Page 1

SEBM016205

1

-

MACHINE MODEL SERIAL NUMBER

D155AX-5 70001 and up

This shop manual may contain attachments and optional equipment that are not available in your

•

area. Please consult your local Komatsu distributor for those items you may require.

Materials and specifications are subject to change without notice.

D155AX-5 mounts the SA6D140E-2 or SA6D140E-3 engine.

•

For details of the engine, see the 6D140-2 or 140-3 Series Engine Shop Manual.

C 2001 1

All Rights Reserved

Printed in Japan 04-01(03)

00-1D155AX-5

5

Page 2

CONTENTS

No. of page

01 GENERAL ..............................................................................01-1

10 STRUCTURE AND FUNCTION ............................................10-1

20 TESTING AND ADJUSTING................................................20-1

30 DISASSEMBLY AND ASSEMBLY .......................................30-1

40 MAINTENANCE STANDARD...............................................40-1

90 OTHERS ................................................................................90-1

00-2 D155AX-5

1

Page 3

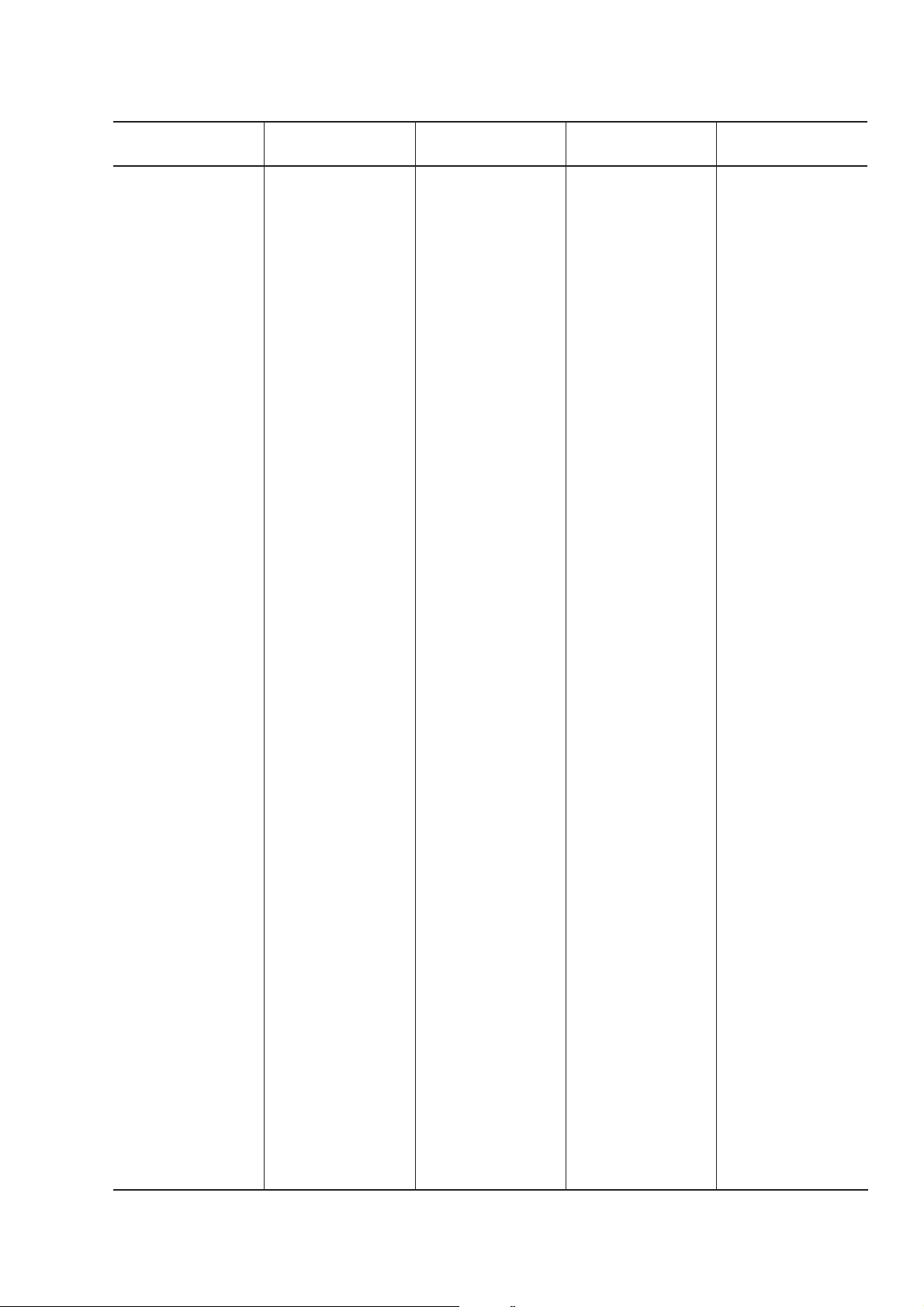

The affected pages are indicated by the use of the

following marks. It is requested that necessary actions

must be taken to these pages according to the list

below.

LIST OF REVISED PAGES

Mark Indication Action required

fi Page to be newly added Add

‡ Page to be replaced Replace

( ) Page to be deleted Discard

Pages having no marks are not revised at this time.

