Kollmorgen MKD-C, MKD-N060007, MKD-N060607, MKD-N120007, MKD-N120607 Product Safety Manual

...Page 1

MKD®-C, MKD®-N

Product Safety Guide

Edition: -, January 2019

Part Number 904-200024-99

English Deutsch Français Italiano Português Español Русский

Original language is English. All other content is translated from the genuine English content.

For safe and proper use, follow

these instructions.

Keep them for futurereference.

Page 2

Record of Document Revisions

Revision Remarks

...

Table with lifecycle information of this document see (➜ # 79)

A, 01/2019 First edition

Contents

Product Safety Guide English (➜ # 3) Product Safety Guide Português (➜ # 47)

Product Safety Guide Deutsch (➜ # 23) Product Safety Guide Español (➜ # 49)

Product Safety Guide Français (➜ # 43) Product Safety Guide Русский (➜ # 51)

Product Safety Guide Italiano (➜ # 45)

Appendix/Dimensions (➜ # 55) Appendix/Faults and Warnings (➜ # 74)

Appendix/Connections (➜ # 57) Appendix/Approvals (➜ # 77)

Hardware Revision (HR)

MKD-N MKD-C Firmware WorkBench Remarks

A A from 1.18 from 1.18 MKD-C and MKD-N start revisions

Technical changes which improve the performance of the device may be made without prior notice!

This document is the intellectual property of Kollmorgen. All rights reserved. No part of this work may be reproduced

in any form (by photocopying, microfilm or any other method) or stored, processed, copied or distributed by electronic

means without the written permission of Kollmorgen.

Technische Änderungen zur Verbesserung der Leistung der Geräte ohne vorherige Ankündigung vorbehalten.

Dieses Dokument ist geistiges Eigentum von Kollmorgen. Alle Rechte vorbehalten. Kein Teil dieses Werkes darf in

irgendeiner Form (Fotokopie, Mikrofilm oder in einem anderenVerfahren) ohne schriftliche Genehmigung von Kollmorgen reproduziert oder elektronisch verarbeitet, vervielfältigt oder verbreitet werden.

Sous réserve de modifications techniques apportés en vue d'amélioration des appareils!

Ce document est la propriété intellectuelle de Kollmorgen.Tous droits réservés. Sans autorisation écrite de

l'entreprise Kollmorgen, aucune partie de cet ouvrage n'a le droit d'être ni reproduite par des moyens quelconques

(impression, photocopie, microfilm ou autre procédure) ni traitée, polycopiée ou distribuée électronique.

Il produttore si riserva la facoltà di apportare modifiche tecniche volte al miglioramento degli apparecchi

Questo documento è la proprietà intellettuale di Kollmorgen. Tutti i diritti riservati. Nessuna parte del documento può

essere riprodotta in qualsiasi forma (fotocopia, microfilm o altro processo) senza l’approvazione scritta della ditta Kollmorgen o rielaborata, riprodotta o diffusa mediante l’uso di sistemi elettronici.

Alterações técnicas que melhoram o desempenho do dispositivo podem ser feitos sem aviso prévio!

Este documento é uma propriedade intelectual da Kollmorgen. Todos os direitos reservados. Nenhuma parte deste

trabalho pode ser reproduzida sob qualquer forma (por fotocópia, microfilme ou qualquer outro método) ou

armazenado, processado, copiado ou distribuído por meios eletrônicos sem a permissão escrita da Kollmorgen.

Los cambios técnicos que mejoran el rendimiento del dispositivo pueden llevarse a cabo sin aviso previo.

Este documento es propiedad intelectual de Kollmorgen. Todos los derechos reservados. Ninguna parte de esta

obra, bajo concepto alguno, podrá reproducirse (por fotocopia, microfilm ni ningún otro método) ni almacenarse, procesarse, copiarse ni distribuirse por medios electrónicos sin el permiso por escrito de Kollmorgen.

Сохраняется право внесения технических изменений с целью усовершенствования приборов!

Настоящий документ является интеллектуальной собственностью Kollmorgen. Все права защищены.

Воспроизведение любой части данного издания в любой форме (фотокопия, микрофильм или иной метод) или

редактирование, размножение или распространение с помощью электронных систем без письменного

разрешения компании Kollmorgen запрещаются.

2 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 3

MKD Product Safety Guide | 1 English

1 English

1.1 General 4

1.1.1 Notes for the Printed Edition (paper version) 4

1.1.2 Symbols Used 5

1.2 Product Safety 6

1.2.1 You should pay attention to this 6

1.2.2 Use as Directed 8

1.2.3 ProhibitedUse 9

1.2.4 Warning note labels 9

1.3 Product life cycle handling 10

1.3.1 Transport 10

1.3.2 Packaging 10

1.3.3 Storage 10

1.3.4 Installation, setup and normal operation 11

1.3.5 Decommissioning 11

1.3.6 Maintenance and cleaning 11

1.3.7 Disassembly 11

1.3.8 System Repair 12

1.3.9 Disposal 12

1.4 Technical description and general data 13

1.4.1 Package Supplied 13

1.4.2 Part Number Scheme 14

1.4.3 Ambient Conditions in normal operation 15

1.4.4 Electrical Data 15

1.4.5 System limits 15

1.5 Safe Torque Off (STO) 16

1.6 Mechanical Installation 17

1.6.1 Important Notes 17

1.6.2 Guide to Mechanical Installation 17

1.7 Electrical Installation 18

1.7.1 Important Notes 18

1.7.2 Guide to electrical installation 18

1.8 Setup 19

1.8.1 Important Notes 19

1.8.2 Initial System Test 20

1.9 Troubleshooting the MKD System 21

Kollmorgen | kdn.kollmorgen.com | January 2019 3

Page 4

MKD Product Safety Guide | 1 English

1.1 General

This manual, the MKD-C/N Product Safety Guide, presents the relevant information for safe

installation and setup of MKD drive system modules MKD-C power supply and MKD-N servo

drive.

For full informationrefer to the MKD-C/N Installation Manual, to the AKD-N Installation

Manual and additional Kollmorgen documents.

Additional documents include the following:

WorkBench Online Help: describes how to use the system in common applications. It

also provides tips for maximizing your system performance. The Online Help includes the

Parameter and Command Reference Guide which provides documentation for the parameters and commands used to program the system.

EtherCAT Communication: describes how to use the system in EtherCAT applications.

These documents can be found on the DVD in the drive package. All documents can be

downloaded from the Kollmorgen website www.kollmorgen.com.

1.1.1 Notes for the Printed Edition (paper version)

A printed version of the manual is enclosed with each product. For

environmental reasons, the document was reduced in size and printed on DIN A5.

Should you experience difficulties reading the font size of the

scaled-down printed version, you can print and use the PDF version in DIN A4 format 1:1. You can find the PDF version on the

DVD accompanying the product and on the Kollmorgen website.

4 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 5

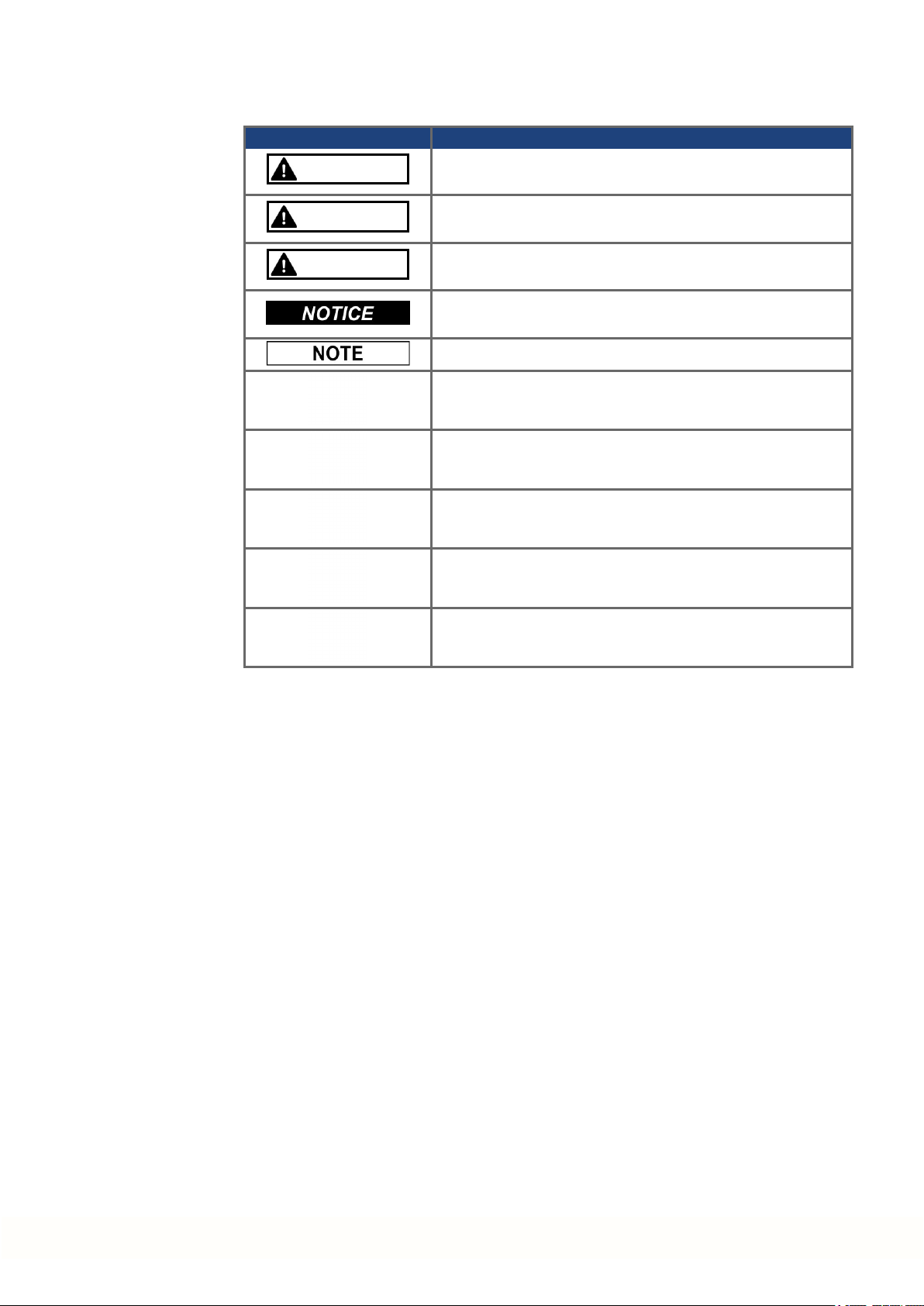

1.1.2 Symbols Used

Symbol Indication

DANGER

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

MKD Product Safety Guide | 1 English

WARNING

CAUTION

Indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

Indicates situations which, if not avoided, could result in property damage.

This symbol indicates important notes.

Warning of a danger (general). The type of danger is specified

by the text next to the symbol.

Warning of danger from electricity and its effects.

Warning of danger from hot surface.

Warning of danger from suspended loads.

Warning of danger from automatic start.

Kollmorgen | kdn.kollmorgen.com | January 2019 5

Page 6

MKD Product Safety Guide | 1 English

1.2 Product Safety

1.2.1 You should pay attention to this

Specialist staff required!

Only properly qualified personnel are permitted to perform such tasks as transport, installation and setup. Qualified specialist staff are persons with expertise in transport, installation,

assembly, commissioning and operation of electrotechnical equipment.

Transport, storage, unpacking: only by personnel with knowledge of handling electrostatically sensitive components.

Mechanical installation: only by personnel with mechanical expertise.

Electrical installation: only by personnel with expertise in electrical engineering.

Basic tests / setup: only by personnel with expertise in electrical engineering and drive

technology.

The qualifiedpersonnel must know and observe ISO 12100 / IEC 60364 / IEC 60664and

national accident prevention regulations.

Read the documentation!

Read the availabledocumentation before installation and commissioning. Improper handling

of the devices can cause harm to people or damage to property. The operator of systems

using the drive system must ensure that all personnel who work with the drive read and understand the manual before using the drive.

Check Hardware Revision!

