Kongsberg 101, 451, 501, 351 User Manual

Instruction Manual

HiPAP®

High Precision Acoustic Positioning

Model 501/451/351/101

HiPAP®

High Precision Acoustic Positioning

Model 501/451/351/101

Instruction Manual

Document history

Rev

Date

Written by

Checked by

Approved by

H

07.03.2013

AJ

AD

JEF

Replaced APC12 with MP8200 8 channel serial line model P/N: 364602.

General updates.

Strandpromenaden 50

P.O.Box 111

N-3191 Horten,

Norway

Kongsberg Maritime AS

Telephone: +47 33 03 41 00

Telefax: +47 33 04 47 53

subsea@kongsberg.com

www.kongsberg.com

Copyright

© 2013 Kongsberg Maritime AS

All rights reserved. The information contained in this document remains the sole

property of Kongsberg Maritime. No part of this document may be copied or

reproduced in any form or by any means, and the information contained within it is not

to be communicated to a third party, without the prior written consent of Kongsberg

Maritime.

Disclaimer

Kongsberg Maritime endeavours to ensure that all information in this document is

correct and fairly stated, but does not accept liability for any errors or omission.

Warning

The equipment to which this manual applies must only be used for the purpose for

which it was designed. Improper use or maintenance may cause damage to the

equipment and/or injury to personnel. The user must be familiar with the contents of

the appropriate manuals before attempting to operate or work on the equipment.

Kongsberg Maritime disclaims any responsibility for damage or injury caused by

improper installation, use or maintenance of the equipment.

Support

All Kongsberg Maritime products:

Phone 24 hour: +47 33 03 24 07

E-mail: km.support@kongsberg.com

Instruction Manual

Additional documents

Display manual

Separate manual supplied with the display. Not a Kongsberg Maritime document.

Keyboard manual

Separate manual supplied with the keyboard. Not a Kongsberg Maritime document.

Trackball

Separate document supplied with the trackball. Not a Kongsberg Maritime document.

Air to air heat exchange unit for Transceiver Unit x81

Not a Kongsberg Maritime document.

Air to air heat exchange unit for Transceiver Unit x21

Not a Kongsberg Maritime document.

Remarks

The reader

The installation information in this manual is intended for the design and installation

engineers at the yard performing the installation. The information is supplied as the

basis for the yard’s own installation drawings applicable to the vessel. On completion of

the installation, this section may be used for reference purposes during system

maintenance.

The maintenance information in this manual is intended to be used by a trained

maintenance technician or engineer, with experience of electronic and digital circuitry,

computers and electromechanical design. The level of information is based on

Kongsberg Maritime’s maintenance philosophy: The onboard technical personnel shall,

with the help of the documentation and the system’s built-in test functions, be able to

identify malfunctions, locate the fault, and replace major parts, modules and

components on the “Line Replaceable Unit” (LRU) level. He/she will however not

attempt to repair the LRUs.

303490/H I

HiPAP® Model 501/451/351/101

High voltage safety warning

The following safety precautions must be followed at all times

during installation and maintenance work:

Switch off all high-voltage power supplies.

Check the operation of any door interlocks and any other

safety devices.

Completely discharge all high-voltage capacitors.

It should be noted that interlocks and safety devices are

normally located only at regular access points, and high voltages

may be exposed during dismantling.

____________________________________________________________

Caution Never work alone on high-voltage equipment!

Refer to general safety procedures.

____________________________________________________________

II 303490/H

Instruction Manual

Table of contents

1 ABOUT THIS MANUAL ........................................................................................ 1

References ......................................................................................................................... 1

Abbreviations .................................................................................................................... 2

Backup ............................................................................................................................... 2

Software upgrade ............................................................................................................... 2

2 SYSTEM DESCRIPTION ....................................................................................... 3

HiPAP® systems - short overview .................................................................................... 4

HiPAP® system configuration .......................................................................................... 4

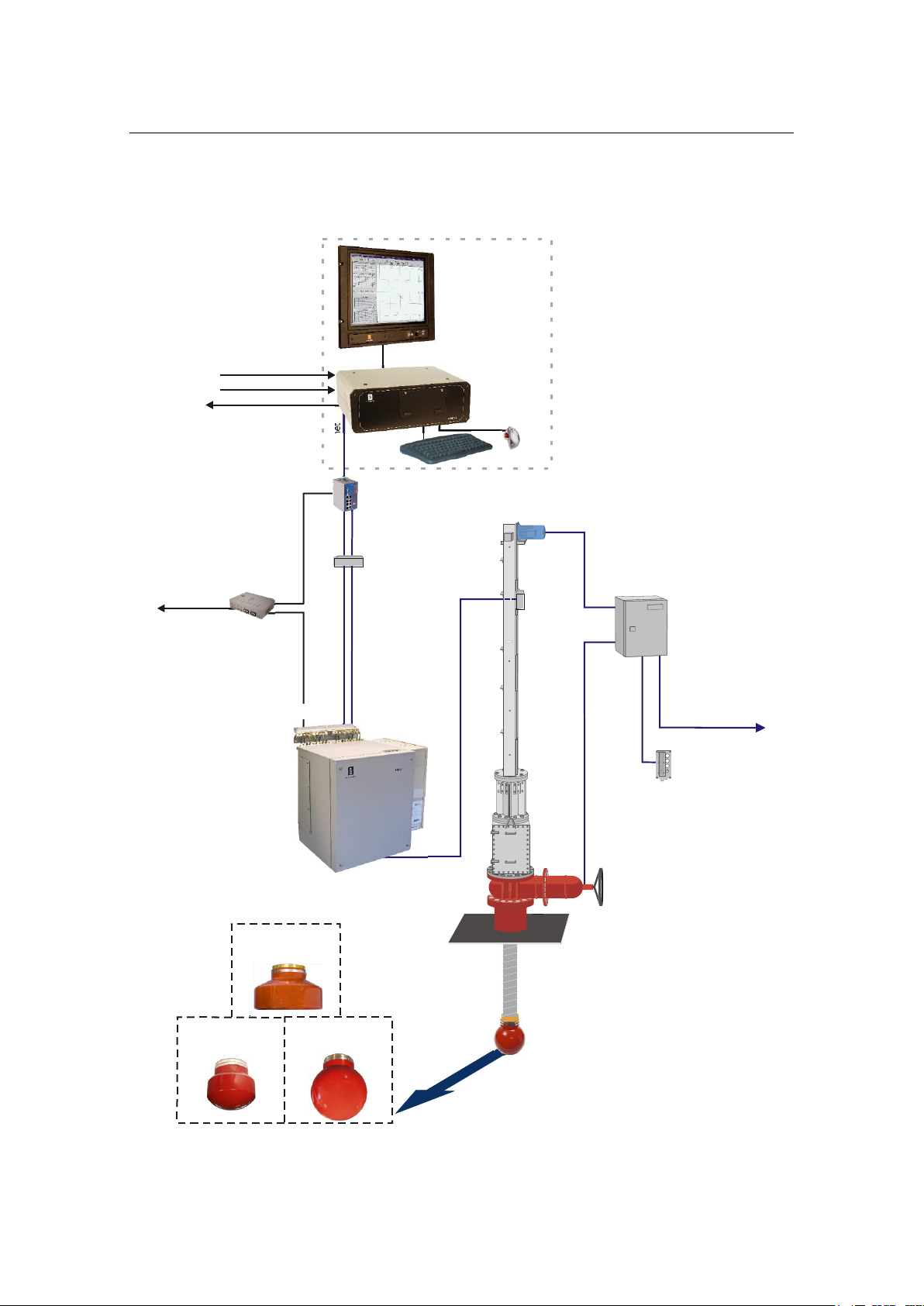

HiPAP® system with Transceiver unit Model x81 ................................................... 5

