Page 1

PROFIBUS DP

Fieldbus Interface for S300 / S400 / S600 / S700

Edition 04/2017

Translation of the original manual

Keep the manual as a product component

during the life span of the product.

Pass the manual to future users / owners

of the product.

Datei srprof_e.***

Page 2

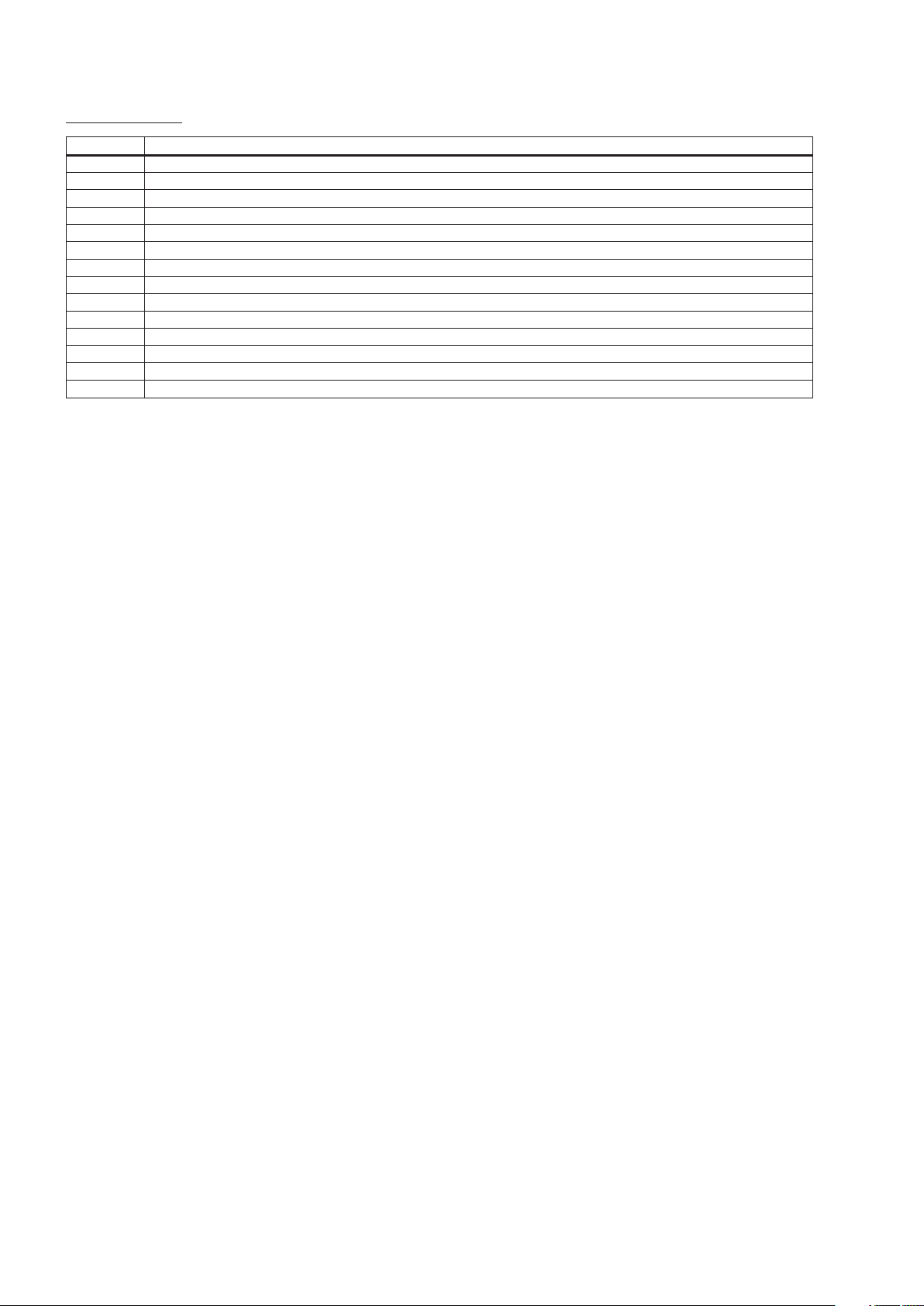

Previous editions

Edition Comments

05 / 1999 Preliminary version

10 / 1999 First edition

06 / 2002 new layout, several corrections, valid from firmware 3.54

11 / 2005 Valid for the S300/S400/S600 series, several corrections, company name changed, front- and back-page new design

12 / 2005 Language improvements in the english version

09 / 2006 New Design

08 / 2007 Branding, S700 new, Symbols, Standards

12 / 2008 Several corrections, PNU1785 expanded

07 / 2009 Product branding

12 / 2009 Several minor corrections, Symbols according to ANSI Z535

12 / 2010 Company name new

07 / 2014 Warning notes updates, design cover page

04 / 2016 Safe voltage changed to 50V, warning symbols updated, european directives updated

04 / 2017 Use as directed updated, hints for PDF usage new, PNU930 "-7" Servo Pump new, opmode -7 new

SINEC is a registered trademark of Siemens AG

Technical changes to improve the performance of the equipment may be made without prior notice!

All rights reserved. No part of this work may be reproduced in any form (by photocopying, microfilm or any other method)

or stored, processed, copied or distributed by electronic means, without the written permission of Kollmorgen Europe

GmbH.

Page 3

Kollmorgen 04/2017 Contents

page

1 General

1.1 About this manual ....................................................................... 5

1.2 Target group ........................................................................... 5

1.3 Hints for the online edition (PDF format) ...................................................... 6

1.4 Use as directed ......................................................................... 6

1.5 Symbols used in this manual ............................................................... 6

1.6 Abbreviations used in this manual ........................................................... 7

2 Installation / Setup

2.1 Installation ............................................................................. 9

2.1.1 Safety notes....................................................................... 9

2.1.2 Inserting the expansion card (S300, S600 and S700) ...................................... 10

2.1.2.1 Front view .................................................................... 10

2.1.2.2 Setup of Station Address and Baud Rate ............................................ 10

2.1.2.3 Connection technology .......................................................... 10

2.1.2.4 Connection diagram ............................................................ 11

2.1.3 Profibus master module setup ........................................................ 12

2.1.3.1 Configuration of the master controller ( e.g. Siemens S7)................................ 12

2.1.4 Standard function block for date exchange with the servo amplifier............................13

2.2 Amplifier setup ......................................................................... 13

2.2.1 Guide to setup .................................................................... 13

2.2.2 Important amplifier configuration parameters............................................. 14

2.2.3 Setup Software ................................................................... 15

2.2.3.1 Screen page PROFIBUS......................................................... 15

2.2.3.2 Screen page PROFIBUS instrument control .......................................... 16

3 Device Profile

3.1 Parameter channel...................................................................... 18

3.1.1 Parameter ID (PKE) ................................................................ 18

3.1.1.1 Interpretation of the response IDs .................................................. 18

3.1.1.2 Response ID 7: Profile specific error numbers ........................................ 19

3.1.2 Index IND........................................................................ 19

3.1.3 Parameter value PWE .............................................................. 20

3.2 The process data channel (PZD) ........................................................... 20

4 Parameter channel (PKW)

4.1 Read/write an amplifier parameter .......................................................... 21

4.2 Summary of the parameter numbers ........................................................ 21

4.2.1 List of the parameters .............................................................. 22

4.2.2 Standard PROFIDRIVE parameters ................................................... 24

4.2.2.1 PNU 940/911: PPO type write/read................................................. 24

4.2.2.2 PNU 918: PROFIBUS node address................................................ 24

4.2.2.3 PNU 963: baud rate............................................................. 24

4.2.2.4 PNU 965: PROFIDRIVE profile number ............................................. 24

4.2.2.5 PNU 970: default parameters ..................................................... 24

4.2.2.6 PNU 971: non volatile saving of parameters .......................................... 24

4.2.2.7 PNU 930: Selection Switch for Operating Mode ....................................... 25

4.2.3 Manufacturer specific parameters ..................................................... 26

4.2.3.1 PNU 1000: instrument ID ........................................................ 26

4.2.3.2 PNU 1001: manufacturer specific error register ....................................... 26

4.2.3.3 PNU 1002: manufacturer specific status register ...................................... 27

4.2.4 Position control parameters .......................................................... 28

4.2.4.1 PNU 1894: velocity multiplier...................................................... 28

4.2.4.2 PNU 1807: axis type ............................................................ 28

4.2.5 Position data for the position control mode .............................................. 28

4.2.5.1 PNU 1790: position ............................................................. 28

4.2.5.2 PNU 1791: velocity ............................................................. 28

4.2.5.3 PNU 1785: motion task type ...................................................... 29

4.2.5.4 PNU 1783: acceleration time...................................................... 29

4.2.5.5 PNU 1784: acceleration jolt limiting................................................. 30

4.2.5.6 PNU 1786: deceleration time ..................................................... 30

PROFIBUS for S300/S400/S600/S700 3

Page 4

Contents 04/2017 Kollmorgen

page

4.2.5.7 PNU 1787: deceleration jolt limiting................................................. 30

4.2.5.8 PNU 1788: next motion task ...................................................... 30

4.2.5.9 PNU 1789: start delay ........................................................... 30

4.2.5.10 PNU 1310: copy motion task...................................................... 30

4.2.5.11 PNU 1311: position, 32 bit floating decimal point format................................. 30

4.2.5.12 PNU 1312: velocity, 32 bit floating decimal point format ................................. 30

4.2.6 Setup mode: position ............................................................... 31

4.2.6.1 PNU 1773: homing type ......................................................... 31

4.2.6.2 PNU 1644: homing direction ...................................................... 31

4.2.7 Actual values ..................................................................... 31

4.2.7.1 PNU 1401: speed .............................................................. 31

4.2.7.2 PNU 1402: incremental position, actual value......................................... 31

4.2.7.3 PNU 1800: actual position value in SI (User) units ..................................... 31

4.2.7.4 PNU 1414: actual position, 32 bit floating decimal point format............................31

4.2.7.5 PNU 1415: actual velocity, 32 bit floating decimal point format............................ 32

4.2.8 Digital I/O configuration ............................................................. 32

4.2.8.1 PNUs 1698/1701/1704/1707: digital input configuration ................................. 32

4.2.8.2 PNUs 1775/1778: digital output configuration ......................................... 32

4.2.9 Analog configuration ............................................................... 32

4.2.9.1 PNU 1607: analog input configuration............................................... 32

4.2.9.2 PNU 1613/1614: analog output configuration ......................................... 32

4.2.10 Manufacturer specific object channel (from PNU 1600)..................................... 33

5 Process data channel

5.1 Instrument control ...................................................................... 36

5.1.1 Control word (STW) ................................................................ 38

5.1.2 Status word (ZSW)................................................................. 39

5.2 Operating modes ....................................................................... 39

5.2.1 Positioning (operating mode 2) ....................................................... 40

5.2.2 Digital speed (operating mode 1) ...................................................... 41

5.2.3 Analog speed (operating mode -1)..................................................... 41

5.2.4 Digital torque (operating mode -2) ..................................................... 42

5.2.5 Analog torque (operating mode -3) .................................................... 42

5.2.6 Electronic gearing (operating mode -4) ................................................. 42

5.2.7 Trajectory (operating mode -5) ....................................................... 42

5.2.8 Digital setpoint & Servo Pump (operating mode -7) ........................................ 43

5.2.9 ASCII channel (operating mode -16) ................................................... 43

5.2.10 Operating mode after switch-on (operating mode -126)..................................... 44

6 Appendix

6.1 Example telegrams ..................................................................... 45

6.1.1 Zero telegram (for initialization) ....................................................... 45

6.1.2 Setting the Opmode ................................................................ 45

6.1.3 Enable the servo amplifier ........................................................... 46

6.1.4 Start jog mode (on positioning opmode) ................................................ 46

6.1.5 Set reference point................................................................. 46

6.1.6 Start homing run .................................................................. 47

6.1.7 Start a motion task ................................................................. 49

6.1.8 Start a direct motion task ............................................................ 49

6.1.9 Polling a warning or error message .................................................... 49

6.1.10 Writing a parameter (via parameter channel PKW) ........................................ 50

6.1.11 Reading actual values .............................................................. 50

6.1.12 Write a parameter via the ASCII channel................................................ 51

6.2 Index ................................................................................ 52

4 PROFIBUS for S300/S400/S600/S700

Page 5

Kollmorgen 04/2017 General

1 General

1.1 About this manual

This manual describes the wiring, setup, range of functions and software protocol for the

SERVOSTAR 300 (S300), SERVOSTAR 400 (S400), SERVOSTAR 600 ( S600) and S700.

