Kongsberg EM 2040P Installation Manual

Multibeamechosounder

EM2040P

Installationmanual

417418/B

December2017©KongsbergMaritimeAS

Documentinformation

•Product:KongsbergEM2040P

•Document:Installationmanual

•Documentnumber:417418

•Revision:B

•Dateofissue:December2017

Note

TheinformationcontainedinthisdocumentremainsthesolepropertyofKongsbergMaritimeAS.No

partofthisdocumentmaybecopiedorreproducedinanyformorbyanymeans,andtheinformation

containedwithinitisnottobecommunicatedtoathirdparty,withoutthepriorwrittenconsentof

KongsbergMaritimeAS.

KongsbergMaritimeASendeavourstoensurethatallinformationinthisdocumentiscorrectandfairly

stated,butdoesnotacceptliabilityforanyerrorsoromissions.

Warning

Theequipmenttowhichthismanualappliesmustonlybeusedforthepurposeforwhichitwas

designed.Improperuseormaintenancemaycausedamagetotheequipmentand/orinjurytopersonnel.

Youmustbefamiliarwiththecontentsoftheappropriatemanualsbeforeattemptingtooperate

orworkontheequipment.

KongsbergMaritimedisclaimsanyresponsibilityfordamageorinjurycausedbyimproperinstallation,

useormaintenanceoftheequipment.

Comments

Toassistusinmakingimprovementstotheproductandtothismanual,wewelcomecommentsand

constructivecriticism.

e-mail:km.documentation@km.kongsberg.com

Fortechnicalsupportissues,pleasecontactkm.support@km.kongsberg.com.

Supportinformation

Ifyourequiremaintenanceorrepair,contactyourlocaldealer.Y oucanalsocontactususingthefollowing

address:km.hydrographic.support@kongsberg.com.Ifyouneedinformationaboutourotherproducts,

visithttp://www.km.kongsberg.com

KongsbergMaritimeAS

www.kongsberg.com

Installationmanual

Tableofcontents

ABOUTTHISMANUAL..............................................................7

EM2040P................................................................................9

Systemdescription.............................................................................................................9

Systemdiagram................................................................................................................10

Systemunits.....................................................................................................................11

Transducerdescription...........................................................................................11

ProcessingUnitdescription....................................................................................11

PortableProcessingUnitdescription.....................................................................11

HydrographicWorkStationdescription.................................................................12

RuggedHydrographicW orkStationdescription...................................................12

RemoteControlUnit(K-Rem)description............................................................12

PREPARATIONS.....................................................................14

Personnelqualications...................................................................................................14

Sonarroomrequirements.................................................................................................15

Environmentalrequirements..................................................................................15

Requirementforwatertightintegrity......................................................................15

Sizeandaccessrequirements.................................................................................16

Requirementsforinsulation,heatingandventilation.............................................16

Requirementsforelectricalinstallations,cablesandcommunication...................17

Requirementsforbilgepumpanddecking.............................................................18

Wheretoinstallthetransducer........................................................................................19

Introductiontotransducerlocation.........................................................................19

Mountthetransducerdeep.....................................................................................19

Avoidprotrudingobjectsnearthetransducer.........................................................20

Keepthetransducerfarawayfromthepropellers.................................................21

Chooseatransducerpositionfarawayfromthebowthruster(s)...........................21

Summaryandgeneralrecommendations...............................................................21

Acousticnoise..................................................................................................................23

Contributingfactors................................................................................................23

Selfnoise................................................................................................................24

Ambientnoise.........................................................................................................27

Electricalselfnoise................................................................................................27

Somemeanstoreduceacousticnoise....................................................................27

Vesselcoordinatesystem.................................................................................................29

INSTALLINGTHETRANSDUCER.............................................32

Rulesfortransducerhandling..........................................................................................32

Installationsummary........................................................................................................34

417418/B

3

EM2040P

Installationrequirements..................................................................................................36

Freeviewingsector................................................................................................36

Installationprinciples.......................................................................................................37

Permanenttransducerinstallation..........................................................................37

Nonpermanenttransducerinstallation...................................................................38

Transducerinstallationusingahullunit................................................................39

ReferencepointontheEM2040Ptransducer.................................................................40

Paintingthetransducerface.............................................................................................41

Approvedanti-foulingpaints...........................................................................................43

INSTALLINGTHEEM2040PHARDWAREUNITS.....................44

InstallingtheProcessingUnit..........................................................................................45

InstallingtheProcessingUnit.................................................................................45

ProcessingUnitrearpaneldescription...................................................................47

ProcessingUnitcircuitboardsandmodules..........................................................48

CBMFboard-dipswitchsetting...........................................................................49

InstallingthePortableProcessingUnit............................................................................50

PortableProcessingUnitdescription.....................................................................50

PortableProcessingUnitfrontpaneldescription..................................................51

InstallingtheHydrographicW orkStation.......................................................................52

InstallingtheHydrographicW orkStation..............................................................52

HydrographicWorkStationrearconnectors(MP5810)........................................55

CABLELAYOUTANDINTERCONNECTIONS.............................57

Readthisrst...................................................................................................................58

Cableplans.......................................................................................................................59

ProcessingUnit,singleswath,cableplan..............................................................60

ProcessingUnit,dualswath,cableplan.................................................................61

PortableProcessingUnit,cableplan......................................................................62

Topsidecableplan..................................................................................................63

ListofEM2040Pcables..................................................................................................64

Cabledrawingsandspecications...................................................................................66

RS-232seriallineusingthreewiresandRJ45connector......................................67

RS-422seriallineusingvewiresandRJ45connector........................................68

RS-232seriallineusedforDGNSSinput..............................................................69

RS-422seriallineusedforDGNSSinput..............................................................70

Clocksynchronisation(1PPS)usingacoaxcable.................................................71

Remotecontrol.......................................................................................................72

RemoteControlusingK-Rem................................................................................73

Dummyplugfornotusingremotecontrol.............................................................74

Externalsynchronisation........................................................................................75

Transducercable.....................................................................................................76

4

417418/B

Installationmanual

TransducercableforPortableProcessingUnit......................................................78

Seapathantennainterfacecable-withplug...........................................................80

Antennainterfacecable..........................................................................................82

SeapathMRUinterfacecable.................................................................................83

DCPowercable......................................................................................................84

DRAWINGFILE......................................................................85

Transducerdimensions....................................................................................................86

Transducermountingbracket...........................................................................................87

385422ProcessingUnitdimensions................................................................................88

424178PortableProcessingUnitdimensions.................................................................89

378828HydrographicW orkStationdimensions.............................................................90

370275RemoteControlUnit(K-REM)dimensions.......................................................92

373962RemoteControlUnit(K-REM)wiringdiagram.................................................94

TECHNICALSPECIFICATIONS................................................95

Performancespecications..............................................................................................96

Interfacespecications.....................................................................................................97

Weightsandoutlinedimensions....................................................................................101

Powerrequirements.......................................................................................................102

Environmentalrequirements..........................................................................................104

Alignmentspecications................................................................................................105

EQUIPMENTHANDLING.......................................................107

TransportingKongsbergMaritimeequipment...............................................................108

Liftingunitsandtransportationboxes...........................................................................109

Inspectionofunitsandtransportationboxesafterarrival..............................................111

Specicationsforstoragepriortoinstallationoruse.....................................................112

Unpackinginstructions..................................................................................................114

Unpackingstandardpartsandunits......................................................................114

Unpackingmechanicalunits................................................................................115

Unpackingelectronicandelectromechanicalunits..............................................116

Unpackingtransducers.........................................................................................117

Specicationsforstorageafterunpacking.....................................................................119

GENERALSAFETYRULES.....................................................121

Generalsafetyrules........................................................................................................121

417418/B

5

EM2040P

6

417418/B

Aboutthismanual

Purposeofmanual

Thepurposeofthismanualistoprovidetheinformation,proceduresandbasicdrawings

requiredforthephysicalinstallationoftheEM2040P.

