Kollmorgen SERVOSTAR 300, SERVOSTAR 400, SERVOSTAR 601...620, SERVOSTAR 640...670 User Manual

Accessories for digital drive systems

Manual

Edition: December 2014

Translation of the original document

European Version (CE region)

Keep all manuals as a product component during the life span of the product.

Pass all manuals to future users and owners of theproduct.

Record of Document Revisions

Edition Comments

04/2007 First edition

07/2007 System S700 updated.

11/2007 Several corrections, connectors added.

Motor cable 1mm² for S700 added, Symbols acc. to ANSI Z535, Y-Connector X0/X8 for S700

03/2008

04/2010

added, configuration of cables, 3YL20->3YL24.

Weight 3YL-24, Product brand, 3YL20 with UL, 3YLN new, S748/772, AKD, Resolver table,

S200 accessories removed.

Order codes brake resistors, Comcoder wire colors, feedback cable color, order codes motor

12/2010

cables, mains filter new types, mains chokes new types, transport tool for AKM8, mounting

clamps for S700, accessories S640/670 removed, 3YL20 removed, company name.

10/2011 Motor cables, cable data, EU order codes mating connectors AKD, AKD Hiperface.

Order codes motor cables S748/772 updated, cable data, combined cables for AKD with SFD,

03/2012

stainless steel connectors for Washdown motors.

SFD cable fotos, all SFD cables to one section, dimensions mains chokes corrected, capacitor

08/2012

modules new, formal improvements

Photos SFD cables, dimensions mains chokes updated, KCM modules new, manufacturing

hints for Kollmorgen cables removed, configured cable tables with photos, typo corrections, fan

05/2013

kit AKM7, mains filter 1NF-20 replaced by 1NF-20B, mounting clamps S700 removed, 24V

mains supply removed, hybrid cables new

11/2013

03/2014

05/2014

Heat sink AKD-N new, Hybrid cables AKD-C/N new, Hybrid cables SFD3/DSL, new Ethernet

cables

New Layout, AKMH mounting kit, KCM updated, AKM7 Fan-Kit updated, hybrid cables

SFD3/DSL added

Length definition of hybrid cables for decentralized systems changed, S700 X8Y set with

X4Amini

08/2014 Brake resistor AKD-x01206 changed, length definitions for decentral hybrid cables updated

12/2014 S640/670 added, AKD-x04807 accessories added

Technical changes which improve the performance of the device may be made without prior notice!

Printed in the United States of America

This document is the intellectual property of Kollmorgen. All rights reserved. No part of this work may be reproduced in any form (by photocopying, microfilm or any other method) or stored, processed, copied or distributed

by electronic means without the written permission of Kollmorgen.