, S600 and S700:

S300

The expansion card -PROFIBUS- offers PROFIBUS compatible connectivity to these servo amplifi

ers. The expansion card and it's mounting is described in the instructions manual.

The expansion card for S300 and S700 is different from the card for S600. The text "PROFIBUS

DP" on the front label marks the card for S300/S700, the text "PROFIBUS" the card for S600.

-PROFIBUS:

S400

PROFIBUS functionality is built-in on delivery.

This manual is part of the complete documentation of the digital servo amplifiers. The installation

and setup of the servo amplifier, as well as all the standard functions, are described in the corre

sponding instructions manuals.

Other parts of the documentation of the digital servo amplifiers:

-

-

Title

Instructions manual for the Servo Amplifier Kollmorgen

Online-Help with Object Reference Guide Kollmorgen

Further documentation:

Title

Installation Guideline for PROFIBUS DP/FMS PNO

Profile for Variable Speed Drives PNO

SINEC Produktinformation S79200-A0737-X-02-7437 Siemens

SINEC Installationsanleitungen S79200-A0737-X-01-7419 Siemens

SINEC Einführung CP5412 (A2) C79000-G8900-C068 Siemens

SINEC DP-Masterbetrieb mit dem COML DP projektieren C79000-G8900-C069 Siemens

SINEC DP-Programmierschnittstelle C79000-G8900-C071 Siemens

1.2 Target group

This manual addresses personnel with the following qualifications:

Transport : only by personnel with knowledge of handling electrostatically sensitive

Unpacking: only by electrically qualified personnel.

Installation : only by electrically qualified personnel.

Setup : only by qualified personnel with extensive knowledge of electrical

Programming: Software developers, project-planners, experienced PLC programmers

The qualified personnel must know and observe the following standards:

Publisher

Publisher

components.

engineering and drive technology

with PROFIBUS DP expertise

IEC 60364, IEC 60664, and regional accident prevention regulations.

Qualified Personnel only!

During operation there are deadly hazards, with the possibility of death,

severe injury or material damage.

l

The user must ensure that the safety instructions in this manual are

followed.

l

The user must ensure that all personnel responsible for working with

the servo amplifier have read and understood the instructions manual.

Training courses are available on request.

PROFIBUS for S300/S400/S600/S700 5

Page 6

General 04/2017 Kollmorgen

1.3 Hints for the online edition (PDF format)

Bookmarks:

Table of contents and index are active bookmarks.

Table of contents and index in the text:

The lines are active cross references. Click on the desired line and the appropriate page is indi

cated.

Page/chapter numbers in the text:

Page/chapter numbers with cross references are active. Click at the page/chapter number to reach

the indicated target.

-

1.4 Use as directed

Please observe the chapter "Use as directed” in the instructions manual for the servo amplifier.

The PROFIBUS interface serves only for the connection of the servo amplifier to a master with

PROFIBUS connectivity.

The servo amplifiers are components that are built into electrical apparatus or machinery, and can

only be setup and operated as integral components of such apparatus or machinery.

We only guarantee the conformity of the servo amplifier with the directives listed in the EU Declara

tion of Conformity, if the components that we specify are used, and the installation regulations are

followed.

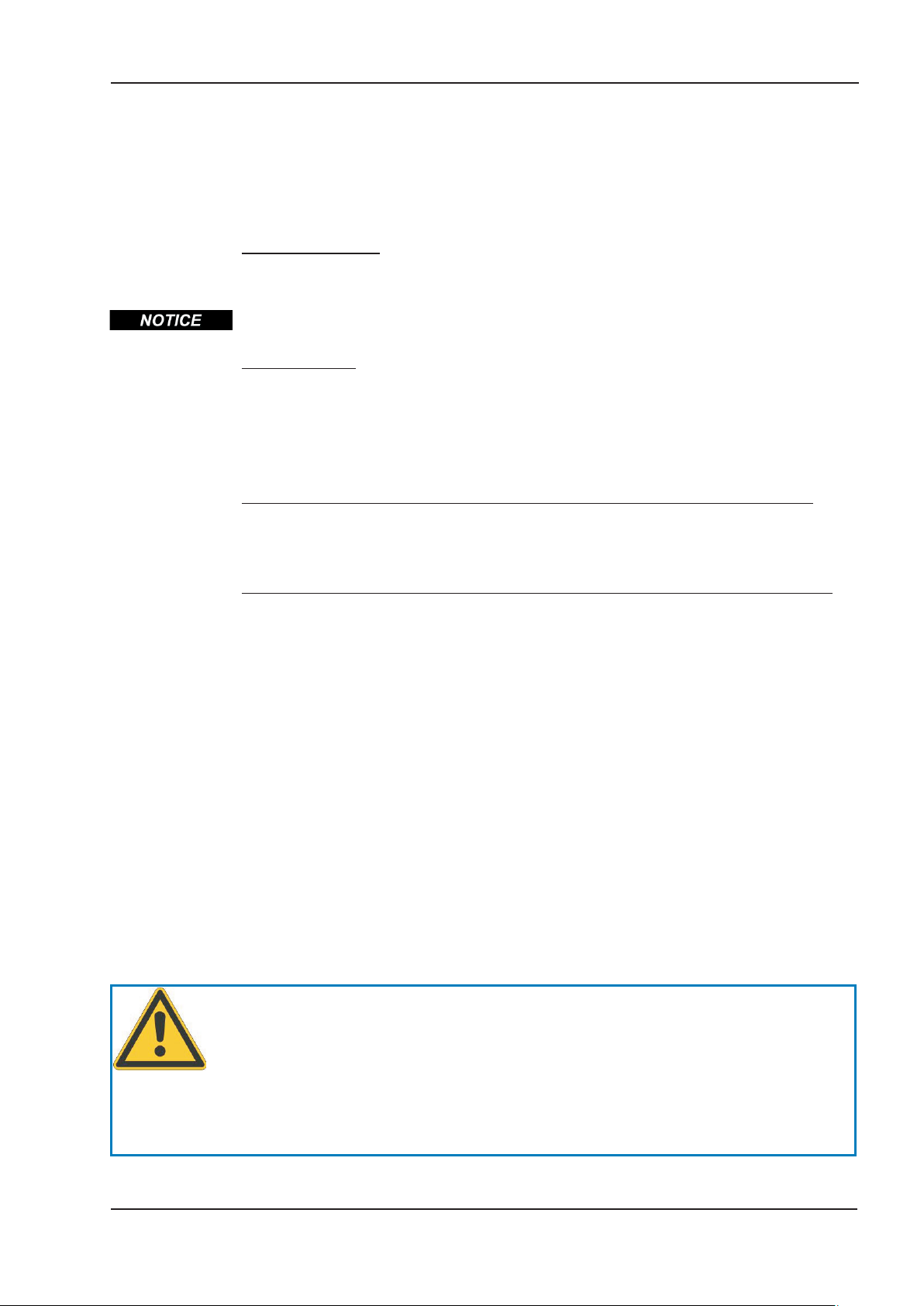

1.5 Symbols used in this manual

Symbol Indication

Indicates a hazardous situation which, if not avoided, will result in death or se-

DANGER

WARNING

CAUTION

rious injury.

Indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

This is not a safety symbol. Indicates situations which, if not avoided, could re

sult in property damage.

This is not a safety symbol.

This symbol indicates important notes.

Warning of a danger (general). The type of danger is specified by the warning

text next to it.

Warning of danger from electricity and its effects.

-

-

Warning of danger from automatic start.

6 PROFIBUS for S300/S400/S600/S700

Page 7

Kollmorgen 04/2017 General

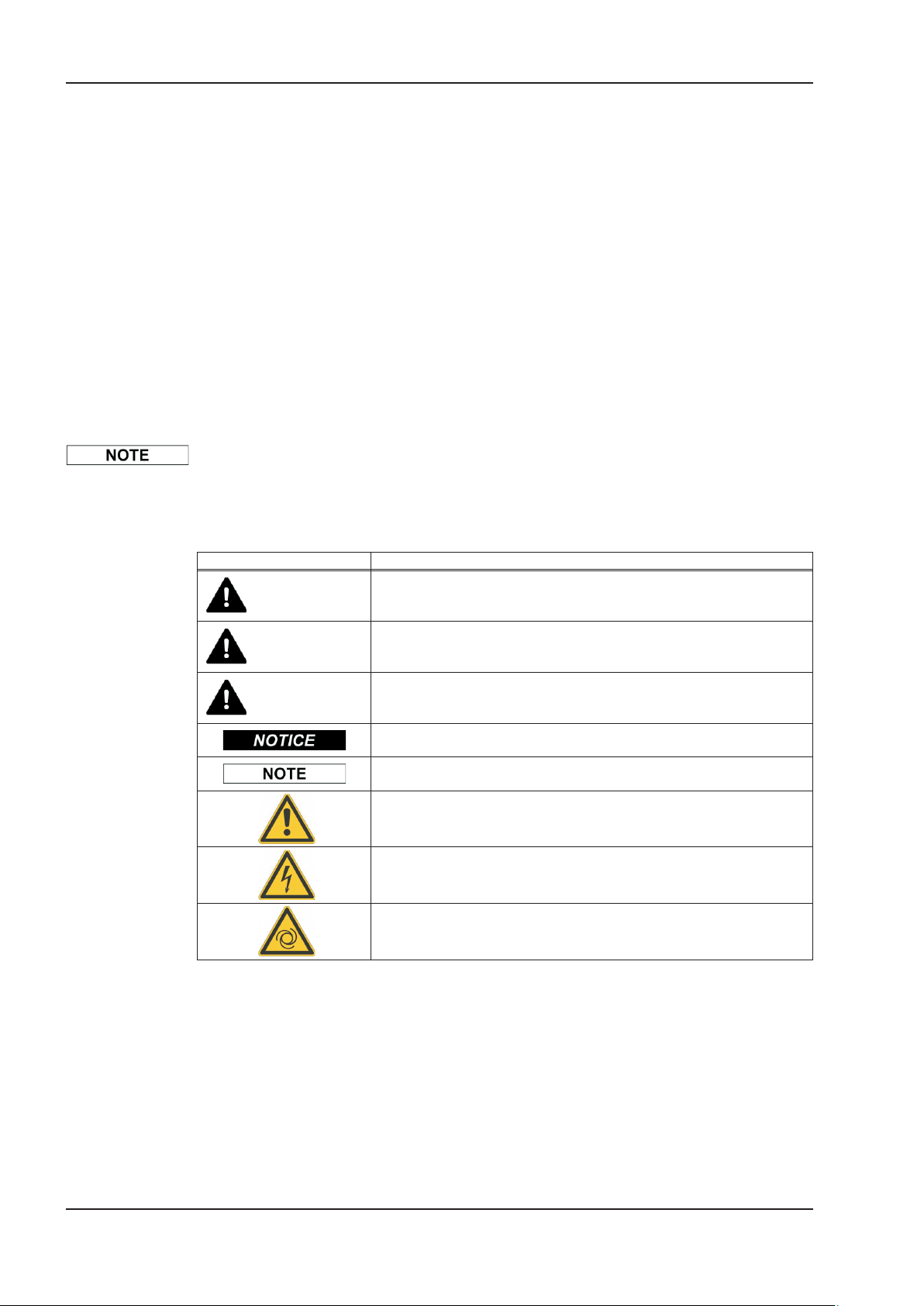

1.6 Abbreviations used in this manual

The abbreviations used in this manual are explained in the table below.

Abbrev. Meaning

AGND Analog ground

BTB/RTO Ready to operate

CLK Clock signal

COM Serial interface for a PC-AT

DGND Digital ground

DIN German Institute for industrial Standards

Disk Magnetic storage (diskette, hard disk)

EEPROM Electrically erasable programmable memory

EN European standard

IEC International Electrotechnical Commission

INC Incremental Interface

LED Light-emitting diode

MB Megabyte

NI Zero pulse

NSTOP Limit-switch input for CCW rotation (left)

PZD Process data

PSTOP Limit-switch input for CW rotation (right)

RAM Volatile memory

RES Resolver

ROD A quad B encoder

PLC Programmable logic controller

S300 SERVOSTAR 300

S400 SERVOSTAR 400

S600 SERVOSTAR 600

SSI Synchronous serial interface

VAC AC voltage

VDC DC voltage

PROFIBUS for S300/S400/S600/S700 7

Page 8

General 04/2017 Kollmorgen

This page has been deliberately left blank.

8 PROFIBUS for S300/S400/S600/S700

Page 9

Kollmorgen 04/2017 Installation / Setup

2 Installation / Setup

2.1 Installation

2.1.1 Safety notes

WARNING

High Voltages up to 900V!

