Kollmorgen SERVOSTAR 300, SERVOSTAR 400, SERVOSTAR 601, SERVOSTAR 640, SERVOSTAR 620 User Manual

...Page 1

Accessories for digital drive systems

Manual

Edition: December 2014

Translation of the original document

European Version (CE region)

Keep all manuals as a product component during the life span of the product.

Pass all manuals to future users and owners of theproduct.

Page 2

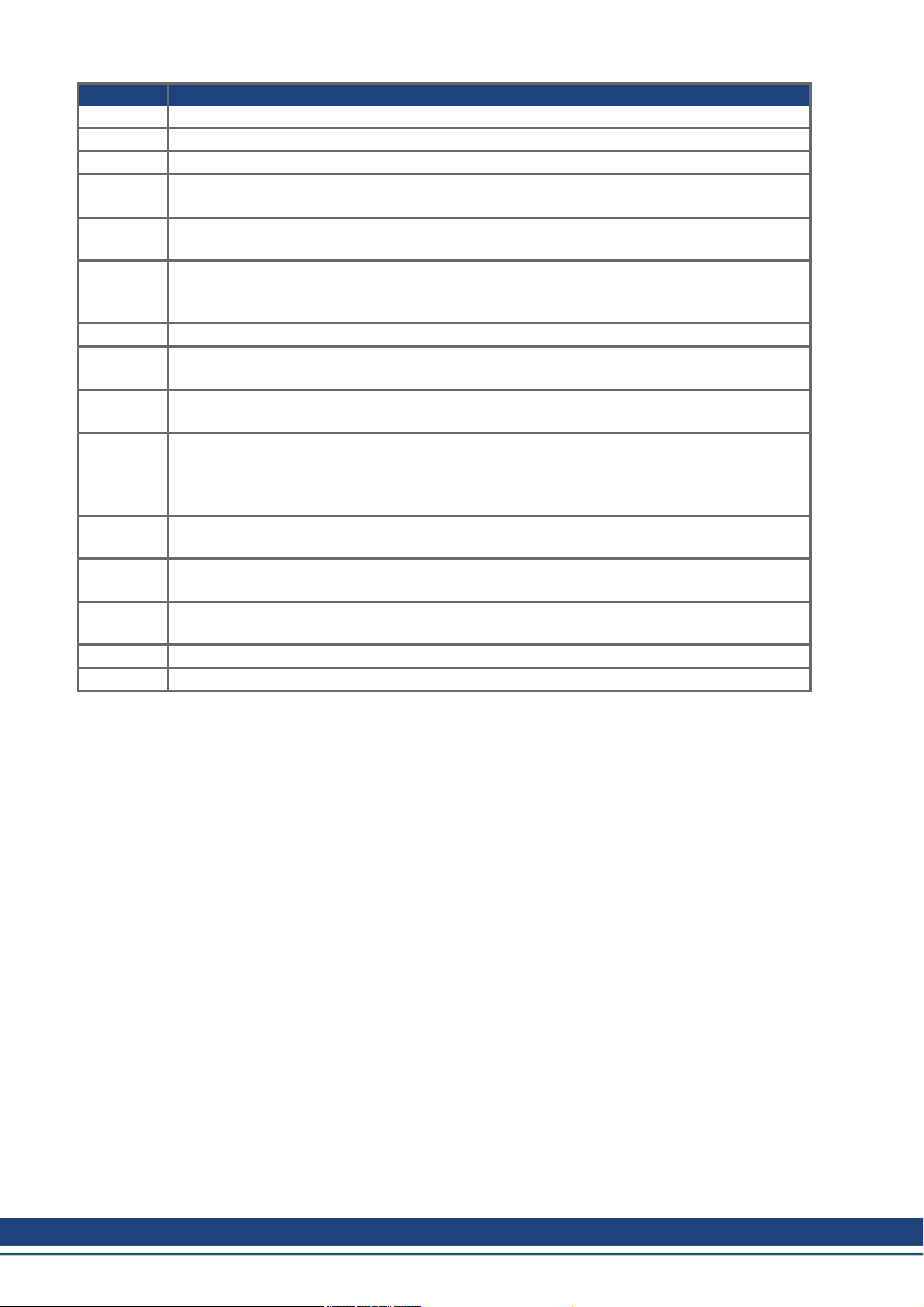

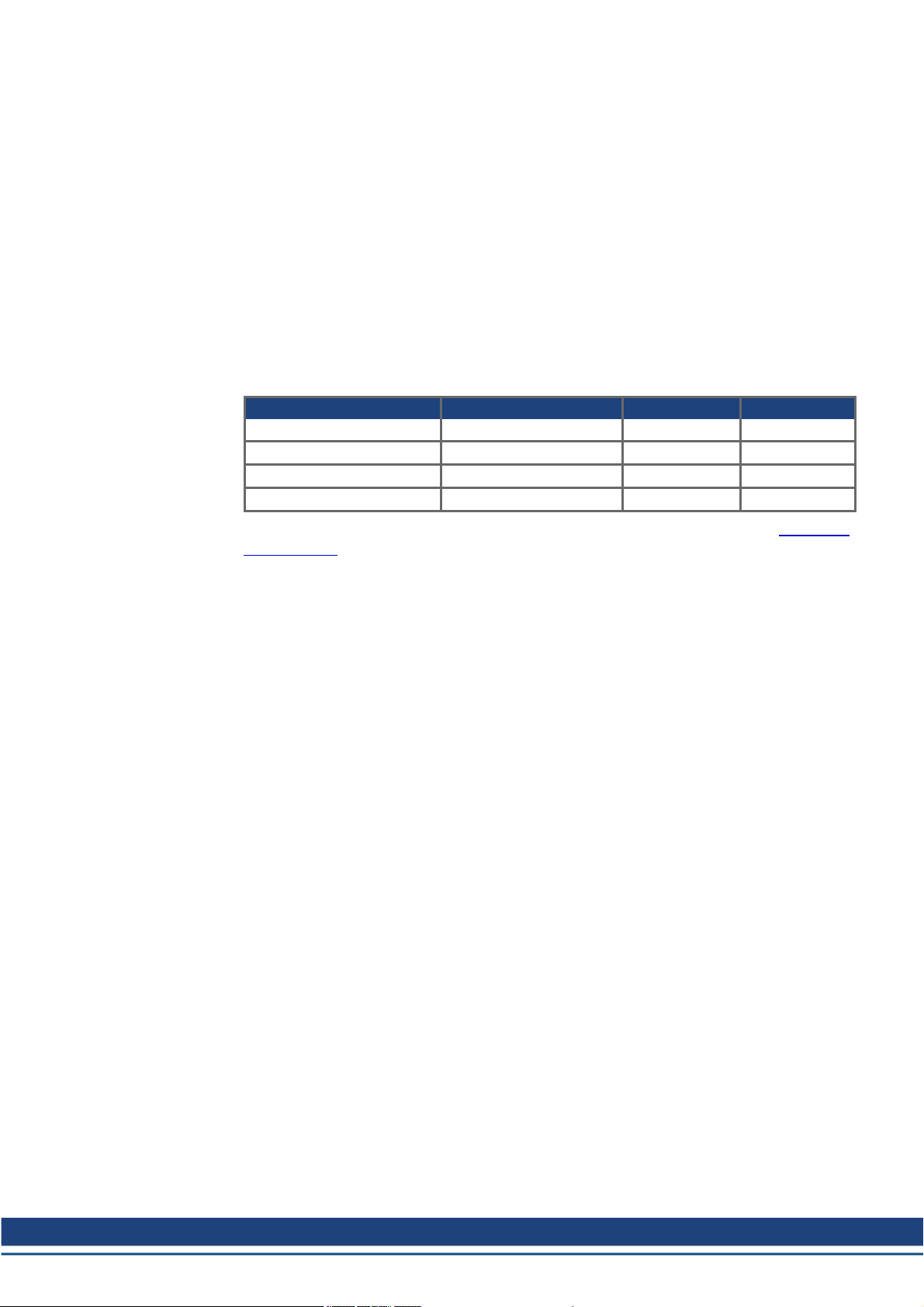

Record of Document Revisions

Edition Comments

04/2007 First edition

07/2007 System S700 updated.

11/2007 Several corrections, connectors added.

Motor cable 1mm² for S700 added, Symbols acc. to ANSI Z535, Y-Connector X0/X8 for S700

03/2008

04/2010

added, configuration of cables, 3YL20->3YL24.

Weight 3YL-24, Product brand, 3YL20 with UL, 3YLN new, S748/772, AKD, Resolver table,

S200 accessories removed.

Order codes brake resistors, Comcoder wire colors, feedback cable color, order codes motor

12/2010

cables, mains filter new types, mains chokes new types, transport tool for AKM8, mounting

clamps for S700, accessories S640/670 removed, 3YL20 removed, company name.

10/2011 Motor cables, cable data, EU order codes mating connectors AKD, AKD Hiperface.

Order codes motor cables S748/772 updated, cable data, combined cables for AKD with SFD,

03/2012

stainless steel connectors for Washdown motors.

SFD cable fotos, all SFD cables to one section, dimensions mains chokes corrected, capacitor

08/2012

modules new, formal improvements

Photos SFD cables, dimensions mains chokes updated, KCM modules new, manufacturing

hints for Kollmorgen cables removed, configured cable tables with photos, typo corrections, fan

05/2013

kit AKM7, mains filter 1NF-20 replaced by 1NF-20B, mounting clamps S700 removed, 24V

mains supply removed, hybrid cables new

11/2013

03/2014

05/2014

Heat sink AKD-N new, Hybrid cables AKD-C/N new, Hybrid cables SFD3/DSL, new Ethernet

cables

New Layout, AKMH mounting kit, KCM updated, AKM7 Fan-Kit updated, hybrid cables

SFD3/DSL added

Length definition of hybrid cables for decentralized systems changed, S700 X8Y set with

X4Amini

08/2014 Brake resistor AKD-x01206 changed, length definitions for decentral hybrid cables updated

12/2014 S640/670 added, AKD-x04807 accessories added

Technical changes which improve the performance of the device may be made without prior notice!

Printed in the United States of America

This document is the intellectual property of Kollmorgen. All rights reserved. No part of this work may be reproduced in any form (by photocopying, microfilm or any other method) or stored, processed, copied or distributed

by electronic means without the written permission of Kollmorgen.