Targetaudience

Aboutthismanual

Themanualisintendedfortechnicalpersonnel;suchasskilledshipyardworkers,

electricians,qualiedengineersandnavalarchitects.Itisassumedthatyouunderstand

thegeneralprinciplesofmaritimeelectronicequipment.Y oumustalsobefamiliarwith

computerhardware,interfacetechnologyandinstallationofelectronicandmechanical

products.

Weassumethatyouarefamiliarwiththebasicacousticprinciplesofsoundinwater.

Wealsoexpectthatyouhavesomeexperiencewithmultibeamand/orsinglebeamecho

soundersinhydrographicapplications..

Installationinstructions

Youmustfollowtheinstructionsinthismanualtoensureoptimalperformance.Asa

guide,installationproceduresarepresentedintheordertheymustbedone.

Theequipmentdescribedinthismanualincludesthecompletesystemwithrelevant

cabinets.Unitsprovidedlocallybythecustomer,installationshipyardorlocal

representativearenotdescribed.

Themanualalsodenestheequipmentresponsibility,andprovidesapplicable

instructionsforunpackingandstorageofunits.

Note

Youmustfollowtheinstructionsgiveninthismanual.Ifnotitmayaffectthewarranty.

KongsbergMaritimeASwillacceptnoresponsibilityforanydamageorinjurytothe

system,vesselorpersonnelcausedbyequipmentthathasbeenincorrectlyinstalledor

maintained,orbydrawings,instructionsorproceduresthathavenotbeenprepared

byus.

Installationdrawings

Theinstallationshipyardmustprovideallnecessaryinstallationdrawings.

417418/B

7

EM2040PInstallationmanual

KongsbergMaritimeASmay,onspecialorder,provideassistancetothesedrawings.

Note

Ifrequired,alldocumentsprovidedbytheshipyardforthephysicalinstallationof

theEM2040Pmustbeapprovedbythevessel’ snationalregistryandcorresponding

maritimeauthorityand/orclassicationsociety.Suchapprovalmustbeobtainedbefore

theinstallationcanbegin.Theshipownerandshipyarddoingtheinstallationare

responsibleforobtainingandpayingforsuchapproval.

TheoutlinedimensionsoftheEM2040PunitsarefoundintheDrawinglechapter

inthismanual.

Onlineinformation

ForinformationabouttheEM2040PandotherproductsfromKongsbergMaritime,

visitourwebsite.

•https://www.km.kongsberg.com

Registeredtrademarks

Observetheregisteredtrademarksthatapply.

Windows

®

isaregisteredtrademarkofMicrosoftCorporationintheUnitedStatesand

othercountries.

®

EM

isaregisteredtrademarkofKongsbergMaritimeASinNorwayandothercountries.

8

417418/B

Topics

Systemdescription,page9

Systemdiagram,page10

EM2040P

EM2040P

Systemunits,page11

Systemdescription

TheEM2040Portableisatruewidebandhighresolutionshallowwatermultibeamecho

sounder.Itisanidealtoolforanyhighresolutionmappingandinspectionapplication.

EM2040PisbasedontheEM2040technology.Thereceiverandtransmitterare

integratedinacommonsonarhead.

Keyfeatures

•Frequencyrangefrom200to400kHz

•Highresolution

•Dualswathoption,allowingsufcientsounddensityalongtrackatreasonablesur-

veyspeed

•FMchirpallowingmuchlongerrangecapability(depthandcoverage)com-

paredtoCWpulses

•Completeroll,pitchandyawstabilization

•Neareldfocusingonbothtransmitandreceive

•Shortpulselengths,largebandwidth.Shortestpulseis14μs

•IHO-S44specialordercompliant

•Seabedimage

•Watercolumnloggingasanoption

•Swathcoverage:140degrees

417418/B

9

EM2040PInstallationmanual

•Beamwidth:1x1degreeat400kHz

•Transducerdepthrating:30metres

•Easytoinstall

Systemdiagram

ThesystemdiagramidentiesthemaincomponentsofabasicEM2040Psystem.Only

themainconnectionsbetweentheunitsareshown.Detailedinterfacecapabilitiesand

powercablesarenotshown.

AHydrographicW orkStation

BInterfaces:

•Soundspeedsensor

•Tide

•Centredepthoutput

CProcessingUnit

DInterfaces:

•Positioningsystems

•Attitude(roll,pitchand

heave)

•Soundspeedsensor

–WithK-Controller

upgrade

•Velocity

•Heading

•Clock

•Triggerinput/output

•Clocksynchronisation

(1PPS)

ETransducer

10

417418/B

EM2040P

Systemunits

Transducerdescription

Atransducerisadevicethatconvertsoneformofenergytoanother.Inanechosounder

systemthetransducerconvertsbetweenelectricenergyandsound.TheEM2040Phas

transducersfortransmittingandreceivingsoundpulsesinonehousing,andwecallthis

housinga"sonarhead".

Asinglecablewithanunderwaterplug,connectsthe

transducertotheProcessingUnit.

TheEM2040Ptransducerhasseparatelinear

transducerarraysfortransmitandreceiveinaMills

crossconguration.Thetransducercontainsallanalog

electronicsanddigitalcontrolunitswithEthernet

interfacetotheProcessingUnit.Thetransmitteriselectronicallysteerablealongtrack

whilethereceiverissteerableathwartship.

Thetransmittransducerconsistsofthreeseparatelinearrays,onelookingstraightdown

andthetwootherspointing45degreestoeachside.

Thetransducersaremadefromcompositeceramicswhichenablesawidebandwidth.

Thematerialinthepartofthetransducerhousingwhichisexposedtoseawaterishard

anodisedaluminium.

