Page 1

SERVICE MANUAL

FIELD SERVICE

This service manual is designed for machine with

This service manual is designed for machine with

firmware ver. A121-30G0-0622-05 (Controller F/W)

firmware ver. A121-30G0-0622-05 (Controller F/W)

and onward.

and onward.

2011.022011.02

Ver. 3.0Ver. 3.0

Page 2

FIELD SERVICE TOTAL CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS ..............................................................S-1

IMPORTANT NOTICE ................................................................................................S-1

DESCRIPTION ITEMS FOR DANGER,

WARNING AND CAUTION ..............................................................................................S-1

SAFETY WARNINGS .................................................................................................S-2

INDICATION OF WARNING ON THE MACHINE .....................................................S-17

MEASURES TO TAKE IN CASE OF AN ACCIDENT ....................................................S-20

Composition of the service manual ................................................................................. C-1

Notation of the service manual ....................................................................................... C-2

bizhub C35 Main body

OUTLINE ........................................................................................................................ 1

MAINTENANCE.............................................................................................................. 9

ADJUSTMENT/SETTING ............................................................................................. 95

TROUBLESHOOTING................................................................................................ 193

APPENDIX.................................................................................................................. 267

Lower Feeder Unit

OUTLINE ........................................................................................................................ 1

MAINTENANCE.............................................................................................................. 3

Adjustment/Setting........................................................................................................ 13

i

Page 3

Blank Page

ii

Page 4

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY AND IMPORTANT WARNING ITEMS

Read carefully the safety and important warning items described below to understand them

before doing service work.

IMPORTANT NOTICE

Because of possible hazards to an inexperienced person servicing this product as well as

the risk of damage to the product, KONICA MINOLTA BUSINESS TECHNOLOGIES, INC.

(hereafter called the KMBT) strongly recommends that all servicing be performed only by

KMBT-trained service technicians.

Changes may have been made to this product to improve its performance after this Service

Manual was printed. Accordingly, KMBT does not warrant, either explicitly or implicitly, that

the information contained in this service manual is complete and accurate.

The user of this service manual must assume all risks of personal injury and/or damage to

the product while servicing the product for which this service manual is intended.

Therefore, this service manual must be carefully read before doing service work both in the

course of technical training and ev

the product properly.

Keep this service manual also for future service.

DESCRIPTION ITEMS FOR DANGER, WARNING AND CAUTION

In this Service Manual, each of three expressions “ DANGER”, “ WARNING”, and

“ CAUTION” is defined as follows together with a symbol mark to be used in a limited

meaning.

When servicing the product, the relevant works (disassembling, reassembling, adjustment,

repair, maintenance, etc.) need to be conducted with utmost care.

en after that, for performing maintenance and control of

DANGER: Action having a high possibility of suffering death or serious injury

WARNING: Action having a possibility of suffering death or serious injury

CAUTION: Action having a possibility of suffering a slight wound, medium

trouble, and property damage

Symbols used for safety and important warning items are defined as follows:

:Precaution when servicing the

product.

:Prohibition when servicing the

product.

:Direction when servicing the

product.

General

precaution

General

prohibition

General

instruction

Electric hazard High temperature

Do not touch

with wet hand

UnplugGround/Earth

Do not

disassemble

S-1

Page 5

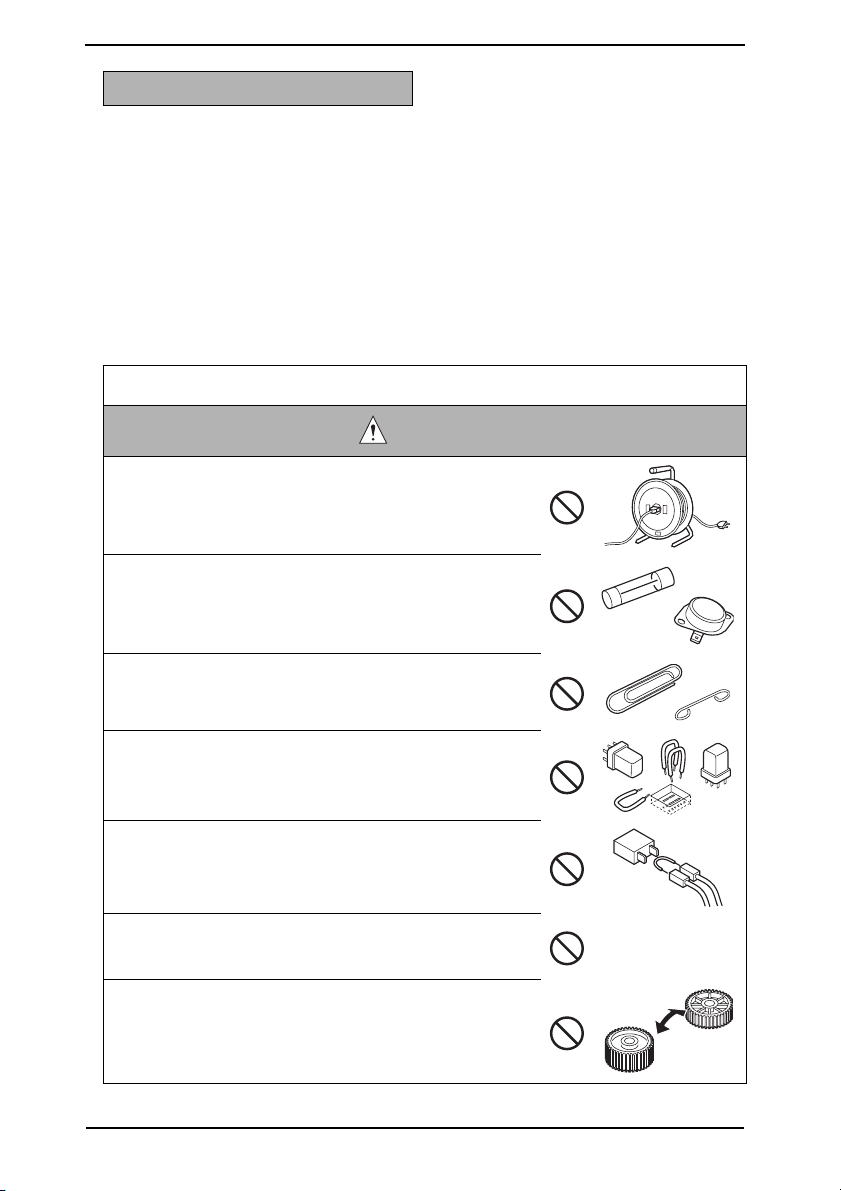

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY WARNINGS

[1] MODIFICATIONS NOT AUTHORIZED BY KONICA MINOLTA

BUSINESS TECHNOLOGIES, INC.

KONICA MINOLTA brand products are renowned for their high reliability. This reliability is

achieved through high-quality design and a solid service network.

Product design is a highly complicated and delicate process where numerous mechanical,

physical, and electrical aspects have to be taken into consideration, with the aim of arriving

at proper tolerances and safety factors. For this reason, unauthorized modifications involve

a high risk of degradation in performance and safety. Such modifications are therefore

strictly prohibited. the points listed below are not exhaustive, but they illustrate the reasoning behind this policy.

Prohibited Actions

DANGER

• Using any cables or power cord not specified by KMBT.

• Using any fuse or thermostat not specified by KMBT.

Safety will not be assured, leading to a risk of fire and

injury.

• Disabling fuse functions or bridging fuse terminals with

wire, metal clips, solder or similar object.

• Disabling relay functions (such as wedging paper between

relay contacts).

• Disabling safety functions (interlocks, safety circuits, etc.).

Safety will not be assured, leading to a risk of fire and

injury.

• Making any modification to the product unless instructed

by KMBT.

• Using parts not specified by KMBT.

S-2

Page 6

SAFETY AND IMPORTANT WARNING ITEMS

[2] POWER PLUG SELECTION

In some countries or areas, the power plug provided with the product may not fit wall outlet

used in the area. In that case, it is obligation of customer engineer (hereafter called the CE)

to attach appropriate power plug or power cord set in order to connect the product to the

supply.

Power Cord Set or Power Plug

WARNING

•Use power supply cord set which meets the following

criteria:

- provided with a plug having configuration intended for

the connection to wall outlet appropriate for the product’s rated voltage and current, and

- the plug has pin/terminal(s) for grounding, and

- provided with three-conductor cable having enough cur-

rent capacity, and

- the cord set meets regulatory requirements for the area.

Use of inadequate cord set leads to fire or electric shock.

• Attach power plug which meets the following criteria:

- having configuration intended for the connection to wall

outlet appropriate for the product’s rated voltage and

current, and

- the plug has pin/terminal(s) for grounding, and

- meets regulatory requirements for the area.

Use of inadequate cord set leads to the product connecting to inadequate power supply (voltage, current capacity,

grounding), and may result in fire or electric shock.

• Conductors in the power cable must be connected to terminals of the plug according to the following order:

•Black or Brown:L (line)

•White or Light Blue:N (neutral)

•Green/Yellow:PE (earth)

Wrong connection may cancel safeguards within the

product, and results in fire or electric shock.

kw

S-3

Page 7

SAFETY AND IMPORTANT WARNING ITEMS

[3] CHECKPOINTS WHEN PERFORMING ON-SITE SERVICE

KONICA MINOLTA brand products are extensively tested before shipping, to ensure that all

applicable safety standards are met, in order to protect the customer and customer engineer (hereafter called the CE) from the risk of injury. However, in daily use, any electrical

equipment may be subject to parts wear and eventual failure. In order to maintain safety

and reliability, the CE must perform regular safety checks.

1. Power Supply

Connection to Power Supply

WARNING

• Check that mains voltage is as specified.

Connection to wrong voltage supply may result in fire or

electric shock.

• Connect power plug directly into wall outlet having same

configuration as the plug.

Use of an adapter leads to the product connecting to

inadequate power supply (voltage, current capacity,

grounding), and may result in fire or electric shock.

If proper wall outlet is not available, advice the customer

to contact qualified electrician for the installation.

•Plug the power cord into the dedicated wall outlet with a

capacity greater than the maximum power consumption.

If excessive current flows in the wall outlet, fire may

result.

• If two or more power cords can be pl

outlet, the total load must not exceed the rating of the wall

outlet.

If excessive current flows in the wall outlet, fire may

result.

• Make sure the power cord is plugged in the wall outlet

securely.

Contact problems may lead to increased resistance,

overheating, and the risk of fire.

ugged into the wall

kw

• Check whether the product is grounded properly.

