Page 1

S700

Digital Servo Amplifier S701x2…S724x2 (STO dual channel)

Instruction Manual

Edition 07/2014

Translation of the original instruction manual.

Valid for Hardware Revision 02.10

Keep all manuals as a product component

during the life span of the product.

Pass all manuals to future users and owners

of the product.

File s701_e.***

Page 2

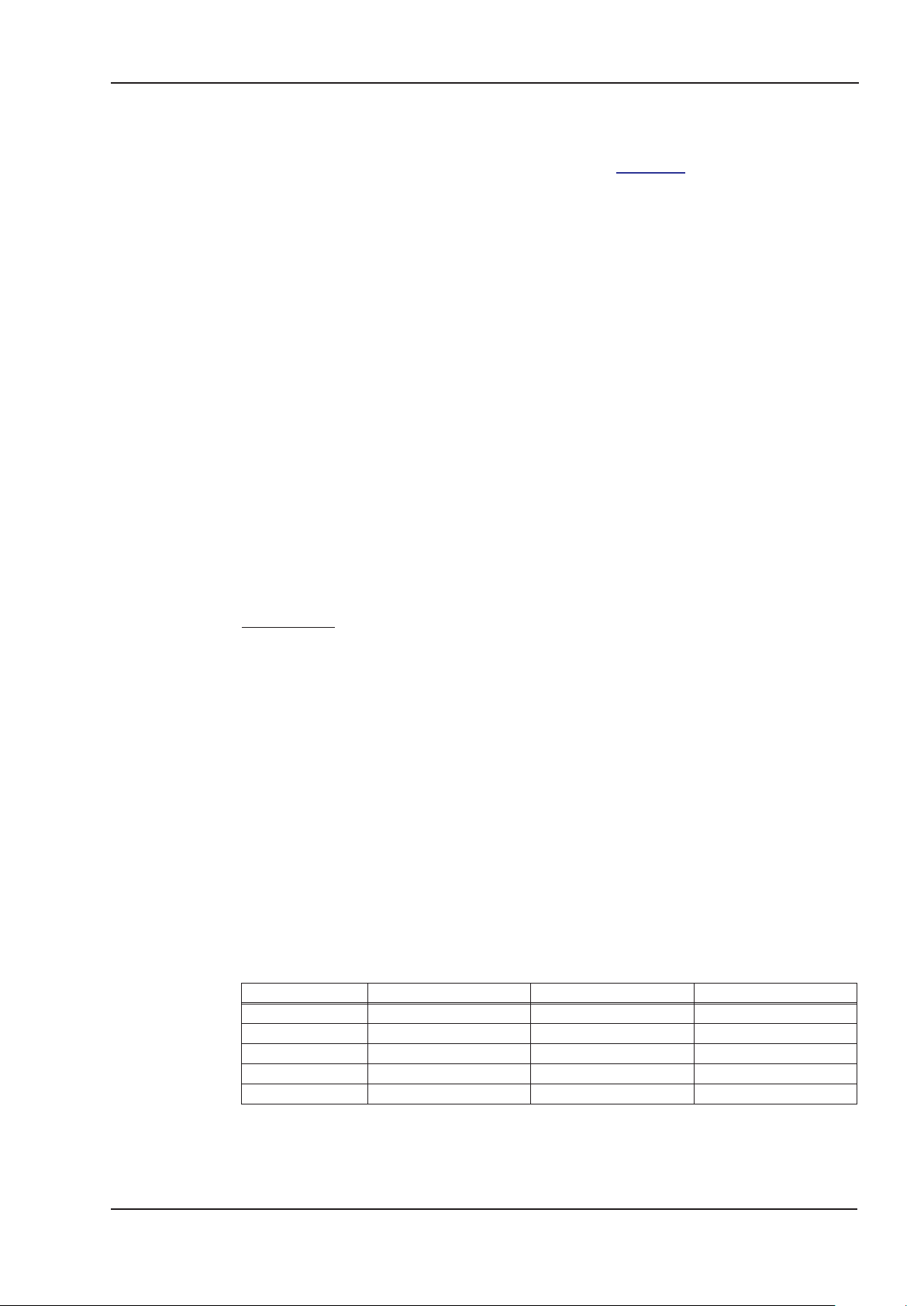

Record of Document Revisions:

Revision Remarks

Product brand, memory card, part number scheme, faults, EnDat 2.2, Multilink, certificates,

02/2010

GOST-R, SSI input (X5 clock - inverted), PosI/O-Monitor added, Safety Card S1 added, TÜV pro

ved safety, FAN option F2, X4A/3 changed from XGND to STO2-Enable, Stop and Emergency

Stop examples moved to WIKI

07/2010

New DriveGUI icon, bridge DGND-GND (dig-I/O) changed, type 6 integrated, transport and storage classes

12/2010 Expansion module 2CAN, company name, name plate, CE certificate

06/2011

Part number scheme updated, encoder emulation via X1, BiSS-C, Feedback systems visualized,

STO SIL3/PLe, certificates removed

09/2011 New Certificates added, safety characteristic data updated

06/2012 Fusing corrected, expansion card FB2to1 new, Emergency Stop updated

Feedback - ENCVON note, FBTYPE 34, KCM modules, CE declaration of conformity, formal im07/2013

provements, BiSS C Renishaw, according to IEC 82079, safety cards S1/S2 replaced by S3/S4,

diagram "Behavior in the event of an error" updated.

08/2013 Correction S4 safety card (SLP not possible)

12/2013

05/2014

Hint automatic restart, fault table, switch off behaviour in case of faults, SSI emulation timing up-

dated, safe to touch voltage 40V->60V

Warning symbols updated, fusing brake resistor/dc bus, notes dc bus coupling, X8Y set with X4A

mini

07/2014 Wiring thermo sensor updated (Feedback)

-

Hardware Revision (HR)

Hardware

Revision

usable

Firmware

Revision

usable

DRIVEGUI.EXE

Revision

Remarks

00.20 2.21 1.30 Build 0060 prototype

01.21 2.50 - 3.49

02.00 3.50 - 4.99

02.10

³ 5.18 ³ 2.20 Build 0004

³ 1.30 Build 0060

³ 1.30 Build 0063

short housing, X5, X6, X7

connector X0 and X8 mirror-operated, EtherCAT onboard, charging circuit (parallel connection ability)

memory card usable, two channel STO, X4A coded

to pin 2

WINDOWS is a registered trademark of Microsoft Corporation

HIPERFACE is a registered trademark of Max Stegmann GmbH

®

SERCOS s a registered trademark of sercos

international e.V.

EnDat is a registered trademark of Dr.Johannes Heidenhain GmbH

EtherCAT is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH

Technical changes which improve the performance of the device may be made without prior notice!

Printed in the Federal Republic of Germany

All rights reserved. No part of this work may be reproduced in any form (by photocopying, microfilm or any

other method) or stored, processed, copied or distributed by electronic means without the written permission

of Kollmorgen Europe GmbH.

Page 3

Kollmorgen 07/2014 Contents

Seite

1 General

1.1 About this manual................................................................7

1.2 Notes for the printed edition (paper version) ...........................................7

1.3 Notes for the online edition (PDF format)..............................................7

1.4 Symbols used ...................................................................8

1.5 Standards used..................................................................8

1.6 Abbreviations used ...............................................................9

2 Safety

2.1 You should pay attention to this ....................................................10

2.2 Use as directed.................................................................12

2.3 Prohibited use..................................................................13

2.4 Handling ......................................................................13

2.4.1 Transport .................................................................13

2.4.2 Packaging ................................................................13

2.4.3 Storage ..................................................................14

2.4.4 Maintenance, Cleaning ......................................................14

2.4.5 Disassembling .............................................................14

2.4.6 Repair ...................................................................15

2.4.7 Disposal..................................................................15

3 Approvals

3.1 Conformance with UL ............................................................17

3.2 CE conformance................................................................18

3.2.1 European Directives and Standards for the machine builder .........................18

3.2.2 CE Declaration of Conformity .................................................19

3.3 GOST-R conformance ...........................................................20

3.4 Functional Safety ...............................................................21

3.4.1 Safety Certificate S700 ......................................................21

3.4.2 Safety Certificate S700 with Safety Card ........................................22

4 Package

4.1 Package supplied ...............................................................23

4.2 Nameplate ....................................................................23

4.3 Part number scheme ............................................................24

5 Technical description

5.1 The S700 family of digital servo amplifiers............................................25

5.2 Technical data .................................................................28

5.2.1 Rated data S7xx0 ..........................................................28

5.2.2 Rated data S7xx6 ..........................................................29

5.2.3 Inputs, outputs, aux. voltage supply ............................................30

5.2.4 Connectors ...............................................................30

5.2.5 Recommended tightening torques .............................................30

5.2.6 Fusing ...................................................................30

5.2.7 Ambient conditions, ventilation, mounting position .................................31

5.2.8 Conductor cross-sections ....................................................31

5.3 Motor holding brake .............................................................32

5.4 LED display....................................................................33

5.5 Grounding system ..............................................................33

5.6 Dynamic braking (brake circuit) ....................................................33

5.7 Switch-on and switch-off behavior ..................................................36

5.7.1 Behavior in standard operation ................................................37

5.7.2 Behavior in the event of an error (with standard setting) ............................38

5.8 Stop-, Emergency Stop-, Emergency Off Function to IEC 60204 ..........................39

5.8.1 Stop .....................................................................39

5.8.2 Emergency Stop ...........................................................40

5.8.3 Emergency Off.............................................................40

S701x2-S724x2 Instructions Manual 3

Page 4

Contents 07/2014 Kollmorgen

Seite

5.9 Safety function STO .............................................................41

5.9.1 Safety characteristic data ....................................................41

5.9.2 Enclosure.................................................................41

5.9.3 Wiring ...................................................................41

5.9.4 Important notes ............................................................42

5.9.5 Use as directed STO ........................................................42

5.9.6 Prohibited Use STO ........................................................42

5.9.7 Technical data and pinning ...................................................43

5.9.8 Functional description .......................................................44

5.9.9 Functional test .............................................................49

5.10 Shock-hazard protection..........................................................51

5.10.1 Leakage current ...........................................................51

5.10.2 Residual current protective device (RCD)........................................51

5.10.3 Isolating transformers .......................................................51

6 Mechanical Installation

6.1 Important notes.................................................................53

6.2 Guide to mechanical installation....................................................53

6.3 Assembly .....................................................................54

6.4 Dimensions ....................................................................55

6.5 Fan assembly ..................................................................56

7 Electrical installation

7.1 Important notes.................................................................57

7.2 Guide to electrical installation......................................................58

7.3 Wiring ........................................................................59

7.3.1 Shielding connection to the front panel..........................................60

7.3.2 Motor connector X9 with shielding connection ....................................60

7.3.3 Technical data for connecting cables ...........................................61

7.4 Components of a servo system ....................................................62

7.5 Block diagram..................................................................63

7.6 Connector assignments ..........................................................64

7.7 Connection diagram (Overview)....................................................65

7.8 Electrical supply ................................................................66

7.8.1 Connection to various mains supply networks ....................................66

7.8.2 24V auxiliary supply (X4).....................................................68

