Kongsberg EM 2040C Maintenance Manual

Maintenance manual

EM 2040C

Multibeam echo sounder

Multibeamechosounder

EM2040C

Maintenancemanual

378511/A

August2016©KongsbergMaritimeAS

Documentinformation

•Product:KongsbergEM2040C

•Document:Maintenancemanual

•Documentnumber:378511

•Revision:A

•Dateofissue:August2016

Note

TheinformationcontainedinthisdocumentremainsthesolepropertyofKongsbergMaritimeAS.No

partofthisdocumentmaybecopiedorreproducedinanyformorbyanymeans,andtheinformation

containedwithinitisnottobecommunicatedtoathirdparty,withoutthepriorwrittenconsentof

KongsbergMaritimeAS.

KongsbergMaritimeASendeavourstoensurethatallinformationinthisdocumentiscorrectandfairly

stated,butdoesnotacceptliabilityforanyerrorsoromissions.

Warning

Theequipmenttowhichthismanualappliesmustonlybeusedforthepurposeforwhichitwas

designed.Improperuseormaintenancemaycausedamagetotheequipmentand/orinjurytopersonnel.

Theusermustbefamiliarwiththecontentsoftheappropriatemanualsbeforeattemptingtooperate

orworkontheequipment.

KongsbergMaritimedisclaimsanyresponsibilityfordamageorinjurycausedbyimproperinstallation,

useormaintenanceoftheequipment.

Comments

Toassistusinmakingimprovementstotheproductandtothismanual,wewelcomecommentsand

constructivecriticism.

e-mail:km.documentation@kongsberg.com

Fortechnicalsupportissues,pleasecontactkm.support@kongsberg.com.

Supportinformation

Ifyourequiremaintenanceorrepair,contactyourlocaldealer.Y oucanalsocontactususingthefollowing

address:km.hydrographic.support@kongsberg.com.Ifyouneedinformationaboutourotherproducts,

visithttp://www.km.kongsberg.com

KongsbergMaritimeAS

www.kongsberg.com

Maintenancemanual

Tableofcontents

ABOUTTHISMANUAL..............................................................7

EM2040C................................................................................8

Systemdescription.............................................................................................................9

Systemdiagram................................................................................................................11

Systemunits.....................................................................................................................12

Sonarheaddescription...........................................................................................12

ProcessingUnitdescription....................................................................................12

HydrographicWorkStationdescription.................................................................12

Ethernetswitch.......................................................................................................13

RemoteControlUnit(K-Rem)description............................................................13

TROUBLESHOOTING..............................................................14

BIST(Built-InSelfTest)dialogbox...............................................................................15

PREVENTIVEMAINTENANCE..................................................19

Inspectingandcleaningthesonarheadface....................................................................20

Paintingthesonarheadface............................................................................................22

Approvedanti-foulingpaints...........................................................................................23

ILLUSTRATEDSPAREPARTSCATALOGUE..............................25

Orderingspareparts.........................................................................................................26

Listofspareparts.............................................................................................................27

ProcessingUnitsparepart-singleversion-oneCBMFboard.............................27

ProcessingUnitsparepart-dualversion-twoCBMFboards..............................27

CBMFboardsparepart..........................................................................................28

ConcurrentPP833CPUboardsparepart...............................................................28

Ethernetswitchsparepart......................................................................................29

Fanunitsparepart..................................................................................................30

Powersupplysparepart.........................................................................................30

PROCESSINGUNIT................................................................31

ProcessingUnitoverview................................................................................................32

ProcessingUnitfamiliarization........................................................................................32

ProcessingUnitfrontpaneldescription...........................................................................33

ProcessingUnitrearpaneldescription............................................................................34

ProcessingUnitcircuitboardsandmodules....................................................................35

ConcurrentPP833CPUboard.........................................................................................36

ConcurrentPP833CPUboardoverview................................................................36

ConcurrentPP833CPUboardconnectors.............................................................37

CP219Ethernetswitch.....................................................................................................38

378511/A

3

EM2040C

Ethernetswitchoverview.......................................................................................38

Ethernetswitchconnectors.....................................................................................38

CBMFboard....................................................................................................................39

CBMFboardoverview...........................................................................................39

CBMFboardconguration....................................................................................40

CBMFboardconnectors........................................................................................41

CABLELAYOUTANDINTERCONNECTIONS.............................42

Readthisrst...................................................................................................................43

Cableplans.......................................................................................................................44

Singlehead,singleswathcableplan,ProcessingUnit...........................................45

Singlehead,dualswathcableplan,ProcessingUnit.............................................46