If current leakage occurs in an ungrounded product, you

may suffer electric shock while operating the product.

Connect power plug to grounded wall outlet.

S-4

Page 8

SAFETY AND IMPORTANT WARNING ITEMS

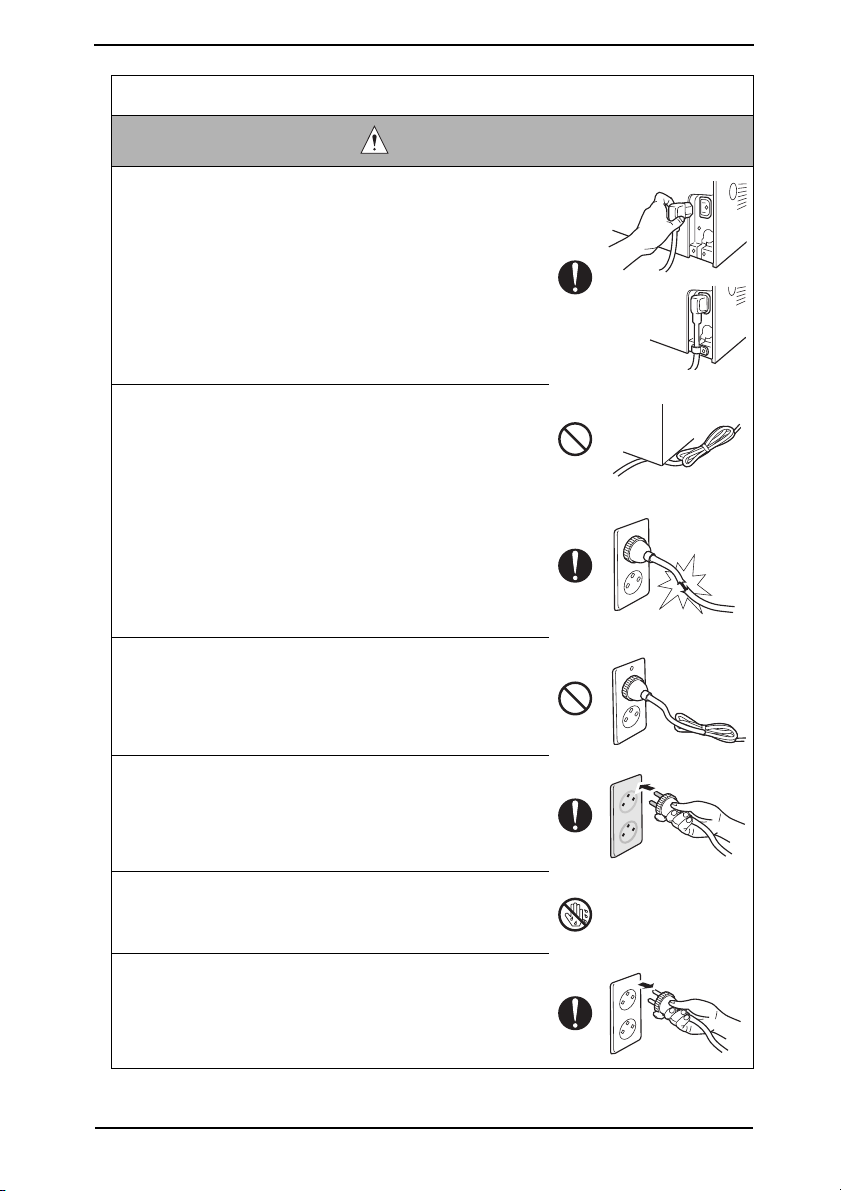

Power Plug and Cord

WARNING

• When using the power cord set (inlet type) that came with

this product, make sure the connector is securely inserted

in the inlet of the product.

When securing measure is provided, secure the cord with

the fixture properly.

If the power cord (inlet type) is not connected to the product securely, a contact problem may lead to increased

resistance, overheating, and risk of fire.

• Check whether the power cord is not stepped on or

pinched by a table and so on.

Overheating may occur there, leading to a risk of fire.

• Check whether the power cord is damaged. Check

whether the sheath is damaged.

If the power plug, cord, or sheath is damaged, replace

with a new power cord (with plug and connector on each

end) specified by KMBT. Using the damaged power cord

may result in fire or electric shock.

• Do not bundle or tie the power cord.

Overheating may occur there, leading to a risk of fire.

• Check whether dust is collected around the po

and wall outlet.

Using the power plug and wall outlet without removing

dust may result in fire.

• Do not insert the power plug into the wall outlet with a wet

hand.

The risk of electric shock exists.

• When unplugging the power cord, grasp the plug, not the

cable.

The cable may be broken, leading to a risk of fire and

electric shock.

wer plug

S-5

Page 9

SAFETY AND IMPORTANT WARNING ITEMS

Wiring

WARNING

•Never use multi-plug adapters to plug multiple power cords

in the same outlet.

If used, the risk of fire exists.

• When an extension cord is required, use a specified one.

Current that can flow in the extension cord is limited, so

using a too long extension cord may result in fire.

Do not use an extension cable reel with the cable taken

up. Fire may result.

2. Installation Requirements

Prohibited Installation Places

WARNING

• Do not place the product near flammable materials or vola-

tile materials that may catch fire.

A risk of fire exists.

• Do not place the product in a place exposed to water such

as rain.

A risk of fire and electric shock exists.

When not Using the Product for a long time

WARNING

• When the product is not used over an extended period of

time (holidays, etc.), switch it off and unplug the power

cord.

Dust collected around the power plug and outlet may

cause fire.

S-6

Page 10

SAFETY AND IMPORTANT WARNING ITEMS

Ventilation

CAUTION

• The product generates ozone gas during operation, but it

will not be harmful to the human body.

If a bad smell of ozone is present in the following cases,

ventilate the room.

a. When the product is used in a poorly ventilated room

b. When taking a lot of copies

c. When using multiple products at the same time

Stability

CAUTION

•Be sure to lock the caster stoppers.

In the case of an earthquake and so on, the product may

slide, leading to a injury.

Inspection before Servicing

CAUTION

• Before conducting an inspection, read all relevant docu-

mentation (service manual, technical notices, etc.) and

proceed with the inspection following the prescribed procedure in safety clothes, using only the prescribed tools.

Do not make any adjustment not described in the docu-

mentation.

If the prescribed procedure or tool is not used, the product may break and a risk of injury or fire exists.

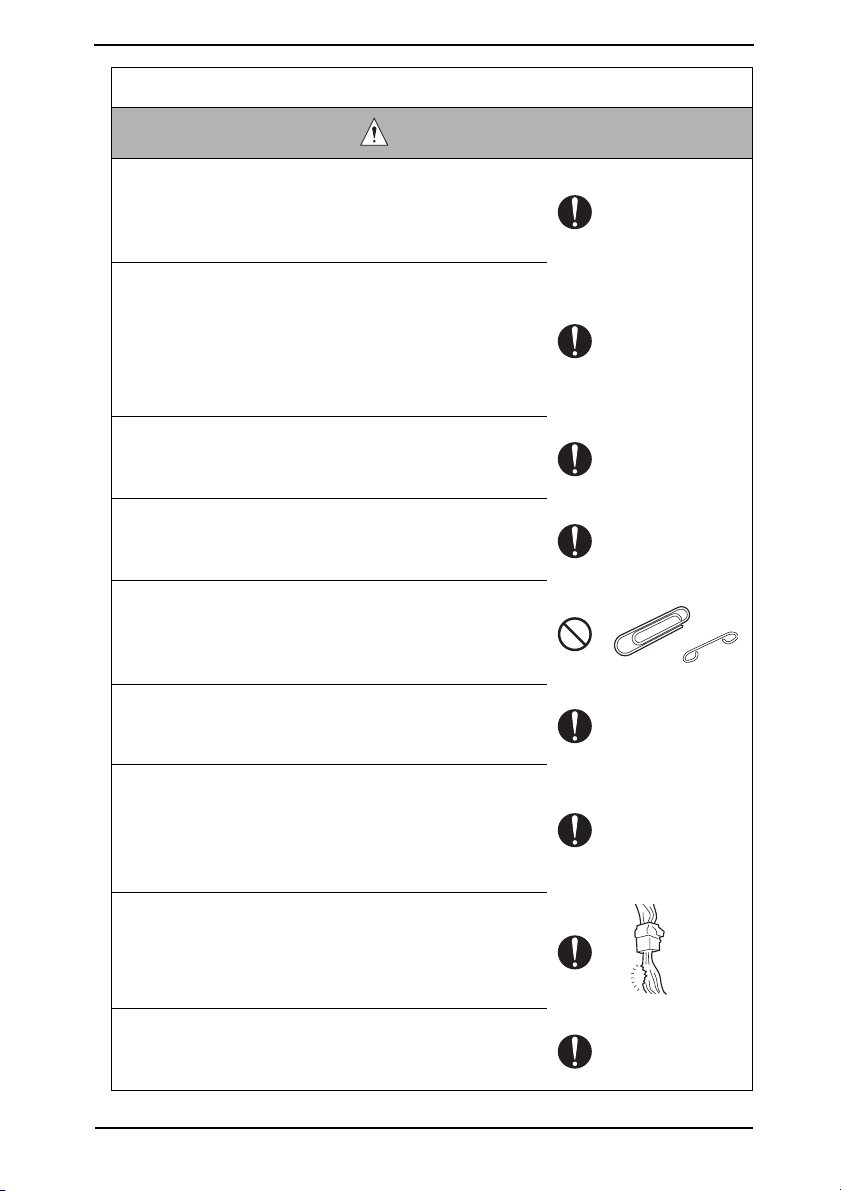

• Before conducting an inspection, be sure to disconnect

the power plugs from the product and options.

When the power plug is inserted in the wall outlet, some

units are still powered even if the POWER switch is

turned OFF. A risk of electric shock exists.

• The area around the fixing unit is hot.

Yo u may get burnt.

S-7

Page 11

SAFETY AND IMPORTANT WARNING ITEMS

Inspection before Servicing

CAUTION

• Do not leave the machine unattended during transporta-

tion, installation, and inspection of the machine. If it is to

be unavoidably left unattended, face protrusions toward

the wall or take other necessary risk reducing action.

The user may stumble over a protrusion of the machine

or be caught by a cable, falling to the floor or being

injured.

Work Performed with the Product Powered On

WARNING

• Take every care when making adjustments or performing

an operation check with the product powered.

If you make adjustments or perform an operation check

with the external cover detached, you may touch live or

high-voltage parts or you may be caught in moving gears

or the timing belt, leading to a risk of injury.

