Page 1

RGM

®

User Manual

Edition: B, February 2019

Part Number:903-800006-00

Original Documentation

For safe and proper use, follow these instructions.

Keep them for future reference.

Page 2

RGM User Manual |

Record of Document Revisions

Revision Remarks

A, 10/2017 Launch version

B, 6/2018 RGM-C

Trademarks

l EtherCAT is a registered trademark and patented technology, licensed by Beckhoff Automation

GmbH

l Windows is a registered trademark of Microsoft Corporation

Current patents

l US Patent 8,154,228 (Dynamic Braking For Electric Motors)

l US Patent 8,214,063 (Auto-tune of a Control System Based on Frequency Response)

Patents referring to fieldbus functions are listed in the matching fieldbus manual.

Technical changes which improve the performance of the device may be made without prior notice!

Printed in the United States of America

This document is the intellectual property of Kollmorgen. All rights reserved. No part of this work may be

reproduced in any form (by photocopying, microfilm or any other method) or stored, processed, copied or

distributed by electronic means without the written permission of Kollmorgen.

Kollmorgen | kdn.Kollmorgen.com | February 2019 2

Page 3

RGM User Manual |

This page intentionally left blank.

3 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 4

RGM User Manual | 1 Table of Contents

1 Table of Contents

1 Table of Contents 4

2 Introduction to RGM 5

2.1 General 6

2.1.1 About this manual 6

2.2 Safety 7

2.2.1 You should pay attention to this 7

2.3 Package 7

2.3.1 Delivery Package 7

2.4 Important Brake Usage Guidelines 8

3 Power Supply Voltage & Current Ratings 9

4 Maximum Speed 10

5 Torque Ratings 11

6 Duty Cycle 12

7 Rotation Limits 13

8 Accuracy & Repeatability 14

9 Maximum Thermal Ratings 15

10 Monitoring Thermistor 16

11 Brake Function & Manually Releasing the Brake 17

11.1 About the Brake Function 17

11.2 Manually Releasing the Brake 17

12 Bolting Joint-to-Joint, Mounting Screws 19

13 Environmental Requirements 20

14 IP Rating 21

15 Joint-to-Joint Plastic Rings & Rubber Bands 22

16 Rear Cover Removal & Daisy Chain Connections 24

17 Daisy Chain Wire Sizes, Colors, and Functions 27

18 RGM Workbench Software & Drive Commissioning 28

19 Serial Cable Part Number 29

20 CANopen Termination 30

21 Brake Initialization 31

21.1 RGM Enable/ Brake Initialization Procedure 31

22 Regeneration Warning 32

23 End Effectors 33

24 Board Layout 34

24.1 CANopen 34

24.2 EtherCAT 35

25 Data Sheets 36

25.1 RGM14 37

25.2 RGM17 38

25.3 RGM20 39

25.4 RGM25 40

26 Index 41

Kollmorgen | kdn.Kollmorgen.com | February 2019 4

Page 5

RGM User Manual | 2 Introduction to RGM

2 Introduction to RGM

2.1 General 6

2.1.1 About this manual 6

2.2 Safety 7

2.2.1 You should pay attention to this 7

2.3 Package 7

2.3.1 Delivery Package 7

2.4 Important Brake Usage Guidelines 8

5 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 6

RGM User Manual | 2 Introduction to RGM

2.1 General

2.1.1 About this manual

This manual describes the RGM robotic joint modules. Each RGM combines a frameless torque motor, low

voltage DC drive, brake, strain wave gear, dual feedback system, and a thermal sensor in a single joint

assembly to be used in a robot configuration. Please review the entire manual which includes information on:

l Power

l Speed and Torque Ratings

l Duty Cycle

l Rotation Limits

l Thermal Ratings and Monitoring Thermistor

l Brake Function

l Installation and Mounting

l Rear Cover Removal and Daisy Chaining

l Wiring

l RGMEWV

l CANopen

l End Effectors

Kollmorgen | kdn.Kollmorgen.com | February 2019 6

Page 7

RGM User Manual | 2 Introduction to RGM

2.2 Safety

This section helps you to recognize and avoid dangers to people and objects.

2.2.1 You should pay attention to this

Specialist staff required!

Only properly qualified personnel are permitted to perform such tasks as transport, assembly, setup and

maintenance. Qualified specialist staff are persons who are familiar with the transport, installation, assembly,

commissioning and operation of motors and who bring their relevant minimum qualifications to bear on their

duties:

l Transport: only by personnel with knowledge of handling electrostatically sensitive components.

l Mechanical Installation: only by mechanically qualified personnel.

l Electrical Installation: only by electrically qualified personnel.

l Setup: only by qualified personnel with extensive knowledge of electrical engineering and drive tech-

nology

The qualified personnel must know and observe IEC 60364 / IEC 60664 and national accident prevention

regulations.

Read the documentation!

Read the available documentation before installation and commissioning. Improper handling of the motor can

cause harm to people or damage to property. The operator must therefore ensure that all persons entrusted to

work on the motor have read and understood the manual and that the safety notices in this manual are

observed.

Pay attention to the technical data!

Adhere to the technical data and the specifications on connection conditions (rating plate and documentation).

If permissible voltage values or current values are exceeded, the motors can be damaged, for example by

overheating.

Perform a risk assessment!

The manufacturer of the machine must generate a risk assessment for the machine, and take appropriate

measures to ensure that unforeseen movements cannot cause injury or damage to any person or property.

Additional requirements on specialist staff may also result from the risk assessment.

Transport safely!

Lift and move motors with more than 20 kg weight only with lifting tools. Lifting unassisted could result in back

injury.

Hot surface!

The surfaces of the motors can be very hot in operation, according to their protection category. Risk of minor

burns! The surface temperature can exceed 100°C. Measure the temperature, and wait until the motor has

cooled down below 40°C before touching it.

2.3 Package

2.3.1 Delivery Package

l Joint from the RGM series

l Thermal precaution instructions

7 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 8

RGM User Manual | 2 Introduction to RGM

2.4 Important Brake Usage Guidelines

The RGM brake is designed for use as a static holding brake (park brake) only. It is not intended to be used

as a dynamic brake or to be suddenly engaged while the RGM is moving. Permanent damage to brake

assembly components may occur if brake is engaged while still in motion.

