Page 1

Page 2

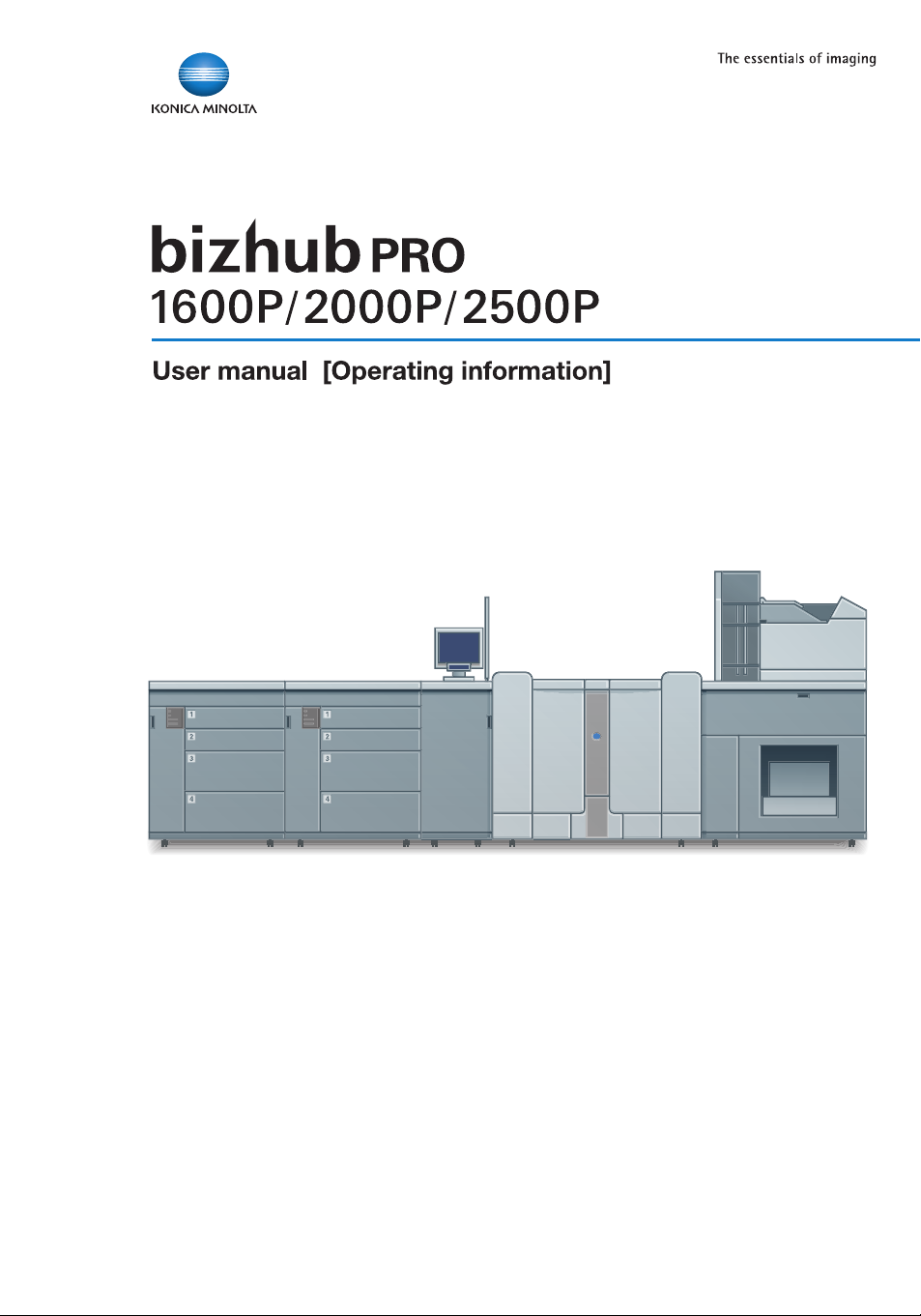

User manual

bizhub PRO

1600P/2000P/2500P

Operating information

Page 3

Copyright

Copyright

2006-2008 Océ

All rights reserved. No part of this work may be reproduced, copied, adapted, or

transmitted in any form or by any means without written permission from Océ.

Océ makes no representation or warranties with respect to the contents hereof and

specifically disclaims any implied warranties of merchantability or fitness for any

particular purpose.

Further, Océ reserves the right to revise this publication and to make changes from

time to time in the content hereof without obligation to notify any person of such

revision or changes.

Edition 2008-07

US

Page 4

Trademarks

List of trademarks

Xerox, DocuTech, DigiPath and FreeFlow are registered trademarks of Xerox

Corporation.

Adobe and PostScript are registered trademarks of Adobe Systems Incorporated.

Products in this publication are referred to by their general trade names. In most, if

not all cases, these designations are claimed as trademarks or registered trademarks

of their respective companies.

Trademarks

3

Page 5

Trademarks

4

Page 6

Table of Contents

Table of Contents

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Notes for the reader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Introduction to the bizhub PRO 1600P/2000P/2500P . . . . . . . . . . . . . . . 11

Available documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 2

Power information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

The power modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Turn on the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Shut down the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chapter 3

Overview of the system components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Introduction to the main system components . . . . . . . . . . . . . . . . . . . . . 22

The operator panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

The operator attention light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

The output locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

The paper modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Chapter 4

Working with the operator panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

The dashboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

The Schedule view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Introduction to the 'Schedule' view . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Load the media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Instructions for printing to the stacker/stapler (iMFS) . . . . . . . . . . . . . 44

Stop a job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

The Jobs view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Introduction to the 'Jobs' view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Schedule a waiting job for printing . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Reprint a job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Give priority to a scheduled job. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Delete a job. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Print a scheduled job later. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Make a proof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Print the job parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Bundle and split jobs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Print all the jobs for which the media are available. . . . . . . . . . . . . . . 68

5

Page 7

Table of Contents

Print the jobs that have a label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Checking and changing the job properties . . . . . . . . . . . . . . . . . . . . . 71

The Trays view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Introduction to the 'Trays' view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Assign the media to a paper tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

The System view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

The Printer section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

The Setup section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

The Media section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

The Transaction section (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Change the media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Change the number of sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Change the output location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Change the number of staples . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Change the sorting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Change the type of offset stacking . . . . . . . . . . . . . . . . . . . . . . . . . 82

Check the first set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Shift the image in the document printing mode . . . . . . . . . . . . . . . 87

Introduction to the 'Printer' section . . . . . . . . . . . . . . . . . . . . . . . . . 94

Check the status of the toner reservoirs. . . . . . . . . . . . . . . . . . . . . 96

Check the status of the staple cartridges . . . . . . . . . . . . . . . . . . . . 98

Reset the day counters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Find the meter readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Introduction to the 'Setup' section. . . . . . . . . . . . . . . . . . . . . . . . . 102

Work with the workflow profiles . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Change the language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Change the warning time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Change the advanced media settings . . . . . . . . . . . . . . . . . . . . . 114

Make an intermediate check print. . . . . . . . . . . . . . . . . . . . . . . . . 118

Introduction to the 'Media' section . . . . . . . . . . . . . . . . . . . . . . . . 120

Introduction to the media handling . . . . . . . . . . . . . . . . . . . . . . . . 122

Add temporary media to the 'Media catalog' . . . . . . . . . . . . . . . . 124

Perform a media registration for standard-size media . . . . . . . . . 126

Perform a media registration for large media . . . . . . . . . . . . . . . . 131

Introduction to the 'Transaction' section . . . . . . . . . . . . . . . . . . . 137

Activate the transaction printing function . . . . . . . . . . . . . . . . . . . 140

Shift the image in the transaction printing mode . . . . . . . . . . . . . 142

Handle the media messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Chapter 5

Keeping the printer running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Add toner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Finisher: Add staples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Stacker/stapler (iMFS): Replace the staple cartridge. . . . . . . . . . . . . . . 155

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

6

Page 8

Table of Contents

Appendix A

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Product specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

7

Page 9

Table of Contents

8

Page 10

Chapter 1 Introduction

9

Page 11

Notes for the reader

Notes for the reader

Introduction

This manual helps you to use the machine. The manual contains a description of the

machine and guidelines to use and operate the machine. There are also tips to

increase your knowledge of the machine and to help you manage the workflow even

better.

Definition

Attention Getters

Parts of this manual require your special attention. These parts provide important,

additional information or are about the prevention of damage to your properties.

Note, Attention, and Caution

Caution: A part marked with Caution contains information to prevent

personal injury.

Attention: A part marked with Attention contains information to prevent

damage to items, for example the machine or a file.

Note: A part marked with Note contains additional information about the correct

operation of the machine.

Safety information

The safety information for this product is included in a separate user manual with the

title Safety information. This manual is part of the documentation set that you

received with your product.

10 Chapter 1 Introduction

Page 12

Introduction to the bizhub PRO 1600P/2000P/2500P

Introduction to the bizhub PRO 1600P/2000P/2500P

Introduction

The bizhub PRO 1600P/2000P/2500P is a series of high-volume, cut-sheet printers.

The machines are intended for both document printing and stream printing.

Duplex technology enables the machine to print on the front and back side of a sheet

at the same time. Depending on the version, the sustained print speed, including

reconditioning, ranges from 80-125 sheets per minute (A4 / Letter). That means the

machine can print 160 - 250 images per minute (A4 / Letter) when printing a 2-sided

document.

The print speed for 1-sided documents (A4/Letter) is 125 images per minute.

This section gives a short description of the main features of the machine.

Note: Not all the configurations mentioned in this user manual are available

worldwide. Please contact your local dealer for the available configurations in your

country.

Overview of the main features

■ Advanced scheduling concept on the operator panel to keep the machine running.

■ Load and assign the media while the machine prints.

■ Support of up to 12 paper trays (total input capacity up to 13,800 sheets) and a

roll feeder.

■ Support of up to 3 stackers, a finisher, a stacker/stapler and other external

finishers.

■ Support of a large range of media, media sizes and media weights.

■ Support of PS/PCL/PDF and streaming PS.

11

Page 13

Available documentation

Available documentation

Introduction

This machine is delivered with a documentation set that consists of the following

items.

■ A CD-ROM with all the manuals mentioned below

■ A hardcopy user manual entitled 'Safety information'.

■ Integrated Online Helps in the printer driver, the Settings Editor and other

proprietary applications.