Check the Hardware Revision Number of the product (see product label). Hardware Revsion

Number of MKD-C and MKD-N can differ from each other. This numberis the link between

your product and the manual. The product HardwareRevision Numbermust match the Hardware Revision Number on thecover page of the manual.

Pay attention to the technical data!

Adhere to the technical data and the specifications on connection conditions. If permissible

voltage values or current values are exceeded, the devices can be damaged. Unsuitable

motor or wrong wiring will damage the system components. Check the combination of drive

andmotor. Compare the rated voltage and current of the units.

Perform a risk assessment!

The manufacturerof the machine must generate a risk assessment for the machine, andtake

appropriate measures to ensure that unforeseen movements cannot cause injury or damage

to any person or property. Additional requirements on specialist staff may also result from the

risk assessment.

The manufacturershould define periodic checks of the electrical components and application.

Automatic Restart!

The drive might restart automatically after power on, voltage dip or interruption of the supply

voltage, depending on theparameter setting.

Risk of death orserious injury for humans working in the machine.

If the parameterDRV.ENDEFAULT for one MKD-N is set to 1, then place a warning sign to

the machine (Warning: Automatic Restart at Power On)and ensure, that poweron is not possible, while humans are in a dangerous zoneof the machine. In case of usingan undervoltage protection device, you must observe EN 60204-1:2006 chapter 7.5 .

6 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 7

MKD Product Safety Guide | 1 English

Observe electrostatically sensitive components!

The devices contain electrostatically sensitive components which may bedamaged by incorrect handling. Electrostatically discharge your body before touching the device. Avoid contact with highly insulatingmaterials (artificial fabrics, plastic film etc.). Place the device on a

conductive surface.

Hot surface!

Drives may have hot surfaces during operation. The housing can reach temperatures above

80°C. Risk of minorburns! Measure the temperature, and wait until the housing has cooled

down below 40 °C before touching it.

Earthing!

It is vital that you ensure that the drive is safely earthed to the PE (protective earth) busbarin

the switch cabinet. Risk of electric shock. Without low-resistance earthing no personal protection can be guaranteed.

Leakage Current!

Since the leakage current to PE is more than 3.5 mA, in compliance with IEC61800-5-1 the

PE connection must either be doubledor a connecting cable with a cross-section >10 mm²

must be used. Deviating measures accordingto regional standards might be possible.

Residual current protective or monitoring devices!

MKD-C with MKD-N can cause a d.c. current in the protective earthingconductor. Wherea

residual current-operated protective (RCD) or monitoring(RCM) device is used for protection

in case of direct or indirect contact, only an RCD or RCM of Type B is allowed on the supply

side of MKD-C.

Lethal voltages!

The equipment produces highelectric voltages up to 900V. Lethal danger exists at live parts

of the device. Do not open or touch the equipment during operation. Keep theIP 54 cabinet

doors closed duringoperation. Built-in protection measures such as insulation or shielding

may not be removed. Work on the electrical installation may only be performed by trained

andqualified personnel, in compliance with the regulations for safety at work, and only with

switched off mains supply, and secured against restart.

Never undo any electrical connections to the MKD while it is live. Thereis a dangerof electrical arcing with damage to contacts and personal injury. Wait at least 5 minutes after disconnecting the product from the supply voltages (mains supply and 24V supply) before

touching potentially live sections of the equipment (such as contacts) or removing any connections.

Functional Safety

Safety functionality is not approved nor certified. Do not use this functionality in applications

with functional safety request.

Never modify the drive!

It is not allowed to modify the drive hardware without permission by the manufacturer. Opening the housingcauses loss of warranty.

Kollmorgen | kdn.kollmorgen.com | January 2019 7

Page 8

MKD Product Safety Guide | 1 English

1.2.2 Use as Directed

The MKD-C series powersupplies are exclusively intended for operatingMKD-N servo drive

modules within a cabinet and AKD-N decentralized servo drives.

The MKD-N family of servo drives is exclusively intended for driving suitable synchronous

servomotors with closed-loop control of torque, speed, and/or position.

MKD system modules arecomponents that are built into electrical plants or machines and

can only be operatedas integral components of these plants or machines. The manufacturer

of the machinemust generate a risk assessment for the machine.

When the system modules are built into machines or plant, the drive must not be used until it

has been established that the machine orplant fulfills the requirements of the regional directives.

Kollmorgen multi axes drive system

MKD must only be operated in a motion system with components from Kollmorgen. Required

additional Kollmorgencomponents are the mains chokes, hybrid string cables, hybrid motor

cables, motor power and feedback cables, servomotors.

Assembling

MKD modules must only be operated in environments suitable for the ambient conditions

defined on(➜ # 15).

Wiring

Use only Kollmorgen cables for connecting the system components.

Power supply

MKD-C must be powered from a 3 phase industrial supply network

(not more than 42 kA symmetrical rated current at 400 V and 480 V) via a mains choke 3YL.

MKD-N series drives must be powered by MKD-C intelligent power supply modules with DC

voltage from 55 VDC up to 800 VDC.

Fusing

The devices must be operatedwith fuse protection against power overload.

Motor voltage rating

The rated voltage of the motors must be at least as high as the DC bus link voltagedivided by

√2 produced by the drive (U

nMotor

>=UDC/√2).

For the cases of group installations and of DC powered drives

MKD has not been evaluated by Kollmorgen, UL, or TÜV for group installations norare ratings defined for DC input voltage.

Auxiliary voltage supply, Standby power

Standby power for the drive strings must only be used for supplying the MKD-N electronics.

24 VDC supply unit must accord to PELV (EN 60204-1) requirements.

Safe torque off

Safety functionality is not approved nor certified. Do not use this functionality in applications

with functional safety request.

8 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 9

1.2.3 Prohibited Use

Otheruse thanthat described in chapter “Use as directed”is not intended and can lead to personnel injuries and equipment damage.

The system may not be used

The use of the device in the following environments is also prohibited:

Wiring the system with hybrid cables from othermanufacturers than Kollmorgen is not

allowed. Changing Kollmorgen cables or connectors is not allowed.

MKD Product Safety Guide | 1 English

with a machine that does not comply with appropriate national directives or standards,

for driving elevators,

in applications with continuous, operational short circuits to the external regen resistor

contacts.

in applications with any short circuits to the DC-Bus link contacts.

potentially explosive areas

environments with corrosive and/or electrically conductive acids, alkaline solutions, oils,

vapors, dusts

ships or offshoreapplications

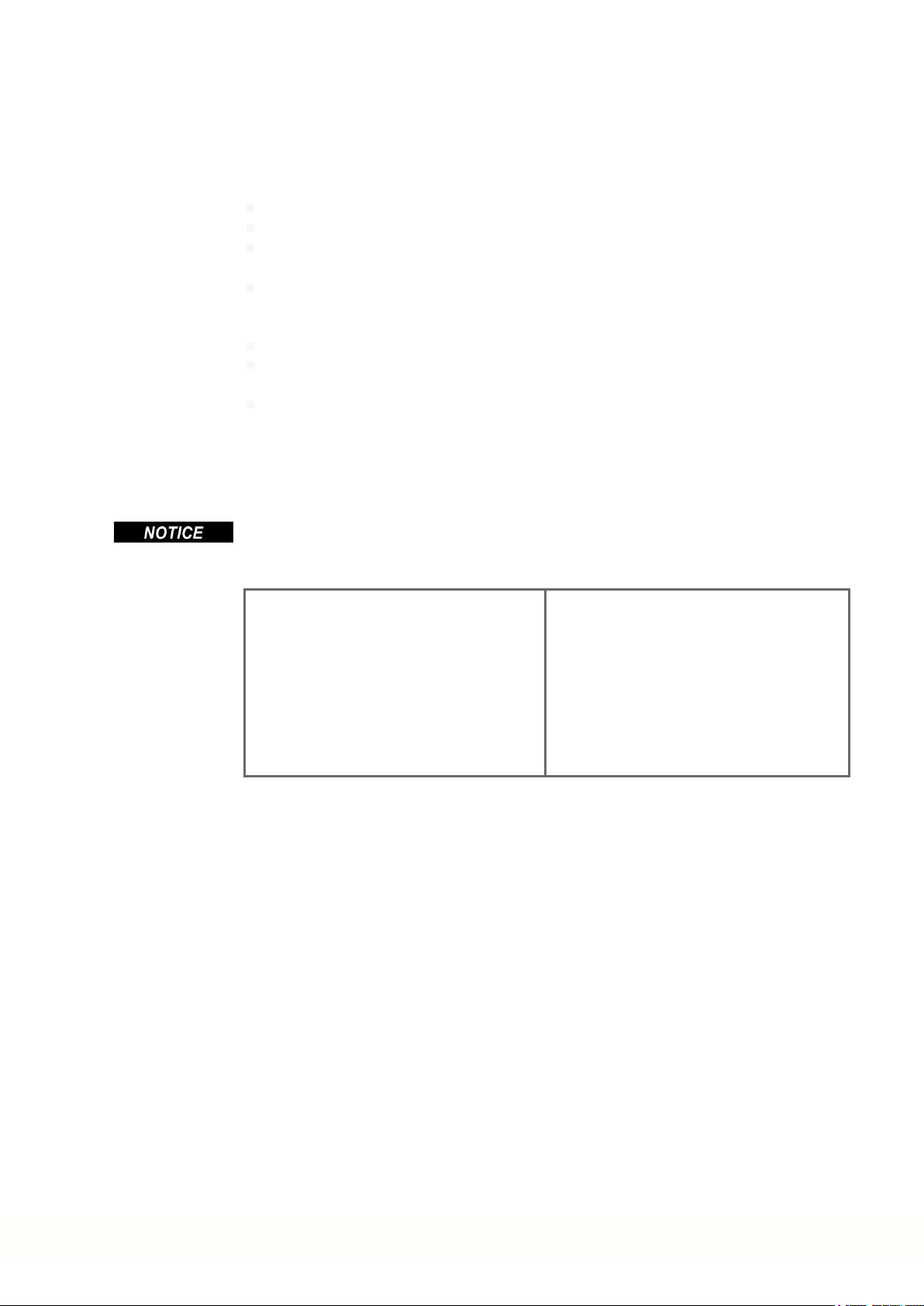

1.2.4 Warning note labels

If these signs are damaged, they must be replaced immediately.

1.2.4.1 Notes placed on the product

The minimum size of the

protective earthing conductor

shall comply with the local safety

regulations for highprotectice

earthingconductor current.

Residual Voltage

Wait 5 minutes after removing

powerbefore servicing.

Kollmorgen | kdn.kollmorgen.com | January 2019 9

Page 10

MKD Product Safety Guide | 1 English

1.3 Product life cycle handling

1.3.1 Transport

Transport the MKD modules in accordance with IEC 61800-2as follows:

Transport only by qualified personnel in the manufacturer’s original recyclable packaging.

Avoid shocks while transporting.

Vibration/Shock: MKD modules are tested for environmental class 3M1 of IEC 60721-3-2.

Store at or below maximum stacking height of 8 cartons

Transport only within specified temperature ranges: -25 to +70 °C, max. rate of change 20

K/hour, class 2K3.

Transport only within specified humidity: maximum 95% relative humidity, no condensation, class 2K3.

The devices contain electrostatically sensitive components that can be damaged by incorrect handling. Electrostatically discharge yourself before touching the device. Avoid contact

with highly insulating materials, such as artificial fabrics and plastic films. Place the device

on a conductive surface.

If the packagingis damaged, check the unit for visible damage. Inform the shipper andthe

manufacturer of any damageto the package or product.

