Konica QMS 4060 Service manual

4060 Service and Parts Manual

1750040-001A

CHAPTER 1 GENERAL INFORMATION

General Information

SERVICE MANUAL

Chapter 1 contents include

Section

1-1 Introduction...................................................................................................... 1-3

1-2 Printer Specifications....................................................................................... 1-4

1-2.1 Printer General Specifications ...................................................... 1-4

1-2.2 Printer Print Speed Specifications ................................................ 1-5

1-2.3 Printer Physical Specifications ..................................................... 1-6

1-2.4 Printer Electrical Specifications.................................................... 1-6

1-2.5 Environmental Specifications For All Equipment........................ 1-8

1-3 Summary of Printer Optional Features and Feature Specifications................. 1-9

1-4 Large-Capacity Hopper (LCH) ........................................................................ 1-9

1-4.1 LCH Overview.............................................................................. 1-9

1-4.2 LCH Paper Handling Specifications............................................. 1-10

1-4.3 LCH Physical Specifications ........................................................ 1-11

1-4.4 LCH Electrical Specifications....................................................... 1-12

1-4.5 LCH Environmental Specifications .............................................. 1-12

1-5 Large-Capacity Stacker (LCS)......................................................................... 1-12

1-5.1 LCS Overview .............................................................................. 1-12

1-5.2 LCS Paper Handling Specifications.............................................. 1-13

1-5.3 LCS Physical Specifications ......................................................... 1-14

1-5.4 LCS Electrical Specifications ....................................................... 1-14

1-5.5 LCS Environmental Specifications............................................... 1-14

1-6 Printer Custom Paper Tray............................................................................... 1-15

1-7 Printer Consumable Specifications.................................................................. 1-15

1-8 Best Printing Area Specifications .................................................................... 1-17

1-9 System Configuration Component Locations and Descriptions...................... 1-20

1-9.1 Front and Right Side of the Printer ............................................... 1-20

1-9.2 Behind the Front Door .................................................................. 1-22

1-9.3 Behind the Upper Right Cover ..................................................... 1-24

1-9.4 Behind the Lower Right Cover ..................................................... 1-25

1-9.5 Rear and Left Side of the Printer .................................................. 1-26

1-9.6 Rear-Inside of the Printer.............................................................. 1-28

1-9.7 Large-Capacity Hopper (LCH) Accessory ................................... 1-30

1-9.8 Large-Capacity Stacker (LCS) Accessory .................................... 1-31

1-10 Printer Component Block Diagram ................................................................. 1-32

1-11 Safety and Regulatory Information.................................................................. 1-36

1-12 Servicing Approach ......................................................................................... 1-36

:

1-1

General Information

SERVICE MANUAL

NOTE

This page intentionally left blank.

-2

General Information

SERVICE MANUAL

1-1. Introduction

This chapter provides specifications, safety compliance, options, available supplies, printing paper

and design, system configuration, related manuals, and servicing approach for the 4060 cut sheet

printer and supporting optional Large-Capacity Hopper (LCH) and Large-Capacity Stacker (LCS)

paper handlers.

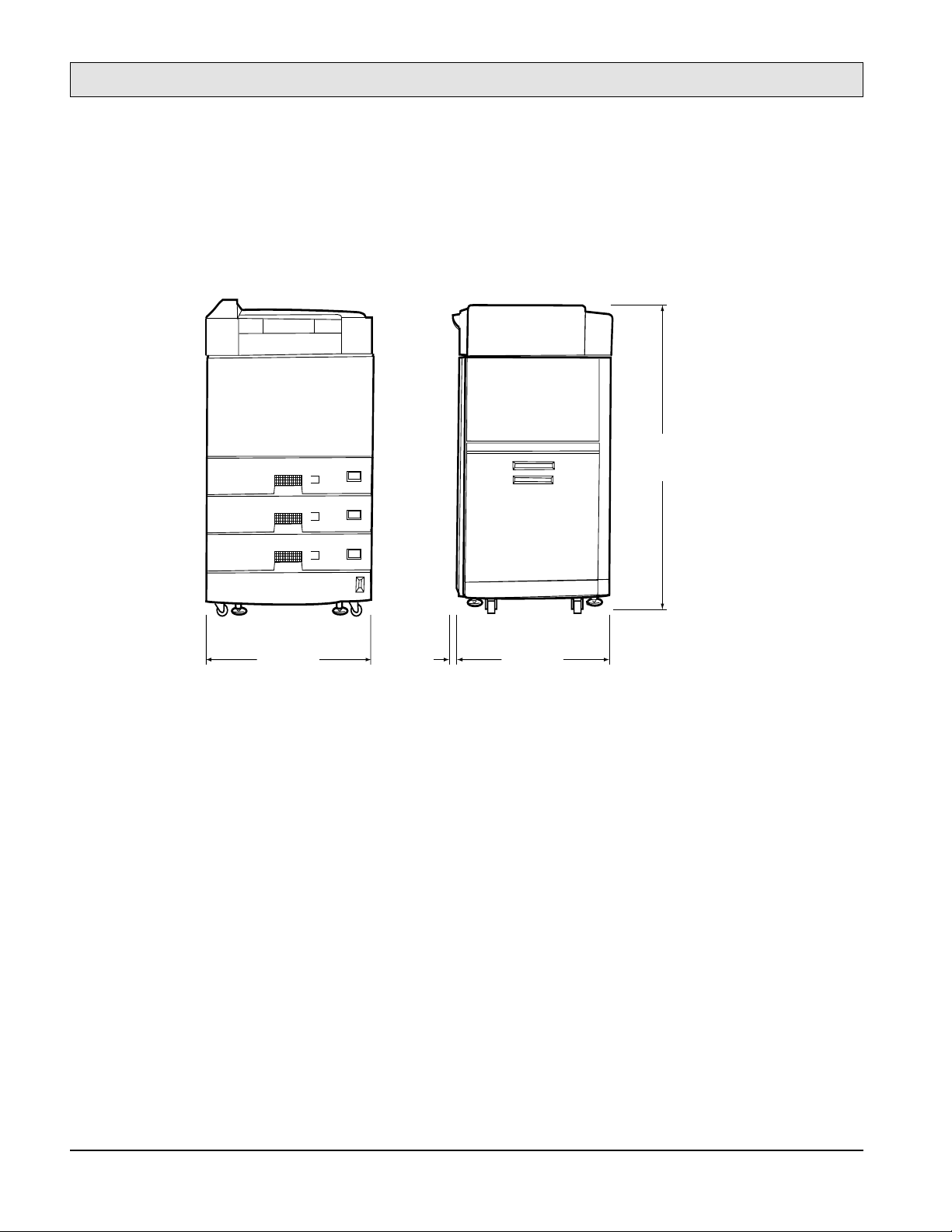

The 4060 non-impact printer combines semiconductor laser optical technology and twocomponent dry development process technology to print on cut-sheet plain paper. Figure 1-1

illustrates an installed printer and the external large capacity paper handling options.

LTR

LTR

LTR

LCS M3894SA LCH

Figure 1-1. 4060 Printer With Optional LCH and LCS Paper Handlers

1-3

General Information

SERVICE MANUAL

1-2. Printer Specifications

This section provides general, print speed, physical, electrical, environmental specifications as

well as safety standards applicable to all equipment and an illustration of the printer laser

equipment warning label.

