CONTENTS

CONTENTS

SAFETY AND IMPORTANT

WARNING ITEMS ................................................. C-1

IMPORTANT NOTICE........................................... C-1

DESCRIPTION ITEMS FOR DANGER,

WARNING AND CAUTION ................................... C-1

SAFETY WARNINGS ........................................... C-2

SAFETY INFORMATION ...................................... C-4

SAFETY CIRCUITS .............................................. C-5

INDICATION OF WARNING

ON THE MACHINE ............................................... C-6

1. GENERAL DESCRIPTIONS

1.1 SPECIFICATIONS ........................................... 1-1

1.1.1 Unit specifications ..................................... 1-1

1.1.2 Printer controller specifications.................. 1-2

1.2 OPTIONS ......................................................... 1-3

1.2.1 Paper deck (PD-101)................................. 1-3

1.2.2 Paper cassette LG..................................... 1-3

1.2.3 Printer controller option ............................. 1-3

2. OPERATION

2.1 OPERATION METHOD of KL-3015................. 2-1

3. OUTLINE OF SYSTEM FUNCTION

3.1 PROCESS ........................................................ 3-1

3.1.1 Image writing ............................................. 3-1

[1] Overview ................................................... 3-1

[2] Structure and function of the write unit....... 3-1

3.1.2 Forming the image .................................... 3-3

[1] Image forming process .............................. 3-3

[2] Process description ................................... 3-4

3.1.3 Fixing......................................................... 3-7

[1] Overview ................................................... 3-7

3.2 MECHANICAL SECTION................................. 3-8

3.2.1 Center cross sectional view/Laser

beam path ................................................. 3-8

[1] Center cross sectional view ....................... 3-8

[2] Laser beam path ....................................... 3-8

3.2.2 Electronic parts layout ............................... 3-9

[1] Circuit boards layout, display layout .......... 3-9

[2] Motor - solenoid - heater layout ............... 3-10

[3] Switch, sensor layout .............................. 3-11

3.2.3 Drive system diagram.............................. 3-12

[1] Main motor drive section 1 ...................... 3-12

[2] Main motor drive section 2 ...................... 3-13

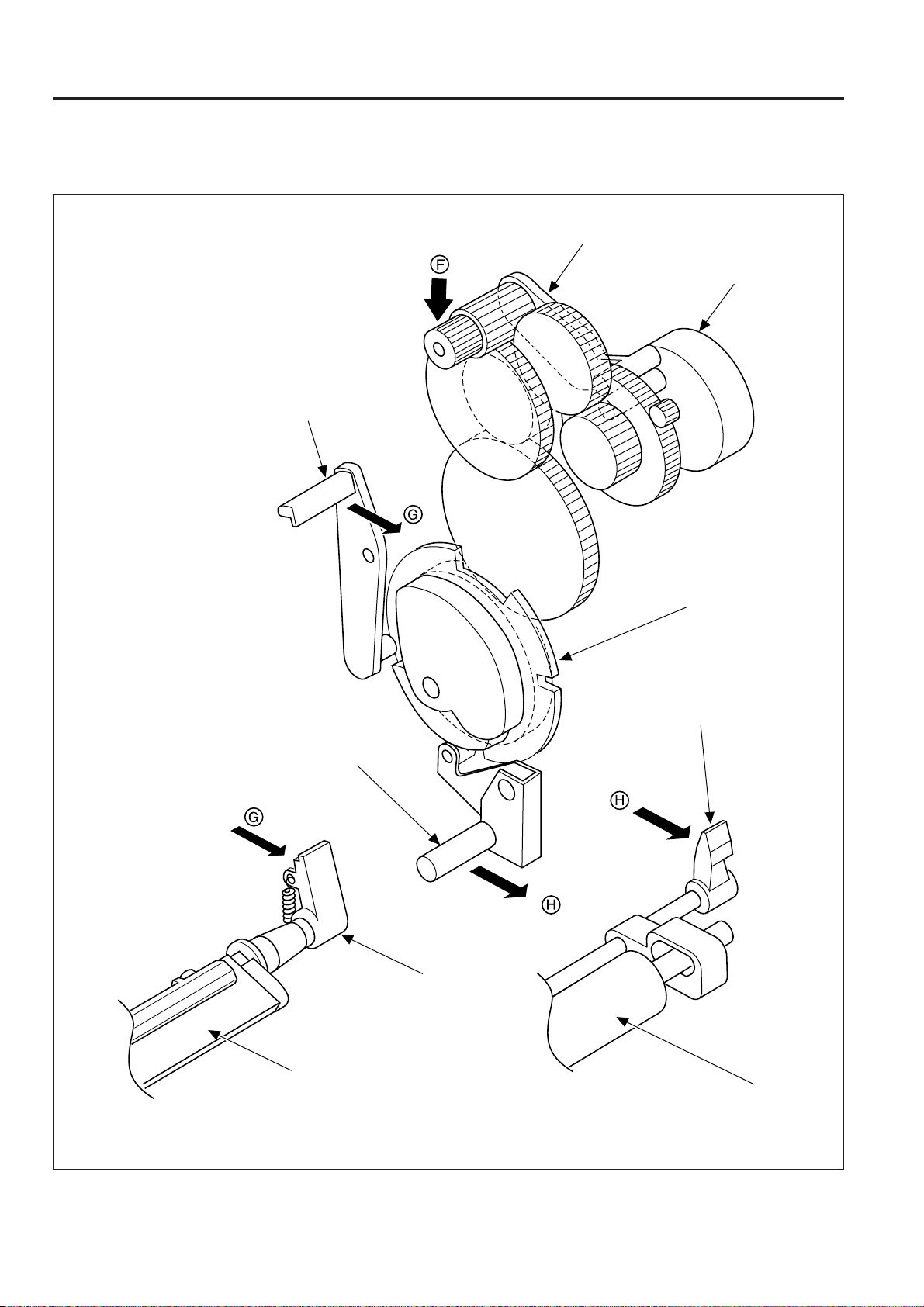

[3] Paper feed section .................................. 3-14

[4] Developing drive section 1 ...................... 3-15

[5] Developing drive section 2 ...................... 3-16

[6] Toner supply section ............................... 3-17

[7] Cleaning blend/transfer roller

Drive section ........................................... 3-18

3.3 OPERATION AND CONTROL....................... 3-19

3.3.1 Write section............................................ 3-19

[1] Write unit structure .................................. 3-19

[2] Write section operation ............................ 3-19

[3] Write section control ................................ 3-20

CONTENTS

3.3.2 Paper feed section .................................. 3-22

[1] Paper feed section layout ........................ 3-22

[2] Paper feed unit structure ......................... 3-22

[3] Paper feed operation ............................... 3-23

[4] Paper feed section control ....................... 3-25

3.3.3 Drum cartridge......................................... 3-27

[1] Drum cartridge structure.......................... 3-27

[2] Drum cartridge operation ......................... 3-27

[3] Drum section control ............................... 3-29

3.3.4 Developing section .................................. 3-32

[1] Developing section structure ................... 3-32

[2] Developing unit operation ........................ 3-32

[3] Developing section control ...................... 3-34

3.3.5 Toner supply unit..................................... 3-37

[1] Toner supply unit structure ...................... 3-37

[2] Toner supply section operation................ 3-37

[3] Toner supply unit control ......................... 3-39

3.3.6 Transfer unit ............................................ 3-40

[1] Transfer unit structure ............................. 3-40

[2] Transfer conveyor section operation ....... 3-40

[3] Controlling the transfer section ................ 3-42