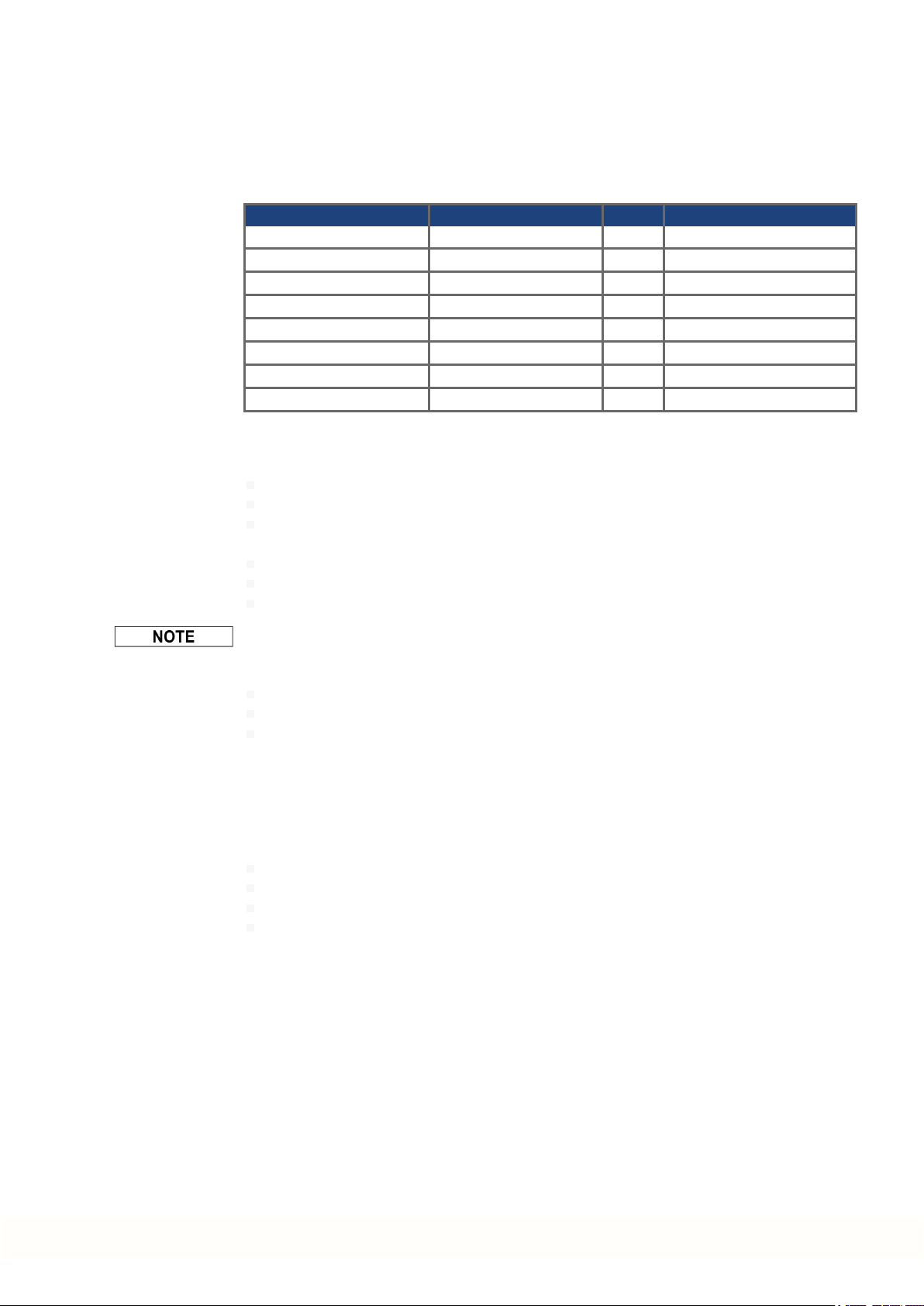

1.3.2 Packaging

1.3.3 Storage

The MKD packaging consists of recyclable cardboard with inserts and a label on the outside

of the box.

Model Package Dimensions

(mm) HxWxL

MKD-C003007 580x 350 x 170 22.5

MKD-N060007

MKD-N060607

MKD-N120007

MKD-N120607

MKD-N121207

MKD-N240007 580x 350 x 110 9.5

MKD-N480007 580x 350 x 140 11.5

Store the MKD modules in accordance with IEC 61800-2as follows:

Store only in the manufacturer’s original recyclable packaging.

Store at or below maximum stacking height of 8 cartons

Store only within specified temperature ranges: -25 to +55 °C, max.rate of change20

K/hour, class 1K4.

Storage only within specified humidity: 5 to 95% relative humidity, no condensation, class

1K3.

Store the MKD in accordance with the following durationrequirements:

Less than 1 year: without restriction.

More than 1 year: capacitors in the MKD-C must be re-formed before setting upand

operating the system. Re-forming procedures are described in the Kollmorgen

Developer Network (Forming).

580x 350 x 110 8.5

Total Weight

(kg)

10 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 11

1.3.4 Installation, setup and normal operation

Installation and setup information aregiven in this Guide:

Mechanical installation (➜ # 17)

Electrical installation (➜ # 18)

Setup (➜ # 19)

Normal operationtested for environmental class 3K3 according to IEC 61800-2 (➜ # 15).

The manufacturerof the machine defines the necessary end user expertise based onthe risk

assessment for the machineand describes the requirements for normal operation based on

the application.

1.3.5 Decommissioning

Only professional staff who are qualified in electrical engineering are allowedto decommission parts of the system.

DANGER: Lethal Voltages!

There is a dangerof serious personal injury or death by electrical shock or electrical arcing.

Switch off the mainswitch of the switchgearcabinet.

Securethe system against restarting.

Block the mainswitch.

Wait at least 5 minutes after disconnecting.

MKD Product Safety Guide | 1 English

1.3.6 Maintenance and cleaning

The device does not require maintenance. Opening the device voids the warranty. The inside

of the unit can only be cleaned by the manufacturer.

Do not immerse orspray the device. Avoid that liquidenters the device.

To clean the device exterior:

1. Decommission the device (see chapter 1.3.5 "Decommissioning").

2. Casing: Clean with isopropanol or similar cleaning solution.

Caution : Highly Flammable! Risk of injury by explosion and fire.

Observe the safety notes given on the cleaning liquid package.

Wait at least 30 minutes after cleaning beforeputting the device back into operation.

3. Protective grill on fan: Clean with a dry brush.

1.3.7 Disassembly

Only professional staff who are qualified in electrical engineering are allowedto disassemble

parts of the system.

1. Decommission the device (see chapter 1.3.5 "Decommissioning").

2. Check temperature.

CAUTION: High Temperature! Risk of minor burns. During operation, the heat sink of

the drive may reach temperatures above 80°C (176°F). Before touching the device,

check the temperature and wait until it has cooled below 40°C (104°F).

3. Remove the connectors. Disconnect the potential earth connection last.

4. Demount: loosen the fasteningscrews. Remove the device.

Kollmorgen | kdn.kollmorgen.com | January 2019 11

Page 12

MKD Product Safety Guide | 1 English

1.3.8 System Repair

Only professional staff who are qualified in electrical engineering are allowedto exchange

parts of the drive system.

CAUTION: Automatic Start! During replacement work a combinationof hazards and mul-

tiple episodes may occur.

Work on the electrical installation may only be performed by trained and qualifiedpersonnel, in compliance with the regulations for safety at work, and only with use of prescribed personal safety equipment.

Exchange of the device

Only the manufacturer can repair the device. Opening the device voids the warranty.

1. Decommission the device (see chapter 1.3.5 "Decommissioning").

2. Demount the device (see chapter 1.3.7 "Disassembly").

3. Send the device to the manufacturer.

4. Install a new device as described in this manual.

5. Setup the system as describedin this manual.

Exchange of other drive system parts

If parts of the drive system (forexample cables) must be replaced, proceed as follows:

1.3.9 Disposal

1. Decommission the device (see chapter 1.3.5 "Decommissioning").

2. Exchange the parts.

3. Check all connections for correct fastening.

4. Setup the system as describedin this manual.

To dispose the unit properly, contact a certified electronic scrap disposal merchant.

In accordance with the WEEE-2012/19/EC guideline and similar, the manufacturer accepts

returns of old devices and accessories for professional disposal. Transport costs are the

responsibility of the sender.

Contact Kollmorgen and clarify the logistics.

Send thedevices in the original packaging to the manufacturer address:

North America South America

KOLLMORGEN

201West Rock Road

Radford, VA 24141, USA

Europe Asia

KOLLMORGEN Europe GmbH

Pempelfurtstr. 1

40880 Ratingen, Germany

KOLLMORGEN

AvenidaJoão Paulo Ablas, 2970

Jardim da Glória, Cotia – SP

CEP 06711-250, Brazil

KOLLMORGEN

Floor 4, Building 9, No. 518,

North Fuquan Road, Changning District,

Shanghai 200335, China

12 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 13

1.4 Technical description and general data

1.4.1 Package Supplied

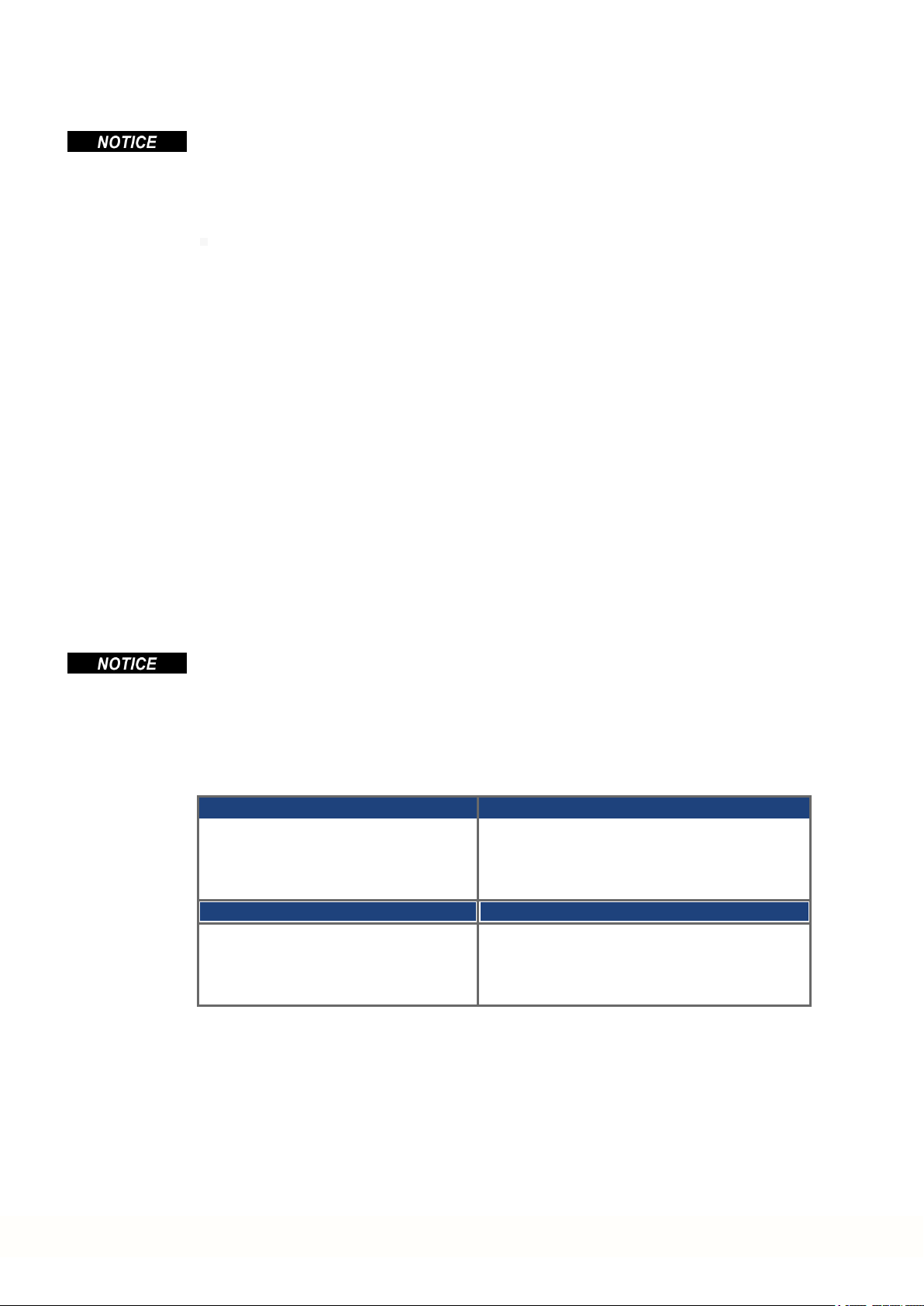

Available MKD Modules

Variant Description Power Remarks

MKD-C003007-NAEC Central Power supply 30kW Standard

MKD-N060007-DSEC Drive Module 2.5 kW Single Axis, 6A

MKD-N060607-DSEC Drive Module 5kW Dual Axes, 2 x 6A

MKD-N120007-DSEC Drive Module 5kW Single Axis, 12A

MKD-N120607-DSEC Drive Module 7.5 kW Dual Axes, 12A + 6A

MKD-N121207-DSEC Drive Module 10 kW Dual Axes, 2 x 12A

MKD-N240007-DSEC Drive Module 10 kW SingleAxis, 24A

MKD-N480007-DSEC Drive Module 20 kW SingleAxis, 48A

When a MKD module is ordered, the following items are included in the package:

MKD-C package:

The ordered module itself

Printedcopy of MKD Product Safety Guide

DVD containing the setup software, WorkBench, and all product documentation in digital

format.