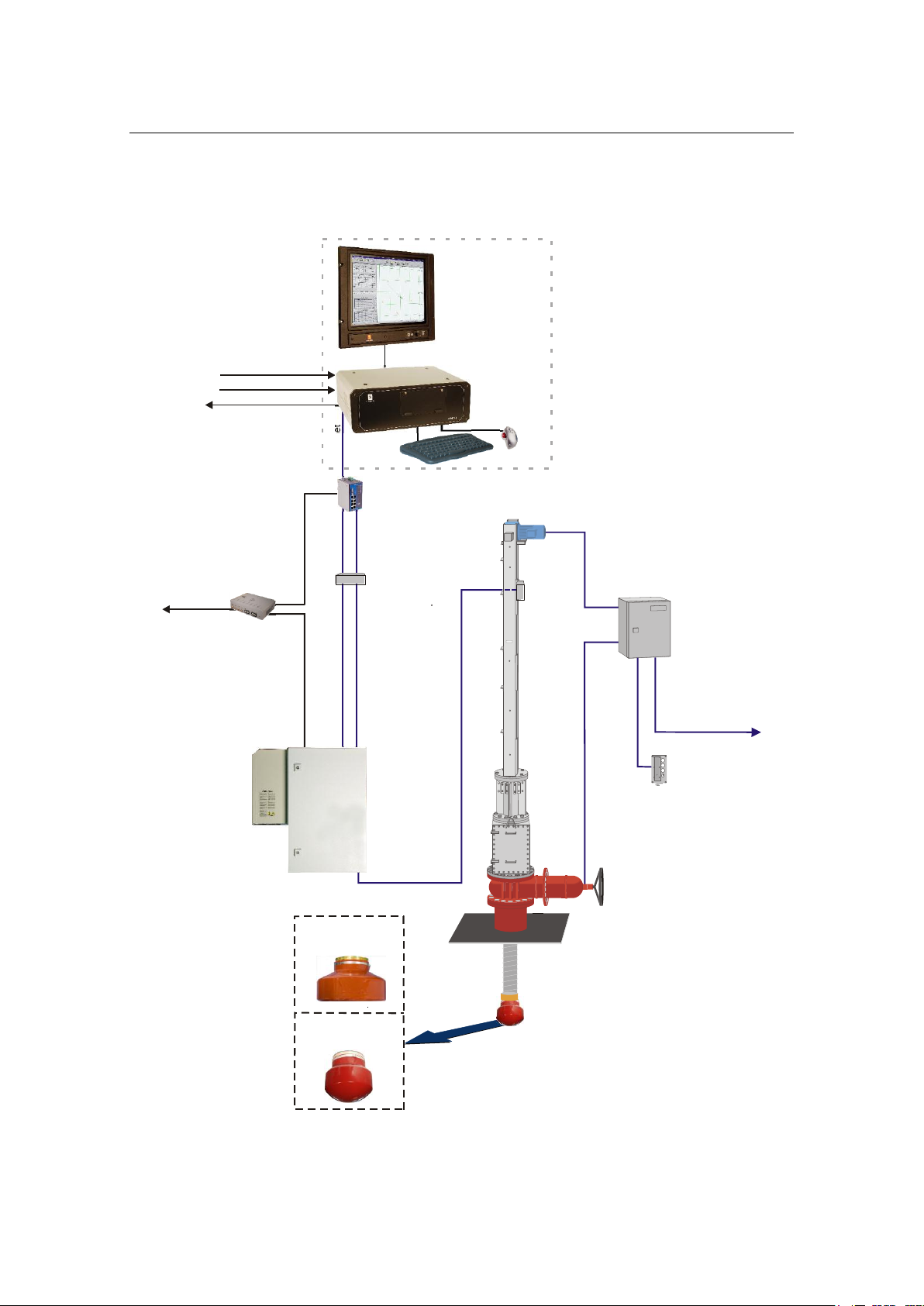

HiPAP® system with Transceiver unit Model x21 ................................................... 6

HiPAP® redundant system ....................................................................................... 7

Operator station ......................................................................................................... 8

Transceiver unit (system-specific) ............................................................................ 8

Hull unit (system-specific) ........................................................................................ 9

APOS ................................................................................................................................. 9

Sensors ............................................................................................................................... 9

Conversion kits for upgrading of an “old” HiPAP® system ............................................. 9

System units - short description ...................................................................................... 10

Operator Station ...................................................................................................... 10

Keyboard ................................................................................................................. 11

Trackball.................................................................................................................. 11

Display .................................................................................................................... 11

1PPS converter (option) .......................................................................................... 11

Ethernet switch/Converter ....................................................................................... 11

Fibre Splice Box ...................................................................................................... 12

Transceiver units ..................................................................................................... 12

110 Vac to 230 Vac transformer - option for both transceiver units ....................... 15

3 TECHNICAL SPECIFICATIONS ....................................................................... 16

Operator Station ............................................................................................................... 17

Fibre Splice Box .............................................................................................................. 17

Ethernet switch/Converter ............................................................................................... 18

303490/H III

HiPAP® Model 501/451/351/101

Transceiver units.............................................................................................................. 18

Common data .......................................................................................................... 18

Model x81 ............................................................................................................... 19

Model x21 ............................................................................................................... 20

110 Vac to 230 Vac transformer (option) ........................................................................ 20

SSBL accuracy ................................................................................................................ 20

Transducer reference point ...................................................................................... 20

HiPAP® 501 ........................................................................................................... 22

HiPAP® 451 ........................................................................................................... 23

HiPAP® 351 ........................................................................................................... 23

HiPAP® 101 ........................................................................................................... 25

LBL accuracy .................................................................................................................. 25

Range capabilities ............................................................................................................ 27

Fibre-optic cable .............................................................................................................. 28

Patch cables ............................................................................................................. 29

Connector type ST ................................................................................................... 30

4 INSTALLATION ................................................................................................... 31

Supply conditions ............................................................................................................ 33

Equipment responsibility......................................................................................... 33

Installation guidelines ............................................................................................. 33

Assistance from Kongsberg Maritime..................................................................... 33

Before you start ............................................................................................................... 34

Precautions and requirements.................................................................................. 34

Standard tools .................................................................................................................. 34

Special tools ..................................................................................................................... 35

Computer ......................................................................................................................... 35

1PPS converter (option) .................................................................................................. 37

Ethernet switch/Converter ............................................................................................... 37

Fibre Splice Box .............................................................................................................. 37

Transceiver units.............................................................................................................. 38

Basic installation instructions ................................................................................. 38

Vibrations ................................................................................................................ 38

Important information about ventilation and maintenance ..................................... 38

Transceiver unit Model x81 installation.................................................................. 39

IV 303490/H

Instruction Manual

Adapter Kit for x81 Transceiver ............................................................................. 41

Transceiver unit Model x21 installation.................................................................. 42

5 CABLES .................................................................................................................. 46

Cable gland assembly procedure ..................................................................................... 47

Securing and terminating the cables........................................................................ 48

Basic cable requirements ................................................................................................. 49

Cable planning ................................................................................................................. 52

Computer ......................................................................................................................... 52

Computer connections ............................................................................................. 52

Computer Dual Net connection ............................................................................... 53

GPS input signals connections ........................................................................................ 54

1PPS converter (option) .................................................................................................. 54