During controller and application software development, software bugs may cause trajectory errors or other

types of errors. These errors may trigger unexpected events that cause the drive to fault and disable,

suddenly engaging the brake while RGM is in motion. To avoid accidental damage, it is recommended during

development activities that users configure the fault event actions using RGM Workbench to “NONE” or set

the range where the event is triggered to a value that is well outside normal operation. Fault event actions can

be reset to operational values after the development process is complete and the risk of accidental brake

damage is minimized.

The user must determine whether the loss of functionality and lack of fault monitoring to protect the brake

during development activities warrants the risk of increasing operational and safety concerns.

For assistance in disabling fault events, please contact Kollmorgen Applications Engineering.

Kollmorgen | kdn.Kollmorgen.com | February 2019 8

Page 9

RGM User Manual | 3 Power Supply Voltage & Current Ratings

3 Power Supply Voltage & Current Ratings

RGM requires 48 VDC nominal supply voltage (44 VDC minimum, 52 VDC maximum). The RGM drive will

experience an Overvoltage fault at 55VDC. Kollmorgen recommends that an electrolytic capacitor with at

least 15,000 microfarads capacitance be installed between the DC power supply and the first joint. It is also

recommended that the power supply be capable of handling a regenerative load (i.e., a regen resistor in the

supply is turned on if the DC bus exceeds 52VDC). As a reference, for a 6 axis (6 DOF) robot, a switching DC

supply with approximately 12 Amps (600W) capacity is suggested.

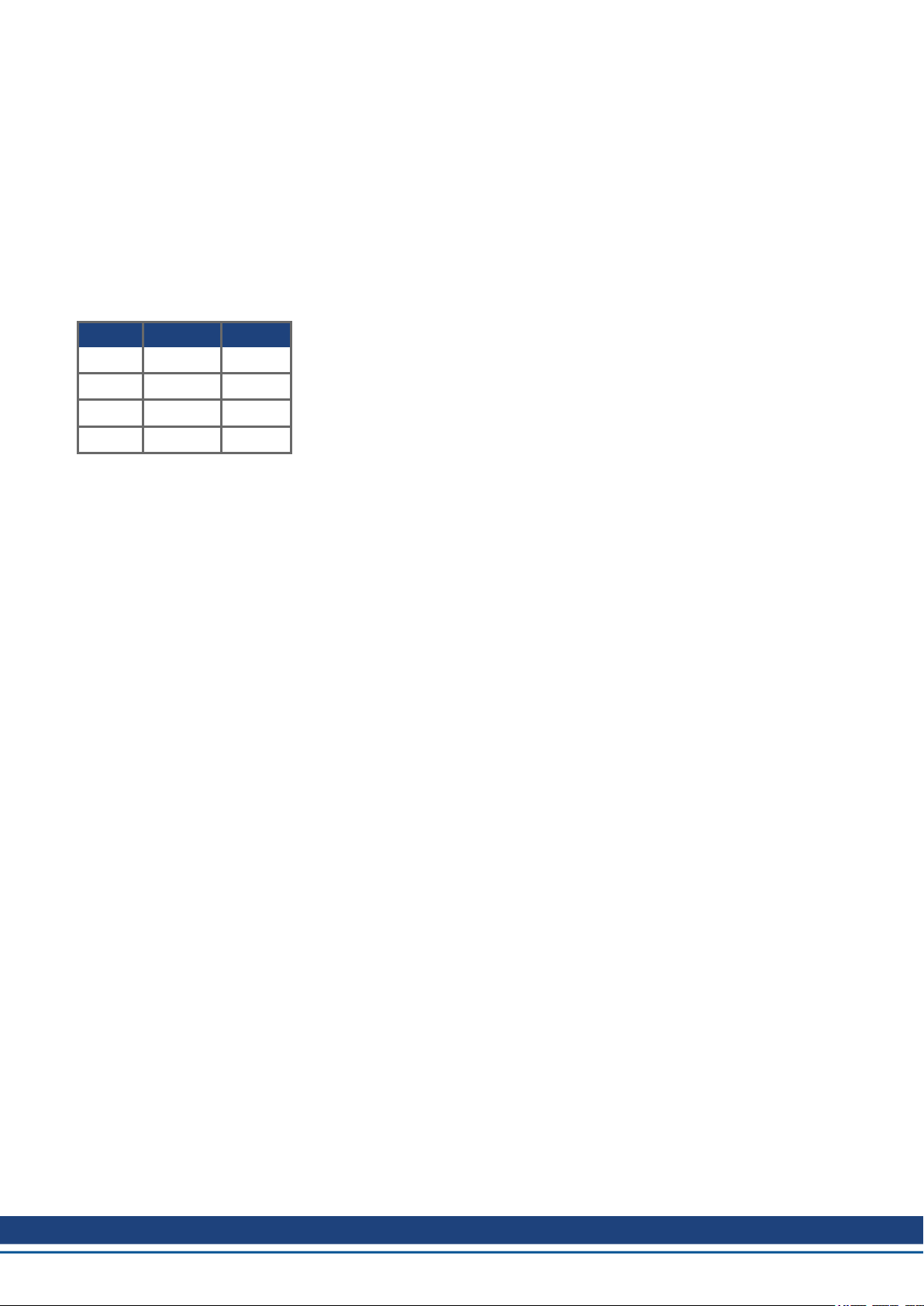

Although the table below shows currents that individual joint may draw momentarily, not all joints will draw

these values simultaneously during typical robot motions. Therefore, it is not necessary to add all values in

the table. Kollmorgen testing has shown that a 12A supply should be sufficient.