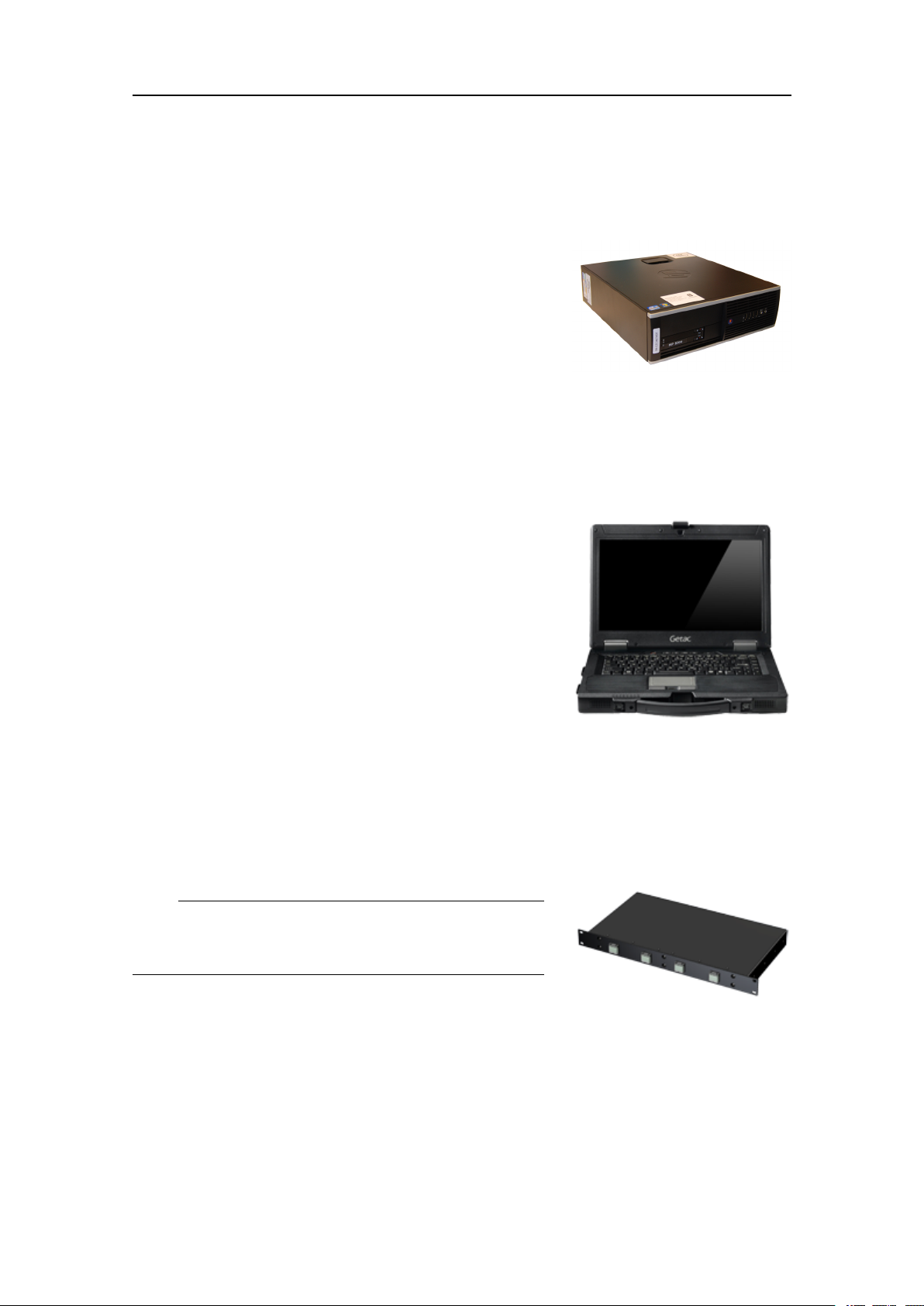

ProcessingUnitdescription

TheProcessingUnitisthecentralcontrollingdeviceintheEMmultibeamsystem.Itis

providedtoprocessthesignalstoandfromthetransducer(s).

Itisanindustrialcomputerwhichisdesignedand

testedforruggeduse.

TheProcessingUnitalsosupplies48Vdcpowertothe

transducer(s).

PortableProcessingUnitdescription

TheEM2040PProcessingUnitisavailableinaportableversion.

Theportableversionhasthesamefunctionalityasthe

standardEMProcessingUnitinarugged,splashproof

enclosure.Italsosupportsasinglecableinterfaceto

theSeapath130Series.

417418/B

11

EM2040PInstallationmanual

HydrographicWorkStationdescription

TheHydrographicWorkStationistheoperatorstationfortheEM2040P.

Adedicatedmaritimecomputerisprovidedwiththe

EM2040PMultibeamechosounder.Itissetupwith

allnecessarysoftware.

TheHydrographicWorkStationisbasedonthe

Microsoft

®

Windowsoperatingsystem.

TheHydrographicWorkStationisnormallymounted

neartheoperatorworkspace.

RuggedHydrographicWorkStationdescription

TheHydrographicWorkStationistheoperatorstationfortheEM2040P.

Adedicatedmaritimecomputerisprovidedwiththe

EM2040PMultibeamechosounder.Itissetupwith

allnecessarysoftware.

TheHydrographicWorkStationisalsoavailablein

asemiruggedorfullyruggedversionforportableuse.

RemoteControlUnit(K-Rem)description

Adedicatedjunctionboxhasbeendesignedtoprovideremoteon/offswitcheswithlight

indicationandinterfacetoaremotesynchronizingsystem.Thejunctionboxcontainsa

terminalblockandfourswitcheswithlampsmountedinthefront.

Note

TheRemoteControlUnitisnotastandardpartof

theEM2040Pdelivery.

TheRemoteControlUnitiscalledK-Rem.Itis

preparedforremotecontrolandinterfacetoanexternal

synchronizationsystemforfourKongsbergechosounders.

•OneSub-bottomproler(SBP120orSBP300)

•TwoEMmultibeamechosounders

•OneEAsinglebeamechosounder

12

417418/B

TheRemoteControlUnitisdesignedtobemountedina19inchrack,butitisalso

possibletomountitonaatsurfaceorinabulkhead.Itisalsopreparedformounting

ontelescopicrails.

EM2040P

417418/B

13

EM2040PInstallationmanual

Topics

Personnelqualications,page14

Sonarroomrequirements,page15

Preparations

Wheretoinstallthetransducer,page19

Acousticnoise,page23

Vesselcoordinatesystem,page29

Personnelqualications

TheinstallationoftheEM2040Pisademandingtask.Itisveryimportantthatthe

personnelinvolvedintheinstallationtasksarecompetentandexperiencedcraftsmen.

Asaminimum,thefollowingcertiedcraftsmenmustbeavailable.

•Navalarchitects

•Welders

•Electricians

•Projectmanager

Note

Thequalityoftheweldingiscriticaltothesafetyofthevessel.W eldingmustonlybe

donebyacertiedwelder .

Ifapplicable,thenalinstallationweldsmustbeapprovedbythevessel’ snational

registry,thecorrespondingmaritimeauthorityand/orclassicationsociety.Observethe

relevantrulesandregulationsrelatedtowelding.

14

417418/B

Sonarroomrequirements

Topics

Environmentalrequirements,page15

Requirementforwatertightintegrity,page15

Sizeandaccessrequirements,page16

Requirementsforinsulation,heatingandventilation,page16

Requirementsforelectricalinstallations,cablesandcommunication,page17

Requirementsforbilgepumpanddecking,page18

Preparations

Environmentalrequirements

TheEM2040Punitsmustbeinstalledinadryanddust-freeenvironment.Theunits

arenotfullyprotectedagainsthumidity ,dustorwater.

Itisimportantthatthesonarroomiskeptdry.TheEM2040Punitsmustnotbeexposed

toexcessivetemperatures,moistureorhumidity.Suchconditionscancausecorrosive

attacksandsubsequentfailurestotheelectroniccircuitry.Visitthesonarroomat

regularintervalstochecktemperatureandhumidity,andtakethenecessaryactions

iftheenvironmentalconditionsarepoor.

ObservetheenvironmentalspecicationsrelatedtotheEM2040Punits.

Requirementforwatertightintegrity

Thesize,locationanddesignofthesonarroommustfullalltherequirementstothe

vessel’swatertightintegrity.

Intheeventofamajorleakinthesonarroom,itmustbepossibletocloseallwatertight

hatchesand/ordoorstothesonarroomtomaintainthevesselstabilityandsafety.

Thephysicalsizeofthesonarroommustbelimited,sothatintheeventofamajor

leak,theoodingofthesonarroomwillnotinduceinstability,orcausethevesselto

capsizeorsink.