Mating connectors MKD-C: X12, X13, X14, X15, X16, X25

OneMKD-N DC-Bus link cover

Two connector covers M23 for AKD-N

MKD Product Safety Guide | 1 English

The M23 connector covers are required forprotecting X2 of the last AKD-N in the strings.

MKD-N package:

The ordered module itself

Data Sheet

Mating connectors MKD-N: X9, X24, X26

Accessories:

Accessories must be ordered separately if required.

Accessories for AKD-N see regional Accessories Manual or AKD-N Installation Manual.

Spare parts

Connector Kit MKD-C-Conkit (X12, X13, X14, X15, X16, X25)

Connector Kit MKD-N-Conkit 6 to 12 A single (X9, X24, X26, X29A)

Connector Kit MKD-N-Conkit 6 to 12 A double (X9, X24, X26, X29A, X29B)

Connector Kit MKD-N-Conkit 24 to 48 A (X9, X24, X26, X29A, X30A)

Kollmorgen | kdn.kollmorgen.com | January 2019 13

Page 14

MKD Product Safety Guide | 1 English

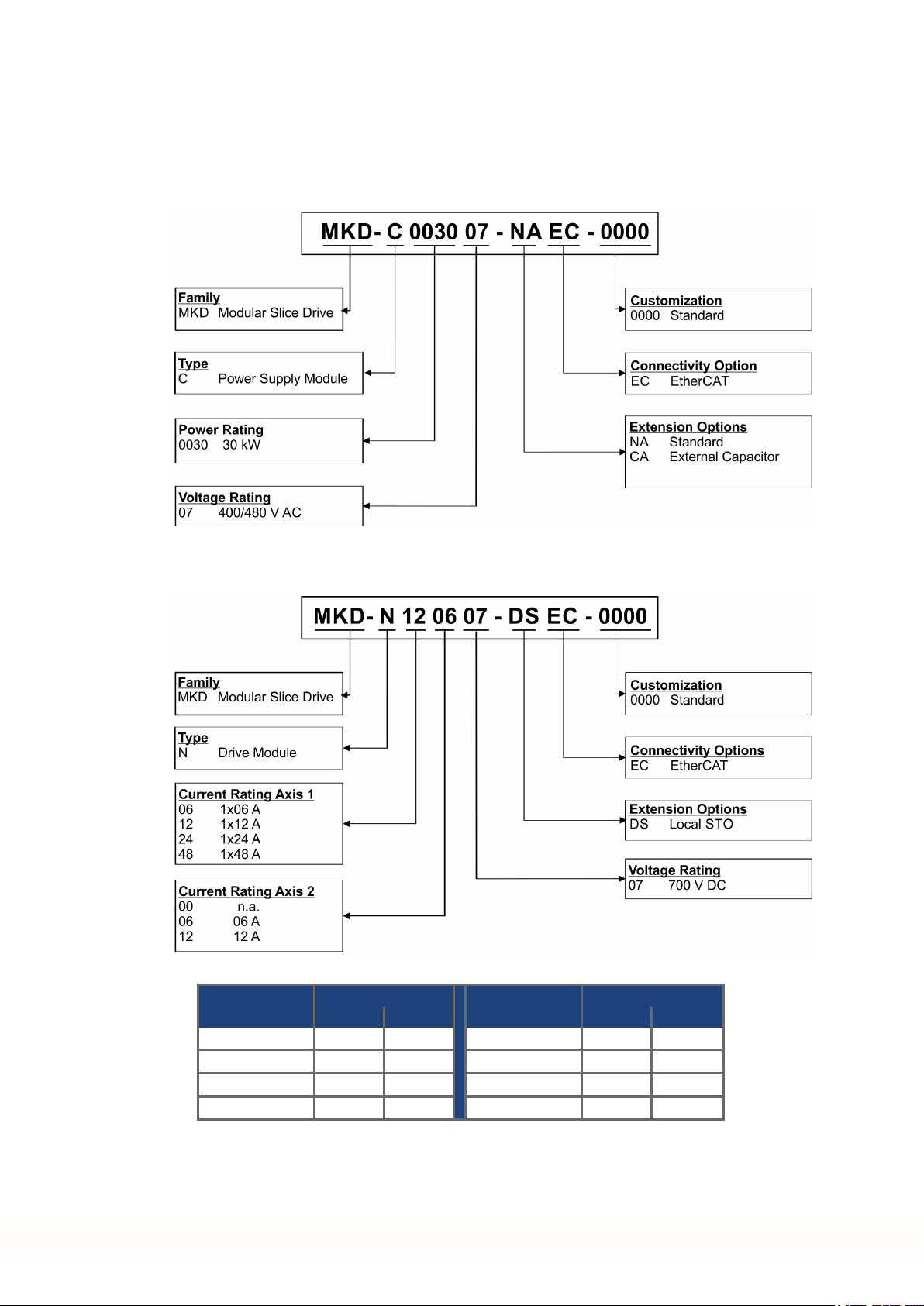

1.4.2 Part Number Scheme

Use the part numberscheme for product identification only, not for the order process,

because not all combinations of features arepossible, always.

1.4.2.1 MKD-C modules

Customization code codingfor customerspecials (not relevant for functional safety).

1.4.2.2 MKD-N modules

Available drive modules:

Current rating Current rating

Single Axis Axis 1 Axis 2 Dual Axes Axis 1 Axis 2

MKD-N0600 06 A - MKD-N0606 06 A 06 A

MKD-N1200 12 A - MKD-N1206 12 A 06 A

MKD-N2400 24 A - MKD-N1212 12 A 12 A

MKD-N4800 48 A -

Customization code codingfor customerspecials (not relevant for functional safety).

14 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 15

1.4.3 Ambient Conditions in normal operation

Storage, Transport (➜ # 10)

Normal operation Environmental class 3K3 accordingto IEC 61800-2

Surrounding air tem-

perature in operation

Humidity in operation Relative humidity 5 to 85%, nocondensation, class 3K3

Site altitude Up to 1000 meters above mean sealevel without restriction

Pollution level Pollution level 2 as per IEC 60664-1

Vibrations Class 3M1 according to IEC 60721-3-3

Environmental area Cabinet IP 54 according to IEC 60529

Mounting position Vertical

Ventilation Built-in fan.

CAUTION

0 to +40 °C under rated conditions

+40 to +55 °C with continuous current derating4 % perKelvin

1,000 to max. 2,000 meters above mean sea level with power

derating1.5%/100 m

Continuous noise up to 60dBA during operation. Keep cabinet

doors closed duringoperation. To reduce inconvenience, we suggest to use ear protection if cabinet doors must be opened during

normal operation.

The device shuts down in case of excessively high temperature

in the control cabinet. Make sure sufficient forcedventilationis

supplied within the control cabinet.

MKD Product Safety Guide | 1 English

1.4.4 Electrical Data

Electrical data (➜ # 53)

1.4.5 System limits

Length String 2/3 Maximum 100 m total cable length perstring.

Number of MKD-C Limitedby fieldbus protocol.

Number of MKD-N

axes

Number of AKD-N Maximum 14per string, total maximum 28 onstrings 2 and3,

Output current Use coincidence factor of the axes for distribution and system

Total power At 565 V to 680 V limited to 30kW.

String 2/3 power At 565 V to 680 V limited to 10kW for each string.

String standby power At 55 V limited to 180W for each string.

Motor Brake power You can control up to 3 motorbrakes per string. Available power

Service Interface X18 Ethernet TCP/IP, 100 Mbit/s, max. cable distance 100m

Maximum 14axes for string 1, total maximum 28 axes if string 1

and2 are combined (observe total power and current restrictions).

(observe total power and current restrictions).

poweroptimization.

String 1: 43 A, String 2: 16 A, String 3: 16 A

for brakes is 76 W per string(= 3.2 A @ 24 VDC).

Kollmorgen | kdn.kollmorgen.com | January 2019 15

Page 16

MKD Product Safety Guide | 1 English

1.5 Safe Torque Off (STO)

Safety functionality is not approved nor certified. Do not use this functionality in applications

with functional safety request.

Refer to the MKD Installation Manual for full information on functional safety.

The safety properties given by Kollmorgenlisted in the appendix (➜ # 77) can be reached if

the Kollmorgen components are used. The resulting Functional Safety classification (SIL

and/or PL level)must be calculatedacross the drive system.

MKD-C connector X16:

global STO (String 2/3) inputs of the system powered by this MKD-C.

MKD-N connector X26:

local STO (axis 1 and axis 2 if built-in) input of the drive module.

AKD-N connectors X6:

local STO input of the AKD-N-DS/DT drive modules.

Global STO

There is one STO input for every DC Power string. The string STO input release the power

output stageof all AKD-N (without option DS/DT) connected to the string as longas a 24 V

signal is applied to this input.

Local STO

The local STO input releases the power output stage of the MKD-N drive axis as longas a 24

V signal is applied to this input.

16 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 17

1.6 Mechanical Installation

Dimensions and mounting hints see (➜ # 55)and refer to the MKD Installation Manual.

1.6.1 Important Notes

MKD-C and MKD-N devices must be mountedin cabinets only with protection class IP 54

according to IEC 60529.

MKD Product Safety Guide | 1 English

CAUTION

Risk of electrical shock, if the servo amplifier (or the motor) is not properly EMC-grounded.

Do not use painted (i.e. non-conductive) mounting plates.

In unfavourable circumstances, use copper mesh tape between the earthing bolts and

earth potential to deflect currents.

Protect the device from impermissible stresses. In particular, do not let any components

become bent or any insulation distances altered during transport and handling. Avoid contact with electronic components and contacts.

The modules will switch itself off in case of overheating. Ensure that the mountingspace

matches the requirements (➜ # 15).

Do not mount devices that produce magnetic fields directly beside the device. Strong magnetic fields can directly affect internal components. Install devices which produce magnetic

field with distance to the MKD-C and/orshield themagnetic fields.

1.6.2 Guide to Mechanical Installation

For details refer to the MKD Installation Manual.The following tools are required (at a min-

imum) to install the MKD-C and MKD-N modules; yourspecific installationmay require additional tools.

M4 hexagon socket-cap screws (ISO 4762)

3 mm T-handle Allen key

No. 2 Phillips head screwdriver

Small slotted screwdriver

High EMC Voltage Level!

Install the modules as follows:

1. Prepare the site. The MKD modules must be mounted in a closed control cabinet (➜ #

15). The site must be free from conductive or corrosive materials.

2. Check that the ventilation of the modules is unimpeded, and keepwithin the permitted

ambient temperature (➜ # 15). Keep the required space clearance above andbelow the

modules (➜ # 56).

3. If cooling systems are used forthe control cabinet, position the cooling system so that

condensation water cannot drip onto the modules or peripheral devices.

4. Assemble the power supply module and the drive modules on the conductive, grounded

mounting plate in the cabinet.

5. Ground the modules, the mounting plate, motor housing, GND of 24V supply and CNCGND of the control system.

For mechanical installation of AKD-N to the machine, refer to the AKD-N Installation

Manual.

Kollmorgen | kdn.kollmorgen.com | January 2019 17

Page 18

MKD Product Safety Guide | 1 English

1.7 Electrical Installation

Connectors and Wiring overview see (➜ # 57)and refer to the MKD Installation Manual.