Model VDC Is Amps

RGM 14 48 +/-10% 3.80

RGM17 48 +/-10% 4.88

RGM 20 48 +/-10% 7.50

RGM 25 48 +/-10% 10.0

9 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 10

RGM User Manual | 4 Maximum Speed

4 Maximum Speed

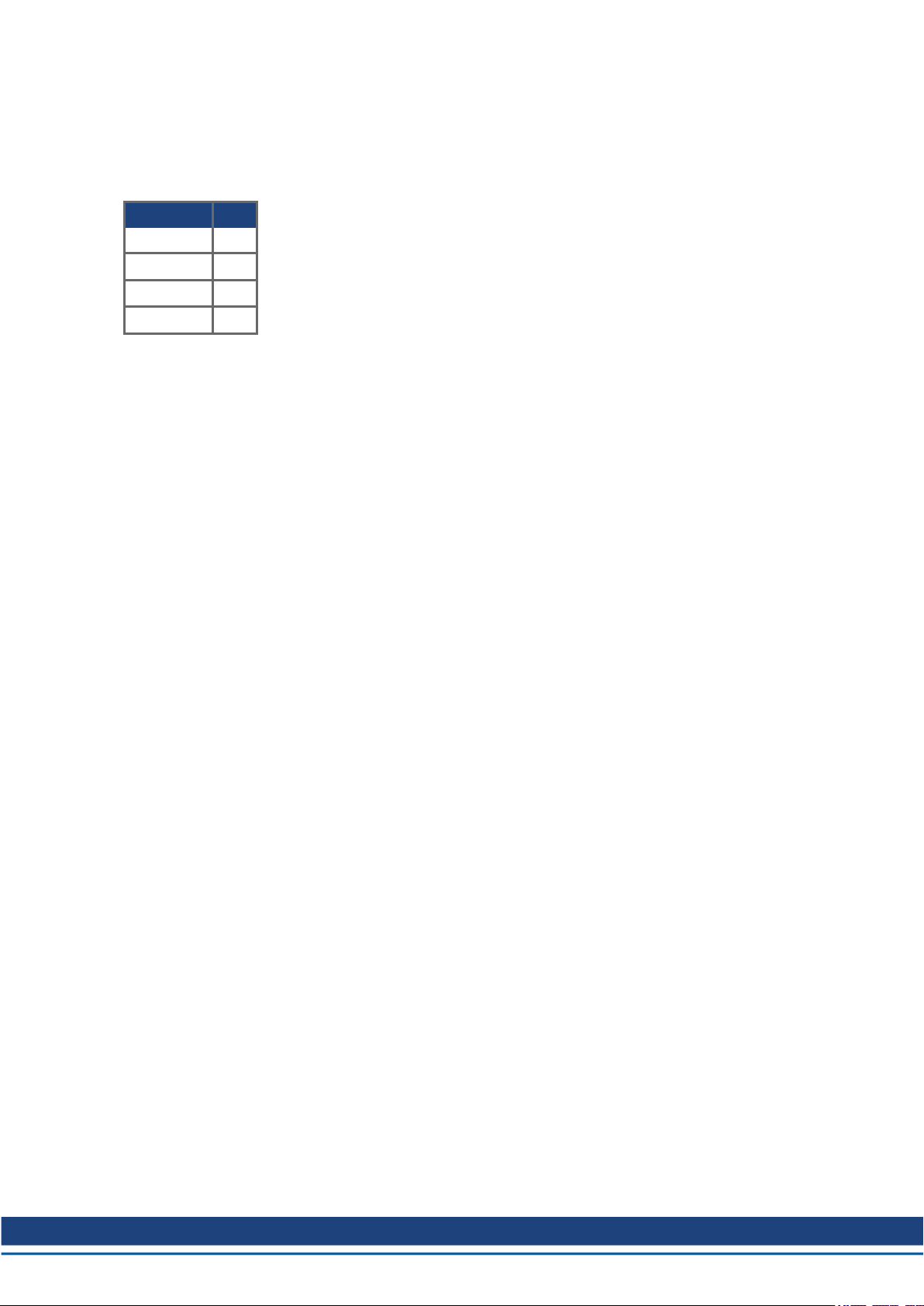

Maximum intermittent speed capability for each RGM size is listed in the table below. See Duty Cycle to

determine RMS continuous speed and continuous torque capability based on the joint duty cycle percentage

in the intended application.

