Page 1

UPGRADE NOTICE for BDS5T / VSA

The following are features of the MC3 board that is incorporated into the BDS5T and the VSA.

NOTICE: Some changes may be required to existing wiring or probram in order to make the BDS5T

compatible to the BDS5 or the VSA, or the VSA compatible to the VFS5.

HARDWARE:

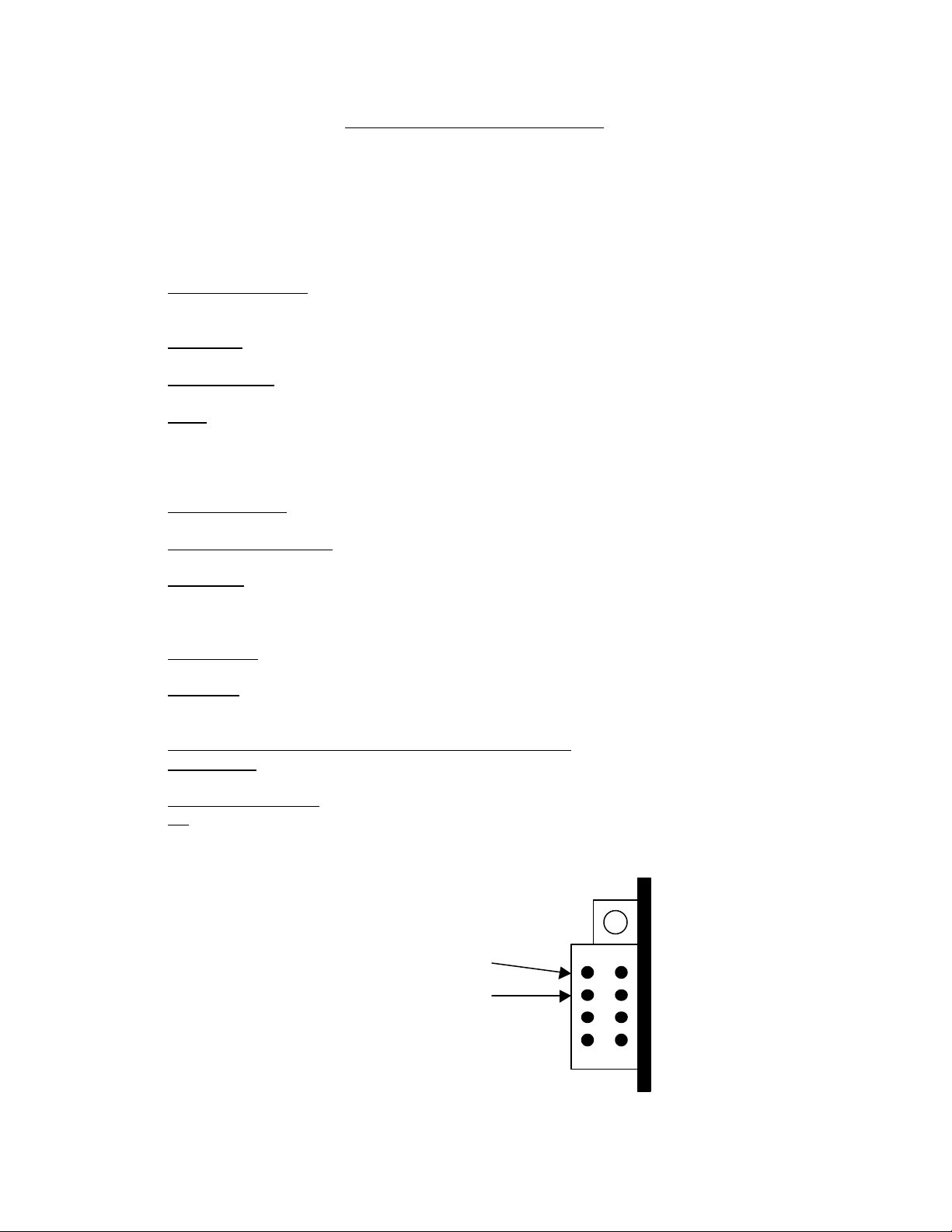

• On-board analog input

The analog input is on the connector T1 of the BDS5T and connector C10 on the VSA, Pin 5 is Diff.

Hi and Pin 6 is Diff. Low.

• Tach output

Scaled for 1750 RPM/volts

• Communications

To convert from RS232 to RS485 install a jumper between pins 9 and 10 on connector J1

• Inputs

Built-in filters

SOFTWARE:

• Program Execution

Twice as fast as BDS5

• PL, PLIM, TRIP, and PDF

State is remembered through power-down

• A2D Switch

When using the on-board analog input set A2D to 1. When using the encoder input for master / slave

application set A2D to 0. The gear ration when using the on-board analog input is GEARI / GEARO =

700 / 16384 for 10 volts = 10000 RPM.

• CAM function

Cam now has 1024 points, NORM ) ECAM starts the CAM function.

• PDF switch

Set to 1 for brushless motors. For induction motor control if PDF=1, the auto tune feature is available.

If PDF=0, the control scheme is identical to the VFS5 and the auto tune feature is not available.

• Supports 10-bit resolver resolution for higher speed applications.

• User variables

2,000 user variables (x1 – x2000)

• Program memory is 27K

• “P”

May be omitted when printing one variable.

Diff Hi

Diff Lo

Front View of Connector C10 on VSA, T1 on BDS5T

Page 2

Page 3

BDS5

I

NSTALLATION AND SETUP MANUAL

Old Number M93101 - I

New Number MB5000H

SSUE 4

Page 4

Page 5

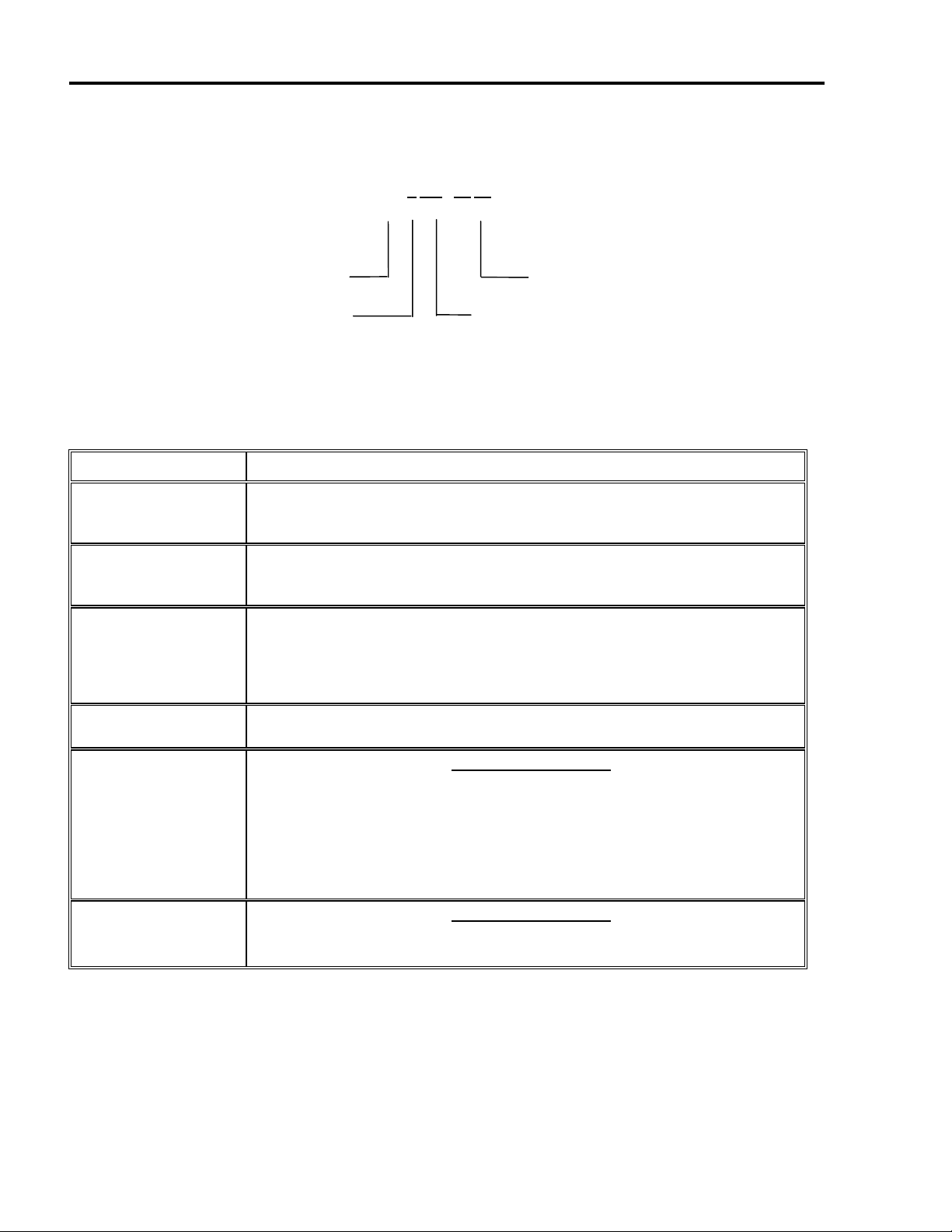

BDS5 T

ECHNICAL MANUAL CONFIGURATION

T

NSTALLATION AND SETUP MANUAL

( I

ECHNICAL MANUAL CONFIGURATION

M93101 )

PAGE NO.