Dualhead,singleswathcableplan,ProcessingUnit.............................................47

Dualhead,dualswathcableplan,ProcessingUnit................................................48

Topsidecableplan..................................................................................................50

ListofEM2040Ccables.................................................................................................51

Cabledrawingsandspecications...................................................................................53

RS–232seriallineusingthree3wiresandRJ45connector..................................54

RS-422seriallineusingvewiresandRJ45connector........................................55

1PPS(Onepulsepersecond)usingacoaxcable...................................................56

Remotecontrol.......................................................................................................58

RemoteControlusingK-Rem................................................................................59

Dummyplugfornotusingremotecontrol.............................................................60

ExternalSynchronisation.......................................................................................61

DRAWINGFILE......................................................................65

Sonarheaddimensions(lowproleconnector)...............................................................66

Sonarheaddimensions(roundconnector).......................................................................67

ProcessingUnitdimensions.............................................................................................68

HydrographicWorkStationoutlinedimensions..............................................................69

RemoteControlUnit(K-REM)outlinedimensions........................................................71

RemoteControlUnit(K-REM)wiringdiagram..............................................................73

TECHNICALSPECIFICATIONS................................................74

Performancespecications..............................................................................................75

Interfacespecications.....................................................................................................77

Weightsandoutlinedimensions......................................................................................81

Powerrequirements.........................................................................................................83

Environmentalrequirements............................................................................................84

EQUIPMENTHANDLING.........................................................86

TransportingKongsbergMaritimeequipment.................................................................87

Liftingunitsandtransportationboxes.............................................................................89

4

378511/A

Maintenancemanual

Inspectionofunitsandtransportationboxesafterarrival................................................91

Specicationsforstoragepriortoinstallationoruse.......................................................92

Unpackinginstructions....................................................................................................94

Unpackingstandardpartsandunits........................................................................94

Unpackingmechanicalunits..................................................................................95

Unpackingelectronicandelectromechanicalunits................................................96

Unpackingtransducers...........................................................................................97

Specicationsforstorageafterunpacking.......................................................................99

Packinginstructionsforstorageorshipping..................................................................101

Storageafteruse.............................................................................................................103

Cleaninganelectroniccabinetorunit..................................................................103

Cleaningamechanicalorelectromechanicalunit................................................104

Handlinginstructionsforprintedcircuitboardsandelectronicmodules......................106

Circuitboardunpackingandhandling.................................................................106

ReturningaprintedcircuitboardoranelectronicmoduletoKongsberg

Maritime..........................................................................................................108

AboutElectrostaticDischarge(ESD)...................................................................109

Disposalofoldproducts................................................................................................111

Handlingofunderwaterconnectors...............................................................................112

GENERALSAFETYRULES.....................................................113

Generalsafetyrules........................................................................................................113

378511/A

5

EM2040C

6

378511/A

Aboutthismanual

Aboutthismanual

Thepurposeofthismanualistopresentthedescriptionsanddrawingsrequiredtodo

basicmaintenancetasksontheEM2040CMultibeamechosounder.Theequipment

describedinthismanualincludesthecompletesystemwithassociatedcabinets,butnot

thosesystemunitsprovidedlocallybythecustomer,installationshipyardorlocaldealer.

Targetaudience

Themanualisintendedfortechnicalpersonnel;qualiedmaintenanceengineers

andtechnicians.Youmustunderstandthegeneralprinciplesofmaritimeelectronic

equipment.Youmustalsobefamiliarwithcomputerhardware,signalprocessing,

interfacetechnologyandtraditionaltroubleshootingonelectronicandmechanical

products.

Weassumethatyouarefamiliarwiththebasicacousticprinciplesofsoundinwater,

andthatyouhavesomeexperiencewithmultibeam,splitbeamand/orsinglebeam

echosoundersinscienticapplications.

Onlineinformation

AllrelevantenduserdocumentationprovidedforyourKongsbergEM2040Ccanbe

downloadedfromourwebsite.

•https://www.km.kongsberg.com

OurwebsitewillalsogiveyouinformationaboutotherKongsbergproducts.

Technicalinformationisavailableforregisteredusersinourpasswordprotected

database.

Registeredtrademarks

Observetheregisteredtrademarksthatapply.

®

EM

isaregisteredtrademarkofKongsbergMaritimeASinNorwayandothercountries.

Windows

othercountries.