Max Speed RPM

RGM14 35

RGM17 30

RGM20 25

RGM25 20

Kollmorgen | kdn.Kollmorgen.com | February 2019 10

Page 11

RGM User Manual | 5 Torque Ratings

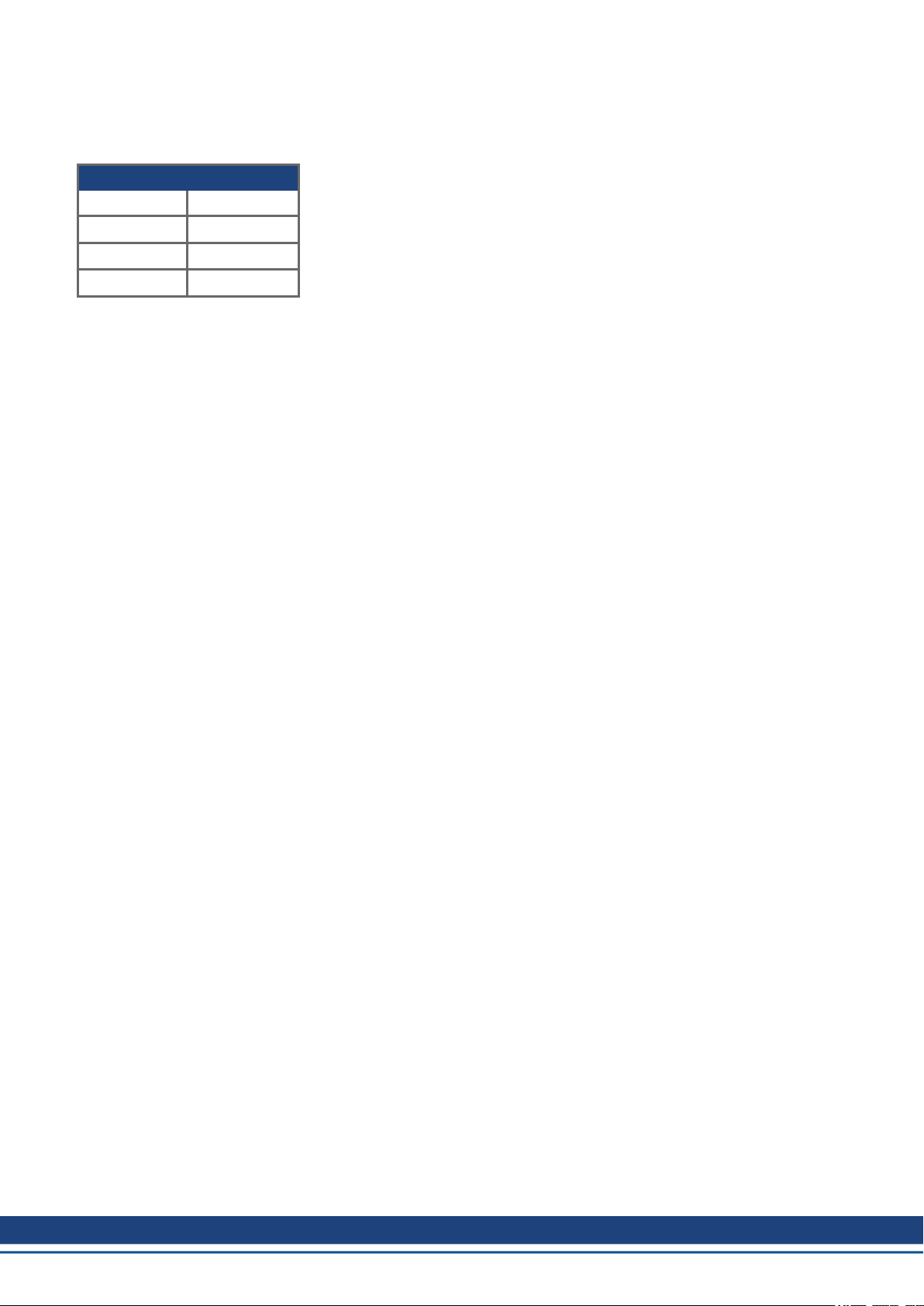

5 Torque Ratings

Maximum instantaneous (acceleration) torque capability for each RGM size is listed in the table below.

Max Intermittent Torque (Nm)

RGM14 34

RGM17 66

RGM20 102

RGM25 194

11 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 12

RGM User Manual | 6 Duty Cycle

6 Duty Cycle

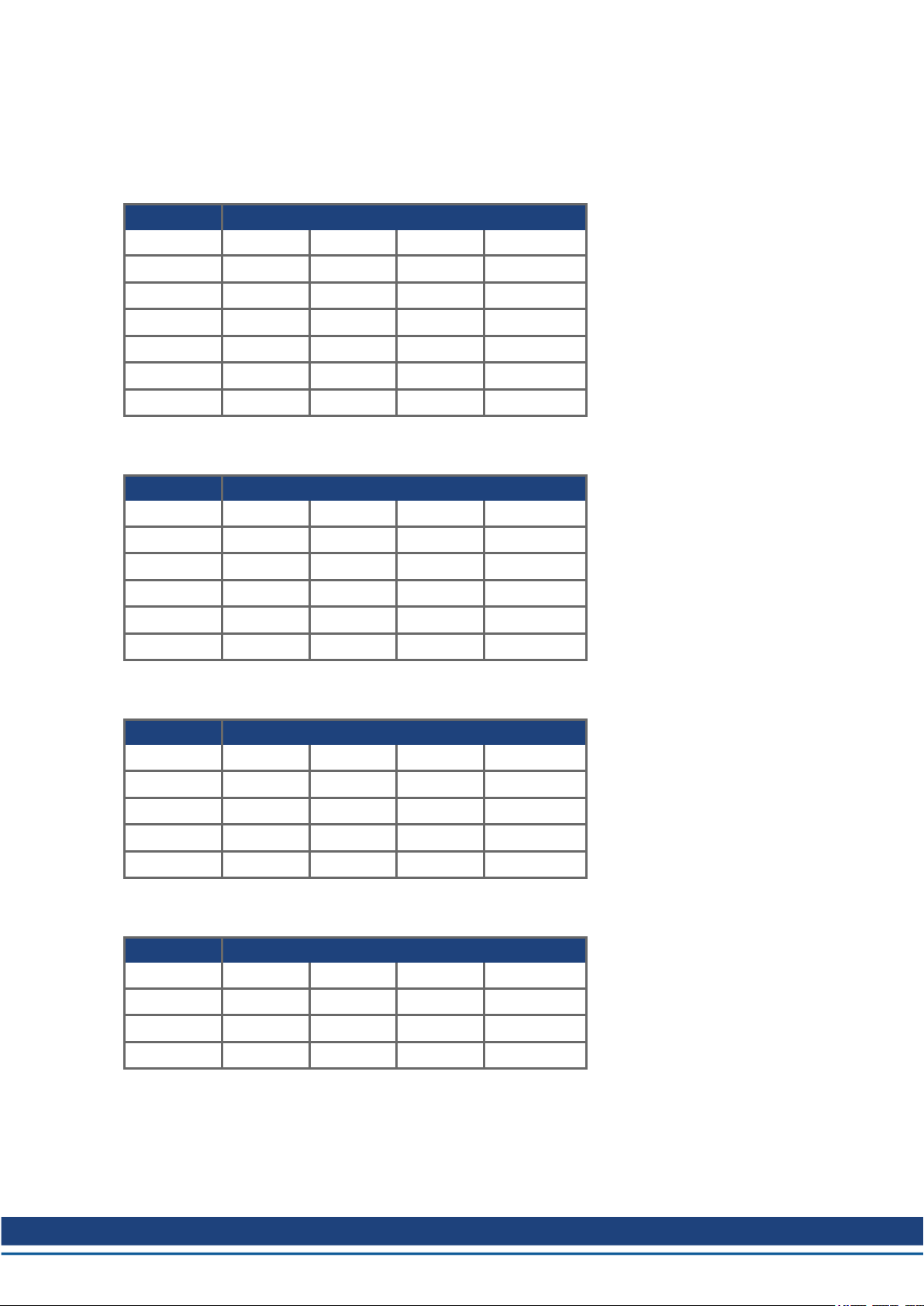

See tables below for continuous torque capability at rotational speed based on size of RGM joint and duty

cycle percentage (%).

RGM14 - Continuous Torque Capability (Nm)

负 载 周期

RPM 25% 50% 75% 100%

5 13.5 13.5 13.5 13.5

10 13.5 13.5 13.5 13.5

15 13.5 13.5 13.5 13.5

20 13.5 13.5 13.5 13.5

25 13.5 13.5 11.1 9.6

30 0.5 .035 0.29 0.25

RGM17 - Continuous Torque Capability (Nm)

负 载 周期

RPM 25% 50% 75% 100%

5 49 49 49 49

10 49 49 49 44

15 49 49 45.5 40

20 49 49 40.9 35.4

25 47 42.7 34.9 30.2

RGM20 - Continuous Torque Capability (Nm)

负 载 周期

RPM 25% 50% 75% 100%

5 61 61 61 60.7

10 61 61 61 56.4

15 61 61 60.3 52.2

20 61 57 49.4 42.8

RGM25 - Continuous Torque Capability (Nm)

负 载 周期

RPM 25% 50% 75% 100%

5 133 133 128 111

10 133 118 96.6 83.7

15 79.8 56.4 46.1 39.9

Kollmorgen | kdn.Kollmorgen.com | February 2019 12

Page 13

RGM User Manual | 7 Rotation Limits

7 Rotation Limits

RGMunits may be rotated continuously in either direction when used as a single axis. However, when

assembled into a robot with multiple axes/degrees of freedom and the "daisy chain" wiring in the center of the

output plate is used to connect joint-to-joint or joint-to-arm, the maximum rotation in either direction is +/- 360°

mechanical. If this angular limit is exceeded, connecting wires may be damaged and the warranty will be

voided.