Transceiver unit Model x81 ............................................................................................. 57

Model x81 - transducer cable connection ............................................................... 58

Transducer cable with plug ..................................................................................... 59

Transceiver unit Model x21 ............................................................................................. 61

Model x21 - transducer cable connection ............................................................... 63

Transducer cable with plug ..................................................................................... 63

Transducer to transceiver unit cables installation............................................................ 64

Cable information .................................................................................................... 64

HiPAP® 501/451 .................................................................................................... 65

HiPAP® 351/101 (x81) ........................................................................................... 65

HiPAP® 351/101 (x21) ........................................................................................... 65

Fibre-optic cable installation ........................................................................................... 66

6 OPERATION .......................................................................................................... 69

HiPAP® operation ........................................................................................................... 69

7 MAINTENANCE ................................................................................................... 70

Safety ............................................................................................................................... 71

Before you start ............................................................................................................... 72

Maintenance philosophy .................................................................................................. 72

Verification.............................................................................................................. 73

Maintenance schedule...................................................................................................... 74

Maintenance chart ................................................................................................... 74

Preventive maintenance ................................................................................................... 74

303490/H V

HiPAP® Model 501/451/351/101

8 CABLE PLAN AND INTERCONNECTIONS ................................................... 75

9 SYSTEM UNITS - DETAILED DESCRIPTION ............................................... 76

Computer ......................................................................................................................... 76

Computer internal ................................................................................................... 77

How to open the computer ...................................................................................... 78

Keyboard ................................................................................................................. 78

Trackball.................................................................................................................. 78

1PPS converter (option) .................................................................................................. 78

Ethernet switch/Converter ............................................................................................... 78

Replacement ............................................................................................................ 78

Configuration .......................................................................................................... 79

Fibre Splice Box .............................................................................................................. 79

Transceiver unit Model x81 ............................................................................................. 79

Model x81 internal layout ....................................................................................... 80

Model x81 power sockets ........................................................................................ 81

Transceiver unit Model x81, PCB rack ................................................................... 82

Replacement of Model x81 parts ............................................................................ 82

Fuses ........................................................................................................................ 90

Transceiver unit Model x21 ............................................................................................. 91

Model x21 internal layout ....................................................................................... 91

Model x21 power socket ......................................................................................... 93

Replacement of Model x21 parts ............................................................................ 93

Circuit boards and units ................................................................................................... 97

Computer circuit boards and power unit ................................................................. 97

Transceiver units ..................................................................................................... 99

Transmit synchronization with external equipment .............................................. 105

10 SPARE PARTS ................................................................................................. 110

Operator station ............................................................................................................. 110

Transceiver Model x81 .................................................................................................. 111

HiPAP® 501/451/351 system ............................................................................... 111

HiPAP® 101 system ............................................................................................. 112

Transducer cable with plug ................................................................................... 112

Transceiver unit Model x21 ........................................................................................... 113

VI 303490/H

Instruction Manual

HiPAP® 351 system ............................................................................................. 113

HiPAP® 101 system ............................................................................................. 113

Transducer cable with plug ................................................................................... 113

11 HIPAP® MODELS AND POSITIONING PRINCIPLES ........................... 114

HiPAP® 501 ......................................................................................................... 115

HiPAP® 451 ......................................................................................................... 115

HiPAP® 351 ......................................................................................................... 116

HiPAP® 101 ......................................................................................................... 116

Positioning principles and processing ........................................................................... 116

SSBL positioning .................................................................................................. 117

LBL positioning .................................................................................................... 118

Combined SSBL and LBL positioning ................................................................. 122

HiPAP® processing .............................................................................................. 123

Cymbal acoustic protocol ...................................................................................... 124

12 RESPONDER OPTION ................................................................................... 126

Basic responder information .......................................................................................... 126

Responder Driver Unit .................................................................................................. 127

Technical specifications ................................................................................................ 128

Responder Driver Unit kit ..................................................................................... 128

Responder Driver Unit .......................................................................................... 128

Fibre to responder drive converter kit ................................................................... 129

Installation ..................................................................................................................... 129

Responder Driver Unit .......................................................................................... 129

Fibre to responder drive converter ........................................................................ 130

Cable layout and interconnections ................................................................................. 130

Maintenance................................................................................................................... 130

Responder Driver Unit .......................................................................................... 130

Fibre to responder drive converter ........................................................................ 132

Spare parts ..................................................................................................................... 133

Drawings ........................................................................................................................ 133

Responder Driver Unit - outline dimension .......................................................... 134

Responder Driver Unit .......................................................................................... 135

Responder sync cable, Transceiver unit Model x21 ............................................ 136

303490/H VII

HiPAP® Model 501/451/351/101

Responder sync cable, Transceiver unit Model x81 ............................................ 136

Responder Driver Unit - wiring diagram .............................................................. 137

Fibre to responder drive converter - wiring diagram ........................................... 138

13 LASER OPTION .............................................................................................. 139

Basic laser information.......................................................................................... 139

Installation ............................................................................................................. 141

Cable layout and interconnections ........................................................................ 141

Maintenance .......................................................................................................... 142

Spare parts ............................................................................................................. 143

Laser kit for TU Model x81 .................................................................................. 143

Drawings ............................................................................................................... 143

TU Model x81 – wiring diagram w/laser .............................................................. 144

Hoist indicator ADAM 617 – wiring diagram ...................................................... 145

14 EQUIPMENT HANDLING ............................................................................ 146

Transportation ................................................................................................................ 146

Storage prior to installation or use ........................................................................ 147

Inspection .............................................................................................................. 149

Storage after unpacking ................................................................................................. 152

After use storage.................................................................................................... 153

Re-packing ..................................................................................................................... 154

ESD precautions ............................................................................................................ 154

Temperature protection.................................................................................................. 155

15 HIPAP® COMMISSIONING CHECK AND VERIFICATION ................. 156

16 DRAWING FILE .............................................................................................. 157

Drawings ........................................................................................................................ 158

Keyboard - outline dimensions ............................................................................. 159

19“ display - outline dimensions ........................................................................... 160

Computer - desktop mounting and outline dimensions ......................................... 161

Computer - rack mounting and outline dimensions .............................................. 162

Transceiver unit Model x81, with cooling unit mounted on the right side - outline

dimensions/mounting, page 1 ................................................................................ 163

VIII 303490/H

Instruction Manual

Transceiver unit Model x81, with cooling unit mounted on the right side - outline

dimensions/mounting, page 2 ................................................................................ 164

Transceiver unit Model x81, with cooling unit mounted on the front door (option) -

outline dimensions/mounting, page 1.................................................................... 165

Transceiver unit Model x81, with cooling unit mounted on the front door (option) -

outline dimensions/mounting, page2..................................................................... 166

Transceiver unit Model x21 - outline dimensions/mounting, page 1 ................... 167

Transceiver unit Model x21 - outline dimensions/mounting, page 2 ................... 168

Standard AC power cable ...................................................................................... 169

EMC ground cable ................................................................................................ 170

External trigger cable ............................................................................................ 170

Computer RS-232 / RS-422 serial line cable ........................................................ 171

Transducer cable for HiPAP® 501/451 system, page 1 ........................................ 173

Transducer cable for HiPAP® 501/451 system , page 2 ....................................... 174

Transducer cable for HiPAP® 351/101 system, w/Transceiver unit Model x81,

page 1 .................................................................................................................... 175

Transducer cable for HiPAP® 351/101 system, w/Transceiver unit Model x81,

page 2 .................................................................................................................... 176