2 Kollmorgen | December 2014

Page 3

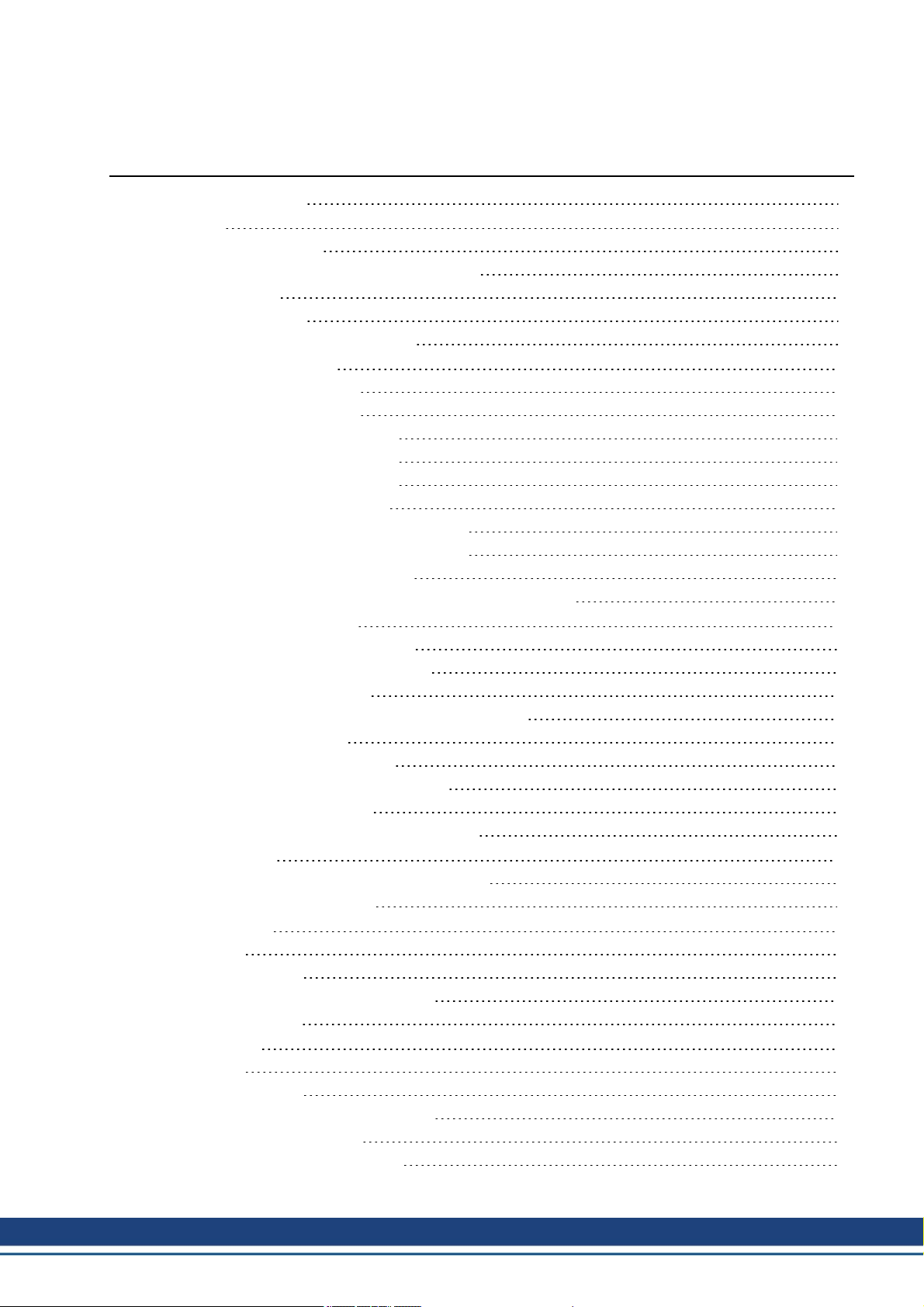

Accessories Europe | Table of Contents

1 Table of Contents

1 Table of Contents 3

2 General 7

2.1 About this manual 7

2.2 Hints for the online edition (PDF format) 7

2.3 Safety Notes 8

2.3.1 Symbols Used 8

2.3.2 You should pay attention to this 9

3 Digital Drive Systems 10

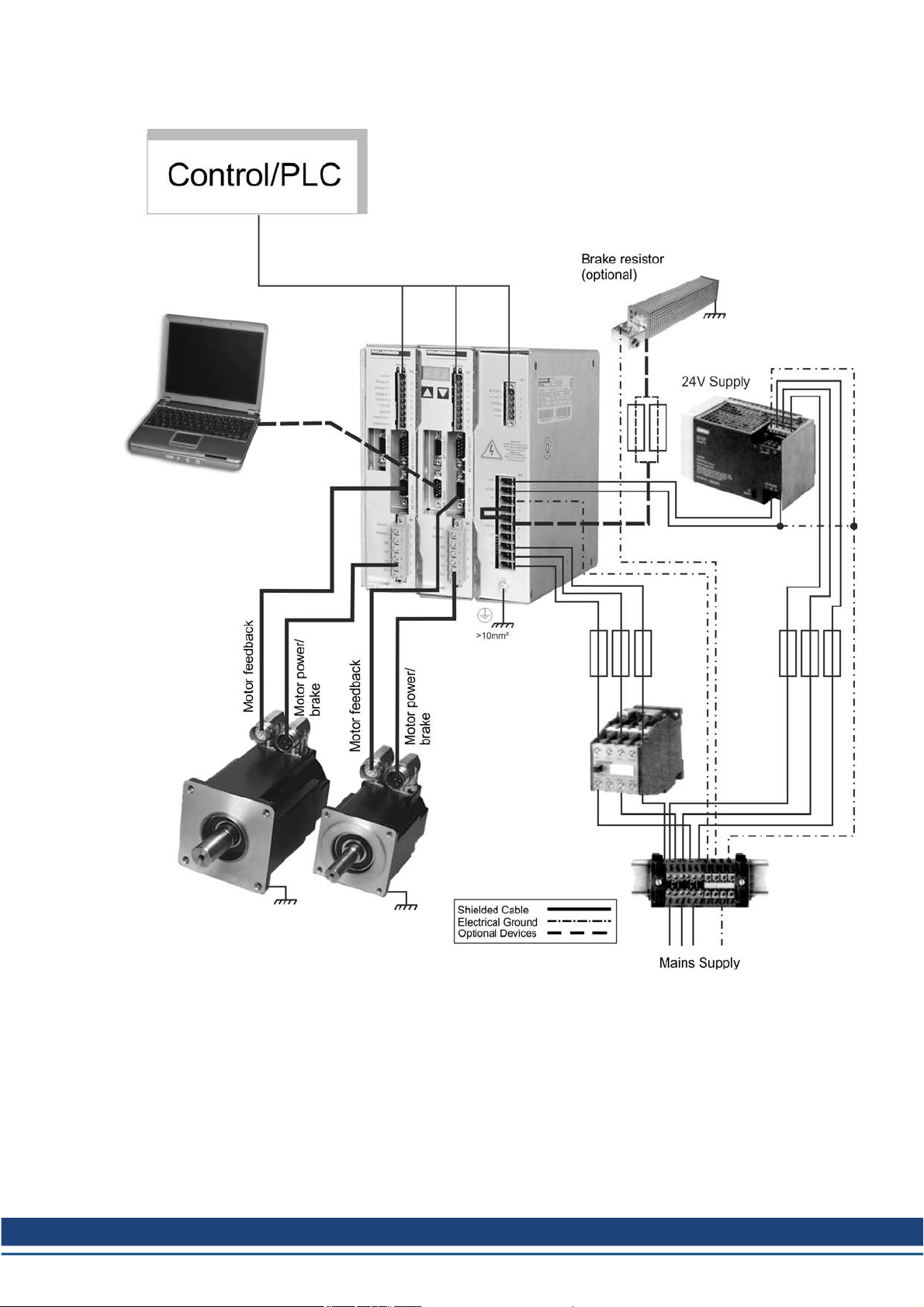

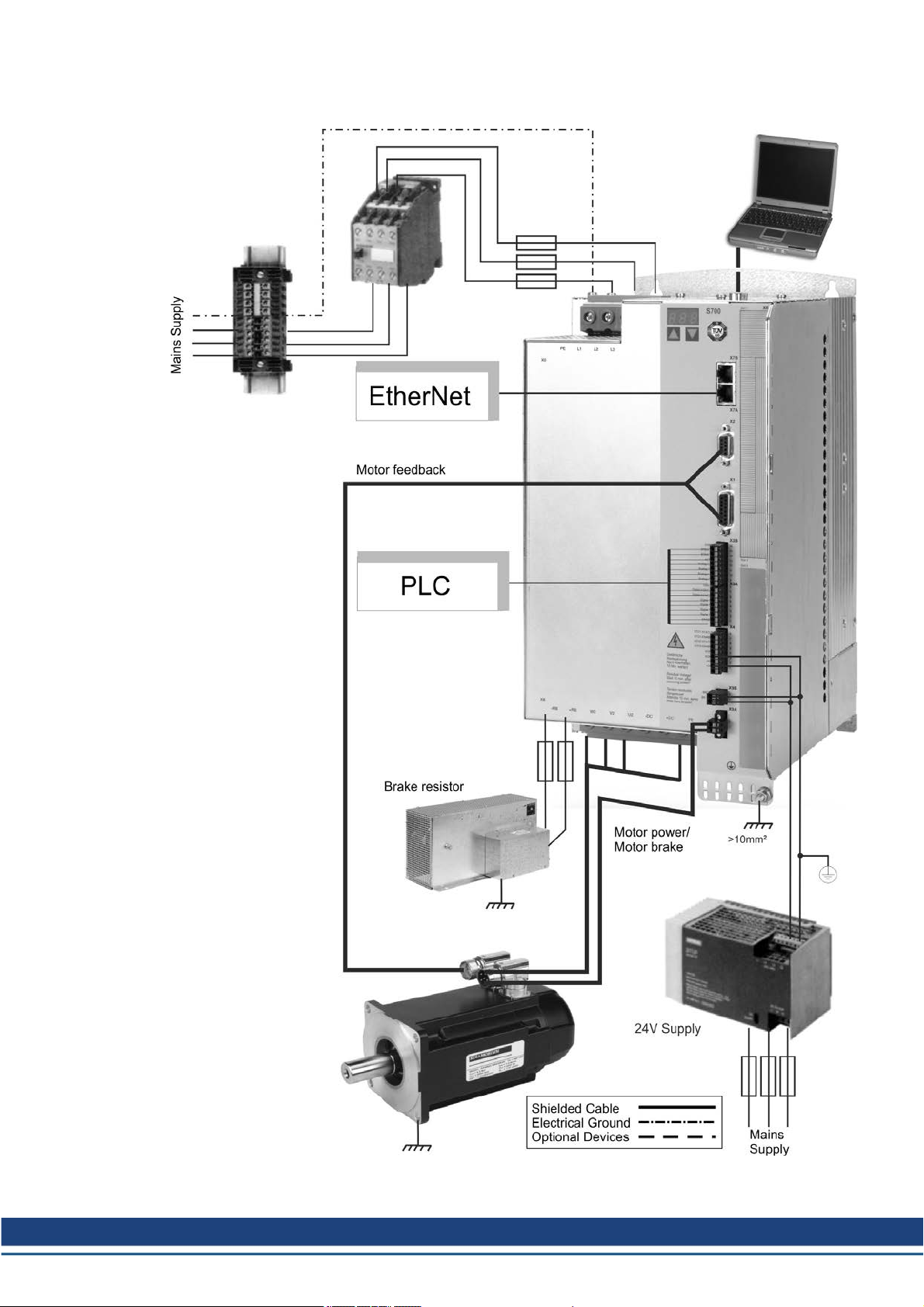

3.1 Drive System with S300 10

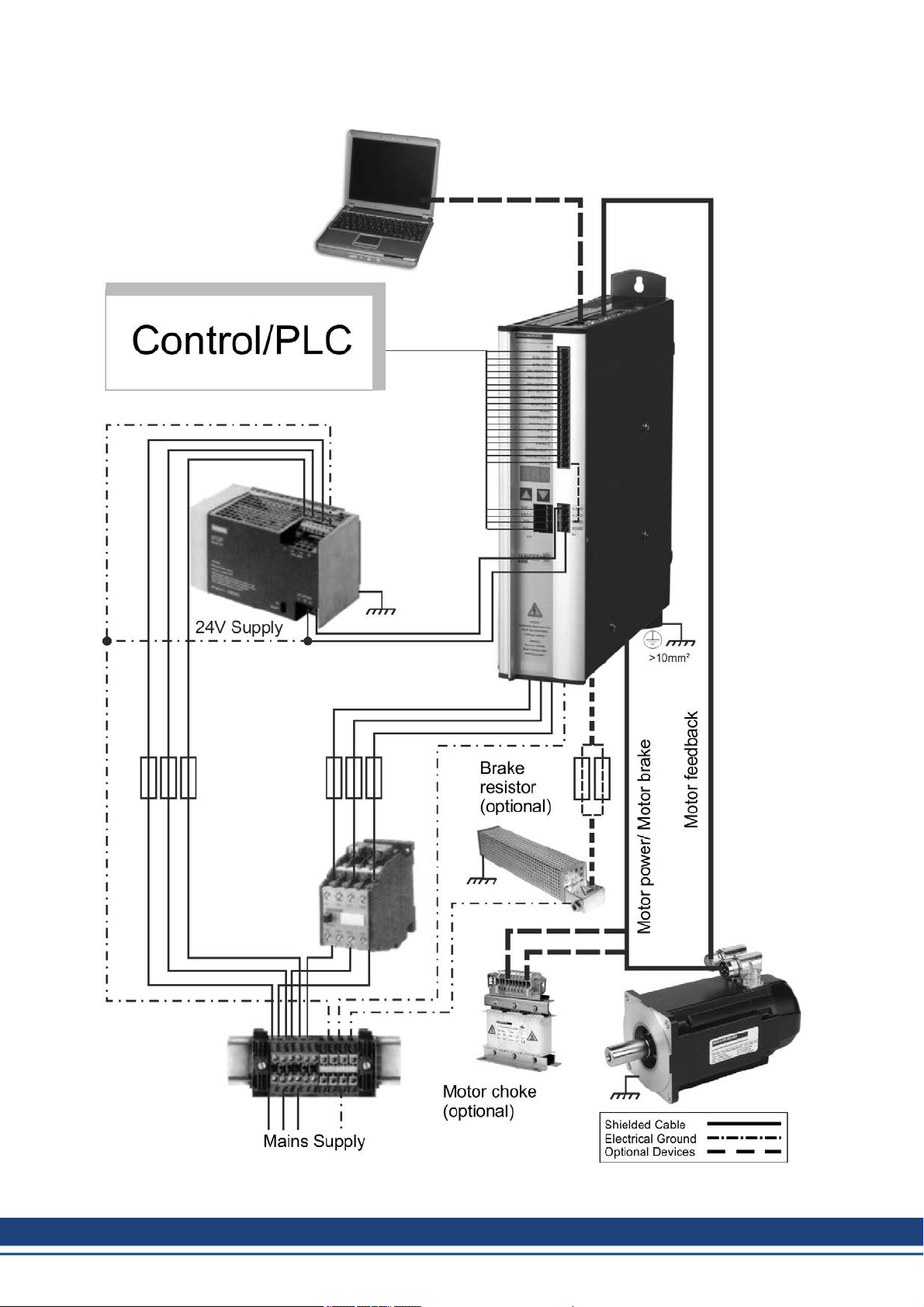

3.2 Drive System with S400 11

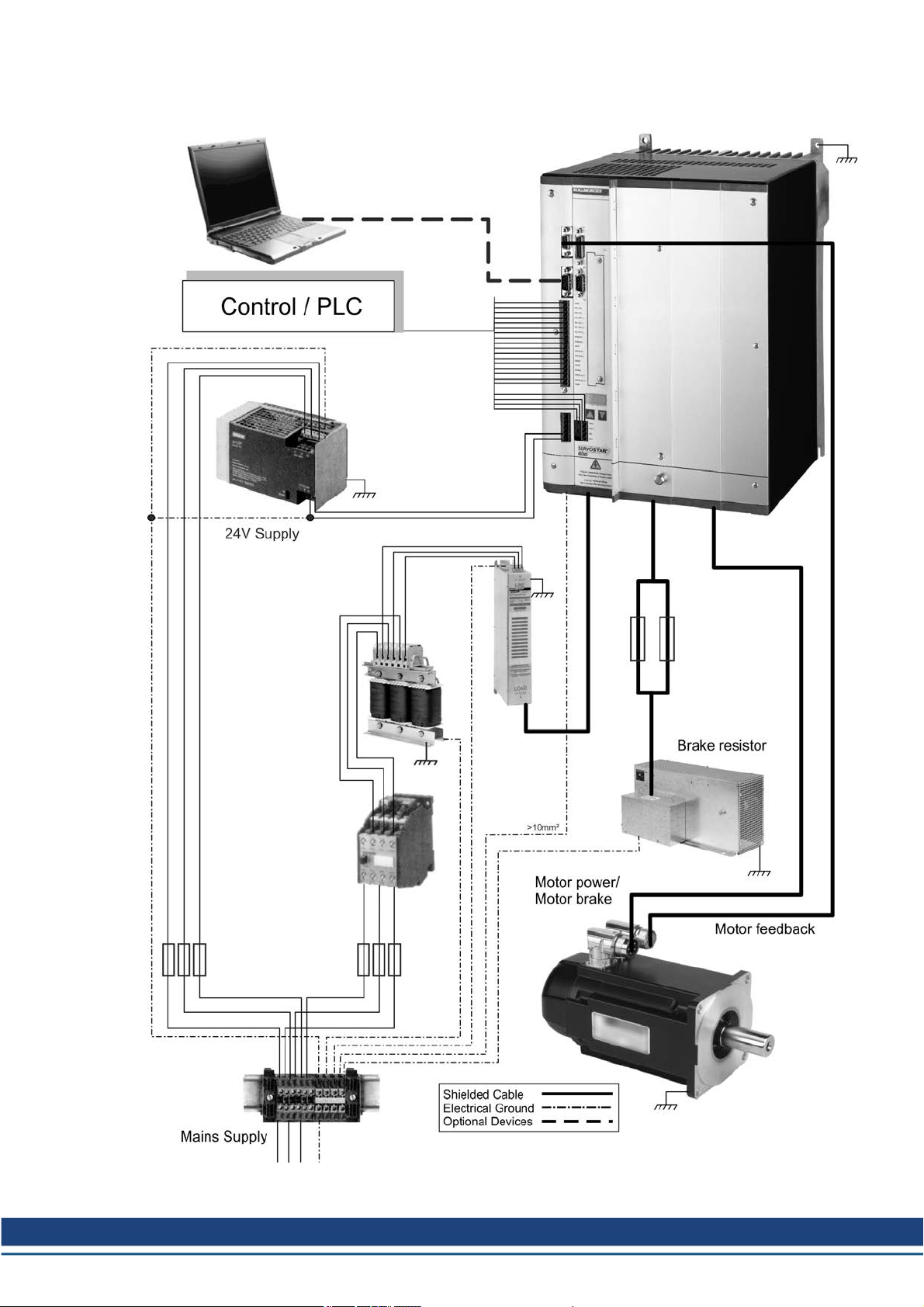

3.3 Drive System with S601...620 12

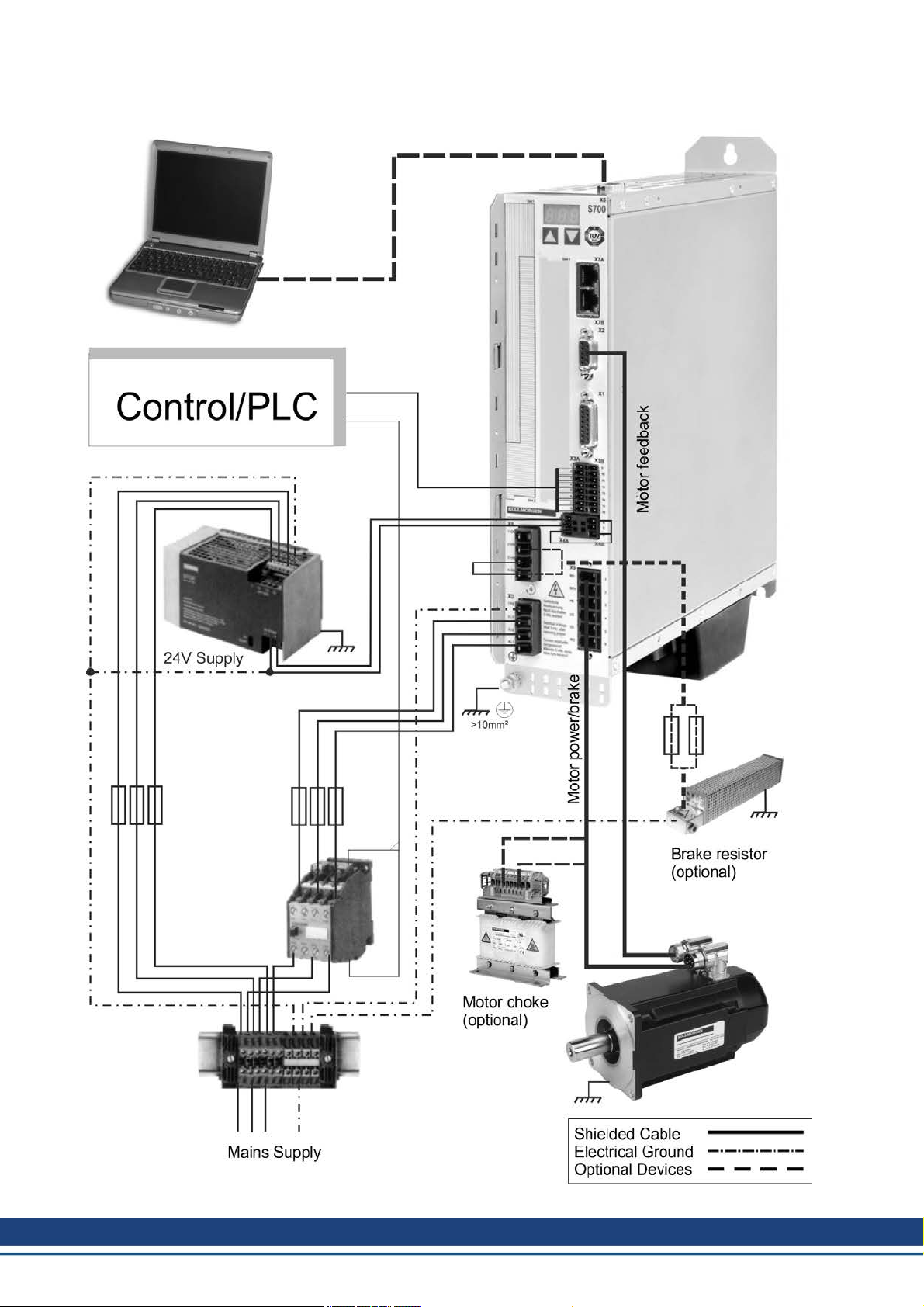

3.4 Drive System with S640...670 13

3.5 Drive System with S701...724 14

3.6 Drive System with S748/772 15

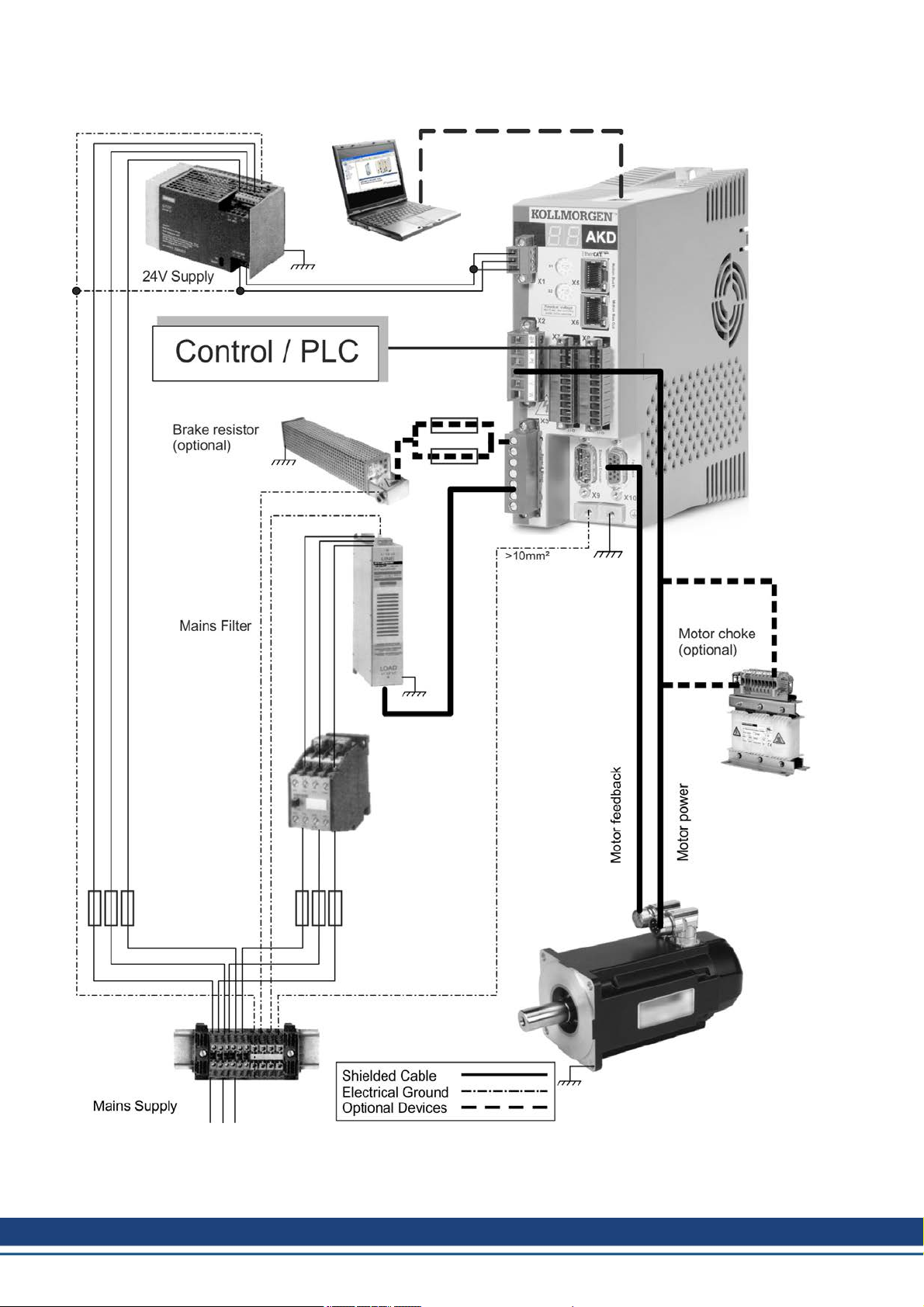

3.7 Drive System with AKD-x00306...02406 16

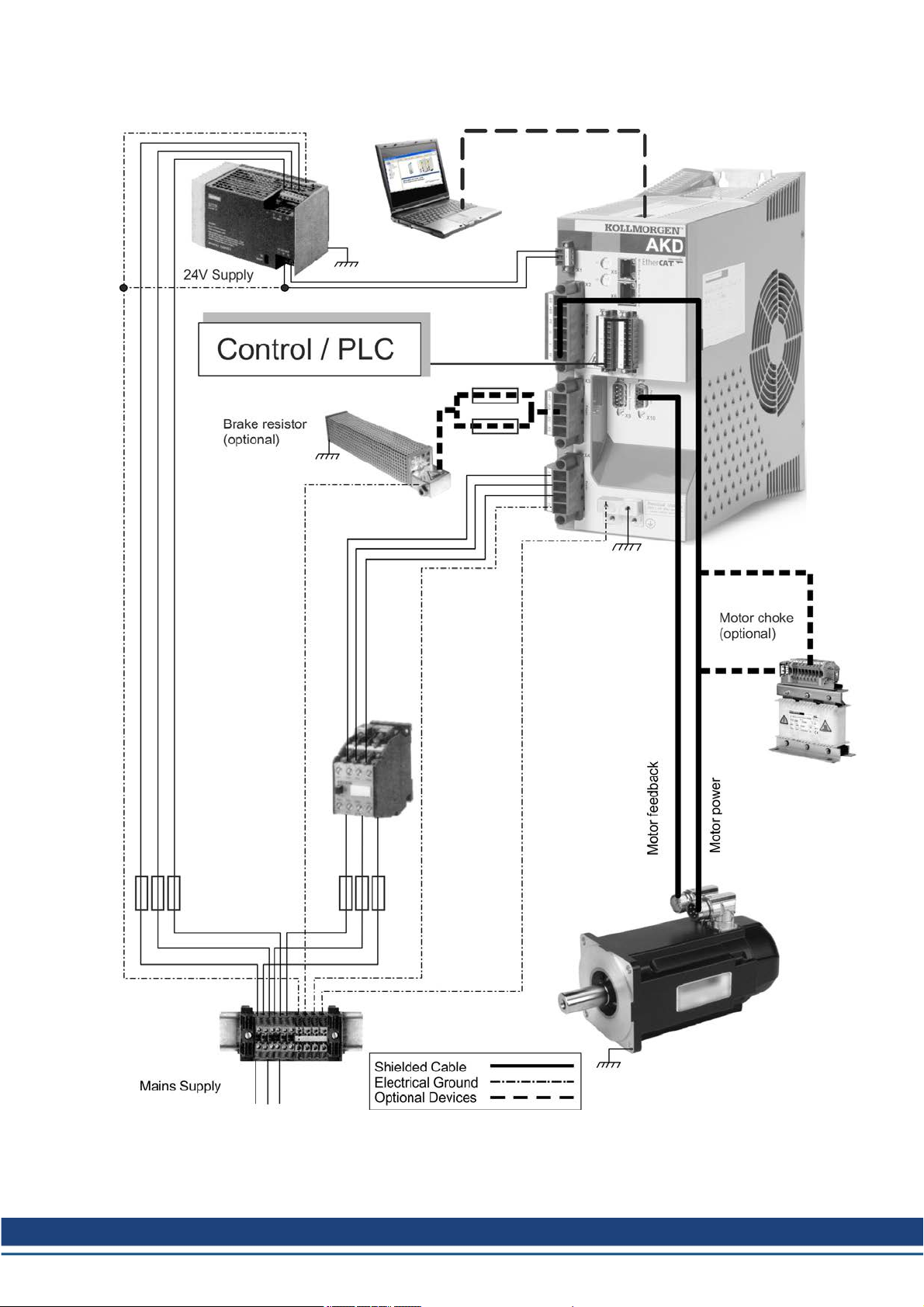

3.8 Drive System with AKD-x00307...02407 17

3.9 Drive System with AKD-x04807 18

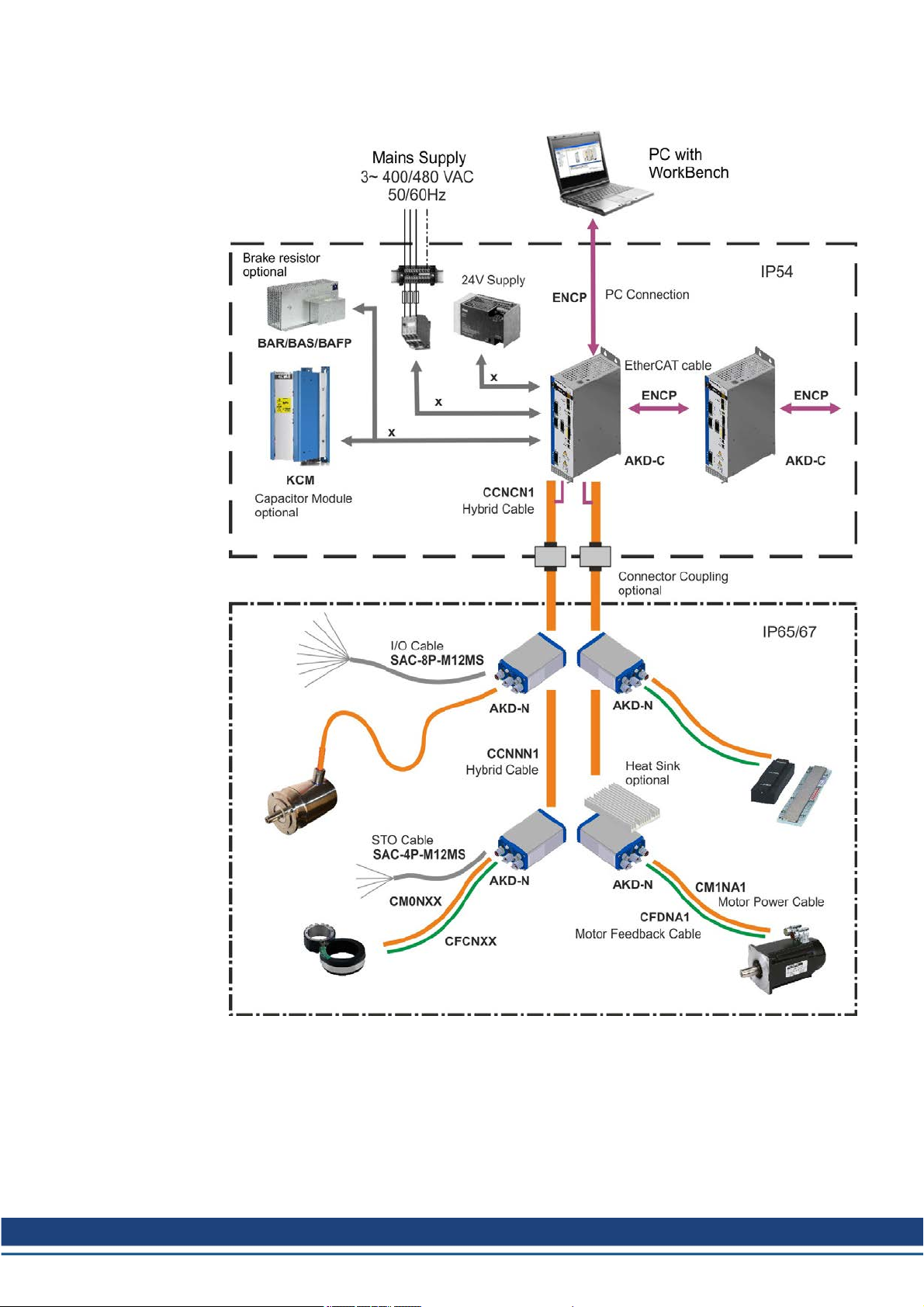

3.10 Decentralized Drive System with AKD-C and AKD-N 19

4 Mechanical Accessories 20

4.1 Mounting Kit for AKMH Motors 20

4.2 Suspension Unit for AKM motors 20

4.3 Fan Kit for AKM7 motors 21

4.4 Mechanical accessories for AKD-N and AKD-C 22

4.4.1 Heat Sink forAKD-N 22

4.4.2 Mounting clamps forAKD-N 22

4.4.3 Sealing plugs for AKD-N connectors 23

4.4.4 Connector Kit forAKD-C 23

4.4.5 Cabinet connector coupling for AKD-C/N 23

5 Shield clamps 24

5.1 Auxiliary terminals on the servo amplifier 24

5.2 External shielding busbar 25

6 Mains chokes 26

6.1 General 26

6.2 Important notes 26

6.3 Type assignment and order codes 26

6.4 Mains choke 3L 27

7 Mains filters 28

7.1 General 28

7.2 Important notes 28

7.3 Type assignment and order codes 28

7.4 Mains filters 1NF-10...12 29

7.5 Mains filters 1NF-20B, 1NF-25 30

Kollmorgen | December 2014 3

Page 4

Accessories Europe | Table of Contents

7.6 Mains filters 3NF-07...30 31

7.7 Mains filters 3EF-42...130 32

8 Brake resistors 33

8.1 General 33

8.2 Important notes 33

8.3 Type assignment and order codes 34

8.4 External brake resistor BAFP(U) 35

8.5 External brake resistor BAR(U) 36

8.6 External brake resistor BAS(U) 37

9 Capacitor Modules 38

9.1 General 38

9.2 Important notes 38

9.3 Type assignment and order codes 39

9.4 Example installation with AKD-P, KCM-P and KCM-E 39

9.5 KCM Module 40

10 Motor chokes 41

10.1 General 41

10.2 Important notes 42

10.3 Type assignment and order codes 42

10.4 Motor choke 3YL-24 43

10.5 Motor choke 3YLN-xx 44

11 Cables 45

11.1 Technical data for cables 45

11.2 Tools 45

11.3 PC connection 46

11.3.1 AKD 46

11.3.2 S300, S400, S600, S700 46

11.4 Power Voltage Supply, external brake resistor, DC bus link 48

11.4.1 Mating connector (part of delivery) 48

11.4.2 Mating connector (optional) 48

11.4.3 Recommended cable type 49

11.4.4 Preparingcables for AKD/S300/S400/S601...620/S700 49

11.4.5 Preparingcables for S640/670 and S748/772 51

11.5 24V auxiliary voltage supply 52

11.5.1 Mating connector (part of delivery) 52

11.5.2 Recommended cable type 52

11.5.3 Preparingcables 53

11.6 Digital/analog Inputs/Outputs 54

11.6.1 Digital In/Outputs for AKD-C 54

11.6.2 Digital In/Outputs for AKD-N 54

11.6.3 Digital/analog I/O for S300/S400/S600/S700 and AKD-B/P/T/M 55

11.6.4 Preparingcables 56

11.7 Encoder Emulation, Stepper motor control, Master-Slave 57

11.7.1 Mating connector, cable type 57

11.7.2 Connection 57

4 Kollmorgen | December 2014

Page 5

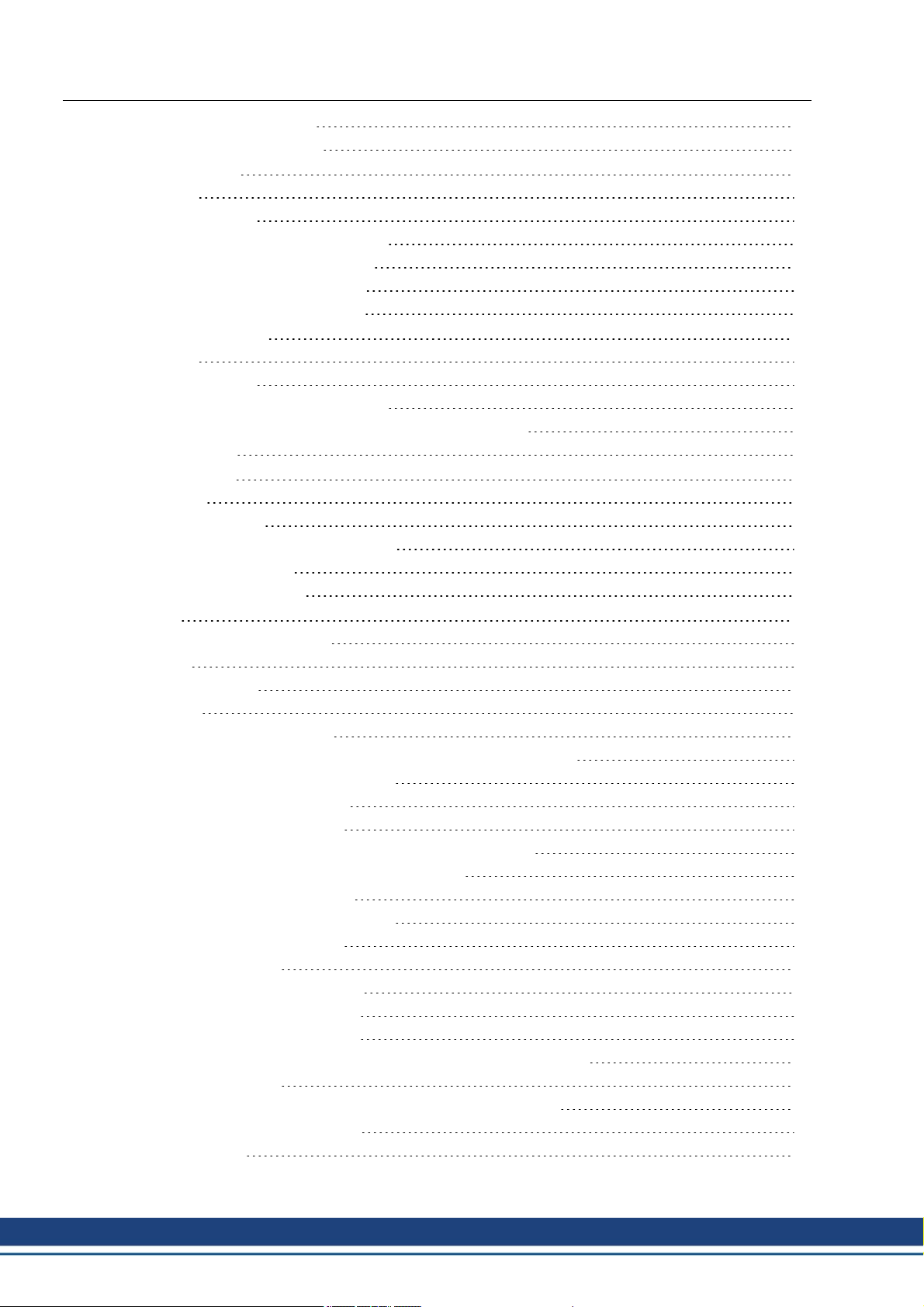

Accessories Europe | Table of Contents