Risk of electric shock. Residual charges in the capacitors can still have

dangerous levels several minutes after switching off the supply voltage.

Power and control connections can still be live, even though the motor is

not rotating.

Install and wire up the equipment only while it is not electrically con

l

nected.

Make sure that the control cabinet is safely isolated (lock-out, warning

signs etc.).The individual supply voltages will not be switched on until

setup is carried out.

-

Measure the voltage in the intermediate (DC-link) circuit and wait until it

l

has fallen below 50V.

CAUTION

Automatic Start!

Risk of death or serious injury for humans working in the machine. Drives

with servo amplifiers in fieldbus systems are remote-controlled machines

They can start to move at any time without previous warning.

l

Implement appropriate protective measures to ensure that any unintended start-up of the machines cannot result in dangerous situations

for personnel or machinery.

l

The user is responsible for ensuring that, in the event of a failure of the

servo amplifier, the drive is set to a state that is functional safe, for in

stance with the aid of a safe mechanical brake.

l

Software limit-switches are not a substitute for the hardware

limit-switches in the machine.

Install the servo amplifier as described in the instructions manual. The wiring for the analog setpoint

input and the positioning interface is not required.

Because of the internal representation of the position-control parameters, the position controller can

only be operated if the final limit speed of the drive does not exceed:

rotatory

at sinusoidal² commutation: 7500 rpm

at trapezoidal commutation: 12000 rpm.

linear

at sinusoidal² commutation: 4 m/s

at trapezoidal commutation: 6.25 m/s

-

All the data on resolution, step size, positioning accuracy etc. refer to calculatory values.

Non-linearities in the mechanism (backlash, flexing, etc.) are not taken into account.

If the final limit speed of the motor has to be altered, then all the parameters that were previously

entered for position control and motion blocks must be adapted.

PROFIBUS for S300/S400/S600/S700 9

Page 10

Installation / Setup 04/2017 Kollmorgen

2.1.2 Inserting the expansion card (S300, S600 and S700)

The expansion card for S300/S700 is different from the card for S600.

The text "PROFIBUS DP" on the front label marks the card for S300/S700, the text "PROFIBUS"

the card for S600.

To fit the PROFIBUS expansion card into the servo amplifier, proceed as follows:

l

Remove the cover of the option slot (see installation manual of the servo amplifier.)

l

Take care that no small items (such as screws) fall into the open option slot.

l

Push the expansion card carefully into the guide rails that are provided, without twisting it.

l

Press the expansion card firmly into the slot, until the front cover touches the fixing lugs. This

ensures that the connectors make good contact.

l

Use the screws on the expansion card to secure it in the drive.

2.1.2.1 Front view

Shown is the expansion card for S300/S700.

2.1.2.2 Setup of Station Address and Baud Rate

During setup it makes sense to use the keypad on the front panel to preset the station addresses

for the individual amplifiers (see chapter "Setup" in the instructions manual).

After changing the station address you must turn the 24V auxiliary supply for the servo amplifier off

and on again for the new address to take affect.

Possible ways for setup:

l

keypad on the front panel of the servo amplifier (see instructions manual)

l

setup software: screen page “CAN / Fieldbus” (see online help)

l

serial interface with a sequence of ASCII commands:

ADDR nn Þ SAVE Þ COLDSTART (with nn = address)

The Baudrate is defined by the hardware configuration in the master controller. Baudrates up to 12

MBaud are possible. During bus initialization, the master controller sends the amplifier the desired

baud rate.

2.1.2.3 Connection technology

Cable selection, cable routing, shielding, bus connector, bus termination and transmission times are

all described in the “Installation guidelines for PROFIBUS-DP/” from PNO, the PROFIBUS User

Organization.

10 PROFIBUS for S300/S400/S600/S700

Page 11

Kollmorgen 04/2017 Installation / Setup

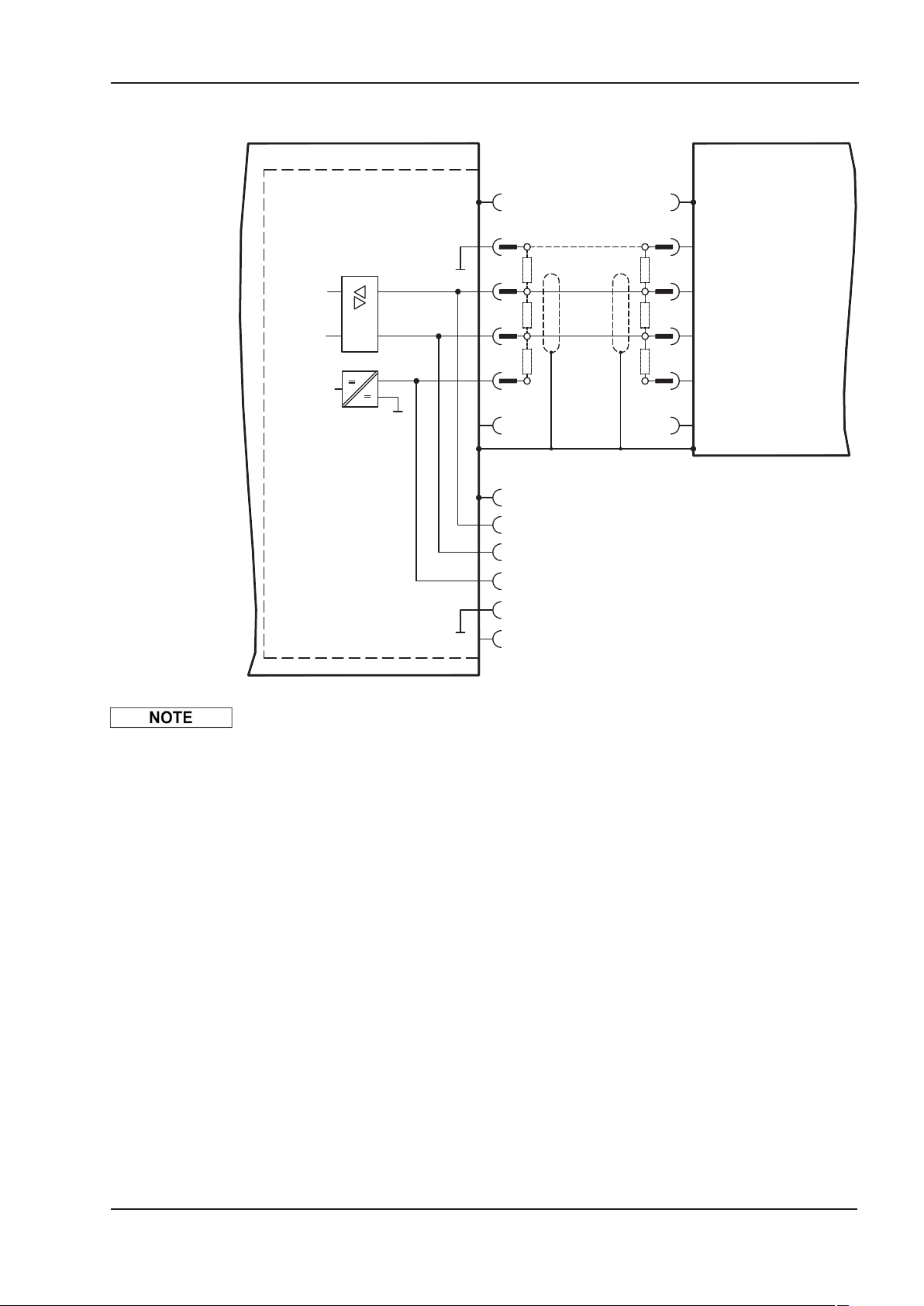

PROFIBUS

X12A

X12B

1

5

8

3

6

4

1

8

3

6

5

4

+5V

1

5

4

6

3

8

RS485-A

+5V

RS485-B

GND1

390Ù

220Ù

390Ù

390Ù

220Ù

390Ù

2.1.2.4 Connection diagram

Servo amplifier

With S600 terminals AGND and DGND (connector X3) must be joined together !

PROFIBUS for S300/S400/S600/S700 11

Page 12

Installation / Setup 04/2017 Kollmorgen

2.1.3 Profibus master module setup

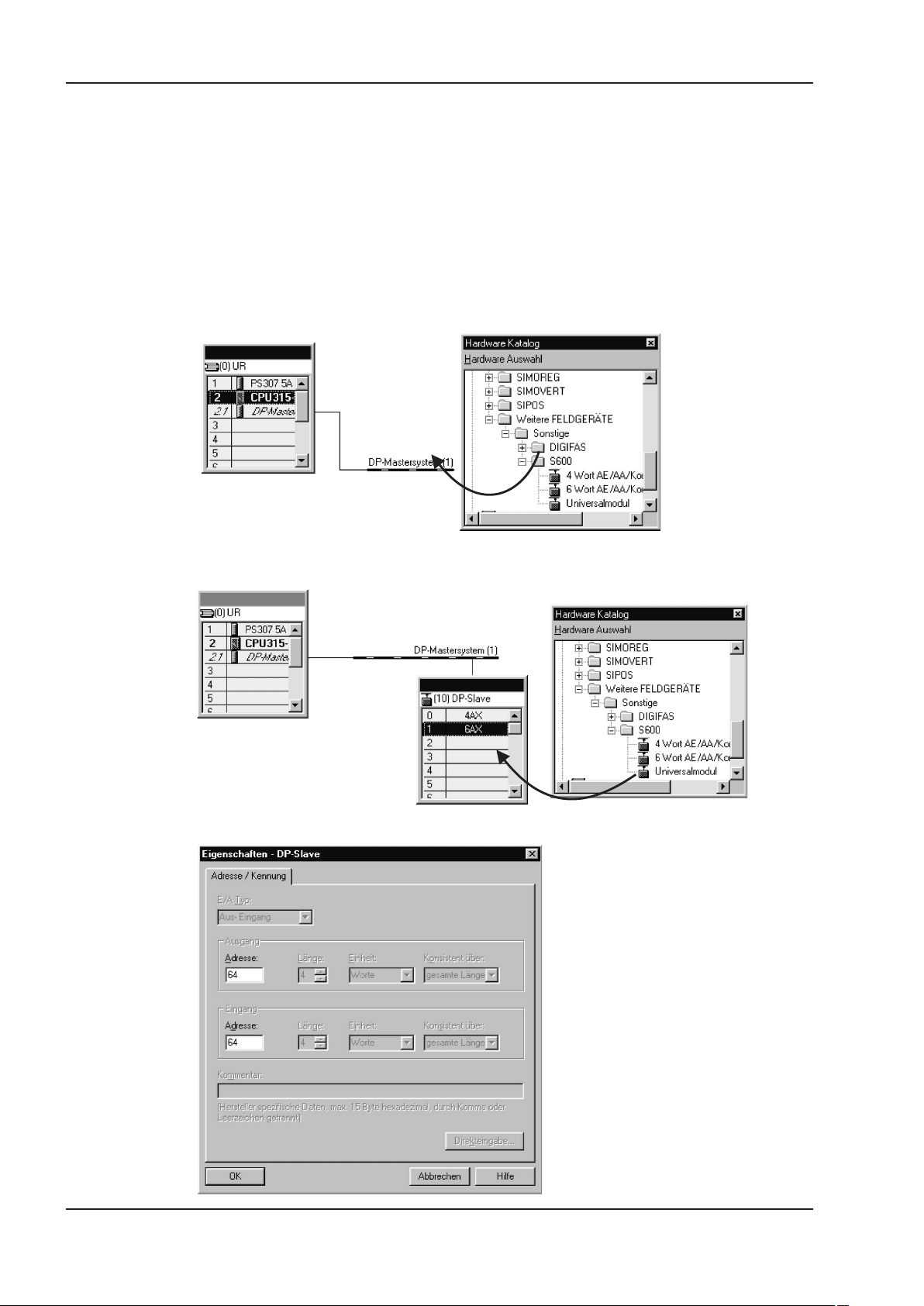

2.1.3.1 Configuration of the master controller ( e.g. Siemens S7)

The graphics interface makes it very easy to configure the Siemens S7 for the PROFIBUS network.

After you have set up the control layout, configure the interface module that is used as follows: Use

our library file KOLL045D.GSD to configure the Profibus master for the servo amplifier. The follow

ing shows a Siemens PLC. Other machine controllers can also be configured for the Kollmorgen

Profibus expansion card. Open the Hardware catalog and drag the symbol for the corresponding

field unit onto the representation of the bus system. A window opens auto- matically for the general

parameterization of the field unit (please observe: the S300/S700 are displayed here like a S600).