Transducer cable for Transceiver unit Model x21, page 1 .................................... 177

Transducer cable for Transceiver unit Model x21, page 2 ................................... 178

Transducer hull unit cable, for all HiPAP® systems, page 1 ................................ 179

Transducer hull unit cable, for all HiPAP® systems, page 2 ................................ 180

Transceiver unit Model x81 - wiring diagram ..................................................... 181

Transceiver unit Model x21 - wiring diagram, page 1 ......................................... 182

Transceiver unit Model x21 - wiring diagram, page 2 ......................................... 183

Cable conversion kit for Transceiver unit Model x81 - drawing .......................... 184

Adapter Kit for Transceiver x81 Unit ................................................................... 185

Junction box conversion kit for Transceiver unit Model x21 – drawing, page 1 .. 186

Junction box conversion kit for Transceiver unit Model x21 – drawing, page 2 .. 187

1PPS converter – component layout drawing ....................................................... 188

17 CABLE PLAN AND INTERCONNECTIONS ............................................. 189

18 INDEX ............................................................................................................... 190

303490/H IX

1 ABOUT THIS MANUAL

This document is the Instruction manual for the (High Precision

Acoustic Positioning) HiPAP® Model 501/451/351/101 systems

(named HiPAP® systems in rest of the manual).

The manual contains descriptions, specifications, procedures

and illustrations required to install and maintain the HiPAP®

system units.

The manual also defines the equipment responsibility, and

provides general information about preservation, packing and

storage of the units, and provides the Factory Acceptance Tests

and the HiPAP® test and alignment procedures.

The system is described down to circuit board level, named as

the Line Replaceable Units (LRUs). Block diagrams and

drawings are used to simplify the descriptions.

About this manual

References

Conversion kits for upgrading of old HiPAP® systems are also

included.

319957 - APOS for HiPAP® 501/451/351/101 Instruction Manual

311046 - HiPAP® hull units Model 501/451/351/101 Instruction

Manual

331070 - HiPAP® Commissioning check and verification

859-216300 - Backup files document

303490/H 1

HiPAP® Model 501/451/351/101

APOS

Acoustic Positioning Operator Station

BOP

Blow Out Preventer

CG

Centre of Gravity

DP

Dynamic Positioning

DVI

Digital Visual Interface

GNSS

Global Navigation Satellite System

GPS

Global Positioning System

HiPAP®

High Precision Acoustic Positioning

HPR

Hydroacoustic Position Reference

LBL

Long Base Line

LRU

Line Replaceable Unit

MULBL

Multi-User Long Base Line

PCB

Printed Circuit Board

ROV

Remotely Operated Vehicle

RTB

Responder Terminal Block

SSBL

Super Short Base Line

SSLBL

Super Short and Long Base Line

Abbreviations

Abbreviations used in this manual:

Backup

You are advised to take a backup of all operator stations at

regular intervals (1-3 months), and every time major changes

have been performed in configuration and /or user settings.

Software upgrade

____________________________________________________________

Caution A system backup must be performed when the

software has been upgraded.

____________________________________________________________

The backup procedures are included in a separate document, the

Backup files document, doc no 859-216300.

This document is supplied with every system delivered.

2 303490/H

2 SYSTEM DESCRIPTION

This chapter provides a brief description of the HiPAP®

systems and configurations. It also gives a short description of

each unit.

Topics

HiPAP® systems - short overview on page 4

HiPAP® system configuration on page 4

Operator station on page 8

Transceiver units on page 8

Hull units on page 9

APOS on page 9

System description

Sensors on page 9

Conversion kits for upgrading of old HiPAP® systems on page 9

System units - short description on page 10

Related topics

HiPAP® models information on page 114

Responder option on page 126

Laser option on page 139

303490/H 3

HiPAP® Model 501/451/351/101

HiPAP® systems - short overview

The HiPAP® systems are designed for optimal positioning of

subsea objects in both shallow and deep water.

All HiPAP® systems; HiPAP® 501, HiPAP® 451, HiPAP®

351 and HiPAP® 101 have common software and hardware

platforms, and thereby offer the same kind of additional

functionality and options.

The HiPAP® 501, HiPAP® 451, HiPAP® 351 systems are

medium frequency systems operating from 21 kHz to 31 kHz.

The HiPAP® 101 system is a low frequency systems

operating from 10 kHz to 15.5 kHz.

HiPAP® system configuration

A HiPAP® system may be configured as:

Standard HiPAP® systems:

HiPAP® systems used with Transceiver unit Model x81,

see figures on page 5

HiPAP® systems used with Transceiver unit Model x21,

see figure on pages 6

HiPAP® Dual Net system:

HiPAP® systems used with Transceiver unit Model x81,

see figure on page 7

4 303490/H

(Cd31053a)

Operator

Station

Heading sensor

Motion sensor

Data output

Fibre B (optional)

Ethernet

Ethernet

Ethernet interfaced

with APOS/APC

Fibre A

Responder sync.

Fibre A

Fibre B

Hull

Unit

Ethernet

switch/

Converter

Fibre Splice

Box

Junction

Box

Responder

Driver Unit (option)

Responder

Transceiver unit

Model x81

Hoist

Control Unit

Remote

Control

Unit

HiPAP 100

transducer

HiPAP 350

transducer

HiPAP 500

transducer

Option 1

Option 2

System description

HiPAP® system with Transceiver unit Model x81

303490/H 5

Ethernet

Responder sync.

Responder

Driver Unit (option)

Responder

(Cd31053)

Transceiver unit

Model x21

Hoist

Control Unit

Operator

Station

Heading sensor

Motion sensor

Data output

Ethernet

Fibre A

Fibre B (optional)