378511/A

®

isaregisteredtrademarkofMicrosoftCorporationintheUnitedStatesand

7

EM2040C

Topics

Systemdescription,page9

Systemdiagram,page11

EM2040C

Systemunits,page12

8

378511/A

Systemdescription

TheEM2040CisashallowwatermultibeamechosounderbasedontheEM2040

technology,anidealtoolforanyhighresolutionmappingandinspectionapplication.

Keyfacts

•Highresolution

•Widefrequencyrange

•Shortpulselengths,largebandwidth

•FMchirp

•Completerollandpitchstabilization

•Neareldfocusingbothontransmitandreceive

•Watercolumn

EM2040C

•Seabedimage

•Swathcoverage:

–Singlehead:130degrees

–Dualhead:200degrees

•Depthrating:

–EM2040C:50m

–EM2040CX:1500m

•Easytoinstall

•Dualswathasoption

Thereceiverandtransmitterareintegratedinacommonsonarhead,withthesame

dimensionsastheEM3002.ThesystemfullstheIHO-S44specialorderandthemore

stringentLINZspecication.

TheEM2040CisavailableinaCXversionwherethesubseaparthasadepthratingof

1500mforoperationonROVorAUV

Yawstabilizationisavailableindualheadconguration.Eachheadusesonesector,and

byindependentlysteeringeachsectorthesystemcanstabilizefortheyawmovement

ofthevessel.

Theoperatingfrequencyrangeisfrom200to400kHzwithfrequencyselectioninstep

of10kHz,enablingtheusertochooseontheythebestoperatingfrequencyforthe

application.Duetotheverylargeoperatingbandwidthavailablethesystemwillhavean

outputsamplerateofmorethan60kHz.Thesystemwillthuseffectivelyoperatewith

veryshortpulselengths,lessthan25microseconds,whichgivesarawrangeresolution

(cτ/2)of18mmandanaccuracyoflessthan10mm(cτ/4).

378511/A

9

EM2040C

Indualheadmode,bothheadsareoperatedindependentlycreatingoneswathfrom

eachheadsimultaneously .Thisisduetoaveryexiblesolutionbyusingtwodifferent

frequenciesforeachhead.

ByutilizingbothCWandFMchirppulses,thesystemcanachieveamuchlongerrange

capabilitywithahigherresolution.Themaximumdepthrangeis520mat200kHzand

aswathwithupto690mwithdualhead.

Theangularcoveragefor200to300kHzisupto130degreeswithonesonarhead,

allowingcoverageof4.3timeswaterdepth.Withtwosonarheads,tilted35-40degrees

toeachside,200degreescanbecovered.Thisallowssurveyingtothewatersurfaceor

upto10timeswaterdepthonatbottoms.Forfrequenciesabove320kHztheangular

coverageperheadisgraduallydecreasingto70degreesat400kHz.

AsanoptiontheEM2040Ccanbedeliveredwiththedualswathcapability,allowinga

sufcientsoundingdensityalongtrackatahighvesselspeed.

10

378511/A

(CD020105_101_001)

E

EM2040C

Systemdiagram

ThesystemdiagramidentiesthemaincomponentsofabasicEM2040Csystem,as

wellastheconnectionsbetweentheunits.Interfacecapabilitiesandpowercablesare

notshown.

AHydrographicWork

Station

BHydrographicWork

Stationinterfaces:

•Soundspeedsensor

•Tide

•Centerdepthoutput

CProcessingUnit

DProcessingUnit

interfaces:

•Positioningsystems

•Attitude(roll,pitchand

heave)

•Velocity

•Heading

•Clock

ProcessingUnitspecial

interfaces:

•Triggerinput/output

•Clocksynchronisation

(1PPS)

ESonarHead

378511/A

11

EM2040C

Systemunits

Sonarheaddescription

Atransducerisadevicethatconvertsoneformofenergytoanother.Inanechosounder

systemthetransducerconvertsbetweenelectricenergyandsound.TheEM2040Chas

transducersfortransmitandreceiveinonehousing,andwecallita"sonarhead".

TheEM2040Csonarheadisashortcylindrical

containerwiththetransducerslocatedononeend,and

withcableconnectorandfasteningholesontheother.

Theendwiththetransducersisthesonarhead’s"face".

Asinglecablewithanunderwaterplug,connectsthe

sonarheadtotheProcessingUnit.

ProcessingUnitdescription

TheProcessingUnitisthecentralcontrollingdeviceintheEMmultibeamsystem.Itis

providedtoprocessthesignalstoandfromthesonarhead(s).

Itisanindustrialcomputerwhichisdesignedand

testedforruggeduse.

TheProcessingUnitalsosupplies48Vdcpowerto

thesonarhead(s).

OneortwoProcessingUnitsmayberequired,dependingonthesystemconguration.

