Page 1

S200 Position Node Installation Guide

Hardware Installation Manual

M-SS-S2A-11

Revision A Sept 25, 2007

Revision B Nov 13, 2007

Revision C Apr 30, 2010

Revision D Apr 13, 2012

Keep all product manuals as a product component during the life span of the servo amplifier.

Pass all product manuals to future users/owners of the servo amplifier.

Page 2

Record of Revisions

Date Issue Description

9/14/07 A Separated Installation and Operation into separate manuals

10/13/07 B Reversed Polarity of DINP10 on Schematics

4/30/10 C Corrected J11 Labels section 6.1. Updated Branding, general grammar and

clarity

4/13/12 D Update Branding

©2006 2007 Kollmorgen - All rights reserved. Printed in the USA.

NOTICE:

Kollmorgen® is a registered trademark of the Danaher Corporation. Kollmorgen makes every attempt to ensure

accuracy and reliability of the specifications in this publication. Specifications are subject to change without notice.

Kollmorgen provides this information "AS IS" and disclaims all warranties, express or implied, including, but not

limited to, implied warranties of merchantability and fitness for a particular purpose. It is the responsibility of the

product user to determine the suitability of this product for a specific application.

Safety Symbols

WARNING

warning notices could result in personal injury or death.

Cautions direct attention to general precautions that, if not followed, could

Warnings alert users to potential physical danger or harm. Failure to follow

CAUTION

result in personal injury and/or equipment damage.

Notes highlight information critical to your understanding or use of the

NOTE

Safety

WARNING

Only qualified personnel are permitted to transport, assemble, commission, and maintain this equipment. Properly

qualified personnel are persons who are familiar with the transport, assembly, installation, commissioning and

operation of motors, and who have the appropriate qualifications for their jobs.

Read all available documentation before assembling and using. Incorrect handling of products described in this

manual can result in injury and damage to people and/or machinery. Strictly adhere to the technical information

regarding installation requirements.

Keep all covers and cabinet doors shut during operation.

Be aware that during operation, the product has electrically charged components and hot surfaces. Control

and power cables can carry a high voltage, even when the motor is not rotating.

Never disconnect or connect the product while the power source is energized.

After removing the power source from the equipment, wait at least 5 minutes before touching or

disconnecting sections of the equipment that normally carry electrical charges (e.g., capacitors, contacts,

screw connections). To be safe, measure the electrical contact points to each other and to electrical safety

earth with a meter before touching the equipment.

product.

READ these instructions before connecting power. Damage can result from

MISWIRING at the power terminals.

DANGEROUS voltages are present on power input and motor output terminals.

Page 3

Kollmorgen 4/13/2012 Table of Contents

Table of Contents

1.0 Product Documentation .......................................................................................................3

2.0 Product Overview ......................................................................................................................4

2.1 Model Number Scheme .................................................................................................5

2.2 Valid Drive Model Numbers for the S200 Position Node.............................................6

3.0 Specifications.............................................................................................................................7

3.1 Drive Family Power.......................................................................................................7

3.2 Input Power Specifications............................................................................................9

3.3 DC Input Drives - Control and Power .........................................................................10

3.4 Control Loop Performance ..........................................................................................10

3.5 Mechanical Specifications...........................................................................................12

3.6 I/O Specifications.........................................................................................................12

3.7 Environmental Specifications......................................................................................14

3.8 Smart Feedback Device (SFD) ....................................................................................14

4.0 accessories................................................................................................................................15

4.1 Cables...........................................................................................................................15

4.1.1 Motor and feedback cables.....................................................................................................15

4.1.2 Serial Communications Cable................................................................................................15

4.2 Connector Kits.............................................................................................................16

4.2.1 Base Unit Connector Kits.......................................................................................................16

4.2.2 Position Node Connector Kits................................................................................................19

4.3 Din Rail Terminal Break Outs.....................................................................................20

4.4 Operator Interface Terminals.......................................................................................20

4.5 Systems Capabilities....................................................................................................20

5.0 Installation................................................................................................................................21

5.1 Unpacking and Inspecting............................................................................................21

5.2 Mounting......................................................................................................................21

5.3 Dimensions ..................................................................................................................22

5.4 Mounting Outline.........................................................................................................23

6.0 Wiring Diagrams......................................................................................................................24

6.1 Low Power AC Drive Wiring Diagram.......................................................................24

6.2 High Power AC Wiring Diagram ................................................................................25

6.3 DC Models Drive Wiring Diagram..............................................................................26

7.0 Connector Pinout and Discriptions..........................................................................................27

7.1 PE All Drive Models....................................................................................................27

7.2 J1 – Low Power AC Input Power Models Drive Power..............................................28

7.3 J1 – AC Input Control Power High Power AC Models...............................................30

7.4 TB1: High Power AC Power Connections ..................................................................31

7.5 J1 – DC Input Power Models Drive Power Connector................................................33

7.6 J2 – Motor Power Connector.......................................................................................34

7.7 J3 – SFD Feedback Connector.....................................................................................34

7.8 J4 – Command I/O Connector .....................................................................................35

7.9 J5: Serial Port Connections..........................................................................................36

7.10 J11 CAN bus Connections.........................................................................................36

7.11 J12 Connector ............................................................................................................37

7.12 J13 Encoder Feedback Connector..............................................................................38

8.0 DC Input Power Model Power Supply Requirements.............................................................39

8.1 Control Voltage............................................................................................................40

8.2 Grounding....................................................................................................................40

8.3 Bus Capacitance...........................................................................................................40

8.4 Bus Switching and Fusing ...........................................................................................41

9.0 Detailed Wiring Information....................................................................................................42

S200 Position Node Installation Guide i

Page 4

Product Overview 4/13/2012 Kollmorgen

9.1 Definitions Discussion.................................................................................................42

9.2 PE Earth Ground Connections.....................................................................................42

9.3 Serial port Wiring ........................................................................................................42

9.4 Wiring Discrete Digital Inputs.....................................................................................43

9.4.1 Typical wiring with sinking switches: ...................................................................................43

9.4.2 Typical Wiring with Sourcing Switches ................................................................................44

9.4.3 Wiring DINP5 and DINP10...................................................................................................44

9.5 Wiring Discrete Digital Outputs..................................................................................45

9.6 Using the DAC Monitors.............................................................................................46

9.7 Wiring Encoder Output Signals...................................................................................46

9.8 Motor Wiring...............................................................................................................46

9.9 Regen Resistor Wiring.................................................................................................47

9.10 Step and Direction or Electronic Gearing Wiring......................................................47

9.11 Encoder Motor Feedback...........................................................................................48

10.0 System Startup.......................................................................................................................52

10.1 Wiring Checks ...........................................................................................................52

10.2 Switch Settings ..........................................................................................................52

10.3 Apply control Power..................................................................................................52

10.4 Control Wiring Checks..............................................................................................53

10.5 Additional Safety Checks ..........................................................................................53

10.6 Applying Bus Power..................................................................................................53

10.7 Motor Motion Checks................................................................................................54

10.8 System Tuning...........................................................................................................54

Appendix A - Cables......................................................................................................................55

A.1 Long Cables ................................................................................................................55

A.2 Custom Composite Cables..........................................................................................55

Appendix B - Regulatory Information...........................................................................................57

B.1 Conformance Requirements...................................................................................57

B.2 CE Approval ..........................................................................................................57

B.3 CE EMC Compliance ............................................................................................57

B.3.1. CE Test Setup...................................................................................................................57

B.3.2 CE Test Setup....................................................................................................................58

B.3.3 Declaration of Conformity.................................................................................................58

B.4 Installation and Commissioning ............................................................................60

B.5 Safety requirements ...............................................................................................60

B.6 European Compliance............................................................................................60

B.7 UL and cUL Conformance.....................................................................................62

B.8 Additional Safety Precautions................................................................................62

B.9 EMC Compliance with EN61800-3.......................................................................63

B.10 AC Mains Conducted Emissions...........................................................................64

B.11 Regen Resistor.......................................................................................................66

B.12 Additional EMC Information Sources...................................................................66

Sales and Service......................................................................................................67

ii S200 Position Node Installation Guide

Page 5

Kollmorgen 4/13/2012 Product Documentation

1.0 PRODUCT DOCUMENTATION

The S200 Position node system documentation contains information broken into several manuals and documents.

Not all documents are required but no document stands alone. The documents are:

Hardware Installation Manual

This document includes all aspects of product specifications and installation procedures. Wiring diagrams,

mounting dimensions and recommendations, and physical properties can be found here. It is required to properly

mount and wire the S200 Position Node product.

User’s Operation Manual

This document provides all information required to get an S200 Position Node product set up and configured for

operation in the application. It includes functional descriptions, interface details, and troubleshooting information.

Information regarding serial communications using Modbus is also provided in this document.

S200 Position Node with CANopen Reference Manual

This document provides reference material and examples for communicating to the S200 Position Node over the

CANopen field bus protocol.

S200 Position Node with DeviceNet Reference Manual

This document provides reference material and examples for communicating to the S200 Position Node over the

DeviceNet field bus protocol.

Support materials

There may be a number of supporting documents located at our web site. Please check for the latest information.

Locating Support Materials

All support materials are posted on the Kollmorgen website at www.Kollmorgen.com

under Drives \ AC Servo Drives \ S200.

Firmware and Software Updates

A good general practice remains: If it’s not broken, don’t fix it. There are times when firmware and software

upgrade is required. These files can also be found at www.Kollmorgen.com

companion S200 Position Node User’s Guide.

Abbreviations and Definitions

Some common abbreviations used in this document are defined at the first use but the reader may note the

following:

S200 PN

‘x

’ : A lower case x may be used to signify a ‘don’t care’ character in a string, number, or model number.

GUI

Home

PE

REGEN

REGEN Resistor

excessive REGEN energy.

Hall Channel

information. Three channels provide 1-part-in-6 resolution per motor electrical cycle.

Bus

OIT

HMI: Human Interface Terminal; Same as OIT

: Short hand notation for the S200 Position Node product.

: Graphical User Interface also called S200 OC Tools.

: A reference position to which other positioning motion is referenced.

: Protective Earth Ground

: Regenerated energy from a back-driven motor pumping energy back into the drive.

: An external power resistor attached to the drive that allows the drive to burn off

: A term used for a motor feedback signal that provides coarse absolute positioning

: Short for Main Internal DC Bus Power Supply that is the DC voltage source for motor power.

: Operator Interface Terminal; Same as HMI

. Procedures can be found in the

. These files can be found

S200 Position Node Installation Guide 3

Page 6

Kollmorgen 4/13/2012 Product Overview

2.0 PRODUCT OVERVIEW

The S200 Position Node with CANopen/DeviceNetTM brings greater flexibility to the S200 drive platform

by adding profile generation and field bus capabilities. It also brings added I/O, Digital Oscilloscope

emulation, and the ability to use incremental encoder with commutation tracks (ComCoder) for motor

feedback.

The S200 Position Node brushless position node servo drives with CANopen push high performance

servo technology into lower power applications than was previously possible without having to

compromise on reliability or package size. Couple a S200 position node drive with an AKM servo motor

for a complete servo control solution designed to excel in applications such as semiconductor fabrication,

electronic assembly, packaging, medical, and woodworking equipment.

The S200 position node servo drives with CANopen communication are the first all digital industrial drives

with a velocity loop bandwidth up to 400 Hz offering unmatched system throughput and simplified tuning.

High resolution (24 bit) feedback and high performance 3-5 kHz current loop bandwidth provide smooth

motion and rapid start and stop action to optimize machine performance. Smart feedback and industry

leading high bandwidth deliver fast and accurate commissioning by eliminating the need for servo loop

tuning in most applications.

A separate "keep alive" power input allows rapid recovery from emergency stop conditions. Optically

isolated inputs/outputs, positive locking connectors and full fault protection promise long machine life and

immunity to accidental damage. A single motor power/feedback cable simplifies connectivity. All

connectors and LED status indicators are easily accessible from the front of the drive.

HIGHLIGHTS

DC or AC input voltage:

DC type: 20 V ... 90 V

AC type: 110 V ... 240 V, 1Ø or 3Ø, 50/60 Hz

Highest performance all digital servo in the industry

Operation and Setup via a PC using the S200 OC Tools setup software

Easy set up and tuning with Smart Feedback Device

Optimized performance with Kollmorgen AKM motors

Rugged optically isolated I/O

UL508C recognition, CE (EN50178, EN61800-3)

Very compact footprint

Full fault protection

Velocity, Position, and Electronic Gearing, Step and Direction control

Indexing - 180 unique motion tasks can be defined and initiated via the serial port, Can

Port, or discrete inputs

Jogs, Relative, Absolute, Simple Registration, and Home motion tasks can be easily

setup and executed

Individual motion tasks can be linked or blended with each other

Digital Oscilloscope Functions

Built-in CANopen / DeviceNet Communication bus

Incremental Encoder Input port allows ComCoder motor feedback for position loop

control.