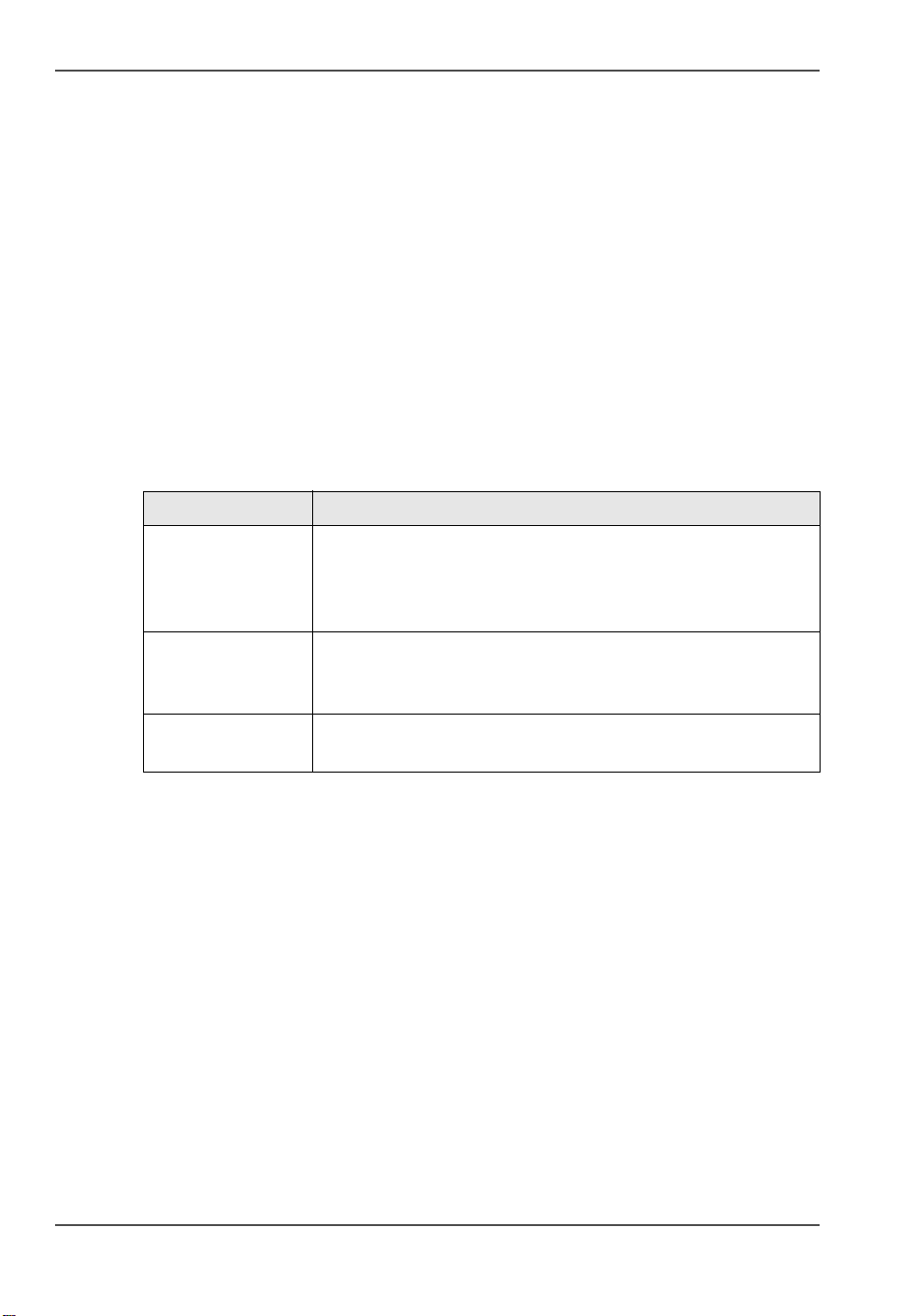

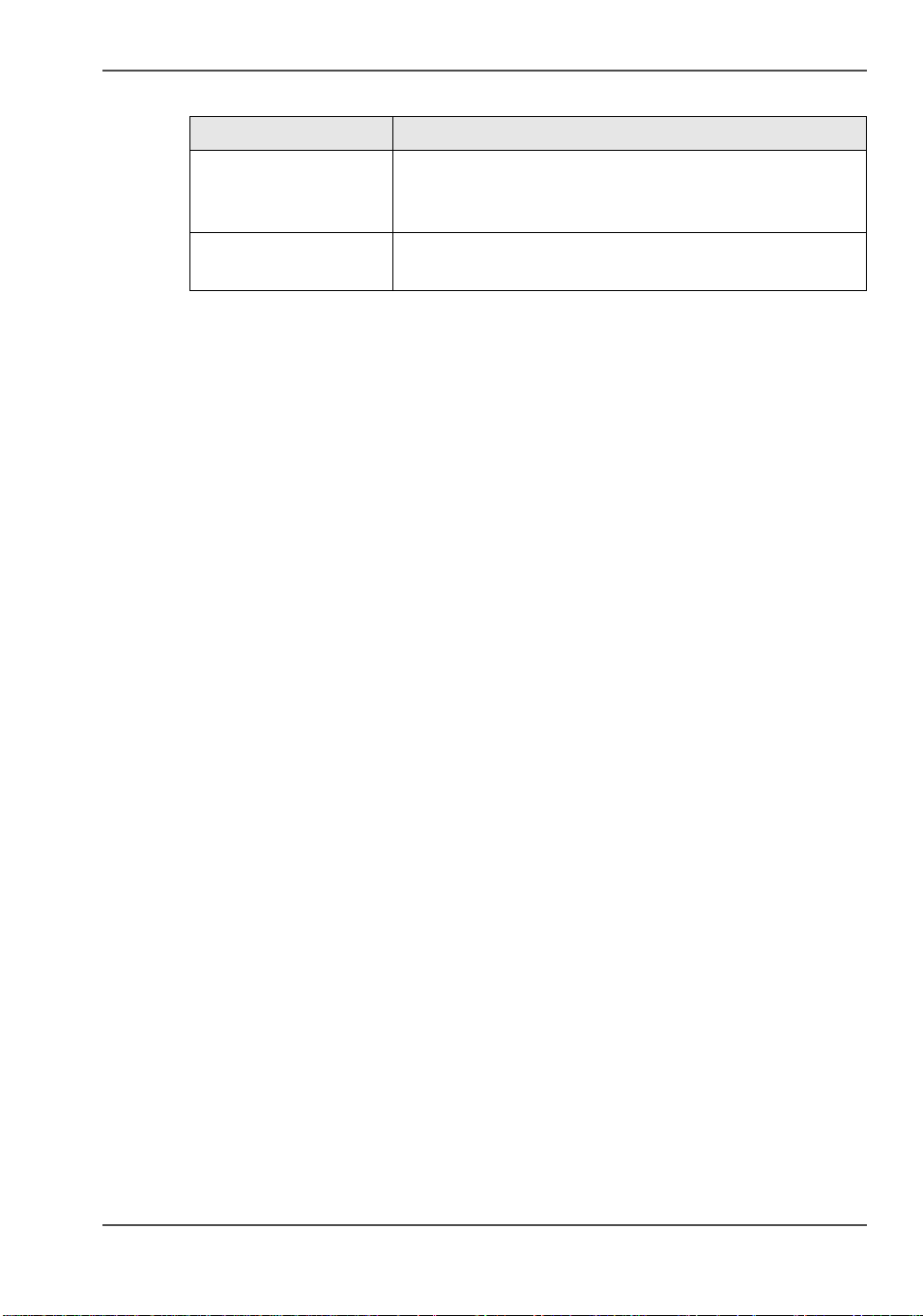

Main Content of the User Manuals

The following table provides an overview of the main content of the user manuals.

[1]

[1] Main Content of the User Manuals

User Manual Main content

Operating

information

Maintenance tasks

Safety information

■ Overview of the main system components

■ Working with the operator panel

■ Handling and managing jobs on the operator panel

■ Add media, toner and staples

■ Replacing parts

■ Cleaning parts

■ Solve a paper jam in the engine module

■ Instructions for safe use

■ Safety Data Sheets

12 Chapter 1 Introduction

Page 14

Chapter 2 Power information

13

Page 15

The power modes

The power modes

Introduction

This section describes the power switches and the main power modes of the

machine.

The table in this section describes, among other things, the low-power mode and the

sleep mode. These modes are energy-saving modes. You can set the timers for these

modes in the Settings Editor on the controller. Furthermore, you can set a calendar

timer in the Settings Editor. Then the machine will wake up from the sleep mode at

the indicated time. You can use the calendar timer for example to make sure that the

machine is ready for use at the beginning of your working day. The machine can

warm up before you start your working day. Please refer to the online help on the

Settings Editor for more information about these timers.

Description of the power switch and the On/Off button

The machine has the following switch and button to control the power supply.

■ Power switch

The power switch is located at the back side of the machine. The power switch

connects and disconnects the machine to the mains power.

■ On/Off button with amber and green LEDs .

The On/Off button on the machine (see ‘Introduction to the main system

components’ on page 22) allows you to toggle between the stand-by mode and

the sleep mode. This is only possible if the power switch is in the '1' position

and the start-up phase is completed.

