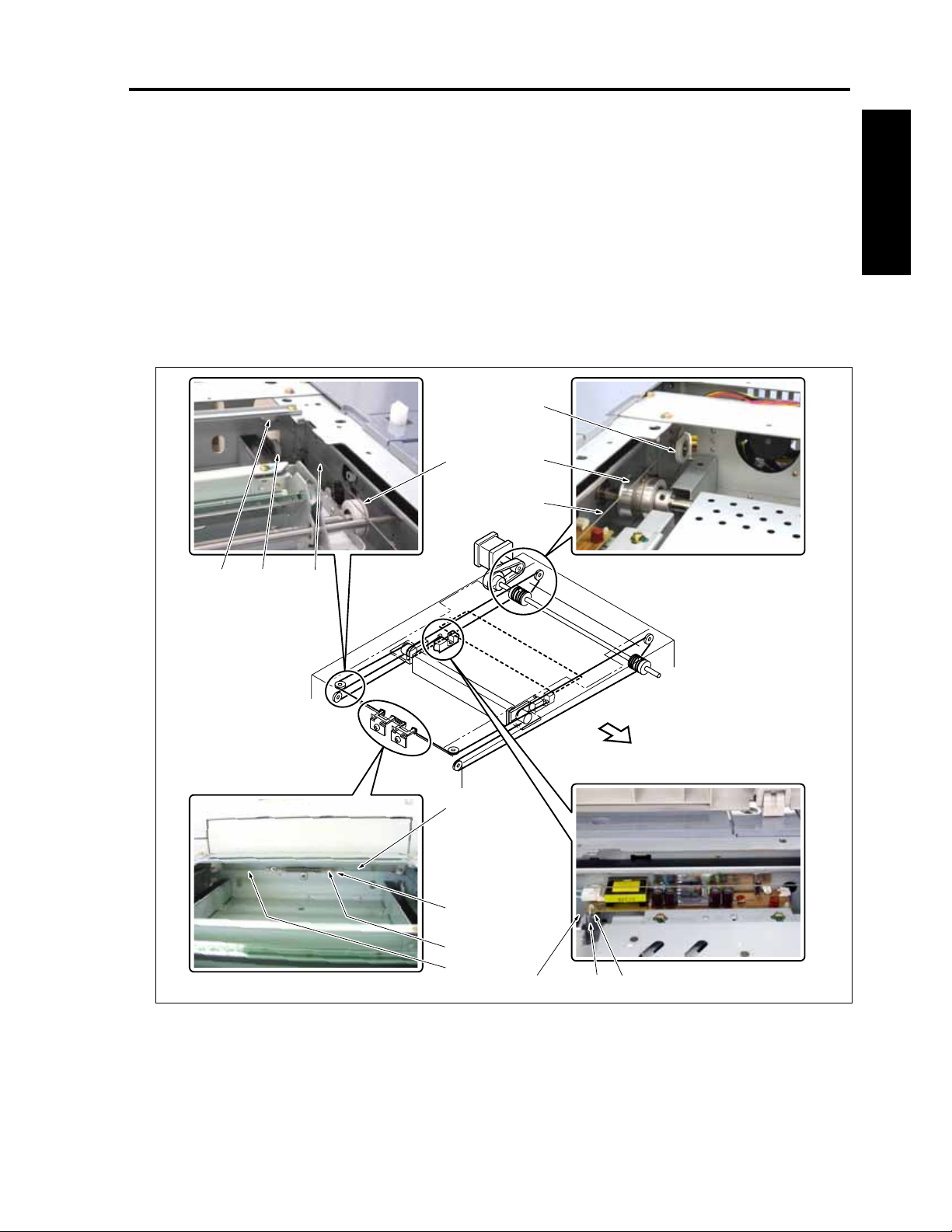

2.6 Removing the scanner wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

2.7 Reinstalling the scanner wire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

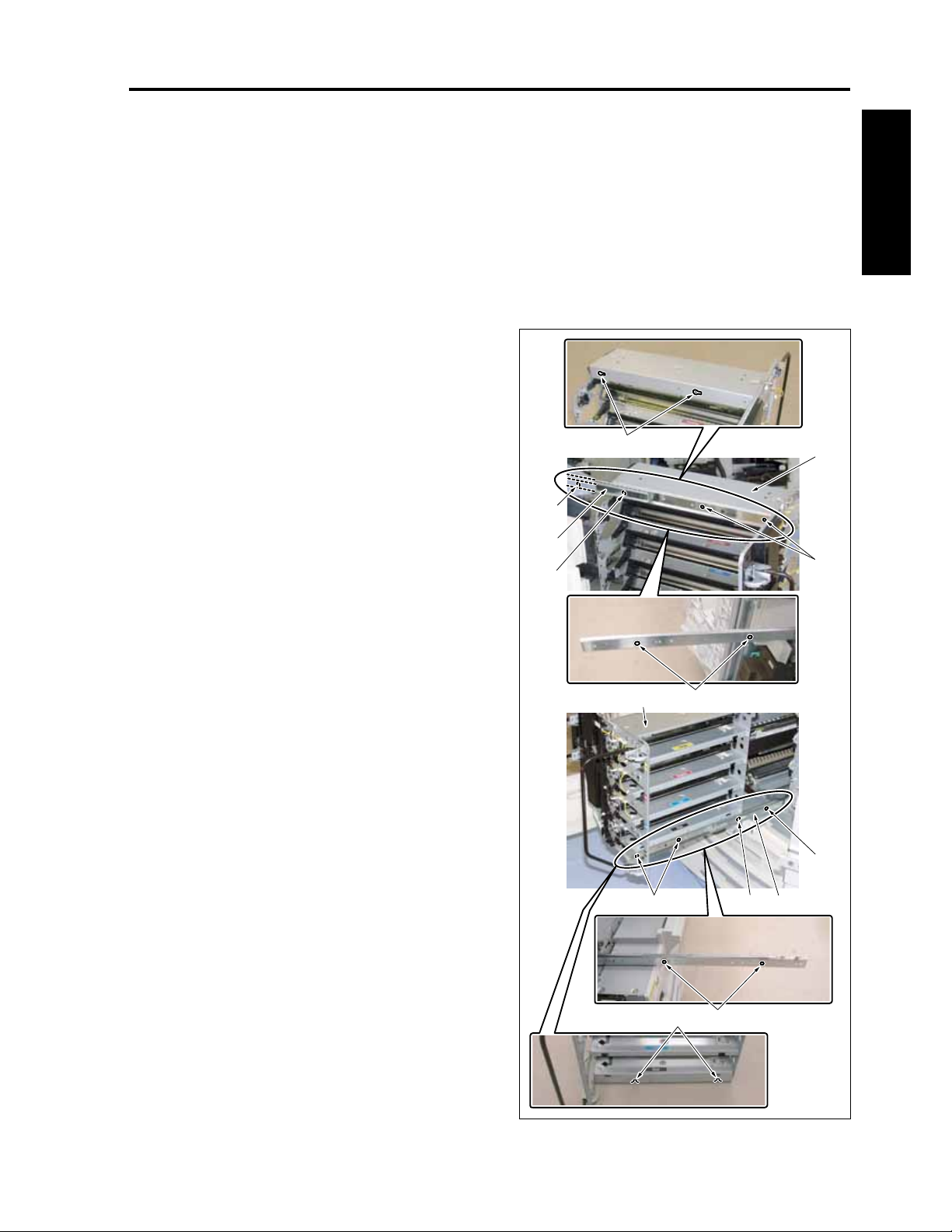

3. WRITING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

3.1 Screw that must not be removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

3.2 Removing and reinstalling the write unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

4. PROCESS UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

4.1 Flow of the disassembly of the process unit section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

4.2 Cleaning the charging corona unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

4.3 Cleaning/replacing, removing and reinstalling the charging wire assy

/the charging control plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

4.4 Pulling out the process unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

4.5 Removing and reinstalling the transfer belt unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

4.6 Replacing the belt cleaning brush unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

4.7 Replacing the belt cleaning blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

4.8 Replacing the toner collection sheet /1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

4.9 Replacing the belt separation claw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

4.10 Replacing the transfer belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-39

4.11 Replacing the 1st transfer roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-41

4.12 Replacing the 2nd transfer roller /U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-42

4.13 Replacing the drum cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-43

I DIS./ASSEMBLYII ADJUSTMENTIII SERVICE TOOL

IV SERVICEV CODE LISTVI DIAGRAMS

i

Page 4

CONTENTS CF5001 Field Service Ver.1.0 Sep 2003

4.14 Removing and reinstalling the drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-44

4.15 Replacing the developing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-46

4.16 Replacing the developer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-48

4.17 Replacing the belt separation claw solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-50

4.18 Removing and reinstalling the process unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-51

4.19 Removing and reinstalling the image correction unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-52

I DIS./ASSEMBLY

II ADJUSTMENT

III SERVICE TOOL

IV SERVICEV CODE LISTVI DIAGRAMS

5. TONER SUPPLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-53

5.1 Opening and closing the toner supply section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-53

5.2 Replacing the charging dust filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-54

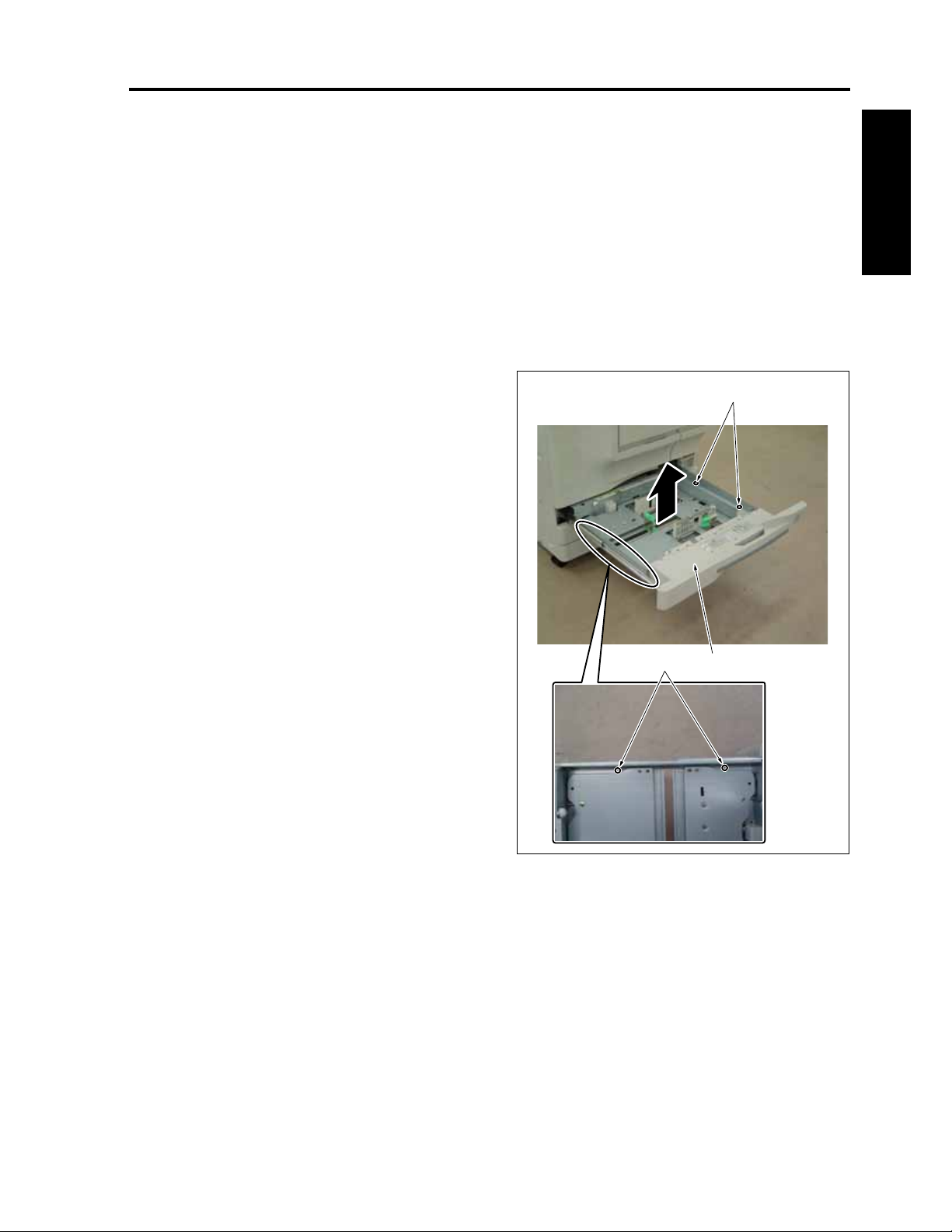

6. PAPER FEED TRAYS /1 to /3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-55

6.1 Removing and reinstalling the paper feed unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-55

6.2 Removing and reinstalling the paper feed trays /1 to /3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-57

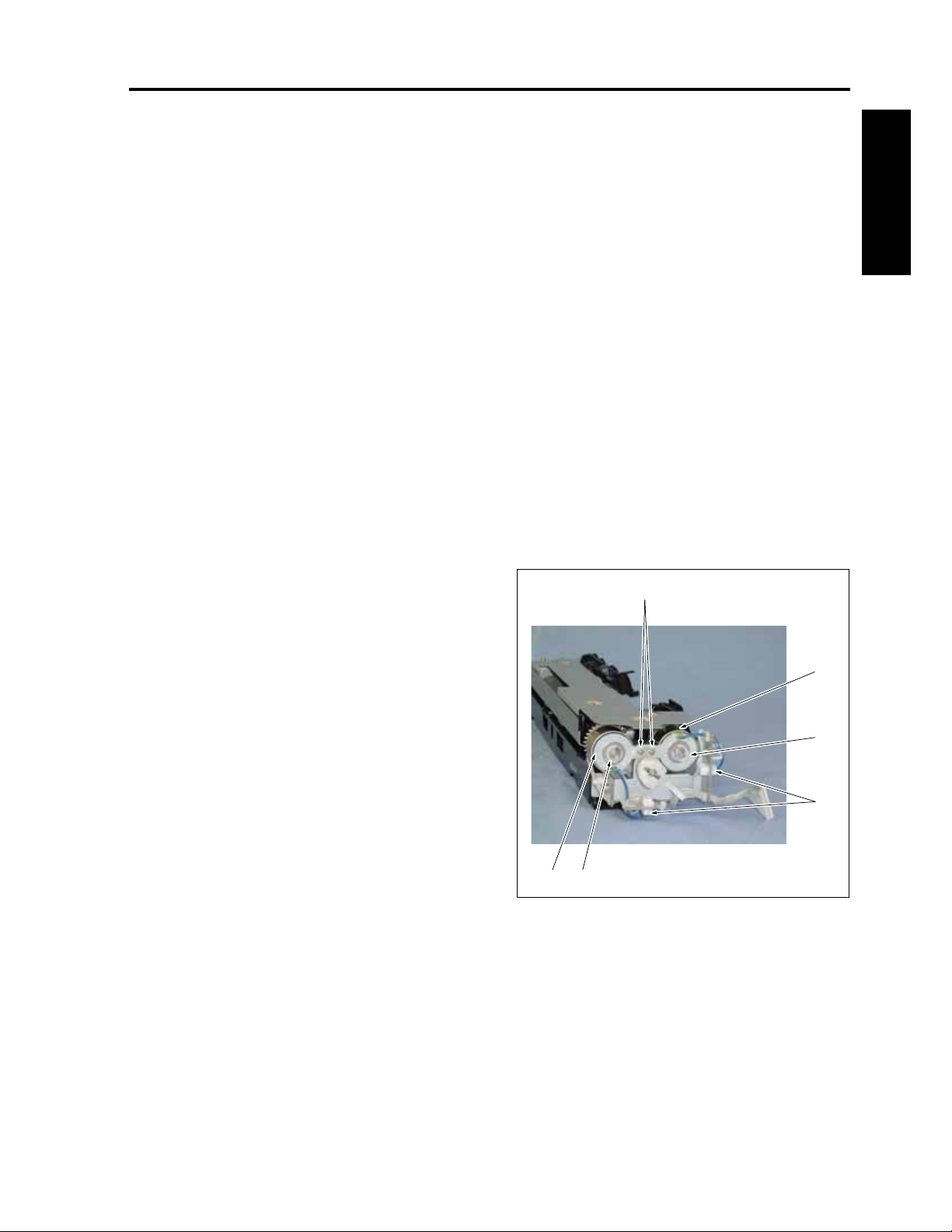

6.3 Replacing the paper feed roller and the feed rubber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-58

6.4 Replacing the double feed prevention rubber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-60

6.5 Replacing the paper feed clutch and the pre-registration clutch . . . . . . . . . . . . . . . . . . . . . . . . . 1-61