1.7.1 Important Notes

Only professional staff who are qualified in electrical engineering are allowedto install the

drive system. Wires with colorgreen with one or more yellow stripes must not be used other

than for protective earth (PE) wiring.

DANGER

There is a dangerof serious personal injury or death by electrical shock or electrical arcing.

Capacitors can still have dangerous voltages present up to 5 minutes after switchingoff the

supply power. Control and power connections can still be live, even if the motor is not rotating.

Only install and wire the equipment when it is not live.

Make sure that the cabinet is safely disconnected (forinstance, with a lock-out and warning signs).

Never remove electrical connections to the drive while it is live.

Wait at least 5 minutes after disconnecting the drive from the main supply power before

touching potentially live sections of the equipment (e.g. contacts) or undoingany connections.

To be sure, measure the voltage in the DC bus link and wait until it has fallen below 50 V.

Since the leakage current to PE is more than 3.5 mA, in compliance with IEC61800-5-1 the

PE connection must either be doubledor a connecting cable with a cross-section >10 mm²

must be used. Deviating measures accordingto regional standards might be possible.

WrongDC Bus link voltage, unsuitable motoror wrong wiringwill damage the system components. Check the combination of drive and motor. Compare the rated voltage and current

of the units. Implement the wiring according to the connection diagrams: (➜ # 57).

It is permissible to use the setup software to alter the settings of the device. Any other alterations will invalidate the warranty.

High Voltage up to 900 V!

1.7.2 Guide to electrical installation

For details refer to the MKD Installation Manual. Install the drive electrical system as follows:

1. Select cables accordance with the planned system topology, see (➜ # 15).

2. Observe the maximum cable length definition (➜ # 15).

3. Install shielding and ground the system components, see (➜ # 61).

4. Wire the system components.

- Observe "Recommendations for EMI noise reduction": see MKD Installation Manual

- Connect all interface according to the wiring diagrams in the MKD Installation Manual.

5. Check the wiring against the wiringdiagrams in the MKD Installation Manual.

For electrical installation of AKD-N to the machine, referto the AKD-N Installation Manual.

18 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 19

1.8 Setup

For detailed information on functional safety refer to the MKD Installation Manual.

Programming parameters and control loop behavior: see WorkBench online help.

The fieldbus setup is describedin the corresponding manual on the DVD.

1.8.1 Important Notes

Beforetesting andsetup, the manufacturer of the machine must generate a risk assessment

for the machine and take appropriate measures so that unforeseen movements cannot

cause injury or damage to any person or property.

Only professional personnel with extensive knowledge in the fields of electrical engineering

anddrive technology are allowed to test and set up the drive.

MKD Product Safety Guide | 1 English

DANGER

There is a dangerof serious personal injury or death by electrical shock. Lethal danger exists

at live parts of the device.

Built-in protection measures such as insulation orshielding may not be removed.

Work on the electrical installation may only be performed by trained and qualifiedpersonnel, in compliance with the regulations for safety at work, and only with switched off

mains supply, and secured against restart.

WARNING

Risk of death orserious injury for humans working in the machine. The drive might restart

automatically after power on, voltage dip or interruption of the supply voltage, depending on

the parameter setting. If parameterDRV.ENDEFAULT is set to 1,

then place a warning sign ("WARNING: Possible Automatic Restart" or similar) to the

machine.

Ensure, that power on is not possible, while humans are in a dangerous zone of the

machine.

CAUTION

Risk of minor burns. The heat sink of the drive can reach temperatures up to 80°C in operation.

Check the heat sink temperaturebefore handlingthe drive.

Wait until the heat sink has cooled down to 40°C before touching it.

Lethal Voltage!

Automatic Restart!

High Temperature!

If a device has been stored for more than 1 year, you must re-form the capacitors in the DC

bus link circuit. Re-forming procedures aredescribed in the KollmorgenDeveloper Network

(Forming).

Kollmorgen | kdn.kollmorgen.com | January 2019 19

Page 20

MKD Product Safety Guide | 1 English

1.8.2 Initial System Test

1. Unpack the devices and accessories. Observe the safety instructions in the documentation.

2. Mount the devices and wire the system.

3. Validate mechanical and electrical installation.

4. Validate IP addresses

5. Make sure you have on hand the following information about the drive components:

rated mains supply voltage

motor type (motor data, if the motor type is not listed in the motordatabase)

feedback unit built into the motor (type, poles/lines/protocol)

moment of inertia of the load

1.8.2.1 Set system addresses

The MKD-C IP address can beset with the rotary switch. When connecting the MKD-C directly to a PC, static IP addressing (not 0) is recommended.

Example: if S1 is set to 5 – the IP address is 192.168.0.5

WorkBench looks for IP address in the subnet to detect devices in the LAN and start communication. Refer to the WorkBench Online Help for information.

1.8.2.2 Confirm connections

Switch on 24 VDC logic power for the system (mains supply voltage is not neededfor communications).

Confirm that the greenlink LED 1 on the MKD-C and on the PC are both illuminated.

While the PC is connecting, yourstatus bar will show the following acquiring icon:

Wait for this icon to changeto the limited functionality icon (this process can take up to one

minute).

Although Windows displays this limited functionality icon for the drive connection, the PC

can communicate fully with the drive. Using WorkBench, you can now configure the drive

throughthis connection.

1.8.2.3 Install and start WorkBench

WorkBench is available from the DVD included with the drive and on theKollmorgen Website: www.kollmorgen.com. Select the install file and follow the instructions given by the

installer.

Once installation is complete, click the WorkBench icon to start the program.

1.8.2.4 Parameterize and enable the axes in WorkBench

Refer to the WorkBench Online Help for information.

20 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 21

1.9 Troubleshooting the MKD System

Drive problems occur for a variety of reasons, depending on the conditions in yourapplication. The causes of faults in multi-axis systems can be very complex. If you cannot resolve

a fault, Kollmorgen customersupport can give you furtherassistance.

Eliminate errors and faults in compliance with work safety rules. Troubleshooting only by

qualified and trained staff.

Details on the removal of faults can be found in the WorkBench onlinehelp.

MKD Product Safety Guide | 1 English

Kollmorgen | kdn.kollmorgen.com | January 2019 21

Page 22

MKD Product Safety Guide | 1 English

---/ ---

22 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 23

MKD Product Safety Guide | 2 Deutsch

2 Deutsch

2.1 Allgemeines 24

2.1.1 Hinweise für die gedruckte Ausgabe(Papierversion) 24

2.1.2 Verwendete Symbole 25

2.2 Produktsicherheit 26

2.2.1 Das sollten Sie beachten 26

2.2.2 Bestimmungsgemäße Verwendung 28

2.2.3 Nicht bestimmungsgemäße Verwendung 29

2.2.4 Warnaufkleber 29

2.3 Produkt Lebenszyklus, Handhabung 30

2.3.1 Transport 30

2.3.2 Verpackung 30

2.3.3 Lagerung 30

2.3.4 Installation, Setup und Normalbetrieb 31

2.3.5 Außer Betrieb nehmen 31

2.3.6 Wartung und Reinigung 31

2.3.7 Demontage 31

2.3.8 System Reparatur 32

2.3.9 Entsorgung 32

2.4 Technische Beschreibung und allgemeine Daten 33

2.4.1 Lieferumfang 33

2.4.2 Typenschlüssel 34

2.4.3 Umgebungsbedingungen im normalen Betrieb 35

2.4.4 Elektrische Daten 35

2.4.5 Systemgrenzen 35

2.5 Safe Torque Off (STO) 36

2.6 Mechanische Installation 37

2.6.1 Wichtige Hinweise 37

2.6.2 Anleitung für die mechanische Installation 37

2.7 Elektrische Installation 38

2.7.1 Wichtige Hinweise 38

2.7.2 Anleitung für die elektrische Installation 38

2.8 Setup 39

2.8.1 Wichtige Hinweise 39

2.8.2 Basis Systemtest 40

2.9 Fehlerbehebung beim MKD System 41

Kollmorgen | kdn.kollmorgen.com | January 2019 23

Page 24

MKD Product Safety Guide | 2 Deutsch

2.1 Allgemeines

Der MKD-C/N Product Safety Guide liefert die relevanten Informationen für sichere Instal-

lation und Inbetriebnahme der MKD Systemmodule MKD-C Netzteil und MKD-N Servoverstärker.

Vollständige Informationen finden Sie im MKD-C/N InstallationManual , in derAKD-N

Betriebsanleitung und weiteren Kollmorgen Dokumenten.

Weitere Dokumente auf der beiliegenden DVD:

WorkBenchOnlinehilfe: Beschreibt die VerwendungdesSystems in gängigenApplikationen. Sie liefert auch Hinweise für die Optimierung der Systemleistung. Die Online

Hilfe beinhaltet den Parameter and Command Reference Guide mit Informationenzu Para-

metern und Befehlen, die zum Programmieren des Systems benutzt werden.

EtherCAT Communication: beschreibt die Verwendung des Systems in EtherCAT Applikationen.

Diese Dokumente finden Sie auf der DVD in der Verpackungdes Servoverstärkers. Alle

Dokumente können Sie von der Kollmorgen Website www.kollmorgen.com herunterladen.

2.1.1 Hinweise für die gedruckte Ausgabe (Papierversion)

Jedem Produkt liegt eine gedruckte Ausgabe dieses Handbuchs

bei. Aus ökologischen Gründen wurde das Dokument verkleinert

auf DIN A5 gedruckt.

Sollten Sie Schwierigkeiten haben, die Schriftgröße des verkleinert gedruckten Exemplars zu lesen, können Sie die PDF Version im DIN A4 Format 1:1 ausdrucken und verwenden. Sie finden

die PDF Version auf der dem Produkt beiliegenden DVD und auf

der Kollmorgen Internetseite.

24 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 25

2.1.2 Verwendete Symbole

Symbol Bedeutung

GEFAHR

WARNUNG

MKD Product Safety Guide | 2 Deutsch

Weist auf eine gefährliche Situation hin, die, wenn sie nicht vermieden wird, zum Todeoder zu schweren, irreversiblenVerletzungen führenwird.

Weist auf eine gefährliche Situation hin, die, wenn sie nicht vermieden wird, zum Todeoder zu schweren, irreversiblenVerletzungen führenkann.

VORSICHT

Weist auf eine gefährliche Situation hin, die, wenn sie nicht vermieden wird, zu leichten Verletzungen führen kann.

Dieses Symbol weist auf eine Situation hin, die, wenn sie nicht

vermieden wird, zu Beschädigung von Sachen führenkann.

Dieses Symbol weist auf wichtige Informationen hin.

Warnungvor einer Gefahr(allgemein). Die Art der Gefahr wird

durch dennebenstehenden Warntext spezifiziert.

Warnungvor gefährlicher elektrischer Spannungund derenWirkung.

Warnungvor Gefahr durch heiße Oberfläche.

Warnungvor Gefahr durch hängende Last.

Warnungvor Gefahr durch automatischem Anlauf.

Kollmorgen | kdn.kollmorgen.com | January 2019 25

Page 26

MKD Product Safety Guide | 2 Deutsch

2.2 Produktsicherheit

2.2.1 Das sollten Sie beachten

Fachpersonal erforderlich

Für Arbeitenwie Transport, Installation, Inbetriebnahme und Instandhaltung darf nur qualifiziertes Personal eingesetzt werden. Qualifiziertes Personal sind Personen, die mit Transport, Installation, Inbetriebnahme und Betrieb von elektrischen Antrieben vertraut sind.

Transport, Lagerung, Auspacken: nur durch Personal mit Kenntnissen in der Behandlung

elektrostatisch gefährdeter Bauelemente.

Mechanische Installation: nur durch Personal mit Kenntnissen in mechanischen Arbeiten.

Elektrische Installation: nur durch Personal mit Kenntnissen in elektrotechnischenArbeiten.

Inbetriebnahme: nur durch Fachleute mit weitreichendenKenntnissen in den Bereichen

Elektrotechnik und Antriebstechnik.

Das Fachpersonal muss ebenfalls ISO 12100 / IEC 60364 / IEC 60664 und nationale Unfallverhütungsvorschriften kennen undbeachten.