1-2.1. Printer General Specifications

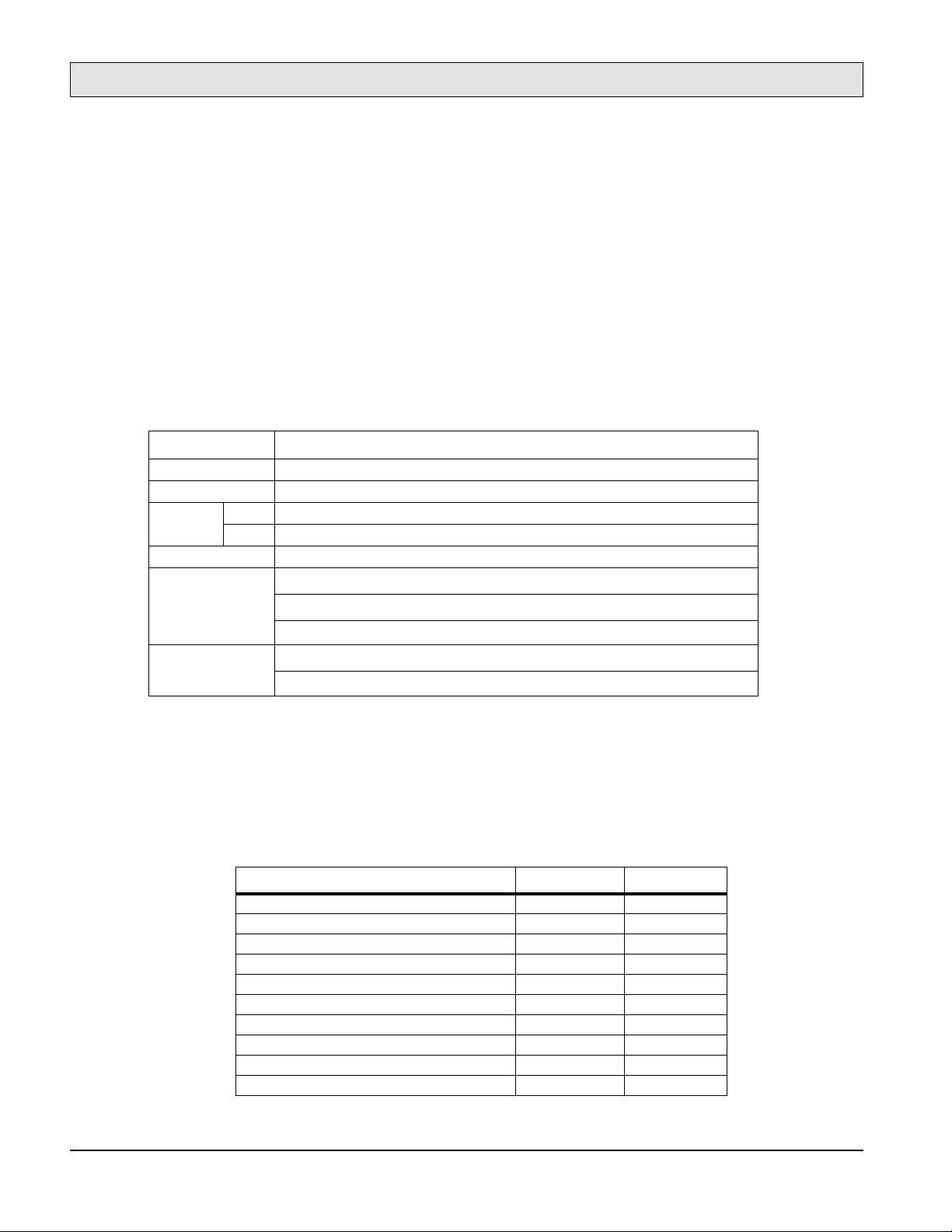

Table 1-1 lists general specifications for the 4060 printer.

Table 1-1. 4060 Printer General Specifications

Item Specifications

Printing technology Laser diode, Electro-photography

Printing speed 40 ppm (Letter and A4 landscape)

Paper Size Letter, Legal, Ledger. Executive, A3, A4, A5, B4 (JIS), B5 (JIS)

Type Plain Paper, Label paper, Recycle paper, Transparency paper, Bond paper, Pre-punched paper

Resolution 600 × 600 dpi

Paper capacity

Stacker capacity

3 trays × 500 sheets (64 g/m2) standard

•

1 tray × 500 sheets (64 g/m2) optional custom tray

•

3,000 sheets (A4, Letter size only) optional Large-Capacity Hopper (LCH)

•

500 sheets (64 g/m2) face down tray

•

2,000 sheets optional Large-Capacity Stacker (LCS)

•

1-2.2. Printer Print Speed Specifications

Table 1-2 lists the specifications for the 4060 printer print speeds.

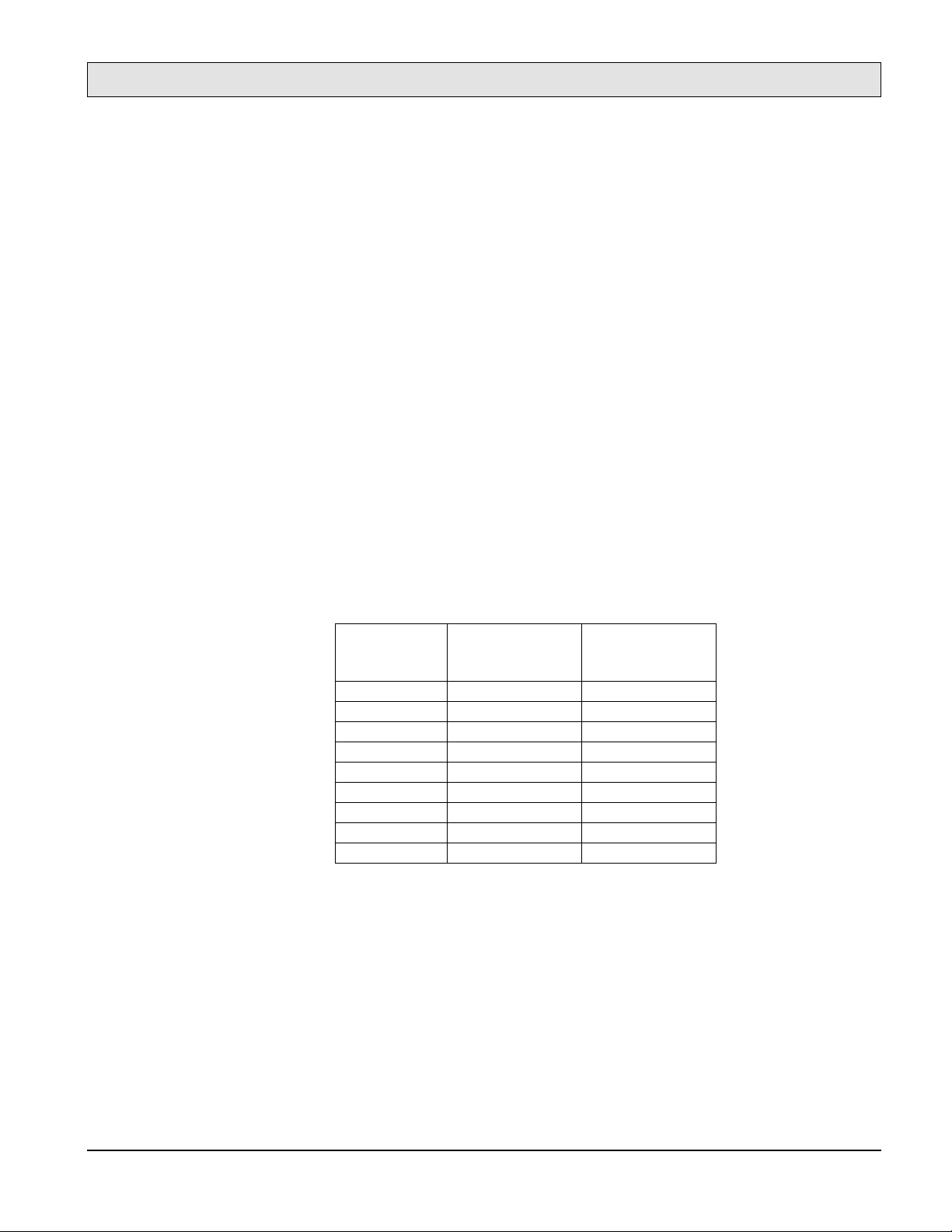

Table 1-2. 4060 Printer Print Speed Specifications

Paper Size (direction) Simplex *2 Duplex *2

Letter (landscape) 40 40

Legal (portrait) 25 25

Ledger (portrait) 21 15

Executive (portrait) 40 40

A3 (portrait) 21 15

A4 (landscape) 40 40

A5 (portrait) 40 40

B4 (JIS) (portrait) 24 24

B5 (JIS) (portrait) 30 30

B4 (ISO) (portrait) *1 21 15

-4

B5 (ISO) (portrait) *1 40 40

Custom (paper width = 120mm to 297mm,

paper length = 182mm to 215.9mm) *1

Custom (paper width = 120mm to 297mm,

paper length = 215.9mm to 431.8mm) *1

Notes

:

*1: Can be fed from optional custom paper tray only.

*2: Unit of measure: Images Per Minute (IPM). All the speeds have ±5% tolerance.