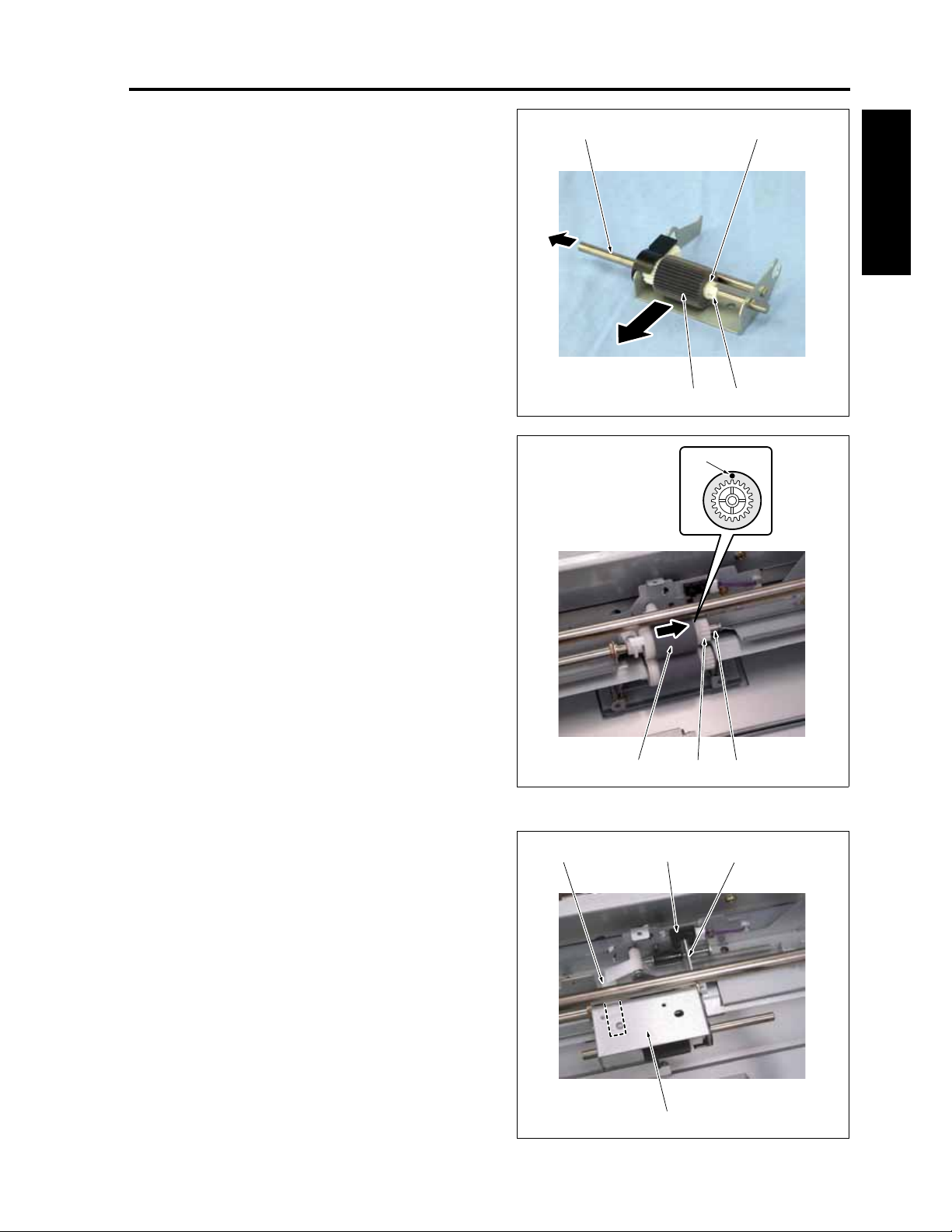

6.6 Removing and reinstalling the tray up/down wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-62

7. BY-PASS TRAY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-66

7.1 Replacing the paper feed roller and the feed roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-66

7.2 Replacing the double feed prevention roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-68

7.3 Replacing the paper feed clutch /BP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-69

8. VERTICAL CONVEYANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-71

8.1 Removing and reinstalling the vertical conveyance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-71

8.2 Replacing the intermediate conveyance clutch /1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-74

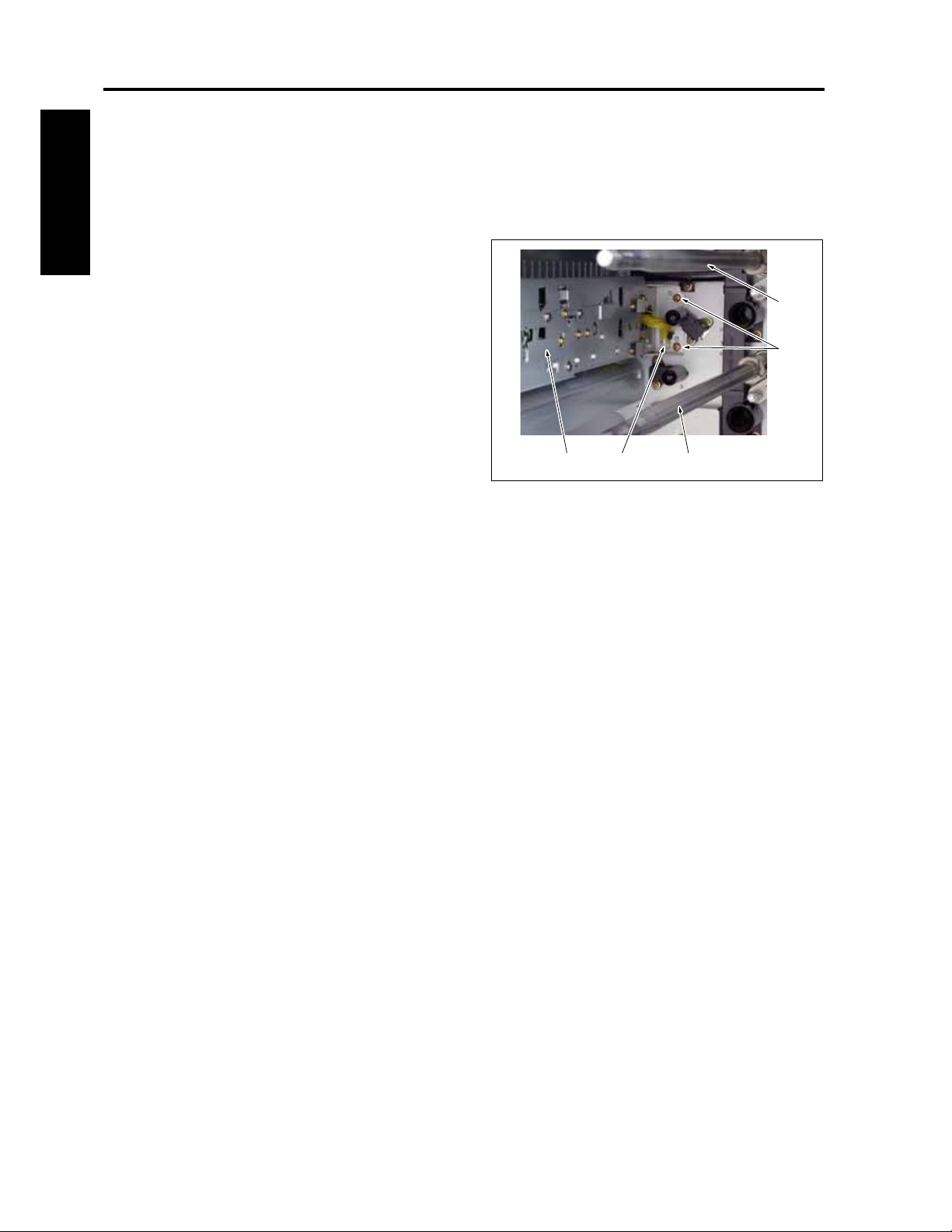

9. FIXING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-75

9.1 Screws that must not be removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-75

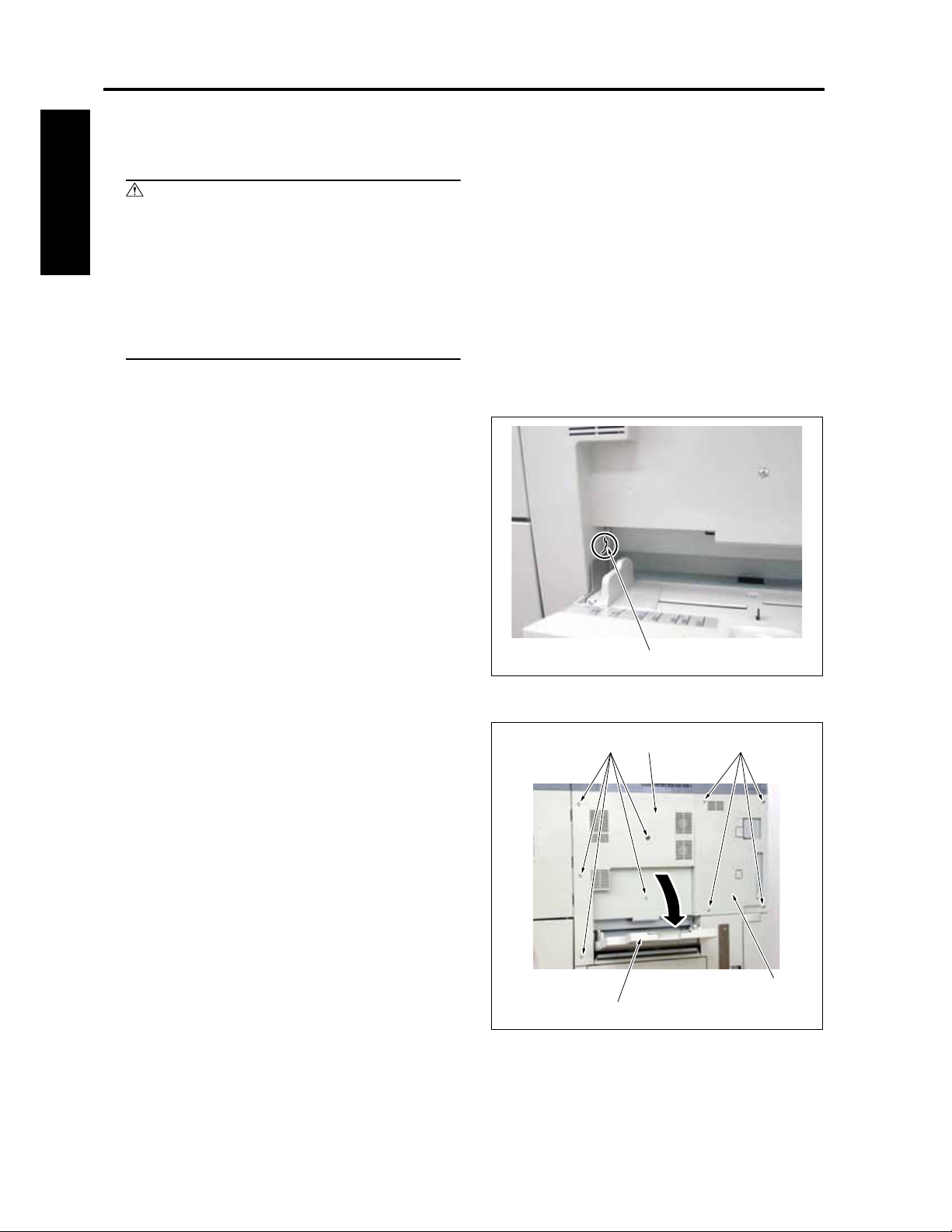

9.2 Removing and reinstalling the fixing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-76

9.3 Replacing the fixing upper heater lamps /1 and /2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-77

9.4 Replacing the fixing lower heater lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-79

9.5 Replacing the fixing roller /U, ball bearing /U and the heat insulating sleeve /U . . . . . . . . . . . . . 1-82

9.6 Replacing the fixing roller /L, ball bearing /L and the heat insulating sleeve /L . . . . . . . . . . . . . . 1-84

9.7 Replacing the fixing temperature sensor /3, and removing and reinstalling

the fixing temperature sensor /1 and the thermostat /1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-86

9.8 Replacing the fixing temperature sensor /4, and removing and reinstalling

the fixing temperature sensor /2 and the thermostat /L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-91