2 Kollmorgen | December 2014

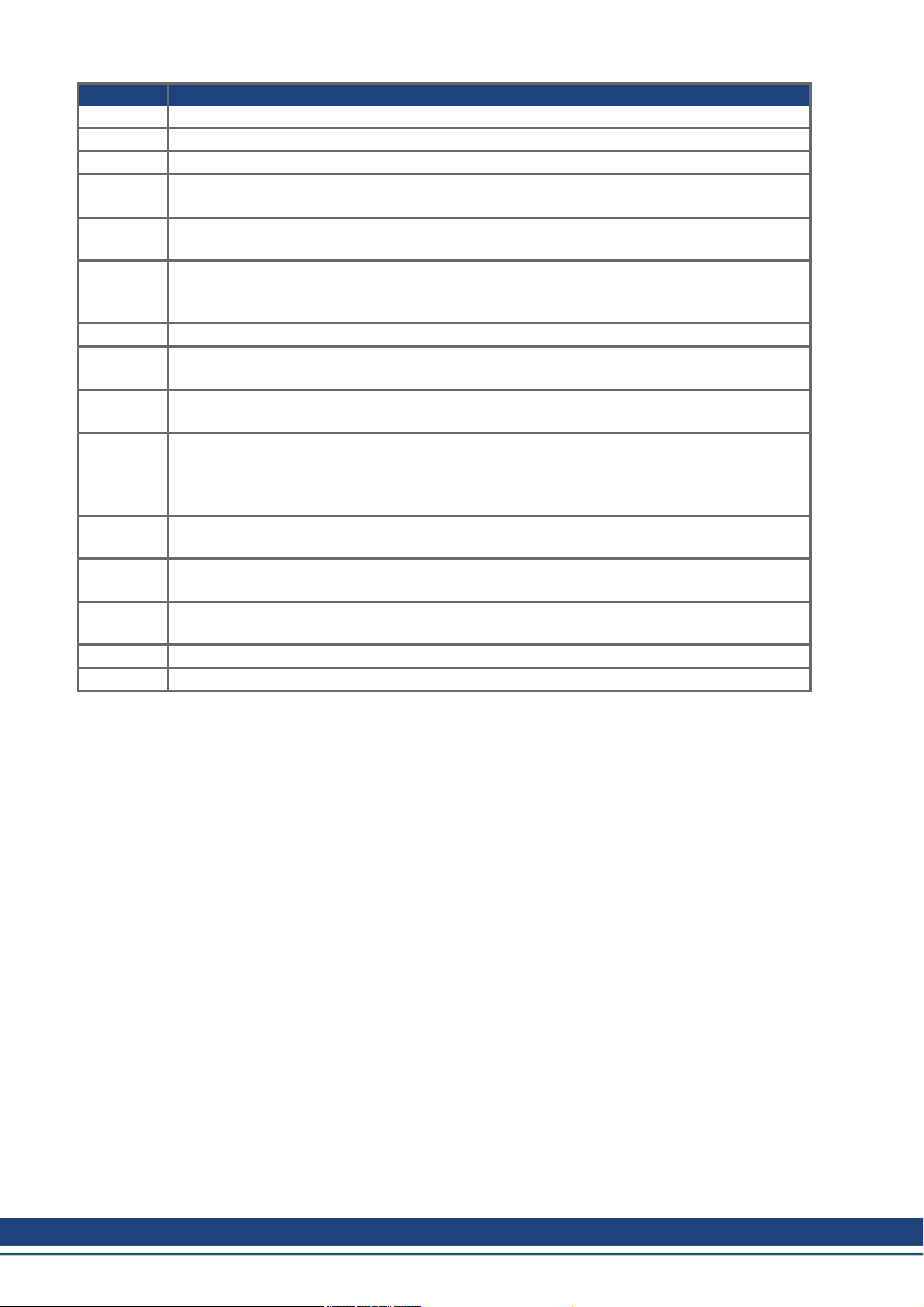

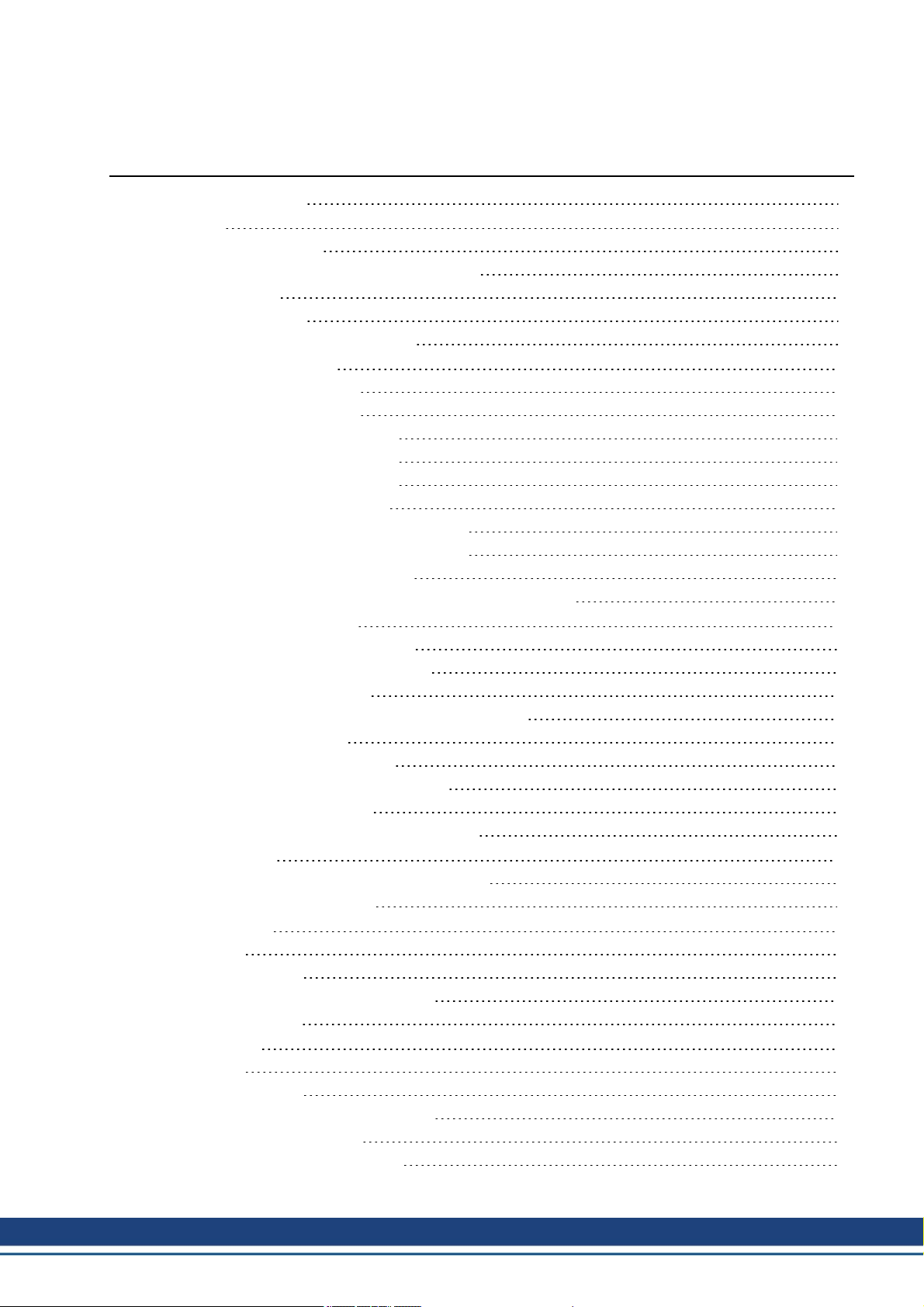

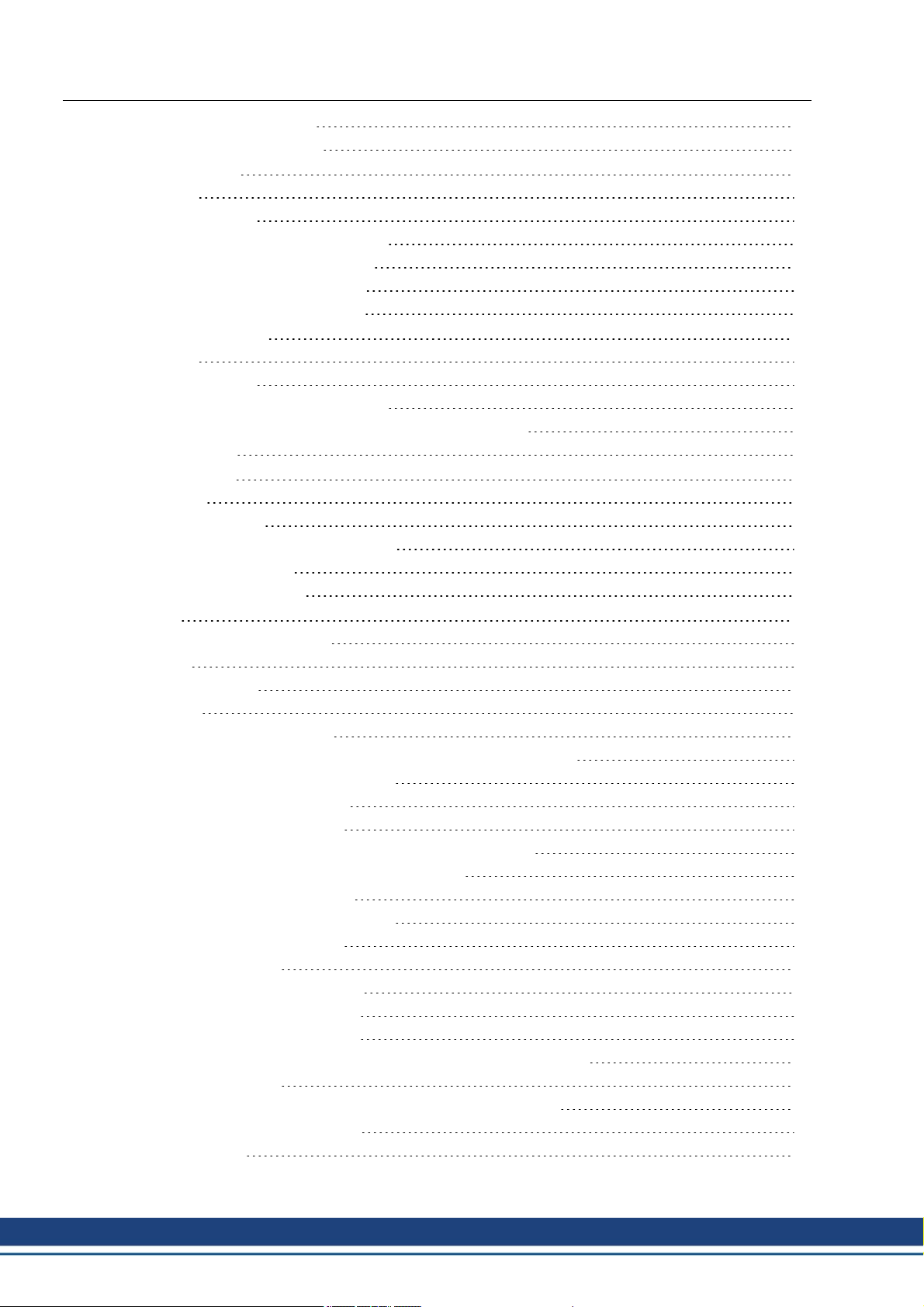

Accessories Europe | Table of Contents

1 Table of Contents

1 Table of Contents 3

2 General 7

2.1 About this manual 7

2.2 Hints for the online edition (PDF format) 7

2.3 Safety Notes 8

2.3.1 Symbols Used 8

2.3.2 You should pay attention to this 9

3 Digital Drive Systems 10

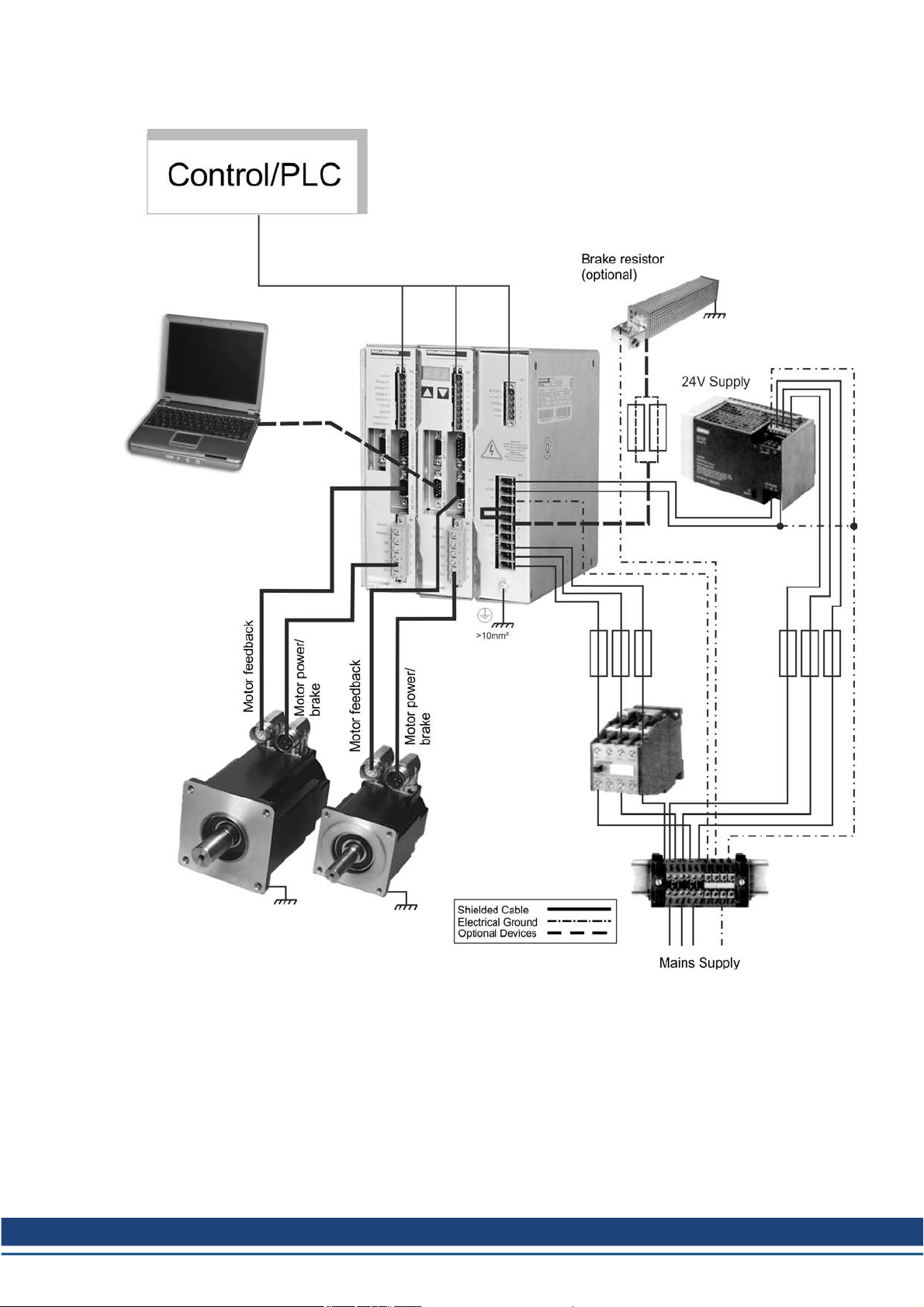

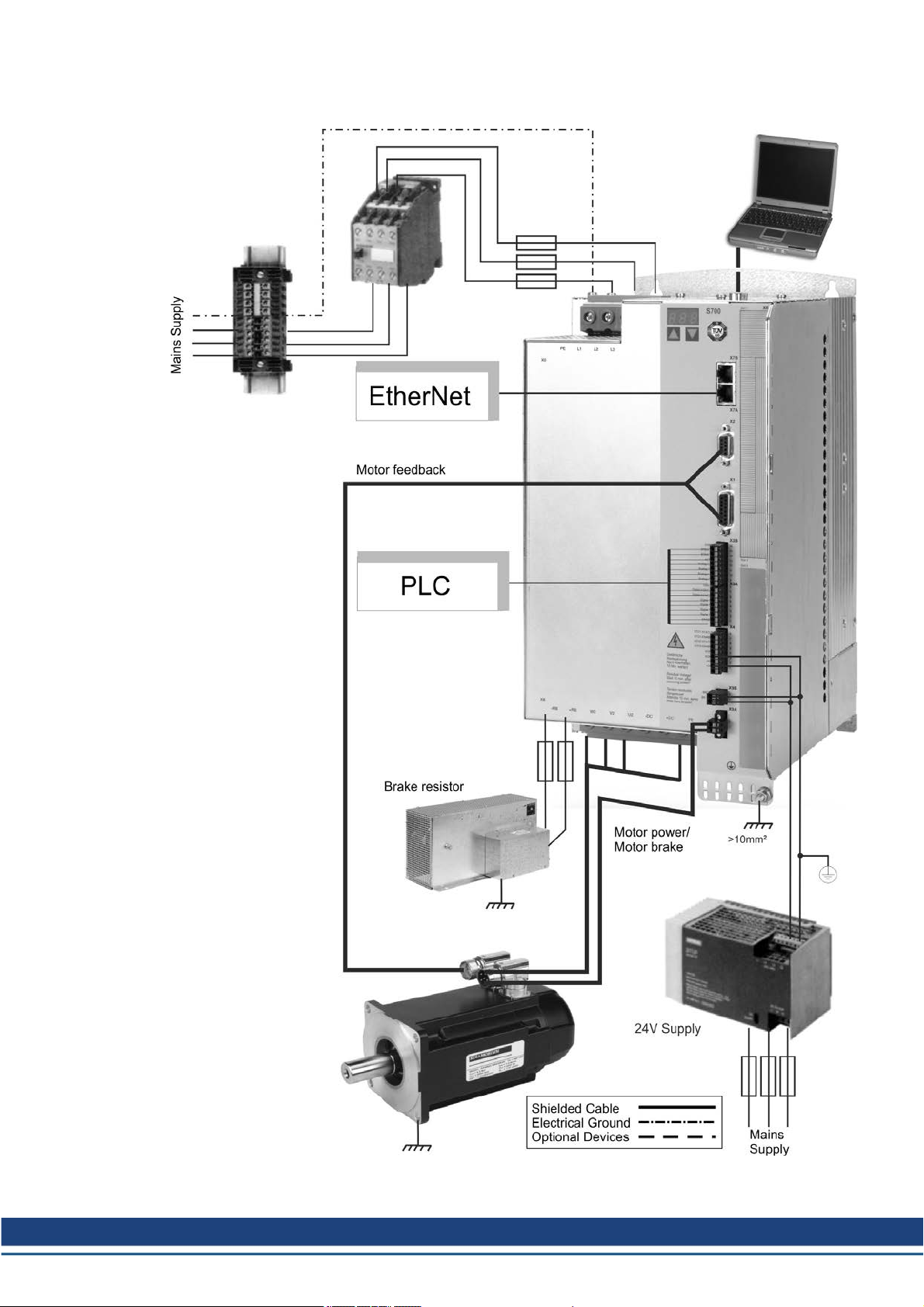

3.1 Drive System with S300 10

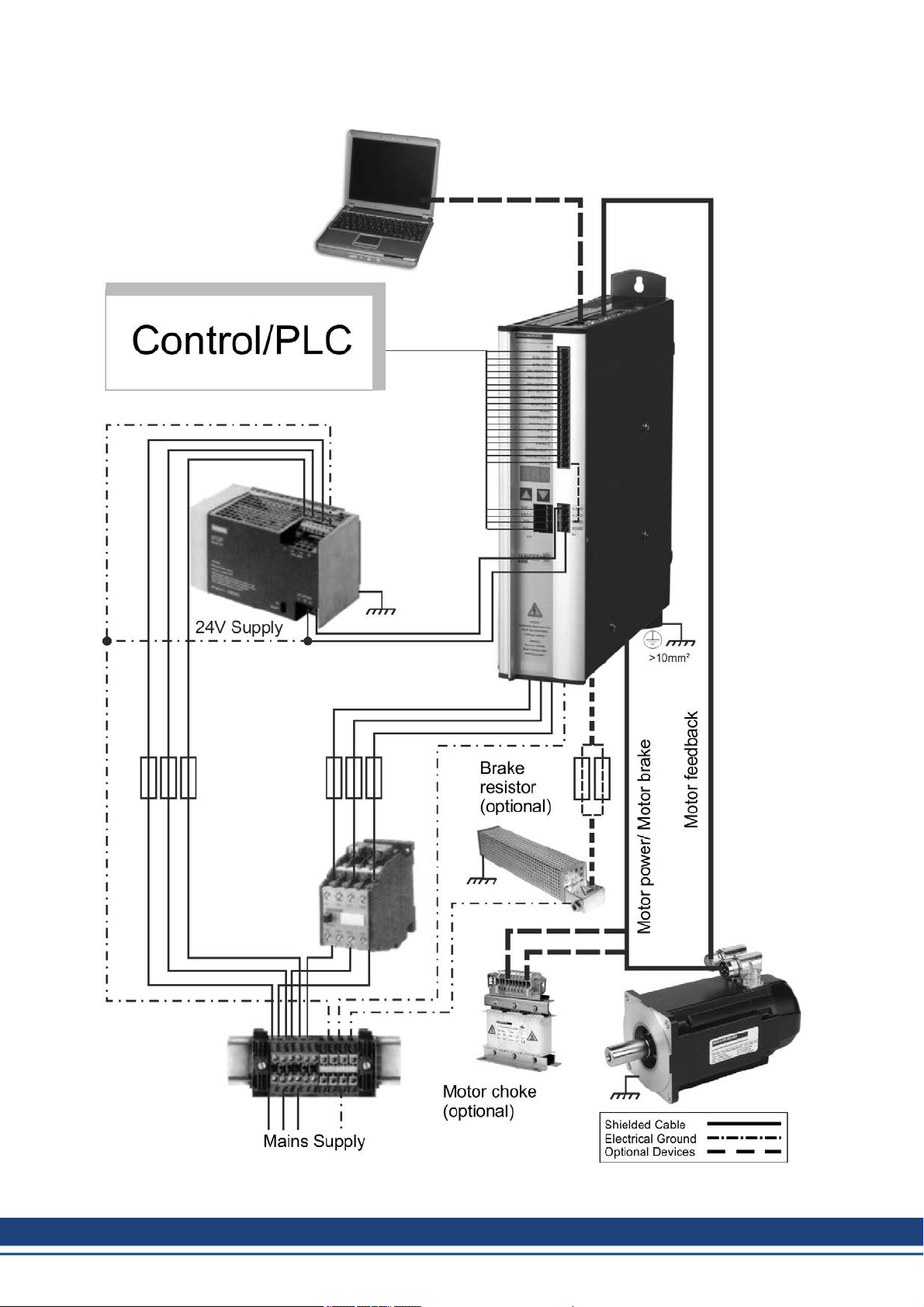

3.2 Drive System with S400 11

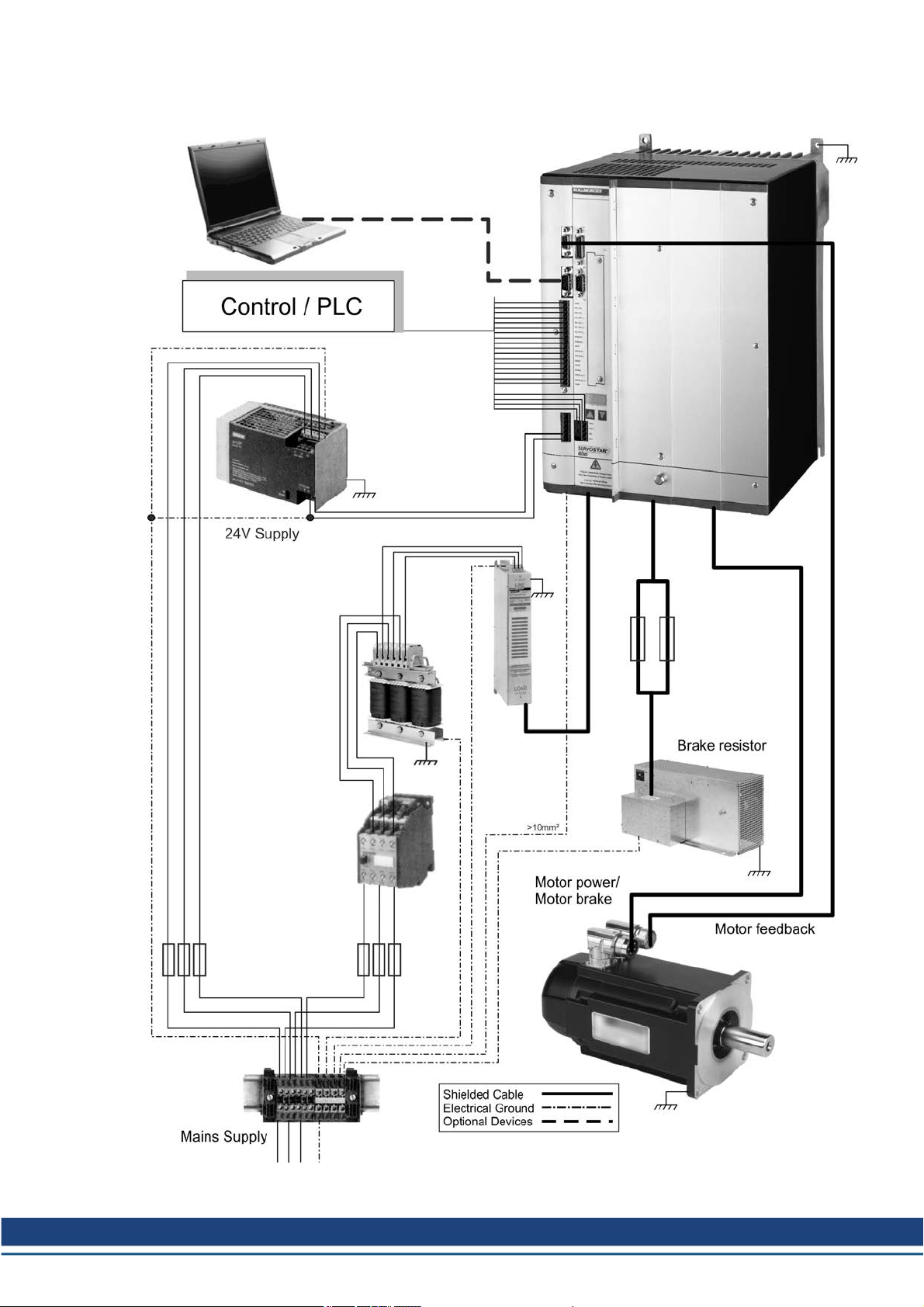

3.3 Drive System with S601...620 12

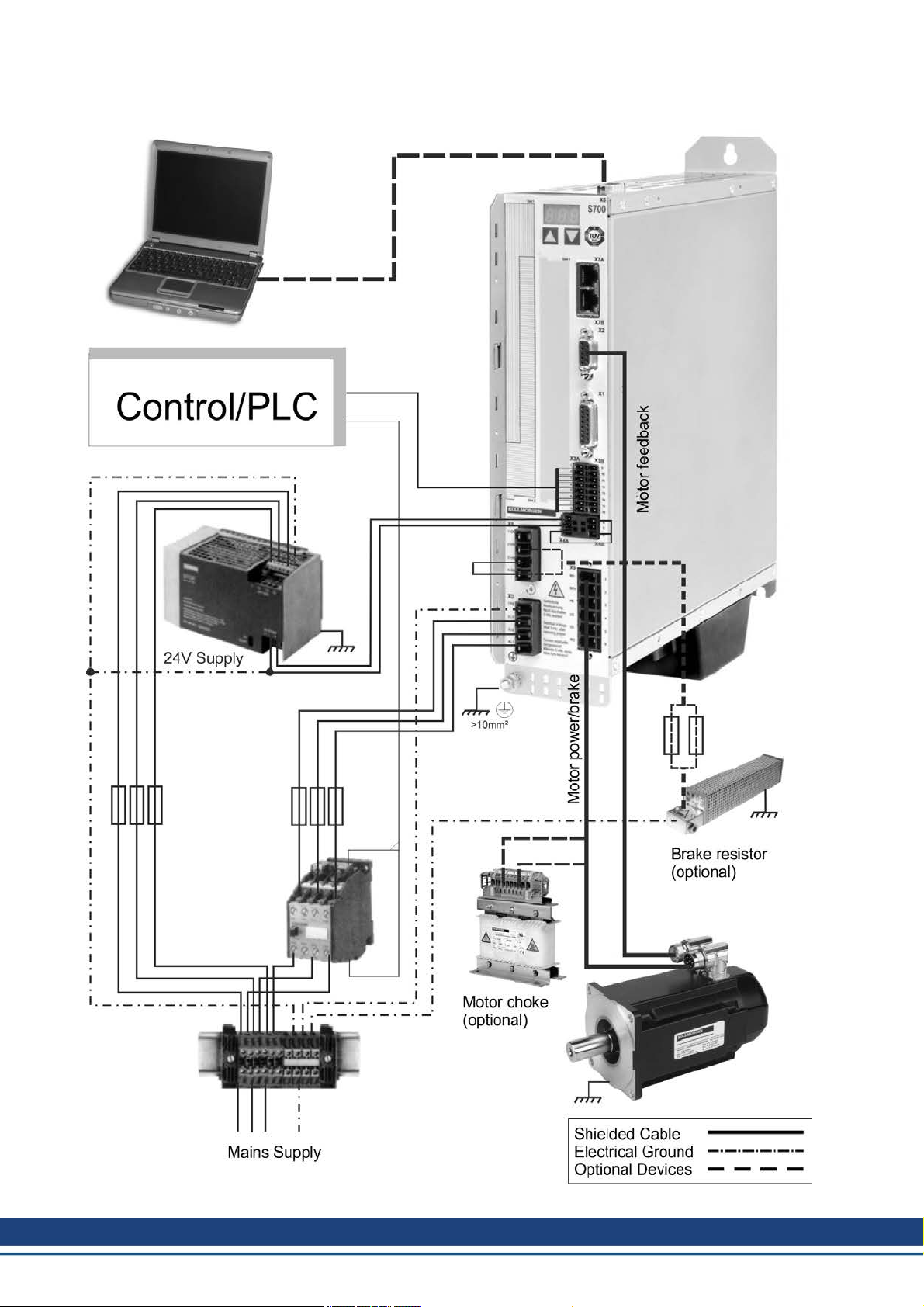

3.4 Drive System with S640...670 13

3.5 Drive System with S701...724 14

3.6 Drive System with S748/772 15

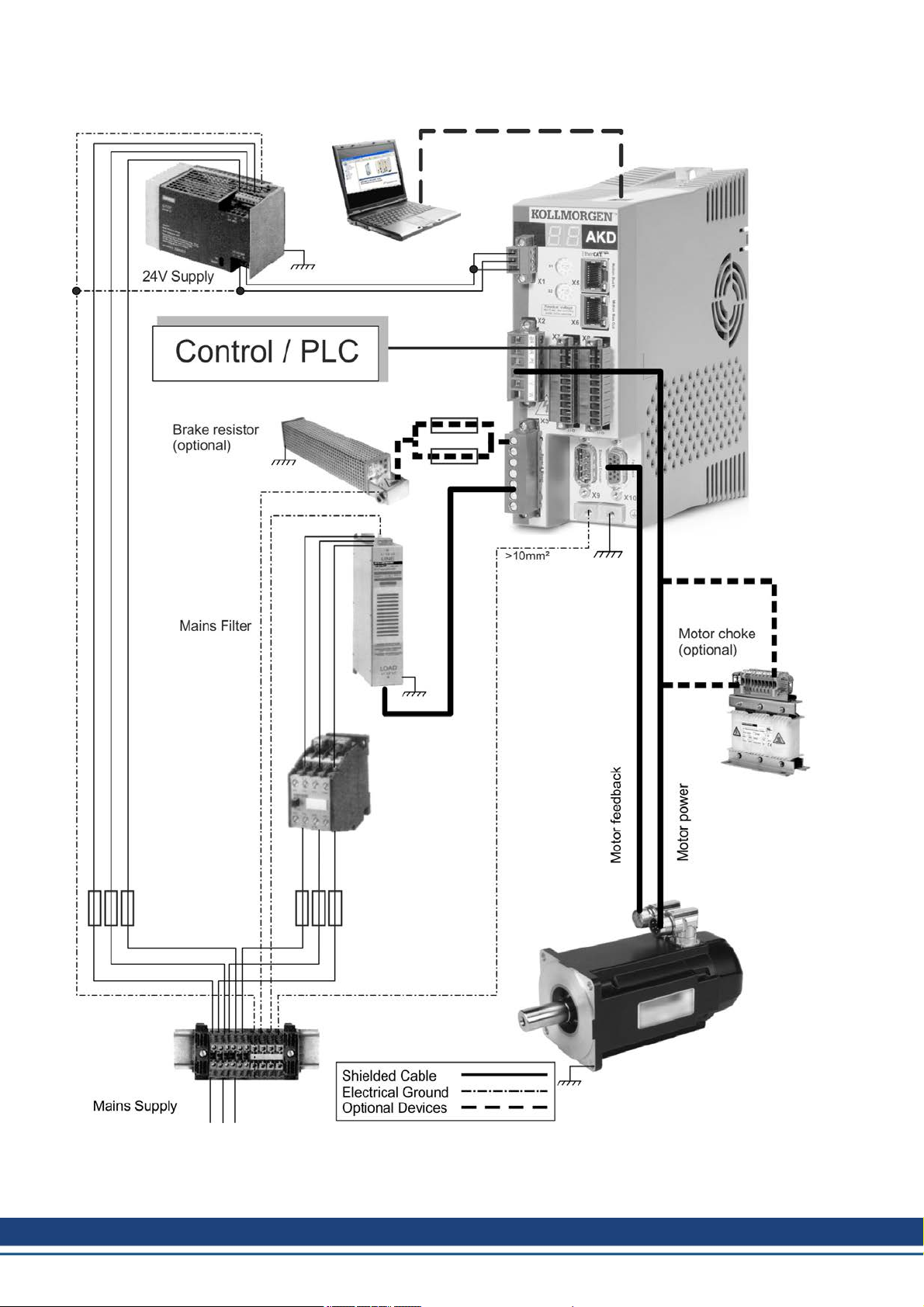

3.7 Drive System with AKD-x00306...02406 16

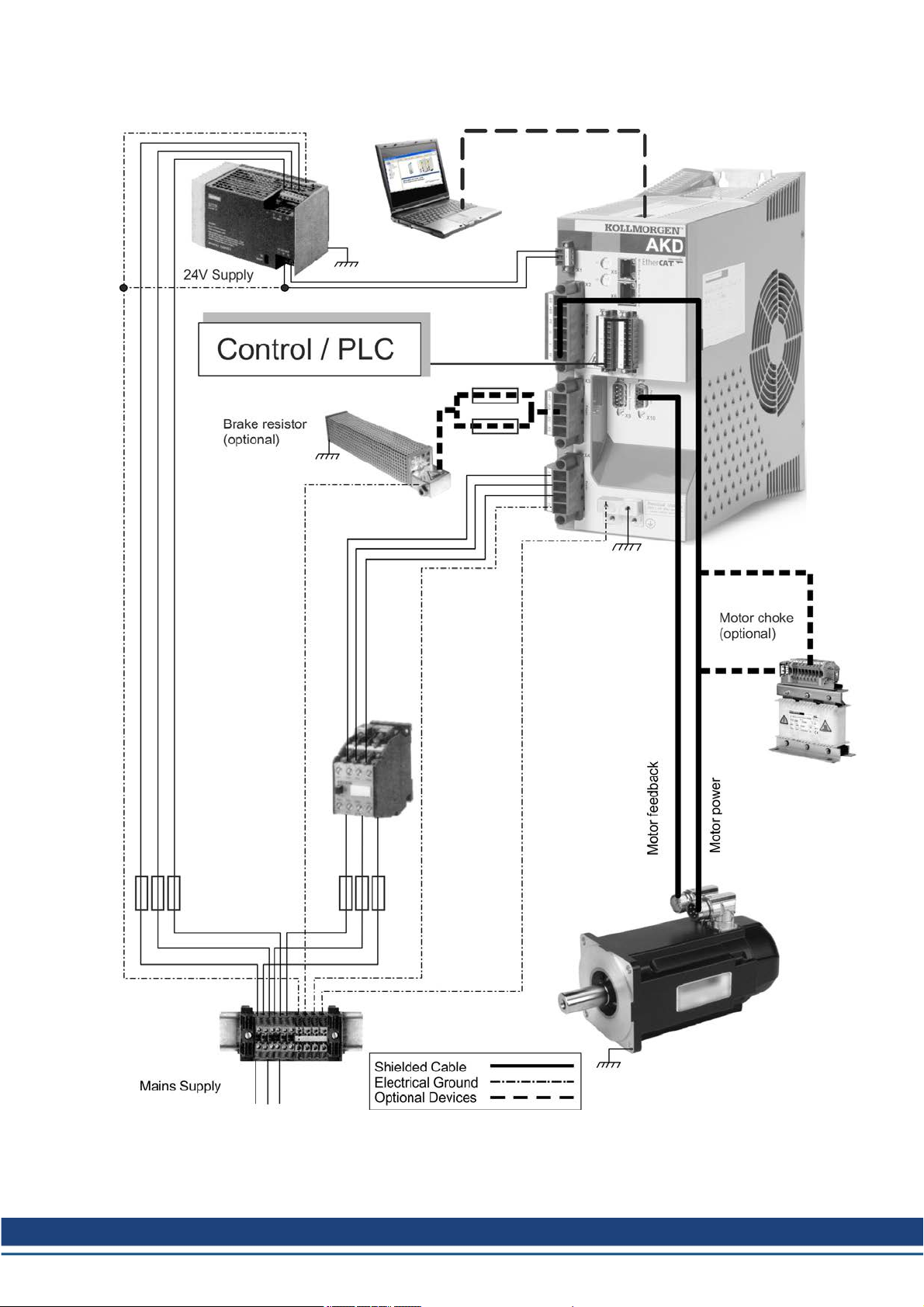

3.8 Drive System with AKD-x00307...02407 17

3.9 Drive System with AKD-x04807 18

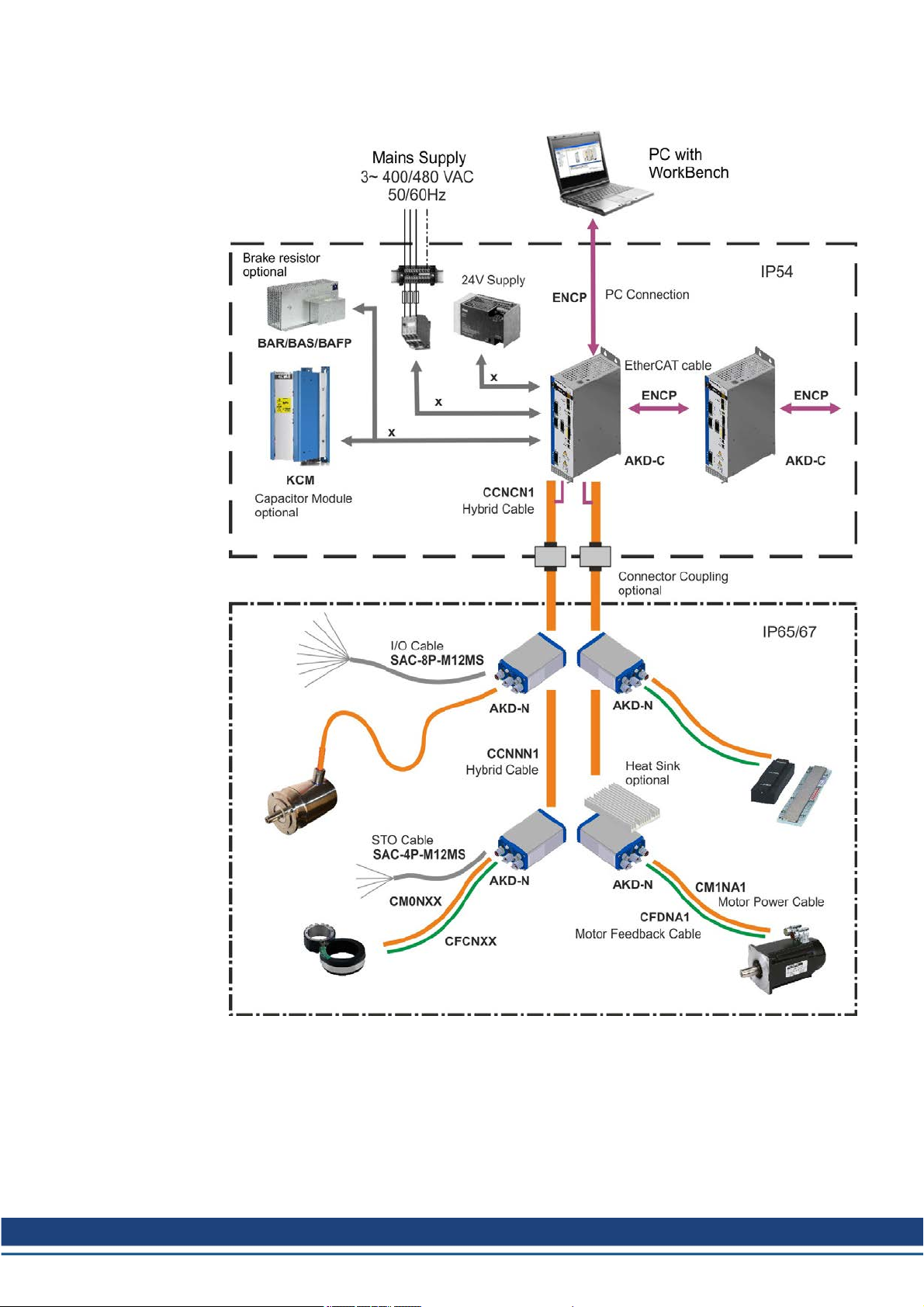

3.10 Decentralized Drive System with AKD-C and AKD-N 19

4 Mechanical Accessories 20

4.1 Mounting Kit for AKMH Motors 20

4.2 Suspension Unit for AKM motors 20

4.3 Fan Kit for AKM7 motors 21

4.4 Mechanical accessories for AKD-N and AKD-C 22

4.4.1 Heat Sink forAKD-N 22

4.4.2 Mounting clamps forAKD-N 22

4.4.3 Sealing plugs for AKD-N connectors 23

4.4.4 Connector Kit forAKD-C 23

4.4.5 Cabinet connector coupling for AKD-C/N 23

5 Shield clamps 24

5.1 Auxiliary terminals on the servo amplifier 24

5.2 External shielding busbar 25

6 Mains chokes 26

6.1 General 26

6.2 Important notes 26

6.3 Type assignment and order codes 26

6.4 Mains choke 3L 27

7 Mains filters 28

7.1 General 28

7.2 Important notes 28

7.3 Type assignment and order codes 28

7.4 Mains filters 1NF-10...12 29

7.5 Mains filters 1NF-20B, 1NF-25 30

Kollmorgen | December 2014 3

Accessories Europe | Table of Contents

7.6 Mains filters 3NF-07...30 31

7.7 Mains filters 3EF-42...130 32

8 Brake resistors 33

8.1 General 33

8.2 Important notes 33

8.3 Type assignment and order codes 34

8.4 External brake resistor BAFP(U) 35

8.5 External brake resistor BAR(U) 36

8.6 External brake resistor BAS(U) 37

9 Capacitor Modules 38

9.1 General 38

9.2 Important notes 38

9.3 Type assignment and order codes 39

9.4 Example installation with AKD-P, KCM-P and KCM-E 39

9.5 KCM Module 40

10 Motor chokes 41

10.1 General 41

10.2 Important notes 42

10.3 Type assignment and order codes 42

10.4 Motor choke 3YL-24 43

10.5 Motor choke 3YLN-xx 44

11 Cables 45

11.1 Technical data for cables 45