7.8.3 Mains supply connection (X0), three phase ......................................68

7.8.4 Mains supply connection (X0), two phase without neutral ...........................68

7.8.5 Mains supply connection (X0), single phase with neutral ............................69

7.9 DC bus link (X8) ................................................................70

7.9.1 DC Bus topology ...........................................................71

7.9.2 External brake resistor (X8) ..................................................72

7.9.3 Capacitor Module KCM ......................................................72

7.10 Motor and holding brake connection (X9) ............................................74

4 S701x2-S724x2 Instructions Manual

Page 5

Kollmorgen 07/2014 Contents

Seite

7.11 Feedback systems ..............................................................75

7.12 Primary and secondary feedback types ..............................................76

7.12.1 Resolver (X2) .............................................................77

7.12.2 Sine Encoder with BiSS analog (X1)............................................78

7.12.3 Encoder with BiSS digital (X1) ................................................79

7.12.4 Sine Encoder with EnDat 2.1 (X1) .............................................80

7.12.5 Encoder with EnDat 2.2 (X1)..................................................81

7.12.6 Sine Encoder with HIPERFACE (X1) ...........................................82

7.12.7 Sine Encoder with SSI (X1)...................................................83

7.12.8 Sine Encoder without data channel (X1).........................................84

7.12.9 Sine Encoder with Hall (X1) ..................................................85

7.12.10 ROD (AquadB) 5V, 1.5MHz (X1) ..............................................86

7.12.11 ROD (AquadB) 5V, 350kHz (X1)...............................................87

7.12.12 ROD (AquadB) 5V, 350kHz with Hall (X1) .......................................88

7.12.13 ROD (AquadB) 24V (X3).....................................................89

7.12.14 ROD (AquadB) 24V with Hall (X3, X1) ..........................................90

7.12.15 SSI Encoder (X1) ..........................................................91

7.12.16 Hall sensors (X1)...........................................................92

7.13 Electronic Gearing, Master-Slave operation...........................................93

7.13.1 Encoder control types .......................................................93

7.13.2 Connection to stepper motor controllers (step and direction) .........................94

7.13.3 Master-slave operation ......................................................95

7.14 Encoder Emulation, position output .................................................96

7.14.1 Incremental encoder output - A quad B (X1) .....................................96

7.14.2 SSI encoder output (X1) .....................................................97

7.15 Digital and analog inputs and outputs ...............................................98

7.15.1 Analog Inputs (X3B) ........................................................98

7.15.2 Digital Inputs (X3A, X3B and X4A, X4B).........................................99

7.15.3 Digital Outputs (X3A, X3B) ..................................................101

7.16 RS232 interface, PC connection (X6) ..............................................102

7.17 CANopen interface (X6) .........................................................103

7.18 EtherNET interface (X7) .........................................................104

7.19 Memory card..................................................................105

8Setup

8.1 Important notes................................................................107

8.2 Setup software ................................................................108

8.2.1 Use as directed ...........................................................108

8.2.2 Software description .......................................................108

8.2.3 Hardware requirements, operating systems .....................................109

8.2.4 Installation under WINDOWS ................................................109

8.3 Quickstart ....................................................................110

8.3.1 Preparation ..............................................................110

8.3.2 Connect .................................................................112

8.3.3 Important Screen Elements..................................................113

8.3.4 Setup Wizard.............................................................114

8.3.5 Motion Service (Jog Mode) ..................................................117

8.3.6 More Setup Screens .......................................................118

8.4 Multi axis system ..............................................................119

8.5 Keypad operation and LED display ................................................119

8.5.1 Keypad operation .........................................................120

8.5.2 Status display ............................................................120

8.5.3 Standard menu ...........................................................120

8.5.4 Advanced menu ..........................................................121

8.6 Error messages ...............................................................122

8.7 Warning messages.............................................................123

8.8 Trouble Shooting ..............................................................124

S701x2-S724x2 Instructions Manual 5

Page 6

Contents 07/2014 Kollmorgen

Seite

9 Expansions

9.1 Expansion cards for slot 1 .......................................................125

9.1.1 Guide to installation of expansion cards in slot 1 .................................125

9.1.2 Expansion card -I/O-14/08- ..................................................126

9.1.3 Expansion card -PROFIBUS- ................................................129

9.1.4 Expansion card -SERCOS-..................................................130

9.1.5 Expansion card - DEVICENET - ..............................................132

9.1.6 Expansion card -SYNQNET-.................................................135

9.1.7 Expansion card - FB-2to1 - ..................................................137

9.1.8 Expansion module -2CAN- ..................................................139

9.2 Expansion cards for slot 2 .......................................................141

9.2.1 Guide to installation of expansion cards in slot 2 .................................141

9.2.2 Option "F2", controlled Fan ..................................................141

9.2.3 Expansion cards "PosI/O" & "PosI/O-Monitor" ...................................142

9.3 Expansion cards for slot 3 .......................................................151

9.3.1 Guide to installation of expansion cards in slot 3 .................................151

9.3.2 Option "F2", controlled Fan ..................................................151

9.3.3 Expansion cards "PosI/O" & "PosI/O-Monitor" ...................................151

9.3.4 Expansion card "Safety 2-2" (S4) .............................................152

9.3.5 Expansion card "Safety 1-2" (S3) .............................................155

10 Appendix

10.1 Glossary .....................................................................159

10.2 Order codes ..................................................................161

10.2.1 Servo amplifiers...........................................................161

10.2.2 Memory Card.............................................................161

10.2.3 Expansion cards ..........................................................162

10.2.4 Mating connectors .........................................................162

10.3 Repair- or Disposal request Telefax form............................................163

10.4 Index ........................................................................164

6 S701x2-S724x2 Instructions Manual

Page 7

Kollmorgen 07/2014 General

1 General

1.1 About this manual

1.2

This manual describes the S701x-S724x series of digital servo amplifiers (standard ver

sion: 1.5A ...24A rated current).

S7480x and S7720x amplifiers are described in an additional manuals.

A more detailed description of the expansion cards that are currently available and the

digital connection to automation systems can be found, together with our application

notes, in Acrobat-Reader format on the accompanying CD-ROM (system requirements:

WINDOWS, Internet Browser, Acrobat Reader) in different languages.

Technical data and dimensional drawings of accessories such as cables, brake resistors,

mains supplies, etc., can be found in the accessories manual.

This documentation (PDF) can be printed out on any standard commercial printer.

A printed copy of the documentation is available from us at extra cost.

More background information can be found in our "Product WIKI", available at

www.wiki-kollmorgen.eu

.

-

Notes for the printed edition (paper version)

A printed version of the manual is enclosed with each product.

For environmental reasons, the document was reduced in size

and printed on DIN A5.

Should you experience difficulties reading the font size of the

scaled-down printed version, you can print and use the PDF

version in DIN A4 format 1:1.

You can find the PDF version on the CD-ROM accompanying

the product and on the Kollmorgen website.

1.3 Notes for the online edition (PDF format)

Bookmarks:

Table of contents and index are active bookmarks.

Table of contents and index in the text:

The lines are active cross references. Click on the desired line and the appropriate page

is accessed.

Page numbers and chapter numbers in the text:

Page numbers and chapter numbers in the main text are active references. Click at the

page number or chapter number to reach the indicated target.

S701x2-S724x2 Instructions Manual 7

Page 8

General 07/2014 Kollmorgen

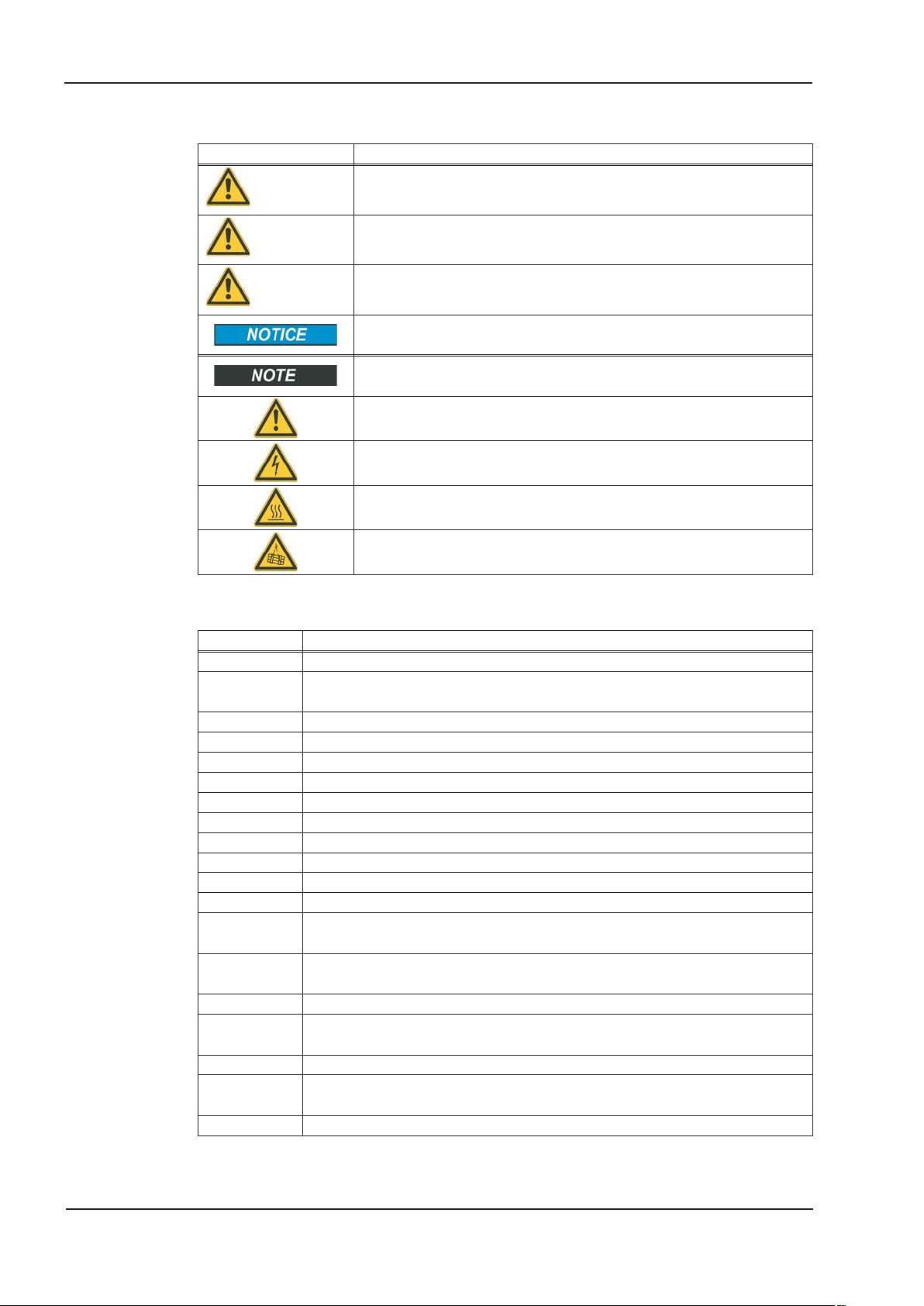

1.4 Symbols used

Symbol Indication

Indicates a hazardous situation which, if not avoided, will result in

DANGER

WARNING

CAUTION

death or serious injury.

Indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result

in minor or moderate injury.

Indicates situations which, if not avoided, could result in property

damage.

This is not a safety symbol.

This symbol indicates important notes.

Warning of a danger (general). The type of danger is specified by the

warning text next to it.

Warning of danger from electricity and its effects.

Warning of hot surfaces.

1.5 Standards used

Standard Content

ISO 4762 Hexagon socket head cap screws

ISO 13849

ISO 12100 Safety of machinery: Basic concepts, general principles for design

IEC 60085 Electrical insulation - Thermal evaluation and designation Maintenance

IEC 60204 Safety of Machinery: Electrical equipment of machinery

IEC 60364 Low-voltage electrical installations

IEC 60439 Low-Voltage Switchgear and Controlgear Assemblies

IEC 60529 Protection categories by housing (IP Code)

IEC 60664 Insulation coordination for equipment within low-voltage systems

IEC 60721 Classification of environmental conditions

IEC 61000 Electromagnetic compatibility (EMC)

IEC 61131 Programmable controllers

IEC 61491

IEC 61508

IEC 61800 Adjustable speed electrical power drive systems

IEC 62061

ISO 82079 Preparation of instructions for use - Structuring, content and presentation

UL 840

UL 508C UL Standard for Safety Power Conversion Equipment

Safety of machinery: Safety-related parts of control systems

(former EN 954)

Electrical equipment of industrial machines – Serial data link for real-time

communications between controls and drives.

Functional safety of electrical/electronic/programmable electronic

safety-related systems

Functional safety of electrical/electronic/programmable electronic

safety-related systems

UL Standard for Safety for Insulation Coordination Including Clearances

and Creepage Distances for Electrical Equipment

Warning of suspended loads.