9.9 Replacing the fixing drive gear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-96

9.10 Replacing the fixing cleaning unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-98

9.11 Replacing the fixing torque limiter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-100

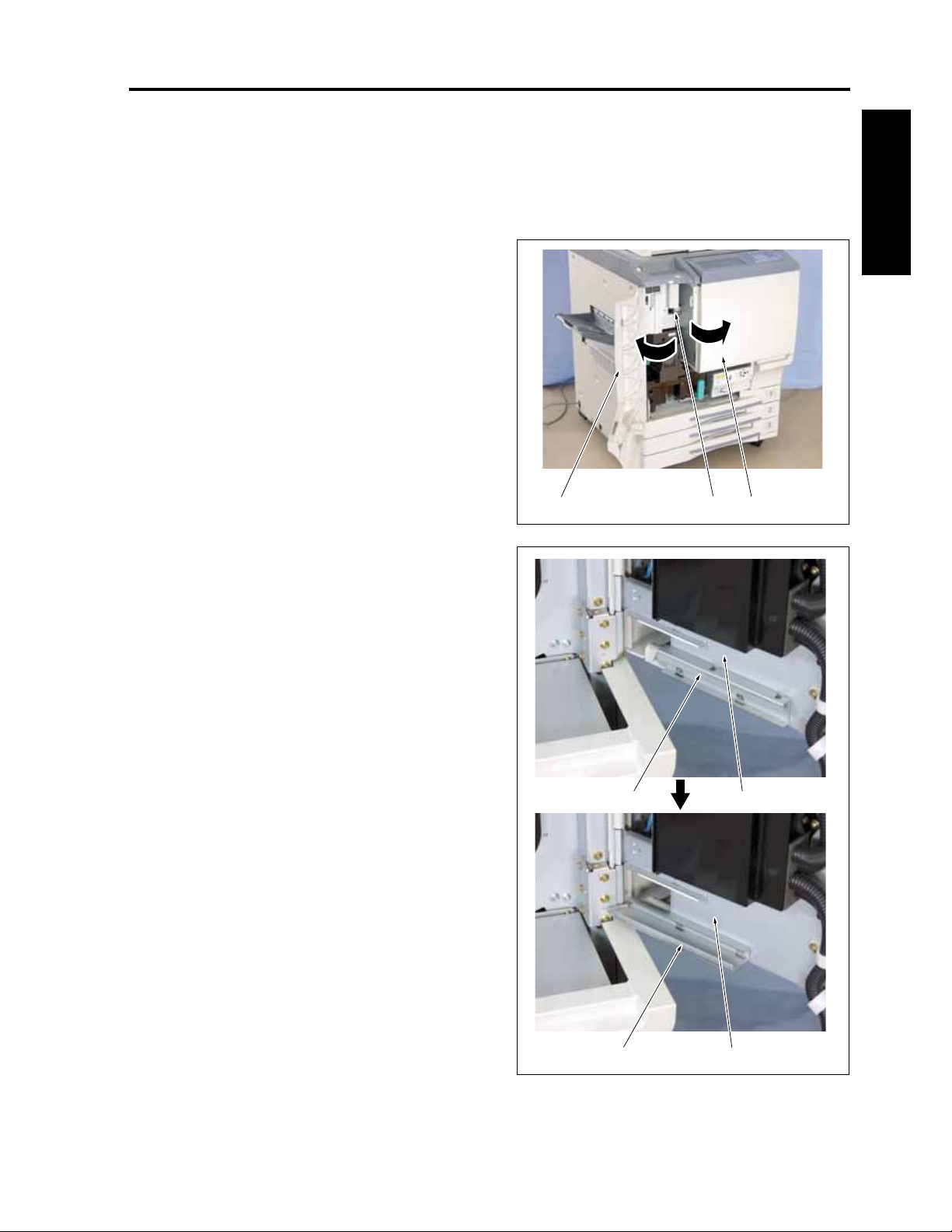

10. REGISTRATION/ADU/REVERSE/PAPER EXIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-102

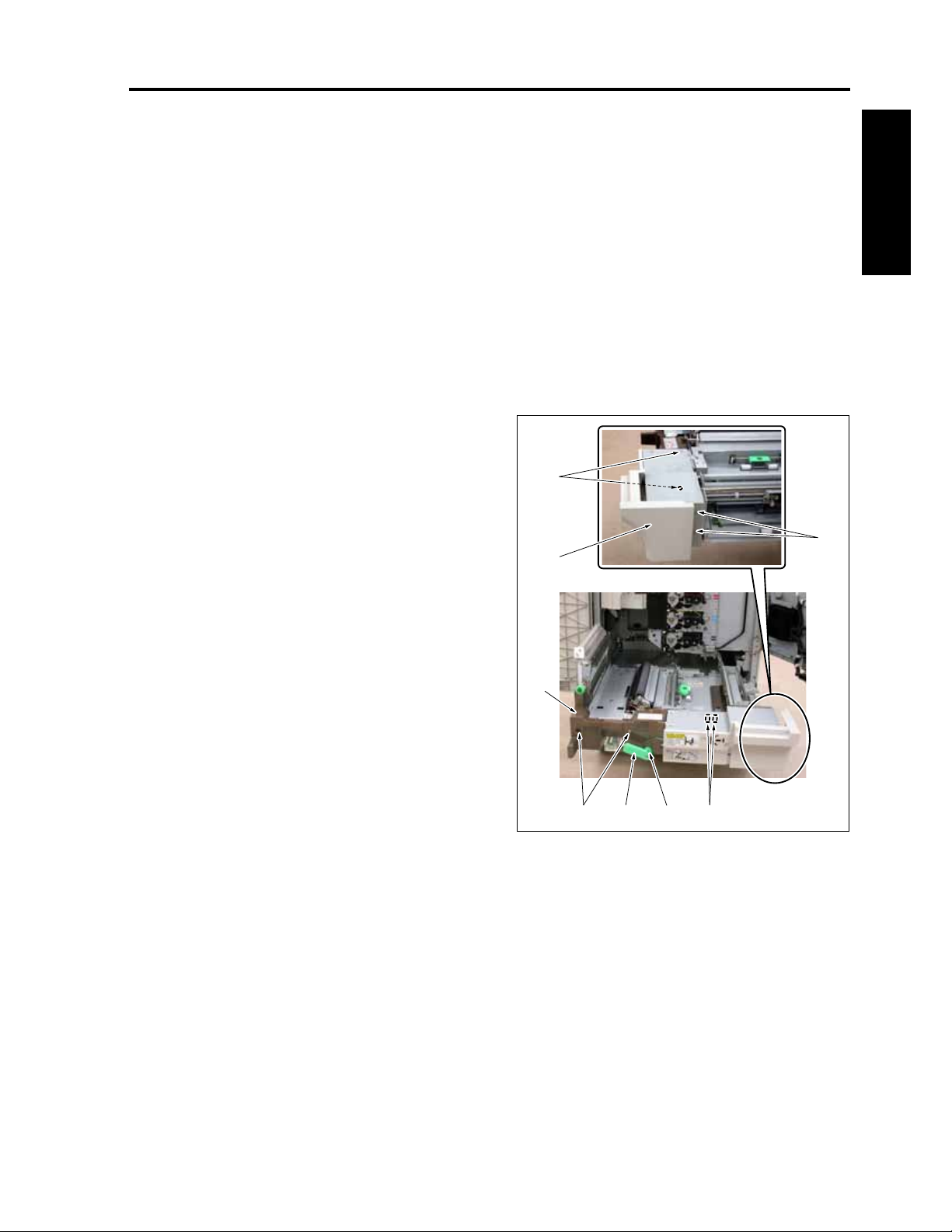

10.1 Removing and reinstalling the ADU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-102

10.2 Replacing the registration cleaning sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-104

10.3 Replacing the separation discharging plate unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-105

10.4 Replacing the transfer ground plate unit and the 2nd transfer roller /L . . . . . . . . . . . . . . . . . . . 1-106

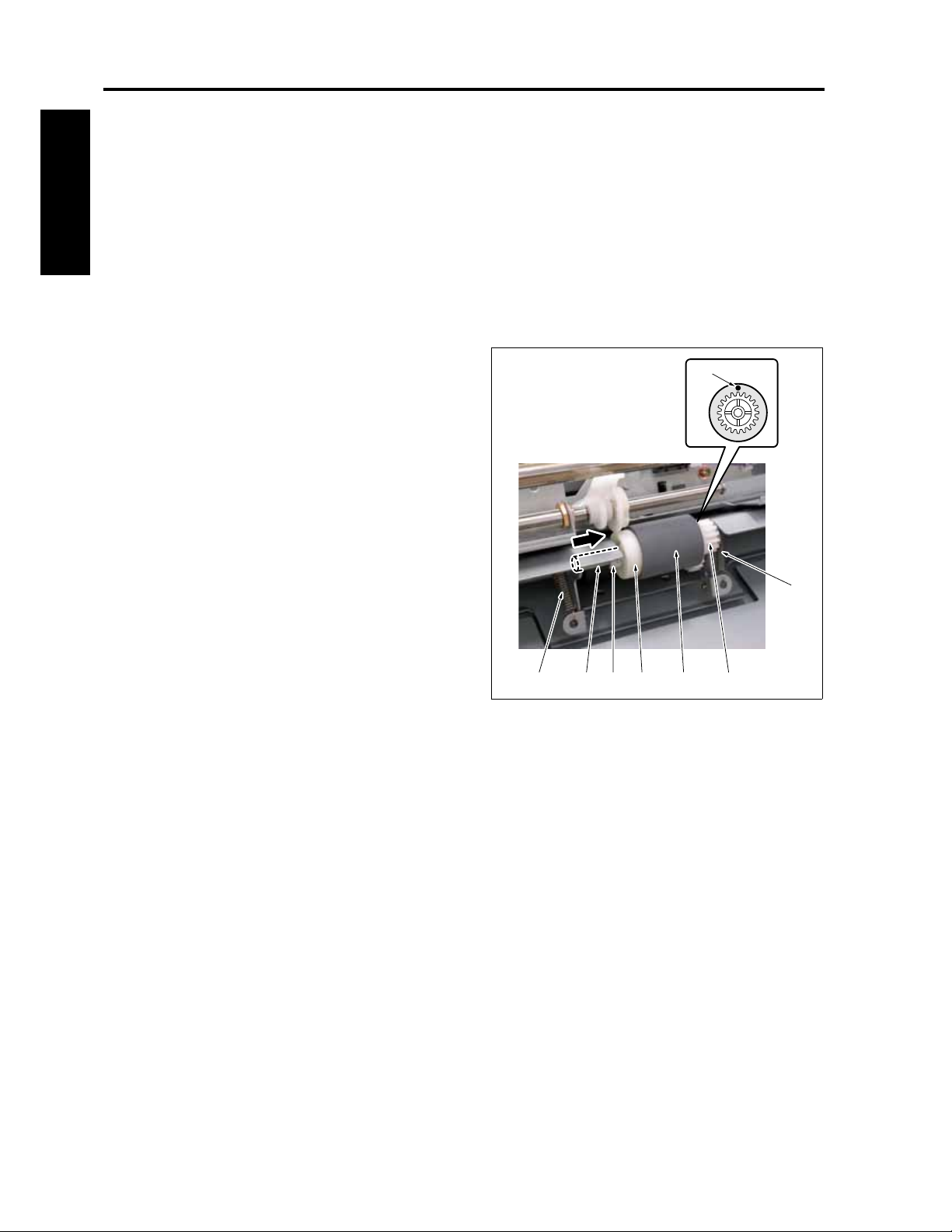

10.5 Replacing the registration roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-107

10.6 Replacing the intermediate conveyance clutches /2 and /3. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-109

10.7 Replacing the ADU conveyance clutches /1 and /2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-110

10.8 Replacing the ADU pre-registration clutch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-111

10.9 Replacing the decurler roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-112

ii

Page 5

CF5001 Field Service Ver.1.0 Sep 2003 CONTENTS

11. OTHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-114

11.1 Installation of the Key Counter Socket (OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-114

11.2 Installation / Remove of the Memory Unit (OPTION). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-115

AFR-20 DISASSEMBLY/ASSEMBLY

1. EXTERIOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-117

1.1 RADF hinge opening/closing angle adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-117

1.2 Removing and reinstalling the front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-119

1.3 Removing and reinstalling the rear cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-120

1.4 Removing and reinstalling the registration roller cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-121

2. PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-122

2.1 Cleaning the no paper sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-122

2.2 Removing and reinstalling the paper feed unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-123

2.3 Replacing the paper feed roller and the feed roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-125

2.4 Replacing the double feed prevention roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-127

3. PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-129

3.1 Cleaning the registration roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-129

3.2 Cleaning the registration sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-130

3.3 Removing and reinstalling the conveyance belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-131

4. REVERSE/PAPER EXIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-133

4.1 Cleaning the paper exit roller/the paper exit sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-133

4.2 Cleaning the reverse roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-133

5. REMOVING AND REINSTALLING RADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-134

C-208 DISASSEMBLY/ASSEMBLY

1. EXTERIOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-135

1.1 Removing and reinstalling the front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-135

1.2 Removing and reinstalling the clutch replacement cover and the rear cover . . . . . . . . . . . . . . 1-137

1.3 Removing and reinstalling the paper feed pick-up cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-138

2. PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-139

2.1 Cleaning the paper dust removing brush. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-139

2.2 Removing and reinstalling the paper feed unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-140

2.3 Replacing the paper feed roller and the feed roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-141

2.4 Replacing the double feed prevention roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-142

2.5 Replacing the paper feed clutch and the pre-registration clutch . . . . . . . . . . . . . . . . . . . . . . . . 1-144

3. TRAY UP/DOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-145

3.1 Removing and reinstalling the rear drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-145

3.2 Removing and reinstalling the up/down wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-150

I DIS./ASSEMBLYII ADJUSTMENTIII SERVICE TOOL

IV SERVICEV CODE LISTVI DIAGRAMS

FN-9/FN120 DISASSEMBLY/ASSEMBLY

1. EXTERIOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-159

1.1 Removing and reinstalling of the booklet tray (FN-9 only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-159

1.2 Removing and reinstalling of the top cover /1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-160

1.3 Removing and reinstalling of the top cover /2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-160

1.4 Removing and reinstalling of the side cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-161

1.5 Removing and reinstalling of the finisher door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-161

iii

Page 6

CONTENTS CF5001 Field Service Ver.1.0 Sep 2003

1.6 Removing and reinstalling of the rear cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-162

1.7 Removing and reinstalling of the main tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-163

1.8 Removing and reinstalling of the main paper exit opening cover . . . . . . . . . . . . . . . . . . . . . . . 1-164

1.9 Removing and reinstalling of the booklet paper exit opening cover (FN-9 only) . . . . . . . . . . . . 1-164

2. CONVEYANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-165

2.1 Replacing the paper exit roller /A (sponge roller). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-165

I DIS./ASSEMBLY

II ADJUSTMENT

2.2 Replacing the intermediate conveyance roller (sponge roller). . . . . . . . . . . . . . . . . . . . . . . . . . 1-167

2.3 Removing and reinstalling of the paper exit opening unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-168

3. MAIN TRAY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-170

3.1 Replacing the tray up/down motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-170

3.2 Removing and reinstalling of the up/down wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-171

4. STACKER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-175

4.1 Replacing the stacking assist roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-175

4.2 Removing and reinstalling of the stacker unit cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-175

4.3 Removing and reinstalling of the stacker unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-176

5. STAPLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-179

5.1 Removing and reinstalling of the stapler unit cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-179

5.2 Replacing the clincher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-180

5.3 Replacing the stapler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-182

PK-5 DISASSEMBLY/ASSEMBLY

1. PUNCH SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-185

III SERVICE TOOL

1.1 Replacing the Punch unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-185

1.2 Cleaning the Punch Edges and Punch Scraps Full PS (PS802) . . . . . . . . . . . . . . . . . . . . . . . . 1-188

Cover Inserter D DISASSEMBLY/ASSEMBLY

1. External Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-189

1.1 Removing / Re-installing the External covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-189

2. Paper feed unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-191

IV SERVICEV CODE LISTVI DIAGRAMS

2.1 Replacing the Paper feed roller and Feed roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-191

2.2 Replacing the Double feed prevent roller and Torque limiter . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-192

TMG-3 DISASSEMBLY/ASSEMBLY

1. TRIMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-193

1.1 Replacing the trimmer knife /U and trimmer knife /L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-193

II ADJUSTMENT

1. HOW TO USE THE ADJUSTMENT SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2. ADJUSTMENTS WHEN REPLACING PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3. LIST OF ADJUSTMENT ITEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

