Page 1

Installation Manual

Installation Manual

for

KSM31R

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 1 of 28

Page 2

Installation Manual

Installation Manual for Extension Module KSM 31R.

Note:

The German version is the original version of the installation manual

Status: 09/2015

Valid from FW release 2.0.2.31

Subject to change without prior notification

The contents of this documentation has been collated with greatest care and corresponds

with our present status of information.

However, we would like to point out, that this document cannot always be updated at the

same time as the technical further development of the products.

Information and specifications can be changed at any time. Please keep yourself informed

about the current version under www.kollmorgen.com.

Devices of the

Kollmorgen Europe GmbH

Pempelfurtstraße 1

DE-40880 Ratingen

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 2 of 28

Page 3

Installation Manual

Table of Contents

1 IMPORTANT NOTES .......................................................................................... 4

1.1 Definitions ........................................................................................................................................... 4

1.2 Co-valid documents ............................................................................................................................. 4

1.3 Abbreviations used .............................................................................................................................. 5

2 SAFETY REGULATIONS .................................................................................... 6

2.1 Operation and service ......................................................................................................................... 6

2.2 Transportation / storage ..................................................................................................................... 6

3 DEVICE TYPES ................................................................................................... 7

3.1 Characteristic data of device ................................................................................................................ 7

3.2 Identification ....................................................................................................................................... 8

3.3 Scope of delivery ................................................................................................................................. 8

4 CONNECTION AND INSTALLATION ................................................................. 9

4.1 General notes on installation ............................................................................................................... 9

4.2 Installation and assembly of the KSM module ................................................................................... 10

4.3 Installation of backplane bus system ................................................................................................. 10

4.4 Assembling the modules .................................................................................................................... 11

4.4.1 Assembly on C-rail............................................................................................................. 11

4.4.2 Assembly on backplane bus .............................................................................................. 12

4.5 Terminal assignment ......................................................................................................................... 14

5 SAFETY RELATED WIRING OF OUTPUTS ..................................................... 16

5.1 General specifications for wiring and testing ..................................................................................... 16

5.2 Wiring of the relay outputs ................................................................................................................ 17

5.2.1 Single-pole switching relay output without testing ............................................................. 17

5.2.2 Single-pole switching relay with external switching amplifier and testing ......................... 18

5.2.3 Dual-channel switching relay output with external monitoring group feedback ................ 19

5.2.4 Two-channel relay output – external control circuit with monitoring .................................. 20

5.2.5 Dual-channel relay output with external control circuit in PL e .......................................... 21

6 CONFIGURING THE KSM31R .......................................................................... 22

6.1.1 Basic configuration ............................................................................................................ 22

6.1.2 Step 2 ................................................................................................................................ 23

6.1.3 Step 3 ................................................................................................................................ 23

6.1.4 Step 4 ................................................................................................................................ 24

7 MAINTENANCE ................................................................................................ 25

7.1 Modification / handling changes to the device .................................................................................. 25

7.2 Exchanging a module ......................................................................................................................... 25

7.3 Maintenance intervals ....................................................................................................................... 25

8 TECHNICAL DATA ........................................................................................... 26

8.1 Environmental conditions .................................................................................................................. 26

8.2 Load carrying capacity of outputs ...................................................................................................... 26

8.3 Technical data of switching relay ....................................................................................................... 26

8.4 Safety-related characteristic data ...................................................................................................... 27

8.4.1 Single-channel use of the relay output according to 5.2.2 ................................................ 27

8.4.2 Dual-channel use of the relay output according to 5.2.3, 5.2.4 or 5.2.5............................ 27

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 3 of 28

Page 4

Installation Manual

Description

Reference

Installation manual for KSM module

series KSM10/11/12

HB-37350-810-01-xxF-DE KSM

Installation manual

Acceptance test

TÜV certificate for product modules

KSM31R

1 Important notes

Definition of individual target groups

Project engineers for secure drive systems:

Engineers and technicians

Assembly, electric installation, maintenance and replacement of devices

Maintenance electricians and service technicians

Commissioning, operation and configuration:

Technicians and engineers

1.1 Definitions

The designation KSM is used as generic term for all derivatives from the KSM product range.

Wherever this description refers to a certain derivative, the complete designation is used.

The term “safe” used in the following text in any case refers to the classification as a safe

function for application up to Pl e acc. to EN ISO 13849-1 or SIL3 acc. to EN 61508.