3.3.7 Fixing and paper exit section................... 3-44

[1] Configuration of fixing and

paper exit section .................................... 3-44

[2] Operation of the fixing and

paper exit section .................................... 3-44

[3] Control of the fixing section ..................... 3-45

4. DISASSEMBLY AND REASSEMBLY

4.1 DISASSEMBLY PROCEDURES...................... 4-1

4.1.1 Cautions During Disassembly and

Reassembly .............................................. 4-1

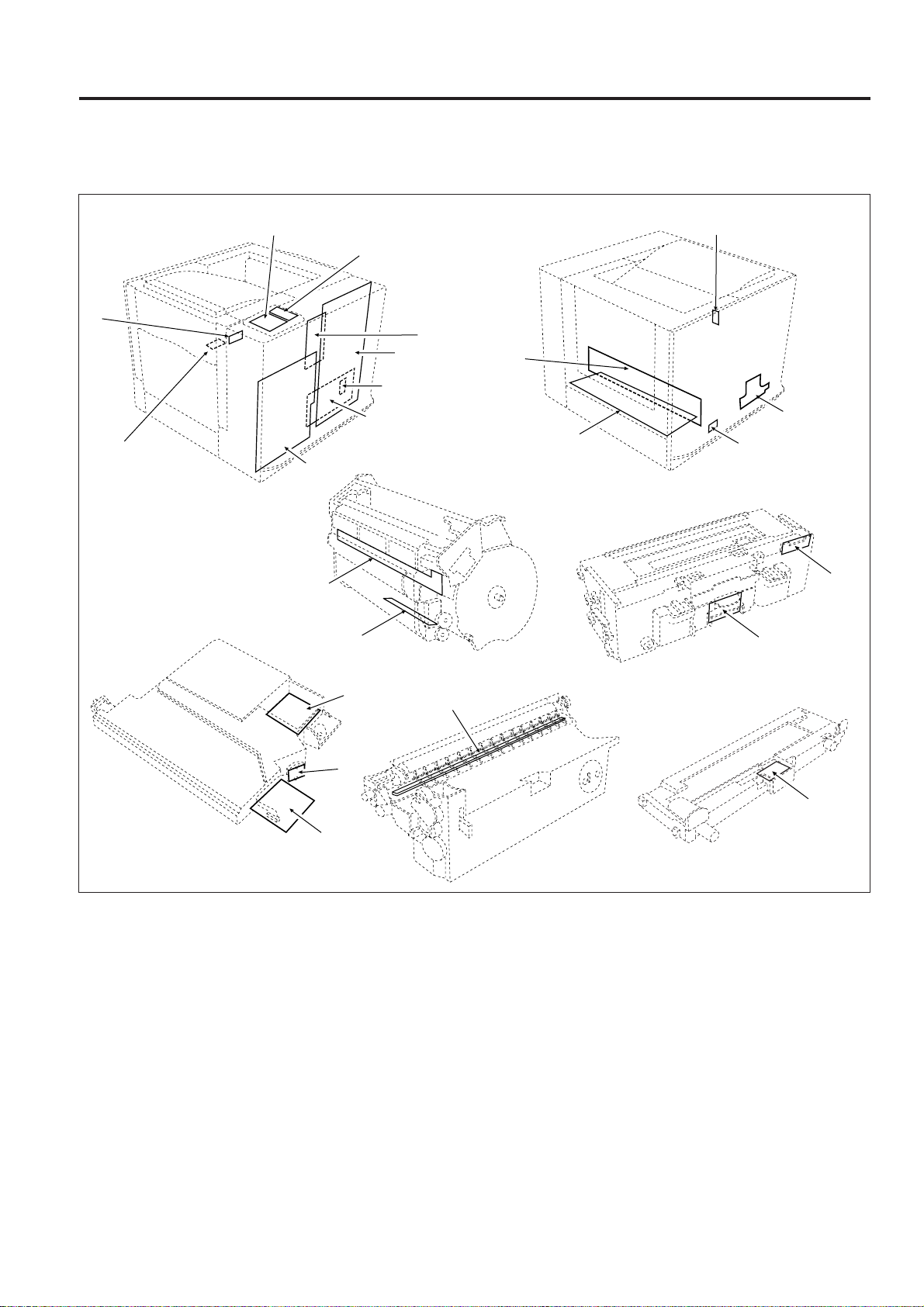

4.1.2 DISASSEMBLY PROCEDURE

FLOWCHART ........................................... 4-2

4.2 DISASSEMBLY AND ASSEMBLY .................. 4-4

4.2.1 Printer Controller Unit................................ 4-4

[1] Removing and installing the printer

controller unit............................................. 4-4

4.2.2 Outer Section ............................................ 4-5

[1] Removing and installing

the outer section........................................ 4-5

[2] Removing the multi feed tray ..................... 4-7

[3] Removing the operation panel ...................4-7

[4] Removing the shield box ........................... 4-8

4.2.3 Toner Supply Unit...................................... 4-9

[1] Replacing the toner bottle .......................... 4-9

[2] Removing and installing

the toner supply unit .................................. 4-9

4.2.4 Write Unit ................................................ 4-11

[1] Removing and installing the write unit ..... 4-11

[2] Cleaning the anti-dust glass .................... 4-12

4.2.5 Main Drive Unit........................................ 4-13

[1] Removing the humidity sensor PCB ........ 4-13

[2] Removing the main drive unit .................. 4-13

4.2.6 Paper Feed Section................................. 4-14

[1] Replacing the paper feed pick up roller ... 4-14

[2] Replacing the multi feed pick up roller ..... 4-14

[3] Removing and installing

the paper feed unit................................... 4-14

[4] Disassembly and reassembly of

paper feed section................................... 4-15

4.2.7 Fixing Unit ............................................... 4-17

[1] Removing and installing the fixing unit..... 4-17

4.2.8 High Voltage Power Source..................... 4-18

[1] Installing and removing the high voltage

power source........................................... 4-18

4.2.9 Engine Controller PCB ............................ 4-19

[1] Removing and installing

the engine controller PCB........................ 4-19

4.2.10 Drive Unit............................................... 4-20

[1] Removing and installing the drive unit ..... 4-20

4.2.11 Main Cooling Fan/Ozone

Regulation Cover................................... 4-20

[1] Removing and installing

the main cooling fan ................................ 4-20

[2] Installing and removing

the ozone regulation cover ...................... 4-20

4.1.12 DC power source................................... 4-21

[1] Removing and installing

the DC power source............................... 4-21

4.2.13 Paper Exit Unit....................................... 4-21

[1] Removing and installing

the paper exit unit .................................... 4-21

4.2.14 Other sections ....................................... 4-22

[1] Removing the main unit relay PCB .......... 4-22

[2] Removing the paper size sensor PCB ..... 4-22

CONTENTS

5. ADJUSTMENT

5.1 ADJUSTMENT ................................................. 5-1

5.2 ENGINE I/O CHECK MODE............................. 5-2

5.2.1 Using the Engine I/O check mode ............. 5-2

5.2.2 I/O check code list (input).......................... 5-3

5.2.3 I/O check list (output) ................................ 5-5

5.2.4 Multi code list............................................. 5-6

5.3 ENGINE NVRAM SERVICE MODE ................. 5-8

5.3.1 Using the Engine NVRAM service mode ... 5-8

5.3.2 Address map table in mode 25 .................. 5-9

6. DIAGRAMS

6.1 OVERALL WIRING DIAGRAM ........................ 6-1

Overall wiring diagram (1/2)................................ 6-1

Overall wiring diagram (2/2)................................ 6-2

6.2 CIRCUIT DIAGRAM......................................... 6-3

Printer controller PCB circuit diagram (1/6)......... 6-3

Printer controller PCB circuit diagram (2/6)......... 6-4

Printer controller PCB circuit diagram (3/6)......... 6-5