• Take every care when servicing with the external cover

detached.

High-voltage exists around the drum unit. A risk of electric shock exists.

• If it is absolutely necessary to service the machine with

the door open or external covers removed, always be

attentive to the motion of the internal parts.

A normally protected part may cause unexpected hazards.

Safety Checkpoints

WARNING

• Check the exterior and frame for edges, burrs, and other

damage.

The user or CE may be injured.

• Whenever mounting an option on the machine, be attentive to the motion of the fellow worker of the joint work.

The fellow worker may be injured with his or her finger or

hand pinched between the machine and the option.

S-8

Page 12

SAFETY AND IMPORTANT WARNING ITEMS

Safety Checkpoints

WARNING

• When mounting an option on the machine, be careful

about the clearance between the machine and the option.

Yo u may be injured with your finger or hand pinched

between the machine and the option.

• When removing a part that secures a motor, gear, or other

moving part, disassembling a unit, or reinstalling any of

such parts and units, be careful about moving parts and

use care not to drop any part or unit. During the service

procedure, give sufficient support for any heavy unit.

Yo u may be injured by a falling part or unit.

• Check the external covers and frame for possible sharp

edges, burrs, and damage.

They can be a cause of injury during use or servicing.

• When accessing a hard-to-view or narrow spot, be caref

about sharp edges and burrs of the frame and parts.

They may injure your hands or fingers.

• Do not allow any metal parts such as clips, staples, and

screws to fall into the product.

They can short internal circuits and cause electric shock

or fire.

• Check wiring for squeezing and any other damage.

Current can leak, leading to a risk of electric shock or

fire.

•Carefully remove all toner remnants and dust from electri-

cal parts and electrode units such as a charging corona

unit.

Current can leak, leading to a risk of product trouble or

fire.

• Check high-voltage cables and sheaths for any damage.

Current can leak, leading to a risk of electric shock or

fire.

ul

• Check electrode units such as a charging corona unit for

deterioration and sign of leakage.

Current can leak, leading to a risk of trouble or fire.

S-9

Page 13

SAFETY AND IMPORTANT WARNING ITEMS

Safety Checkpoints

WARNING

• Before disassembling or adjusting the write unit (P/H unit)

incorporating a laser, make sure that the power cord has

been disconnected.

The laser light can enter your eye, leading to a risk of

loss of eyesight.

• Do not remove the cover of the write unit. Do not supply

power with the write unit shifted from the specified mounting position.

The laser light can enter your eye, leading to a risk of

loss of eyesight.

• When replacing a lithium battery, replace it with a new lithium battery specified in the Parts Guide Manual. Dispose

of the used lithium battery using the method specified by

local authority.

Improper replacement can cause explosion.

• After replacing a part to which AC voltage is applied (e.g.,

optical lamp and fixing lamp), be sure to check the installation state.

A risk of fire exists.

• Check the interlock switch and actuator for loosening and

check whether the interlock functions properly.

If the interlock does not function, you may receiv

electric shock or be injured when you insert your hand in

the product (e.g., for clearing paper jam).

• Make sure the wiring cannot come into contact with sharp

edges, burrs, or other pointed parts.

Current can leak, leading to a risk of electric shock or

fire.

e an

• Make sure that all screws, components, wiring, connectors, etc. that were removed for safety check and maintenance have been reinstalled in the original location. (Pay

special attention to forgotten connectors, pinched cables,

forgotten screws, etc.)

A risk of product trouble, electric shock, and fire exists.

S-10

Page 14

SAFETY AND IMPORTANT WARNING ITEMS

Handling of Consumables

WARNING

• Toner and developer are not harmful substances, but care

must be taken not to breathe excessive amounts or let the

substances come into contact with eyes, etc. It may be

stimulative.

If the substances get in the eye, rinse with plenty of water

immediately. When symptoms are noticeable, consult a

physician.

•Never throw the used cartridge and toner into fire.

Yo u may be burned due to dust explosion.

Handling of Service Materials

CAUTION

• Unplug the power cord from the wall outlet.

Drum cleaner (isopropyl alcohol) and roller cleaner (acetone-based) are highly flammable and must be handled

with care. A risk of fire exists.

• Do not replace the cover or turn the product ON before

any solvent remnants on the cleaned parts have fully

evaporated.

A risk of fire exists.

• Use only a small amount of cleaner at a time and take

care not to spill any liquid. If this happens, immediately

wipe it off.

A risk of fire exists.

• When using any solvent, ventilate the room well.

Breathing large quantities of organic solvents can lead to

discomfort.

S-11

Page 15

SAFETY AND IMPORTANT WARNING ITEMS

[4] LASER SAFETY

• This is a digital machine certified as a Class 1 laser product. There is no possibility of

danger from a laser, provided the machine is serviced according to the instruction in this

manual.

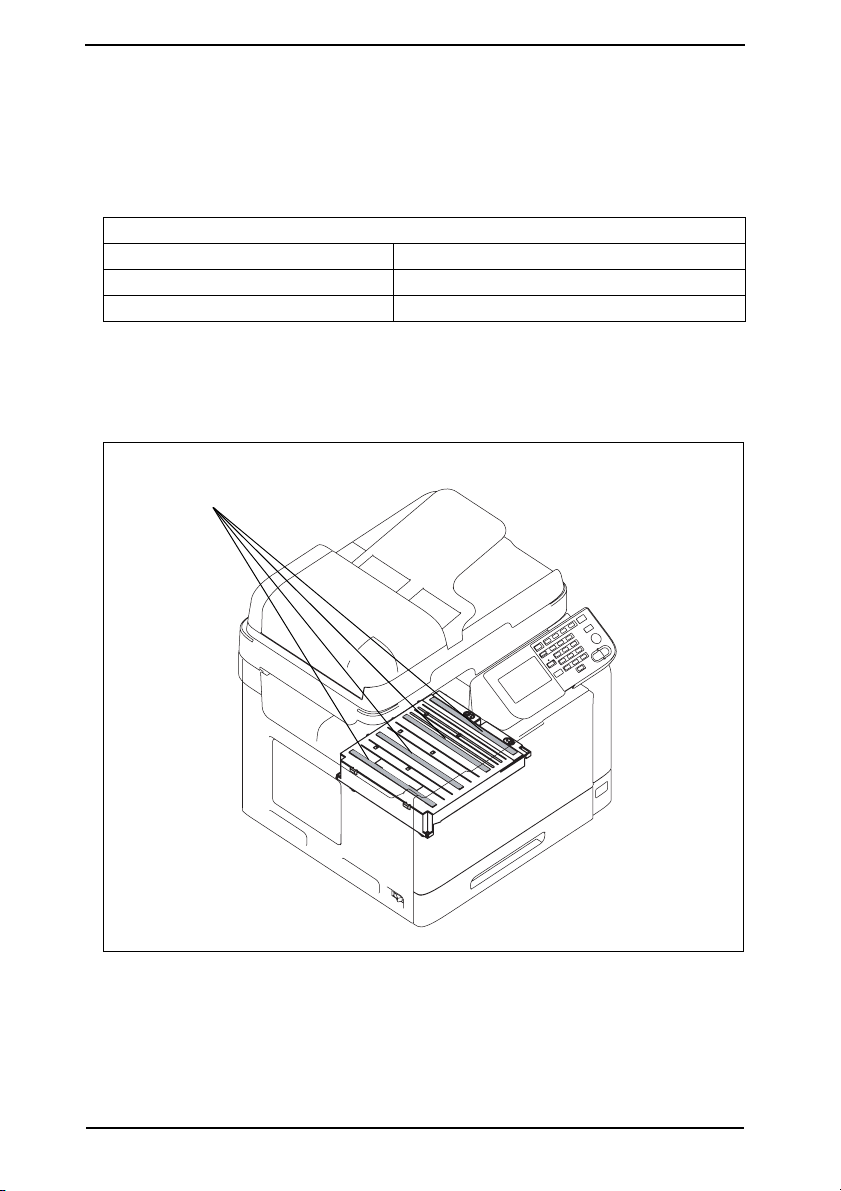

4.1 Internal Laser Radiation

semiconductor laser

Maximum power of the laser diode 15 mW

Maximum average radiation power (*) 11.2 µW

Wavelength 770 - 800 nm

*at laser aperture of the Print Head Unit

• This product employs a Class 3B laser diode that emits an invisible laser beam. The

laser diode and the scanning polygon mirror are incorporated in the print head unit.

• The print head unit is NOT A FIELD SERVICEABLE ITEM. Therefore, the print head unit

should not be opened under any circumstances.

Laser Aperture of

the Print Head Unit

S-12

A121P0C504DA

Page 16

SAFETY AND IMPORTANT WARNING ITEMS

U.S.A., Canada

(CDRH Regulation)

• This machine is certified as a Class 1 Laser product under Radiation Performance Stan-

dard according to the Food, Drug and Cosmetic Act of 1990. Compliance is mandatory

for Laser products marketed in the United States and is reported to the Center for

Devices and Radiological Health (CDRH) of the U.S. Food and Drug Administration of

the U.S. Department of Health and Human Services (DHHS). This means that the device

does not produce hazardous laser radiation.

• The label shown on page S-15 indicates compliance with the CDRH regulations and

must be attached to laser products marketed in the United States.

.

CAUTION

• Use of controls, adjustments or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure.

semiconductor laser

Maximum power of the laser diode 15 mW

Wavelength 770 - 800 nm

All Areas

CAUTION

• Use of controls, adjustments or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure.

semiconductor laser

Maximum power of the laser diode 15 mW

Wavelength 770 - 800 nm

Denmark

ADVARSEL

• Usynlig laserstråling ved åbning, når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling. Klasse 1 laser produkt der opfylder IEC60825-1

sikkerheds kravene.

halvlederlaser

Laserdiodens højeste styrke 15 mW

bølgelængden 770 - 800 nm

S-13

Page 17

SAFETY AND IMPORTANT WARNING ITEMS

Finland, Sweden

LUOKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

VAR OITU S!

• Laitteen käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa käyttäjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

puolijohdelaser

Laserdiodin suurin teho 15 mW

aallonpituus 770 - 800 nm

VARNING!

• Om apparaten används på annat sätt än i denna bruksanvisning specificerats,

kan användaren utsättas för osynlig laserstrålning, som överskrider gränsen för

laserklass 1.

halvledarlaser

Den maximala effekten för laserdioden 15 mW

våglängden 770 - 800 nm

VAR O!

• Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättomälle lasersäteilylle. Älä katso säteeseen.

VARNING!

