Konica BIZHUB PRO 1050, BIZHUB PRO 1050P User Manual

/

CMS REPLACEMENT INSTRUCTIONS

(Customer Maintenance Support)

CMS REPLACEMENT INSTRUCTIONS

1. Main body : Pick-up roller assembly/separation roller assembly

2. Main body : Fusing section

3. Main body : Cleaning web

4. Main body : Transfer/separation charger unit

5. DF-603 : Pick-up roller unit/separation roller unit

6. PF-701 : Pick-up roller unit/separation roller unit

Introduction

CMS:

The CMS (Customer Maintenance Support) is a system that supports the customer who conducts

a parts replacement operation by himself without getting an technical assistance from the customer engineer, to minimize the downtime (shutdown period of the machine operation) of the

machine of the customer.

Notices to the customer who employs the CMS:

When you want to employ the CMS, be sure to follow the instructions given by the customer engineer.

And also, when you conduct a part replacement operation, be sure to read each replacement

instruction and follow the specific instructions given in it.

For your safety while in the replacement operation, be sure to keep this CMS Instructions for

Replacement safely, and also be careful not to get it lost.

Should it get lost, contact our service representative.

Registered trademark

• bizhub PRO is a registered trademark of KONICA MINOLTA BUSINESS TECHNOLOGIES, INC.

Copyright © 2004 KONICA MINOLTA BUSINESS TECHNOLOGIES, INC.

CONTENTS

For your safe operation ............................................................. 1

1. Main body: Pick-up roller assembly/

separation roller assembly .................................................... 6

2. Main body: Fusing section.................................................. 19

3 Main body: Cleaning web ................................................... 26

4. Main body: Transfer/separation charger unit....................... 33

5. DF-603: Pick-up roller unit/separation roller unit ................. 39

6. PF-701:Pick-up roller unit/separation roller unit................... 46

For your safe operation

1

For your safe operation

For your safe operation, the following are the descriptions of the notices and requests

that you have to follow when replacing parts. Be sure to read them carefully before

conducting any part replacement operation.

• Be sure to keep this CMS Replacement Instructions not to get it lost.

• Be sure to follow the caution items given in the CMS Replacement Instructions.