Printer controller PCB circuit diagram (4/6)......... 6-6

Printer controller PCB circuit diagram (5/6)......... 6-7

Printer controller PCB circuit diagram (6/6)......... 6-8

Operation PCB circuit diagram ........................... 6-9

LD drive PCB circuit diagram............................ 6-10

Paper feed PCB circuit diagram ....................... 6-11

Motor control PCB circuit diagram .................... 6-12

Polygon drive PCB circuit diagram ................... 6-13

Main unit relay PCB circuit diagram.................. 6-14

DC Power source circuit diagram ..................... 6-15

PCL PCB circuit diagram .................................. 6-16

Discharging lamp PCB circuit diagram ............. 6-17

Paper size sensor PCB circuit diagram ............ 6-18

INDEX sensor PCB circuit diagram .................. 6-19

Density sensor PCB circuit diagram ................ 6-20

Humidity sensor PCB circuit diagram ............... 6-21

Toner density sensor (Y) circuit diagram .......... 6-22

Toner density sensor (M) circuit diagram.......... 6-23

Toner density sensor (C) circuit diagram .......... 6-24

Toner density sensor (K) circuit diagram .......... 6-25

Developing relay PCB 1 circuit diagram ........... 6-26

Developing relay PCB 2 circuit diagram ........... 6-27

Developing relay PCB 3 circuit diagram ........... 6-28

Developing relay PCB 4 circuit diagram ........... 6-29

Developing relay PCB 5 circuit diagram ........... 6-30

Drum unit relay PCB circuit diagram................. 6-31

6.3 ERROR MESSAGE........................................ 6-32

6.4 TIMING CHART ............................................. 6-37

Timing chart 1 ( Warm up ) ................................. 6 - 37

Timing chart 2 (1/2) ............................................ 6 - 38

Timing chart 2 (2/2) ............................................ 6 - 39

Timing chart 3 (1/2) ............................................ 6 - 40

Timing chart 3 (2/2) ............................................ 6 - 41

Timing chart 4..................................................... 6 - 42

Timing chart 5..................................................... 6 - 43

Timing chart 6 (1/4) ............................................ 6 - 44

Timing chart 6 (2/4) ............................................ 6 - 45

Timing chart 6 (3/4) ............................................ 6 - 46

Timing chart 6 (4/4) ............................................ 6 - 47

7. CONSUMABLES INSTALLATION

Drum Cartridge Installation Manual .................... 7-1

Black Developer Unit Installation Procedure....... 7-5

Color Developer Unit Installation Procedure ....... 7-9

Transfer Maintenance Kit (Transfer unit/Oil roller

unit) Installation Procedure............................... 7-13

1

GENERAL DESCRIPTIONS

1.1 SPECIFICATIONS

GENERAL DESCRIPTIONS

1.1.1 Unit specifications

a. Basic specifications

Type: Non-impact Page Printer

Imaging method : Laser indirect electrostatic method

(KNC Process)

Lamp source : Semiconductor laser

Light sensitive medium :

OPC drum

Developer : Dry type, 2 components

(Yellow, Magenta, Cyan, Black)

Resolution : 600 dpi x 600 dpi

Warm-up time : Approx. 190 seconds.

Maximum print size:

Color:

Letter (8.5" x 11" / 216 mm x 279

mm) or A4 (210 mm x 297 mm)

Monochrome:

Legal (8.5" x 14" / 216 mm x 356

mm)

Minimum print size: Color / Monochrome:

Postcard ( 100 mm x 148 mm)

Fixing method: Heat roller

Output method: Face-down output: 250-sheet stack

Face-up output: 10-sheet stack

Output selection: Manual switching of

face-up tray open/

close

First printout time:

Mode Standard OHT

paper feed tray

Size FU FD FU

A4

Letter

Executive

Legal

Monocolor

Full color 33 sec 35 sec 80 sec

Monocolor

Full color 32 sec 34 sec 80 sec

Monocolor

Full color 32 sec 34 sec Monocolor

Full color - - -

26 sec 28 sec 70 sec

25 sec 27 sec 70 sec

25 sec 27 sec -

26 sec 28 sec -

multi feed tray

Continuous print speed:

Mode Standard OHT

paper feed multi feed multi feed

Size tray tray tray

A4 Monocolor 15 ppm 7.8 ppm 1 ppm

Full color 3 ppm 2.8 ppm 1 ppm

Letter Monocolor 15 ppm 7.8 ppm 1 ppm

Full color 3 ppm 2.8 ppm 1 ppm

Executive Monocolor 15 ppm 7.8 ppm -

Full color 3 ppm 2.8 ppm -

Legal Monocolor 13 ppm 7.8 ppm -

Full color - - -

Feed direction : Vertical (portrait)

Paper feed : Paper feed tray (64-90 g/m2 / 17-24 lb)

Letter, Executive, A4, B5 (Approx.

