Page 1

www.DanaherMotion.com

KOLLMORGEN

SERVOSTAR® MC

M-SS-005-03

Revision E

Firmware Version 5.0.0

Page 2

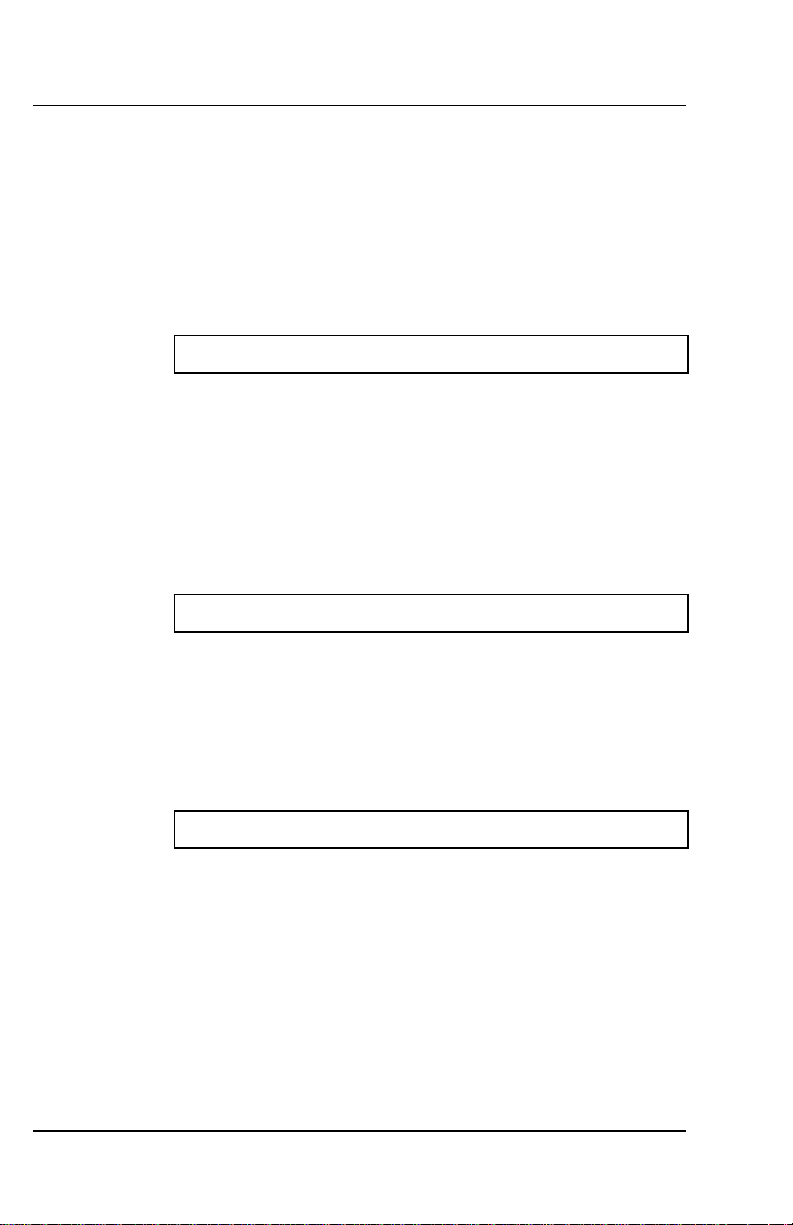

Record of Manual Revisions

Revision Date Description of Revision

0 3/1/1999 Preliminary issue for review

1 5/14/1999 Initial release

2 6/5/2000 New PCI and stand-alone models, new firmware features

3 8/31/2001 New firmware features

D 5/11/2005 Update examples

E 6/20/2005 Updated firmware version and dates

©1999 – 2005 Danaher Motion. All rights reserved. Printed in the USA.

DANAHER MOTION® is a registered trademark of Danaher Corporation. Danaher

Motion makes every attempt to ensure accuracy and reliability of the specifications in

this publication. Specifications are subject to change without notice. Danaher Motion

provides this information "AS IS" and disclaims all warranties, express or implied,

including, but not limited to, implied warranties of merchantability and fitness for a

particular purpose. It is the responsibility of the product user to determine the

suitability of this product for a specific application.

SERVOSTAR, GOLDLINE Motors, MOTIONLINK, Motioneering, BASIC Moves Development

Studio, Kollmorgen API and MC-BASIC are trademarks of the Kollmorgen Corporation.

VxWorks is a trademark of Wind River.

Visual Basic, Visual C++, Windows, Windows 95, Windows NT are trademarks of Microsoft

Corporation.

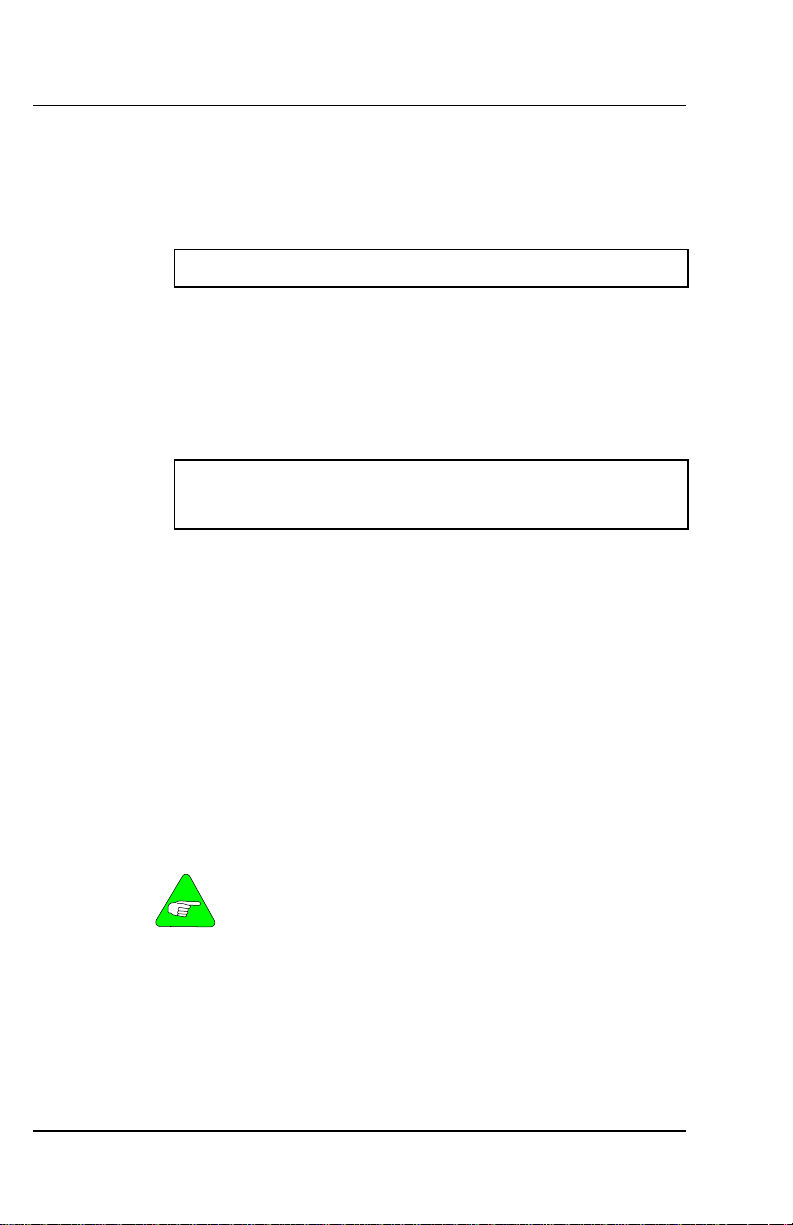

Safety-alert symbols used in this document are:

WARNING

CAUTION

NOTE

Warnings alert users to potential physical danger or harm. Failure

to follow warning notices could result in personal injury or death.

Cautions direct attention to general precautions, which if not

followed, could result in personal injury and/or equipment damage.

Notes highlight information critical to your understanding or use of

the product.

Page 3

Danaher Motion 06/2005 Table of Contents

Table of Contents

1. OVERVIEW ................................................................................................................................ 1

1. 1 SYSTEM HARDWARE ......................................................................................................... 2

1. 2 OPERATING SYSTEM......................................................................................................... 2

1. 3 MC-BASIC LANGUAGE COMPILER................................................................................. 2

1. 4 I/O......................................................................................................................................... 3

1. 5 SERCOS ............................................................................................................................... 3

1. 6 API........................................................................................................................................ 4

1. 7 MULTI-TASKING ................................................................................................................ 4

1. 8 USER COMMUNICATION.................................................................................................. 4

1.8.1. SERIAL COMMUNICATION .................................................................................. 5

1.8.2. TCP/IP COMMUNICATION.................................................................................. 6

1.8.3. SEND /RECEIVE DATA ........................................................................................ 8

2. BASIC MOVES DEVELOPMENT STUDIO........................................................................ 11

2. 1 COMMUNICATION .......................................................................................................... 11

2. 2 MC-BASIC.......................................................................................................................... 11

2.2.1. INSTRUCTIONS.................................................................................................. 12

2.2.2. TYPE ................................................................................................................. 12

2.2.3. CONSTANTS AND VARIABLES .......................................................................... 14

2.2.4. DATA TYPES..................................................................................................... 16

2.2.5. SYSTEM ELEMENTS .......................................................................................... 19

2.2.6. UNITS................................................................................................................ 20

2.2.7. EXPRESSIONS.................................................................................................... 20

2.2.8. AUTOMATIC CONVERSION OF DATA TYPES .................................................... 20

2.2.9. MATH FUNCTIONS............................................................................................ 23

2.2.10. STRING FUNCTIONS.......................................................................................... 24

2.2.11. SYSTEM COMMANDS........................................................................................ 25

2.2.12. PRINTING .......................................................................................................... 28

2.2.13. FLOW CONTROL ............................................................................................... 30

2. 3 PROGRAM DECLARATIONS ........................................................................................... 36

2.3.1. PROGRAM ......................................................................................................... 36

2.3.2. SUBROUTINE..................................................................................................... 36

2.3.3. USER-DEFINED FUNCTIONS ............................................................................. 37

2. 4 LIBRARIES......................................................................................................................... 38

2.4.1. GLOBAL LIBRARIES.......................................................................................... 40

M-SS-005-03 Rev E i

Page 4

Table of Contents 06/2005 Danaher Motion

2. 5 C-FUNCTIONS...................................................................................................................40

2.5.1. OBJECT FILES ....................................................................................................40

2.5.2. PROTOTYPE FILE ...............................................................................................41

2.5.3. SPECIAL CONSIDERATIONS ...............................................................................44

2. 6 SEMAPHORES ...................................................................................................................45

2.6.1. MUTUAL EXCLUSION SEMAPHORES .................................................................45

2.6.2. SYNCHRONIZATION SEMAPHORES ....................................................................46

2. 7 VIRTUAL ENTRY STATION...............................................................................................46

2. 8 OUTPUT REDIRECTION ..................................................................................................47

2. 9 FILE OPERATIONS ...........................................................................................................47

2.9.1. OPEN ...............................................................................................................47

2.9.2. OPEN #, INPUT #, CLOSE, LOC ................................................................48

2.9.3. TELL................................................................................................................48

2.9.4. SEEK................................................................................................................48

3. PROJECT...................................................................................................................................49

3. 1 PROJECT STRUCTURE ....................................................................................................49

3. 2 TASKS .................................................................................................................................49

3.2.1. GENERAL PURPOSE TASKS ...............................................................................49

3.2.2. CONFIGURATION TASK .....................................................................................51

3.2.3. AUTOEXEC TASK ..............................................................................................51

3. 3 PROGRAM DECLARATIONS............................................................................................52

3.3.1. ARRAYS.............................................................................................................53

3. 4 MULTI-TASKING...............................................................................................................55

3.4.1. LOADING THE PROGRAM...................................................................................57

3.4.2. PREEMPTIVE MULTI-TASKING & PRIORITY LEVELS ........................................57

3.4.3. INTER-TASK COMMUNICATIONS AND CONTROL..............................................57

3.4.4. MONITORING TASKS FROM THE TERMINAL .....................................................59

3.4.5. RELINQUISHING RESOURCES ............................................................................59

3. 5 EVENT HANDLER .............................................................................................................60

3.5.1. ONEVENT ..........................................................................................................60

3.5.2. EVENTON ..........................................................................................................61

3.5.3. EVENTOFF.........................................................................................................61

3.5.4. EVENTLIST ........................................................................................................61