The system software “SafePLC” serves the purpose of configuring and programming

KSM modules.

The modules of the KSM series are internally built up of two independent processing units.

In the following these are referred to as system A and system B.

1.2 Co-valid documents

Note:

• Thoroughly read the manuals before you start the installation and the commissioning

of the KSM module.

• Paying attention to the documentation is a prerequisite for trouble-free operation and

fulfilment of possible warranty claims.

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 4 of 28

Page 5

Installation Manual

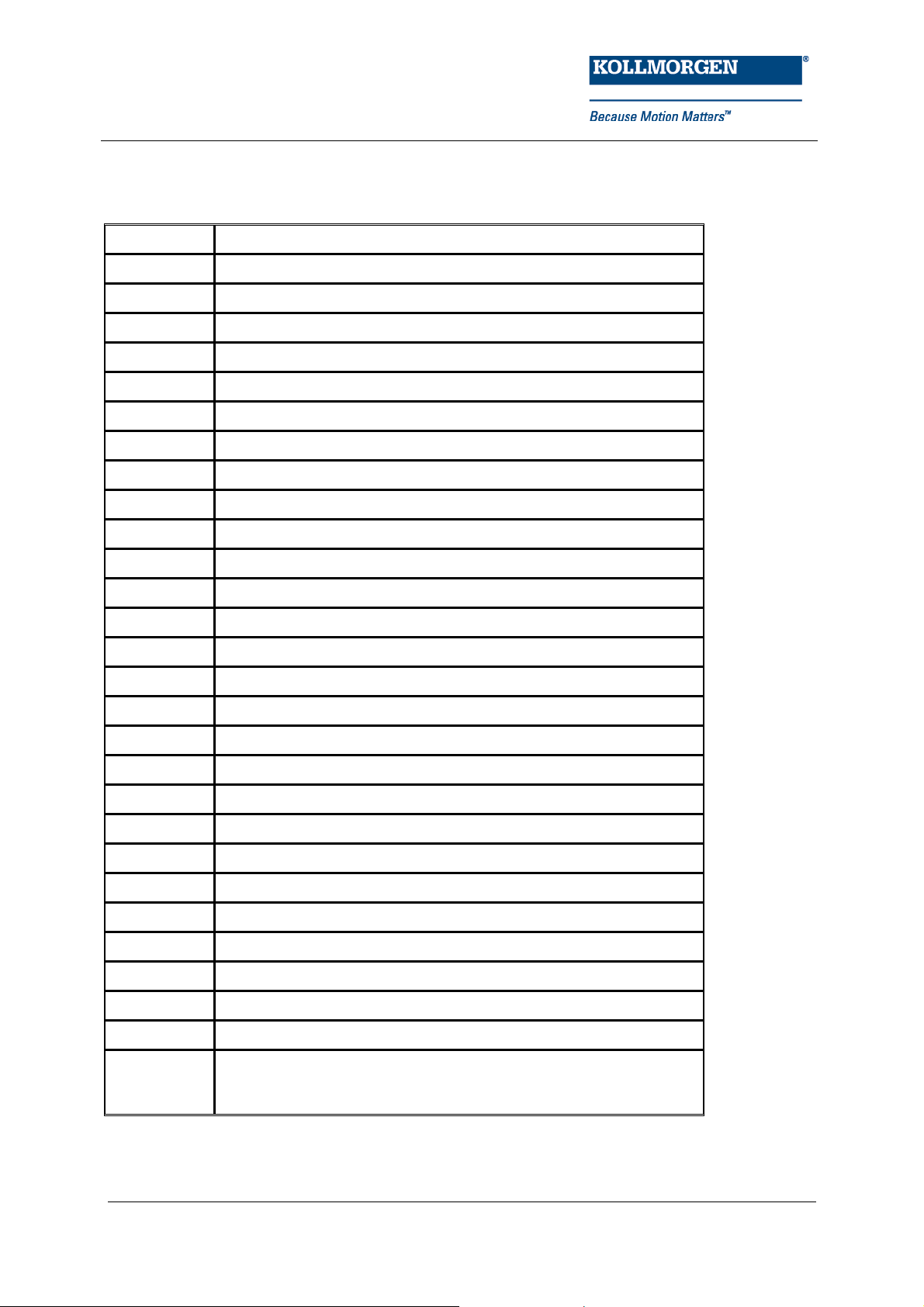

Abbreviation

Meaning

AC

Alternating voltage

IL

Instruction list

ELIA

Employer's liability insurance association

CLK

Clock (cycle)