Ensurethatallwatertightdecksandbulkheadsareinspectedperiodicallytoverifythat

therearenounprotectedopeningsorimproperpenetrationsthatwillallowprogressive

oodingfromthesonarroom,andthatthewatertightdoorsandhatchesareinplaceand

inworkingorder.

Ensurebilgehighlevelalarmsarearrangedtoprovidetheearliestwarningsofabnormal

accumulation.Thehighlevelbilgealarmsmustbesetaslowaspossibletothedeck

orbilgewellandpositionedalongthecentreareaofthecompartmentorinalocation

atwhichtheuidswillgravitatetorst.

417418/B

15

EM2040PInstallationmanual

Allcablesleadinginandoutofthesonarroommustberuninsteelconduits.Thesesteel

conduitsmustreachupandabovethefreeboarddeck.

Sizeandaccessrequirements

Awelldesignedsonarroomwithawellttedsizeandeasyaccessreducestheriskof

corrosion,andsimpliesmaintenance.Thisincreasessystemreliability.

Note

Thephysicalsizeofthesonarroommustbelimited,sothatintheeventofamajorleak,

theoodingoftheroomwillnotinduceinstability,orcausethevesseltocapsizeorsink.

Thesonarroommustbelargeenoughtohouseallthesystemunits.Theroommust

provideenoughspacetoallowefcientmaintenance.Y oumustbeabletokeepallthe

cabinetdoorsfullyopenwithoutunduerestrictiontoyourmovements.

1Theroommustnotbeusedforanyotherheavymachinery.

2Theroommustnotbeunnecessarilyobstructedbygirders,pipesetc,whichmay

causeinstallationproblemsorimpedemaintenance.

3Theroommustbeaccessibleunderallconditionsatseaorataberth.

4Alldoorsorhatchesmustbedesignedsothatthetoolsandequipmentcanbe

removedwithoutbeingdisassembled.

5Allcablesleadinginandoutofthesonarroommustberuninsteelconduits.These

steelconduitsmustreachupandabovethefreeboarddeck.

Requirementsforinsulation,heatingandventilation

Thebulkheadsinthesonarroommustbeinsulatedandprovidedwithaninteriorwall

tothedeck.Theroommustbeequippedwithheater,anditmustbeconnectedtothe

vessel'sventilationsystem.

Insulationrequirements

Theinsulationinthesonarroomshouldbetheminimumequivalentof50mmof

rock-wool.Pipingpassingthroughthespacepronetocondensationmustbeproperly

insulated.

Heatingrequirements

Heatingisaneffectivemethodforreducinghumidity .Theheaterinthesonarroommust

dimensionedtomaintaintheequipmentwithinitsenvironmentaltolerances.Typical

heatingpowerisminimum1000W .Theheatermustbeinstalledclosetothedeck.

16

417418/B

Preparations

Ventilationrequirements

Thesonarroommustbeconnectedtothevessel'sventilationsystemtoensureasupply

ofcoolingair.Ifaventilationsystemisnotavailable,installtwo3”pipesfromthesonar

roomtoasuitablefreshairlocationondeck.

Thefreshairshouldentertheroomasclosetotheooraspossible,andshouldbe

extractedfromashighaspossible.Afunnelshapeddrip-collectormustbemounted

belowtheventpipestodivertmoisturetothebilge.Onthemaindeck,thebest

ventilationisprovidedwhentheoutletpipeisatleastfourmetershigherthantheinlet

pipe.Tokeepoutseawater,rainandspray,theventilationpipesmustbettedwith

goosenecksoranequivalentdesign.

Note

Ifthevesselislikelytooperateintropicalconditions,asuitableairconditioningsystem

mustbeinstalled.Theairconditioningsystemmustbeabletoprovideanambient

temperaturethatdoesnotexceedthemaximumoperatingtemperaturesoftheEM2040P

unitsthatareinstalledintheroom.

Requirementsforelectricalinstallations,cablesand communication

Theelectricalinstallationsinthesonarroommustmeetminimumrequirementsto

providesuitablelightsandsupplypower.

Lightrequirements

Thesonarroommustbeequippedwithsuitablelightingtosimplifytheinstallation

andtoaidfuturemaintenance.

Communicationrequirements

Thesonarroommustbeequippedwithatelephone,anintercomsystem,oranyother

meansoforalcommunicationbetweenthesonarroomandthebridgeand/orcontrol

room(s).

Powerrequirements

Eachunitinthesonarroomshouldbeprovidedwithaseparatecircuitbreakeronthe

mainssupply.

Aminimumnumberofadditionalelectricaloutletsmustbeprovidedforotherequipment.

Propervesselgroundmustbeprovided.

Cablingrequirements

ThesonarroomunitsareconnectedtootherEM2040Punitslocatedindifferent

compartmentsonthevessel.Theunitsmayalsobeconnectedtoperipheraldevices.If

417418/B

17

EM2040PInstallationmanual

thesecablespassthroughhatchesorareaswheretheymaybedamaged,theymustbe

runinconduits.Minimum2”conduitisrecommended.

Makesurethatallsystemcablesareproperlyconnectedandsecured,andinstalled

withsomeslack.Theslackisessentialtowithstandvibrations,andtofacilitatefuture

maintenanceandreplacements.

Requirementsforbilgepumpanddecking

Ifthesonarroomislocatedbelowthewaterline,itmustbeconnectedtothevessel's

bilgepumpsystem.

Bilgepumprequirement

Ifitisnotpossibletoconnectthesonarroomtothevessel'sbilgepumpsystem,a

separatebilgepumpforthecompartmentmustbeinstalled.

Deckingrequirement

Oncetheinstallationhasbeencompleted,thesonarroommustbesuitablydecked

withoutrestrictingaccesstotheequipmentandthecables.

18

417418/B

Wheretoinstallthetransducer

Topics

Introductiontotransducerlocation,page19

Mountthetransducerdeep,page19

Avoidprotrudingobjectsnearthetransducer,page20

Keepthetransducerfarawayfromthepropellers,page21

Chooseatransducerpositionfarawayfromthebowthruster(s),page21

Summaryandgeneralrecommendations,page21

Preparations

Introductiontotransducerlocation

Asingleanswertothequestion"wheretoinstallthetransducer"cannotbegiven.

Thephysicallocationofthetransducerdependsonthevessel'sdesignandconstruction,

howthehullisshaped,andhowthewaterrunsalongthehull.Therearehowevera

numberofimportantguidelines,andsomeoftheseareevenconicting.

Note

Theinformationheremustbeconsideredasgeneraladvice.EachEM2040Pinstallation

mustbehandledseparatelydependingonthehulldesignandtheotherelectricaland

mechanicalsystemsinstalledonthevessel.

Mountthetransducerdeep

InordertoachievethebestpossibleEM2040Pperformance,mountthetransduceras

deepaspossibleunderthevessel’shull.

Thereareseveralreasonsforthisrecommendation.

Flownoise

Considerthesituationswhenthevesselisunloaded,andpitchinginheavyseas.The

vesselisridinghigh,andthebowmayevenbeliftedoutofthewater.Thiswillcausea

lotofairtofollowtheshapeofthehull.

Theupperwaterlayersoftheseacontainamyriadofsmallairbubblescreatedbythe

breakingwaves.Inheavyseastheupper5to10metresmaybelledwithair,andthe

highestconcentrationswillbenearthesurface.Airbubblesabsorbandreectthesound

energy,andtheymayinworstcasesblockthesoundtransmissionaltogether.