250 sheets)

Multi-feed tray (64-116 g/m2/17-36 lb)

Letter, Legal, Executive, A4, B5,

A5 (Approx. 50 sheets)

Postcards, OHT (Approx. 20 sheets)

Envelopes (Approx. 5 sheets) ,

Labels (5 mm stack)

500-sheet paper feed tray (PD-101)

(64-90 g/m2 / 17-24 lb)

Letter, A4 (Approx. 500 sheets)

Paper cassette LG (64-90 g/m2/17-24 lb)

Legal (Approx. 250 sheets)

b. Control panel

6 keys

3 LEDs

16 column 2 line LCD

FD : Face-down tray

FU : Face-up tray

Note : We reserve the right to make changes without prior notice for the purpose of product specification improvements.

1 - 1

GENERAL DESCRIPTIONS

c. Machine Specifications

Outer dimensions : W: 18.7" (476 mm) x D: 18.6" (472

mm) x 14.7" (374 mm)

Depth: 30.8"(782 mm) (When multi-

tray and face-up output tray are

released)

Weight : Approx. 30kg (Excluding print paper)

Power : 120 V 60 Hz

220 V / 230 V / 240 V 50 Hz

Power consumption :Max.1080 W / 120 V Model

Max.1380 W/220V,230V,240V Model

45 W or less (at Power Save mode)

Sound pressure level:Printing: 62 dB; Standby: 47 dB

Machine life: 500,000 prints (Monocolor) / 250,000

prints (Color) or five years whichever

comes earlier

Replacement parts: Fixing unit (Every 120,000 prints)

Paper feed roller of the Paper feed tray

(Every 120,000 prints)

d. Operating environment

Temperature : 10 °C to 32.5 °C

Humidity : 15 % to 80 %RH (no moisture)

1.1.2 Printer controller specifications

CPU : MIPS R4300

Frequency: 133 MHz

ROM : 8 Mbyte DIMM (PCL5C)

16 Mbyte DIMM (PCL5C and

PostScript: option)

RAM : 16 Mbyte DIMM (standard)

Max. 96 Mbyte (Upgrade Memory

8 MB/16 MB/32 MB)

PDL : PCL5C compatible

PostScript Level 3 (option)

Internal font : Roman 46Fonts (PCL5C: standard)

Roman 136 Fonts (PostScript Level 3:

option)

Interface : IEEE 1284 compliant parallel port

(Centronics/Byte / ECP)

Amphe.36 pins

Language displays: USA: English

Europe: English, French, Italian,

German, Spanish

Other options : Ethernet Card (EC-101)

AUI (10 Base 5)

RJ45 (10 Base-T / 100 Base-TX)

Token Ring card (TC-101)

RJ45 (UTP), DB9 (STP)

Hard disk drive (HD-101)

PostScript DIMM (PS-101)

Note : We reserve the right to make changes without prior notice for the purpose of product specification improvements.

1 - 2

1.2 OPTIONS

GENERAL DESCRIPTIONS

1.2.1 Paper deck (PD-101)

The paper deck installs beneath the KL-3015 unit and can

supply 500 A4 or Letter size paper sheets.

When the paper deck is installed, the 250 sheet tray that

comes with the main unit as standard equipment installs on

the lower side of the paper deck and the 500 sheet tray

installs on the upper side (main unit side).

1.2.3 Printer controller option

a. PostScript DIMM (PS-101)

Adobe PostScript Level 3 is available as a PDL for optional

use.

This installs in place of the ROM DIMM on the printer

controller board.

b. RAM DIMM

This installs in the DIMM socket on the printer controller

board and allows expanding the printer controller RAM

capacity to a maximum of 96 Mbytes.

1.2.2 Paper cassette LG

The paper cassette LG is a custom tray for legal size paper

and replaces the tray 250 that comes with the main unit as

standard equipment.

c. Internal hard disk (HD-101)

This is a 2.5 inch 1400 Mbyte IDE type hard disk that installs

direction in the IDE interface on the printer controller board.

The internal hard disk is used for print job spooling (PCL,

PostScript) and download font storage (PostScript).

1 - 3

GENERAL DESCRIPTIONS

d. Ethernet interface card (EC-101)

This is a optional card to add the Ethernet interface function

to the printer controller board and allows to use KL-3015 as a

network printer.

This card is equipped with a 100Base-TX / 10Base-T

connector and an AUI interface connector.

e. Token Ring interface card (TC-101)

This is a optional card to add the Token Ring interface

function to the printer controller board and allows to use KL3015 as a network printer.

1 - 4

2

OPERATION

OPERATION

2.1 OPERATION METHOD of KL-3015

As for the operation method of KL-3015, make use of the following manners and KL-3015 test print function.

NO.

1

Operation Panel Function

2

Menu Help

3

Printer Setup

4

Network Setup

5

Driver Install

6

Color Management

7

Using Fiery Web Tool

8

Consumable replacement

9

Printing from Applications

10

Printing pages from Operation Panel

Items

Getting Started Network Setup User's Manual CD-ROM Test print

2 - 1

3

OUTLINE of SYSTEM FUNCTION

3.1 PROCESS

OUTLINE of SYSTEM FUNCTION

3.1.1 Image writing

[1] Overview

The print data from the computer sent to the PRNCB (printer

controller) as PCL or PostScript draw command.

The PRNCB analyzes the draw command and makes picture

image into the memory, these are divided to CMYK each

Draw command

(PCL or PostScript)

Computer

PRNCB Write unit

Image data

per pixel

ENGCB

colors. The image data sent from the PRNCB is PWM

processed inside the ENGCB (engine controller) and output

as pulse signals to drive the LD (laser diode) of the write unit.

The laser beam from the LD is beamed as a scanning light

onto the OPC drum by way of the internal path in the write

unit.