3.5.5. EVENTDELETE...................................................................................................61

3.5.6. EVENTS AT START-UP .......................................................................................61

3.5.7. PROGRAM FLOW AND ONEVENT .....................................................................61

3. 6 SETTING UP AXES............................................................................................................ 6 2

3.6.1. AXIS DEFINITION...............................................................................................62

3.6.2. AXIS NAME .......................................................................................................62

3.6.3. DRIVE ADDRESS................................................................................................63

ii Rev E M-SS-005-03

Page 5

Danaher Motion 06/2005 Table of Contents

3.6.4. STARTING POSITION ......................................................................................... 63

3.6.5. BASIC MOVES AUTO SETUP PROGRAM.......................................................... 63

3.6.6. USER UNITS...................................................................................................... 64

3.6.7. POSITION UNITS ............................................................................................... 64

3.6.8. VELOCITY UNITS.............................................................................................. 65

3.6.9. ACCELERATION UNITS ..................................................................................... 65

3.6.10. JERK UNITS....................................................................................................... 66

3. 7 ACCELERATION PROFILE ............................................................................................. 66

3. 8 POSITION AND VELOCITY ............................................................................................. 67

3. 9 LIMITS ............................................................................................................................... 69

3.9.1. POSITION LIMITS .............................................................................................. 70

3.9.2. AXIS VELOCITY LIMITS.................................................................................... 73

3. 10 VELOCITY, ACCELERATION AND JERK RATE PARAMETERS.................................. 73

3. 11 VERIFY SETTINGS............................................................................................................ 74

3.11.1. ENABLING......................................................................................................... 74

3.11.2. MOTION FLAGS ................................................................................................ 74

3.11.3. MOVE................................................................................................................ 74

3. 12 SERCOS ............................................................................................................................. 75

3.12.1. COMMUNICATION PHASES ............................................................................... 76

3.12.2. TELEGRAMS...................................................................................................... 76

3.12.3. TELEGRAM TYPES ............................................................................................ 77

3.12.4. CYCLIC VS. NON-CYCLIC COMMUNICATION................................................... 78

3.12.5. IDNS................................................................................................................. 78

3.12.6. POSITION AND VELOCITY COMMANDS............................................................ 79

3.12.7. SERCOS SUPPORT........................................................................................... 79

3. 13 LOOPS ............................................................................................................................... 81

3.13.1. STANDARD POSITION LOOP.............................................................................. 82

3.13.2. DUAL-FEEDBACK POSITION LOOP ................................................................... 82

3.13.3. VELOCITY LOOP............................................................................................... 83

3. 14 SIMULATED AXES............................................................................................................ 83

4. SINGLE-AXIS MOTION......................................................................................................... 85

4. 1 MOTION GENERATOR .................................................................................................... 85

4.1.1. MOTION CONDITIONS....................................................................................... 85

4.1.2. MOTION BUFFERING......................................................................................... 87

4.1.3. OVERRIDE VERSUS PERMANENT ...................................................................... 87

4.1.4. ACCELERATION PROFILE.................................................................................. 88

4.1.5. JOG.................................................................................................................... 88

4.1.6. STOP ................................................................................................................. 89

4.1.7. PROCEED........................................................................................................... 89

M-SS-005-03 Rev E iii

Page 6

Table of Contents 06/2005 Danaher Motion

4.1.8. MOVE ................................................................................................................90

4.1.9. VELOCITY OVERRIDE........................................................................................98

4. 2 MOTION EXAMPLES ........................................................................................................98

4.2.1. POSITION CAPTURE ...........................................................................................98

4.2.2. HOMING.............................................................................................................99

4.2.3. REGISTRATION ................................................................................................101

4.2.4. GATING............................................................................................................102

4.2.5. CLAMPING.......................................................................................................102

4.2.6. PIPEMODE ....................................................................................................103

5. MASTER-SLAVE....................................................................................................................105

5. 1 MASTER SOURCES .........................................................................................................105

5. 2 GEARING..........................................................................................................................106

5.2.1. ENABLE GEARING ...........................................................................................106

5.2.2. DISABLE GEARING ..........................................................................................106

5.2.3. INCREMENTAL MOVES....................................................................................107

5. 3 CAMMING........................................................................................................................108

5.3.1. KEY FEATURES................................................................................................108

5.3.2. GEARRATIO................................................................................................109

5.3.3. INCREMENTAL MOVES....................................................................................109

5.3.4. CAM TABLES...................................................................................................109

5.3.5. CAM CYCLES...................................................................................................111

5.3.6. CREATE CAM TABLES.....................................................................................113

5.3.7. OPERATING CAMS...........................................................................................115

5. 4 SIMULATED AND MASTER-SLAVE AXES ....................................................................119

5.4.1. FIXED-SPEED MASTERS ..................................................................................119

5.4.2. MONITOR PHYSICAL AXES .............................................................................119

5.4.3. SYNCHRONIZE SLAVE AXES ...........................................................................119

6. GROUPS...................................................................................................................................121

6. 1 SET UP..............................................................................................................................121

6. 2 DELETEGROUP ..............................................................................................................121

6. 3 ACCELERATION PROFILES ..........................................................................................121

6.3.1. ACCELERATION AND DECELERATION.............................................................121

6. 4 POSITION.........................................................................................................................122

6.4.1. VECTOR...........................................................................................................122

6.4.2. SCALAR ...........................................................................................................122

6. 5 VELOCITY ........................................................................................................................123

6. 6 LIMITS ..............................................................................................................................123

6.6.1. GENERATOR ....................................................................................................123

6.6.2. REALTIME........................................................................................................123

iv Rev E M-SS-005-03

Page 7

Danaher Motion 06/2005 Table of Contents

6.6.3. POSITION......................................................................................................... 123

6.6.4. VELOCITY....................................................................................................... 124

6. 7 ACCELERATION............................................................................................................. 124

6. 8 VELOCITY, ACCELERATION, DECELERATION AND JERK RATES......................... 124

6. 9 MOTION........................................................................................................................... 125

6.9.1. ATTACH TASK AND AXIS ............................................................................... 125

6.9.2. ENABLE........................................................................................................ 125

6.9.3. MOTION FLAGS .............................................................................................. 126

6.9.4. STOP ............................................................................................................. 126

6.9.5. PROCEED.................................................................................................... 127

6.9.6. MOVE ........................................................................................................... 127

6.9.7. CIRCLE........................................................................................................ 128

6.9.8. CHAIN COMMANDS ........................................................................................ 129

6.9.9. BLENDING....................................................................................................... 129

6. 10 MOVE CONTROL............................................................................................................ 131

6.10.1. SETTLING TIME .............................................................................................. 132

6.10.2. START MOVES ................................................................................................ 132

6.10.3. CHAIN MOVES................................................................................................ 133

6.10.4. MULTI-STEP MOVES ...................................................................................... 133

6.10.5. SYNCHRONIZE MULTIPLE AXES..................................................................... 134

6.10.6. CLEAR A PENDING MOVE.............................................................................. 135

6. 11 VELOCITY OVERRIDE................................................................................................... 135

7. COMPENSATION TABLES................................................................................................. 137

7.1.1. SPECIFICATION ............................................................................................... 137

7.1.2. ACCESS DATA ................................................................................................ 138

7.1.3. DEFINE............................................................................................................ 138

7.1.4. LOAD/SAVE FROM A FILE .............................................................................. 139

7.1.5. SET AND QUERY VALUES............................................................................... 139

7.1.6. ACTIVATE....................................................................................................... 139

7.1.7. QUERY ACTUAL POSITIONS ........................................................................... 139

7.1.8. MULTI-DIMENSIONAL CORRECTION.............................................................. 139

8. PHASER................................................................................................................................... 141

8.1.1. PROFILER........................................................................................................ 141

8.1.2. EXECUTE ........................................................................................................ 142

8.1.3. CANCEL .......................................................................................................... 142

8.1.4. SERIAL PHASER........................................................................................... 142

9. GENERIC ELEMENTS......................................................................................................... 143

9. 1 ELEMENTID.................................................................................................................... 143

9.1.1. DECLARATION................................................................................................ 144

9.1.2. ASSIGNMENT .................................................................................................. 144

M-SS-005-03 Rev E v

Page 8

Table of Contents 06/2005 Danaher Motion

9.1.3. LIMITATIONS ...................................................................................................145

9.1.4. FUNCTIONS......................................................................................................146

9. 2 WITH.................................................................................................................................148

10. INPUT/OUTPUT .....................................................................................................................149

10. 1 STANDARD I/O ................................................................................................................149

10. 2 SOFTWARE I/O................................................................................................................149

10.2.1. BIT-ORIENTED SOFTWARE I/O........................................................................149

10.2.2. LONG-WORD-ORIENTED SOFTWARE I/O........................................................150

10. 3 PLS (PROGRAMMABLE LIMIT SWITCH) .....................................................................150

10.3.1. ENABLE AND DISABLE ....................................................................................150

10.3.2. SWITCH POSITIONS..........................................................................................151

10.3.3. REPETITION INTERVAL....................................................................................152

10.3.4. POLARITY........................................................................................................152

10.3.5. HYSTERESIS.....................................................................................................152

10.3.6. ENABLE AND DISABLE ....................................................................................152

10.3.7. PLS OUTPUT STATE........................................................................................153

10.3.8. SET UP.............................................................................................................153

10. 4 EXTERNAL ENCODERS..................................................................................................154

10. 5 PC104................................................................................................................................155

10.5.1. CONFIGURING PC104 CARDS .........................................................................155

10.5.2. INSTALLATION.................................................................................................155

10.5.3. COMMANDS.....................................................................................................156

11. ERROR HANDLING..............................................................................................................157

11. 1 CONTEXT.........................................................................................................................157

11.1.1. TASK CONTEXT...............................................................................................157

11.1.2. SYSTEM CONTEXT...........................................................................................159

11.1.3. TERMINAL CONTEXT.......................................................................................160

11. 2 WATCHDOG ....................................................................................................................160

11.2.1. WATCHDOG SETUP.........................................................................................161

11.2.2. CYCLE THE WATCHDOG.................................................................................161

11.2.3. RESET THE WATCHDOG..................................................................................161

11. 3 UEA (USER ERROR ASSERTION)..................................................................................162

11. 4 EXCEPTIONS...................................................................................................................162

11.4.1. DECLARATION.................................................................................................162

11.4.2. DELETION........................................................................................................163

11.4.3. ASSERTION ......................................................................................................163

11.4.4. LOG .................................................................................................................164

11.4.5. QUERY.............................................................................................................164

11.4.6. PRINT...............................................................................................................164

11.4.7. LIMITATIONS ...................................................................................................164

vi Rev E M-SS-005-03

Page 9

Danaher Motion 06/2005 Table of Contents

APPENDIX A ................................................................................................................................... 165

SAMPLE NESTING PROGRAM............................................................................................... 165

SUBROUTINE EXAMPLE........................................................................................................ 166

SAMPLE AUTOSETUP PROGRAM ........................................................................................ 167

APPENDIX B.................................................................................................................................... 171

NON-HOMOGENOUS GROUPS............................................................................................. 171

KINEMATICS ..................................................................................................................... 171

COUPLING............................................................................................................................... 173

JOINTS............................................................................................................................... 174

ROBOT MODELS ............................................................................................................... 175

INTERPOLATION................................................................................................................ 176

CARTESIAN PROFILE......................................................................................................... 179

WORKING ENVELOPE ....................................................................................................... 180

ROBOT CONFIGURATIONS ................................................................................................ 181

POINTS ..................................................................................................................................... 181

DECLARATION ..................................................................................................................182

VARIABLES ....................................................................................................................... 182

CONSTANT POINTS ........................................................................................................... 182

VECTORS........................................................................................................................... 183

PROPERTIES ...................................................................................................................... 183

POINT DIMENSION............................................................................................................ 183

POINT ASSIGNMENT ......................................................................................................... 184

SINGLE COORDINATE POINT ASSIGNMENT...................................................................... 184

POINT QUERY ................................................................................................................... 184

SINGLE COORDINATE POINT QUERY................................................................................ 184

OPERATORS ...................................................................................................................... 184

POINTS IN FUNCTIONS ...................................................................................................... 186

MOTION COMMANDS........................................................................................................ 187

ANALOG BEHAVIOR ......................................................................................................... 187

POINT AS AN EXPRESSION ............................................................................................... 187

GROUP POINT PROPERTIES............................................................................................... 188

IN FUNCTIONS................................................................................................................... 188

QUERY .............................................................................................................................. 189

OPERATORS ...................................................................................................................... 189

PASS STRUCTURE ............................................................................................................. 189

LIMITATIONS .................................................................................................................... 190

CONVEYER TRACKING .......................................................................................................... 190

WINDOW DECLARATION .................................................................................................. 191

TRACKING......................................................................................................................... 191

M-SS-005-03 Rev E vii

Page 10

Table of Contents 06/2005 Danaher Motion

MOVING FRAME ................................................................................................................191

TRACKING PROCESS..........................................................................................................192

CUSTOMER SUPPORT ............................................................................................................194

viii Rev E M-SS-005-03

Page 11

Danaher Motion 06/2005 Overview

1. OVERVIEW

This manual describes how to use the SERVOSTAR MC (Multi-axis

Controller) product. To execute the examples described in this manual, you

must at least have a SERVOSTAR MC and BASIC Moves Development

installed on your host computer. Some examples further require that

Studio

you have a drive installed and connected to the MC using the SERCOS

Interface

procedures for all the necessary installations.