Enter the address of the participant here.

-

Next, use the same method as above to drag the module from the Hardware catalog into the box for

the field unit, whereby the 4-word module must lie in Cell 0 and the 6-word module in Cell 1.

Another window opens, in which you can set the parameters for the module.

12 PROFIBUS for S300/S400/S600/S700

Page 13

Kollmorgen 04/2017 Installation / Setup

2.1.4 Standard function block for date exchange with the servo amplifier

Kollmorgen supplies a S7-function block (FB10) for use Siemens PLC that make it possible to han

dle the servo amplifier control functions very simply.

This function block and its description can be found as a text file on the CDROM and in the down

load section of our website.

2.2 Amplifier setup

2.2.1 Guide to setup

Only properly qualified personnel with professional expertise in control and drive technology are

permitted to setup the servo amplifier.

Check assembly

+ installation

Connect PC,

start setup software

CAUTION: Automatic Start!

Risk of death or serious injury for humans working in the machine. The drive performing unplanned movements during commissioning cannot be ruled out. Make sure that, even if the drive

starts to move unintentionally, no danger can result for personnel or machinery. The measures

you must take in this regard for your task are based on the risk assessment of the application.

Check that all the safety instructions, which are included in both the

instructions manual for the servo amplifier and in this manual, have

been observed and implemented.

Use the setup software for setting the parameters for the servo am

plifier.

-

-

-

Setup the

basic functions

Save

parameters

Test the

bus connection

Now setup the basic functions of the servo amplifier including tuning

the servo loops. This part of setup is described in the online help

system of the setup software.

When the optimization is finished, save the controller parameters in

the servo amplifier.

Remove the Enable signal (Terminal X3) and switch off the mains

power supply for the servo amplifier.

The 24V DC auxiliary voltage remains switched on.

Test the installation of the PROFIBUS connection and the interface

to the PROFIBUS master.

Check the PROFIBUS-DP parameter settings and the station con

figuration.

Check the parameter settings for the PROFIBUS interface module.

Check the PLC user program and the parameter settings for the

function block.

-

PROFIBUS for S300/S400/S600/S700 13

Page 14

Installation / Setup 04/2017 Kollmorgen

2.2.2 Important amplifier configuration parameters

The following parameters configure the amplifier for the Profibus interface. They can be set using

the setup software for the amplifier.

EXTWD (PNU 1658)

With this parameter, the observation time (watch dog) for the fieldbus-slot communication can be

set. The observation is only active, if a value higher than 0 is assigned to EXTWD (EXTWD=0,

observation switched off) and the output stage is enabled. If the set time runs out, without the

watchdog-timer being newly triggered by the arrival of a telegram, then the warning n04 (response

monitoring) is generated and the drive is stopped. The amplifier remains ready for operation and the

output stage enabled. Before a new driving command (setpoint) is accepted, this warning must be

deleted (function CLRFAULT or INxMODE=14).

ADDR (PNU 918)

With this command, the node address of the amplifier is set. When the address has been changed,

all parameters should be saved to the EEPROM and the amplifier switched off and on again.

Since the modular structure of the S400 as a multi-axis system requires its own addressing, there is

the additional parameter ADDRFB (PNU 2012) for this series, with which a field bus address differ

ent from the internal device address (ADDR) can be defined. As long as ADDRFB = 0, ADDR is

the bus address. If ADDRFB > 0, then ADDRFB is the bus address. ADDR is set automatically by

the S400 master module in descending order.

-

AENA (PNU 1606)

With this parameter, the state of the software-enable after switch-on can be defined. The software-enable allows an external control to enable/disable the output stage. For amplifiers with analog setpoints (OPMODE=1,3) the software-enable is set automatically after switch-on and the

devices are ready for operation immediately (if hardware-enable is present). For all others, software-enable will be set to the value of AENA. The variable AENA also has functionality when resetting the amplifier after an error (by digital input 1 or the CLRFAULT command). If an error can be

reset by the software, the software-enable is set to the value of AENA after the error is cleared. In

this way the behavior of the amplifier after a software-reset is similar to after the drive is switched

on.

INPT, INPT0 (PNU 1904)

With INPT (S300/S700: INPT0) a delay for the in-position message can be set. With the start of a

motion task the in-position message is deleted and the monitoring of the position is activated after

expiration of the adjusted time. This function is particularly important for positioning procedures

within the in-position window. In this case the in-position message is delayed for a defined time.

14 PROFIBUS for S300/S400/S600/S700

Page 15

Kollmorgen 04/2017 Installation / Setup

2.2.3 Setup Software

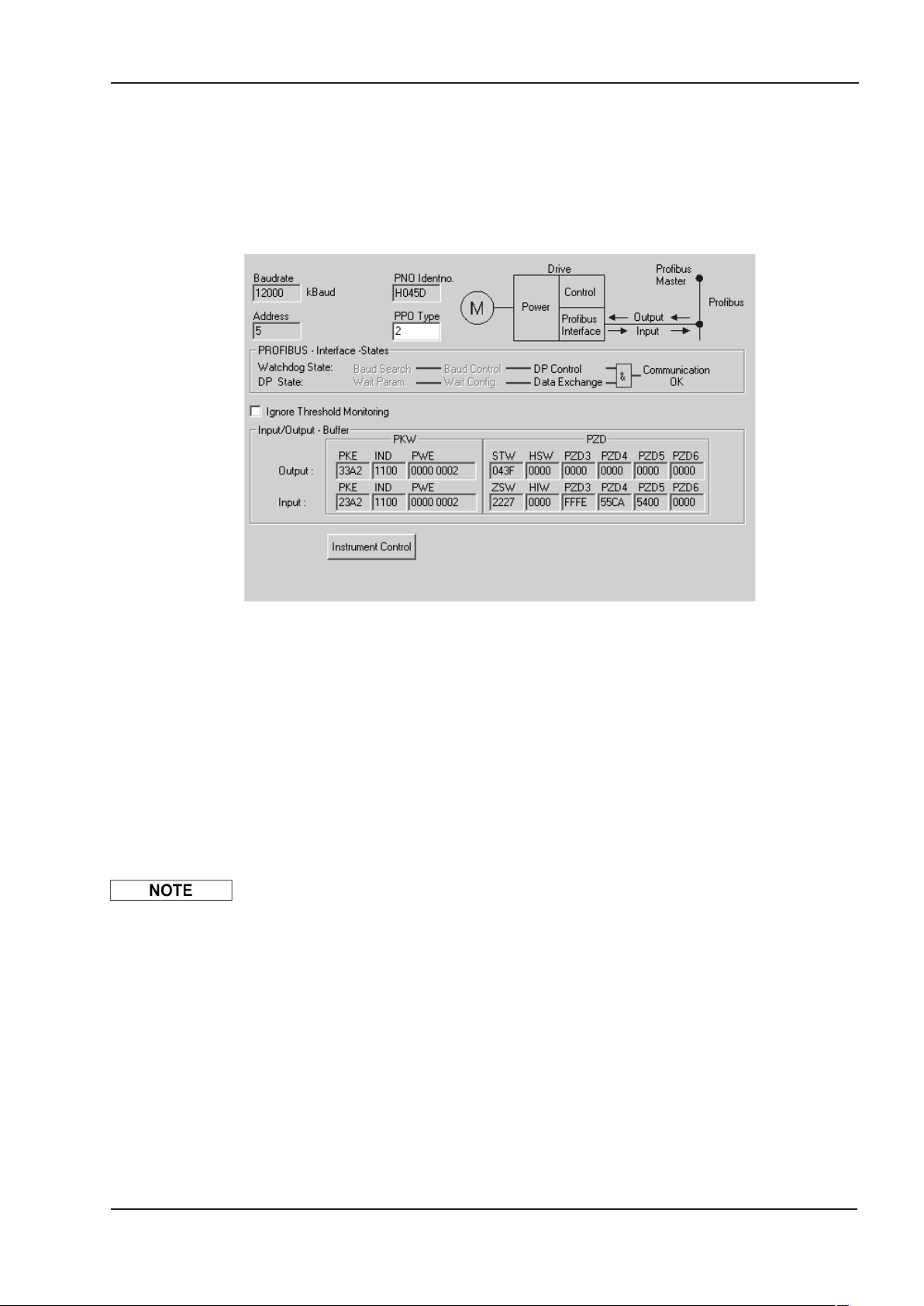

2.2.3.1 Screen page PROFIBUS

This screen will only appear, if the PROFIBUS hardware is built into the servo amplifier. The screen

page displays the PROFIBUS-specific parameters, the bus status, and the data words in the trans

mit and receive directions, as seen by the bus-master. This page is helpful when searching for

errors and commissioning the bus communication. The picture below shows the S300/S700 screen.

-

Baudrate: The baud rate set by the PROFIBUS master.

PNO Identno.: The PNO identification is the number for the servo amplifier from the list

of ID-numbers set by the PROFIBUS user organization.

Address: Station address of the amplifier (setting see p.10).

PPO type: servo amplifier only supports PPO-type 2 of the PROFIDRIVE profile.

PROFIBUS Interface states:

Shows the present status of the bus communication. Data can only be

transferred across the PROFIBUS when the “Communication OK”

message is black (not shown in gray).

Input: The last PROFIBUS object received by the master.

Output: The last PROFIBUS object sent by the master.

The data for input/output are only transferred, if the threshold monitoring for the servo amplifier has

been activated in the master’s hardware configuration.

PROFIBUS for S300/S400/S600/S700 15

Page 16

Installation / Setup 04/2017 Kollmorgen

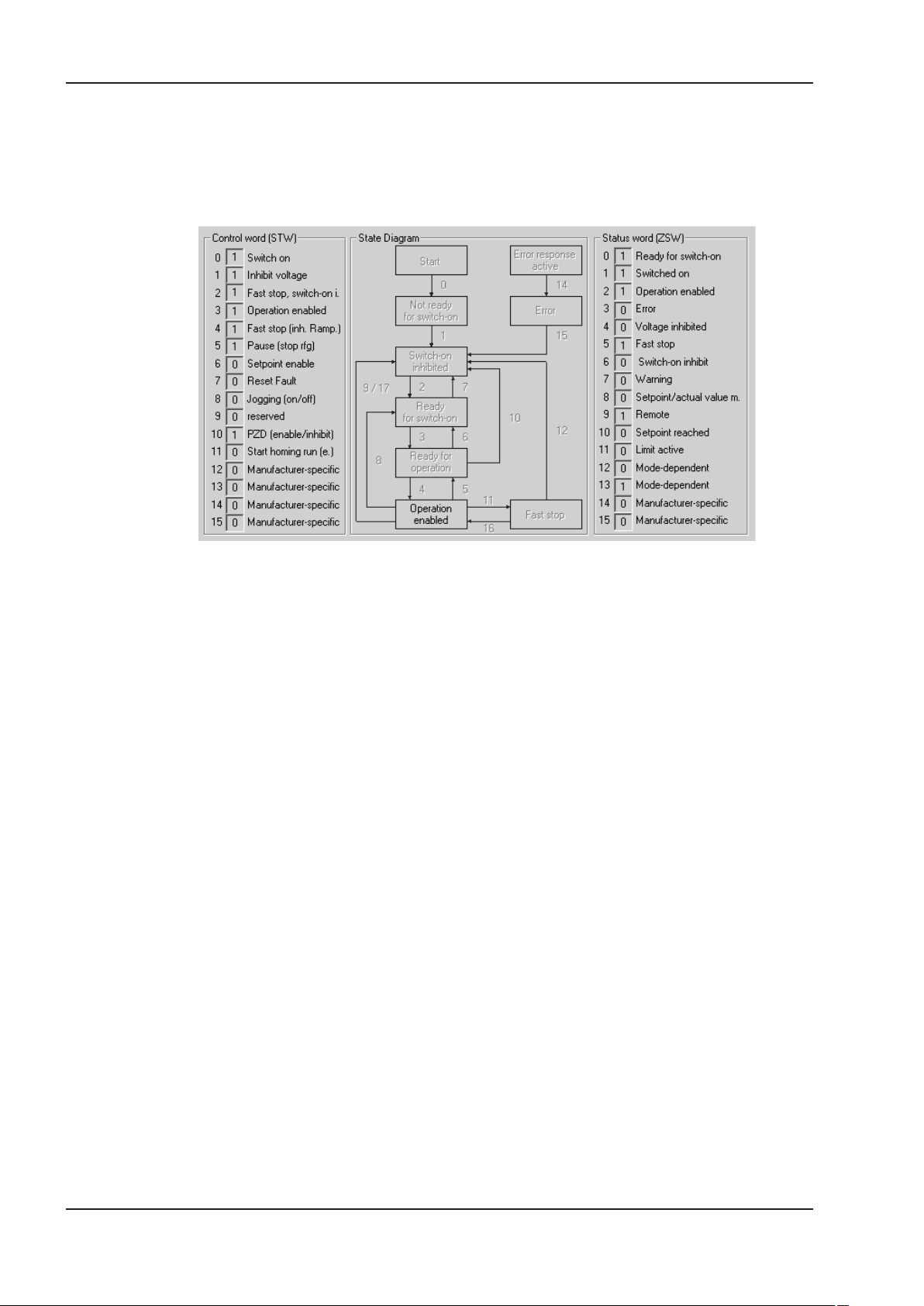

2.2.3.2 Screen page PROFIBUS instrument control

On this screen page the individual bits of the control word (STW) and the status word (ZSW) are

shown. The device status resulting from the status word is visualized in the status machine. The

current status is shown as black, all others are grey. Additionally the previous status is shown by

emphasizing the number of the appropriate arrow. The picture below shows the S300/S700 screen.