4. MODE CHANGE MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

4.1 Setting method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

4.2 Display transition of 36 modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

4.3 Display transition of 25 modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

4.4 Display transition of Key Operation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

iv

Page 7

CF5001 Field Service Ver.1.0 Sep 2003 CONTENTS

5. CHECKING BY THE P FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

5.1 Checking method of the P function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

6. 25 MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

6.1 List of adjustment items for 25 mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

6.2 Setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

6.3 Setting software DIPSW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

6.4 Paper size setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

6.4.1 Standard size setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

6.4.2 Non-standard size setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

6.4.3 Wide paper setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

6.5 PM count setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

6.5.1 Count reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

6.5.2 Change setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

6.6 Data collection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

6.7 Parts counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

6.7.1 Count of special parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

6.7.2 Count of each parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

6.8 Password setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

6.9 Telephone number setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

6.10 M/C serial number setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

6.11 Indication of ROM version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

6.12 ISW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

6.13 Setting date input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

6.14 Board change mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

7. 36 MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

7.1 Setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

7.2 Process adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

7.2.1 High voltage adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

7.2.2 Drum peculiarity adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

7.2.3 Sensor output check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

7.2.4 Exclusive paper setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

7.2.5 Recall standard data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-59

7.3 Image adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

7.3.1 Magnification adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

7.3.2 Timing adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-66

7.3.3 RADF adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-74

7.3.4 Centring adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-76

7.3.5 Non-image area erase check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-79

7.3.6 Recall standard data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-80

7.4 Image quality adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-81

7.4.1 Scanner gamma adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-81

7.4.2 Printer gamma adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-82

7.4.3 Sharpness adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-87

7.4.4 Contrast adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-88

7.4.5 Image judge adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-88

7.4.6 ACS adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-90

7.4.7 Density adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-91

I DIS./ASSEMBLYII ADJUSTMENTIII SERVICE TOOL

IV SERVICEV CODE LISTVI DIAGRAMS

v

Page 8

CONTENTS CF5001 Field Service Ver.1.0 Sep 2003

7.4.8 Tone adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-93

7.4.9 Recall standard data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-94

7.5 Running test mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-95

7.5.1 Setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-95

7.6 Test pattern output mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-96

7.7 Test pattern density setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-100

I DIS./ASSEMBLY

II ADJUSTMENT

III SERVICE TOOL

IV SERVICEV CODE LISTVI DIAGRAMS

7.8 Finisher adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-100

7.8.1 Stitch and fold stopper adjustment (FN-9 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-101

7.8.2 Fold stopper adjustment (FN-9 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-101

7.8.3 Cover sheet tray size adjustment (Cover Inserter D only) . . . . . . . . . . . . . . . . . . . . . . . . 2-102

7.8.4 Trimming stopper adjustment (TMG-3 only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-102

7.8.5 Punch adjustment (PK-5 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-103

7.8.6 Three-folding adjustment (FN-9 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-105

7.8.7 2 positions staple pitch adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-106

7.9 List output mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-106

8. 47 MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-107

8.1 47 mode/multi mode setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-107

8.2 Adjustment data display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-108

8.3 Hard disk check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-108

8.4 Input check list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-109

8.5 Output check list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-121

9. OTHER ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-131

9.1 Paper feed roller/BP pressure adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-131

9.2 Paper feed height (upper limit) adjustment (by-pass) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-132

9.3 Pick-up movement amount adjustment (by-pass) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-134

9.4 Paper feed tray /1 to /3 mis-centering adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-135

9.5 Paper feed tray/1 to /3 sheet feed pressure adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-136

9.6 FNS adjustment of the by-pass conveyance guide plate magnet . . . . . . . . . . . . . . . . . . . . . . . 2-138

9.7 FNS adjustment of the by-pass gate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-139

9.8 FNS adjustment of the shift position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-141

9.9 FNS adjustment of the paper exit opening solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-142

9.10 FNS adjustment of the position of paper exit arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-144

9.11 FNS adjustment of the position of alignment plate/U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-146

9.12 FNS adjustment of the position of alignment plate/L (only for FN-9) . . . . . . . . . . . . . . . . . . . . . 2-148

9.13 FNS adjustment of the stapling position (flat stapling) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-150

9.14 FNS adjustment of the stapling position in a vertical direction. . . . . . . . . . . . . . . . . . . . . . . . . . 2-152

9.15 FNS adjustment of the stapling position (flat stapling) (only for FN-9). . . . . . . . . . . . . . . . . . . . 2-156

9.16 FNS adjustment of the angle of the folding stopper (only for FN-9). . . . . . . . . . . . . . . . . . . . . . 2-158

9.17 FNS adjustment of the folding force (only for FN-9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-160

9.18 FNS adjustment of the three-holding position (only for FN-9) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-161

9.19 FNS adjustment of the stapler drive belt position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-162

9.20 TU adjustment of the sheet cutting parallelism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-166

9.21 LCT tray mis-centering adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-167

9.22 LCT skew adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-169

9.23 LCT paper feed roller pressure adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-171

9.24 LCT up/down plate horizontal adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-172

9.25 LCT sheet feed pressure adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-173

vi

Page 9

CF5001 Field Service Ver.1.0 Sep 2003 CONTENTS

9.26 LCT paper feed height (upper limit) adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-174

9.27 LCT pick-up release amount adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-176

9.28 PK Adjusting the tilt of the punch hole position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-178

9.29 Sensitivity adjustment for the PK paper edge sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-179

9.30 PI Centering Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-180

9.31 Adjusting the tilt of PI (when PK punch is used) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-181

III SERVICE TOOL

1. ISW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1 Description of the ISW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.2 Installing the USB driver for ISWTrns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.3 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.3.1 Board used for the ISW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.3.2 Data flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.3.3 ISW transfer type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.3.4 Instances of ISW transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

1.3.5 Setup procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

2. UPDATING WITH ISW Trns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

2.1 Setting Up ISW Trns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

2.1.1 Installing the application program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

2.1.2 Setting up ISW Trns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

2.1.3 ISW Trns Main Window Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

2.1.4 Parallel port setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

2.2 Copying Transfer Data (Update Data) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

2.3 Connecting the CF5001. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

2.4 Updating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

2.4.1 Update operation overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

2.4.2 Checking the ROM version of the copier (before updating). . . . . . . . . . . . . . . . . . . . . . . . 3-16

2.4.3 Preparing the copier to transfer.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

2.4.4 Running ISW Trns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

2.4.5 Selecting transfer file (update data) conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

2.4.6 Selecting a version of transfer files (update data) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

2.4.7 Verifying transfer files (update data) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

2.4.8 Transmitting transfer files (update data). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

2.4.9 Exiting ISW Trns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

2.4.10 Verifying the ROM version of the copier (after updating) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

2.5 ISW Trns Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

2.6 Troubleshooting ISW Trns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

2.6.1 Unable to run ISW Trns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

2.6.2 Send file is not displayed when a combo box item is selected. . . . . . . . . . . . . . . . . . . . . . 3-22

2.6.3 NG produced by a file check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

2.6.4 “??” produced by a file check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

2.6.5 Unsuccessful file transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

2.7 Connecting to the ISW connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

2.7.1 Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3 INTERNET ISW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.1 What is the Internet ISW? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

I DIS./ASSEMBLYII ADJUSTMENTIII SERVICE TOOL

IV SERVICEV CODE LISTVI DIAGRAMS

vii

Page 10

CONTENTS CF5001 Field Service Ver.1.0 Sep 2003

3.2 Operating environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.3 Main features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.4 Initial setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

3.4.1 Setting on Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

3.4.2 Setting on Web browser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

3.5 Internet ISW using E-Mail remote notification system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

I DIS./ASSEMBLY

II ADJUSTMENT

III SERVICE TOOL

3.5.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

3.5.2 Transmitting E-Mail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

3.6 Internet ISW using Web utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

3.6.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

3.6.2 How to use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

3.7 Precautions for use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

3.7.1 Prior announcement to administrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

3.7.2 If power failure occurs during data rewriting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

3.7.3 ISW of multiple programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

3.7.4 If ISW fails in low power mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

3.8 Proxy server authentication in Internet ISW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

3.8.1 What is a proxy server? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

3.8.2 Authentication of proxy server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

3.8.3 Type and command list for authentication on proxy server . . . . . . . . . . . . . . . . . . . . . . . . 3-42

3.8.4 Remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

4 MAIL REMOTE NOTIFICATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

4.1 What is the Mail remote notification system?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

4.2 Operation environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

4.3 Initial setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

4.4 How to use the Mail remote notification system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

4.5 Disabling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-59

IV SERVICE

1. SERVICE SCHEDULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

IV SERVICEV CODE LISTVI DIAGRAMS

1.1 Service schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.2 Maintenance items. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

1.3 Periodic check items (main body) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

1.4 Periodic check items (AFR-20) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

1.5 Periodic check items (C-208). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

1.6 Periodic check items (FN-120/FN-9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

1.7 Periodic check items (Cover Inserter D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

1.8 Periodic check items (TMG-3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

1.9 Replacement parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

1.10 Important maintenance parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

2. COPY MATERIAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

2.1 Product. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

2.2 Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

2.3 PM parts kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

3. SERVICE MATERIAL LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

4. CE TOOLS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

viii

Page 11

CF5001 Field Service Ver.1.0 Sep 2003 CONTENTS

V CODE LIST

1. JAM CODE LIST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2. ERROR CODE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

3. ABOUT ABNORMAL UNIT ISOLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

VI DIAGRAMS

1. PARTS LAYOUT DRAWING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1.1 CF5001 parts layout drawing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1.2 AFR-20 parts layout drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

1.3 C-208 parts layout drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

1.4 FN-120/FN-9 parts layout drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

1.5 TMG-3 parts layout drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

2. CONNECTOR LAYOUT DRAWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

2.1 Main Body connector layout drawing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

2.2 AFR-20 connector layout drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-39

2.3 C-208 connector layout drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-39

2.4 FN-120/FN-9 connector layout drawing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-40

2.5 TMG-3 connector layout drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-41

3. TIMING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-42

3.1 Main Body timing chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-42

3.2 AFR-20 timing chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-44

3.3 C-208 timing chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-51

3.4 FN-120/FN-9 timing chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-52

3.5 TMG-3 timing chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-56

4. OVERALL WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-59

4.1 AFR-20 Overall Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-59

4.2 C-208 Overall Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-61

4.3 FN-120/FN-9 Overall Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-63

4.4 TMG-3 Overall Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-65

4.5 Cover Inserter D Overall Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-67

4.6 PK-5 Overall Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-68

5. APPENDIX

5.1 CF5001 Overall Wiring Diagram (1/8)

5.2 CF5001 Overall Wiring Diagram (2/8)

5.3 CF5001 Overall Wiring Diagram (3/8)

5.4 CF5001 Overall Wiring Diagram (4/8)

5.5 CF5001 Overall Wiring Diagram (5/8)

5.6 CF5001 Overall Wiring Diagram (6/8)

5.7 CF5001 Overall Wiring Diagram (7/8)

5.8 CF5001 Overall Wiring Diagram (8/8)

I DIS./ASSEMBLYII ADJUSTMENTIII SERVICE TOOL

IV SERVICEV CODE LISTVI DIAGRAMS

ix

Page 12

CONTENTS CF5001 Field Service Ver.1.0 Sep 2003

I DIS./ASSEMBLY

II ADJUSTMENT

III SERVICE TOOL

IV SERVICEV CODE LISTVI DIAGRAMS

Blank page

x

Page 13

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY AND IMPORTANT WARNING ITEMS

Read carefully the Safety and Important Warning Items described below to understand them before doing ser-

vice work.

IMPORTANT NOTICE

Because of possible hazards to an inexperienced person servicing this copier as well as the risk of damage to

the copier, Minolta Corporation strongly recommends that all servicing be performed only by Minolta-trained ser-

vice technicians.

Changes may have been made to this copier to improve its performance after this Service manual was printed.

Accordingly, Minolta Corporation does not warrant, either explicitly or implicitly, that the information contained in

this Service manual is complete and accurate.

The user of this Service manual must assume all risks of personal injury and/or damage to the copier while ser-

vicing the copier for which this Service manual is intended.

Therefore, this Service manual must be carefully read before doing service work both in the course of technical

training and even after that, for performing maintenance and control of the copier properly.

Keep this Service manual also for future service.

DESCRIPTION ITEMS FOR DANGER, WARNING AND

CAUTION

In this Service manual, each of three expressions “ DANGER”, “ WARNING”, and “ CAUTION” is defined

as follows together with a symbol mark to be used in a limited meaning.

When servicing the copier, the relevant works (disassembling, reassembling, adjustment, repair, maintenance,

etc.) need to be conducted with utmost care.

DANGER

WARNING

CAUTION

Symbols used for safety and important warning items are defined as follows:

:Precaution when using the copier.

:Prohibition when using the copier.

:Action having a high possibility of suffering death or serious injury

:Action having a possibility of suffering death or serious injury

:Action having a possibility of suffering a slight wound, medium trouble, and

property damage

General precaution Electric hazard High temperature

General prohibition Do not touch with wet hand Do not disassemble

:Direction when using the copier.

General instruction

S-1

Unplug

Ground/Earth

Page 14

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY WARNINGS

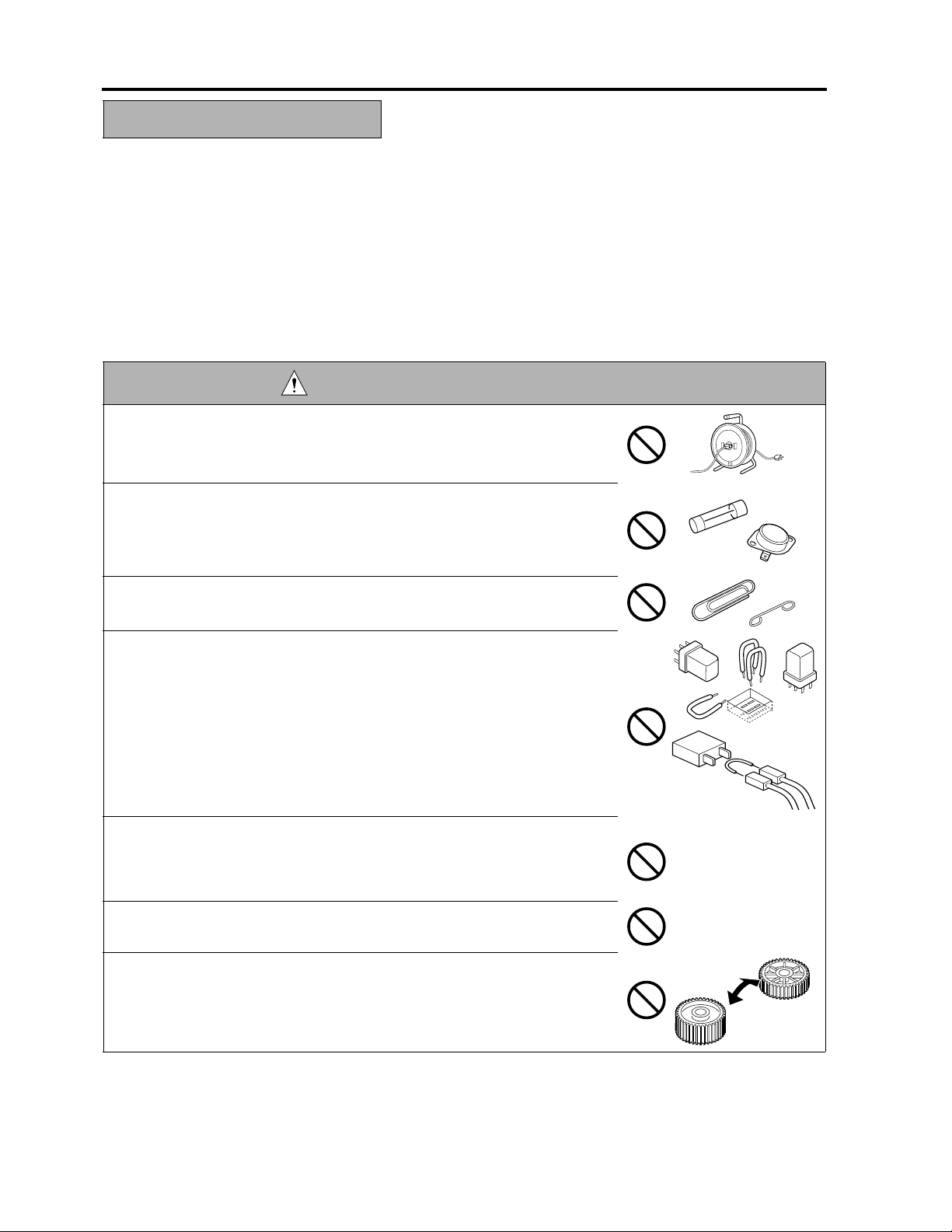

1. MODIFICATIONS NOT AUTHORIZED BY MINOLTA

Minolta copiers are renowned for their high reliability. This reliability is achieved through high-quality design and

a solid service network.