-- ...............................Title P age..................................................................................................................... 0

-- ...............................Technical Manual Configuration................................................................................. 0

-- ...............................Configuration Table..................................................................................................... 0

-- ...............................Customer Response...................................................................................................... 0

-- ...............................Copyright Page ............................................................................................................ 0

-- ...............................Foreword...................................................................................................................... 0

-- ...............................How to Use This Manual............................................................................................. 0

i-ii................................T able of Contents......................................................................................................... 0

iii / (iv blank)..............List of Figures.............................................................................................................. 0

v / (vi blank)................List of Tables...............................................................................................................0

vii / (viii blank)...........List of Drawings .......................................................................................................... 0

1-1 -- 1-16...................Text Pages....................................................................................................................0

2-1 -- 2-26...................Text Pages....................................................................................................................0

3-1 -- 3-10...................Text Pages....................................................................................................................0

4-1 -- 4-4.....................Text Pages....................................................................................................................0

5-1 -- 5-6.....................Text Pages....................................................................................................................0

DESCRIPTION

ISSUE NO.*

A-1 / (A-2 blank)........Appendix A Warranty Information............................................................................. 0

B-1 -- B-22..................Appendix B Drawings.................................................................................................0

C-1 -- C-12..................Appendix C Error Codes............................................................................................. 0

D-1 -- D-2...................Appendix D Regional Sales Offices ........................................................................... 0

E-1 / (E-2 blank).........Appendix E On-line Reference Guide ........................................................................ 0

Glossary-i -- xiv..........Glossary....................................................................................................................... 0

Index-i -- iv.................Index............................................................................................................................ 0

* Zero in this column indicates an original page

Page 6

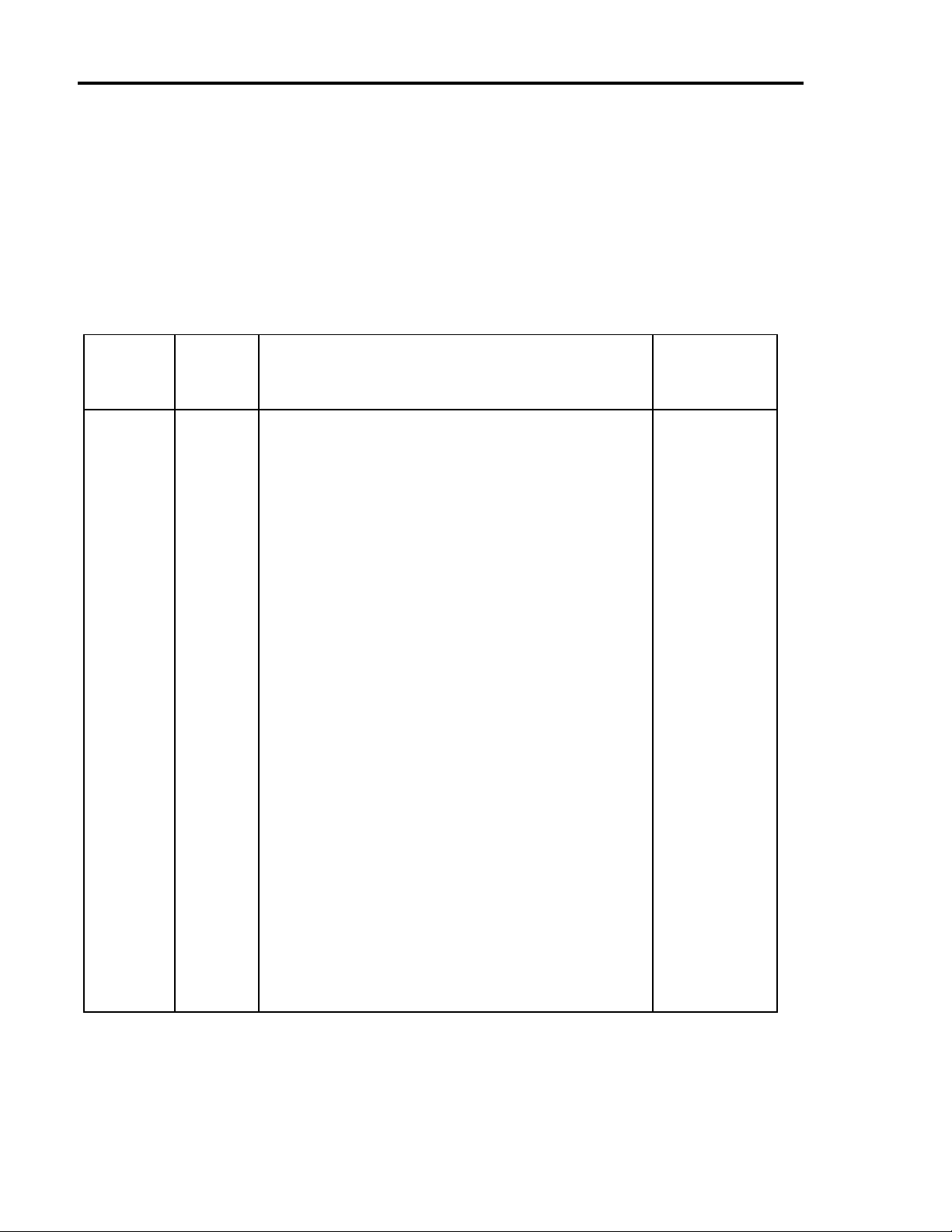

ONFIGURATION TABLE

C

ONFIGURATION TABLE

C

NSTALLATION AND SETUP MANUAL

( I

BDS5

M93101 )

RECORD

ISSUE NO.

(Revision) DATE CHANGED PAGES/BRIEF DESCRIPTION OF CHANGE CHANGE NO.

3

4

15 Mar 95

10 Nov 95

Replaces issue dated 15 Feb 95

Add Appendix E and include On-line Reference Guide Disk

OF REVISIONS

Original Release

- -

Page 7

T

HANK YOU

Thank you and congratulations for choosing Industrial Drives' servo products for your motion control

requirements. W e seek to provide our custom ers with quality products, excellent support and outs tanding

value. In an effort to provide you with dependable and useful docum entation, we off er you an opportunity

to critique this manual with your comments and suggestions. Your feedback on this reader comments

form is very important to us. Please answer the questions below and return the form to:

!

INDUSTRIAL DRIVES -

Technical Manual Department

201 Rock Road

Radford, VA 24141

U.S.A.