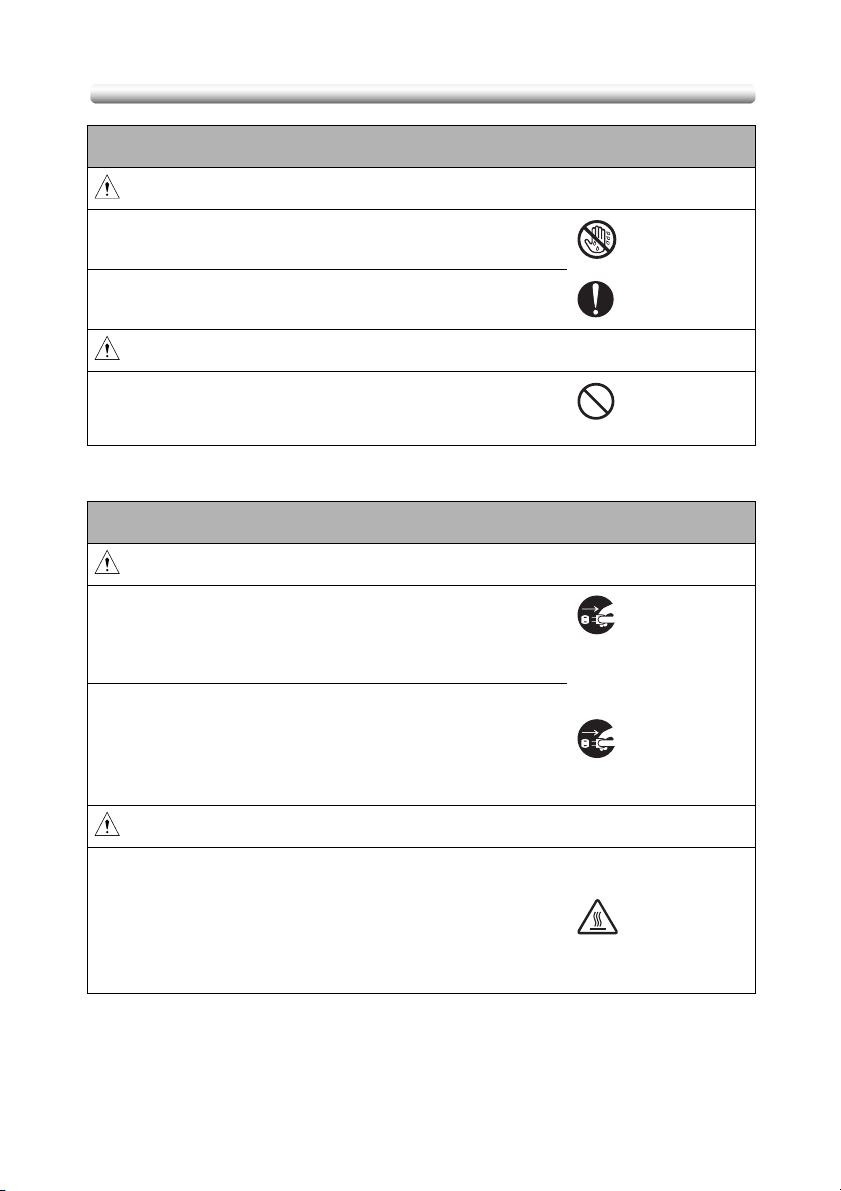

Meaning of the graphic expression

In this CMS Replacement Instructions and on the copier, various types of graphic expressions are

employed to allow you to conduct a part replacement operation properly without causing harm to

you as well as other people, and also damage to the property.

The expressions and their meaning are as shown below.

WARNING

CAUTION

Indicates an action having a high possibility of suffering death or a

serious injury when handled inappropriately without taking no notice

of this expression.

Indicates an action having a high possibility of suffering an injury or

causing damage to the property when handled inappropriately with-

out taking no notice of this expression.

Examples of graphic symbols

This symbol indicates an action that requires an additional caution (including

warning). A specific description of the caution is given in the symbol.

Ex.) [ ] This is a graphic symbol representing "High temperature."

This symbol indicates an action prohibited. A specific description of the prohibi-

tion is given inside the symbol or in its vicinity.

Ex.) [ ] This is a graphic symbol representing "Do not disassemble."

This symbol indicates an action that must be carried out. A specific description of

the action is given inside the symbol.

Ex.) [ ] This is a graphic symbol representing "Unplug power cord."

2

For your safe operation (continued)

Operations before replacing any part:

CAUTION

When conducting a part replacement operation, be sure to get guid-

ance from the customer engineer. And also, read the CMS Replace-

ment Instructions carefully before conducting a part replacement

operation by following the prescribed procedure and using tools also

prescribed. Be sure not to conduct any operations other than those

described in the CMS Replacement Instructions. When the pre-

scribed procedure and tools are not employed, this may cause

damage to the copier or you may get injured.

Before starting operations, be sure to unplug the power cords of the

copier main body and the optional equipment from the power outlet.

When the power cord is plugged into the power outlet, some electri-

cal components may be energized even if the power switch is

turned off. So, be careful not to get an electric shock.

The temperature gets high in the vicinity of the fusing unit. Be careful

not to come into contact with it, or you may get burned.

CMS part replacement operation:

WARNING

Do not allow any metal parts such as clips, staples and screws to fall

into the inside or opening of the copier.

They may cause a short circuit to the internal parts of the copier,

thus leading up to a risk of an electric shock or fire.

Check the wiring harness for squeezing and any other damage.

Current may leak, thus leading up to a risk of an electric shock or

fire.

3

For your safe operation (continued)

Power plug:

WARNING

• Be sure to avoid plugging or unplugging the power cord with a

wet hand. You may get an electric shock.

• Be sure to plug the power cord securely into the power outlet.

Otherwise, a fire may result, or you may get an electric shock.

CAUTION

• When unplugging the power cord from the power outlet, be care-

ful not to pull the power cord. Otherwise, a fire may result with the

power cord damaged, or you may get an electric shock.

When any abnormal condition is found:

WARNING

• When the copier gets hot abnormally, or when it gives out smoke,

a foul smell or abnormal noise, turn off the power switch at once.

And then be sure to unplug the power cord from the power outlet

and contact our service technician.

• When the copier is let fall or when the cover is damaged, turn off

the power switch at once. And then, be sure to unplug the power

cord from the power outlet and contact our service technician.

Using the copier as it is may lead up to a fire, or you may get an

electric shock.

CAUTION

• Some internal parts of the copier develops a high temperature,

and you may get a burn when you come into contact with one of

these parts. When checking the internal parts while in a part

replacement operation, be careful not come into contact with a

section like these (around the fusing unit) with a symbol indicating

"High Temperature" provided.

4

Caution notice/Caution label

For this copier, there are the caution notices or labels for safety operations

provided at the locations as shown below. Be sure to take every care to avoid

any accidents while in the part replacement operation.

(Entrance of the reverse exit unit)

(Right side of the fixing unit)

(Top surface of the fixing unit)

CAUTION

DO NOT put your

hand between the

main body and

developing fixing

unit; otherwise

you may be

injured.

CAUTION

The fixing unit is

very hot.