Fibre A

Fibre B

Hull

Unit

Ethernet

switch/

Converter

Fibre Splice

Box

HiPAP 100

transducer

HiPAP 350

transducer

Junction

Box

Ethernet interfaced

with APOS/APC

Remote

Control

Unit

Option 1

Option 2

HiPAP® Model 501/451/351/101

HiPAP® system with Transceiver unit Model x21

6 303490/H

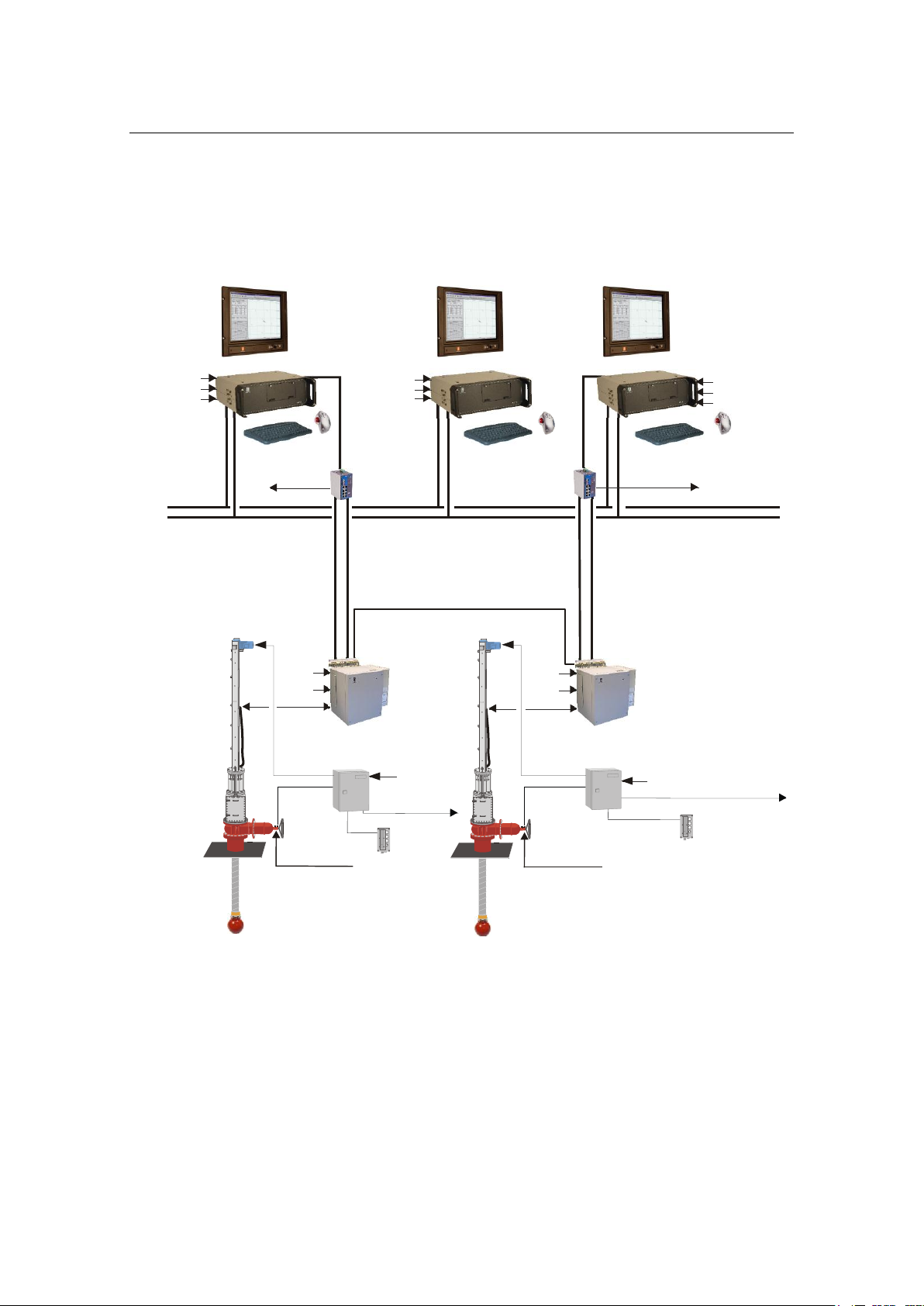

HiPAP® redundant system

Operator Station Operator Station

Operator Station

Dual Ethernet

Ethernet

Ethernet

Fibre A

Fibre A

Fibre B (optional)

Fibre B (optional)

Hoist

Control Unit

Hull Unit

Hull Unit

Power

Power

Hoist

Control Unit

Power A

Power A

Power B

(option)

Power B

(option)

Power

(Cd31085)

Gate valve

Gate valve

position indicator

Gate valve

position indicator

HiPAP 500/350

transducer

Power

Gate valve

HiPAP 500/350

Remote

Control

Unit

Remote

Control

Unit

GPS

GPS

GPS

Heading sensor

Heading sensor

Heading sensor

Motion sensor

Motion sensor

Motion sensor

Responder

Responder

Ethernet

switch/

Converter

Ethernet

switch/

Converter

HiPAP

Transceiver Unit

Model x81

500

HiPAP

Transceiver Unit

Model x81

500

(Sync for Dual HiPAP only)

Ethernet interfaced

with APOS/APC

Ethernet interfaced

with APOS/APC

Option 1

Option 1

Option 2

Option 2

Example of a HiPAP® redundant system:

System description

303490/H 7

HiPAP® Model 501/451/351/101

Operator station

The operator station may be configured in two ways:

1. Stand alone

Computer

Display

Keyboard

Trackball

The stand alone configuration can be fitted as:

Contained in a standard 19” rack

The display and the computer are fitted into a standard

19” rack unit. The keyboard and the trackball may be

placed on a desk, or on a suitable shelf. The transceiver

unit is installed close to the hull unit.

The display, the computer and the keyboard are fitted

into drawers in a standard 19” rack unit.

Desktop system

The display, the computer, the keyboard and the

trackball sit on a desk top or a purpose-built shelf.

2. Operator console

If the HiPAP® system is delivered together with a Kongsberg

DP system the operator station may be installed in a standard

Kongsberg DP console.

Transceiver unit (system-specific)

Two types of transceiver units are available:

HiPAP® Transceiver unit Model x81are used for the

systems 501, 451 and 351.

HiPAP® systems used with Transceiver unit Model x81,

see figures on pages 5 and 7.

HiPAP® Transceiver unit Model x21 are used for the

systems 351 and 101.

8 303490/H

APOS

Sensors

System description

HiPAP® systems used with Transceiver unit Model x21,

see figure on page 6.

Hull unit (system-specific)

Hull units w/transducer, gate valves, Hoist Control Unit with

Ethernet interface are described in the HiPAP® hull units Model

501/451/351/101 Instruction Manual.

The HiPAP® system is operated from APOS, a Windows based

software system. The system can be operated from one single

APOS station or from a wide number of APOS operator stations

connected on a network.

The HiPAP® system has a wide range of interfaces to sensors

from different manufacturers.

The HiPAP® system needs high accuracy heading, roll and

pitch sensors to be interfaced.

The accuracy of the sensors has direct impact on the position.

Conversion kits for upgrading of an “old” HiPAP® system

Transceiver unit Model x81 to be used with a transducer cable

with plug.

See information on page 59

Transceiver unit Model x21 to be used with a transducer cable

with plug.

See information on page 63

For more information, contact Kongsberg Maritime.

303490/H 9

HiPAP® Model 501/451/351/101

System units - short description

Topics

Operator Station on page 10

Keyboard on page 11

Trackball on page 11

Display on page 11

1PPS converter on page 11

Ethernet switch/ Converter on page 11

Fibre Splice Box on page 12

Transceiver units on page 12

Operator Station

The HiPAP® System is operated through either one or several

Operator Stations.

The Operator Station consists of the following main units:

A Windows™ based personal computer

A display for presentation of information

Keyboard and mouse

The same computer is used for all types of installation, desktop

or rack with additional mounting brackets or rails as required.

Power

The computer can be powered from either a 115 VAC or 230

VAC supply.

USB disk

An USB disk containing programs for backup and restore is

delivered at the system setup. These programs can only be used

when the system boots from the USB disk.

10 303490/H

System description

(Cd31162)

Keyboard

The keyboard is a PS/2 keyboard. It is a QWERTY keyboard

with US layout and includes back-lighting.

Trackball

The trackball is a standard trackball with a scroll wheel and

three buttons.

Display

Refer to the separate manual supplied with the display.