IEC International Electrotechnical Commission ISO International Organization for Standardization

UL Underwriters Laboratories

8 S701x2-S724x2 Instructions Manual

Page 9

Kollmorgen 07/2014 General

1.6 Abbreviations used

Abbrev. Meaning

AGND Analog ground

xAF Fuse, x Amps, fast

xAM Fuse, x Amps, medium

xAT Fuse, x Amps, slow

BTB/RTO Ready to operate

CAN Fieldbus (CANopen)

CE Communité Europeenne

CLK Clock signal

COM Serial interface for a Personal Computer

DGND Digital ground (for 24V, digital inputs and digital outputs)

Disk Magnetic storage (diskette, hard disk)

EEPROM Electrically erasable programmable memory

EMC Electromagnetic compatibility

F-SMA Fiber Optic Cable connector according to IEC 60874-2

IGBT Insulated-gate bipolar transistor

LED Light-emitting diode

MB Megabyte

NI Zero pulse

PC Personal computer

PL Performance Level

PLC Programmable logic control

PWM Pulse-width modulation

RAM Volatile memory

R

or R

Brake

RBext External brake resistor

RBint Internal brake resistor

RES Resolver

ROD Digital encoder (A quad B)

SDI Safe direction

SIL Safety Integrity Level

SIL CL Safety Integrity Level Claim Limit

SLI Safe limited increments

SLP Safe limited position

SLS Safely limited speed

SOS Safe operating stop

SS1 Safe stop 1

SS2 Safe stop 1

SSI Synchronous serial interface

SSR Safe speed range

STO Safe torque off (former AS)

V AC Alternating voltage

V DC DC voltage

VDE Society of German Electrical Technicians

Brake resistor (sometimes called "regen resistor")

B

S701x2-S724x2 Instructions Manual 9

Page 10

Safety 07/2014 Kollmorgen

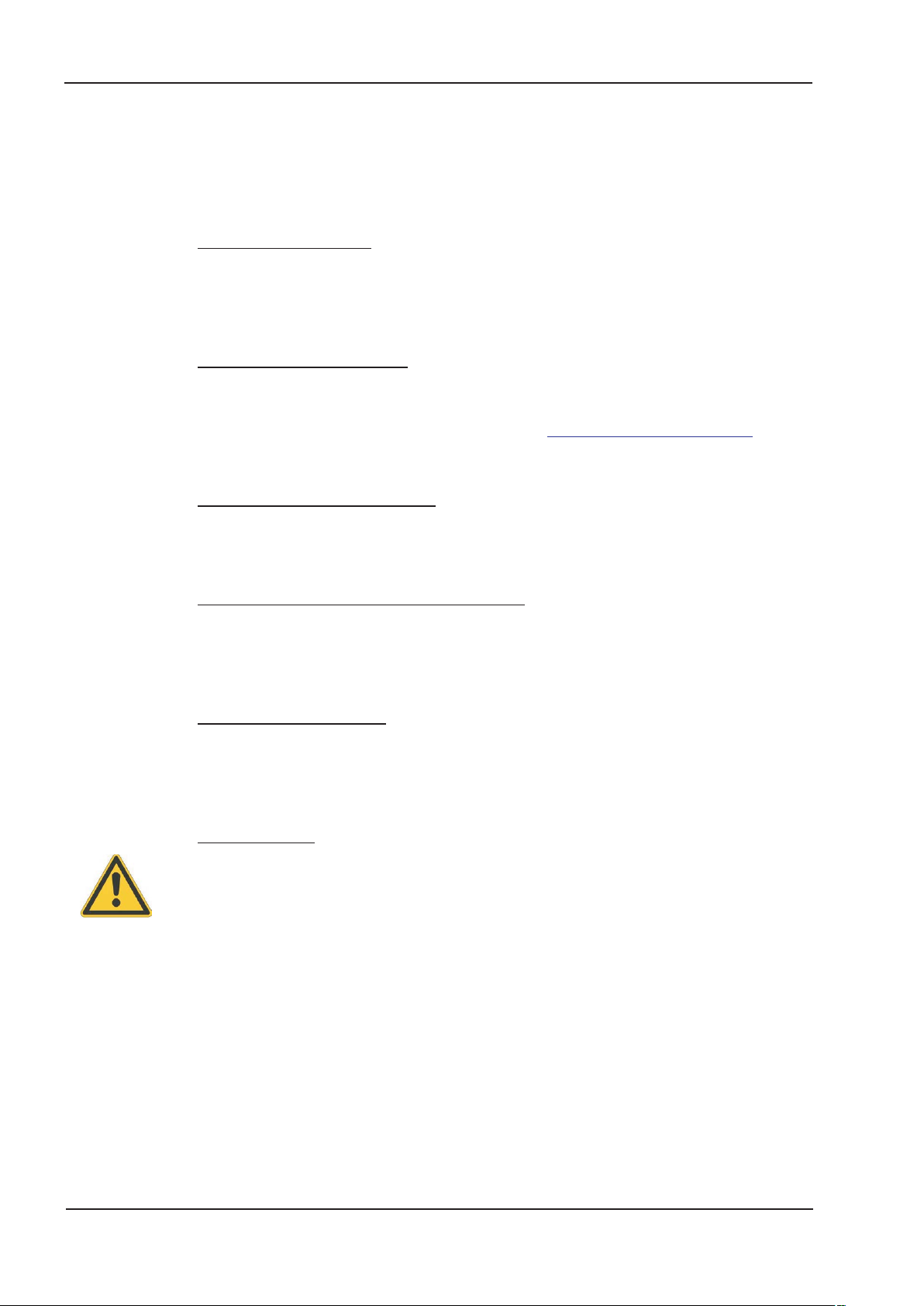

2 Safety

This section helps you to recognize and avoid dangers to people and objects.

2.1 You should pay attention to this

Read the documentation!

Read the available documentation before installation and commissioning. Improper handling of the servo amplifiers can cause harm to people or damage to property. The operator must therefore ensure that all persons entrusted to work on the S700 have read and

understood the manual and that the safety notices in this manual are observed.

Check the Hardware Revision!

Check the Hardware Revision Number of the product (see product label). This revision

number must match the Hardware Revision Number on the cover page of the manual. If

the numbers do not match up, visit the Tech-WIKI (http://www.wiki-kollmorgen.eu

'Others/Archive' (Sonstiges/Archive) section contains the various manual versions based

on the hardware version number.

Pay attention to the technical data!

). The

Adhere to the technical data and the specifications on connection conditions (rating plate

and documentation). If permissible voltage values or current values are exceeded, the

servo amplifiers can be damaged.

Observe electrostatically sensitive components!

The servo amplifiers contain electrostatically sensitive components which may be damaged by incorrect handling. Discharge your body before touching the servo amplifier. Avoid

contact with highly insulating materials (artificial fabrics, plastic film etc.). Place the servo

amplifier on a conductive surface.

Perform a risk assessment!

The manufacturer of the machine must generate a risk assessment for the machine, and

take appropriate measures to ensure that unforeseen movements cannot cause injury or

damage to any person or property. Additional requirements on specialist staff may also

result from the risk assessment.

utomatic restart

A

The drive might restart automatically after power on, voltage dip or interruption of the

supply voltage, depending on the parameter setting. Risk of death or serious injury for

humans working in the machine. If the parameter AENA is set to 1, then place a warning

sign to the machine (Warning: Automatic Restart at Power On) and ensure, that power on

is not possible, while humans are in a dangerous zone of the machine. In case of using

an undervoltage protection device, you must observe EN 60204-1:2006 chapter 7.5.

10 S701x2-S724x2 Instructions Manual

Page 11

Kollmorgen 07/2014 Safety

Specialist staff required!

Only properly qualified personnel are permitted to perform such tasks as transport,

assembly, setup and maintenance. Qualified specialist staff are persons who are familiar

with the transport, installation, assembly, commissioning and operation of drives and who

bring their relevant minimum qualifications to bear on their duties:

Transport : only by personnel with knowledge of handling electrostatically

sensitive components.

Unpacking: only by electrically qualified personnel.

Installation : only by electrically qualified personnel.

Setup : only by qualified personnel with extensive knowledge of electrical

engineering and drive technology

The qualified personnel must know and observe IEC 60364 / IEC 60664 and national

accident prevention regulations.

Hot surface!

The surfaces of the servo amplifiers can be hot in operation. Risk of minor burns!

The surface temperature can exceed 80°C. Measure the temperature, and wait until the

motor has cooled down below 40°C before touching it.

Earthing!

It is vital that you ensure that the servo amplifiers are safely earthed to the PE (protective

earth) busbar in the switch cabinet. Risk of electric shock. Without low-resistance earthing no personal protection can be guaranteed and there is a risk of death from electric

shock.

High voltages!

The equipment produces high electric voltages up to 900V. During operation, servo

amplifiers may have uncovered live sections, according to their level of enclosure protection. Capacitors can have dangerous voltages present up to eight minutes after switching

off the supply power. There is a risk of death or severe injury from touching exposed contacts. Do not open or touch the equipment during operation. Keep all covers and cabinet

doors closed during operation. Touching the equipment is allowed during installation and

commissioning for properly qualified persons only.

There is a danger of electrical arcing when disconnecting connectors, because capacitors

can still have dangerous voltages present after switching off the supply power. Risk of

burns and blinding. Wait at least eight minutes after disconnecting the servo amplifiers

from the main supply power before touching potentially live sections of the equipment

(such as contacts) or removing any connections. Always measure the voltage in the DC

bus link and wait until the voltage is below 60 V before handling components.

Reinforced Insulation!

Thermal sensors, motor holding brakes and feedback systems built into the connected

motor must have reinforced insulation (according to IEC61800-5-1) against system components with power voltage, according to the required application test voltage. All

Kollmorgen components meet these requirements.

Never modify the servo amplifiers!

It is not allowed to modify the servo amplifiers without permission by the manufacturer.

Opening the housing causes loss of warranty and all certificates become unvalid.

Warning signs are added to the device housing. If these signs are damaged, they must

be replaced immediately.

S701x2-S724x2 Instructions Manual 11

Page 12

Safety 07/2014 Kollmorgen

2.2 Use as directed

Servo amplifiers are safety components that are built into electrical plant or machines,

and can only be operated as integral components of such plant or machines.

The manufacturer of the machine must generate a risk assessment for the machine, and

take appropriate measures to ensure that unforeseen movements cannot cause injury or

damage to any person or property.

If the servo amplifiers are used in residential areas, in business and commercial areas, or

in small industrial operations, then additional filter measures must be implemented by the

user.

Cabinet and Wiring

The servo amplifiers must only be operated in a closed control cabinet, taking into

account the ambient conditions defined on page 31. Ventilation or cooling may be necessary to keep the temperature within the cabinet below 40°C.

Use only copper conductors for wiring. The conductor cross-sections can be derived from

the standard IEC 60204 (alternatively for AWG cross-sections: NEC Table 310-16, 60°C

or 75°C column).

Power supply

S7xx6 : Servo amplifiers in the S7xx6 series (overvoltage category III acc. to EN

61800-5-1) can be supplied from 1-phase or 3-phase grounded (earthed) industrial

supply networks (TN-system, TT-system with grounded neutral point, no more than 42kA

symmetrical rated current at 110V

S7xx0

: Servo amplifiers in the S7xx0 series (overvoltage category III acc. to EN

-10%

to 230V

+10%

).

61800-5-1) can be supplied from 3-phase grounded (earthed) industrial supply networks

(TN-system, TT-system with grounded neutral point, no more than 42kA symmetrical

rated current at 208V

, 230V, 240V, 400V or 480V

-10%

+10%

).

Periodic overvoltage between phases (L1, L2, L3) and the housing of the servo

amplifier must not exceed 1000V crest. In accordance with IEC 61800, voltage spikes (<

50µs) between phases must not exceed 1000V. Voltage spikes (< 50µs) between a

phase and the housing must not exceed 2000V.

Motors

The S700 family of servo amplifiers is exclusively intended for driving suitable brush less

synchronous servomotors, asynchronous motors and DC motors with control of torque,

speed and/or position.

The rated voltage of the motors must be at least as high as the DC bus link voltage divi-

ded by

produced by the servo amplifier (U

2

nMotor

³ UDC/

).

2

Safety

Observe the chapter "use as directed" on page 42 when you use the safety function STO.

To achieve PL e or SIL CL3, the safe switching of the pulse inhibitor must be tested periodically by analyzing the feedback signal from the safety control (ð p. 50).

Observe the user documentation for safety cards S1-2(S3) / S2-2(S4) when you use a

safety expansion card.

12 S701x2-S724x2 Instructions Manual

Page 13

Kollmorgen 07/2014 Safety

2.3 Prohibited use

Other use than described in chapter 2.2 is not intended and can lead to damage of per

sons, equipment or things.

The use of the servo amplifier in the following environments is prohibited:

- potentially explosive areas

- environments with corrosive and/or electrically conductive acids, alkaline solutions,

oils, vapors, dusts

- directly on non-grounded supply networks or on asymmetrically grounded supplies

with a voltage >240V.

- on ships or off-shore applications

Commissioning the servo amplifier is prohibited if the machine in which it was installed,

- does not meet the requirements of the EC Machinery Directive

- does not comply with the EMC Directive or with the Low Voltage Directive

- does not comply with any national directives

The control of holding brakes by the S700 alone may not be used in applications, where

functional safety is to be ensured with the brake.

2.4 Handling

2.4.1 Transport

l

Transport by qualified personnel in the manufacturer’s original recyclable packaging

l

Avoid shocks while transporting

l

Transport temperature: -25 to +70°C, max. rate of change 20K / hour,

l

Transport humidity: max. 95% relative humidity, no condensation,

l

If the packaging is damaged, check the unit for visible damage. In such an event, inform the shipper and the manufacturer.

The servo amplifiers contain electrostatically sensitive components, that can be damaged

by incorrect handling. Discharge yourself before touching the servo amplifier. Avoid

contact with highly insulating materials, such as artificial fabrics and plastic films. Place

the servo amplifier on a conductive surface.

-

class 2K3 acc. to EN61800-2, EN 60721-3-1

class 2K3 acc. to EN61800-2, EN 60721-3-1

2.4.2 Packaging

l

Recyclable cardboard with inserts

l

Dimensions: S701...S712 (HxWxD) 125x415x350 mm

S724 (HxWxD) 155x415x350 mm

l

Labeling: name plate on outside of box

S701x2-S724x2 Instructions Manual 13

Page 14

Safety 07/2014 Kollmorgen

2.4.3 Storage

l

Storage only in the manufacturer’s original recyclable packaging

l

Max. stacking height: 8 cartons

l

Storage temperature: -25 to +55°C, max. rate of change 20K / hour,

class 1K4 acc. to EN61800-2, EN 60721-3-1

l

Storage humidity: 5 … 95% relative humidity, no condensation,

class 1K3 acc. to EN61800-2, EN 60721-3-1

l

Storage duration:

Less than 1 year: without restriction.