13 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 14

RGM User Manual | 8 Accuracy & Repeatability

8 Accuracy & Repeatability

Accuracy of RGM output plate absolute encoder is 0.1° mechanical. Repeatability is 0.001° mechanical.

Kollmorgen | kdn.Kollmorgen.com | February 2019 14

Page 15

RGM User Manual | 9 Maximum Thermal Ratings

9 Maximum Thermal Ratings

The harmonic gearing used in RGM is the most thermally sensitive component in the assembly. It is

restricted to a maximum case temperature of 50°C. Users are advised that when operating RGM in

ambient temperatures higher than the standard rated temperature of 22°C, de-rated torque/speed performance

should be expected and duty cycles should be adjusted lower than shown in Duty Cycle to prevent exceeding

50°C case temperature of the gearing. Otherwise, grease may be degraded and premature failure of the

gearing may occur. If RGM is used outside the recommended thermal rating of the gearing, RGM warranty

may be voided. RGM is equipped with an internal linear thermistor on the gearing case to assist customers

with proper thermal and duty cycle management, so that maximum performance and longest life of RGM can

be achieved.

15 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 16

RGM User Manual | 10 Monitoring Thermistor

10 Monitoring Thermistor

The thermistor in RGM is connected to the drive electronics PCB printed circuit board) inside the rear cover.

When the user’s computer/controller is communicating with RGM via the serial port or CANopen

communication bus drive analog input 4 is the gear case (50°C max rating) thermistor. It is the user’s

responsibility to include provisions in the control system to monitor the thermistor at frequent intervals and

take actions such as reducing speed of motion or reducing duty cycle to keep gear case temperature within

rated limits.

Thermistor CID Sub Index Data

Gear 2206h 0 C° 16-bit

Kollmorgen | kdn.Kollmorgen.com | February 2019 16

Page 17

RGM User Manual | 11 Brake Function & Manually Releasing the Brake

11 Brake Function & Manually Releasing the Brake

Please be sure to review "Important Brake Usage Guidelines" (➜ p. 8)

11.1 About the Brake Function

RGM is equipped with a power-off park brake, meaning that the brake is mechanically engaged and prevents

rotation (within its inherent +/- 0.9° backlash characteristic) of the output plate when no power is applied. In

normal operation, when the RGM drive is enabled by the user’s controller, the energized brake coil will

release, accompanied by an audible "click". Normal motion commands may be performed after the brake

releases. In the same manner, when the RGM drive is disabled by the user’s controller, power is removed

from the coil and the brake will mechanically engage with an audible "click".

11.2 Manually Releasing the Brake

If the user needs to manually rotate the output plate of the RGM unit when no power is available to electrically

release the brake, it is possible to manually release it. Remove the 3 screws and the blue rear cover as shown

in Figure 1: Removing the Rear Cover of an RGM.

Figure 1: Removing the Rear Cover of an RGM.

Using a thin diameter tool, push downward on the brake release button to compress the spring below it (see

"Push to release the RGM's brake." (➜ p. 18)). As long as the button is held downward to keep the spring

compressed, the user may manually rotate the unit to desired position.

17 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 18

RGM User Manual | 11 Brake Function & Manually Releasing the Brake

Figure 2: Push to release the RGM's brake.

Kollmorgen | kdn.Kollmorgen.com | February 2019 18

Page 19

RGM User Manual | 12 Bolting Joint-to-Joint, Mounting Screws

12 Bolting Joint-to-Joint, Mounting Screws

When assembling multiple RGM units together in a joint-to-joint configuration or adding an arm to the output

plate of an RGM, the required screw sizes and tightening torque values are listed in the table below. Class

12.9 steel socket head cap screws are suggested, with a corrosion resistant coating such as Zinc. Stainless

steel screws are not recommended due to their reduced strength.

RGM Mounting Screws

Model Fastener Size Torque (Nm)

RGM14 M3 x 8mm long SHCS 1.81

RGM17 M3 x 6mm long SHCS 1.81

RGM20 M3 x 8mm long SHCS 1.81

RGM25 M4 x 10mm long SHCS 4.29

The application of removable thread locking adhesive to all screws is recommended.

19 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 20

RGM User Manual | 13 Environmental Requirements

13 Environmental Requirements

Normal performance ratings for RGM may be achieved in a room ambient temperature of 22°C. RGM may be

used in ambient temperatures up to 40°C with de-rated performance and duty cycle capabilities. In such

cases, it will be necessary to monitor the thermistor and adjust the motion cycle accordingly to protect the

gearing. RGM is designed for stationary mounting in a general indoor industrial environment. RGM should not

be used in applications where excessive dust, high shock and vibration (vehicles, etc.), corrosive

substances, explosive materials or operation in a vacuum are required. See IP Rating for moisture resistance

and IP rating details. Consult factory for non-standard applications.

Kollmorgen | kdn.Kollmorgen.com | February 2019 20

Page 21

RGM User Manual | 14 IP Rating

14 IP Rating

RGM is designed to meet an IP54 rating (resistant to dust and splashing water) when properly installed using

the rear cover gaskets, cover screws with o-rings, plastic joint-to-joint seal rings and joint-to-joint flexible seal

bands (see Environmental Requirements), which are available for purchase from Kollmorgen as an accesory

(RGMXX Customer Parts Kit).. The customer has responsibility for assuring proper fit of the rings and bands

when assembled into the application and for properly installing and confirming a seal at the rear cover if it has

been removed. The customer’s hardware design must include proper sealing provisions (fit, o-ring, gasket,

etc.) at the RGM mounting flange to achieve IP54 compliance.

21 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 22

RGM User Manual | 15 Joint-to-Joint Plastic Rings & Rubber Bands

15 Joint-to-Joint Plastic Rings & Rubber Bands

For applications where multiple RGM units will be assembled together in a direct joint-to-joint configuration

and sealing (IP54 or lower) is desired, Kollmorgen offers an optional seal kit for the bolted joint (RGMXX

Customer Parts Kit). This kit includes mounting screws, a plastic sealing ring (see Figure 4) and a flexible

seal band (see Figure 5).