LD drive pulse Laser beam

OPC Drum

[2] Structure and function of the write unit

The internal structure of the write unit and the laser beam

path are shown in the drawing below.

Reflecting

Index

sensor

Laser

diode

Collimator lens

Index lens

Cylindrical

lens 1

mirror

Index mirror

Cylindrical

lens 2

fø lens

Laser Beam Path

Semiconductor laser (LD) Collimator lens

Polygon mirrorCylindrical lens 1 (Cy1)

fø lens

Reflecting mirror

Index mirror

Cylindrical lens 2 (Cy2)

OPC drum

3 - 1

Index lens Index sensor

OUTLINE of SYSTEM FUNCTION

The lenses and mirrors in the laser beam path have the

following functions.

1. Collimator lens

The collimator lens operation is shown in the figure. This

lens receives a light beam from a source having a widening

angle as shown and beams it outward in parallel rays.

Semiconductor laser

Collimator

lens

Parallel

rays

2. Polygon mirror

This is a rotating mirror for converting laser light into

scanning light and is driven by M5 (polygon). This

equipment utilizes a 6-sided mirror.

3. fø lens

When an ordinary converging lens is used the laser beam

speed varies at the center and ends when scanning the drum

surface due to the fixed position of the polygon mirror as

shown in the figure.

Laser beam

4. Cylindrical lens

Two lenses, the cylindrical lens 1 (Cy1) and the cylindrical

lens 2 (Cy2) are used to eliminate the tilt error of the polygon

mirror.

If the cylindrical lenses 1 and 2 are placed around the

polygon mirror as shown in the figure, the laser light is

collected on the polygon mirror by the cylindrical lens 1. The

light reflecting from the polygon mirror is again collected

above the drum by the cylindrical lens 2.

Cylindrical lens 1

laser diode

(cy1)

Cylindrical lens 2

Polygon mirror

fø lens

Mirror

(cy2)

Drum

The polygon mirror and drum surface have a mutual

interaction versus the cylindrical lens 2 regarding image and

object points so that when there is a tilt in the polygon mirror,

the light path is corrected by the cylindrical lens 2 and

scanning of the correct position performed.

a

Polygon

mirror

a > b > c

b

c

Speed of

scanning

slows

towards the

center.

Drum

An fø lens is utilized to obtain a fixed scanning speed.

Laser beam

a = b = c

a

Polygon

mirror

fø lens

b

c

Uniform

scanning

speed

Drum

5. Index sensor

The index sensor outputs an index signal (pulse) indicating

the degree that the light beam enters the index lens. This

index signal is used for the timing of the lead write position

each time an axial scan is made.

3 - 2

3.1.2 Forming the image

[1] Image forming process

OUTLINE of SYSTEM FUNCTION

Light exposure

(laser beam)

Charge

PCL

Cleaning

Separation

needle

Discharging

lamp

The image forming process is performed in the following

sequence.

ø 120 mm

Developing

Y

M

C

Bk

Transfer

PCL CHARGE EXPOSURE

CLEANING

DRUM CHARGE

REMOVAL

(fixing)

DEVELOPING

TRANSFER,

SEPARATION

(paper)

In full color printing, the CHARGE, EXPOSURE, DEVELOPING process is repeated in the order Y, M, C. TRANSFER is

performed after the CHARGE of Bk, EXPOSURE and DEVELOPING.

3 - 3

OUTLINE of SYSTEM FUNCTION

[2]Process description

This machine being a color printer is provided with a 4 color

developer (Y,M,C,Bk).

The KNC developing method is used and a full color image

is formed by overlapping the 4 toner colors on the drum.

(1st color charge)

Charge electrode

(2nd color charge)

(1st color exposure)

(2nd color exposure) (2nd color develop)

KNC (MB "K" New Color) Developing Method

⊇

ℑ

In this method the electrical charge on the light sensitive

ℑ

portion is eliminated and toner made to adhere to that

ℑ

portion. (reverse developing).

ℑ

This process is repeated until several toner colors have

ℑ

been formed on the light sensitive portion.

⊄

(1st color develop)

Developing sleeve

Toner

DrumDrum Drum

↓

Charge electrode

Drum Drum

Drum

1. Charge

The charge is applied with the Scolotron method.

A fixed voltage is applied to the wire grid and a uniform

charge applied to the drum.

Charge electrode

2. Exposure

Exposure with the laser beam from the write unit removes the

electrical charge on the drum.

The second and following exposures with the laser beam

eliminate the charges on the drum by laser light on the toner

layer even when toner is already adhering to it.

3 - 4

3. Developing

Toner with a negative charge is made to adhere to the

portions where the charge has been eliminated by light

exposure. The second and following developing operations

work by means of a static charge between the drum and

developing toner even at developing points where the toner

already adheres.

The developing bias is a DC bias voltage overlapped with an

AC bias voltage.

Drum

OUTLINE of SYSTEM FUNCTION

Drum

Separation

needle

Toner

Paper

6. Discharging

In order to improve separator performance, charge decline of

the drum is performed by applying light from a charge

removal lamp.

4. Transfer

In this process the toner is transferred to the paper by

applying a positive bias charge to the transfer roller.

Drum

Toner

Transfer roller

Paper

5. Separator

In order to prevent the paper from winding around the drum

after the transfer process, a charge removal brush eliminates

the charge remaining from AC voltage overlapped with an

DC bias voltage, from the paper and from the toner that was

transferred to the paper.

Drum

Discharging lamp

Paper

6. Transfer roller cleaning

In order to clean off the toner adhering to the transfer roller

after the print sequence is complete, a bias voltage of reverse

polarity is applied per each rotation of the transfer roller and

the toner on the transfer roller is made suctioned to the drum

side.

Drum

3 - 5

OUTLINE of SYSTEM FUNCTION

8. Cleaning

The remaining toner on the drum is removed by the cleaning

blade. The cleaning blade in this machine function by

compression release operation. This compression state is

only used after the last developing (Black) during multicolor

mode.

Cleaning blade

9. PCL (Pre Charge Lamp)

Before charging, the PCL uses light to remove the remaining

charge on the drum.

PCL

Drum

3 - 6

3.1.3 Fixing

[1] Overview

OUTLINE of SYSTEM FUNCTION

5. Fixing temperature

Set temperature: 180 °C

Fixing roller - upper

Fixing cleaning roller

Fixing oil roller

Fixing

Heater

lamp

Fixing roller - lower

The toner transferred to the paper is made to adhere to the

paper by means of heat and pressure.