11.7.3 Termination resistors 57

11.7.4 Preparingcables 58

11.8 Ethernet cable 59

11.8.1 Order codes Ethernet cable, configured 59

11.9 CAN bus cable 60

11.9.1 CAN bus cable AKD 60

11.9.2 Can bus cable for S300/S400/S600/S700 60

11.10 Hybrid cables 62

11.10.1 AKD to AKM1 Motor (i-tec connector) 62

11.10.2 AKD to AKM2-6 (IP65 connector) 63

11.10.3 AKD-C to AKD-N in the decentralizeddrive system 65

11.10.4 AKD-N to AKD-N in the decentralizeddrive system 65

11.11 Motor cables 66

11.11.1 General 66

11.11.2 Motor cables, configured 66

11.11.2.1 Order codes motor cables for S300 67

11.11.2.2 Order codes motor cables for S400 67

11.11.2.3 Order codes motor cables for S601...620 68

11.11.2.4 Order codes motor cables for S701-712 69

11.11.2.5 Order codes motor cables for S724 70

11.11.2.6 Order codes motor cables for S748, S640/670 70

11.11.2.7 Order codes motor cables for AKD-B/P/T/M 72

11.11.2.8 Order codes motor cables for AKD-N 74

11.11.3 Preparing motorcables (motorend) 75

11.11.3.1 Motor series AKM2...8, 6SMx7, DBL2...6, DBK 75

11.11.3.2 Motor series AKM8, DBL7/8 75

11.11.4 Preparing motorcables (servo amplifier end) 77

11.11.4.1 Preparing cables for S300/S400 77

11.11.4.2 Preparing cables for S601...620 78

11.11.4.3 Preparing cables for S701...724 79

11.11.4.4 Preparing cables for AKD-x00306/x00606 79

11.11.4.5 Preparing cables for AKD-x01206/X02406/X0xx07 80

11.11.4.6 Preparing cables for S640/670 and S748/772 80

11.12 Feedback cables 82

11.12.1 Resolver cables 82

11.12.1.1 Resolver cables for S300/S400/S600/S700 82

11.12.1.2 Resolver cable for AKD 83

11.12.2 SFD cables for AKD 83

11.12.3 Encoder cables 84

11.12.3.1 Encoder cables for S300/S400/S600/S700 84

11.12.3.2 Encoder cables for AKD 85

11.12.4 ComCoder cables 86

11.12.4.1 ComCoder cables for S300/S400/S600/S700 86

11.12.4.2 Comcoder cables for AKD 87

Kollmorgen | December 2014 5

Page 6

Accessories Europe | Table of Contents

This page intentionally left blank.

6 Kollmorgen | December 2014

Page 7

2 General

2.1 About this manual

This manual describes accessories for Kollmorgen digital servo amplifiers. It contains essential technical data. The manual is only valid in conjunction with the instructions manual for

the servo amplifier and servo motor you are using in your application.

You will find copies of theinstructions manual for Kollmorgenservo amplifiers and servo

motors on the CD ROM included in the scope of supply and on our Internet site. The documents are available in Acrobat Reader format in multiple languages (system requirements:

WINDOWS, Internet browser, Acrobat Reader).

Servo amplifier product family names appear in abbreviated format:

Servo amplifier Abbreviation Servo amplifier Abbreviation

SERVOSTAR 300 S300 S701...724 S701...724

SERVOSTAR 400 S400 S748/772 S748/772

SERVOSTAR 601...620 S601...620 AKD-xyyyzz AKD

SERVOSTAR 640...670 S640...670

Accessories Europe | 2 General

More detail information can be found in the "European Product WIKI" available at www.wiki-

kollmorgen.eu.

2.2 Hints for the online edition (PDF format)

Bookmark:

Table of contents and index are active bookmarks.

Table of contents and index in the text:

The lines are active cross references. Click on the desired line and the appropriate page is

indicated.

Page/chapter numbers in the text:

Page/chapter numbers with cross references are active. Click at the page/chapter numberto

reach the indicated target.

Kollmorgen | December 2014 7

Page 8

Accessories Europe | 2 General

2.3 Safety Notes

This section helps you to recognize and avoid dangers to people and objects.