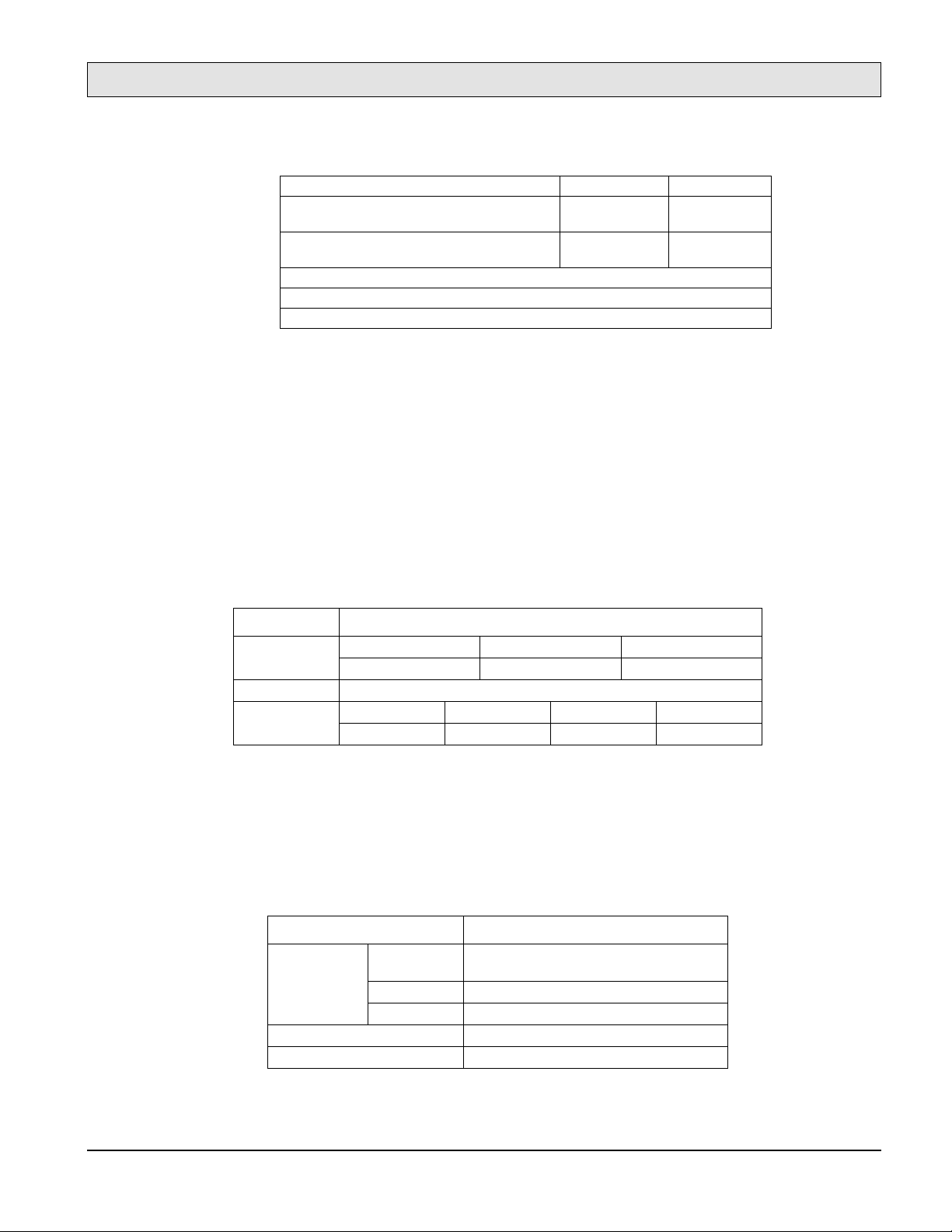

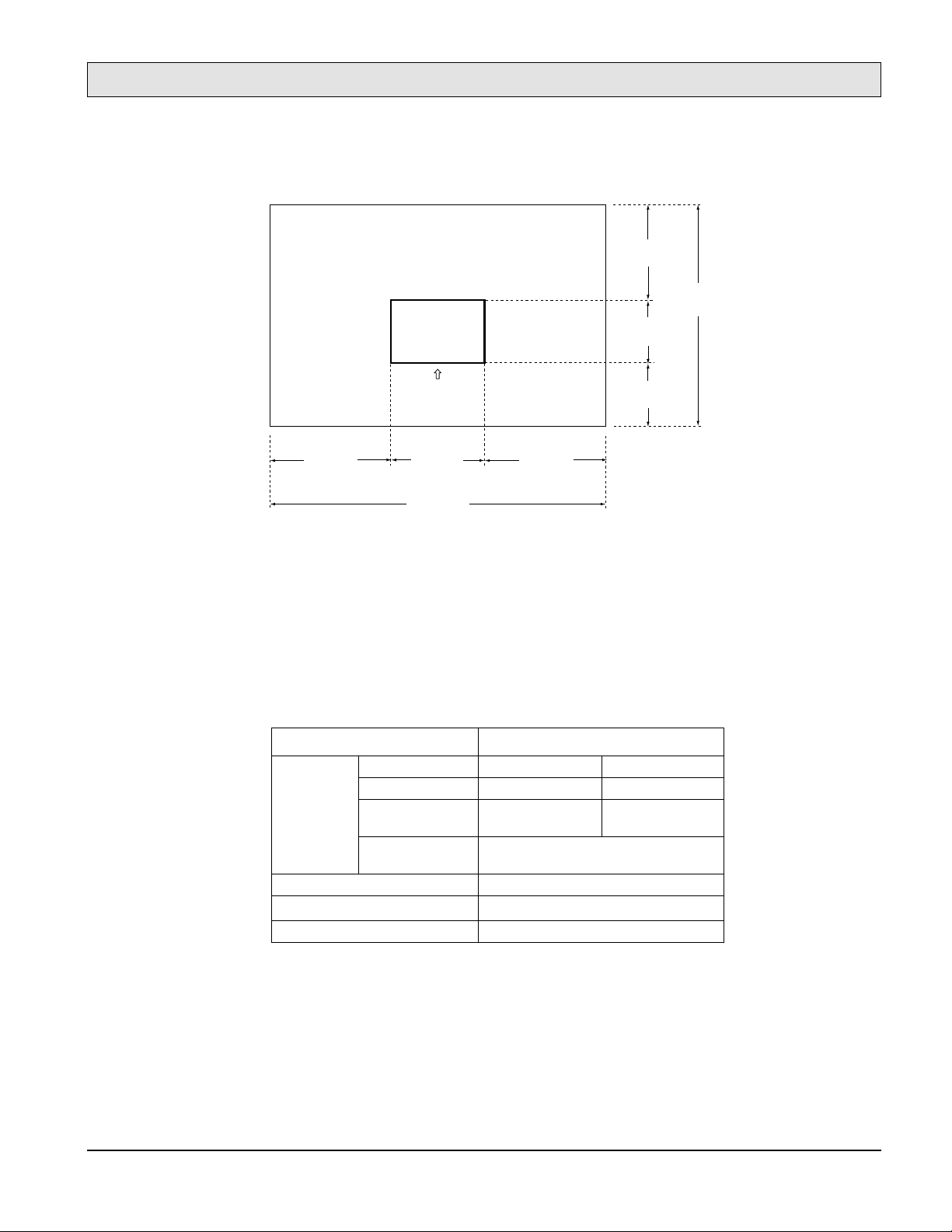

1-2.3. Printer Physical Specifications

Table 1-3 lists the printer physical specifications.

General Information

SERVICE MANUAL

24 24

34 34

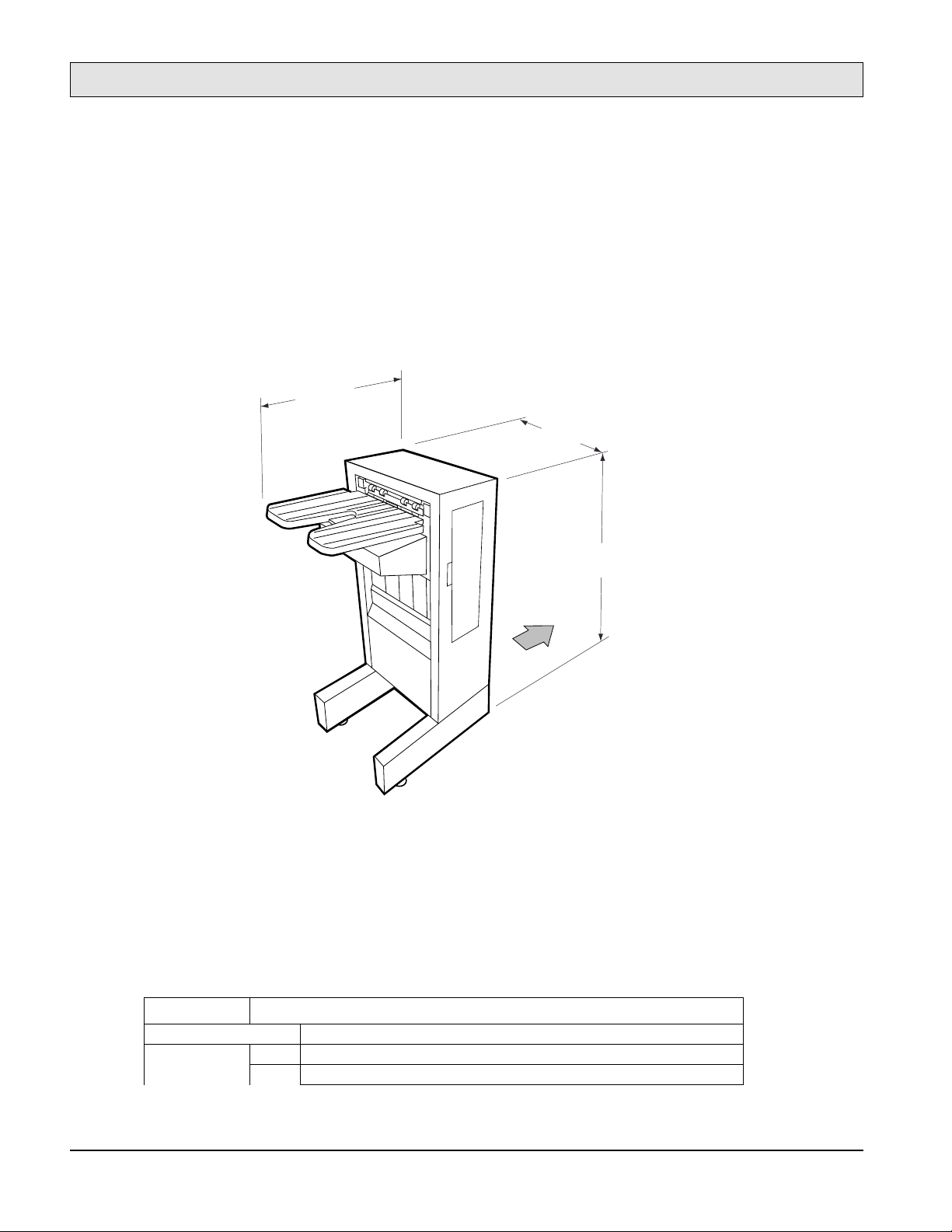

Figure 1-2 illustrates the physical specifications and Figure 1-3 illustrates the required printer

service area dimensions.

Table 1-3. 4060 Printer Physical Specifications

Item Specification

Dimensions Width Depth Height

585 mm (23.0 in) 640 mm (25.2 in) 1,030 mm (40.6 in)

Weight Approximately 135 kg

Service area Front Back Left Right

650 mm (25.6 in) 850 mm (33.5 in) 850 mm (33.5 in) 850 mm (33.5 in)

1-2.4. Printer Electrical Specifications

Table 1-4 lists the printer electrical specifications.