More than 1 year: capacitors must be re-formed before setting up and operating the

servo amplifier. To do this, remove all electrical connections and apply single-phase

230V AC for about 30 minutes to the terminals L1 and L2.

2.4.4 Maintenance, Cleaning

The devices do not require any maintenance, opening the devices invalidates warranty.

Cleaning : — if the casing is dirty: clean with Isopropanol or similar

NOTICE: Do not immerse or spray

— Dirt inside the unit: must be cleaned by the manufacturer

— For dirty protective grill on fan: clean with a dry brush

2.4.5 Disassembling

Observe the sequence below, if a servo amplifier has to be disassembled (e.g. for replacement).

1. Electrical disconnection

a. Switch off the main switch of the switchgear cabinet and the fuses that supply

the system.

b. Warning: Contacts can still have dangerous voltages present up to 8 min

after switching off mains voltage. Risk of electric shock! Wait at least eight minutes

after disconnecting the servo amplifier from the main supply power before touching

potentially live sections of the equipment (e.g. contacts) or undoing any

connections. To be sure, measure the voltage in the DC Bus link and wait until it

has fallen below 60V.

c. Remove the connectors. Disconnect the earth (ground) connection at last.

2. Check temperature

Caution

During operation the heat sink of the servo amplifier may reach

temperatures above 80°C (176°F). Risk of minor burns! Before touching

the device, check the temperature and wait until it has cooled down below

40°C (104°F).

3. Disassembling

Remove the fan housing and disassemble the servo amplifier (reverse of the procedure

described in chapter "Mechanical installation).

14 S701x2-S724x2 Instructions Manual

Page 15

Kollmorgen 07/2014 Safety

2.4.6 Repair

Repair of the servo amplifier must be done by the manufacturer. Opening the devices

means loss of the guarantee. Use the telefax form on page 163 for repair request. You'll

receive the current dispatch information.

Disassemble the equipment as described in chapter 2.4.5 and send it in the original

packaging to the address given in the dispatch information.

2.4.7 Disposal

In accordance to the WEEE-2002/96/EC-Guidelines we take old devices and accessories

back for professional disposal. Transport costs are the responsibility of the sender. Use

the telefax form on page 163 for disposal request. You'll receive the current dispatch

information.

Disassemble the equipment as described in chapter 2.4.5 and send it in the original

packaging to the address given in the dispatch information.

S701x2-S724x2 Instructions Manual 15

Page 16

Safety 07/2014 Kollmorgen

This page has been deliberately left blank.

16 S701x2-S724x2 Instructions Manual

Page 17

Kollmorgen 07/2014 Approvals

3 Approvals

Certificates can be found in our Product WIKI on page Approvals.

3.1 Conformance with UL

The S7xx0 servo amplifiers are listed under UL file number E217428.

The S7xx6 servo amplifiers are not listed under UL.

UL-certified servo amplifiers (Underwriters Laboratories Inc.) fulfil the relevant U.S. standards (in this case UL 840 and UL 508C). The UL certification relates only to the mechanical and electrical construction design of the device. This standard describes the fulfillment by design of minimum requirements for electrically operated power conversion

equipment, such as frequency converters and servo amplifiers, which is intended to eliminate the risk of fire, electric shock, or injury to persons, being caused by such equipment.

The technical conformance with the U.S. standard is determined by an independent UL

inspector through the type testing and regular checkups. Apart from the notes on installation and safety in the documentation, the customer does not have to observe any other

points in direct connection with the UL-certification of the equipment.

UL 508C: UL 508C describes the fulfillment by design of minimum requirements for electrically operated power conversion equipment, such as frequency converters and servo

amplifiers, which is intended to eliminate the risk of fire being caused by such equipment.

UL 840: UL 840 describes the fulfillment by design of air and insulation creepage spacings for electrical equipment and printed circuit boards.

UL Markings

l

Use 60°C or 75°C copper wire only for every model of this section.

l

Use Class 1 wire only.

l

Tightening torque for field wiring terminals:

X0, X8, X9: 0.7 - 0.8Nm (6.20 to 7.08 lbf in)

l

Use in a pollution degree 2 environment.

l

These devices provide solid state motor overload protection at 130% of full load

current.

l

Integral solid state short circuit protection does not provide branch circuit protection.

Branch circuit protection must be provided in accordance with the National Electrical

Code and any additional local codes.

l

These devices are not provided with motor over-temperature sensing.

l

Suitable for use on a circuit capable of delivering not more than 42kA rms symmetrical amperes for a max. voltage of 480 Vac.

l

Supply circuit protection:

Model Fuse class Rating Max. Fuse Rating

S7010 RK5, CC, J, T 600VAC 200kA 6A (Time-Delay)

S7030 RK5, CC, J, T 600VAC 200kA 6A (Time-Delay)

S7060 RK5, CC, J, T 600VAC 200kA 10A (Time-Delay)

S7120 RK5, CC, J, T 600VAC 200kA 15A (Time-Delay)

S7240 RK5, CC, J, T 600VAC 200kA 30A (Time-Delay)

l

The drives may be connected together via the “common bus” (DC bus link) based on

the instructions on p. 70ff. The devices may also be grouped from the AC input side

based on the max. input fuse (e.g. 3 pcs. S7010 with one common 6A fuse in line).

S701x2-S724x2 Instructions Manual 17

Page 18

Approvals 07/2014 Kollmorgen

3.2 CE conformance

Conformance with the EC Machine Directive 2006/42/EC, the EC EMC Directive

2004/108/EC and the Low Voltage Directive 2006/95/EC is mandatory for the supply of

servo amplifiers within the European Community.

The servo amplifier meets the noise immunity requirements to the 2nd environmental

category (industrial environment). For noise emission the amplifier meets the requirement

to a product of the category C2 (motor cable £ 10m).

This product can cause high-frequency interferences in non industrial environments. This

can require measures for interference suppression like additional external EMC filters.

With a motor cable length of 10m or longer, the servo amplifier meets the requirement to

the category C3.

The servo amplifiers have been tested by an authorized testing laboratory in a defined

configuration, using the system components that are described in this documentation.

Any divergence from the configuration and installation described in this documentation

means that you will be responsible for carrying out new measurements to ensure conformance with regulatory requirements.

3.2.1 European Directives and Standards for the machine builder

Servo amplifiers are safety components that are intended to be incorporated into electrical plant and machines for industrial use. When the servo amplifiers are built into machines or plant, the amplifier must not be used until it has been established that the machine

or equipment fulfills the requirements of the

l

EC Machinery Directive (2006/42/EC)

l

EC EMC Directive (2004/108/EC)

l

EC Low Voltage Directive (2006/95/EC)

Standards to be applied for conformance with the EC Machinery Directive (2006/42/EC)

IEC 60204-1 (Safety and Electrical Equipment in Machines)

ISO 12100 (Safety of Machines)

The manufacturer of the machine must generate a risk assessment for the machine, and

must implement appropriate measures to ensure that unforeseen movements cannot

cause injury or damage to any person or property.

The machine manufacturer must check whether other standards or EC Directives must

be applied to the machine.

Standards to be applied for conformance with the EC Low Voltage Directive(2006/95/EC)

IEC 60204-1 (Safety and Electrical Equipment in Machines)

IEC 60439-1 (Low-voltage switchgear and controller assemblies)

Standards to be applied for conformance with the EC EMC Directive (2004/108/EC)

IEC 61000-6-1 / 2 (Interference Immunity in Residential & Industrial Areas)

IEC 61000-6-3 / 4 (Interference Generation in Residential & Industrial Areas)

The manufacturer of the machine is responsible for ensuring that it meets the limits required by the EMC regulations. Advice on the correct installation for EMC can be found in

this documentation.

We only guarantee the conformance of the servo system with the standards cited in this

chapter if the components (motor, cables, chokes etc.) are those supplied by us.

18 S701x2-S724x2 Instructions Manual

Page 19

Kollmorgen 07/2014 Approvals

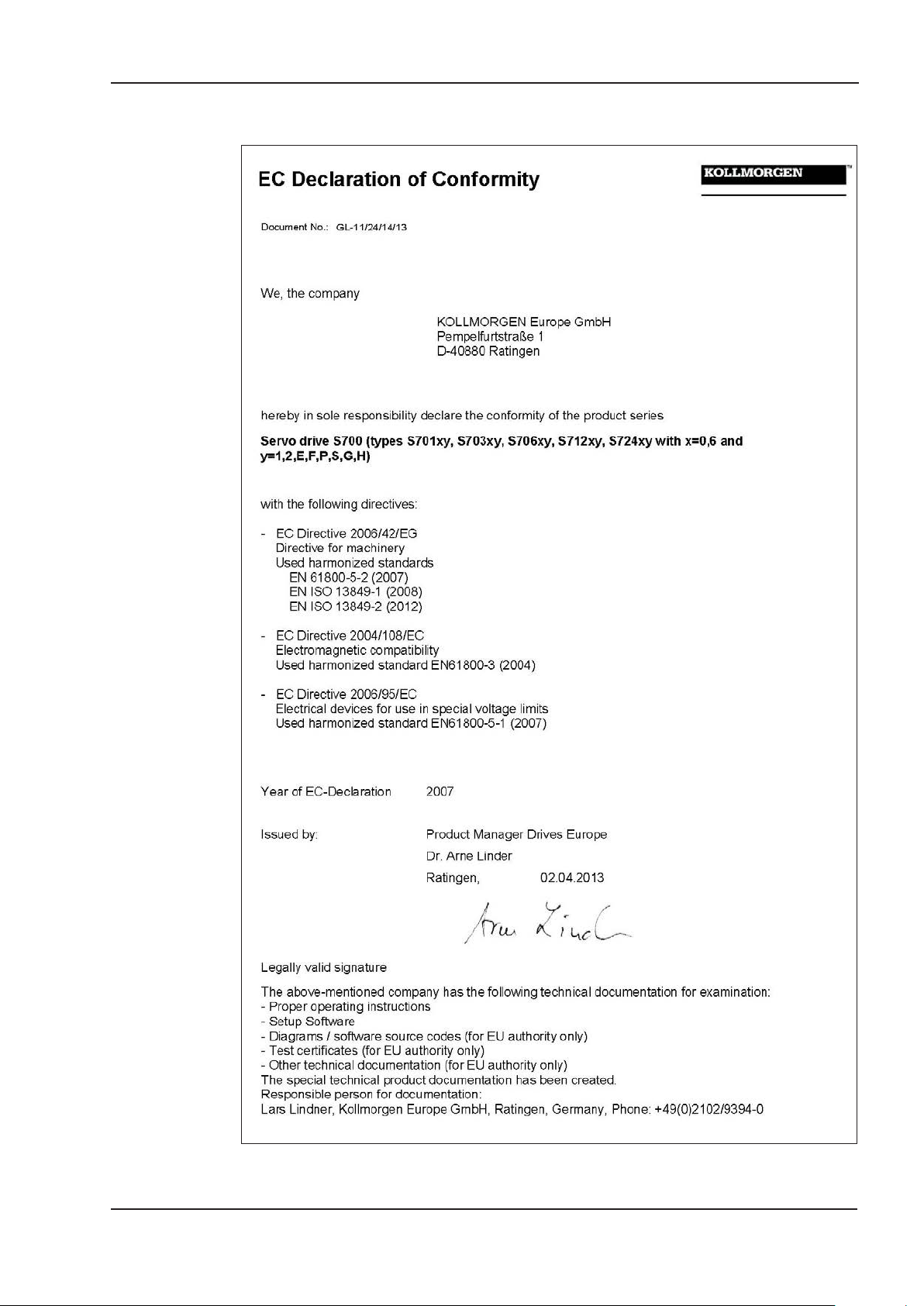

3.2.2 CE Declaration of Conformity

S701x2-S724x2 Instructions Manual 19

Page 20

Approvals 07/2014 Kollmorgen

3.3 GOST-R conformance

Certificate for servo amplifier and accessories (cover page, page 1 of 3).