417418/B

19

EM2040PInstallationmanual

Cavitation

Cavitationistheformationofsmallairbubblesclosetothetransducerface.Thebubbles

appearbecausethelocalpressurebecomesnegativeduringpartsoftheacousticpressure

cycles.Thecavitationthresholdincreaseswiththehydrostaticpressure.Thenoiseis

madewhenthebubblesimplode.

Transmittinginair

Thetransducermustneverbeliftedfreeofthewatersurface.Ifthetransduceris

activatedwhenoutofwateritmaybedamagedbeyondrepair.Mountingthetransducer

atadeeppositiononthehullwillinnormallypreventthis.

Slamming

Slamminghappensifthevesselhullclimbsoutofthewaterinheavyseas.Theforceof

thewaterwhenthehullfallsdownmaypushthetransducerup,andmaycausedamage

bothtothetransducerandtoitsmounting.Thisisespeciallyimportantforlowfrequency

transducerswithlargefaces.Theeffectofslammingcanbereducedbymountingthe

transducerasdeepaspossibleonthehull.

Note

KongsbergMaritimeAStakesnoresponsibilityforanydamagestothetransducer,the

cableorthemountingarrangement,causedbyslamming.

Avoidprotrudingobjectsnearthetransducer

Objectsprotrudingfromthehullwillgenerateturbulenceandownoise.Thiswill

reducetheEM2040Pperformance.

Protrudingobjectsmaybezincanodes,transducersoreventhevessel'skeel.Holesand

pipeoutletsarealsoimportantnoisesources,aswellasroughsurfacescausedbybad

welding.Eventracesofsealingcompound,sharpedges,boltsoremptyboltholeswill

createnoise.Alltheseprotrudingobjectsmayactasresonantcavitiesamplifyingthe

ownoiseatcertainfrequencies.

Donotplaceatransducerinthevicinityofprotrudingobjects,andespeciallynotclose

behindthem.Makesurethatthesurfaceofthetransducerface,thehullplatingandputty

aroundthetransducerisasevenandsmoothaspossible.Mountingscrewsorboltsmust

notbeextrudingfromthetransducer,theinstallationhardwareorthehullplating.If

necessary,grindandpolishallsurfaces.

20

417418/B

Preparations

Keepthetransducerfarawayfromthepropellers

Thepropulsionpropellersisthedominantnoisesourceonmostvessels.Thenoise

iseasilytransmittedthroughthewater.Thisnoisemayoftenreducetheoverall

performanceofyourEM2040P.

Thetransducermustbeinstalledasfarawayfromthepropellersaspossible.Thebest

positionsarethereforeontheforepartofthehull.Positionsoutsidethedirectlineof

sightfromthepropellersarebest.

Onsmallvesselswerecommendmountingthetransduceronthatsideofthekeelwhere

thepropellerbladesmoveupwards.Thisisbecausethepropellercavitationisweakest

onthatside.Thecavitationstartswhenthewaterowsinthesamedirectionasthe

propellerblades.Thisiswherethepropellerbladesmovedownwards.

Chooseatransducerpositionfarawayfromthebow thruster(s)

Bowthrusterpropellersareextremelynoisy.

Wheninoperation,thenoiseandcavitationbubblescreatedbythethrustermaymake

yourEM2040PMultibeamechosounderuseless,almostnomatterwherethetransducer

isinstalled.Whenthebowthrustersarenotinoperation,thetunnelcreatesturbulence.If

yourvesselispitching,thetunnelmaybelledwithairoraeratedwaterintheupper

positionandreleasethisinthelowerposition.

Ingeneral,thetransducershouldthereforebeplacedwellawayfromthebowthruster(s).

However,thisisnotaninvariablerule.Certainthrusterdesigns-combinedwiththeir

physicallocationsonthehull-maystillofferasuitablelocationforthetransducer,even

closetothethruster.Ifyouareindoubt,consultanavalarchitect.

Summaryandgeneralrecommendations

Someoftheinstallationguidelinesprovidedfortransducerlocationmaybeconicting.

Forthisreason,eachvesselmustbetreatedindividuallyinordertondthebest

compromise.

Ingeneral,themostimportantfactoristoavoidairbubblesinfrontofthetransducer

face.Forthisreason,therecommendedtransducerlocationisnormallyintheforepartof

thehull,wellaheadofthenoisecreatedbythebowwave.

Themaximumdistancefromthebowisnormallyequaltoonethirdofthetotalwater

linelengthofthehull.

Ifthevesselhullhasabulbousbow,thismaywellbeagoodtransducerlocation,but

alsointhiscasetheowpatternoftheaeratedwatermustbetakenintoconsideration.

Theforemostpartofthebulbisoftenagoodlocation.

Thisappliestothevesselinnormaltrimandspeed.

417418/B

21

EM2040PInstallationmanual

Important

Thetransducermustneverbetiltedbackwardswhenthevesselismovingatnormal

speed.

Donotplaceatransducerinthevicinityofprotrudingobjects,andespeciallynotclose

behindthem.

Makesurethatthesurfaceoftheresultinginstallationisassmoothandstreamlinedas

possible.

22

417418/B

Preparations

Acousticnoise

Aswithanyotherhydroacousticsystems,thequalityoftheEM2040Pechodataand

presentationsaresubjecttounwantedacousticnoise.Theechoesfromanylargeand

smalltargetmustbedetectedinsidethenoise.

Itisimportantthatwekeepthenoiselevelaslowaspossible.Theisnecessaryto

obtainlongrangeanddependableinterpretationsoftheechoes.Evenwiththeadvanced

noiselteringofferedbytheEM2040P,wemustaddressthenoisechallenge.Thisis

importantduringtheplanningandpreparationsfortheEM2040Pinstallation.

Topics

Contributingfactors,page23

Selfnoise,page24

Ambientnoise,page27

Electricalselfnoise,page27

Somemeanstoreduceacousticnoise,page27

Contributingfactors

Severalfactorsarecontributingtotheperformanceofthehydroacousticequipment

usedonboardavessel.

Suchfactorsinclude:

•Thequalityandpropertiesofthetransmittedsignal

•Thequalityofthereceivingsystem

•Theoperationalsettingsmadeduringoperation

•Thepropertiesofthetarget(s)

•Thesignal-to-noiseratio

Themajorityofthesefactorscanneitherbecontrollednorimprovedbymeans

ofinstallationmethodsortransducerlocations.Thequalityandpropertiesofthe

transmittingandreceivingsystemsarekeyfactorsduringourproductdevelopment,while

ourenduserdocumentationaimstohelptheusertomaketherightltersettingsduring

operation.Asforthetargetproperties,thereisnothinganyofuscandowiththose.

Thesignal-to-noiseratio,however,canbeimprovedbymakingthecorrectchoices

duringinstallation.

Signal-to-noiseratio(oftenabbreviatedSNRorS/N)isameasureusedin

scienceandengineeringthatcomparesthelevelofadesiredsignaltothelevelof

backgroundnoise.Itisdenedastheratioofsignalpowertothenoisepower,often

expressedindecibels.Aratiohigherthan1:1(greaterthan0dB)indicatesmore

417418/B

23

EM2040PInstallationmanual

signalthannoise.WhileSNRiscommonlyquotedforelectricalsignals,itcan

beappliedtoanyformofsignal[...].

http://en.wikipedia.org/wiki/Signal_to_noise_ratio(September2013)

Thesignalistheechothatwewanttoknowsomethingabout,whilethenoiseisany

unwantedsignalsordisturbances.Theechomustbedetectedinthenoiseandthereforeit

isnecessarytokeepthenoiselevelisaslowaspossibleinordertoobtainlongrange

anddependableinterpretation.