• Osynlig laserstråining när denna del är öppnad och spärren är urkopplad.

Betrakta ej stråien.

Norway

ADVERSEL

• Dersom apparatet brukes på annen måte enn spesifisert i denne bruksanvisning, kan brukeren utsettes för unsynlig laserstrålning, som overskrider grensen

for laser klass 1.

halvleder laser

Maksimal effekt till laserdiode 15 mW

bølgelengde 770 - 800 nm

S-14

Page 18

SAFETY AND IMPORTANT WARNING ITEMS

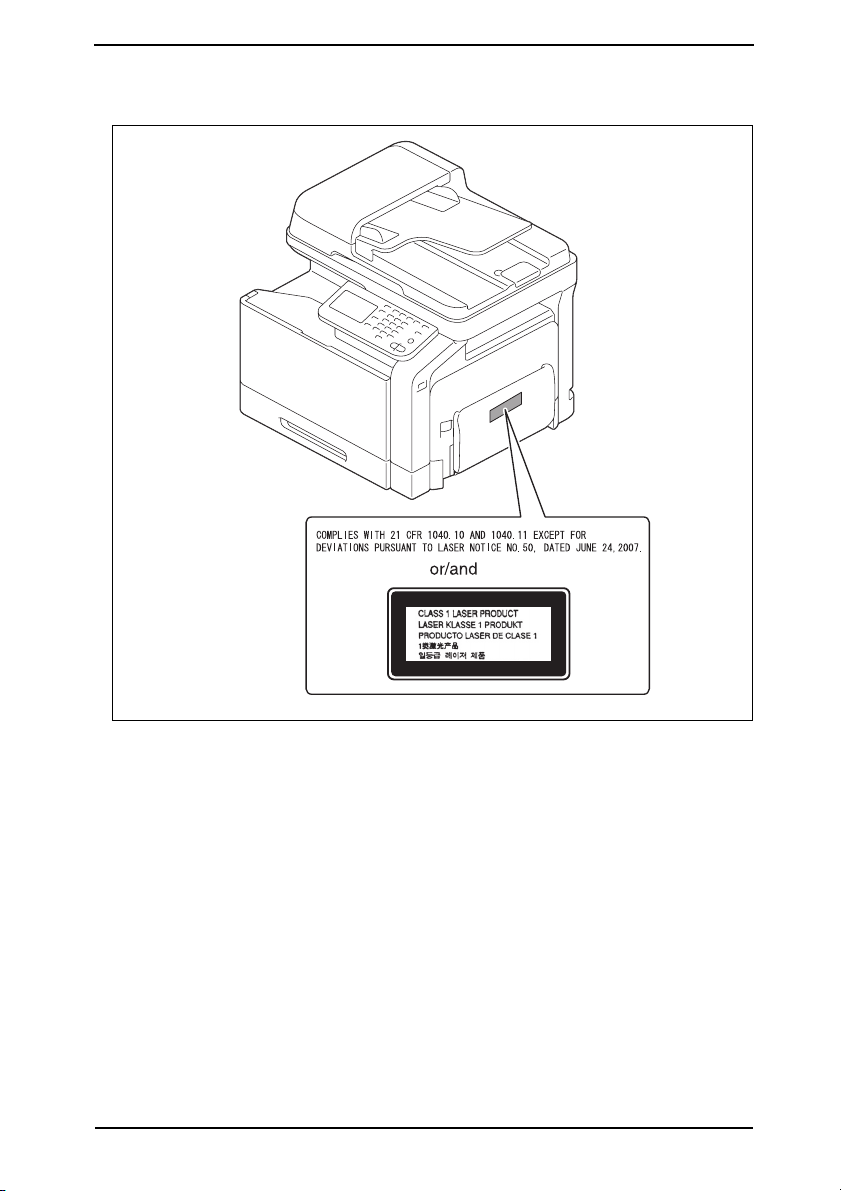

4.2 Laser Safety Label

• A laser safety label is attached to the outside of the machine as shown below.

A121P0E505DA

S-15

Page 19

SAFETY AND IMPORTANT WARNING ITEMS

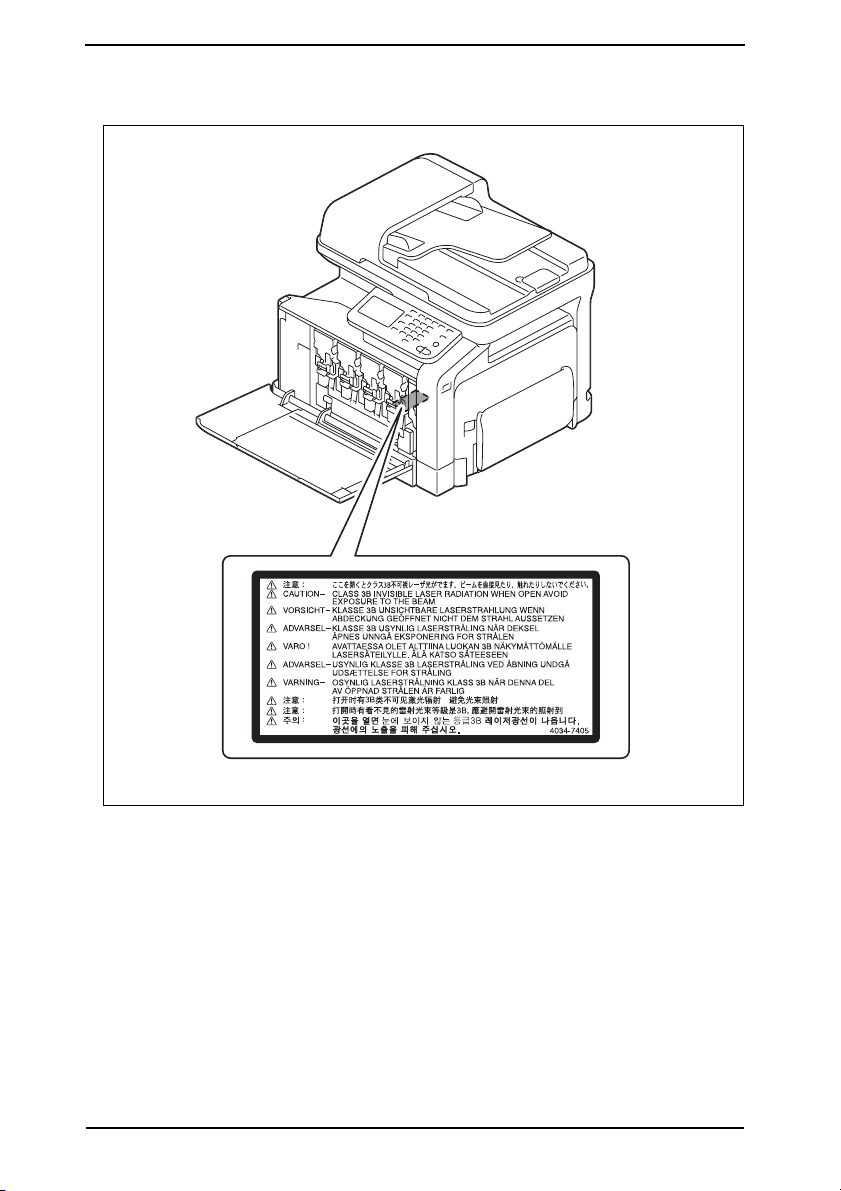

4.3 Laser Caution Label

• A laser caution label is attached to the inside of the machine as shown below.

A121P0C501DA

4.4 PRECAUTIONS FOR HANDLING THE LASER EQUIPMENT

• When laser protective goggles are to be used, select ones with a lens conforming to the

above specifications.

• When a disassembly job needs to be performed in the laser beam path, such as when

working around the printerhead and PC Drum, be sure first to turn the printer OFF.

• If the job requires that the printer be left ON, take off your watch and ring and wear laser

protective goggles.

• A highly reflective tool can be dangerous if it is brought into the laser beam path. Use

utmost care when handling tools on the user’s premises.