20 S701x2-S724x2 Instructions Manual

Page 21

Kollmorgen 07/2014 Approvals

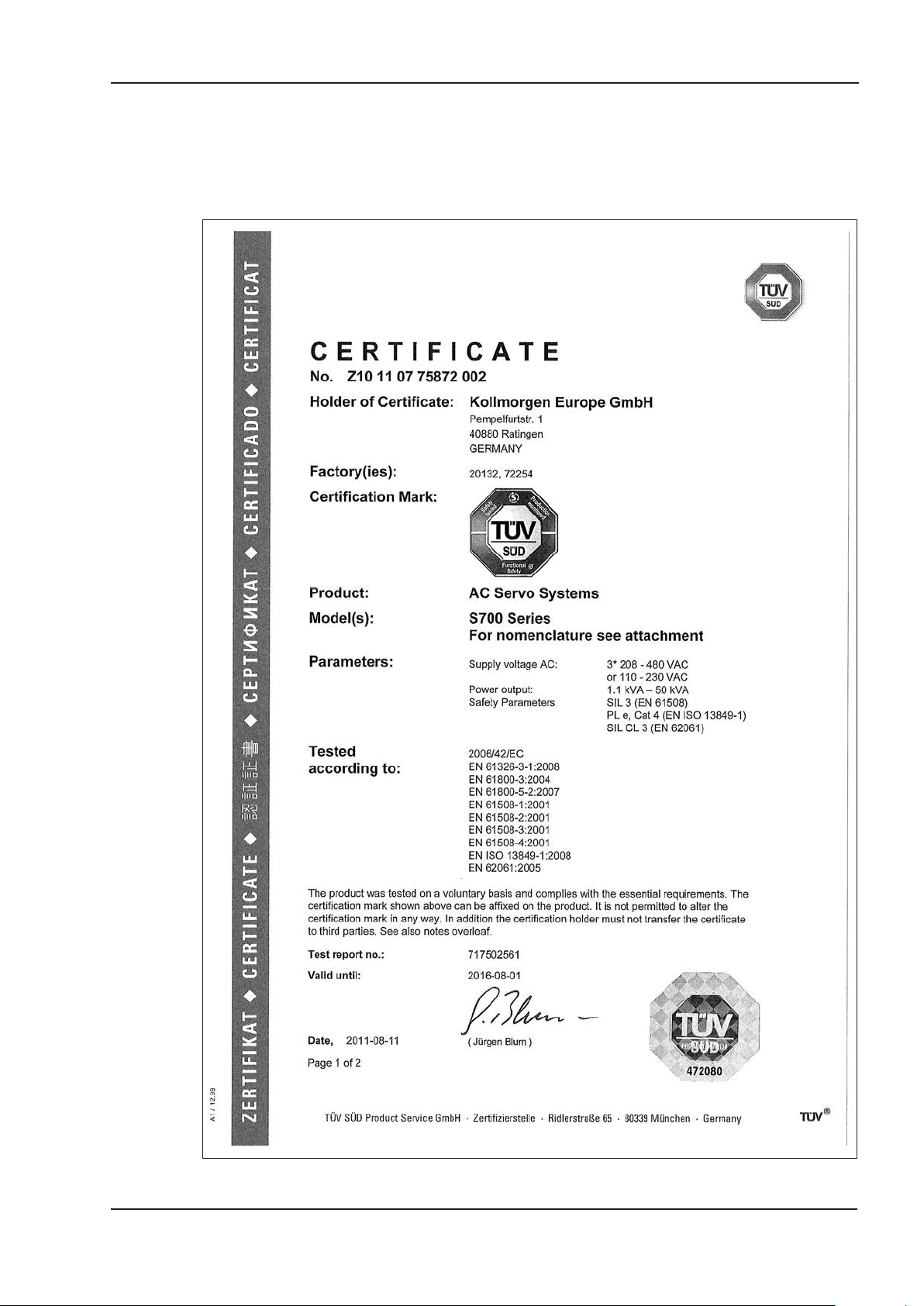

3.4 Functional Safety

3.4.1 Safety Certificate S700

Cover page, page 1 of 2.

S701x2-S724x2 Instructions Manual 21

Page 22

Approvals 07/2014 Kollmorgen

3.4.2 Safety Certificate S700 with Safety Card

Cover page, page 1 of 2.

22 S701x2-S724x2 Instructions Manual

Page 23

Kollmorgen 07/2014 Package

4 Package

4.1 Package supplied

When an amplifier from the S700 series is ordered (order numbers ðp.161), the following

is supplied:

— Servo amplifier S700

— Instruction Manual S700

— Operating Manual Safety Expansion Card Sx (in case of a built-in safety card)

— Online documentation and setup software on CD-ROM

— Mating connectors X0, X3A, X3B, X4A, X4B, X8

The mating SubD connectors are not part of the package!

Accessories :

— Motor cable (prefabricated) with special shield clamp, or both power connectors

separately, with the motor cable as a cut-off length

— Feedback cable (prefabricated)

or both feedback connectors separately, with the feedback cable as a cut-off length

— Motor choke 3YL or 3YLN, for motor cables longer than 25 meters

— External brake resistor BAR(U), Capacitor Modul KCM-x

— Communication cable to the PC (ð p.102) for setting parameters from a PC

— Power cable, control cables, fieldbus cables (as cut-off lengths)

(must be ordered separately, if required; description see accessories

manual)

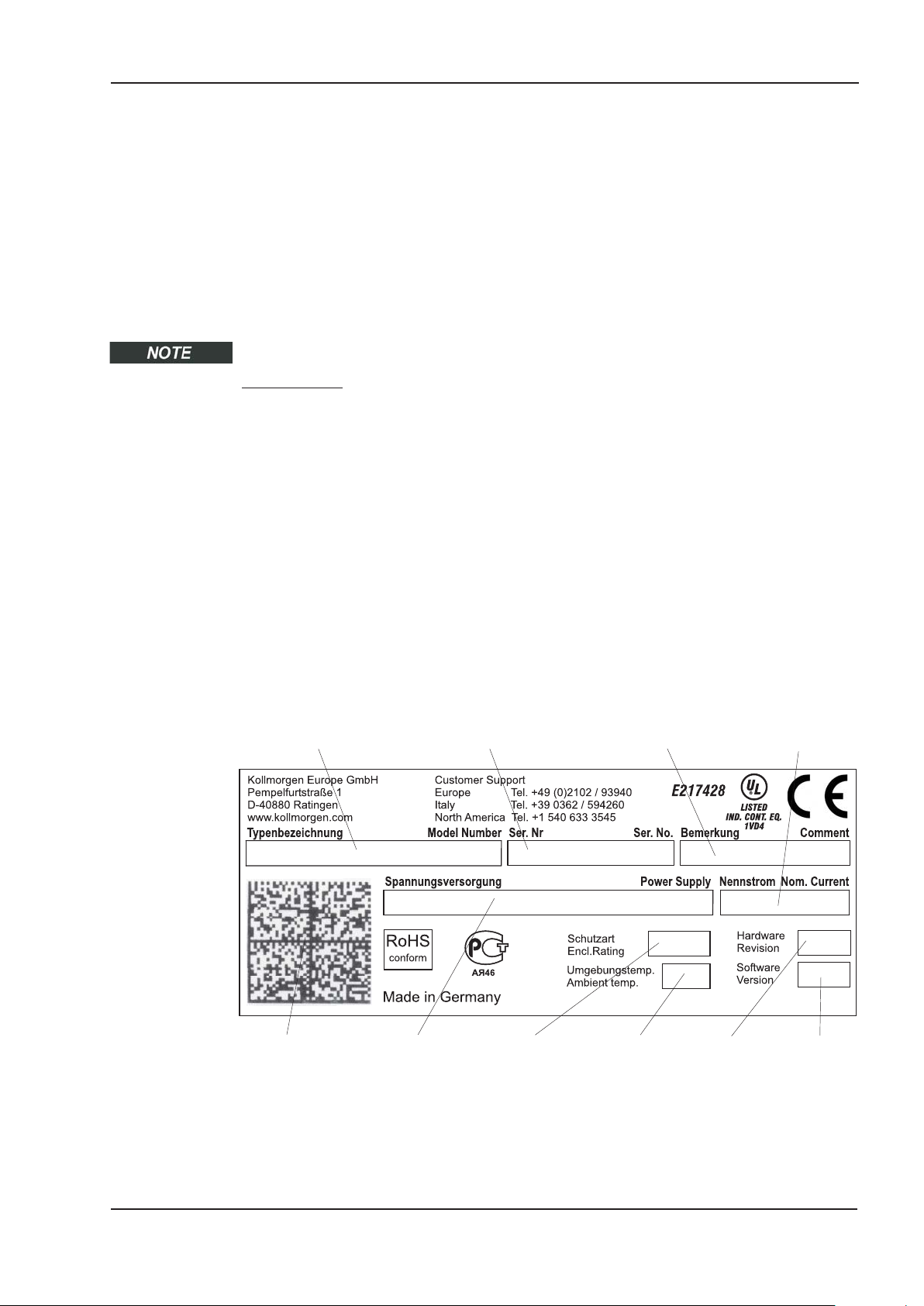

4.2 Nameplate

The nameplate depicted below is attached to the side of the servo amplifier.

The information described below is printed in the individual fields.

Servo amplifier type

2D bar code

Electrical supply

Installed load

Enclosure

Rating

CommentsSerial number

max. ambient

temperature

Output current

in cont. operation

Hardware

Revision

Software

Version

S701x2-S724x2 Instructions Manual 23

Page 24

Package 07/2014 Kollmorgen

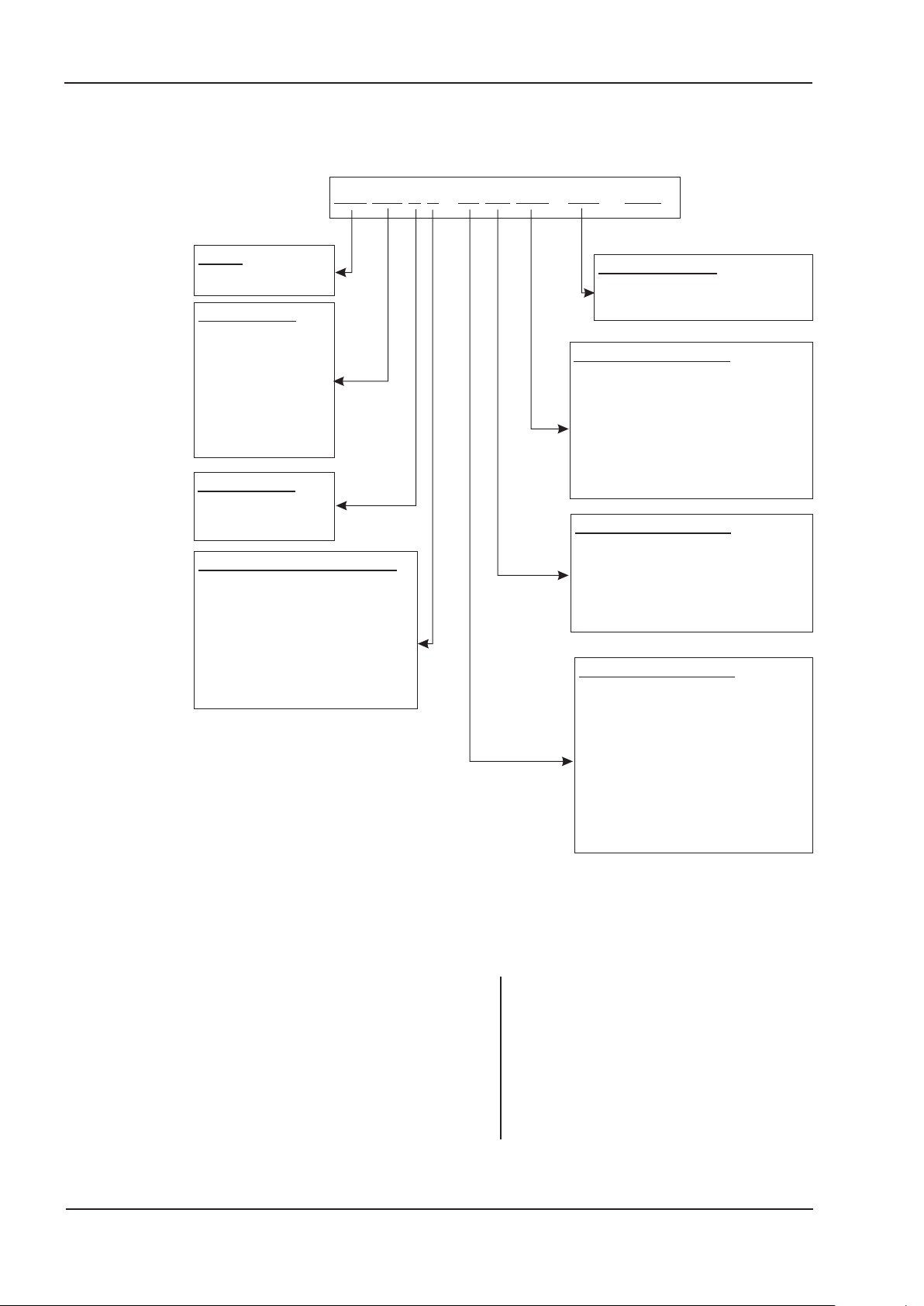

4.3 Part number scheme

The part number is identical with the order code.