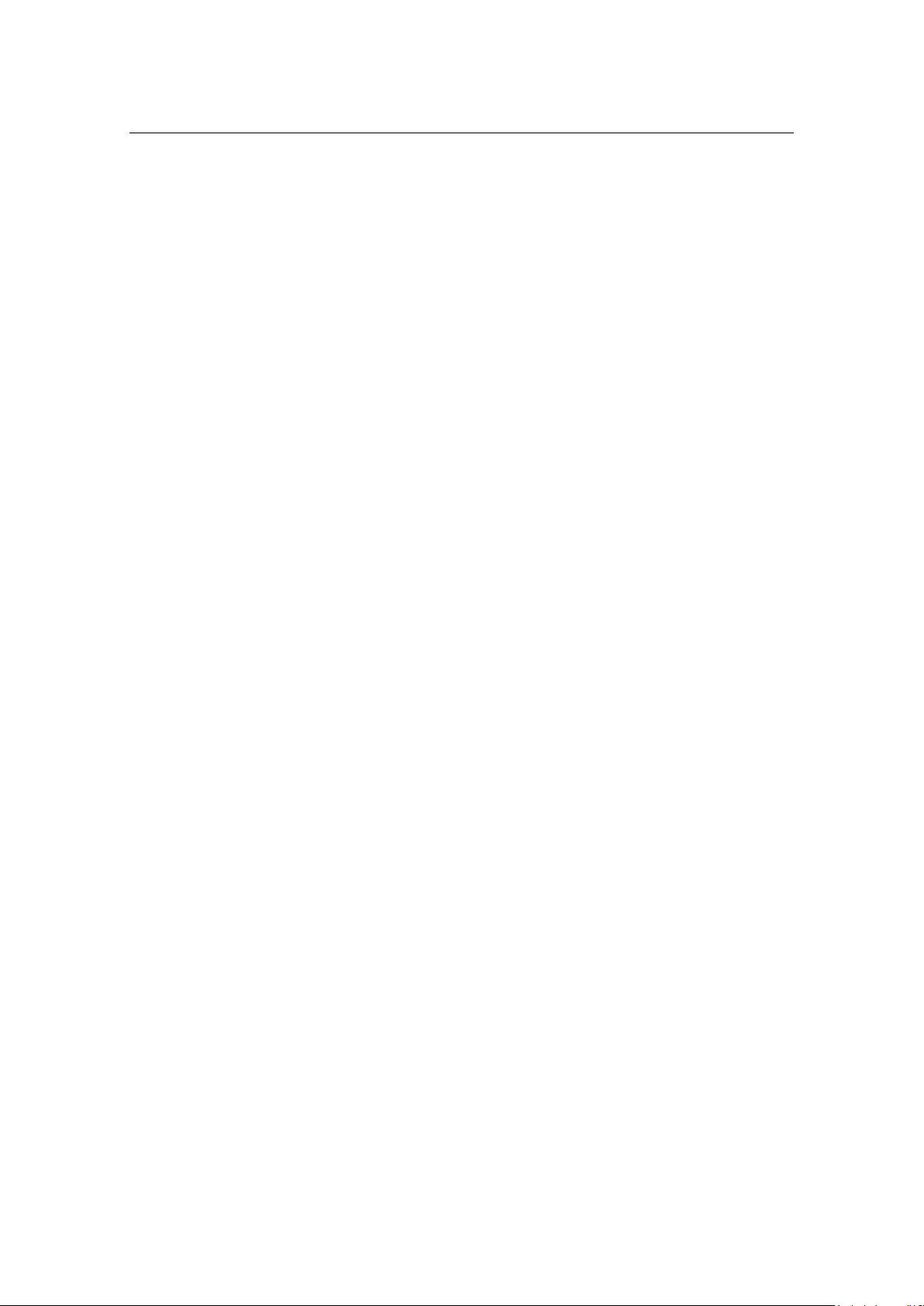

1PPS converter (option)

The 1PPS converter is an option to a standard HiPAP® system.

1PPS; One Pulse per Second.

The signal is normally taken from a GPS receiver or a time

synchronize unit.

This pulse is used to synchronize the clock on the APOS/HiPAP

system with a reference clock.

In addition to the pulse, a message with correct time must be

transmitted on the same serial line as used for the 1PPS input.

A 1PPS converter passes the RS-232 GPS Position Data through

but shapes the 1PPS pulse to a fixed pulse length and converts it

from TTL level to RS-232 level.

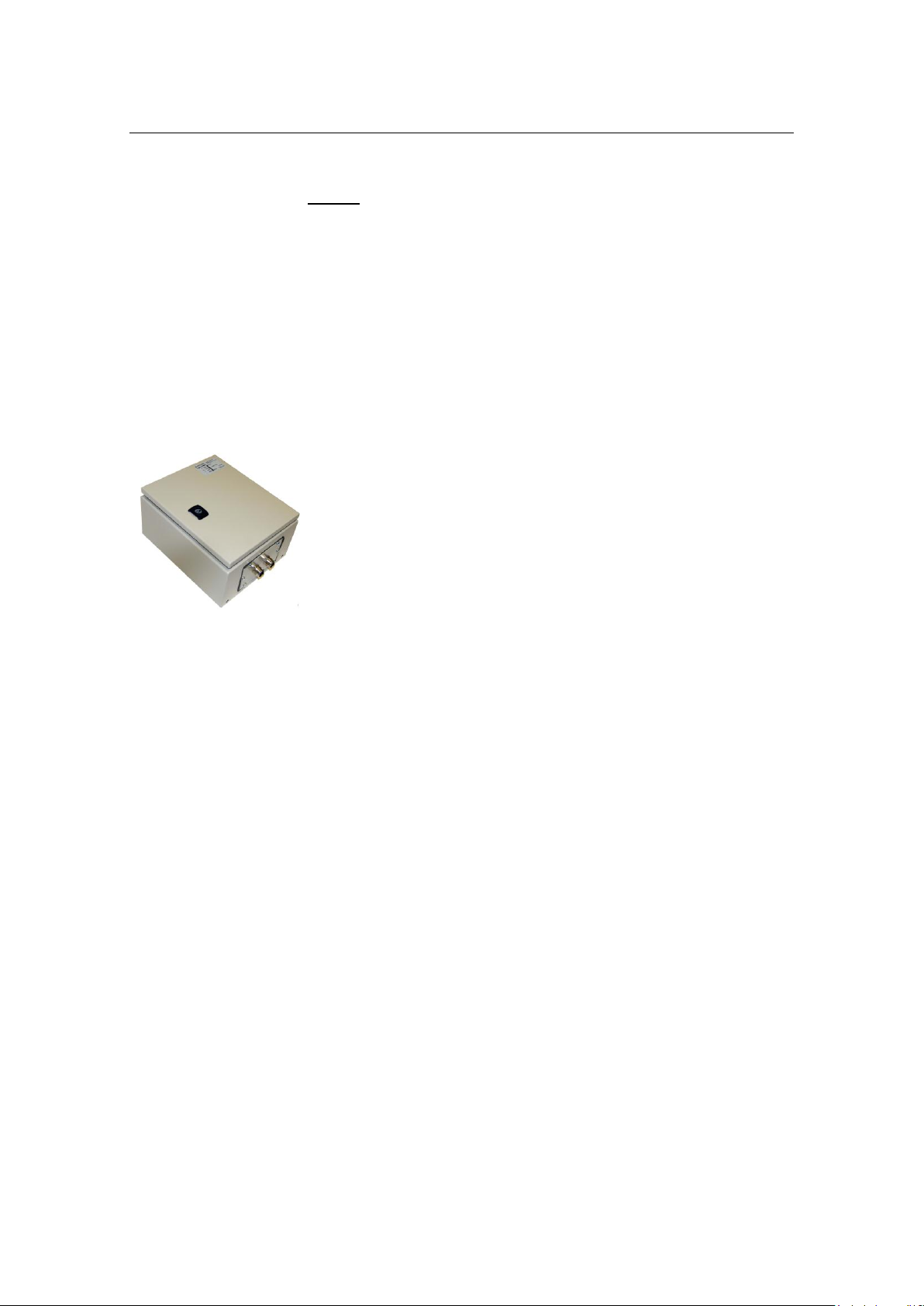

Figure 1 1PPS converter

Ethernet switch/Converter

The Ethernet switch/Converter is used for:

Interface Optical fibre cable to transceiver

303490/H 11

HiPAP® Model 501/451/351/101

Responder Driver Unit

Hoist Control Unit with Ethernet

Gate Valve Main Control Unit with Ethernet

Fibre Splice Box

The Fibre Splice Box has eight (8) ports. This box is used to

splice the system fibre-optic cables.