Copier design is a highly complicated and delicate process where numerous mechanical, physical, and electrical

aspects have to be taken into consideration, with the aim of arriving at proper tolerances and safety factors. For

this reason, unauthorized modifications involve a high risk of degradation in performance and safety. Such mod-

ifications are therefore strictly prohibited. the points listed below are not exhaustive, but they illustrate the rea-

soning behind this policy.

DANGER : PROHIBITED ACTIONS

• Using any cables or power cord not specified by Minolta.

• Using any fuse or thermostat not specified by Minolta. Safety will not be

assured, leading to a risk of fire and injury.

• Disabling fuse functions or bridging fuse terminals with wire, metal clips, sol-

der or similar object.

• Disabling relay functions (such as wedging paper between relay contacts)

• Disabling safety functions (interlocks, safety circuits, etc.) Safety will not be

assured, leading to a risk of fire and injury.

• Making any modification to the copier unless instructed by Minolta.

• Using parts not specified by Minolta.

S-2

Page 15

SAFETY AND IMPORTANT WARNING ITEMS

2. CHECKPOINTS WHEN PERFORMING ON-SITE SERVICE

Minolta copiers are extensively tested before shipping, to ensure that all applicable safety standards are met, in

order to protect the customer and customer engineer (hereafter called the CE) from the risk of injury. However,

in daily use, any electrical equipment may be subject to parts wear and eventual failure. In order to maintain

safety and reliability, the CE must perform regular safety checks.

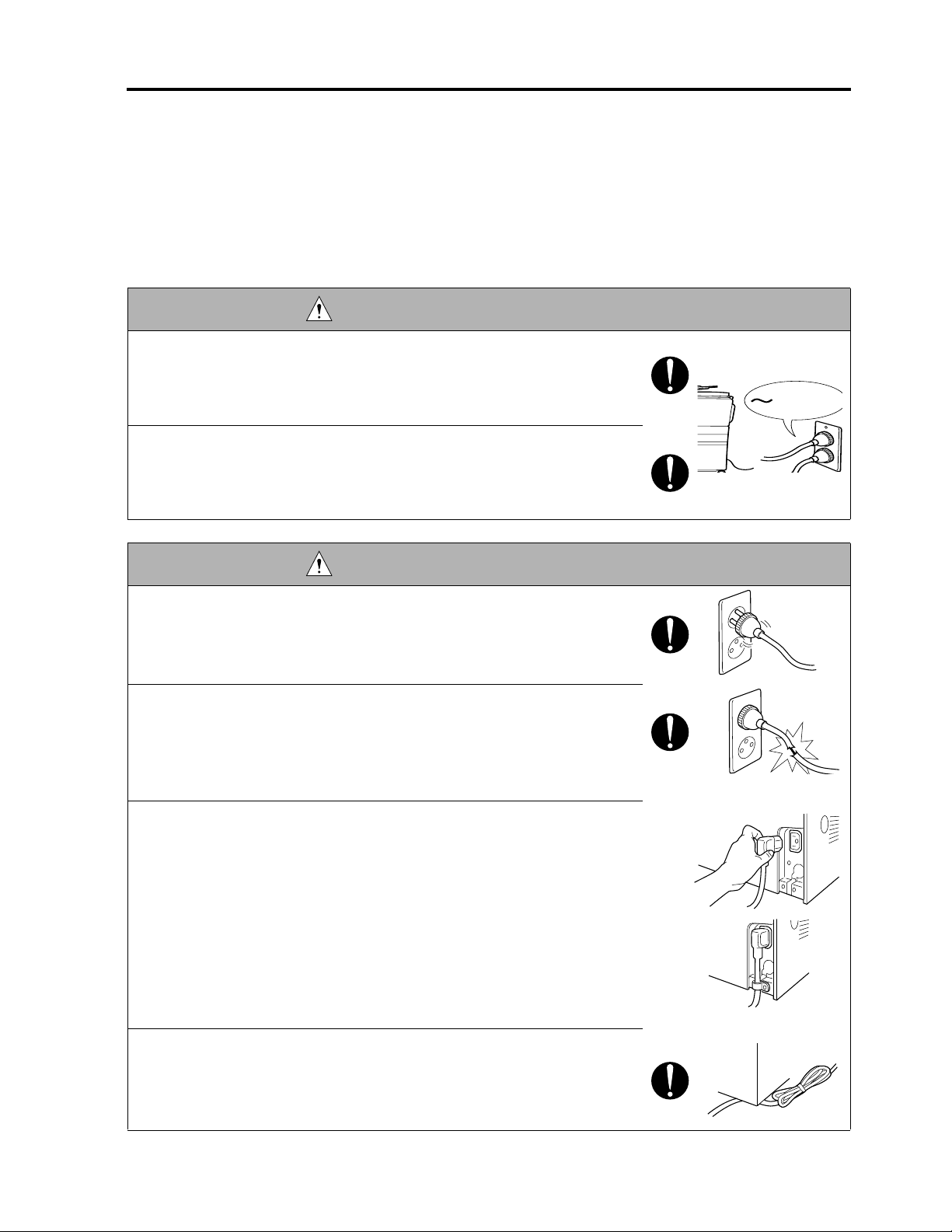

2.1 Power Supply

WARNING: Wall Outlet

• Check that mains voltage is as specified. Plug the power cord into the dedi-

cated wall outlet with a capacity greater than the maximum power consump-

tion.

If excessive current flows in the wall outlet, fire may result.

• If two or more power cords can be plugged into the wall outlet, the total load

must not exceed the rating of the wall outlet.

If excessive current flows in the wall outlet, fire may result.

kw

WARNING: Power Plug and Cord

• Make sure the power cord is plugged in the wall outlet securely.

Contact problems may lead to increased resistance, overheating, and the

risk of fire.

• Check whether the power cord is damaged. Check whether the sheath is

damaged.

If the power plug, cord, or sheath is damaged, replace with a new power

cord (with plugs on both ends) specified by Minolta. Using the damaged

power cord may result in fire or electric shock.

• When using the power cord (inlet type) that came with this copier, be sure to

observe the following precautions:

a. Make sure the copier-side power plug is securely inserted in the socket

on the rear panel of the copier.

Secure the cord with a fixture properly.

b. If the power cord or sheath is damaged, replace with a new power cord

(with plugs on both ends) specified by Minolta.

If the power cord (inlet type) is not connected to the copier securely, a

contact problem may lead to increased resistance, overheating, and risk

of fire.

• Check whether the power cord is not stepped on or pinched by a table and

so on.

Overheating may occur there, leading to a risk of fire.

S-3

Page 16

SAFETY AND IMPORTANT WARNING ITEMS

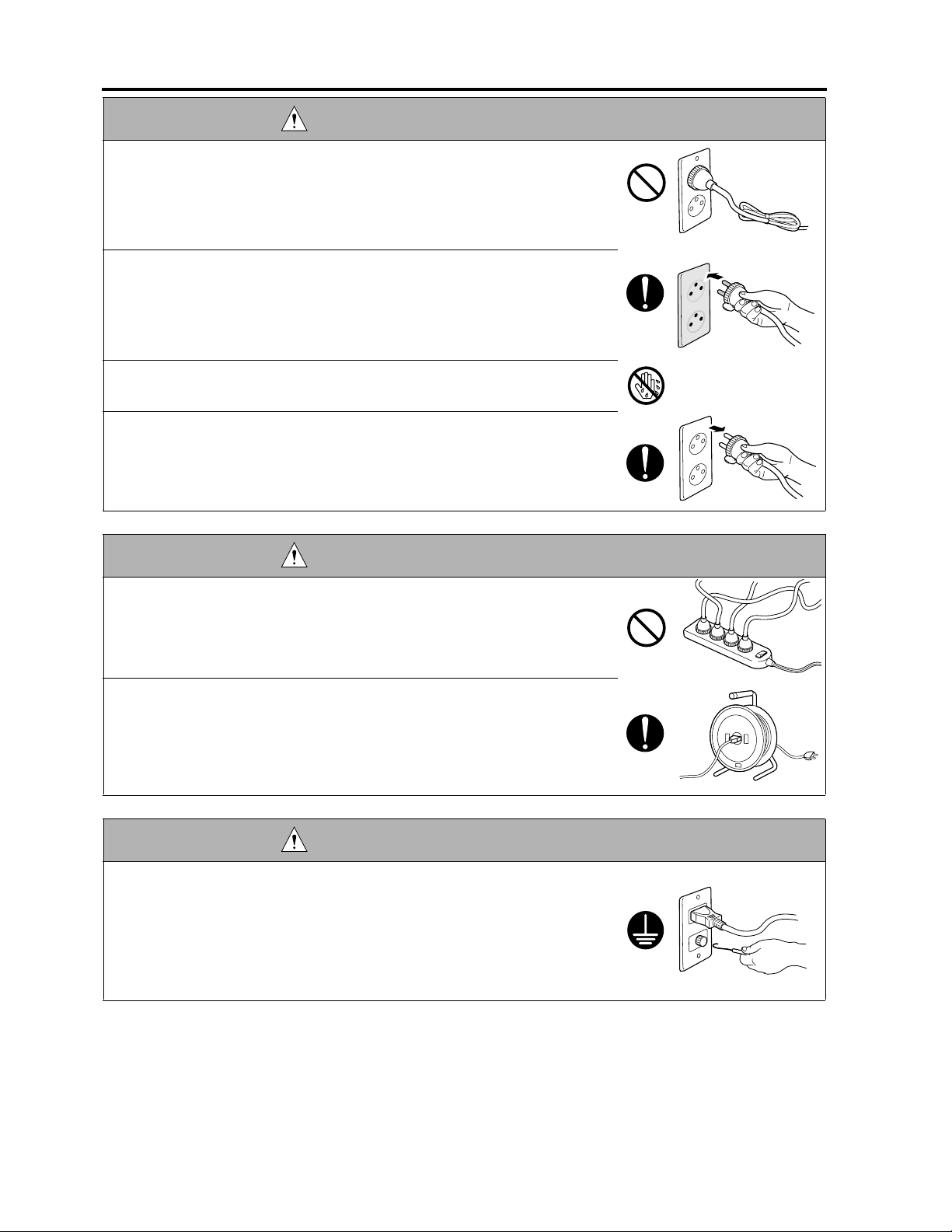

WARNING: Power Plug and Cord

• Do not bundle or tie the power cord.

Overheating may occur there, leading to a risk of fire.

• Check whether dust is collected around the power plug and wall outlet.

Using the power plug and wall outlet without removing dust may result in

fire.

• Do not insert the power plug into the wall outlet with a wet hand.

The risk of electric shock exists.

• When unplugging the power cord, grasp the plug, not the cable.

The cable may be broken, leading to a risk of fire and electric shock.

WARNING: Wiring

• Never use multi-plug adapters to plug multiple power cords in the same out-

let.

If used, the risk of fire exists.

• When an extension cord is required, use a specified one.

Current that can flow in the extension cord is limited, so using a too long

extension cord may result in fire.

Do not use an extension cable reel with the cable taken up. Fire may

result.

WARNING: Ground Lead

• Check whether the copier is grounded properly.

If current leakage occurs in an ungrounded copier, you may suffer electric

shock while operating the copier. Connect the ground lead to one of the

following points:

a. Ground terminal of wall outlet

b. Ground terminal for which Class D work has been done

S-4

Page 17

SAFETY AND IMPORTANT WARNING ITEMS

WARNING: Ground Lead

• Pay attention to the point to which the ground lead is connected.

Connecting the ground lead to an improper point such as the points listed

below results in a risk of explosion and electric shock:

a. Gas pipe (A risk of explosion or fire exists.)

b. Lightning rod (A risk of electric shock or fire exists.)

c. Telephone line ground (A risk of electric shock or fire exists in the case

of lightning.)

d. Water pipe or faucet (It may include a plastic portion.)

2.2. Installation Requirements

WARNING: Prohibited Installation Place

• Do not place the copier near flammable materials such as curtains or volatile

materials that may catch fire.

A risk of fire exists.

• Do not place the copier in a place exposed to water such as rain water.

A risk of fire and electric shock exists.

WARNING: Nonoperational Handling

• When the copier is not used over an extended period of time (holidays, etc.),

switch it off and unplug the power cord.

Dust collected around the power plug and outlet may cause fire.

CAUTION: Temperature and Humidity

• Do not place the copier in a place exposed to direct sunlight or near a heat

source such as a heater.

A risk of degradation in copier performance or deformation exists.

Do not place the copier in a place exposed to cool wind.

Recommended temperature and humidity are as follows:

Temperature: 10 °C to 30 °C

Humidity: 10 % to 80 % (no dew condensation)

Avoid other environments as much as possible.

CAUTION: Ventilation

• Do not place the copier in a place where there is much dust, cigarette smoke,

or ammonia gas.

Place the copier in a well ventilated place to prevent machine problems

and image faults.

S-5

Page 18

SAFETY AND IMPORTANT WARNING ITEMS

CAUTION: Ventilation

• The copier generates ozone gas during operation, but it is not sufficient to be

harmful to the human body.

If a bad smell of ozone is present in the following cases, ventilate the room.

a. When the copier is used in a poorly ventilated room

b. When taking a lot of copies

c. When using multiple copiers at the same time

CAUTION: Vibration

• When installing the copier, read the Installation Guide thoroughly. Be sure to

install the copier in a level and sturdy place.

Constant vibration will cause problems.

• Be sure to lock the caster stoppers.

In the case of an earthquake and so on, the copier may slide, leading to a

injury.

CAUTION: Inspection before Servicing

• Before conducting an inspection, read all relevant documentation (Service

manual, technical notices, etc.) and proceed with the inspection following the

prescribed procedure in safety clothes, using only the prescribed tools. Do

not make any adjustment not described in the documentation.

If the prescribed procedure or tool is not used, the copier may break and a

risk of injury or fire exists.

• Before conducting an inspection, be sure to disconnect the power plugs from

the copier and options.

When the power plug is inserted in the wall outlet, some units are still pow-

ered even if the POWER switch is turned OFF. A risk of electric shock

exists.

• The area around the fixing unit is hot.

You may get burnt.

DANGER: Work Performed with the Copier Powered

• Take every care when making adjustments or performing an operation check

with the copier powered.

If you make adjustments or perform an operation check with the external

cover detached, you may touch live or high-voltage parts or you may be

caught in moving gears or the timing belt, leading to a risk of injury.

S-6

Page 19

SAFETY AND IMPORTANT WARNING ITEMS

DANGER: Work Performed with the Copier Powered

• Take every care when servicing with the external cover detached.