Mark Pages

Revision

number

‡ 00- 1 5

00- 2 1

‡ 00- 2-1 5

‡ 00- 2-2 5

‡ 00- 2-3 5

‡ 00- 2-4 5

‡ 00- 2-5 5

00- 3

00- 4

00- 5

00- 6

00- 7

00- 8

00- 9

00-10

00-11

00-12

00-13

00-14

00-15

00-16

00-17

00-18

00-19

00-20

00-21

01- 1

01- 2

01- 3

01- 4 3

01- 5 3

01- 6 3

01- 7 3

01- 8 3

01- 9 3

01-10 3

01-11 3

01-12 3

10- 1

10- 2 3

10- 3 3

10- 4 3

Mark Pages

10- 5 3

10- 6 3

10- 7

10- 8 3

10- 9 3

10-10 3

10-11

10-12

10-13

10-14

10-15

10-16 3

10-17

10-19

10-20

10-21

10-22

10-24

10-25

10-26

10-27

10-28

10-29

10-30

10-31

10-32

10-34

10-35

10-36

10-37

10-38

10-39

10-40

10-41

10-42

10-43

10-44

10-46

10-47

10-48

10-49

10-50 3

Revision

number

Mark Pages

10-52

10-53

10-54 3

10-56

10-57

10-58 3

10-59

10-60 3

10-61

10-62

10-63

10-64

10-65

10-66 3

10-67

10-68

10-69 3

10-70

10-71 3

10-72

10-73

10-74

10-75

10-76

10-77

10-78

10-79

10-80

10-81

10-82

10-83

10-84

10-85 3

10-86

10-87

10-88

10-89

10-91

10-92

10-93 3

10-94

10-95

Revision

number

Mark Pages

10- 96

10- 97

10- 98

10- 99

10-100

10-101

10-102

10-103

10-104

10-105 3

10-106 3

10-107

10-108

10-109

10-110

10-111

10-112

10-113

10-114

10-116

10-117

10-118

10-119

10-120

10-121 3

10-122

10-124

10-125

10-126

10-127

10-128

10-129

10-130

10-131

10-132

10-133

10-134

10-135

10-136

10-137

10-138

10-139

Revision

number

Mark Pages

10-140

10-141

10-142

10-143

10-144

10-145

10-146

10-147

10-148

10-149

10-150

10-151

10-152

10-153

10-154

10-156

10-157

10-158

10-159

10-160

10-161

10-162

10-163

10-164

10-165

10-166

10-167

10-168

10-169

10-170

10-171

10-172

10-173

10-174

10-175

10-176

10-177

10-178

10-179

10-180

10-181

10-182

Revision

number

00-3D155AX-5

00-2-1

5

Page 4

Mark Pages

10-183

10-184

10-185

10-186 3

10-187

10-188

10-189

10-189-1 3

10-189-2 3

10-189-3 3

10-189-4 3

10-190

10-191

10-192

10-193 3

10-193-1 3

10-194 3

10-195 3

10-196 3

10-196-1 3

10-196-2 3

10-196-3 3

10-197

10-198

10-199

10-200

10-201 3

10-202

10-203 3

10-203-1 3

10-204 3

10-205 3

10-205-1 3

10-205-2 3

10-206

10-207

10-208

10-209

10-210 3

10-211 3

10-211-1 3

10-212 3

10-213 3

10-214 3

10-215 3

10-215-1 3

10-216

10-217

20- 1

20- 2 4

20- 2-1 4

20- 3 4

20- 4

20- 5

20- 6

20- 7

20- 8 4

Revision

number

Mark Pages

20- 9

20- 10

20- 11

20- 12

20- 13

20- 14

20- 15

20- 16 4

20- 17 4

20- 18 4

20- 19 4

20- 20 4

20- 21 4

20- 22 4

20-101 4

20-102 4

20-103 4

20-103-1 4

20-103-2 4

20-104 4

20-104-1 4

20-105 4

20-105-1 4

20-106 4

20-107 4

20-107-1 4

20-108 4

20-109 4

20-109-1 4

20-110 4

20-110-1 4

20-111 4

20-111-1 4

20-111-2 4

20-111-3 4

20-111-4 4

20-111-5 4

20-111-6 4

20-112 4

20-112-1 4

20-112-2 4

20-113

20-113-1 4

20-114 4

20-115 4

20-116 4

20-117 4

20-117-1 4

20-118 4

20-118-1 4

20-119

20-120

20-121

20-122

20-123

20-124

20-125

Revision

number

Mark Pages

20-126

20-127

20-128

20-129

20-130

20-131

20-132

20-133

20-134

20-135 4

20-136 4

20-137

20-138

20-138-1 4

20-138-2 4

20-138-3 4

20-139 4

20-140

20-140-1 4

20-140-2 4

20-140-3 4

20-140-4 4

20-141

20-142

20-143

20-144

20-145

20-146 4

20-147

20-148

20-149

20-150

20-151

20-152

20-153

20-154

20-155

20-156

20-157

20-201 4

20-202

20-203

20-204

20-205

20-206

20-207

20-208

20-209

20-210

20-211

20-212

20-214 4

20-215

20-216

20-217

20-218

20-219

Revision

number

Mark Pages

20-219-1 4

20-219-2 4

20-219-3 4

20-219-4 4

20-219-5 4

20-219-6 4

20-220

20-221

20-222

20-223

20-224

20-225

20-226

20-227

20-228

20-229

20-229-1 4

20-229-2 4

20-229-3 4

20-229-4 4

20-229-5 4

20-229-6 4

20-229-7 4

20-229-8 4

20-229-9 4

20-230 4

20-231

20-231-1 4

20-231-2 4

20-232 4

20-233

20-234

20-235

20-235-1 4

20-235-2 4

20-235-3 4

20-235-4 4

20-235-5 4

20-235-6 4

20-235-7 4

20-235-8 4

20-235-9 4

20-235-10 4

20-235-11 4

20-235-12 4

20-236

20-238 4

20-239 4

20-240 4

20-241

20-251 4

20-252 4

20-253 4

20-254 4

20-255 4

20-256 4

20-257 4

Revision

number

Mark Pages

20-258 4

20-259 4

20-260 4

20-261 4

20-262 4

20-301 4

20-302

20-303

20-304

20-305

20-306

20-307

20-308

20-309

20-310

20-311

20-312

20-313

20-314

20-315

20-316

20-317

20-318

20-319

20-320

20-321

20-322

20-401 4

20-402

20-403

20-404

20-405

20-406

20-407

20-408

20-409

20-410

20-411

20-412

20-413

20-414

20-415

20-416

20-417

20-418

20-419

20-420

20-421

20-422

20-423

20-424

20-425

20-426

20-427

20-428

20-429

20-430

Revision

number

00-4 D155AX-5

00-2-2

5

Page 5

Mark Pages

20-431

20-432

20-433

20-434

20-435

20-436

20-437

20-438

20-439

20-440

20-441

20-442

20-443

20-444

20-445

20-446

20-447

20-448

20-501

20-502

20-503

20-504

20-505

20-506

20-507

20-508

20-509

20-510

20-511

20-512

20-513

20-514

20-515

20-516

20-517

20-518

20-519

20-520

20-601 4

20-602

20-603

20-604

20-605

20-606

20-607

20-608

20-609

20-610

20-611

20-612

20-613

20-614

20-615

20-616

20-617

20-618

20-619

Revision

number

Mark Pages

20-620

20-621

20-622

20-623

20-624

20-625

20-626

20-627

20-628

20-629

20-630

20-632

20-633

20-634

20-635

20-636

20-701 4

20-702 4

20-703 4

20-704 4

20-705 4

20-706 4

20-707 4

20-708 4

20-709 4

20-710 4

20-711 4

20-712 4

20-713 4

20-714 4

20-715 4

20-716 4

20-717 4

20-718 4

20-719 4

20-720 4

20-721 4

20-722 4

20-723 4

20-724 4

20-725 4

20-726 4

20-727 4

20-728 4

20-729 4

20-730 4

20-731 4

20-732 4

20-733 4

20-734 4

20-735 4

20-736 4

20-737 4

20-738 4

20-739 4

20-740 4

20-741 4

Revision

number

Mark Pages

20-742 4

20-743 4

20-744 4

20-745 4

20-746 4

20-801 4

20-802 4

20-803 4

20-804 4

20-805 4

20-806 4

20-807 4

20-808 4

20-809 4

20-810 4

20-811 4

20-812 4

20-813 4

20-814 4

20-815 4

20-816 4

20-817 4

20-818 4

20-819 4

20-820 4

20-821 4

20-822 4

20-823 4

20-824 4

20-825 4

20-826 4

20-827 4

20-828 4

20-829 4

20-830 4

20-831 4

20-832 4

20-833 4

20-834 4

20-835 4

20-836 4

20-837 4

20-838 4

20-839 4

20-840 4

20-841 4

20-842 4

20-843 4

20-844 4

20-845 4

20-846 4

20-847 4

20-848 4

20-849 4

20-850 4

20-851 4

20-901 4

Revision

number

Mark Pages

20-902 4

20-903 4

20-904 4

20-905 4

20-906 4

20-907 4

20-908 4

20-909 4

20-910 4

20-911 4

20-912 4

20-913 4

20-914 4

20-915 4

20-916 4

20-917 4

20-918 4

20-919 4

20-920 4

20-921 4

20-922 4

20-923 4

20-924 4

20-925 4

20-926 4

20-927 4

20-928 4

20-929 4

20-930 4

20-931 4

20-932 4

20-933 4

20-934 4

20-935 4

20-936 4

20-937 4

20-938 4

20-939 4

20-940 4

20-941 4

20-942 4

20-943 4

20-944 4

20-945 4

20-946 4

20-947 4

20-948 4

20-949 4

20-950 4

20-951 4

‡ 30- 1 5

30- 2 1

30- 3 1

30- 4 1

30- 5 1

30- 6 1

30- 7 1

Revision

number

Mark Pages

30- 8 1

30- 9 1

30- 10 1

30- 11 1

30- 12 2

30- 13 2

30- 14 2

30- 15 2

30- 16 2

30- 17 1

30- 18 1

30- 19 1

30- 20 1

30- 21 1

30- 22 1

30- 23 1

30- 24 1

30- 25 1

Revision

number

‡ 30- 26 5

‡ 30- 27 5

‡ 30- 28 5

‡ 30- 29 5

‡ 30- 30 5

‡ 30- 31 5

‡ 30- 32 5

fi 30- 32-1 5

‡ 30- 33 5

fi 30- 33-1 5

fi 30- 33-2 5

fi 30- 33-3 5

30- 34 1

30- 35 1

30- 36 1

30- 37 1

30- 38 1

30- 39 1

30- 40 1

30- 41 1

‡ 30- 42 5

30- 43 1

30- 44 1

30- 45 1

30- 46 1

‡ 30- 47 5

30- 48 1

30- 49 1

‡ 30- 50 5

30- 51 1

30- 52 1

30- 53 1

30- 54 1

30- 55 1

30- 56 1

30- 57 1

30- 58 1

30- 59 1

30- 60 1

00-5D155AX-5

00-2-3

5

Page 6

Mark Pages

30- 61 1

30- 62 1

Revision

number

‡ 30- 63 5

30- 64 1

fi 30- 64-1 5

fi 30- 64-2 5

30- 65 1

30- 66 1

30- 67 1

30- 68 1

30- 69 1

30- 70 1

30- 71 1

30- 72 1

30- 73 1

30- 74 1

‡ 30- 75 5

30- 76 1

30- 77 1

30- 78 1

‡ 30- 79 5

30- 80 1

30- 81 1

30- 82 1

30- 83 1

30- 84 1

30- 85 1

30- 86 1

30- 87 1

30- 88 1

30- 89 1

30- 90 1

30- 91 1

30- 92 1

30- 93 1

30- 94 1

30- 95 1

30- 96 1

30- 97 1

30- 98 1

30- 99 1

30-100 1

30-101 1

30-102 1

30-103 1

30-104 1

30-105 1

30-106 1

30-107 1

30-108 1

30-109 1

30-110 1

30-111 1

30-112 1

30-113 1

30-114 1

30-115 1

Mark Pages

Revision

number

30-116 1

30-117 1

30-118 1

30-119 1

30-120 1

30-121 1

‡ 30-122 5

‡ 30-123 5

30-124 1

30-125 1

30-126 1

30-127 1

30-128 1

30-129 1

30-130 1

30-131 1

30-132 1

30-133 1

30-134 1

‡ 30-135 5

30-136 1

30-137 1

30-138 1

30-139 1

30-140 1

30-141 1

‡ 30-142 5

‡ 30-143 5

‡ 30-144 5

‡ 30-145 5

‡ 30-146 5

30-146-1 2

30-146-2 2

30-146-3 2

30-146-4 2

30-146-5 2

30-146-6 2

30-146-7 2

30-146-8 2

30-146-9 2

30-146-10 2

30-146-11 2

30-146-12 2

30-146-13 2

30-146-14 2

30-146-15 2

30-146-16 2

30-146-17 2

30-147 1

30-148 1

30-149 1

30-150 1

‡ 30-151 5

‡ 30-152 5

‡ 30-153 5

30-154 1

30-155 1

Mark Pages

30-156 1

30-157 1

30-158 1

30-159 1

30-160 1

30-161 1

30-162 1

30-163 1

30-164 1

30-165 1

30-166 1

30-167 1

30-168 1

30-169 1

30-170 1

30-171 1

30-172 1

30-173 1

30-174 1

30-175 1

30-176 1

30-177 1

30-178 1

30-179 1

30-180 1

30-181 1

30-182 1

30-183 1

30-184 1

30-185 1

30-186 1

30-187 1

30-188 1

30-189 1

30-190 1

30-191 1

30-192 1

30-193 1

30-194 1

30-195 1

30-196 1

30-197 1

30-198 1

30-199 1

30-200 1

30-201 1

30-202 1

30-203 1

30-204 1

30-205 1

30-207 1

30-208 1

30-209 1

30-210 1

30-211 1

30-212 1

30-213 1

Revision

number

Mark Pages

Revision

number

30-214 1

30-215 1

30-216 1

30-217 1

30-218 1

30-219 1

30-220 1

30-221 1

30-222 1

30-223 1

30-224 1

30-225 1

30-226 1

30-227 1

30-228 1

30-229 1

30-230 1

30-231 1

30-232 1

30-233 1

30-234 1

30-235 1

30-236 1

30-237 1

30-238 1

30-239 1

30-240 1

30-241 1

30-242 1

30-243 1

30-244 1

30-245 1

30-246 1

30-247 1

30-248 1

30-249 1

30-250 1

30-251 1

30-252 1

30-253 1

30-254 1

30-255 1

30-256 1

30-257 1

30-258 1

30-259 1

30-260 1

30-261 1

30-262 1

30-263 1

30-264 1

30-265 1

30-266 1

30-267 1

30-268 1

30-269 1

‡ 30-270 5

Mark Pages

30-271 1

30-272 1

30-273 1

30-274 1

30-275 1

30-276 1

30-277 1

30-278 1

30-279 1

30-280 1

30-281 1

30-282 1

30-283 1

30-284 1

30-285 1

30-286 1

30-287 1

30-288 1

30-289 1

30-290 1

30-291 1

30-292 1

30-293 1

30-294 1

30-295 1

30-296 1

Revision

number

‡ 30-297 5

30-298 1

‡ 30-299 5

30-300 1

30-301 1

30-302 1

30-303 1

‡ 30-304 5

‡ 30-305 5

‡ 30-306 5

‡ 30-307 5

‡ 30-308 5

fi 30-309 5

40- 1 3

40- 2

40- 3

40- 4

40- 6

40- 7

40- 8

40- 10

40- 11

40- 12

40- 13

40- 14

40- 16 3

40- 17

40- 18

40- 19

40- 20

40- 21

00-2-4

00-6 D155AX-5

5

Page 7

Mark Pages

40-22

40-24

40-25

40-26

40-28 3

40-29 3

40-29-1 3

40-29-2 3

40-30

40-31

40-32

40-33

40-34

40-35

40-36

40-37

40-38 3

40-39

40-40 3

40-42 3

40-43

40-44 3

40-46 3

40-47

40-48 3

40-49

40-50

40-51

40-52

40-53

40-54

40-56

40-57

40-58

40-59

40-60

40-61

40-62

40-63

40-64

40-66

40-67

40-68

40-69

40-70

40-71

40-72

40-73 3

40-74

40-75 3

40-76

40-78

40-79

90- 1 3

90- 3

90- 5

90- 7 3

Revision

number

Mark Pages

90- 9 3

90-11 3

90-13 3

90-15 3

90-17 3

90-19 3

Revision

number

Mark Pages

Revision

number

Mark Pages

Revision

number

Mark Pages

Revision

number

00-2-5

00-7D155AX-5

5

Page 8

00-8 D155AX-5

00-2-6

4

(Blank page)