Transceiver units

The HiPAP® transceiver units are steel cabinets, containing a

rack holding the system electronics modules. The units are fitted

with an air to air heat exchange unit.

The transceiver units are designed to be mounted on a suitable

bulkhead and are fitted with vibration/shock absorbers to reduce

the effects of transceiver unit vibrations.

Topics

Transceiver unit Model x81 on page 13

Transceiver unit Model x21 on page 14

12 303490/H

System description

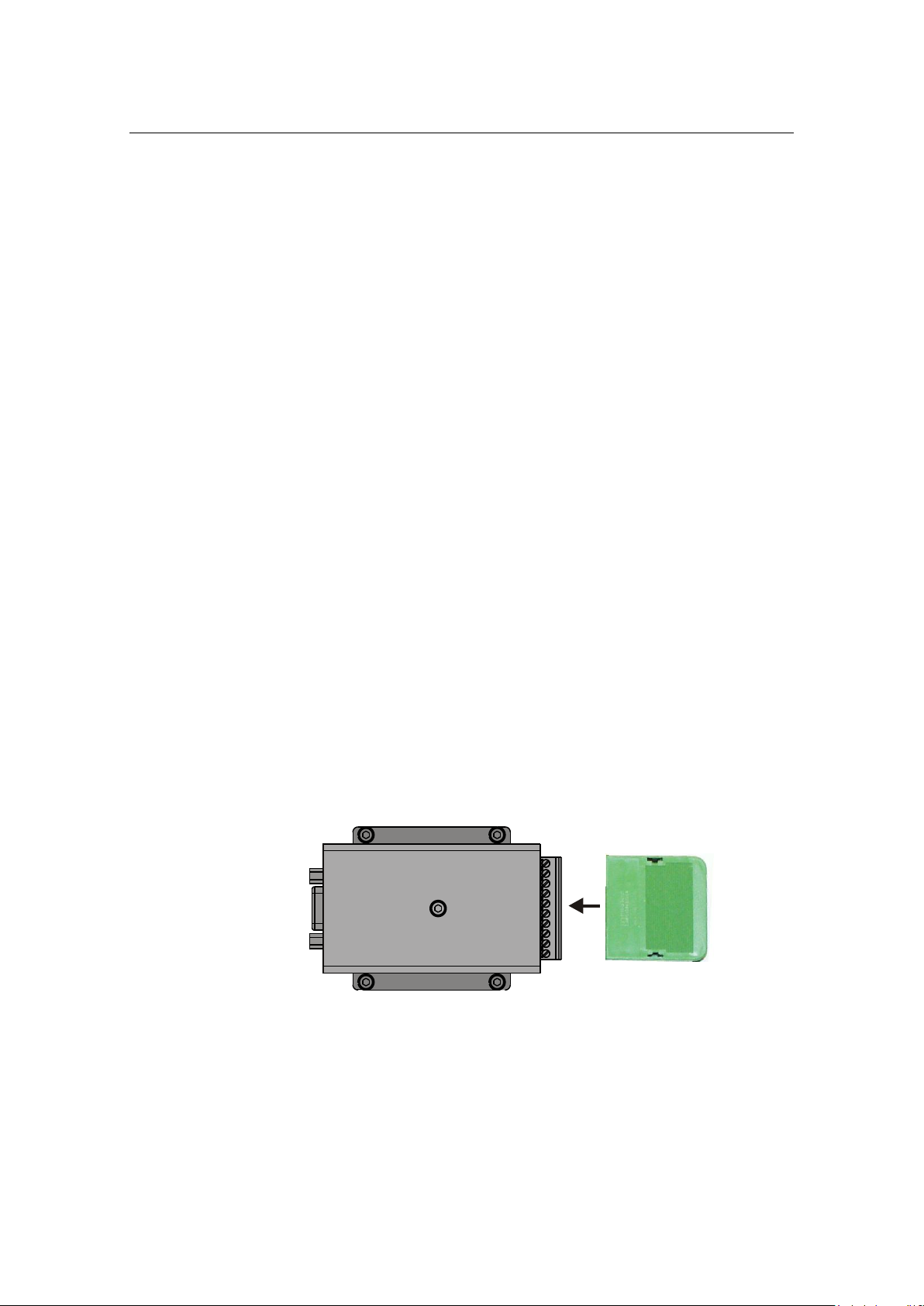

Transceiver unit Model x81

Transceiver unit x81 may be delivered with:

With the air to air heat exchange unit mounted on the right

side as standard.

or

With the air to air heat exchange unit mounted on the unit

door (optional).

An access door for plugging connectors and service is located

on the left side of the unit.