HydrographicWorkStationdescription

TheHydrographicW orkStationistheoperatorstationoftheEM2040C.

Adedicatedmaritimecomputerisprovidedwiththe

EM2040CMultibeamechosounder.Itissetupwith

allnecessarysoftware.

TheHydrographicW orkStationisbasedonthe

Microsoft

TheHydrographicW orkStationisnormallymounted

onthebridge.

®

Windows

®

7operatingsystem.

12

378511/A

EM2040C

Ethernetswitch

AhighcapacityEthernetswitchmayberequired.

IfyouusemorethanoneProcessingUnit,anEthernetswitchisrequired.Thisisused

toconnecteachProcessingUnittotheHydrographicW orkStation.Ahighcapacity

Ethernetswitch(1000BASE-T)isincludedintheEM2040Cdelivery.

Note

ItisveryimportantthatahighqualityEthernetcableisused.YoumustuseCAT-5E

qualityorbetter .UsingcableswithlowerbandwidthcapacitywillreducetheEM2040C

performance.

1000BASE-T(alsoknownasIEEE802.3ab)isastandardforgigabitEthernetover

copperwiring.Each1000BASE-Tnetworksegmentcanbeamaximumlength

of100meters(330feet),andmustuseCategory5cableorbetter(includingCat

5eandCat6).

https://en.wikipedia.org/wiki/Gigabit_Ethernet(January2016)

RemoteControlUnit(K-Rem)description

Adedicatedjunctionboxhasbeendesignedtoprovideremoteon/offswitcheswithlight

indicationandinterfacetoaremotesynchronizingsystem.Thejunctionboxcontainsa

terminalblockandfourswitcheswithlampsmountedinthefront.

Note

TheRemoteControlUnitisnotastandardpartof

theEM2040Cdelivery.

TheRemoteControlUnitiscalledK-Rem.Itis

preparedforremotecontrolandinterfacetoanexternalsynchronizationsystemfor

thefollowingKongsbergechosounders:

•OneSub-bottomproler(SBP120orSBP300)

•TwoEMmultibeamechosounders

•OneEAsinglebeamechosounder

TheRemoteControlUnitisdesignedtobemountedina19inchrack,butitisalso

possibletomountitonaatsurfaceorinabulkhead.Itisalsopreparedformounting

ontelescopicrails.

378511/A

13

EM2040C

.