S-16

Page 20

SAFETY AND IMPORTANT WARNING ITEMS

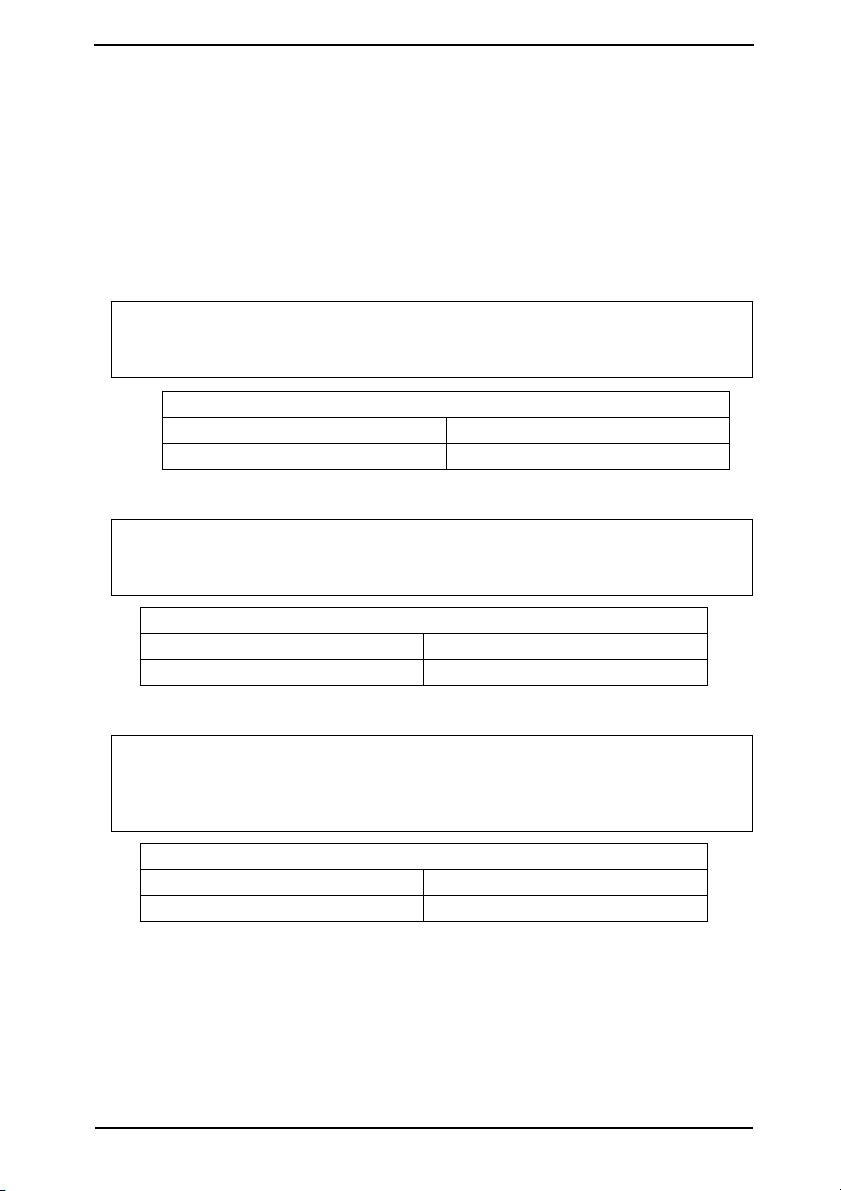

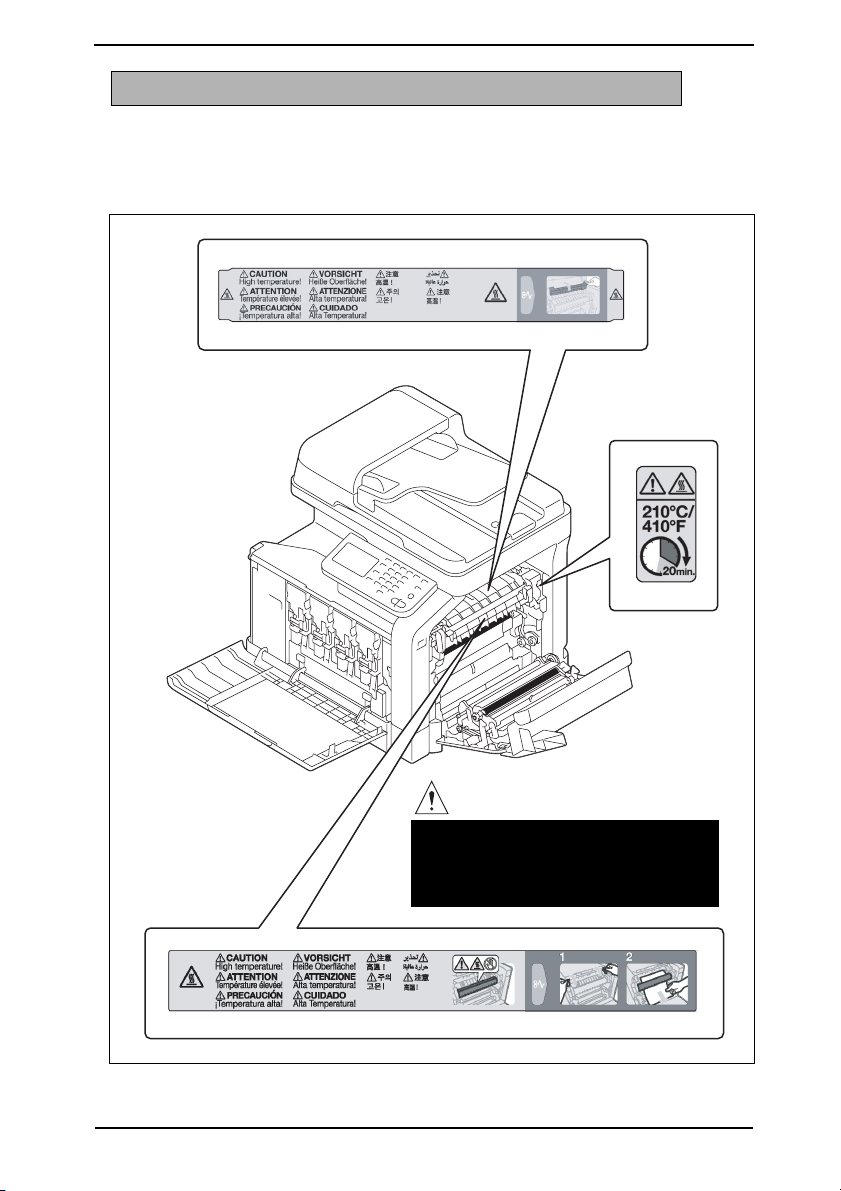

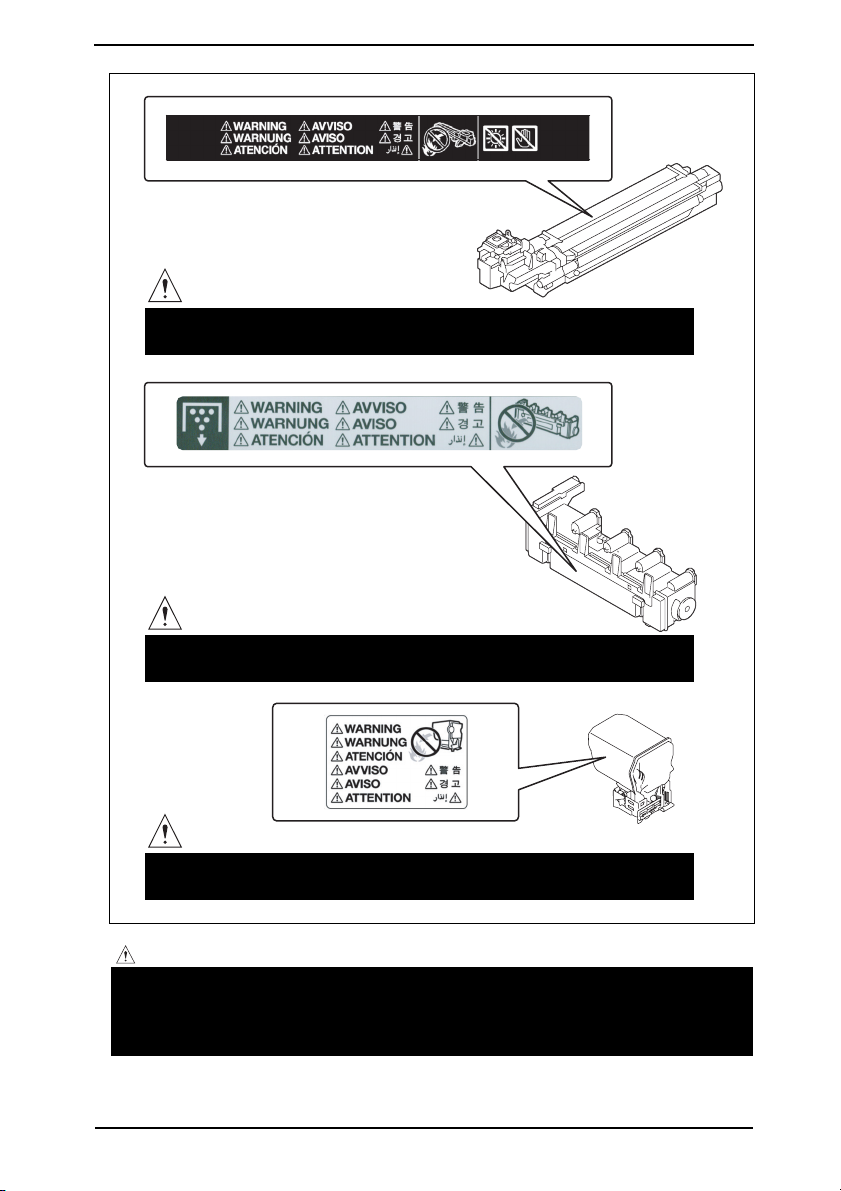

INDICATION OF WARNING ON THE MACHINE

Caution labels shown below are attached in some areas on/in the machine.

When accessing these areas for maintenance, repair, or adjustment, special care should

be taken to avoid burns and electric shock.

CAUTION

• The area around the Fuser Unit is

extremely hot.

Touching any part other than those

indicated may result in burns.

A121P0C503DA

S-17

Page 21

SAFETY AND IMPORTANT WARNING ITEMS

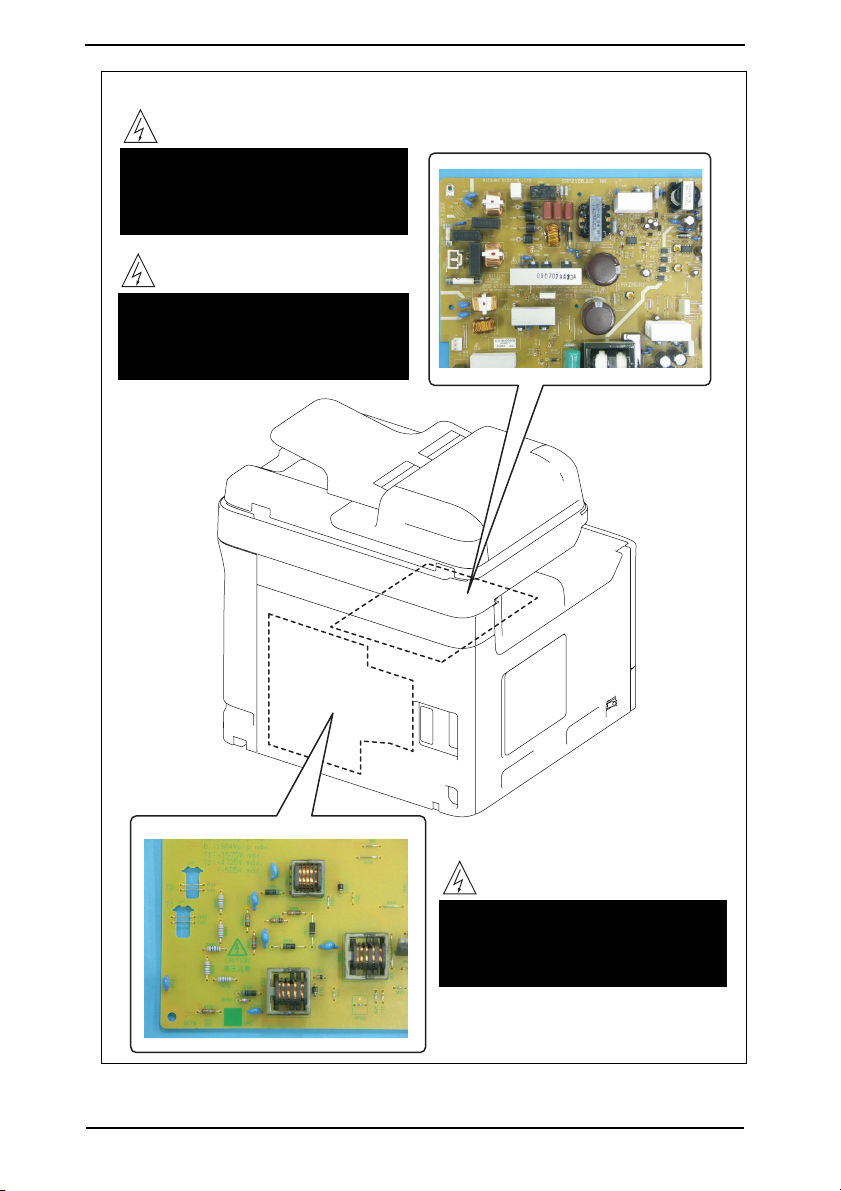

High voltage

• This area generates high voltage.