14 Chapter 2 Power information

Page 16

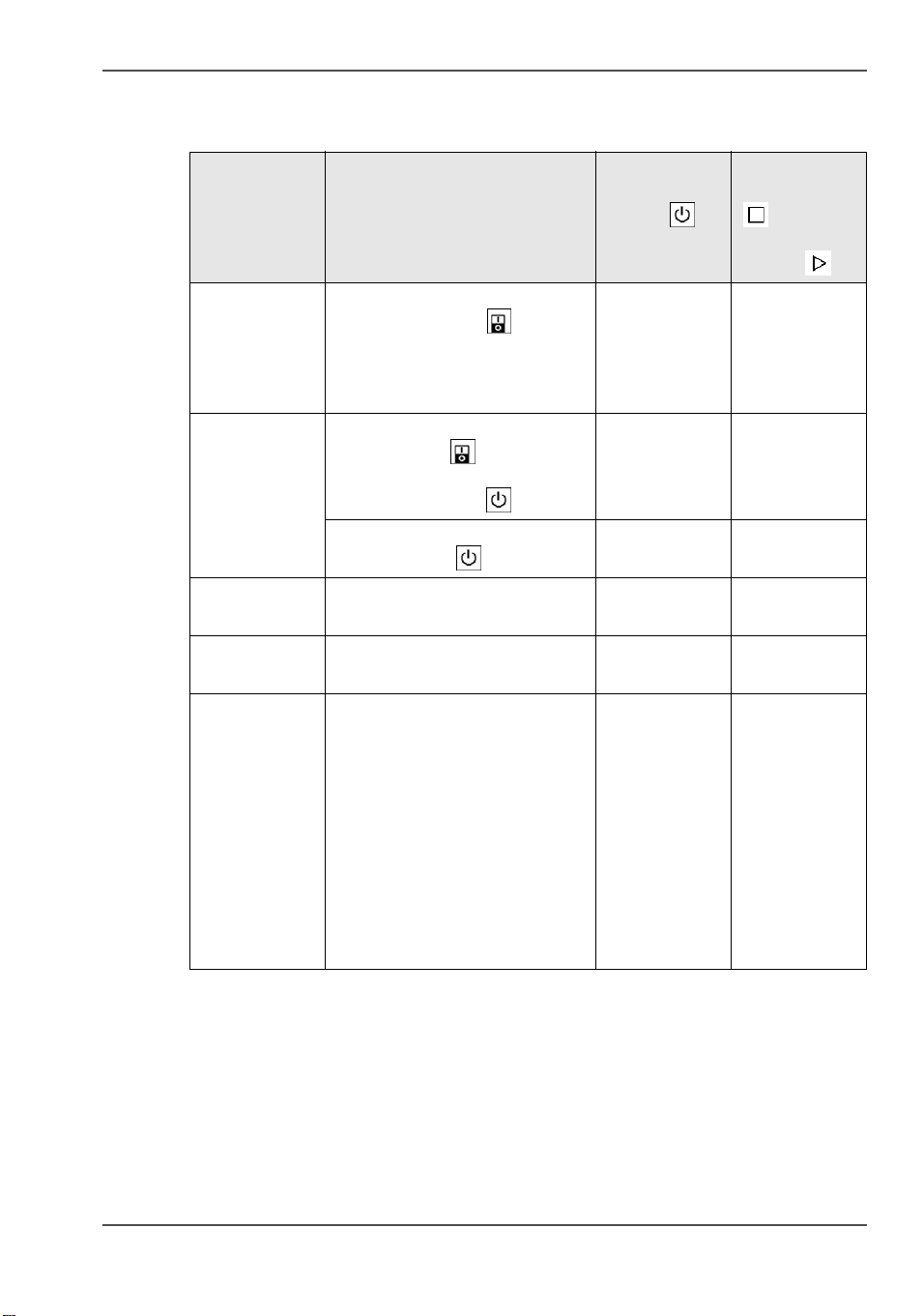

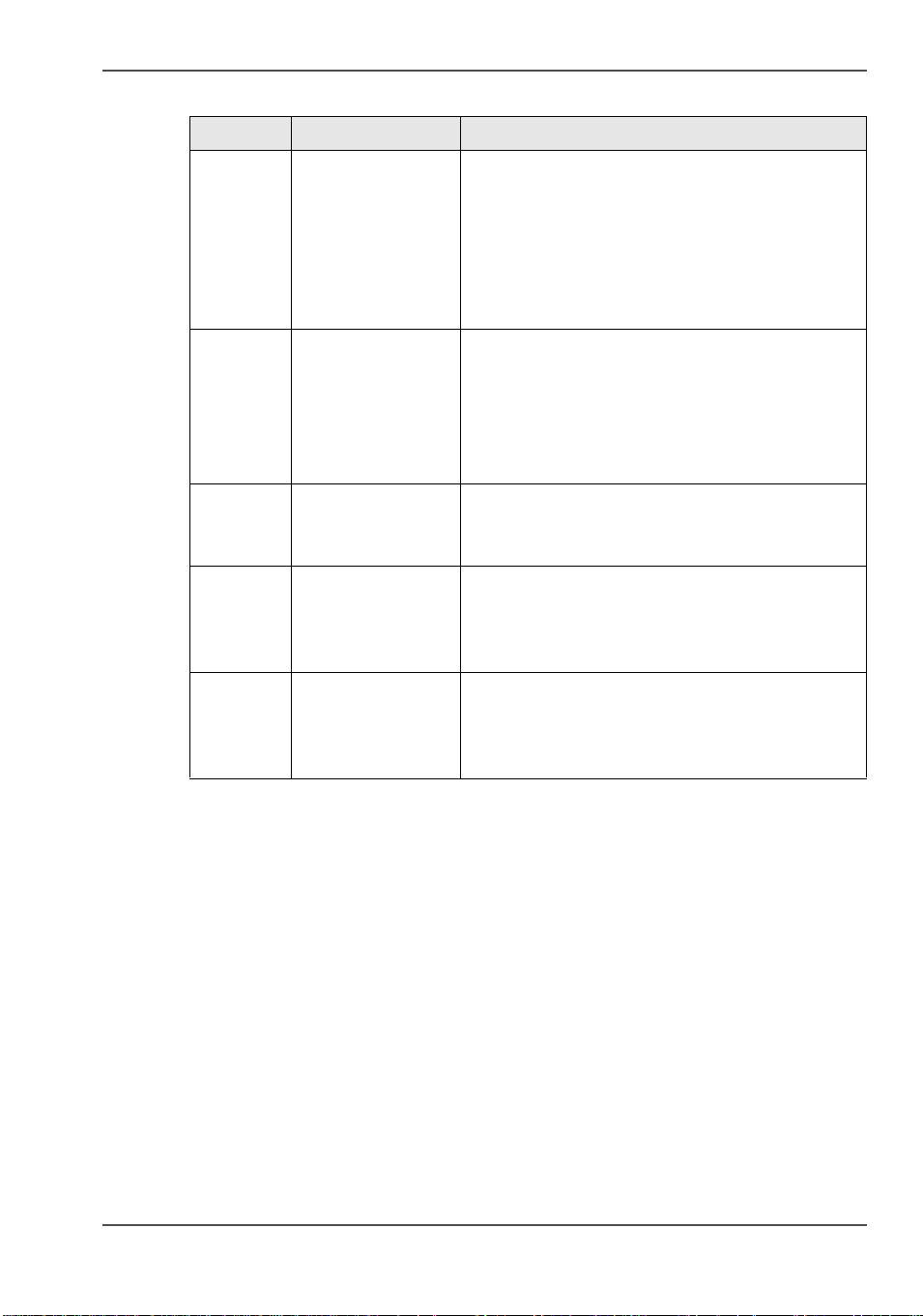

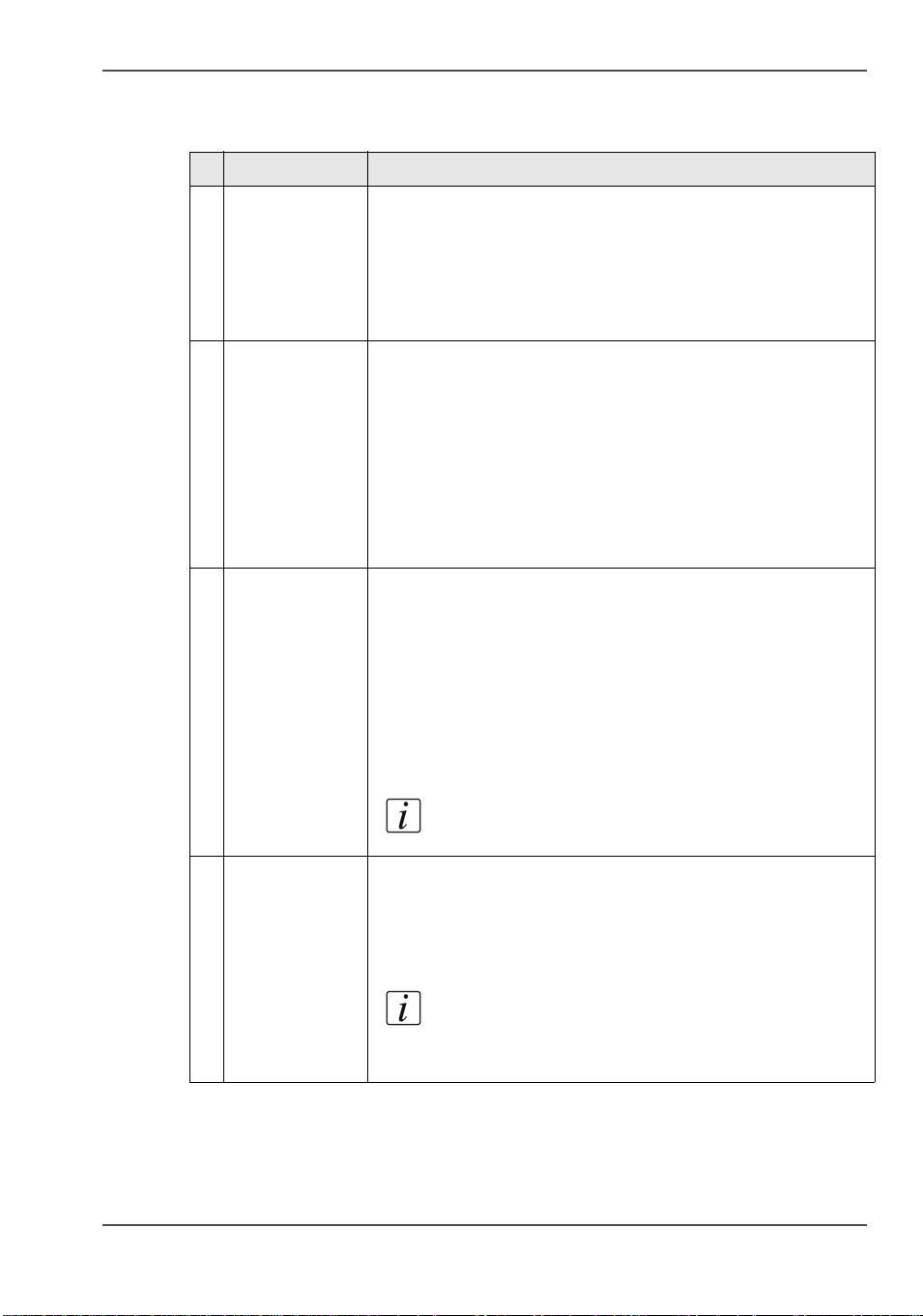

Description of the main power modes

[2]

[2] The main power modes (1 – 2)

The power modes

Power mode Description Status of the

On/Off

button

Off The machine is completely off.

Off Off

The power switch is in the

'O' position. There is no power

consumption. The machine

cannot receive or print jobs.

Starting up

(divided into 2

stages)

Stage 1: After you put the

power switch in the 'I'

position, but before you press

Blinking

amber

the On/Off button .

Stand-by

mode

Stage 2: After you press the

On/Off button .

The machine is ready to print

jobs.

Continuous

green

Continuous

green

Run mode The machine is busy. Continuous

green

Low-power

mode

The machine automatically

enters low-power mode when

Continuous

green

the machine has been in

stand-by mode for a defined

period of time and no button

was pressed.

The machine wakes up when a

job arrives in the list of

'Scheduled jobs' or when you

press a button. The machine

will start to warm up.

Status of the

Hold button

and

Release

button

Off

On

On

On

On

15

Page 17

The power modes

[2] The main power modes (2 – 2)

Power mode Description Status of the

On/Off

button

Going into

sleep mode

Sleep mode The machine automatically

The machine is preparing to go

into sleep mode.

goes from the low-power mode

Blinking

amber

Continuous

amber

into the sleep mode after a

defined time.

You can also place the machine

into the sleep mode manually.

Press the On/Off button to

do this. The machine will enter

the sleep mode as soon as the

list of 'Scheduled jobs' is empty.

The machine will wake up from

the sleep mode when you press

the On/Off button or when

the calendar timer expires. The

machine will also wake up

when a printable job arrives in

the list of 'Scheduled jobs',

provided that the function

'Automatic wake-up' in the

Settings Editor is enabled.

Status of the

Hold button

and

Release

button

On

Off

16 Chapter 2 Power information

Page 18

Turn on the machine

Introduction

This section describes how to turn on the machine when it is completely off.

Note: When the machine is in sleep mode (see ‘The power modes’ on page 14), you

must press the On/Off button to wake up the machine.

Turn on the machine

1. Put the power switch at the back of the machine in the 'I' position.

The On/Off button blinks amber while the machine and the controller start up.

Wait until the operator panel asks you to press the On/Off button .

2. Press the On/Off button .

The On/Off button remains green.

The machine warms up.

Turn on the machine

17

Page 19

Shut down the machine

Shut down the machine

Introduction

This section describes how to shut down the machine completely, for example for

the holidays.

Note: If you want to put the machine into the sleep mode manually (see ‘The power

modes’ on page 14), for example at the end of a working day, you must press the

On/Off button . Then the machine will go into the sleep mode as soon as the list

of 'Scheduled jobs' is empty. When the machine is in the sleep mode, the On/Off

button is continuous amber.