CPU

Central Processing Unit

DC

Direct voltage

DI1..DI14

Digital Input

DIN

Deutsches Institut für Normung (German Institute for Standardization)

DO

Digital Output

EMU

Emergency Monitoring Unit

EMC

Electromagnetic compatibility

ELC

Emergency Limit Control

EN

European Standard

HISIDE

Output with 24 VDC nominal level switching to plus

IP20

Degree of protection for housing

ISO

International Organisation for Standardisation

LED

Light Emitting Diode

LOSIDE

Output switching to reference potential

OLC

Operational Limit Control

PIA

Process image of outputs

PII

Process image of inputs

P1,P2

Pulse outputs

PLC

Programmable Logic Controller

POR

Power on Reset

PSC

Position Supervision Control

SELV

Safety Extra Low Voltage

SSI

Synchronous Serial Interface

VDE

Verband der Elektrotechnik, Elektronik und Informationstechnik e. V.

technology)

1.3 Abbreviations used

(association for electrical engineering, electronics and information

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 5 of 28

Page 6

Installation Manual

2 Safety regulations

Intended use

You can only operate the KSM31R module with a basic module. This means that the same

safety regulations apply as for the KSM10/11/12 modules.

2.1 Operation and service

The module must always be de-energized before installation and removal, or before

disconnecting signal lines.

When installing or removing the module appropriate measures must be applied to prevent

electrostatic discharge to the externally arranged terminal and plug connections.

2.2 Transportation / storage

Information concerning transport, storage and proper handling must be strictly followed.

The climate related specifications in chapter “Technical data” must be complied with.