S200 Position Node Installation Guide 4

Page 7

Product Overview 4/13/2012 Kollmorgen

INCREASED MACHINE THROUGHPUT & LONGER LIFE

Servo system performance is synonymous with machine throughput. The S200 POSITION NODE

family takes servo performance to new heights.

Industry-leading current loop bandwidth up to 5 kHz and velocity loop bandwidth up to

400 Hz means machine throughput can be increased by as much as 2 to 3 times.

Robust design including full fault protection, locking connectors and optical isolation

promise greater machine “up-time”.

Smooth motion, a benefit of sinusoidal current control and high resolution (24 bit)

feedback minimizes harsh torque disturbances that can cut short the life of mechanical

components.

Both the AC and the DC input drives are equipped with separate control power input to

speed recovery from “E-Stop” conditions.

CANopen Field Bus or DeviceNet communications

REDUCED ENGINEERING & SUPPORT TIME

Simplified tuning, friendly Graphical User Interface and shared components with Stepper

products.

Windows-based Graphical User Interface models the tree format found in Explorer so

learning is quick and easy.

Digital Oscilloscope emulator for easier setup.

Easy to debug with full fault diagnostics reduce engineering support time.

Field bus connectivity.

CE- / UL- CONFORMITY

The S200 position node with CANopen meets all relevant standards:

EMC Directive 89/336/EWG, standard used ENG61800-3

Low Voltage Directive 73/23/EWG, standard used 50178

UL / cUL 508C recognized

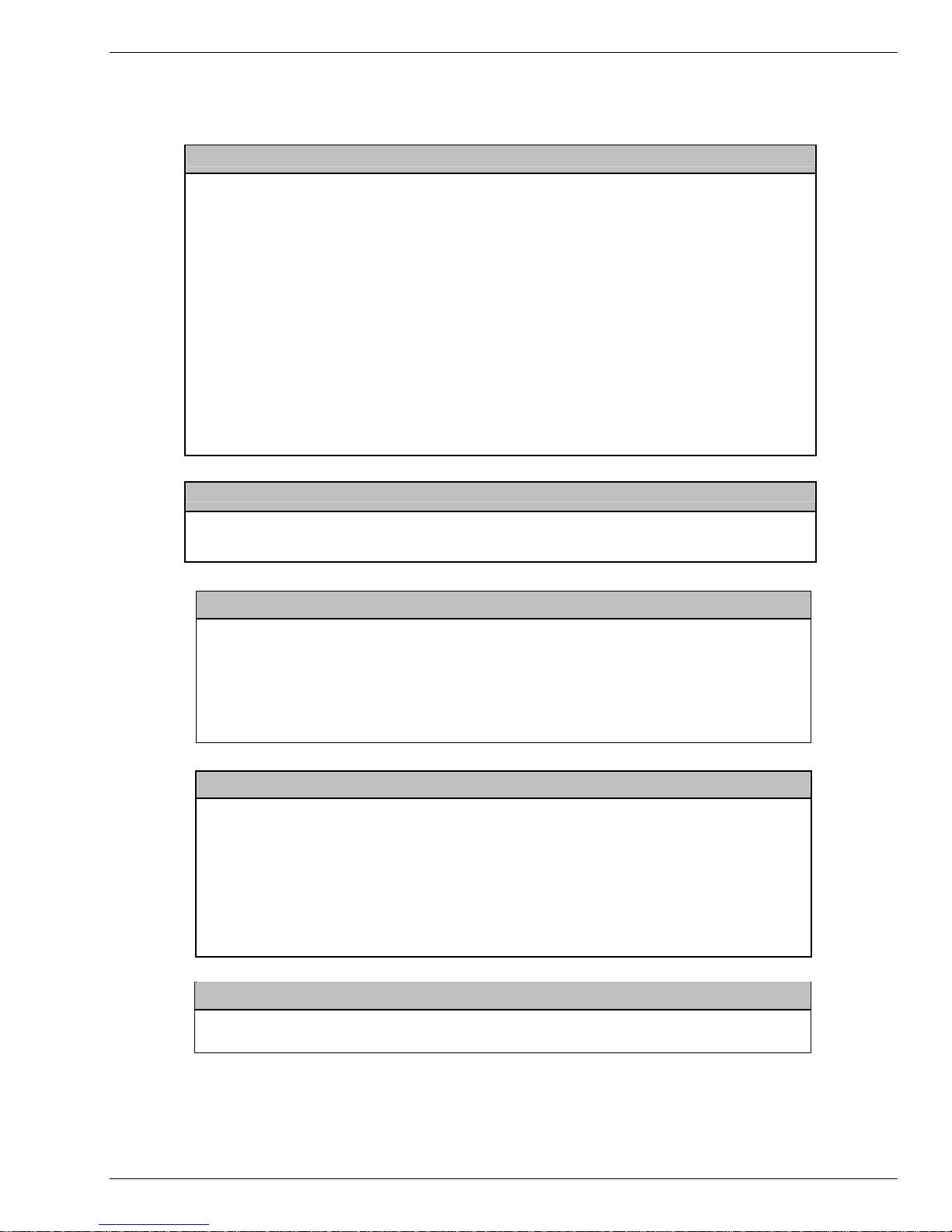

2.1 MODEL NUMBER SCHEME

S2 03 3 0 CN S - 002

Family

S2 - S200 Servo Family

Current Rating

- 1.5 A

02

4.5 A

03 - 3 A

9 A

06

- 6 A

18 A

Voltage

- 20-90 VDC

3

- 120 VAC doubler/240 VAC 1-phase

5

- 120/240 VAC

6

RMS

RMS

continuous,

RMS

peak

RMS

continuous,

RMS

RMS

continuous,

peak

peak

Electrical Option

- No Electrical Option

0

Customization - omit for standard drives

000 - 019 Reserved for factory use only

020 - 999

Feedback Support

S - SFD/Halls - Base Unit

SFD/Comcoder - CAN option card

Smart Feedback Device (SFD) - SynqNet Option Card

Sine encoder - SynqNet Option Card

EnDat 2.1 - SynqNet Option Card

Functionality

VT - Velocity/Torque modes

DN - Position Node w/DeviceNet Interface

CN SD - SynqNet option card w/ micro-D connectors

SR - SynqNet option card w/ standard RJ connectors

Reserved for customers only

Position Node w/CANOpen Interface

5 S200 Position Node Installation Guide

Page 8

Product Overview 4/13/2012 Kollmorgen

2.2 VALID DRIVE MODEL NUMBERS FOR THE S200 POSITION

NODE

DC Input Power Drive Models

S20330-CNS: 90 VDC, 3/9 A

S20330-DNS: 90 V

S20630-CNS: 90 V

S20630-DNS: 90 VDC, 6/18 A

, 3/9 A

DC

, 6/18 A

DC

AC Input Power Drive Models

S20250-CNS: 120VAC doubler/240VAC, 1 phase, 1.5/4.5 ARMS Base Unit, Profile Node with CanOpen

S20250-DNS: 120VAC doubler/240VAC, 1 phase, 1.5/4.5 ARMS Base Unit, Profile Node with DeviceNet

S20260-CNS: 120/240 VAC, 1/3-phase, 1.5/4.5 ARMS Base Unit, Profile Node with CanOpen

S20260-DNS: 120/240 VAC, 1/3-phase, 1.5/4.5 ARMS Base Unit, Profile Node with DeviceNet

S20350-CNS: 120VAC doubler/240VAC, 1 phase, 3/9 ARMS Base Unit, Profile Node with CanOpen

S20350-DNS: 120VAC doubler/240VAC, 1 phase, 3/9 ARMS Base Unit, Profile Node with DeviceNet

S20360-CNS: 120/240 VAC, 1/3-phase, 3/9 ARMS Base Unit, Profile Node with CanOpen

S20360-DNS: 120/240 VAC, 1/3-phase, 3/9 ARMS Base Unit, Profile Node with DeviceNet

S20650-CNS: 120VAC doubler/240VAC, 6/18 ARMS Base Unit, Profile Node with CanOpen

S20650-DNS: 120VAC doubler/240VAC, 6/18 ARMS Base Unit, Profile Node with DeviceNet

S20660-CNS: 120/240 VAC, 1/3-phase 6/18 ARMS Base Unit, Profile Node with CanOpen

S20660-DNS: 120/240 VAC, 1/3-phase 6/18 ARMS Base Unit, Profile Node with DeviceNet

S21260-CNS: 120/240 VAC, 1/3-phase 6/18 ARMS Base Unit, Profile Node with CanOpen

S21260-DNS: 120/240 VAC, 1/3-phase 6/18 ARMS Base Unit, Profile Node with DeviceNet

Base Unit, Profile Node with CanOpen

RMS

Base Unit, Profile Node with DeviceNet

RMS

Base Unit, Profile Node with CanOpen

RMS

Base Unit, Profile Node with DeviceNet

RMS

6 S200 Position Node Installation Guide

Page 9

Kollmorgen 4/13/2012 Specifications

3.0 SPECIFICATIONS

Unless otherwise specified, the specifications are worst case

limits and apply over the specified operating ambient

NOTE

3.1 DRIVE FAMILY POWER

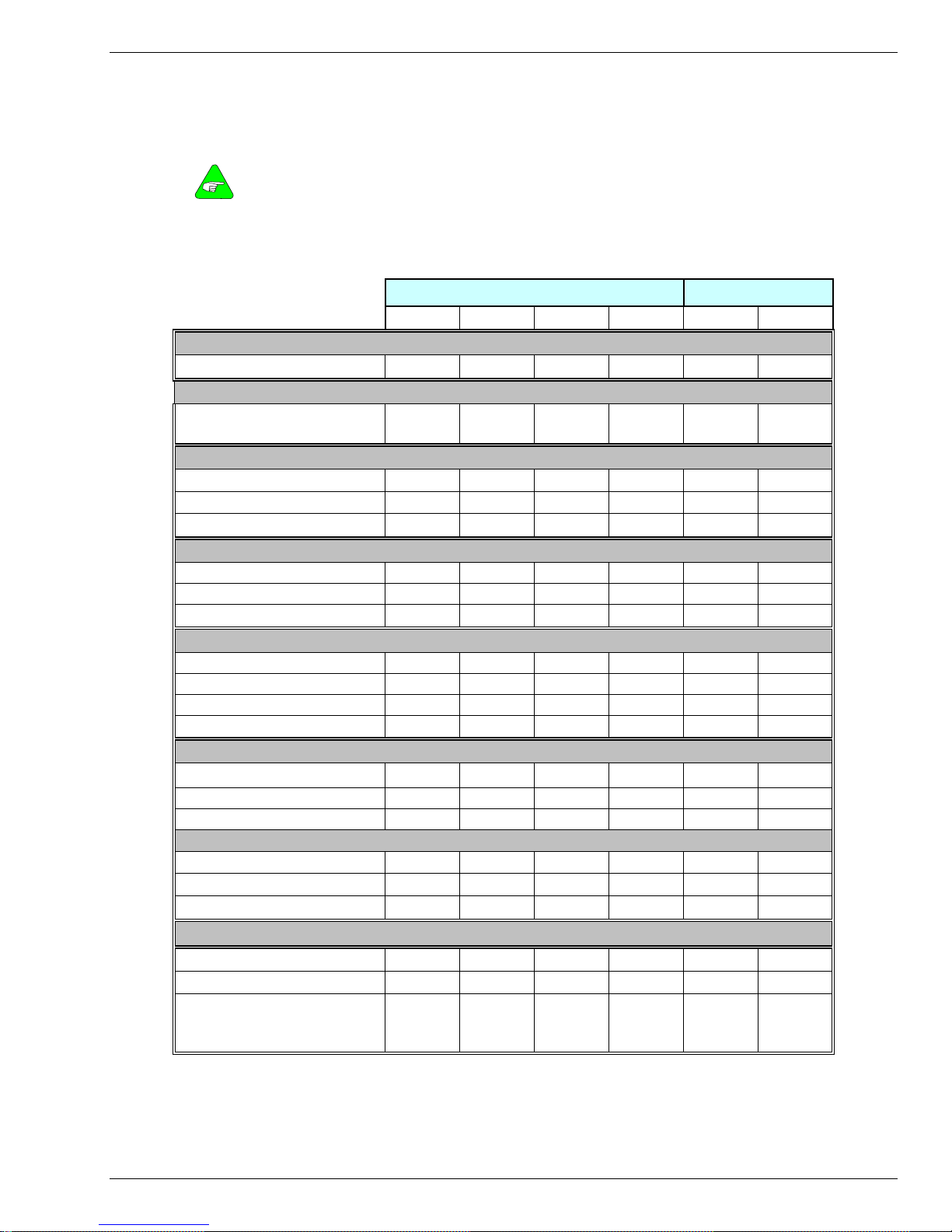

Drive Model Number S20260 S20360 S20660 S212660 S20330 S20630

Peak Output Current (A

(0 to 40°C) Ambient (A

Minimum Peak Current Time

(Starting from 0 amps) seconds 3 3 3 3 3 3

temperature and over the specified operating line voltage.