Version 5.0.0 of the firmware incorporates many new commands, functions,

and properties, and, in some instances, the behavior of functions,

commands, and properties found in previous versions of the firmware have

been changed. This edition of the SERVOSTAR

to version 5.0.0 firmware, and is not necessarily backward compatible with

previous versions of the firmware. If you have used previous versions of the

MC, you may find that some functions, commands, or properties which you

are familiar with, now have different behavior, or may no longer exist. Refer

to the SERVOSTAR

covers all versions of the firmware.

When you complete this manual you should feel comfortable using all the

features available in the SERVOSTAR MC. Related manuals:

The SERVOSTAR MC is Danaher Motion’s multi-axis controller. The MC has

the features and performance required of today’s multi-axis controllers, and

is designed for easy integration into motion control systems and for simplicity

of use. The key benefits of the product are:

Motion Components Guaranteed to Work Together

Danaher Motion can provide a complete motion control system,including

controller, drives, and motors. All the components are supplied by

DanaherMotion, and are tested and guaranteed to work together.

Complete Digital System at an Affordable Price

The MC is fully digital, including communication with the drives. The analog

interface is eliminated, but the price is competitive with analog systems.

Local Field Bus for Simple Set up, Less Wiring, More Flexibility

The MC communicates via fiber-optic cables using an industrial field bus

called SERCOS. SERCOS greatly simplifies system set-up and wiring, while

improving system flexibility and reliability compared to its analog

counterparts.

Windows

C++™, and other Popular Languages

The MC product family includes Danaher Motion's Kollmorgen API, which

allows Windows NT

Communication uses dual-port RAM, so the process is fast and reliable.

TM

cables. The SERVOSTAR MC Installation Manual describes the

MC User's Manual applies

MC Reference Manual for additional information, as it

SERVOSTAR

SERVOSTAR

SERVOSTAR

SERVOSTAR

MC Installation Manual

MC BASIC Moves Development Studio Manual

SC/MC API Reference Manual

MC InstallationManual

-Based Software Supports Microsoft Visual Basic™, Visual

application integration with the MC controller.

M-SS-005-03 Rev E 1

Page 12

Overview 06/2005 Danaher Motion

1. 1 SYSTEM HARDWARE

The MC hardware is available in two types of implementation: a plug-in

circuit board for a host computer, and a stand-alone model.

The PCI plug-in board hardware installs in a host computer (typically a PC),

running the Windows NT 4.0, Windows 2000/XP operating systems. The MC

contains a fully-independent computer system., so it does not compete with

the host processor system for resources. The MC uses Pentium 233 MHz or

faster microprocessor to provide the power your system needs today, and

the x86 upgrade path allows for future enhancement. The MC includes large

on-board memory with ample capacity for your programs and enough space

for expansion. There is also an onboard Flashdisk for storage of your

programs.

The stand-alone model of the MC is designed for installation as a component

part in industrial equipment. It consists of the PCI version plug-in board and a

power supply in an enclosure. The stand-alone model does not have a host

CPU to provide a Windows operating system and environment, so it can not

directly provide an operator interface. For interactive operation of the standalone MC, you will need a host computer running BASIC Moves

Development Studio software and communicating with the MC via Ethernet

or serial communications with Windows NT, Windows 2000/XP operating

system. For additional information concerning communications configuration

refer to the SERVOSTAR

All implementation models of the SERVOSTAR MC are functionally

equivalent for servo motion control

MC Installation Manual.

1. 2 OPERATING SYSTEM

The SERVOSTAR MC is based on the VxWorks RealTime Operating

System (RTOS), providing a stable platform for the SERVOSTAR's software.

VxWorks is produced by Wind River Systems, Incorporated. VxWorks is

continuously evolving, providing a clear path for future upgrades to the MC.

1. 3 MC-BASIC LANGUAGE COMPILER

The MC uses a language interpreter that semi-compiles commands so they

typically execute in less than 5 microseconds. MC-BASIC

has familiar commands such as FOR…NEXT, IF…THEN, PRINTUSING,

PEEK and POKE as well as common string functions such as CHR$,

INSTR, MID$, and STRING$. It allows arrays (up to 10 dimensions) with full

support for double precision floating-point math. MC-BASIC is extended to

provide support for functions required for motion systems control, (e.g., point

to point moves, circular and linear interpolation, camming, and gearing). In

addition, there is support for multi-tasking and event-driven programs.

Gearing and camming have the versatility required for motion control. You

can slave any axis to any master. You can enable and disable gearing at any

time. The gear ratio is expressed as a double-precision value. The MC also

supports simulated axes, which can be master or slave in gearing and

camming applications and incremental moves run by any axis, master or

slave, at any time.

2 Rev E M-SS-005-03l

is true BASIC. It

Page 13

Danaher Motion 06/2005 Overview

Camming links master and slave axes by a cam table. Camming has all the

features of gearing, plus the cam table can have any number of points. The

cam points are in x-y format so spacing can be provided independently.

Multiple tables can be linked together, allowing you to build complex cam

profiles from simpler tables. There is a cycle counter that lets you specify

how many cycles to run a cam before ending.

The MC supports multi-tasking with up to 256 tasks, running at up to 16

different priority levels. Each task can generate OnEvent(s), for code that you

want executed when events occur such as switches tripping, a motor

crossing a position, or just about any combination of factors.

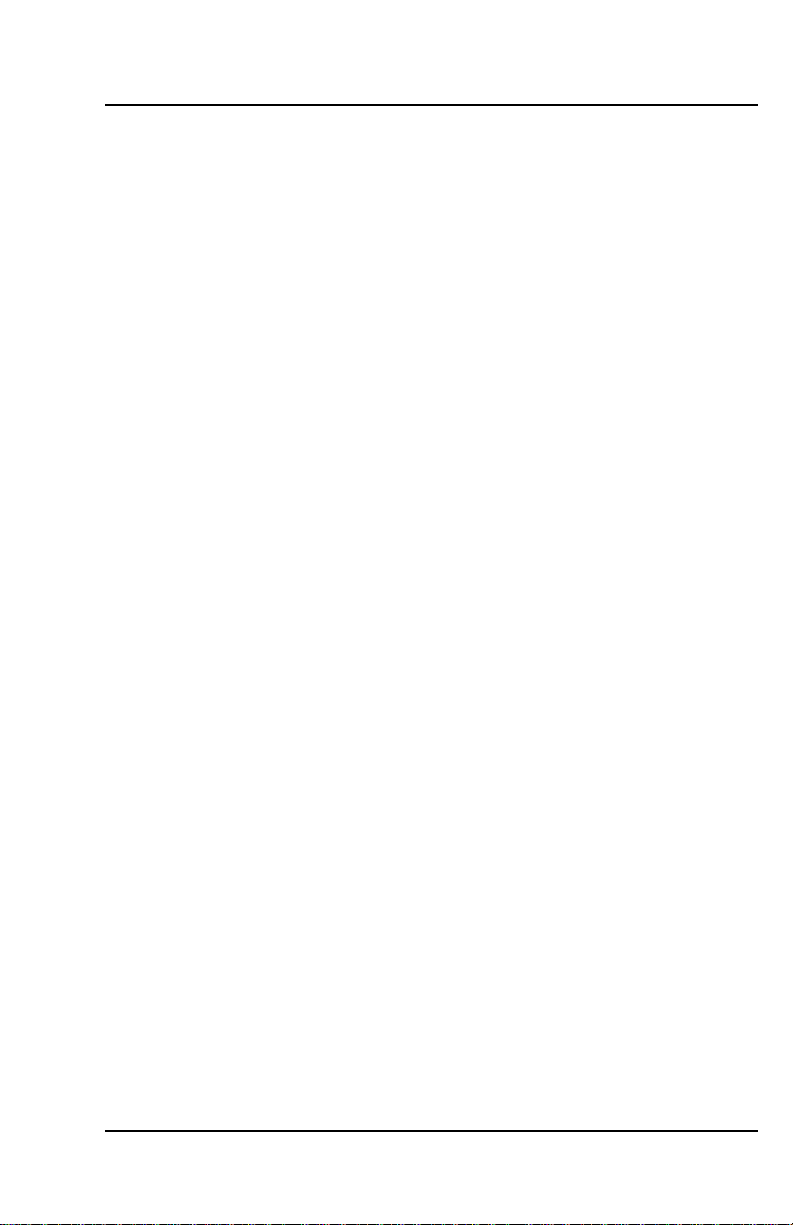

1. 4 I/O

The MC provides 23 optically-isolated inputs and 20 optically-isolated

outputs as standard features, in addition to limit switches and other drive I/O

points that are connected directly to the drives and transferred to the MC via

SERCOS. Additionally, each SERVOSTAR drive provides hardware for six

I/O points: three digital inputs, one digital output, a 14-bit analog input, and a

12-bit analog output. An auxiliary encoder can also be connected to any

SERVOSTAR drive.