Be careful not to touch here when

the power is turned ON to avoid

getting an electric shock.

Electric hazard

• To avoid electrical shock, after

turning OFF the power switch, do

not touch the DC power supply for

9 minutes.

S-18

High voltage

• This area generates high voltage.

Be careful not to touch here when

the power is turned ON to avoid

getting an electric shock.

A121P0C506DA

Page 22

SAFETY AND IMPORTANT WARNING ITEMS

WARNING

• Do not burn used Imaging Unit.

Toner expelled from the fire is dangerous.

WARNING

• Do not burn used Waste Toner Bottle.

Toner expelled from the fire is dangerous.

WARNING

• Do not burn used Toner Cartridges.

Toner expelled from the fire is dangerous.

A0VDP0C504DA

CAUTION:

• You may be burned or injured if you touch any area that you are advised by any

caution label to keep yourself away from. Do not remove caution labels. And also,

when the caution label is peeled off or soiled and cannot be seen clearly, replace

it with a new caution label.

S-19

Page 23

MEASURES TO TAKE IN CASE OF AN ACCIDENT

MEASURES TO TAKE IN CASE OF

AN ACCIDENT

1. If an accident has occurred, the distributor who has been notified first must immediately

take emergency measures to provide relief to affected persons and to prevent further

damage.

2. If a report of a serious accident has been received from a customer, an on-site evalua-

tion must be carried out quickly and KMBT must be notified.

3. To determine the cause of the accident, conditions and materials must be recorded

through direct on-site checks, in accordance with instructions issued by KMBT.

4. For reports and measures concerning serious accidents, follow the regulations speci-

fied by every distributor.

S-20

Page 24

Composition of the service manual

This service manual consists of Theory of Operation section and Field Service section to

explain the main machine and its corresponding options.

Theory of Operation section gives, as information for the CE to get a full understanding of

the product, a rough outline of the object and role of each function, the relationship

between the electrical system and the mechanical system, and the timing of operation of

each part.

Field Service section gives, as information required by the CE at the site (or at the cus-

tomer’s premise), a rough outline of the service schedule and its details, maintenance

steps, the object and role of each adjustment, error codes and supplementary information.

The basic configuration of each section is as follows. However some options may not be

applied to the following configuration.

<Theory of Operation section>

OUTLINE: Explanation of system configuration,

product specifications, unit configuration, and paper path

COMPOSITION/OPERATION: Explanation of configuration of each unit,

operating system, and control system

<Field service section>

OUTLINE: Explanation of system configuration, and product

specifications

MAINTENANCE: Explanation of service schedule, maintenance steps, ser-

vice tools, removal/reinstallation methods of major parts,

and firmw

ADJUSTMENT/SETTING: Explanation of utility mode, service mode, and mechanical

adjustment etc.

TROUBLESHOOTING: Explanation of lists of jam codes and error codes, and

their countermeasures etc.

APPENDIX: Parts layout drawings, connector layout drawings, timing

chart, overall layout drawing are attached.

are version up method etc.

C-1

Page 25

Notation of the service manual

A. Product name

In this manual, each of the products is described as follows:

bizhub C35: Main body

(1)

(2) Microsoft Windows 2000: Windows 2000

Microsoft Windows XP: Windows XP

Microsoft Windows Vista: Windows Vista

Microsoft Windows 7: Windows 7

Microsoft Windows Server 2003: Windows Server 2003

Microsoft W

When the description is made in combination of the OS’s mentioned above:

B. Brand name

The company names and product names mentioned in this manual are the brand name or

the registered trademark of each company.

C. Feeding direction

• When the long side of the paper is parallel with the feeding direction, it is called short

edge feeding. The feeding direction which is perpendicular to the short edge feeding is

called the long edge feeding.

• Short edge feeding will be identified with [S (abbreviation for Short edge feeding)] on the

paper size. No specific notation is added for the long edge feeding.

When the size has only the short edge feeding with no long edge feeding, [S] will not be

added to the paper size.

<Sample notation>

indows Server 2008: Windows Server 2008

Windows 7/Vista/Server 2008/XP/Server

2003/2000

Windows 7/Vista/XP/2000

Windows Server 2008/Server 2003

Paper size Feeding direction Notation

A4

A3 Short edge feeding A3

Long edge feeding A4

Short edge feeding A4S

C-2

Page 26

SERVICE MANUAL

FIELD SERVICE

Main body

2011.02

Ver. 3.0

Page 27

Revision history

After publication of this service manual, the parts and mechanism may be subject to change for

improvement of their performance.

Therefore, the descriptions given in this service manual may not coincide with the actual machine.

When any change has been made to the descriptions in the service manual, a revised version will be

issued with a revision mark added as required.

Revision mark:

• To indicate clearly a section revised, is shown at the left margin of the revised section.

The number inside represents the number of times the revision has been made.

1

1

• To indicate clearly a page that contains the revision, is shown near the page number of the

1

corresponding page.

The number inside represents the number of times the revision has been made.

1

NOTE

Revision marks shown in a page are restricted only to the latest ones with the old ones deleted.

• When a page revised in Ver. 2.0 has been changed in Ver. 3.0:

The revision marks for Ver. 3.0 only are shown with those for Ver. 2.0 deleted.

• When a page revised in Ver. 2.0 has not been changed in Ver. 3.0:

The revision marks for Ver. 2.0 are left as they are.

2011/01 3.0

2010/12 2.0

2010/06 1.1 Error correction

2010/05 1.0 — Issue of the first edition

Date Service manual Ver. Revision mark Descriptions of revision

3

2

1

Description addition of the Step3 firmware

(A12130G1062205)/Error corrections

Description addition of the Step2 firmware

(A12130G0042905)/Error corrections

Page 28

Field Service Ver. 3.0 Feb. 2011

CONTENTS

bizhub C35 Main body

OUTLINE

1. SYSTEM CONFIGURATION................................................................................... 1

2. PRODUCT SPECIFICATIONS ................................................................................ 2

2.1 Type ...................................................................................................................... 2

2.2 Functions .............................................................................................................. 2

2.3 Media.................................................................................................................... 3

2.4 Maintenance ......................................................................................................... 3

2.5 Machine specifications.......................................................................................... 4

2.6 Operating environment ......................................................................................... 4

2.7 Print functions....................................................................................................... 4

2.8 Scan functions ...................................................................................................... 5

2.9 Fax functions ........................................................................................................ 6

MAINTENANCE

3. PERIODICAL MAINTENANCE ITEM...................................................................... 9

3.1 Periodical replacement parts list (CRU)................................................................ 9

3.2 Periodical replacement parts list (FRU) ................................................................ 9

3.2.1 Main body ..................................................................................................... 9

3.2.2 Option ........................................................................................................... 9

3.3 Concept of parts life.............................................................................................. 9

4. PERIODICAL MAINTENANCE PROCEDURE ..................................................... 10

4.1 Processing section.............................................................................................. 10

4.1.1 Replacing the toner cartridge (C, M, Y, K) .................................................. 10

4.1.2 Replacing the imaging unit (C, M, Y, K) ...................................................... 13

4.2 Transfer section .................................................................................................. 16

4.2.1 Replacing the waste toner bottle................................................................. 16

4.2.2 Replacing the transfer roller unit ................................................................. 17

4.2.3 Replacing the transfer belt unit ................................................................... 18

4.3 Fusing section..................................................................................................... 22

4.3.1 Replacing the fuser unit .............................................................................. 22

4.4 Feed section ....................................................................................................... 24

4.4.1 Replacing the tray1 feed roller .................................................................... 24

4.4.2 Replacing the tray2 feed roller .................................................................... 26

5. SERVICE TOOL .................................................................................................... 27

5.1 Service material list ............................................................................................ 27

bizhub C35

OUTLINEMAINTENANCEADJUSTMENT / SETTING

TROUBLESHOOTING

APPENDIX

i

Page 29

5.2 CE tool list .......................................................................................................... 27

6. FIRMWARE REWRITING..................................................................................... 28

6.1 Checking the current firmware version............................................................... 28

6.2 Firmware upgrading procedure by USB memory device.................................... 28

bizhub C35

6.2.1 Preparations for firmware upgrading........................................................... 28

6.3 Firmware upgrading procedure by updater ........................................................ 30

6.3.1 Updating method ........................................................................................ 30

6.3.2 Checking the version after the firmware update ......................................... 40

7. OTHER MAINTENANCE ITEM............................................................................. 41

7.1 Items not allowed to be disassembled and adjusted .......................................... 41

OUTLINEMAINTENANCEADJUSTMENT / SETTING

7.2 Disassembly/reassembly parts list ..................................................................... 42

7.3 Cleaning parts list............................................................................................... 43

7.4 Disassembly/reassembly procedure................................................................... 43

7.4.1 Front door ................................................................................................... 43

7.4.2 Rear cover .................................................................................................. 43

7.4.3 Left cover .................................................................................................... 44

7.4.4 Rear right cover .......................................................................................... 44

7.4.5 Operation panel .......................................................................................... 45

7.4.6 ADF............................................................................................................. 46

7.4.7 ADF feed roller unit..................................................................................... 48

7.4.8 ADF separation pad.................................................................................... 50

7.4.9 Scanner unit................................................................................................ 51

7.4.10 Tray1 ........................................................................................................... 53

7.4.11 Tray2 ........................................................................................................... 54

7.4.12 Hard disk (HDD) ......................................................................................... 54

7.4.13 FAX board (FAXB) ...................................................................................... 56

7.4.14 MFP board (MFPB)..................................................................................... 57

7.4.15 Printer control board (PRCB) ...................................................................... 61

7.4.16 DC power supply (DCPU)........................................................................... 63

7.4.17 High voltage unit (HV1)............................................................................... 65

TROUBLESHOOTING

7.4.18 PH Unit ....................................................................................................... 66