AC Input DC Input

)1

RMS

) 4.5 9 18 30 9 18

RMS

Continuous Output Current (A

0 to 30°C ambient (A

40° C ambient (A

50° C ambient (A

RMS

RMS

) 2.3 4.5 9 15 4.5 7.5

RMS

) 1.5 3 6 12 3 6

) 1 2 4 8 2 4

RMS

)2

Peak Output Power

240 VAC (VA), 3 phase 1500 3000 6000 10000 - -

120 VAC (VA), 1 phase 750 1500 2400 - - -

75 VDC (VA) - - - - 750 1500

Drive Continuous Output Power

240 VAC, 3 Phase (watts) 600 1100 2000 4000 - -

240 VAC, 1 Phase (watts) 500 900 1500 2500 - -

120 VAC, 1 Phase (watts) 250 450 - - - -

75 VDC (watts) - - - - 250 500

Continuous Motor Shaft Power at 3000 RPM (Nominal Bus – 10%)

0 to 30°C ambient (watts) 3-ph 300 750 1500 2500 - -

0 to 30°C ambient (watts) 1-ph 300 750 1300 2200 180 315

40° C ambient (watts) 200 500 1000 2000 125 250

RMS Line Current at Continuous Output Power

240 VAC 3 Phase (A

240 VAC 1 Phase (A

120 VAC 1 Phase (A

) 2.7 5 9 16 - -

RMS

) 3.4 6.5

RMS

) 3.4 6.5 12 (Note 3) - - -

RMS

12

(Note 3)

18 (Note 3) - -

+BUS Current – 75 VDC at Continuous Output Power3

Average (ADC) - - - - 3 6.7

Instantaneous Peak (A

Power Dissipation at 40°C

(watts)

P

CONT

) - - - - 12.7 25.5

PEAK

17 29 60 110 8 12

S200 Position Node Installation Guide 7

Page 10

Specifications 4/13/2012 Kollmorgen

1

Drive Model Number: S20260 S20360 S20660 S212660 S20330 S20630

Shunt Regulator

Peak Power kW (500 ms) 4.4 at 36 6.4 at 25 10 at 15 10 at 15 - -

Cont. Power watts 440 at 36 640 at 25 1000 at

Maximum Regen Duty Cycle (%) 10 at 36 10 at 25 10 at 15 15 at 15 - -

Regen Value () 25 – 50 25 – 50 12 – 50 8 – 50 - -

Bus Capacitance Energy Absorption (joules)

340 VDC Nominal BUS 15.5 15.5 20 45 - -

75 VDC BUS with 4,000 µf -

(5 volt increase to 80 VDC)

Output Current Ripple Freq fS

(kHz)

- - -

20 20 20 >16 31.2 31.2

AC Input DC Input

15

1500 at

15

- -

1.5 1.5

Minimum Motor Inductance l-l

5 2.5 1.25 0.9 - -

(mH)

At 75 VDC - - - - 0.4 0.2

Maximum Motor Inductance l-l

300 150 75 45 30 15

(mH)

Maximum Motor Power Cable Length4

18 AWG cable (m) 50 50 25 - 50 25

14 AWG Cable (m) 50 50 50 50 50 50

2

3

4

Peak Output Current listed is for sine mode. In six-step mode, the peak output currents

are scaled to give the same output torque as in sine mode with a pure sinusoidal Back

EMF motor.

To convert A

For Operation above 40

At higher ambient temperatures (above 30

a thermally conductive surface to limit the heatsink temperature to less than 75

to A(0-pk), multiply A

RMS

o

C ambient: Derate linearly to 67% at 50o C .

* 1.414.

RMS

o

C) the S20360 drive needs to be mounted on

o

C.

Single phase operation of the S20660 requires derating of continuous output power to

avoid excessive AC line front-end currents.

See Appendix – Cables for voltage loss vs cable length.

8 S200 Position Node Installation Guide

Page 11

Specifications 4/13/2012 Kollmorgen

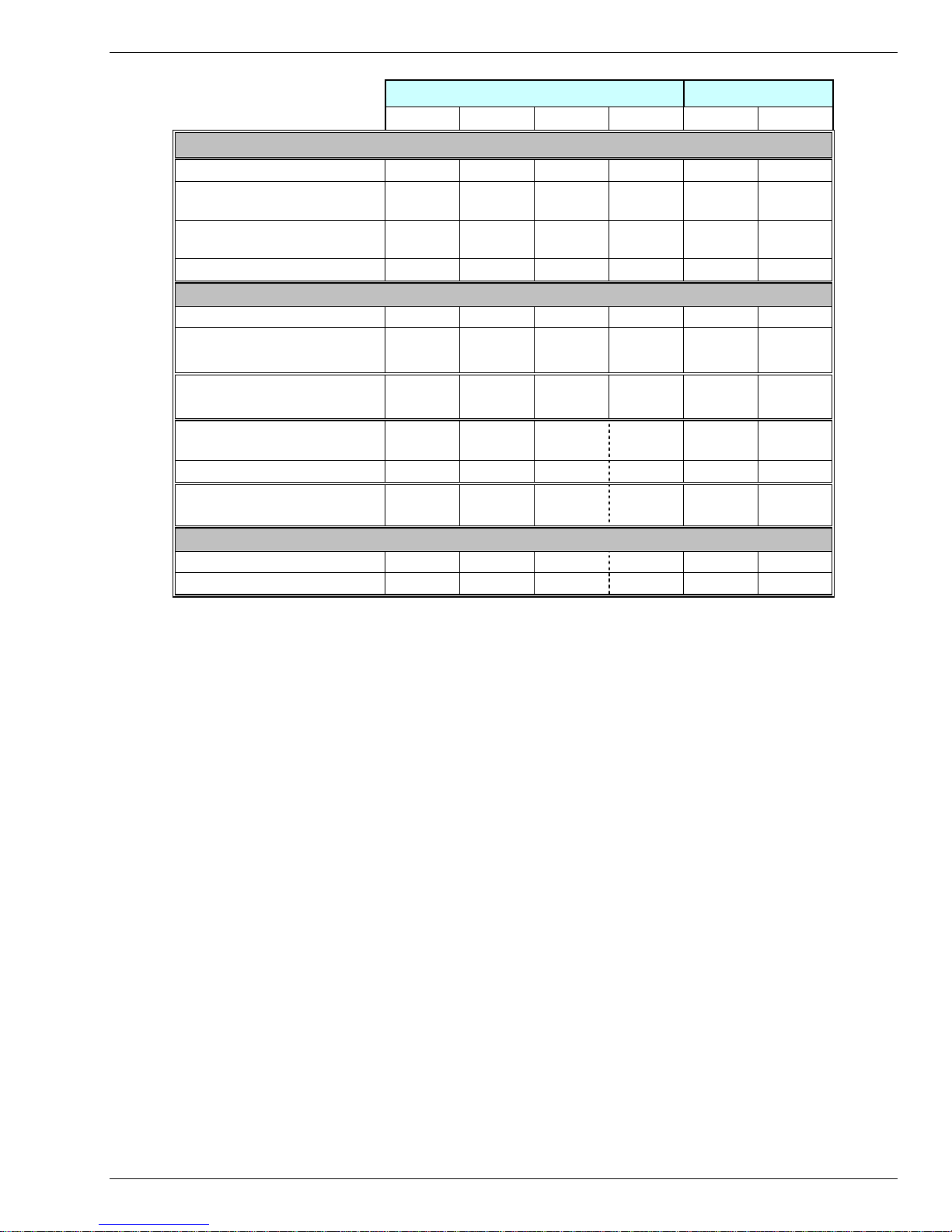

3.2 INPUT POWER SPECIFICATIONS

AC Control Power Supply

Input Voltage Range (RMS)

Ride Through Time for AC Line Drop

AC Motor Power Supply

Input Voltage Range (RMS) VAC 90 to 265

Phases 1 or 3

Transformer Suggested KVA 2 to 3

Maximum AC Line KVA1 100

1

Maximum AC Line is specified to limit the mains surges to the drive.

AC Bus Voltage and Faults

240 VAC Input Nominal Bus Voltage 320 VDC

120 VAC Input Nominal Bus Voltage 155 VDC

BUS Under voltage Fault Factory Default is None

BUS Over voltage (BusOV) Fault 407 VDC + 5%

BUS Regen Voltage = 0.974*BusOV = 397 VDC Nominal

85 VAC to 265 VAC single phase

47 to 63 Hz

120 VDC to 375 VDC

85 VAC 60 Hz > 0.78 60 Hz cycles

120 VAC 60 Hz > 3.3 60 Hz cycles

240 VAC 60 Hz >18.5 60 Hz cycles

AC Inrush Current & Fusing

Worse Case Inrush Peak Current at 240 VAC 140 A 0-p

Inrush pulse width 1.5 ms

Recommended Fusing Line Inputs

Type – 250 VAC Time Delay Fuse

240 VAC 3 Phase

(A

)

RMS

240 VAC 1 Phase

(A

)

RMS

120 VAC 1 Phase

(A

)

RMS

Control Power Applied to Drive Operational 1.25 seconds

S20260 S20360 S20660 S21260

FRN-R-5 FRN-R-8 FRNR-15 FRN-R-25

FRN-R-5 FRN-R-10 FRN-R-20 FRN-R-30

FRN-R-5 FRN-R-10 FRN-R-20

AC Power on Delay

-

9 S200 Position Node Installation Guide

Page 12

Specifications 4/13/2012 Kollmorgen

3.3 DC INPUT DRIVES - CONTROL AND POWER

DC Control Power

Control Voltage Range (VDC)

(J1-1 to J1-2)

Control Input power (watts)1 2 to 8

1

(20 watt min supply recommended) Refer to the DC Power Supply Section for detailed

application information and requirements.

+10 to +90

DC BUS Voltage and Faults

+BUS Voltage Range (VDC)

(J1-3 to J1-2)

+BUS Under voltage Fault +17 VDC nominal

+BUS Overvoltage Fault +91 VDC nominal

+20 to +90

DC Power On Delay

Control Power Applied to Drive

Operational

1.5 seconds

3.4 CONTROL LOOP PERFORMANCE

Motor Phase Current Waveform Pure sinusoidal or six-step, depending on

Motor Current Control

feedback device

(In Sine or six-step mode output torque = Motor KT*Drive IFB)

Motor Shaft Torque (Ignoring motor magnetic saturation)

Peak KT (N-m/A

Instantaneous KT (N-m/A

10 S200 Position Node Installation Guide

)*Drive Ipeak (A

RMS

)*IFB (A

RMS

RMS

)

RMS

)

Page 13

Specifications 4/13/2012 Kollmorgen

Current Loop Bandwidth

Maximum Bandwidth

AC Input Drive (kHz) 3

DC Input Drive (kHz) 5

Recommended Bandwidth

AC Input Drive (kHz) 2

DC Input Drive (kHz) 3

SFD Auto Set (kHz) AC &

DC

Bandwidth Variation For

Fixed Motor L

(% regulated independent of

bus volt)

Update Period (µs) 0.8

2

± 2.5

Recommended Max Motor Electrical Frequency (Hz)

AC Input Drive (Hz) 600

DC Input Drive (Hz) 900

Velocity Loop Performance

Maximum Stable Bandwidth (Hz with SFD) 400

Update Period (µs) 0.8

Range (rpm) 0 to 18,300

Command Resolution

< 0.001 rpm analog

0.558 rpm serial

Velocity Loop Compensation

KVP Range (Depends on Ipeak) 0.00044 to 0.106 (Ipeak)(1/rad/sec)

KVP Resolution (%) 10

KVI Range (Hz) 0 to > 22

KVI Resolution (%) 10

1

Range (Hz) 24.3 to > 46627

ARF0

1

ARF1

Range (Hz) 24.3 to > 46627

1

Values for ARF0, ARF1; from 3012 to 24873 Hz cannot be set.