Page 9

30

DISASSEMBLY AND ASSEMBLY

Method of using manual ............................ 30- 3

Precautions when carring out operation ... 30- 5

Special tool list............................................. 30- 7

Special tool sketch ....................................... 30-17

STARTING MOTOR

Removal and Installation ...................... 30-26

ALTERNATOR

Removal and Installation ...................... 30-27

ENGINE OIL COOLER CORE

Removal and Installation ...................... 30-28

FUEL INJECTION PUMP

Removal .................................................. 30-29

Installation .............................................. 30-30

WATER PUMP

Removal and Installation ...................... 30-31

TURBOCHARGER

Removal and Installation ...................... 30-32

NOZZLE HOLDER

Removal and Installation ...................... 30-33

FUEL INJECTOR

Removal and Installation ................... 30-33-1

ENGINE FRONT SEAL

Removal .................................................. 30-34

Installation .............................................. 30-35

ENGINE REAR SEAL

Removal .................................................. 30-37

Installation .............................................. 30-38

CYLINDER HEAD

Removal .................................................. 30-42

Installation .............................................. 30-47

THERMOSTAT

Removal and Installation ...................... 30-49

AIR CONDITIONER COMPRESSOR

Removal .................................................. 30-50

Installation .............................................. 30-51

AIR CONDITIONER CONDENSER

Removal and Installation ...................... 30-52

FUEL TANK

Removal and Installation ...................... 30-53

RADIATOR

Removal .................................................. 30-54

Installation .............................................. 30-56

RADIATOR, OIL COOLER, GUARD

Removal .................................................. 30-57

Installation .............................................. 30-59

FAN DRIVE

Removal .................................................. 30-60

Installation .............................................. 30-61

HYDRAULIC COOLER

Removal and Installation ...................... 30-62

ENGINE

Removal .................................................. 30-63

Installation .............................................. 30-65

DAMPER

Removal .................................................. 30-66

Installation .............................................. 30-67

Disassembly ........................................... 30-68

Assembly ................................................ 30-71

POWER TRAIN UNIT

Removal .................................................. 30-75

Installation .............................................. 30-79

Separation .............................................. 30-80

Connection ............................................. 30-84

PTO

Disassembly ........................................... 30-85

Assembly ................................................ 30-89

TORQUE CONVERTER

Disassembly ........................................... 30-94

Assembly ................................................ 30-97

TORQFLOW TRANSMISSION

Disassembly ......................................... 30-100

Assembly .............................................. 30-109

HSS CASE

Disassembly ......................................... 30-120

Assembly .............................................. 30-129

HYDRAULIC PUMP

Removal ................................................ 30-142

Installation ............................................ 30-146

HSS PUMP

Disassembly ...................................... 30-146-1

Assembly ........................................... 30-146-8

HSS MOTOR

Removal and Installation .................... 30-147

POWER TRAIN MAIN RELIEF VALVE

Removal and Installation .................... 30-148

Disassembly and Assembly ............... 30-149

HSS, PPC CHARGE VALVE

Removal and Installation .................... 30-150

HSS, PCC CHARGEING VALVE

Disassembly ......................................... 30-151

Assembly .............................................. 30-152

TRANSMISSION CONTROL VALVE

Removal ................................................ 30-153

Installation ............................................ 30-154

Disassembly and Assembly ............... 30-155

30-1D155AX-5

5

Page 10

BRAKE VALVE

Removal and Installation .................... 30-157

Disassembly and Assembly ............... 30-158

FINAL DRIVE

Removal ................................................ 30-160

Installation ............................................ 30-162

Disassembly ......................................... 30-163

Assembly .............................................. 30-168

TRACK FRAME

Removal ................................................ 30-174

Installation ............................................ 30-176

IDLER ASSEMBLY

Removal ................................................ 30-177

Installation ............................................ 30-178

Disassembly ......................................... 30-179

Assembly .............................................. 30-181

RECOIL SPRING

Removal and Installation .................... 30-184

Disassembly ......................................... 30-185

Assembly .............................................. 30-190

TRACK ROLLER

Removal ................................................ 30-194

Installation ............................................ 30-195

Disassembly ......................................... 30-196

Assembly .............................................. 30-199

BOGIE

Removal ................................................ 30-202

Installation ............................................ 30-204

Disassembly ......................................... 30-205

Assembly .............................................. 30-209

CARRIER ROLLER

Removal and Installation ................... 30-213

Disassembly ......................................... 30-214

Assembly .............................................. 30-216

TRACK SHOE

Checking before removal ................... 30-219

Removal (normal) ................................ 30-219

Removal (when there is abnorma-

lity inside track frame) ................. 30-220

Installation ............................................ 30-221

Overall disassembly ............................ 30-222

Overall assembly ................................. 30-227

Press-fitting jig dimention table for

link press .............................................. 30-241

ONE LINK

Disassembly ......................................... 30-242

Assembly .............................................. 30-244

MASTER LINK

Disassembly ......................................... 30-246

Assembly .............................................. 30-248

PIVOT SHAFT

Removal and Installation .................... 30-251

EQUALIZER BAR

Removal ................................................ 30-252

Installation ............................................ 30-253

EQUALIZER BAR SIDE BUSHING

Removal and Installation .................... 30-254

SEGMENT TEETH

Removal and Installation .................... 30-255

HYDRAULIC TANK

Removal and Installation .................... 30-256

MAIN CONTROL VALVE

Removal ................................................ 30-257

Installation ............................................ 30-258

Disassembly ......................................... 30-259

Assembly .............................................. 30-262

HSS OIL COOLER BYPASS VALVE

Removal and Installation .................... 30-266

Disassembly, assembly of HMT

oil cooler bypass valve ....................... 30-267

BLADE PPC VALVE

Removal ................................................ 30-268

Installation ............................................ 30-269

RIPPER PPC VALVE

Removal ................................................ 30-270

Installation ............................................ 30-271

BLADE PPC VALVE

Disassembly ......................................... 30-272

Assembly .............................................. 30-273

BLADE LIFT CYLINDER

Removal and Installation .................... 30-275

BLADE TILT CYLINDER

Removal and Installation .................... 30-276

RIPPER LIFT CYLINDER

Removal and Installation .................... 30-277

RIPPER TILT CYLINDER

Removal and Installation .................... 30-278

HYDRAULIC CYLINDER

Disassembly ......................................... 30-279

Assembly .............................................. 30-282

BLADE

Removal ................................................ 30-286

Installation ............................................ 30-287

Disassembly ......................................... 30-288

Assembly .............................................. 30-290

MULTI-SHANK RIPPER

Disassembly ......................................... 30-292

Assembly .............................................. 30-294

ROPS GUARD

Removal and Installation .................... 30-296

OPERATOR CAB

Removal and Installation .................... 30-297

HOOD

Removal and Installation .................... 30-298

FLOOR FRAME

Removal ................................................ 30-299

Installation ............................................ 30-304

DASHBOARD

Removal ................................................ 30-305

Installation ............................................ 30-306

MONITOR

Removal and Installation .................... 30-307

HSS CONTROLLER

Removal and Installation .................... 30-308

30-2

1

D155AX-5

Page 11

DISASSEMBLY AND ASSEMBLY

P Sleeve

SPECIAL TOOL SKETCH

02

01

SYM.

30°

3

+0.4

+0.2

ø190.7

ø180±0.2

ø175

C0.5

STKM16A 1

PLATE

PART NAME MATERIAL

S400P

80

30°

R1

60

1 2.7

QTY/SET

17.7

MASS

(kg)

465.5±0.2

ø190 x t10TUBE

t22

REMARKES

)2

)1

C2

C2

+0.4

ø178

+0.2

ø210

C1

8

HEAT TREATMENT

PART NAME QTY

20

DDD00866

MATERIAL

- - -

SLEEVE 1

SEE DWG

7 9 1 T - 6 5 0 - 2 1 1 0

P Plate

C1

22

C1

2-20 D R I L L S

200

102

HEAT TREATMENT

- - -

PART NAME QTY

PLATE 1

7 9 1 T - 6 5 0 - 2 1 2 0

DDD00867

MATERIAL

SS400P

D155AX-5

30-25

1

Page 12

DISASSEMBLY AND ASSEMBLY

STARTING MOTOR

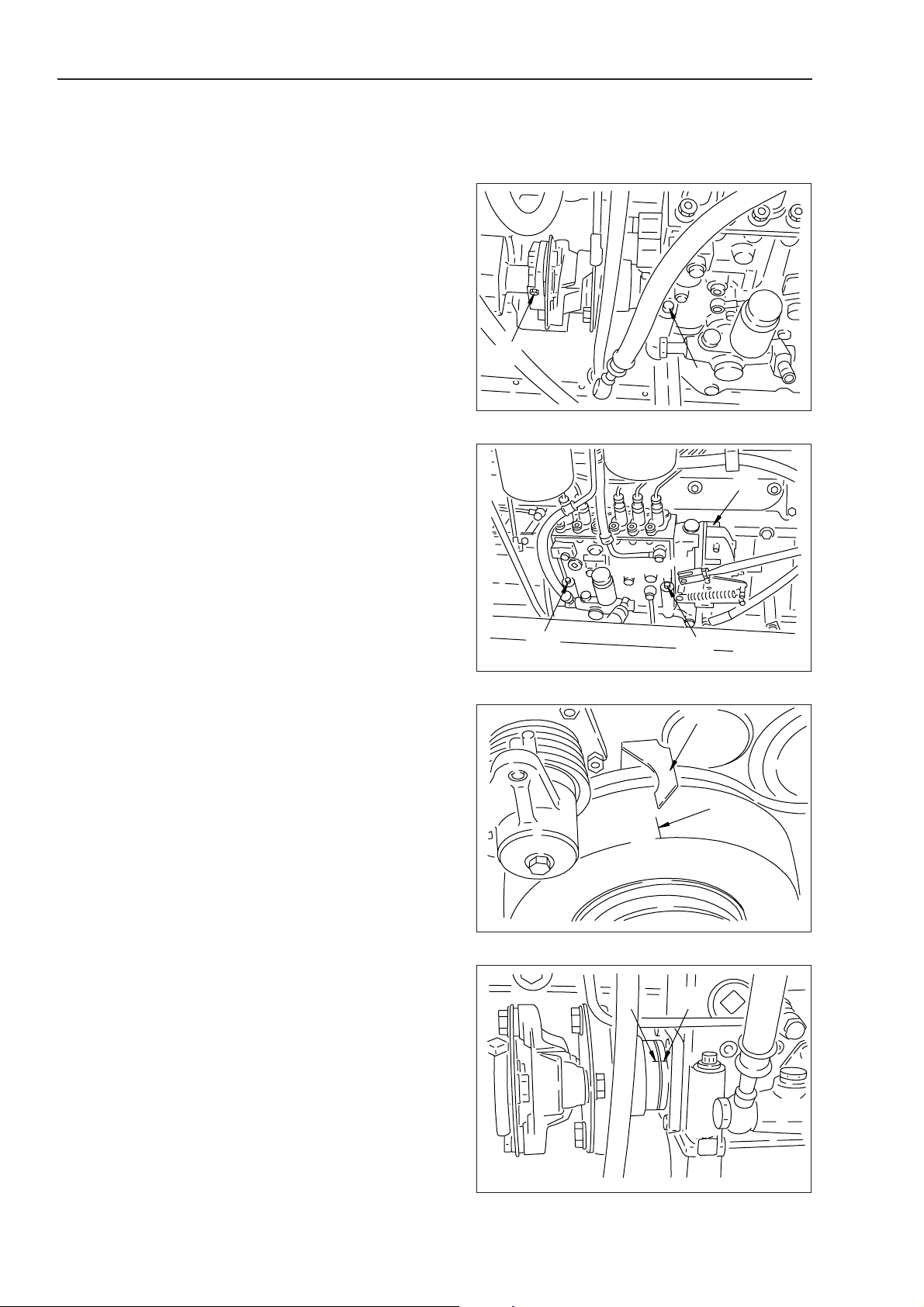

REMOVAL OF STARTING

MOTOR ASSEMBLY

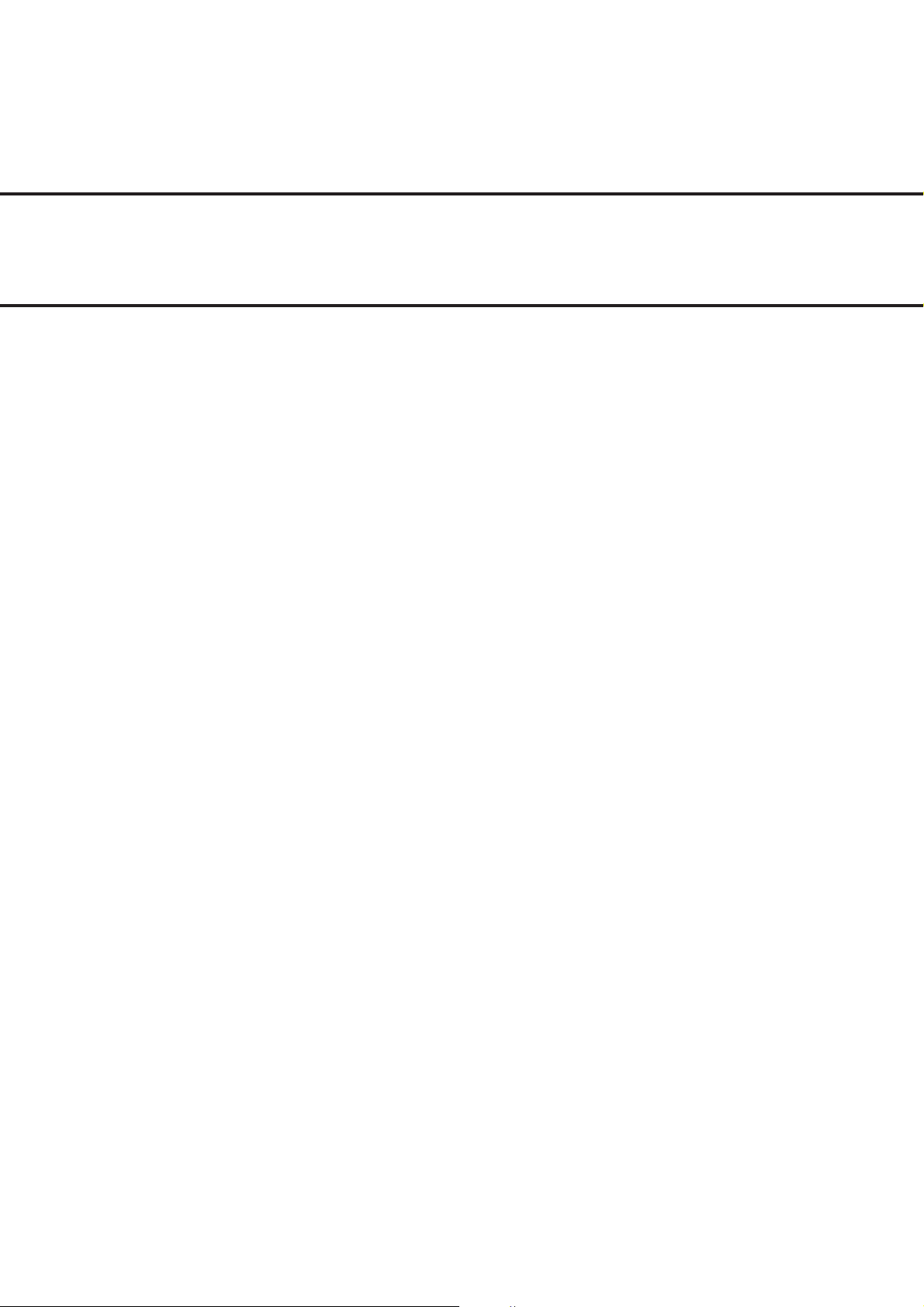

Disconnect the cable from the negative (–) ter-

minal of the battery.

1. Open engine right side cover (top) and remove

cover (bottom).

2. Disconnect 3 starting motor wires (1) and 1 wiring connector (2).

3. Remove 3 bolts, then remove starting motor

assembly (3).

INSTALLATION OF STARTING

MOTOR ASSEMBLY

• Carry out installation in the reverse order to

removal.