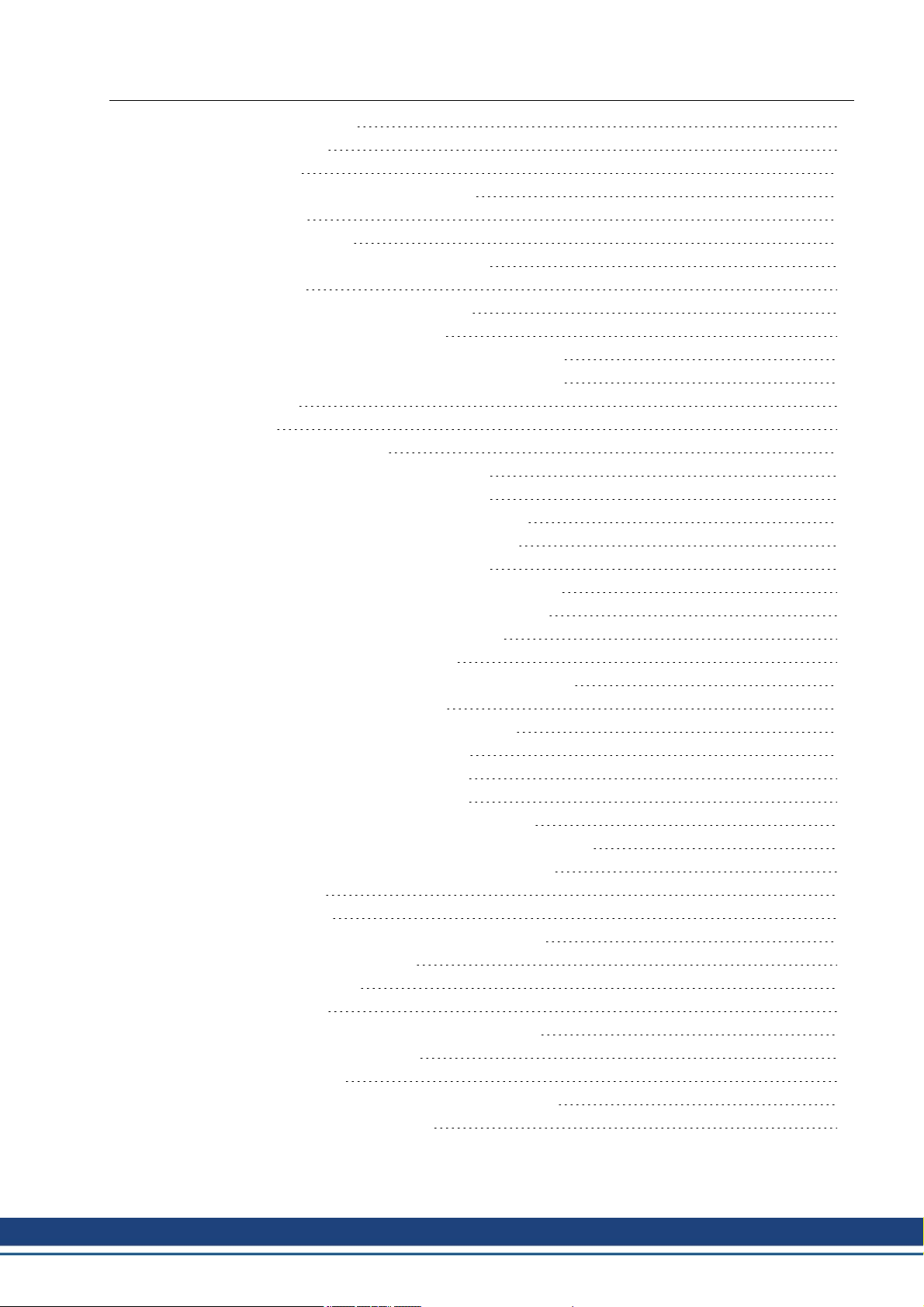

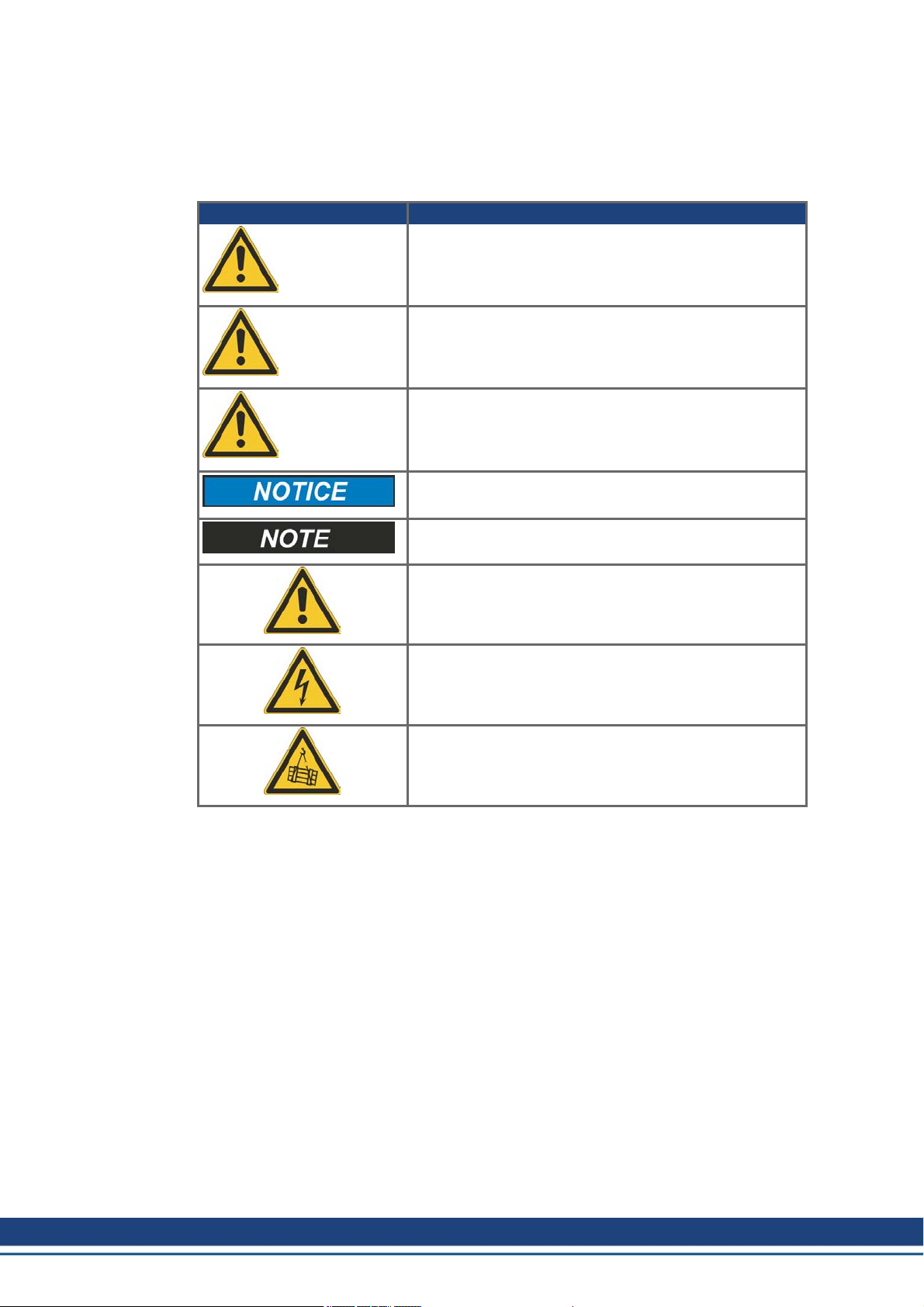

2.3.1 Symbols Used

Symbol Indication

Indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

DANGER

Indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

WARNING

Indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

CAUTION

Indicates situations which, if not avoided, could result in

property damage.

This symbol indicates important notes.

Warning of a danger(general). The type of danger is specified by the text next to the symbol.

Warning of dangerfrom electricity and its effects.

Warning of suspended loads.

8 Kollmorgen | December 2014

Page 9

2.3.2 You should pay attention to this

Read the documentation!

Read the available documentation before installation and commissioning. Improper handling

of the devices can cause harm to people or damage to property. The operator must therefore

ensure that all persons entrusted to work on the devices have read and understood the

manual and that the safety notices in this manual are observed.

Always observe the whole drive system built with servo amplifier, cables, motor, accessories (filters, chokes, etc.). This means, that all documentation which exist for the components, must be available, must be read and must be understood.

Pay attention to the technical data!

Adhere to the technical data and the specifications on connection conditions (ratingplate and

documentation). If permissible voltage values or current values are exceeded, the devices

can be damaged, e.g. through overheating.

Specialist staff required!

Only properly qualifiedpersonnel are permitted to perform such tasks as transport,

assembly, setup and maintenance. Qualified specialist staff are persons who are familiar

with the transport, installation, assembly, commissioning and operation of power electronics

andwho bringtheir relevant minimum qualifications to bear on their duties. The qualified personnel must know and observe IEC 60364 / IEC 60664 and national accident prevention regulations.

Additional requirements on specialist staff may also result from the risk assessment.

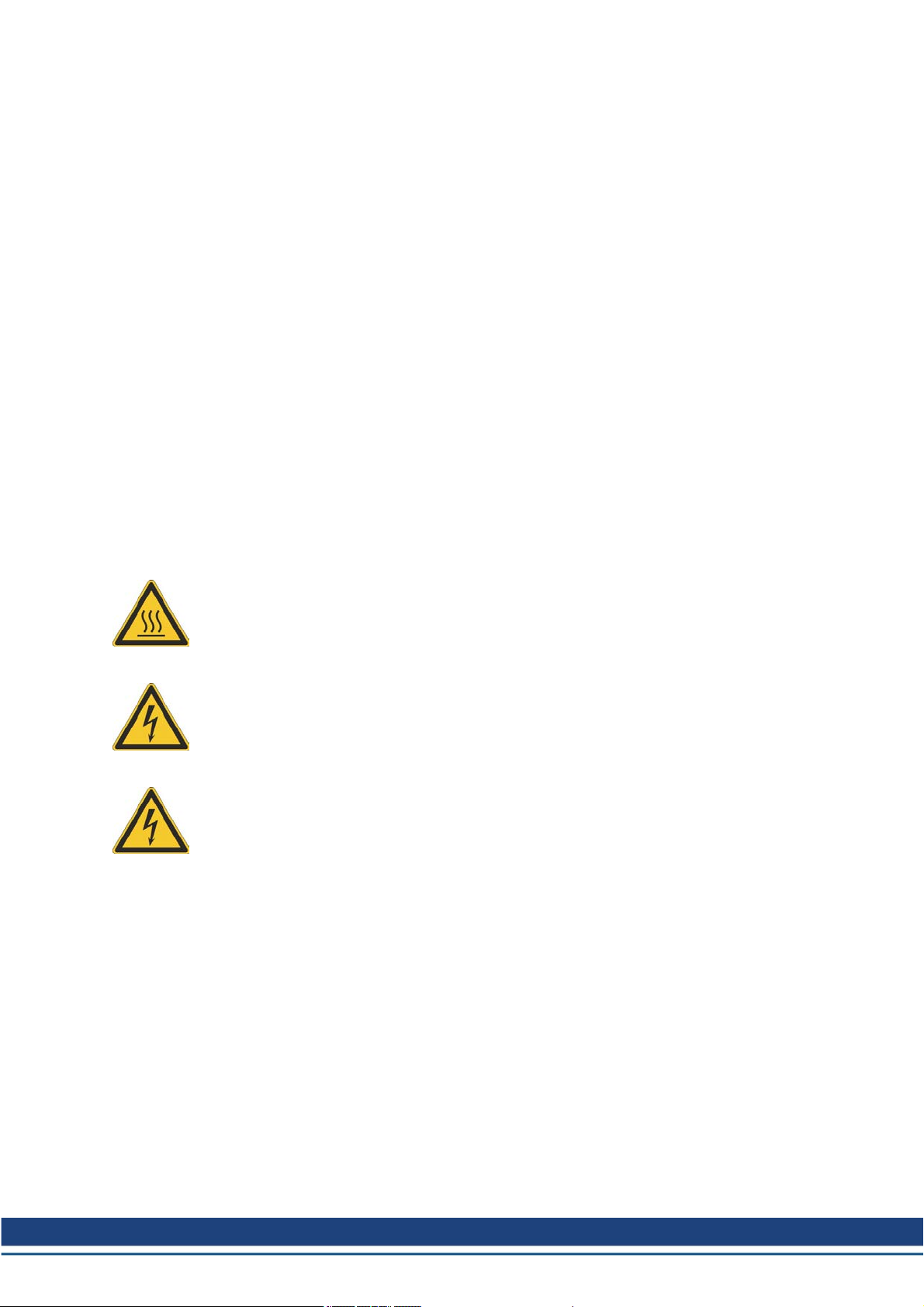

Hot surface!

Some devices can reach temperatures of up to 250°C during operation. Touching them can

result in burns. Observe the permissible mounting position and ensure that a sufficient distance is maintained from neighboring assemblies.

Accessories Europe | 2 General

Earthing!

It is vital that you ensure that the device housing is safely earthed to the PE (protective

earth) busbar in the switch cabinet. Without low-resistance earthing no personal protection

can be guaranteed and there is a risk of death from electric shock.

High voltages!

Keep the switching cabinet closed when the equipment is in operation. Not having optical displays does not guarantee an absence of voltage. Power connections may carry voltage even

if the motor is not turning.

Do not unplug any connectors during operation. There is a risk of death or severe injury from

touching exposed contacts. Power connections may be live even when the motor is not rotating. This can cause flashovers with resultinginjuries to persons and damage to the contacts.

DC Bus link connections can carry dangerous voltage levels over an hour after the line

voltage has been switched off (self-discharge time). Danger of death from electric shock.

Beforecommencing work on the modules’ power terminals, check the voltage at the connection terminals is de-energized to ground and to each other.

.

Kollmorgen | December 2014 9

Page 10

Accessories Europe | 3 Digital Drive Systems

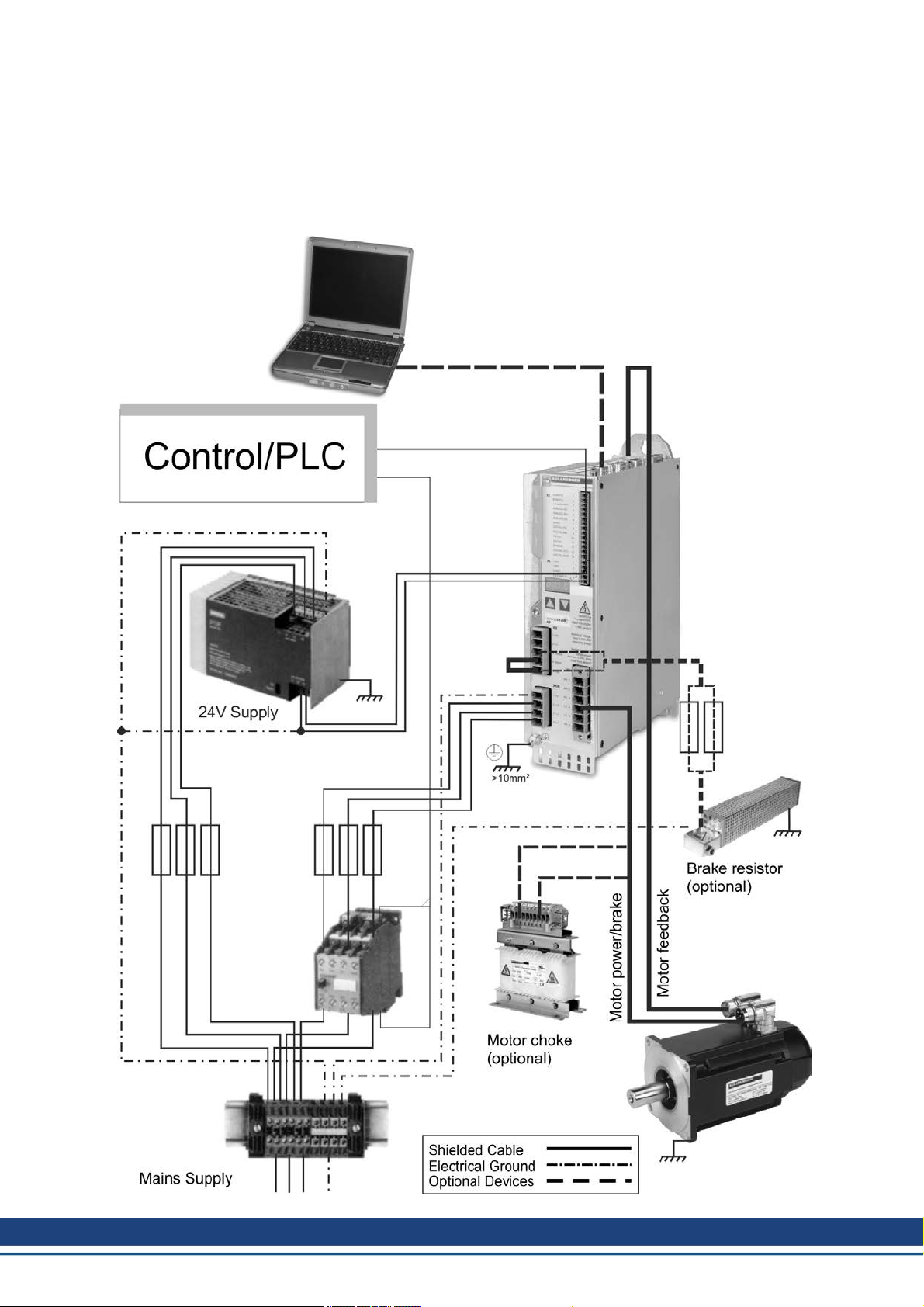

3 Digital Drive Systems

The systems shown are simply a possible scenario for setting up a digital drive system with

relevant servo amplifier components.

3.1 Drive System with S300

10 Kollmorgen | December 2014

Page 11

3.2 Drive System with S400

Accessories Europe | 3 Digital Drive Systems

Kollmorgen | December 2014 11

Page 12

Accessories Europe | 3 Digital Drive Systems

3.3 Drive System with S601...620

12 Kollmorgen | December 2014

Page 13

3.4 Drive System with S640...670

Accessories Europe | 3 Digital Drive Systems

Kollmorgen | December 2014 13

Page 14

Accessories Europe | 3 Digital Drive Systems

3.5 Drive System with S701...724

14 Kollmorgen | December 2014

Page 15

3.6 Drive System with S748/772

Accessories Europe | 3 Digital Drive Systems

Kollmorgen | December 2014 15

Page 16

Accessories Europe | 3 Digital Drive Systems

3.7 Drive System with AKD-x00306...02406

16 Kollmorgen | December 2014

Page 17

3.8 Drive System with AKD-x00307...02407

Accessories Europe | 3 Digital Drive Systems

Kollmorgen | December 2014 17

Page 18

Accessories Europe | 3 Digital Drive Systems

3.9 Drive System with AKD-x04807

18 Kollmorgen | December 2014

Page 19

Accessories Europe | 3 Digital Drive Systems

3.10 Decentralized Drive System with AKD-C and AKD-N

All components inside the borders aresuppliedby Kollmorgen with the exception of cables

signedwith "x". These cables are not suppliedby Kollmorgen, you should use cables or

wires according to EN 60204.