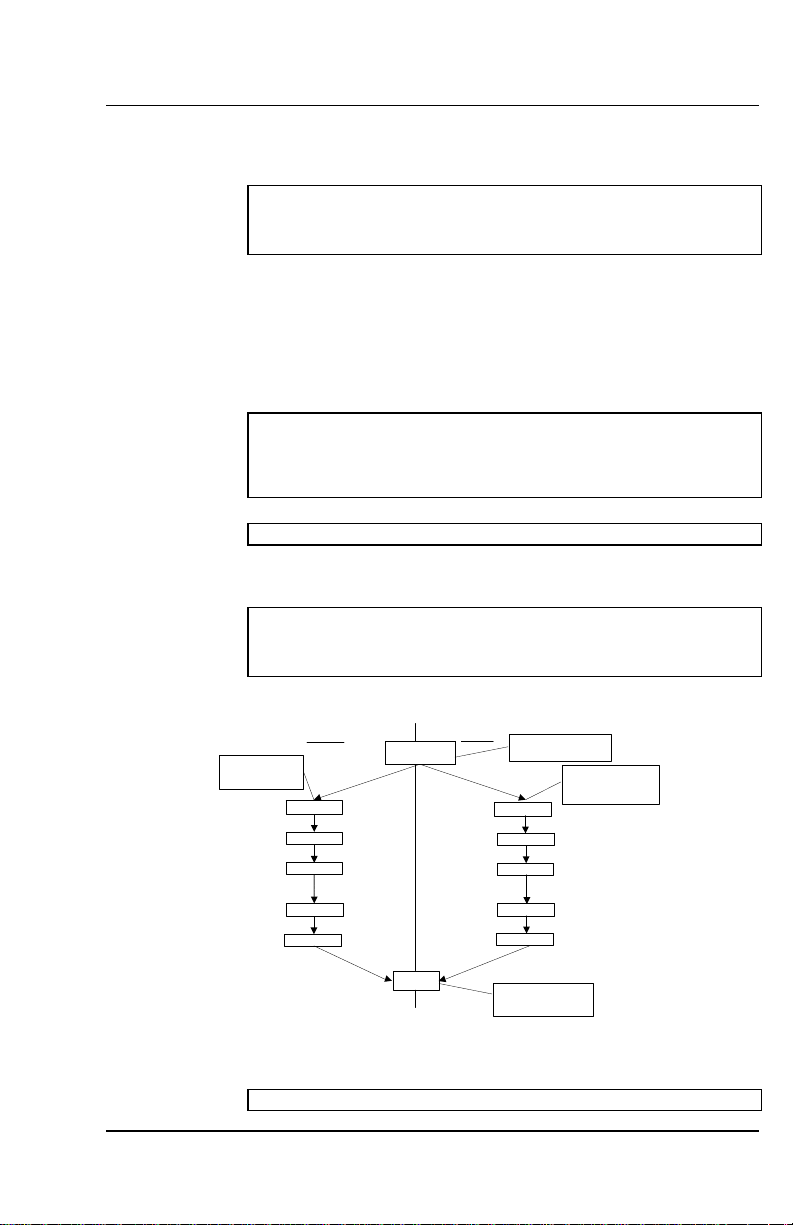

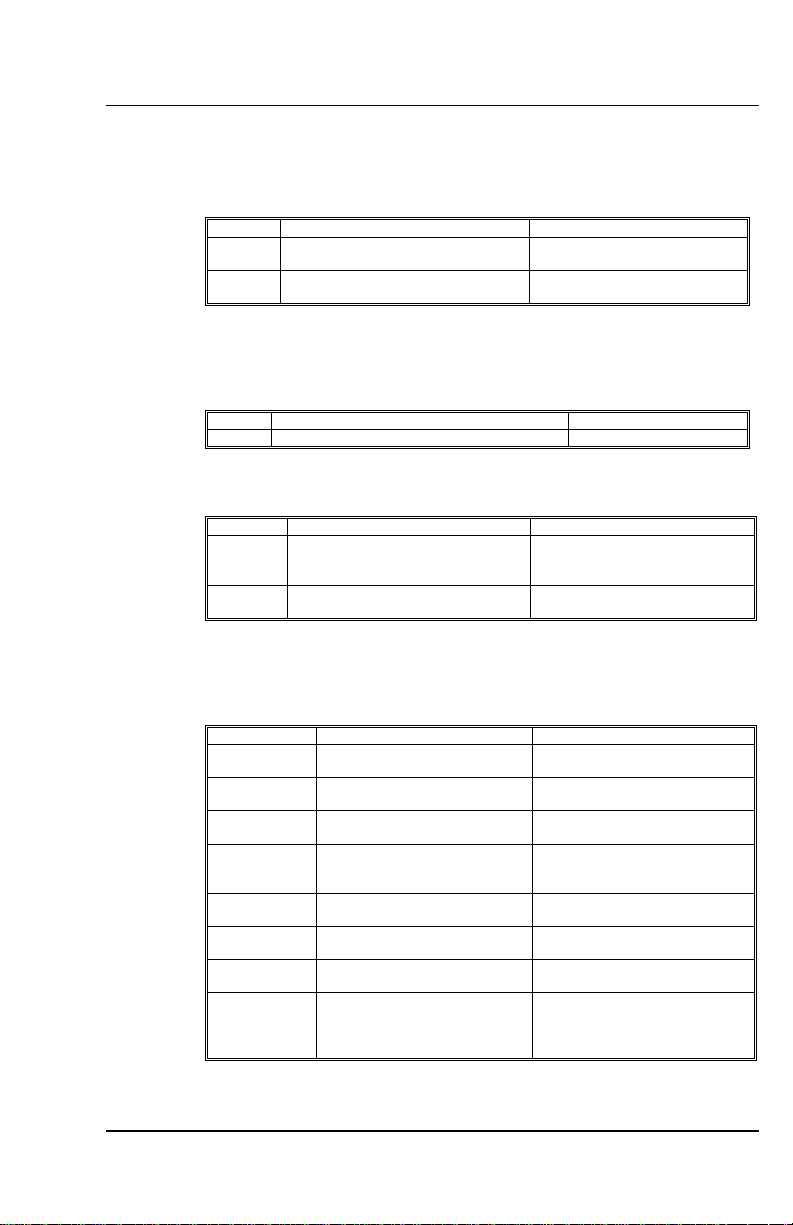

If you need more I/O, the MC includes a PC104 bus. Each MC can

accommodate as many as two PC104 cards. You can also add I/O to your

PC bus or other field buses such as DeviceNet and ProfiBus, and your

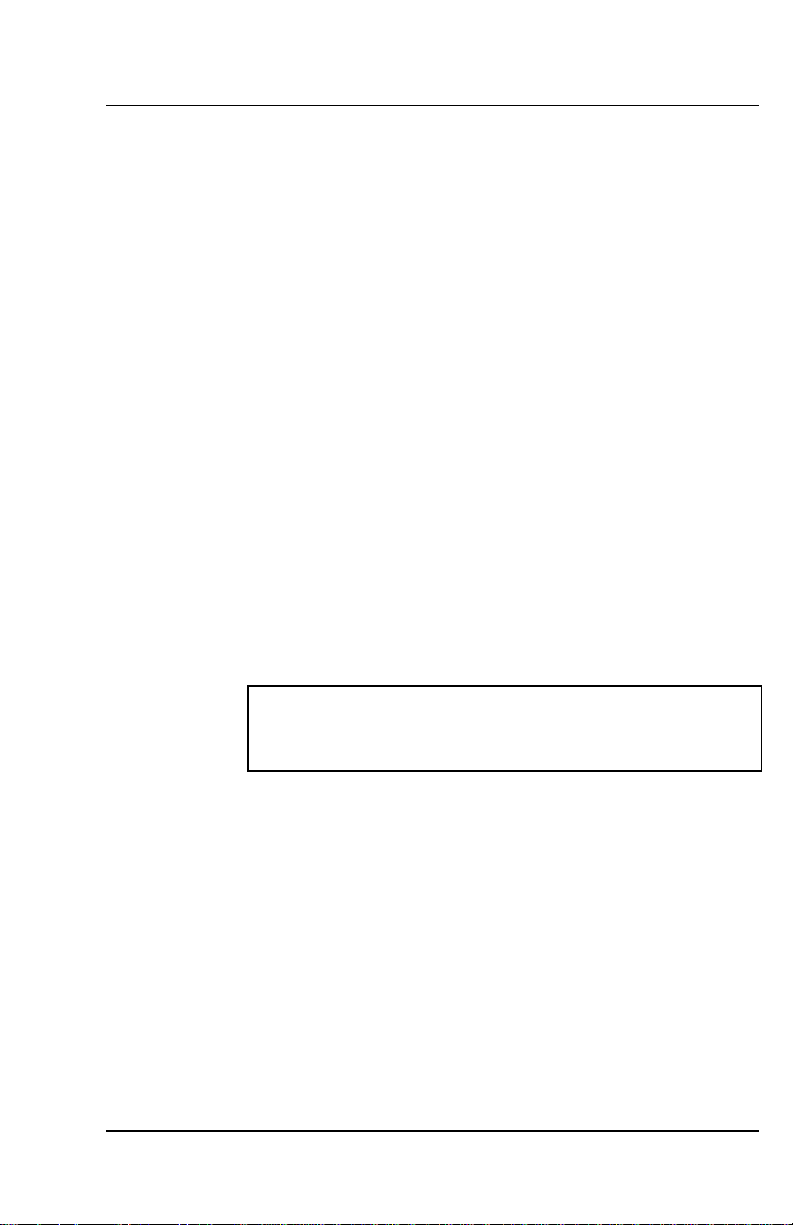

application controls it all. The figure below shows the various possible I/O

options.

SERVOSTAR

Auxillary I/O

SERCOS

SERVOSTAR MC

Standard I/O

PC-104

Mezzanine Bus

PC-104

I/O Cards

PC I/O Cards

PCI Bus

PC Field

Bus Cards

Field

Bus

Host CPU

Field I/O

1. 5 SERCOS

The SERCOS interface™ (developed in the mid-1980’s) provides an

alternative to the analog interface for communicating between motion

controllers and drives. In 1995, SERCOS became an internationally

accepted standard as IEC 1491 and later was continued to standard IEC

61491. The popularity of SERCOS has been steadily growing. All signals are

transmitted between controller and drives on two fiber optic cables. This

eliminates grounding noise and other types of Electro-Mechanical

Conductance (EMC) and Electro-Mechanical Interference (EMI).

M-SS-005-03 Rev E 3

Page 14

Overview 06/2005 Danaher Motion

Because SERCOS is digital, it can transmit signals such as velocity and

position commands with high resolution. The SERVOSTAR

®

MC and

accompanying drives ( SERVOSTAR CD series), support 32-bit velocity

commands. This provides a much higher resolution than can be achieved

with the analog interface. The most common SERCOS functions are

provided in such a way that you do not have to be an expert to gain the

benefits.

1. 6 API

DanaherMotion's Kollmorgen API is a software package that allows you to

communicate with the SERVOSTAR MC from popular programming

languages, such as Visual Basic. The API provides complete access to all

the elements of your system across dual-port ram. See the SERVOSTAR

SC/MC API Reference Manual for more information.