High-voltage exists around the drum unit. A risk of electric shock exists.

WARNING: Safety Checkpoints

• Check the exterior and frame for edges, burrs, and other damages.

The user or CE may be injured.

• Do not allow any metal parts such as clips, staples, and screws to fall into the

copier.

They can short internal circuits and cause electric shock or fire.

• Check wiring for squeezing and any other damage.

Current can leak, leading to a risk of electric shock or fire.

• When disconnecting connectors, grasp the connector, not the cable.

(Specifically, connectors of the AC line and high-voltage parts)

Current can leak, leading to a risk of electric shock or fire.

• Carefully remove all toner remnants and dust from electrical parts and elec-

trode units such as a charging corona unit.

Current can leak, leading to a risk of copier trouble or fire.

• Check high-voltage cables and sheaths for any damage.

Current can leak, leading to a risk of electric shock or fire.

• Check electrode units such as a charging corona unit for deterioration and

sign of leakage.

Current can leak, leading to a risk of trouble or fire.

• Before disassembling or adjusting the write unit incorporating a laser, make

sure that the power cord has been disconnected.

The laser light can enter your eye, leading to a risk of loss of eyesight.

• Do not remove the cover of the write unit. Do not supply power with the write

unit shifted from the specified mounting position.

The laser light can enter your eye, leading to a risk of loss of eyesight.

• When replacing a lithium battery, replace it with a new lithium battery speci-

fied in the Parts Guide Manual. Dispose of the used lithium battery using the

method specified by local authority.

Improper replacement can cause explosion.

S-7

Page 20

SAFETY AND IMPORTANT WARNING ITEMS

WARNING: Safety Checkpoints

• After replacing a part to which AC voltage is applied (e.g., optical lamp and

fixing lamp), be sure to check the installation state.

A risk of fire exists.

• Check the interlock switch and actuator for loosening and check whether the

interlock functions properly.

If the interlock does not function, you may receive an electric shock or be

injured when you insert your hand in the copier (e.g., for clearing paper

jam).

• Make sure the wiring cannot come into contact with sharp edges, burrs, or

other pointed parts.

Current can leak, leading to a risk of electric shock or fire.

• Make sure that all screws, components, wiring, connectors, etc. that were

removed for safety check and maintenance have been reinstalled in the orig-

inal location. (Pay special attention to forgotten connectors, pinched cables,

forgotten screws, etc.)

A risk of copier trouble, electric shock, and fire exists.

DANGER: HANDLING OF SERVICE MATERIALS

• Toner and developer are not harmful substances, but care must be taken not

to breathe excessive amounts or let the substances come into contact with

eyes, etc. It may be stimulative.

If the substances get in the eye, rinse with plenty of water immediately.

When symptoms are noticeable, consult a physician.

• Never throw the used cartridge and toner into fire.

You may be burned due to dust explosion.

DANGER : HANDLING OF SERVICE MATERIALS

• Unplug the power cord from the wall outlet.

Drum cleaner (isopropyl alcohol) and roller cleaner (acetone-based) are

highly flammable and must be handled with care. A risk of fire exists.

S-8

Page 21

SAFETY AND IMPORTANT WARNING ITEMS

DANGER : HANDLING OF SERVICE MATERIALS

• Do not replace the cover or turn the copier ON before any solvent remnants

on the cleaned parts have fully evaporated.

A risk of fire exists.

• Use only a small amount of cleaner at a time and take care not to spill any

liquid. If this happens, immediately wipe it off.

A risk of fire exists.

• When using any solvent, ventilate the room well.

Breathing large quantities of organic solvents can lead to discomfort.

3. MEASURES TO TAKE IN CASE OF AN ACCIDENT

• If an accident has occurred, the distributor who has been notified first must immediately take emergency

measures to provide relief to affected persons and to prevent further damage.

• If a report of a serious accident has been received from a customer, an on-site evaluation must be carried

out quickly and Minolta Corporation must be notified.

• To determine the cause of the accident, conditions and materials must be recorded through direct on-site

checks, in accordance with instructions issued by Minolta Corporation.

• For reports and measures concerning serious accidents, follow the regulations given in “Serious Accident

Report/Follow-up Procedures”.

4. CONCLUSION

• Safety of users and customer engineers depends highly on accurate maintenance and administration.

Therefore, safety can be maintained by the appropriate daily service work conducted by the customer

engineer.

• When performing service, each copier on the site must be tested for safety. The customer engineer must

verify the safety of parts and ensure appropriate management of the equipment.

S-9

Page 22

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY INFORMATION

IMPORTANT INFORMATION

The Center for Devices and Radiological Health (CDRH) of the U.S. Food and Drug Administration implemented

regulations for laser products manufactured since August 1, 1976. Compliance is mandatory for products mar-

keted in the United States.

This copier is certified as a “Class 1” laser product under the U.S.

Department of Health and Human Services (DHHS) Radiation Performance Standard according to the Radiation

Control for Health and Safety Act of 1968. Since radiation emitted inside this copier is completely confined within

protective housings and external covers, the laser beam cannot escape during any phase of normal user opera-

tion.

S-10

Page 23

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY CIRCUITS

This machine is provided with the following safety circuits to prevent machine faults from resulting in serious

accidents.

•

Overall protection circuit

•

Fixing upper lamp /1 (L2), Fixing upper lamp /2 (L3), Fixing lower lamp (L4) overheating prevention circuit

These safety circuits are described below to provide

the service engineer with a renewed awareness of

them in order to prevent servicing errors that may

impair their functions.

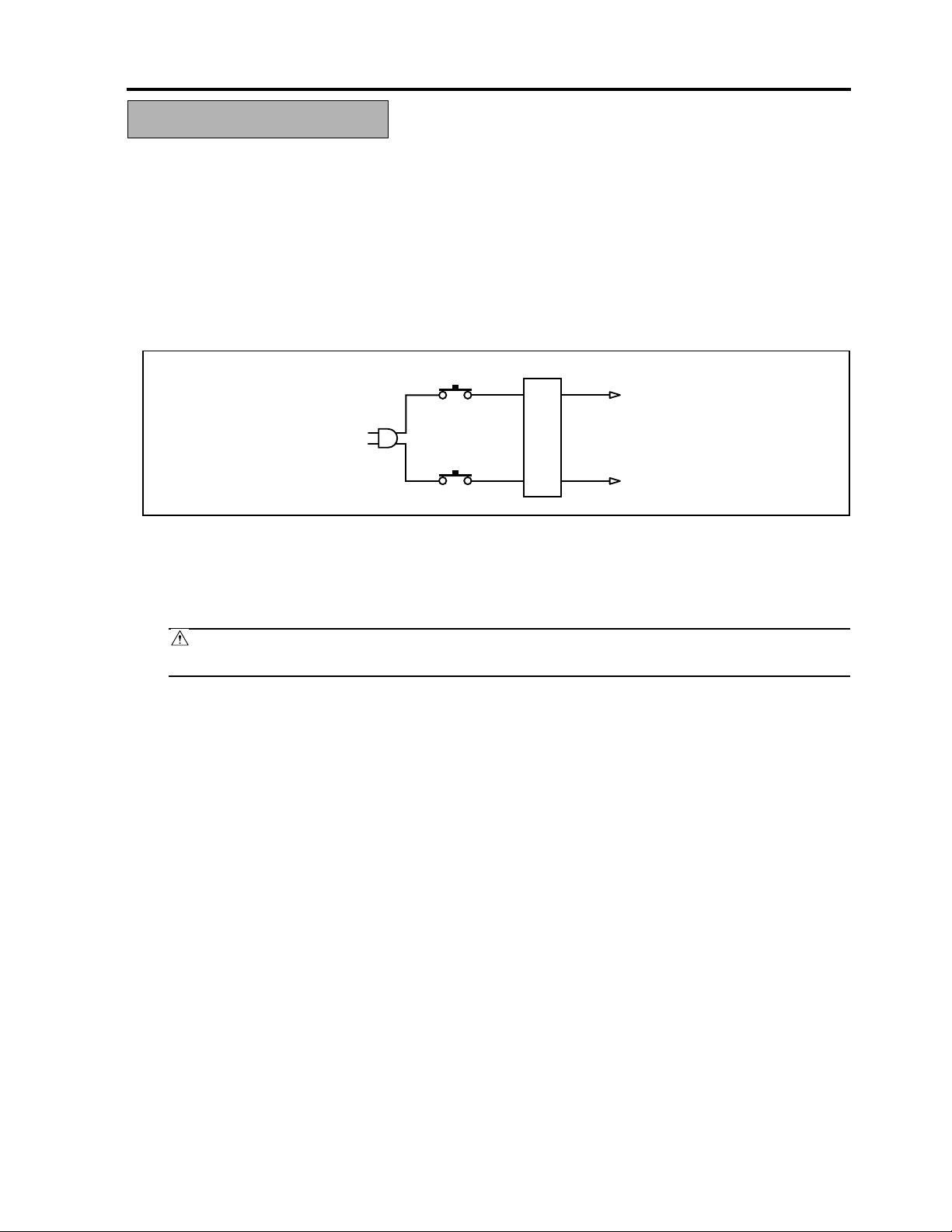

1. Overall protection circuit

CBR1

NF

CBR2

1.1 Protection by circuit breaker /1 (CBR1) and circuit breaker /2 (CBR2)

CBR1 and CBR2 interrupt the AC line instantaneously when an excessive current flows due to a short in

the AC line.

CAUTION:

The CBR1 and CBR2 functions must not be deactivated under any circumstances.

8050sf001

S-11

Page 24

SAFETY AND IMPORTANT WARNING ITEMS

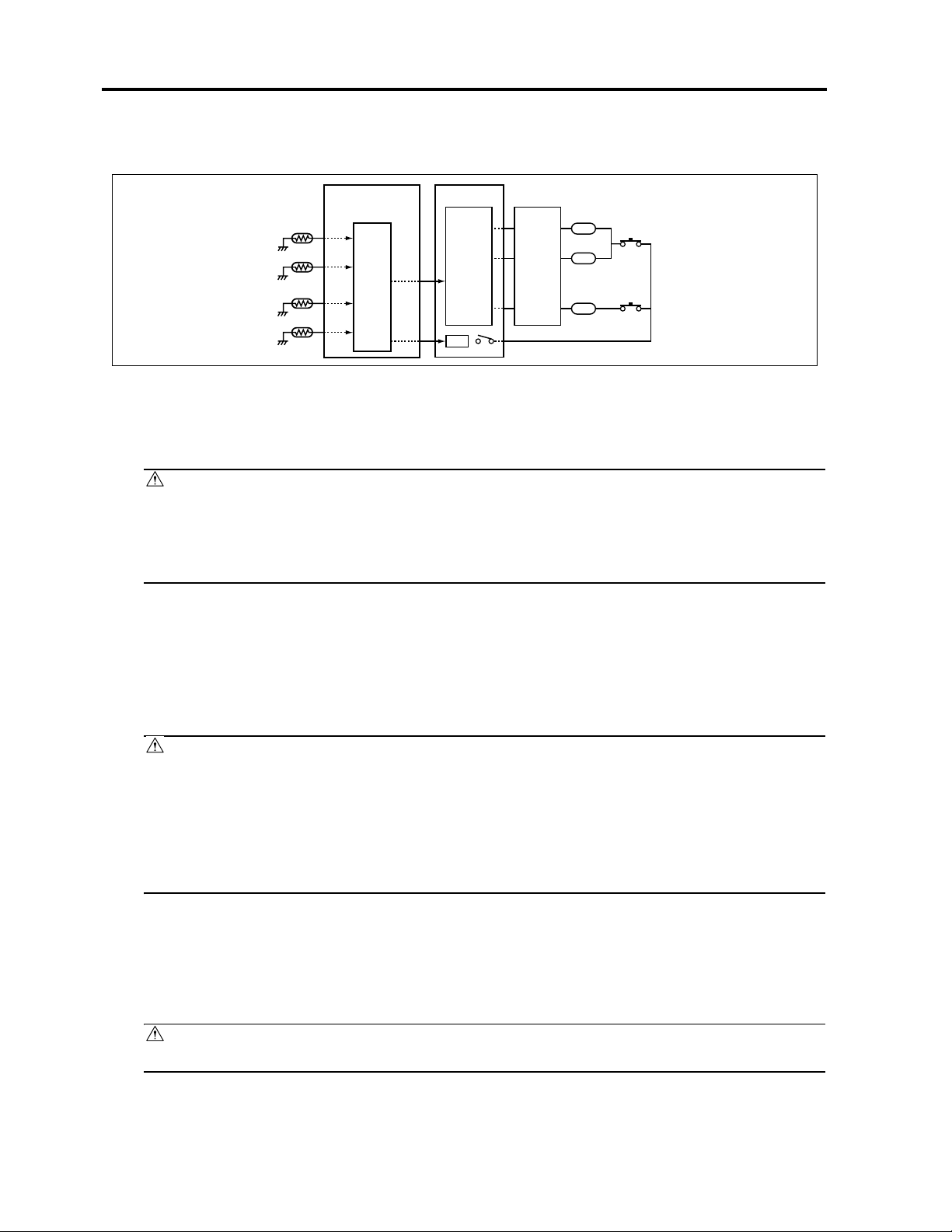

2. Fixing upper lamp /1 (L2), Fixing upper lamp /2 (L3), Fixing lower lamp (L4) overheating

prevention circuit

PRCB ACDB

TH1

TH3

TH2

TH4

Control

section

AC driver

section

RL1

RL1

FHCB

L2

TS1

L3

TS2

L4

8050sf002e

2.1 Protection by software

The output voltage from fixing temperature sensor /1 (TH1) and fixing temperature sensor /2 (TH2) is read

by the CPU. If this voltage is abnormal, L2, L3, and L4 are turned OFF by opening main relay (RL1).

CAUTION:

• The clearance between the fixing upper roller and TH1 and the clearance between the fixing

lower roller and TH2 must not be changed. When replacing them, make sure to comply with the

specified clearances.

• The RL1 function must not be deactivated under any circumstances.

2.2 Protection by the hardware circuit

The output voltages from fixing temperature sensor /1 (TH1), fixing temperature sensor /2 (TH2), fixing

temperature sensor /3 (TH3), and fixing temperature sensor /4 (TH4) are compared with the abnormality

judgment reference value in the comparator circuit. If the output voltage from TH1, TH2, TH3, or TH4

exceeds the reference value, L2, L3, and L4 are turned OFF by opening RL1.

CAUTION:

• The clearance between the fixing upper roller and TH1 and the clearance between the fixing

lower roller and TH2 must not be changed. When replacing them, make sure to comply with the

specified clearances.

• Periodically check the contact between the fixing upper roller and TH3 and the contact

between the fixing lower roller and TH4, and replace them if any abnormality is detected.

• The RL1 function must not be deactivated under any circumstances.

2.3 Protection by thermostat /1 (TS1) and thermostat /2 (TS2)

When the temperature of the fixing upper roller exceeds the specified value, TS1 is turned OFF, thus inter-

rupting the power to L2 and L3 directly. When the temperature of the fixing lower roller exceeds the speci-

fied value, TS2 is turned OFF, thus interrupting the power to L4 directly.

CAUTION:

Do not use any other electrical conductor in place of TS1 and TS2.