To avoid getting

burned DO NOT

TOUCH.

CAUTION

DO NOT INSERT your finger

into the two RADF hinge

portions; otherwise you may

be injured.

CAUTION

DO NOT put your

hand between

the main body

and developing

fixing unit;

otherwise you

may be injured.

CAUTION

This product employs a Class

IIIb Laser Diode that emits an

invisible laser beam. The cover

should not be opened under

any circumstances.

5

1. Main body:

Pick-up roller assembly/

Pick-up roller assembly/

separation roller assembly

separation roller assembly

REPLACEMENT INSTRUCTIONS

2004.10

Ver. 1.0

6

1. Main body: pick-up roller assembly/separation roller assembly replacement instructions

(1) Purpose

To return to the normal operation as soon as possible when a decrease in the paper feedability is found due

to the deterioration of the pick-up roller or separation roller.

(2) Procedure for removal

NOTE

• The method for replacing the pick-up roller assembly/separation roller assembly is the same for

the tray /1 and the tray /2. The explanation here is given of the tray /1.

1.

Turn OFF the sub power switch.

Sub

power

switch

1050fs5012z

2.

Front door

/Left

Main power switch

Front door

/Right

Open the front door /Right and the front door /

Left, and then turn OFF the main power switch.

3.

Unplug the power cord from the wall outlet.

1050fs2001y

Caution:

• When conducting the replacement opera-

tions, be sure to turn OFF the main power

switch and the sub power switch and then

unplug the power cord from the wall outlet.

7

1. Main body: pick-up roller assembly/separation roller assembly replacement instructions

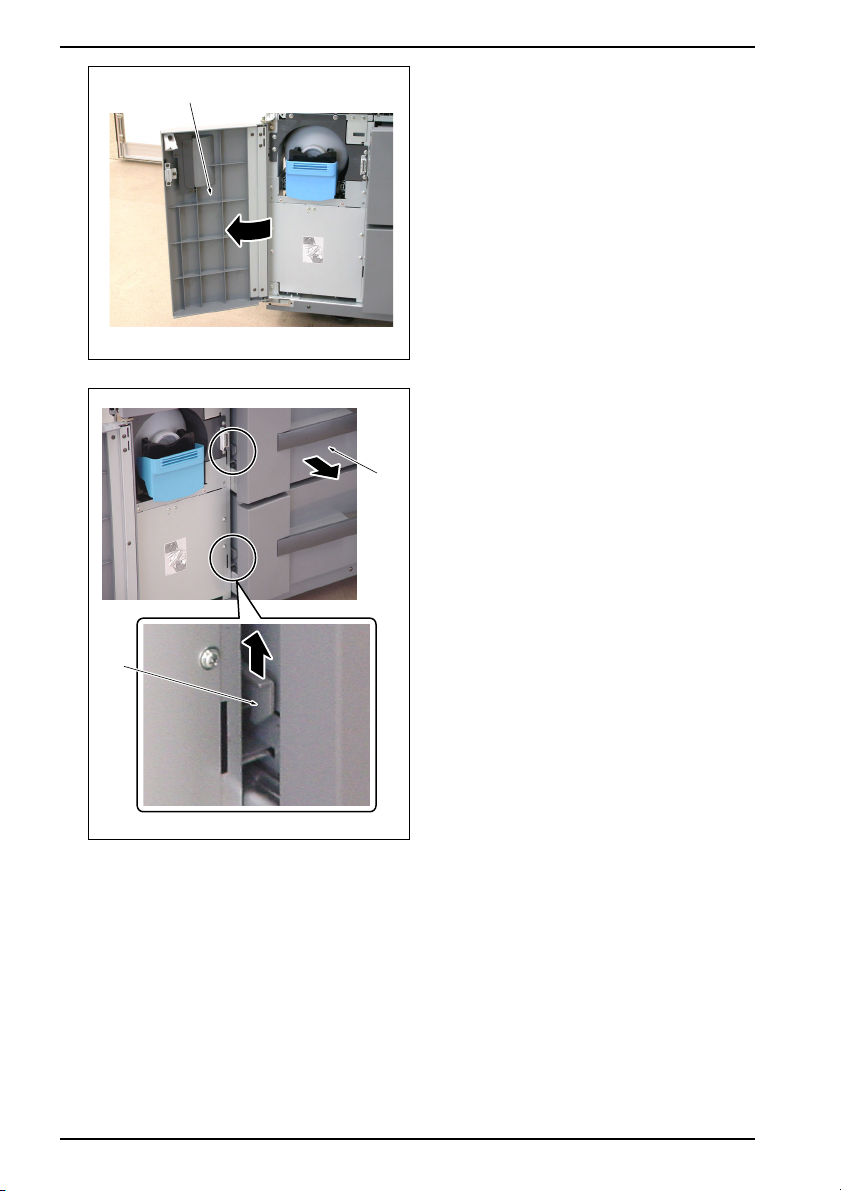

4.