Table 1-4. 4060 Printer Electrical Specifications

Item Specifications

Input power Voltage 120 to 127 VAC ± 10%, 12A

200 to 240 VAC ± 10% 7A

Phase Single-phase

Frequency 50/60Hz ±5%

Power consumption 1,300 VA or less than during operating

Heat capacity 894 kcal per hour

1-5

General Information

SERVICE MANUAL

40.5 in.

LTR

(1030 mm)

LTR

LTR

23.0 in.

(585 mm)

1.38 in

(35 mm)

25.2 in.

(640 mm)

Figure 1-2. 4060 Printer Physical Dimensions

-6

Printer

General Information

SERVICE MANUAL

33.5 in.

(850 mm)

84.3 in.

(2140 mm)

25.2 in.

(640 mm)

25.6 in.

(650 mm)

33.5 in.

(850 mm)

Operating

Side

23.0 in.

(585 mm)

90.0 in.

(2285 mm)

33.5 in.

(850 mm)

Figure 1-3. 4060 Printer Required Service Area Dimensions

1-2.5. Environmental Specifications For All Equipment

Table 1-5 lists environmental specifications applicable to the printer, LCH, and LCS units.

Table 1-5. 4060 Printer, LCH Option, and LCS Option Environmental Specifications

Item Specification

Ambient

Condition

Acoustic noise 55 dBA or less (printer only)

Dust

Ozone emission 0.1 PPM or less

Device condition Operating Non-operating

Temperature 10 to 35 °C 0 to 35 °C

Humidity 20 to 80% RH

(no condensation)

Temperature and

humidity gradients

15 °C per hour or less and 30% RH per day or

less (no condensation)

0.15 mg./m

3

(stearic acid)

20 to 80% RH

(no condensation)

1-3. Summary of Printer Optional Features and Feature Specifications

Table 1-6 lists the options available with the 4060 printer along with their associated

specifications.

1-7

General Information

SERVICE MANUAL

Table 1-6. 4060 Printer Available Options and Specifications Summary

Item Specification Model Number

Large-Capacity Hopper

(LCH)

Large-Capacity Stacker

(LCS)

Custom paper tray

3,000 sheets (75 g/m

2,000 sheets (75 g/m

500 sheets (75 g/m

2

)

2

)

2

)

4060 (Letter)

4060 (A4)

4060 (120 VAC)

4060 (240 VAC)

-8

1-4. Large-Capacity Hopper (LCH)

1-4.1. LCH Overview

General Information

SERVICE MANUAL

Models

4060

and

4060

are the user-installable optional Large-Capacity Hoppers (LCH) units for

the 4060 printer, connecting to the right side of the printer. The

only, and the

4060

can feed A4 size paper. Both LCHs can be installed up to 3000 sheets of paper

(75g/m2).

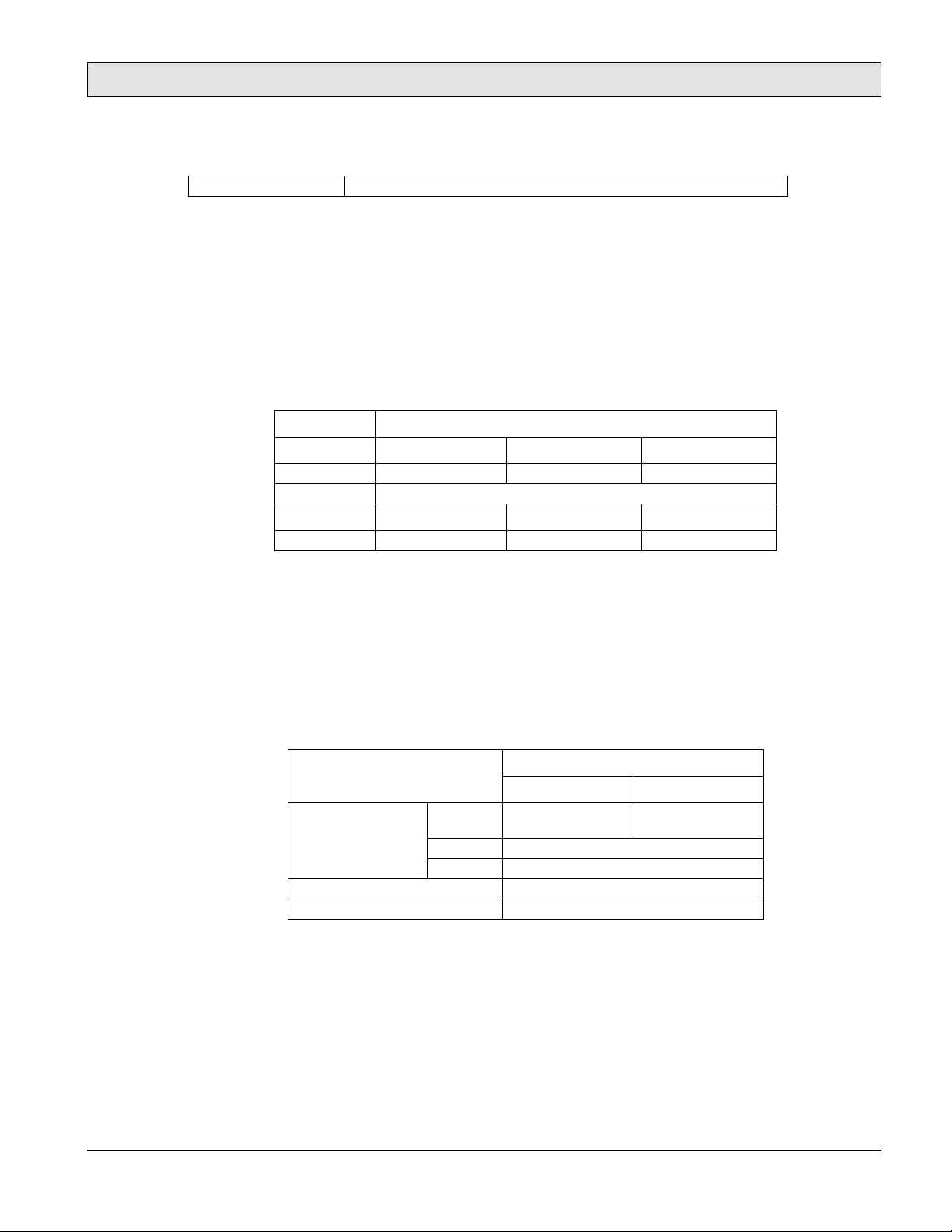

Figure 1-4 illustrates the Large-Capacity Hopper unit.

11.3 in.

(287 mm)

PRINTER

4060

can feed Letter size paper

17.6 in.

(446 mm)

Figure 1-4. Large-Capacity Hopper Physical Dimensions

1-4.2. LCH Paper Handling Specifications

Table 1-7 lists the LCH paper related specifications.

Table 1-7. LCH Paper Handling Specifications

Item Specifications

22.2 in.

(562 mm)

1-9

General Information

SERVICE MANUAL

Processing speed 40 ppm (4060: Letter landscape and 4060: A4 landscape)

Paper Size 4060: Letter and 4060: A4

Typ e

Paper capacity

Plain paper, Label paper, Transparency, Bond paper, Pre-punched paper 64 to 90g/m

3,000 sheets (75g/ m

2

)

1-4.3. LCH Physical Specifications

Table 1-8 lists the LCH physical dimensions, unit weight, and required service area dimensions

and Figure 1-4 illustrates these dimensions. Figure 1-5 illustrates the LCH service area

requirements.

Table 1-8. LCH Physical Specifications

Item Specification

Dimensions Width Depth Height

287 mm (11.3 in) 446 mm (17.6 in) 562 mm (22.2 in)

Weight About 17 kg (38 lbs)

Service area Front Back Right

650 mm (25.6 in) 850 mm (33.5 in) 850 mm (33.5 in)

2

-10

33.5 in.

(850 mm)

21.25 in.

(540 mm)

Printer LCHLCS

Operating

Side

23.0 in.

(585 mm)

122.6 in.

(3114 mm)

33.5 in.

(850 mm)

84.3 in.

(2140 mm)

25.2 in.

(640 mm)

25.6 in.

(650 mm)

33.5 in.

(850 mm)

11.38 in.

(289 mm)

Figure 1-5. LCH, Printer, and LCS Required Service Area Dimensions

1-4.4. LCH Electrical Specifications

Table 1-9 lists the LCH electrical specifications.

Table 1-9. LCH Electrical Specifications

Item Specification

Input power 24VDC, supplied from 4060 printer

Power consumption 30VA or less during operation

1-4.5. LCH Environmental Specifications

General Information

SERVICE MANUAL

Refer to Table 1-5 for LCH environmental specifications.