Kollmorgen | December 2014 19

Page 20

Accessories Europe | 4 Mechanical Accessories

4 Mechanical Accessories

4.1 Mounting Kit for AKMH Motors

IEC mounting kits with 1 shaft center screw and 4 flangescrews. Hygienic mounting is possible only with these screws.

Description Order Code

Mounting Hardware AKMH2, Ax flange / Cx front mounting MTG-KIT-AKMH2-IEC

Mounting Hardware AKMH3, Ax flange / Cx front mounting MTG-KIT-AKMH3-IEC

Mounting Hardware AKMH4, Ax flange / Cx front mounting MTG-KIT-AKMH4-IEC

Mounting Hardware AKMH5, Ax flange / Cx front mounting MTG-KIT-AKMH5-IEC

Mounting Hardware AKMH6, Ax flange / Cx front mounting MTG-KIT-AKMH6-IEC

NEMA mounting kits are described in the US selection guide, available from the Kollmorgen

website www.kollmorgen.com).

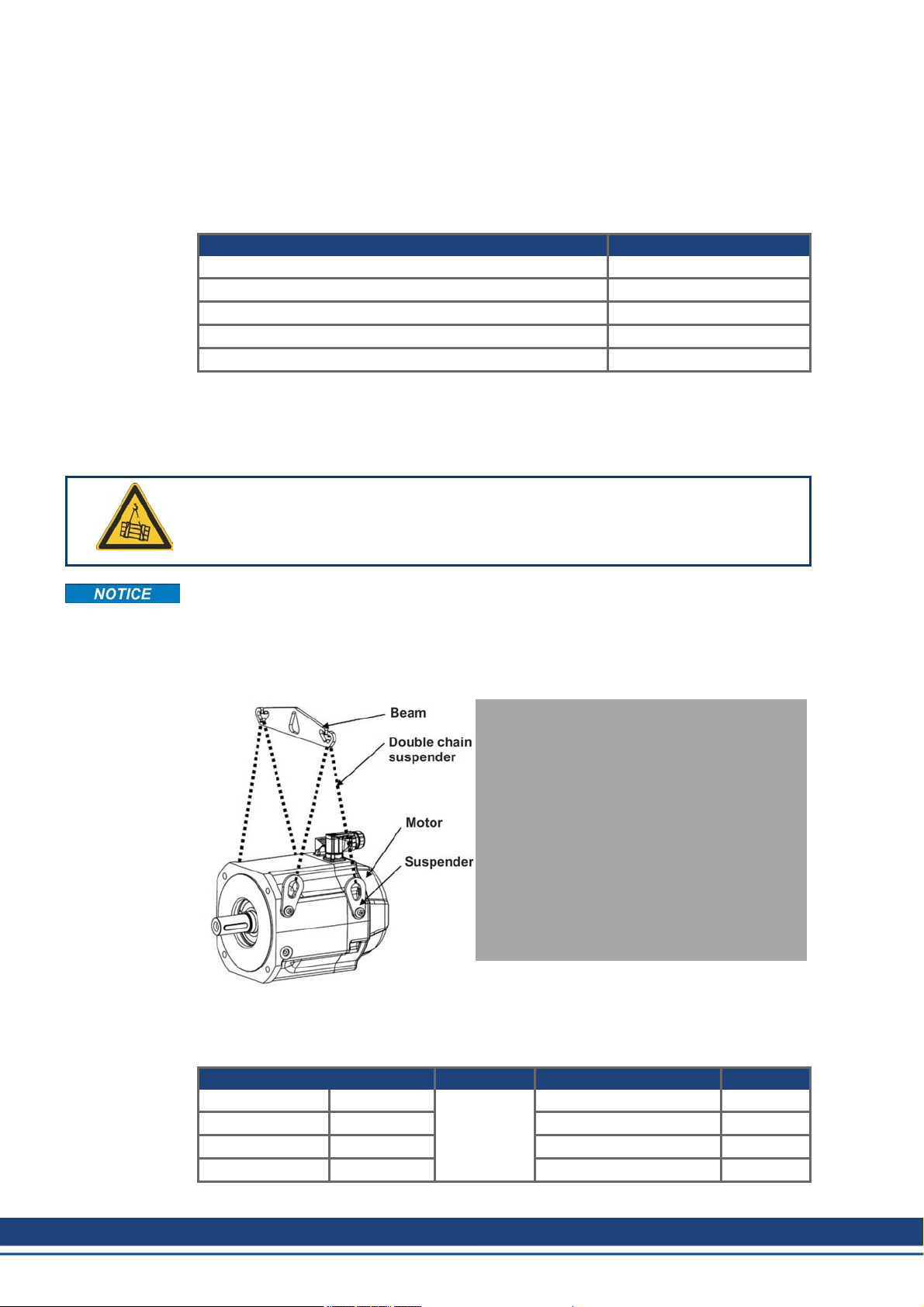

4.2 Suspension Unit for AKM motors

DANGER

Suspended load. Risk of death if load falls. Never step under the load,

while the motor is raised!

You must read the instructions manual for the suspension unit ZPMZ 120/292. Observe the

"safety instructions" and "use as directed" hints before starting transportation work.

The Suspension Unit ZPMZ 120/292 is designed for suspended handlingexclusively of

motors (i.e., without attached units such as gearboxes, clutches, etc.) with a maximum

weight of 120 kg and maximum nominal span of the extreme suspension hooks of 292 mm.

The suspended unit consists of a Beam, suspended off the crane hook and two double-run

chain suspenders. The motormay be borne on two or four runs of thechain suspender.

The suspenders (number depends on the motor type) are delivered with the motor.

Technical Data

Lifting capacity 120kg Weight 0,83 kg

Nominal span 292 mm Number of cycles a year 20.000

Lugwidth 44,7 mm Average load 60 %

Lugheight 51 mm Order code FA00092

20 Kollmorgen | December 2014

Page 21

4.3 Fan Kit for AKM7 motors

Observe the mounting instructions delivered with the fankit. The fan housing can be mounted either with both the supplied brackets andspacers or with the brackets only. The choice

of mounting method depends on the application. If strong vibrations are expected, you should

use both brackets and spacers. Motors with integrated brakes require the longs spacers.

Mounting the fan kit enlarges the motor by approximately 65 mm. The detailed final dimensions of AKM7 motors with mounted fan kit can be found in the instructions manual of the

AKM motor series. Ventilation of AKM7 motors allow increased current of the motors. This

higher current usually requires larger wiring cross section compared to not ventilated motors.

The necessary data for current and wiring cross section can be found in the technical data

section of the AKM instructions manual.

Technical Data

Supply voltage 24 VDC

Supply current 270mA

Electrical power 6.5 W

Surface Coated with polyester powder coating in matt black, not resistant

Protection class IP 20

Connection Cable gland 10 mm, cable diameter 4 mm to 6 mm, recommended cable

Terminals 0.33 mm² to 4 mm²

Weight 2.52 kg

Order code AKM7-FAN

Accessories Europe | 4 Mechanical Accessories

against solvents

3x0.75 mm² (not part of delivery)

Kollmorgen | December 2014 21

Page 22

Accessories Europe | 4 Mechanical Accessories

4.4 Mechanical accessories for AKD-N and AKD-C

You must read the AKD-N/AKD-C installation manuals. Observe the safety instructions

given there before commencing mounting/installation work.

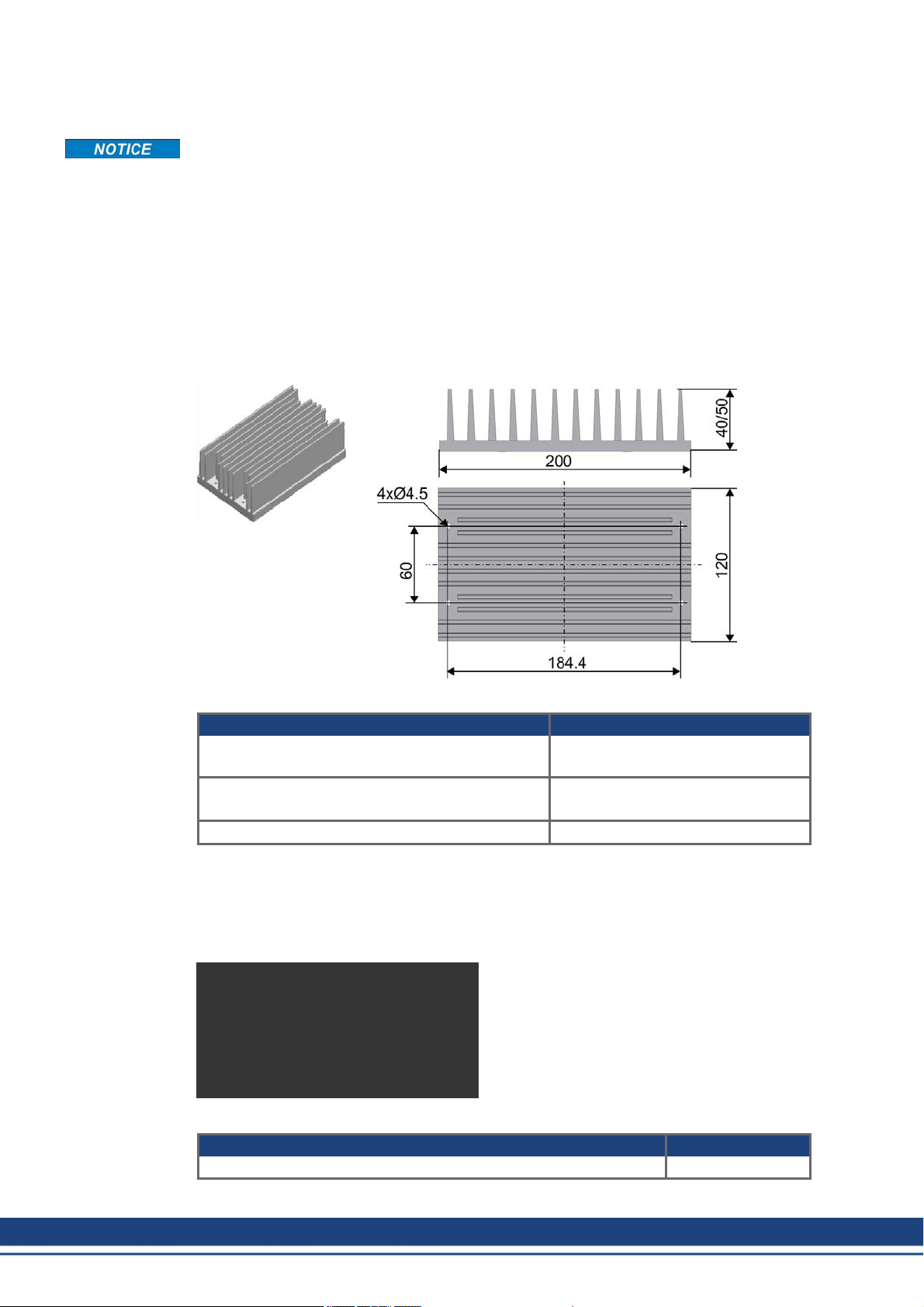

4.4.1 Heat Sink for AKD-N

When mounting AKD-N to themachinery, temperature management is important to ensure

maximum performance of the drive system. In case of medium or bad cooling situation (as

described in the AKD-N Installation Manual), youcan mount a heat sink to the AKD-N.

Heat flow is optimized by a heat conducting film, which must be placed between heat sink

andAKD-N.

Mounting holes in the heat sink and winding holes in the AKD-N are prepared for M4x16

hexagon socket screws to ISO 4762. Use a 3 mm T-handle Allen key for mounting.

Order Codes

Article Order codes

Heat sink Kit 40 mm with Heat conducting film and

4 screws M4x16

Heat sink Kit 50 mm with Heat conducting film and

4 screws M4x16

Heat conducting film 849-373000-04

4.4.2 Mounting clamps for AKD-N

The AKD-N servo amplifier is mounted to the machine with special mounting clamps. The

delivery package contains 4 clamps. In case of lost or damaged clamps, you can ordera set

of four clamps.

Order Codes

Article Order codes

AKD-N Mounting Clamps Set, 4 clamps AKD-N-M/C-Set

AKD-N 3,6 HEATSINK KIT 40MM

AKD-N 3,6 HEATSINK KIT 50MM

22 Kollmorgen | December 2014

Page 23

4.4.3 Sealing plugs for AKD-N connectors

The sealing plugs in the delivery package are screwed to unused AKD-N connectors to

ensure the IP class for the machine environment. In case of lost plugs, you can order a set

with 3 different plug sizes.

Order Code

Article Order Codes

AKD-N Sealing Plug Set, 4xM12, 2xM23, 2xM17 AKD-N-S/P-Set

4.4.4 Connector Kit for AKD-C

Mating connectors X12, X13, X14, X15, and X17 are part of delivery. If a mating connector is

lost or damaged, you can order the AKD-C Connector Kit.

Order Code

Accessories Europe | 4 Mechanical Accessories

Article Order Codes

AKD-N Connector Kit, included matingconnectors X12, X13, X14,

X15, and X17

4.4.5 Cabinet connector coupling for AKD-C/N

The connector couplingmust be built into the outer wall of a cabinet. The connector coupling

connects powerand signal lines as well as shielding of the hybrid cables and ensures the

long-term sealed transition between cabinet environment (IP54) and machine environment

(IP65/67).

Inside the cabinet the CCNCN1 cable (➜ p. 65) to AKD-C can be plugged in, outside the

cabinet the CCNNN1 cable (➜ p. 65) to AKD-N can be plugged in.

Order Codes

Article Order Codes

Hybrid Connector Coupling AKD-C/AKD-N AKD-CN-Coupling*

*in process

AKD-C-CONKIT

Kollmorgen | December 2014 23

Page 24

Accessories Europe | 5 Shield clamps

5 Shield clamps

You must read the instructions manuals for the servo amplifier/servo motor you areusing in

your application. Observe the safety instructions they contain before commencing mounting/installation work.

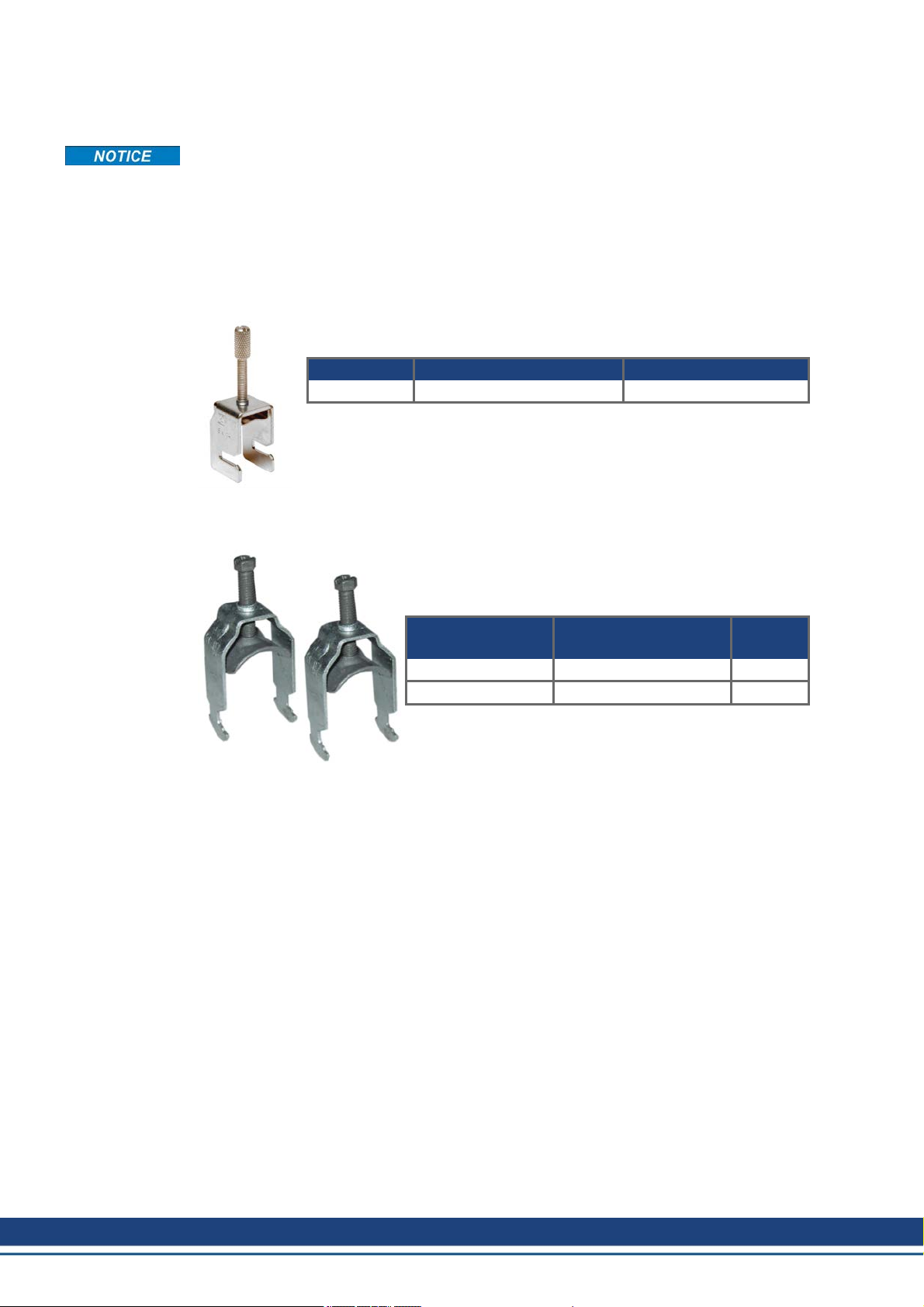

5.1 Auxiliary terminals on the servo amplifier

S300, S701...724 and AKD

These servo amplifiers feature slots on the front panel for the connection of

additional shield clamps.

Article Tension range Order Codes

SK14 6-13mm DE-108248

S640/670, S748/772

The shroud supplied with these servo amplifiers features

slots for the connection of additional shield clamps.

We recommend using the following shield clamp:

Manufacturer Article Tension

range

OBO (Bettermann) BBS-Schelle Typ 2056 16-22mm

OBO (Bettermann) BBS-Schelle Typ 2056 28-34mm

The clamps are part of delivery of the servo amplifier.