Topics

BIST(Built-InSelfT est)dialogbox,page15

Troubleshooting

14

378511/A

Troubleshooting

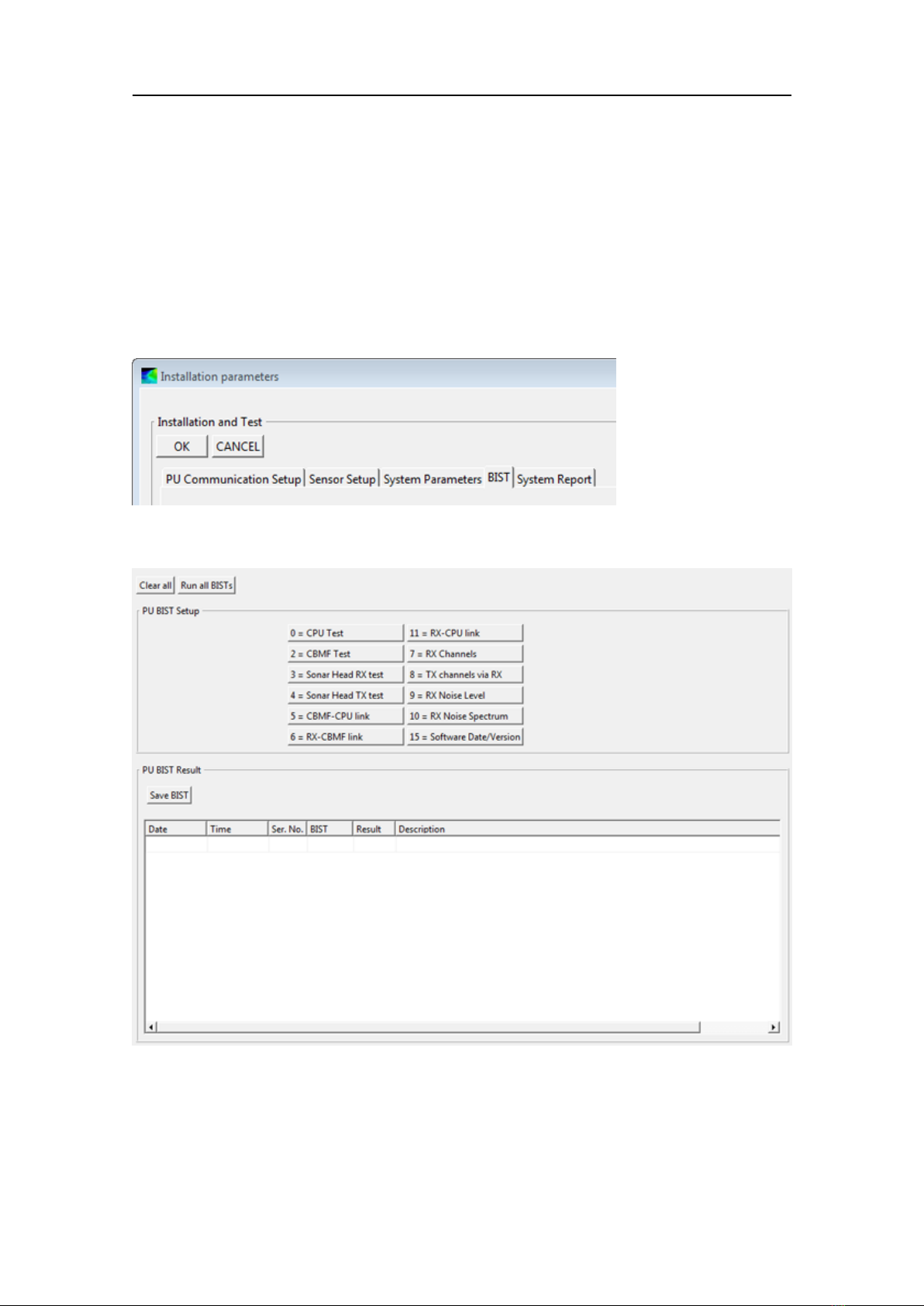

BIST(Built-InSelfTest)dialogbox

TheBIST(Built-InSystemTest)dialogboxcontrolsthetestanddiagnoseprogramthat

checkstheperformanceoftheEM2040C.

Howtoopen

ThisdialogboxisopenedfromtheBISTtabintheInstallationparametersframe.

Description

Details

Clearall

SelectClearalltoclearresultsofpreviousBISTtests.

378511/A

15

EM2040C

RunallBIST s

SelectRunallBISTstorunallavailableBISTtests.

Caution

Donotusethisoptionindrydock.SomeoftheBISTtestswillcausetheecho

soundertoping,andthismustnotbeperformedwiththetransducersoutofwater.

PUBISTSetup

YoucanruneachBISTtestseparately,selecttheoneyouwanttoruninthelist

inPUBISTSetup.

Note

Thetestisexecutedwhenthebuttonisselected.

VerifythatallBISTtestbuttonsturnsgreenwhentestisperformed.Ifanyofthe

testsfailsthespecictestbuttonwillturnredoryellow,andadescriptionofthe

testresultwillbedisplayedinthePUBISTresulteld.

0CPUTest

ThistestpresentstheCPUtype,theCPUclockfrequency ,thecurrent

andmaximumtemperaturesfortheCPUdieandfortheCPUboard.

Inadditionsomekeyvoltagesarereported,andnallythenetwork

addressesfortheboard’sinterfaces.

2CBMFtest

ThistestpresentsthenumberofCBMFboards,partnumberandserial

number,rmwareandsoftwarerevisionnumberandthecurrentFPGA

dietemperature.Inadditionsomekeyvoltagesarereported.

3SonarHeadRXtest

ThistestpresentsthenumberofRXunitsdetected,serialnumberand

partnumberoftheSonarHead,rmwareandsoftwarerevisionnumber

andthecurrentFPGAdietemperature.Inadditionsomekeyvoltages

arereported.

4SonarHeadTXtest

ThistestpresentsthenumberofTXunitsdetected,serialnumberand

partnumberoftheSonarHead,rmwareandsoftwarerevisionnumber,

thecurrentFPGAdietemperatureandseveraltemperaturesinsidethe

SonarHead.Inadditionsomekeyvoltagesarereported.

16

378511/A

5CBMF-CPUlink

ThistestcheckstheGBitEthernetinterfacebetweentheCPUboardand

theCBMFboard.Alargesetofknowndataistransferredfromthe

CBMFboardandthedatareceivedischeckedbytheCPUboard.

6RX-CBMFlink

ThistestcheckstheGBitEthernetinterfacebetweentheRXtransducer

unitandtheCBMFboard.Alargesetofknowndataistransferred

fromtheRXtransducerunittotheCBMFboard.Thedatareceived

ischeckedbytheCBMFboard.