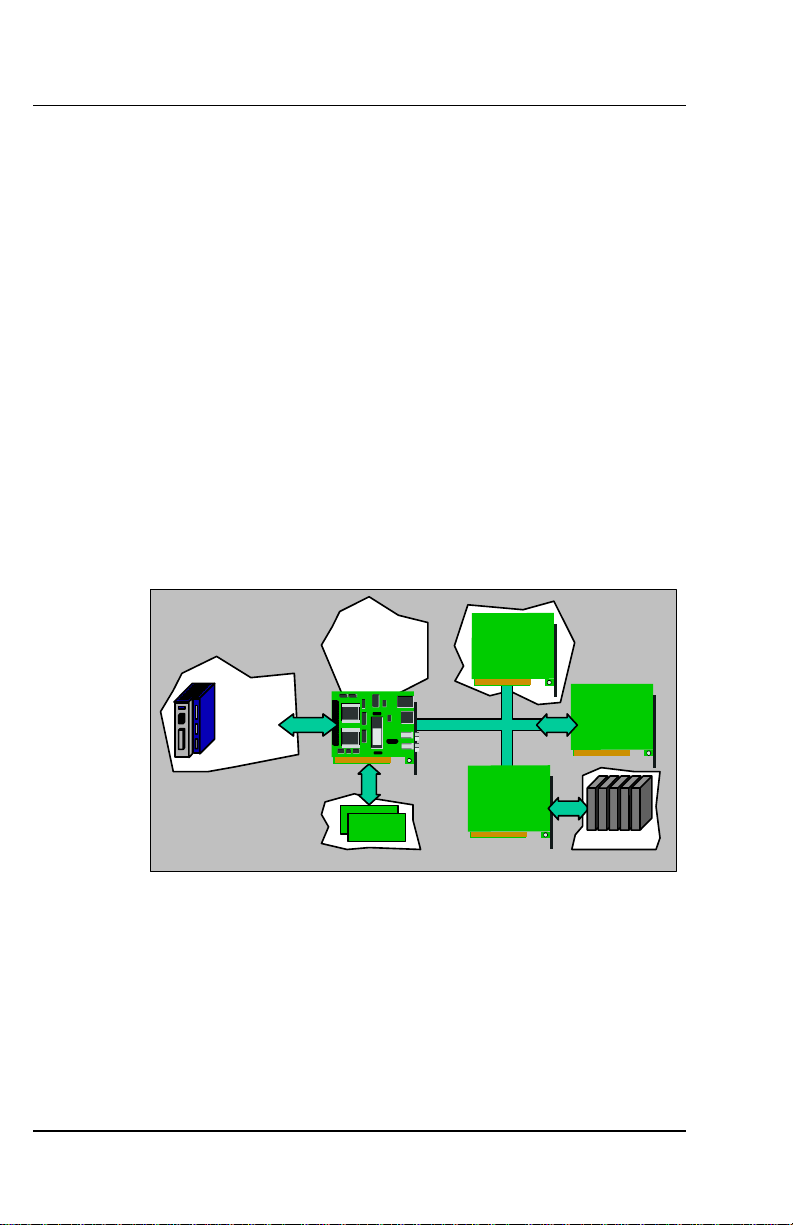

1. 7 MULTI-TASKING

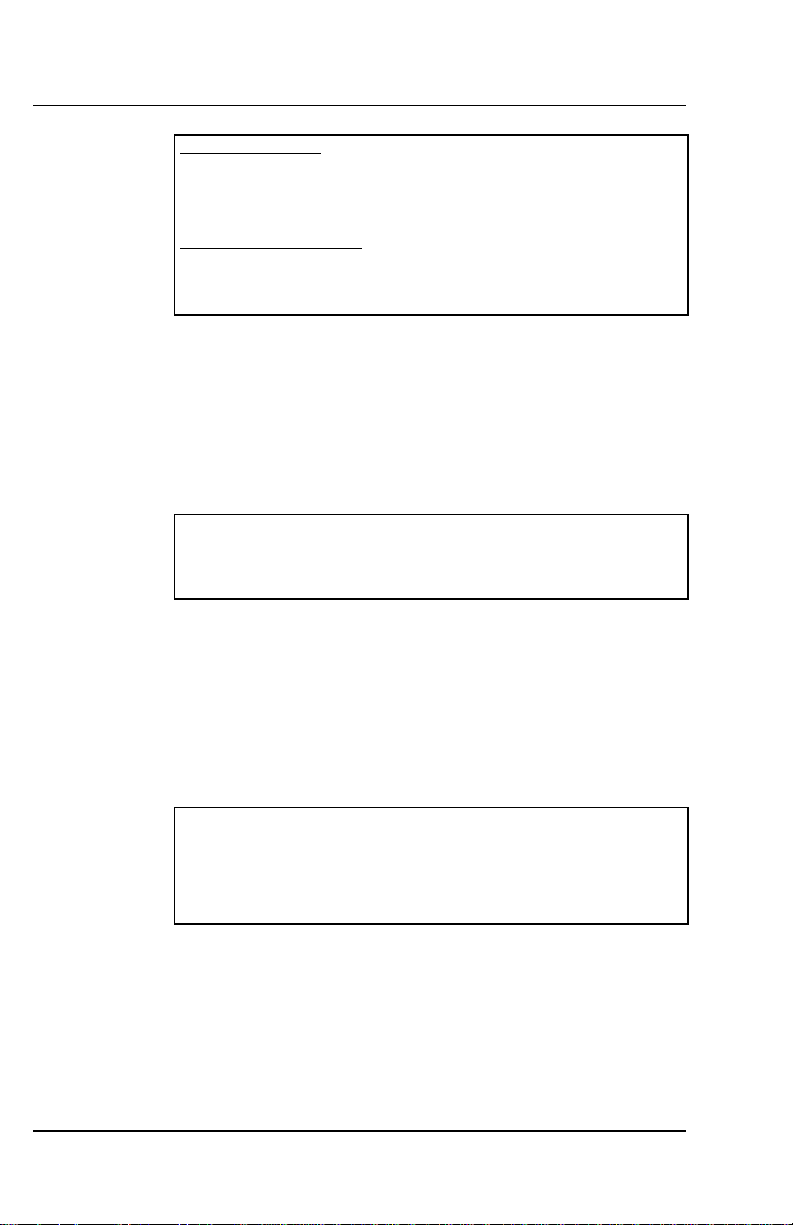

The SERVOSTAR MC is a fully multi-tasking system (see figure below) in

which you can create multiple tasks and multiple elements (e.g., axes) that

operate independently of one another. Also, because the API supports

multiple applications communicating concurrently, you can write one or more

applications that have access to all of the tasks and elements.

3rd Party Soft PLC

Visual C

Visual BASIC

Kollmorgen API

Host CPU

Task 3

Task 2

Task 1

Dual Port RAM

SERVOSTAR MC

Axis 3

Axis 2

Axis 1

1. 8 USER COMMUNICATION

The ETHERNET and Serial ports of the MC are used for ASCII data transfer.

Non-printable characters are sent using CHR$. Data access is streamoriented. There is no data framing. MC Basic applications gain access to

either raw serial port or TCP socket. The TCP socket guaranties error free

data transfer, while the serial port does not offer error recovery. The

transmitted data does not have any meaning in terms of directly controlling

the MC.

User communication provides the basic features of serial and TCP/IP data

communication, which is not limited to a specific communication protocol,

enabling the usage of any protocol over serial or TCP/IP through an MC

application.

4 Rev E M-SS-005-03l

Page 15

Danaher Motion 06/2005 Overview

1.8.1. Serial Communication

The MC has two RS-232 ports, which can be used for user communication.

When COM1 is used for communication with BASIC Moves over API, tasks

cannot access it to eliminate interference with BMDS communications. Use

DIPswitch bit #8 to configure this port:

ON (default) COM1 is reserved for communication with the host and cannot

be used by any other application

OFF COM1 is available for user communication

DIP Switch bit #8 state

When DIPswitch bit # 8 is ON, the MC's firmware prints boot status

messages from COM1 using the following serial communication parameters:

Baudrate 9600 bps

Parity none

Stopbits 1

Databits 8

State ON of DIPswitch read as 0.

For example:

Switches 6 & 8 are OFF. All others are ON.

-->?sys.dipswitch bin

NOTE

0b10100000

-->

1.8.1.1. WITH HOST

When DIPswitch #8 is ON, the MC can communicate with the host via serial

port. This mode of communication requires Virtual Miniport driver, which is

installed during setup of BMDS. The driver simulates Ethernet connection

over serial interface using following fixed parameters:

Baudrate 115200 bps

Parity None

Stopbits 1

Databits 8

IP address 192.1.1.101

Subnet mask 255.255.255.0

All the parameters are fixed and cannot be modified.

If the driver is installed correctly and BMDS is running, it appears in the list of

Ethernet adapters as shown below:

C:\>ipconfig /all

Ethernet adapter Local Area Connection 5:

Connection-specific DNS Suffix . . . . :

Description . . . . . . . . . . . . . . : Giant Steps Virtual miniport

Physical Address. . . . . . . . . . . . : 00-02-1B-D1-A5-FC

DHCP Enabled. . . . . . . . . . . . . . : No

IP Address. . . . . . . . . . . . . . . : 192.1.1.1

Subnet Mask . . . . . . . . . . . . . . : 255.255.255.0

Default Gateway . . . . . . . . . . . . :

DNS Servers . . . . . . . . . . . . . . :

M-SS-005-03 Rev E 5

Page 16

Overview 06/2005 Danaher Motion

1.8.1.2. OPEN SERIAL PORT

Configurate the serial port with OPEN. Set the following port properties:

BaudRate - baud rate of the device set to a specified value.

Parity – enable/disable parity detection. When enabled, parity is odd or even.

DataBits - number of data bits.

StopBit - number of stop bits.

Xonoff – sets raw mode or ^S/^Q flow control protocol mode (optional parameter

disabled by default).

For example:

OPEN COM2 BUADRATE=9600 PARITY=0 DATABITS=8 STOPBIT=1 AS #1

Opens COM2 at 9600 bps baud-rate, No parity, 8-bit data, 1 stop bit.

OPEN assigns a device handle to the communication port. Any further

references to the communication port uses the device handle number. The

device handle range is 1…255. To change the communication parameters,

close the serial port and reopen it using the new parameters. For more

information, see PRINT # and INPUT$.

1.8.2. TCP/IP Communication

Use TCP/IP communication with other computers and intelligent I/O devices

over the Ethernet network. MC-BASIC uses TCP/IP API (sockets).

TCP/IP provides multi-thread communications. The same physical link

(Ethernet) is shared between several applications. This way, the MC can

connect to BASIC Moves and one or more intelligent I/O devices.

The MC supports both client and server roles for TCP/IP communications.

The TCP/IP client connects to a remote system, which waits for a connection

while the TCP/IP server accepts a connection from a remote system.

Usually, the MC serves as client while interfacing to an intelligent I/O

connected to the LAN, and as a server when working toward remote host like

a software PLC. The MC uses Realtek RTL8019AS Ethernet NIC at a bit rate

of 10 M bps.

1.8.2.1. SETUP

TCP communication starts by opening a socket either to connect to a remote

computer (remote host) or accept a connection from a remote host. Use

CONNECT or ACCEPT, depending on the MC functionality (client or server).

OPENSOCKET creates a TCP socket and assigns the socket descriptor to

the specified device handle. The socket is created with OPTIONS

NO_DELAY (send data immediately= 1). Otherwise, the data is buffered in

the protocol stack until the buffer is full or a time-out is reached. This

improves responsiveness when small amounts of data are sent. This option

is recommended for interactive applications with relatively small data

transfer. Otherwise, OPTIONS = 0.

OPENSOCKET OPTIONS=1 AS #1

OPENSOCKET assigns a device handle to the communication port (as

OPEN). Any further reference to the communication port uses the device

handle number. The device handle range is 1…255.

6 Rev E M-SS-005-03l

Page 17

Danaher Motion 06/2005 Overview

There are several ways to set the IP address of the controller. By default, the

MC boots without a valid IP address. The following options are available to

set the IP address of the controller:

Static IP address setting

Use SYS.IPADDRESSMASK in the Config.prg file to assign the IP

address and Subnet mask:

SYS.IPADDRESSMASK=”212.25.84.109:255.255.255.128”

Dynamic address setting by Windows API

API assigns an IP address to the MC when it establishes TCP

communication with the controller. The IP address and Subnet mask

are taken out of a pre-defined address pool. BASIC Moves uses this

address assigning method. Refer to the BASIC Moves Development

®

User Manual and SERVOSTAR® MC Reference Manual for

Studio

detailed information.

DHCP

IP address is assigned by the DHCP server. If your network does not

support DHCP, the controller tries to get the address from the DHCP

server and times out after few minutes. During that time, communication

with the controller is not possible.

SYS.IPADDRESSMASK=”dhcp”

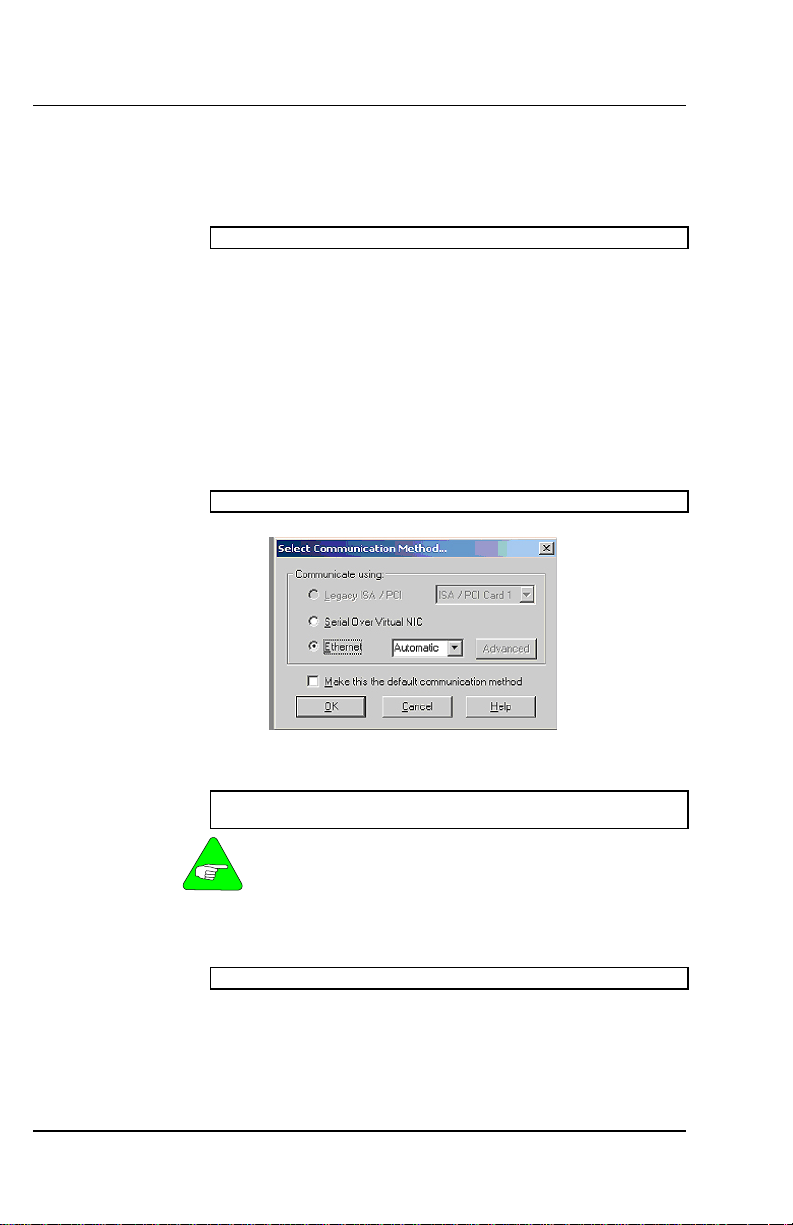

If DHCP is used, select Automatic connection method as shown below:

Get the controller’s IP address

Use SYS.IPADDRESSMASK to query the IP address and Subnet mask

of the MC.

-->?SYS.IPADDRESSMASK

172.30.3.11:255.255.0.0

The MC has several IP interfaces: Ethernet, IP over serial and IP

over DPRAM. However SYS.IPADDRESSMASK is only valid fo r

Ethernet interfaces. Others have fixed IP addresses, which

NOTE

cannot be changed.

PING tests that a remote host is reachable. The remote host must

support ICMP echo request.

?PING(”212.25.84.109”)

1.8.2.2. MC AS TCP CLIENT

When acting as a client, the MC tries to connect to a remote server until a

time out value expires or the connection is rejected. Use CONNECT when

the MC acts as a client.