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 6 of 28

Page 7

Installation Manual

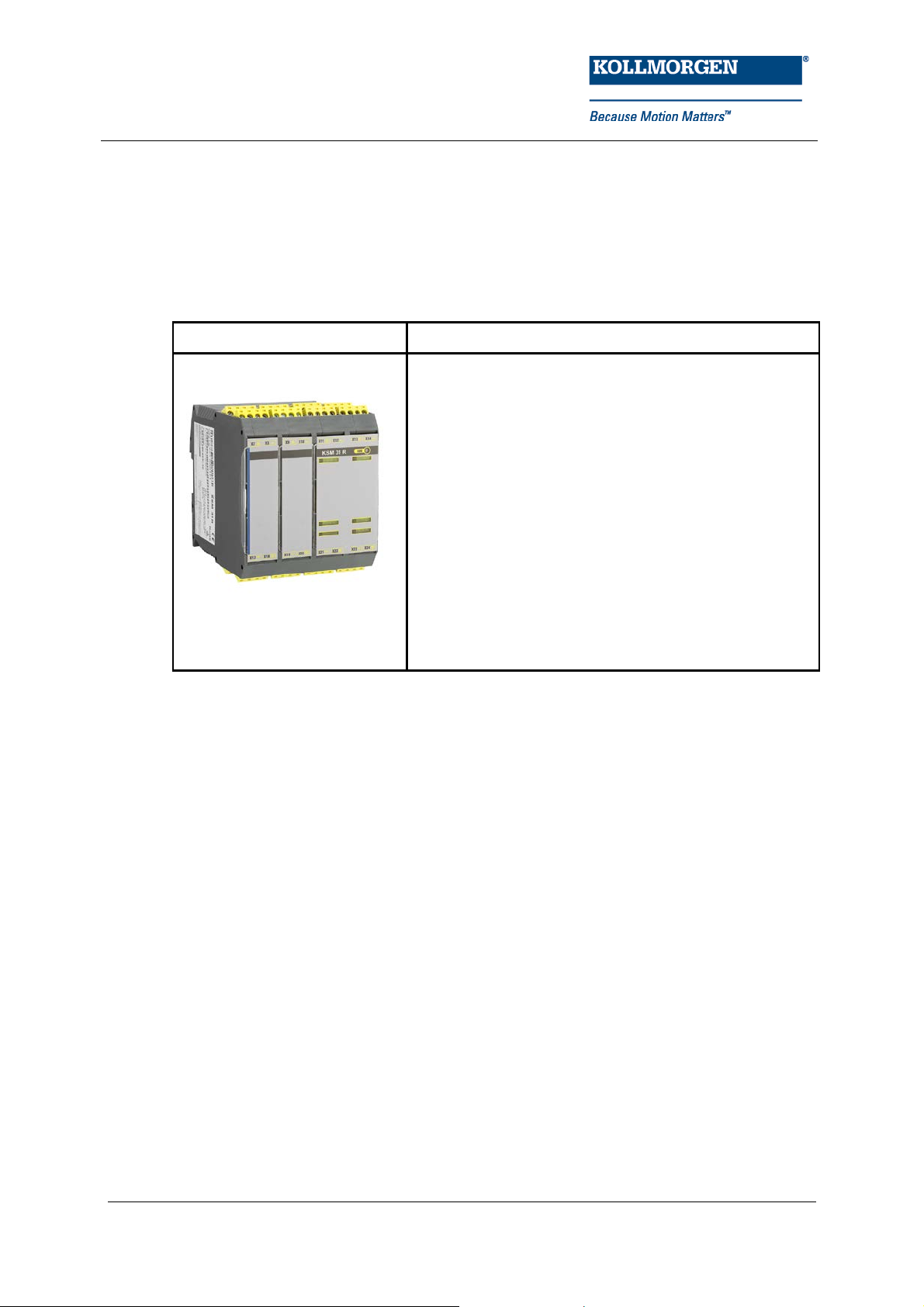

Type designation

Device design

Design of module with the following periphery:

3 Device types

3.1 Characteristic data of device

12 digital inputs (DI 1-4 and DI8-12 OSSD)

2 I/Os optionally configurable as input or output

4 secure relay outputs

2 pulse outputs

2 signal outputs

12 status LEDs for inputs

10 status LEDs for I/O/relay output

1 backplane bus interface

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 7 of 28

Page 8

Installation Manual

3.2 Identification

The type plate is located on the left side wall of the module and contains the following

information:

Type designation

Part number

Serial number

Identification of hardware release

Identification of software release

Safety categ ory

Input characteristics

Output characteristics

Type plate KSM31R (image enlarged)

3.3 Scope of delivery

The scope of delivery contains:

KSM31R module:

• A plug for all the signal terminals

• A backplane bus connector

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 8 of 28

Page 9

Installation Manual

4 Connection and install a t ion

4.1 General notes on installation

Strictly follow the safety regulations when installing!

Type of protection IP20

Route all signal lines for the interfacing of digital inputs and contact monitoring separately.

In any case isolate 230 VAC voltages from low voltage lines, if these voltages are used in

connection with the application.

The cable lengths for digital inputs and outputs must not exceed 30 m.

Measures concerning the electromagnetic compatibility (EMC)

The KSM module is intended for use in the drive environment and meets the

EMC-requirements mentioned above.

It is also assumed that the electromagnetic compatibility of the overall system is ensured by

application of appropriate measures.

Safety note:

Electric power supply lines of the KSM and “discontinuous-action lines” of the power

converter must be isolated from each other.

Signal lines and power lines of the power converter must be routed through separate cable

ducts. The distance between the cable ducts should be minimum 10 mm.

Only shielded cables must be used to connect the position and speed sensors. The signal

transmission cable must be RS-485-standard compliant (lines twisted in pairs).

Care must be taken to ensure that the shielding is correctly connected in the 9-pin

SUB-D plugs of the position and speed sensors. Only metal or metal coated plugs are

permitted.

The shielding on the sensor side must comply with appropriate methods.

EMC-compliant installation of the power converter technology in the environment of th e

KSM module must be assured. Special attention must be paid to the routing of cables, the

shielding of motor cables and the connection of the braking resistor. Strict compliance with

the installation instructions of the power converter manufacturer is mandatory.

All contactors in the environment of the power converter must be equipped with appropriate

suppressor circuits.

Suitable measures to protect against overvoltages must be applied.

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 9 of 28

Page 10

Installation Manual

KSM5x

KSM31R

KSM11

4.2 Installation and assembly of the KSM module

The module is solely to be installed in control cabinets, with a degree of protection of at

least IP54.

The modules must be vertically fastened on a top hat rail

The ventilation slots must be kept unobstructed, to ensure adequate air circulation inside

the module.

4.3 Installation of backplane bus system

The KSM31R module is connected to the base unit via the backplane bus.

Example: KSM11 + KSM31R + KSM5x

(Base unit + KSM31R + communication module)

The KSM31R module is supplied with power via the backplane bus from the base unit.

The digital outputs are supplied with power via plug connector X11 on the KSM31R module.

Note:

• A maximum of 2 extension modules can be connected to a base unit.