7.4.19 Backup battery............................................................................................ 68

7.4.20 Developing motor (M1) ............................................................................... 70

7.4.21 Main motor (M2) ......................................................................................... 70

7.4.22 Color PC drum motor (M4) ......................................................................... 70

APPENDIX

7.4.23 DC power su

7.4.24 Cooling fan motor (FM11) ........................................................................... 71

7.4.25 MFP board cooling fan motor (FM12)......................................................... 72

Field Service Ver. 3.0 Feb. 2011

pply fan motor (FM10)............................................................ 71

ii

Page 30

Field Service Ver. 3.0 Feb. 2011

7.4.26 Tray2 media feed clutch (CL1) / Tray1 media feed clutch (CL2).................. 73

7.4.27 Registration clutch (CL3) ............................................................................ 74

7.4.28 Toner supply clutch/Y (CL4) / Toner supply clutch/M (CL5)

Toner supply clutch/C (CL6) / Toner supply clutch/K (CL7)......................... 75

7.4.29 Loop detection clutch (CL8) ........................................................................ 78

7.4.30 Switchback roller feed clutch (CL11) / Switchback roller reverse clutch

(CL12) ......................................................................................................... 81

7.4.31 Duplex conveyance roller clutch (CL13)...................................................... 84

7.4.32 2nd transfer release solenoid (SD2) ........................................................... 85

7.4.33 Temperature/ humidity sensor (TEM/HUMS) .............................................. 87

7.4.34 IDC sensor (IDC) ........................................................................................ 88

7.4.35 Speaker (SP1)............................................................................................. 90

7.5 Cleaning procedure ............................................................................................ 91

7.5.1 Tray1 feed roller........................................................................................... 91

7.5.2 Tray2 feed roller........................................................................................... 91

7.5.3 ADF feed roller ............................................................................................ 92

7.5.4 Laser irradiation section .............................................................................. 92

ADJUSTMENT/SETTING

8. HOW TO USE THE ADJUSTMENT/SETTING

SECTION .............................................................................................................. 95

9. Utility ..................................................................................................................... 96

9.1 List of utility mode............................................................................................... 96

9.2 Starting/Exiting ................................................................................................. 103

9.2.1 Starting procedure .................................................................................... 103

9.2.2 Exiting procedure ......................................................................................103

9.3 Statistics Page.................................................................................................. 104

9.3.1 Sample of STATISTICS PAGE .................................................................. 104

9.4 Restore Defaults ............................................................................................... 109

10. SERVICE MODE................................................................................................. 119

10.1 List of service mode.......................................................................................... 119

10.2 Starting/Exiting ................................................................................................. 123

10.2.1 Starting procedure .................................................................................... 123

10.3 Serial Number................................................................................................... 124

10.4 Firmware Version.............................................................................................. 124

10.5 Printer Adjustment ............................................................................................ 125

10.5.1 Leading Edge Adjustment ......................................................................... 125

10.5.2 Side Edge Adjustment .............................................................................. 126

10.5.3 Left ADJ Duplex ........................................................................................ 127

bizhub C35

OUTLINEMAINTENANCEADJUSTMENT / SETTING

TROUBLESHOOTING

APPENDIX

iii

Page 31

10.5.4 2nd Image Transfer-Simplex Pass ............................................................ 128

10.5.5 2nd Image Transfer-Manual Duplex.......................................................... 128

10.5.6 Thick Paper Image Density....................................................................... 129

bizhub C35

10.5.7 Monochrome Density Adj.......................................................................... 129

10.5.8 Image ADJ Param..................................................................................... 129

10.5.9 Fuser Temp Control .................................................................................. 130

10.5.10 Fuser Control ............................................................................................ 130

10.5.11 AIDC Mode ............................................................................................... 130

10.5.12 Thick Mode ............................................................................................... 131

OUTLINEMAINTENANCEADJUSTMENT / SETTING

10.5.13 Fine Line ADJ ........................................................................................... 131

10.5.14 Grayscacle Page....................................................................................... 131

10.6 Main Scan Adjust ............................................................................................. 132

10.6.1 Main Scan Page........................................................................................ 132

10.6.2 Scan Adjust Value..................................................................................... 132

10.7 Service Fax Settings......................................................................................... 134

10.7.1 Restrict Fax TX ......................................................................................... 134

10.7.2 Restrict Fax RX......................................................................................... 134

10.7.3 Restrict PC-Fax TX ................................................................................... 134

10.7.4 TX Speed.................................................................................................. 134

10.7.5 RX Speed ................................................................................................. 135

10.7.6 ECM RX OFF............................................................................................ 135

10.7.7 Redial V34 Dis. ......................................................................................... 135

10.7.8 RX V34 OFF ............................................................................................. 135

10.7.9 V17 Mod. Permit. ...................................................................................... 135

10.7.10 Retry Start Pg ........................................................................................... 136

10.7.11 DT Detect.................................................................................................. 136

10.7.12 BT Detect.................................................................................................. 136

10.7.13 Cable Equalize.......................................................................................... 136

10.7.14 Echo Measure........................................................................................... 136

10.7.15 CFR to Phase C........................................................................................ 137

TROUBLESHOOTING

10.7.16 TX Level.................................................................................................... 137

10.7.17 Connect. Timeout ..................................................................................... 137

10.7.18 CED Level................................................................................................. 137

10.7.19 eRTN % .................................................................................................... 138

10.7.20 V34 Symbol Rate...................................................................................... 138

APPENDIX

10.7.21 Data Format.............................................................................................. 138

10.7.22 V34 Tran.Pt ............................................................................................... 138

10.7.23 Fax Target ................................................................................................. 138

Field Service Ver. 3.0 Feb. 2011

iv

Page 32

Field Service Ver. 3.0 Feb. 2011

10.7.24 Fax Factory Default ................................................................................... 139

10.7.25 Fax Image Initialized ................................................................................. 139

10.7.26 Fax Maint. ................................................................................................. 140

10.7.27 DTMF Test ................................................................................................ 140

10.7.28 Modem Test .............................................................................................. 140

10.7.29 Fax Diagnostics Code............................................................................... 141

10.7.30 Data Dmp. List ..........................................................................................141

10.7.31 Fax EventLog ............................................................................................ 141

10.7.32 Restrict Internet Fax TX ............................................................................ 141

10.7.33 Restrict Internet Fax RX............................................................................ 141

10.8 Scanner Adjustment ......................................................................................... 142

10.8.1 FB Leading Edge ...................................................................................... 142

10.8.2 FB Side Edge ............................................................................................ 143

10.8.3 ADF(F) Leading Edge ...............................................................................144

10.8.4 ADF(F) Side Edge..................................................................................... 145

10.8.5 ADF(B) Leading Edge ............................................................................... 146

10.8.6 ADF(B) Side Edge .................................................................................... 147

10.8.7 FB CD Multiplier ........................................................................................ 148

10.8.8 FB FD Multiplier ........................................................................................ 149

10.8.9 ADF(F) CD Multiplier................................................................................. 150

10.8.10 ADF(F) FD Multiplier ................................................................................. 151

10.8.11 ADF(B) CD Multiplier ................................................................................ 152

10.8.12 ADF(B) FD Multiplier................................................................................. 153

10.8.13 Tilt(F)......................................................................................................... 154

10.8.14 Tilt(B) ........................................................................................................ 154

10.9 Print Menu ........................................................................................................ 155

10.9.1 Mgmt. List ................................................................................................. 155

10.9.2 Event Log .................................................................................................. 157

10.9.3 Adjust Information ..................................................................................... 157

10.9.4 Element Page............................................................................................ 158

10.9.5 Halftone 64................................................................................................ 159

10.9.6 Halftone 128.............................................................................................. 159

10.9.7 Halftone 256.............................................................................................. 159

10.9.8 Gradation .................................................................................................. 160

10.9.9 Scanner Adjustment.................................................................................. 160

10.9.10 Scan Event Log......................................................................................... 160

10.10 Supplies ............................................................................................................ 160

10.10.1 Consumable Replace-Transfer Belt Unit ................................................... 160

bizhub C35

OUTLINEMAINTENANCEADJUSTMENT / SETTING

TROUBLESHOOTING

APPENDIX

v

Page 33

10.10.2 Consumable Replace-Transfer Roller Unit................................................ 161

10.10.3 Consumable Replace-Fusing Unit ............................................................ 161

10.11 BK Clear ........................................................................................................... 161

bizhub C35

10.12 Firmware Update.............................................................................................. 162

10.12.1 Details....................................................................................................... 162

10.12.2 Execute..................................................................................................... 162

10.13 CS Remote Care .............................................................................................. 163

10.13.1 Outlines..................................................................................................... 163

10.13.2 Setting up the CS Remote Care ............................................................... 163

OUTLINEMAINTENANCEADJUSTMENT / SETTING

10.13.3 Service Engr ID......................................................................................... 165

10.13.4 Subscribe.................................................................................................. 165

10.13.5 Maintenance Start. ................................................................................... 165

10.13.6 Maintenance End...................................................................................... 165

10.13.7 Manual Trans. ........................................................................................... 166

10.13.8 Basic Settings........................................................................................... 166

10.13.9 WebDAV Settings ..................................................................................... 167

10.13.10 CSRC Clock.............................................................................................. 168

10.13.11 CSRC Settings.......................................................................................... 168

10.13.12 RAM Clear ................................................................................................ 170

10.13.13 CS Remote Care Operation under Enhanced Security Mode .................. 170

10.14 Clear Admin Password ..................................................................................... 170

10.15 CE Password .................................................................................................... 171

10.16 Soft Switch ....................................................................................................... 172

10.17 Engine DipSW .................................................................................................. 172

10.18 Function............................................................................................................ 173

10.18.1 Print-Test Print A4/Test Print Letter........................................................... 173

10.18.2 Comp. Check ............................................................................................ 173

10.18.3 Sensor Check/Scanner Sensor Check ..................................................... 175

10.19 Toner Out Mode................................................................................................ 176

10.20 IU Yield Settings ............................................................................................... 176

TROUBLESHOOTING

10.21 Enable Warning ................................................................................................ 177

10.21.1 Toner Low ................................................................................................. 177

10.21.2 Imaging Unit Low ...................................................................................... 177

10.21.3 Waste Toner Box Near Full ....................................................................... 177

10.22 Installation Date................................................................................................ 177

10.23 Loadable Driver Information ............................................................................. 178

APPENDIX

10.24 Loadable Driver Download ............................................................................... 178

11. Billing Setting ...................................................................................................... 181

Field Service Ver. 3.0 Feb. 2011

vi

Page 34

Field Service Ver. 3.0 Feb. 2011

11.1 List of billing setting .......................................................................................... 181