11.2 Tools 45

11.3 PC connection 46

11.3.1 AKD 46

11.3.2 S300, S400, S600, S700 46

11.4 Power Voltage Supply, external brake resistor, DC bus link 48

11.4.1 Mating connector (part of delivery) 48

11.4.2 Mating connector (optional) 48

11.4.3 Recommended cable type 49

11.4.4 Preparingcables for AKD/S300/S400/S601...620/S700 49

11.4.5 Preparingcables for S640/670 and S748/772 51

11.5 24V auxiliary voltage supply 52

11.5.1 Mating connector (part of delivery) 52

11.5.2 Recommended cable type 52

11.5.3 Preparingcables 53

11.6 Digital/analog Inputs/Outputs 54

11.6.1 Digital In/Outputs for AKD-C 54

11.6.2 Digital In/Outputs for AKD-N 54

11.6.3 Digital/analog I/O for S300/S400/S600/S700 and AKD-B/P/T/M 55

11.6.4 Preparingcables 56

11.7 Encoder Emulation, Stepper motor control, Master-Slave 57

11.7.1 Mating connector, cable type 57

11.7.2 Connection 57

4 Kollmorgen | December 2014

Accessories Europe | Table of Contents

11.7.3 Termination resistors 57

11.7.4 Preparingcables 58

11.8 Ethernet cable 59

11.8.1 Order codes Ethernet cable, configured 59

11.9 CAN bus cable 60

11.9.1 CAN bus cable AKD 60

11.9.2 Can bus cable for S300/S400/S600/S700 60

11.10 Hybrid cables 62

11.10.1 AKD to AKM1 Motor (i-tec connector) 62

11.10.2 AKD to AKM2-6 (IP65 connector) 63

11.10.3 AKD-C to AKD-N in the decentralizeddrive system 65

11.10.4 AKD-N to AKD-N in the decentralizeddrive system 65

11.11 Motor cables 66

11.11.1 General 66

11.11.2 Motor cables, configured 66

11.11.2.1 Order codes motor cables for S300 67

11.11.2.2 Order codes motor cables for S400 67

11.11.2.3 Order codes motor cables for S601...620 68

11.11.2.4 Order codes motor cables for S701-712 69

11.11.2.5 Order codes motor cables for S724 70

11.11.2.6 Order codes motor cables for S748, S640/670 70

11.11.2.7 Order codes motor cables for AKD-B/P/T/M 72

11.11.2.8 Order codes motor cables for AKD-N 74

11.11.3 Preparing motorcables (motorend) 75

11.11.3.1 Motor series AKM2...8, 6SMx7, DBL2...6, DBK 75

11.11.3.2 Motor series AKM8, DBL7/8 75

11.11.4 Preparing motorcables (servo amplifier end) 77

11.11.4.1 Preparing cables for S300/S400 77

11.11.4.2 Preparing cables for S601...620 78

11.11.4.3 Preparing cables for S701...724 79

11.11.4.4 Preparing cables for AKD-x00306/x00606 79

11.11.4.5 Preparing cables for AKD-x01206/X02406/X0xx07 80

11.11.4.6 Preparing cables for S640/670 and S748/772 80

11.12 Feedback cables 82

11.12.1 Resolver cables 82

11.12.1.1 Resolver cables for S300/S400/S600/S700 82

11.12.1.2 Resolver cable for AKD 83

11.12.2 SFD cables for AKD 83

11.12.3 Encoder cables 84

11.12.3.1 Encoder cables for S300/S400/S600/S700 84