(Excl. bus module)

• You must not connect several base units with extension modules to one backplane

bus connection.

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 10 of 28

Page 11

Installation Manual

4.4 Assembling the modules

The modules are mounted on C-standard rails by means of snap-on latches.

4.4.1 Assembly on C-rail

The devices are inserted into the rail under an oblique angle and then snapped on downwards.

For disassembling use a screwdriver, insert it into the slot of the downwards pointing latch

and then move it up.

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 11 of 28

Page 12

Installation Manual

4.4.2 Assembly on backplane bus

After assembling the backplane bus, you can install the device. For this purpose insert the

module from above into the plug connection under a oblique angle and snap it onto the C-rail.

Insert the module from above under an oblique angle.

Snap-on downwards on to the C-rail.

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 12 of 28

Page 13

Installation Manual

The backplane plug connection can later be extended. The system configuration can thus be

extended by additional modules.

Snap the backplane bus element into the C-rail and insert it into the counter-piece by sliding

it sideways.

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 13 of 28

Page 14

Installation Manual

Terminal

Designation

Function

X07:1

K1/11

Readback contact relay 1

X08:1

K3/11

Readback contact relay 3

X09:1

K5/11

Readback contact relay 5

X10:1

K7/11

Readback contact relay 7

X11:1

U24 external

IO voltage supply device +24 VDC

X12:1

IO01

I/O extension 1 (EAEx.1 / EAAx.1)

X13:1

Not used

X14:1

Digital IN01

Digital input 01 (Ex.1)

X17:1

K1.1

Relay output 1

X18:1

K3.1

Relay output 3

4.5 Terminal assignment

X07:2

X07:3

X07:4

X08:2

X08:3

X08:4

X09:2

X09:3

X09:4

X10:2

X10:3

X10:4

X11:2

X11:3

X11;4

K1/12

K2/11

K2/12

K3/12

K4/11

K4/12

K5/12

K6/11

K6/12

K7/12

K8/11

K8/12

U24 external

GND external

GND external

Readback contact relay 1

Readback contact relay 2

Readback contact relay 2

Readback contact relay 3

Readback contact relay 4

Readback contact relay 4

Readback contact relay 5

Readback contact relay 6

Readback contact relay 6

Readback contact relay 7

Readback contact relay 8

Readback contact relay 8

IO voltage supply device +24 VDC

IO voltage supply device 0 VDC

IO voltage supply device 0 VDC

X12:2

X12:3

X12:4

X13:2

X13:3

X13:4

X14:2

X14:3

X14:4

X17:2

X17:3

X17:4

X18:2

X18:3

X18:4

IO02

P1

P2

Ax.1

Ax.2

Digital IN02

Digital IN03

Digital IN04

K1.2

K2.1

K2.2

K3.2

K4.1

K4.2

I/O extension 2 (EAEx.2 / EAAx.2)

Pulse output P1

Pulse output P2

Not used

Semi-conductor output Ax.1 (not a safety output)

Semi-conductor output Ax.2 (not a safety output)

Digital input 02 (Ex.2)

Digital input 03 (Ex.3)

Digital input 04 (Ex.4)

Relay output 1

Relay output 2

Relay output 2

Relay output 3

Relay output 4

Relay output 4

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 14 of 28

Page 15

Installation Manual

X19:1

K5.1

Relay output 5

X20:1

K7.1

Relay output 7

X21:1

Not used

X22:1

Not used

X23:1

Digital IN05

Digital input 05 (Ex.5)

X24:1

Digital IN09

Digital input 09 (Ex.9) (OSSD)

X19:2

X19:3

X19:4

X20:2

X20:3

X20:4

X21:2

X21:3

X21:4

X22:2

X22:3

X22:4

X23:2

X23:3

X23:4

K5.2

K6.1

K6.2

K7.2

K8.1

K8.2

Digital IN06

Digital IN07

Digital IN08

Relay output 5

Relay output 6

Relay output 6

Relay output 7

Relay output 8

Relay output 8

Not used

Not used

Not used

Not used

Not used

Not used

Digital input 06 (Ex.6)

Digital input 07 (Ex.7)

Digital input 08 (Ex.8)

X24:2

X24:3

X24:4

Digital IN10

Digital IN11

Digital IN12

Note)

X: 1-> KSM31R device 1

2-> KSM31R device 2

Digital input 10 (Ex.10) (OSSD)