S7060 2 -EIF2 PM -NA1- 000

Family

S7 S700

Current Rating

01 1.5 Arms

03 3 Arms

06 6 Arms

12 12 Arms

24 24 Arms

3

48

72

Voltage Rating

0 208...480V

6 110...230V

Electrical/mechanical Options

2 standard

F standard and coated PCBs

12A and 24A rated current only:

S extended Ipeak

H extended Ipeak and

48 Arms

3

72 Arms

coated PCBs

2

Firmware Options

NA no option

(EtherCAT&CANopen)

Expansion Cards Slot 3

NA no expansion card in slot 3,

EtherCAT&CANopen onboard

F2 Fan controller

PM PosI/O

PA PosI/O-Monitor

3

Safety card S1-2, SIL CL3

S3

3

Safety card S2-2, SIL CL2

S4

Expansion Cards Slot 2

NA no expansion card in Slot 2,

EtherCAT&CANopen onboard

F2 Fan controller

PM PosI/O

PA PosI/O-Monitor

Expansion Cards Slot 1

NA no expansion card in Slot 1,

EtherCAT&CANopen onboard

2C 2CAN module mounted

DN DEVICENET

PB PROFIBUS

SE SERCOS II

SN SYNQNET

EI I/O Extension

FB FB-2to1

1 is void with standard

2 additional coding defines customer specific specials.

3 described in seperate documentation

Example 1: S70602-EIF2PM-NA-000

S7 S700

06 6A rated current

0 208...480V rated voltage

2 no electr./mech. option

EI I/O expansion card in Slot 1

F2 Expansion card Controlled Fan in Slot 2

PM PosI/O expansion card in Slot 3

NA Standard (EtherCAT&CANopen onboard)

000 no customer specific specials

Example 2: S7126S-EIF2S4-NA-000

S7 S700

12 12A rated current

6 110...230V rated voltage

S extended Ipeak (30A)

EI I/O Erweiterungskarte in Slot 1

F2 Expansion card Controlled Fan in Slot 2

S4 Safety Card S2-2 in Slot 3

NA Standard (EtherCAT&CANopen onboard)

000 no customer specific specials

24 S701x2-S724x2 Instructions Manual

Page 25

Kollmorgen 07/2014 Technical description

5 Technical description

5.1 The S700 family of digital servo amplifiers

Standard version

l

Large supply voltage range: 1 x 110V

l

Overvoltage category III acc. to IEC 61800-5-1

l

2 housing dimensions: S701...S712 70 mm

… 3 x 480V

-10%

S724 100 mm

l

CANopen onboard

l

EtherCAT onboard

l

RS232 and 24V pulse direction interface onboard

l

Resolver-, Encoder-, AquadB Encoder-, ComCoder- evaluation onboard

l

Position controller onboard

l

Safe Stop STO onboard (up to SIL CL3, PLe)

l

3 frontside slots for expansion cards

l

Memory Card slot onboard

l

Synchronous servomotors, linear motors, asynchronous motors and DC motors can

be used

+ 10%

Power section

l

S7xx6: Directly on grounded mains supply, 1x110V

S7xx0: Directly on grounded mains supply, 3x208V

l

TN-network or TT-network with grounded neutral point, 42kA max. symmetrical cur-

… 3x230V

-10%

… 3x480V

-10%

+10%

+10%

, 50/60Hz

, 50/60Hz

rent rating, connection to other supply types only via isolating transformer,ðp.66

l

B6 bridge rectifier, integral supply filter and soft-start circuit

l

Fusing (e.g. fusible cutout) to be provided by the user

l

Shielding All shielding connections are made directly on the amplifier

l

Output stage IGBT module with floating current measurement

l

Brake circuit with dynamic distribution of the generated power between

several amplifiers on the same DC bus link circuit. Internal

brake resistor as standard, external brake resistors if required.

l

DC bus link voltage 135...900 V DC, can be connected in parallel.

l

Interference suppression filters are integrated for the electrical supply feed and the

24V auxiliary supply voltage (with motor cable £ 10m for C2 as per IEC 61800-3, with

motor cable > 10m for C3 as per IEC 61800-3).

S701x2-S724x2 Instructions Manual 25

Page 26

Technical description 07/2014 Kollmorgen

Integrated safety

l

Appropriate insulation and creepage distances and electrical isolation ensure safe

electrical separation, as per IEC 61800-5-1, between the power input / motor con

nections and the signal electronics.

l

Soft-start, overvoltage detection, short-circuit protection, phase-failure monitoring.

l

Temperature monitoring of the servo amplifier and motor (if our motors and prefabricated cables are used).

l

Safe stop (up to SILCL3 acc. to IEC 62061, PLe acc. to ISO13849-1) ð p.41.

l

Slot for safety card with more safety functions for the safe drive operation, ð p.152

Auxiliary supply voltage 24V DC

l

Electrically isolated, internal fusing (amplifier and fan/brake separated), from an external 24V DC power supply unit.

l

Separate 24V supply input for digital outputs

Operation and parameter setting

l

With our user-friendly setup software DRIVEGUI.EXE, for setup via the serial interface of a PC.

l

If no PC is available: direct operation by two keys on the servo amplifier and a 3-character LED display.

l

Fully programmable via RS232 interface.

l

Read and write access to parameter records and firmware via smartcard.

-

Completely digital control

l

Digital current controller (space vector, pulse-width modulation, 62.5 µs)

l

Adjustable digital speed controller (62.5 µs)

l

Integrated position controller, with adaptation possibilities for all applications (250 µs,

optionally 125 µs)

l

Integrated 24V step/direction interface for connecting a servomotor to a stepper controller

Inputs and Outputs

l

2 programmable analog inputs ð p. 98

l

4 programmable digital inputs ð p. 99

l

2 programmable digital inputs/outputs (direction selectable) ð p. 101

l

Programmable logical combinations of digital signals

l

1 input Enable ð p. 100

l

2 inputs STO Enable ð p. 99

26 S701x2-S724x2 Instructions Manual

Page 27

Kollmorgen 07/2014 Technical description

Expansions

Slot 1

Expansion cards in slot 1 can be combined with F2 Option in slot 2. More combinations of

slot 1 and slot 2 expansion cards are not possible.

l

I/O-14/08 expansion card, ð p. 126

l

PROFIBUS expansion card, ð p. 129

l

sercos®II expansion card, ð p. 130

l

DeviceNet expansion card, ð p. 132

l

SynqNet expansion card, ð p. 135

l

FB-2to1 expansion card, ð p. 137

l

-2CAN- expansion module, separated connectors for CAN bus and RS232 ð p. 139

Slot 2

l

PosI/O expansion card, ð p. 142

l

PosI/O-Monitor expansion card, ð p. 142

l

F2 Option, controlled fan, later insertion not possible, ð p. 141, can be combined

with expansion cards in slot 1.

Slot 3

l

PosI/O expansion card, ð p. 151

l

PosI/O-Monitor expansion card, ð p. 151

l

F2 Option, controlled fan, later insertion not possible, ð p. 151

l

Safety expansion card (S3) S1-2 (SIL CL3), ð p. 155

l

Safety expansion card (S4) S2-2 (SIL CL2), ð p. 152

Several third-party expansion cards (ModBus, LightBus, FIP-IO etc. please contact the

manufacturer for further information)

Macro programming

More information can be found in our Technical WIKI (www.wiki-kollmorgen.eu).

l

62.5µs / 250µs / 1ms / 4ms / 16ms / IDLE / IRQ

l

128 kByte memory

l

IEC 61131 structured text

l

400 easy instructions every 62.5 µs

l

CAN objects for multi axis control

S701x2-S724x2 Instructions Manual 27

Page 28

Technical description 07/2014 Kollmorgen

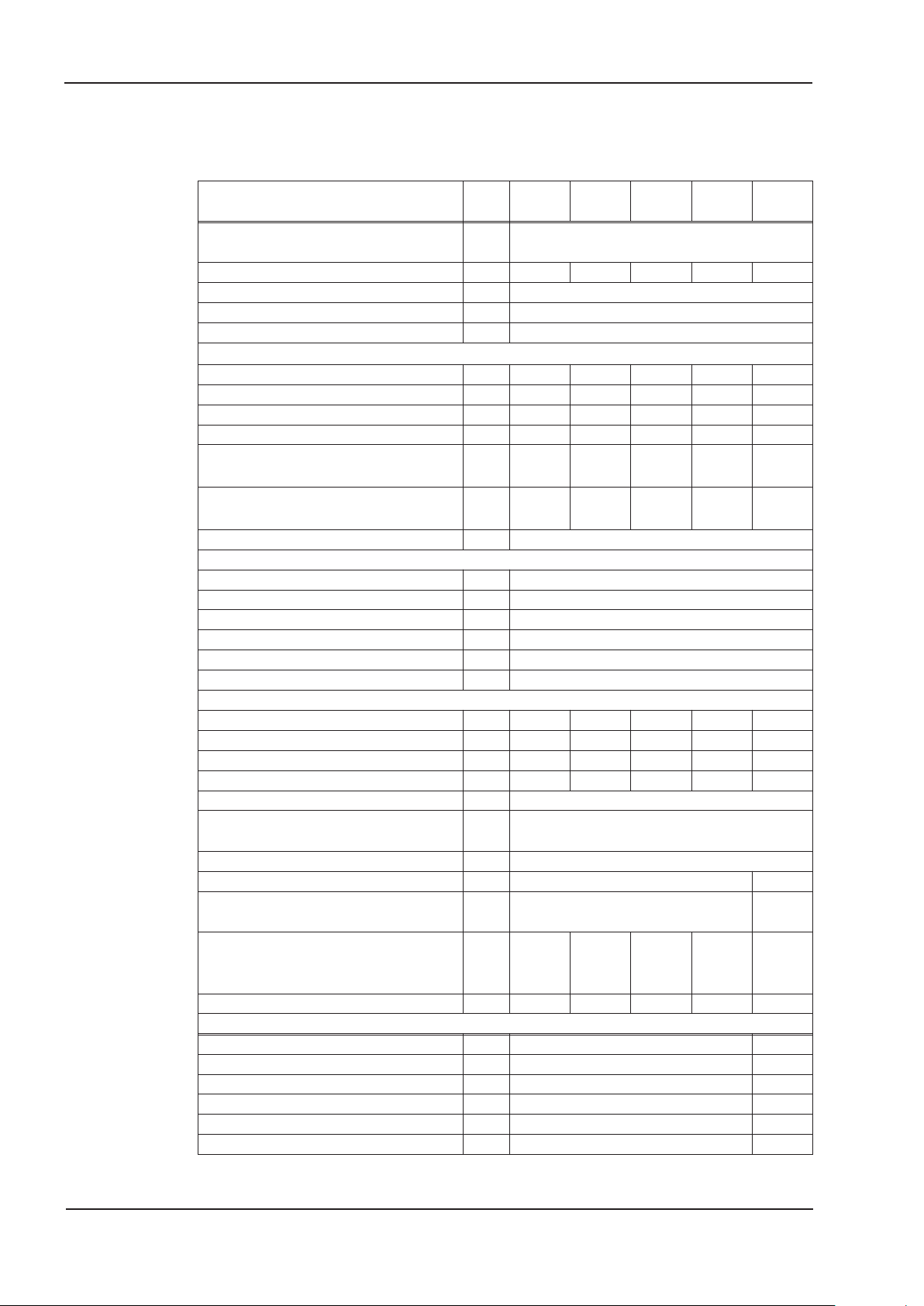

5.2 Technical data

5.2.1 Rated data S7xx0

Electrical data DIM S70102 S70302 S70602

Rated supply voltage

(grounded supply, phase to phase)

V~

3 x 208V

… 3 x 480V

-10%

S71202/

S7120S

+10%

S72402/

S7240S

, 50/60 Hz

Rated input power for cont. operation kVA 1.1 2.2 4.5 9 18

Permitted switch on/off frequency 1/h 30

Auxiliary voltage supply — ð p.30

Maximum DC bus link voltage V= 900

Rated output current (rms value, ± 3%)

at 3x208V Arms 2.5 5 6 12 24

at 3x230V Arms 2 4 6 12 24

at 3x400V Arms 1.5 3 6 12 24

at 3x480V Arms 1.5 3 6 12 24

Peak output current

(for approx.2s, ± 3%)

Peak output current

(for approx.5s, ± 3%)

Arms 4,5 9 18 24/30 48/72

Arms 3 6 12 24 48

Switching frequency of output stage kHz 8

Voltage rise speed dU/dt, (measured without connected motor, see hints on page 74!)

at 3x208V kV/µs 3.0

at 3x230V kV/µs 3.3

at 3x400V kV/µs 5.7

at 3x480V kV/µs 6.9

Technical data for brake circuit — ð p.34

Threshold for overvoltage switch-off VDC ð p.34

Motor inductance min.

at 3x208V mH 7.7 3.9 1.9 1.2 0.7

at 3x230V mH 8.5 4.3 2.1 1.3 0.8

at 3x400V mH 14.8 7.4 3.7 2.2 1.4

at 3x480V mH 17.8 8.9 4.4 2.7 1.7

Motor inductance max. mH Consult our customer support

Form factor of the output current (rated conditions, min. load inductance)

— 1.01

Bandwidth of current controller kHz > 1,2 (bis 5)

Residual voltage drop at rated current V 4 6

Thermal dissipation, output stage

disabled

W max. 20 max.25

Thermal dissipation at rated current

(incl. PSU losses, without brake

W 40 70 100 160 330

dissipation)