S-12

Page 25

SAFETY AND IMPORTANT WARNING ITEMS

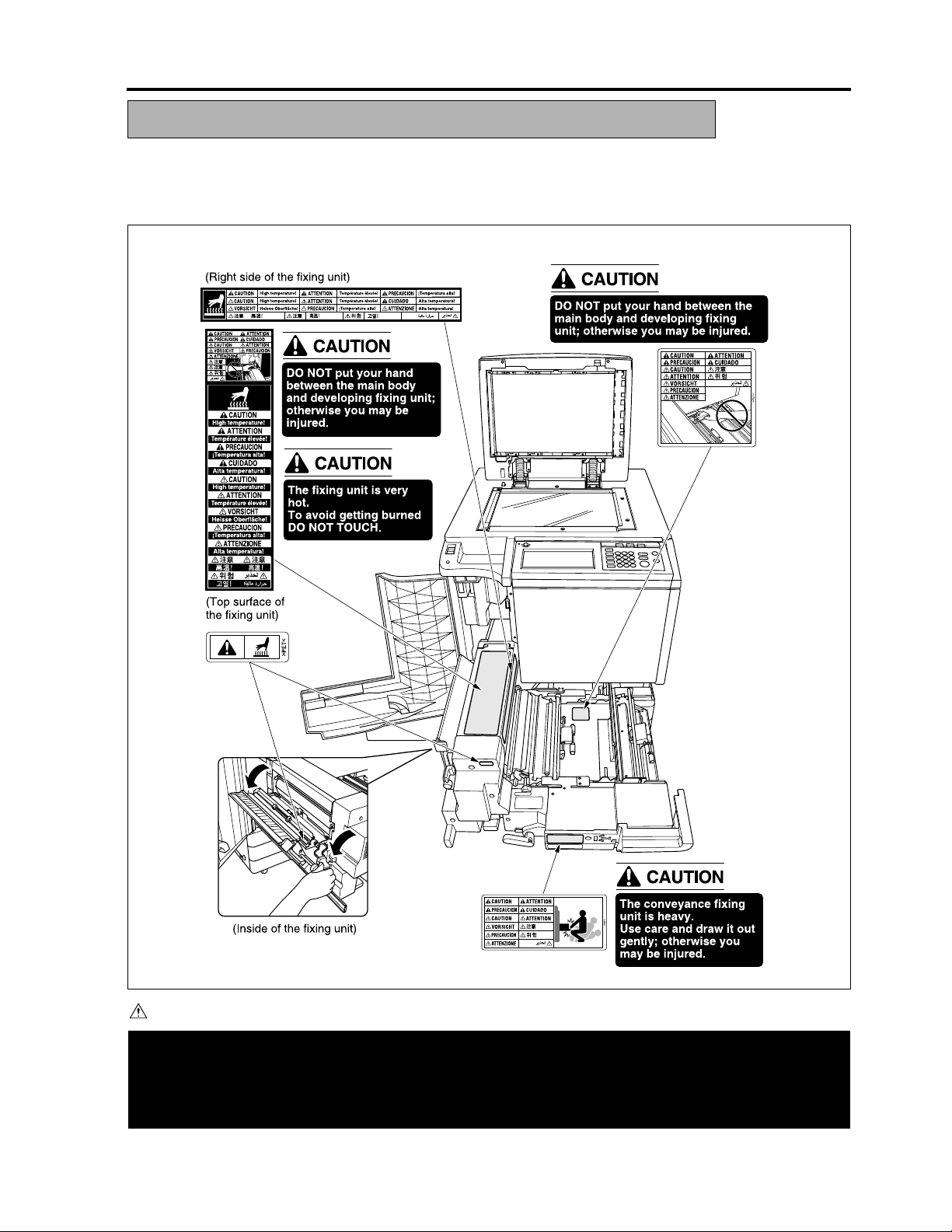

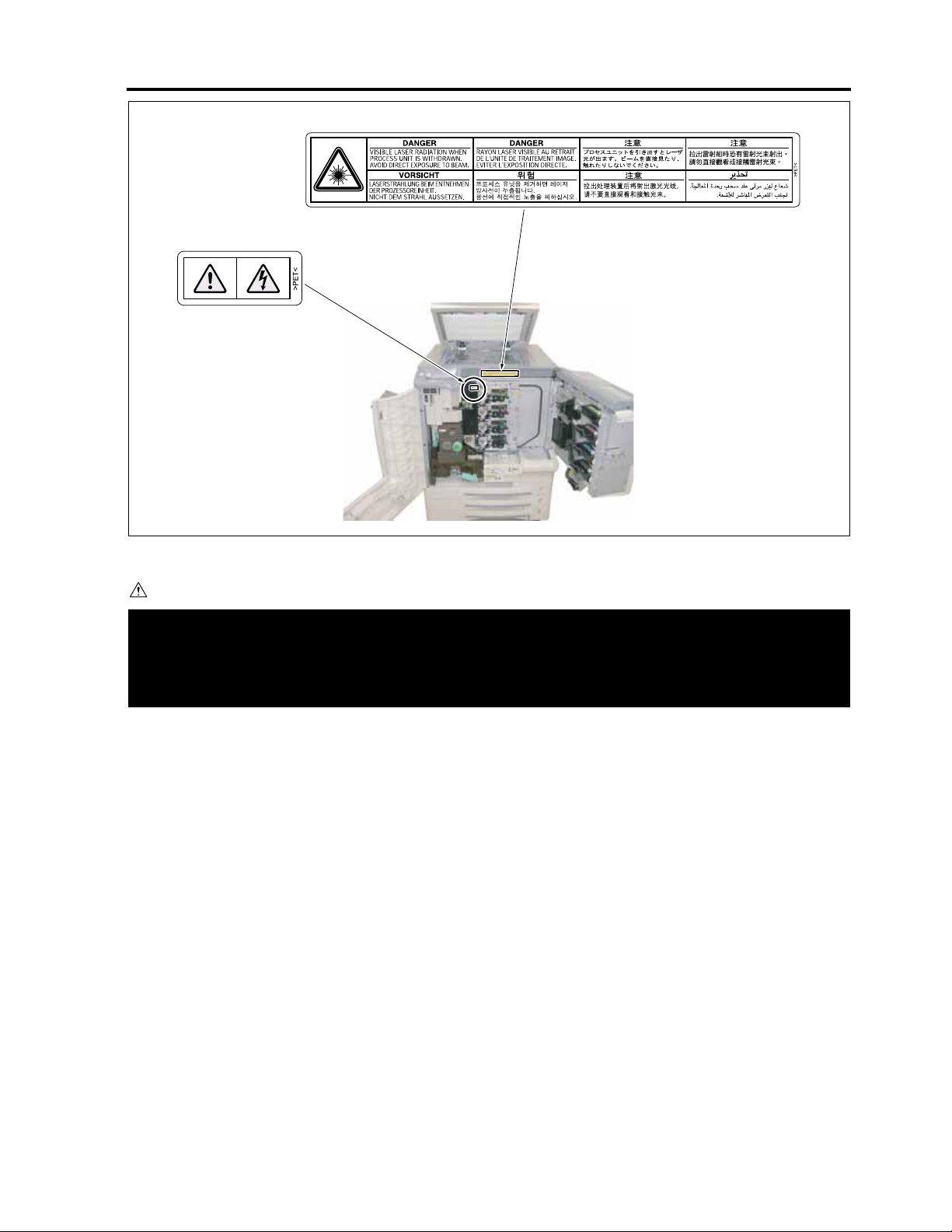

INDICATION OF WARNING ON THE MACHINE

Caution labels shown below are attached in some areas on/in the machine.

When accessing these areas for maintenance, repair, or adjustment, special care should be taken to avoid

burns and electric shock.

CAUTION

Please adhere to all caution labels to avoid burns or injury.

S-13

8050sf003e

Page 26

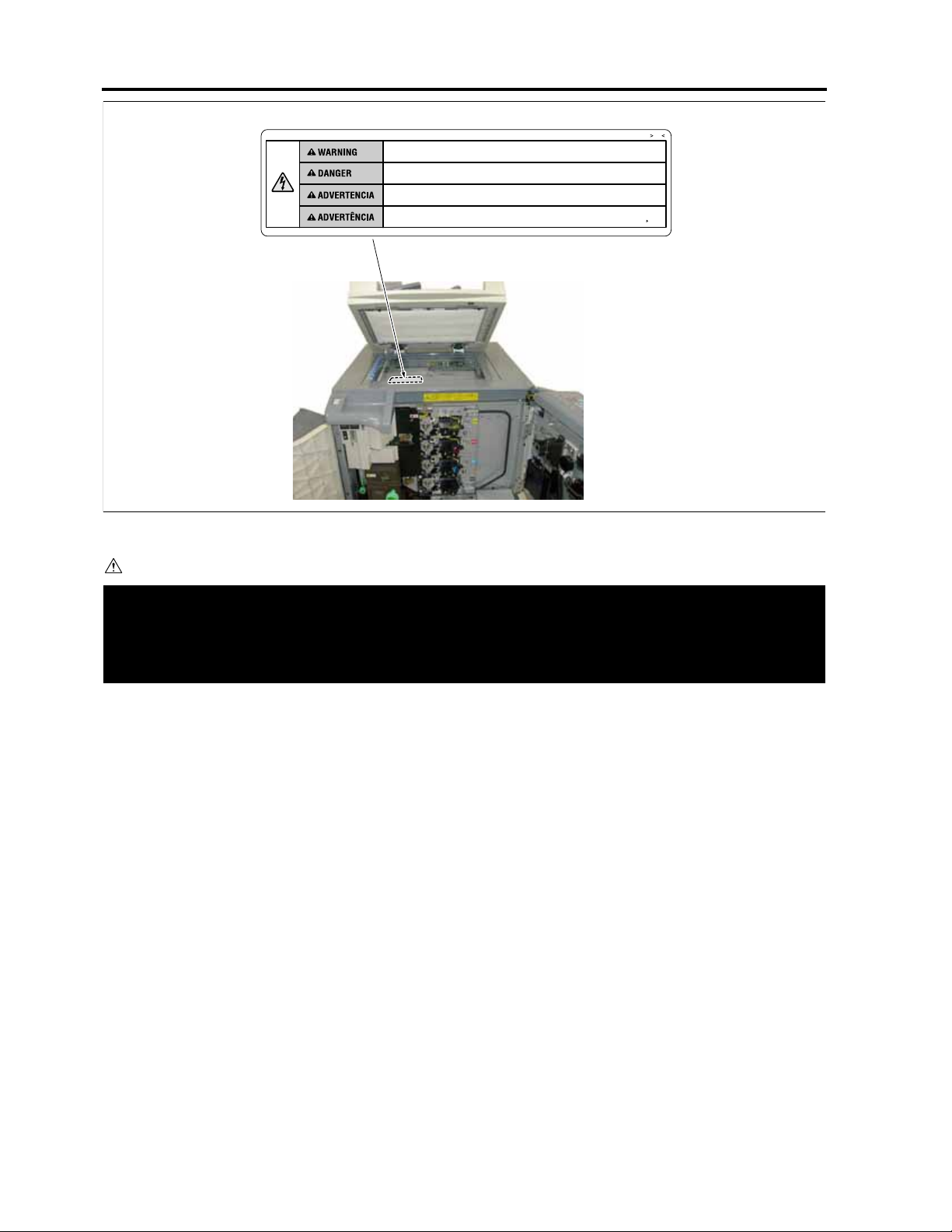

SAFETY AND IMPORTANT WARNING ITEMS

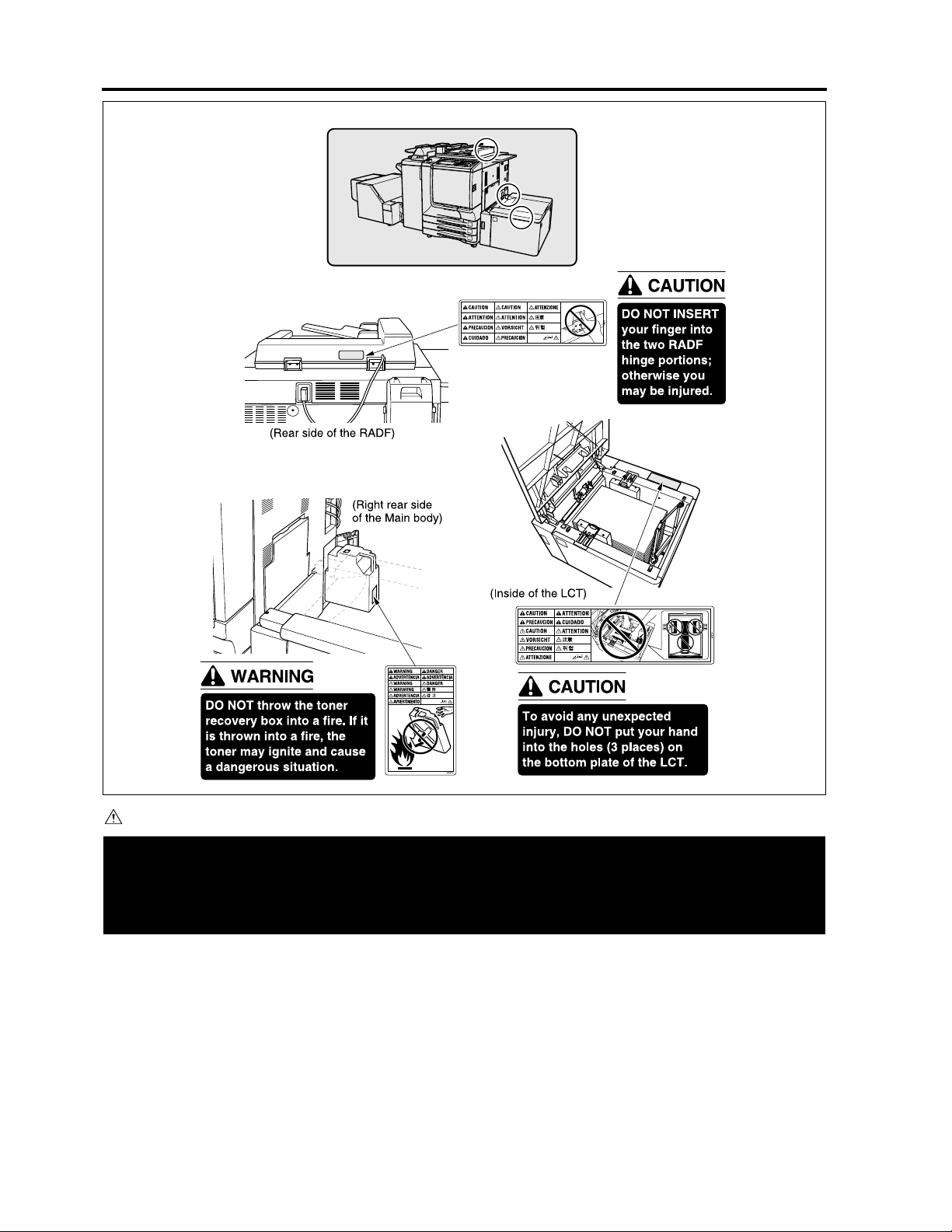

CAUTION

-

Please adhere to all caution labels to avoid burns or injury.