11.12.3.2 Encoder cables for AKD 85

11.12.4 ComCoder cables 86

11.12.4.1 ComCoder cables for S300/S400/S600/S700 86

11.12.4.2 Comcoder cables for AKD 87

Kollmorgen | December 2014 5

Accessories Europe | Table of Contents

This page intentionally left blank.

6 Kollmorgen | December 2014

2 General

2.1 About this manual

This manual describes accessories for Kollmorgen digital servo amplifiers. It contains essential technical data. The manual is only valid in conjunction with the instructions manual for

the servo amplifier and servo motor you are using in your application.

You will find copies of theinstructions manual for Kollmorgenservo amplifiers and servo

motors on the CD ROM included in the scope of supply and on our Internet site. The documents are available in Acrobat Reader format in multiple languages (system requirements:

WINDOWS, Internet browser, Acrobat Reader).

Servo amplifier product family names appear in abbreviated format:

Servo amplifier Abbreviation Servo amplifier Abbreviation

SERVOSTAR 300 S300 S701...724 S701...724

SERVOSTAR 400 S400 S748/772 S748/772

SERVOSTAR 601...620 S601...620 AKD-xyyyzz AKD

SERVOSTAR 640...670 S640...670

Accessories Europe | 2 General

More detail information can be found in the "European Product WIKI" available at www.wiki-

kollmorgen.eu.

2.2 Hints for the online edition (PDF format)

Bookmark:

Table of contents and index are active bookmarks.

Table of contents and index in the text:

The lines are active cross references. Click on the desired line and the appropriate page is

indicated.

Page/chapter numbers in the text:

Page/chapter numbers with cross references are active. Click at the page/chapter numberto

reach the indicated target.

Kollmorgen | December 2014 7

Accessories Europe | 2 General

2.3 Safety Notes

This section helps you to recognize and avoid dangers to people and objects.

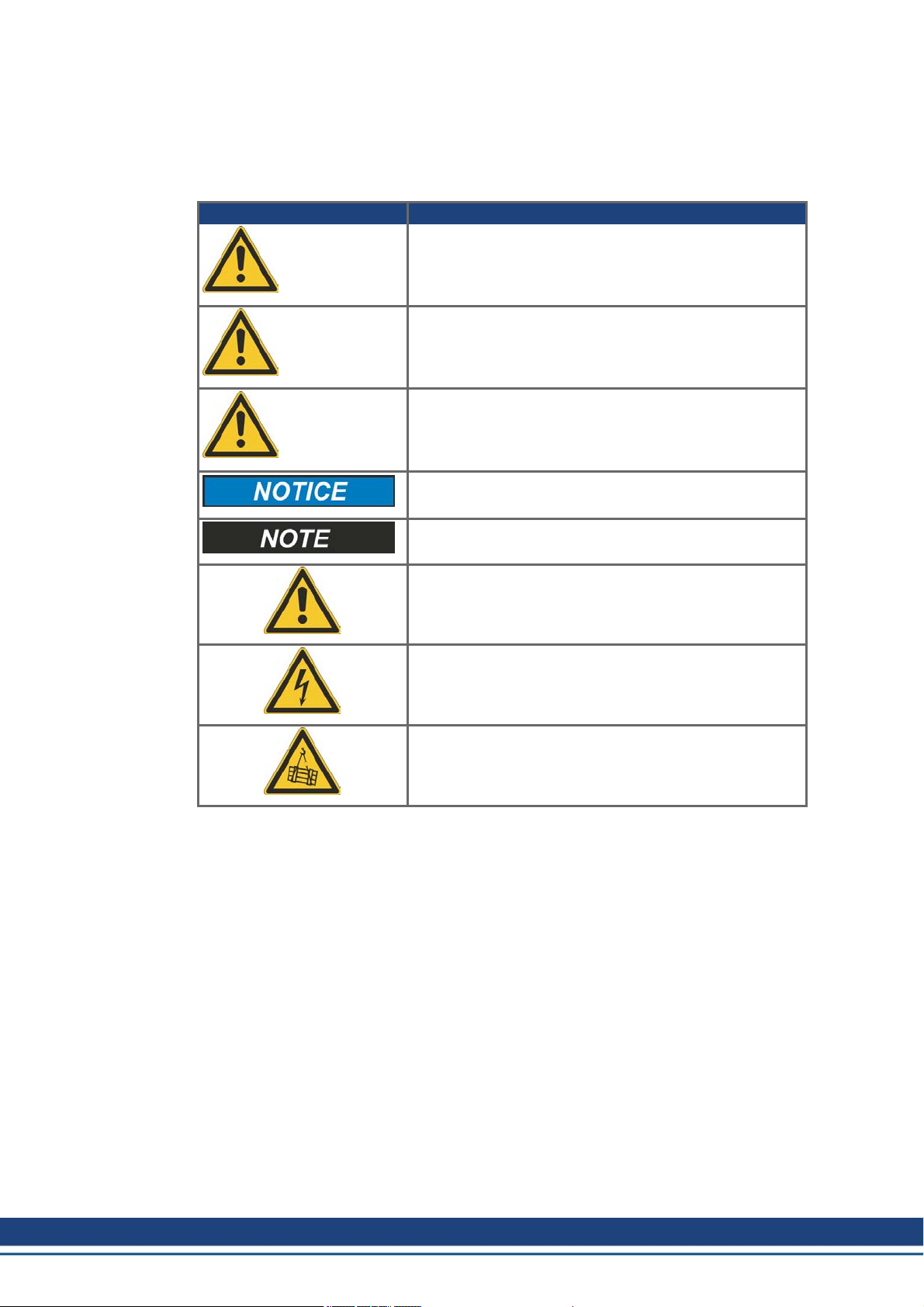

2.3.1 Symbols Used

Symbol Indication

Indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

DANGER

Indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

WARNING

Indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

CAUTION

Indicates situations which, if not avoided, could result in

property damage.

This symbol indicates important notes.

Warning of a danger(general). The type of danger is specified by the text next to the symbol.

Warning of dangerfrom electricity and its effects.

Warning of suspended loads.

8 Kollmorgen | December 2014

2.3.2 You should pay attention to this

Read the documentation!

Read the available documentation before installation and commissioning. Improper handling