Current Loop Specifications

- 3 dB Bandwidth (Hz) > 2000

- 45° Phase Lag (Hz) > 1000

11 S200 Position Node Installation Guide

Page 14

Specifications 4/13/2012 Kollmorgen

General Performance

Max Tracking Rate (rpm) > 48600

Max Recommended Rate (rpm) 25000

Max Tracking Acceleration (rpm/sec) > 16x106

Maximum Feedback Cable Length 50 m (164 ft)

3.5 MECHANICAL SPECIFICATIONS

S20330-CNS

S20330-DNS

S20630-CNS

S20630-DNS

Drive Height (A)

Drive Width (B)

Drive Depth1 (C)

Mounting Hardware

Drive Weight

Nominal

1

Depth measurement is for drive only. Add approximately 50.8 mm (2 in) to depth given in the table

to accommodate mating connectors and wire bend radius.

152.4 mm 152.4 mm 175.0 mm 175.0 mm 177.0 mm

6.00 in 6.00 in 6.9 in 6.90 in 6.97 in

28.7 mm 48.3 mm 54.8 mm 54.8 mm 76.2 mm

1.90 in 1.90 in 2.16 in 2.16 in 3.0 in

100.8 mm 100.8 mm 131.6 mm 131.6 mm 152 mm

3.97 in 3.97 in 5.18 in 5.18 in 5.98 in

M4 or #8 M4 or #8

0.40 kg 0.5 kg 0.77 kg 0.82 kg 1.5 kg

1.00lb 1.10 lb 1.69 lb 1.80 lb 3.2 lb

S20250-CNS

S20250-DNS

S20260-CNS

S20260-DNS

S20350-CNS

S20350-DNS

S20360-CNS

S20360-DNS

M4 or #8

S20650-CNS

S20650-DNS

S20660-CNS

S20660-DNS

M4 or #8 M4 or #8

S21260-CNS

S21260-DNS

Physical Dimensions and Specifications

3.6 I/O SPECIFICATIONS

Note: Analog command is not allowed in this product. Digital Velocity and Motion Task position

loop control is the only possibilities.

Maximum Range (volts) 0.5 – 4.5

Full Scale Tolerance (%)

Typical (Worse Case) +/- 1 (± 5)

Linearity (% Full Scale) <0.1

Monotonic to < 2

Offset (mV) < 100

Offset Drift (µV/°C typ.) 250

12 S200 Position Node Installation Guide

Analog Output (DacMon)

DACMON1, DACMON 2 (J4 14,15)

-16

Full Scale

Page 15

Specifications 4/13/2012 Kollmorgen

Quadrature Input CHA (J12-12, 13) CHB (J12-14,15)

Type RS-422/RS-485, TTL, Open Collector

Input Voltage +/- 200mV Differential

Input Termination Please see diagrams in manual

Maximum Line Frequency 625 kHz (corresponds to 2.5 MHz

General Purpose Digital Inputs

DINP1-4, DINP6-9 (J4 2-5 and J12 2-5)

Input Voltage ± ( 4.0 - 30.0) volts

Referenced to DINPCOM (J4-5)

Input Current 0.65 - 6.7 mA

Response Time 1.0 ms

DINP5/DINP10 (J4-10 & 11, J12-8 & 9)

Input Voltage 3.0 – 6.0 volts

Input Current 9.0 – 24.0 mA

DOUT1, DOUT2, DOUT3 (J4-6,7,8,9 J12-6,7)

Maximum Output Voltage - 0.30 to 30.0 volts

Clamp Voltage 33 volt ± 6%

Maximum Output Current 50 mA

On voltage 1.0 volts at 10 mA

1.2 volts at 50 mA

Response Time 1.0 ms

Quadrature Output (CHA- J4-19, 20 CHB- J4-21,22 CHZ- J4-17,18)

Type RS-422/RS-485

Quadrature Input

compatible

quadrature pulse rate)

General Purpose Outputs

Quadrature Outputs

Output Voltage 5.0 V Differential Output - Unloaded

Hysteresis 1/2 Quadrature Count corresponding to

Resolution

(With SFD)

13 S200 Position Node Installation Guide

Maximum Output Frequency 2.5 MHz

Marker Pulse Width Approximately 120 degrees

1/8 Encoder Line Count

125, 128, 500, 512, 1000, 1024, 2000,

2048, 2500, 4096, 5000, 8192, 10000,

16384, 20000, 32768

Page 16

Specifications 4/13/2012 Kollmorgen

3.7 ENVIRONMENTAL SPECIFICATIONS

Environmental Specifications

Operating Temperature (° C) – Full

Rating

Operating Temperature (° C) – Derated

Linearly Derate Continuous Current to

67% of 40

o

C Rating

Pollution Degree 2

Storage Temperature (° C) -20 to 70

Humidity (% non-condensing) 10 to 90

Altitude <1500 m (5000 feet)

0 to 40

40 – 50

3.8 SMART FEEDBACK DEVICE (SFD)

SFD (Smart Feedback Device)

Resolution/Rev (arc min) 24 bits = 0.0013

Repeatability (arc min RMS) < ± 2

-19

Rev = ± 0.04

Noise

No Filtering (arc min RMS) < 2

150 Hz Single Pole Filtered (arc min

< 2

RMS)

10 Hz Single Pole Filtered (arc min

< 2

-19

RMS)

DC Offset Temperature Drift < 2

-18

Absolute Accuracy

AKM1 (arc min) ± 2

AKM2 or 3, 4 (arc min) ± 2

-10.3

-11.1

Communications Update Period (µs) 51.2

-17

Rev RMS = 0.16

-18

Rev RMS = 0.08

Rev RMS = 0.02

Rev/° C = 0.08 arc min/° C

Rev = ±17

Rev = ±10

14 S200 Position Node Installation Guide

Page 17

Kollmorgen 4/13/2012 Accessories

4.0 ACCESSORIES

4.1 CABLES

Kollmorgen offers pre-made high quality cables for help in installation.

4.1.1 Motor and feedback cables

Motor and Feedback cable selections are covered in our Motioneering package to help select the correct sets

based on motor and drive size selection.

4.1.2 Serial Communications Cable

Kollmorgen offers a 6 ft serial communications cable designed to connect directly between the S200 Position

Node and standard PC 9 Pin communications port. Order Part Number P7S2-232-D.

S200 Position Node Installation Guide 15

Page 18

Accessories 4/13/2012 Kollmorgen

4.2 CONNECTOR KITS

Kollmorgen offers several connector kit options to help interface drive connections. Please note that there are

connector kits that are designed to interface to just the base unit drive and connector kits designed for the

auxiliary S200 Position Node auxiliary features. More than one connector kit may be required.

4.2.1 Base Unit Connector Kits

CK-S200-MF connector kit includes motor

and feedback connectors for all low power

base unit models. (JJ2 and J4).

This connector kit is useful in applications

and customers not using Kollmorgen Cables

Sets.

Applicable Drive Models:

S202x0-xNS, S20350-xNS, S20360-xNS,

S20660-xNS.

CK-S200-MP-AC connector kit includes

motor and power connectors for all low power

AC Input base unit models. (J1 and J2).

This connector kit is useful in applications

and customers not using Kollmorgen

Armature cables.

Applicable Drive Models:

S20250-xNS, S20260-xNS, S20350-xNS,

S20360-xNS, S20660-xNS.

16 S200 Position Node Installation Guide

Page 19

Accessories 4/13/2012 Kollmorgen

CK-S200-IP-DC connector kit includes power

and signal connectors for the S200 Base Unit

models. (J1 and J4).

This connector kit provides the auxiliary

connectors required when purchasing

Kollmorgen Cable sets.

Applicable Drive Models:

S20330-xNS, S20630-xNS

CK-S200-IP-DC-TB connector kit includes the

power connector and signal connector with

terminal block break out for the DC S200

Base Unit models. (J1 and J4).

This connector kit provides the auxiliary

connectors required when purchasing

Kollmorgen Cable sets when screw terminals

are preferred over soldering of J4.

Applicable Drive Models:

S20330-xNS, S20630-xNS

CK-S200-IN-AC connector kit includes both

the command signal connector, J4, and the

AC power connector, J1, for the low power

S200 Base Unit models. Solder cup

connector.

This connector kit provides the auxiliary

connectors required when purchasing

Kollmorgen Cable sets.

Applicable Drive Models:

S20250-xNS, S20260-xNS, S20350-xNS,

S20360-xNS, x20660-xNS.

17 S200 Position Node Installation Guide

Page 20

Accessories 4/13/2012 Kollmorgen

CK-S200-IN-AC-TB connector kit includes

both the command signal connector, J4, and

the AC power connector, J1, for the low

power S200 Base Unit models. Cage Clamp

connector kit.

This connector kit provides the auxiliary

connectors required when purchasing

Kollmorgen Cable sets where terminal screws

are preferred over soldering of J4.

Applicable Drive Models:

S20250-xNS, S20260-xNS, S20350-xNS,

S20360-xNS, x20660-xNS.

CK-S200-IN-AC connector kit includes

command signal connector, J4, for the S200

Base Unit models. Solder cup connector.

Applicable Drive Models:

All models

CK-S200-IN-AC-TB connector kit

includes command signal connector, J4,

for the S200 Base Unit models. Cage

clamp screw terminal connector.

Applicable Drive Models:

All models

18 S200 Position Node Installation Guide

Page 21

Accessories 4/13/2012 Kollmorgen

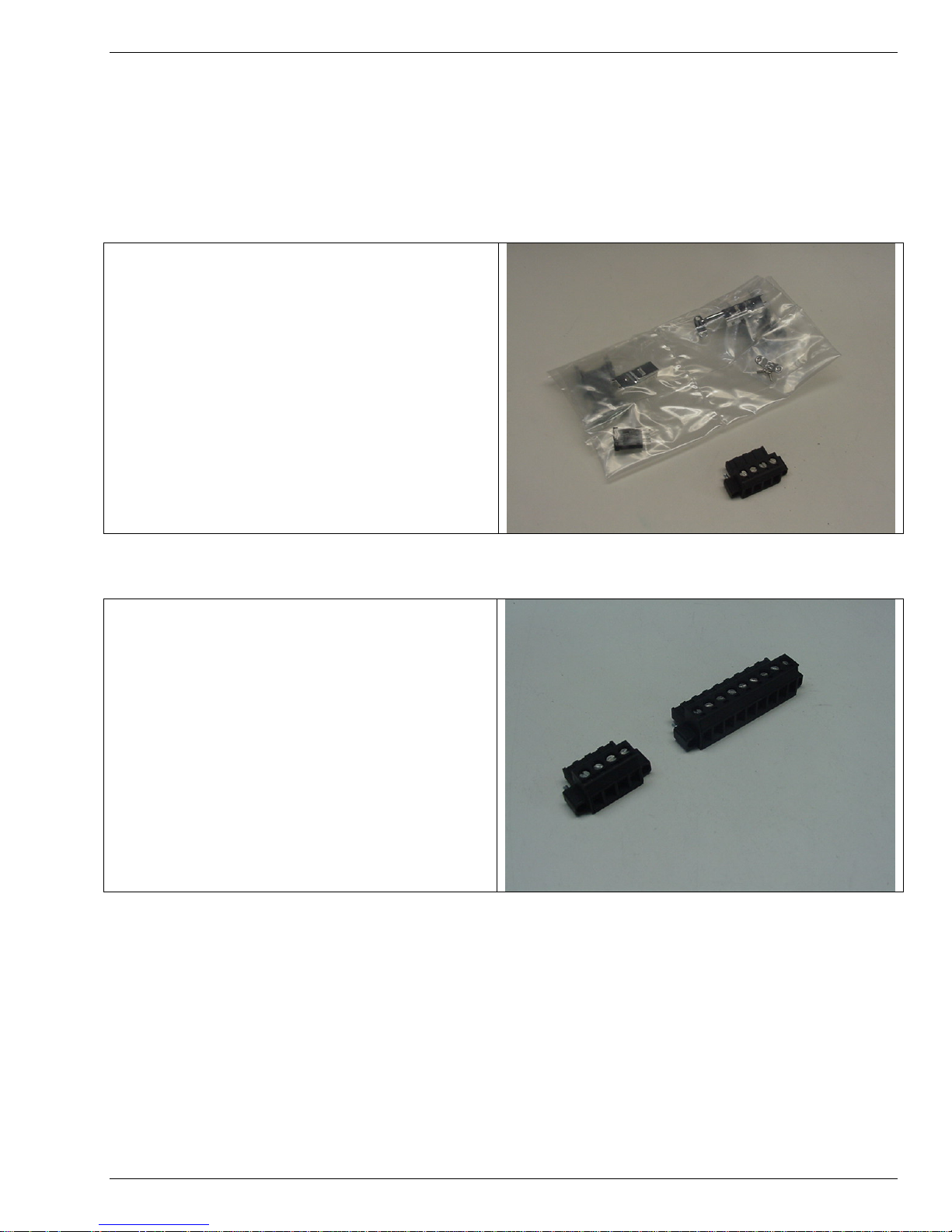

4.2.2 Position Node Connector Kits

CK-S200-CNDN connector kit includes:

command signal connector, J12, and the

encoder connector, J13 for the S200

Position Node auxiliary functions. Solder

cup connectors.