FAX: 703/731/0847

Name: Title:

Company:

Street Address:

City: State: Zip:

Telephone: Fax:

Product:

Manual Part Number:

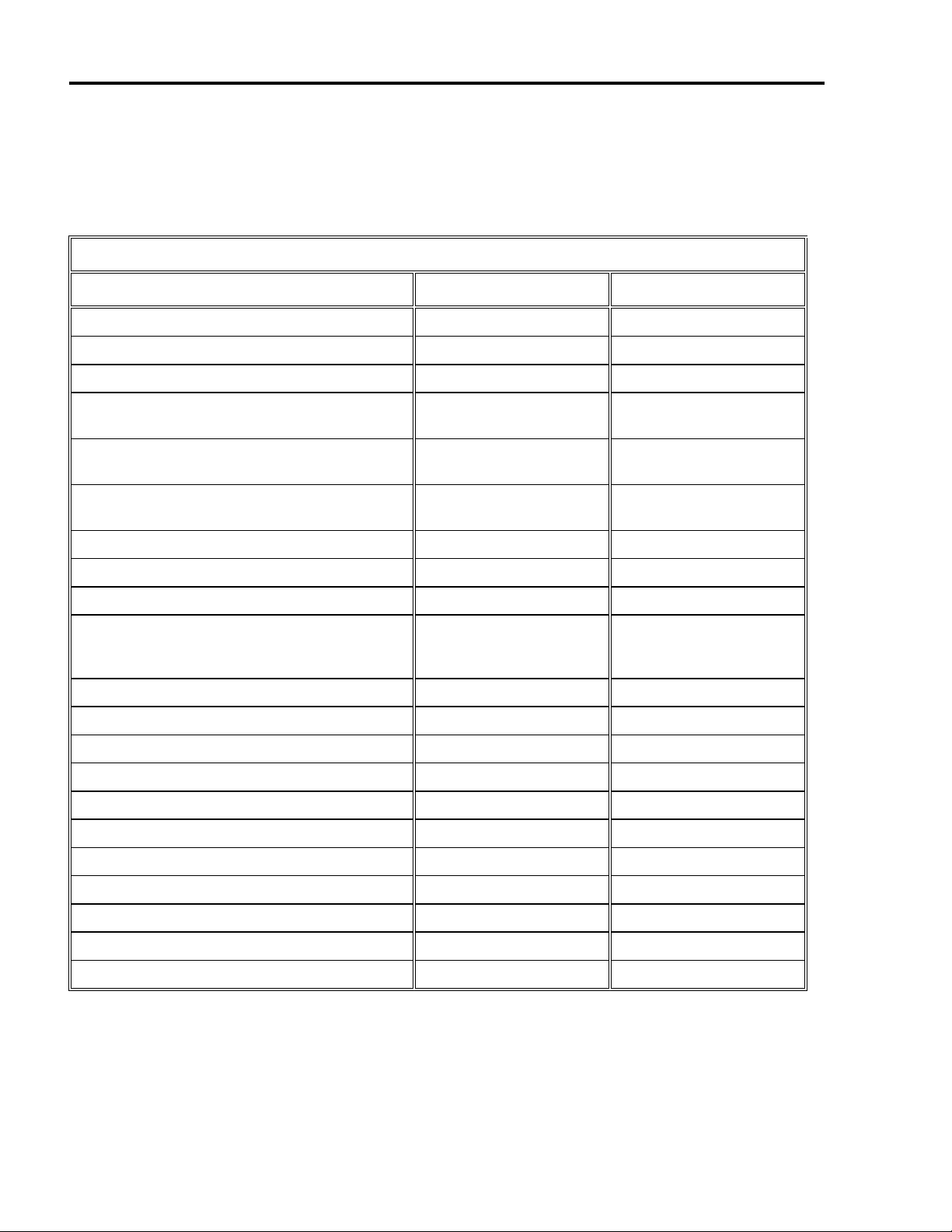

Please check the rating that best represents your opinion on each topic.

Excellent Good Fair Poor

1. Overall clarity and readability.

2. Organization of the manual.

3. Information completeness.

4. Information accuracy.

5. Installation procedures.

6. Ability to quickly find information you need.

7. Graphics.

8. Figures (usefulness).

9. Tables (usefulness).

10. Overall rating of this manual.

!!!!

!!!!

!!!!

!!!!

!!!!

!!!!

!!!!

!!!!

!!!!

!!!!

Please list any errors.

What did you like least about this manual?

What did you like most about this manual?

How would you improve this manual?

Signature: Date:

Page 8

Page 9

Copyright 1993, Industrial Drives, A Kollmorgen Division. All rights reserved.

Printed in the United States of America.

NOTICE:

Not for use or disclosure outside of Industrial Drives except under written agreement.

All rights reserved. No part of this book shall be reproduced, stored in a retrieval system, or transmitted by any

means, electronic, mechanical, photocopying, recording, or otherwise without the written permission from the

publisher. While every precaution has been taken in the preparation of the book, the publisher assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the

information co ntained herein.

This document is proprietary information of Industrial Drives, A Kollmorgen Division, furnished for customer use

ONLY. No other uses are authorized without written permission of Industrial Drives.

Information in this document is subject to change without notice and does not represent a commitment on the part of

Industrial Drives or the Kollmorgen Corporation. Therefore, information contained in this manual may be updated

from time-to-time due to product improvements, etc., and may not conform in every respect to former issues.

IBM-PC is a trademark of International Business Machines Corporation.

OPTO-22 is a trademark of the OPTO-22 Company.

U.L. is a trademark of Underwriters Laboratories.

N.E.C. is a trademark of the National Electric Code.

GOLDLINE, BDS4, BDS5, PSR4/5, Motion Link, PC-Scope, and Macro Moves are trademarks of the Kollmorgen

Corporation.

WARNING

Dangerous voltages, currents, temperatures, and energy levels exist in this

product and in the associated servo motor(s). Extreme caution should be

exercised in the application of this equipment. Only qualified individuals

should attempt to install, set-up, and operate this equipment. Ensure that the

motor, drive, and the end-user assembly are all properly grounded per NEC

requirements.

INDUSTRIAL DRIVES

201 Rock Road

Radford, VA 24141

Phone: 703/639/2495

Fax: 703/731/0847

Page 10

Page 11

BDS5 F

OREWORD

F

OREWORD

The commitment to quality at Industrial Drives is our

first priority. In all aspects of our business: research,

development, product design and customer service,

we strive to guarantee total quality. This pledge is

founded on a solid history of innovative technologi cal

achievements dating back to 1948. One of the finest

tributes to that achievement can now be seen at the

Smithsonian which has on display the first stellar

inertial navigation system developed by Dr. Charles

Stark Draper. This system contains the first models

of torque motors built by the founding organization of

Industrial Drives. During the period of 1948 to 1960,

our "firsts" in the industry numbered more than a

dozen; they ranged from the simple but invaluable

(such as the direct-drive DC torque motor and movie

theater projection motors) to the exotic: submarine

periscope drive motors for the U.S. Navy, electric

drives, Curtis Wright electric brake coils, and

numerous other innovations.

For more than a decade, Industrial Drives (known in

the early days as part of Inland Motor Division of

Kollmorgen) has c ontinued to enhance its

sophisticated engineering solutions to pioneer new

product development.

The results of these and other efforts has encouraged

some of the most significant innovations in the servo

industry. We developed the application of servo

motors and drives in the Machine Tool market. We

were the first with water-cooled servos, the integral

brake, the flux forcing concept and the brushless

motor. We developed the electronically commutated

electric car motor. Industrial Drives pioneered rare

earth magnet development for the servo motor

industry.

Between 1974 and 1980, Industrial Drives continued

to lead the industry in servo application innovations.

Our commitment to engineering excellence never

waivered. In fact, that commitment grew stronger

with the development of brushless submarine and

submersible motors (visiting the Titanic graveyard),

multi-axis electronic drives and antenna pedestal

drives (delivering unprecedented accuracy and

revolutionizing the entire industrial automation

process).

The decade of the 1980's brought continued

advancements in technology and penet ration of new

markets requiring precise motion control. Already in

the fifth generation of brushless products, Industrial

Drives continues to lead the way with digital servo

positioning capability and our newest motor offering,

the GOLDLINE Series, incorporating the very latest

high-energy, rare earth magnets (neodymium iron

boron). Once again, we are setting the standards that

others only hope to duplicate. Recently

acknowledged by the Frost and Sullivan Foundation,

a leading market specialist in the motion control

industry, Industrial Drives and its parent, Kollmorgen

Corporation, continue to rank first in servo

technology.

Other achievements? Yes, too many in fact to

mention. Each achievement stands as a testimony to

the committed quality and excellence in design

technology. This constancy of purpose is unyielding

in an era of rapidly changing technology.

Page 12

BDS5 H

OW TO USE THIS MANUAL

H

OW TO USE THIS MANUAL

INTRODUCTION

This Installation and Setup Manual is designed to

help you properly install a BDS5 Servo System. You

do not have to be an expert in motion control to

operate the system however this manual does assume

you have the fundamental und erstanding of basi c

electronics and motion control concepts. Many of

these are explained in the glossary of this manual.

The BDS5 is a programmable motion control device.

An understanding of c omputer programming

techniques will be beneficial to all users. For

applications that require complex programs, a

professional programmer should be consulted.

RECOMMENDATIONS

It is recommended that you read this entire manual

before you attempt to install the BDS5 so you can

promptly find any information you need. This will

also familiarize you with system components, and

their relationship to one another.

After installation and before you apply your own

application check all system functions and features to

insure you have installed your BDS5 properly.

Proper installation can prevent potential difficulties

before they cause harm to your system. Be sure to

follow all instructions carefully and pay special

attention to safety.