Serial 70001 – 75000

2

1

DED00001

Serial No. 75001 and up

1

3

DED00002

30-26

5

D155AX-5

Page 13

DISASSEMBLY AND ASSEMBLY

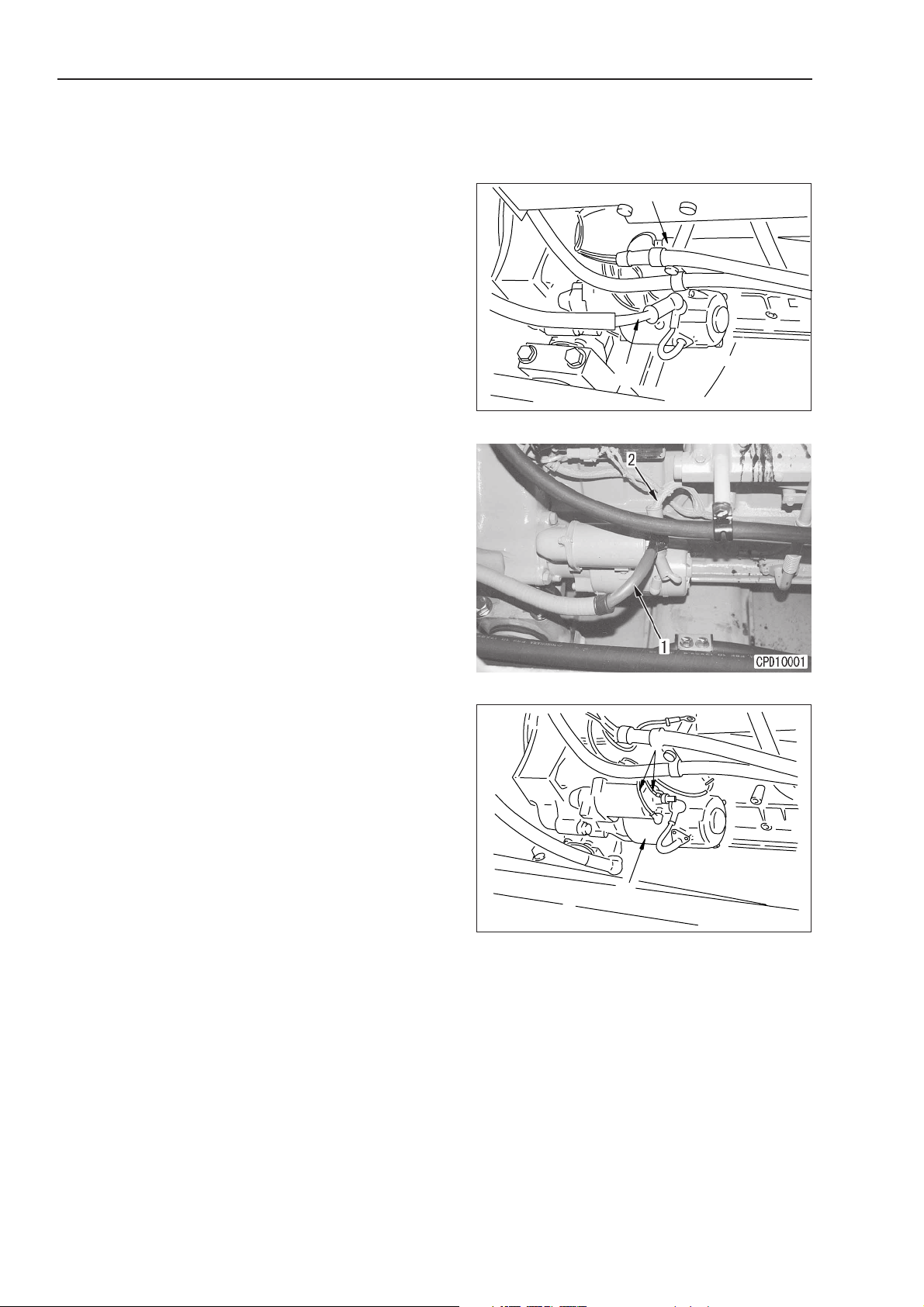

REMOVAL OF ALTERNATOR

ASSEMBLY

Disconnect the cable from the negative (–) ter-

minal of the battery.

1. Open engine right side cover (top) and remove

cover (bottom).

2. Disconnect alternator wiring (1) and (2).

3. Loosen locknut (3), then turn adjustment nut (4)

to loosen tension of V-belt (5).

4. Remove bolts (6) and (7), then remove alternator assembly (8) together with belt cover. 1

e Remove the V-belt from the pulley when re-

moving the alternator assembly.

ALTERNATOR

Serial No. 70001-75000

1

2

DED00003

Serial No. 75001 and up

INSTALLATION OF

ALTERNATOR ASSEMBLY

• Carry out installation in the reverse order to

removal.

1

e After installing the alternator, adjust the belt

tension. For details, see TESTING AND ADJUSTING, TESTING AND ADJUSTING ALTERNATOR BELT TENSION.

8

6

5

3

4

7

DED00004

D155AX-5

30-27

5

5

Page 14

DISASSEMBLY AND ASSEMBLY

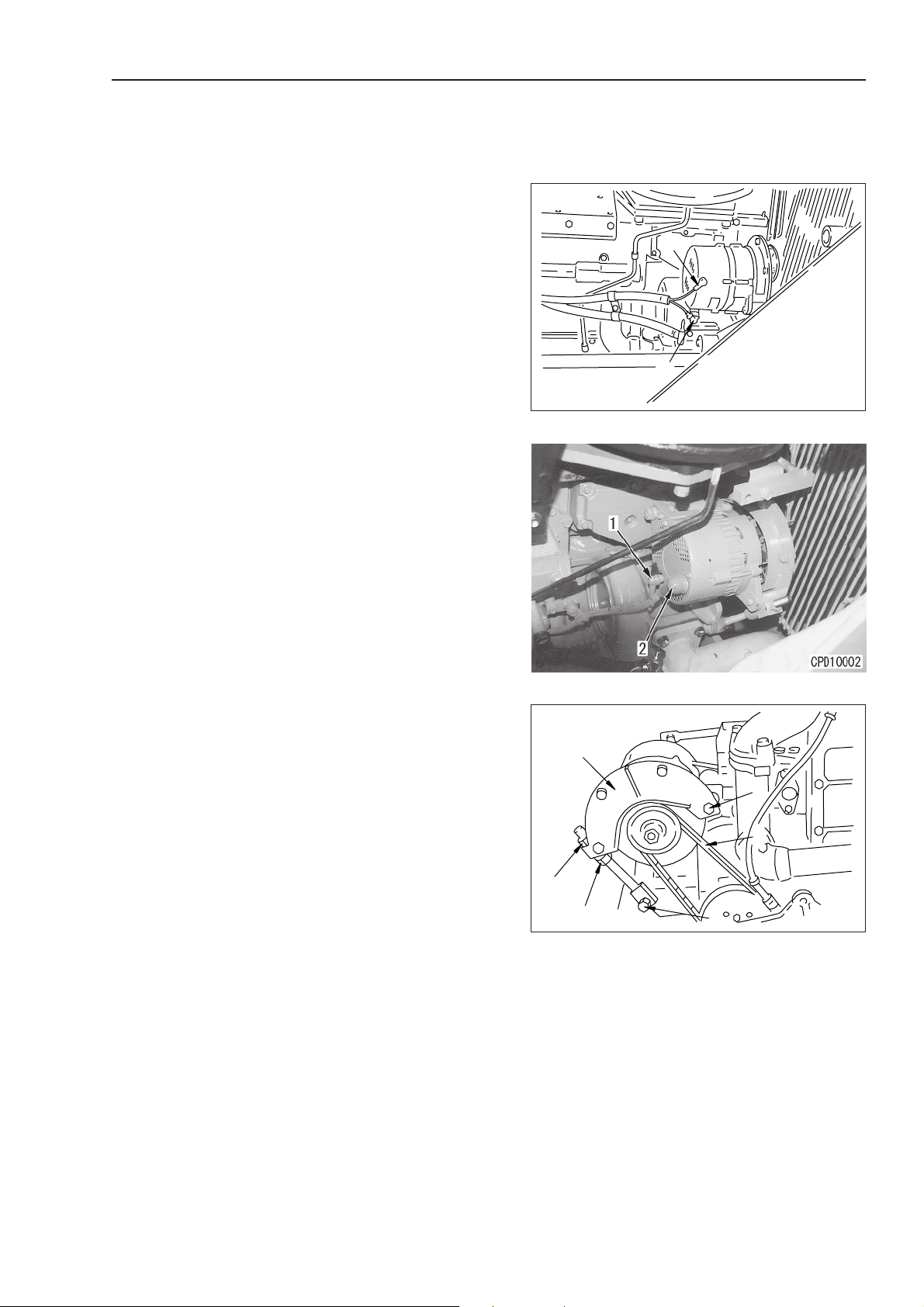

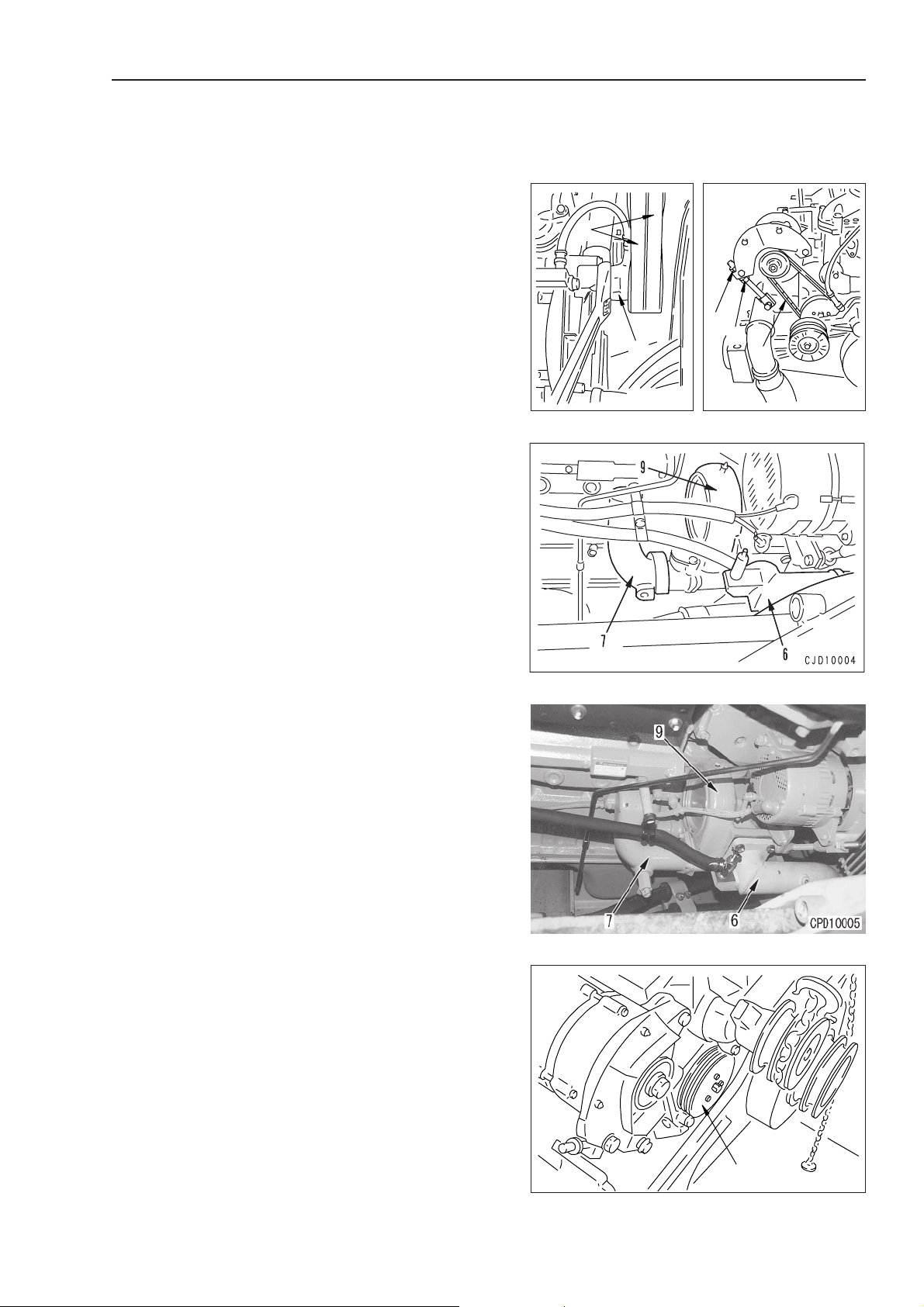

REMOVAL OF ENGINE OIL

COOLER CORE ASSEMBLY

e Drain coolant.

ENGINE OIL COOLER

Serial No. 70001 – 75000

6

1. Remove wiring clamp (1).

2. Remove muffler water drain tube (2).

3. Remove adiabatic plate (3).

4. Disconnect turbocharger lubrication tube (4) at

turbocharger end, then move it towards rear.

5. Disconnect connector (5).

6. Remove oil cooler assembly (6).

7. Remove core assembly (8) from cover (7).

1

4

2

Serial No. 75001 and up

3

1

5

DED00005

INSTALLATION OF ENGINE OIL

COOLER CORE ASSEMBLY

• Carry out installation in the reverse order to

removal.

• Refilling with water

Add water through water filler to the specified

level.

e Run the engine to circulate the water through

the system. Then check the water level again.