24 Kollmorgen | December 2014

Page 25

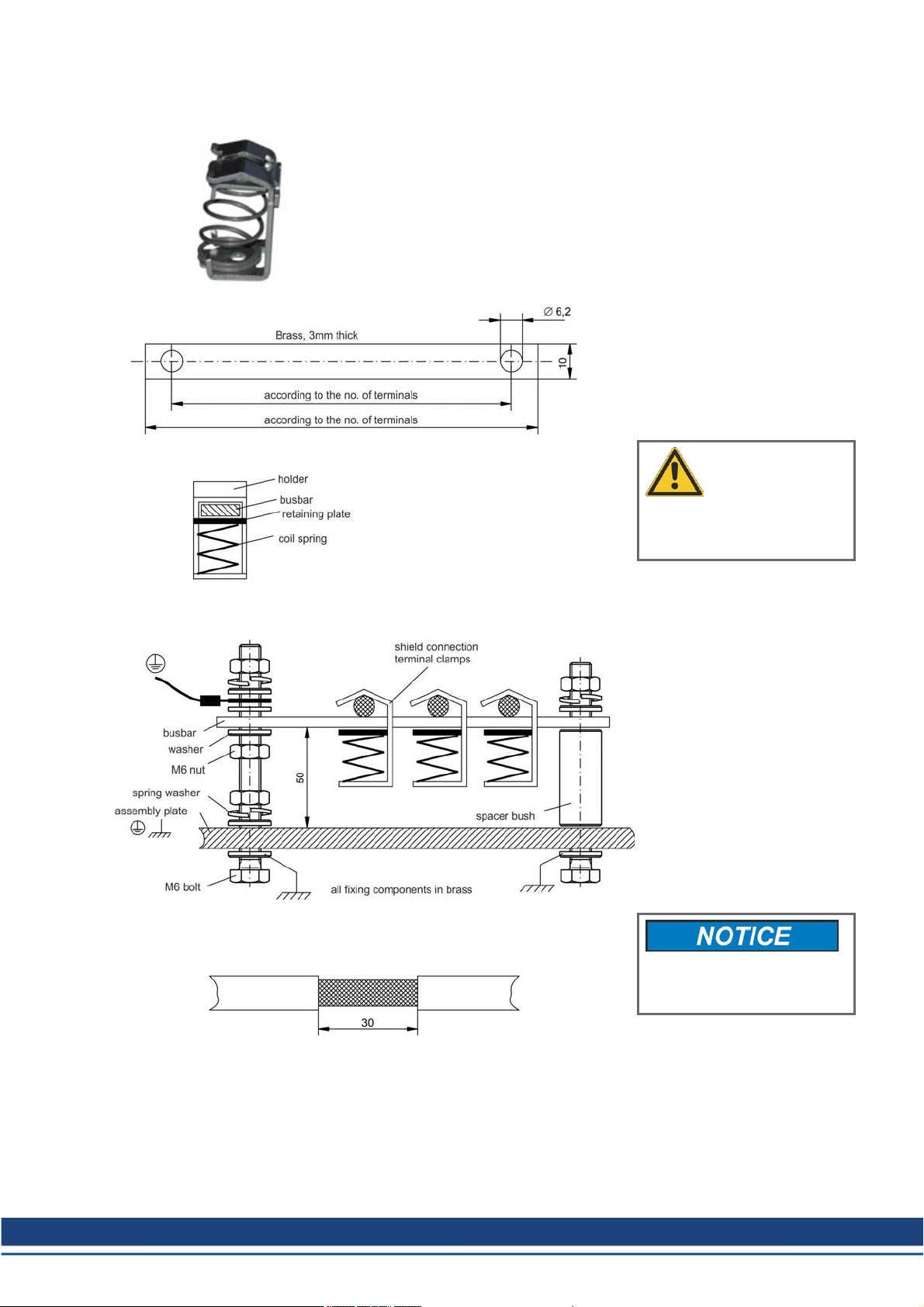

5.2 External shielding busbar

Accessories Europe | 5 Shield clamps

The power cable shields (line in, motor cable, external regen resistor)

can be routed to an additional busbar via shield clamps.

Kollmorgen recommends using Weidmüller KLBÜ shield clamps.

A possible scenario for setting up a busbar for the above shield

clamps is described below.

1. Cut a busbar of the required

length from a brass rail (cross-section 10 x 3 mm) and drill holes in it

as indicated. All shield clamps

required must fit between the drill

holes.

CAUTION

Risk of injury due to the spring

force of the coil spring. Use pincers.

2. Squeeze together the coil

spring and the supporting plate

and push the busbar through the

opening in the holder.

3. Mount the busbar with the

shield clamps fitted on the

assembly plate. Use either metal

spacer bushes or screws with nuts

and accessories to maintain a spacing of 50 mm. Earth the busbar

using a single conductor with a

cross-section of at least 2.5mm².

4. Strip the external cable sheath

to a length of approximately 30

mm, taking care not to damage

the braided shield. Push the

shield clamp up and route the

cable to it via the busbar.

Make sure there is good contact between the shield clamp

and the braided shield.

Kollmorgen | December 2014 25

Page 26

Accessories Europe | 6 Mains chokes

6 Mains chokes

You must read the instructions manuals for the servo amplifier and servo motoryou are using

in your application. Observe the safety instructions given there.

6.1 General

A 3L mains choke must be used on S640/670 servo amplifiers in order to reduce mains harmonics.

In special cases, if mains voltage is more than3% asymmetrical, then the S748/772 must be

used with a mains choke. In unfavorable combination of mains impedance and DC bus capacitance the unloaded DC bus may reach voltage up to 800V without choke. For EMC reasons

the chokes should be mounted isolatedto the cabinet. Single conductors can be used for wiring, shielded cables are not required. More information seeWIKI "Mains Choke".

Purpose of mains choke:

l Prevents impermissible loading of semiconductors in the event of rapid current rise during

commutation.

l Prevents voltage dips in the mains voltage causedby commutation.

l Reduces current ripple in the DC link, thereby increasing the service life of the DC link

capacitors.

6.2 Important notes

DANGER

Power terminals are capable of conducting hazardous voltage up to

10minutes after the mains voltage has been disconnected. Risk of electric shock. Before starting work on power terminals, check that the phaseto-earth and phase-to-phase voltages have de-energised.

Due to the high earth leakage currents induced by the system, you should observe the

requirements of EN 61800-5-1 (e.g. fixed installation, ≥ 10 mm² or double protective earth)

when carrying out mounting and installationwork. You must read the instructions manual for

the servo amplifier/servo motor you are using in your application and observe the safety

instructions they contain before commencing mounting/installation work.

Mounting: 50mm free space required above and below the device.

Connection diagram: see servo amplifier instructions manual.

6.3 Type assignment and order codes

Servo amplifier Mains choke

S640/670 (with asymmetrical mains >3% only) 4% uk

S748/772 (with asymmetrical mains >3% only) 2% uk

AKD, S300, S400, S601...620, S701...724 not required

Order Codes

Article uk Order codes

Mains choke 3L0,5-63-4 (0.47mH, 63A) 4% DE-92201

Mains choke 3L0,4-80-4 (0.37mH, 80A) 4% DE-92100

Mains choke 3L0,2-160-4 (0.19mH, 160A) 4% DE-92099

Mains choke 3L0,24-50-2 (0.24mH, 50A) 2% DE-201476

Mains choke 3L0,2-75-2 (0.20mH, 75A) 2% DE-201477

26 Kollmorgen | December 2014

Page 27

6.4 Mains choke 3L

A number of servo amplifiers can be connected to one and the same mains choke; the rated

current of the mains choke must be greater than or at least equal to the total current of the

connected servo amplifiers.

Accessories Europe | 6 Mains chokes

Photo: 3L0,2-160-4, all models

are similar

Technical Data

Inducti-

Type [mH] [A] [%] [mm] [mm] [mm] [mm] [mm] [mm] [mm²] [kg]

3L 0,5-63-4 0.47 63 4 185 170 77 122 215 8x12 16 9.65

3L 0,4-80-4 0.37 80 4 210 175 85 125 240 8x12 16 12.5

3L 0,2-160-4 0.19 160 4 291 273 116.5 148.5 310 10x18 95 27

3L 0,24-50-2 0.24 50 2 152.5 114.3 88.9 114.3 163 6.5 10 5.9

3L 0,2-75-2 0.20 75 2 185 170 77 122 220 8x12 35 9.9

vity

Nominal

Current

uk A B C D E F Termi-

nals

Weight

Kollmorgen | December 2014 27

Page 28

Accessories Europe | 7 Mains filters

7 Mains filters

7.1 General

AKD-x00306 to AKD-x02406 and S640/670 servo amplifiers require an external mains filter.

All other servo amplifiers feature built-in mains filters (see the relevant instructions manual).

The filtering effect of the mains filters can only be assured if the permissible throughput rating

of the mains filters is not exceeded even on peak loading of the servo amplifiers with Ipeak.

The max. available throughput rating of the mains filter must be higher than themax. power

consumption of the servo amplifiers and higherthan the maximum power consumption of the

motors. More information can be found on the WIKI page "Mains Filter".

7.2 Important notes

DANGER

Power terminals are capable of conducting hazardous voltage up to 10

minutes after the mains voltage has been disconnected. Risk of electric

shock. Before starting work on power terminals, check that the phase-toearth and phase-to-phase voltages have de-energized.

Due to the high earth leakage currents induced by the system, you should observe the

requirements of EN 61800-5-1 (e.g. fixed installation, ≥10 mm² or double protective earth)

when carrying out mounting and installationwork. You must read the instructions manuals for

the used components and observe the safety instructions they contain before commencing

mounting/installation work.See servo amplifier instructions manual for connection diagrams.

7.3 Type assignment and order codes

Servo amplifier Mains filter

S300, S400, S601...620, S700, AKD-x00307...04807 (240 to 480V) not required

S640/670 3EF

AKD-B/P/T/M 00306...02406 (120 to 240V) 1NF, 3NF

Article Order code Remarks

Mains filter 1NF-10 (230 VAC, 10A) DE-201565 1~, 230V AC, CE*, UL

Mains filter 1NF-12 (230 VAC, 12A) DE-201566 1~, 230V AC, CE*, UL

Mains filter 1NF-20B (125V/230 VAC, 20A) DE-201865 1~, IEC 230V AC, UL 125 V AC, CE*

Mains filter 1NF-25 (230 VAC, 25A) DE-201568 1~, 230V AC, CE*, UL

Mains filter 3NF-07 (480 VAC, 07A) DE-201569 3~, 480V AC, CE*, UL

Mains filter 3NF-16 (480 VAC, 16A) DE-201570 3~, 480V AC, CE*, UL

Mains filter 3NF-30 (480 VAC, 30A) DE-201571 3~, 480V AC, CE*, UL

Mains filter 3EF-42 (480 VAC, 42A) DE-92102 3~, 480V AC, CE*, UL

Mains filter 3EF-75 (480 VAC, 42A) DE-92103 3~, 480V AC, CE*, UL

Mains filter 3EF-100 (480 VAC, 42A) DE-92104 3~, 480V AC, CE*, UL

Mains filter 3EF-130 (480 VAC, 42A) DE-92105 3~, 480V AC, CE*, UL

* No EC directive matches mains filters actually. You can use the filters in Europe, they are manufactured according to harmonized standards concerning creeping and voltage distances.

28 Kollmorgen | December 2014

Page 29

7.4 Mains filters 1NF-10...12

Accessories Europe | 7 Mains filters

Observe the safety instructions ➜ p. 28.

For single-phase operation only.

Technical Data

Nominal

Type

1NF-10 10 230 85 49 40.3 54 75 5.3 6.3 87 0.29 Fast-on

1NF-12 12 230 156 57.5 45.4 130.5 143 5.3 6 156 0.73 Fast-on

* at 40°C environment temperature

Current

[A]*

Nominal

Voltage

[V]

A

[mm]B[mm]C[mm]D[mm]F[mm]M[mm]N[mm]P[mm]

Kollmorgen | December 2014 29

Weight

[kg]

Connec-

tion

Page 30

Accessories Europe | 7 Mains filters

7.5 Mains filters 1NF-20B, 1NF-25

Observe the safety instructions ➜ p. 28.

For single-phase operation only.

Technical Data

Type Nominal

Current [A]*

1NF-20B 20 230V 125V 0.93

1NF-25 25 230V 230V 0.7

* at 50°C environment temperature

30 Kollmorgen | December 2014

Nominal Voltage

IEC UL/CSA Weight

[kg]

Connection Phase

Terminals

Wires up to 4mm²

Torque 0.6 to 0.8 Nm

Wires up to 10mm²

Torque 1.5 to1.8 Nm

Connection PE

Bolt M 6

Torque 3.5 to 4 Nm

Page 31

7.6 Mains filters 3NF-07...30

Accessories Europe | 7 Mains filters

Observe the safety instructions ➜ p. 28.

Technical Data

Type Nom.

Current*A[mm]B[mm]C[mm]D[mm]F[mm]G[mm]M[mm]P[mm]

3NF-07 7 A 190 40 70 160 180 20 4.5 180 0.5 4mm²,

3NF-16 16 A 250 45 70 220 235 25 5.4 240 0.8

3NF-30 30 A 270 50 85 240 255 30 5.4 260 1.2

* at 50°C environment temperature

Kollmorgen | December 2014 31

Weight

[kg]

Terminals PE

0.7..0.8Nm

10mm²,

1.9..2.2Nm

Bolt

M5,

2.2Nm

Page 32

Accessories Europe | 7 Mains filters

7.7 Mains filters 3EF-42...130

Observe the safety instructions ➜ p. 28.

Technical Data

Type Nom.

Current*L1[mm]L2[mm]L3[mm]L4[mm]B1[mm]B2[mm]B3[mm]H1[mm]

3EF-42 42 A 305 335 320 355 35 60 7 150 10 5

3EF-72 75 A 300 330 314 380 55 80 7 185 25 6

3EF-100 100 A 300 330 314 380 55 80 7 220 25 8

3EF-130 130 A 350 380 364 440 65 90 7 220 50 10

32 Kollmorgen | December 2014

Terminals

[mm²]PEBolt

[mm]

Page 33

8 Brake resistors

8.1 General

Duringbraking with the aid of the motor, energy is fed back into the servo amplifier. This

regenerative energy is dissipated as heat in the brake resistor. The brake resistor is switched

on by the brake circuit. Different resistance values have to be used depending on the servo

amplifier. All resistors meet the requirements of CE directives and are UL-registered.

Hints for calculation of the brake power can be found in our Product WIKI on page "Cal-

culation of brake power", more information to the resistors are given on WIKI page "Brake

Resistors".

8.2 Important notes

WARNING

The brake resistor surface temperature can exceed 250°C. Risk of burns!

Measure the temperature and wait until temperature dropped down below

40°C, before touching the resistor housing.

Accessories Europe | 8 Brake resistors

Inadequate levels of cooling air or incorrect installation can lead to overheating and destruction of the resistor and surrounding components.

l May only be installed in switchgear cabinets, comply with the permissible installation

types and clearances (see dimensional drawing).

l Ensure there is unobstructed convection for cooling purposes.

l Use temperature-resistant materials in the vicinity of the resistor.

l The connection terminals must never be located within the flow range of the heated waste

air.

The following requirements must be met to ensure the brake resistors work properly:

l Compliance with required installation clearances

l Compliance with permissible installation type

l Unhindered access of cooling air

l Unhindered diverting of warmed up air

l Rated data with maximum ambient temperature 40°C, in case of ambient temperature

higher than 40°C, power must be reduced by 4% per 10K temperature rise

You must read the instructions manual for the servo amplifier/servo motor youare using in

your application and observe the safety instructions they contain before commencing mounting/installation work.

A connection diagram appears in the servo amplifier's instructions manual.

Kollmorgen | December 2014 33

Page 34

Accessories Europe | 8 Brake resistors

8.3 Type assignment and order codes

Servo amplifier Brake resistor

S300 (S3xx61) BAR(U) 66 optional

S300 (S3xx01) BAR(U) 91 optional

S400, S601...620, S701-712 BAR(U) 33 optional

S640, S748 BAS(U) 15 usually required

S670, S772 BAS(U) 10 usually required

S724 BAR(U)/BAS(U) 23 optional

AKD-x00306* BAFP(U)/BAR(U)/BAS(U) 33 usually required

AKD-x00606* BAFP(U)/BAR(U)/BAS(U) 33 usually required

AKD-x01206* BAR(U)/BAS(U) 15 optional

AKD-x02406* BAR(U)/BAS(U) 15 optional

AKD-x00307* BAR(U)/BAS(U) 33 optional

AKD-x00607* BAR(U)/BAS(U) 33 optional

AKD-x01207* BAR(U)/BAS(U) 33 optional

AKD-x02407* BAR(U)/BAS(U) 23 optional

AKD-x04807* BAS(U) 10 optional

AKD-C01007 BAR(U)/BAS(U) 33 optional

Resistance/Ω

Remarks

Order codes

Article Amplifier Resis-

tance

Brake resistor BAS(U) 2000-10 S670,S772,

Brake resistor BAS(U) 3000-10 10 3000 4800 DE-103875

Brake resistor BAS(U) 6000-10 10 6000 9600 DE-103876

Brake resistor BAR(U) 500-15 AKD-x01206 & x02406,

Brake resistor BAR(U) 1000-15 15 1000 1600 DE-201440

Brake resistor BAS(U) 2000-15 15 2000 3200 DE-103871

Brake resistor BAS(U) 3000-15 15 3000 4800 DE-103872

Brake resistor BAS(U) 6000-15 15 6000 9600 DE-103873

Brake resistor BAR(U) 600-23 AKD-x02407, S724 23 600 960 DE-200613

Brake resistor BAR(U) 1000-23 23 1000 1600 DE-200614

Brake resistor BAS(U) 2000-23 23 2000 3200 DE-200615

Brake resistor BAS(U) 3000-23 23 3000 4800 DE-200616

Brake resistor BAS(U) 4000-23 23 4000 6400 DE-200617

Brake resistor BAFP(U) 100-33 AKD-x00306 to -x00606

Brake resistor BAFP(U) 200-33 33 200 320 DE-201438

Brake resistor BAR(U) 250-33 33 250 400 DE-106254

Brake resistor BAR(U) 500-33 33 500 800 DE-106255

Brake resistor BAR(U) 1500-33 33 1500 2400 DE-106258

Brake resistor BAS(U) 3000-33 33 3000 4800 DE-201407

Brake resistor BAR(U) 300-66 S300 (S3xx61) 66 300 480 DE-107161

Brake resistor BAR(U) 600-66 66 600 960 DE-107162

Brake resistor BAR(U) 1000-66 66 1000 1600 DE-107163

Brake resistor BAR(U) 300-91 S300 (S3xx01) 91 300 480 DE-107164

Brake resistor BAR(U) 600-91 91 600 960 DE-107165

Brake resistor BAR(U) 1000-91 91 1000 1600 DE-107166

*= AKD-x means AKD variants -B, -P, -T and -M

AKD-x04807

S640, S748

AKD-x00307 to -x01207,

AKD-C01007, S400,

S601...620, S701-712

Rated

Power

[Ω]

10 2000 3200 DE-103874

15 500 800 DE-201439

33 100 160 DE-201437

[W]

Max.