Thenoisethatcontributestothesignaltonoiseratiomaybedividedintothefollowing

typesofnoise:

•Selfnoise

•Ambientnoise

•Electricalnoise

•Reverberation

AThetransducercanpickupnoisefrom

•Biologicaldisturbances

•Interference

•Cavitation

•Propellernoise

•Flownoise

•Acousticnoisefromotherhydroacousticsystems

BThetransducercablesarelong,andmaypickupelectricnoisefromgenerators,

pumps,coolingsystemsandotherelectricorelectromechanicaldevices.

CThepreampliersareverysensitive,andtheycaneasilypickupelectricalnoise

frominternalandexternalpowersupplies.Thepreampliersarealsovulnerablefor

analoguenoisecreatedbytheirownelectroniccircuitry.Digitalnoisecreatedby

theconverterandprocessingcircuitrycanalsocreateproblems.

DConverterstransformtheanalogueechoestodigitalformat.

ESignalprocessingcircuitrycancreatedigitalnoise.

Selfnoise

Anyvesselequippedwithahydroacousticsystem(forexampleechosounderorsonar)

willproducemoreorlessselfnoise.

Therearemanysourcesofsuchselfnoise.W ewillheregointosomedetailsinorderto

analysethedifferentsourcesofselfnoiseonavesselandhowtheymayinuenceupon

thenoiselevelofthehydroacousticinstruments.

24

417418/B

Preparations

Machinerynoise

Themaincontributortomachinerynoiseisusuallythemainengineonboardthevessel.

Thecontributionfromauxiliarymachinerymay,however,beconsiderable,especiallyif

itisinpoorshape.Themachinerynoisecanbetransmittedtothetransduceras:

•Structure-bornenoisethroughtheshipstructureandthetransducermountings

•Water-bornenoisethroughthehullintothewatertothetransducer

Electricalnoise

Modernvesselsarenormallyequippedwithalotofelectricinstrumentssuchas

hydroacousticsystems,radars,navigationsystems,andcommunicationequipment.Any

electricinstrumentsmayinsomecauseelectricalinterferenceandnoise.International

regulationsandcerticationsareusedtocontrolandreducethis,buteventheseare

limitediftheelectricalsystemsarepoorlyinstalledand/ormaintained.

Propellernoise

Propellernoiseisoftenthemainsourceofnoiseathighervesselspeeds.Variablepitch

propellersorfastmovingpropellersusuallymakemorenoisethanxedpropellersor

slowmovingpropellers.

Propellernoiseisusuallywater-borne.Insomecases,however,shaftvibrationsor

vibrationsinthehullnearthepropellermaybestructure-bornetothetransducer.Ifa

propellerbladeisdamaged,thismayincreasethenoiseconsiderably.

Propellercavitationisaseveresourceofnoise."Singing"propellersmightbeasourceof

noise,whichinterferesatdiscretefrequencies.Insomecasesstaticdischargefromthe

rotatingpropellershaftmaybequitedisturbing.

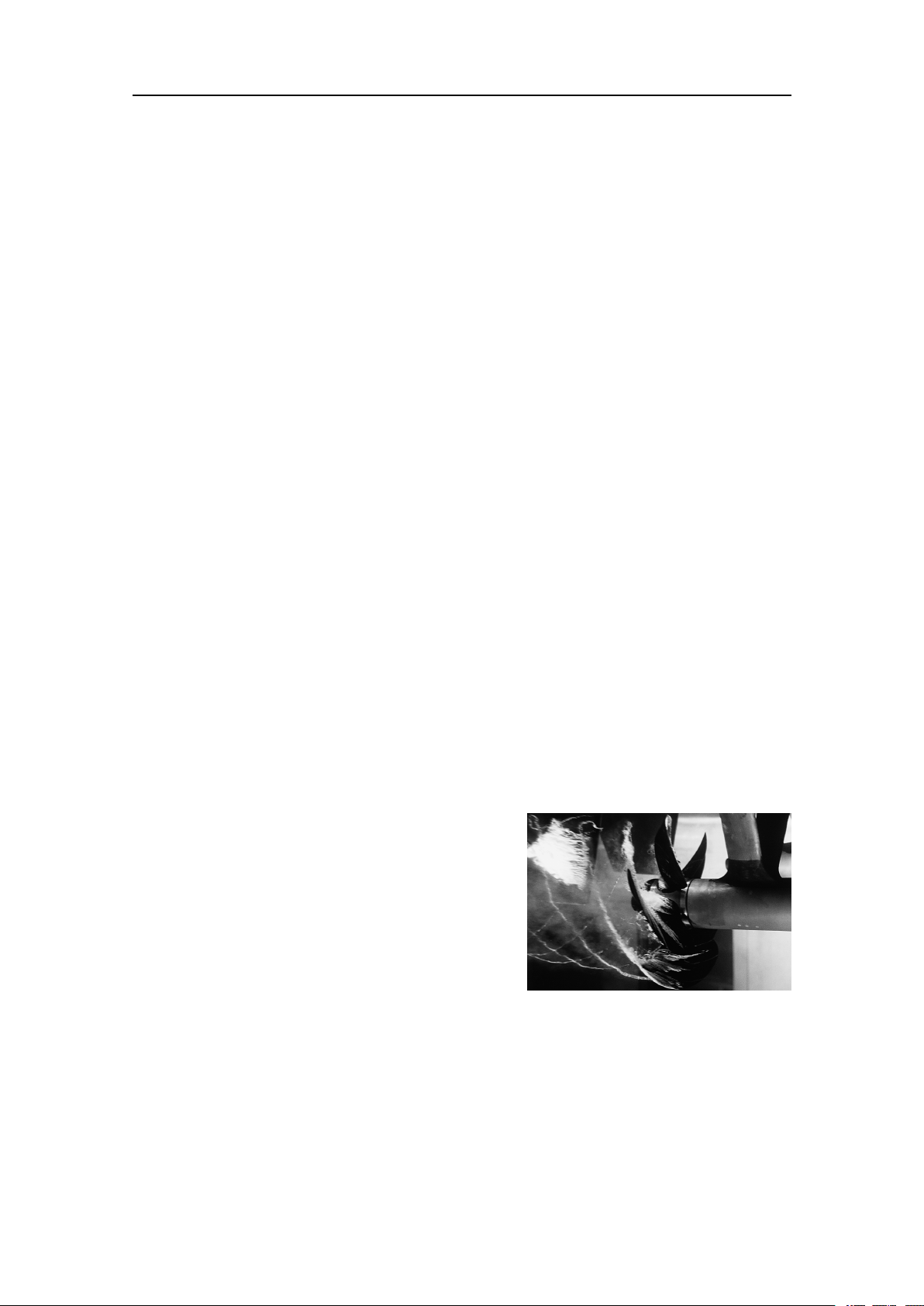

Cavitation

Cavitationistheformationofsmallairbubbles

closetothetransducerface.Thebubblesappear

becausethelocalpressurebecomesnegative

duringpartsoftheacousticpressurecycles.

Thecavitationthresholdincreaseswiththe

hydrostaticpressure.Thenoiseismadewhen

thebubblesimplode.

Cavitationnoisemayappearnearextruding

objectsathigherspeeds,butmoreoftenitis

causedbythepropellers.Propellercavitationisaseveresourceofnoise.Thecavitation

startswhenthewaterowsinthesamedirectionasthepropellerblades.Thisiswhere

thepropellerbladesmovedownwards.