1. Fixing roller - upper

This roller has a rubber coating over a metal surface and a

PFA tube sheath over the surface. This roller is driven by a

motor in the main drive unit.

The center of the roller is warmed by a heating lamp and this

temperature varies according to the type of paper that the

toner must adhere to.

2. Fixing roller - lower

This roller has a rubber coating over a metal surface and a

PFA tube sheath over the surface. A compression spring

provides a 1.72 kg/cm force to press contact on the upper

fixing roller.

3. Fixing oil roller

The roller contains a certain quantity of oil which is supplied

in minute amounts to the upper fixing roller. This improves

separation and prevents OHT permeability and the paper

winding around the upper fixing roller.

4. Fixing cleaning roller

This roller cleans off toner which adheres to the fixing oil

roller by cleaning the surface of the fixing oil roller.

3 - 7

OUTLINE of SYSTEM FUNCTION

3.2 MECHANICAL SECTION

3.2.1 Center cross sectional view/Laser beam path

[1] Center cross sectional view

PCL

Write unit

Drum cartridge

Fixing unit

Transfer unit

Charge electrode unit

Toner supply unit

Toner bottle

Y Developing unit

M Developing unit

Color Developing unit

C Developing unit

Bk Developing unit

Multi feed tray

Paper feed tray

[2] Laser beam path

Index mirror

Separation

needle

Cylindrical

lens 1

Discharging

lamp

Laser

diode

Paper feed unit

Transfer

roller

Index

sensor

Index lens

fø lensPolygon mirror Cylindrical lens 2

3 - 8

Mirror

3.2.2 Electronic parts layout

10

[1] Circuit boards layout, display layout

OUTLINE of SYSTEM FUNCTION

17

23

6

20

21

3

1

7

15

12

11

5

16

14

19

18

8

9

4

2

1 ENGCB Engine controller PCB

2 LDB LD drive PCB

3 PSIZEB Paper size sensor PCB

4 INDXSB INDEX sensor PCB

5 MRLB Main unit relay PCB

6 DVRLB1 Developing relay PCB1

7 DVRLB2 Developing relay PCB2

8 DVRLB3 Developing relay PCB3

9 DVRLB4 Developing relay PCB4

10 DVRLB5 Developing relay PCB5

11 GMDB Density sensor PCB

12 PCLB PCL PCB

22

13

13 OSLB Discharging lamp PCB

14 DRLB Drum unit relay PCB

15 HV High voltage power source

16 DCPS DC power source

17 OB Operation PCB

18 HUMB Humidity sensor PCB

19 PFB Paper feed PCB

20 DMCB Motor control PCB

21 PRNCB Printer controller PCB

22 PMDB Polygon drive PCB

23 LCD Operation panel LCD display

3 - 9

OUTLINE of SYSTEM FUNCTION

[2] Motor - solenoid - heater layout

8

6

4

2

7

3

5

9

1

10

1 M1 Main motor

2 M2 Paper feed motor

3 M3 Developing motor

4 M4 Control motor

5 M5 Polygon motor

6 M6 Main unit cooling fan

7 SD1 Developing control SD

8 SD2 Toner supply SD

9 SD3 Paper feed SD

10 L1 Fixing heater lamp

3 - 10

[3] Switch, sensor layout

13

12

14

OUTLINE of SYSTEM FUNCTION

4

1

3

10

2

7

5

11

17

8

6

9

16

1 SW1 Main switch

2 MS1 Interlock switch

3 PS1 Cam position PS

4 PS2 Toner supply PS

5 PS3 Main wire cleaner home position PS

6 PS4 Registration PS

7 PS5 Waste toner full detection PS

8 PS6 Paper detect PS

9 PS7 Multi feed paper detect PS

15

10 PS8 Paper eject PS

11 INDXS Index sensor

12 YTDS Toner density sensor (Y)

13 MTDS Toner density sensor (M)

14 CTDS Toner density sensor (C)

15 BKTDS Toner density sensor (K)

16 TH1 Fixing temperature sensor

17 TS1 Fixing thermostat

3 - 11

OUTLINE of SYSTEM FUNCTION

3.2.3 Drive system diagram

[1] Main motor drive section 1

Drum gear

Toner collection screw

(Drum cartridge)

Toner

collection screw

(Transfer unit)