Applicable Drive Models:

All models with DNS or CNS suffix.

CK-S200-CNDN-TB connector kit includes:

command signal connector, J12, and the

encoder connector, J13 for the S200 Position

Node auxiliary functions. For applications

desiring screw terminal (cage clamp) over

soldered connections

Applicable Drive Models:

All models with DNS or CNS suffix.

4.3 REGEN RESISTOR

Kollmorgen offers the ERH-26 fully enclosed, thermally

protected regen resistor rated at 26 ohms, 150 watts. The

resistor has connection leads and an integrated thermal switch

with fast-on type connectors. The thermal switch can be wired

into the user’s safety circuit. The ERH-26 is a UL Recognized

component.

19 S200 Position Node Installation Guide

Page 22

Accessories 4/13/2012 Kollmorgen

4.3 DIN RAIL TERMINAL BREAK OUTS

Soon to be offered. Ask service representative for latest availability.

4.4 OPERATOR INTERFACE TERMINALS

Kollmorgen does not currently offer direct purchase of Operator Interface Terminals other than with complete

systems. There are many units available in the general industrial equipment market place. Virtually any terminal

that has the ability to be configured for your application and has support for MODbus RTU with the ability to read

and write registers formatted for double registers (32 bit) in both long integer and floating point formats should be

compatible with the S200 Position Node product.

4.5 SYSTEMS CAPABILITIES

Kollmorgen offers a variety of pre-configured systems from component kits to pre-wired systems in NEMA 12

enclosures. Please consult your local Kollmorgen representative for details.

20 S200 Position Node Installation Guide

Page 23

Kollmorgen 4/13/2012 Installation

5.0 INSTALLATION

5.1 UNPACKING AND INSPECTING

Open the box and remove all the contents. Check to ensure there is no visible damage to any

of the equipment.

Use proper procedures when handling electronic

CAUTION

CAUTION

NOTE

components to avoid damage to equipment.

Remove all packing material and equipment from the

shipping container. Be aware that some connector kits and

other equipment pieces may be quite small and can be

accidentally discarded. Do not dispose of shipping materials

until the packing list has been checked.

Upon receipt of the equipment, inspect components to

ensure that no damage has occurred in shipment. If damage

is detected, notify the carrier immediately. Check all

shipping material for connector kits, documentation,

diskettes, CD-ROM, or other small pieces of equipment.

5.2 MOUNTING

The S200 drives are designed for operation in a cabinet using the following installation

instructions:

Mount the drives vertically inside a cabinet on a flat, solid, electrically conductive, mounting

surface connected to PE (protective earth ground) and capable of supporting the weight of the

unit.

Provide a good connection to PE. Remove the paint on the mounting surface over an area

extending at least 12 mm (0.5 in) from the mounting bolts to achieve good electrical connection

over a large area between the drive and grounded mounting surface.

Ensure the environment within the cabinet meets the requirements listed in the environmental

specifications table.

S200 Position Node Installation Guide 21

Page 24

Installation 4/13/2012 Kollmorgen

5.3 DIMENSIONS

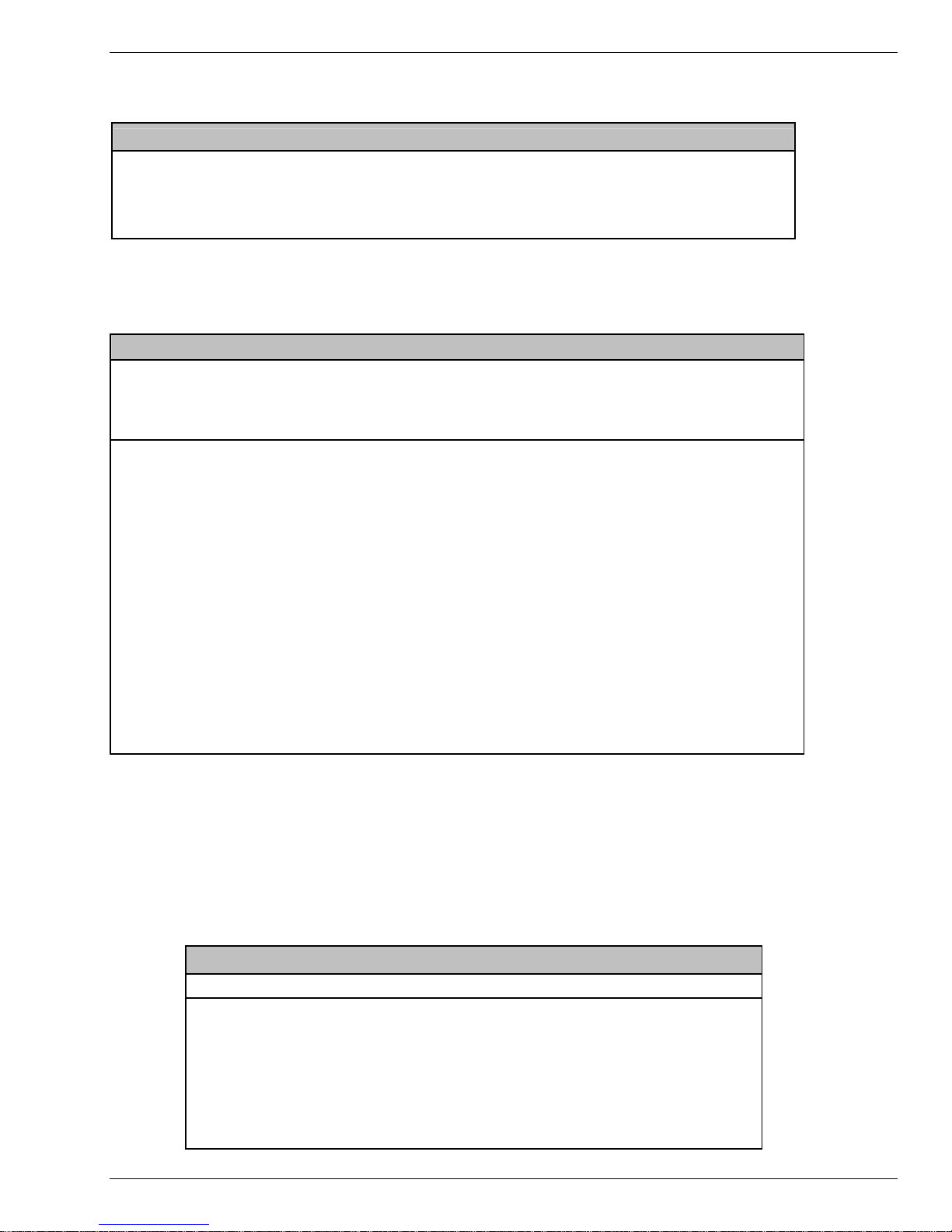

Mounting Dimensions

S20330-CNS

S20330-DNS

S20630-CNS

Drive Dimensions

Drive Height (A) 152.4 mm 175.0 mm 175.0 mm 177.0 mm

6.00 in 6.90 in 6.90 in 6.97 In

Drive Width (B) 48.3 mm 54.8 mm 64.0 mm 76.2 mm

1.90 in 2.16 in 2.52 in 3.0 in

Drive Depth1 (C) 100.8 mm 131.6 mm 131.6 mm 152 mm

3.97 in 5.18 in 5.18 in 5.98 in

Clearance Requirements

Top and Bottom (D) 12.7 mm 25.4 mm 25.4 mm 25.4 mm

0.50 in 1.0 in 1.0 in 1.0 in

Side to Side (E) 12.7 mm 25.4 mm 25.4 mm 25.4 mm

0.50 in 1.0 in 1.0 in 1.0 in

Mounting Dimensions

Horizontal Mounting

Offset (F)

0.97 in 1.01 in 1.01 in 1.25 in

Vertical Mounting Offset

(G)

0.16 in 0.17 in 0.17 in 0.19 in

Vertical Mounting Height

(H)

5.68 in 6.67 in 6.67 in 6.67 in

Drive to Drive Mounting

(J)

2.40 in 3.16 in 3.52 in 4.0 in

Mounting Hardware

Drive Weight

S20630-DNS

24.6 mm 25.6 mm 25.6 mm 31.7 mm

4.1 mm 4.3 mm 4.3 mm 4.8 mm

144.3 mm 169.5 mm 169.5 mm 169.5 mm

60.96 mm 80.3 mm 89.4 mm 101.6 mm

M4 or #8 M4 or #8 M4 or #8 M4 or #8

0.5 kg 0.85 kg 0.5 kg 1.5 kg

1.10 lb 1.86 lb 1.10 lb 3.2 lb

S202x0-CNS

S202x0-DNS

S203x0-CNS

S203x0-DNS

S206x0-CNS

S206x0-DNS

S21260-CNS

S21260-CNS

1

Depth measurement is for drive only. Add approximately 50.8 mm (2 in) to depth given in

the table to accommodate mating connectors and wire bend radius.