Insomecasesaresonantphenomenonissetupinaholenearthehull.Thissoundwill

haveadiscretefrequency,whileallotherownoisewillhaveawidefrequencyspectrum.

(ImagefromU.S.Navyinthepublicdomain.)

417418/B

25

EM2040PInstallationmanual

Flownoise

Theupperwaterlayersoftheseacontainamyriadofsmallairbubblescreatedbythe

breakingwaves.Whenthehullmovesthroughwateritwillcauseadisturbance,andthis

willgeneratefriction.Thefrictionzoneiscalledtheowboundarylayer.Theowin

thisboundarylayermaybelaminarorturbulent.

•Thelaminarowisanicelyordered,parallelmovementofthewater.

•Theturbulentowisadisorderlyowpattern,fullofeddies.

ATurbulentow

BLaminarow

CAirbubbles

Airbubblesabsorbandreectthesoundenergy,andtheymayinworstcasesblockthe

soundtransmissionaltogether.

Theboundarylayerincreasesinthicknesswhenitbecomesturbulent.Theboundary

layeristhinintheforwardpartofthevesselhull,andincreasesasitmovesaft.The

thicknessdependsonshipsspeedandontheroughnessofthehull.Allobjectssticking

outfromthehull,ordentsinthehull,willdisturbtheowandwillincreasethethickness

oftheboundarylayer.Whentheowspeedishigh,theturbulencecanbeviolentenough

todestroytheintegrityofthewater.Smallvoidsorcavitiesinthewaterwilloccurand

thisiscalledcavitation.

Rattlenoise

Rattlenoisemaybecausedbylooseobjectsinthevicinityofthetransducer,likexing

bolts.Therattlemayalsocomefromlooseobjectsinsidethehull.

Interference

Interferencefromotherhydroacousticequipmentonboardthesamevesselmaybean

annoyingsourceofdisturbance.Unlessthesamefrequencyisusedformorethanone

pieceofequipmentonlythetransmittedpulsewillcontributetotheinterference.

Inphysics,interferenceisthephenomenoninwhichtwowavessuperposeeach

othertoformaresultantwaveofgreaterorloweramplitude.Interferenceusually

referstotheinteractionofwavesthatarecorrelatedorcoherentwitheachother,

eitherbecausetheycomefromthesamesourceorbecausetheyhavethesameor

26

417418/B

nearlythesamefrequency.Interferenceeffectscanbeobservedwithalltypesof

waves,forexample,light,radio,acoustic,surfacewaterwavesormatterwaves.

https://en.wikipedia.org/wiki/Interference_(wave_propagation),April2016

Ambientnoise

Ambientnoiseisusuallynotalimitingfactortotheperformanceofsonarsandecho

sounders.

Theambientnoisemaybesplitupasfollows:

•Seanoise:Airbubbles,seismicdisturbances,waves,boundaryturbulence,etc.

•Biologicalnoise:Fish,mammals

•Manmadenoise:Othervessels,interference

•Precipitationnoise:Heavyrainorhail

Preparations

Insomeareas,wheremanyvesselsoperatetogether,theengineandpropellernoisefrom

othervesselsmaybedisturbing.Interferencefromhydroacousticinstrumentslocated

inothervesselsmayalsobealimitingfactor.Theseanoisedependsontheweather

conditions.Inbadweathertheseanoisecanbequitehighduetothewaves.

Electricalselfnoise

Electricalorelectronicselfnoiseispickeduporgeneratedinanyotherpartofthe

equipmentthanthetransducer.

Humpickedupbythetransducercablesorpickedupfromthepowersupplyisusually

themostcommonsourceofelectricalselfnoise.Athigherfrequencies–whererather

widebandwidthsarenecessary–thenoisefromcomponents,transistorsorother

analogueelectronicmaybealimitingfactor.

Somemeanstoreduceacousticnoise

Severalfactorsarecontributingtotheperformanceofthehydroacousticequipment

usedonboardavessel.CarefulplanningoftheEM2040Pinstallationmayreduce

theacousticnoise.

Unfortunately,itisimpossibletosimplyprovideanumberofspecicproceduresto

reducethenoise.

Animportantfactoristhephysicallocationofthetransducers.Thisdependsonthe

vessel'sdesignandconstruction,howthehullisshaped,andhowthewaterrunsalong

thehull.Otherfactorsdealwithotherequipmentmountedonboard,andthiswillalsobe

vesseldependant.Atmoderateshipspeedsthemachinerynoiseisusuallydominant.At

mediumspeedstheownoiseincreasesmorerapidlyandtakesover,whileathigher

speedthepropellernoisewillbethemaincontributor.

417418/B

27

EM2040PInstallationmanual

Note

Theinformationheremustbeconsideredasgeneraladvice.EachEM2040Pinstallation

mustbehandledseparatelydependingonthehulldesignandtheotherelectricaland

mechanicalsystemsinstalledonthevessel.

Reducingownoise

•Theshapeofthetransducer(ordomearoundit)mustbeasstreamlinedaspossible.

•Thehullplatinginfrontofthetransducermustbeassmoothaspossible.

Important

Beespeciallyawareofbilgekeelsandzincalloyanodes.Thekeelmustberoundedoff

withoutsharpedges.Neitherextrudingobjectsnorabrupttransitionsmustbepresent.

Reducingmachinerynoise

•Themainengineandrelevantauxiliaryenginesandequipmentmustbexedtorigid

foundationstoavoidvibrations.

•Anyhullstructurethatmayvibrateshouldbedampedorcoatedtoreducethe

vibrations.

Theuseofshockabsorbersoroatingraftsmaysometimesreducethisnoise.The

structure-bornenoisemaybereducedbyisolation,forexamplebyprovidingvibration

clampingbetweenthetransducerandthehullstructure.

Reducingpropellernoise

•Sufcientclearancebetweenthepropellersandthehull,therudderandthekeelmust

beprovided.

•Placethezincalloyanodesinplaceswherethewaterowistheleastdisturbed.

•Ensurethatthepropellersbladesarecorrectlydesignedandwithoutdamages.

•Theuseofabafebetweenthepropellersandthetransducermayreducenoise

appreciably.

•Staticdischargescausedbytherotatingpropellershaftmayberemovedbyproper

groundingorbymountingacoalbrushfromtheshafttovesselground.

Reducingrattlenoise

Ensurethatnopartsnearthetransducerscanrattleasaresultofwateroworvibrations.

Reducinginterference

Interferencefromthetransmissionpulsesfromotherhydroacousticinstrumentson

boardthevesselisdifculttoavoid.Theproblemmaybereducedbychoosingthe

workingfrequenciescarefullyandtosomeextentbyseparatingthedifferenttransducers.

Onvesselswithalargenumberofseparatehydroacousticsystemsinstalledandin

28

417418/B

Preparations

simultaneoususe,aseparatesynchronizingsystem(forexampletheK-Sync)should

beconsidered.

Reducingelectricalnoise

•Makesurethatallunitsareproperlygrounded,asthisisimportanttoavoidelectrical

noise.

•Useshieldedcableswithcorrectgrounding.

•SeparateEM2040Pcablesfromothercableswithhighvoltages,largecurrentsor

transients.

•Placeallhighvoltagepowercablesinmetalconduits.