CONVENTIONS

To assist you in understanding the material in this

manual, conventions have been estab l ished to

enhance reader comprehension. Explanations of

these conventions are as follows:

Safety warnings, cautions, and notes present

•

material that is important to user safety. Be sure

to read any safety notices you see as they could

prevent equipment damage, personal injury, or

even death to you or a co-worker.

• Bold

•

•

•

•

text highlights other important information

that is critical to system operations.

CAPITALIZED text stresses attention to the

details of the procedure.

Underlined text emphasizes crucial words in

sentences that could be misunderstood if the

word is not recognized.

DOUBLE BLOCKED

that are to be typed into the computer by the

user to interface with the BDS5.

SINGLE BLOCKED

that are displayed by the BDS5 on the computer

terminal to inform the user of system operations

or problems.

text defines words

text defines words

Page 13

OW TO USE THIS MANUAL

H

BDS5

ABBREVIATIONS

CCW Counter Clockwise

CW Clockwise

D/L Direction Limit

GC Goldline Cable

GCS Goldline Cable Set

LED Light Emitting Diode

NEC National Electrical Code

P/N Part Number

R/D Resolver-to-Digital

Regen Regeneration

TL Test Limits

UL Underwriters Laboratories

NOTICE:

This manual is the first of a two part manual

structure. The

the user on the normal operating procedures and

practices to be used with the BDS5. Programming is

explained as well as other software considerations.