1. Before bolting the two RGM units together, place the flexible band over the housing behind the output

plate as shown in Figure 3.

Figure 3: Position the band at the start of the process.

2. Then place the plastic ring into the housing pilot at the output plate end as shown below in Figure 4.

Figure 4: Placing the plastic ring into the housing pilot.

3. Confirm that the plastic ring is pushed inward until it is flush with the housing as shown in Figure 5 ,

so it does not obstruct access to the threaded holes on the OD of the mounting plate.

Kollmorgen | kdn.Kollmorgen.com | February 2019 22

Page 23

RGM User Manual | 15 Joint-to-Joint Plastic Rings & Rubber Bands

Figure 5: Push the flexible seal band until flush with the housing plate.

4. After the two RGM units are bolted together and the screws are properly torqued (Figure 6 left), slide

the plastic ring outward so it covers the screws and touches the stationary flange of the second RGM

unit (Figure 6 right).

Figure 6: Units are bolted together (left), and the plastic ring is set to cover the screws (right).

5. Then move the flexible seal band so it holds the plastic ring in position (Figure 7).

Figure 7: Move the flexible seal band so it holds the plastic ring in place.

23 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 24

RGM User Manual | 16 Rear Cover Removal & Daisy Chain Connections

16 Rear Cover Removal & Daisy Chain Connections

RGM units are provided with 4 wires that pass through the center of the gear output plate to make it easy for

the user to “daisy chain” power and communication from one robot joint to the next. Red (+) and Black (-)

provide 48VDC supply to the next joint. The twisted pair with White (High) and Blue (Low) provide CANopen

communication to the next joint. When bolting two RGM assemblies together in a joint-to-joint configuration

(see section 10), great care must be taken to avoid damaging these wires.

1. Remove the 3 screws and blue rear cover as shown in Figure 8.

Figure 8: Remove the blue cover

2. Route the incoming wires through the upper access hole in the housing as shown in Figure 9. Care

must be taken to route them cleanly around the motor power wires that attach to the drive PCB in this

same area.

Figure 9: Routing wires between joints

3. As the two joints are gradually drawn together to reach their final bolting position, avoid slack and keep

constant tension on the wires to avoid pinching or mashing them. See Figure 10.

Kollmorgen | kdn.Kollmorgen.com | February 2019 24

Page 25

RGM User Manual | 16 Rear Cover Removal & Daisy Chain Connections

Figure 10: Keep wires tight to avoid pinching

4. Insert the red and black power wires with ferrules into the vertical poke-in connector shown in Figure

11. Note polarity on the PCB silkscreen, insert red into the “+” position and black into the “-“position.

For best results, be sure the smooth side of the crimped ferrule is facing the white spring side of the

connector slot when pushing it in. See Board Layout (➜ p. 34) for a diagram of the PCB.

Figure 11: Power and CANopen connections

5. After insertion, give the wires a light tug to confirm they are properly inserted.

If the wire needs to be removed from the poke-in connector, push downward on the white spring portion of the connector with a small screwdriver and lightly pull upward on the wire until it releases.

25 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 26

RGM User Manual | 16 Rear Cover Removal & Daisy Chain Connections

6. Plug the CANopen (blue and white twisted pair) into connector P1 on the drive PCB as shown in Fig-

ure 11. Be sure the connectors fully seat on the post pins. PCB silkscreen note positions for W (white

- CAN high) and B (blue - CAN low).

To remove, pull straight up on the body of the black plastic connector housing.. Be sure wires are arranged to

avoid accidentally pinching them when the cover is re-installed.

Kollmorgen | kdn.Kollmorgen.com | February 2019 26

Page 27

RGM User Manual | 17 Daisy Chain Wire Sizes, Colors, and Functions

17 Daisy Chain Wire Sizes, Colors, and Functions

Color Function Size

RGM14 RGM17 RGM20 RGM25

Red 48 VDC Positive 20 AWG 18 AWG

Black 48 VDC Negative 20 AWG 18 AWG

White CANopen High 24AWG

Blue CANopen Low 24AWG

CANopen connector housing – TE part number 7-87499-2

CANopen connector contact – TE part number 102128-1 contacts and TE crimp tool 91517-1

27 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 28

RGM User Manual | 18 RGM Workbench Software & Drive Commissioning

18 RGM Workbench Software & Drive Commissioning

Please refer to separate document "RGM Workbench User Manual" for software and interface instructions.

Kollmorgen | kdn.Kollmorgen.com | February 2019 28

Page 29

RGM User Manual | 19 Serial Cable Part Number

19 Serial Cable Part Number

A serial communication cable (part #969745) is available for purchase from Kollmorgen.

29 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 30

RGM User Manual | 20 CANopen Termination

20 CANopen Termination

RGM drive CAN addresses are assigned electronically via the serial port (connector P3) during the

commissioning process. See separate documents for further instructions.

l RGM Workbench User Manual

l RGM CANopen Manual

Note that the CANopen network requires 1 termination resistor at the source (master) and 1 termination

resistor at the final drive at the end of the network. RGM drive PCB is equipped with a jumper resistor at

connector location P2. Placing the jumper across both posts of connector P2 puts the termination resistor into

the circuit. Removing the jumper or moving it to a position that only contacts one of the P2 posts will remove

the termination resistor from the circuit.

Kollmorgen | kdn.Kollmorgen.com | February 2019 30

Page 31

RGM User Manual | 21 Brake Initialization

21 Brake Initialization

When the RGM joint is enabled it is possible that, depending on the robot position, gravitational forces from

the robot’s weight can prevent the brake from disengaging. The recommended initialization sequence is to:

1. Enable the drive.

2. Then move the axis back and forth to insure the brake solenoid is fully retracted

The RGM uses a pin in spoke brake, a 4 spoke wheel is on mounted on the motor, this means there is a brake

position every 90 degrees of the motor position or .89 degrees of the gear output. The pin which contacts the

spokes during braking is activated with a solenoid. Power must be applied to the solenoid to release the

brake. Once the solenoid is energized to release the brake, the controller needs to move (shake) the joint back

and forth to ensure the brake pin is not hung on the brake wheel. The recommended move distance is +/- 0.5

degrees of gear motion.