1-11

General Information

SERVICE MANUAL

1-5. Large-Capacity Stacker (LCS)

1-5.1. LCS Overview

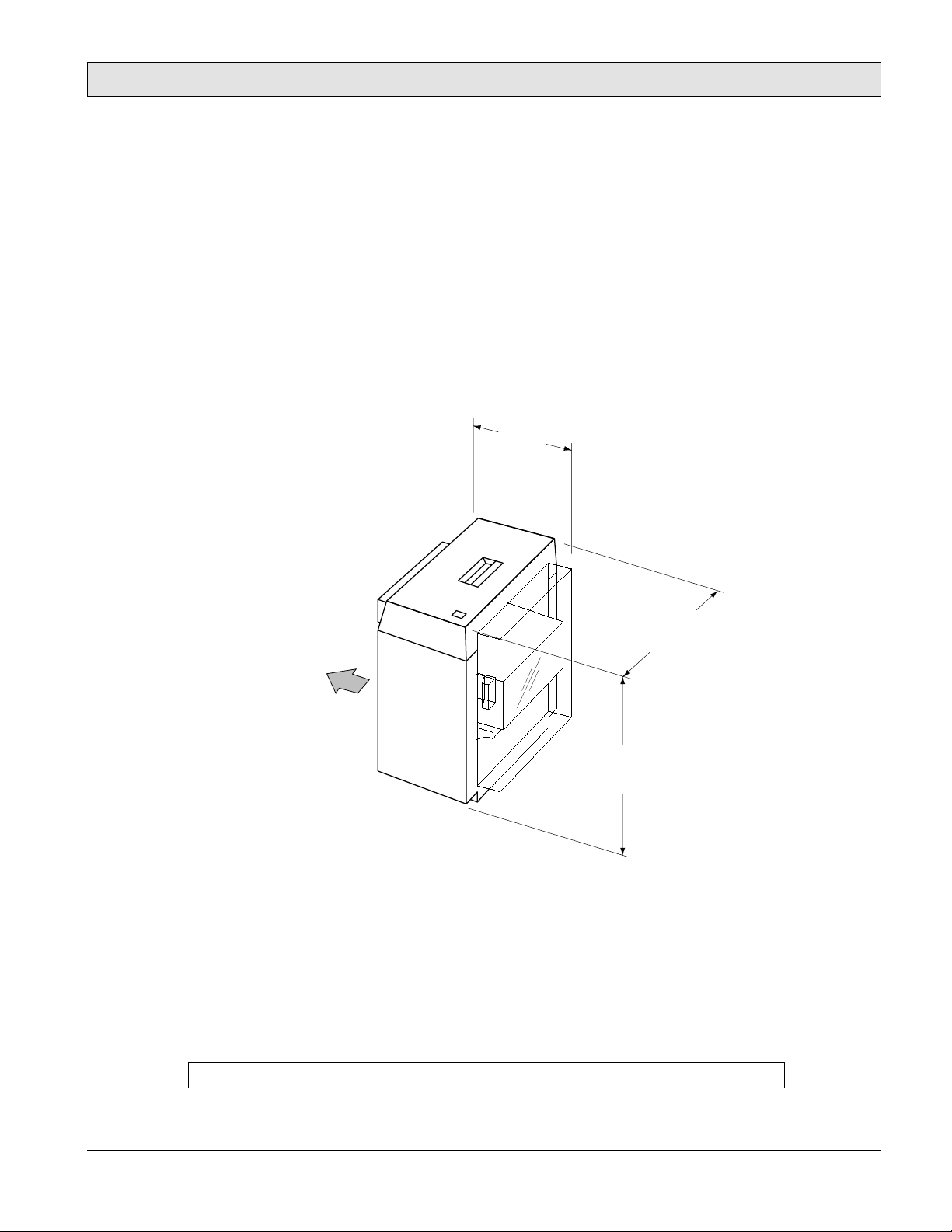

Figure 1-6 shows the user-installable optional Large-Capacity Stacker (LCS) paper handler that

connects to the left side of the printer. Model

4060

LCS can stack up to 2000 sheets of paper (75g/m2).

21 in.

(533 mm)

is for 120V, and model

17.4 in.

(442 mm)

4060

is for 240V. The

Figure 1-6. Large-Capacity Stacker Physical Dimensions

1-5.2. LCS Paper Handling Specifications

Table 1-10 lists the LCS paper handling specifications.

Table 1-10. LCS Paper Handling Specifications

36.0 in.

(913 mm)

PRINTER

-12

Item Specifications

Processing speed 40 ppm

Paper Size Letter, Legal, Ledger, Executive, A3, A4, A5, B4(JIS) (ISO), and B5 (JIS) (ISO)

Type Plain paper, Label paper, Transparency, Bond paper, Pre-punched paper 64 to 90g/m2

General Information

SERVICE MANUAL

Paper capacity 2,000 sheets (75g/ m2)

1-5.3. LCS Physical Specifications

Table 1-11 lists the LCS physical dimensions, unit weight, and also provides the required service

access area dimensions.

Figure 1-6 illustrates these specifications.

Table 1-11. LCS Physical Specifications

Item Specification

Dimensions Width Depth Height

533 mm (21 in) 442 mm (17.4 in) 913 mm (36.0 in)

Weight About 32 kg (70 lbs)

Service area

Front Back Left

650 mm (25.6 in) 850 mm (33.5 in) 850 mm (33.5 in)

1-5.4. LCS Electrical Specifications

Table 1-12 lists the LCS electrical specifications.

Table 1-12. LCS Electrical Specifications

Item

Input Power Voltage 100 to 120 VAC

±

Phase Single-phase

Frequency 50/60 Hz 5%

Power consumption 120 VA or less during operation

Heat capacity 83 kcal per hour

1-5.5. LCS Environmental Specifications

Table 1-5 lists the LCS environmental specifications.

Specification

4060 4060

10%

200 to 240 VAC

10%

±

1-13

General Information

SERVICE MANUAL

1-6. Printer Custom Paper Tray

Model 4060 printer custom paper tray is user-installable, optional custom paper tray for the 4060

printer that is compatible and switchable with the standard printer paper tray. The custom paper

tray can hold up to 500 sheets (75g/m2) of free sized paper as listed in Table 1-13 specifications.

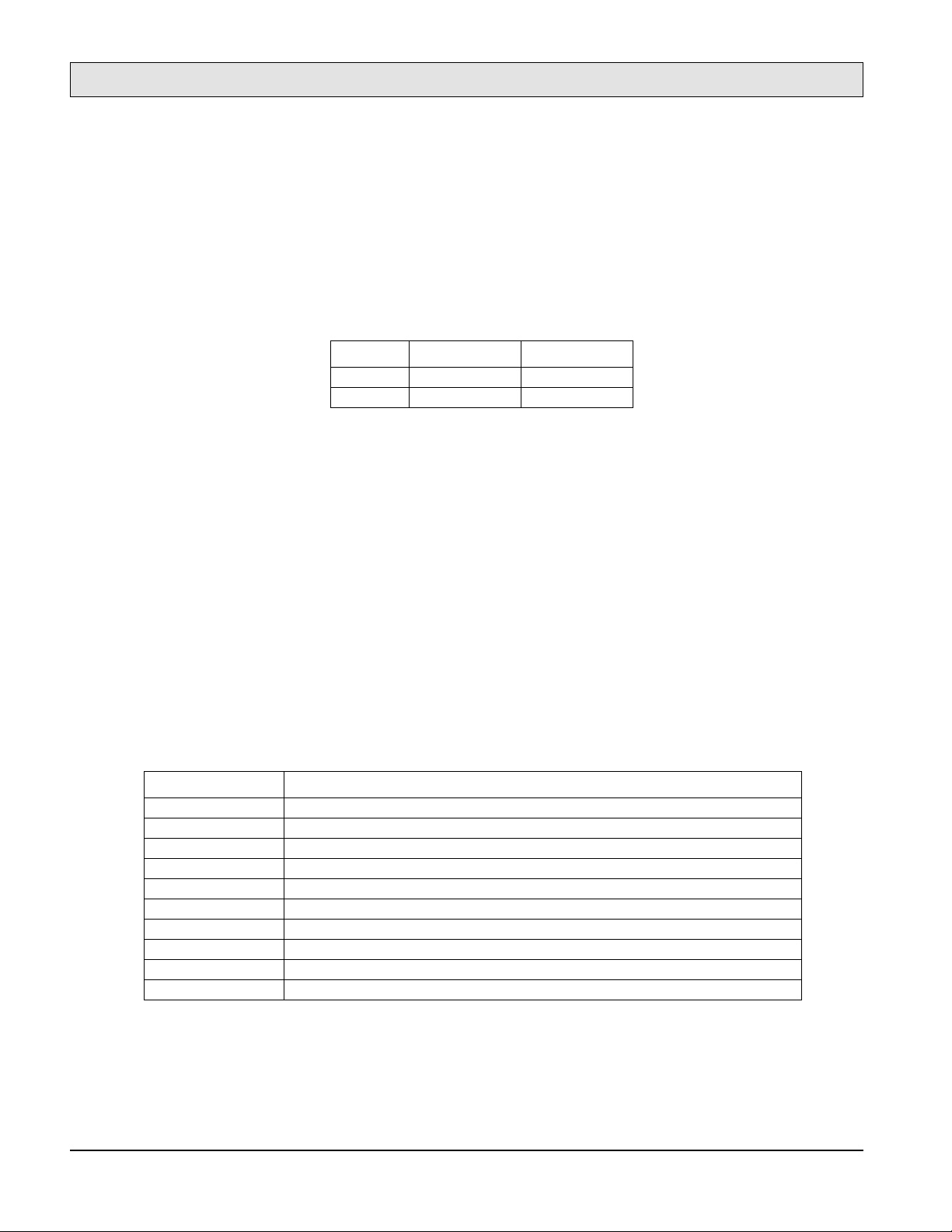

Table 1-13. Custom Paper Tray Physical Specifications

Paper Size Inches Millimeters

Minimum 4.7 x 7.2 120 x 182

Maximum 11.7 x 17 297 x 431.8

Paper size information for the custom tray is selectable. The custom tray also supports the

following standard media sizes: Letter, Legal, Ledger, Executive, A3, A4, A5, B4 and B5.