M1

Transfer roller

3 - 12

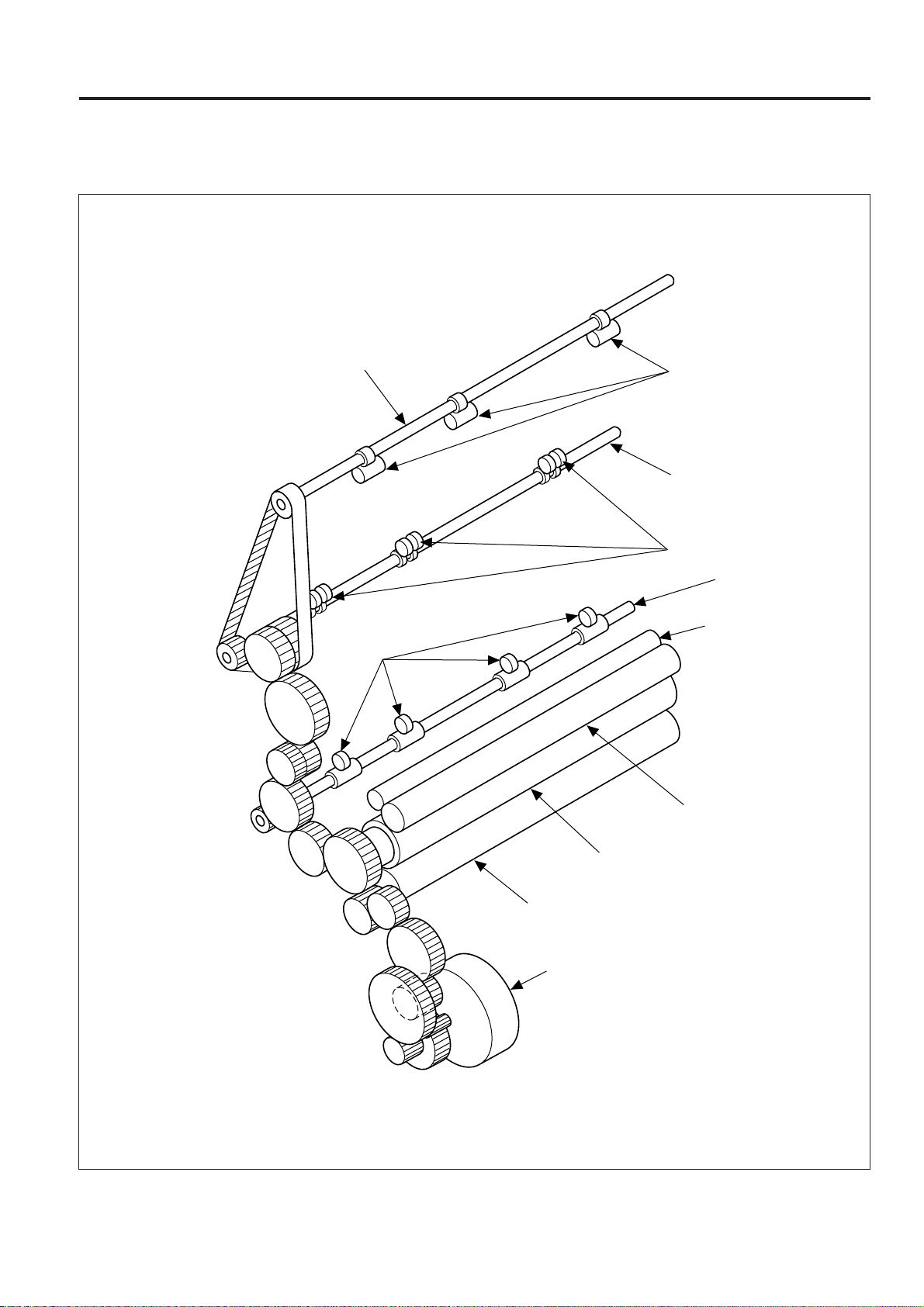

[2] Main motor drive section 2

OUTLINE of SYSTEM FUNCTION

Drive shaft (Upper)

Fixing paper exit

roller (Upper)

Driven roller (A)

Drive shaft (Lower)

Driven roller (B)

Fixing paper exit

roller (Lower)

Fixing cleaner roller

3 - 13

Oil roller

Fixing roller (Upper)

Fixing roller (Lower)

M1

OUTLINE of SYSTEM FUNCTION

[3] Paper feed section

Paper feed conveyance roller

Paper feed driven roller

Paper feed pickup roller

Multi feed pickup roller

Paper feed

conveyance roller

Paper feed

planetary gear

Paper feed

planetary arm

Paper feed delivery stopper (A)

SD3

Paper feed delivery stopper (B)

M2

3 - 14

[4] Developing drive section 1

OUTLINE of SYSTEM FUNCTION

M3

Planetary gear

Developing drive

planetary arm (Upper)

Sun gear

SD1

Developing drive

planetary arm (Lower)

Sun gear

3 - 15

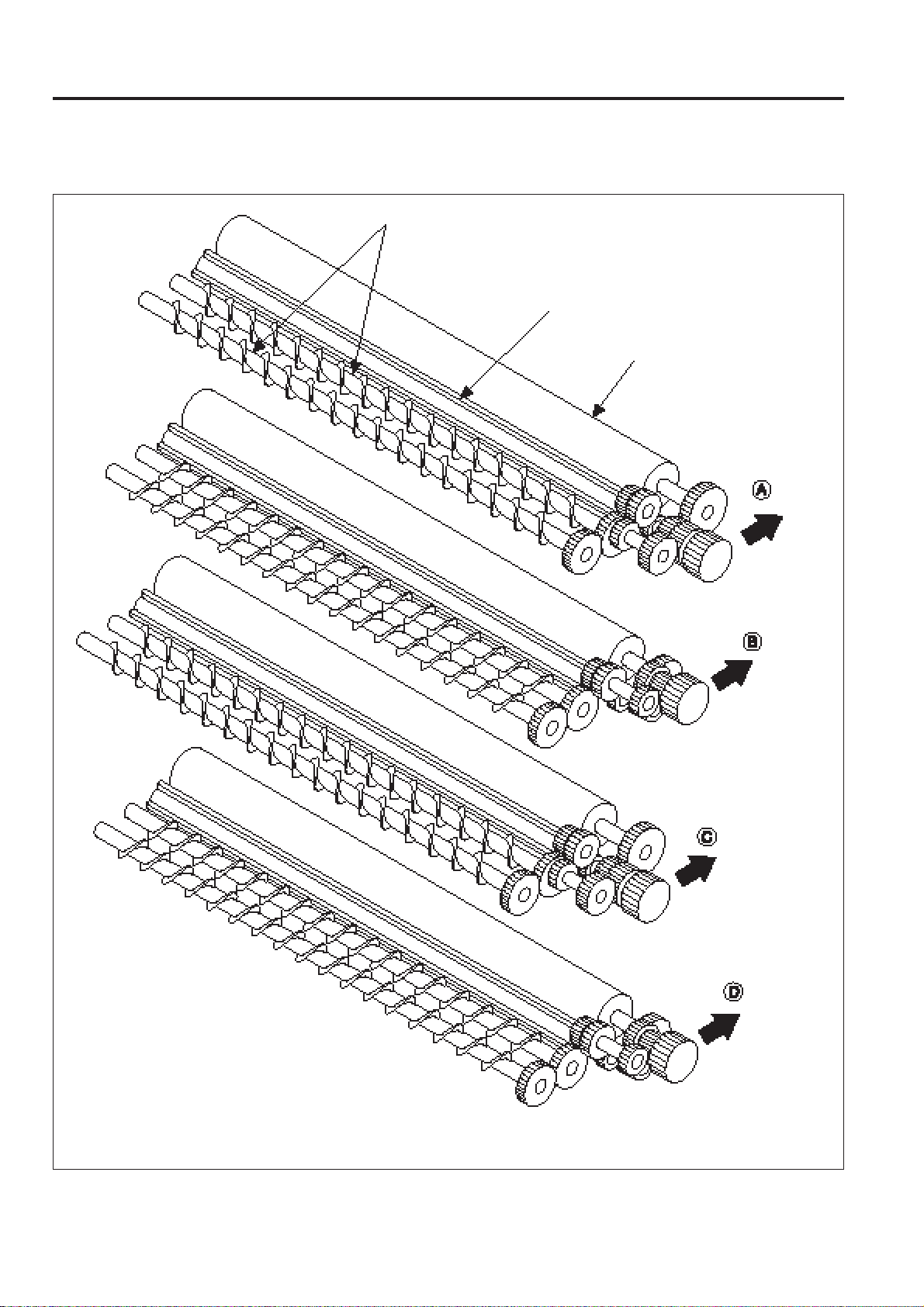

OUTLINE of SYSTEM FUNCTION

[5] Developing drive section 2

Developing Unit (Y)