11.2 Starting/Exiting ................................................................................................. 181

11.2.1 Starting procedure .................................................................................... 181

11.3 Count Setting.................................................................................................... 182

11.3.1 Count Mode .............................................................................................. 182

11.3.2 Large Paper size Mode ............................................................................. 182

11.4 Restriction Code Settings ................................................................................. 182

12. FAX PROTOCOLS .............................................................................................. 183

12.1 G3 ECM (G3 Error Correction Mode) ............................................................... 183

12.2 Line control ....................................................................................................... 184

12.2.1 Procedure of G3 mode communication..................................................... 184

12.3 Table of reference code .................................................................................... 185

12.4 How to analyze the T30 protocol monitor ......................................................... 186

TROUBLESHOOTING

13. JAM DISPLAY ..................................................................................................... 193

13.1 List of JAM display............................................................................................ 193

13.1.1 JAM display resetting procedure............................................................... 193

13.2 Sensor layout.................................................................................................... 194

13.3 Solution............................................................................................................. 195

13.3.1 Initial check items...................................................................................... 195

13.3.2 Misfeed at fusing/paper exit section.......................................................... 195

13.3.3 Misfeed at transfer section ........................................................................ 196

13.3.4 Misfeed at tray1 paper feed section .......................................................... 197

13.3.5 Misfeed at tray 2 paper feed section ......................................................... 198

13.3.6 Misfeed at tray 3/tray 4 paper feed section ............................................... 199

13.3.7 Misfeed at tray 3/tray 4 vertical conveyance section ................................. 200

13.3.8 Misfeed at duplex paper transport section ................................................ 201

13.3.9 Misfeed at duplex paper feed section........................................................ 202

13.3.10 Misfeed at ADF section............................................................................. 203

13.3.11 Controller JAM .......................................................................................... 204

14. PROCESS CAUTION INFROMATION ................................................................ 205

14.1 Display procedure............................................................................................. 205

14.2 List.................................................................................................................... 205

14.3 Solution............................................................................................................. 205

14.3.1 Temperature/ humidity sensor failure ........................................................ 205

14.3.2 IDC sensor failure ..................................................................................... 206

14.3.3 Color regist test pattern failure .................................................................. 206

14.3.4 Color regist adjust failure .......................................................................... 206

bizhub C35

OUTLINEMAINTENANCEADJUSTMENT / SETTING

TROUBLESHOOTING

APPENDIX

vii

Page 35

15. MALFUNCTION CODE....................................................................................... 207

15.1 Trouble code (Service Call) .............................................................................. 207

15.2 List.................................................................................................................... 207

15.3 Trouble resetting procedure.............................................................................. 210

bizhub C35

15.4 Solution ............................................................................................................ 211

15.4.1 0010: Color PC drum motor malfunction .................................................. 211

15.4.2 0017: Main motor malfunction .................................................................. 211

15.4.3 0018: Developing motor malfunction ........................................................ 212

15.4.4 0045: MFP board cooling fan motor malfunction ...................................... 212

15.4.5 004A: Cooling fan motor malfunction........................................................ 213

OUTLINEMAINTENANCEADJUSTMENT / SETTING

15.4.6 004E: DC power supply fan motor malfunction......................................... 213

15.4.7 0062: Tray 3 media feed motor malfunction.............................................. 214

15.4.8 0063: Tray 4 media feed motor malfunction.............................................. 214

15.4.9 0094: 2nd image transfer pressure/retraction failure ................................ 215

15.4.10 0096: 1st image transfer pressure/retraction failure ................................. 216

15.4.11 0300: Polygon motor malfunction ............................................................. 216

15.4.12 0310: Laser malfunction ........................................................................... 217

15.4.13 0500: Heating roller warm-up failure......................................................... 217

15.4.14 0502: Thermistor open-circuit failure ........................................................ 217

15.4.15 0503: Thermistor resistance failure .......................................................... 217

15.4.16 0510: Abnormally low heating roller temperature ..................................... 217

15.4.17 0520: Abnormally high heating roller temperature.................................... 217

15.4.18 0F52: Toner level sensor/Y malfunction.................................................... 218

15.4.19 0F53: Toner level sensor/M malfunction ................................................... 218

15.4.20 0F54: Toner level sensor/C malfunction.................................................... 218

15.4.21 0F55: Toner le

15.4.22 13DD: Backup data error .......................................................................... 218

15.4.23 13E2: Engine flash ROM write error ......................................................... 219

15.4.24 13E3: Engine flash ROM device fault ....................................................... 219

15.4.25 13F0: Engine control failure...................................................................... 219

TROUBLESHOOTING

15.4.26 6751: Gain adjustment error ..................................................................... 219

15.4.27 6790: Offset adjustment error ................................................................... 219

15.4.28 6792: White reference plate search error ................................................. 219

15.4.29 6793: Scanner communication error......................................................... 219

15.4.30 9401: Lamp illumination check error......................................................... 219

APPENDIX

15.4.31 6791: Register setting error ...................................................................... 220

15.4.32 B116: Communication error with the fax board......................................... 221

15.4.33 C023: Flash ROM error ............................................................................ 221

Field Service Ver. 3.0 Feb. 2011

vel sensor/K malfunction.................................................... 218

viii

Page 36

Field Service Ver. 3.0 Feb. 2011

15.4.34 C026: Controller ROM error (Access error) .............................................. 221

15.4.35 C027: Controller ROM error (Data error) .................................................. 221

15.4.36 C050: HDD access error........................................................................... 222

15.4.37 C051: HDD full error ................................................................................. 222

15.4.38 C060: Firmware update error.................................................................... 223

15.4.39 C072: Counter not installed ...................................................................... 223

15.4.40 C080: Memory error.................................................................................. 223

15.4.41 C900: Successful completion of counter backup ...................................... 224

15.4.42 C907: Abnormal end of counter backup ................................................... 224

15.4.43 FFFF: Interface communication error........................................................ 224

16. POWER SUPPLY TROUBLE .............................................................................. 225

16.1 Machine is not energized at all (DCPU operation check) ................................. 225

16.2 Control panel indicators do not light ................................................................. 225

16.3 Fusing heaters do not operate.......................................................................... 226

17. IMAGE QUALITY PROBLEM .............................................................................. 227

17.1 How to identify problematic part ....................................................................... 227

17.1.1 Initial check items...................................................................................... 227

17.2 Solution............................................................................................................. 228

17.2.1 Scanner system: white lines, white bands, colored lines and colored bands in

sub scan direction ..................................................................................... 228

17.2.2 Scanner system: white lines, white bands, colored lines and colored bands in

main scan direction ................................................................................... 229

17.2.3 Scanner system: color spots ..................................................................... 230

17.2.4 Scanner system: fog ................................................................................. 231

17.2.5 Scanner system: blurred image, blotchy image ........................................ 232

17.2.6 Scanner system: incorrect color image registration, sync shift (lines in main

scan direction)........................................................................................... 233

17.2.7 Scanner system: moire ............................................................................. 234

17.2.8 Scanner system: skewed image ............................................................... 235

17.2.9 Scanner system: distorted image.............................................................. 236

17.2.10 Scanner system: low image density, rough image .................................... 237

17.2.11 Scanner system: blank copy, black copy................................................... 238

17.2.12 Printer monocolor: white lines, white bands, colored lines and colored bands

in sub scan direction ................................................................................. 239

17.2.13 Printer monocolor: white lines, white bands, colored lines and colored bands

in main scan direction ............................................................................... 240

17.2.14 Printer monocolor: uneven density in sub scan direction.......................... 241

17.2.15 Printer monocolor:

uneven density in main scan direction........................ 242

17.2.16 Printer monocolor: low image density ....................................................... 243

bizhub C35

OUTLINEMAINTENANCEADJUSTMENT / SETTING

TROUBLESHOOTING

APPENDIX

ix

Page 37

bizhub C35

OUTLINEMAINTENANCEADJUSTMENT / SETTING

Field Service Ver. 3.0 Feb. 2011

17.2.17 Printer monocolor: gradation reproduction failure..................................... 244

17.2.18 Printer monocolor: foggy background....................................................... 245

17.2.19 Printer monocolor: void areas, white spots............................................... 246

17.2.20 Printer monocolor: colored spots .............................................................. 247

17.2.21 Printer monocolor: blurred image ............................................................. 248

17.2.22 Printer monocolor: blank copy, black copy................................................ 249

17.2.23 Printer monocolor: uneven image............................................................. 250

17.2.24 Printer 4-color: white lines, white bands, colored lines and colored bands in

sub scan direction..................................................................................... 251

17.2.25 Printer 4-color: white lines, white bands, colored lines and colored bands in

main scan direction................................................................................... 252

17.2.26 Printer 4-color: uneven density in sub scan direction ............................... 253

17.2.27 Printer 4-color: uneven density in main scan direction ............................. 254

17.2.28 Printer 4-color: low image density ............................................................ 255

17.2.29 Printer 4-color: poor color reproduction .................................................... 256

17.2.30 Printer 4-color: incorrect color image registration ..................................... 257

17.2.31 Printer 4-color: void areas, white spots..................................................... 258

17.2.32 Printer 4-color: colored spots.................................................................... 259

17.2.33 Printer 4-color: poor fusing performance, offset ....................................... 260

17.2.34 Printer 4-color: brush effect, blurred image .............................................. 261

17.2.35 Printer 4-color: back marking.................................................................... 262

17.2.36 Printer 4-color: uneven image................................................................... 263

18. IC protector ......................................................................................................... 264

18.1 Outline.............................................................................................................. 264

18.2 IC protector list ................................................................................................. 264

18.2.1 Main body ................................................................................................. 264

18.2.2 Lower feeder unit PF-P08 ......................................................................... 265

APPENDIX

19. PARTS LAYOUT DRAWING................................................................................ 267

TROUBLESHOOTING

APPENDIX

19.1 Main body......................................................................................................... 267

19.2 ADF .................................................................................................................. 271

19.3 Lower feeder unit (option)................................................................................. 272

20. CONNECTOR LAYOUT DRAWING.................................................................... 273

20.1 Printer control board (PRCB) ........................................................................... 273

20.2 MFP board (MFPB) .......................................................................................... 274

20.3 FAX board (FAXB) ............................................................................................ 274

20.4 PC control board (PCCB) ................................................................................. 275

20.5 DF control board (DFCB) ................................................................................. 275

x

Page 38

Field Service Ver. 3.0 Feb. 2011

21. CONNECTOR LAYOUT DRAWING .................................................................... 276

22. TIMING CHART .................................................................................................. 277