The printing speed from the custom tray is listed in Table 1-2 (measured on and after the second

page in continuous printing mode).

1-7. Printer Consumable Specifications

This section explains how the replacement rate is established for the printer consumables. The

4060 User Manual

procedures.

Table 1-14 lists the consumables and their respective replacement cycle specifications. Ensure that

consumables are replaced at the recommended intervals by monitoring the usage of the printer.

Consumable Item Replacement cycle

Toner 20,000 images for continuous printing, with 4% coverage for each bottle (average 18,000 images)

Developer 1,600 drum count for each bottle (160,000 images for continuous printing, average 114,000 images)

Drum 2,500 drum count (250,000 images for continuous printing, average 178,500 images)

Transfer Charger 2,500 drum count (250,000 images for continuous printing, average 178,500 images)

Fuser 3,000 page length count (approx. 300,000 images)

Cleaning Roller 40,000 images for continuous printing with 4% coverage (average 36,000 images)

Ozone Filter 3,200 drum count (320,000 images for continuous printing, average 228,000 images)

Collector Bottle 20,000 images for continuous printing with 4% coverage (average 18,000 images)

Printer Pick Roller Kit 5,000 page length count each (approx. 500,000 images)

LCH Pick Roller Kit 5,000 page length count each (approx. 500,000 images)

provides details about consumables kit contents, ordering, and replacement

Table 1-14. Consumables and Replacement Cycle

Notes supporting Table 1-14:

(1) All the values for replacement cycle shown above are based upon printing on A4 size

paper.

-14

General Information

SERVICE MANUAL

(2) All the listed values are theoretical. The damage due to improper handling, maintenance,

papers, environments, and other uncontrollable occasions are not considered in these

values.

(3) All the values for replacement cycle/life shown above depends on printing usage’s and

conditions:

Drum Counts

•

: The drum counter will increment every 150 seconds (equals 100

images of A4 paper at continuous printing). This counter increments during

Warming-up, Intermittent printing and Auto-patrol sequence.

Calculation of the average printed images is based on 1/1.4 of continuous printing;

the combination of intermitted printing mode and continuous printing mode.

Page Length count

•

: The page length counter will increase after 100 simplex A4

images are stacked. On duplex printing the page length counter is incremented by

two.

For the Printer Pick Roller Kit and the LCH Pick Roller Kit, this counter always

increments as simplex printing. When another size paper is used, the counter

increments according to the Table 1-15 listed values.

Table 1-15. Page Length Count

Paper size

Letter 1 2

Legal 2 4

Ledger 2 4

Executive 1 2

A5 1 2

A4 1 2

A3 2 4

B4 (JIS) 2 4

B5 (JIS) 1.5 3

Increment by 100

sheets at simplex

printing

Increment by 100

sheets at duplex

printing

1-15

General Information

SERVICE MANUAL

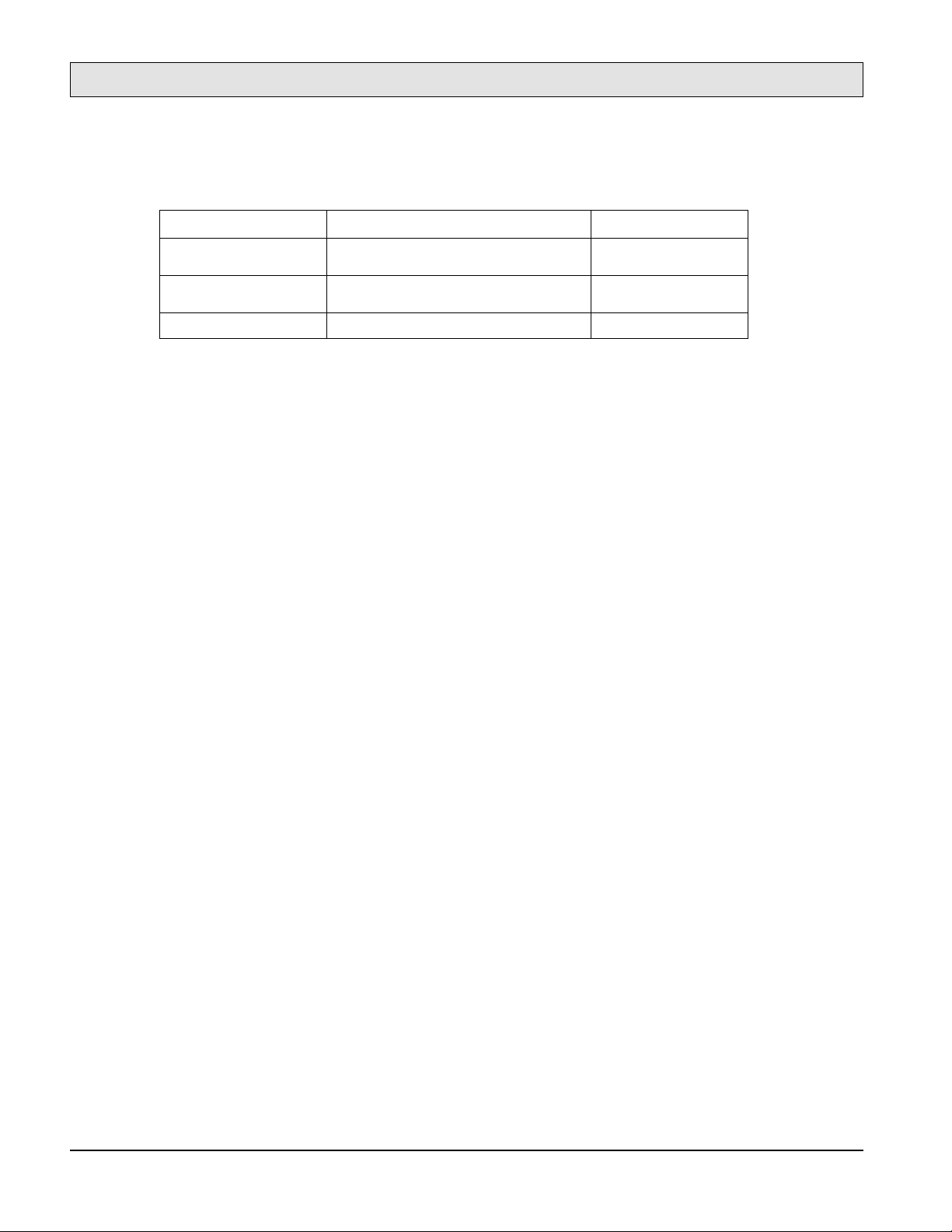

1-8. Best Printing Area Specifications

The printed images must be in an area within a 0.5 inch (12 mm) border. Printing outside of this

boundary may be of lower quality.

Figure 1-7 shows the best printing area.

Margin

Best area

Figure 1-7. Best Printing Area

If data is printed outside the best printing area, you may obtain poor print quality

Figure 1-8 shows the print area of the 4060 printer.

ED

F

G

Feed direction

Paper

| D-E | 1.5 mm

| F-G | 1.5 mm

Figure 1-8. Print Area Specifications

If data is printed outside the printing-assured area as listed in Table 1-16 it will cause poor print

quality such as:

Paper feed skew (up to ±2mm) that may cause missing characters.

•

Bad paper transport that may cause a paper jam.

•

-16

Table 1-16. Print Area Specifications

A (mm) B (mm) A (mm) B (mm)

A5 139.6 201.6 LEDGER 271.0 423.4

A4 288.6 201.6 EXECUTIVE 175.75 258.3

A3 288.6 411.6 B5(JIS) 248.6 355.6

LETTER 271.0 207.5 B4 (JIS 173.6 248.6

LEGAL 207.5 347.2

Figure 1-9 shows the printing position precision.

General Information

SERVICE MANUAL

1-17

General Information

SERVICE MANUAL

– MAGNIFICATION

– SKEW

Ideal print area

H

I

A

Print area

Paper

| H-I | 2.5 mm

| J-K | 1.5 mm

J

K

Feed direction

Print section

Paper

| A-B | 2mm/432mm

-18

– OFFSET

B

Feed direction

ED

Paper

| D-E | 1.5 mm

| F-G | 1.5 mm

F

G

Figure 1-9. Print Positions

General Information

.

.

.

.

.

.

.

.

....

.

.

.

.

.

.