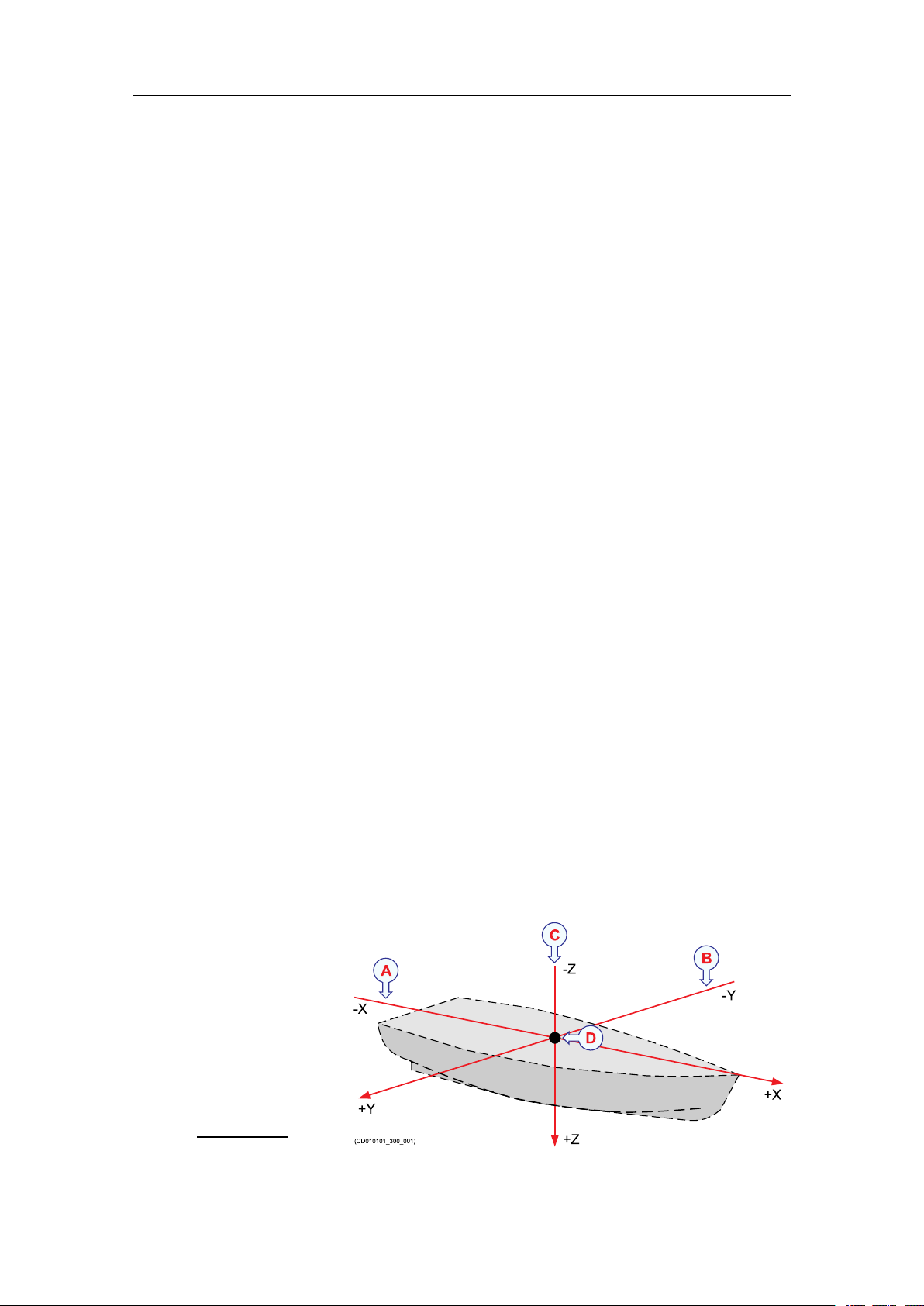

Vesselcoordinatesystem

Thevesselcoordinatesystemisestablishedtodenetherelativephysicallocations

ofsystemsandsensors.

Whenyouhaveseveraldifferentsensorsandtransducersonyourvessel,andyouwish

eachofthemtoprovideaccuratedata,youneedtoknowtheirrelativephysicalpositions.

Theantennaofapositionsensoristypicallymountedhighabovethesuperstructure,

whileamotionsensorislocatedclosetothevessel’scentreofgravity.Bothofthese

arephysicallypositionedfarawayfromthetransduceronadepthsensor,whichmaybe

locatedclosertothebow.

Veryoften,theinformationfromonesensordependsondatafromanother.Itisthen

importantthattherelevantmeasurementsarecompensatedfortheserelativedistances.

Example

Ifyouwishtomeasuretheactualwaterdepth,youwillneedtoknowthe

verticaldistancefromtheechosoundertransducertothewaterline.Since

thevessel’sdisplacementchangeswiththeamountofcargo,fueletc,the

physicallocationofthewaterlineonthehullmusteitherbemeasuredata

regularbasis,ormeasuredwithasecondsensor.

Inordertoestablish

asystemtomeasure

therelativedistance

betweensensors,a

virtualcoordinatesystem

isestablished.This

coordinatesystemuses

threevectors;X,YandZ.

ATheX-axisis

thelongitudinal

directionofthe

vessel,andin

417418/B

29

EM2040PInstallationmanual

parallelwiththedeck.ApositivevalueforXmeansthatasensororareference

pointislocatedaheadofthereferencepoint(origin).

BTheY-axisisthetransverse

directionofthevessel,andinparallelwiththedeck.

ApositivevalueforYmeansthatasensororareferencepointislocatedonthe

starboard

CTheZ-axisisvertical

thatasensororanewreferencepointislocatedunder

DReferencepoint(origin)

sideofthereferencepoint(origin).

,andinparallelwiththemast.ApositivevalueforZmeans

thereferencepoint(origin).

Coordinatesystemorigin

Theoriginisthecommonreferencepointwhereallthreeaxisinthevesselcoordinate

systemmeet.Allphysicallocationsofthevessel’ssensors(radarandpositioningsystem

antennas,echosounderandsonartransducers,motionreferenceunitsetc)arereferenced

totheorigin.Inmostcases,thelocationofthevessel’s"ofcial"originhasbeendened

bythedesignerorshipyard.Thisoriginisnormallyidentiedwithaphysicalmarking,

andalsoshownonthevesseldrawings.

Frequentlyusedlocationsare:

•Aftimmediatelyovertherudder(frame0)

•Vessel’scentreofgravity

•Thephysicallocationofthemotionreferenceunit(MRU)

Coordinatesystemalternativeorigins

Ifnecessary,otheroriginlocationsmaybedenedforspecicproductsorpurposes.One

exampleistheNavigationReferencePointthatisfrequentlyused.Wheneveravessel

issurveyedtoestablishaccurateoffsetinformation,thesurveyormayalsoestablishan

alternativeoriginlocation.Wheneverrelevant,anysuchalternativelocationsmust

bedenedusingoffsetvaluestothe"ofcial"originestablishedbythedesigneror

shipyard.Acommonlyusedalternativeoriginisthephysicallocationofthevessel’s

motionreferenceunit(MRU).

Deningthephysicallocationofeachsensor

Bymeansofthevesselcoordinatesystem,thephysicallocationofeverysensorcan

bedenedusingthreenumericalvaluesforX,YandZ.Thesevaluesmustdenethe

verticalandhorizontaldistancesfromasinglereferencepoint;theorigin.Thephysical

locationofthemotionreferenceunit(MRU)isoftenthemostimportantsensortodene.

Formanysystems,thevesselheadingisalsoacriticalmeasurement.

30

417418/B

Loading...

Loading...