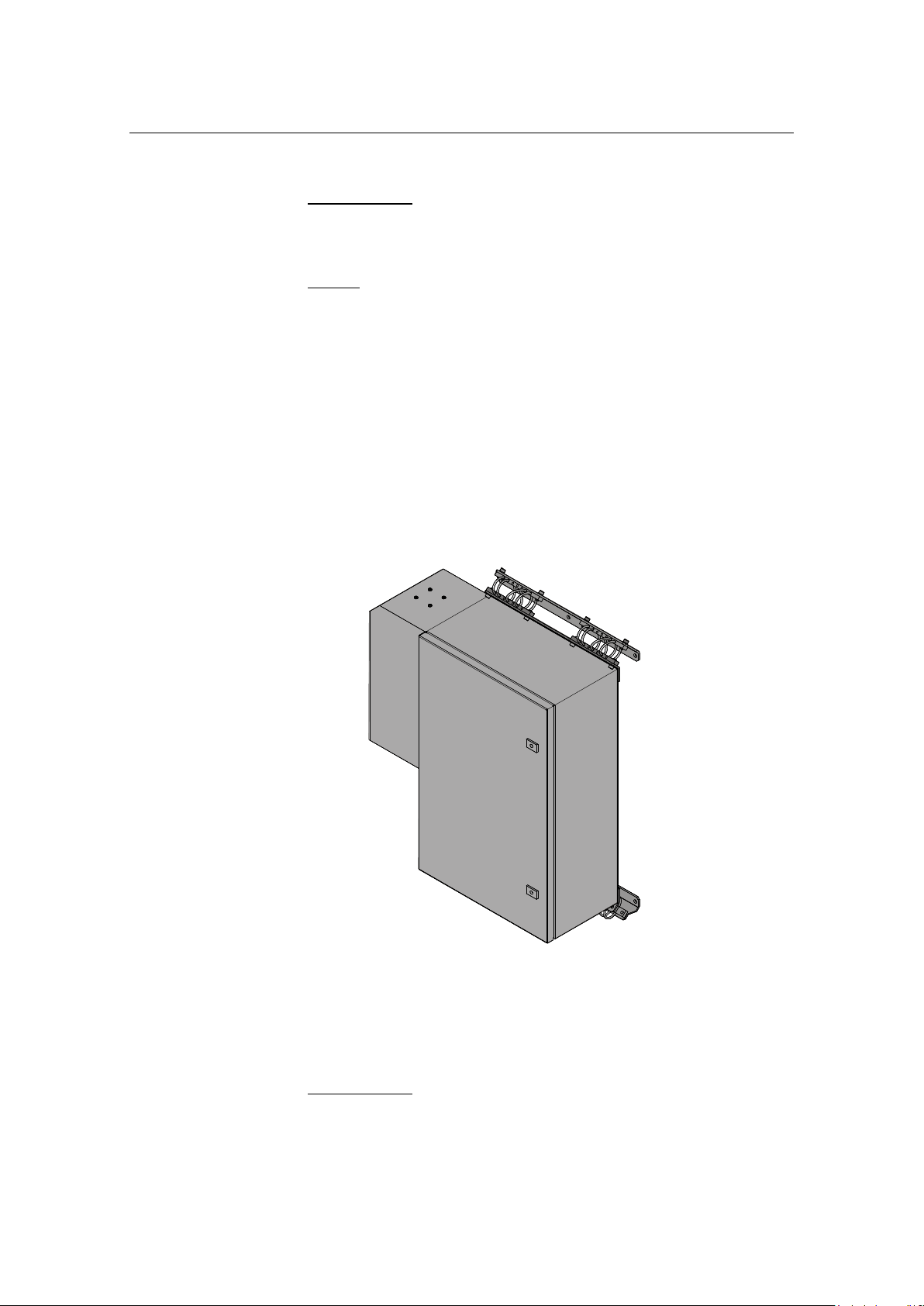

Figure 2 Standard Transceiver unit Model x81 w/air to air heat exchange unit mounted

on the right side

Used for the HiPAP® 501 with eight (8) TRX32 boards

Used for the HiPAP® 451 with two (2) TRX32 boards

Used for the HiPAP® 351 with two (2) TRX32 boards

Used for the HiPAP® 101 with one (1) TRX32 board

System upgrade

The HiPAP® 451 can be upgraded to full HiPAP® 501

performance. This is done by:

Installation of 6 additional transmitter/receiver boards

(TRX32) in the transceiver unit.

APOS software upgrade.

303490/H 13

HiPAP® Model 501/451/351/101

(Cd31072)

Connections

All cables to and from the transceiver unit enter the unit through

the base of the unit.

Power

The transceiver unit is powered from a 230 Vac supply. The

power switch (Main switch) is located inside the transceiver

unit.

Refer to figure on page 80

If you only have 110 Vac power available, you must use a 110

Vac to 230 Vac transformer - see page 15.

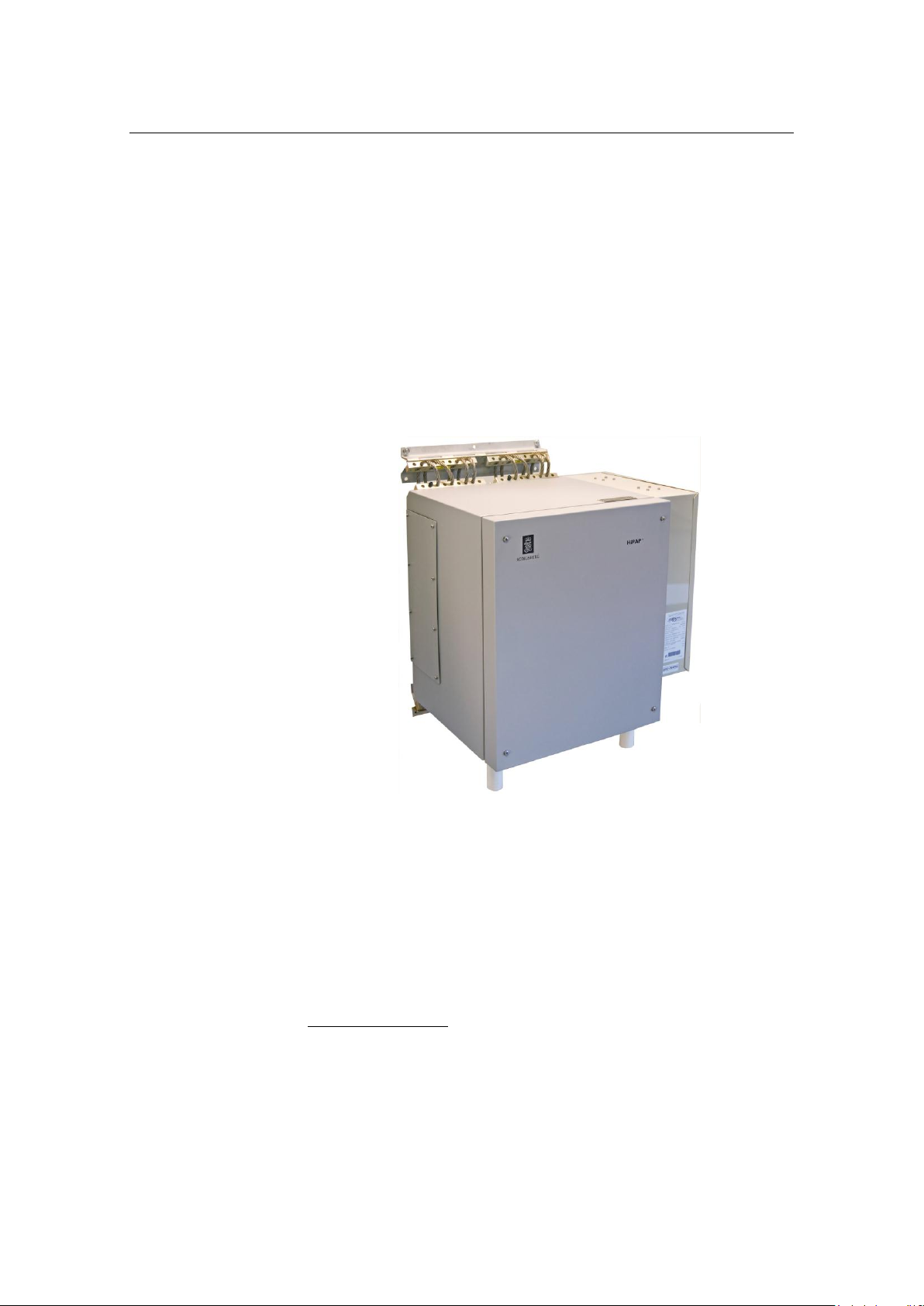

Transceiver unit Model x21

Transceiver unit x21 are delivered with the air to air heat

exchange unit mounted on the left side.

Figure 3 Transceiver unit Model x21

Used for the HiPAP® 351 with two (2) TRX32 boards

Used for the HiPAP® 101 with one (1) TRX32 board

Connections

All cables to and from the transceiver unit enter the unit through

the base of the unit.

14 303490/H

System description

If your only have 110 Vac power available, an external

transformer from 110 Vac to 220 Vac must be installed on the

main power line to both the Transceiver unit Model x81 and

the Transceiver unit Model x21

Order no see page 20

Power

The transceiver unit is powered from a 230 Vac supply. The

power switch (Main switch) is located inside the transceiver

unit.

Refer to figure on page 91

If you only have 110 Vac power available, you must use a 110

Vac to 230 Vac transformer - see page 15.

110 Vac to 230 Vac transformer - option for both transceiver units

303490/H 15

HiPAP® Model 501/451/351/101

3 TECHNICAL SPECIFICATIONS

This chapter gives the technical specifications of the HiPAP®

system units.

Topics

Operator station on page 17

Fibre Splice Box on page 17

Ethernet switch/Converter on page 18

Transceiver unit Model x81 on page 18

Transceiver unit Model x21 on page 20

110 Vac to 230 vac transformer - option on page 20

SSBL accuracy on page 20

LBL accuracy on page 25

Range capabilities on page 27

Fibre-optic cable on page 28

Related topics

Transmit on external trigger on page 105

16 303490/H

Loading...

Loading...