16 PROFIBUS for S300/S400/S600/S700

Page 17

Kollmorgen 04/2017 Device Profile

PKW

PKE IND PWE

PZD

STW

ZSW

HSW

HIW

PZD1 PZD2 PZD3 PZD4

Typ 1 : Octet-String 12

Typ 2 : Octet-String 20

Typ 3 : Octet-String 4

Typ 4 : Octet-String 12

PKW:

PKE:

IND:

PWE:

PZD:

STW:

ZSW:

HSW:

HIW:

12 345 678910

12 13 14 15 16 17 18 19 20

BYTE

Typ 5 : Octet-String 28

PZD6 PZD7PZD5 PZD8

21 2322 24 272625 28

PZD9 PZD10

4th octet reserved

Abbreviations

Parameter ID value

Parameter ID (1st and 2nd octet)

Index with PPO (3rd octet)

Parameter value (5th to 8th octet)

Control word

Status word

Main setpoint

Main actaul value

Process data

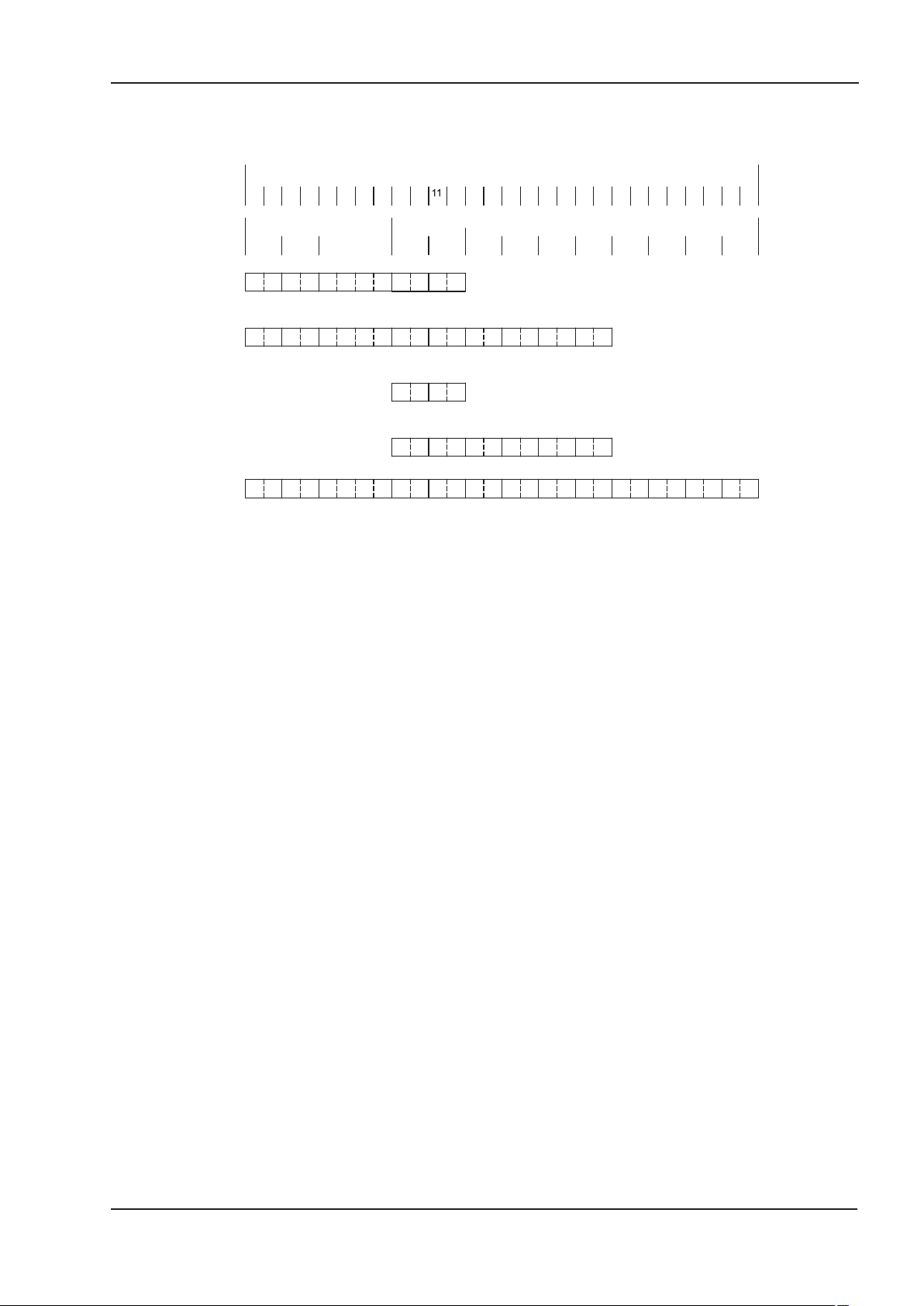

3 Device Profile

The PROFIBUS profile PROFIDRIVE includes the following parameter process-data objects (PPO):

The servo amplifier only uses the PPO-type 2 (with 4 words PKW-section and 6 words PZD-section). The PKW-section is used mainly for the transmission of parameters for the servo amplifier,

the PZD-section is used principally for handling motion functions.

The telegram can be divided into two sections or data channels:

1. PKW-section (4 words, Bytes 1 to 8)

2. PZD-section (6 words, Bytes 8 to 20)

The PKW data channel can also be termed the service or parameter channel. The service channel

only uses confirmed communication services, and is used by the servo amplifier as a parameter

channel.

The PKW channel has no real-time capability.

The PZD data channel can also be termed the process data channel. The process data channel

uses unconfirmed communication services. The response of the servo amplifier to an unconfirmed

service can only be seen in the reaction of the amplifier (status word, actual values).

The PZD channel has real-time capability.

PROFIBUS for S300/S400/S600/S700 17

Page 18

Device Profile 04/2017 Kollmorgen

12345

BIT

867910121315 14

BYTE 1 BYTE 2

AK

SPM

PNU

SPM

PNU

AK

0

Abbreviations

(not implemented at present)

task / response ID

Parameter number

3.1 Parameter channel

3.1.1 Parameter ID (PKE)

Marked lines in the table are valid for the servo amplifier

Master —> Slave Slave —> Master

Task ID

0 no task 0 0

1 request parameter value 1,2 7

2 alter parameter value [W] 1 7/8

3 alter parameter value [DW] 2 7/8

4 request description element 3 7

5 alter description element 3 7/8

6 request parameter value [A] 4,5 7

7 alter parameter value [A/W] 4 7/8

8 alter parameter value 5 7/8

9 request number of array elements 6 7

10 - 15 reserved

Function

Response ID positive Response ID negative

3.1.1.1 Interpretation of the response IDs

Marked lines in the table are valid for the servo amplifier

Response ID Interpretation

0 no task

1 transmit parameter value

2 transmit parameter value

3 transmit description element

4 transmit parameter value

5 transmit parameter value

6 transmit number of array elements

7 task not possible (with error no.)

8 no operating authority for PKW interface

9 spontaneous message [W]

10 spontaneous message [DW]

11 spontaneous message [A/W]

12 spontaneous message [A/DW]

Abbreviatoins in the tables:

A: Array

W: Word

DW: Double-word

18 PROFIBUS for S300/S400/S600/S700

Page 19

Kollmorgen 04/2017 Device Profile

15 14 1213

BYTE 3

5810 9 7 6BIT 4 3

BYTE 4

210

0

IND reserved

3.1.1.2 Response ID 7: Profile specific error numbers

Error no. Description

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19-100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

>115

illegal PNU

parameter value cannot be changed

Lower or upper limit violated

Erroneous sub-index

no array

Incorrect data type

setting not allowed (can only be reset)

Descriptive element cannot be changed

PPO-write, requested in IR, not available

descriptive data not available

access group incorrect

No parameter change rights

Password incorrect

Text cannot be read in cyclic data transmission

Name cannot be read in cyclic data transmission

text array not available

PPO-write missing

opmode switch over not possible at STW Bit 10=1(PZDenable)

other error

reserved

faulty task ID

software error (command table)

only possible in disabled state

only possible in enabled state

BCC-error in the EEPROM data

only possible after task is stopped

wrong value [16,20]

wrong parameter (OCOPY x [- y] z)

wrong motion block no. (0,1..180,192..255)

wrong parameter (PTEACH x [y])

EEPROM write error

wrong value

BCC-error in motion block

Object is read only or write only

not possible due to operation status (e.g. output stage enabled)

reserve

3.1.2 Index IND

An Index (IND) unequal to 0 is used for reading and writing amplifier parameters with

PNUs > 1600. See page 33 for further description.

PROFIBUS for S300/S400/S600/S700 19

Page 20

Device Profile 04/2017 Kollmorgen

15 14 1213

BYTE 7

5810 9 7 6 4 3

BYTE 8

21081415

BYTE 5

13 12 10 9

BYTE 6

57

BIT

643210

LSBMSB

LSWMSW

3.1.3 Parameter value PWE

The data for the PNU-variable is contained in the PWE, and is placed flush right (PKE):

4-byte data (double-word) PWE 5-8 (PWE 8 LSB)

Commands are transferred right justified with task ID 3. If a command cannot be executed, the

response identification AK = 7 signals the error, and an error number is given out. The error num

bers are described on page 19.

-

3.2 The process data channel (PZD)

Cyclical data are exchanged across the PROFIBUS through the process data section of the 20-byte

telegram. Each PROFIBUS cycle triggers an interrupt in the servo amplifier and new process data is

exchanged and processed. The interpretation of the PZD by the amplifier depends on the operating

mode that is set. The operating mode is set through a PROFIBUS parameter (PNU 930,

ð p. 25).

In all operating modes, data word 1 of the process data (PZD1) in the direction from control system

to servo amplifier is used for instrument control, and in the direction from servo amplifier to control

system it has the function of a status indicator for the amplifier.

The interpretation of the process data PZD2 – PZD6 changes depending on the operating mode, as

can be seen in Chapter 5.2.

When the servo amplifier is switched on, the PROFIDRIVE operating mode that is always set to

–126 (safe state). Before changing the operating mode, bit 10 of the control word STW must

always be set to 0. The new operating mode only becomes active when bit 10 of the control word is

set to 1 (see p. 25).

20 PROFIBUS for S300/S400/S600/S700

Page 21

Kollmorgen 04/2017 Parameter channel (PKW)

4 Parameter channel (PKW)

The digital servo amplifiers of the servo amplifier series have to be adapted to the circumstances of

your machine. The parameters for the controllers are set using either the setup software or via the

PROFIBUS.

4.1 Read/write an amplifier parameter

Read (AK = 1) or write (AK = 3) amplifier parameters

To read or write an amplifier parameter through PROFIBUS, the corresponding PNU must be used.

The parameters that are written to the servo amplifier can be transferred to the non-volatile memory

by using the command “non-volatile parameter save” (PNU 971).

Telegram layout:

Request Response

PKE/AK 1 (read) / 3 (write) 2 (OK) / 7 (error)

PKE/PNU see 4.2.1 as transmitted

PWE

for AK = 3 see p.22ff for data type

for AK = 1 data type irrelevant

4.2 Summary of the parameter numbers

for AK = 3 returns the PWE of the request

for AK = 1 see p.22f for data type

All the parameter numbers (PNUs) for the servo amplifier are listed in numerical order in the table

on page 22ff, with a short description. The parameter numbers in the range 900 – 999 are profile-specific for the PROFIBUS drive profile PROFIDRIVE. Parameter numbers > 999 are manufacturer- specific.

