Page 1

UK

Kompernaß GmbH · Burgstrasse 21 · D-44867 Bochum

www.kompernass.com

ID Nr.: KH3173-03/06-V2

KH3173_IB_UK.qxd 12.06.2006 15:35 Uhr Seite 1

Page 2

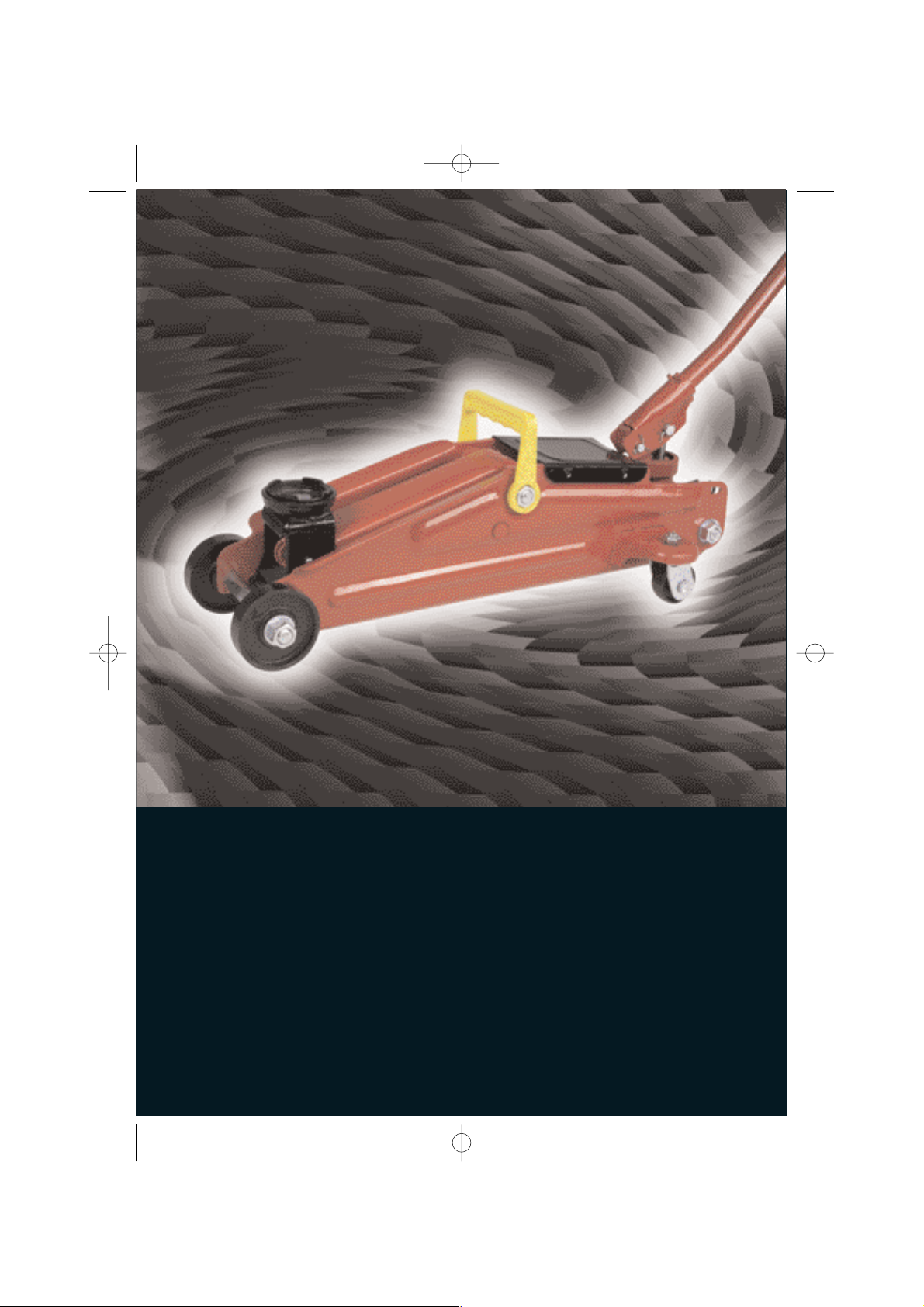

Mobile Hydraulic Vehicle Jack KH 3173

Operating instructions

KH3173_IB_UK.qxd 12.06.2006 15:35 Uhr Seite 2

Page 3

KH3173_IB_UK.qxd 12.06.2006 15:35 Uhr Seite 3

Page 4

KH3173_IB_UK.qxd 12.06.2006 15:35 Uhr Seite 4

Page 5

- 3 -

KH3173

Mobile Hydraulic Vehicle Jack

KH 3173

Keep this manual for future reference

and pass it on with the device to any

future owners!

Intended Use

The Mobile Hydraulic Vehicle Jack is

intended for the short term lifting of

motor vehicles and only for domestic

use.

The Mobile Hydraulic Vehicle Jack is not

intended for permanently holding raised

motor vehicles in position and is not

intended for use in commercial or

industrial areas.

Safety instructions

• Only use the Mobile Hydraulic Vehicle

Jack if it is in a faultless condition.

The appliance may not be used if it

has been visibly damaged!