User's Manual

is intended to instruct

Page 14

BDS5 T

ABLE OF CONTENTS

T

ABLE OF CONTENTS

CHAPTER 1. SYSTEM DESCRIPTION

1.1 Introduction..................................................... 1-1

1.2 Product Description ........................................ 1-1

1.3 Features........................................................... 1-1

1.4 Part Number Description................................ 1-3

1.4.1 BDS5 Model Number.................................. 1-4

1.4.2 Compensation Module Model Number........ 1-5

1.4.3 PSR4/5 Model Number................................ 1-6

1.4.4 ER-External Resistor Kit Model Number....1-7

1.4.5 Molex Assembly Tools................................ 1-7

1.5 Specifications and Ratings.............................. 1-8

1.6 Theory of Operation......................................1-12

1.7 Simplified Schematic Diagram

and System Diagram..................................... 1-13

CHAPTER 2. INSTALLATION

2.1 Introduction..................................................... 2-1

2.2 Safety Information .......................................... 2-1

2.3 Unpacking And Inspection.............................. 2-2

2.4 Installation Requirements................................ 2-2

2.4.1 Environmental Considerations..................... 2-2

2.4.2 Enclosures.................................................... 2-2

2.5 Mounting......................................................... 2-2

2.5.1 Mounting the BDS5..................................... 2-2

2.5.2 Mounting the PSR4/5................................... 2-3

2.5.3 Mounting the External Regen Resistor ........ 2-3

2.6 Wiring............................................................. 2-3

2.6.1 Wiring the Ground....................................... 2-4

2.6.2 Wiring the Power Connections .................... 2-4

2.6.2.1 Wiring the Motor......................................2-4

2.6.2.2 Motor Protection....................................... 2-5

2.6.2.3 Motor Thermostat.....................................2-5

2.6.2.4 Motor Brake.............................................. 2-5

2.6.2.5 Wiring the DC Bus....................................2-6

2.6.2.6 Wiring the AC Line................................... 2-6

2.6.2.7 Wiring the Regen Resistor........................2-6

2.6.3 Wiring the PSR4/5 Front Panel

Connectors...................................................... 2-6

2.6.3.1 Wiring the Control Power to C1 ............... 2-6

2.6.3.2 Wiring to the PSR4/5 Fault

Output on C1...................................................2-6

2.6.3.3 Wiring PSR4/5 Connector C2................... 2-6

2.6.4 Wiring the BDS5 Front Panel

Connectors...................................................... 2-7

2.6.4.1 Wiring C1, Encoder Equivalent................ 2-7

2.6.4.2 Encoder Equivalent Input.......................... 2-9

2.6.4.3 Pulse Input (OPT2 Card) .......................... 2-9

2.6.4.4 Encoder Equivalent Output....................... 2-9

2.6.4.5 Wiring C2, Customer I/O ........................ 2-10

2.6.4.6 Wiring C3, Resolver............................... 2-11

2.6.4.7 Wiring C4, Logic Power Supply............. 2-11

2.6.4.8 Wiring C5, Serial Communications........ 2-12

2.6.4.9 Wiring C6, Fan Power (20 Amp

Units Only)................................................... 2-14

2.6.4.10 Wiring C7, Standard I/O....................... 2-14

2.6.4.11 Wiring C8, Optional I/O.......................2-15

2.6.4.12 J1 Configuration Jumper....................... 2-16

2.6.5 Establishing Communications.................... 2-16

2.6.5.1 Required Data Format............................. 2-16

2.6.5.2 First Transmission................................... 2-16

2.6.5.3 Checking the Control Power...................2-17

2.6.5.4 If You Can't Communicate......................2-18

2.7 Initial Check-Out...........................................2-18

2.7.1 Checking Discrete Inputs...........................2-19

2.7.2 Checking General Purpose Outputs ........... 2-19

2.7.3 Cycle Ready............................................... 2-20

2.7.4 Checking STATUS.................................... 2-20

2.7.5 Checking Encoder Output.......................... 2-20

2.7.6 Checking Encoder Input............................. 2-20

2.7.7 Checking Pulse Input (Optional)................ 2-20

2.7.8 Checking Analog Input (Optional)............. 2-20

2.7.9 Checking the Resolver ............................... 2-21

2.7.10 Checking the Resolver Cable................... 2-21

2.7.11 Checking the AC Line Voltages............... 2-22

2.7.12 Checking the DC Bus Voltage................. 2-22

2.7.13 Checking the Motor................................. 2-23

CHAPTER 3. OPERATION

3.1 Introduction..................................................... 3-1

3.2 Start-Up and Checkout.................................... 3-1

3.2.1 If You Get ERROR 17, FEEDBACK

LOSS .............................................................. 3-2

3.2.2 If You Get ERROR 14, POWER BUS........ 3-2

3.2.3 If Your BDS5 System is Unstable................ 3-2

3.2.4 Jogging the Motor ........................................ 3-3

3.2.5 Low Speed Adjustment................................ 3-3

3.3 System Compensation..................................... 3-4

3.3.1 Critical Damping.......................................... 3-4

3.3.2 Underdamping..............................................3-4

3.3.3 Overdamping................................................3-5

3.3.4 Ringing.........................................................3-5

3.4 Tuning............................................................. 3-5

3.4.1 If Your System Is Completely Unstable.......3-6

3.4.2 Reducing ILIM.............................................3-6

3.5 Tune Command............................................... 3-6

i

Page 15

ABLE OF CONTENTS

T

BDS5

3.6 Tuning The BDS5 Yourself............................3-7

3.6.1 Tuning the Velocity Loop ............................3-7

3.6.2 Tuning the Position Loop.............................3-7

3.7 RECORD and PLAY......................................3-8

3.8 Problems..........................................................3-9

3.8.1 Overloading the Motor.................................3-9

3.8.2 Compliance ..................................................3-9

3.8.3 Non-Linear Mechanics.................................3-9

3.8.4 Resonance..................................................3-10

3.8.5 Low-Pass Filters.........................................3-10

CHAPTER 4. MAINTENANCE

4.1 Introduction ..................................................... 4-1

4.2 Preventative Maintenance...............................4-1

4.2.1 Transient Voltages .......................................4-1

4.2.2 Surge Current...............................................4-2

4.2.3 Electrical Noise............................................4-2

4.2.4 Radio Frequency Energy..............................4-2

4.3 Periodic Maintenance......................................4-2

4.3.1 Ventilation....................................................4-3

4.3.2 Grounding Integrity......................................4-3

CHAPTER 5. TROUBLESHOOTING

APPENDIX A. WARRANTY INFORMATION

APPENDIX B. DRAWINGS

APPENDIX C. ERROR CODES

APPENDIX D. REGIONAL SALES OFFICES

APPENDIX E. ON-LINE REFERENCE GUIDE

5.1 Introduction ..................................................... 5-1

5.2 Spare Parts ......................................................5-1

5.2.1 BDS5 Spare Parts List..................................5-1

5.2.2 PSR4/5 Spare Parts List...............................5-1

5.2.3 Ordering Information...................................5-2

5.3 LED Status Indicators.....................................5-2

5.3.1 BDS5 LED's................................................. 5-2

5.3.2 PSR4/5 LED's ..............................................5-2

5.4 Error Log.........................................................5-3

5.4.1 Error Levels..................................................5-3

5.4.2 DEP..............................................................5-4

5.4.3 Error History................................................5-4

5.4.4 Displaying Error Messages ..........................5-4

5.4.5 Firmware Errors...........................................5-4

5.5 Enable and fault logic......................................5-5

5.5.1 Firmware Faults, Area 1...............................5-5

5.5.2 Fault Logic, Area 2.......................................5-5

5.5.3 Fault Latch, Area 3.......................................5-5

5.5.4 Ready Latch, Area 4.....................................5-5

5.5.5 ACTIVE, Area 5..........................................5-5

5.5.6 Relay and STATUS Control, Area 6............5-6

5.5.7 Motor Brake.................................................5-6

5.5.8 Output Relay................................................5-6

5.6 Factory Support and Repair Policies...............5-6

ii

Page 16

BDS5 L

IST OF FIGURES

L

FIGURE PAGE FIGURE PAGE

IST OF FIGURES

1.1 BDS5 Model Number Scheme........................ 1-4

1.2 Compensation Model Number Scheme........... 1-5

1.3 PSR4/5 Model Number Scheme..................... 1-6

1.4 External Regen Resistor Model

Number Scheme..............................................1-7

2.1 Safety-Alert Symbols...................................... 2-1

2.2 Master BDS5 and Slave BDS5....................... 2-8

2.3 Encoder Phasing For Clockwise Rotation....... 2-8

2.4 BDS5 (C1)...................................................... 2-9

3.1 Critical Damping............................................. 3-4

3.2 Underdamping.................................................3-5

3.3 Overdamping...................................................3-5

3.4 Ringing............................................................3-5

iii / (iv blank)

Page 17

BDS5 L

IST OF TABLES

L

TABLE PAGE TABLE PAGE

IST OF TABLES

1.1 BDS5 Model Number Scheme........................ 1-4

1.2 PSR4/5 Model Number Scheme..................... 1-6

1.3 External Regen Resistor Model

Number Scheme..............................................1-7

1.4 Specifications.................................................. 1-8

1.5 Environmental Specifications ....................... 1-12

1.6 Mechanical Specifications............................ 1-12

2.1 Motor Cable Color Code.................................2-4

2.2 PSR4/5 Logic Power....................................... 2-7

2.3 Communications Requirements.....................2-12

2.4 Terminal Wiring............................................2-13

2.5 PC Wiring..................................................... 2-14

2.6 PSR4/5 C2 Wiring........................................2-17

2.7 Target of PRD vs. R/D Resolution................2-21

2.8 Target of PRD vs. R/D Resolution After

Clockwise /4 Revolution............................... 2-21

2.9 Goldline Resolver Cable Wiring................... 2-21

2.10 PRD Range for "Zero Position".................. 2-23

3.1 Tuning Criterion..............................................3-4

3.2 Allowed Tune Command Stability Settings.... 3-6

3.3 Velocity Loop Bandwidth vs. KVI ................. 3-7

3.4 Velocity Loop Bandwidth vs. KP

5.1 Error Severity Levels and Actions..................5-7

MAX

.......... 3-8

v / (vi blank)

Page 18

Page 19

BDS5 L

IST OF DRAWINGS

L

DRAWING PAGE

D-93030 BDS5 System Overview.........................................................1-14

A-84847 Typical BDS5 System Interconnect........................................ 1-16

A-96372M BDS5 Connectors................................................................2-25

A-84732 BDS5 Enable Fault Logic Diagram........................................B-3

A-93103 BDS5 Wiring Diagram .......................................................... B-4

A-93703 Mounting Hole Pattern BDS4A, BDS5, PSR4/5A.................B-11

A-62370 Outline B-102-X-12,14........................................................... B-13

A-62371 Outline B-104,6,-X-12,14.......................................................B-14

IST OF DRAWINGS

A-43268 Outline B-20X-X-21,31,23,33-(S)..........................................B-15

A-63093 Outline B-40X-X-A1,A3,B1,B3(-S).......................................B-16

A-63099 Outline B-602,4-X-A1,A3,B1,B3(-S)..................................... B-17

A-63100 Outline B-606-X-A1,A3,B1,B3(-S)........................................ B-18

A-63097 Outline B-802,4-X-A1,A3,B1,B3(-S)..................................... B-19

A-63096 Outline B-806-X-A1,A3,B1,B3(-S)........................................ B-20

A-93569 Outline & Dimension BDS5-3 & 6 Amp................................B-21

A-93571 Outline & Dimension BDS5-10 Amp.....................................B-22

A-93570 Outline & Dimension BDS5-20 Amp.....................................B-23

A-93880 Outline & Dimension BDS5-30/40 Amp................................B-24

A-96010 Outline & Dimension BDS5-55 Amp.....................................B-25

A-93581 Outline & Dimension PSR4/5A-12 & 20 Amp.......................B-26

A-93031 Outline & Dimension PSR4/5-50 & 75 Amp.......................... B-27

C-84723 PSR4/5 Simplified Schematic.................................................B-28

A-84888 Velocity Loop Tuning Flow Chart..........................................B-29

vii / (viii blank)

Page 20

Page 21

BDS5 C

HAPTER

C

YSTEM DESCRIPTION

S

1

HAPTER

YSTEM DESCRIPTION

1 - S

1.1 INTRODUCTION

The information in this chapter will enable you to

understand the BDS5's basic functions and features.

These concepts will allow you to apply them to your

own unique applications.

1.2 PRODUCT DESCRIPTION

The BDS5 is a full-featured, high-performance,

brushless positioning servo in one compact enclosure

it is the smallest, totally-integrated package

available to motion control users. The BDS5

combines a positioner, a servo amplifier, and an I/O

interface into one unit. The BDS5 sets new standards

for motion control with its simple BASIC-like

command structure and sophisticated decision-making

capability. The BDS5 provides the outstanding servo

performance that you have come to expect from

Industrial Drives. Using a high-performance

microprocessor, the BDS5 does not have to

compromise on either positioner software or servo

performance. This single microprocessor closes all

servo loops, resulting in a truly integrated positioning

system. The BDS5 has the features and performance

you need in your next positioning application.

1.3 FEATURES

The BDS5 offers a wide feature set to accommodate

real world positioning requirements:

LOW COST

•

The BDS5 i s very affordable--even though it is full of

advanced features. Use all or only a portion of these

features to accomplish your application.

EASY TO INSTALL

•

The BDS5 is easy to install because the servo

amplifier and the positioner are integrated into one

package. Many interconnects, including the

tachometer and encoder, are eliminated.

SIMPLE PROGRAMMING LANGUAGE

•

The BDS5 uses simple BASIC-like commands such as

RUN, GOTO (for branching), and GOSUB /

RETURN (for subroutines). In addition to a simple

comparison statement, advanced IF / ELIF / ELSE /

END IF statements result in more readable and less

error-prone programs. You can comment every line in

your program.

1-1

Page 22

HAPTER

C

YSTEM DESCRIPTION

1 - S

BDS5

ADVANCED MOTION CONTROL MOVES

•

The simple language does not prevent you from

solving complex proble ms. The BDS5 has separa te

acceleration and deceleration rates, as well as linear,

half S-curve, and full S-curve acceleration profiles.

The BDS5 has Macro Moves for applications where

simple indexes cannot do the job. A Macro Move is a

combination of up to 30 accelerations, traverses, and

decelerations, which are fully precalculated for faster

execution. You can program teach modes where

position end points can be changed by a factory

operator

MASTER/SLAVE - ELECTRONIC GEARBOX

•

The electronic gearbox is used to link two motors

together so that the velocity of the slave is

proportional to the velocity of the master. The ratio

can be from 32767:1 to 1:32767 and can be negative

to allow the slave to move in the opposite direction.

Also, the "index-on-gearing" feature permits phase

adjustments.

MASTER/ SLAVE - PROFILE REGULATION

•

With profile regulation you can control the slave's

motion profile according to an external master motor

or frequency. Profile regulation modifies the velocity

and acceleration of the slave axis without affecting the

final position of the move. You can use profile

regulation to implement "feed rate override."

MOTION GATING AND REGISTRATION

•

The BDS5 can precalculate moves to begin motion

within one millisecond after a transition on the GATE

input. This provides rapid and repeatable motion

initiation. The BDS5 has the ability to capture the

current position within 25 microseconds after a

transition of the HOME input. This results in fast

homing and accurate registration sequences.