7RXChannels

TheSonarHeadhasaprogrammablesignalgeneratorboardthatisused

toinjectatestsignalatthepreamplierinputs.ThistestchecksallRX

channels.TheBISTreportlistsphaseandamplituderesponseofallRX

channelsfor200,300and400kHz.

Troubleshooting

8TXchannelsviaRX

ThistestchecksallTXchannels(includingthetransducers).This

isdonebytransmittingatonebyoneTXchannelandcheckingthe

receivedlevel(throughthewater)bythereceiverunit(s).Thistestmay

requirethatthewaterdepthisnottolarge.Awarningwillbegivenif

thisisthecase.

Caution

Donotpingindrydock.FortheEM2040CthisBISTtestmustnot

berunindrydock.

9RXNoiseLevel

Thistestmeasurestheaverageisotropicspectralnoiselevelforeach

receiverchannel(indBrel1μPa/Hz)atthreebands:180-220kHz,

280-320kHzand360-400kHz

Thereceiverdirectivityindex,thetransducersensitivityandthelter

bandwidthisusedtoconverttoisotropicspectralnoiselevel.Thenoise

levelshouldnormallybebelow50dB.

378511/A

10RXNoiseSpectrum

Thistestmeasurestheisotropicspectralnoiselevelforeachreceiver

channelasdoneintheRXnoiseleveltest.Thenoisespectrumlevelis

displayedfor5kHzbandsforgroupsof32channels.Inadditionthe

averagelevelforallchannelsaredisplayed.Thisspectrumtestcanbe

usedtosearchforexternalnoisesources.

17

EM2040C

11RX-CPUlink

Thistestisnotimplementedyet.

15SoftwareDate/V ersion

ThistestpresentsthesoftwaredateandversionsfortheProcessing

UnitandSonarHead.

PUBISTResult

Save:Whenthetestsequencehasruntocompletionthetestresultsmaybesaved

byselectingSave.

Thetestresultswillbesavedasa.txtleandyoucanselectlenameandstorage

locationinthedialogboxthatappears.

TheresultsofthetestwillbeshowninthePUBISTResultelds,containing:

•Date:Datewhentestwasrun

•Time:Systemtimewhentestwasrun

•Ser.no:Serialnumber

•BIST:ThenumberoftheBISTtestthathasbeenrun

•Result:Theoverallresultofthetest

•Description:AdescriptionofthetestreturnedfromtheProcessingUnit(PU)

18

378511/A

Preventivemaintenance

Topics

Inspectingandcleaningthesonarheadface,page20

Paintingthesonarheadface,page22

Approvedanti-foulingpaints,page23

Preventivemaintenance

378511/A

19

EM2040C

Inspectingandcleaningthesonarheadface

Marinegrowth(biologicalfouling)onthesonarheadfacereducestheEM2040C

performance.Forthisreason,itisimportanttokeepthesonarheadfaceclean.Every

timeyourvesselisindrydock,youmustremovethemarinegrowth.Atthesametime,

youmustinspectthesonarheadcloselyforphysicaldamage.

Prerequisites

Thefollowingtoolsandconsumablesarerequired.

•Personalprotection

•Freshwater

•Amildsyntheticdetergentandaplasticbrush

•Apieceofwoodorplasticwithoutsharpcorners

•Citricacid(<50%)(onlyifrequired)

Context

Duringnormaluse,thesonarheadissubjectedtobiologicalfouling.Ifthismarine

growthisexcessive,itwillreducetheperformanceoftheEM2040C.Whenever

opportunityarise,typicallywhenthevesselisdrydocked,thesonarheadfacemustbe

cleanedforshellsandothermarinegrowth.

Itisimportanttocheckthesonarheadforphysicaldamage.Anycracks,fracturesor

holesintheredprotectivecoatingmayresultinawaterleak,andaleakmaycause

irreparabledamagetothesonarhead.

Asonarheadmustalwaysbehandledasadelicateitem.Wrongfulactionsmaydamage

thesonarheadbeyondrepair.Observethesesonarheadhandlingrules:

•Donotactivatethesonarheadwhenitisoutofthewater.

•Donothandlethesonarheadroughly,avoidimpacts.

•Donotexposethesonarheadtodirectsunlightorexcessiveheat.

•Donotusehighpressurewater,sandblasting,metaltoolsorstrongsolventstoclean

thesonarheadface.

•Donotdamagetheouterprotectiveskinonthesonarheadface.

•Donotliftthesonarheadbythecables.