Typical Motion Parameters

T move Degree Deg/sec Deg/sec

0.05 1 40 1600

0.1 1 20 400

0.2 1 10 100

2

21.1 RGM Enable/ Brake Initialization Procedure

1. Controller Enables Drive, this turns on Power bridge and applies 48 Vdc to brake for .5 seconds

2. Controller commands +/-.5-degree relative motions with motion time of .06 seconds

1. +.5 degrees

2. -.5 degrees

3. +.5 degrees

4. -.5 degree

3. Perform a longer move to insure brake is not stuck on the pin.

Times shown are typical

31 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 32

RGM User Manual | 22 Regeneration Warning

22 Regeneration Warning

A rotating motor has kinetic energy, regeneration occurs when the kinetic energy that was stored in the motor

during motion is returned to the system during deceleration. This energy must be absorbed by the DC bus

Capacitators, which in turn raises the bus voltage or dissipated by friction.

It is possible under certain conditions that regenerative action will raise the bus voltage above the RGM

drives rated maximum voltage. If this occurs the drives will shut down with an over voltage fault. If

regeneration does shut down the drive, the user will either need to modify the application by slowing down the

process, or use a power supply with regeneration capability.

Kollmorgen | kdn.Kollmorgen.com | February 2019 32

Page 33

RGM User Manual | 23 End Effectors

23 End Effectors

Kollmorgen does not currently offer tool mount or end effector accessories for RGM. If customers intend to

design their own mechanical interface for mounting an end effector, mechanical dimensions of the RGM

output plate can be found on the Kollmorgen website. If the end effector will rely upon the RGM daisy chain

wiring for DC power, then motion of the output plate must be restricted to +/- 360°. If end effector power will

be provided by another wiring path, and the RGM daisy chain will not be used for this purpose or connected to

the end effector, then continuous rotation of the RGM output plate is possible. Customer is responsible for

communication and I/O to the end effector external to the RGM wiring circuit.

33 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 34

24 Board Layout

24.1 CANopen

RGM User Manual | 24 Board Layout

Kollmorgen | kdn.Kollmorgen.com | February 2019 34

Page 35

RGM User Manual | 24 Board Layout

24.2 EtherCAT

35 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 36

RGM User Manual | 25 Data Sheets

25 Data Sheets

25.1 RGM14 37

25.2 RGM17 38

25.3 RGM20 39

25.4 RGM25 40

Kollmorgen | kdn.Kollmorgen.com | February 2019 36

Page 37

RGM User Manual | 25 Data Sheets

25.1 RGM14

RGM14 Specifications

Specifications RGM14A-ANCN-XXX

Supply Voltage 48 (+/- 10%) VDC

Maximum Supply Currents 10 Amps RMS

Continuous Supply Current 3.8 Amps RMS

Maximum Intermittent Torque 34 Nm

Maximum Intermittent Speed 35 RPM, 210°/sec

Continuous Torque (22°C Ambient, 50% Duty Cycle) 13.5 Nm (see graph/table)

Speed at Continuous Torque (22°C, 50% Duty Cycle) 20 RPM

Torque Constant (Kt) 0.110 Nm/Amp RMS

Maximum Angular Movement (with center shaft wiring connected)

Maximum Angular Movement (without center shaft wiring connected)

Maximum Gear Case Temperature 50° C

Absolute Encoder Resolution 19 bits, 0.0007° Mechanical

Accuracy 0.1° Mechanical

Repeatability 0.001° Mechanical

Communication Fieldbus CANopen DS301 and DS402

Center Shaft Wiring (4 wires)

Red

Black

White

Blue

Weight 1.48 kg

IP Rating (when properly installed per instructions)* IP54

Mounting Fasteners M3 x 8mm long class 12.9 socket head cap

* Requires optional Kollmorgen ring, band and gasket kit plus customer interface surface to complete seal

+/- 360° Mechanical

infinite° Mechanical

20 AWG / + 48VDC

20 AWG / -48VDC

24 AWG / CANopen high

24 AWG / CANopen low

screw

RGM14 - 连 续 转矩 能 力 (Nm)

Duty Cycle

RPM 25% 50% 75% 100%

5 13.5 13.5 13.5 13.5

10 13.5 13.5 13.5 13.5

15 13.5 13.5 13.5 13.5

20 13.5 13.5 13.5 13.5

25 13.5 13.5 11.1 9.6

30 0.5 0.35 0.29 0.25

* at 22°C ambient. Performance will be reduced at higher ambient

temperatures

37 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 38

RGM User Manual | 25 Data Sheets

25.2 RGM17

RGM17 Specifications

Specifications RGM14A-ANCN-XXX

Supply Voltage 48 (+/- 10%) VDC

Maximum Supply Currents 10 Amps RMS

Continuous Supply Current 4.88 Amps RMS

Maximum Intermittent Torque 66 Nm

Maximum Intermittent Speed 30 RPM, 180°/sec

Continuous Torque (22°C Ambient, 50% Duty Cycle) 49 Nm (see graph/table)

Speed at Continuous Torque (22°C, 50% Duty Cycle) 20 RPM

Torque Constant (Kt) 0.129 Nm/Amp RMS

Maximum Angular Movement (with center shaft wiring connected)

Maximum Angular Movement (without center shaft wiring

connected)

Maximum Gear Case Temperature 50° C

Absolute Encoder Resolution 19 bits, 0.0007° Mechanical

Accuracy 0.1° Mechanical

Repeatability 0.001° Mechanical

Communication Fieldbus CANopen DS301 and DS402

Center Shaft Wiring (4 wires)

Red

Black

White

Blue

Weight

IP Rating (when properly installed per instructions)* IP54

Mounting Fasteners M4 x 10mm long class 12.9 socket head cap

* Requires optional Kollmorgen ring, band and gasket kit plus customer interface surface to complete seal

+/- 360° Mechanical

infinite° Mechanical

20 AWG / + 48VDC

20 AWG / -48VDC

24 AWG / CANopen high

24 AWG / CANopen low

1.97 kg

screw

RGM17 - 连 续 转矩 能 力 (Nm)