78

DDD00006

30-28

5

D155AX-5

Page 15

DISASSEMBLY AND ASSEMBLY

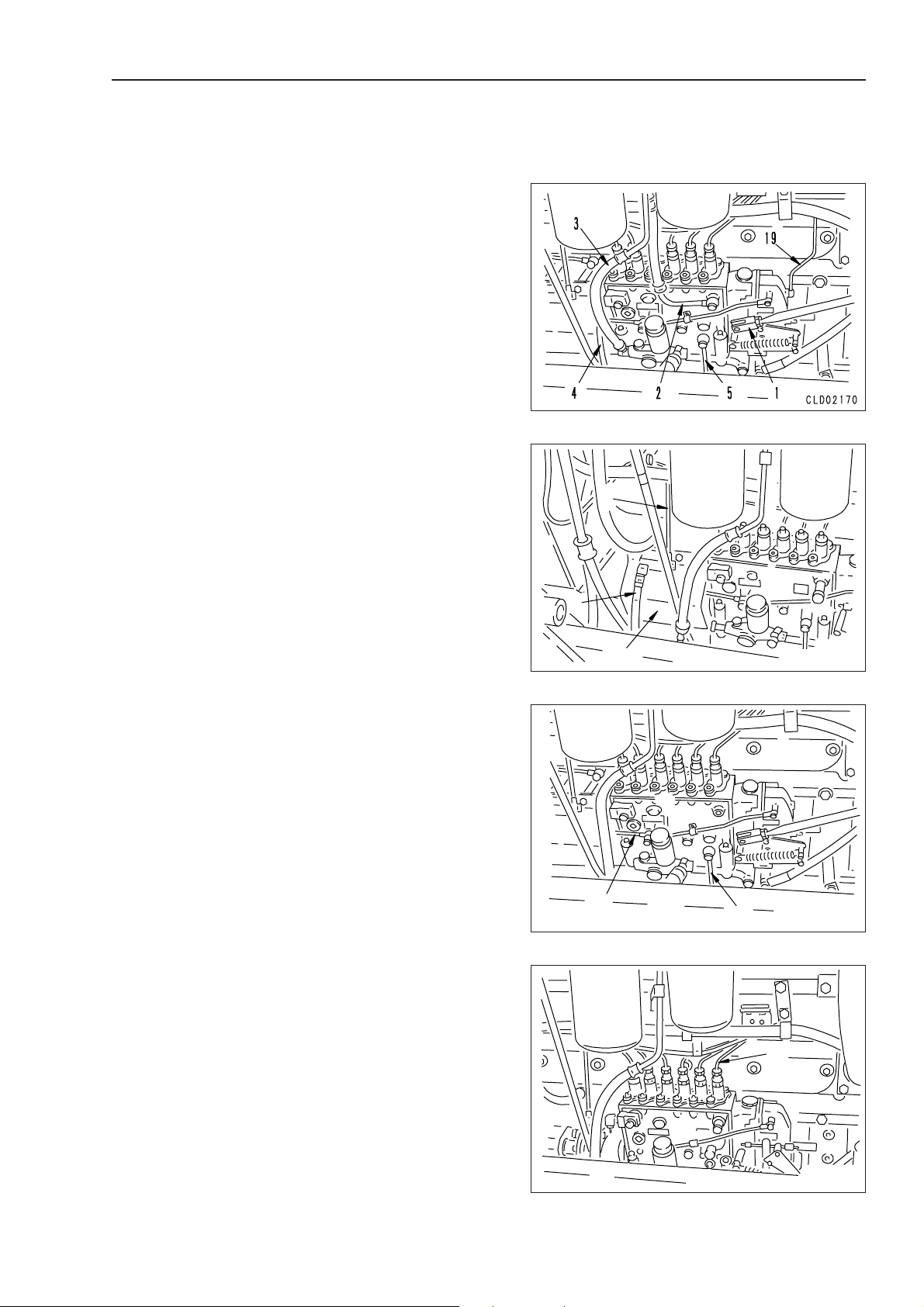

DED00009

9

10

REMOVAL OF FUEL INJECTION

PUMP ASSEMBLY

Serial No. 70001 – 75000

1. Close valve of fuel supply piping.

2. Rotate crankshaft in normal direction and align

match mark of fuel injection pump.

fl This makes it easier to check the compres-

sion top dead center position of the No. 1

cylinder when installing the fuel injection

pump.

3. Open engine left side cover (top) and remove

cover (bottom).

4. Disconnect fuel control rod (1), and fuel hoses

(2), (3), (4), and (5). 1

FUEL INJECTION PUMP

7

5. Remove boost compensator tube (19).

6. Disconnect fuel hose (6) and tube (7).

7. Remove coupling cover (8).

8. Remove lubrication tubes (9) and (10).

9. Disconnect 6 delivery tubes (11). 2

6

8

DED00008

D155AX-5

11

DED00010

30-29

5

5

Page 16

DISASSEMBLY AND ASSEMBLY

10. Loosen tightening bolt (12) at drive shaft end,

and remove 4 pump mounting bolts (13).

11. Remove fuel injection pump assembly (14) to-

gether with coupling. 3

FUEL INJECTION PUMP

12

13

DED00011

14

INSTALLATION OF FUEL

INJECTION PUMP ASSEMBLY

Serial No. 70001 – 75000

• Carry out installation in the reverse order to

removal.

1

e Adjust the linkage. For details, see TEST-

ING AND ADJUSTING, ADJUSTING FUEL

CONTROL LINKAGE.

2

3 Sleeve nut: 123.5 ± 1.0 Nm {2.4 ± 0.1 kgm}

3

e Install the fuel injection pump as follows.

1) After installing pump assembly, align

damper (I,J) marks (15) and pointer (16)

correctly.

2) Loosen bolt of coupling (18) to align

match mark (17) of injection pump.

13

18

17

13

DED00012

16

15

DED00013

30-30

5

DED00014

D155AX-5

Page 17

DISASSEMBLY AND ASSEMBLY

3

4

5

DED00016

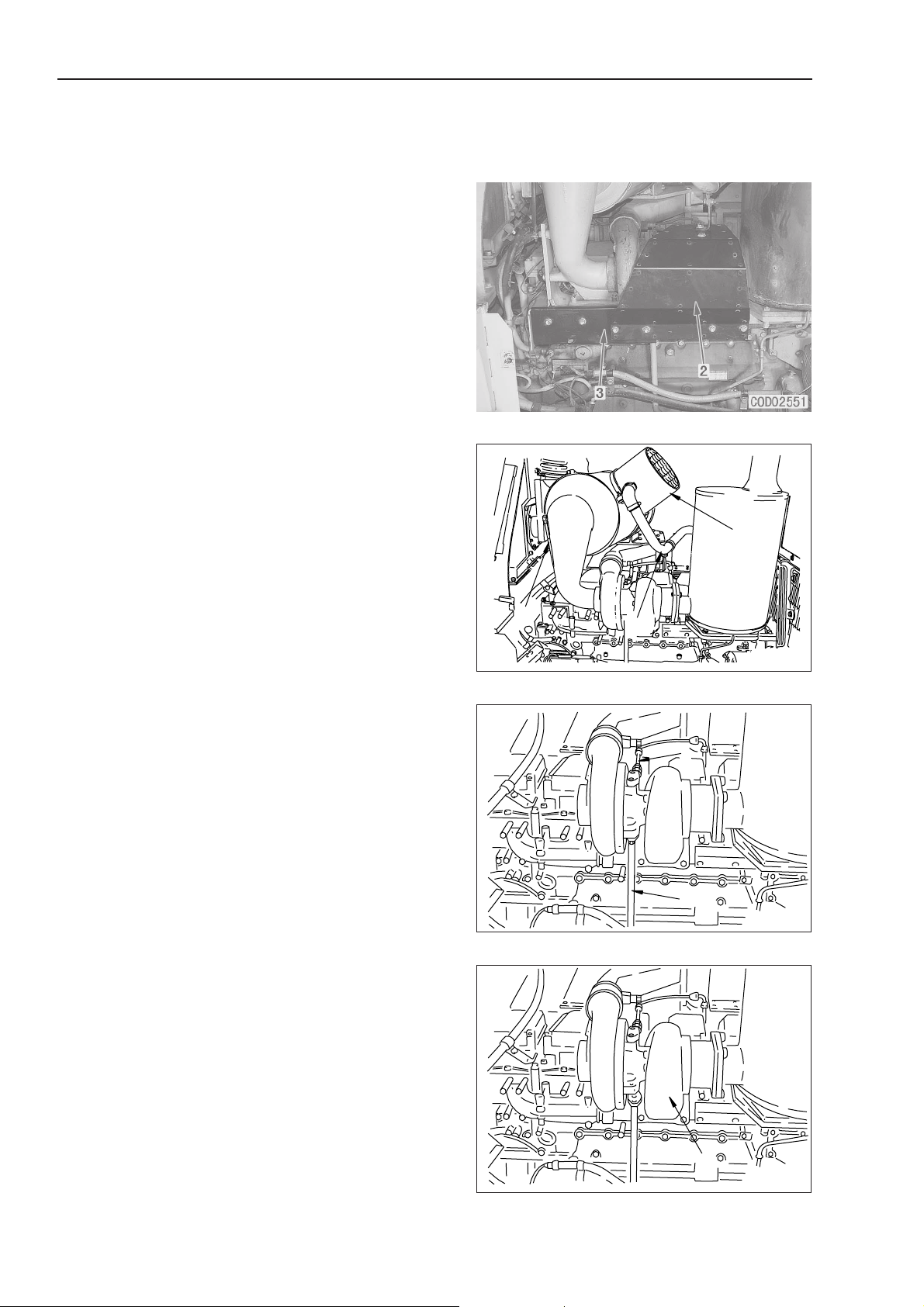

REMOVAL OF WATER PUMP

ASSEMBLY

1. Drain coolant.

2. Using an adjustable wrench, push tension pul-

ley (2) of fan belt (1), and remove fan belt.

3. Loosen locknut (3), then loosen adjustment nut

(4), and remove V-belt (5). 1

WATER PUMP

1

4. Remove connectors (6) and (7).

5. Remove pulley (8).

6. Remove water pump assembly (9).

INSTALLATION OF WATER

PUMP ASSEMBLY

• Carry out installation in the reverse order to

removal.

2

DED00015

Serial No. 70001 – 75000

Serial No. 75001 and up

1

e After installing the V-belt, adjust the belt ten-

sion. For details, see TESTING AND ADJUSTING, TESTING AND ADJUSTING ALTERNATOR BELT TENSION.

• Refilling with water

Add water through water filler to the specified

level.

e Run the engine to circulate the water through

the system. Then check the water level again.

8

D155AX-5

DED00018

30-31

1

5

Page 18

DISASSEMBLY AND ASSEMBLY

REMOVAL OF

TURBOCHARGER ASSEMBLY

Serial No. 70001 - 75000

1. Remove hood assembly.

For details, see REMOVAL OF HOOD ASSEMBLY.

2. Remove adiabatic covers (2) and (3).

3. Disconnect tube (4) and hose (5), then lift off air

cleaner assembly (6).

4 Air cleaner assembly: 35 kg

4. Disconnect lubrication hose (7) and drain tube

(8). 1

5. Remove turbocharger assembly (9). 2

TURBOCHARGER

INSTALLATION OF

TURBOCHARGER ASSEMBLY

Serial No. 70001 – 75000

• Carry out installation in the reverse order to

removal.

1

3 Hose mounting bolt:

66.2 ± 7.4 Nm {6.75 ± 0.75 kgm}

2

3 Turbocharger mounting bolt:

49.0 ± 9.8 Nm {5 ± 1 kgm}

6

5

4

DBD00026

7

8

DED00021

30-32

5

9

DED00020

D155AX-5

Page 19

DISASSEMBLY AND ASSEMBLY

REMOVAL OF

TURBOCHARGER ASSEMBLY

Serial No. 75001 and up

1. Remove hood assembly.

For details, see REMOVAL OF HOOD ASSEMBLY.

2. Remove adiabatic covers (1) and (2).

3. Disconnect tube (3) and hose (4), then lift off air

cleaner assembly (5).

4 Air cleaner assembly: 35 kg

4. Disconnect lubrication hose (6) and drain tube

(7). 1

5. Remove turbocharger assembly (8). 2

TURBOCHARGER

INSTALLATION OF

TURBOCHARGER ASSEMBLY

Serial No. 75001 and up

• Carry out installation in the reverse order to

removal.

1

3 Hose mounting bolt:

66.2 ± 7.4 Nm {6.75 ± 0.75 kgm}

2

3 Turbocharger mounting bolt:

49.0 ± 9.8 Nm {5 ± 1 kgm}

D155AX-5

30-32-1

5

Page 20

30-32-2 (Blank Page)