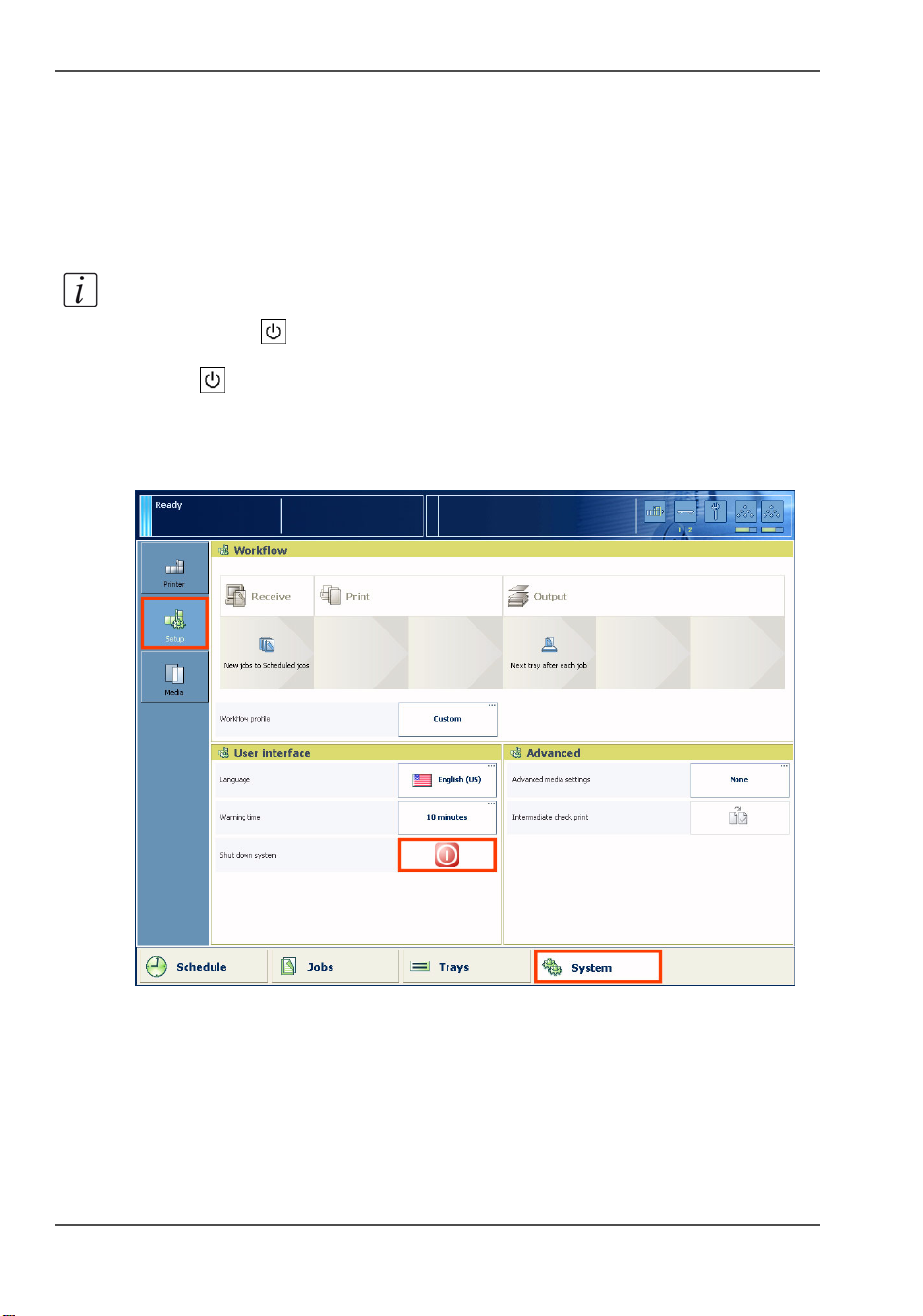

Illustration

[1]

[1] Shut down the machine

Shut down the machine

1. On the operator panel, press the 'System' button.

2. Press the 'Setup' button.

3. Press the 'Shut down system' button in the 'User interface' section.

A dialog box asks you to confirm that you really want to shut down the machine.

18 Chapter 2 Power information

Page 20

Shut down the machine

4. Press 'Yes'.

A message indicates when the shutdown will begin. Wait until the following has

happened.

■ The Hold button and the Release button are off

■ The On/Off button blinks amber

■ The screen of the operator panel is off.

5. Put the power switch at the back of the machine in the 'O' position.

19

Page 21

Shut down the machine

20 Chapter 2 Power information

Page 22

Chapter 3 Overview of the system components

21

Page 23

Introduction to the main system components

Introduction to the main system components

Introduction

The following illustration shows the main system components. The table describes

the main components. Please follow the links in the table for comprehensive

information.

[2]

2

1

1

2

3

3

[2] The main system components

4

4

The main system components

[3]

[3] The main system components (1 – 2)

5

7

6

8

Component Function

1 Operator panel The operator panel helps you with your daily

work, for example the scheduling of the jobs.

Furthermore, the operator panel helps you to

solve errors or perform maintenance tasks (see

‘The operator panel’ on page 24).

2 Operator attention

light

The operator attention light enables you to check

the status of the system from a distance (see ‘The

operator attention light’ on page 26).

3Roll feeder

(optional)

A roll feeder is an optional device that adds

paper input capacity to your printer. When you

use a roll feeder, you can only use 1 or 2 paper

modules. A combination of 3 paper modules and

a roll feeder is not possible. The operator panel

displays the roll feeder and gives feedback about

the status of the roll feeder. For example whether

the roll is full or empty. Please refer to the

documentation of the roll feeder manufacturer

for more information, for example about

replacing an empty roll.

22 Chapter 3 Overview of the system components

Page 24

Introduction to the main system components

[3] The main system components (2 – 2)

Component Function

4 Paper module The paper module contains 4 paper trays. The

paper trays contain the media that will be

printed. The default configuration of the system

contains 1 paper module. You can add 1 or 2

more paper modules to the default configuration

to increase the media input capacity (see ‘The

paper modules’ on page 31).

5 Engine module The engine module contains the components that

print the media. Access to the engine module is

only required when a paper jam occurs or when

maintenance is required. The doors at the

left-hand side and right-hand side of the engine

module give access to the toner units.

6 Stacker The stacker is the output location of a default

configuration. The system supports up to 3

stackers (see The output locations on page 28).

7 Finisher (optional) The finisher on top of the stacker is an optional

output location for the print jobs. The finisher

can staple the jobs (see The output locations on

page 28).

8 Stacker/stapler

(optional)

The stacker/stapler (iMFS) is an optional output

location for the print jobs (see The output

locations on page 28). The stacker/stapler

supports a large number of media sizes.

23

Page 25

The operator panel

The operator panel

Introduction

The operator panel is a touch screen panel. You must touch the buttons on the

operator panel to access the various functions. The operator panel is divided into 4

main views. The taskbar at the bottom of the screen contains the buttons that give

access to the 4 main views. Furthermore, the operator panel has 2 hardkeys ( and

) at the bottom of the panel.

This section gives an overview of the main keys and buttons of the operator panel.

Note: You can clean the screen of the operator panel with a 50% mix of water and

isopropyl alcohol (K2). Use a lint-free cloth. Always put the cleaner onto the cloth

and not directly on the screen.

Illustration

[3]

3 4 5 6

1 2

[3] The operator panel

24 Chapter 3 Overview of the system components

Page 26

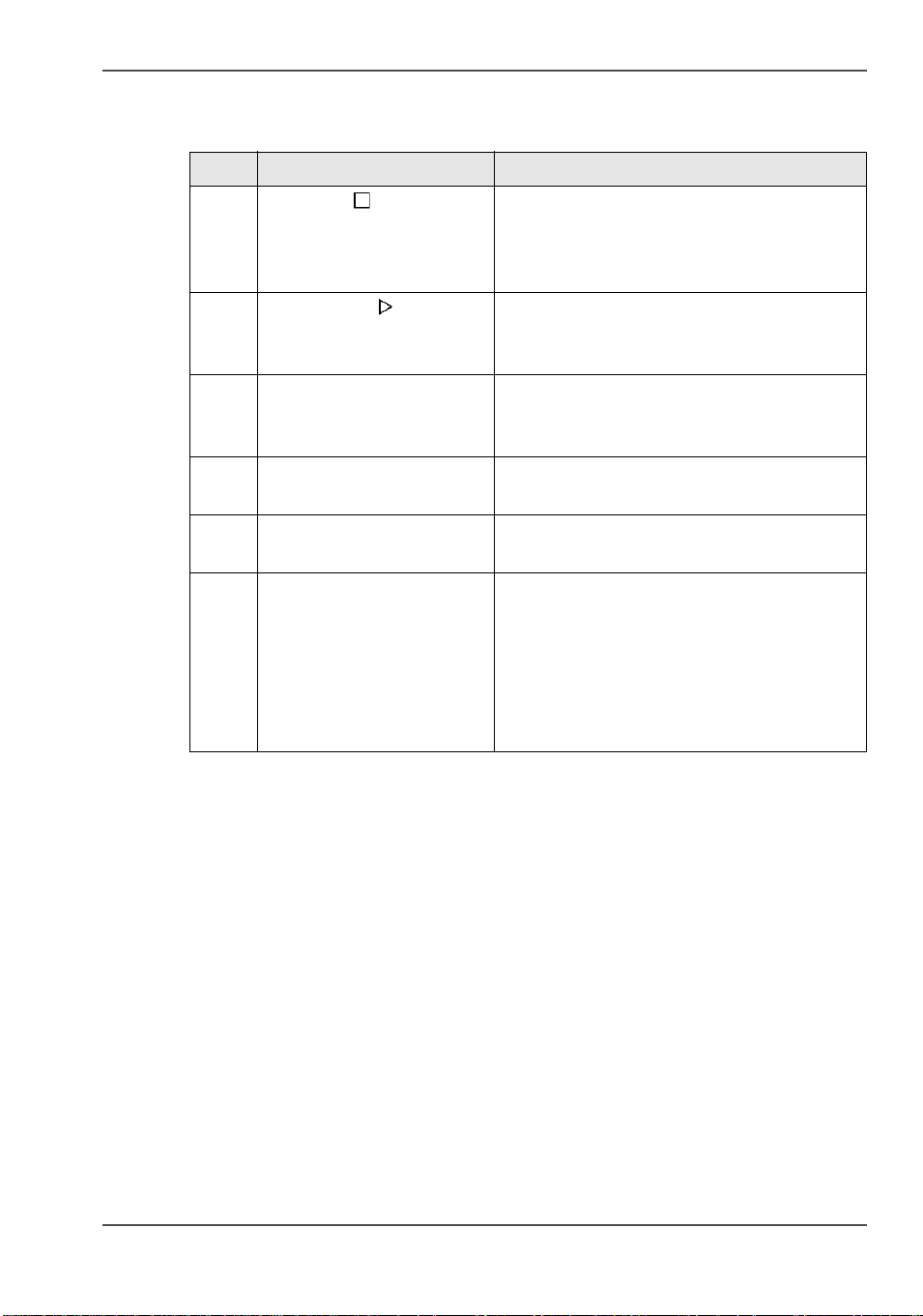

The main components of the operator panel

[4]

[4] The main components of the operator panel

Component Function

The operator panel

1 Hold key

■ Put the machine on hold

■ Stop printing after a set

■ Stop printing as soon as possible (see

‘Stop a job’ on page 45).