22 S200 Position Node Installation Guide

Page 25

Installation 4/13/2012 Kollmorgen

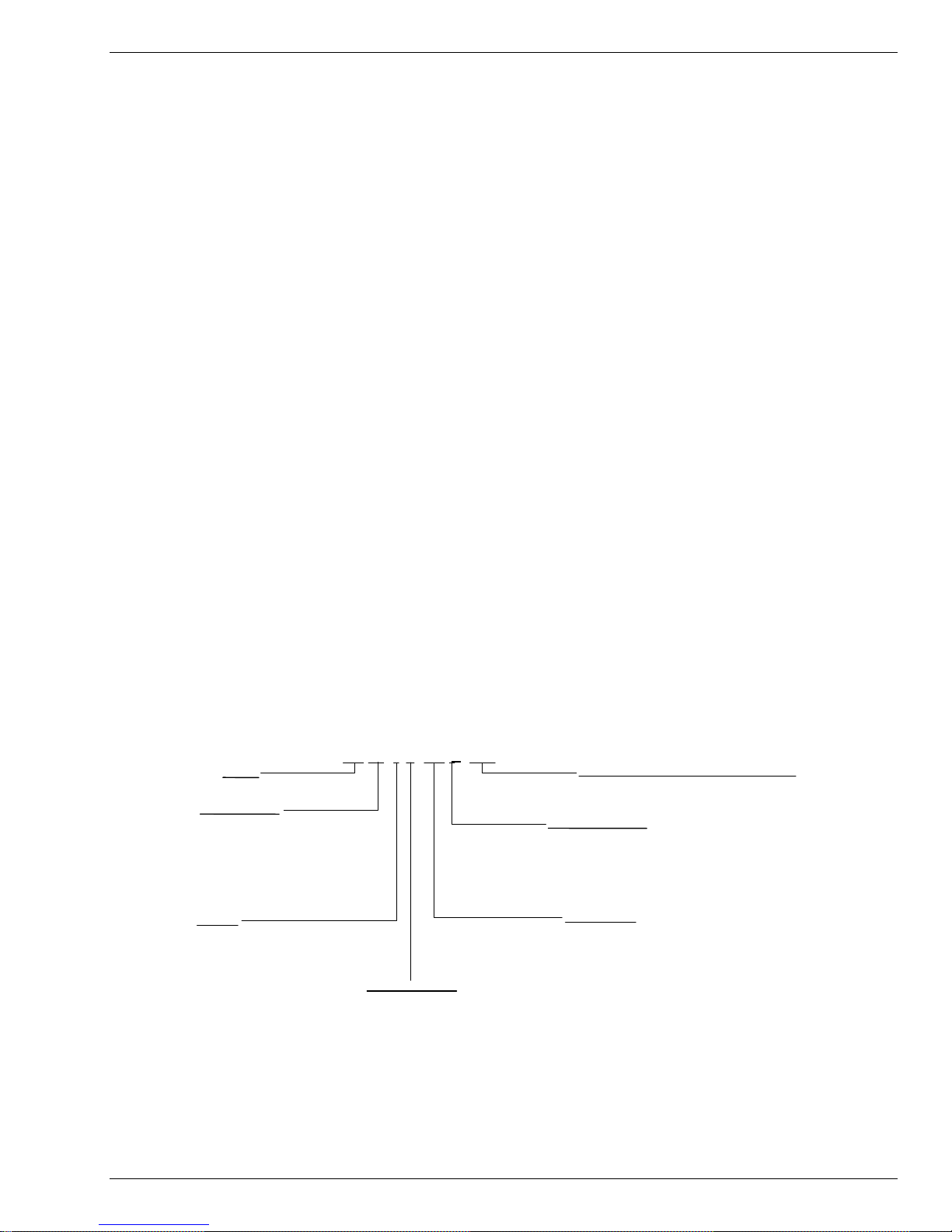

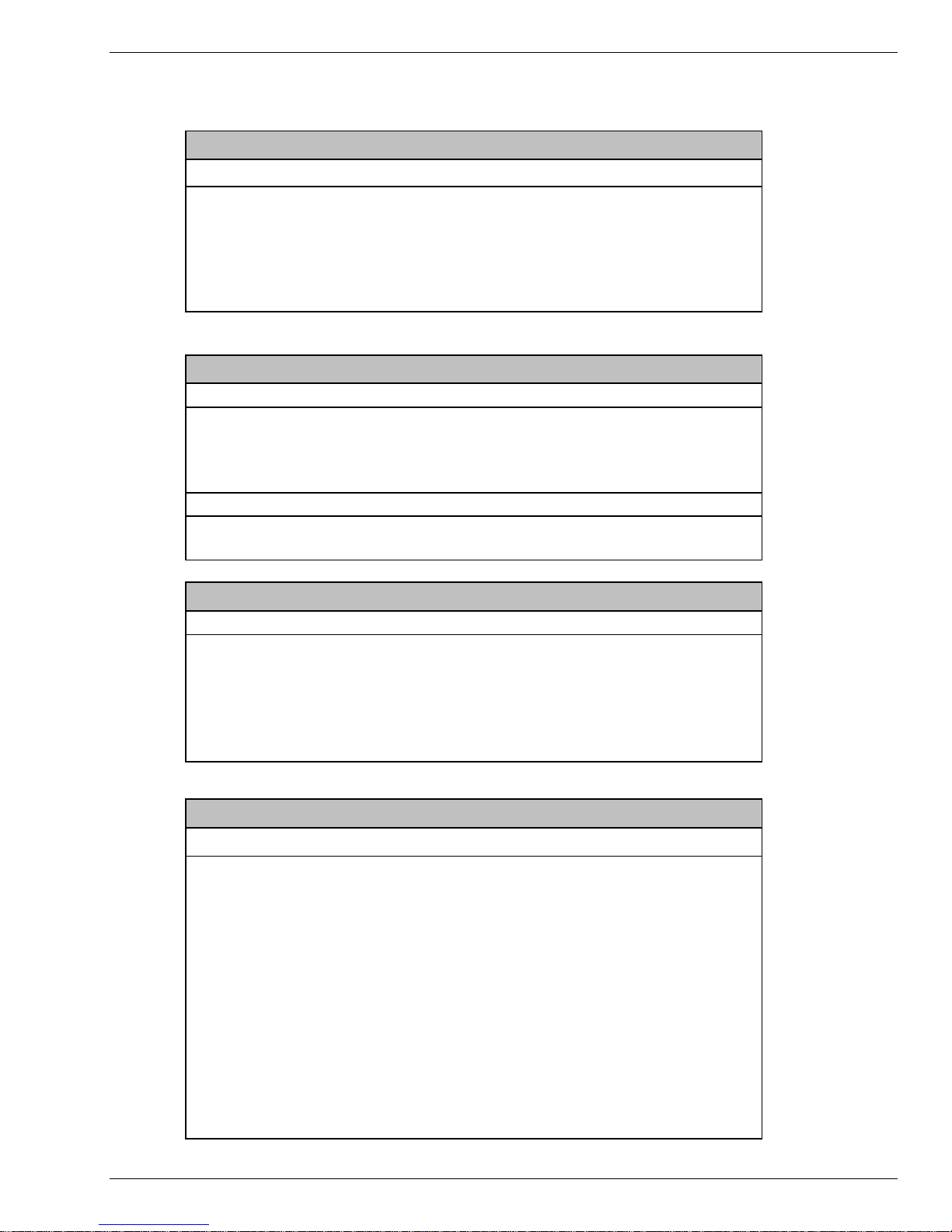

5.4 MOUNTING OUTLINE

DEPTH

(C)

0.18 mm

4.57 in

RECOMMENDED MOUNTING

HARDWARE M4 OR #8

F 0.18 mm

TOP VIEW

WIDTH

(B)

4.57 in

HORIZONTAL

MOUNTING

OFFSET (F)

VERTICAL

MOUNTING

OFFSET (G)

FRONT VIEW

RIGHT SIDE VIEW

HEIGHT

(A)

VERTICAL

MOUNTING

HEIGHT (H)

VERTICAL

MOUNTING

OFFSET (G)

REAR VIEW

23 S200 Position Node Installation Guide

Page 26

Kollmorgen 4/13/2012 Wiring Diagrams

A

A

3

6.0 WIRING DIAGRAMS

The following diagrams present the electrical connection diagrams for High Power AC units, Low Power AC units,

and DC Power units.

6.1 LOW POWER AC DRIVE WIRING DIAGRAM

DINP COM

DINP1

DINP2

DINP3

DINP4

DOUT 1 -

DOUT 1

DOUT 2 -

DOUT 2 +

DINP5 +

DINP5 -

NC

I/O RET

DAC MON 1

DAC MON 2

I/O RET

CH Z OUT

CH Z OUT

CH A OUT

CH A OUT

CH B OUT

CH B OUT

I/O RET

NA CMD +

NA CMD -

I/O RET

DINP COM

DINP6

DINP7

DINP8

DINP9

DOUT 3 -

DOUT 3 +

DINP 10-

DINP10 +

5V Source

5V COM

CH A / Step

CH A / Step

CH B / DIR

CH B / DIR

J4

S200 Drive

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

J12

AC Input

Power

Models

S20260-xNS

S20360-xNS

S20660-xNS

J13

J3

J2

J1

J5

J11

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

1

2

3

4

1

2

3

4

5

6

7

8

9

1

4

5

6

1

2

4

5

CU

CV

CW

I/O RET

CH Z IN

CH Z IN

PTC

PTC RET

5V SOURCE

I/O RET

CH A IN

CH A IN

CH B IN

CH B IN

+5V

5V RET

SFD COM -

SFD COM+

PE

W

V

U

REGEN

BUS -

NC

BUS+

C1 CNTL

C2 CNTL

L3

L2

L1

NC

RX Data

I/O RET

I/O RET

Tx Data

NC

V-

CAN L

SHIELD

CAN H

V+

Protective Earth

Optional

Regen

RS 232

Configuration

Port

Optional

Encoder

Feedback

SFD

MOTOR

Optional

CanBus

Connection

120/240VAC Control

Power 47-63Hz Fused

120/240VAC Mains

47-63Hz Fused

S200 Position Node Installation Guide 24

Protective Earth

Page 27

Wiring Diagrams 4/13/2012 Kollmorgen

A

6.2 HIGH POWER AC WIRING DIAGRAM

DINP COM

DINP1

DINP2

DINP3

DINP4

DOUT 1 -

DOUT 1 +

DOUT 2 -

DOUT 2 +

DINP5 +

DINP5 -

NC

I/O RET

DAC MON 1

DAC MON 2

I/O RET

CH Z OUT

CH Z OUT

CH A OUT

CH A OUT

CH B OUT

CH B OUT

I/O RET

ANA CMD +

ANA CMD -

I/O RET

DINP COM

DINP6

DINP7

DINP8

DINP9

DOUT 3 -

DOUT 3 +

DINP 10-

DINP10 +

5V Source

5V COM

CH A / Step

CH A / Step

CH B / DIR

CH B / DIR

J4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

J12

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

S200 Drive

C Input

Power

Model

S21260-xNS

J13

J3

TB1

J1

J5

J11

CU

1

CV

2

CW

3

4

I/O RET

5

CH Z IN

6

CH Z IN

7

PTC

PTC

9

5V

10

I/O

11

CH A IN

12

CH A IN

13

CH B IN

14

CH B IN

15

+5V

1

5V RET

2

SFD COM -

3

SFD COM+

4

5

6

PE

1

W

2

V

3

U

4

REGEN

5

BUS -

6

BUS+

7

L3

8

L2

9

L1

10

Protective Earth

1

C2 CNTL

2

C1 CNTL

3

NC

1

RX

2

I/O

3

I/O

4

Tx

5

NC

6

V+

1

CAN H

2

SHIELD

3

CAN L

4

V-

5

NC

Optional

Encoder

Feedback

SFD

MOTOR

Optional

Regen

Resistor

RS 232

Configuration

Port

120/240VAC Mains

47-63Hz Fused

120/240VAC Control

Power 47-63Hz Fused

25 S200 Position Node Installation Guide

Protective

Page 28

Wiring Diagrams 4/13/2012 Kollmorgen

A

A

p

p

6.3 DC MODELS DRIVE WIRING DIAGRAM

DINP COM

DINP1

DINP2

DINP3

DINP4

DOUT 1 -

DOUT 1 +

DOUT 2 -

DOUT 2 +

DINP5 +

DINP5 -

NC

I/O RET

DAC MON 1

DAC MON 2

I/O RET

CH Z OUT

CH Z OUT

CH A OUT

CH A OUT

CH B OUT

CH B OUT

I/O RET

NA CMD

NA CMD -

I/O RET

J4

S200 Drive

DC Input

Power

Models

J13

J3

J2

CU

CV

CW

I/O RET

CH Z IN

CH Z IN

PTC

PTC RET

5V SOURCE

I/O RET

CH A IN

CH A IN

CH B IN

CH B IN

+5V

5V RET

SFD COM -

SFD COM+

PE

W

V

U

Optional

Encoder

Feedback

DINP COM

DINP6

DINP7

DINP8

DINP9

DOUT 3 -

DOUT 3 +

DINP10-

DINP10 +

5V Source

5V COM

CH A / Ste

CH A / Ste

CH B / DIR

CH B / DIR

J12

J1

J5

J11

+ CNTL

BUS/CNTL GND

+ BUS

Note: J1 Pin 2 and all I/O RET pins are

tied together within the drive.

RX Data

I/O RET

I/O RET

Tx

NC

V+

CAN H

SHIELD

CAN L

V-

NC

Optional CAN

Bus Connection

RS 232

Configuration

Port

Main Power

20 – 90 V

Protective Earth

26 S200 Position Node Installation Guide

Page 29

Kollmorgen 4/13/2012 Connector Pinout And Discriptions

7.0 CONNECTOR PINOUT AND DISCRIPTIONS

The following section describes the user connections to the S200 Position Node by connector. The front part of

this section presents AC / DC input Power and Power Terminal wirings for various drive models. J1 and TB1 vary

according to the model. Please refer to the proper description for your model.

7.1 PE ALL DRIVE MODELS

Each S200 Position Node product has at least one screw terminal from its frame exposed to the front of the

product for customer wiring to Protective Earth (PE) ground. This connection should be made with heavy gage,

high strand count wire and a ring lug terminal directly back to the incoming earth ground distribution block. Power

should not be applied if this connection does not exist.

PE Ground Terminals

(TYPICAL)

S200 Position Node Installation Guide 27

Page 30

Connector Pinout And Descriptions 4/13/2012 Kollmorgen

7.2 J1 – LOW POWER AC INPUT POWER MODELS DRIVE POWER

Models S202x60-xNS, S203x0-xNS, S206x0-xNS

The S200 AC input drives are capable of direct line operation. All units are fully isolated and do not require

external isolation transformers. The inrush current on the connection to the line is internally limited to a safe level

for the drive. There are no voltage selection or ranging switches required to operate within the specified voltage

input ranges. Please note warnings that follow.