D155AX-5

Page 21

DISASSEMBLY AND ASSEMBLY

1

2

DBD00413

3

4

5

DBD00414

3

4

5

6

DBD00415

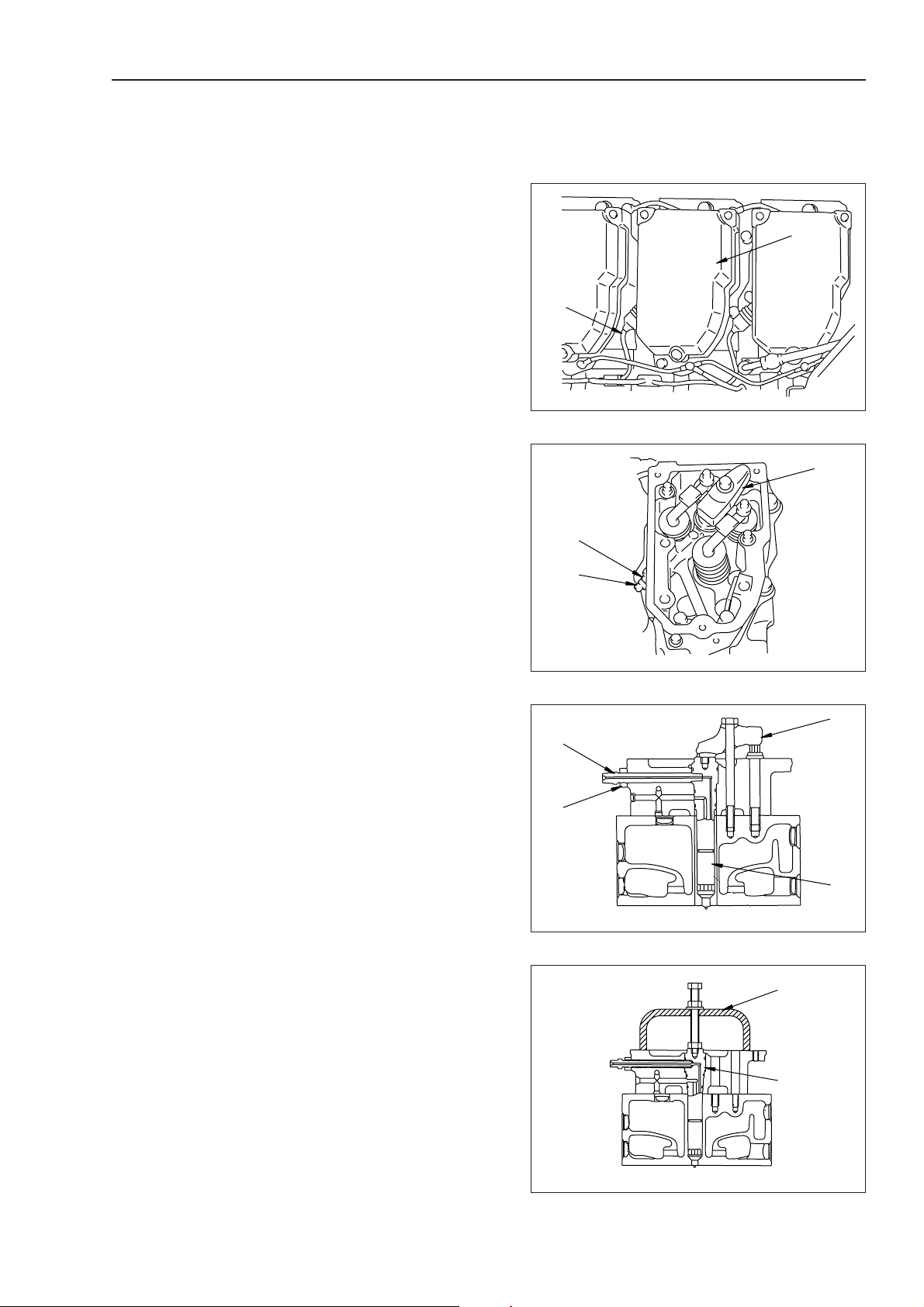

REMOVAL OF NOZZLE

HOLDER ASSEMBLY

Serial No. 70001 – 75000

1. Remove hood assembly.

For details, see REMOVAL OF HOOD ASSEMBLY.

2. Remove cylinder head cover (1). 1

e For No. 4 and 5 cylinders, remove the air

cleaner assembly and air supply connector.

3. Disconnect delivery tube (2). 2

4. Loosen locknut (3), and remove connector (4).

3

5. Remove holder (5). 4

6. Using tool A, remove nozzle holder assembly

(6). 5

NOZZLE HOLDER

INSTALLATION OF NOZZLE

HOLDER ASSEMBLY

Serial No. 70001 – 75000

• Carry out installation in the reverse order to

removal.

1

3 Cylinder head cover mounting bolt:

24.5 ± 4.9 Nm {2.5 ± 0.5 kgm}

2

3 Delivery tube sleeve nut:

23.5 ± 0.98 Nm {2.4 ± 0.1 kgm}

3

3 Connector:

31.9 ± 2.5 Nm {3.25 ± 0.25 kgm}

3 Locknut: 39.2 ± 4.9 Nm {4.0 ± 0.5 kgm}

4

3 Holder mounting bolt:

66.2 ± 7.4 Nm {6.75 ± 0.75 kgm}

5

e When assembling the nozzle holder, clean

the nozzle holder mount and check that there

is no dirt or dust inside the sleeve before

assembling.

Tighten the mounting bolts uniformly in turn

to prevent excessive tightening on one side.

A

6

DBD00416

D155AX-5

30-33

5

5

Page 22

DISASSEMBLY AND ASSEMBLY

REMOVAL OF FUEL INJECTOR

ASSEMBLY

Serial No. 75001 and up

1. Remove hood assembly. For details, see RE-

MOVAL OF HOOD ASSEMBLY.

2. Remove common rail high-pressure pipe (1).

1

3. Disconnect wiring connector (2).

fl Insert a flat-head screwdriver in the slit of

the connector to press the stopper and disconnect the connector.

FUEL INJECTOR

4. Remove cylinder head cover (3). 2

fl For Nos. 4 and 5, remove the air cleaner

assembly and air intake connector.

5. Remove mounting bolts and rocker arm (4).

fl Loosen locknut (5) and then loosen adjust-

ment screw (6) by 2 - 3 turns so that an

excessive force will not be applied to the

push rod when the rocker arm is installed.

3

6. Remove 2 nuts (7) of solenoid valve above fuel

injector. 4

7. Pull out spring clamp (8) and disconnect clamp

(9).

8. Remove mounting bolts (12) of holder (11) of

connector (having an O-ring) (10) and to remove

holder, then insert connector (10) to remove it.

4

30-33-1

5

D155AX-5

Page 23

DISASSEMBLY AND ASSEMBLY

9. Remove holder (13) of fuel injector, then remove

injector assembly (14). 5

fl Do not hold the solenoid of the injector with

priers, etc. to remove the injector.

INSTALLATION OF FUEL

INJECTOR ASSEMBLY

Serial No. 75001 and up

• Carry out installation in the reverse order to

removal.

FUEL INJECTOR

1

3 High-pressure pipe sleeve nut:

39.2 ± 7.4 Nm {4.0 ± 5.0 kgm}

fl If there is any slit "b" or pit "c" on the taper

sealing part (Part "a": The part of 2 mm from

the end) of the high-pressure pipe joint or if

part "d" (Tape seal end: Part of 2 mm from

the end) has level difference that is felt with

a nail (or if part "d" is fatigued) and the fuel

may leak, replace the high-pressure pipe.

2

3 Cylinder head mounting bolt:

29.4 ± 34.3 Nm {3.0 ± 3.5 kgm}

3

fl When tightening the mounting bolts, check

that the ball of the adjustment screw is fitted to the socket of the push rod.

3 Rock arm mounting bolt:

93 ± 103 Nm {9.5 ± 10.5 kgm}

fl Adjust the valve clearance. For details, see

ADJUSTING VALVE CLEARANCE.

D155AX-5

30-33-2

5

Page 24

DISASSEMBLY AND ASSEMBLY

4

fl Method of installing wiring harness.

1) Fit O-ring (15).

2) Install cap (16).

3) Tighten nut (14).

4) Secure clamp with bolt (18).

3 Terminal nut:

1.8 ± 2.2 Nm {0.18 ± 0.22 kgm}

fl Eliminate the slack of the wiring harness and

press it against the injector body.

5

fl Method of installing fuel injector.

1) Install fuel injector assembly (14) and holder

(13) to the cylinder head temporarily.

2) Tighten mounting bolt (19) of holder (13)

temporarily.

3) Tighten sleeve (20) temporarily.

4) Tighten holder mounting bolt (19) se

curely.

5) Tighten sleeve (20) securely.

fl Apply engine oil to the spherical part of the

spherical washer.

ENGINE REAR SEAL

3 Holder mounting bolt:

58.8 ± 73.5 Nm {6.0 ± 7.5 kgm}

30-33-3

5

D155AX-5

Page 25

DISASSEMBLY AND ASSEMBLY

DAD00046

Make mark with punch

fl After installing the flywheel, use tool 1 to

measure the face runout and radial runout.

fl Face runout: Max. 0.30 mm

fl Radial runout: Max. 0.30 mm

ENGINE REAR SEAL

D155AX-5

30-41

1

Page 26

DISASSEMBLY AND ASSEMBLY

REMOVAL OF CYLINDER HEAD

ASSEMBLY

Serial No. 70001 – 75000

Disconnect the cable from the negative (-) ter-

minal of the battery.

1. Drain coolant.

2. Close fuel supply valve.

3. Remove hood assembly.

For details, see REMOVAL OF HOOD ASSEMBLY.

4. Remove engine side covers (left, right).

5. Remove adiabatic covers (2) and (3).

6. Disconnect tube (4) and hose (5), and lift off air

cleaner assembly (6).

4 Air cleaner assembly : 35 kg

CYLINDER HEAD

6

7. Remove tube (7), then lift off muffler assembly

(8).

4 Muffler assembly : 45 kg

8. Remove bracket (9).

9. Disconnect turbocharger lubrication hose (10)

and return tube (11). 1

5

10

4

DBD00026

8

7

DBD00027

9

30-42

5

11

DBD00028

D155AX-5

Page 27

DISASSEMBLY AND ASSEMBLY

DBD00041

i !8 !9o r!4 !5t !0 @2 @3!1

u!7 @0w q!3 !6y e@1 @4!2

DAD00042

@2 !8 !4 !0 y w e

u

!1

!5 !9 @3

@1 !7 !3 o t q r i !2 !6 @0 @4

INSTALLATION OF CYLINDER

HEAD ASSEMBLY

Serial No. 70001 – 75000

• Carry out installation in the reverse order to

removal.

1

3 Mounting bolt : 66.2 ± 7.4 Nm

{6.75 ± 0.75 kgm}

2

fl Tighten the bolts in the order 1 - 3 as

shown in the diagram on the right, then

tighten in the order 4 - N.

3 Exhaust manifold mounting bolt :

1st step : 29.4 ± 4.9 Nm

{3.0 ± 0.5 kgm}

2nd step : 66.2 ± 7.4 Nm

{6.75 ± 0.75 kgm}

3

3 Joint bolt : 29.4 ± 4.9 Nm

{1.15 ± 0.15 kgm)

4

fl Install the hoses without twisting or interfer-

ence.

3 Joint bolt : 29.4 ± 4.9 Nm

{3.0 ± 0.5 kgm}

5

fl Tighten the bolts in the order of 1 - N as

shown in the diagram on the right.

3 Intake manifold mounting bolt :

1st step : 29.4 ± 4.9 Nm

{3.0 ± 0.5 kgm}

2nd step : 66.2 ± 7.4 Nm

{6.75 ± 0.75 kgm}

6

3 Intake connector mounting bolt :

49.0 ± 9.8 Nm {5 ± 1 kgm}

7

3 Joint bolt : 8.8 ± 1.0 Nm

{0.9 ± 0.1 kgm}

8

3 Delivery tube sleeve nut :

23.5 ± 1.0 Nm {2.4 ± 0.1 kgm}

9

3 Head cover mounting bolt :

24.5 ± 9.8 Nm {2.5 ± 1.0 kgm}

0

fl Clean the mounting bolt oil holes before in-

stalling.

fl Check that the ball of the adjustment screw

is fitted properly into the socket of the push

CYLINDER HEAD

rod.

fl Adjust the valve clearance.

For details, see TESTING AND ADJUSTING, ADJUSTING VALVE CLEARANCE.

3 Rocker arm assembly :

98 ± 4.9 Nm {10 ± 0.5 kgm}

3 Locknut :

48.0 ± 2.9 Nm {4.9 ± 0.3 kgm}

A

fl Adjust the crosshead as follows.

1) Loosen locknut, then turn adjustment

screw back.

2) Press top of crosshead lightly and

tighten adjustment screw.

3) When adjustment screw contacts

valve stem, screw in a further 20°.

4) Tighten locknut to hold in position.

3 Locknut : 58.8 ± 5.9 Nm

{6.0 ± 0.6 kgm}

B

3 Locknut : 39.2 ± 4.9 Nm

{4.0 ± 0.5 kgm}

D155AX-5

30-47

5

Page 28

DISASSEMBLY AND ASSEMBLY

C

3 Connector : 31.9 ± 2.5 Nm

{3.25 ± 0.25 kgm}

D

3 Holder mounting bolt : 66.2 ± 7.4 Nm

{6.75 ± 0.75 kgm}

CYLINDER HEAD

2

3

6

E

fl Check that there is no dirt or dust on the

cylinder head mounting surface or inside the

cylinder.

fl When installing the gasket, check that the

grommet does not come out.

fl Coat the bolt thread and seat face completely

with molybdenum disulphide (LM-P).

fl Tighten the cylinder head mounting bolts in

the order given in the diagram.

2 Cylinder head mounting bolt :

Anti-friction compound (LM-P)

3 Cylinder head mounting bolt :

1st step : Tighten to 147 ± 9.8 Nm

{15 ± 1 kgm}

2nd step : Tighten to 215.6 ± 4.9 Nm

{22 ± 0.5 kgm}

3rd step : 1) When using tool B

• Using an angle tightening

wrench, tighten bolt 90° .

2) When not using tool B

• Make marks on bolt and flywheel with a felt pen, then

tighten bolt 90°.

+30°

0

5

1

Make marks on

cylinder head and bolt

4

7

DAD00043

B

DBD00044

+30

90°

0

fl Tighten bolt 7 to 66.2 ± 7.4 Nm {6.75 ± 0.75

kgm} one time.

fl After tightening, make one punch mark on

the bolt head to indicate the number of times

it has been tightened.

• If any bolt already has five punch marks,

do not reuse it. Replace it with a new

bolt.

• Refilling with water

• Add water through water filler to the speci-

fied level.

fl Run the engine to circulate the water through

the system. Then check the water level

again.

30-48

1

DAD00045

Make mark with punch

DAD00046

D155AX-5

Page 29

DISASSEMBLY AND ASSEMBLY

1

2

3

DBD00421

REMOVAL OF THERMOSTAT

ASSEMBLY

1. Drain coolant.

2. Remove alternator assembly.

For details, see REMOVAL OF ALTERNATOR ASSEMBLY.