of the devices can cause harm to people or damage to property. The operator must therefore

ensure that all persons entrusted to work on the devices have read and understood the

manual and that the safety notices in this manual are observed.

Always observe the whole drive system built with servo amplifier, cables, motor, accessories (filters, chokes, etc.). This means, that all documentation which exist for the components, must be available, must be read and must be understood.

Pay attention to the technical data!

Adhere to the technical data and the specifications on connection conditions (ratingplate and

documentation). If permissible voltage values or current values are exceeded, the devices

can be damaged, e.g. through overheating.

Specialist staff required!

Only properly qualifiedpersonnel are permitted to perform such tasks as transport,

assembly, setup and maintenance. Qualified specialist staff are persons who are familiar

with the transport, installation, assembly, commissioning and operation of power electronics

andwho bringtheir relevant minimum qualifications to bear on their duties. The qualified personnel must know and observe IEC 60364 / IEC 60664 and national accident prevention regulations.

Additional requirements on specialist staff may also result from the risk assessment.

Hot surface!

Some devices can reach temperatures of up to 250°C during operation. Touching them can

result in burns. Observe the permissible mounting position and ensure that a sufficient distance is maintained from neighboring assemblies.

Accessories Europe | 2 General

Earthing!

It is vital that you ensure that the device housing is safely earthed to the PE (protective

earth) busbar in the switch cabinet. Without low-resistance earthing no personal protection

can be guaranteed and there is a risk of death from electric shock.

High voltages!

Keep the switching cabinet closed when the equipment is in operation. Not having optical displays does not guarantee an absence of voltage. Power connections may carry voltage even

if the motor is not turning.

Do not unplug any connectors during operation. There is a risk of death or severe injury from

touching exposed contacts. Power connections may be live even when the motor is not rotating. This can cause flashovers with resultinginjuries to persons and damage to the contacts.

DC Bus link connections can carry dangerous voltage levels over an hour after the line

voltage has been switched off (self-discharge time). Danger of death from electric shock.

Beforecommencing work on the modules’ power terminals, check the voltage at the connection terminals is de-energized to ground and to each other.

.