Digital input 11 (Ex.11) (OSSD)

Digital input 12 (Ex.12) (OSSD)

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 15 of 28

Page 16

Installation Manual

X14

DI1

DI2

DI3

DI4

EA1

EA2

P1

P2

X12

K1/11

K1/12

K2/11

K2/12

X07

5 Safety related wiring of out put s

5.1 General specifications for wiring and testing

The wiring suggestions below show both the options for functional use of the relay outputs

and the wiring that is necessary for diagnostics in each case. Diagnosis must always be

carried out in the case of any safety-relevant use of the relay outputs. Apart from the wiring,

diagnostics requires integration into the application program of the monitoring function for

secure outputs “EMU” – For more details on this topic, refer to the programming manual.

Safety note:

• When using the relay outputs for safety-relevant functions, you must observe the

information below, in particular the specifications on wiring diagnostics.

• The diagnostics for achieving the respective Pl and SIL in accordance with the wiring

suggestions below, require you to integrate an associated diagnostics function into

the application program – For more details on this topic, refer to the programming

manual.

• For applications with frequent safety shut-down requests, these tests should be

performed more frequently, e.g. at the beginning of the shift, 1 × per week. However,

a test should at least be carried out cyclically 1 × year.

• You must parameterize the HISIDE outputs of the KSM31R module as safety outputs

(see configuration of KSM31R)

Wiring example relay with feedback:

Fig.: Feedback of AK1

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 16 of 28

Page 17

Installation Manual

K1

K2

L+

L-

X17

X17.1

X17.2

X17.3

X17.4

5.2 Wiring of the relay outputs

5.2.1 Single-pole switching relay output without testing

For a single-pole connection without external testing, bear in mind that the KSM31R module

will not recognize bonding of the internal relay or of one or more external contacts. The

following circuit example is only suitable for safety applications on a limited basis; at

a maximum, Pl b according to EN 13849-1 can be achieved!

Fig.: Single-pole switching relay output.

Safety note:

Not recommended for safety applications!

In this context see also the notes in EN 13849-1 concerning the application and the required

fault exclusions.

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 17 of 28

Page 18

Installation Manual

X17

X14

K1

K2

IO01

IO02

P1

P2

X12

DI01

DI02

DI03

DI04

L +

L -

X17.1

X17.2

X17.3

X17.4

X14.1

X14.2

X14.3

X14.4

X12.1

X12.2

X12.3

X12.4

X7

K1/11

K1/12

K2/11

K2/12

X7.1

X7.2

X7.3

X7.4

5.2.2 Single-pole switching relay with external switching amplifier and testing

If you are using only one relay output, you will need a set-up to test the complete chain,

i.e. including all the downstream electro-mechanical, pneumatic or hydraulic components as

well as a message / warning device if faults are detected to achieve PL c or above.

You need positively guided auxiliary contacts for downstream electro-mechanical devices or

failsafe alarm contacts for the valve position for the hydraulic or pneumatic components.

The me ssage / warning device must ensure that the operator recognizes the dangerous

situation immediately.

The achievable PI mainly depends on the test rate, PI d acc. to EM 13849-1 can be achieved

at a maximum.

Fig.: Single-pole relay output with testing

Safety note:

Only conditionally recommended for safety applications! In this context see also the

notes in EN 13849-1 concerning the application and the required fault exclusions.

For PL c or above, a test rate > 100 * request rate is necessary. For Pl d, you must

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 18 of 28

carry out testing at least once a year.

For PL c and above, a message / warning feature is required that informs the

operator immediately about a dangerous situation.

Page 19

Installation Manual

X17

X14

K1

K2

IO01

IO02

P1

P2

X12

DI01

DI02

DI03

DI04

L +

L -

X17.1

X17.2

X17.3

X17.4

X14.1

X14.2

X14.3

X14.4

X12.1

X12.2

X12.3

X12.4

X7

K1/11

K1/12

K2/11

K2/12

X7.1

X7.2

X7.3

X7.4

5.2.3 Dual-channel switching relay output with external monitoring group feedback

For safety-related applications from Pl d onwards according to EN ISO 13849-1, two relays

on the KSM31R module and two external power contactors are used.

Fig.: Two-channel switching relay output with external monitoring – group feedback

The two external monitoring contacts are switched in series, supplied by clock signal P1 and

read-in from DI01 (configured as an EMU input). In the case of higher requirements, you

must consider that at least one switching process must take place every 24 hours.