M-SS-005-03 Rev E 7

Page 18

Overview 06/2005 Danaher Motion

The MC requests a connection from a remote host, according to a specific IP

address and port. CONNECT blocks task execution until the connection is

established or until the command fails. To unblock a task waiting in

CONNECT, close the corresponding socket using CLOSE. In addition, killing

a task (KILLTASK) blocked by CONNECT closes the socket to release the

task. CONNECT may fail due to the following reasons:

1. Invalid socket descriptor

2. Remote host has no application attached to specified port.

3. Destination address is not reachable

The following example illustrates a typical procedure of establishing a

connection to a remote host, and sending and receiving data:

OPENSOCKET OPTIONS=0 AS #1

CONNECT (#1,”212.25.84.100”,6002)

PRINT #1,”HELLO”

?INPUT$(LOC(1),#1)

CLOSE #1

1.8.2.3. MC AS TCP SERVER

When acting as a server. the MC endlessly waits for a connection from the

remote host. Use ACCEPT when the MC acts as server. ACCEPT binds a

socket to a specified port and waits for a connection. Simultaneous

ACCEPTs on the same port are not allowed. ACCEPT blocks the execution

of the calling task until a connection is established. To unblock the task

waiting in ACCEPT, close the corresponding socket with CLOSE. In addition,

killing a task (KILLTASK) blocked in ACCEPT closes the socket and

releases the task. The following example illustrates a typical procedure of

waiting for a connection from a remote host, and sending and receiving data:

OPENSOCKET OPTIONS=0 AS #1

ACCEPT (#1,20000)

PRINT #1,”HELLO”

?INPUT$(LOC(1),#1)

CLOSE #1

1.8.3. Send /Receive Data

Serial and TCP communication use the same commands to send and

receive data. After establishing communication over TCP or after configuring

the serial port communication parameters, send and receive data regardless

the communication type. Data flow differences are communication speed

and the size of the input and output buffers. TCP/IP communication uses

larger communication buffers.

1.8.3.1. RECEIVE DATA

The input-buffer of the serial ports is a fixed512 bytes size. User

communication allows receiving strings using INPUT$. To check if data is

ready at the input buffer, use LOC. The following example checks the

number of bytes available at the input buffers and reads all the available

data:

-->?LOC(1)

11

-->STRING_VAR = INPUT$(11, #1)

-->?STRING_VAR

Hello World

8 Rev E M-SS-005-03l

Page 19

Danaher Motion 06/2005 Overview

If INPUT$ requests reading a data length larger than available data, the

command returns only the available data:

-->?LOC(1)

11

-->STRING_VAR = INPUT$(20, #1)

-->?STRING_VAR

Hello World

LOC can be used within the INPUT$:

STRING_VAR = INPUT$(LOC(1), #1)

A partial read of the input buffer is allowed. This way, several calls to

INPUT$ empty the input-buffer:

-->?LOC(1)

11

-->STRING_VAR = INPUT$(3, #1)

-->?STRING_VAR

Hel

-->?LOC(1)

8

-->STRING_VAR = INPUT$(8, #1)

-->?STRING_VAR

lo World

When calling INPUT$, the system does not wait for data. If the input-buffer is

empty, the command returns without any return value:

-->?LOC(1)

0

-->STRING_VAR = INPUT$(10, #1)

-->?len(STRING_VAR)

0

1.8.3.2. SEND DATA

PRINT # and PRINTUSING # send data over the serial port. Both

commands use the same formatting as PRINT and PRINTUSING.

PRINT # and PRINTUSING # appends a carriage-return (ASCII

value 13) and line-feed (ASCII value 10) characters at the end of

each message. To print a message without the terminating

NOTE

For example, the following uses PRINT # to send data:

-->STRING_MESSAGE = "ERROR"

-->PRINT #1, STRING_MESSAGE,"A1.PCMD=";A1.PCMD;

The output is:

ERROR A1.PCMD=0.000000000000000e+00

The values of the following variables are sent one after the other. The output

is (hexadecimal) 0x37 0x28:

I1=55

I2=40

PRINT #1, I1;I2

The output is:

5540

carriage-return and line-feed characters use a semicolon at the

end of the command.

M-SS-005-03 Rev E 9

Page 20

Overview 06/2005 Danaher Motion

1.8.3.3. SEND DATA BLOCK

PRINTTOBUFF # and PRINTUSINGTOBUFF # allows buffering of data

before actually being sent. This eliminates inter-character delays.

printtobuff #handle,chr$(0); chr$(message_length);

chr$(0);send=false

printtobuff #handle,chr$(request[ii]);send=false

printtobuff #handle,chr$(request[ii]);send=true

1.8.3.4. SEND/RECEIVE NULL CHARACTER

When using a specific protocol over Serial or TCP/IP ModBus RTU or

ModBus TCP), the NULL character is part of the message. The message

block cannot be saved in a STRING type variable since the NULL character

terminates the string.

To send a NULL character in a message, send the data as single bytes

instead of a string type message:

COMMON SHARED X[10] AS LONG

X[1]=0x10

X[2]=0

X[3]=0x10

PRINT #1, CHR$(X[1]);CHR$(X[2]);CHR$(X[3]);

The output is the following stream of bytes:

0x10, 0x0, 0x10

When the received data contains a NULL character, read the data from the

input buffer as single bytes instead of reading it into a string type variable.

Convert the incoming data to a numeric value to get its ASCII value:

DIM SHARED TEMP[10] AS DOUBLE

FOR IDX = 1 TO LOC(1)

TEMP[IDX] = ASC(INPUT$(1,#1))