Noise emission max. dB(A) 43 43 58 65 65

Mechanical data

Weight kg 4.4 5.5

Height, without connectors mm 345 348

Height, with connectors mm 379 382

Width mm 70 100

Depth, without connectors mm 243 243

Depth, with connectors mm 285 285

28 S701x2-S724x2 Instructions Manual

Page 29

Kollmorgen 07/2014 Technical description

5.2.2 Rated data S7xx6

Electrical data DIM

Rated supply voltage

(grounded supply, phase to phase)

S70162S70362S70662S71262S7126SS72462S7246

V~

1 x 110V

… 3 x 230V

-10%

+10%

S

, 50/60 Hz

Rated input power for cont. operation kVA 1 2 2,3 4,5 4,5 9 9

Permitted switch on/off frequency 1/h 30

Auxiliary voltage supply — ð p.30

Maximum DC bus link voltage V= 455

Rated output current (rms value, ± 3%)

at 1x110V (1~) Arms 1,5 36771010

at 1x230V (1~) Arms 1,5 36881111

at 3x110V (3~) Arms 2,5 5 6 12 12 24 24

at 3x230V (3~) Arms 2,5 5 6 12 12 24 24

Peak output current (rms value, ±3%)

at 1x110V (1~), for 2s / 5s Arms 3/3 3/3 6/6 7/7 7/7 10/10 10/10

at 1x230V (1~), for 2s / 5s Arms 4,5/3 9/6 12/12 12/12 12/12 13/13 13/13

at 3x110V (3~), for 2s / 5s Arms 4,5/3 9/6 18/12 24/24 30/24 48/48 72/48

at 3x230V (3~), for 2s / 5s Arms 4,5/3 9/6 18/12 24/24 30/24 48/48 72/48

Switching frequency of output stage kHz 8

Voltage rise speed dU/dt, (measured without connected motor)

at 1x110V kV/µs 2

at 1x230V kV/µs 3,3

at 3x110V kV/µs 2

at 3x230V kV/µs 3,3

Technical data for brake circuit — ð p.35

Threshold for overvoltage switch-off VDC ð p.35

Motor inductance min.

at 1x110V mH 5,7 5,7 2,9 2,5 2,5 1,7 1,7

at 1x230V mH 843332,82,8

at 3x110V mH 3,8 1,9 0,96 0,72 0,57 0,36 0,24

at 3x230V mH 8 4 2 1,5 1,2 0,75 0,5

Motor inductance max. mH Contact our customer support

Form factor of the output current (rated conditions, min. load inductance)

— 1.01

Bandwidth of current controller kHz > 1,2 (bis 5)

Residual voltage drop at rated current V 4 6

Thermal dissipation, output stage

disabled

W max. 20 max.25

Thermal dissipation at rated current

(incl. PSU losses, without brake

W 3045609090175175

dissipation)

Noise emission max. dB(A) 43 43 58 65 65 65 65

Mechanical data

Weight kg 4,4 5,5

Height, without connectors mm 345 348

Height, with connectors mm 379 382

Width mm 70 100

Depth, without connectors mm 243 243

Depth, with connectors mm 285 285

S701x2-S724x2 Instructions Manual 29

Page 30

Technical description 07/2014 Kollmorgen

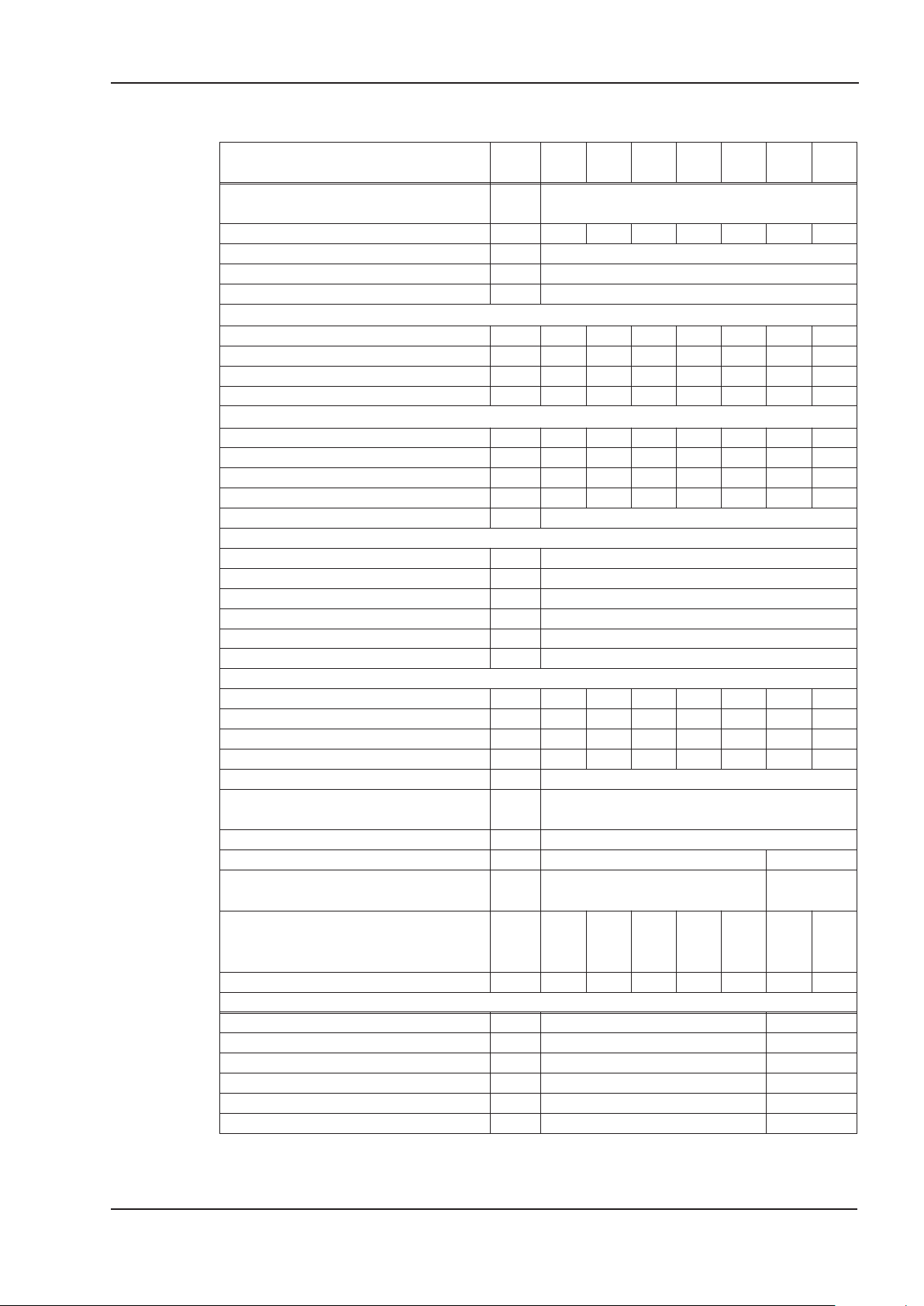

5.2.3 Inputs, outputs, aux. voltage supply

Interface electr. data

Analog inputs 1 and2

Max. common-mode voltage

Digital control inputs

Digital control outputs

BTB/RTO output, relay contacts

24V-IO for digital outputs 20V - 30V

Auxiliary supply voltage, electrically isolated 24V (-0% +15%)

current without / with motor brake 1A / 3A

Min./max. output current to brake 0.15A / 2A

5.2.4 Connectors

as per IEC 61131-2 type1,

max. 30VDC, 15mA

as per IEC 61131-2 type1,

max. 30VDC, 100mA

max. 30VDC, max 42VAC

±10V

±10V

500mA

Connector Type

Control signals X3A,B,C Mini-Combicon connector 1,5mm² 4A 160V

Aux. voltage X4A,B Mini-Combicon connector 1,5mm² 4A 160V

Power signals X0, X8, X9 Power-Combicon connector 6mm² 24A 1000V

Resolver input X2 SubD 9pin (socket) 0,5mm² 1A <100V

Encoder input X1 SubD15pin (socket) 0,5mm² 1A <100V

PC interface, CAN X6 SubD 9pin (plug) 0,5mm² 1A <100V

Encoder-Emulation,

ROD/SSI X5 (optional)

SubD 9pin (plug) 0,5mm² 1A <100V

*1 single-line connection

*2 single-line connection with recommended conductor cross section (chapter 5.2.8)

*3 rated voltage with pollution level 2

5.2.5 Recommended tightening torques

Connector Tightening torque

X0, X8, X9 0.7 to 0.8 Nm

Grounding bolt 3.5 Nm

5.2.6 Fusing

Internal fusing, wire fuse or electronic

Circuit Internal fuse

Auxiliary voltage 24V 4A/4A

Brake resistor electronic

STO-Enable 2 A

max. cross

section

*1

permiss.

current

permiss.

*2

voltage

*3

External fusing by user (US fuses in brackets)

Wire fuses or similar S701 / S703 S706 S712 S724

AC supply feed F

24V feed F

Brake resistor F

N1/2/3

H1/2

B1/2

6 AT (6A)* 10 AT (10A)* 16 AT (15A)* 30/35 AT (30A)*

max. 8 AT (8A)

40 A** 40 A** 40 A** 50 A**

* EU fuses: types gRL or gL, 400V/500V, T means time-delay

US fuses: class RK5 or CC or J or T, 600VAC 200kA, time-delay

** Bussmann FWP-xx

Tips and detailed information can be found in the Product-Wiki on page "Fuses

"

30 S701x2-S724x2 Instructions Manual

Page 31

Kollmorgen 07/2014 Technical description

5.2.7 Ambient conditions, ventilation, mounting position

Storage hints

Transport hints

Ambient temperature in operation

Humidity in operation

Site altitude

Pollution level

Vibrations

Enclosure protection

Mounting position

Ventilation

The servo amplifier shuts down (error F01 and F13, see p.122, motor has no torque) in

case of excessively high temperature in the control cabinet.

Make sure that there is sufficient forced ventilation within the control cabinet.

5.2.8 Conductor cross-sections

Following IEC 60204, we recommend for single-axis systems:

Interface Cross section Techn. requirements

AC connection

DC bus link

Brake resistor

Motor cables without choke,

max. 25 m

Motor cables with choke

3YL or 3YLN, 25 - 50m*

Resolver, motor thermal control, max.100m*

Encoder, motor thermal control, max. 50m*

ComCoder, motor thermal

control, max. 25m

Setpoints, AGND, max 30m 0.25 mm² (24awg) twisted pairs, shielded

Control signals, BTB, DGND,

max 30m

Holding brake (motor) min. 0.75 mm² (19awg)

+24 V and XGND, max 30m max. 2.5 mm² (14awg)

For multi-axis systems, observe the specific operating conditions for your system.

To reach functional safety with the max. permitted cable length, observe cable

requirements ð p. 61.

* Kollmorgen North America supplies cables up to 39 meters

* Kollmorgen Europe supplies cables up to max. length

ð p.13

ð p.13

0...+40°C under rated conditions

+40...+55°C with power derating 2.5% / °C

rel. humidity 85%, no condensation

up to 1000 meters a.m.s.l. without restriction

1000…2500 meters a.m.s.l. with power derating

1.5% / 100meters

Pollution level 2 as per IEC 60664-1

Class 3M1 according to IEC 60721-3-3

IP 20 according to IEC 60529

vertical ð p.54

built-on fan

S701...706: 1.5 mm² (16awg)

S712: 2.5 mm² (14awg)

S724: 4 mm² (12awg)

S701...724: 6 mm² (10awg)

S701...706: 1...1.5 mm² (16awg)

S712: 2.5 mm² (14awg)

S724: 4 mm² (12awg)

S701...706: 1 mm² (16awg)

S712: 2.5 mm² (14awg)

S724: 4 mm² (12awg)

4x2x0.25 mm² (24awg)

7x2x0.25 mm² (24awg)

8x2x0.25 mm² (24awg)

0.5 mm² (21awg)

600V,80°C

1000V, 80°C, shielded

for lengths >0.20m

600V,80°C, shielded,

capacitance <150pF/m

600V,80°C, shielded,

capacitance <150pF/m

twisted pairs, shielded,

capacitance <120pF/m

twisted pairs, shielded,

capacitance <120pF/m

twisted pairs, shielded,

capacitance <120pF/m

600V, 80°C, shielded,

check voltage drop

check voltage drop

S701x2-S724x2 Instructions Manual 31

Page 32

Technical description 07/2014 Kollmorgen

5.3 Motor holding brake

A 24V / max. 2A holding brake in the motor can be controlled directly by the amplifier.

CAUTION

This function does not ensure functional safety! Danger by falling load (in

case of suspended load, vertical axes). An additional mechanical brake is

required for funktional safety, which must be safely operated, e.g. via the

Safety Card S1-2 (see p.155).

The brake only works with sufficient voltage level (ð p.30). Check voltage drop, measure

the voltage at brake input and check brake function (brake and no brake).