SERVICE MANUAL

1-9. System Configuration Component Locations and Descriptions

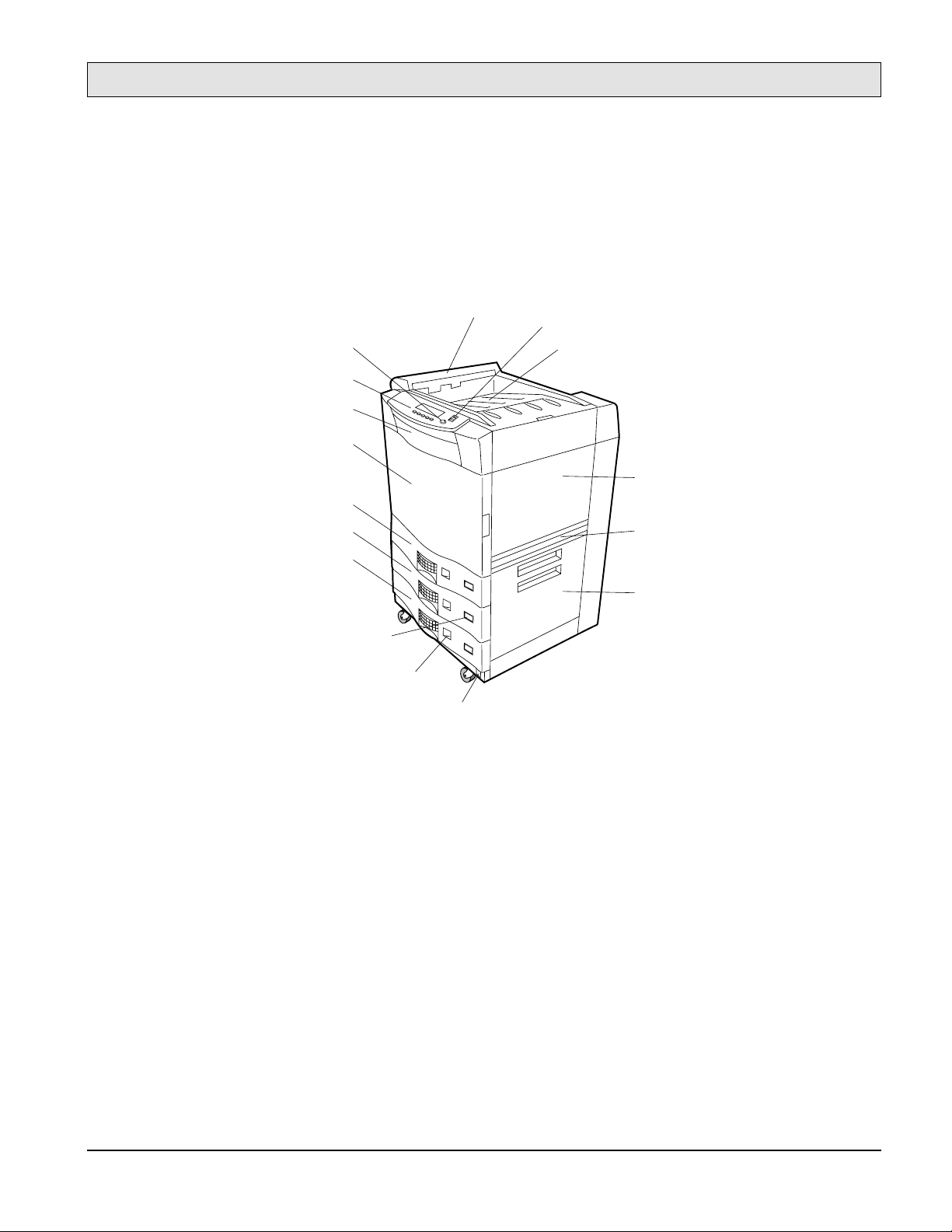

1-9.1. Front and Right Side of the Printer

Ejection unit

Standby switch

Display contrast

Control panel

Front cover

Front door

Tray1

Paper stacker shelf

Upper right cover

Tray2

Tray3

Paper size indicators

Paper level indicators

Main power switch

LCH cover

Lower right cover

Figure 1-10. Front and Right Side of the Printer

The front of the printer contains the Control Panel and the controls most often used. In Figure 110, starting at the Control Panel at the top left and reading clockwise, refer to the following points

of interest:

The

•

•

Control Panel

as the LCD display) that presents messages about printer activity.

The

Display contrast

consists of function buttons and a liquid crystal display (also referred to

allows you to adjust the brightness of the LCD display.

The

•

•

•

•

Ejection unit

The

Standby switch

The

Paper stacker shelf

The

Upper right cover

deposits paper on the paper stacker shelf.

readies the printer for printing.

holds printed pages.

provides access to the toner and developer areas.

1-19

General Information

.

.

.

.

.

.

.

.

....

.

.

.

.

.

.

SERVICE MANUAL

The

•

•

•

•

•

•

LCH cover

The

Lower right cover

The

Paper size indicators

The

Main power switch

The

Paper level indicators

The

Trays 1, 2, and 3

should be exchanged to the paper input guide when LCH is installed.

covers the paper path from the paper trays.

show what size of paper is in each tray.

applies power to the printer.

tell you the amount of paper in the paper trays.

hold the printer’s standard paper supply. You can also obtain and

install optional adjustable custom trays that hold custom sizes of paper.

The

•

•

Front door

The

Front cover

provides access to the printer’s interior.

provides access to the printer’s floppy disk drive bay.

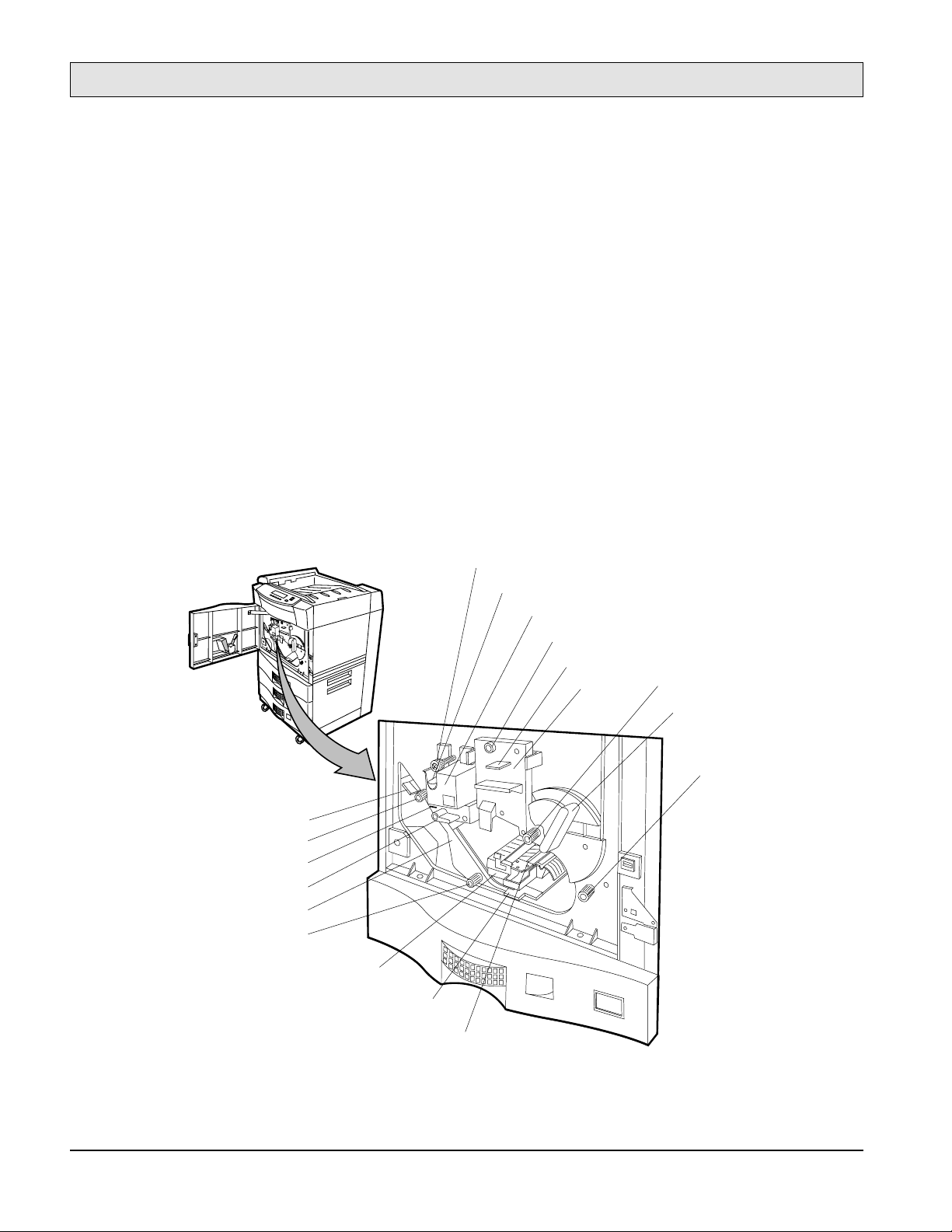

1-9.2. Behind the Front Door

Fuser locking knob

Cleaning roller

Fuser unit

Drum unit locking knob

Precharger cleaner

Drum unit

Knob 2

Lever b1

-20

Lever 5

Decurler roller knob

Decurler lever

Lever 4

Duplex unit

Duplex roller knob

Handle 3

Lever 6

Transfer unit

Figure 1-11. Behind the Front Door

Knob 1

LTR

General Information

SERVICE MANUAL

When you open the front door of the printer, you see the printer internal components shown in

Figure 1-11:

The

•

Fuser unit

fuse the toner to the paper.

The

•

Drum unit

cleaning unit.

The

•

Transfer unit

paper from the drum.

The

•

Duplex unit

ing.

The

•

•

•

•

Cleaning roller

The

Drum unit locking knob

The

Decurler roller knob

The

Duplex roller knob

sided printing).

•

•

•

Knob 1

Knob 2

Handle 3

is used to clear paper jams as the paper exits the paper trays and enters the drum area.

is used to clear paper jams as the paper exits the paper trays and enters the drum area.

lowers the transfer assembly guide to clear paper jams in the drum area.

applies heat and pressure to the paper using upper and lower rollers which

contains the precharger, photoconductor drum, precharger cleaner, and toner

moves the print image from the drum to the paper and then separates the

reverses and transports the paper to the printing unit for double sided print-

lubricates and collects excess toner on the fuser roller.

secures the drum.

is used to clear paper jams in the immediate area.

is used to clear paper jams in the duplex paper path (during double-

Decurler lever

•

Lever b1

•

Lever 4

•

Lever 5

•

Lever 6

•

provides access to paper in the decurler area to clear paper jams.

sets and release the developer unit when the drum or developer unit is removed.

releases tension on paper in the fuser area to clear paper jams.

provides access to paper in the reverser area to clear paper jams.

provides access to paper in the duplexer area to clear paper jams.