For better understanding, you can look up the ASCII commands which are in the column “ASCII

command” in the online help the setup software. A description of all ASCII commands can be found

in the ASCII reference lists (referring to the servo amplifier type) located on the product CDROM

and on our website.

Parameter numbers >1600 use the object channel (see p.33ff).

In the S400/S600 some amplifier parameters (e.g. GV) have 2 PNU numbers. Both of them can be

used to read and write the parameter (e.g. PNU 1200 and PNU 1672).

PROFIBUS for S300/S400/S600/S700 21

Page 22

Parameter channel (PKW) 04/2017 Kollmorgen

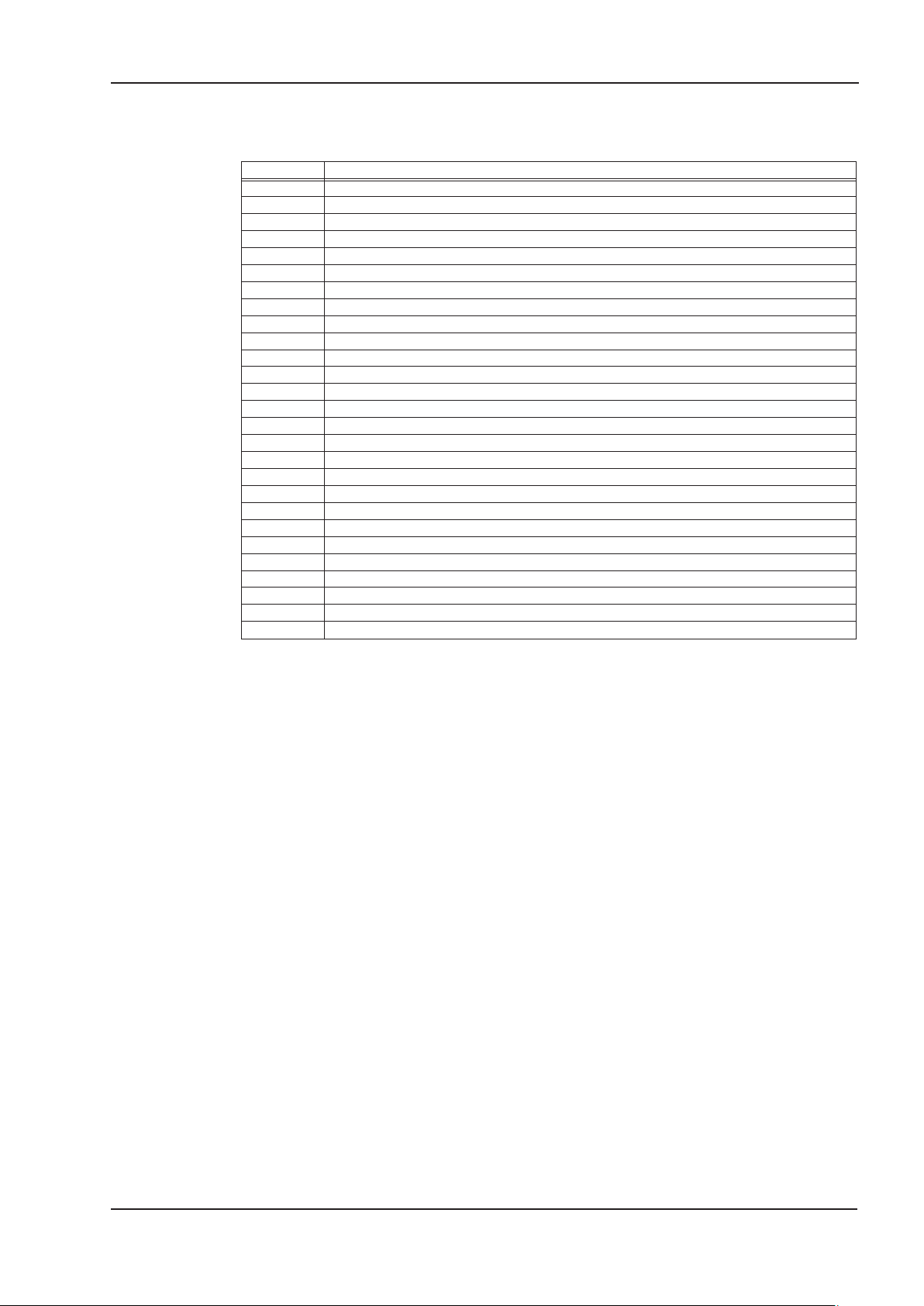

4.2.1 List of the parameters

PNU ASCII command

S400/S600 S300/S700 Data type Acc Description S400/S600 S300/S700

Profile parameter

904 904 UINT32 ro Number of the supported PPO-write, always 2 - - 904

911 911 UINT32 ro Number of the supported PPO-read, always 2 - - 911

918 918 UINT32 ro Participant address on PROFIBUS ADDR ADDR 918

930 930 UINT32 r/w Selector for operating mode - - 930

963 963 UINT32 ro PROFIBUS baud rate - - 963

965 965 Octet-String2 ro Number of the PROFIDRIVE profile (0302H) - - 965

970 970 UINT32 wo Load default parameter set RSTVAR RSTVAR 970

971 971 UINT32 wo non-volatile parameter save SAVE SAVE 971

Manufacturer-specific parameters

General parameters

1000 1000

1001 1001 UINT32 ro Manufacturer-specific error register ERRCODE ERRCODE 1001

1002 1002 UINT32 ro Manufacturer-specific status register - - 1002

Speed controller parameters

1672 1672 UINT32 r/w Kp – gain factor for speed controller GV GV 1200

1677 1677 UINT32 r/w Tn – integral-action time for speed controller GVTN GVTN 1201

1676 UINT32 r/w PID – T2 – time constant for speed controller GVT2 ARxPx - Filter 1202

1601 1601 UINT32 r/w Setpoint ramp+, speed controller ACC ACC 1203

1634 1634 UINT32 r/w Setpoint ramp-, speed controller DEC DEC 1204

1637 1637 UINT32 r/w Emergency stop ramp, speed controller DECSTOP DECSTOP 1205

1890 1890 / 1891 UINT32 r/w Maximum speed VLIM VLIM / VLIMN 1206

1895 1895 UINT32 r/w Overspeed VOSPD VOSPD 1207

1642 1642 UINT32 r/w Count direction DIR DIR 1208

Position controller parameters

1894 1894 UINT32 r/w Velocity multiplier for jogging/homing VMUL VMUL 1250

1807 1807 UINT32 r/w Axis type POSCNFG POSCNFG 1251

1798 1798 INTEGER32 r/w InPosition window PEINPOS PEINPOS 1252

1799 1799 INTEGER32 r/w Following error window PEMAX PEMAX 1253

1860 1860 INTEGER32 r/w Position register 1 SWE1 SWE1 1254

1862 1862 INTEGER32 r/w Position register 2 SWE2 SWE2 1255

1864 INTEGER32 r/w Position register 3 SWE3 1256

1866 INTEGER32 r/w Position register 4 SWE4 1257

1803 1803 UINT32 r/w Denominator resolution PGEARO PGEARO 1258

1802 1802 UINT32 r/w Numerator resolution PGEARI PGEARI 1259

1814 1814 UINT32 r/w Minimum acceleration/braking time PTMIN PTMIN 1260

1669 1669 UINT32 r/w Feed-forward factor for position controller GPFFV GPFFV 1261

1666 1666 UINT32 r/w KV - factor for position controller GP GP 1262

1671 UINT32 r/w KP - factor for position controller GPV 1263

1670 UINT32 r/w Tn - integral-action time for position controller GPTN 1264

1816 1816 UINT32 r/w Maximum velocity for positioning mode PVMAX PVMAX 1265

1856 1856 UINT32 r/w Configuration variable for software switch SWCNFG SWCNFG 1266

Position data for the position control mode

1790 1790 INTEGER32 r/w Position O_P O_P 1300

1791 1791 INTEGER16 r/w Velocity O_V O_V 1301

1785 1785 UINT32 r/w Motion task type O_C O_C 1302

1783 1783 INTEGER16 r/w Starting time (acceleration) O_ACC1 O_ACC 1304

1786 1786 INTEGER16 r/w Braking time (deceleration) O_DEC1 O_DEC 1305

1784 INTEGER16 r/w Jolt limiting (acceleration) O_ACC2 1306

1787 INTEGER16 r/w Jolt limiting (deceleration) O_DEC2 1307

1788 1788 UINT32 r/w Number of next motion task O_FN O_FN 1308

1789 1789 UINT32 r/w Start delay for next motion task O_FT O_FT 1309

1310 1310 2 * UINT16 wo Copy a motion task OCOPY OCOPY 1310

1311 special r/w Position, 32 bit floating decimal point format 1311

1312 special r/w Velocity, 32 bit floating decimal point format 1312

1857 UINT32 r/w Configuration variable 2 for software switch SWCNFG2 1267

Visible

String4

ro Instrument ID - - 1000

PNU (old)

S400/S600

22 PROFIBUS for S300/S400/S600/S700

Page 23

Kollmorgen 04/2017 Parameter channel (PKW)

PNU ASCII command

S400/S600 S300/S700 Data type Acc Description S400/S600 S300/S700

Position set-up mode

1773 1773 UINT32 r/w Homing type NREF NREF 1350

1644 1644 UINT32 r/w Homing direction DREF DREF 1351

1602 1602 UINT32 r/w Acceleration ramp (jogging/homing) ACCR ACCR 1352

1636 1636 UINT32 r/w Braking ramp DECR DECR 1353

1831 1831 UINT32 r/w Reference offset ROFFS ROFFS 1354

1896 1896 UINT32 ro Homing run velocity VREF VREF 1355

1889 1889 UINT32 ro Jogging velocity VJOG VJOG 1356

Actual values

1400 1810 INTEGER32 ro Actual position 20 bits/turn PRD PRD 1400

1401 INTEGER32 ro Speed 1401

1402 INTEGER32 ro Incremental position, actual value 1402

1800 1800 INTEGER32 ro SI-position, actual value PFB PFB 1403

1815 1815 INTEGER32 ro SI-velocity, actual value PV PV 1404

1797 1797 INTEGER32 ro SI following error PE PE 1405

1688 1688 INTEGER32 ro RMS current I I 1406

1880 1880 INTEGER32 ro SI-speed, actual value V V 1407

1873 1873 INTEGER32 ro Heatsink temperature TEMPH TEMPH 1408

1872 1872 INTEGER32 ro Internal temperature TEMPE TEMPE 1409

1882 1882 INTEGER32 ro DC-bus (DC-link) voltage VBUS VBUS 1410

1792 1792 INTEGER32 ro Regen power PBAL PBAL 1411

1689 1764 INTEGER32 ro I2t - loading I2T MI2T 1412

1876 1876 INTEGER32 ro Running time TRUN TRUN 1413

1414 special ro Position, 32 bit floating decimal point format 1414

1415 special ro Velocity, 32 bit floating decimal point format 1415

Digital I/O configuration

1698 1698 UINT32 r/w Function of digital input 1 IN1MODE IN1MODE 1450

1701 1701 UINT32 r/w Function of digital input 2 IN2MODE IN2MODE 1451

1704 1704 UINT32 r/w Function of digital input 3 IN3MODE IN3MODE 1452

1707 1707 UINT32 r/w Function of digital input 4 IN4MODE IN4MODE 1453

1699 1699 INTEGER32 r/w Auxiliary variable for digital input 1 IN1TRIG IN1TRIG 1454

1702 1702 INTEGER32 r/w Auxiliary variable for digital input 2 IN2TRIG IN2TRIG 1455

1705 1705 INTEGER32 r/w Auxiliary variable for digital input 3 IN3TRIG IN3TRIG 1456

1708 1708 INTEGER32 r/w Auxiliary variable for digital input 4 IN4TRIG IN4TRIG 1457

1775 1775 INTEGER32 r/w Function of digital input 1 O1MODE O1MODE 1458

1778 1778 INTEGER32 r/w Function of digital input 2 O2MODE O2MODE 1459

1776 1776 UINT32 r/w Auxiliary variable for digital output 1 O1TRIG O1TRIG 1460

1779 1779 UINT32 r/w Auxiliary variable for digital output 2 O2TRIG O2TRIG 1461

1852 1852 UINT32 r/w

Analog configuration

1607 1607 UINT32 r/w Configuration of the analog input functions ANCNFG ANCNFG 1500

1613 UINT32 r/w Configuration monitor function analog output 1 ANOUT1 1501

1611 1611 UINT32 r/w Offset voltage for analog input 1 ANOFF1 ANOFF1 1502

1617 1617 UINT32 r/w Filter time constant for analog input 1 AVZ1 AVZ1 1503

1897 1897 UINT32 r/w Scaling factor for velocity, analog input 1 VSCALE1 VSCALE1 1504

1713 1713 UINT32 r/w Scaling factor for current, analog input 1 ISCALE1 ISCALE1 1505

1614 UINT32 r/w Configuration monitor function analog output 2 ANOUT2 1506

1612 1612 UINT32 r/w Offset voltage for analog input 2 ANOFF2 ANOFF2 1507

1898 1898 UINT32 r/w Scaling factor for velocity, analog input 2 VSCALE2 VSCALE2 1508

1714 1714 UINT32 r/w Scaling factor for current, analog input 2 ISCALE2 ISCALE2 1509

Motor parameters

1735 1735 UINT32 r/w Brake configuration MBRAKE MBRAKE 1550

1753 1753 UINT32 r/w Motor number from motor database MNUMBER MNUMBER 1551

Manufacturer specific object channel

³1600 Þ p. 33 and description of the ASCII-commands in the online help. ³1600

State of 4 digital inputs, Enable,

2 digital outputs

STATIO STATIO 1462

S400/S600

Abbreviations in the “Access” column

PNU (old)

Abbrev. Description

wo “write only” access

ro “read only” access

r/w read and write access

PROFIBUS for S300/S400/S600/S700 23

Page 24

Parameter channel (PKW) 04/2017 Kollmorgen

4.2.2 Standard PROFIDRIVE parameters

4.2.2.1 PNU 940/911: PPO type write/read

These parameters describe the numbers of the supported PPO-types write und read.