MATHEMATICS Algebraic math is provided for

•

commands such as:

12 2 3

XXX

The BDS5 has 100 program labels, 50 user-definable

variables, and 50 user-definable switches. It also has

15 mathematical/logical operations and over 150

system variables.

()

=× +

Quantities such as position, velocity, and acceleration

are automatically scaled into user-defined units. This

feature lets you program the BDS5 in convenient units,

such as feet, inches, miles, RPM, and degrees.

SUPERIOR SERVO LOOP CONTROL

•

The BDS5 offers smooth, high-resolution control.

Standard BDS5 position repeatability is better than

one arc-minute, bidirectional. The BDS5 has a 32-bit

position word. The BDS5 position loop completely

eliminates the digital dither normally associated with

positioning systems. Long-term speed stability is

0.01%. The standard system converter (12-bit)

provides a resolution of 0.0005 RPM and a maximum

speed of 8000 RPM.

SELF-TUNING

•

The BDS5 c an tune itself. You do not have to b e a

servo expert to set up a system quickly. Just specify

the desired bandwidth, and let the BDS5 do the rest.

POWERFUL MICROPROCESSOR

•

The heart of the BDS5 is the 16-bit processor that

delivers high performance. The result: the BDS5 can

control a motor and execute its motion program faster

than a standard positioner can.

DIGITAL SERVO LOOPS

•

Both the position and velocity loops are totally digital.

The digital loops give the BDS5 features not available

in standard velocity drives, such as self-tuning, very

low velocity offset, and digitally-adjustable servo

tuning parameters. The optional analog input permits

you to use the BDS5 as an analog velocity drive.

FEED-FORWARD GAIN

•

The digital feed-forward gain reduces following error

and motion initiation delay, thereby increasing

machine throughput.

DIAGNOSTICS

•

The BDS5 offers a complete set of error diagnostics.

When an error occurs, the BDS5 displays an English

USER UNITS

•

1-2

Page 23

BDS5 C

HAPTER

YSTEM DESCRIPTION

1 - S

language error message. The BDS5 remembers the

last 20 errors even thr ough power loss. In addition,

the BDS5 lets you write your own error handler.

During a fault condition, you can use the error handler

to set outputs, alert an operator, and shut down your

process smoothly. The BDS5 offers trace and singlestep modes so that you can debug your program. The

BDS5 has complete fault monitoring, including travel

limit switches, feedback loss, and software position

limits, as well as hardware safety circuits (watchdogs)

and checksums for more reliable and safer operation.

I/O

•

The BDS5 has up to 32 I/O sections that you connect

via ribbon cable to standard OPTO-22 compatible I/O

boards or to INDUSTRIAL DRIVES I/O-32. The

I/O-32 provides either fixed 24-volt or removable,

industry standard, optically-isolated I/O in a

GOLDLINE style package.

SERIAL COMMUNICATIONS

•

The BDS5's serial communications provide a powerful

link to other popular factory automation devices such

as PLC's, process control computers, and smart

terminals. The BDS5 offers RS-232 for most

terminals and RS-422/RS-485 for multidrop

communications. With multidrop you can put up to 26

axes on one serial line. The BDS5 can autobaud from

300 baud to 19.2k baud, eliminating the need to set

dip switches to start communicating.

MOTION LINK

•

Industrial Drives also offers MOTION LINK, a

powerful, menu-driven communications package for

your IBM-PC (c) compatible computer. With this

package, the BDS5's programs and variables can be

retrieved from or saved to a disk drive. Also, on-line

help and a full screen editor are built into MOTION

LINK.

MENU-DRIVEN SOFTWARE

•

The BDS5's programming language allows you to

write operator-friendly, menu-driven software. By

incorporating an INDUSTRIAL DRIVES Data Entry

Panel, or any other serial co mmunicati ons device, the

operator can be prompted for specific process data.

MONITOR MODE

•

The BDS5 provides interactive communications and

permits all system variables and parameters to be

examined and modified at any time--even during

actual program execution or while the motor is

running.

1.4 PART NUMBER DESCRIPTION

A model number is printed on a gold and black tag on

the front of your BDS5, PSR4/5, Compensation Card

and External Regen Resistor modules. The model

number identifies how the equipment is configured.

Each component is described to explain what the

model configurations are. You should verify that the

model numbers represent the equipment desired for

your application. Also verify the compatibility

between components of the servo system. The model

numbers are as follows:

1-3

Page 24

HAPTER

C

YSTEM DESCRIPTION

1 - S

BDS5

1.4.1 BDS5 Model Number

B D S 5 A - 2

A B C D E F G H I

UL Designator

Voltage and Current Ratings User Program

Options Firmware Version

Motor and Winding R/D Resolution

Figure 1.1. BDS5 Model Number Scheme

Table 1.1. BDS5 Model Number Scheme

LEGEND DEFINITION

A

A

V

B

1

2

C

03

06

10

20

30

40

55

D

0

E

0

1

F

0

1

2

9

G

0

1

H

0

I

Motor and Wi nding

R/D Resolution

2

4

Firmware Version Firmware Version ( Assigned by Industri al Drives, not normally specified when ordering)

User Program User Program (This is reserved for systems that are programmed by Industrial Drives. This

UL Designator

UL Listed (standar d)

Non - UL Listed

Voltage Rating

115 VAC

230 VAC

Current Rating

3 Amps/Phase

6 Amps/Phase

10 Amps/Phase

20 Amps/Phase

30 Amps/Phase

40 Amps/Phase

55 Amps/Phase

Mechanical Options (0 indicates st andard feature)

Standard

Communication Options

RS-232 (standard)

RS-422/RS-485

Input Options

Encoder Input (standard)

Analog Input

Pulse Input

No Input

I/O Options

8 I/O (standard)

32 I/O

R/D Accuracy Options

8 ARC min (standard)

Motor and Wi nding

Specifies Motor Model Type, Winding

R/D Resolution

12-Bit (4096 counts /rev)

14-Bit (16384 counts /rev)

Most current f irmware supplied -- unless otherwise s pecified.

is not normally s pecified when ordering.)

4 0 - 0 0 0 1 0 \ 6 0 5 C - 2 - / ______

1-4

Page 25

BDS5 C

1.4.2 Compensation Module Model Number

/ 2 0 4 A

2 0 3

A B H

Voltage Rating Motor and Winding

Current Rating

Figure 1.2. Compensation Model Number Scheme

A partial model number is printed on a gold and black

tag on the front of the compensation module (the black

plastic box secured to the front of your BDS5 by two

screws). See Figure 1.2 for the descriptions of the

model number (that is, what ABB and HHHH mean).

The model number is as follows:

The compensation module depends on your motor and

the voltage and current rating of your BDS5. It is

important that the motor, the BDS5, and the

compensation module model numbers all agree. For

example, if your BDS5 model number is

CAUTION

HAPTER

YOU MUST HAVE THE

PROPER COMPENSATION

MODULE INSTALLED FOR

YOUR MOTOR AND BDS5.

THE COMPENSATION

MODULE CHANGES IF THE

AMPLIFIER RATINGS

CHANGE, EVEN FOR THE

SAME MOTOR.

YSTEM DESCRIPTION

1 - S

BDS5-203-00000\204A

then your compensation module model number must

be:

203/204A

and your motor must be a 204A. An example of a

204A motor model number is:

B-204-A

-1-101/2021,

,

-21.

Failure to install the proper

compensation module can

cause damage to the BDS5,

the motor, or both.

1-5

Page 26

HAPTER

C

YSTEM DESCRIPTION

1 - S

1.4.3 PSR4/5 Model Number

BDS5

P S R 4 / 5A - 2 2 0

A B C D E

UL Designator Options

Voltage Rating Current Rating

Figure 1.3. PSR4/5 Model Number Scheme

Table 1.2. PSR4/5 Model Number Scheme

- 0 0 0 3

LEGEND DEFINITIONS

A

A

V

B

1

2

C

12

20

50

75

UL Designator

UL Listed (standard)

Non - UL Listed

Voltage Rating

115 VAC

230 VAC

Current Rating

12 Amps/Phase

20 Amps/Phase

50 Amps/Phase

75 Amps/Phase

D

E

E

1-6

00

00

01

02

03

00

Mechanical Options

No Option (standard)

Electrical Regen Options for 12 and 20 Amp Models Only

Standard Internal 40 W Regen (standard)

External Regen (230 VAC Only) 8.8 Ohms, 400 W., Requires ER-01 Resistor

Kit

External Regen (115 VAC Only) 5.5 Ohms, 200 W., Requires ER-02 Resistor

Kit

External Regen (230 VAC Only) 5.8 Ohms, 700 W., Requires ER-03 Resistor

Kit

Electrical Regen Options for 50 and 75 Amp Models Only

No internal shunt regeneration (standard)

Requires external regeneration resistor kit ER-2X

Page 27

BDS5 C

1.4.4 ER-External Resistor Kit Model Number

Contact Industrial Drives Application Engineering to size regeneration capability.