The brake function must be enabled through the BRAKE setting (screen page: Motor). In

the diagram below you can see the timing and functional relationships between the

ENABLE signal, speed setpoint, speed and braking force. All values can be adjusted with

parameters, the values in the diagram are default values.

During the internal ENABLE delay time of 100ms (DECDIS), the speed setpoint of the

servo amplifier is internally driven down along an adjustable ramp to 0V. The output for

the brake is switched on when the speed has reached 5 rpm (VELO), at the latest after 5s

(EMRGTO). The release delay time (t

brake that is built into the motor are different for the various types of motor (see motor

manual), the matching data are loaded from the motor database when the motor is selec

ted. A description of the interface can be found on page 74.

) and the engage delay time (t

brH

) of the holding

brL

32 S701x2-S724x2 Instructions Manual

-

Page 33

Kollmorgen 07/2014 Technical description

5.4 LED display

A 3-character LED display indicates the status of the amplifier after switching on the 24V

supply (ð p.121). When the keys on the front panel are used, the parameter and function

numbers are shown, as well as the numbers for any errors and warnings that may occur

(ð p.122ff).

5.5 Grounding system

AGND — analog inputs, internal analog ground

DGND — 24V-IO, digital inputs and digital outputs, optically isolated.

GND — internal digital ground, encoder Emulation, RS232, CAN

XGND — 24V supply, STO Enable, ventilator, brake

5.6 Dynamic braking (brake circuit)

During braking with the aid of the motor, energy is fed back into the servo amplifier. This

generated energy is dissipated as heat in the brake resistor. The brake resistor is switched in by the brake circuit.

The setup software can be used to adapt the brake circuit (thresholds) according to the

electrical supply voltage.

Our customer service can help you with the calculation of the brake power that is necessary for your system. A simple method

sible at www.wiki-kollmorgen.eu

Functional description:

1.- Individual amplifiers, not coupled through the DC bus link circuit (DC+, DC-)

When the energy fed back from the motor has an average or peak power that exceeds

the preset level for the brake power rating, then the servo amplifier generates the warning

“n02 brake power exceeded” and the brake circuit is switched off.

The next internal check of the DC bus link voltage (after a few milliseconds) detects an

overvoltage and the output stage is switched off, with the error message “Overvoltage

F02” (ð p.122).

The BTB/RTO contact (terminals X3B/14,15) will be opened at the same time (ð p.101)

2.- Several servo amplifiers coupled through the DC bus link (DC+, DC-)

Using the built-in brake circuit, several amplifiers of the same series can be operated off a

common DC bus link (observe page 70), without requiring any additional measures.

90% of the combined power of all amplifiers is always available for peak and continuous

power. The switch-off on overvoltage takes place as described under 1. (above) for the

amplifier that has the lowest switch-off threshold (resulting from tolerances).

. A description of the interface can be found on page 72.

is described in the "Product Wiki" which is acces-

Technical data of the brake circuits depend on the amplifiers type and the mains voltage

situation. See table on the next page.

S701x2-S724x2 Instructions Manual 33

Page 34

Technical description 07/2014 Kollmorgen

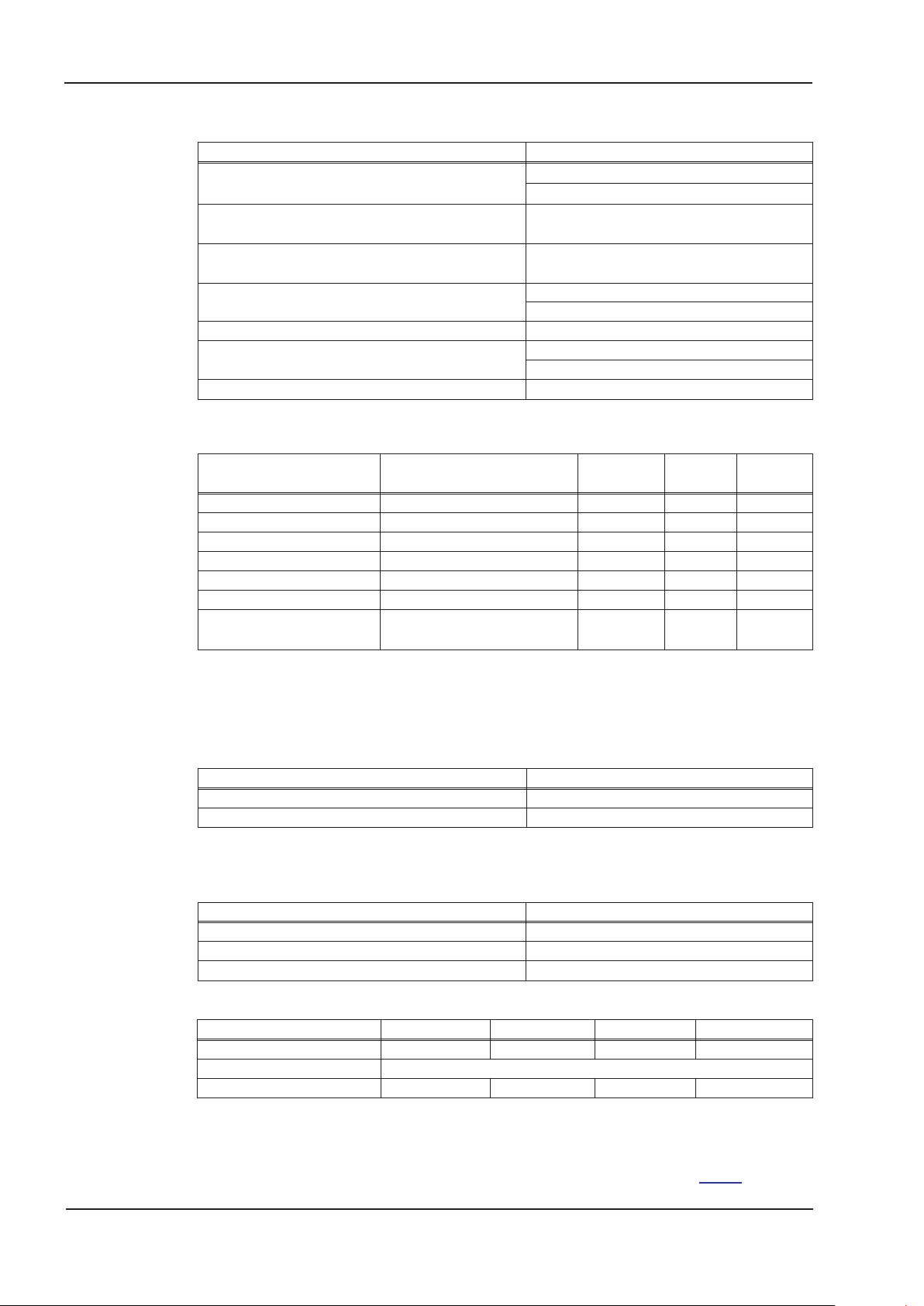

Technical Data S7xx0:

Brake circuit Supply voltage

Type Rated data DIM 230 V 400 V 480 V

Switch-on threshold of brake circuit V 400 720 840

Overvoltage F02 V 455 800 900

Internal brake resistor (RBi) Ohm 33

Continuous power internal brake resistor (RBi) W 50

Max. brake power (average for 1s) kW 0,9 0,85 0,86

S70102

Pulse brake power kW 4 15 21

External brake resistor (RBe), optional Ohm 33

Continuous brake power external (RBe) kW 0,3

Switch-on threshold of brake circuit V 400 720 840

Overvoltage F02 V 455 800 900

Internal brake resistor (RBi) Ohm 33

Continuous power internal brake resistor (RBi) W 50

Max. brake power (average for 1s) kW 0,9 0,85 0,86

S70302

Pulse brake power kW 4 15 21

External brake resistor (RBe), optional Ohm 33

Continuous brake power external (RBe) kW 1

Switch-on threshold of brake circuit V 400 720 840

Overvoltage F02 V 455 800 900

Internal brake resistor (RBi) Ohm 33

Continuous power internal brake resistor (RBi) W 75

Max. brake power (average for 1s) kW 1,38 1,3 1,26

S70602

Pulse brake power kW 4 15 21

External brake resistor (RBe), optional Ohm 33

Continuous brake power external (RBe) kW 1

Switch-on threshold of brake circuit V 400 720 840

Overvoltage F02 V 455 800 900

Internal brake resistor (RBi) Ohm 33

Continuous power internal brake resistor (RBi) W 100

Max. brake power (average for 1s) kW 1,93 1,75 1,7

Pulse brake power kW 4 15 21

S71202/S7120S

External brake resistor (RBe), optional Ohm 33

Continuous brake power external (RBe) kW 1,5

Switch-on threshold of brake circuit V 400 720 840

Overvoltage F02 V 455 800 900

Internal brake resistor (RBi) Ohm 23

Continuous power internal brake resistor (RBi) W 200

Max. brake power (average for 1s) kW 3,93 3,55 3,45

Pulse brake power kW 6 23 30

S72402/S7240S

External brake resistor (RBe), optional Ohm 23

Continuous brake power external (RBe) kW 4

Suitable external brake resistors can be found in our accessories manual.

34 S701x2-S724x2 Instructions Manual

Page 35

Kollmorgen 07/2014 Technical description

Technical data S7xx6:

Brake circuit Supply voltage

Type Rated data DIM 110 V 230 V

Switch-on threshold of brake circuit V 200 400

Overvoltage F02 V 235 455

Internal brake resistor (RBi) Ohm 33

Continuous power internal brake resistor (RBi) W 50

Max. brake power (average for 1s) kW 0,9

S70162

Pulse brake power kW 1,2 4

External brake resistor (RBe), optional Ohm 33*

Continuous brake power external (RBe) kW 0,3

Switch-on threshold of brake circuit V 200 400

Overvoltage F02 V 235 455

Internal brake resistor (RBi) Ohm 33

Continuous power internal brake resistor (RBi) W 50

Max. brake power (average for 1s) kW 0,9

S70362

Pulse brake power kW 1,2 4

External brake resistor (RBe), optional Ohm 33*

Continuous brake power external (RBe) kW 1

Switch-on threshold of brake circuit V 200 400

Overvoltage F02 V 235 455

Internal brake resistor (RBi) Ohm 33

Continuous power internal brake resistor (RBi) W 75

Max. brake power (average for 1s) kW 1,38

S70662

Pulse brake power kW 1,2 4

External brake resistor (RBe), optional Ohm 33*

Continuous brake power external (RBe) kW 1

Switch-on threshold of brake circuit V 200 400

Overvoltage F02 V 235 455

Internal brake resistor (RBi) Ohm 33

Continuous power internal brake resistor (RBi) W 100

Max. brake power (average for 1s) kW 1,93

Pulse brake power kW 1,2 4

S71262/S7126S

External brake resistor (RBe), optional Ohm 33*

Continuous brake power external (RBe) kW 1,5

Switch-on threshold of brake circuit V 200 400

Overvoltage F02 V 235 455

Internal brake resistor (RBi) Ohm 23

Continuous power internal brake resistor (RBi) W 200

Max. brake power (average for 1s) kW 3,93

Pulse brake power kW 1,74 6

S72462/S7246S

External brake resistor (RBe), optional Ohm 23*

Continuous brake power external (RBe) kW 4

* Can be reduced to 15 Ohm (PBALRES 15) if required.

Suitable external brake resistors can be found in our accessories manual.

S701x2-S724x2 Instructions Manual 35

Page 36

Technical description 07/2014 Kollmorgen

5.7 Switch-on and switch-off behavior

This chapter describes the switch-on and switch-off behavior of the S700 and the steps

required to achieve operational stopping or emergency stop behavior that complies with

standards.

The servo amplifier’s 24 V supply must remain constant. The ASCII commands

ACTFAULT

STOPMODE

(error response, also depends on the specific error, see ERRCODE) and

(Enable signal response) dictate how the drive will behave.

ACTFAULT /

STOPMODE

0

1 (default)

Behavior (see also ASCII reference in the online help

ware)

Motor coasts to a standstill in an uncontrolled manner

Motor is braked in a controlled manner

of the setup soft-

Behavior during a power failure

The servo amplifiers use an integrated circuit to detect if one or more input phases

(power supply feed) fail. The behavior of the servo amplifier is set using the setup software: Under “Response to Loss of Input Phase” (PMODE) on the Basic Setup screen,

select:

l

Warning if the higher-level control system is to bring the drive to a standstill: Warning n05 is output if an input phase is missing, and the motor current is limited to 4 A.

The servo amplifier is not disabled. The higher-level control system can now selectively end the current cycle or start bringing the drive to a standstill. Therefore, the error message “MAINS BTB, F16" is output on a digital output of the servo amplifier

and evaluated by the control system, for instance.

l

Error message if the servo amplifier is to bring the drive to a standstill: Error message F19 is output if an input phase is missing. The servo amplifier is disabled and the

BTB contact opens. Where the factory setting is unchanged (ACTFAULT=1), the motor is braked using the set “EMERGENCY STOP RAMP”.

Behavior when undervoltage threshold is reached