Since only PPO-type 2 is supported (see Chapter 3), this parameter is always set to 2.

4.2.2.2 PNU 918: PROFIBUS node address

With this parameter the PROFIBUS - node address of the amplifier can be read.

S400/S600

The range of addresses can be extended from 1..63 to 1..127 with the ASCII-command MDRV.

Setting up the station address, see page 10.

4.2.2.3 PNU 963: baud rate

This parameter defines the index of the baud rate that is used for PROFIBUS communication, and

can only be read. The baud rate is given out by the PROFIBUS-master.

The table below shows the indices with the according baud rates (in kBaud):

Index 0 123456789

Baud rate

12000 6000 3000 1500 500 187.5 93.75 45.45 19.2 9.6

4.2.2.4 PNU 965: PROFIDRIVE profile number

This parameter can be used to read out the number of the PROFIDRIVE profile. Profile Number 3,

Version 2 is used.

4.2.2.5 PNU 970: default parameters

With this parameter you can reject all the parameters that are set and load the manufacturer’s

default values.

4.2.2.6 PNU 971: non volatile saving of parameters

With this parameter you can save all the parameter settings to the EEPROM. To do this, the param

eter must have the value PWE = 1 when the transfer takes place.

-

24 PROFIBUS for S300/S400/S600/S700

Page 25

Kollmorgen 04/2017 Parameter channel (PKW)

4.2.2.7 PNU 930: Selection Switch for Operating Mode

The “Selector for operating modes” is defined by the drive profile, and mirrors the operating modes

of the drive profile to the operating modes of the servo amplifier. The following table shows a sum

mary of the operating modes:

If process data are exchanged across the PROFIBUS, then the operating modes of the drive profile

must only be selected with PNU 930.

-

Operating

mode of

drive profile

2 8 Positioning mode according to PROFIDRIVE profile

1 0 Digital speed control according to PROFIDRIVE profile

0 - reserved

-1 1 Speed control, analog setpoint

-2 2 Torque control, digital setpoint

-3 3 Torque control, analog setpoint

-4 4 Position control, electronic gearing

-5 5 Position control, external trajectory

-6 - reserved

-7 - Speed control, digital setpoint & Servo Pump

-8 to -15 - reserved

-16 - ASCII channel for expanded parameterization

-17 to -125 - reserved

-126 - Initial settings when amplifier is switched on

Operating mode servo amplifier

(ASCII command “OPMODE”)

Description

The individual operating modes are described in chapter 5.2. A change of operating mode can only

be undertaken in connection with the control word.

The operating mode must be changed according to the following sequence:

1. Inhibit setpoints and process data

Bit 10 in the control word is set to 0, so that no new setpoints will be accepted by the

servo amplifier and no new control functions can be initiated. A new operating mode

can, however, be selected while a motion function is being performed.

The control word is only inhibited to the extent that the servo amplifier can always be

switched into a safe state.

2. Select the new operating mode with PNU 930

The new operating mode is selected with parameter 930 through the parameter channel,

but not yet accepted.

3. Set/receive the setpoints and actual values

Enter the corresponding setpoints in the setpoint area of the process data.

Here you must take note that the normalization and data formats depend on the operating

mode that is selected. The interpretation of the actual values is also altered

(see Þ p. 17 and p. 39ff). The user program must respond accordingly.

4. Enable the setpoints

Bit 10 of STW is set to 1. The setpoints are immediately accepted and processed.

The new actual values are output with the appropriate normalization and data format.

After switch-on or after a coldstart the servo amplifier is always in the safe operating mode.

In the safe operating mode (-126), no motion functions can be initiated via the PROFIBUS.

However, it is possible to perform motion functions with the the setup Software.

If the operating mode is changed, then motion functions can only be operated via the PROFIBUS. If

the operating mode is changed via another communication channel, then the amplifier is emergency

braked and the error F21 (Handling error, expansion card) is signaled.

PROFIBUS for S300/S400/S600/S700 25

Page 26

Parameter channel (PKW) 04/2017 Kollmorgen

4.2.3 Manufacturer specific parameters

4.2.3.1 PNU 1000: instrument ID

The instrument ID consists of four ASCII characters, with the contents “Sxyz”.

- x stands for the servoamplifier family

- yz stands for the current level of the output stage

4.2.3.2 PNU 1001: manufacturer specific error register

The assignment of the error register can be seen in the following table. The explanation of the indi

vidual errors can be found in the assembly & installation instructions for the servo amplifier.

Bit Description

0 Error F01: Heatsink temperature

1 Error F02: Overvoltage

2 Error F03: Following error

3 Error F04*: Feedback

4 Error F05: Undervoltage

5 Error F06*: Motor temperature

6 Error F07*: Auxiliary voltage

7 Error F08: Overspeed

8 Error F09*: EEPROM

9 Error F10*: Flash-EEPROM

10 Error F11*: Mechanical holding brake

11 Error F12*: Motor phase

12 Error F13: Internal temperature

13 Error F14*: Output stage

14 Error F15: I²t max.

15 Error F16: Mains supply-BTB

16 Error F17*: A/D-converter

17 Error F18*: Regen circuit

18 Error F19: Mains supply phase

19 Error F20*: Expansion card error

20 Error F21*: Handling error, plug-in card

21 Error F22: Earth short

22 Error F23: CAN-Bus off

23 Error F24: Warning

24 Error F25: Commuation error

25 Error F26: Limit switch

26 Error F27: AS functionality

27-30 Error F28 - F31*: reserved

31 Error F32*: System error

When the cause of the error has been cleared, the error state can be canceled by setting Bit 7 in

the control word (STW).

The error response of the servo amplifier to the reset will differ, depending on the error that has

occurred:

For errors that are marked by an asterisk (*), setting the reset bit initiates a cold-start of the ampli

fier, whereby the PROFIBUS communication to this amplifier will also be interrupted for several sec

onds. Depending on the circumstances, this break in communication may have to be separately

handled by the PLC.

For the other errors, the reset leads to a warm start, during which the communication will not be

interrupted.

-

-

A description of the individual errors and recommendations for removing them can be found in the

amplifier's installation manual.

26 PROFIBUS for S300/S400/S600/S700

Page 27

Kollmorgen 04/2017 Parameter channel (PKW)

4.2.3.3 PNU 1002: manufacturer specific status register

The bit assignment can be seen in the following table:

Bit Description

0 Warning 1: I²t threshold exceeded (set, as long as I

1 Warning 2: Regen power exceeded (set, as long as the set regen power is exceeded)

2 Warning 3: Following error

3 Warning 4: Threshold monitoring (field bus) active

4 Warning 5: Mains supply phase missing

5 Warning 6: Software limit-switch 1 has been activated

6 Warning 7: Software limit-switch 2 has been activated

7 Warning 8: Faulty motion task has been started

8 Warning 9: No reference point was set at the start of the motion task

9 Warning 10: PSTOP active

10 Warning 11: NSTOP active

11 Warning 12: Motor default values were loaded (HIPERFACE

12 Warning 13: Expansion card is not working properly

13 Warning 14: Sine encoder commutation not carried out

14 Warning 15: Speed - current table error INxMODE 35

15 Warning 16: Reserve

Motion task active (is set as long as a position control task is active - motion task, jogging, homing).

16

Reference point set (is set after a homing run, or when an absolute position (multi-turn) encoder is used.

17

This is canceled when the amplifier is switched on, or when a homing run is started.

Actual position = home position (is set as long as the reference switch is activated).

18

InPosition (is set as long as the difference between the target position for a motion task and the actual

position is smaller than PEINPOS. The InPosition signal is suppressed if a following task is started at

19

the target position.

Position latch set (positive edge) – this is set if a rising edge is detected on the INPUT2 (IN2MODE=26)

20

that is configured as a latch. This is canceled if the latched position is read out (LATCH16/LATCH32)

—

21

Position 1 reached (is set if the configured condition for this signal (SWCNFG, SWE1, SWE1N) is met.

Depending on the configuration, this bit is set on exceeding SWE1, or going below SWE1, on reaching

22

the InPosition window SWE1...SWE1N or on leaving the InPosition window SWE1...SWE1N.

Position 2 reached (see above)

23

Position 3 reached (see above)

24

Position 4 reached (see above)

25

Initialization completed (is set if the internal initialization of the amplifier is completed).

26

—

27

Speed = 0 (is set as long as the motor speed is below the standstill threshold VEL0).

28

Safety relay has been triggered (is set as long as the safety relay is open AS)

29

Output stage enabled (is set when software and hardware enables are set).

30

Error present (is canceled when the amplifier is switched on, or if the function “Cancel error” is called.

31

In the process data, Bits 16 to 31 of the manufacturer-specific status register are given out.

Warnings 3 and 4 can be reset through Bit 13 in the control word.

is above the threshold)

rms

®

or EnDat®feedback)

PROFIBUS for S300/S400/S600/S700 27

Page 28

Parameter channel (PKW) 04/2017 Kollmorgen

4.2.4 Position control parameters

4.2.4.1 PNU 1894: velocity multiplier

This parameter is used to enter a multiplier for the jogging/homing velocity. In Positioning opmode,

the velocity for jogging/homing is set through PZD2 jogging/homing is started using bit 8/ bit 11 in

the control word (STW).

The actual jog velocity is calculated according to the following formula:

V Bit V Bit velocity multipli

() ()32 16

Jog vel Jog PZD,. ,

The default value for PNU 1894 is 1.

4.2.4.2 PNU 1807: axis type

This parameter is used to define the axis type.

4.2.5 Position data for the position control mode

=´er Bit()16

Value S300/S700 S400 S600

0 Linear axis Linear axis Linear axis

1 Modulo axis Rotary axis Rotary axis

2 Modulo axis Modulo axis

2

4.2.5.1 PNU 1790: position

Since the servo amplifier calculates all positioning operations internally only on an incremental

basis, there are limitations on the usable range of values for distances that are given in SI (user)

units.

The range for the incremental position covers the values from -2

The resolution that is determined by the PGEARO (PNU1803 ind1) and PGEARI (PNU1802 ind1)

parameters and the variable PRBASE fix the sensibly usable range for positioning operations.

The variable PRBASE determines, through the equation

motor turn. The value of PRBASE can only be 16 or 20.

PGEARO contains the number of increments that must be traversed when the distance to be

moved is PGEARI. The default values for PGEARO correspond to one turn.

The number of turns that can be covered are given as follows:

-2048..+2047 for PRBASE=16 and -32768..+32767 for PRBASE=20

The sensibly usable position range is derived as follows:

PGEARI

31 31

--221

* ...( ) *

PGEARO

31 31

...( )

--221

4.2.5.2 PNU 1791: velocity

The usable range for the velocity is not limited by the available data area. It is limited by the maxi

mum applicable speed nmax, which is given by the speed parameter VLIM as the final limit speed

for the motor.

The maximum velocity is thus given by:

n

=´ ´2

SI

,max max

n

PGEARI

PGEARO

PGEARI

PGEARO

PRBASE

31

to (231-1).