Developing Unit (M)

Developing Unit (C)

Agitator screw

Developing liquid wheel

Developing sleeve

Developing Unit (Bk)

3 - 16

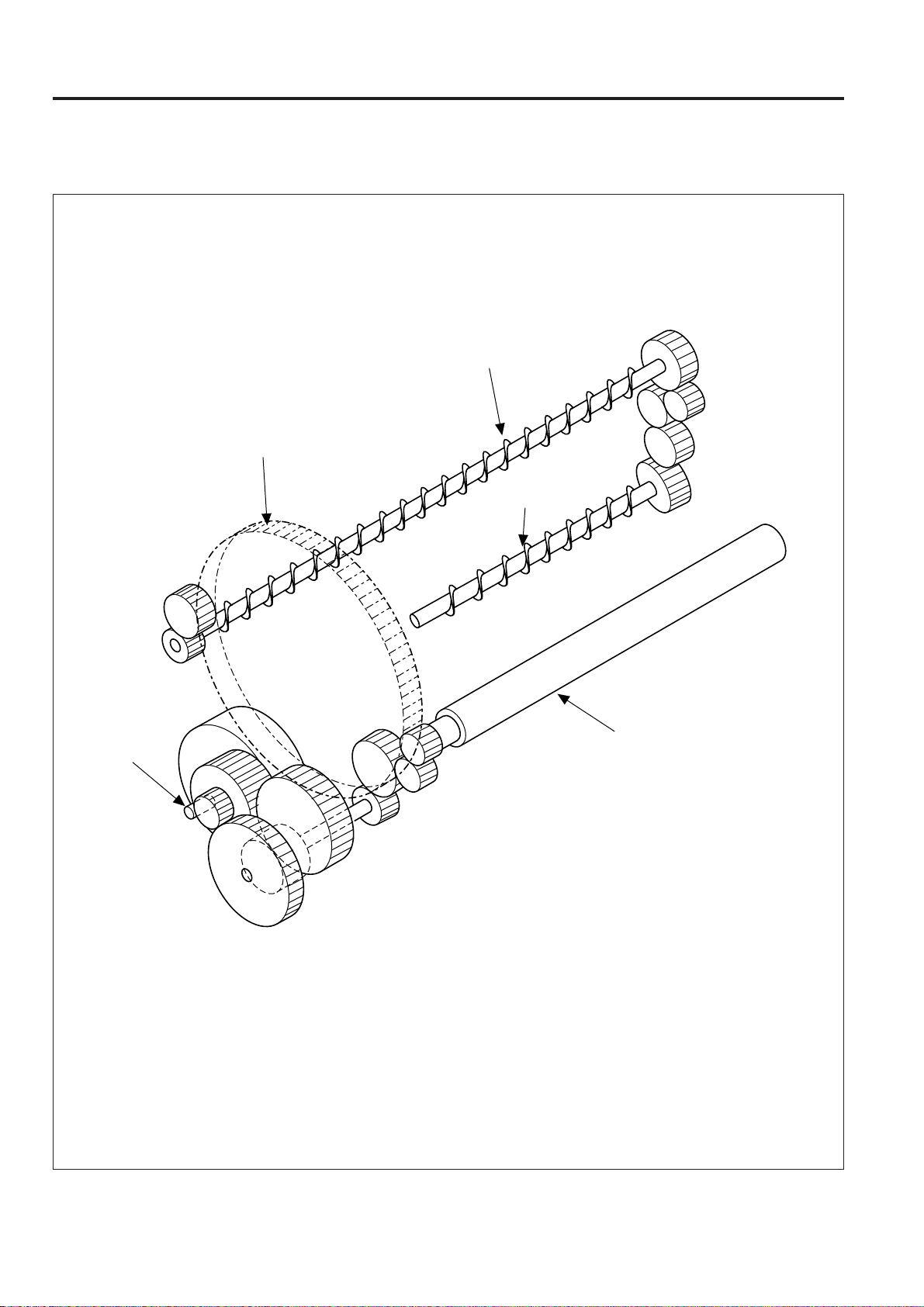

[6] Toner supply section

Planetary gear

OUTLINE of SYSTEM FUNCTION

Toner supply arm

Toner supply planetary arm

SD2

M3

Encoder plate

Toner supply screw (C)

Toner supply screw (M)

Sun gear

Toner supply arm holder case

Toner supply

screw (Bk)

Toner supply

control arm

Toner supply screw (Y)

Toner supply

control planetary arm

3 - 17

OUTLINE of SYSTEM FUNCTION

[7] Cleaning blend/transfer roller Drive section

Blade release arm

Control planetary arm

M4

Transfer roller

release arm

Cam gear

Transfer roller release lever

Blade release lever

Cleaning blade

Transfer roller

3 - 18

3.3 OPERATION AND CONTROL

3.3.1 Write section

[1] Write unit structure

OUTLINE of SYSTEM FUNCTION

Index lens

Index sensor PCB

LD drive PCB

Laser diode

Collimator lens

Cylindrical lens 1

Heat sink

(Bottom side)

Polygon drive PCB

Reflecting mirror

The write unit is comprised of an LD drive PCB, index

sensor PCB, polygon drive PCB, and various lenses and

mirrors for the laser beam path.

Refer to " 3.1.1 Image writing" for details on the internal

laser beam path.

A laser light shield plate that opens and closes by means of

a spring is installed to ensure safety. When the front door

on the main unit is opened, an actuator triggers the light

shield plate to block the laser beam output window.

Cylindrical lens 2

Laser light shield plate

Index mirror

fø lens

Polygon mirror

with air bearing

M5

[2] Write section operation

The image data from the PRNCB (printer controller) is

converted in the ENGCB (engine controller) into a pulse

signal (LD-PWM) with a pulse width corresponding to the

LD (laser diode) emissions per each image dot. This pulse

signal is sent to the LDB (LD drive).

The LDB regulates the laser output by means of the

control signal from the ENGCB.

The M5 (polygon) of write unit rotates the polygon mirror

to axially scan the drum with the laser beam from the LD.

Note: Take care not to bend or damage the heat sink

on the back of the unit when placing the write unit

that was removed in a convenient location.

3 - 19

Since is damaged with dirt and dust it used the

air bearing, never open the write unit lid.

Loading...

Loading...