NEXT IDX

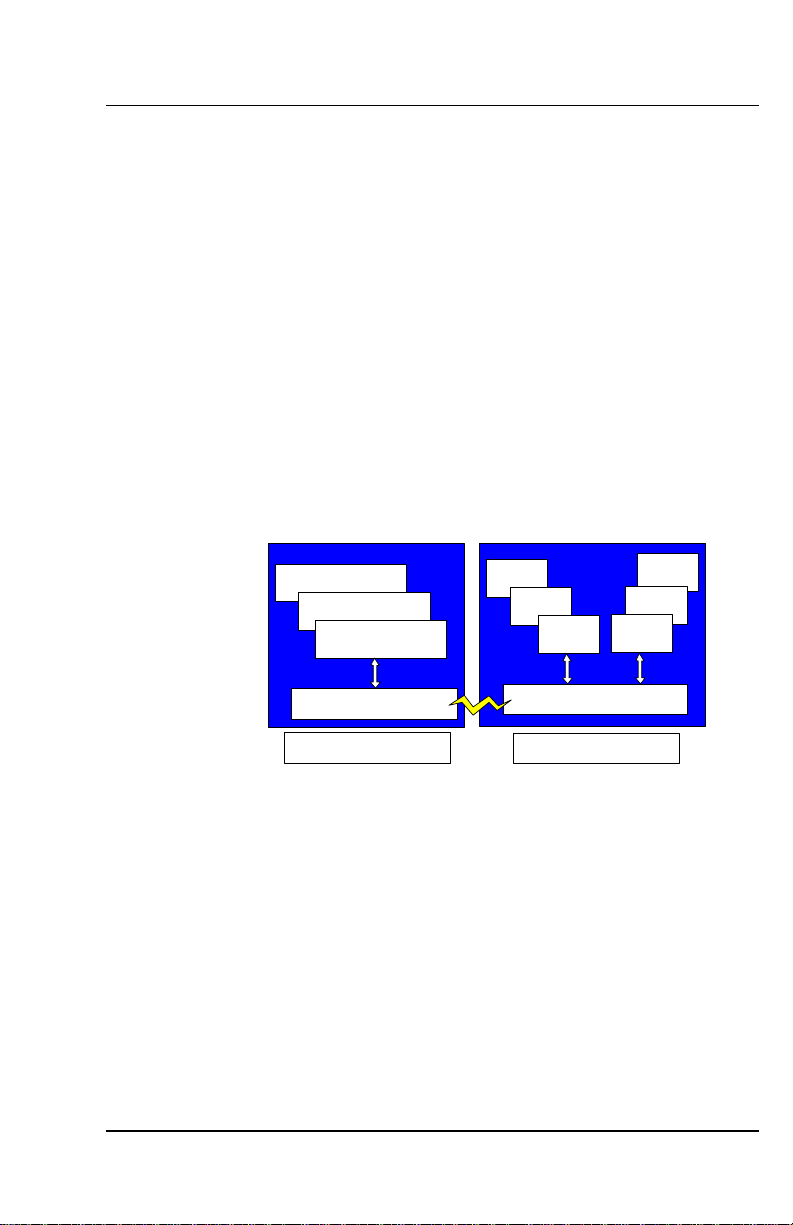

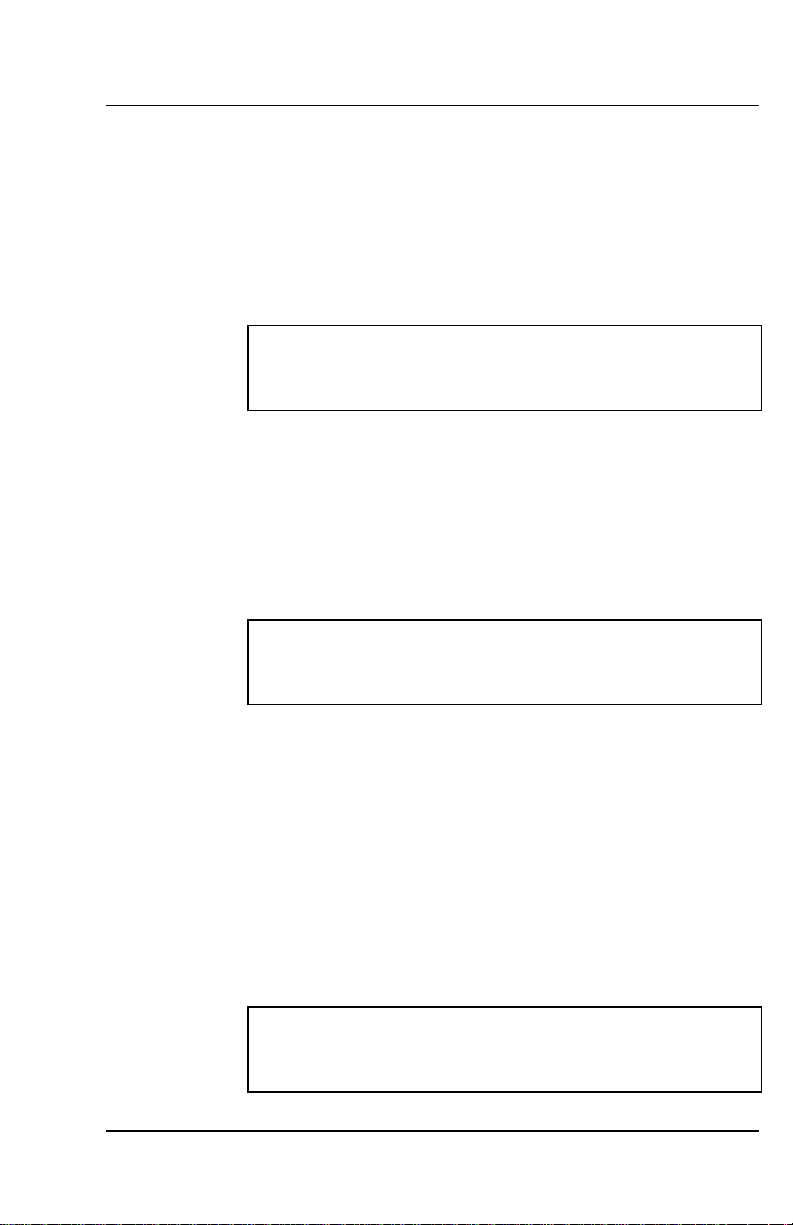

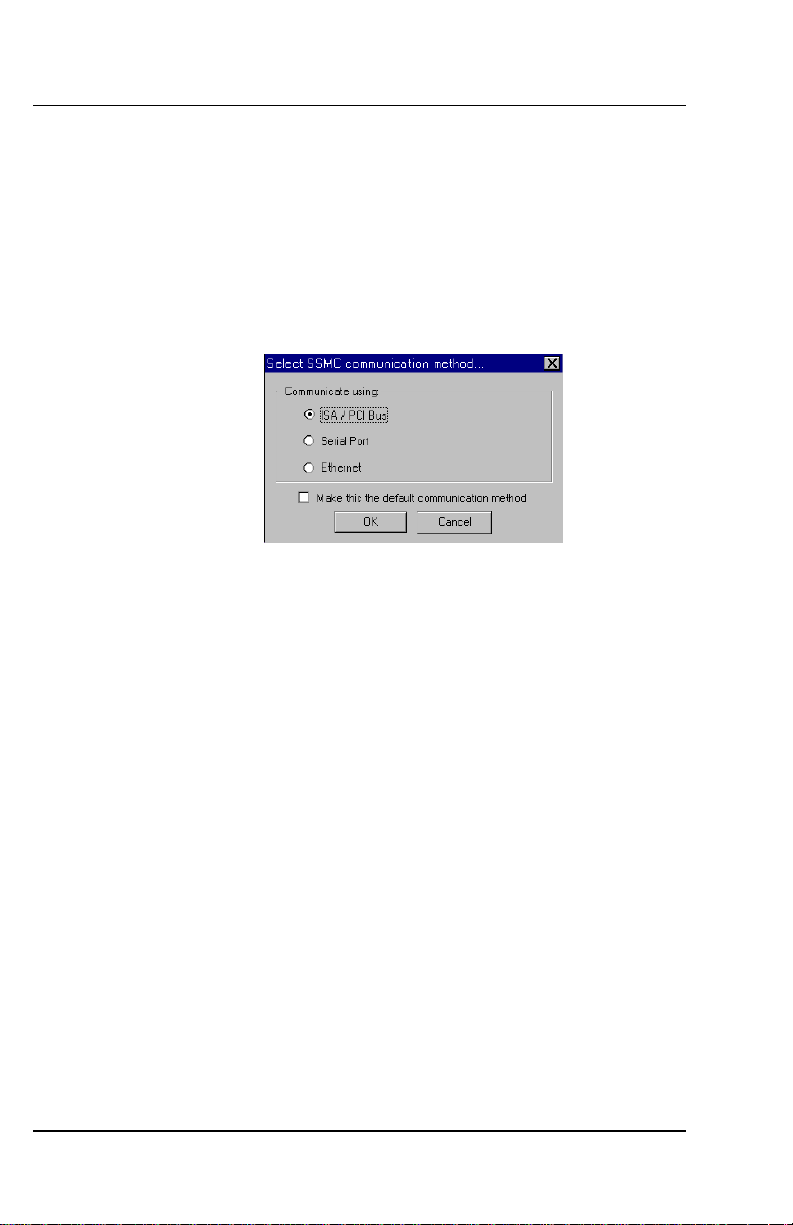

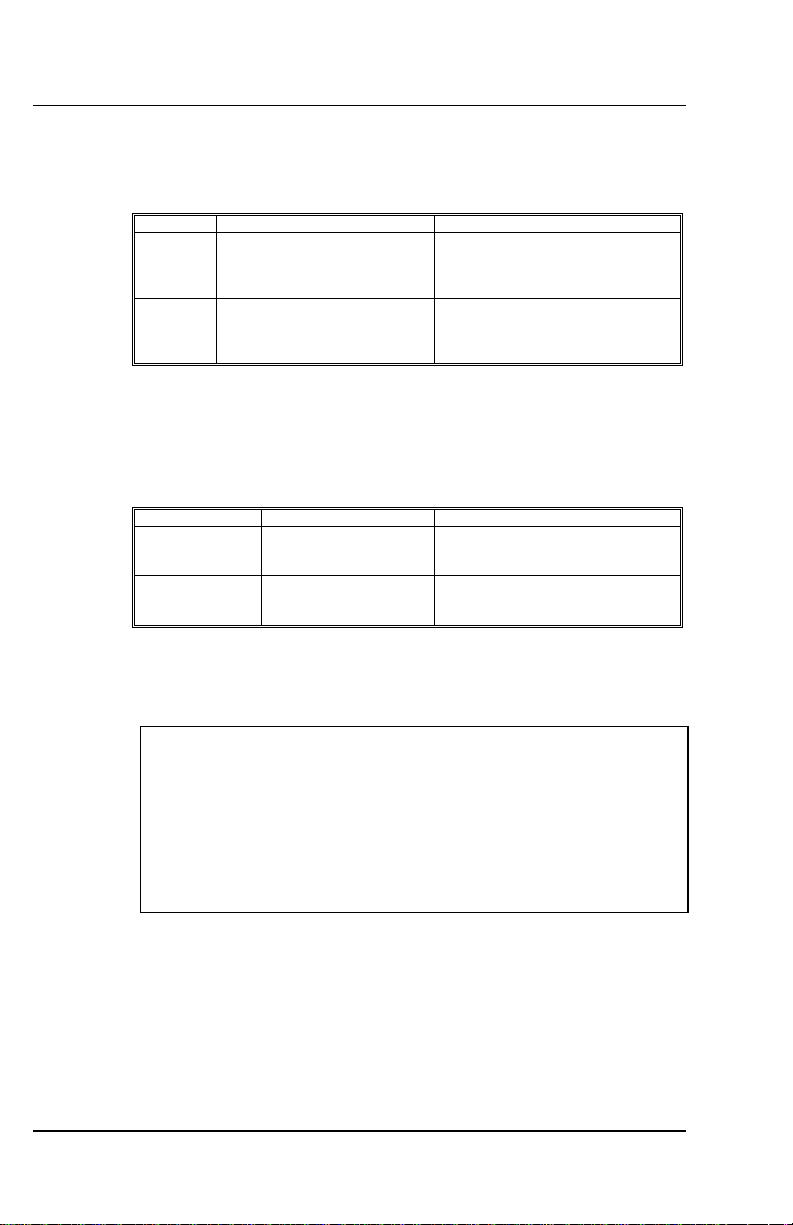

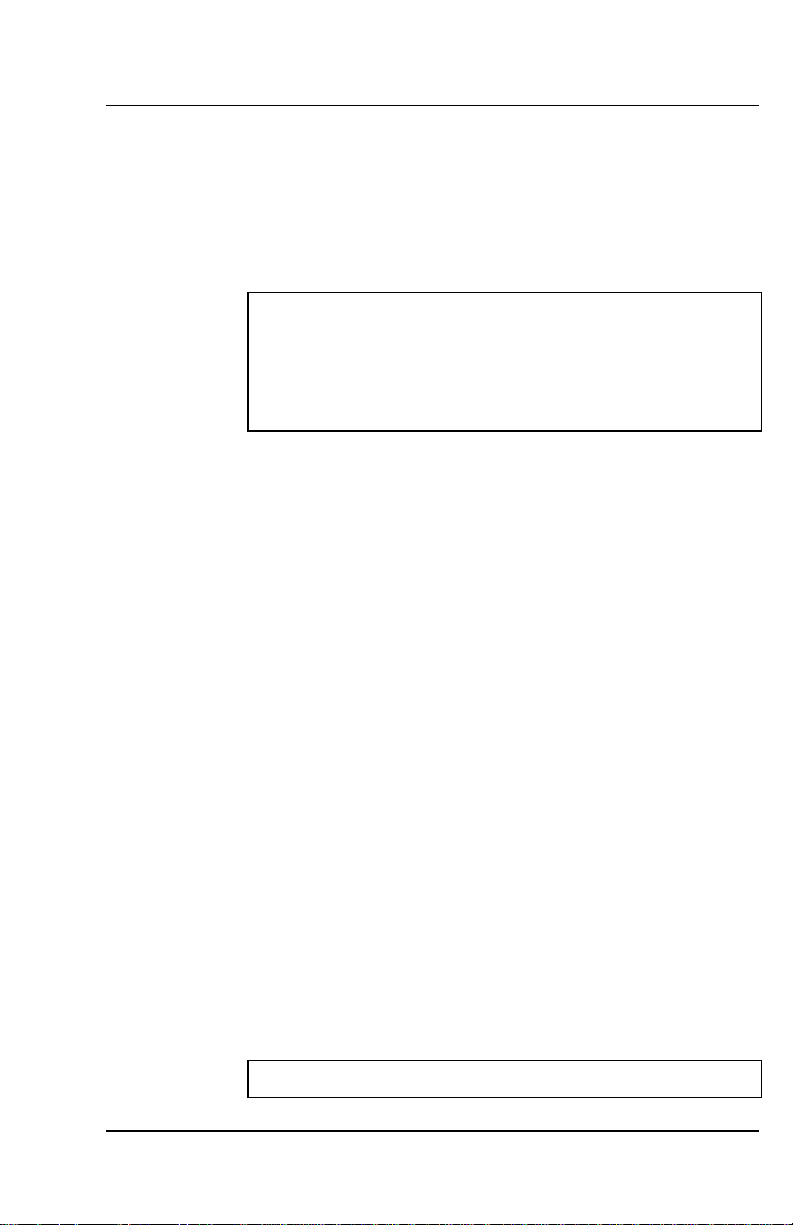

The figure below gives a general description of the TCP/IP communication

for both the client and host.

Client

Open TCP connection

(open socket)

Connect to specific

port and specific IP

address

Connect

Read

Write

Listen to specific

port and accept

connection

Server

Accept

Read

Write

Open Socket

Read

Write

Close

Read

Write

Close TCP connection

(close socket)

1.8.3.5. CLOSE CONNECTION

CLOSE closes the connection and releases the device handle:

-->CLOSE #1

10 Rev E M-SS-005-03l

Page 21

Danaher Motion 06/2005 BASIC Moves Development Studio

2. BASIC MOVES DEVELOPMENT STUDIO

BASIC Moves Development Studio (BMDS) provides Windows-based

project control for each application. BASIC Moves Development Studio

supports development for multi-tasking and also provides numerous tools

and wizards to simplify programming the MC.

BASIC Moves also provides modern debugging features such as allowing

task control by visually setting breakpoints, watch variables, and single

stepping. BASIC Moves automatically displays the data recorded on the MC

during operation. BASIC Moves provides all the tools you need for

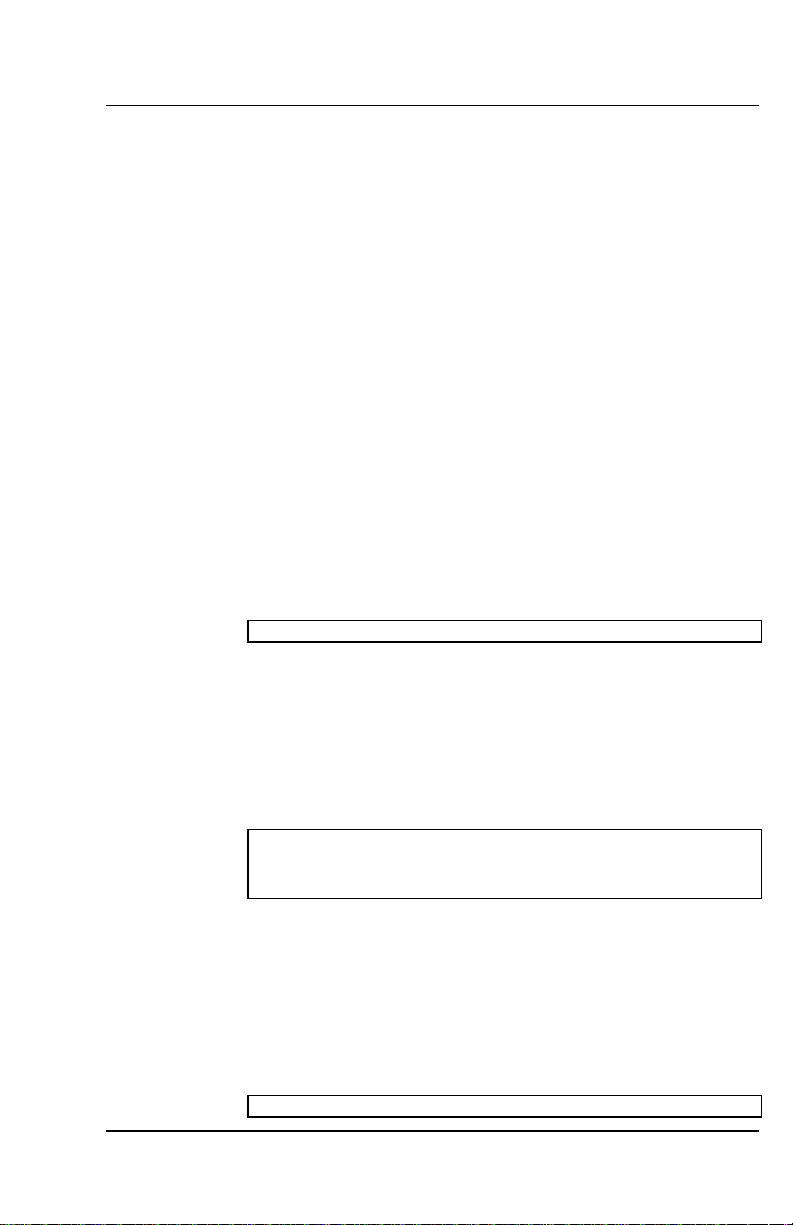

developing and debugging your application. When you start Basic Moves,

your first action is to select a method for communicating with your MC.

If you are using either a PCI or ISA model MC, choose ISA/PCI Bus. If you

are using a Stand-alone model MC, select either Serial Port or Ethernet

(communication method configured for your system). For more information

concerning communication with the stand-alone MC, refer to the Software

Installation section of the SERVOSTAR

MC Installation Manual.