PRBASE

n

= 2

, the number of increments per

for PGEARI <= PGEARO or

for PGEARI > PGEARO

with n

in turns/second

max

-

or, in incremental units, as:

250

m

incr

. max. max

=´ ´ = ´2

vn

PRBASE PRBASE

sn

max

sec

1 4000

2

with n

in turns/second

max

28 PROFIBUS for S300/S400/S600/S700

Page 29

Kollmorgen 04/2017 Parameter channel (PKW)

4.2.5.3 PNU 1785: motion task type

Bit Value Meaning

The position value that is given is evaluated as an absolute position.

0

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15 -

16

The position value that is given is evaluated as a relative traversing distance.

1

The two following bits then determine the type of relative motion.

If Bit 1and Bit 2 are set to 0 and Bit 0 set to 1, then the relative motion task is performed

0

according to the “InPosition” bit.

The new target position is given by the old target position plus the traversing distance.

1

Bit 1 has priority over Bit 2.

If Bit 1and Bit 2 are set to 0 and Bit 0 set to 1, then the relative motion task is performed

0

according to the “InPosition” bit.

The new target position is given by the actual position plus the traversing distance.

1

no following task available

0

There is a following task, but it must be defined through parameter O_FN, PNU 1788

1

Change over to next motion task, with braking to 0 at the target position.

0

Change over to next motion task, without standstill at the target position.

1

The type of velocity transition is determined by Bit 8.

Change over to next motion task, without evaluating inputs.

0

A following motion task is started by a correspondingly configured input.

1

Start the next motion task by Input State = low or if bit 7 = 1after the delay set in

0

PNU 1789.

Start the next motion task by Input State = high or if bit 7 = 1after the delay set in

1

PNU 1789.

The next motion task is started immediately.

0

The next motion task is started after the delay time set by PNU 1789 or, if Bit6=1,previ

1

ously by a corresponding input signal.

Only for following motion tasks and Bit4=1:from the target position for the previous mo-

0

tion task onwards, the velocity is altered to the value for the following motion task.

The change of velocity is made so that the velocity at the target position of the previous

1

motion task matches the value given for the following motion task.

reserved

-

Accelerations are calculated according to the run-up/acceleration and run-down/braking

0

times for the motion task.

the deceleration/aceleration ramps are interpreted in mm/s²

1

The target position and target velocity of a motion task are interpreted as increments.

0

The target position and target velocity are recalculated as increments before the start of

1

the motion task. The parameters PGEARI and PGEARO are used for this purpose.

The programmed velocity is used as the velocity for the motion task.

0

The velocity for the motion task is determined by the voltage present on analog input 1at

1

the start of the motion task.

reserved

S300/S700 only: a motion task with trapezoid profile is started

0

S300/S700 only: a table motion task (sin

1

2

profile) is started. Bit 9 must be set to 0.

-

Bits 0 to 15 are transmitted as motion task type in PZD 6 (mode "positioning") with direct motion

tasks.

Bit 16 is not affected by the motion task type transmitted with the process data in PZD 6 and there

-

fore must be written with PNU 1785 to the parameter channel.

4.2.5.4 PNU 1783: acceleration time

This parameter defines the total time or rate (depending on the type of units selected for accelera

tion) to reach the target velocity for the motion task.

-

PROFIBUS for S300/S400/S600/S700 29

Page 30

Parameter channel (PKW) 04/2017 Kollmorgen

4.2.5.5 PNU 1784: acceleration jolt limiting

For S400/S600 only. This parameter defines the form of the acceleration ramp.

If a value ¹ 0 is entered here, then a sin²-ramp (S-curve) is used to reach the target velocity.

To employ sine²-ramps, the configuration variable SPSET has to be set to 2 (via the ASCII-channel

or the ASCII-terminal in the setup software) and to be saved.

4.2.5.6 PNU 1786: deceleration time

This parameter defines the total time or rate (depending on the type of units selected for decelera

tion) to reduce the velocity to 0 at the target position.

4.2.5.7 PNU 1787: deceleration jolt limiting

For S400/S600 only. This parameter defines the form of the braking/deceleration ramp.

If a value ¹ 0 is entered here, then a sin²-ramp (S-curve) is used for braking/deceleration.

4.2.5.8 PNU 1788: next motion task

S400/S600:

The motion task number of the motion task to be started can be from 1 to 180 (motion tasks in

EEPROM) or 192 to 255 (motion tasks in RAM).

S300/S700:

The motion task number of the motion task to be started can be from 1 bis 200 (motion tasks in

EEPROM) or 201 .. 300 (motion tasks in RAM).

4.2.5.9 PNU 1789: start delay

This parameter is used to set a delay time before the start of a motion task.

4.2.5.10 PNU 1310: copy motion task

This parameter can be used to copy motion tasks. The source motion task must be entered in the

high-value portion of PWE (PZD5&6)andthetarget motion task must be entered in the low-value

portion of PWE (PZD 7 & 8).

-

4.2.5.11 PNU 1311: position, 32 bit floating decimal point format

For S400/S600 only. With this object the target position for motion task 0 (direct motion task, see

ASCII – command O_P) can be set in 32 Bit Floating decimal point format (IEEE).

Right of decimal point positions will be truncated. This objekt is, aside from the data format, identi

cal PNU 1790. The defaults are indicated in micrometers.

Use:

Controls that support only 16 Bit integer and 32 Bit floating decimal point.

4.2.5.12 PNU 1312: velocity, 32 bit floating decimal point format

For S400/S600 only. With this object the velocity for motion task 0 (direct motion task, see ASCII –

command O_V) can be set in 32 Bit Floating decimal point format (IEEE).

Right of decimal point positions will be truncated. This objekt is, aside from the data format, identi

cal PNU 1791.

Use:

Controls that support only 16 Bit integer and 32 Bit floating decimal point.

-

-

30 PROFIBUS for S300/S400/S600/S700

Page 31

Kollmorgen 04/2017 Parameter channel (PKW)

4.2.6 Setup mode: position

4.2.6.1 PNU 1773: homing type

This parameter can be used to determine which type of homing run should be applied. The assign

ment can be seen in the following table:

PWE Type of homing run

Reference point at the present position

0

Initiator with resolver zero mark

1

Hardware limit-switch resolver zero mark

2

Initiator without resolver zero mark

3

Hardware limit-switch without resolver zero mark

4

Zero mark / feedback unit

5

Reference point at the actual position

6

Hardware limit-switch with resolver zero mark

7

Absolute SSI-position

8

Move to Mechanical Stop

9

4.2.6.2 PNU 1644: homing direction

This parameter can be used to determine the direction of motion for homing runs. If set equal 0,

then the direction of motion is negative; for a value 1 it is positive, and fora2itdepends on the dis

tance to the reference point in the direction in which the homing run started.

4.2.7 Actual values

4.2.7.1 PNU 1401: speed

-

-

For S400/S600 only.

The parameter value is the actual speed of the motor in increments / 250 µsec, which are the amplifier’s internal units.

4.2.7.2 PNU 1402: incremental position, actual value

For S400/S600 only.

The parameter value is the actual position value in increments.

4.2.7.3 PNU 1800: actual position value in SI (User) units

The parameter value is the actual SI (user unit) position value.

4.2.7.4 PNU 1414: actual position, 32 bit floating decimal point format

For S400/S600 only. With this object the actual position (see ASCII-command PFB) can be read in

a 32 Bit Floating decimal point format (IEEE).

Right of decimal point positions will be truncated. This object is, aside from the data format, identi

cal to PNU1800.

Use:

PLC Controls that support only 16 Bit integer and 32 Bit floating decimal point.

-

PROFIBUS for S300/S400/S600/S700 31

Page 32

Parameter channel (PKW) 04/2017 Kollmorgen

4.2.7.5 PNU 1415: actual velocity, 32 bit floating decimal point format

For S400/S600 only. With this object the actual velocity (see ASCII-command PV) can be read in a

32 Bit Floating decimal point format (IEEE).

Right of decimal point positions will be truncated. This object is, aside from the data format, identi

cal to PNU1815.

Use:

PLC Controls that support only 16 Bit integer and 32 Bit floating decimal point.

4.2.8 Digital I/O configuration

All settings for the digital inputs and outputs only become effective after being saved in the

EEPROM and then switching off and on again, or making a cold start of the servo amplifier. Details

on each configuration setting can be seen in the user manual for the setup software.

4.2.8.1 PNUs 1698/1701/1704/1707: digital input configuration

This parameter can be used to configure the digital inputs 1 to 4 individually.

The configurable functions depend on the used amplifier and are described in the ASCII Object Ref

erence.

4.2.8.2 PNUs 1775/1778: digital output configuration

-

-

These parameters can be used to configure the two digital outputs individually. The configurable

functions depend on the used amplifier and are described in the ASCII Object Reference.

4.2.9 Analog configuration

All settings for the analog inputs and outputs only become effective after being saved in the

EEPROM and then switching off and on again, or making a cold start of the servo amplifier. The

significance of the functions can be seen in the user manual for the setup Software.

4.2.9.1 PNU 1607: analog input configuration

This parameter can be used to configure the two analog inputs together. The configurable functions

depend on the used amplifier and are described in the ASCII Object Reference.

4.2.9.2 PNU 1613/1614: analog output configuration

With S400/S600 only. This parameter can be used to configure the two analog outputs individually.

PWE Function

Off

0

n act

1

I act

2

n setp

3

I setp

4

S_fault

5

Slot

6

32 PROFIBUS for S300/S400/S600/S700

Page 33

Kollmorgen 04/2017 Parameter channel (PKW)

4.2.10 Manufacturer specific object channel (from PNU 1600)

With PNUs>1600 you can programm each ASCII-parameter/command of the servo amplifier. The

PNU can be calculated by the object number with a specific offset (ASCII command reference list:

DPR).

All PNUs described in this manual can be reached with index=1. In the ASCII reference list you find

for every parameter the PNU and the referring index. More functions of the object channel can be

used with the indices listed below.

The offset and the indices that must be used depend on the object number:

Objekt number Offset PNUs Index

0 ...447 1600 1600 ...2047 00h ...08h (1 ... 8dez)

448 ...847 1200 1648 ...2047 10h ...18h (16 ... 24dez)

848 ...1047 800 1648 ...2047 20h ...28h (32 ...40dez)

Index 0/10h/ 20h depending on the object no. (see above)

short description Number of entries

Unit —

Access ro

Data type UNSIGNED8

Value range 8

EEPROM —

Index 1/11h/ 21h depending on the object no. (see above)

short description read/write a parameter

Unit see corresponding ASCII-command

Access see corresponding ASCII-command

Data type see corresponding ASCII-command

Value range see corresponding ASCII-command

Default value —

EEPROM see corresponding ASCII-command

Index 2/12h/ 22h depending on the object no. (see above)

short description read lower limit

Unit see corresponding ASCII-command

Access Read only

Data type see corresponding ASCII-command

Value range see corresponding ASCII-command

Default value —

EEPROM —

Index 3/13h/ 23h depending on the object no. (see above)

short description read upper limit

Unit see corresponding ASCII-command

Access Read only

Data type see corresponding ASCII-command

Value range see corresponding ASCII-command

Default value —

EEPROM —

Index 4/14h/ 24h depending on the object no. (see above)

short description read default value

Unit see corresponding ASCII-command

Access Read only

Data type see corresponding ASCII-command

Value range see corresponding ASCII-command

Default value —

EEPROM —

PROFIBUS for S300/S400/S600/S700 33

Page 34

Parameter channel (PKW) 04/2017 Kollmorgen

Index 5/15h/ 25h depending on the object no. (see above)

short description read object format

Unit —

Access Read only

Data type see corresponding ASCII-command

Value range see corresponding ASCII-command

Default value —

EEPROM —

Desription:

The following object formats are possible:

0 Function (no parameters – write only)

1 Function (32-Bit parameter)

2 Function (32-Bit parameter with weighting 3)

3 8-Bit integer

4 8-Bit unsigned integer

5 16-Bit integer

6 16-Bit unsigned integer

7 32-Bit integer

8 32-Bit unsigned integer

9 32-Bit integer (weighting 3)

Index 6/16h/ 26h depending on the object no. (see above)

short description read object control data

Unit —

Access Read only

Data type UNSIGNED32

Value range 0 ... 2

Default value —

EEPROM —

Description:

32

–1

0x00010000 when altered, the variable has to be saved and the amplifier reset

0x00020000 variable will be saved in the serial EEPROM

0x00200000 variable is read-only, must not be written via PROFIBUS

Index 7/17h/ 27h and 8/18h/ 28h