1-21

General Information

.

.

.

.

.

.

.

.

....

.

.

.

.

.

.

SERVICE MANUAL

1-9.3. Behind the Upper Right Cover

Toner hopper

Toner collector bottle

Developer collector bottle

Developer unit

Upper right cover

Figure 1-12. Behind the Upper Right Cover

By opening the upper right cover, you gain access to the printer’s consumables, as shown in Figure

1-12:

The

•

Toner hopper

contains a supply of toner. The Control Panel notifies you through the

controller when the toner supply is running low, and when the printer is out of toner.

The

•

Developer unit

contains a supply of developer that, when mixed with toner, forms the

visual image on the photoconductor drum. The Control Panel notifies you through controller

when the developer life is over.

The

•

This bottle is the empty bottle after suppling the new developer.

•

The

•

Developer collector bottle

Toner collector bottle

collects used toner for disposal.

collects used developer for disposal.

-22

1-9.4. Behind the Lower Right Cover

General Information

SERVICE MANUAL

Upper paper feed unit

Middle paper feed unit

Lower paper feed unit

Figure 1-13. Printer Lower-right Side View

By opening the lower right cover, you gain access to the paper feed units as shown in Figure 1-13:

The

•

Upper, Middle, and Lower paper feed units

feed paper picked from the three paper

trays.

1-23

General Information

SERVICE MANUAL

1-9.5. Rear and Left Side of the Printer

Main controller

(Under top cover)

Optical unit

(Under main controller)

Ejection unit

Upper left cover

LCS cover

Ozone filter

LCH connector

AC input

power connector

LCS connector

Lower connector

not used

Figure 1-14. Rear and Left Side of the Printer

The rear of the printer has the features shown in Figure 1-14:

The

•

•

Ozone filter

The

Ejection unit

inhibits ozone exhaust.

ejects the paper to paper stacker and this cover of unit can be opened to

clear paper jams in this area.

The

•

LCS cover

provides access to the LCS paper path (if installed).

LCS attachment

points (under covers)

-24

SERVICE MANUAL

The LCS cover should be exchanged to the paper exit guide when LCS is installed.

•

General Information

The

•

•

•

•

LCS attachment covers

The

LCS connector

The

Lower connector

The

AC input power connector

provides an LCS cable interface (if installed).

is for future upgrades.

conceal LCS securing hardware.

can accept either 120-127 or 200-240 VAC input power

(fuser unit must be matched to the input voltage).

The

•

•

LCH connector

The

Optical unit

provides an LCH cable interface.

(located underneath the main controller) consists of two semi-conductor

laser diodes and a rotating mirror spindle motor and lens. The laser generator outputs dualbeams from the laser diodes.

1-25

General Information

SERVICE MANUAL

1-9.6. Rear-Inside of the Printer

Drive unit E

Drive unit D

Drive unit M

High voltage

power supply

RN101

ACN4J

CNFAN2

CNFAN1

DCNJ10

DCNJ1DCNJ2

DCNJ9

DCNJ6

DCNJ5

DCNJ3

Low voltage power supply

(Behind Mechanism

Controller Board)

CN7

PC Board

CN5

CN6

CN8

CN9

CN10

PC Board

CN11

CN12

Mechanism Controller

Board

CN14

CN13

Figure 1-15. Printer Rear Inside View

The rear of the printer has the features shown in Figure 1-15:

•

•

-26

The

Drive unit D

The

Drive unit E

controls toner feed drive screw for toner flow control.

controls the ejection unit feed belt.

General Information

SERVICE MANUAL

The

•

•

Drive unit M

The

High voltage power supply

controls the printer print unit.

develops and regulates high voltages to the drum unit

components (precharger, photoconductor drum, and cleaning unit), the transfer assembly

components (transfer charger and AC charger) and the developer unit.

The

•

Low voltage power supply

develops and regulates low voltages used by the motors

and the control circuits and so on.

The

•

Mechanism controller

contains the control circuits which control the mechanical

movement of paper through the printer.

1-9.7. Large-Capacity Hopper (LCH)

LCH release handle

Paper shelf lowering button

LCH door

Door handle

PRINTER

Figure 1-16. Large-Capacity Hopper

Paper shelf

The cut sheet printer can also load paper from the optional Large-Capacity Hopper (LCH)

accessory (shown in Figure 1-16). The LCH sits on rails attached to the printer and is electrically

connected to the printer by a cable, and obtains its power from the printer. The LCH highlights are:

The

•

•

LCH release handle

The

Paper shelf lowering button

, when squeezed, detaches the LCH from the printer.

, when pressed, lowers the shelf for paper replenish-

ment.

1-27

General Information

SERVICE MANUAL

The see-through

•

The

•

•

Door handle

The elevator-type movable

LCH door

provides easy access to the paper supply.

allows visual inspection of the paper supply.

Paper shelf

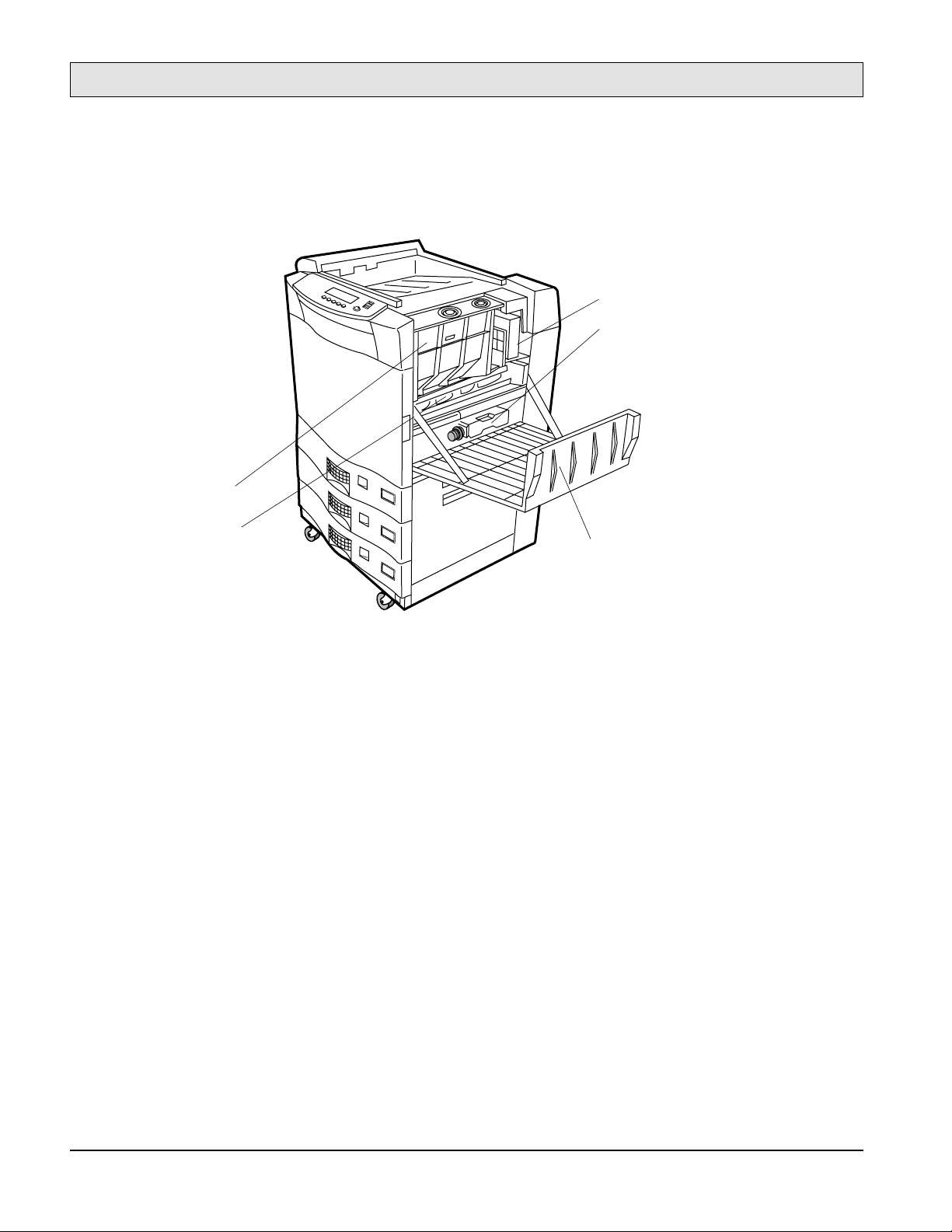

1-9.8. Large-Capacity Stacker (LCS)

supports the paper supply.

ON

OFF

Main Power Switch

Input power cord connector

LCS Interface

control cable

Figure 1-17. Large-Capacity Stacker

The cut sheet printer can stack paper onto the optional Large-Capacity Stacker (LCS) accessory

stacker (shown in Figure 1-17). The LCS uses a standard power cord that may be plugged into any

wall outlet. The LCS is mechanically connected to the printer and is electrically connected to the

printer by a cable. Power is controlled by the ON/OFF switch.

-28

Loading...

Loading...