2 Release key

■ Allow the machine to print

■ Resume printing when the machine is on

hold.

3 'Schedule' button Access the 'Schedule' view (see

‘Introduction to the 'Schedule' view’ on

page 37).

4 'Jobs' button Access the 'Jobs' view (see ‘Introduction to

the 'Jobs' view’ on page 48).

5 'Trays' button Access the 'Trays' view (see ‘Introduction to

the 'Trays' view’ on page 89).

6 'System' button Access the 'System' view

(see ‘Introduction to the 'Printer' section’ on

page 94)

(see ‘Introduction to the 'Setup' section’ on

page 102)

(see ‘Introduction to the 'Media' section’ on

page 120)

25

Page 27

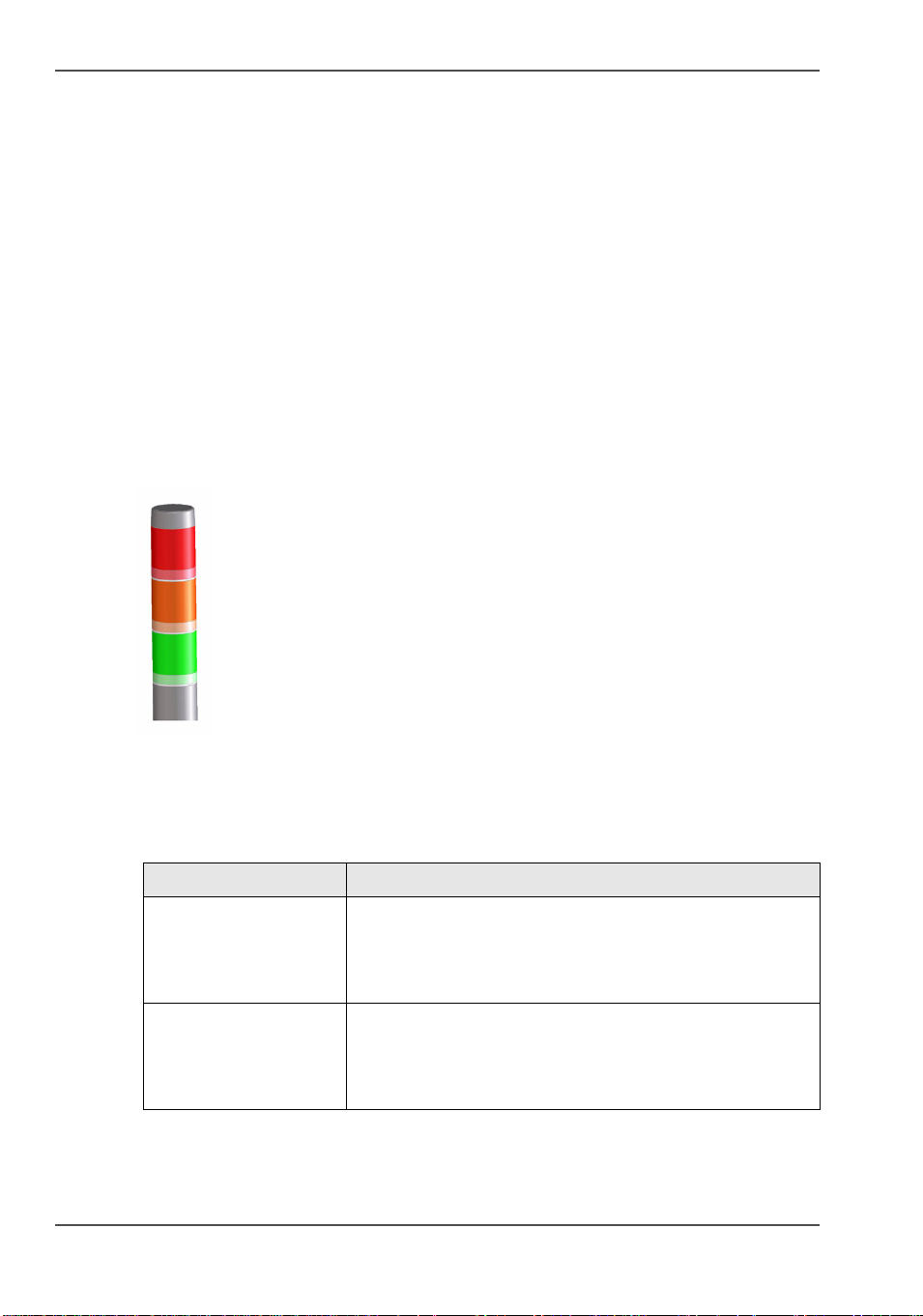

The operator attention light

The operator attention light

Introduction

The operator attention light informs you about the status of the machine. To improve

the productivity, the operator attention light can warn you some time before the

machine stops. You can set the warning time on the operator panel (see ‘Change the

warning time’ on page 111).

The operator attention light contains 3 lights (red, orange and green) that indicate the

current status of the machine. The colors of the lights match the status that is

currently indicated on the operator panel. For example, when operator interaction is

required soon, both the dashboard (see ‘The dashboard’ on page 34) and the operator

attention light will display an orange warning. The dashboard displays a message

with the required action.

This section describes the meaning of the colors of the operator attention light.

[4]

[4] The operator attention light

Status colors

[5]

[5] The colors of the operator attention light (1 – 2)

Color Description

Red The machine has stopped, for example because a

required media type is not available or an error has

occurred.

Operator attention is required now.

Orange The machine will stop soon, for example because an

output location is almost full. The orange light lights up

when the machine reaches the warning time.

Operator attention is required soon.

26 Chapter 3 Overview of the system components

Page 28

The operator attention light

[5] The colors of the operator attention light (2 – 2)

Color Description

Green The machine is busy printing. The machine can print

longer than the defined warning time.

Operator attention is not required.

All lights off The machine is idle. There are no jobs scheduled for

printing.

27

Page 29

The output locations

The output locations

Introduction

The machine supports several output locations for the printed jobs. The default

configuration of your machine contains a stacker and the system output. The finisher

and the stacker/stapler are optional output locations. Furthermore, you can connect

several optional external finishers to the machine.

Note: You need the optional finisher, the optional stacker/stapler or another

optional external finisher to staple the jobs.

Illustration

[5]

3

2

[5] The output locations

4

6

1

5

28 Chapter 3 Overview of the system components

Page 30

Overview of the output locations

[6]

[6] Description of the output locations (1 – 2)

Component Description

1 'Stacker' The stacker is the default output location of the machine. The

stacker capacity is 6,000 sheets, in 2 stacks of 3,000 sheets

each (80 g/m

The stacker does not contain staple cartridges. Therefore, the

stacker cannot be the output location for jobs that require

staples.

2 'System output' The system output is the output location for the following

prints.

■ Error prints

■ Configuration reports

■ Job tickets

■ The test sheets for the media registration.

Make sure that you regularly remove the sheets from the

system output.

2

or 20 lb. bond).

The output locations

3'Finisher'

(optional)

4 'Finisher upper

output'

The optional finisher contains the following output trays.

■ 3 output trays

■ 1 upper output (see no. 4 below)

The finisher contains 2 staple cartridges to staple the jobs.

The 3 output trays can receive A4, Letter and similar media

sizes. Stapled jobs (A4, Letter and similar media sizes only)

go into the output trays. The total capacity of the output trays

2

is 3,700 sheets (80 g/m

or 20 lb bond).

Note: The output trays cannot receive tab sheets.

The finisher upper output is part of the finisher. The upper

output can receive all formats. However, the upper output is

mainly intended for large media or jobs with mixed size

media. The maximum capacity of the upper output is 500

2

sheets (80 g/m

or 20 lb bond).

Note: The upper output does not contain staple

cartridges. Therefore, the upper output cannot be

the output location for jobs that require staples.

29

Page 31

The output locations

[6] Description of the output locations (2 – 2)

Component Description

5 'Stacker/stapler'

(optional)

6 'Stacker/stapler

upper output'

The optional stacker/stapler contains 1 staple cartridge to

staple the jobs. The staple cartridge can staple your document

with 1 or 2 staples. The stacker/stapler can stack and staple

various media sizes. The device supports the stapling of

mixed media sizes, as long as the width of the media is the

same. The capacity of the lower tray is 2,000 sheets (80 g/m

or 20 lb bond).

Note: The stacker/stapler does not support the

stapling of tab sheets.

The upper output is the upper tray of the stacker/stapler. The

2

capacity of the upper output is 250 sheets (80 g/m

or 20 lb

bond).

2

30 Chapter 3 Overview of the system components

Page 32

The paper modules

Introduction

The paper trays contain the media that are required for the print jobs. The default

configuration of the machine contains 1 paper module with 4 paper trays. You can

add 1 or 2 more paper modules to the machine. Then the total number of paper trays

is extended to 8 or 12 respectively. You can find more information about the

capacities of the paper trays and the supported media size in the appendix of this

manual.

This section describes the control panel on each paper module.

Note: You can use the control panel on the paper modules to open the paper trays

and load the media. However, the recommended way to open the paper trays and

assign the media is via the 'Schedule' view. You can also open the paper trays and/or

assign the media via the 'Trays' view (see ‘Assign the media to a paper tray’ on

page 92).

Illustration

[6]

5

1

1

2

2

1 3

2

4

The paper modules

3

3

4

4

[6] The control panel on the paper modules

The control panel

Each paper module contains a control panel next to the upper paper tray. The control

panel consists of 4 sections that correspond with the 4 paper trays. Each section

displays the current filling level of the corresponding paper tray. Furthermore, the

control panel indicates whether or not the media in the paper tray is assigned. The

following table describes the various parts of the control panel.

31

Page 33

The paper modules

[7]

[7] The parts of the control panel

Number Description

1 The LEDs indicate the current amount of sheets in the

2 Press the button to open the corresponding paper tray. You can

3 When the check mark is green, the media in the paper tray is

4 When the arrows are red, the media in the paper tray is not

5 The 'Not assigned' button. This button applies to the paper tray in

corresponding paper tray. Each lit-up LED indicates the presence

2

of about 100 sheets (based on media of 80 g/m

or 20 lb bond).

only open 1 paper tray at a time.

defined. The system knows which media is in the paper tray.

defined. The system does not know which media is in the paper

tray. The 'Trays' view on the operator panel indicates that no

media is assigned to the paper tray.

which you have just placed the media.

You can press the 'Not assigned' button when you load a new

media type into a paper tray without defining this media type on

the operator panel first. Then the printer cannot accidentally use

the media in this paper tray before the media is correctly defined

on the operator panel. You can define the media type in the 'Trays'

view on the operator panel later (see ‘Assign the media to a paper

tray’ on page 92).

Note: Make sure that the paper tray is open when you

press the 'Not assigned' button.

32 Chapter 3 Overview of the system components

Page 34

Chapter 4 Working with the operator panel

33

Page 35

The dashboard

Introduction

The dashboard

Introduction

The dashboard is the upper blue part of the operator panel. The dashboard is always

visible, irrespective of the current view (see ‘The operator panel’ on page 24). The

dashboard gives the following feedback.

■ The status of the system

■ The current process

■ Instructions for the operator

■ The status of the supplies

■ The status of the external finisher, if applicable

■ Whether maintenance is required.

Illustration

The following illustration shows the dashboard while the machine is busy. The

vertical status bar is green. No action is required.