Safety note:

To achieve PI d and above according to EN ISO 13849-1, a sufficiently high testing

rate is required.

For applications with frequent safety shut-down requests, these tests should be

performed more frequently, e.g. at the beginning of the shift, 1 × per week.

For Pl d, you must carry out a cyclical test at least once a year; to achieve Pl e this

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 19 of 28

test is needed at least once per month.

Page 20

Installation Manual

X17

X14

K1

K2

IO01

IO02

P1

P2

X12

DI01

DI02

DI03

DI04

L +

L -

X17.1

X17.2

X17.3

X17.4

X14.1

X14.2

X14.3

X14.4

X12.1

X12.2

X12.3

X12.4

X7

K1/11

K1/12

K2/11

K2/12

X7.1

X7.2

X7.3

X7.4

P

N

Abschaltkanal 1

Abschaltkanal 2

Shut-down circuit 1

Shut-down circuit 2

5.2.4 Two-channel relay output – external control circuit with monitoring

For safety applications from PI d and higher acc. to EN ISO 13849-1. The external circuit is

controlled in dual-channel mode via two relay outputs. Each of the two external cutout paths

is monitored. For PL e acc. to EN ISO 13849-1 a sufficiently high testing rate

(see the remarks) and MTTF

= high is required for the external circuit.

D

Safety note:

To achieve PI d and above according to EN ISO 13849-1, a sufficiently high testing

rate is required.

For applications with frequent safety shut-down requests, these tests should be

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 20 of 28

performed more frequently, e.g. at the beginning of the shift, 1 × per week.

For Pl d, you must carry out a cyclical test at least once a year; to achieve Pl e this

test is needed at least once per month.

Page 21

Installation Manual

X17

X14

K1

K2

IO01

IO02

P1

P2

X12

DI01

DI02

DI03

DI04

L +

L -

X17.1

X17.2

X17.3

X17.4

X14.1

X14.2

X14.3

X14.4

X12.1

X12.2

X12.3

X12.4

X7

K1/11

K1/12

K2/11

K2/12

X7.1

X7.2

X7.3

X7.4

Ple

STO

5.2.5 Dual-channel relay output with external control circuit in PL e

For safety applications from PI d and higher acc. to EN ISO 13849-1. The external circuit is

controlled in dual-channel mode via the relay outputs. For PL e according to EN ISO 13849-1,

a sufficiently high testing rate (see the remarks) is required as well as PL e for the external

circuit.

Safety note:

For safety circuits, EN ISO 13849-1 yields the following requirements for the test interval:

Cat 3 / PL d: Testing once per year

Cat 4 / PL e: Testing once per month.

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 21 of 28

Page 22

Installation Manual

6 Configuring the KSM31R

6.1.1 Basic configuration

After starting the “Safe PLC” program you must first choose the basic unit, followed by the

extension KSM31R.

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 22 of 28

Page 23

Installation Manual

Inputs

Occupied

Free

Metering length

6.1.2 Step 2

On the KSM31R module, you must set the bus address using the address switch.

This setting is made on the back of the module

Note:

• The address range of the KSM31R module is from 1...15.

• Address “0” is reserved for the basic device.

6.1.3 Step 3

In the main menu of the “Safe PLC” program one can open the configuration dialog for the

KSM31R module by “double-clicking” on the basic device.

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 23 of 28

Page 24

Installation Manual

6.1.4 Step 4

The following settings must be made in the KSM31R configuration dialog:

• Logical address of KSM31R device x: Setting the address switch of the KSM31R module.

• Group1 EAAx.1-EAAx.6 or group1 EAAx.7-EAAx.10: When using these outputs one can

choose between safety and standard outputs.

Attention:

You should always configure group EAAx.1-EAAx.6 or group 1 EAAx.7-EAAx.10 as safety

outputs to be able to use them in a safety application.

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 24 of 28

Page 25

Installation Manual

Module replacement

See technical data

Function test

See chapter “Start-up”

7 Maintenance

7.1 Modification / handling changes to the device

Repair

Repair work on the device can only be performed in the factory.

Warranty

By opening the module without permission the warranty will become null and void.

Note:

• By modifying the module the safety approval will become null and void!

7.2 Exchanging a module

When replacing an KSM31R module, you must observe the following points:

Switch off the electric power supply for all the KSM modules and disconnect them.

Remove all the plug-in connections of the KSM31R module.

Take the module off the top hat rail, make a note of the bus address and pack it in an

EMC-compliant way.