•Donotsteponthesonarheadcables.

•Donotdamagethesonarheadcables,avoidsharpobjects.

Procedure

1Allowforsufcientaccesstocleanandinspecttheentiresurfaceofthesonarhead.

20

378511/A

Preventivemaintenance

2Removebiologicalfoulingcarefullyusingaplasticbrush,asuitablesynthetic

detergentandfreshwater.

Biologicalmaterialwhichisstronglyrootedinthesubstratecanberemoved

carefullywithapieceofwoodorplastic.

Ifrequired,youcanalsousecitricacid.Apply,leaveitworkingforseveralhours,

andrinsethoroughlywithfreshwater.

Note

Donotusehighpressurewater ,sandblasting,metaltoolsorstrongsolventsto

cleanthesonarheadface.

Donotdamagetheouterprotectiveskinonthesonarheadface.

3Allowthesonarheadsurfacetodry.

4Inspectthesonarheadcloselyforanysignofdents,cracks,fracturesorholes.

Ifyoundsuspiciousdamage,takehighresolutionpicturesthatshowthedamage,

andcontactKongsbergsupportforadvice.

5Applyanti-foulingpaintasdescribedinthededicatedprocedure.

Note

Becausesomepainttypesmaybeaggressivetothepolyurethaneinthesonarhead,

consultourlistofapprovedpaints.

Relatedtopics

Paintingthesonarheadface,page22

Approvedanti-foulingpaints,page23

378511/A

21

EM2040C

Paintingthesonarheadface

Inordertoreducethemarinegrowth(biologicalfouling)onthesonarheadface,it

maybecoveredwithathinlmofsuitableanti-foulingpaint.Thesonarheadmustbe

paintedimmediatelyafterinstallation,andthenagainasoftenasrequiredtomaintain

theprotection.

Prerequisites

Thefollowingtoolsandconsumablesarerequired.

•Personalprotection

•Freshwater

•Amildsyntheticdetergentandaplasticbrush

•Fine-gradesandpaper(240inchgritsize)

•Primer

•Anti-foulingpaint

•Wetlmgauge

Becausesomepainttypesmaybeaggressivetothepolyurethaneinthesonarhead,

consultourlistofapprovedpaints.

Context

Thesonarheadhasnotbeendesignedwithanyprotectionagainstbiologicalfouling.

Anti-foulingpaintmaythereforebeappliedtothesonarheadface.

Tominimizethenegativeacousticaleffectsthelayerofanti-foulingpaintmustbeas

thinaspossible.

Note

Theanti-foulingpaintwillreducetheacousticalperformanceofthesonarhead.The

surfaceroughnessofthesonarheadsubstrateandthethicknessofthepaintmayalso

inuencetheperformance.KongsbergMaritimecannotbeheldresponsibleforany

negativeconsequencesoftheanti-foulingpaint.

Observetherelevantinstructionsandsafetyinformationprovidedbythepaint

manufacturer.

Procedure

1Cleanthesonarheadthoroughly.Makesurethatyouremovealloilgreaseresidues,

aswellassaltandothercontamination.

2Allowthesonarheadsurfacetodry.

22

378511/A

Preventivemaintenance

3Abradethesonarheadsurfaceusingasandingpaperwith240inchgritsize.

Donotexceedasurfaceroughness(R

)of35micronsasthiscaninuencethe

max

EM2040Cperformance.

4Removealldust.

5Applytheprimer,andletitdry.

6Applythepaint.

Observetheinstructionsprovidedbythepaintmanufacturer.Useairlessspray.

Applytheminimumspeciedlmthicknesspercoatandforthecompletelayer.

Itisnotpossibletomeasuredrylmthicknessonsonarheadsurface.Y oumust

thereforeuseawetlmgaugetofrequentlymeasurethepaintthickness.

Note

Westronglyrecommendthatyoudonotuseapaintbrushand/oraroller .

7Allowthepainttodry.

Furtherrequirements

Thecontractororshipyardmustkeepadailypaintlogrecordingallrelevantinformation

fromthesurfacetreatment.

Relatedtopics

Inspectingandcleaningthesonarheadface,page20

Approvedanti-foulingpaints,page23

Approvedanti-foulingpaints

Thisisourlistofapprovedantifoulingpaintsforallsonarheadtypes.Alwaysreferto

themanufacturer'sdocumentationanddatasheetsforacompleteprocedureandfor

relevantsafetyinformation.

Important

Donotpaintthesonarheadwithtraditionalhullplatingpaint.Useonlythecorrect

typeofapprovedpaintspeciedbelow .