Dokumentation lesen

Lesen Sie vor derMontage und Inbetriebnahmedie vorliegende Dokumentation. Falsches

Handhaben der Geräte kann zu Personen- oder Sachschäden führen. Der Betreiber muss

dahersicherstellen, dass alle mit Arbeiten am Antriebssystem betrauten Personen das Handbuch gelesenund verstanden haben und dass die Sicherheitshinweise in diesem Handbuch

beachtet werden.

Hardware Revision prüfen

PrüfenSie die Hardware-Revisionsnummer des Produkts (siehe Typenschild). Hardware

Revisionsnummer von MKD-C und MKD-N können voneinander abweichen. Die Nummer ist

die Verknüpfung zwischen dem Produkt und dem Handbuch. Diese Revisionsnummer muss

mit der Hardware-Revisionsnummerauf der Betriebsanleitungübereinstimmen.

Technische Daten beachten

Halten Sie die technischen Daten und die Angaben zu den Anschlussbedingungen ein. Wenn

zulässige Spannungswerte oder Stromwerte überschritten werden, können die Geräte

geschädigt werden. Ein ungeeigneter Motor oder fehlerhafte Verdrahtung beschädigen die

Systemkomponenten. Prüfen Sie die Kombination aus Verstärker und Motor. Gleichen Sie

die Nennspannung und den Nennstrom der Komponentenab.

Risikobeurteilung erstellen

Der Hersteller der Maschine muss eine Risikobeurteilung für die Maschine erstellen und

geeignete Maßnahmentreffen, dass unvorhergesehene Bewegungennicht zu Verletzungen

oder Sachschädenführen können. Aus der Risikobeurteilung leiten sich eventuell auch

zusätzliche Anforderungen an das Fachpersonal ab.

Der Hersteller der Maschine muss regelmäßige Überprüfungen der elektrischen Komponenten und Applikationenfestlegen.

Automatischer Wiederanlauf!

Der Antriebkannabhängig von der Parametereinstellung nach dem Einschalten derNetzspannung, bei Spannungseinbrüchen oder Unterbrechungenautomatisch anlaufen.

Es besteht die Gefahr von tödlichen oder schweren Verletzungen für Personen, die in der

Maschine arbeiten.

Wenn der Parameter DRV.ENDEFAULT eines MKD-N auf 1 gesetzt ist, warnen Sie an der

Maschine mit einem Warnschild (Warnung: Automatischer Wiederanlauf nach Einschalten!)

undstellen Sie sicher, dass ein Einschalten der Netzspannung nicht möglich ist, während

sich Personen im gefährdeten Bereich der Maschineaufhalten. WennSie einen Unterspannungsschutz benutzen, beachten Sie Kapitel 7.5 der EN 60204-1:2006.

26 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 27

MKD Product Safety Guide | 2 Deutsch

Elektrostatisch empfindliche Bauteile

Die Geräte enthalten elektrostatisch gefährdete Komponenten, die durch unsachgemäßen

Gebrauch beschädigt werdenkönnen. Entladen Sie Ihren Körper elektrostatisch, bevor Sie

das Gerät berühren. Vermeiden Sie es, hoch isolierendeStoffe zu berühren (Kunstfasern,

Plastikfolie usw.). Legen Sie das Gerät auf eineleitfähige Oberfläche.

Heiße Oberfläche

Die Oberflächenvon Verstärkernkönnen im Betrieb sehr heiß werden. Das Gehäuse kann

Temperaturen über80 °C erreichen. Gefahr leichter Verbrennungen. Messen Sie die Temperatur. Warten Sie, bis das Gehäuse auf unter 40 °C abgekühlt ist, bevor Sie es berühren.

Erdung

Stellen Sie die ordnungsgemäßeErdungdes Gerätes mit derPE-Schiene im Schaltschrank

als Bezugspotential sicher. Gefahr durch elektrischen Schlag.

Ohne niederohmigeErdungist keinepersonelle Sicherheit gewährleistet

Ableitstrom

Da der Ableitstrom zu PE mehr als 3,5 mA beträgt, muss in Übereinstimmungmit der Norm

EN61800-5-1 derPE-Anschluss entweder doppelt ausgeführt oder ein Anschlusskabel mit

einem Querschnitt von >10 mm² verwendet werden. Abweichende Maßnahmen sindin Übereinstimmung mit regionalen Vorschriften möglich.

Fehlerstrom Schutzschalter oder Überwachungsgeräte!

MKD-C mit MKD-N kanneinen Gleichstrom im Schutzerder erzeugen. Wo für denSchutz im

Falle einerdirekten oder indirekten Berührung eineFehlerstrom-Schutzeinrichtung (RCD)

oder ein Fehlerstrom-Überwachungsgerät (RCM) verwendet wird, ist auf der Stromversorgungsseite des MKD-C nur einRCD oder RCM vom Typ B zulässig.

Tödliche Spannung!

Die Geräte erzeugen hohe elektrische Spannungen bis zu 900 V. Lebensgefahrbeim Berührenvon spannungsführenden Teilen. Öffnen oder berühren Sie die Geräte während des

Betriebs nicht. Halten Sie während des Betriebs alle Türen des IP54 Schaltschranks

geschlossen. Eingebaute Schutzmaßnahmenwie Isolation oder Schirmung dürfen nicht entfernt werden. Arbeiten an der elektrischen Installation sollen nur von geschultem und qualifizierten Personal unter Beachtungder Arbeitssicherheitsbestimmungen bei abgeschalteter

undgegenWiedereinschalten gesicherter Netzspannungdurchgeführt werden.

Trennen Sie nie die elektrischen Verbindungen zum MKD, während dieserSpannung führt.

Es besteht die Gefahr von Lichtbogenbildung mit Verletzungsgefahr (Verbrennungen oder

Erblindung)und Schäden anKontakten. Warten Sie nach dem Trennen des Gerätes von den

Versorgungsspannungen(Netzversorgung und 24V Versorgung)mindestens 5 Minuten,

bevor Sie Geräteteile, die potenziell Spannung führen (z. B. Kontakte), berührenoder

Anschlüsse trennen.

Funktionale Sicherheit

Die Safety Funktionensind nicht freigegeben undnicht zertifiziert. Benutzen Sie diese Funktion nicht in Applikation, die funktionale Sicherheit erfordern.

Geräte nicht verändern

Veränderungan der Servoverstärker Hardware ohne Erlaubnis des Herstellers sind nicht

zulässig. Öffnen derGeräte bedeutet Verlust der Gewährleistung.

Kollmorgen | kdn.kollmorgen.com | January 2019 27

Page 28

MKD Product Safety Guide | 2 Deutsch

2.2.2 Bestimmungsgemäße Verwendung

MKD-C Netzteile sind ausschließlich für den Betriebvon MKD-N Servoverstärker Modulen

imSchaltschrank und AKD-N dezentralen Servoverstärkerngeeignet.

Die MKD-N Servoverstärkersind ist ausschließlich zum Antrieb von geeigneten SynchronServomotoren mit geschlossenem Drehmoment-, Drehzahl- und/oder Positionsregelkreis vorgesehen.

MKD Systemmodule sind Komponenten, die in elektrische Anlagen oder Maschinen eingebaut werdenund nurals integrierte Bestandteile dieser Anlagen oder Maschinen betrieben

werden können. Der Hersteller der Maschine muss eine Risikoanalyse der Maschine erstellen.

Wenn dieSystemmodule in Maschinen oder Anlagen eingebaut werden, darf derAntrieb

nicht verwendet werden, bis sichergestellt wurde, dass die Maschine oder Anlage die regionalen Richtlinien erfüllt.

Kollmorgen Multi-Achsen Antriebssystem

MKD darf nur in Antriebssystemen mit Komponenten von Kollmorgen eingesetzt werden.

Zusätzlich benötigte Kollmorgen Komponentensind die Netzdrossel, Hybrid Strangkabel,

Hybrid Motorkabel, Motorleistungskabel und Motorfeedbackkabel sowie Servomotoren.

Montage

MKD Module dürfen nurin geschlossenen Schaltschränken betrieben werden, die sich für die

definiertenUmgebungsbedingungen eignen(➜ # 35).

Verdrahtung

Verwenden Sie nurKollmorgen Leitungen zur Verbindung der Systemkomponenten.

Spannungsversorgung

MKD-C muss an einem 3 phasigen, industriellen Versorgungsnetz betrieben werden

(maximaler symmetrischerNennstrom bei 400 V und 480 V: 42 kA) übereine Netzdrossel

3YL.

MKD-N Servoverstärkermüssen von den intelligenten MKD-C Netzteilen mit einerGleichspannung von 55VDC bis 800 VDC versorgt werden.

Sicherungen

Die Geräte müssen mit einerAbsicherung gegen Überlast betrieben werden.

Motor-Nennspannung

Die Nennspannung der Motoren muss mindestens so hoch sein wie die vom Verstärker

erzeugte DC-Zwischenkreisspannung geteilt durch √2 (U

nMotor

>=UDC/√2).

Gruppeninstallationen und mit Gleichstrom versorgte Antriebe

Der MKD wurde weder von Kollmorgen, UL noch dem TÜV für Gruppeninstallation untersucht. Es sind keine Werte für eineDC Spannungsversorgung definiert.

Hilfsspannungsversorgung, Standby Versorgung

Die Standby Versorgung fürdie Antriebsstränge darf nur für die Versorgung der MKD-N Elektronik verwendet werden. Das 24 VDC Netzteil muss die Anforderungen von PELV (EN

60204-1) erfüllen.

Safe Torque Off

Die Safety Funktionensind nicht freigegeben undnicht zertifiziert. Benutzen Sie diese Funktion nicht in Applikation, die funktionale Sicherheit erfordern.

28 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 29

2.2.3 Nicht bestimmungsgemäße Verwendung

Eine andere Verwendung als in Kapitel "Bestimmungsgemäße Verwendung" beschrieben ist

nicht bestimmungsgemäß und kann zu Schäden bei Personen, Gerät oder Sachen führen.

Das System soll nicht verwendet werden

in Maschinen, die nicht den geltenden nationalen Richtlinien oder Normen entsprechen,

zum Antrieb von Aufzügen,

in Anwendungen mit häufigen, betriebsmäßigen Kurzschlüssen der Anschlüsse des

Bremswiderstandes,

in Anwendungen mit Kurzschlüssen der DC+/DC- Zwischenkreisanschlüsse.

Die Verwendung des Gerätes in den folgenden Umgebungen ist ebenfalls untersagt:

explosionsgefährdete Bereiche,

Umgebungenkorrosiven und/oder elektrisch leitenden Säuren, alkalischen Lösungen,

Ölen, Dämpfen und Staub,

Schiffe oder Offshore-Anwendungen.

Verdrahtung des Systems mit Hybridkabeln anderer Hersteller als Kollmorgen ist nicht

erlaubt. Verändern von Kollmorgen Kabeln oderSteckern ist nicht erlaubt.

MKD Product Safety Guide | 2 Deutsch

2.2.4 Warnaufkleber

Beschädigte Warnsymbole müssen sofort ersetzt werden.

2.2.4.1 Hinweise auf dem Produkt

The minimum size of the

protective earthing conductor

shall comply with the local safety

regulations for highprotectice

earthingconductor current.

Übersetzung:

Die Mindestgröße der Schutzerdungsleiter

soll den örtlichen Sicherheitsvorschriften für

hohen Schutzerdungsstrom entsprechen.

Residual Voltage

Wait 5 minutes after removing

powerbefore servicing.

Übersetzung:

Restspannung

5 Minuten nach

.

Abschalten der Leistung

bis zur Wartung warten.

Kollmorgen | kdn.kollmorgen.com | January 2019 29

Page 30

MKD Product Safety Guide | 2 Deutsch

2.3 Produkt Lebenszyklus, Handhabung

2.3.1 Transport

Transportieren Sie die MKD Module gemäß EN 61800-2 wie folgt:

Transport nur durch qualifiziertes Personal in der wiederverwertbaren Originalverpackung

des Herstellers.

Beim Transport Stöße vermeiden.

Vibration/Schock: MKD Module sind geprüft für Klasse 3M1 gemäß IEC 60721-3-2.

Höchstens mit der maximalen Stapelhöhe (8Kartons) stapeln.

Nur innerhalb der angegebenen Temperaturbereichetransportieren: -25bis +70°C, max.