Set the bus address of the new module using the address switch and mount it on the top

hat rail.

Reconnect all connections.

Switch on the electric power converter.

Switch on the supply voltage.

Note:

• Pluggable connections of the KSM module must generally not be disconnected or

connected in live condition.

7.3 Maintenance intervals

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 25 of 28

Page 26

Installation Manual

Class of protection

IP 20

Ambient temperature

0 °C* ... 50 °C

Climatic category

3 acc. to DIN 50 178

Lifetime

90000 h at 50 °C ambient

Output

Voltage

Current

Ax.1, Ax.2

24 VDC

100 mA

EAAx.1-2

*)

24 VDC

250 mA

K1-K8

24 VDC

230 VAC/2 A

2 A

2 A

Switching capacity min./max.

3 / 2000 (1 mVA / 7 VA)

Switching performance

At 0.1 Hz DC 13

24 V / 4 A

Electrical service life

50,000 switching cycles

Switching frequency

20 switching cycles / s

Mechanical service life

> 40 × 106 switching cycles

8 Technical data

8.1 Environmental conditions

8.2 Load carrying capacity of outputs

The outputs can be loaded as follows:

48 VDC

2 A

Note:*) See th e KSM installation m anual

8.3 Technical data of switching relay

According to IEC/EN 609 47-5-1 AC 15

According to IEC/EN 609 47-5-1 DC 13

250 V / 3 A

24 V / 1 A

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 26 of 28

Page 27

Installation Manual

Max. achievable safety class

• SIL 2 acc. to EN61508

EN ISO 13849-1

System structure

• 1-channel with diagnose (1001)

• Category 2 acc. to EN 13849-1

Rating of operating mode

“high demand” acc. t o EN 61508

Probability of an endangering failure

KSM31R = 2,2 * 10

-9 /

KAT 4

Proof test interval (EN61508)

20 years; after this time, the module must be

Max. achievable safety class

• SIL 3 acc. to EN61508

EN ISO 13849-1

System structure

• 2-channel with diagnose (1002)

• Category 4 acc. to EN 13849-1

Rating of operating mode

“high demand” acc. t o EN 61508

Probability of an endangering failure

KSM31R = 2,2 * 10

-9 /

KAT 4

Proof test interval (EN61508)

20 years; after this time, the module must be

8.4 Safety-related characteristic data

8.4.1 Single-channel use of the relay output according to 5.2.2

• Performance level d according to

(high demand rate)

per hour (PFH value)

+ 1-channel / relay 20 * 10

-9

max. 8

replaced

8.4.2 Dual-channel use of the relay output according to 5.2.3, 5.2.4 or 5.2.5

• Performance level e acc. to

(high demand rate)

per hour (PFH value)

+ 2-channel / relay 1,0 * 10

replaced

-9

max. 4

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 27 of 28

Page 28

Installation Manual

North America

Europe

South America

China and SEA

About Kollmorgen

Kollmorgen is a leading provider of motion syste ms and com ponents for machine builders. Through world-class

knowledge in motion, industry-leading quality and deep expertise in linking and integrating stan dar d and cu sto m

products, Kollmorgen delivers breakthrough solutions that are unmatched in performance, reliability and easeof-use, giving machine builders an irrefutable marketplace advantage.

For assistance with your app li cati on n eed s, visit www.kollmorgen.com

or contact us at:

Kollmorgen

203A West Rock Road

Radford, VA 24141 USA

Web: www.kollmorgen.com

Mail: support@kollmorgen.com

Phone: 1-540-633-3545

Fax: 1-540-639-4162

Kollmorgen

Avenida Tamboré - 1077 Tamboré - Barueri SP Brasil

CEP: 06460-000, Brazil

Web: www.kollmorgen.com

Tel.: +55 11 4191-4771

Kollmorgen

Pempelfurtstraße 1

40880 Ratingen, Germany

Web: www.kollmorgen.com

Mail: technik@kollmorgen.com

Phone: + 49-2102-9394-0

Fax: + 49 -2102-9394-3155

Kollmorgen

Room 202, Building 3, Lane 168,

Lin Hong Road, Changning District

Shanghai, China

Web: www.kollmorgen.cn

Mail: sales.china@kollmorgen.com

Tel.: +86 - 400 661 2802

HB-37350-810-31-09F-EN KSM31R Installation Manual.doc Page 28 of 28

Loading...

Loading...