Open the toner supply door.

Toner supply door

1050fs2063z

5.

Raise up the tray lock lever lightly and pull out the

tray.

Tray

Tray

lock

lever

1050fs2700c

8

Pick-up

roller

1. Main body: pick-up roller assembly/separation roller assembly replacement instructions

6.

Rotate the pick-up roller in the arrow-marked

direction (counterclockwise as seen from the

front) and place the coupling in the longitudinal

direction.

NOTE

• The rotation of the pick-up roller is restricted

only to the arrow-marked direction (counter-

clockwise). It does not rotate in the reverse

direction (clockwise). So, be sure not to turn it

in this direction forcibly.

7.

Remove the 2 C-clips.

8.

Remove the bearing /Front.

9.

Slide the bearing /Rear to the rear side.

Bearing /Rear

C-clipCoupling

1050fs2701c

Bearing

/Front

1050fs2702z

9

1. Main body: pick-up roller assembly/separation roller assembly replacement instructions

10.

Hold the pick-up roller assembly by hand and lift

the paper feed roller up to tilt while rotating it

around the pick-up roller shaft, and then remove

Sensor

it from the notch of the bearing and the joint.

NOTE

• When removing the pick-up roller, be careful

not to damage the sensor with the metal

frame.

Joint Paper feed roller

Metal

frame

Notch

Pick-up roller shaft

Pick-up roller assembly

1050fs2703c

10

1. Main body: pick-up roller assembly/separation roller assembly replacement instructions

Pick-up roller assembly

Arm

Pick-up roller shaft

Pick-up

roller

assembly

11.

Remove the pick-up roller shaft from the arm of

the paper feed guide plate and then remove the

pick-up roller assembly.

Entrance guide plate

Screw

1050fs2704c

1050fs2705c

11

12.

Remove the 2 screws and then remove the

entrance guide plate.

1. Main body: pick-up roller assembly/separation roller assembly replacement instructions

13.

Separation roller assembly

Remove the 2 screws and release the fixing of

the separation roller assembly.

Joint

Screw

1050fs2706c

Coupling pin

Separation roller

assembly

1050fs2707c

14.

After pulling out the front side of the separation

roller assembly, remove the coupling pin in the

rear from the joint.

15.

When installing a new replacement part, see "(3)

Procedure for reinstallation" (on the next page).

12

1. Main body: pick-up roller assembly/separation roller assembly replacement instructions

(3) Procedure for reinstallation

NOTE

• The method for replacing the pick-up roller assembly/separation roller assembly is the same for

the tray /1 and the tray /2. The explanation here is given of the tray /1.

• After completion of the installation, rotate the pick-up roller in the direction of the paper feed

(counterclockwise as seen from the front) to check to see if the paper feed roller, the belt and the

coupling section rotate smoothly. The rotation of the pick-up roller is restricted only to the direc-

tion of the paper feed (counterclockwise as seen from the front) and be absolutely sure not to turn

it clockwise.

• Be sure to take note that the direction of the pick-up roller assembly is different for the main body

and the PF-701.

1.

Insert the new separation roller assembly askew

and engage the coupling pin with the joint.

Joint

Coupling pin

Separation roller

assembly

1050fs2707z

NOTE

• Be sure to engage the coupling pin with the

joint.

13

1. Main body: pick-up roller assembly/separation roller assembly replacement instructions

2.

Separation roller assembly

Install the separation roller assembly with the 2

screws.

NOTE

• When installing the separation roller assem-

bly, be sure to screw it while pressing it down.

Screw

Entrance guide plate

Screw

1050fs2706z

1050fs2705z

3.

Attach the entrance guide plate with the 2

screws.

14

Pick-up roller assembly

Paper feed

guide plate

arm

Sensor

1. Main body: pick-up roller assembly/separation roller assembly replacement instructions

4.

Insert the pick-up roller shaft of the new pick-up

roller assembly into the paper feed guide plate

arm.

Pick-up roller

shaft

1050fs2704z

5.

With the pick-up roller shaft being used as a ful-

crum, rotate the pick-up roller assembly and

insert the shaft and the coupling of the paper

feed roller into the notch of the bearing and the

joint respectively.

Coupling

Joint

Pick-up roller shaft

Paper feed roller

Pick-up roller assembly

Metal

frame

Shaft

Notch

1050fs2703z

NOTE

• Be sure to engage the coupling of the paper

feed roller with the joint.

• When installing the pick-up roller assembly,

be careful not to damage the sensor with the

metal frame.

15

Loading...

Loading...