Änderungsrate 20 K/Stunde, Klasse 2K3.

Nur innerhalb der angegebenen Feuchtigkeitsbereiche transportieren: max. 95 % relative

Luftfeuchtigkeit, nicht kondensierend, Klasse 2K3.

Die Geräte enthalten elektrostatisch gefährdete Komponenten, die durch unsachgemäßen

Gebrauch beschädigt werdenkönnen. Entladen Sie sich elektrostatisch, bevor Sie das

Gerät berühren. Vermeiden Sie es, hoch isolierende Stoffe zu berühren (Kunstfasern, Plastikfolie usw.). Legen Sie das Gerät auf eine leitfähigeOberfläche.

Wenn dieVerpackung beschädigt ist, prüfen Sie das Gerät auf sichtbare Schäden. Informieren Sie den Spediteurund denHerstellerüber Schädenan der Verpackung oder Produkt.

2.3.2 Verpackung

2.3.3 Lagerung

Die MKD Verpackungbesteht aus recyclingfähigem Karton mit Einsätzen und einem Aufkleberauf der Außenseite der Verpackung.

Modell Verpackungsmaße

(mm) HxBxL

MKD-C003007 580x 350 x 170 22,5

MKD-N060007

MKD-N060607

MKD-N120007

MKD-N120607

MKD-N121207

MKD-N240007 580x 350 x 110 9,5

MKD-N480007 580x 350 x 140 11,5

Lagern Sie die MKD Module gemäß EN 61800-2wie folgt:

Nur in derwiederverwertbaren Originalverpackungdes Herstellers lagern.

Höchstens mit der maximalen Stapelhöhe (8 Kartons) stapeln.

Nur innerhalb der angegebenen Temperaturbereichelagern: -25 bis +55 °C, max. Änderungsrate 20 K/Stunde, Klasse 1K4.

Nur innerhalb der angegebenen Feuchtigkeitsbereiche lagern: 5 bis 95 % relative Luftfeuchtigkeit, nicht kondensierend, Klasse 1K3.

MKD Module gemäß den folgendenAnforderungen an die Lagerungsdauer lagern:

Weniger als 1 Jahr: keine Beschränkungen.

Mehr als 1 Jahr: Kondensatoren im MKD-C müssen formiert werden, bevor das System in Betrieb genommen wird. Verfahrenzur Formierung sind im Kollmorgen Developer Network (Formierung) beschrieben.

580x 350 x 110 8,5

Gesamtgewicht (kg)

(kg)

30 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 31

2.3.4 Installation, Setup und Normalbetrieb

Information zu Installation und Setup finden Sie in diesem Guide:

Kapitel Mechanische Installation(➜ # 37)

Kapitel Elektrische Installation (➜ # 38)

Kapitel Setup (➜ # 39)

Normalbetrieb wurde getestet für Umgebungsklasse 3K3 gemäß IEC 61800-2 (➜ # 35).

Der Hersteller der Maschine definiert die erforderlichen Fachkenntnisse des Endnutzers

gemäß der Risikobeurteilung für die Maschine und beschreibt abhängigvon der Applikation

die Erfordernisse für den normalen Betrieb.

2.3.5 Außer Betrieb nehmen

Nur Fachpersonal mit Kenntnissen im Bereich der Elektrotechnik darf Systemkomponenten

außer Betrieb nehmen.

GEFAHR: Tödliche Spannung! Es besteht die Gefahr vonschwerenoder tödlichen Ver-

letzungen durch elektrischen Schlag oderLichtbogenbildung.

Schalten Sie den Hauptschalter des Schaltschranks aus.

SichernSie das System gegenWiedereinschalten.

BlockierenSie denHauptschalter .

Warten Sie mindestens 5 Minuten nach Abschalten der Spannung.

MKD Product Safety Guide | 2 Deutsch

2.3.6 Wartung und Reinigung

Das Gerät ist wartungsfrei. Wenn das Gerät geöffnet wird, erlischt die Garantie. Das Innere

des Geräts kann nur vom Hersteller gereinigt werden.

Das Gerät nicht in Flüssigkeiten tauchen oder besprühen. Vermeiden Sie, dass Flüssigkeit

in das Gerät eindringt

So reinigen Sie das Gerät von außen:

1. NehmenSie das Gerät außer Betrieb(siehe Kapitel 2.3.5 "Außer Betrieb nehmen").

2. Gehäuse: Mit Isopropanol oder einer ähnlichen Reinigungslösung reinigen.

VORSICHT : Leicht Entflammbar! Gefahr von Verletzung durch Verpuffung und Feuer.

Beachten Sie die Sicherheitshinweise auf der Verpackung des Reinigungsmittels.

Warten Sie nach derReinigungmindestens 30 Minuten, bevor Sie das Gerät wiederin

Betriebnehmen.

3. Schutzgitter am Lüfter: Mit einer trockenen Bürste reinigen.

2.3.7 Demontage

Nur Fachpersonal mit Kenntnissen im Bereich der Elektrotechnik darf Systemkomponenten

demontieren.

1. NehmenSie das Gerät außer Betrieb(siehe Kapitel 2.3.5 "Außer Betrieb nehmen").

2. Prüfen Sie die Temperatur.

VORSICHT: Hohe Temperatur! Gefahr leichterVerbrennungen. Im Betrieb kann der

Kühlkörper Temperaturen über 80 °C erreichen. Bevor Sie das Gerät berühren, messen

Sie die Temperaturund warten Sie, bis der Verstärker auf unter40 °C abgekühlt ist.

3. EntfernenSie die Stecker. Trennen Sie denPE Anschluss zuletzt.

4. Ausbauen: LösenSie die Befestigungsschrauben und entfernen Sie das Gerät.

Kollmorgen | kdn.kollmorgen.com | January 2019 31

Page 32

MKD Product Safety Guide | 2 Deutsch

2.3.8 System Reparatur

Nur Fachpersonal mit Kenntnissen im Bereich der Elektrotechnik darf Systemkomponenten

austauschen.

VORSICHT: UnerwarteterAnlauf! Bei der Durchführungvon Austauscharbeiten kannes

zur Kombinationvon Gefährdungen und multiplen Folgen kommen.

Arbeiten sind nur unter Beachtung der Vorschriften für Arbeitssicherheit, durch geschultes

Personal und mit Benutzungder jeweils vorgeschriebenen persönlichen Schutzausrüstung zulässig.

Austausch des Gerätes

Nur derHerstellerkanndas Gerät reparieren. Öffnen des Gerätes bedeutet Verlust der

Gewährleistung.

1. NehmenSie das Gerät außer Betrieb(siehe Kapitel 2.3.5 "Außer Betrieb nehmen").

2. Demontieren Sie das Gerät (siehe Kapitel 2.3.7 "Demontage").

3. Senden Sie das Gerät an den Hersteller.

4. Installieren Sie einneues Gerät wie in diesem Handbuch beschrieben.

5. Nehmen Sie das System in Betrieb, wie in diesem Handbuch beschrieben.

Austausch sonstiger Teile des Antriebssystems

Wenn Teile des Antriebssystems ausgetauscht werden müssen (zum Beispiel Kabel), gehen

Sie wie folgt vor:

2.3.9 Entsorgung

1. NehmenSie das Gerät außer Betrieb(siehe Kapitel 2.3.5 "Außer Betrieb nehmen").

2. Tauschen Sie dieTeile aus.

3. Prüfen Sie alle Steckverbindungen auf korrekten Sitz.

4. Nehmen Sie das System in Betrieb, wie in diesem Handbuch beschrieben.

Für die fachgerechte Entsorgung des Gerätes wenden Sie sich an einenzertifizierten Elektronikschrottverwerter.

Gemäß der Richtlinie WEEE-2012/19/EG u.ä. nimmt der Hersteller Altgeräte und Zubehör

zur fachgerechten Entsorgung zurück. Die Transportkosten muss der Versender tragen.

Setzen Sie sich mit Kollmorgenin Verbindung und klärenSie dielogistische Abwicklung.

Senden Sie dieGeräte in der Originalverpackung an diein der folgenden Tabelle aufgeführten

Herstelleradressen.

Nordamerika Südamerika

KOLLMORGEN

201West Rock Road

Radford, VA 24141, USA

Europa Asien

KOLLMORGEN Europe GmbH

Pempelfurtstr. 1

40880 Ratingen, Germany

KOLLMORGEN

AvenidaJoão Paulo Ablas, 2970

Jardim da Glória, Cotia – SP

CEP 06711-250, Brazil

KOLLMORGEN

Floor 4, Building 9, No. 518,

North Fuquan Road, Changning District,

Shanghai 200335, China

32 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 33

2.4 Technische Beschreibung und allgemeine Daten

2.4.1 Lieferumfang

Verfügbare MKD Module

Variante Beschreibung Leistung Bemerkungen

MKD-C003007-NAEC Zentrales Netzteil 30 kW Standard

MKD-N060007-DSEC Antriebsmodul 2,5 kW Einachsig, 6A

MKD-N060607-DSEC Antriebsmodul 5 kW Zweiachsig, 2 x 6A

MKD-N120007-DSEC Antriebsmodul 5 kW Einachsig, 12A

MKD-N120607-DSEC Antriebsmodul 7,5 kW Zweiachsig, 12A + 6A

MKD-N121207-DSEC Antriebsmodul 10 kW Zweiachsig, 2 x 12A

MKD-N240007-DSEC Antriebsmodul 10 kW Einachsig, 24A

MKD-N480007-DSEC Antriebsmodul 20 kW Einachsig, 48A

Wenn einModul derMKD Reihe bestellt wird, sind im Lieferumfang folgende Komponenten

enthalten:

MKD Product Safety Guide | 2 Deutsch

MKD-C Paket:

Das bestellte Modul selbst

Gedruckter MKD Product Safety Guide.

DVD mit der Setup-Software WorkBench und dergesamten Produktdokumentation in

elektronischer Form.

Gegenstecker MKD-C: X12, X13, X14, X15, X16, X25

Eine MKD-N Zwischenkreis Abdeckung

Zwei Steckerabdeckungen M23 für AKD-N

Die M23 Steckerabdeckungen werden für den Schutz des Steckers X2 des letzten AKD-N

im Strang.

MKD-N Paket:

Das bestellte Modul selbst

Datenblatt

Gegenstecker MKD-N: X9, X24, X26, X29, X30 (nur 24A/48A)

Zubehör:

Zubehör muss bei Bedarf getrennt bestellt werden.

Zubehör für AKD-N siehe regionales Zubehör Handbuch oder AKD-N Betriebsanleitung.

Ersatzteile

Steckerkit MKD-C-Conkit (X12, X13, X14, X15, X16, X25)

Steckerkit MKD-N-Conkit 6 to 12 A single(X9, X24, X26, X29A)

Steckerkit MKD-N-Conkit 6 to 12 A double (X9, X24, X26, X29A, X29B)

Steckerkit MKD-N-Conkit 24 to 48 A (X9, X24, X26, X29A, X30A)

Kollmorgen | kdn.kollmorgen.com | January 2019 33

Page 34

MKD Product Safety Guide | 2 Deutsch

2.4.2 Typenschlüssel

Benutzen Sie den Typenschlüssel zur Produktidentifizierung, jedoch nicht für den Bestellprozess, da nicht immer alle Merkmalkombinationen technisch möglich sind.

2.4.2.1 MKD-C Module

Ausführung: Kodierung von kundenspezifische Besonderheiten(nicht Safety relevant).

2.4.2.2 MKD-N Module

Verfügbare Antriebsmodule:

Strombemessung Strombemessung

Einachsig Achse 1 Achse 2 Zweiachsig Achse 1 Achse 2

MKD-N0600 06 A - MKD-N0606 06 A 06 A

MKD-N1200 12 A - MKD-N1206 12 A 06 A

MKD-N2400 24 A - MKD-N1212 12 A 12 A

MKD-N4800 48 A -

Ausführung: Kodierung von kundenspezifische Besonderheiten(nicht Safety relevant).

34 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 35

2.4.3 Umgebungsbedingungen im normalen Betrieb

Lagerung, Transport (➜ # 30)

Normaler Betrieb Umgebungsklasse 3K3 gemäß IEC 61800-2

Umgebungstemperatur

im Betrieb

Feuchtigkeit im

Betrieb

Einsatzhöhe Bis zu 1000 Meter über Normalnull ohne Beschränkungen.