Kollmorgen | December 2014 9

Accessories Europe | 3 Digital Drive Systems

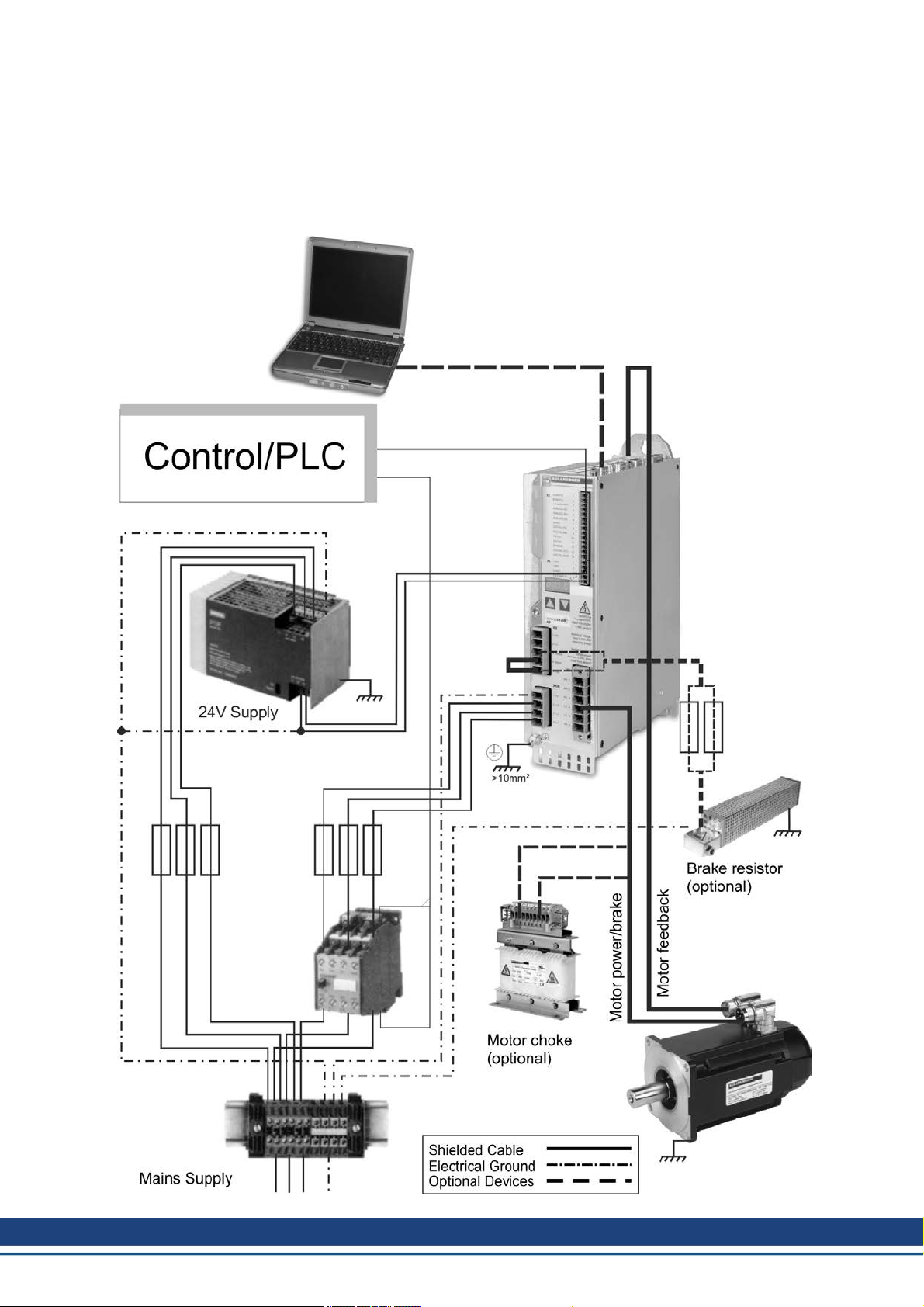

3 Digital Drive Systems

The systems shown are simply a possible scenario for setting up a digital drive system with

relevant servo amplifier components.

3.1 Drive System with S300

10 Kollmorgen | December 2014

3.2 Drive System with S400

Accessories Europe | 3 Digital Drive Systems

Kollmorgen | December 2014 11

Accessories Europe | 3 Digital Drive Systems

3.3 Drive System with S601...620

12 Kollmorgen | December 2014

3.4 Drive System with S640...670

Accessories Europe | 3 Digital Drive Systems

Kollmorgen | December 2014 13

Accessories Europe | 3 Digital Drive Systems

3.5 Drive System with S701...724

14 Kollmorgen | December 2014

3.6 Drive System with S748/772

Accessories Europe | 3 Digital Drive Systems

Kollmorgen | December 2014 15

Accessories Europe | 3 Digital Drive Systems

3.7 Drive System with AKD-x00306...02406

16 Kollmorgen | December 2014

3.8 Drive System with AKD-x00307...02407

Accessories Europe | 3 Digital Drive Systems

Kollmorgen | December 2014 17

Accessories Europe | 3 Digital Drive Systems

3.9 Drive System with AKD-x04807

18 Kollmorgen | December 2014

Accessories Europe | 3 Digital Drive Systems

3.10 Decentralized Drive System with AKD-C and AKD-N

All components inside the borders aresuppliedby Kollmorgen with the exception of cables

signedwith "x". These cables are not suppliedby Kollmorgen, you should use cables or

wires according to EN 60204.

Kollmorgen | December 2014 19

Accessories Europe | 4 Mechanical Accessories

4 Mechanical Accessories

4.1 Mounting Kit for AKMH Motors

IEC mounting kits with 1 shaft center screw and 4 flangescrews. Hygienic mounting is possible only with these screws.

Description Order Code

Mounting Hardware AKMH2, Ax flange / Cx front mounting MTG-KIT-AKMH2-IEC

Mounting Hardware AKMH3, Ax flange / Cx front mounting MTG-KIT-AKMH3-IEC

Mounting Hardware AKMH4, Ax flange / Cx front mounting MTG-KIT-AKMH4-IEC

Mounting Hardware AKMH5, Ax flange / Cx front mounting MTG-KIT-AKMH5-IEC

Mounting Hardware AKMH6, Ax flange / Cx front mounting MTG-KIT-AKMH6-IEC

NEMA mounting kits are described in the US selection guide, available from the Kollmorgen

website www.kollmorgen.com).

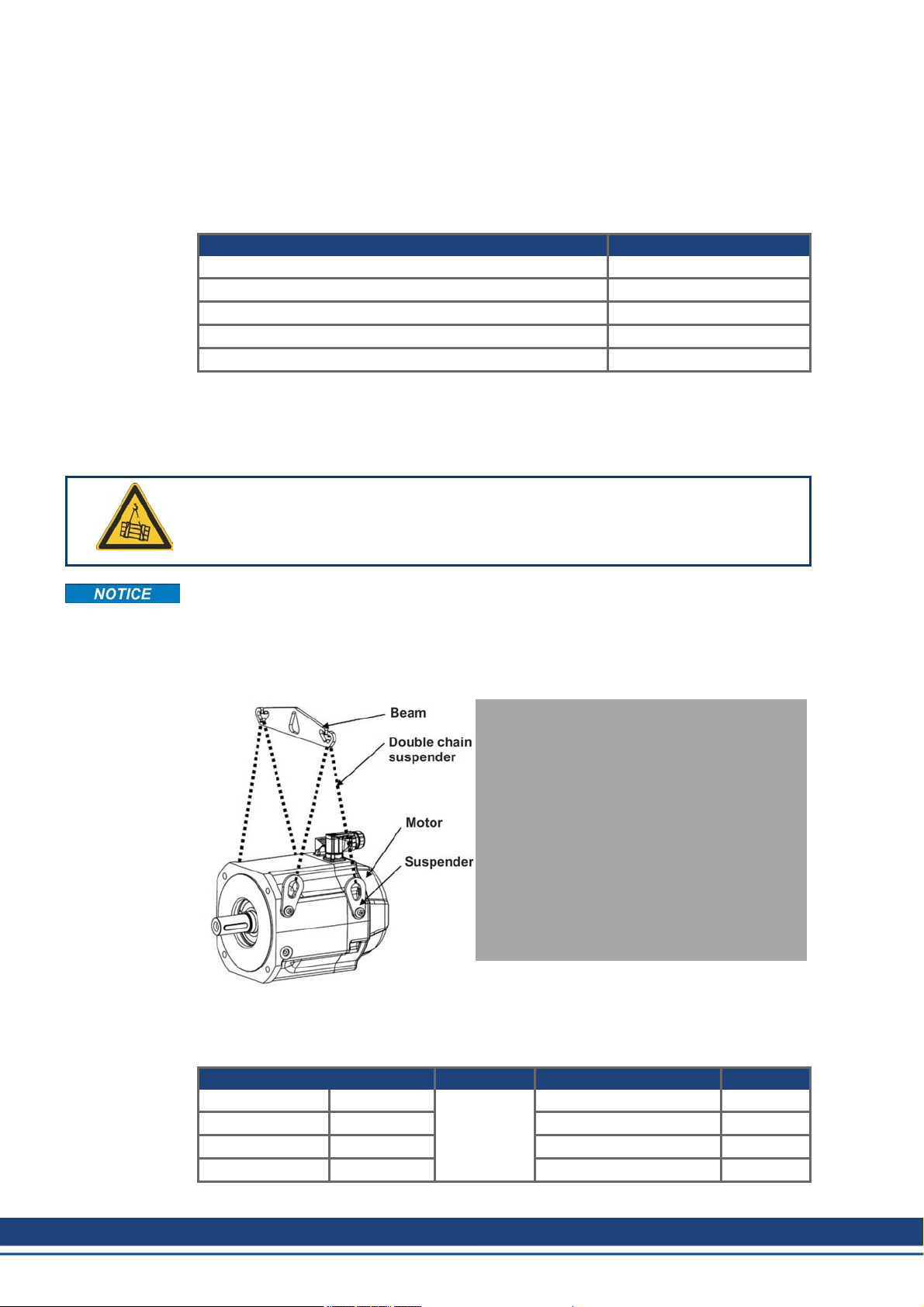

4.2 Suspension Unit for AKM motors

DANGER

Suspended load. Risk of death if load falls. Never step under the load,

while the motor is raised!

You must read the instructions manual for the suspension unit ZPMZ 120/292. Observe the

"safety instructions" and "use as directed" hints before starting transportation work.

The Suspension Unit ZPMZ 120/292 is designed for suspended handlingexclusively of

motors (i.e., without attached units such as gearboxes, clutches, etc.) with a maximum

weight of 120 kg and maximum nominal span of the extreme suspension hooks of 292 mm.

The suspended unit consists of a Beam, suspended off the crane hook and two double-run

chain suspenders. The motormay be borne on two or four runs of thechain suspender.

The suspenders (number depends on the motor type) are delivered with the motor.

Technical Data

Lifting capacity 120kg Weight 0,83 kg

Nominal span 292 mm Number of cycles a year 20.000

Lugwidth 44,7 mm Average load 60 %

Lugheight 51 mm Order code FA00092

20 Kollmorgen | December 2014

4.3 Fan Kit for AKM7 motors

Observe the mounting instructions delivered with the fankit. The fan housing can be mounted either with both the supplied brackets andspacers or with the brackets only. The choice

of mounting method depends on the application. If strong vibrations are expected, you should

use both brackets and spacers. Motors with integrated brakes require the longs spacers.

Mounting the fan kit enlarges the motor by approximately 65 mm. The detailed final dimensions of AKM7 motors with mounted fan kit can be found in the instructions manual of the

AKM motor series. Ventilation of AKM7 motors allow increased current of the motors. This

higher current usually requires larger wiring cross section compared to not ventilated motors.

The necessary data for current and wiring cross section can be found in the technical data

section of the AKM instructions manual.

Technical Data

Supply voltage 24 VDC

Supply current 270mA

Electrical power 6.5 W

Surface Coated with polyester powder coating in matt black, not resistant

Protection class IP 20

Connection Cable gland 10 mm, cable diameter 4 mm to 6 mm, recommended cable

Terminals 0.33 mm² to 4 mm²

Weight 2.52 kg

Order code AKM7-FAN

Accessories Europe | 4 Mechanical Accessories

against solvents

3x0.75 mm² (not part of delivery)

Kollmorgen | December 2014 21

Accessories Europe | 4 Mechanical Accessories

4.4 Mechanical accessories for AKD-N and AKD-C

You must read the AKD-N/AKD-C installation manuals. Observe the safety instructions

given there before commencing mounting/installation work.