2. 1 COMMUNICATION

Communicating with a stand-alone MC is not as automatic as is

comunicating with a PCI or ISA plug-in MC. Assuming you have properly

configured the communication method during installation of the BASIC

Moves Development Studio on your host computer, there are still some

operating procedures you may need to perform.

Ethernet

Serial

2. 2 MC-BASIC

The MC is programmed in MC-BASIC

the BASIC programming language enhanced for multi-tasking motion control.

If you are familiar with BASIC, you already know much of MC-BASIC. For

detailed information on any of the commands (including examples) used in

MC-BASIC, refer to the SERVOSTAR

M-SS-005-03 Rev E 11

If you configured Ethernet communications, subsequent communication

with the MC is automatically enabled and no further intervention is needed

unless you change the Ethernet network environment. If your network

environment changes, you may need to edit the IP address file. Refer to

the SERVOSTAR

The installation package includes the Virtual NIC device driver, which is

started automatically by Basic Moves Development Studio. No special

configuration is required. Refer to the SERVOSTAR

Manual for additional information.

MC Installation Manual for additional information.

MC Installation

® (

Motion Control BASIC), a version of

MC Reference Manual.

Page 22

BASIC Moves Development Studio 06/2005 Danaher Motion

To develop your application on the MC, you must install BASIC Moves

Development Studio. Refer to the software installation section of the

SERVOSTAR

MC Installation Manual for detailed instructions.

2.2.1. Instructions

Instructions are the building blocks of BASIC. Instructions set variables, call

functions, control program flow, and start processes such as events and

motion. In this manual we will use the terms instruction and command

interchangeably. For detailed information on any of the instructions (including

examples), refer to the SERVOSTAR

Syntax is the set of rules that must be observed to construct a legal

command (that is, a command the MC can recognize).

MC-BASIC is line-oriented. The end of the line indicates the end of the

instruction. Whitespace (i. e., spaces and tabs within the statement line and

blank lines), is ignored by the Basic interpreter. You can freely use

indentation to delineate block structures in your program code for easier

readability. The maximum allowed length of a line is 80 characters.

MC-BASIC is case insensitive. Commands, variable names, filenames, and

task names may be written using either upper case or lower case letters. The

only exception is that when printing strings with the “Print” and “PrintUsing”

commands, upper and lower case characters can be specified.

Syntax uses the following notation:

[ ] indicates the contents are required

{ } indicates the contents are optional for the command

Example lines of text are shown in Courier type font and with a border:

X = 1

MC Reference Manual.

2.2.2. Type

There are many types of instructions: comments, assignments, memory

allocation, flow control, task control, and motion. For detailed information on

any of the commands (including examples), refer to the SERVOSTAR

Reference Manual.

Comments allow you to document your program. Indicate a comment with

either the Rem command or a single apostrophe ('). You can add comments

to the end of an instruction with either Rem or an apostrophe.

Rem This is a comment

' This is a comment too.

X = 1 'This comment is added to the line X = 1

X = 1 REM This is a comment too

Use comments generously throughout your program. They are an asset

when you need support from others and they avoid confusing code.

Declarations allocate MC memory for variables and system elements

(groups, cam tables, etc.). This might be a simple type as an integer, or a

complex structure as a cam table.

Assignments Assignment instructions assign a new value to a variable.

The syntax of an assignment is

[Lvalue] [=] [expression]

For example:

X = Y + 1

12 Rev E M-SS-005-03l

MC

Page 23

Danaher Motion 06/2005 BASIC Moves Development Studio

The term, Lvalue, is a shorthand notation, which indicates the value to the

left of the equals sign. Valid Lvalues are variables or writable properties,

which can be assigned. Expressions can be variables, constants, properties

and function calls, as well as various combinations of them in arithmetic and

logical statements . An exception to this rule is generic elements’

assignment, at which the right side of the equal sign is not an expression, but

an axis or a group (either real or generic), and Lvalue is a generic elements.

If you assign a Double (floating point) value (expression, variable or

constant) to a Long variable, the fractional portion of the double value is

truncated, and the integer portion is assigned to the long variable. To query a

variable or expression from the BASIC Moves terminal window, use the

PRINT or ? command:

PRINT 1/100

? X1

MC-BASIC also provides the standard PRINTUSING (PrintU) command for

formatted printing.

Commands for flow control change the way your program is executed.

Without flow control, program execution is limited to processing the line

immediately following the current command. Examples of flow control include

GOTO, FOR…NEXT, and IF…THEN.

MC-BASIC is a multi-tasking language in which many tasks can run

concurrently. Generally, tasks run independently of each other. However,

tasks can control each other using inter-task control instructions. One task

can start, idle, or terminate another task.

Most commands are started and finished immediately. For example:

x = 1 ' this line is executed completely…

y = 2 ' …before this line is started

For general programming, one command is usually finished before the next

command starts. Effects of these commands do not persist beyond the time

required to execute them. However, the effects of many other commands

persist long after the execution of the command. In general programming, for

example, the effects of opening a file or allocating memory persist

indefinitely. In real-time systems, persistence is more complicated because

the duration of persistence is less predictable.

Consider a command that specifies a 1,000,000 counts move on an axis

named, A2:

Move A2 1000000.0

Y = 2

The MC does not wait for the 1,000,000 move to be complete before

executing Y=2. Instead, the first command starts the motion and then the MC

continues with the next line (Y = 2). The move continues well after the move

command has been executed.

Persistence can affect programs. For example, you may not want to start one

move until the previous move is complete. In general, you need access to

persistent processes if you are to control your program according to their

state of execution. As you will see later, MC-BASIC provides this access.

M-SS-005-03 Rev E 13

Page 24

BASIC Moves Development Studio 06/2005 Danaher Motion

2.2.3. Constants and Variables

All constant, variable and system element names must start with an

alphabetical character (a-z, A-Z) and may be followed with up to 31

alphabetical characters, numbers (0-9) and underscores (“_”). Keywords

may not be used as names. For detailed information on any of the constants

and variables (including examples), refer to the SERVOSTAR

MC

Reference Manual.

2.2.3.1. CONSTANTS

Constants are numbers, which are written as ordinary text characters; for

example, 161. Constants can be written in decimal or in hexadecimal (HEX).

To write a constant in hex, precede it by a 0x; for example, 0xF is the hex

representation of 15 decimal.

The MC provides numerous literal constants (reserved words with a fixed

value). You can use these constants anywhere in your program to make your

code more intuitive and easier to read. For example:

A1.Motion = ON

turns on the A1 property Motion. This is more intuitive to read than:

A1.Motion = 1

although the effect is identical.

2.2.3.1.1 Literal Constants Table

ABORT = 4 NEGATIVE = -1

ABOVE = 2 NEXTMOTION or NMOT = 2

BELOW = 1 NOFLIP = 1

CAM = 2 NOOVERLAP = 0

CAPTURING = 16 NOTELEVEL = 3

CLEARMOTION or CMOT = 3 OFF = 0

CLOSE = 0 ON = 1

CONTINUE or CONT = 1 ONPATH = 2

ENDMOTION or EMOT = 3 OPEN = 1

ERRORLEVEL = 2 OVERLAP = 1

EXTERNAL = 1 PI = 3.14159265359

FALL = 2 POSITIVE = 1

FALSE = 0 RESTART = 1

FAULTLEVEL = 1 RIGHTY = 2

FLIP = 2 RISE = 1

GEAR = 1 SILENTLEVEL = 0

GENERATORCOMPLETED or GCOM = 3 SUPERIMMEDIATE or SIMM = 5

HALT = 0 SYNC = 4

HOMING = 10 TASK_ERROR = 4

IDN_CAPTURE1ENABLE = 405 TASK_IGNORE = -1

IDN_CAPTURE1POSITIVELATCHED = 409 TASK_INCORRECT = 9

IDN_CAPTURE1NEGATIVELATCHED = 410 TASK_INTERRUPTED = 0x200

IMMEDIATE or IMMED = 1 TASK_KILLED = 10

INPOSITION or INPOS = 2 TASK_LOCKED = 0x100

LEFTY = 1 TASK_READY = 7

MAXDOUBLE = 1.797693134862311e+308 TASK_RUNNING = 1

MAXLONG = 2147483647 TASK_STOPPED = 2

MINDOUBLE = -1.797693134862311e+308 TRACK = 3

MINLONG = -2147483648 TRUE = 1

MULTIPLE = 1

2.2.3.2. VARIABLES

You must declare a variable in MC-BASIC before you can it. In the

declaration, you define variable name, scope and variable type. MC-BASIC

supports Long for integer values, Double for floating point values, and String

for ASCII character strings.

14 Rev E M-SS-005-03l

Page 25

Danaher Motion 06/2005 BASIC Moves Development Studio

Besides these basic types, MC-BASIC also supports Structure-like variables

and some MC-BASIC specific types, such as points (Joints and Locations),

generic motion elements (Axes and Groups) and UEAs (user error

assertions-Errors and Notes).

DeleteVar deletes a global variable. Since variable name can include

wildcards, a single DELETEVAR can be used to delete more than one

variable.

DeleteVar int1

DeleteVar int* ' Deletes all variables starting with int

Current values of global variables (both scalar and arrays) can be stored in a

Prg file, in assignment format, within an automatically executable Program

Continue…Terminate Program block. Obligatory parameters of SAVE are

the name of storage file, and type of stored variables (could be all types).

Optional parameters are robot type (for point variables), variable name

(which may include wildcards) and mode of writing to storage file (overwriting

or appending). Variable types available for storage through SAVE are longs,

doubles, strings, joints and locations, but not structures, user-defined

exceptions nor generic motion elements.

Save File = “IntFile.Prg” Type = All VariableName = “int*”

‘ Save all variables starting with int in IntFile.Prg (overwrite file)

Save File = “Points.Prg” Type = Joint RobotType = XYZR Mode = Append

‘ Append all joint-type points with XYZR robot-type to Points.Prg file

Scope defines how widely a variable can be accessed. The broadest scope

is global. A global variable can be read from any part of the system software.

Other scopes are more restrictive, limiting access of variables to certain

sections of code. MC-BASIC supports three scopes: global, task, and local.

Task variables can be read from or written to anywhere within the task where

it is defined, but not from outside the task. Local variables can only be used

within their declaration block, i.e. program, subroutine or function blocks. The

scope of a variable is implicitly defined when a variable is declared using the

keywords: Common, Shared, and Dim.

Global variables can be defined within the system configuration task,

Config.Prg, within a task files (Prg files), before the program block, within

library files (Lib files), before the first subroutine or function block, or from the

terminal window of BASIC Moves. To declare a variable of global scope use

the Common Shared instruction.

Task variables are defined within a task or a library. To declare a variable of

task scope use the Dim Shared instruction.

All Dim Shared commands must appear above the Program

statement in task files. In library files, all Dim Shared commands

must appear above the first block of subroutine or function. The

values of variables declared with Dim Shared persist as long as the

task is loaded, which is usually the entire time the unit is

NOTE

operational. This is commonly referred to as being static.

Local variables are defined and used within a program, a subroutine, or a

function. To declare a local variable, use the Dim instruction. The Dim

command for local variables must be entered immediately below the

Program, Sub, or Function statement. Local variables cannot be declared

within event blocks, and events cannot use local variables declared within

the program.

M-SS-005-03 Rev E 15

Page 26

BASIC Moves Development Studio 06/2005 Danaher Motion

2.2.4. Data Types

MC-BASIC has two numeric data types: Long and Double. Long is the only

integer form supported by MC-BASIC. Long and Double are MC-BASIC's

primitive data types.

Type Description Range

Long 32 bit signed integer -2,147,483,648 (MinInteger)to

Double Double precision floating point

(about 16 places of accuracy)

MC-BASIC provides the string data type which consists of a string of ASCIIcoded characters. MC-Basic strings are dynamic. Reallocation of memory for

new strings is preformed through a simple assignment of the string variable,

and there is no need to specify the length of the new string. A full

complement of string functions is provided to create and modify strings.

Type Description Range

String ASCII character string (no string length limit) 0 to 255 (ASCII code)

MC-BASIC has two point data types: JOINT and LOCATION. A point

variable is related to a robot type. Robot type examples: XY – two axes XY

table, XYZ – three axes XYZ system, XYZR – three cartesian axes + roll, etc.

Type Description Range

Joint A set of 2-10 double precision

Location A set of 2-10 double precision

floating point joint (motor)

coordinates

floating point cartesian coordinates

MC-Basic enables definition of structure-like data types, composed of a

limited number of long, double, string and point (joint and/or location) scalar

and array elements. Array elements can have only a single dimension. Name

of structure type and composition of elements are defined by the user within

configuration file (Config.Prg).