NOTE

E R - 0 1 / X X

A B

Resistor Rating Options

Figure 1.4. External Regen Resistor Model Number Scheme

HAPTER

YSTEM DESCRIPTION

1 - S

Table 1.3. External Regen Resistor Model Number Scheme

LEGEND DEFINITIONS

A

01

02

03

20

21

22

23

B

00

1.4.5 Molex Assembly Tools

GOLDLINE series electronics (BDS4's, BDS5's, and

PSR4/5's) use Molex MINI-FIT JR. series connectors.

The necessary connectors and pins are included in

your BDS5 and PSR4/5 connector kits.

Resistor Rating

8.8 Ohms, 400 W., 230V, 12 & 20 Amp Models Only

5.5 Ohms, 200 W., 115V, 12 & 20 Amp Models Only

5.8 Ohms, 700 W., 230V, 12 & 20 Amp Models Only

4.5 Ohms, 500 W., 230V, 50 & 75 Amp Models Only

4.4 Ohms, 1000 W., 230V, 50 & 75 Amp Models Only

2.2 Ohms, 1000 W., 230V, 75 Amp Models Only

2.2 Ohms, 2000 W., 230V, 75 Amp Models Only

Options

None available at this printing.

You can obtain the crimping and extraction tools from

your nearest Mo l ex distributor or by contacti ng Molex

at (708) 969-4550.

Hand Crimping Tool Molex Order# 11-01-0122

Extractor Tool Molex Order# 11-03-0038

1-7

Page 28

HAPTER

C

YSTEM DESCRIPTION

1 - S

BDS5

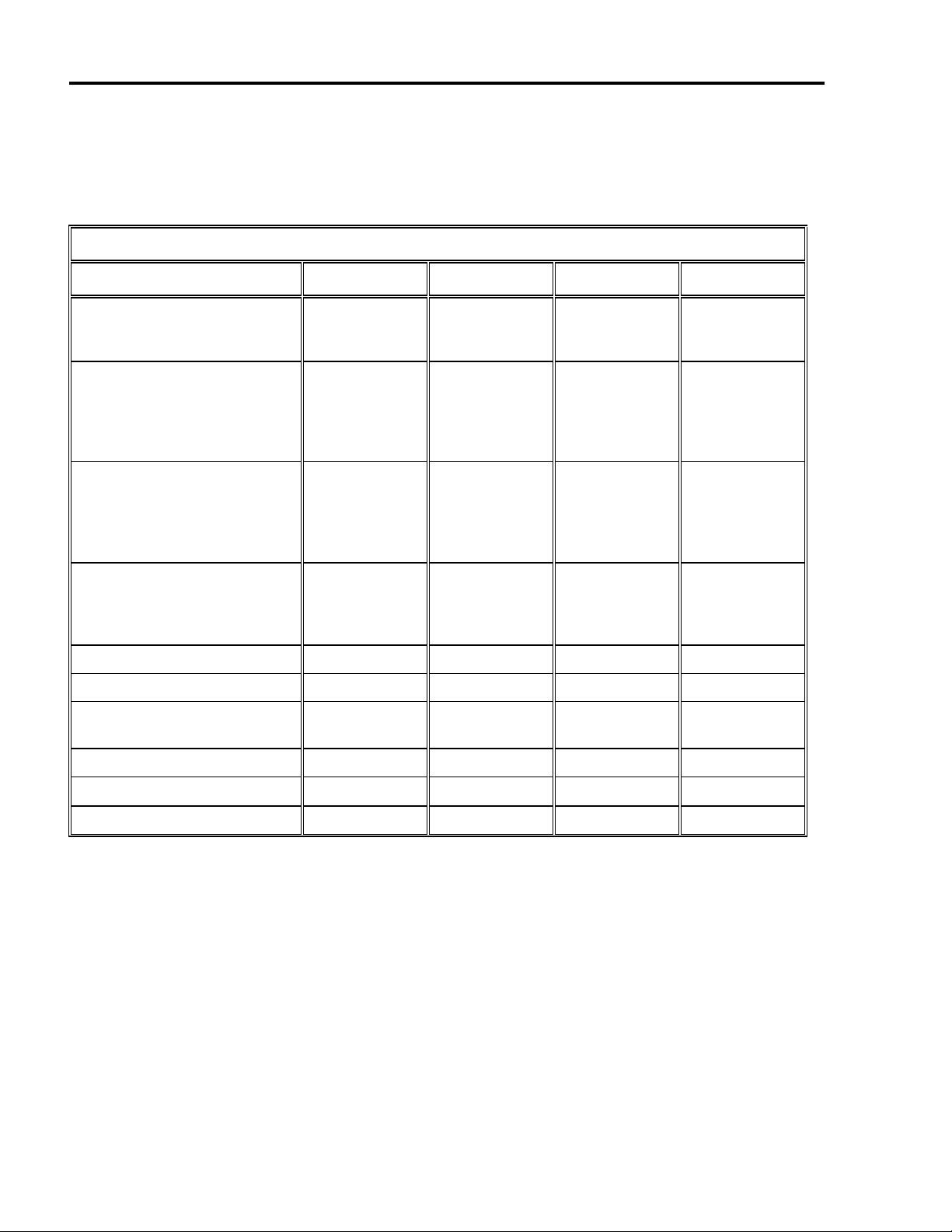

1.5 SPECIFICATIONS AND RATINGS

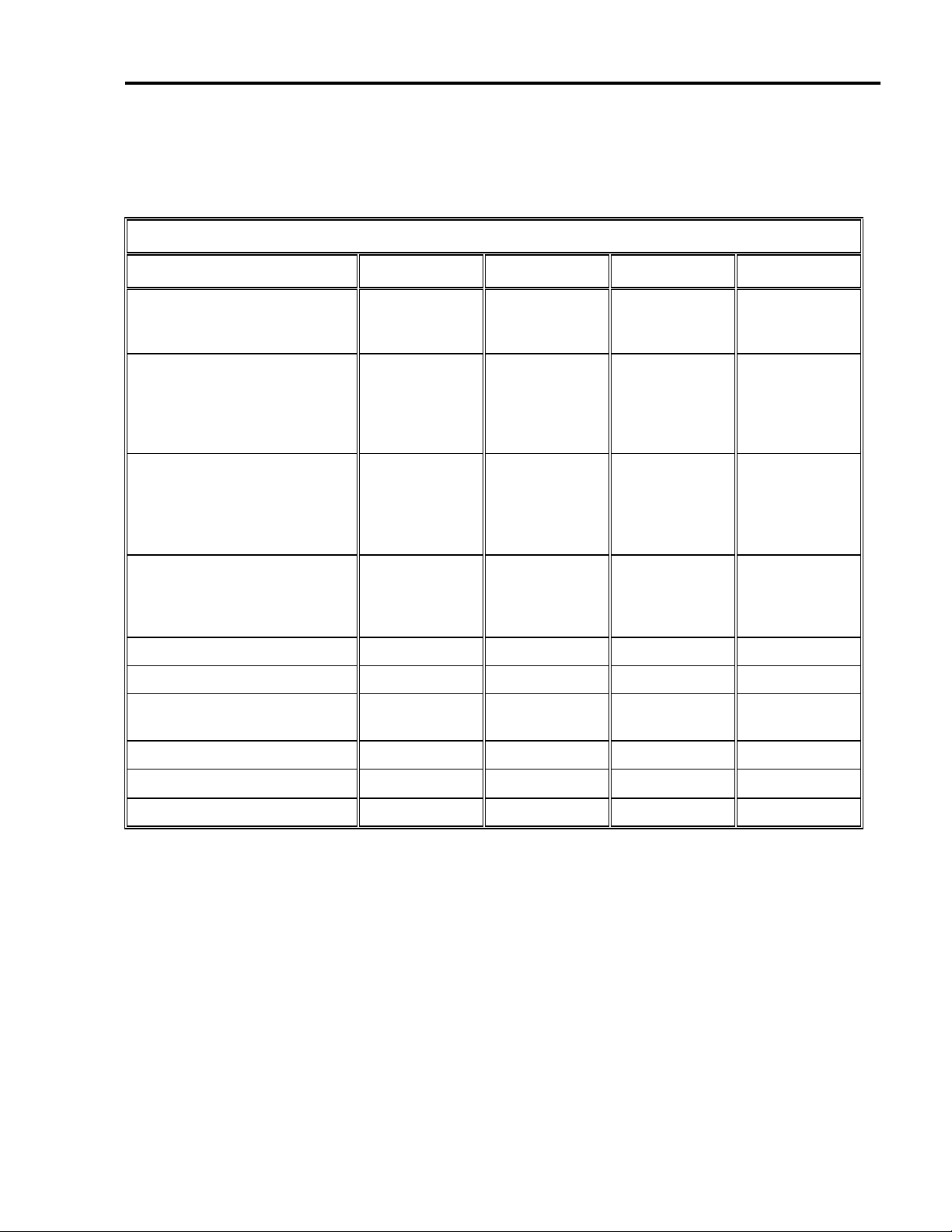

Table 1.4. Specifications

BDS5-1XX-(90-160 VAC L-L OUTPUT TO MOTOR)