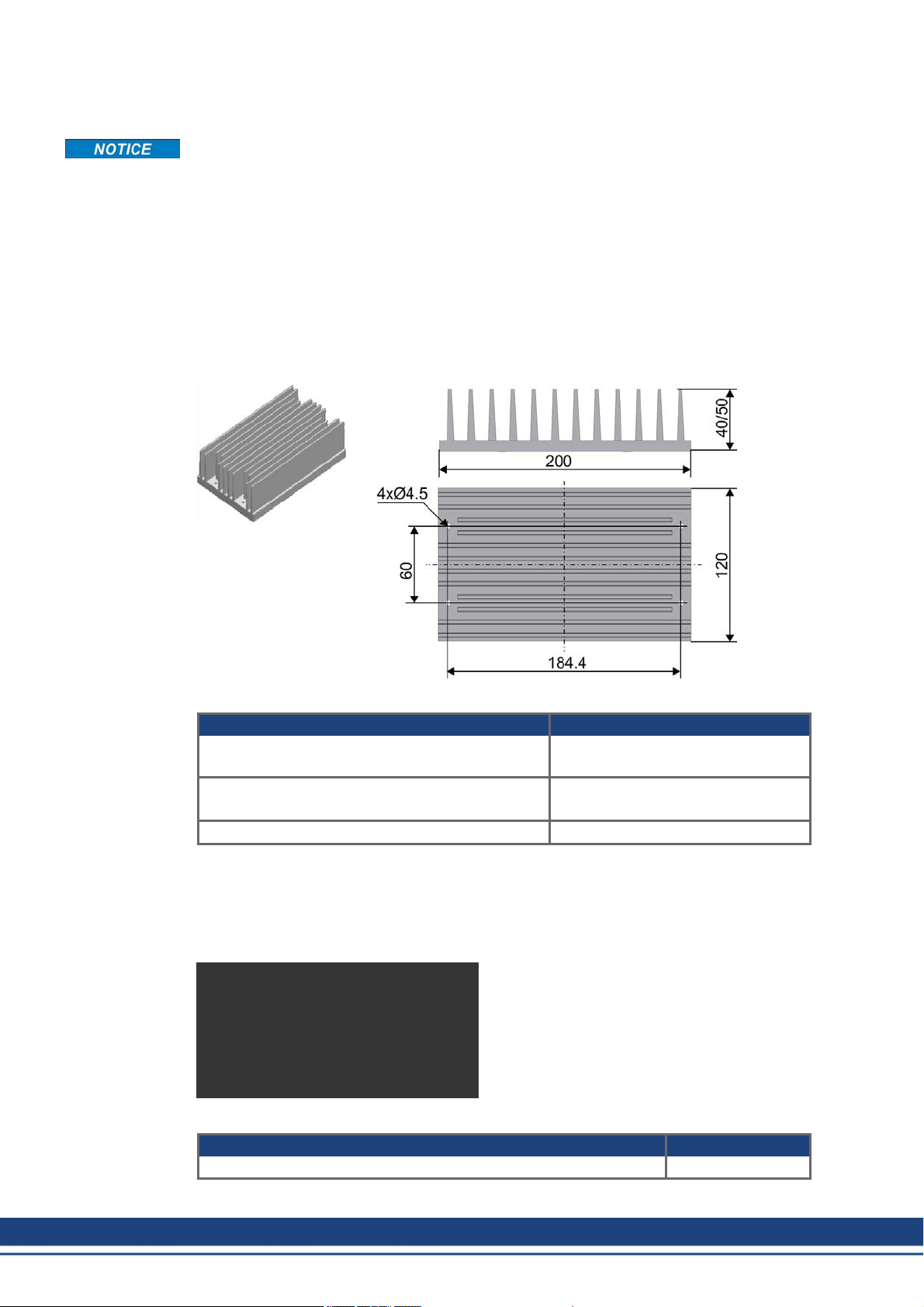

4.4.1 Heat Sink for AKD-N

When mounting AKD-N to themachinery, temperature management is important to ensure

maximum performance of the drive system. In case of medium or bad cooling situation (as

described in the AKD-N Installation Manual), youcan mount a heat sink to the AKD-N.

Heat flow is optimized by a heat conducting film, which must be placed between heat sink

andAKD-N.

Mounting holes in the heat sink and winding holes in the AKD-N are prepared for M4x16

hexagon socket screws to ISO 4762. Use a 3 mm T-handle Allen key for mounting.

Order Codes

Article Order codes

Heat sink Kit 40 mm with Heat conducting film and

4 screws M4x16

Heat sink Kit 50 mm with Heat conducting film and

4 screws M4x16

Heat conducting film 849-373000-04

4.4.2 Mounting clamps for AKD-N

The AKD-N servo amplifier is mounted to the machine with special mounting clamps. The

delivery package contains 4 clamps. In case of lost or damaged clamps, you can ordera set

of four clamps.

Order Codes

Article Order codes

AKD-N Mounting Clamps Set, 4 clamps AKD-N-M/C-Set

AKD-N 3,6 HEATSINK KIT 40MM

AKD-N 3,6 HEATSINK KIT 50MM

22 Kollmorgen | December 2014

4.4.3 Sealing plugs for AKD-N connectors

The sealing plugs in the delivery package are screwed to unused AKD-N connectors to

ensure the IP class for the machine environment. In case of lost plugs, you can order a set

with 3 different plug sizes.

Order Code

Article Order Codes

AKD-N Sealing Plug Set, 4xM12, 2xM23, 2xM17 AKD-N-S/P-Set

4.4.4 Connector Kit for AKD-C

Mating connectors X12, X13, X14, X15, and X17 are part of delivery. If a mating connector is

lost or damaged, you can order the AKD-C Connector Kit.

Order Code

Accessories Europe | 4 Mechanical Accessories

Article Order Codes

AKD-N Connector Kit, included matingconnectors X12, X13, X14,

X15, and X17

4.4.5 Cabinet connector coupling for AKD-C/N

The connector couplingmust be built into the outer wall of a cabinet. The connector coupling

connects powerand signal lines as well as shielding of the hybrid cables and ensures the

long-term sealed transition between cabinet environment (IP54) and machine environment

(IP65/67).

Inside the cabinet the CCNCN1 cable (➜ p. 65) to AKD-C can be plugged in, outside the

cabinet the CCNNN1 cable (➜ p. 65) to AKD-N can be plugged in.

Order Codes

Article Order Codes

Hybrid Connector Coupling AKD-C/AKD-N AKD-CN-Coupling*

*in process

AKD-C-CONKIT

Kollmorgen | December 2014 23

Accessories Europe | 5 Shield clamps

5 Shield clamps

You must read the instructions manuals for the servo amplifier/servo motor you areusing in

your application. Observe the safety instructions they contain before commencing mounting/installation work.

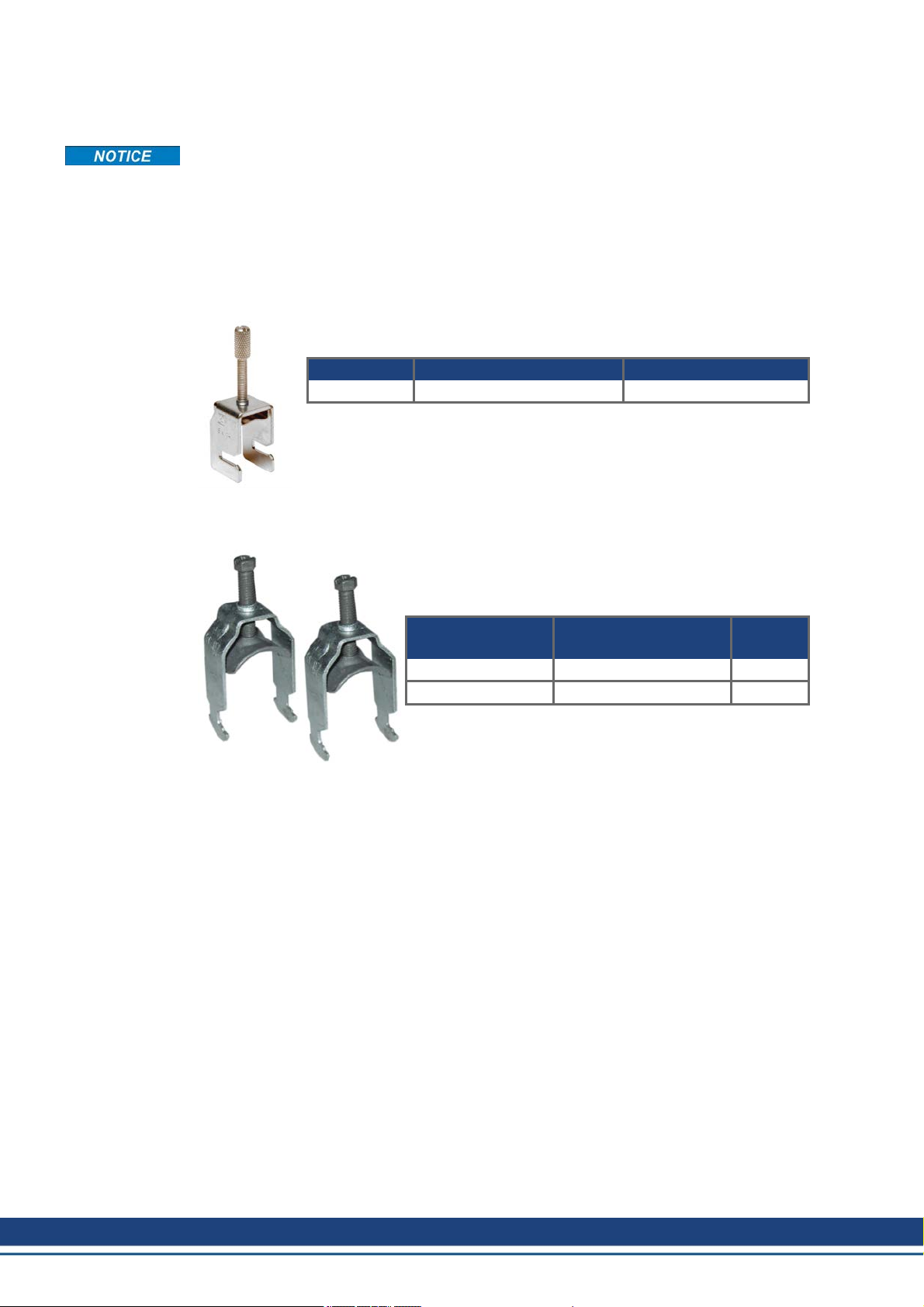

5.1 Auxiliary terminals on the servo amplifier

S300, S701...724 and AKD

These servo amplifiers feature slots on the front panel for the connection of

additional shield clamps.

Article Tension range Order Codes

SK14 6-13mm DE-108248

S640/670, S748/772

The shroud supplied with these servo amplifiers features

slots for the connection of additional shield clamps.

We recommend using the following shield clamp:

Manufacturer Article Tension

range

OBO (Bettermann) BBS-Schelle Typ 2056 16-22mm

OBO (Bettermann) BBS-Schelle Typ 2056 28-34mm

The clamps are part of delivery of the servo amplifier.