S-14

8050sf004e

Page 27

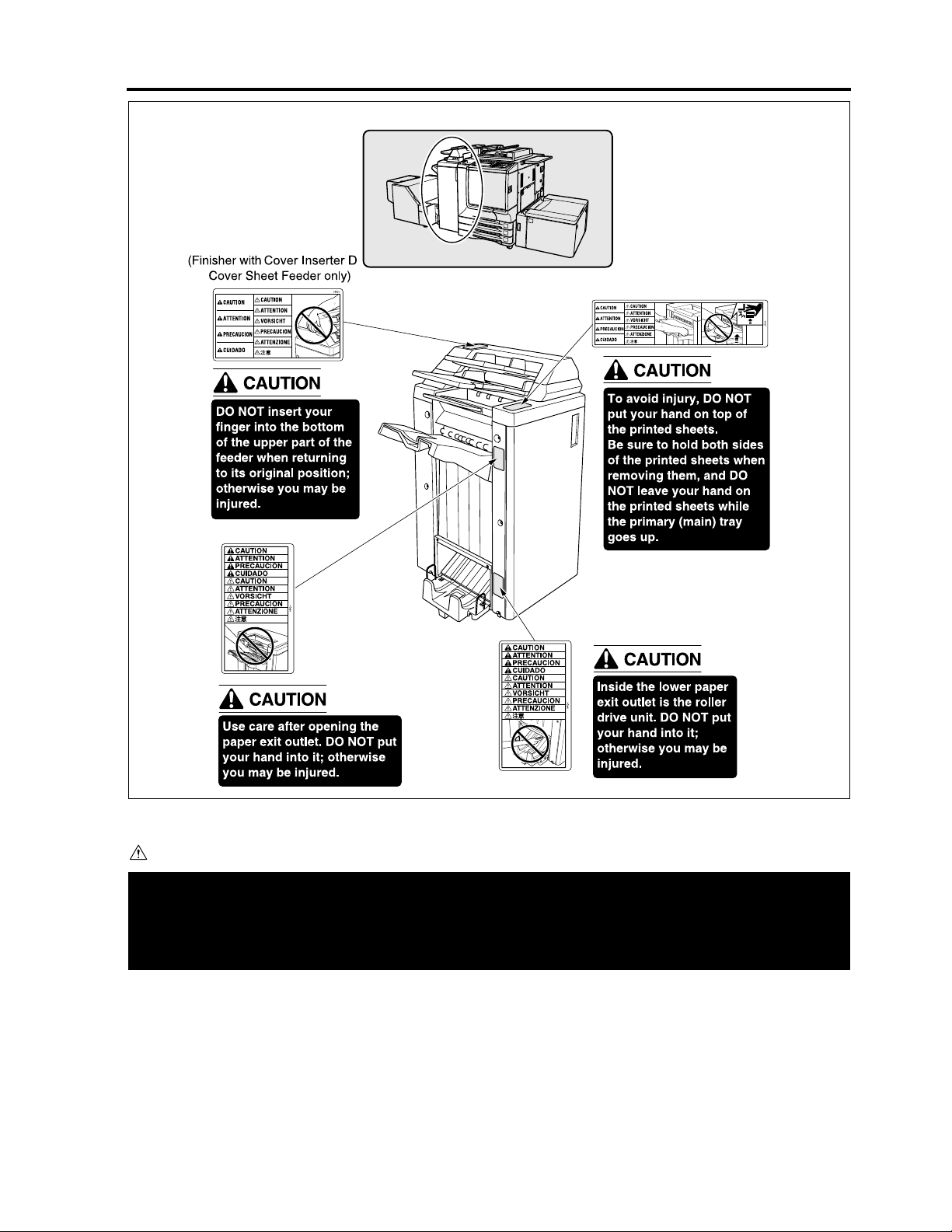

SAFETY AND IMPORTANT WARNING ITEMS

CAUTION

-

Please adhere to all caution labels to avoid burns or injury.

S-15

8050sf005e

Page 28

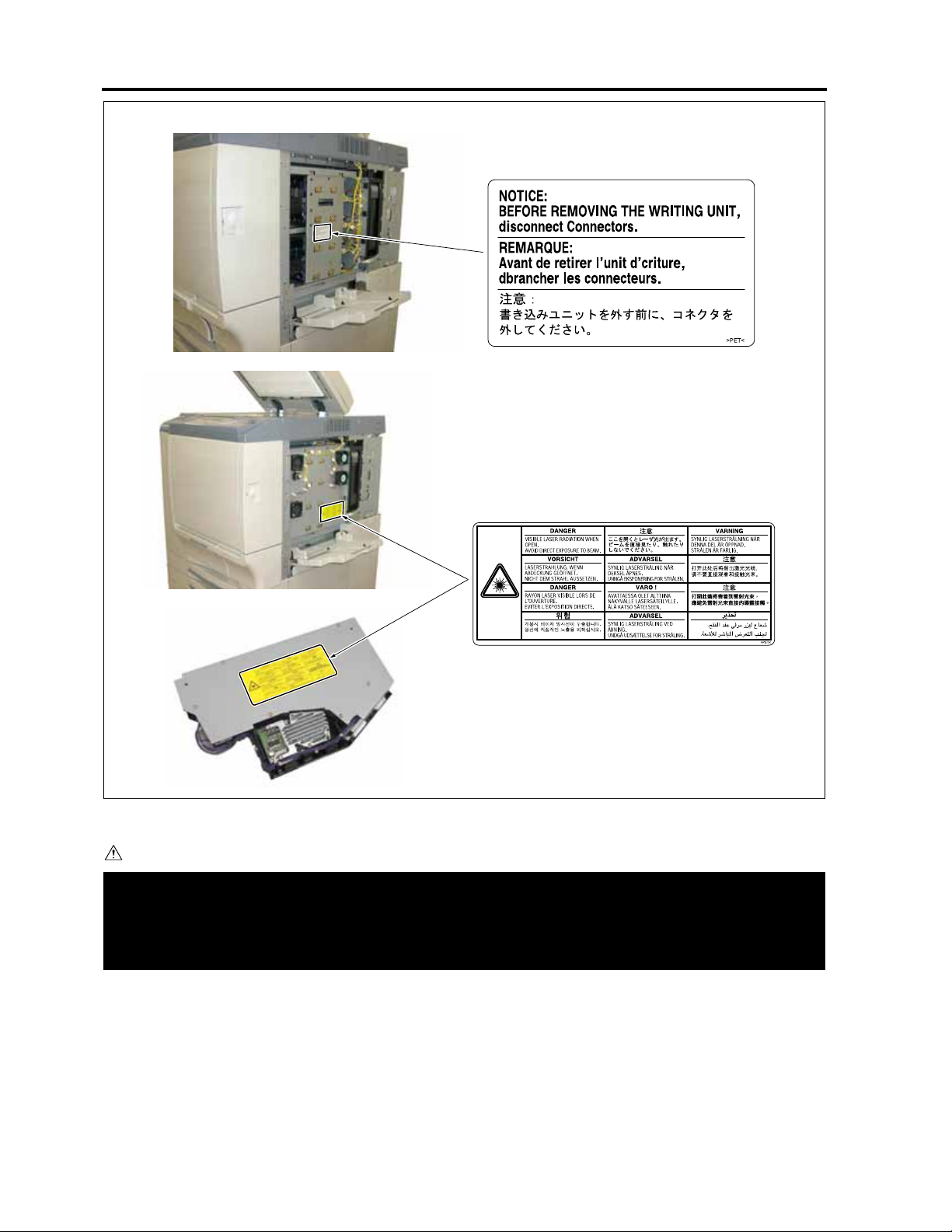

SAFETY AND IMPORTANT WARNING ITEMS

CAUTION

-

Please adhere to all caution labels to avoid burns or injury.

S-16

8050sf006e

Page 29

SAFETY AND IMPORTANT WARNING ITEMS

8050sf007e

CAUTION

-

Please adhere to all caution labels to avoid burns or injury..

S-17

Page 30

SAFETY AND IMPORTANT WARNING ITEMS

Unplug the machine before removing platen glass.

Debrancher le copieur avant de retirer la vitre d'exposition.

Desenchufe la maquina antes de quitar el vidrio.

Desconecte a unidade da tomada antes de remover o vidro de exposicao.

PS

~

8050sf008e

CAUTION

-

Please adhere to all caution labels to avoid burns or injury.

S-18

Page 31

CF5001 Field Service Ver.1.0 Sep 2003 EXTERIOR

I DISASSEMBLY/ASSEMBLY

Caution:

• Make sure the power cord of the copier is

unplugged from the power outlet before dis-

assembly or assembly.

1. EXTERIOR

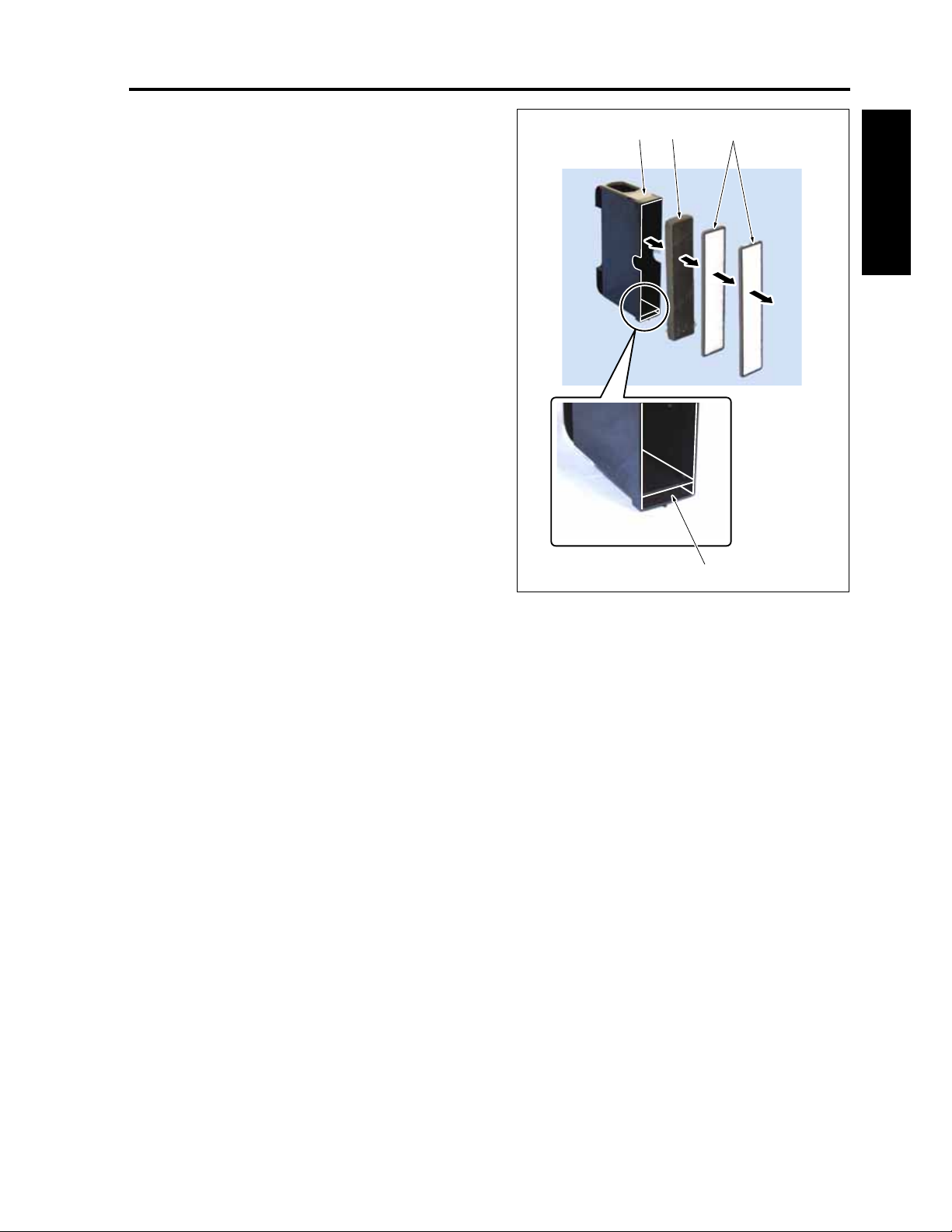

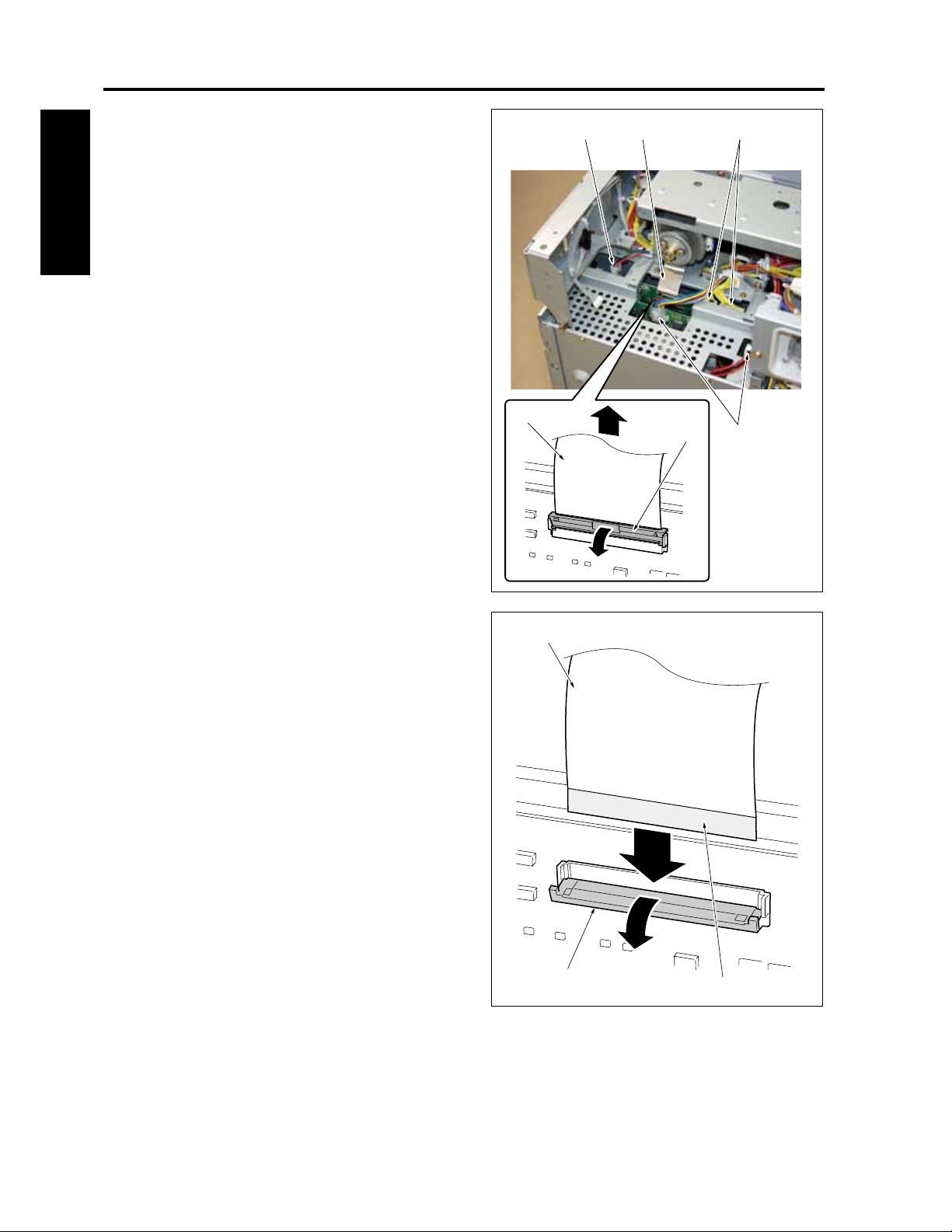

1.1 Replacing the dust filter /2

A. Periodically replaced parts/cycle