Duty Cycle

RPM 25% 50% 75% 100%

5 49 49 49 49

10 49 49 49 44

15 49 49 45.5 40

20 49 49 40.9 35.4

25 47 42.7 34.9 30.2

* at 22°C ambient. Performance will be reduced at higher ambient

temperatures

Kollmorgen | kdn.Kollmorgen.com | February 2019 38

Page 39

RGM User Manual | 25 Data Sheets

25.3 RGM20

RGM20 Specifications

Specifications RGM20A-ANCN-XXX

Supply Voltage 48 (+/- 10%) VDC

Maximum Supply Currents 20 Amps RMS

Continuous Supply Current 7.5 Amps RMS

Maximum Intermittent Torque 102 Nm

Maximum Intermittent Speed 25 RPM, 150°/sec

Continuous Torque (22°C Ambient, 50% Duty Cycle) 61 Nm (see graph/table)

Speed at Continuous Torque (22°C, 50% Duty Cycle) 15 RPM

Torque Constant (Kt) 0.123 Nm/Amp RMS

Maximum Angular Movement (with center shaft wiring connected)

Maximum Angular Movement (without center shaft wiring connected)

Maximum Gear Case Temperature 50 °C

Absolute Encoder Resolution 19 bits, 0.0007° Mechanical

Accuracy 0.1° Mechanical

Repeatability 0.001° Mechanical

Communication Fieldbus CANopen DS301 and DS402

Center Shaft Wiring (4 wires)

Red

Black

White

Blue

Weight 2.56 kg

IP Rating (when properly installed per instructions)* IP54

Mounting Fasteners M3 x 8mm long class 12.9 socket head cap

* Requires optional Kollmorgen ring, band and gasket kit plus customer interface surface to complete seal

+/- 360° Mechanical

infinite° Mechanical

18 AWG / + 48VDC

18 AWG / -48VDC

24 AWG / CANopen high

24 AWG / CANopen low

screw

RGM20 - 连 续 转矩 能 力 (Nm)

Duty Cycle

RPM 25% 50% 75% 100%

5 61 61 61 60.7

10 61 61 61 56.4

15 61 61 60.3 52.2

20 61 57 49.4 42.8

* at 22°C ambient. Performance will be reduced at higher ambient

temperatures

39 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 40

RGM User Manual | 25 Data Sheets

25.4 RGM25

RGM25 Specifications

Specifications RGM14A-ANCN-XXX

Supply Voltage 48 (+/- 10%) VDC

Maximum Supply Currents 20 Amps RMS

Continuous Supply Current 10 Amps RMS

Maximum Intermittent Torque 194 Nm

Maximum Intermittent Speed 20 RPM, 120°/sec

Continuous Torque (22°C Ambient, 50% Duty Cycle) 118 Nm (see graph/table)

Speed at Continuous Torque (22°C, 50% Duty Cycle) 10 RPM

Torque Constant (Kt) 0.141 Nm/Amp RMS

Maximum Angular Movement (with center shaft wiring connected)

Maximum Angular Movement (without center shaft wiring

connected)

Maximum Gear Case Temperature 50° C

Absolute Encoder Resolution 19 bits, 0.0007° Mechanical

Accuracy 0.1° Mechanical

Repeatability 0.001° Mechanical

Communication Fieldbus CANopen DS301 and DS402

Center Shaft Wiring (4 wires)

Red

Black

White

Blue

Weight 4.20 kg

IP Rating (when properly installed per instructions)* IP54

Mounting Fasteners M4 x 10mm long class 12.9 socket head cap

* Requires optional Kollmorgen ring, band and gasket kit plus customer interface surface to complete seal

+/- 360° Mechanical

infinite° Mechanical

18 AWG / + 48VDC

18 AWG / -48VDC

24 AWG / CANopen high

24 AWG / CANopen low

screw

RGM25 - 连 续 转矩 能 力 (Nm)

Duty Cycle

RPM 25% 50% 75% 100%

5 133 133 128 111

10 133 118 96.6 83.7

15 79.8 56.4 46.1 39.9

* at 22°C ambient. Performance will be reduced at higher ambient

temperatures

Kollmorgen | kdn.Kollmorgen.com | February 2019 40

Page 41

RGM User Manual | 26 Index

26 Index

A

Absolute encoder 14

Acceleration 11

Accuracy 14

B

Backlash 17

Brake, park 17

C

CANopen 24, 26-27

E

End Effector 33

H

Harmonic gearing 15

I

IP54 21-22

J

Joint seal kit 22

O

Output plate 19, 24, 33

P

Performance rating 20

R

Rotation 13

S

Screws, mounting 19

Serial cable, about 29

Speed 15

Speed, max RPM 10

Speed, RPM 12

T

Temperature, max. 15

Thermal rating 15

Thermal sensitivity 15

Thermistors 16, 20

41 Kollmorgen | kdn.Kollmorgen.com | February 2019

Page 42

RGM User Manual | 26 Index

Torque 11-12, 15

Torque, tightening 19

V

Voltage 9

W

Wiring 27

Wiring, daisy chain 13, 24

Workbench 28

Kollmorgen | kdn.Kollmorgen.com | February 2019 42

Page 43

About Kollmorgen

Kollmorgen is a leading provider of motion systems and components for machine builders. Through world-class

knowledge in motion, industry-leading quality and deep expertise in linking and integrating standard and custom

products, Kollmorgen delivers breakthrough solutions that are unmatched in performance, reliability and easeof-use, giving machine builders an irrefutable marketplace advantage.

Join the Kollmorgen Developer Network for product support. Ask the community ques-

tions, search the knowledge base for answers, get downloads, and suggest improvements.

North America

Kollmorgen

203A West Rock Road

Radford, VA 24141

USA

Web:

Mail:

www.Kollmorgen.com

support@Kollmorgen.com

Tel.: +1 - 540 - 633 - 3545

Fax: +1 - 540 - 639 - 4162

South America

Kollmorgen

Avenida Tamboré, 1077 Tamboré Barueri - SP Brasil

CEP:06460-000

Web: www.Kollmorgen.com

Tel.: +55 11 4191-4771

Europe

Kollmorgen Europe GmbH

Pempelfurtstraße 1

40880 Ratingen

Germany

Web: www.Kollmorgen.com

Mail: technik@Kollmorgen.com

Tel.: +49 - 2102 - 9394 - 0

Fax: +49 - 2102 - 9394 - 3155

China and Southeast Asia

Kollmorgen Asia

Room 302, Building 5,

Lihpao Plaza, 88 Shenbin Road,

Minhang District, Shanghai, China

Web: www.Kollmorgen.cn

Mail: sales.china@kollmorgen.com

Tel.: +86 - 400 - 668-2802

Fax: +81 - 216 - 248-5367

Loading...

Loading...