[7]

[7] The dashboard - No action is required

The following illustration shows the dashboard while the machine is busy. The

vertical status bar is orange. Next to the status bar, the dashboard displays a message

that indicates which action is required soon.

[8]

[8] The dashboard - Action is required soon

34 Chapter 4 Working with the operator panel

Page 36

The parts of the dashboard

[8]

[8] The dashboard (1 – 2)

Number Function

1 Display the status of the machine, for example 'Initializing...',

2 Display the file name of the current job (for document

The dashboard

'Printing...' or 'Printing will stop...'. Each status message can

have a sub-message with additional information.

printing) or current stream (for stream printing).

Furthermore, the progress of the current job is displayed.

For document printing, the counter can display the following

information.

■ Set X of Y

■ Page X of Y

■ Sheet X of Y or Sheet X.

X represents the current status of the print job. Y represents

the total number of sets, pages or sheets of a print job.

If the sorting method for a job is set to 'By set', and a set

contains at least 40 pages, then the dashboard displays the set

count (Set X of Y) and the page count (Page X of Y) for the

set. If a set contains less than 40 pages, then the dashboard

only displays the set count (Set X of Y).

If the sorting method for a job is set to 'By page', or when you

print stream jobs, the dashboard only displays a sheet count.

35

Page 37

The dashboard

[8] The dashboard (2 – 2)

Number Function

3 Display the action that you must do now or soon. The colors

4 ■ Display the status of the external finisher, if applicable.

of the vertical status bar at the left-hand side match the colors

of the operator attention light (see ‘The operator attention

light’ on page 26). When the color is orange or red, a message

indicates the required action.

Orange means that action is required soon. How long before

an upcoming action the operator panel starts to display the

message depends on the defined warning time (see ‘Change

the warning time’ on page 111).

Red means that action is required now.

Note: The operator panel can only display one

message at a time. When there are more messages,

the operator panel displays the first required or

most important message.

■ Display the status of the staple cartridges (see ‘Check the

status of the staple cartridges’ on page 98).

■ Display a warning that maintenance is required. When

maintenance is required soon, the maintenance icon

becomes orange . When maintenance is required now,

the maintenance icon becomes red .

■ Display the status of the toner reservoirs (see ‘Check the

status of the toner reservoirs’ on page 96).

Note: Only key operators who received the

special maintenance training are allowed to do

maintenance tasks.

36 Chapter 4 Working with the operator panel

Page 38

The Schedule view

Introduction to the 'Schedule' view

Introduction

The 'Schedule' is your daily planning board for print jobs. The 'Schedule' helps you

to keep the machine running.

This section shows and describes the main parts of the 'Schedule'.

Note: The descriptions of the colors of the bars and the indication of the required

amount of sheets are only valid for document printing. For streaming jobs , all the

bars remain grey until the paper trays are empty or the output locations are full.

Then the machine stops and the bars become red. Furthermore, the media toolbar

does not indicate the required amount of sheets.

The 'Schedule' view

[9]

Introduction to the 'Schedule' view

[9] The 'Schedule' view

37

Page 39

Introduction to the 'Schedule' view

1. The jobs pane

The jobs pane shows the jobs on a timeline. The width of the job corresponds to the

(remaining) print time. A vertical line separates the jobs. The vertical line moves to

the left as the printing of a job progresses.

An icon and the job name represent a job. The icon indicates the state of the job, for

example printing .

Furthermore, the icon indicates the stop moments of the machine. For example,

when the setting 'Confirm start of job' in the workflow profiles (see ‘Work with the

workflow profiles’ on page 104) is set to 'On' or when you use the 'Stop after job'

function.

2. The 'Required media' pane

The 'Required media' pane displays the media that are required for each scheduled

job. For each required media, the media properties are displayed (see ‘Introduction

to the 'Trays' view’ on page 89). The bars show the availability of the media. The bars

can have the following colors.

[9]

[9] The colors of the bars

Color of the bar Description

Green The required media is available.

Orange The media is required in the future, but not available then. For

example because the paper trays do not contain sufficient

sheets of the required media.

Yellow The system cannot determine the exact number of sheets that

is available in the paper trays.

Red The media is required now, but not available. The job can

only start when you load the required media.

When you print small jobs, the bars for these jobs may not be completely visible. To

prevent that you do not see the status of these small jobs, the operator panel can show

the following images.

Note: When you set the zoom control (5) to a shorter time-scale, in most cases the

operator panel will display bars for these small jobs.

38 Chapter 4 Working with the operator panel

Page 40

[10]

[10] The possible display of small jobs

Image Description

[10]

[11]

[12]

3. The media toolbar

The media toolbar displays the following information for the media that is selected

in the 'Required media' pane. Furthermore, the media type toolbar contains the 'Load'

button to load and assign the required media.

Introduction to the 'Schedule' view

Green. The required media is available.

Orange. The media is required in the future, but not available

then. For example because the paper trays do not contain

sufficient sheets of the required media.

Red. The media is required now, but not available. The job

can only start when you load the required media.

39

Page 41

Introduction to the 'Schedule' view

[11]

[11] The icons in the media toolbar

Icon Description

[13]

The list of 'Required media' shows the required media for the

scheduled jobs. When the paper module indicator is

completely grey, this means that not one of the required

media is available in the paper trays.

[14]

The list of 'Required media' shows the required media for the

scheduled jobs. When a paper tray is highlighted in green, the

highlighted paper tray contains a media that is required by

one of the scheduled jobs.

[15]

The list of 'Required media' shows the required media for the

scheduled jobs. When a paper tray is highlighted in blue, the

highlighted paper tray contains the media that is also

highlighted in blue in the list of 'Required media'.

[16]

A job can require more sheets of a certain media than is

available in the paper trays. This indicator indicates the

number of extra needed sheets. If no horizontal lines are

visible, the paper trays contain enough sheets to print the job.

[17]

A job can require more sheets of a certain media than is

available in the paper trays. This indicator indicates the

number of extra needed sheets. Each horizontal line indicates

the need for about 100 sheets. Here, about 800 extra sheets

are required.

Note: The indicator also indicates the number of

sheets that is required when a media is not

available in the paper trays.

[18]

A job can require more sheets of a certain media than is

available in the paper trays. This indicator indicates the

number of extra needed sheets. Each horizontal line indicates

the need for about 100 sheets. Here, more than 1,500 extra

sheets are required.

4. The output locations pane

The output locations pane displays the output locations that are required for the

scheduled jobs. The bars show the availability of the output locations. The bars can

be the following colors.

40 Chapter 4 Working with the operator panel

Page 42

[12]

[12] The colors of the bars

Color of the bar Description

Green The output location is required and available.

Orange The output location is required in the future, but not available

Red The output location is required now, but not available. For

5. The zoom control

The zoom control enables you to adjust the time scale visible in the 'Schedule'. When

you press the zoom button, a drop-down list appears. Then you can select the desired

time scale.

Introduction to the 'Schedule' view

then. For example, because the output location will be full

soon.

example, because the output location is full.

41

Page 43

Load the media

Load the media

Introduction

This section describes how to load the media into a paper tray.

When you load the media via the 'Load' button in the 'Schedule', the paper tray is

automatically assigned to the correct media.

When you load and assign the media via the 'Assign' button in the 'Trays' view, you

must assign the paper tray to the loaded media manually.

When no external finisher is connected to the machine, you must put all the media

types face up and header up into the paper trays. The tabs of tab sheets must be at the

right-hand side. When an external finisher is connected to the machine, it is possible

that you must put the media into the paper trays in a different way. Refer to the

documentation of the external finisher for more information about how to place the

media.

When to do

■ The 'Schedule' displays a red bar next to a required media. The red bar indicates

that a scheduled job now requires a media that is not available in the paper trays.

■ The 'Schedule' displays an orange bar next to a required media. The orange bar

indicates that a scheduled job requires media which is either not available in the

paper trays or which is available, but not in sufficient quantity to finish the job.

■ The current job requires more of the same media than is currently loaded in the

paper trays. You can add more of the required media into another paper tray.

■ You already want to load and assign media that are required for the next job (work

ahead).

Attention: Always put the stack of media aligned with the left-hand side of the

paper guides inside the paper trays, as indicated on the sticker inside the paper

trays.

42 Chapter 4 Working with the operator panel

Page 44

Illustration

[19]

[19] The sticker inside the paper trays indicates how to load the media

Load the media

1. Put a small stack of media into the paper tray.

2. Press the green handle on the right-hand guide and push the guide against the edge

of the media.

3. Turn the green knob to adjust the front guide and the rear guide.

4. Put the rest of the media on top of the small stack.

Note: If you want to assign the media later you must press the 'Not assigned' button

(see ‘The paper modules’ on page 31), as indicated on the right-hand side of the

sticker.

Load the media

SR

SR

43

Page 45

Instructions for printing to the stacker/stapler (iMFS)

Instructions for printing to the stacker/stapler (iMFS)

Introduction

Note: This section only applies to the use of oriented media and tab sheets in

combination with the optional stacker/stapler (iMFS).

The machine supports oriented media. Oriented media are media of which the front

side differs from the back side. An example of oriented media is media with a

company logo. If you use oriented media and print to the optional stacker/stapler,

you must place the media into the paper trays as follows:

■ Face up and header down (for long-edge feed)

The face of the media, for example a company logo, is visible and point towards

the front of the printer.

■ Face up and header to the left (for short-edge feed).

The face of the media is visible and points towards the left-hand side of the

printer.

This orientation makes sure that the documents are stapled at the correct position.

Special instructions for the use of oriented media

When a job contains oriented media but no tab sheets, you must put this media

header down into the paper tray. The media must align with the header-down

orientation of the printed images (header down for long-edge feed and header to the

right for short-edge feed).

Special instructions for the use of tab sheets

When a job contains tab sheets, you must do the following.

■ Put all the oriented media for the job, including the tab sheets, header up and

header to the left (for short-edge feed) into the paper tray.

■ Temporarily change the default media orientation in the Settings Editor

application on the Smart Imager controller to 'Header-up'.

To do this, you must go to the setting 'Preferences' - 'Print job defaults' 'Stacker/stapler (iMFS)' or 'Stacker/stapler upper output' - 'Header orientation'.

There you can click the radio button for 'Header-up'.

Jobs that contain tab sheets are sent to the stacker/stapler when no stacker is present.

When a stacker is present, the jobs are sent to the stacker to improve the stack quality.

44 Chapter 4 Working with the operator panel

Page 46

Stop a job

Introduction

When the machine is printing a job, you can stop the machine at the following

moments.

■ Stop after a set

■ Stop after a page

■ Stop after a job.

The following table gives an overview of the stop behavior of the machine. The

procedures in this section describe how to stop the machine via the operator panel.

Note: You can also interrupt a job by ejecting a stack of sheets from the stacker.

When you press the eject button next to the stacker door 1 time, the stacker ejects the

stack when a set is ready. When you press the eject button 2 times, the stacker ejects

the stack as soon as possible.

Stop a job

45

Page 47

Stop a job

The stop behavior of the machine

[13]

[13] When does the machine stop

When Then

You press the Hold key 1 time The machine stops when a set of the

You press the Hold key 2 times The machine stops as soon as possible

active print job is ready. It depends

on the set size and the moment you press

the key, when the machine will stop. For

example, when you have a large set of

1,000 pages and you press the key after

the first page, the printing will continue

for a couple of minutes.