3. Disconnect radiator inlet hose (1).

4. Disconnect bypass tube (2).

5. Remove cover (3).

6. Remove 2 thermostats (4).

THERMOSTAT

INSTALLATION OF

THERMOSTAT ASSEMBLY

• Carry out installation in the reverse order to

removal.

• Refilling with water

Add water through water filler to the specified

level.

fl Run the engine to circulate the water through

the system. Then check the water level

again.

4

4

DBD00422

D155AX-5

30-49

1

Page 30

DISASSEMBLY AND ASSEMBLY

REMOVAL OF AIR

CONDITIONER COMPRESSOR

ASSEMBLY

AIR CONDITIONER COMPRESSOR

Serial No. 70001 – 75000

Using tool X, collect freon gas (R134a).

1. Open engine left side cover (top) and remove

cover (bottom).

2. Remove wiring connector (1).

3. Disconnect hoses (2) and (3). 1

fl Fit blind plugs to prevent dirt or water from

entering the hoses.

4. Loosen 4 mounting bolts (4).

5. Remove V-belt cover (5).

6. Loosen adjustment bolt (6) and remove.

7. Remove mounting bolts (4), remove V-belt (7)

from pulley, then remove compressor assembly

(8). 2

123

4

DBD00423

Serial No. 70001 – 75000

6

5

Serial No. 70001 – 75000

4

7

Serial No. 75001 and up

DBD00424

8

DBD00425

30-50

5

D155AX-5

Page 31

DISASSEMBLY AND ASSEMBLY

3

DED00438

4

5

DED00439

REMOVAL OF ENGINE

ASSEMBLY

Serial No. 70001 – 75000

Disconnect the cable from the negative (–) ter-

minal of the battery.

fl Close the supply valve of the fuel tank.

1. Remove radiator, oil cooler, guard assembly.

For details, see REMOVAL OF RADIATOR, OIL

COOLER, GUARD ASSEMBLY.

2. Disconnect starting motor wiring (1).

3. Disconnect engine speed sensor connectors (2)

(CN009, CN010).

ENGINE

1

DED00436

4. Disconnect wiring connector (3) (CN101).

5. Disconnect 2 air conditioner hoses (4). 1

fl Loosen the sleeve nut slightly, and release

the air conditioner gas (R134a) completely

before disconnecting the hose.

fl Fit blind plugs to prevent dirt or water from

entering the hoses.

fl Disconnect at the air conditioner end, then

remove all the clamps from the floor frame

and move towards the engine.

6. Disconnect 2 heater hoses (5).

fl Disconnect at the air conditioner end, then

move towards the engine.

2

DED00437

D155AX-5

30-63

5

Page 32

DISASSEMBLY AND ASSEMBLY

DED00441

10

7. Disconnect fuel supply hose (6).

8. Disconnect fuel return hose (7).

ENGINE

9. Disconnect fuel control rod (8).

10. Disconnect ground wiring (9).

11. Disconnect universal joint (10) at damper end.

12. Remove front mount bolts (11) and rear mount

bolts (12). 2

11

8

9

7

6

DED00440

12

13. Move engine assembly (13) towards front of

machine, and lift off gradually.

fl Be careful not to damage the wiring or hoses

when removing the engine assembly.

4 Engine assembly : 1,750 kg

30-64

1

DDD00442

13

DED00443

D155AX-5

Page 33

DISASSEMBLY AND ASSEMBLY

Serial No. 75001 and up

¤ Disconnect the cable from the negative (-) ter-

minal of the battery.

fl Close the fuel feed valve.

1. Remove radiator and oil cooler and guard assembly. For details, see REMOVAL OF RADIATOR AND OIL COOLER AND GUARD ASSEMBLY.

2. Disconnect starting motor wiring (1).

3. Disconnect wiring connector (2).

ENGINE

4. Disconnect 2 air conditioner house (3). 1

fl Loosen the sleeve nut of each hose a little to

discharge the all air conditioner refrigerant

(R134a), then disconnect the hose.

fl Plug the hoses to prevent dirt, water, etc.

from entering them.

fl Remove the all clamps on the floor frame

and move the hoses toward the engine.

5. Disconnect 2 heater hoese (4).

6. Disconnect air conditioner wiring connector (5).

7. Disconnect fuel hoses (6), (7), and (8).

D155AX-5

30-64-1

5

Page 34

DISASSEMBLY AND ASSEMBLY

8. Disconnect ground wire (9).

9. Disconnect universal joint (10) from damper.

ENGINE

10. Remove front mounting bolts (11) and rear

mounting bolts (12). 2

11. Moving engine assembly (13) to front of machine body, lift it off gradually.

fl After removing the engine assembly, take

care not to damage the wires, hoses, etc.

4 Engine assembly : 1,750 kg

30-64-2

5

D155AX-5

Page 35

DISASSEMBLY AND ASSEMBLY

REMOVAL OF POWER TRAIN

UNIT ASSEMBLY

Serial No. 70001 – 75000

¤ Park the machine on level ground, lower the

work equipment completely to the ground, then

disconnect the cable from the negative (-) terminal of the battery.

1. Drain oil

6 Hydraulic tank : Approx. 97 ¬

6 Power train case: Approx. 60 ¬

2. Remove floor frame assembly.

For details, see REMOVAL OF FLOOR FRAME

ASSEMBLY.

POWER TRAIN UNIT

3. Open bottom plate at bottom of power train

unit.

4. Remove cover (1) at bottom of fuel tank.

5. Close lever (2) of fuel valve.

6. Disconnect hose (3) leading to priming pump.

7. Disconnect fuel return hoses (4) and (5).

8. Disconnect fuel level sensor wiring connector

(6) (CN422).

9. Lift off fuel tank assembly (7).

fl Sling at three points and use a lever block at

the center to keep the tank horizontal.

fl Move the tank to the rear, and when it clears

the floor frame, raise the rear of the tank

slightly with the lever block. (Do this to

avoid interference with the ripper hoses.)

4 Fuel tank assembly (when full) : 760 kg

10. Disconnect engine speed sensor wiring connec-

tor (8).

11. Disconnect suction tube (9) of 3-spool pump

(HSS lubrication, torque converter, transmission

charge).

fl Remove the cover at the top of the pump.

D155AX-5

30-75

5

Page 36

DISASSEMBLY AND ASSEMBLY

12. Remove suspension rod (10).

13. Remove top cover of centralized pressure detec-

tion port, then remove centralized pressure detection block (11) from frame.

POWER TRAIN UNIT

14. Disconnect hose (12) between hydraulic pump

and control valve.

15. Disconnect wiring connector (13) (HHP).

16. Remove suction tube (14).

fl Be careful not to damage the gasket of the

joint.

17. Disconnect hose (15) between cooler bypass

valve and hydraulic tank.

18. Disconnect hose (16) between charge relief valve

and hydraulic tank.

19. Remove power train oil supply pipe (17).

20. Disconnect power train dipstick tube (18) from

case, and move towards right side of chassis.

30-76

1

D155AX-5

Page 37

DISASSEMBLY AND ASSEMBLY

33. Lift off power train unit assembly (34). 5

fl Check that the wiring and piping has all been

removed, then lift off the power train unit

assembly.

4 Power train unit assembly : 2800 kg

INSTALLATION OF POWER

TRAIN UNIT ASSEMBLY

POWER TRAIN UNIT

Serial No. 70001 – 75000

• Carry out installation in the reverse order to

removal.

1

3 Universal joint mounting bolt :

110.3 ± 22.1 Nm {11.3 ± 2.3 kgm}

2

3 Mount cap mounting bolt :

277.5 ± 32.4 Nm {28.3 ± 3.3 kgm}

3

fl Clamp the protruding portion of the cou-

pling seal, then assemble the clamp thread

so that it is parallel to the cap mount seat

surface.

4

3 Front mount mounting bolt :

926.8 ± 103.0 Nm {94.5 ± 10.5 kgm}

5

fl When assembling the power train assem-

bly, be extremely careful not to damage seal

(32).

• Refilling with oil (Hydraulic tank. power train

case.)

Add engine oil through oil filler to the specified

level.

fl Run the engine to circulate the oil through

the system. Then check the oil level again.

5 Hydraulic tank : Approx. 97 ¬

5 Power train case : Approx. 60 ¬

D155AX-5

30-79

5

1

Page 38

DISASSEMBLY AND ASSEMBLY

SEPARATION OF POWER

TRAIN UNIT ASSEMBLY

• Drain oil

Before setting the power train unit assembly on

the block, drain the oil from the PTO case.

1. Raise power train unit assembly (1) and set on

block 1.

4 Power train unit assembly : 2800 kg

2. Disconnect 3 hoses (2) connected to cooler by-

pass valve.

3. Disconnect HSS pump connecting hose (3).

4. Remove cooler bypass valve assembly (4) to-

gether with bracket.

POWER TRAIN UNIT

5. Disconnect 5 charge relief valve connecting

hoses (5).

6. Disconnect wiring connector (6) (CN406).

7. Remove charge relief valve (7).

8. Disconnect pressure detection hoses (8) and (9),

and remove reducing pressure valve hose (10).

1

fl Disconnect the transmission modulation

pressure detection hose.

10

8

9

DBD00927

30-80

1

D155AX-5

Page 39

DISASSEMBLY AND ASSEMBLY

DLD01003

18

19

DLD01005

21

22

108

4) Remove brake drum (12) together with disc

and plate.

HSS CASE

12

DKD01001

5) Remove plate (13), disc (15), spring (16), and

plate (14) from brake drum.

6) Remove mounting bolts, then remove car-

rier assembly (19) from hub (18).

7) Remove gear assembly (20) from hub as-

sembly (18).

14

16

18

13

15

DKD01002

20

8) Remove ring (21), then remove ring gear

(22) from gear (108).

9) Remove snap ring (23), and pull out shaft

(24).

D155AX-5

23

DLD01004

24

DLD01006

30-121

1

5

Page 40

DISASSEMBLY AND ASSEMBLY

E2

DLD01010

39

10) Remove planetary gear (25), bearing (26),

thrust washer (27), shaft (24), and ball (28).

HSS CASE

25

11) Remove snap ring (31), then remove stopper (32) from hub (18).

26

27

32

31

24

28

DLD01007

18

DKD01008

2. Bevel pinion assembly

1) Using guide bolts 3 and forcing screws remove bevel pinion assembly (33) and shim

(34).

fl Check the number and thickness of the

shims, and keep in a safe place.

2) Disassembly of bevel pinion assembly

i) Remove bolts (35), (36) and pin (37).

Serial No. 75001 –

ii) Hold with press to prevent pinion from

moving, then use tool E2 to remove

locknut (39).

iii) Using push tool 5, remove bevel pinion

(40) from cage (41).

34

r

41

e

33

DLD01009

t

40

30-122

5

DKD01011

D155AX-5

Page 41

DISASSEMBLY AND ASSEMBLY

iv) Remove bearing (42).

v) Remove outer races (43) and (107) from

cage (41).

42

DLD01012

43

HSS CASE

107

41

DLD01013

vi) Remove bearing (109) from bevel pinion

(40).

3. Sun gear

Remove sun gear (45).

fl Remove the sun gear on the opposite side

in the same way.

4. Gear

1) Remove snap ring (47), then remove spacer

(48).

40

45

109

DLD01014

47

48

2) Using gear puller 6, remove gear (49).

D155AX-5

y

DLD01015

DLD01016

49

DLD01017

30-123

5

Page 42

DISASSEMBLY AND ASSEMBLY

DLD01021

57

58

HSS CASE

fl Only inner race (50) of bearing (55) will re-

main.

fl Remove the gear on the opposite side in the

same way.

5. Valve seat

1) Pull out 2 brake circuit tubes (51) and 3 lubrication tubes (52), then remove.

2) Remove valve seat (53).

51

52

49

55

51

50

DKD01018

52

53

51

DKD01019

6. Lubrication tubes, dipstick tube, suction tube

1) Remove lubrication tubes (52) and (56).

2) Remove lubrication tubes (57) and (58).

3) Remove dipstick tube (59) and suction tube

(60).

52

56

DLD01020

59

30-124

5

1

60

DLD01022

D155AX-5

Page 43

DISASSEMBLY AND ASSEMBLY

• Serial No. 75001 –

vi) Turn the nut unit the phase of any one

of the pin insertion holes of the nut (8

places) is matched to that of any one of

the pin insertion holes of the pinion shaft

(5 places). (Returning angle: 0 - 9°)

vii) Insert pin (37) in the above holes. Fit

plate (36) and tighten bolts (35).

2 Bolt : Thread tightener (LT-2)

3 Bolt : 11.8 - 14.7 Nm

{1.2 - 1.5 kgm}

2) Using guide bolt 3, assemble shim (34) and

install bevel pinion assembly (33).

fl There are three types of shim:

0.1, 0.2, 0.5 mm

HSS CASE

y

6. Adjusting tooth contact, backlash

1) Adjusting backlash

Put the probe of dial gauge 6 at right angles in contact with the tip of the bevel gear

teeth. Hold the bevel pinion in position, and

read the measurement when the bevel gear

is moved forward and backward.

fl Standard value for backlash :

fl Measure at least three points on oppo-

site sides.