• Use the Mobile Hydraulic Vehicle Jack

only for raising and lowering motor

vehicles – not for holding them in

a raised position.

Secure the vehicle in the raised position

with axle stands to prevent it from

dropping suddenly.

• Before raising, ensure that the vehicle

cannot roll: Apply the handbrake and

place wedges against the wheels not

being raised.

• Only use the Mobile Hydraulic Vehicle

Jack on firm and level surfaces.

This will help prevent the vehicle from

rolling, or shifting while it is being

raised.

• Never use the Mobile Hydraulic Vehicle

Jack at an oblique angle to the vehicle.

• Do not permit children or infirm persons

to handle the appliance without

supervision. They are not always able

to recognise the potential dangers.

• Never overburden the Mobile Hydraulic

Vehicle Jack – also not for a short

period!

• Never use the Mobile Hydraulic Vehicle

Jack to shift a raised vehicle. The

Mobile Hydraulic Vehicle Jack is not

designed to cope with the loading

that this would cause!

• Do not grip between the lifting arm

and the housing of the Mobile

Hydraulic Vehicle Jack. Thus you can

avoid crush injuries when the lifting

arm moves itself.

• Ensure that no one is in or under the

vehicle when raising and/or lowering

it. Otherwise there is a danger of

accidents.

Technical data

Lifting capacity: 2000 kg

Lifting height: ca. 120 - 355 mm

Rotation range for

lifting lever: 180°

Hydraulic oil

for Mobile Hydraulic Vehicle Jack

Oil viscosity : SAE 10

DESCRIPTION OF THE APPLIANCE

Lifting lever

Carrying grip

Loading plate

Release valve

Lifting lever collet

KH3173_IB_UK.qxd 12.06.2006 15:35 Uhr Seite 3

Page 6

Preparatory steps

1. Push the lifting levers into each

other. Turn them until they are secured

against being pulled apart.

2. Place the lifting levers onto the

release valve at the front.Turn it

clockwise to close it completely.

3. Now place the lifting levers in the

lifting lever collet .

4. Turn the lifting levers clockwise

until they are secure against being

pulled out.

5. On the first utilisation or after an

extended period of non-usage, first

pump the Mobile Hydraulic Vehicle

Jack without any loading (6-7 pump

movements). This distributes the

hydraulic oil evenly again inside the

device.

Raising the vehicle

Important: Refer to the vehicle

owner's handbook to find out where

the lifting points are located. To avoid

damage, the vehicle may only be raised

at these places.

1. Push the loading plate to exactly in

the middle below the lifting point.

Note: Ensure that you place the

vehicle jack in such a position that

the lifting levers are not under

the vehicle.

2. To start, only pump until the loading

plate is just touching the lifting

point. This permits you to make

corrections if needed.

3. Now raise the vehicle until you have

sufficient clearance to position the

axle stands.

4. Permit the vehicle to drop onto the

axle stands in that you slowly open

the release valve by turning it in

an anti-clockwise direction.

Lowering the vehicle

1. First raise the vehicle a little to remove

the axle stands.

2. Then, with the lifting lever , slowly

turn the release valve (anti-clockwise) and carefully allow the vehicle

to descend.

3. As soon as the Mobile Hydraulic Vehicle

Jack is removed from under the vehicle,

the loading plate can be completely

pressed down with the foot.

Cleaning and Care

Note: The hydraulic fluid may only

be topped up by a trained technician,

or by customer service.

The Mobile Hydraulic Vehicle Jack can

simply be cleaned with a lightly oiled

cloth.

Note: Do not alter the setting of the

factory set adjustment screw, this is

only intended for repairs carried out

by customer services.

- 4 -

KH3173

KH3173_IB_UK.qxd 12.06.2006 15:35 Uhr Seite 4

Page 7

- 5 -

Storage

Lower the lifting arm completely. This

permits space-saving storage of the

Mobile Hydraulic Vehicle Jack.

Disposal

Do not dispose of the appliance in your

normal domestic waste.

Dispose of the appliance through an

approved disposal centre or at your

community waste facility. Observe the

currently applicable regulations. In case

of doubt, please contact your waste disposal centre.

The hydraulic oil SAE 10 in the Mobile

Hydraulic Vehicle Jack should be disposed of at an hazardous substances

dump!

Improper disposal of used oil damages

the environment! All inter-mixing with

substances such as solvents, brake and

cooler fluids is forbiden! The address

of your local hazardous substances dump

is available from your community administration.

Warranty & Service

The warranty conditions and the service

address can be found on the warranty

slip.

Kompernaß GmbH

Burgstrasse 21

D-44867 Bochum

www.kompernass.com

Declaration of conformity

We, Kompernaß Handelsgesellschaft

GmbH, Burgstrasse 21, D 44867 Bochum

declare on our own responsibility, that

the product Mobile Hydraulic Vehicle

Jack Typ KH 3173 conforms with all

requirements of the Machine Guidelines:

98/37 EC.

Related harmonised standards:

EN 1494:2000

Kompernaß Handelsgesellschaft GmbH

Burgstr. 21, D 44867 Bochum

Bochum, den 06.06.2006

Hans Kompernaß, General Manager

KH3173

KH3173_IB_UK.qxd 12.06.2006 15:35 Uhr Seite 5

Loading...

Loading...