Power

[W]

Order code

34 Kollmorgen | December 2014

Page 35

8.4 External brake resistor BAFP(U)

Accessories Europe | 8 Brake resistors

Protection class: IP40

WARNING

The surface temperature can exceed 250°C.

Risk of burns and fire! Measure the temperature before touching.

Kollmorgen | December 2014 35

Page 36

Accessories Europe | 8 Brake resistors

8.5 External brake resistor BAR(U)

Protection class: IP20

WARNING

The surface temperature can exceed 250°C.

Risk of burns and fire! Measure the temperature

before touching.

36 Kollmorgen | December 2014

Page 37

8.6 External brake resistor BAS(U)

Accessories Europe | 8 Brake resistors

Protection class: IP20

WARNING

The surface temperature can exceed 250°C.

Risk of burns and fire! Measure the temperature

before touching.

Kollmorgen | December 2014 37

Page 38

Accessories Europe | 9 Capacitor Modules

9 Capacitor Modules

9.1 General

KCM modules (KOLLMORGEN Capacitor Modules) absorb energy generated by the motor

when it is operating in generator mode. Normally, this energy is dissipated as waste via

brake resistors. KCM modules, however, feed the energy they have stored back into the DC

Bus link as and when it is required.

KCM-S Saves energy: The energy stored in the capacitor module during generative brak-

ing is available the next time accelerationhappens. The module’s inception

voltage is calculated automatically during the first load cycles.

KCM-P Power in spite of power failure: If the power supply fails, the module provides the

servo amplifier with the stored energy that is required to bringthe drive to a standstill in a controlled manner (this only applies to the power supply voltage; batteryback the 24 V supply separately).

KCM-E Expansion module forboth applications. Expansion modules are available in two

capacitance classes.

9.2 Important notes

DANGER

DC Bus link terminals in servo systems carry high DC voltage of up to

900 V. Touching the terminals while they are carrying voltage is

extremely dangerous. Switch off (disconnect) the line voltage. You must

only work on the connections when the system is disconnected.

It can take over an hour for the modules to self-discharge. Check the state

of charge with a measuring device that is suitable for a DC voltage of up

to 1,000 V. When measuring a voltage of over 60 V between the

DC+/DC- terminals or to ground, discharge the modules as described in

the KCM Instructions Manual.

You must read the instructions manual for the servo amplifier/servomotor you are using in

your application and observe the safety instructions they contain before commencing mounting/installation work.

Wiring diagram and more important notes concerning wiring can be found in the KCM instructions manual and in the instructions manual of the used servo amplifier.

38 Kollmorgen | December 2014

Page 39

9.3 Type assignment and order codes

Servo amplifier KCM Module Servo amplifier KCM Module

S300 all Modules S640, S670 not allowed

S400 all Modules S748, S772 not allowed

S601 to S620 all Modules AKD-x00306...02406* not allowed

S701 to S724 all Modules AKD-x04807 not allowed

AKD-x00307...02407* all Modules AKD-C01007 all Modules

*= x means variants -B, -P, -T and -M

Order codes

Type/Order Code Remarks

KCM-S200-0000 Energy Saving Module, 1.6 kWs

KCM-P200-0000 Power Module, 2 kWs

KCM-E200-0000 Expansion Module 2 kWs

KCM-E400-0000 Expansion Module 4 kWs

Accessories Europe | 9 Capacitor Modules

9.4 Example installation with AKD-P, KCM-P and KCM-E

Maximum cable length between AKD and KCM: 500 mm. The DC+ and DC- lines should

always be twisted, maximum cross section is 6 mm².

RS422 interface X4 allows data exchange controlled by a terminal software of your choice.

Interface setting: 115200 Baud, 8 Data Bits, 1 Stop Bit, No Parity&Flow Control. The X4 mating connector is in the package. The ready signal reports the ready to operate (high level).

More information is given in the KCM Instructions Manual.

Kollmorgen | December 2014 39

Page 40

Accessories Europe | 9 Capacitor Modules

9.5 KCM Module

Observe the safety instructions ➜ p. 38 and in the instruction manual

of the servo amplifier.

Permissible assembly type: Vertical, ground connections at the bottom.

Otherassembly positions are not permitted. Observe the required free space

to next device. Ensure there is unobstructed convection for cooling purposes.

Technical Data

Storage

Type

KCM-S200 1600

KCM-P200 2000 470 VDC 6.9

KCM-E200 2000 - 4.1

KCM-E400 4000 - 6.2

40 Kollmorgen | December 2014

Capacity

[Ws]

Rated supply

voltage

[V=]

max 850 VDC

Peak supply

voltage

[V=]

max 950VDC

(30s in 6min)

Power

Protection

[kW]

18 IP20

Class

Inception

voltage

[V=]

calculated 6.9

Weight

[kg]

Page 41

10 Motor chokes

10.1 General

Shielded motor cables

For reasons of electromagnetic compatibility, the motor must be supplied with power via a

shielded cable. The structure of a cable with 100% shielding and the capacity equivalent circuit diagram (to earth) are shown below.

Why use motor chokes?

l To compensate high capacitive charge/dischargecurrents typical of shieldedmotor

cables approximately 25 m and longer.

l To reduce current alternation noise in the motor.

l To reduce current ripple in themotor.

Accessories Europe | 10 Motor chokes

The digital servo amplifiers’ high switchingfrequencies andsteep switchingedges give rise

to the transfer of capacitive currents to the shield by the three phases (U, V, W). These currents flow from the shield to earth. Dependingon the cable length and cable capacity (determined by design), this can lead to the generation of shield currents with peak values of up to

20A.

These shield currents place a loadon the servo amplifiers and motor and, on large systems,

lead to shifts in potential which can damage other components.

This effect is evident in particular on systems with multiple amplifiers operating in parallel on

the same mains filter.

The motor chokes slow down the rate of rise of the motor current (reduce edge steepness),

thereby reducing thecurrent transferred to the shield.

Why is the cross-section of the motor cable important?

Motor cables longer than 50 m with a small cross-section (e.g. 4 x 1.0 mm²) and therefore a

higher equivalent resistance are able to reduce the oscillation tendency of the LCR oscillating circuit (amplifier/choke/cable/motor). This cross-section can also be advantageous for

cable lengths shorter than 50 m if the cable capacity and motorinductance are very high.

However, the current loading of the cable must always be within thelimits specified by

EN60204.

Kollmorgen | December 2014 41

Page 42

Accessories Europe | 10 Motor chokes

10.2 Important notes

CAUTION

The choke can become hot during operation (rising to temperatures in

excess of 80° C). Risk of light burns and fire! Therefore, you should make

sure that the choke is mounted a sufficient distance away from neighbored components. Provide the requisite conditions for unobstructed convection to cool the choke.

You must read the instructions manual for the servo amplifier/servo motor youare using in

your application and observe the safety instructions they contain before commencing mounting/installation work. This manual is only valid in conjunction with the instructions manual for

the servo amplifier and servo motor you are using in your application.

Mount the motor choke 3YLN on a conductive earthed assembly plate in the switchgear cabinet. The choke box 3YL-24can be mounted to DIN rails as well.

The motor choke is wired into the cable close to the amplifier. When laying the motor cable,

allow about 400 mm for the connection to the choke.

Connection diagram see the servo amplifierinstructions manual.

10.3 Type assignment and order codes

Servo amplifier Motor choke Condition

S300 3YL-24, 3YLN-xx Motor cable ≥ 25m

S400 3YL-24, 3YLN-xx Motor cable ≥ 25m

S601...620 3YL-24, 3YLN-xx Motor cable ≥ 25m

S640/670 not required

S701...724 3YL-24, 3YLN-xx Motor cable ≥ 25m

S748/772 usually not required, in case of cable length ≥ 25m

AKD-x003 to AKD-x006* 3YLN-06 Motor cable ≥ 25m

AKD-x012* 3YLN-14 Motor cable ≥ 25m

AKD-x024* 3YLN-24 Motor cable ≥ 25m

*= x means variants -B, -P, -T and -M

Order codes

Article Nominal Current Approvals Order code

Motor choke box 3YL-24 24 A CE DE-90074

Motor choke 3YLN-06 6 A CE, UL DE-107929

Motor choke 3YLN-10 10 A CE, UL DE-107930

Motor choke 3YLN-14 14 A CE, UL DE-107931

Motor choke 3YLN-20 20 A CE, UL DE-107932

Motor choke 3YLN-24 24 A CE, UL DE-201447

andunusual conditions, ask our customer support

42 Kollmorgen | December 2014

Page 43

10.4 Motor choke 3YL-24

Accessories Europe | 10 Motor chokes

Technical data:

Rated data Sym Unit 3 YL-24

Rated Current I0rms A Max.3x 24

Frequency fmax kHz 8.3

Inductivity L µH 120

Resistance R mOhm 2.6

Weight G kg 1.4

Cable diameter (Shield clamp) - mm 4 to 13.5

Wire cross section U-V-W max. (terminals) - mm² 4

Wire cross section BR+/- max. (terminals) - mm² 2.5

Kollmorgen | December 2014 43

Page 44

Accessories Europe | 10 Motor chokes

10.5 Motor choke 3YLN-xx

Technical Data:

Rated Data Sym DIM 3YLN-06 3YLN-10 3YLN-14 3YLN-20 3YLN-24

Rated current I0rms A 6 10 14 20 24

Rated voltage Unom V 480

Rated frequency fnom Hz 0 to 150

Max. frequency fmax kHz 8

Inductivity L µH 900 900 900 450 450

Power loss P W 12 14.5 19.4 22.3 23.2

Protection class - - IP00

Temperature class - - F

Operation class - - S1

Weight G kg 4.5 5.5 10 10 10

Cable diameter

(Shield clamp)

Wiring cross section max.

(Terminals)

Width A mm 155 155 190 190 190

Depth B mm 90 105 125 125 125

Height C mm 195 195 230 230 230

Mounting hole distance D mm 130 130 170 170 170

Mounting hole distance E mm 56.5 71.5 78 78 78

Mounting screws F - 4xM6 4xM6 4xM6 4xM6 4xM6

- mm 4 to 13.5

- mm² 10 10 16 16 16

44 Kollmorgen | December 2014

Page 45

11 Cables

Kollmorgen assumes no liability for errors or damage to equipment caused by cables manufactured by customers.

11.1 Technical data for cables

Information on the chemical, mechanical and electrical characteristics of the cables can be

found in our Technical WIKI (Cables).

Insulation material

Sheathing: PUR (polyurethane, code 11Y)

Core insulation: PETP (polyesteraphthalate, code 12Y)

Capacitance (phase to shield)

Motor cable: less than 180 pF/m (cross sections >6mm² have larger capacitance)

Feedback cable: less than 120 pF/m

Hybrid Cable: special requirements

Accessories Europe | 11 Cables

11.2 Tools

Technical data

l The brackets in the core definition indicate the shielding

l All cables are suitable for use as trailing cables

l The technical data refer to use as moveable cables

l Operating life : 10 millionbending cycles

l All cables are UL recognized

Only work with the special tools that are required for the used connectors. You can obtain

these special tools from the manufacturer of the connectors or contacts.

Kollmorgen | December 2014 45

Page 46

Accessories Europe | 11 Cables

11.3 PC connection

11.3.1 AKD

The AKD is connected by a standards net cable with RJ45 connectors to the PC or to a

Switch/Hub.

Article Order Code

Ethernet Cable PC-AKD ➜ p. 59

11.3.2 S300, S400, S600, S700

Kollmorgen digital "Sx" type servo amplifiers are equipped with a serial RS232interface to

facilitate communication with a standardpersonal computer (PC). Various types of interface

can be used on the PC. Appropriate cables and in some cases specific accessories will be

required to establish the connection between servo amplifier and PC.

Article Order Code

Cable PC-S300/S400/S600/S700 3m, 9poles DE-90067

Setup Kit S300/S400/S600/S700 USB DE-107666

Y-Adapter for splitting CAN/RS232 and Multilink ➜ p. 47

Setup Kit S300, S400, S600, S700 USB

PC cable for S300, S400, S600, S700

An interface converter is required to use the USB

interface on a PC. Our "USB" setup kits contain a

USB serial converterand a serial PC cable suitable for the amplifier type.

For the purpose of parameterisation and for firmware upgrades, the servo amplifiers can be connected to the serial RS232 interface on a PC. The

connecting cable must be shielded. The braided

shield on the RS232 connecting cable is conductively connected to the front panel of the servo

amplifier via the connector housing on the Sub-D

male connector.

46 Kollmorgen | December 2014

Page 47

Accessories Europe | 11 Cables

Y Adapter (Splitter) for S300/S600/S700

The signals for the serial link to the PC and the CAN interface are routed via the same connector on the servo amplifier (X6). Our Y adapters can be used for simultaneous access to

both interfaces. In this case, the interface signals arerouted via separate connectors.

Article Order Code

Y-Programming-Adapter 1 Axis DE-108211

Y-Adapter -SR6Y- 4 Axes (Multilink Cable) DE-90060

Y-Adapter -SR6Y6- 6 Axes (Multilink Cable) DE-92042

The multi-axis Y adapters support the simultaneous setup (multi-link) of a number of

S300/S600/S700 in a single setupsession.

Y-adapter for 1 Axis Y-adapter for 4 axes Y-adapter for 6 axes

Kollmorgen | December 2014 47

Page 48

Accessories Europe | 11 Cables

11.4 Power Voltage Supply, external brake resistor, DC bus link

The connectors used (40 A andhigher fixed terminals) are included in the scope of supply of

the servo amplifier. If necessary, the connectors are coded and printed with the corresponding terminal designation. The table indicates the type of cable required for each intendedpurpose.

We do not deliver configured cables for this interface.

You must always observe the specifications in respect of cable cross-sections contained in

the instructions manual for the servo amplifieryou are using in your application. Fit suitable

wire endferrules or plug connectors to stripped conductors. A connection diagram appears in

the servo amplifier instructions manual.

11.4.1 Mating connector (part of delivery)

Mains supply 1 Mains supply 2 DC-link bus Brake resistor

Amplifier # Order Code # Order Code # Order Code # Order Code

S300-230V X0 DE-105856 - - X8 DE-107556 X8 DE-107556

S300-400V X0 DE-107557 - - X8 DE-107558 X8 DE-107558

S400 X0 DE-102583 - - X0 DE-102583 X0 DE-102583

S601...620 X0A DE-92258 X0B DE-92259 X7 DE-90064 X8 DE-90065

S701...724 X0 DE-200451 - - X8 DE-200452 X8 DE-200452

AKD-

x00306/00606*

AKD-x01206* X3 CON-

AKDx02406/0xx07*

AKD-C01007 X12 Connector Kit

X3 CON-

AKDX3A-SL

AKDX3B-SL

X4 CON-

AKDX4-SL

➜ p. 23

- - X3 CONAKDX3A-SL

- - X3 CONAKDX3B-SL

- - X3 CONAKDX3C-SL

- - X14 Connector Kit

➜ p. 23

X3 CON-

AKDX3A-SL

X3 CON-

AKDX3B-SL

X3 CON-

AKDX3C-SL

X14 Connector Kit

➜ p. 23

*= x means variants -B, -P, -T and -M

11.4.2 Mating connector (optional)

Amplifier # Order Code # Order Code

S701...724 X0Y DE-200851 X8Y&X4Amini DE-201942

S701...724 XOF DE-200955 X8F DE-200956

AKD-x02406/0xx07 X3Y CON-AKDX3C-SL-Y

With Y-connectors you can daisy-chain supply voltage or DC-bus link to several amplifiers.

For details seeinstructions manual of the servo amplifier. The F-connectors are for fast wiring (no screws).

X0F X0Y X8F X8Y (&X4Amini) X3Y

Mains supply DC-link bus / Brake resistor

S700 AKD

48 Kollmorgen | December 2014

Page 49

11.4.3 Recommended cable type

Accessories Europe | 11 Cables

max.

Purpose In=1.5...10A In=14...24A In=40...70A

length

recommended cable @ amplifier rated output current

AC-supply* - H07V-K 1.5 H07V-K 4 H07VVC4-K 3G 25

DC-bus link* 0.5 m H07V-K 1.5 H07V-K 4 H07V-K 25

2m H07VVC4-K 2X 1.5 H07VVC4-K 2X 4 H07VVC4-K 2X 25

Ext. brake resistor* 5m H07VVC4-K 2G 1.5 H07VVC4-K 2G 25

* valid only for single-axis systems. For multi-axis systems, please consult our customer support.

11.4.4 Preparing cables for AKD/S300/S400/S601...620/S700

The connections are located on the bottom or front of the servo amplifier. Terminal connectors are used, which are included in the delivery package for the servo amplifier. The connectors are coded and have the appropriate connection designation printed on them. They

must never be mixed up.

Follow the pin assignment in the instructions manual. When connecting an external brake resistor, please note that the link cable must first be removed.

Preparing unshielded cables

If shielding is not necessary, then we recommend using single cores for the wiring inside the

switchgear cabinet.

Strip off about 10 mm of the insulation at the ends of the

cores. Take care to avoid damage to the copper strands

while doing this. Depending on the cross-section of the

core and the type of bootlace ferrule that is used, the

length that has to be stripped may vary by several millimeters.

Apply bootlace ferrules to the conductors. As an alternative, you can also use terminal pins.

Connector example S600:

Push the ends of the conductors into the connector as far

as they will go. Follow the pin assignment in the servo

amplifier's instructions manual. Tighten the screws of the

terminals. Take care that the insulation is not trapped in

the terminals.

Kollmorgen | December 2014 49

Page 50

Accessories Europe | 11 Cables

Preparing shielded cables

First, remove the outer covering of the cable and the

shielding braid over a length

of about 70 mm. Then

remove just the outer covering for about another

50mm, without damaging

the shielding braid.

Strip off about 10 mm of the

insulation from the ends of

the cores. Take care to

avoid damage to the copper

strands while doing this.

Depending on the cross-section of the core and the type

of bootlace ferrule that is

used, the length that has to

be stripped may vary by several millimeters.

Apply bootlace ferrules to

the conductors. As an alternative, you can also use terminal pins instead of

bootlace ferrules.

Connector example S600:

Push the ends of the con-

ductors into the connector

as far as they will go. Follow

the pin assignment in the

instructions manual. Tighten

the screws of the terminals.

Take care that the insulation

is not trapped in the terminals.