• If the result of the inspection shows that

the correct backlash is not being obtained, adjust as follows.

fl Adjust the shim thickness at the left cage.

• If backlash is too small

Loosen mounting bolt of cage and remove shim.

• If backlash is too large

Loosen mounting bolt of cage and add

shim.

DBD00156

0.25 - 0.33 mm

Front

A

DAD00157

D155AX-5

Front

B

DAD00158

30-135

1

5

Page 44

DISASSEMBLY AND ASSEMBLY

HSS CASE

2) Adjusting tooth contact

Testing

i) Coat the tooth face of the bevel pinion lightly

with red lead (minium). Rotate the bevel

gear forward and backward and inspect the

pattern left on the teeth.

ii) Tooth contact should be checked as follows

(from tip of teeth of bevel pinion).

a) Center of tooth contact: 20 - 40 % of

tooth width (from small end)

b) Width of tooth contact: 30 - 50 % of tooth

width

c) Center of tooth contact: 35 - 65 % of

tooth height (from root of tooth)

d) Width of tooth contact: 60 - 80 % of tooth

height

In addition, there should be no strong contact at the addendum or dedendum (tip or

root of the gear teeth) or at the big and

small ends.

fl If the gears are adjusted to this pattern,

the tooth contact will be correct when

load is applied.

Big

end

Root of tooth

Big end

Tip of tooth

Small end

DBD00159

b

a

c

d

Small

end

Adjustment

If the result of the inspection shows that the

correct tooth contact is not being obtained, adjust again as follows.

i) If bevel pinion is too far from center line of

bevel gear.

Contact is at the small end of the convex

tooth face of the bevel gear and at the big

end of the concave tooth face.

• Correct the tooth contact as follows.

Adjust the thickness of the shims at the bevel

pinion to move the bevel pinion in direction

A.

Move the bevel gear in direction B, then

check the tooth contact pattern and backlash again.

ii) If bevel pinion is too close to center line of

bevel gear.

Contact is at the big end of the convex tooth

face of the bevel gear and the small end of

the concave tooth face.

• Correct the tooth contact as follows.

Adjust the thickness of the shims at the bevel

pinion to move the bevel pinion in direction

B.

Move the bevel gear in direction A, then

check the tooth contact pattern and backlash again.

DBD00160

B

A

DBD00161

B

A

DBD00162

30-136

1

D155AX-5

Page 45

DISASSEMBLY AND ASSEMBLY

4

DKD01083

107

108

109

DAD02453

iii) Using eyebolts 1, align bolt hole with

hub and brake drum, then install brake

cover assembly (5).

fl Tighten the mounting bolts tempo-

rarily.

fl The force of the spring is applied, so

tighten the hexagon socket head

bolts uniformly.

iv) Using push tool, press fit inner race (4).

v) Install plate (3) and flange (2).

3 Flange: 58.8 - 73.6 Nm

{6 - 7.5 kgm}

vi) Fully tighten bolts temporarily tightened

in Step iii).

3 Mounting bolt: 98.1 - 122.6 Nm

{10 ± 12.5 kgm}

HSS CASE

q

5

DLD00999

23

• Installation of brake, carrier assembly

1) Angle steering case assembly approx. 15°

so that tool E1 is perpendicular to ground

surface.

2) Using tool E1, install brake, carrier assembly

(1).

3 Mounting bolt: 98.1 - 122.6 Nm

{10 - 12.5 kgm}

fl Assemble the brake, carrier assembly on

the opposite side in the same way.

fl When cover (109) of the rear surface on

HSS case (107) has been removed, install new gasket (108).

2 Gasket (apply to both surfaces):

Gasket sealant (LG-1)

DLD01255

E1

1

DLD00997

D155AX-5

30-141

1

Page 46

DISASSEMBLY AND ASSEMBLY

REMOVAL OF HYDRAULIC

PUMP ASSEMBLY

¤ Park the machine on level ground, lower the

work equipment completely to the ground, then

disconnect the cable from the negative (–) terminal of the battery.

1. Drain hydraulic oil and power train oil.

6 Hydraulic oil : Approx. 97 ¬

6 Power train case : Approx. 60 ¬

2. Remove cab.

For details, see REMOVAL OF CAB ASSEMBLY.

3. Lift off operator’s seat assembly (1).

4 Operator’s seat : 54 kg

HYDRAULIC PUMP

Serial No. 70001 – 75000

4. Remove floor frame left and right side covers

(2).

5. Remove floor mat, then remove cover (3).

Serial No. 75001 and up

30-142

1

5

D155AX-5

Page 47

DISASSEMBLY AND ASSEMBLY

6. Disconnect acceleration rod (4) from yoke.

7. Disconnect deceleration rod (5) from yoke.

8. Disconnect brake rod (6).

fl Loosen locknut (7), and turn joint (8) to dis-

connect.

Joint (8) has a reverse thread.

9. Remove floor assembly (9).

HYDRAULIC PUMP

4 Floor assembly: 26 kg

A. Removal of hydraulic pump assembly

1) Disconnect hose (1) leading to work equipment control valve.

2) Disconnect wiring connector (2) (HHP).

3) Disconnect suction tube joints (3) and (4).

4) Remove 4 mounting bolts (5), then remove

tube (6).

5) Remove mounting bolts, then remove hydraulic pump assembly (7).

4 Hydraulic pump assembly : 19 kg

D155AX-5

30-143

1

5

Page 48

DISASSEMBLY AND ASSEMBLY

B. Removal of 3-spool pump assembly (HSS lubri-

cation + torque converter, transmission charge

+ torque converter charge pump)

1) Remove cover (1).

2) Disconnect HSS motor and brake lubrication

tube (2).

3) Disconnect suction tube (3) from power train

case.

4) Disconnect transmission filter hose (4).

HYDRAULIC PUMP

5) Disconnect filter bypass valve hose (5).

fl It is difficult to disconnect the hose at

the pump end.

6) Remove mounting bolts, then lift off 3-spool

pump assembly (6).

fl Remove together with hose (5).

4 3-spool pump assembly : 24 kg

30-144

1

5

D155AX-5

Page 49

DISASSEMBLY AND ASSEMBLY

C. Removal of HSS pump assembly

1) Disconnect HSS and PPC charge valve hose

(1).

2) Disconnect cooler bypass valve hose (2).

3) Disconnect charge filter hose (3).

4) Disconnect solenoid wiring connector (4)

(PUP.A).

5) Disconnect cooler bypass valve hose (5).

6) Disconnect HSS motor hoses (6) and (7).

7) Disconnect charge relief valve hose (8).

HYDRAULIC PUMP

8) Disconnect engine speed sensor wiring con-

nector (9) (CN010).

9) Disconnect solenoid wiring connector (10)

(PUP.B).

10) Remove mounting bolts, then lift off HSS

pump assembly (10).

4 HSS pump assembly : 116 kg

D155AX-5

30-145

1

5

Page 50

DISASSEMBLY AND ASSEMBLY

D. Removal of charge + scavenging pump assembly

1) Disconnect charge filter hose (1).

fl It is difficult to disconnect the hose at

the pump end.

2) Disconnect power train case suction tube (2).

3) Disconnect suction hydraulic tank tube (3).

HYDRAULIC PUMP

4) Lift off charge + scavenging pump assembly

(4).

fl Raise, then move slowly towards the en-

gine, and lower gradually from clearance.

4 Charge + scavenging pump assembly :

30 kg

INSTALLATION OF HYDRAULIC

PUMP ASSEMBLY

• Carry out installation in the reverse order to

removal.

• Refilling oil

5 Hydraulic oil : Approx. 97 ¬

5 Power train case : Approx. 60 ¬

• Bleeding air

Bleed the air from the pumps and power train.

For details, see TESTING AND ADJUSTING,

Bleeding air.

30-146

1

5

D155AX-5

Page 51

DISASSEMBLY AND ASSEMBLY

HSS, PPC CHARGING VALVE

DISASSEMBLY OF HSS, PPC CHARGING VALVE ASSEMBLY

12

13

20

16

15

19

5

21

18

22

17

14

1

3

4

11

7

10

9

8

6

2

23

DKD01197

1. Remove plug (1), then remove springs (3) and

(4) from valve body (2).

2. Remove plug (5), then remove spool assembly

(6).

3. Remove valve (8), spring (9), valve (10), and

shim (11) from spool (7).

4. Remove plug (12), then remove spring (13).

5. Remove plug (14), then remove spool assembly

(15).

6. Remove valve (17), spring (18), and valve (19)

from spool (16).

7. Remove plug (20), then remove spring (21) and

valve (22).

8. Remove plug (23).

D155AX-5

30-151

1

5

Page 52

DISASSEMBLY AND ASSEMBLY

HSS, PPC CHARGING VALVE

ASSEMBLY OF HSS, PPC CHARGING VALVE ASSEMBLY

12

13

20

16

15

19

14

21

22

1

17

18

11

7

10

9

8

6

5

2

23

4

3

DKD01197

fl Clean all parts, and check for dirt or dam-

age. Coat the sliding surfaces of all parts

with engine oil before installing.

1. Tighten plug (23).

2. Assemble valve (22) and spring (21) to valve

body (2), and tighten plug (20).

3. Assemble valve (19), spring (18), and valve

(17) to spool (16).

4. Assemble spool assembly (15) to valve body

(2), and tighten plug (14).

3 Plug : 63.7 ± 14.7 Nm {6.5 ± 1.5 kgm}

5. Assemble spring (13) and tighten plug (12).

3 Plug : 68.6 ± 9.8 Nm {7 ± 1 kgm}

6. Assemble valve (10), spring (9), valve (8),

and shim (11) to spool (7).

fl Check the number and thickness of the

shims, then assemble.

Shim thickness: 0.5 mm

No. of shims: 4

7. Assemble spool assembly (6) to valve body

(2) and tighten plug (5).

3 Plug : 68.6 ± 9.8 Nm {7 ± 1 kgm}

8. Assemble springs (4) and (3), and tighten

plug (1).

3 Plug : 68.6 ± 9.8 Nm {7 ± 1 kgm}

30-152

1

5

5

D155AX-5

Page 53

DISASSEMBLY AND ASSEMBLY

REMOVAL OF TRANSMISSION

CONTROL VALVE ASSEMBLY

¤ Park the machine on level ground, lower the

work equipment completely to the ground, then

disconnect the cable from the negative (–) terminal of the battery.

1. Remove operator’s seat and floor plate.

For details, see REMOVAL OF HYDRAULIC PUMP

ASSEMBLY.

2. Disconnect hose brackets (1) and (2) from transmission case cover.

3. Disconnect speed control cable (3), and remove

bracket from case cover.

fl Do not disconnect the cable from the bracket.

TRANSMISSION CONTROL VALVE

4. Disconnect directional control cable (4), and re-

move bracket from case cover.

fl Do not disconnect the cable from the bracket.

5. Disconnect transmission modulation pressure

detection hose (5).

6. Disconnect wiring connector of gear speed detection limit switch (5-1).

• Serial No. Only 75001 and up

7. Disconnect backup alarm limit switch wiring connector (6) (CN251), and remove limit switch (7).

8. Using forcing screws, remove transmission cover

(8). 1

9. Disconnect hose (9) coming from charge pump,

and remove plate (10).

10. Remove sleeve (11), then remove block (12).

D155AX-5

30-153

1

5

Page 54

DISASSEMBLY AND ASSEMBLY

10. Remove sleeves (13) and (14). 2

11. Remove block (15), then remove sleeve (16).

3

12. Remove mounting bolts, then remove transmis-

sion control valve assembly (17). 4

INSTALLATION OF

TRANSMISSION CONTROL

VALVE ASSEMBLY

• Carry out installation in the reverse order to

removal.

TRANSMISSION CONTROL VALVE

1

fl Look through the inspection window in the

cover to check that the lever and yoke are

meshed, then tighten the mounting bolts.

fl When installing the cover, tap with a plastic

hammer. If the dowel pin portion is not

inserted, remove the cover, correct the meshing of the lever and yoke, then install again.

23

2 Sleeve : Grease (G2-LI)

4

3 Transmission control valve mounting bolt :

49.0 ± 4.9 Nm {5.0 ± 0.5 kgm}

30-154

1

D155AX-5

Page 55

DISASSEMBLY AND ASSEMBLY

INSTALLATION OF BLADE PPC

VALVE ASSEMBLY

• Carry out installation in the reverse order to

removal.

1 2 3

e The connection position for the pump hose,

drain hose, and PPC hose are distinguished

by color bands at the caulking portion for

the hoses, so check the colors when connecting.

4

e Set the PPC valve in the mounting direction

shown in the diagram on the right when

installing.

(The diagram on the right shows the PPC

valve as seen from the top of the panel.)

Front of

machine

P4

BLADE PPC VALVE

T

P2

(View of valve from above)

P1

P

P3

DAD00788

• Refilling with oil (hydraulic tank)

Add engine oil through oil filler to the specified

level.

e Run the engine to circulate the oil through

the system. Then check the oil level again.

D155AX-5

30-269

1

1

Page 56

DISASSEMBLY AND ASSEMBLY

REMOVAL OF RIPPER PPC

VALVE ASSEMBLY

Fully lower work equipment to the ground. Re-

lease the remaining pressure in the circuit. For

details, see TESTING AND ADJUSTING, RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT. Then loosen the oil filler cap slowly to

release the pressure inside the hydraulic tank.