The S200 series drives are functionally compatible with all standard forms of three phase AC lines:

Grounded neutral WYE

Open-Delta Grounded Leg

TEE

19

Figure 7.1: J1 Connector view from front of drive

Pin Description

J1-1 PE (Protective Earth) – Must be tied back to central earth bar.

J1-2 REGEN – Connection for optional external regen resistor.

J1-3 -BUS DC – Internal DC Bus negative connection (Not normally used)

J1-4 +BUS – Internal DC Bus Positive Connection (Regen Resistor

Termination Point)

J1-5 C2 CTRL VAC – Logic control Power can be tied to 120 or 230Vac input

J1-6 C1 CTRL VAC – Logic Control Power can be tied to 120 or 230Vac input

J1-7 L3 240 VAC – Main Line for Bus power: Used for 3rd Phase

J1-8 L2 240/120 VAC – Main Line for Bus Power. Used for 1 or 3 Phase

J1-9 L1 240/120 VAC – Main Line. Used for 1 or 3 Phase

Please refer to the Specifications Section for appropriate rating and fusing requirements.

It is the customer’s responsibility to supply appropriate fuses or circuit

NOTE

28 S200 Position Node Installation Guide

breakers in the J1 AC drive power lines to comply with local electrical codes.

Page 31

Connector Pinout And Descriptions 4/13/2012 Kollmorgen

For maximum line droop tolerance connect logic power to 230Vac

NOTE

instead of 115Vac

After powering down the drive, monitor the BUS voltage by

connecting a meter from J1-4 (+BUS) to J1-3 (-BUS) to verify the

WARNING

internal BUS capacitors have discharged prior to working on the

drive.

The Regen input is not short circuit protected. The Regen

Resistance MUST be within specified ranges to prevent damage to

WARNING

the drive. For example, between 25 to 50 Ω for the S20260, S20360

drives or 15 to 50 Ω for the S20660.

CAUTION

To avoid damage to the connector and drive, NEVER plug or unplug J1

with power applied.

For single-phase systems Main Bus power must be wired to L1

and L2. Do not connect L3.

WARNING

Selected Regen Resistor must be able to handle constant 390Vdc

connection without risk of fire or must otherwise be thermally

WARNING

protected with an overload device.

J1 Mating Connector Information

Screw Terminal Connector:

12 – 24 AWG Wire Range, Phoenix MSTB2,5/9-STF-5,08-BK

OR Spring Cage Clamp Connector

12 – 24 AWG Wire Range, Phoenix FKC 2,5/9-SFT-5,08-BK

OR Crimp Connector

14-20 AWG Wire Range, Phoenix MSTBC 2,5/9-STZF-5,08-BK

Crimp Contact: 14-16 AWG Wire Range, Phoenix MSTBC-MT 1,5-2,5

Crimp Contact: 18-20 AWG Wire Range, Phoenix MSTBC-MT 0,5-1,0

Refer to www.phoenixcon.com.

29 S200 Position Node Installation Guide

Page 32

Connector Pinout And Descriptions 4/13/2012 Kollmorgen

7.3 J1 – AC INPUT CONTROL POWER HIGH POWER AC MODELS.

Models: S21260-xNS

NOTE

Pin Description

J1-1 PE (Protective Earth) – Must be tied back to central earth bar.

J1-2 C2 CTRL VAC – Logic control Power. Use 120 or 240Vac.

J1-3 C1 CTRL VAC – Logic Control Power. Use 120 or 240 Vac.

Please refer to the Specifications section for fusing and rating information.

It is the customer’s responsibility to supply appropriate fuses or circuit

breakers in the J1 AC drive power lines to comply with local electrical

codes.

For maximum line droop tolerance connect logic power to 230Vac instead of 115Vac

PE C2 C1

NOTE

CAUTION

To avoid damage to the connector and drive, NEVER plug or unplug J1

with power applied.

Mating Connector Information:

Screw Terminal Connector

12 – 24 AWG Wire Range, Phoenix MSTB2,5/3-STF-5,08-BK

OR Spring Cage Clamp Connector

12 – 24 AWG Wire Range, Phoenix FKC 2,5/3-SFT-5,08-BK

OR Crimp Connector

Crimp Shell: 14-20 AWG Wire Range, Phoenix MSTBC 2,5/3-STZF-5,08-BK

Crimp Contact: 14-16 AWG Wire Range, Phoenix MSTBC-MT 1,5-2,5

Crimp Contact: 18-20 AWG Wire Range, Phoenix MSTBC-MT 0,5-1,0

Refer to www.phoenixcon.com.

30 S200 Position Node Installation Guide

Page 33

Connector Pinout And Descriptions 4/13/2012 Kollmorgen

7.4 TB1: HIGH POWER AC POWER CONNECTIONS

Models: S21260-xNS

The S200 AC input drives are capable of direct line operation. All units are fully isolated and do not require

external isolation transformers. The inrush current on the connection to the line is internally limited to a safe level

for the drive. There are no voltage selection or ranging switches required to operate within the specified voltage

input ranges.

PE

W

V

U

Regen

-Bus

+Bus

1 PE Protective Earth (Motor Cable Shield Connection)

2 W Motor Output Phase W

3 V Motor Output Phase V

4 U Motor Output Phase U

5 Regen Optional Regen Resistor Connection (See Wiring Detail Section)

6 - Bus Main DC Bus – Output (Normally not connected)

7 + Bus Main DC Bus + Output (Normally connected with Optional Regen)

8 L3 Mains L3 Incoming Power Connection

9 L2 Mains L2 Incoming Power Connection

10 L1 Mains L1 Incoming Power Connection

Please refer to the Specifications section for fusing and rating information.

The S200 series drives are functionally compatible with all standard forms of

L3

three phase AC lines:

L2

L1

TB1 High Power AC Units Power Connection

Grounded neutral WYE

Open-Delta Grounded Leg

TEE

It is the customer’s responsibility to supply appropriate fuses or circuit

NOTE

31 S200 Position Node Installation Guide

breakers in the TB1 AC drive power lines to comply with local electrical codes.

Page 34

Connector Pinout And Descriptions 4/13/2012 Kollmorgen

For maximum line droop tolerance connect logic power to 230Vac

NOTE

WARNING

WARNING

WARNING

instead of 115Vac

After powering down the drive, monitor the BUS voltage by

connecting a meter from TB1-7 (+BUS) to TB1-6 (-BUS) to verify

the internal BUS capacitors have discharged prior to working on

the drive.

The Regen input is not short circuit protected. The Regen

Resistance MUST be within specified ranges to prevent damage to

the drive. 15 Ohms minimum resistance for the S21260-xNS.

Selected Regen Resistor must be able to handle constant 390Vdc

connection without risk of fire or must otherwise be thermally

protected with an overload device.

WARNING

Do not apply power or operate unit without the terminal block cover in

place.

Recommended Mating Connectors:

Spring Fork Lugs or M4 or #8 screws

Hollingsworth SS20948SF

Molex 19099-032

Or Equivalent

32 S200 Position Node Installation Guide

Page 35

Connector Pinout And Descriptions 4/13/2012 Kollmorgen

7.5 J1 – DC INPUT POWER MODELS DRIVE POWER CONNECTOR

The S200 DC input drives should be powered from power supplies with reinforced isolation.

On DC input drives, J1 is a 3 pin plugable connector.

3

1

CAUTION

NOTE

(J1 Connector view from front of drive).

J1: DC Units Control Power

Pin Description

J1-1 + CNTL (Logic Input Power 10-90Vdc less than 8 watts)

J1-2 BUS / CNTL GND (Logic and Bus Return)

J1-3 + DC BUS Input Power (20 to 90Vdcc)

Please refer to the Specifications section for fusing and rating information.

To avoid damage to the connector and drive, NEVER plug or unplug J1 with

power applied.

Refer to the DC Power Supply Requirements section for detailed

requirements selecting a compatible power supply.

Mating Connector Information

Screw Terminal Connector

12 – 24 AWG Wire Range, Phoenix MSTB2,5/3-STF-5,08-BK

OR Spring Cage Clamp Connector

12 – 24 AWG Wire Range, Phoenix FKC 2,5/3-SFT-5,08-BK

OR Crimp Connector

Crimp Shell: 14-20 AWG Wire Range, Phoenix MSTBC 2,5/3-STZF-5,08-BK

Crimp Contact: 14-16 AWG Wire Range, Phoenix MSTBC-MT 1,5-2,5

Crimp Contact: 18-20 AWG Wire Range, Phoenix MSTBC-MT 0,5-1,0

Refer to www.phoenixcon.com.

33 S200 Position Node Installation Guide

Page 36

Connector Pinout And Descriptions 4/13/2012 Kollmorgen

7.6 J2 – MOTOR POWER CONNECTOR

Applicable Models: All except S21260-xNS (See TB1, above for this model).

1

4

Pin Description

J2-1 PE (Chassis Ground) on S200 AC Input Drives

BUS/CTRL GND on S200 DC Input Drives

Intended for motor ground and motor cable shield connection.

J2-2 Motor Phase W Output

J2-3 Motor Phase V Output

J2-4 Motor Phase U Output

Please refer to the product specifications section for appropriate wire sizing information.

Mating Connector Information

Screw Terminal Connector: 12 – 24 AWG Wire Range, Phoenix MSTB2,5/4-STF-5,08-BK

OR

Spring Cage Clamp Connector: 12 – 24 AWG Wire Range, Phoenix FKC 2,5/4-SFT-5,08BK

OR

Crimp Connector

Crimp Shell: 14-20 AWG Wire Range, Phoenix MSTBC 2,5/4-STZF-5,08-BK

Crimp Contact: 14-16 AWG Wire Range, Phoenix MSTBC-MT 1,5-2,5

Crimp Contact: 18-20 AWG Wire Range, Phoenix MSTBC-MT 0,5-1,0

Refer to www.phoenixcon.com

(J2 Connector view from front of drive).

7.7 J3 – SFD FEEDBACK CONNECTOR

J3 is a 6-pin plugable IEEE 1394 style connector for the feedback device. Although this connector

mechanically accepts standard IEEE 1394 cables, it is electrically not an IEEE 1394 interface. The base

drive accepts either SFD (Smart Feedback Device) or Hall inputs.

Pins Description

12

34

56

(J3 Connector view from front of drive)

Mating Connector Information

IEEE1394, Firewire type, 2.0 mm plug set

22 AWG Max., Molex 55100-0600

Refer to www.molex.com for assembly instructions.

J3-1 +5 V Supply (200 mA) from drive

J3-2 +5 RTN 5V common

J3-3 SFD Communications -

J3-4 SFD Communications +

J3-5 NC

J3-6 NC

Shell Shield Connection

34 S200 Position Node Installation Guide

Page 37

Connector Pinout And Descriptions 4/13/2012 Kollmorgen

A

7.8 J4 – COMMAND I/O CONNECTOR

J4 is a 26-Position High Density D subminiature female connector.

9

18

26

19

1

10

(J4 Connector view from front of drive.)

Pin Description Pin Description

J4-1 DINP COM J4-14 DAC MON1

J4-2 DINP1 (Enable) J4-15 DAC MON2

J4-3 DINP2 J4-16 I/O RTN

J4-4 DINP3 J4-17 Encoder Output Channel Z

J4-5 DINP4 J4-18

Encoder Output Channel

J4-6 DOUT1- J4-19 Channel A Encoder Output

J4-7 DOUT1+ (Fault) J4-20

J4-8 DOUT2- J4-21 Channel B Encoder Output

J4-9 DOUT2+ (RUN) J4-22

J4-10 DINP 5+ J4-23 I/O RTN

J4-11 DIP5 – J4-24 Analog Command Input +

J4-12 Reserved J4-25 Analog Command Input -

J4-13 I/O RTN J4-26 I/O RTN

Channel

Encoder Output

Channel

B

Encoder Output

See Specifications Section for ratings and Wiring Information for wiring details.

Mating Connector Information

26-Pin Male High Density D-Sub with Back shell Kit

24 AWG Max., NorComp 180-026-102-001 – D-Sub Connector

NorComp 978-015-010-03-1 – Back shell Kit

Refer to www.norcomp.net.

Z

35 S200 Position Node Installation Guide

Page 38

Connector Pinout And Descriptions 4/13/2012 Kollmorgen

7.9 J5: SERIAL PORT CONNECTIONS

The S200 Position Node serial port is wired to connector J5 using RS232 physical layer protocol.