Verschmutzungsgrad Verschmutzungsgrad 2 gemäß EN 60664-1

Schwingungen Klasse 3M1 gemäß EN 60721-3-3

Umgebung Schaltschrank IP 54 gemäß IEC 60529

Einbaulage Vertikal

Belüftung Integrierter Lüfter

VORSICHT

0 bis +40 °C unter Nennbedingungen

+40 bis +55 °C mit Dauerstromreduzierung von 4 % pro K

Relative Luftfeuchtigkeit 5 bis 85 %, nicht kondensierend,

Klasse 3K3

1000 bis max. 2000 Meter über Normalnull mit Stromreduzierung

von 1,5 %/100 m

Dauergeräusch bis zu 60dBA im Betrieb. Halten Sie während

des Betriebs die Schaltschranktüren geschlossen. Wir empfehlen, Gehörschutz zu tragen, wenn dieSchaltschranktüren

währenddes Betriebs geöffnet werdenmüssen.

Das Gerät schaltet sich bei stark überhöhter Temperatur im

Schaltschrank ab. StellenSie eineausreichendeZwangsbelüftung im Schaltschrank sicher.

MKD Product Safety Guide | 2 Deutsch

2.4.4 Elektrische Daten

Elektrische Daten (➜ # 53)

2.4.5 Systemgrenzen

Länge Strang 2/3 Maximal 100 m Gesamtkabellänge pro Strang

Anzahl der MKD-C Begrenzt vom Feldbus Protokoll.

Anzahl der MKD-N Achsen Maximal 14 Achsen inStrang 1, insgesamt maximal 28 Ach-

Anzahl AKD-N Maximal 14Achsen pro Strang, insgesamt maximal 28 Ach-

Ausgangsstrom Nutzen Sie den Gleichzeitigkeitsfaktor der Achsen für die

Gesamtleistung Bei 565 V...680 V begrenzt auf 30kW.

Strang 2/3 Leistung Bei 565V...680V begrenzt auf 10kW je Strang.

Strang Standby Leistung Bei 55 V begrenzt auf 180W je Strang.

Leistung Motorbremse Sie können bis zu 3 Motorbremsen pro Strangansteuern.

Serviceschnittstelle X18 Ethernet TCP/IP, 100 Mbit/s, max. Kabellänge 100 m

sen wenn Strang 1 und 2 kombiniert werden(Begrenzung

durch Gesamtleistung und Gesamtstrom).

sen in Strang2 und 3 (Begrenzung durch Gesamtleistung

undGesamtstrom).

Lastverteilung und Optimierung.

Strang1: 43 A, Strang 2: 16 A, Strang 3: 16 A

Verfügbare elektrische Leistung für Bremsen: 76 W pro

Strang(= 3,2 A @ 24 VDC).

Kollmorgen | kdn.kollmorgen.com | January 2019 35

Page 36

MKD Product Safety Guide | 2 Deutsch

2.5 Safe Torque Off (STO)

Die Safety Funktionensind nicht freigegeben undnicht zertifiziert. Benutzen Sie diese Funktion nicht in Applikation, die funktionale Sicherheit erfordern.

In der MKD Betriebsanleitung finden Sie vollständige Informationen überdie funktionale

Sicherheit.

Die von Kollmorgen im Anhang (➜ # 77) angegebenenSafety Kennzahlenkönnen erreicht

werden, wenn Kollmorgen Komponenten verwendet werden. Der resultierende Level derfunktionalen Sicherheit (SIL und/oder PL)muss unterBerücksichtigung des gesamten Antriebssystems berechnet werden.

MKD-C Stecker X16:

globale STO (Strang 2/3) Eingänge für das vom MKD-C versorgte System.

MKD-N Stecker X26:

lokalerSTO (Achse 1 und wenn vorhanden Achse 2 ) Eingang des Antriebsmoduls.

AKD-N Stecker X6:

lokalerSTO Eingangder AKD-N-DS/DT Antriebsmodule.

Globaler STO

Für jedenAntriebsstranggibt es einen STO Eingang. Der STO eines Antriebsstranges gibt

die Endstufen allerAKD-N (ohneOption DS/DT), die am Antriebsstrangangeschlossen sind,

frei, solange ein 24 V Signal an diesem Eingang anliegt.

Lokaler STO

Der lokale STO Eingang gibt die Leistungsendstufe des MKD-N frei, solangeein 24 V-Signal

an diesem Eingang anliegt.

36 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 37

2.6 Mechanische Installation

Abmessungenund Montagehinweise siehe (➜ # 55) und im MKD Installation Manual.

2.6.1 Wichtige Hinweise

MKD-C und MKD-N Geräte müssen imSchaltschrank (Schutzklasse IP 54 gemäß IEC

60529) montiert werden.

MKD Product Safety Guide | 2 Deutsch

VORSICHT

Gefahr durch elektrischen Schlag, wenn der Verstärker (oder der Motor) nicht EMV-gerecht

geerdet ist.

Verwenden Sie elektrisch leitende Montageplatten, z. B. aus Aluminium oder galvanisiertem Stahl.

Verwenden Sie in ungünstigen Fällen ein Kupfergewebeband zwischen Erdungsbolzen

undErdpotential zum Ableiten der Ströme.

Schützen Sie das Gerät vor unzulässigen Belastungen. Achten Sie insbesondere darauf,

dass durch den Transport oder die Handhabung keine Komponenten verbogen oder Isolationsabstände verändert werden. Vermeiden Sie den Kontakt mit elektronischen Komponenten und Kontakten.

Die Module schaltet sich bei Überhitzung selbsttätig aus. Stellen Sie sicher, dass der Einbauraum die Anforderungen erfüllt (➜ # 35).

Montieren Sie keine Geräte, die Magnetfelder erzeugen, direkt neben den Modulen. Starke

Magnetfelder könneninterne Bauteile direkt beeinflussen. Montieren Sie Geräte, die Magnetfelder erzeugen, in ausreichendem Abstand zum MKD-C und/oder schirmen Sie die Magnetfelder ab.

Hoher Ableitstrom!

2.6.2 Anleitung für die mechanische Installation

Einzelheiten siehe MKD Installation Manual. Halten Sie die folgendenWerkzeuge zur Mon-

tage der MKD-C und MKD-N Module bereit; Ihre spezielleApplikation erfordert eventuell

zusätzliche Werkzeuge.

M4-Zylinderschrauben mit Innensechskant (EN 4762)

3 mm-Innensechskantschlüssel mit T-Griff

Nr. 2 Kreuzschlitzschraubendreher

Kleiner Schlitzschraubendreher

Bauen Sie die Modulewie folgt ein:

1. Bereiten Sie den Einbauort vor. Die MKD Module müssen in einem verschließbaren

Schaltschrank montiert werden (➜ # 35). Der Einbauort muss frei von leitenden undkorrosiven Materialien sein.

2. StellenSie sicher, dass die Belüftungdes Verstärkers nicht beeinträchtigt ist, und halten

Sie die zulässige Umgebungstemperatur ein (➜ # 35). Halten Sie dengeforderten Freiraum über und unter den Modulen ein (➜ # 56).

3. Wennfür den Schaltschrank Kühlsysteme verwendet werden, platzieren Sie das Kühlsystem so, dass kein Kondenswasser in die Module oder andere Geräte tropfen kann.

4. Montieren Sie Netzteil und Antriebsmodule nahe beieinander auf der leitenden, geerdeten

Montageplatte im Schaltschrank.

5. Erden Sie dieModule, die Montageplatte, das Motorgehäuse, den GND der

24VVersorgung und denCNC-GND derSteuerung.

Die Montage des AKD-N an die Maschine ist in der AKD-N Betriebsanleitung beschrieben.

Kollmorgen | kdn.kollmorgen.com | January 2019 37

Page 38

MKD Product Safety Guide | 2 Deutsch

2.7 Elektrische Installation

Stecker und Anschluss siehe (➜ # 57) und MKD Installation Manual.

2.7.1 Wichtige Hinweise

Das Antriebssystem darf nur von Fachpersonal mit Kenntnissen im Bereich der Elektrotechnik installiert werden. Grüne Drähte mit gelbenStreifendürfen nur für die Verdrahtung

derSchutzerde (PE) verwendet werden.

GEFAHR

Es besteht die Gefahr von schwerenoder tödlichen Verletzungendurch elektrischenSchlag

oder Lichtbogenbildung. Kondensatoren können bis zu 5 Minuten nach Abschalten der

Stromversorgung gefährlicheSpannung führen. Steuer- und Leistungsanschlüsse können

auch bei nicht aktivem Motorunter Spannung stehen.

Installieren und verdrahten Sie nur abgeschaltete Geräte.

Achten Sie darauf, dass die Anlage sicher freigeschaltet ist (Absperrung, Warnzeichen

usw.).

Trennen Sie nie die elektrischen Verbindungen zum Servoverstärker, während dieser

Spannung führt.

Warten Sie nach dem Freischalten des Servoverstärkers mindestens 5 Minuten, bevor

Sie Geräteteile berührenoder Anschlüsse trennen.

Messen Sie zur Sicherheit die Spannung am DC-Bus-Zwischenkreis, und warten Sie,

bis die Spannung unter 50 V gesunkenist.

Da der Ableitstrom zu PE mehr als 3,5 mA beträgt, muss in Übereinstimmungmit der Norm

EN61800-5-1 derPE-Anschluss entweder gedoppelt oder ein Anschlusskabel mit einem

Querschnitt von >10 mm² verwendet werden. Abweichende Maßnahmensind in Übereinstimmung mit regionalen Vorschriften möglich.

Falsche Zwischenkreisspannung, ein ungeeigneter Motor oder fehlerhafte Verdrahtung

beschädigen die Systemkomponenten. Prüfen Sie die Kombination aus Verstärker und

Motor. Gleichen Sie dieNennspannung und den Nennstrom derKomponenten ab. Führen

Sie die Verdrahtung gemäß der Anschlussbilder aus: (➜ # 57)

Die Setup-Software kann verwendet werden, um die Einstellungen des Gerätes zu ändern.

Jede weitere Veränderung führt zum Erlöschender Garantie.

Hohe Spannung bis 900 V!

2.7.2 Anleitung für die elektrische Installation

Einzelheiten siehe MKD Installation Manual. Installieren Sie das elektrische Antriebssystem

wie folgt:

1. Wählen Sie Kabel gemäß dergeplanten Systemtopologie aus (➜ # 35).

2. Beachten Sie die maximale Leitungslänge (➜ # 35).

3. Montieren Sie die Schirmung underden Sie die Systemkomponenten (➜ # 61).

4. Verdrahten Sie die Systemkomponenten.

- Beachten Sie die "Empfehlungen für die Störunterdrückung": MKD Installation Manual

- Führen Sie die Verdrahtung nach den Anschlussbildern im MKD Installation Manual

durch.

5. Prüfen Sie die Verdrahtung anhandder Anschlusspläne im MKD Installation Manual

durch.

Die elektrische Installation des AKD-N an die Maschine ist in der AKD-N Betriebsanleitung

beschrieben.

38 Kollmorgen | kdn.kollmorgen.com | January 2019

Page 39

2.8 Setup

Vollständige Informationen zu funktionaler Sicherheit finden Sie im MKD Installation

Manual.

ParameterProgrammierung und Regelkreisverhalten: sieheWorkBench OnlineHilfe.

Die Inbetriebnahme des Feldbus ist im zugehörigen Handbuch auf der DVD beschrieben.

2.8.1 Wichtige Hinweise

Der Hersteller der Maschine muss vor der Prüfung undInbetriebnahme eine Risikobeurteilungfür die Maschine erstellen und geeignete Maßnahmen ergreifen, um sicherzustellen, dass unvorhergesehene Bewegungen nicht zu Verletzungenoder Sachschäden

führen können.

Der Verstärker darf nur von Fachpersonal mit umfassenden Kenntnissen in der Elektrotechnik und der Antriebstechnik getestet und konfiguriert werden.

MKD Product Safety Guide | 2 Deutsch

GEFAHR