Donotusehighpressurewater,sandblasting,metaltoolsorstrongsolventstoclean

thesonarheadface.

378511/A

23

EM2040C

Jotun

Address:P .O.Box2021,N-3248Sandefjord,Norway

http://www.jotun.com

•Primer:SafeguardUniversalES

Apply80µmwetlmthickness(50µmdrylmthickness)

•Paint:SeaQuantumUltraS

Apply250µmwetlmthickness(125µmdrylmthickness)

Datasheetsandapplicationguidescanbedownloadedfrom:http://www.jo-

tun.com/ww/en/b2b/technical-info/tds/index.aspx

InternationalMarineCoatings

Address:StoneygateLane,Felling,Gateshead,Tyne&Wear,NE100JYUnited

Kingdom

www.international-marine.com

•Intersleektiecoat+425FCS

ABXA386/BXA390/BXA391Grey(equalparts)

BHKA563/HKA570/HKA571Yellow(equalparts)

Mix"A"andapply.Oncedry,mix"B"andapply.

•Intersmooth360EcoloexSPC

•MicronExtra

Relatedtopics

Inspectingandcleaningthesonarheadface,page20

Paintingthesonarheadface,page22

24

378511/A

Illustratedsparepartscatalogue

Illustratedspareparts

catalogue

Topics

Orderingspareparts,page26

Listofspareparts,page27

378511/A

25

EM2040C

Orderingspareparts

Tomaketheorderprocessasshortandaseffectiveaspossible,pleaseincludethe

followingdetails:

•Partnameand/ordescription

•Ourpartnumber

•Numberofunitsrequired

•Yourshipmentaddress

•Preferredshipmentmethod

•Requireddateofdeliveryfromus

Forcertainspareparts(typicallycompleteunits,printedcircuitboardsandsoftware)the

vesselnameisalsouseful,asthisallowsustoupdateourvesseldatabase.

26

378511/A

Illustratedsparepartscatalogue

Listofspareparts

Topics

ProcessingUnitsparepart-singleversion-oneCBMFboard,page27

ProcessingUnitsparepart-dualversion-twoCBMFboards,page27

CBMFboardsparepart,page28

ConcurrentPP833CPUboardsparepart,page28

Ethernetswitchsparepart,page29

Fanunitsparepart,page30

Powersupplysparepart,page30

ProcessingUnitsparepart-singleversion-oneCBMFboard

ThecompleteProcessingUnitcanbesuppliedasasparepart.Therearetwodifferent

versionsoftheEM2040CProcessingUnit.ThetwoversionsholdoneortwoCBMF

boards.

AsingleheadsingleswathsystemusesoneProcessing

UnitwithoneCBMFboard.

•Partname:ProcessingUnitsingleversion

•Partnumber:385402

•Numberinuse:1or2

•Recommendednumberinspare:1

•Truemanufacturer:KongsbergMaritime(https://www.km.kongsberg.com)

ProcessingUnitsparepart-dualversion-twoCBMFboards

ThecompleteProcessingUnitcanbesuppliedasasparepart.Therearetwodifferent

versionsoftheEM2040CProcessingUnit.ThetwoversionsholdoneortwoCBMF

boards.

AdualheadordualswathsystemusesoneProcessing

UnitwithtwoCBMFboards.

AdualheaddualswathsystemusestwoProcessing

Units,eachwithtwoCBMFboards.

378511/A

27

EM2040C

•Partname:ProcessingUnitdualversion

•Partnumber:385405

•Numberinuse:1or2

•Recommendednumberinspare:1

•Truemanufacturer:KongsbergMaritime(https://www.km.kongsberg.com)

CBMFboardsparepart

ThereareoneortwoCompactBeamformer(CBMF)boardsintheProcessingUnit.The

numberofCBMFboardsdependuponthecongurationoftheEM2040Csystem.

Thisisagenericphoto.TheCBMFboardused

bytheEM2040Cmaylookslightlydifferent

duetominordesignchangesontheprotective

lidand/orthefrontpanel.

•Partname:CBMFboard

•Partnumber:384585

•Numberinuse:1or2

•Recommendednumberinspare:1

•Truemanufacturer:KongsbergMaritime

(https://www.km.kongsberg.com)

ConcurrentPP833CPUboardsparepart

ThereisoneConcurrentPP833CPUboardintheProcessingUnit.

Thisisagenericphoto.TheConcurrentCP833CPUboardusedbytheEM2040C

maylookslightlydifferentduetominordesignchangesontheprotectivelidand/or

thefrontpanel.

28

378511/A

Loading...

Loading...