Pin Function

1 NC

2 Drive Receive RS232 Data

3 DC Common

4 DC Common

5 Drive Transmit RS232 Data

6 NC

Mating Connector Information

Standard RJ11 cord

Or Plug Example AMP 5-555426-3

1 6

J5 RS232 Serial Port Connections

7.10 J11 CAN BUS CONNECTIONS

J11 is a five-pin plugable connector to the CAN physical layer and is compliant with CANOpen

and the DeviceNet specification (less color code requirements).

Mating Connector

PHOENIX MSTB 2,5/ 5-STF-5,08 AU

Or Equivalent

Pin Description DeviceNet Color

J11-1 V-: Power of CAN Bus Black

J11-2 CAN_L: Comm Low Blue

J11-3 Shield Bare

J11-4 CAN_H: Comm High White

J11-5 V+: Power of CAN bus Red

15

36 S200 Position Node Installation Guide

Page 39

Connector Pinout And Descriptions 4/13/2012 Kollmorgen

7.11 J12 CONNECTOR

J12, Option Card General Purpose I/O is a 15-Position High Density D subminiature male

(plug) connector. 5 User-configurable discrete inputs, one user-configurable output, and

encoder (or step and direction) input channels are provided on this 15 Pin High Density D

socket connector. Detailed electrical information is given elsewhere in this document.

15 11

15

J12 Connector Pin Out

Pin Name Description

J12-1 DINP COM

J12-2 DINP6

J12-3 DINP7

J12-4 DINP8

J12-5 DINP9

J12-6 DOUT3 -

J12-7 DOUT3 +

J12-8 DINP10 - Digital Input 10 Cathode 5V nominal operation

J12-9 DINP10 + Digital Input 10 Anode: 5V Nominal operation

J12-10 +5VDC 5V Source from drive. Not to exceed 150mA

J12-11 I/O RTN 5V Common, Common for CMD Channels

J12-12 CMD CH A+ Gearing Input Channel A

J12-13 CMD CH A- Gearing Input Channel /A

J12-14 CMD CH B+ Gearing Input Channel B

J12-15 CMD CH B- Gearing Input Channel /B

Shell PE Shield Earth Connection for 360 Bond

Mating Connector Information

Solder cup, Metalized Shell

Mating Hood/Shell: Metalized

Common rail for DINP6-9

Digital Input 6 +/- 4 to 30V DC Operation

Digital Input 7 +/- 4 to 30V DC Operation

Digital Input 8 +/- 4 to 30V DC Operation

Digital Input 9 +/- 4 to 30V DC Operation

DOUT 3 Opto Isolator Emitter

DOUT3 Opto Isolator Collector

Norcomp 180-015-202-001 (or Equivalent)

Adam Tech DE09-HD-PN-SS (or Equivalent)

37 S200 Position Node Installation Guide

Page 40

Connector Pinout And Descriptions 4/13/2012 Kollmorgen

7.12 J13 ENCODER FEEDBACK CONNECTOR

J13, Option Card Optional Encoder Feedback is a 15-Position High Density D subminiature female (socket)

connector. Connector pin out is described below with more detailed electrical information is given elsewhere in

this document.

1511

15

J13 Connector Pin Out

Pin Name Description

J13-1 CU

J13-2 CV

J13-3 CW

J13-4 NC

J13-5 I/O RET

J13-6 Ch Z+

J13-7 CH ZJ13-8 PTC Motor Thermostat

J13-9 I/O RET

J13-10 5VDC

J13-11 I/O RET

J13-12 CH A+

J13-13 CH AJ13-14 CH B+

J13-15 CH BShell PE

Encoder system wiring and operation can require detailed information. Not all encoder manufactures or motors

that contain encoders are all wired to the same conventions. Detailed information is provided later in this manual.

Mating Connector Information

Solder cup, Metalized Shell

Adam Tech HDT-15-PD-RC (or Equivalent)

Mating Hood/Shell: Metalized

Adam Tech DE09-HD-PN-SS (or Equivalent)

Commutation track U (Hall U) Sourcing Input

Commutation track V (Hall V) Sourcing Input

Commutation track W (Hall W) Sourcing Input

No Connection

5V Common

Encoder Z Channel Input (Marker, Index) Diff High

Encoder /Z Channel Input (Marker, Index) Diff Low

Motor Thermostat Return to 5V Common

5V Encoder Source, 200mA max

5V Common

Encoder Channel A Input Differential High

Encoder Channel /A Input Differential Low

Encoder Channel B Input Differential High

Encoder Channel /B Input Differential Low

Shield Earth Connection for 360 Bond

38 S200 Position Node Installation Guide

Page 41

Kollmorgen 4/13/2012 DC Input Power Model Power Supply Requirements

8.0 DC INPUT POWER MODEL POWER SUPPLY

REQUIREMENTS

Applicable Models: S20330-xNS, S20630-xNS

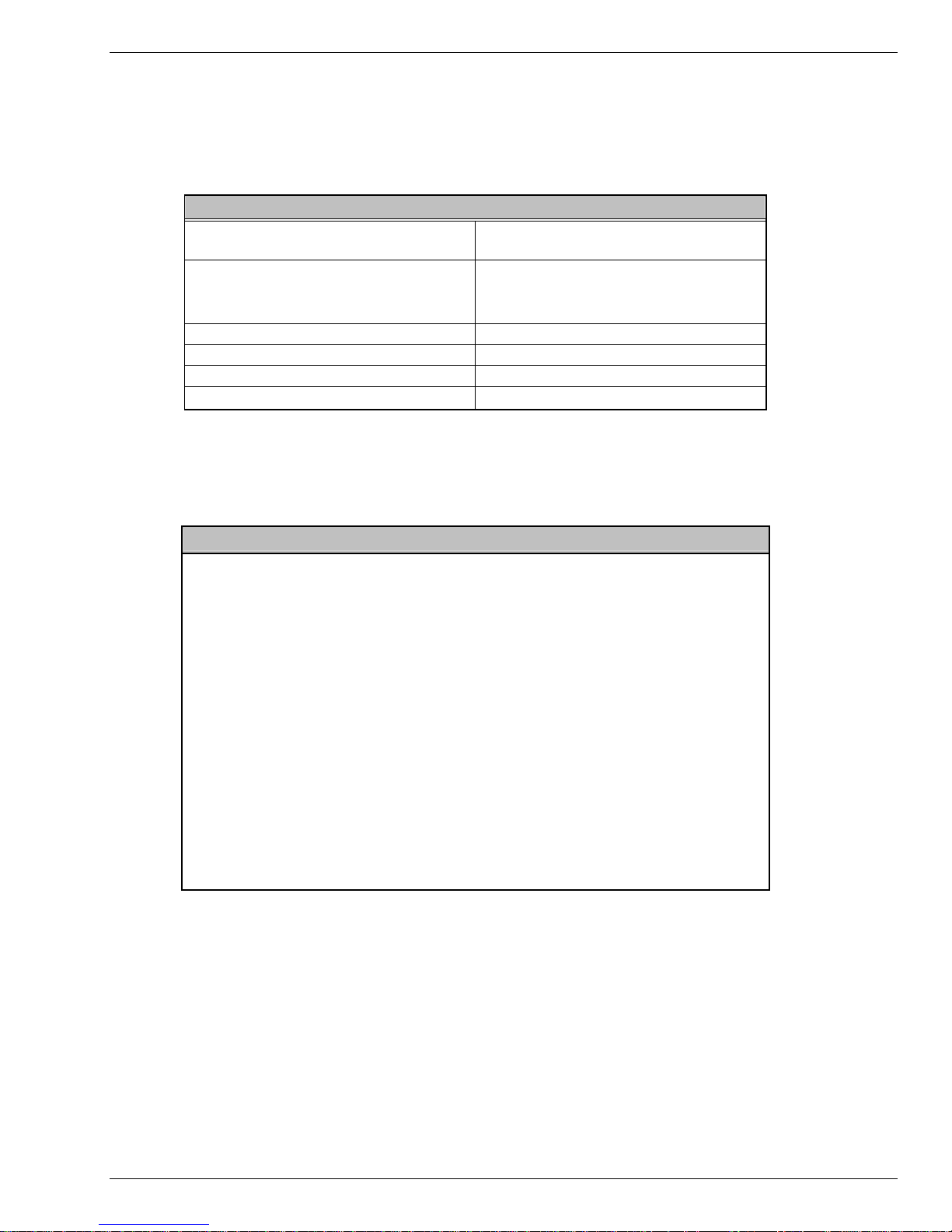

DC Unit Bus Input Power Specifications

Bus Voltage (J1-3 to J1-2) + 20 VDC to + 90 VDC

BUS Supply Current 48 VDC BUS 75 VDC BUS

S20330 Continuous 3.3 ADC at 160 W 3.3 ADC at 250 W

Peak (3 sec) 10 ADC at 480 W 10 ADC at 750 W

S20630 Continuous 6.7 ADC at 320 W 6.7 ADC at 500 W

Peak (3 sec) 20 ADC at 960 W 20 ADC at 3,000 W

BUS Output Capacitance

(min)

S20330-xNS

S20630-xNS

48 VDC BUS 75 VDC BUS

4,000 µf, 63 V 2,000 µf, 100 V

8,000 µf, 63 V 4,000 µf, 100 V

Bus Supply

Characteristics

Wiring from BUS

Supply to Drive

Control Voltage

(J1-1 to J1-2)

Control Supply

Type

Control Supply

Wiring

The BUS Supply should have the following characteristics:

Must provide safety isolation from the power line

Can be regulated or unregulated

Bus Supply Return is connected to the Control Supply Return and I/O

RTN in the drive

Typical BUS Supply:

Unregulated, Isolating, step down transformer with secondary rectified

into capacitive filter

BUS Supply Return is connected to earth ground

10 ft maximum

16 AWG (minimum)

Twisted pair

Daisy chaining of multiple drives is acceptable

No contactor or switching in the BUS wiring

+ 10 VDC to +90 VDC

Isolating

Unregulated or Regulated

Common GND with bus supply and I/O RTN

20 watt supply or 1 amp short circuit

Wire control (J1-1) to bus (J1-3)

or

Wire control (J1-1) to separate supply to preserve status and fault

information. (+ 10 VDC to + 30 VDC supply can be shared by Control

and I/O)

S200 Position Node Installation Guide 39

Page 42

DC Input Power Model Power Supply Requirements 4/13/2012 Kollmorgen

Control Supply

Current

Bus Voltage

20 to 110 mA at 75 VDC

60 to 330 mA at 24 VDC

125 to 660 mA at 12 VDC

Bus voltage outside the operating range (20 to 90 V) causes an undervoltage or over-voltage fault. Under-voltage and over-voltage faults self

clear when the fault condition clears.

Do Not allow the Bus Voltage to exceed

+ 90 VDC. This causes damage to the

NOTE

drive.

Target design center voltage for unregulated supply is + 70 to + 75 VDC.

This provides 15 to 20 VDC margin for line tolerance, transformer

regulation, and regen pump up. Design center voltage for a regulated

supply can be up to + 80 VDC.

8.1 CONTROL VOLTAGE

The control voltage range for normal operation is + 10 VDC to + 90 VDC. The control voltage

can either be wired to the bus voltage so one supply can power the drive, or from a separate

supply. Separately powering the control from the bus allows the bus to be powered down for

safety while drive status and fault information remain available. A single + 10 VDC to + 30 VDC

supply can be shared by Control and I/O.

NOTE

8.2 GROUNDING

Provide safety isolation with the external bus and control supplies from the power line.

NOTE

The Ctrl and Bus voltages and non-opto coupled I/O grounds (I/O RTN) are tied together

inside the drive. The Ctrl and Bus power supplies share a ground pin (Bus/Ctrl Gnd). Join and

connect to the negative terminals of the Ctrl and Bus power supplies. The I/O RTNs are

normally connected to the signal ground of the system. (Some of the I/O is opto coupled and

have separate returns. Thoroughly review this document for details.)

Earth the power supply negative terminal somewhere in the cabinet. Also earth the chassis. In

normal operation, there should be no significant voltage between earth and the Bus/Ctrl Gnd

and I/O RTNs.

NOTE

Do Not allow the Control Voltage to exceed + 90 VDC as it can damage the

drive.

The drive cannot be powered from an electrically Hot supply as it does not

contain an isolation barrier.

The maximum voltage allowed between Bus/Ctrl Gnd and chassis is 100

VDC.

8.3 BUS CAPACITANCE

There is a minimum requirement on the output capacitance of the bus power supply for the DC

input S200. This capacitor is needed to absorb energy during motor deceleration and motor