50 Kollmorgen | December 2014

Page 51

11.4.5 Preparing cables for S640/670 and S748/772

The connections for the power supply, the ballast resistor and the DC-link are made through

terminals on the bottom of the servo amplifier. These terminals can accept core cross-sections from 10 to 50 mm².

The AC supply connection is used as an example for preparing a cable.

Accessories Europe | 11 Cables

Remove the outer covering

of the cable over a length of

about 250 mm, without damaging the shielding braid.

Shorten the shielding to a

length of about 70 mm.

Shorten the three cores for

the supply phases to

200mm. Strip off all cores

for a length of about 25mm.

This length depends on the

core cross-section and the

bootlace ferrules that are

used.

Apply bootlace ferrules to

the conductors.

Connect up the cable

according to the wiring diagram in the instructions

manual for the servo amplifier and take care that no

insulation is trapped in the

terminals.

Kollmorgen | December 2014 51

Page 52

Accessories Europe | 11 Cables

11.5 24V auxiliary voltage supply

Connectors are used, that are included in the delivery package of the servo amplifiers. If

necessary, the connectors are coded and printed with the corresponding terminal designation.

We do not deliver configured cables for this interface.

You must always observe the specifications in respect of cable cross-sections contained in

the instructions manual for the servo amplifieryou are using in your application. Fit suitable

wire endferrules or plug connectors to stripped conductors. A connection diagram appears in

the servo amplifier instructions manual.

11.5.1 Mating connector (part of delivery)

Amplifier Connector Order Code

S300 X4 DE-107555

S400 X0 DE-102583

S601...620 X4 DE-90062

S640/670 X4 DE-92143

S701...724 X4A DE-200449

S701...724 X4B DE-200450

S748/772 X4 DE-201241

S748/772 X9B DE-201193

AKD-B/P/T/M X1 CON-AKDX1-SL

AKD-C X13 Connector Kit ➜ p. 23

11.5.2 Recommended cable type

Purpose recommended cable

24V Aux. Voltage

Observe voltage drop!

H07V-K 1.5 or H07V-K 2.5

52 Kollmorgen | December 2014

Page 53

11.5.3 Preparing cables

The connection is on the front panel of the servo amplifier. A Combicon connector is used,

which is included in the delivery package of the servo amplifiers.

Accessories Europe | 11 Cables

Strip off about 10 mm of the insulation at the ends of the

cores. Take care to avoid damage to the copper strands

while doing this. Depending on the cross-section of the

core and the type of bootlace ferrule that is used, the

length that has to be stripped may vary by several millimeters.

Apply bootlace ferrules to the conductors. As an alternative, you can also use terminal pins.

Connector example S601...620:

Push the ends of the conductors into the connector as far

as they will go. Follow the pin assignment in the instructions manual. Tighten the screws of the terminals. Take

care that the insulation is not trapped in the terminals.

Kollmorgen | December 2014 53

Page 54

Accessories Europe | 11 Cables

11.6 Digital/analog Inputs/Outputs

11.6.1 Digital In/Outputs for AKD-C

The digital control signals are connected to X15 and X16 with single lines.

We do not deliver configured cables for this interface.

Mating connector (part of delivery)

Amplifier # Order Code # Order Code

AKD-C X15 Connector Kit ➜ p. 23 X16 Connector Kit ➜ p. 23

Recommended cable type

Purpose max. length Recommended cable

Digital I/O, STO 30m H07VK 0.5

11.6.2 Digital In/Outputs for AKD-N

All AKD-N servo amplifiers have one 8 poles M12 connector to connect digital control signals.

Maximum cable length 5m.

Digital Signals STO Signals

AKD-N-DS servo amplifiers (devices with local STO input) have an

additional 4 poles M12 connectors to connect the local STO signals.

Maximum cable length 5m.

Kollmorgen recommends pre-configuredPhoenix SAC cables.

Order codes for I/O cables, one end configured

Amplifier Order Code No. of wires Description

AKD-N all types SAC-8P-M12MS 8 poles 5m, M12 mating connector,

unconfigured wires

AKD-N-DS SAC-4P-M12MS 4 poles 5m, M12 mating connector,

unconfigured wires

Otherlength can be ordered from Phoenix Contact Deutschland GmbH.

54 Kollmorgen | December 2014

Page 55

Accessories Europe | 11 Cables

11.6.3 Digital/analog I/O for S300/S400/S600/S700 and AKD-B/P/T/M

The cables for analog signals must be twisted pairs, and shielded. The digital signals can be

connected by single wires.

We do not deliver configured cables for this interface.

Mating connector (part of delivery)

Digital / analog signals STO Signals

Amplifier # Order Code # Order Code # Order Code

S300 X3 DE-107554 - - X4 DE-107555

S400 X3 DE-102585 X1 DE-102584 - -

S601...620 X3 DE-90061 - - X10 DE-101696

S640/670 X3 DE-101695 - - X10 DE-101696

S701...724 X3A DE-200447 X3B DE-200448 X4B DE-200450

S748/772 X3A DE-200447 X3B DE-200448 X4 DE-201241

AKD-B/P/T X7 CON-AKDX7-SL X8 CON-AKDX8-SL X1 CON-AKDX1-SL

AKD-T-IC X7 CON-AKDX7-SL X8 CON-AKDX8-SL X1 CON-AKDX1-SL

X21 CON-AKDX21-SL X22 CON-AKDX22-SL - X23 CON-AKDX23-SL X24 CON-AKDX24-SL - -

AKD-M X7 CON-AKDX7-SL X8 CON-AKDX8-SL X1 CON-AKDX1-SL

X35 CON-AKDX35-SL X36 CON-AKDX36-SL - -

Recommended cable type

Purpose max. length recommended cable

Digital I/O 10m H07VK 0,5

BTB 10m

Digital GND 10m

Analog Setpoint 25m LiYCY (TP) 4x2x0.25

Analog GND 25m

Color code for shielded cable

Signal Color* Cable

AGND GY

analog in 1+ WH

analog in 1- BN

analog in 2+ GN

analog in 2- YE

analog out 1 PK

analog out 2 BU

AGND RD

* according to IEC 60757

LiYCY (TP) 4x2x0.25

Kollmorgen | December 2014 55

Page 56

Accessories Europe | 11 Cables

11.6.4 Preparing cables

For simplicity, the instructions for preparation only show the section with the cores that have

to be shielded and twisted pairs.

Remove the outer covering and the shielding

braid over a length of

about 100 mm.

Remove another section of the outer covering, about 30mm

long, without damaging

the shielding braid.

Secure the cores where

they emerge, with a

cable tie. Strip off the

insulation from the

cores for a length of

about 5 mm, without

damaging the copper

strands. This length can

vary, according to the

type of bootlace ferrule

that is used.

Fit appropriate bootlace

ferrules or terminal pins

to the bared ends of the

cores.

Wire up the screw terminals of the connector according to the wiring diagram (see also the

instructions manual for the servo amplifier). Tighten the screws andtake care that the insulation is not trapped in the terminals.

56 Kollmorgen | December 2014

Page 57

Accessories Europe | 11 Cables

11.7 Encoder Emulation, Stepper motor control, Master-Slave

This interface can be used for several applications (see the amplifiers instructions manual).

The material requirements are always the same.

We do not deliver configured cables for this interface.

11.7.1 Mating connector, cable type

Article Description Order Code

Cable 4x2x0.25 (per meter) DE-92186

Sub-D connector kit Socket 9-pole, housing and screws DE-81784

Connector kit, amplifier

endAKD-B/P/T/M, X9/X10

11.7.2 Connection

The cable used must be shielded, with twisted pairs to (suggestion according to DIN 47100).

Since it is important which signal pairs are twisted together, the following table shows the colors of the individual cores (to IEC 60757).

X10 male connector 15 pin high density, X9

female connector 9 pin, 2 housings, screws

AKD-X9+X10-Kit

SubD9 SubD9, X9 Core color @ 5x2x0.25

S300...S700 AKD-B/P/T/M ROD SSI, Stepper motor control, Master-Slave

1 3 WH WH

2 7 GN n.c.

3 8 YE n.c.

4 1 GY GN

5 2 PK YE

6 4 BU GY

7 5 RD PK

8 n.c. 6 BK BK

9 n.c. 9 BN n.c.

The connector assignment is determinedby the use of the interface; see the servo amplifier

instructions manual.

11.7.3 Termination resistors

Depending on servo amplifier type (see instructions manual for the servo amplifier) and

application, the cable must be terminated by termination resistors at the amplifier end or the

control end. The resistance values depend on the characteristic impedance of the cable

material.

Pin Amplifier Controller Amplifier Controller Amplifier Controller Master Slave

1 - - - - - - - 2 3 - - - - - - 4 5 - - - 6 7 - - - 8 - - - - - - - 9 - - - - - - - -

Interface function (S300/S400/S600/S700)

ROD SSI Stepper control Master-Slave

R ~ 150Ω

R ~ 150Ω R ~ 150Ω

R ~ 150Ω

- - - - - -

-

-

R ~ 150Ω R ~ 150Ω

R ~ 150Ω

- -

- -

R ~ 150Ω

R ~ 150Ω

Kollmorgen | December 2014 57

Page 58

Accessories Europe | 11 Cables

11.7.4 Preparing cables

Remove the outer covering of the

cable over a length of about

25mm, without damaging the

shielding braid.

Push the shielding braid back over

the outer covering of the cable,

and strip off the ends of the cores

over a length of about 5 mm,

without damaging the copper

strands.

Push a suitable piece of heatshrink

tubing over the outer cover, and

heat it up. Leave about 7mm free

at the end.

Solder the ends of the cores (with

the resistors where required) into

the solder buckets of the SubD connector. Insulate the connections

and the resistors so that there can

be no accidental contact between

them or with the connector housing.

Use the strain relief to fix the cable

to the bottom half of the housing.

Do not overtighten the screws, or

the cable will be crushed. Place

the SubD connector, with the wider

side below, in the bottom half of

the housing.

Check the connections before closing the housing, since it cannot be

opened again afterwards without

damage. Place the fixing screw in

position in the housing, and then

press the two halves of the housing firmly together. Take care that

the fixing screw and the SubD connector insert are properly located.

58 Kollmorgen | December 2014

Page 59

11.8 Ethernet cable

Connection to an Ethernet network is possible via two RJ45 connectors in the servo amplifiers.

These cables can be used forall fieldbus connections with standard RJ45 connectors like

EtherCAT, PROFINET, SynqNet and also for the EtherNet TCP/IP Service Port connection

of an AKDservo amplifier.

11.8.1 Order codes Ethernet cable, configured

Article Length Order code

Ethernet cable 0.17 m ENCP-0017-000

Ethernet cable 0.26 m ENCP-0026-000

Ethernet cable 0.30 m ENCP-0030-000

Ethernet cable 0.50 m ENCP-0050-000

Ethernet cable 1.00 m ENCP-0100-000

Ethernet cable 2.00 m ENCP-0200-000

Ethernet cable 3.00 m ENCP-0300-000

Ethernet cable 4.00 m ENCP-0400-000

Ethernet cable 5.00 m ENCP-0500-000

Ethernet cable 10.00 m ENCP-1000-000

Accessories Europe | 11 Cables

Kollmorgen | December 2014 59

Page 60

Accessories Europe | 11 Cables

11.9 CAN bus cable

Accordingto ISO 11898 you should use a bus cable with a characteristic impedance of

120Ω. The usable cable length depends on the transmission rate. The values that we have

measured can be taken as a guide, but they should not be interpreted as limits:

Cable data

l

Characteristic impedance: 100-120 Ω

l Cable capacitance: max. 60 nF/km

l

Conductor (loop) resistance:159.8 Ω/km

Cable length, depending on the transmission rate:

Transmission rate / kbps 1000 500 250

max. cable length / m 20 70 115

The table refers to the total cable length betweenthe ends of the bus. Longer transmission

distances can be achieved with a lower cable capacitance (max. 30nF/km) and lower loop

resistance (115 Ω/km).

11.9.1 CAN bus cable AKD

We deliver configured CAN bus cables for

AKD-xyyyzz-xxCN and AKD-xyyyzz-xxCC.

The CAN Termination connector is required for bus termination of the last AKDconnected to

the CAN bus. For connecting an AKD to a CAN device with SubD9 connector the CAN

RJ12-SubD9 Adapter can be used.

Article Order code

CAN Termination connector AKD-CAN-Termination

CAN RJ12->SubD9 adapter AKD-CAN-RJ12-SubD9

11.9.2 Can bus cable for S300/S400/S600/S700

We do not deliver configured cables for S300/S400/S600/S700.

Usage of the materials in the table below ensure that all the requirements are met.

Part Designation Order code

Cable Li2YCY (TP) 2x2x0.25mm² DE-86834 (cut to length)

SubD kit 9-pin SubD connector (socket) DE-90650

Article Length AKD Order code

CAN Bus cable 0.15 m CBP000-002-m15-00

CAN Bus cable 0.30 m CBP000-002-m30-00

CAN Bus cable 1.00 m CBP000-002-001-00

CAN Bus cable 3.00 m CBP000-002-003-00

If your cable has more connectors than you need, any of them can be left free.

For EMC reasons, the SubD connector housings must fulfil the following conditions:

l metal or metallic-coated housing

l provision for connecting the cable shielding to the housing, large-area connection

60 Kollmorgen | December 2014

Page 61

Wiring diagram

Preparing cables

Accessories Europe | 11 Cables

Remove the outer covering of the

cable over a length of about 60mm,

without damaging the shielding

braid.

Push the shielding braid back over

the outer covering of the cable, and

strip off the ends of the cores over a

length of about 7 mm, without damaging the copper strands. The

length can vary according to the

type of bootlace ferrule that is used.

Push a suitable piece of heat-shrink

tubing over the outer cover, and

heat it up. Leave about 7mm free at

the end. Fit appropriate bootlace ferrules to the cores. Depending on

which type of connector you are preparing, use diagram A (inner bus

connector), or B (outer bus connector). Use ferrules for twin wires if

you have to connect two cores, or

one core and a termination resistor

to a single connection.

Use the strain relief to fix the cable

to the bottom half of the housing. Do

not overtighten the screws, or the

cable will be crushed. Wire up the

terminals according to the wiring

diagram, and place the connector

PCB with the terminals underneath

in the lower half of the housing.

Put the two knurled screws in place,

and press the two halves of the

housing together until the four lugs

snap into position.

Take care that the connector PCB

and the knurled screws are properly

located.

Kollmorgen | December 2014 61

Page 62

Accessories Europe | 11 Cables

11.10 Hybrid cables

11.10.1 AKD to AKM1 Motor (i-tec connector)

You should use the configured Kollmorgen cables.

For AKD-B/P/T/M, with shield clamp, i-tec motor connector

AKD-B/P/T/M series servo amplifiers have a 15 pole highdensity SubD female connector to

connect the feedback and a terminal connector for power wiring.

For SFD3 connection to AKD-B/P/T/M, the feedback connector on the servo amplifier end

contains electronics.

Usable for AKM1 (connector option D, feedback options C- and CA). Define therequired

length in clear text (steps of 1 m). Maximum cable length 25 m.

Servo

amplifier

AKD-B/P/T/M SFD AKD-x00306 & x00606* and AKM1

AKD-B/P/T/M SFD3 &

*= x means variants -B, -P, -T and -M

For AKD-N, i-tec motor connector

AKD-N series servo amplifiers have an 8 pole round connector to connect both motorpower

andfeedback.

Usable for AKM1 (connector option D, feedback option CA).

Maximum cable length 5 m. Length definition: xx=meters, yy=centimeters.

0.2, 0.3, ... , 1.0 (steps 0.1m up to 1m)

1.25, 1.5, ... , 2.0 (steps 0.25m up to 2m).

(4x1+(2x0.34)

+(2x0.75))

Brake

Usable to connect Order code

CCS1A3-010-vvv-00

(connector D, feedback C-)

AKD-x & x* and AKM1 (connector

D, feedback CA)

CCJ1A3-010-vvv-00

Servo

amplifier

AKD-N SFD3 &

62 Kollmorgen | December 2014

(4x1+(2x0.34)

+(2x0.75))

Brake

Usable to connect Order code

AKD-N and AKM1 (connector D,

feedback CA)

CCJNA3-010-xxmyy-00

Page 63

11.10.2 AKD to AKM2-6 (IP65 connector)

You should use the configured Kollmorgen cables.

With shield clamp for AKD-B/P/T/M, motor connector size 1 (up to 22A)

AKD-B/P/T/M series servo amplifiers have a 15 pole highdensity SubD female connector to

connect the feedback and a terminal connector for power wiring. The hybrid cable is splitted

to power and feedback cables on the servo amplifier end. The cable shield can be connected

to the servo amplifier front with the attached shield clamp.

For DSL and SFD3 connection to AKD-B/P/T/M, the feedback connector on the servo amplifier endcontains electronics.

Usable for AKM2 to AKM6 (connector option D, feedback option C-, CA, GE and GF). Define

the required length in clear text (steps of 1 m). Maximum cable length 25 m.

Accessories Europe | 11 Cables

Servo

amplifier

AKD-B/P/T/M SFD AKD-x00306 & x00606* and AKM2-

(4x1+(2x0.34)

+(2x0.75))

Usable to connect Order code

CCS1A1-010-vvv-00

6 (connector D, feedback C-)

AKD-B/P/T/M SFD3/DSL &

Brake

AKDx00306,x00606,x00307,x00607*

CCJ1A1-015-vvv-00

andAKM2-6 (connector D, feedback CA, GE, GF)

*= x means variants -B, -P, -T and -M

For AKD-N, motor connector size 1 (up to 22A)

AKD-N series servo amplifiers have an 8 pole round connector to connect both motorpower

andfeedback.

Usable for AKM2 to AKM6 (connector option D, feedback option CA, GE and GF).

Maximum cable length 5 m.Length definition: xx=meters, yy=centimeters.

0.2, 0.3, ... , 1.0 (steps 0.1m up to 1m)

1.25, 1.5, ... , 2.0 (steps 0.25m up to 2m).

Servo

amplifier

(4x1+(2x0.34)

+(2x0.75))

AKD-N SFD3/DSL &

Brake

Usable to connect Order code

AKD-N and AKM2-6 (connector

CCJNA1-015-xxmyy-00

D, feedback CA, GE, GF)

Kollmorgen | December 2014 63

Page 64

Accessories Europe | 11 Cables

With shield plate for AKD-B/P/T/M, motor connector size 1 (up to 22A)

AKD-B/P/T/M series servo amplifiers have a 15 pole highdensity SubD female connector to

connect the feedback and a terminal connector for power wiring. The hybrid cable is splitted

to power and feedback cables on the servo amplifier end. The cable shield is automatically

connected to the servo amplifier front with themounted shield plate.

For DSL and SFD3 connection to AKD-B/P/T/M, the feedback connector on the servo amplifier endcontains electronics.