(after a page, in most cases within 30

seconds).

You press the 'Stop after job' button in

the toolbar of the 'Jobs' view

The 'Check first set' setting in a

'Workflow profile' is 'On'(see ‘Work

with the workflow profiles’ on page 104)

and this setting is also enabled in the job

The 'Confirm start of job' setting in a

'Workflow profile' is 'On'

Note: When you print streaming jobs or jobs that consist of 1 large set, you must

always press the Hold key 2 times to stop the machine as soon as possible.

Stop after a set

Press the Hold key 1 time.

The red LED of the Hold key starts to blink.

The machine stops when a set of the active print job is ready.

The machine stops when the selected

job is ready.

The 'Jobs' view displays a horizontal red

and white stop bar below the selected

job.

The 'Schedule' view displays a vertical

stop bar behind the selected job.

The machine stops each time the first set

of a print job is ready. You can check the

first set before you continue the print

job.

The machine stops each time at the start

of a job. You must start each job

manually.

46 Chapter 4 Working with the operator panel

Page 48

Stop after a page

Press the Hold key 2 times.

The red LED of the Hold key starts to blink.

The machine stops as soon as possible.

Note: The memory of the machine can contain up to 50 pages. Therefore, it is

possible for the machine to print more than a set before the machine stops.

Stop after a job

1. In the list of 'Scheduled jobs' in the 'Jobs' view, press the job after which the machine

must stop.

2. Press 'Stop after job'.

The machine stops as soon as the selected job has been printed. A red and white stop

bar indicates that the stop-after-job function is active. Press 'Stop after job' again to

[20]

remove the stop bar and continue printing.

Stop a job

[20] Stop after job

Stop a streaming job or transaction stream

Press the Hold key 1 time.

The red LED of the Hold key starts to blink.

The printer will continue to print the pages that are already in the buffer. When the

buffer is empty, the printer stops.

47

Page 49

Introduction to the 'Jobs' view

The Jobs view

Introduction to the 'Jobs' view

Introduction

The 'Jobs' view enables you to manage the print jobs on the machine locally. This

section describes the items of the 'Jobs' view.

Illustration

[21]

[21] The 'Jobs' view

48 Chapter 4 Working with the operator panel

Page 50

The items of the 'Jobs' view

[14]

[14] Description of the 'Jobs' view (1 – 3)

Number Item Function

1 'Waiting jobs' Display the jobs that are not yet scheduled for

2 'Scheduled jobs' Display the active print job and the jobs that are

3 'Printed jobs' Display the jobs that were printed successfully.

4 'Properties' button Check or change the properties of a job. The

5 'To top' button Give priority to a scheduled job. The job is

Introduction to the 'Jobs' view

printing.

scheduled for printing.

The system only moves the printed jobs to the

list of 'Printed jobs' when the setting 'Job history'

in the Settings Editor is enabled.

button is only enabled when you select 1 job.

Note: You can also press a job 2

times to check or change the

properties of that job.

printed when the active print job is ready (see

‘Give priority to a scheduled job’ on page 56).

The button is only enabled when you select 1

job.

6 'Stop after job'

button

Stop the machine after a selected job (see ‘Stop

a job’ on page 45). The button is only enabled

when you select 1 job.

7 'Delete' button Delete the selected job(s) (see ‘Delete a job’ on

page 57). The button is enabled when you select

1 or more jobs.

49

Page 51

Introduction to the 'Jobs' view

[14] Description of the 'Jobs' view (2 – 3)

Number Item Function

8 'Move' or 'Copy'

button

■ 'Move'

Move a job from the list of 'Waiting jobs' to

the list of 'Scheduled jobs'(see ‘Schedule a

waiting job for printing’ on page 52), or the

other way round (see ‘Print a scheduled job

later’ on page 59).The 'Move' button is only

active when you work with jobs in the list of

'Scheduled jobs' or 'Waiting jobs'.

■ 'Copy'

Send a copy of a job that has been printed

before to the list of 'Waiting jobs' to reprint

the job (see ‘Reprint a job’ on page 54). The

'Copy' button is only active when you work

with jobs in the list of 'Printed jobs'.

The button is enabled when you select 1 or

more jobs.

9 'Proof' button Print 1 copy of a job to check whether the result

of the print job meets your expectation (see

‘Make a proof’ on page 61). The button is only

enabled when you select 1 job.

Note: The proof print is not

subtracted from the number of sets

you defined for this job.

10 'Ticket' button Print an overview of the main job settings and

job parameters (see ‘Print the job parameters’

on page 63). The button is only enabled when

you select 1 job.

50 Chapter 4 Working with the operator panel

Page 52

Introduction to the 'Jobs' view

[14] Description of the 'Jobs' view (3 – 3)

Number Item Function

11 'Bundle' or 'Split'

button

Combine a number of jobs into 1 job, for

example to create a set of documents that are

required for a meeting (see Bundle and split jobs

on page 64).

12 'Select' button Select a number of jobs at the same time. You

can use one of the following:

■ Use 'All' to select all the jobs in the list.

■ Use 'None' to deselect all the jobs in the list.

■ Use 'Invert selection' to turn the selected jobs

into deselected jobs, and the other way

round.

■ Use 'Jobs with available media' to select all

the jobs for which the media are currently

available in the paper trays (see Print all the

jobs for which the media are available on

page 68).

■ Use 'Jobs with label' to select all the jobs with

a certain label (see Print the jobs that have a

label on page 69).

Note: The active print job is only

selected when the machine is on hold.

Note: Whether a button is enabled depends on the number of selected jobs, the state

of the jobs and the list that is active. Not all of the above settings are available for

streaming jobs .

51

Page 53

Schedule a waiting job for printing

Schedule a waiting job for printing

Introduction

When a job is sent to the machine (from a printer driver, a software application or a

scanner), the job arrives in the list of 'Waiting jobs' or 'Scheduled jobs'. You can set

the preferred destination in the workflow profiles on the operator panel (see ‘Work

with the workflow profiles’ on page 104).

When you choose to send the jobs to the list of 'Waiting jobs' to have full control over

the order in which the jobs will be printed, you must manually move the jobs to the

list of 'Scheduled jobs' to print the jobs. However, you can use the options of the

'Select' button to send a number of jobs directly to the list of 'Scheduled jobs'.

This section describes how to schedule a waiting job for printing.

Illustration

[22]

[22] Schedule a waiting job for printing

Schedule a waiting job for printing

1. On the operator panel, press the 'Jobs' button.

2. In the list of 'Waiting jobs', press the job you want to print.

52 Chapter 4 Working with the operator panel

Page 54

Schedule a waiting job for printing

Note: You can use the options of the 'Select' button to select a number of waiting

jobs at once. You can also press a number of jobs one by one. To undo the multiple

selection and only select 1 job, you must press the desired job for 2 seconds. Then

only the desired job is selected.

3. Press 'Move'.

The selected job is moved to the bottom of the list of 'Scheduled jobs'.

53

Page 55

Reprint a job

Reprint a job

Introduction

When the machine has successfully printed a job, the system can move the job to the

list of 'Printed jobs'. This list can temporarily store the printed jobs. The list of

'Printed jobs' is not an archive. It is intended to enable you to reprint a job quicker

and easier. Each printed job of day X remains in the list of 'Printed jobs' for 24 hours.

Then the jobs of day X are automatically removed from the system on 00.00 hours

of day X + 1.

When you reprint a job from the list of 'Printed jobs', the job is not moved. The

original job remains in the list of 'Printed jobs'. The system only sends a copy of the

job to the list of 'Waiting jobs'. You cannot send a job directly to the list of 'Scheduled

jobs'. If you no longer need a job, you can delete the job from the list of 'Printed jobs'.

This section describes how to reprint a job.

Note: The system only moves the printed jobs to the list of 'Printed jobs' when the

setting 'Job history' in the Settings Editor is enabled.

Illustration

[23]

[23] Reprint a job

54 Chapter 4 Working with the operator panel

Page 56

Reprint a job

1. Press the 'Jobs' button on the operator panel.

2. In the list of 'Printed jobs', press the job you want to reprint.

3. Press 'Copy'.

The system sends a copy of the job to the list of 'Waiting jobs'.

4. Press the job in the list of 'Waiting jobs'.

5. Press 'Properties' to change the settings, for example the number of prints.

6. Press 'Move'.

The job is moved to the bottom of the list of 'Scheduled jobs'.

Reprint a job

55

Page 57

Give priority to a scheduled job

Give priority to a scheduled job

Introduction

The list of 'Scheduled jobs' contains the jobs that are scheduled for printing. The

machine prints the jobs in the order in which the jobs arrive in the list of 'Scheduled

jobs'. However, you can give priority to an urgent job in the list. Then that job is

printed as soon as the active print job is ready.

This section describes how to give priority to a scheduled job.

Illustration

[24]

[24] Move a job to top

Give priority to a scheduled job

1. On the operator panel, press the 'Jobs' button.

2. In the list of 'Scheduled jobs', press the job to which you want to give priority.

3. Press 'To top'.

The job is moved to the position below the active print job .

56 Chapter 4 Working with the operator panel

Page 58

Delete a job

Introduction

You can delete 1 or more jobs at a time from each list in the 'Jobs' view. When you

delete a job, the job is removed from the system.

This section describes how to delete a job.

Note: You can only delete the active print job when the machine is on hold (see

‘Stop a job’ on page 45).

Illustration

[25]

Delete a job

[25] Delete a job

Delete a job

1. On the operator panel, press the 'Jobs' button.

2. In one of the lists in the 'Jobs' view, press the job you want to delete.

Note: You can use the options of the 'Select' button to select a number of jobs at

once. You can also press a number of jobs one by one. To undo the multiple selection

57

Page 59

Delete a job

3. Press 'Delete'.

4. Press 'Yes' to remove the selected job from the list and from the system.

and only select 1 job, you must press the desired job for 2 seconds. Then only the

desired job is selected.

A dialog box will ask you to confirm that you really want to delete the selected job.

58 Chapter 4 Working with the operator panel

Page 60

Print a scheduled job later

Introduction

When a job is scheduled for printing, the job is present in the list of 'Scheduled jobs'.

However, for various reasons you can choose to print a job later. For example

because the required media are not available or because you first want to make a

proof (see ‘Make a proof’ on page 61).

This section describes how to print a scheduled job later.

Illustration

[26]

Print a scheduled job later

[26] Print a scheduled job later

Print a scheduled job later

1. On the operator panel, press the 'Jobs' button.

2. In the list of 'Scheduled jobs', press the job you want to print later.

Note: From the drop-down list of the 'Select' button, you can also select 'All', 'Jobs

with available media' or 'Jobs with label' to select more jobs at once, except the

active print job . To move the active print job , you must first press the Hold key

. You can also press a number of jobs one by one. To undo the multiple selection

and only select 1 job, you must press the desired job for 2 seconds. Then only the

desired job is selected.

59

Page 61

Print a scheduled job later

3. Press 'Move'.

The job is moved to the bottom of the list of 'Waiting jobs'.

60 Chapter 4 Working with the operator panel

Page 62

Make a proof

Introduction

You can make a proof to check whether the quality and the layout of the output meet

your expectations. When you use the 'Proof' function, the machine prints 1 copy of

the job. You can only make a proof for a job in the list of 'Waiting jobs'.