24 Kollmorgen | December 2014

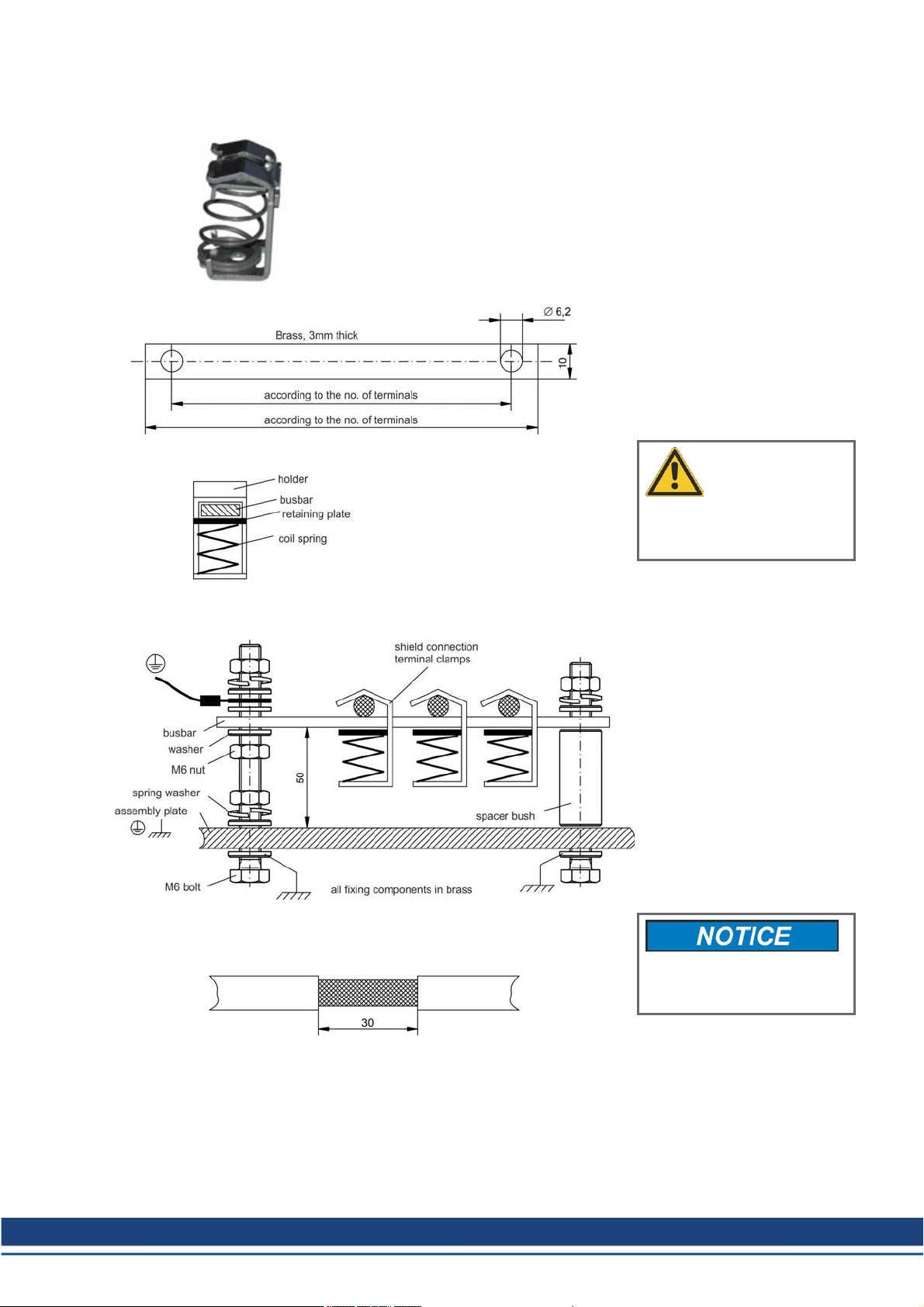

5.2 External shielding busbar

Accessories Europe | 5 Shield clamps

The power cable shields (line in, motor cable, external regen resistor)

can be routed to an additional busbar via shield clamps.

Kollmorgen recommends using Weidmüller KLBÜ shield clamps.

A possible scenario for setting up a busbar for the above shield

clamps is described below.

1. Cut a busbar of the required

length from a brass rail (cross-section 10 x 3 mm) and drill holes in it

as indicated. All shield clamps

required must fit between the drill

holes.

CAUTION

Risk of injury due to the spring

force of the coil spring. Use pincers.

2. Squeeze together the coil

spring and the supporting plate

and push the busbar through the

opening in the holder.

3. Mount the busbar with the

shield clamps fitted on the

assembly plate. Use either metal

spacer bushes or screws with nuts

and accessories to maintain a spacing of 50 mm. Earth the busbar

using a single conductor with a

cross-section of at least 2.5mm².

4. Strip the external cable sheath

to a length of approximately 30

mm, taking care not to damage

the braided shield. Push the

shield clamp up and route the

cable to it via the busbar.

Make sure there is good contact between the shield clamp

and the braided shield.

Kollmorgen | December 2014 25

Accessories Europe | 6 Mains chokes

6 Mains chokes

You must read the instructions manuals for the servo amplifier and servo motoryou are using

in your application. Observe the safety instructions given there.

6.1 General

A 3L mains choke must be used on S640/670 servo amplifiers in order to reduce mains harmonics.

In special cases, if mains voltage is more than3% asymmetrical, then the S748/772 must be

used with a mains choke. In unfavorable combination of mains impedance and DC bus capacitance the unloaded DC bus may reach voltage up to 800V without choke. For EMC reasons

the chokes should be mounted isolatedto the cabinet. Single conductors can be used for wiring, shielded cables are not required. More information seeWIKI "Mains Choke".

Purpose of mains choke:

l Prevents impermissible loading of semiconductors in the event of rapid current rise during

commutation.

l Prevents voltage dips in the mains voltage causedby commutation.

l Reduces current ripple in the DC link, thereby increasing the service life of the DC link

capacitors.

6.2 Important notes

DANGER

Power terminals are capable of conducting hazardous voltage up to

10minutes after the mains voltage has been disconnected. Risk of electric shock. Before starting work on power terminals, check that the phaseto-earth and phase-to-phase voltages have de-energised.

Due to the high earth leakage currents induced by the system, you should observe the

requirements of EN 61800-5-1 (e.g. fixed installation, ≥ 10 mm² or double protective earth)

when carrying out mounting and installationwork. You must read the instructions manual for

the servo amplifier/servo motor you are using in your application and observe the safety

instructions they contain before commencing mounting/installation work.

Mounting: 50mm free space required above and below the device.

Connection diagram: see servo amplifier instructions manual.

6.3 Type assignment and order codes

Servo amplifier Mains choke

S640/670 (with asymmetrical mains >3% only) 4% uk

S748/772 (with asymmetrical mains >3% only) 2% uk

AKD, S300, S400, S601...620, S701...724 not required

Order Codes

Article uk Order codes

Mains choke 3L0,5-63-4 (0.47mH, 63A) 4% DE-92201

Mains choke 3L0,4-80-4 (0.37mH, 80A) 4% DE-92100

Mains choke 3L0,2-160-4 (0.19mH, 160A) 4% DE-92099

Mains choke 3L0,24-50-2 (0.24mH, 50A) 2% DE-201476

Mains choke 3L0,2-75-2 (0.20mH, 75A) 2% DE-201477

26 Kollmorgen | December 2014

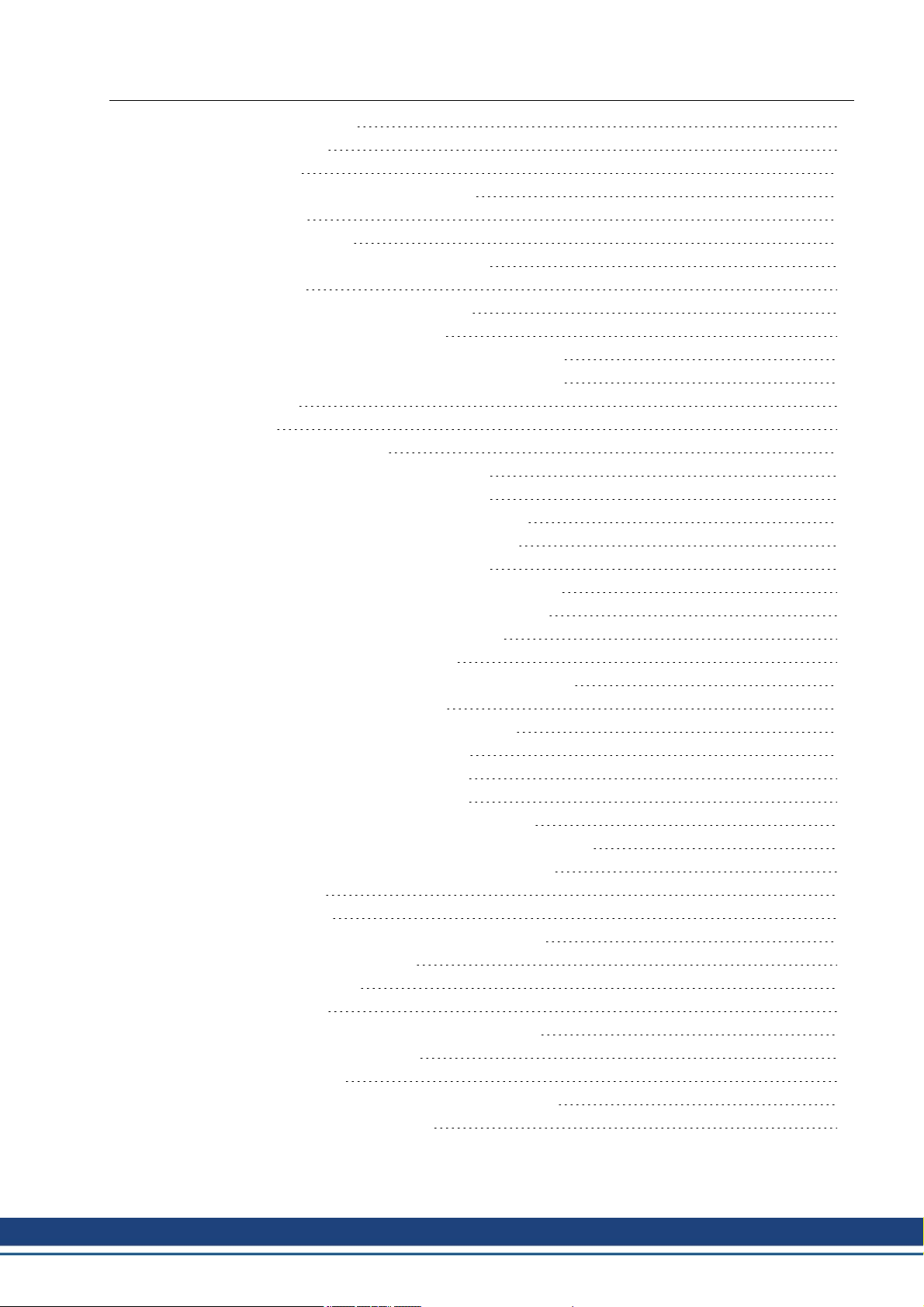

6.4 Mains choke 3L

A number of servo amplifiers can be connected to one and the same mains choke; the rated

current of the mains choke must be greater than or at least equal to the total current of the

connected servo amplifiers.

Accessories Europe | 6 Mains chokes

Photo: 3L0,2-160-4, all models

are similar

Technical Data

Inducti-

Type [mH] [A] [%] [mm] [mm] [mm] [mm] [mm] [mm] [mm²] [kg]

3L 0,5-63-4 0.47 63 4 185 170 77 122 215 8x12 16 9.65

3L 0,4-80-4 0.37 80 4 210 175 85 125 240 8x12 16 12.5

3L 0,2-160-4 0.19 160 4 291 273 116.5 148.5 310 10x18 95 27

3L 0,24-50-2 0.24 50 2 152.5 114.3 88.9 114.3 163 6.5 10 5.9

3L 0,2-75-2 0.20 75 2 185 170 77 122 220 8x12 35 9.9

vity

Nominal

Current

uk A B C D E F Termi-

nals

Weight

Kollmorgen | December 2014 27

Loading...

Loading...