This section describes how to make a proof.

Note: When you make a proof, the printed set is not subtracted from the defined total

number of sets for a job. For example, when you need 10 sets, the printer will still

print 10 sets after you made the proof. This is different from the checking of the first

set (see ‘Check the first set’ on page 85).

Illustration

[27]

Make a proof

[27] Print a proof

Make a proof

1. Press the 'Jobs' button on the operator panel.

2. In the list of 'Waiting jobs', press the job of which you want to make a proof.

61

Page 63

Make a proof

Note: You can select more than 1 job at a time.

3. Press 'Proof'.

A copy of the job goes to the bottom of the list of 'Scheduled jobs'.

The original job remains in the list of 'Waiting jobs'.

You can recognize a proof by the magnifying glass on the job icon .

62 Chapter 4 Working with the operator panel

Page 64

Print the job parameters

Introduction

You can print an overview of the job settings and the job parameters (the so-called

job ticket) before you print a job. The overview can show you for example which

media the job requires.

This section describes how to print the overview of the job parameters.

Illustration

[28]

Print the job parameters

[28] Print the job parameters

Print the job parameters

1. Press the 'Jobs' button on the operator panel.

2. Press the job for which you want to print the job parameters.

You can only select 1 job at a time.

3. Press 'Ticket'.

The job is sent to the bottom of the list of 'Scheduled jobs'. The job may not be

immediately visible in the list of 'Scheduled jobs'.

You can recognize the job by the prefix @_ in front of the job name.

The printed job ticket is sent to the system output (see ‘The output locations’ on

page 28).

63

Page 65

Bundle and split jobs

Bundle and split jobs

Introduction

Create a bundled job

If you want to combine 2 or more documents into 1 set, for example to prepare a

meeting, you can bundle jobs that are present in the list of 'Waiting jobs'. The original

jobs are removed from the list. The bundled job appears at the bottom of the list of

'Waiting jobs'. The system automatically creates a name for the bundled job that is

based on the name of the first job in the bundle.

The number of copies for the bundled job is initially set to 1. You can handle the

bundled job like any other job. For example, you can move the job to the list of

'Scheduled jobs', edit the job, delete the job or make a proof.

Edit a bundled job

You can define the following properties for a bundled job.

■ The order of the jobs in the bundle

■ The number of sets

■ Whether you want to check the first set of the bundled job.

Note: This section describes the above in separate procedures. However, you can

always access the 'Properties' window and change 1 or more properties at the same

time. You cannot change the properties of the individual jobs in the bundle. To do

this, you must first split the bundled job. Then you can change the properties of each

job.

Split a bundled job

In the list of 'Waiting jobs', you can split a bundled job into the original jobs. The

system removes the bundled job. The individual jobs are added at the end of the list

of 'Waiting jobs'.

This section describes how to create, edit and split a bundled job.

General information

■ When you print a bundled job, the machine prints the number of copies that you

indicated for the bundled job. The number of copies of the original jobs is

ignored.

■ When you stop a job after a set (see Stop a job on page 45), the printing stops

after 1 copy of the complete bundle.

■ The jobs in a bundle are accounted separately under the account ID of the original

jobs.

■ You cannot combine a bundled job with another bundled job.

64 Chapter 4 Working with the operator panel

Page 66

Note: All the jobs in the bundle must have the same output destination. Otherwise,

the operator panel displays a warning message. To continue, you must first split the

job, then change the individual jobs and finally bundle the jobs again.

Illustration

[29]

Bundle and split jobs

[29] Create a bundled job

Create a bundled job

1. From the list of 'Waiting jobs', select the jobs you want to bundle.

You can select the jobs one by one, or use one of the options of the 'Select' button.

2. Press 'Bundle'.

The operator panel displays an overview of the bundled job.

3. If required, use the keys 'Up' and 'Down' in the 'Job order' field to change the order

of the jobs.

4. Press 'OK' to accept the job.

65

Page 67

Bundle and split jobs

Illustration

[30]

[30] Edit a bundled job

Change the order of the jobs in a bundled job

1. Select the bundled job.

2. Press 'Properties'.

3. In the 'Job order' field, select the job you want to move.

4. Use the keys 'Up' and 'Down' to move the job to the required position.

5. Press 'OK'.

Change the number of sets for a bundled job

1. Select the bundled job.

2. Press 'Properties'.

3. Press the 'Number of sets' button.

A numerical keyboard appears.

4. Use the numerical buttons to enter the desired number of sets.

Note: Press the arrow button <- to correct the previous entry or press 'Cancel' to

close the numerical keyboard without saving the changes.

5. Press 'OK'.

The numerical keyboard disappears.

6. Press 'OK'.

66 Chapter 4 Working with the operator panel

Page 68

Check the first set of a bundled job

1. Select the bundled job.

2. Press 'Properties'.

3. Press 'Check first set' when the button states 'Off'.

The text changes from 'Off' to 'On'. A check mark indicates that the checking of the

first set is enabled. The machine will automatically go on hold after the first set was

printed.

4. Press 'OK'.

Split a bundled job

1. Select a bundled job in the list of 'Waiting jobs'.

2. Press 'Split'.

The system adds the original jobs to the end of the list of 'Waiting jobs'.

Bundle and split jobs

67

Page 69

Print all the jobs for which the media are available

Print all the jobs for which the media are available

Introduction

You can select and print the jobs for which the media are currently available in the

paper trays all at once. This improves the productivity because a regular change of

media types is not required. This section describes how to select the jobs for which

the media are present in the paper trays.

Illustration

[31]

[31] Select the jobs for which the media are available

Print the jobs for which the media are available

1. On the operator panel, press the 'Jobs' button.

2. Press the 'Select' button.

3. Press 'Jobs with available media'.

The system selects and highlights the jobs for which the required media are available

in the paper trays.

4. Press 'Move'.

The selected jobs are moved to the bottom of the list of 'Scheduled jobs'.

68 Chapter 4 Working with the operator panel

Page 70

Print the jobs that have a label

Introduction

A label is a name or tag that helps the operator to identify certain jobs on the operator

panel. When a job is sent to the machine, a label can be added to that job. The label

can be any name that helps to identify certain jobs. A label is not connected to job

settings.

The label can be defined in the printer driver, in a job ticket or via an automated

workflow. For example, the label ‘Customer X’ can be added to jobs. Then the

operator can select and print all the jobs for 'Customer X' at once. The operator can

select jobs with a label in the list of 'Waiting jobs' or in the list of 'Scheduled jobs'.

This section describes how to select and print jobs with a certain label.

Note: Automated workflows can be defined through the Settings Editor. You can find

more information in the online help of the Settings Editor.

Illustration

[32]

Print the jobs that have a label

[32] Print the jobs with a label

69

Page 71

Print the jobs that have a label

Print the jobs with a label

1. On the operator panel, press the 'Jobs' button.

2. Press 'Select'.

A drop-down list appears.

3. Press 'Jobs with label'.

A pop-up window with an overview of the available labels appears.

4. Press the desired label.

Note: You can select more than 1 label.

5. Press 'OK'.

The pop-up window disappears.

6. Press 'Move'.

The selected jobs are moved to the bottom of the list of 'Scheduled jobs'.

70 Chapter 4 Working with the operator panel

Page 72

Change the media

Checking and changing the job properties

Change the media

Introduction

When a job is sent to the machine, the desired media will usually be indicated in the

job ticket. However, you can replace the indicated media by another media from the

media catalogue with the same size.

This section describes how to change the media for a specific job. The following 3

illustrations give an impression of the screens you will see when you change a media

in the 'Properties' window.

Illustration

[33]

[33] Select the media to replace

71

Page 73

Change the media

[34]

[34] Select another media

[35]

[35] The media is changed

72 Chapter 4 Working with the operator panel

Page 74

Change the media

1. On the operator panel, press the 'Jobs' button.

2. In the list of 'Waiting jobs' or 'Scheduled jobs', press the job you want to edit.

Note: You cannot select the active print job.

3. Press 'Properties'.

Note: You can also press the job 2 times to access the 'Properties' window. This

function is comparable to double-clicking with a mouse.

4. Press the 'Media' tab.

5. Press the icon of the media you want to change (see figure 33 on page 71).

When the Media catalogue contains media with the same size, the operator panel

will display a list of these media (see figure 34 on page 72).

6. Press the new media you want to use.

7. Press 'OK'.

The new media is assigned to the job (see figure 35 on page 72).

8. Press 'OK'.

Change the media

73

Page 75

Change the number of sets

Change the number of sets

Introduction

When a job is sent to the machine, the desired number of sets will be indicated.

However, you can change the number of sets on the operator panel.

This section describes how to change the number of sets for a specific job.

Note: You can enter any value between 1 and 65,000 for all jobs except the active

print job . To change the number of sets for the active print job , you must first

press the Hold key 1 time. Then you can change the number of sets. You cannot

define a lower value than the number of sets that has already been printed.

Illustration

[36]

[36] Change the number of sets

Change the number of sets

1. Press the 'Jobs' button on the operator panel.

2. In the list of 'Waiting jobs' or 'Scheduled jobs', press the job you want to edit.

3. Press 'Properties'.

74 Chapter 4 Working with the operator panel

Page 76

Change the number of sets

Note: You can also press the job 2 times to access the 'Properties' window. This

function is comparable to double-clicking with a mouse.

4. Press the 'Number of sets' button.

A numerical keyboard appears.

5. Use the numerical buttons to enter the desired number of sets.

Note: Press the arrow button <- to correct the previous entry or press 'Cancel' to

close the numerical keyboard without saving the changes.

6. Press 'OK'.

The numerical keyboard disappears.

7. Press 'OK'.

75

Page 77

Change the output location

Change the output location

Introduction

In the Settings Editor, you can set the default output location for print jobs. However,

you can change the output location on the operator panel for each job individually.

Depending on the configuration of your system, you can select one of the following

output locations.

■ 'Finisher upper output'

■ 'Finisher'

■ 'Stacker' or, if you have more than 1 stacker, 'Left-hand stacker', 'Middle stacker'

or 'Right-hand stacker'.

■ 'Stacker/stapler'

■ 'Stacker/stapler upper output'

■ 'External finisher'.

This section describes how to select another output location for a specific job.

Note: There must be a match between the selected output location and the job

requirements. For example, when a job does not require staples, you can select any

output location. If a job requires 1 or 2 staples, you can only select the output

locations that can staple the jobs, for example 'Finisher' or 'External finisher'

because the 'Stacker' cannot staple the jobs. If you make a combination that is not

possible, the operator panel displays an error message.

76 Chapter 4 Working with the operator panel

Page 78

Illustration

[37]

Change the output location

[37] Change the output location

Change the output location

1. On the operator panel, press the 'Jobs' button.

2. In the list of 'Waiting jobs' or 'Scheduled jobs', press the job you want to edit.

3. Press 'Properties'.

Note: You can also press the job 2 times to access the 'Properties' window. This

function is comparable to double-clicking with a mouse.

4. Press 'Finishing'.

The 'Output location' button shows the currently selected output location.

5. Press the 'Output location' button.

A drop-down list with the available output locations appears.

6. Press the desired output location.

7. Press 'OK'.

77

Page 79

Change the number of staples

Change the number of staples

Introduction

When a job is sent to the machine, a desired number of staples for that job can be

indicated. However, you can change the number of staples on the operator panel.