DESCRIPTION BDS5-103 BDS5-106 BDS5-110 BDS5-120

Main DC Bus

Minimum

Maximum

130 VDC

225 VDC

130 VDC

225 VDC

130 VDC

225 VDC

130 VDC

225 VDC

±

15-20 VDC

@0.25 AMPS

Unregulated Logic Bus

+8-12 VDC

@1.00 AMPS

Output Current

(RMS/∅) Convection

Cooled (45°C AMB)

Continuous (RMS)

Peak (2.0 sec) (RMS)

Output KVA

(@ 160 VDC Bus)

Continuous (45°C AMB)

Peak (2.0 sec) (RMS)

Internal Heat Dissipation 30 WATTS 40 WATTS 60 WATTS 110 WATTS

PWM Switching Frequency 10.0 kHz 10.0 kHz 10.0 kHz 10.0 kHz

Motor Current Ripple

Frequency ±10%

Resolver Excitation Frequency 8.5 kHz 8.5 kHz 8.5 kHz 8.5 kHz

Form Factor RMS/AVG

Fan (115 VAC) N/A N/A N/A 0.2 AMPS

3.0 AMPS

6.0 AMPS

0.6 KVA

1.2 KVA

20.0 kHz 20.0 kHz 20.0 kHz 20.0 kHz

≤

1.01

±

15-20 VDC

@0.25 AMPS

+8-12 VDC

@1.00 AMPS

6.0 AMPS

12.0 AMPS

1.2 KVA

2.4 KVA

≤

1.01

±

15-20 VDC

@0.25 AMPS

+8-12 VDC

@1.00 AMPS

10.0 AMPS

20.0 AMPS

2.0 KVA

4.0 KVA

≤

1.01

±

15-20 VDC

@0.25 AMPS

+8-12 VDC

@1.00 AMPS

Fan

Cooled

20.0 AMPS

40.0 AMPS

4.0 KVA

8.0 KVA

≤

1.01

1-8

Page 29

BDS5 C

Table 1.4. Specifications (Cont.)

HAPTER

YSTEM DESCRIPTION

1 - S

BDS5-2XX-(160-253 VAC L-L OUTPUT TO MOTOR)

DESCRIPTION BDS5-203 BDS5-206 BDS5-210 BDS5-220

Main DC Bus

Minimum

Maximum

225 VDC

360 VDC

225 VDC

360 VDC

225 VDC

360 VDC

130 VDC

225 VDC

±

15-20 VDC

@0.25 AMPS

Unregulated Logic Bus

+8-12 VDC

@1.00 AMPS

Output Current

(RMS/∅) Convection

Cooled (45°C AMB)

Continuous (RMS)

Peak (2.0 sec) (RMS)

Output KVA

(@ 160 VDC Bus)

Continuous (45°C AMB)

Peak (2.0 sec) (RMS)

Internal Heat Dissipation 35 WATTS 50 WATTS 75 WATTS 150 WATTS

PWM Switching Frequency 10.0 kHz 10.0 kHz 10.0 kHz 10.0 kHz

Motor Current Ripple

Frequency ±10%

Resolver Excitation Frequency 8.5 kHz 8.5 kHz 8.5 kHz 8.5 kHz

Form Factor RMS/AVG

Fan (115 VAC) N/A N/A N/A 0.2 AMPS

3.0 AMPS

6.0 AMPS

1.2 KVA

2.4 KVA

20.0 kHz 20.0 kHz 20.0 kHz 20.0 kHz

≤

1.01

±

15-20 VDC

@0.25 AMPS

+8-12 VDC

@1.00 AMPS

6.0 AMPS

12.0 AMPS

2.0 KVA

4.0 KVA

≤

1.01

±

15-20 VDC

@0.25 AMPS

+8-12 VDC

@1.00 AMPS

10.0 AMPS

20.0 AMPS

4.0 KVA

8.0 KVA

≤

1.01

±

15-20 VDC

@0.25 AMPS

+8-12 VDC

@1.00 AMPS

20.0 AMPS

40.0 AMPS

8.0 KVA

16.0 KVA

≤

1.01

1-9

Page 30

HAPTER

C

YSTEM DESCRIPTION

1 - S

Table 1.4. Specifications (Cont.)

PSR4/5-1XX-(90 - 160 VAC L-L INPUT)

DESCRIPTION PSR4/5-112- PSR4/5-120-

Main AC Line Input Voltage 90-160 VAC 90-160 VAC

Phase 1-3 1-3

Frequency 47-63 Hz 47-63 Hz

BDS5

Current Cont. (RMS) 3-Phase

Single-Phase

Peak (2.0 sec) 3-Phase

Single-Phase

Peak (50.0 msec) 3-Phase

Single-Phase

Control AC Line Input Voltage 90-132 VAC 90-132 VAC

Phase 1 1

Frequency 47-63 Hz 47-63 Hz

Main DC Bus Output Voltage

(Nominal 115 VAC Input)

Current 115 VAC

Regeneration Shunt Resistor (Internal) 15 OHM 7.5 OHM

Shunt Regulator Current (PK) 15.3 AMPS 30.6 AMPS

Power Dissipation (Cont.) 40 WATTS 40 WATTS

Power Dissipation (PK) 3.5 KW 7.0 KW

Internal Heat Dissipation 120 WATTS 120 WATTS

Regeneration Shunt Resistor (External Min) 5.5 OHM 5.5 OHM

12.0 AMPS

10.0 AMPS

24.0 AMPS

20.0 AMPS

50.0 AMPS

42.0 AMPS

160 VDC

1.1 AMPS RMS

20.0 AMPS

16.0 AMPS

40.0 AMPS

32.0 AMPS

80.0 AMPS

64.0 AMPS

160 VDC

1.1 AMPS RMS

Shunt Regulator Current (PK) 41.8 AMPS 41.8 AMPS

Power Dissipation (Cont.) 200 WATTS 200 WATTS

Power Dissipation (PK.) 9.6 KW 9.6 KW

Soft-Start Surge Current (Max) 80 AMPS 80 AMPS

Charge Time (Max) 25 MSEC 25 MSEC

1-10

Page 31

BDS5 C

Table 1.4. Specifications (Cont.)

HAPTER

YSTEM DESCRIPTION

1 - S

PSR4/5-2XX-(160 - 253 VAC L-L INPUT)

DESCRIPTION PSR4/5-212- PSR4/5-220-

Main AC Line Input Voltage 160 - 253 VAC 160 - 253 VAC

Phase 1-3 1-3

Frequency 47-63 Hz 47-63 Hz

Current Cont. (RMS) 3 Phase

Single Phase

Peak (2.0 sec) 3 Phase

Single Phase

Peak (50.0 msec) 3 Phase

Single Phase

Control AC Line Input Voltage 90-132 VAC 90-132 VAC

Phase 1 1

Frequency 47-63 Hz 47-63 Hz

Main DC Bus Output Voltage

(Nominal 115 VAC Input)

Current 115 VAC

Regeneration Shunt Resistor (Internal) 25 OHM 12 OHM

Shunt Regulator Current (PK) 15 AMPS 30 AMPS

Power Dissipation (Cont.) 40 WATTS 40 WATTS

Power Dissipation (PK) 5.6 KW 11.2 KW

Internal Heat Dissipation 120 WATTS 150 WATTS

Regeneration Shunt Resistor (External Min) 8.8 OHM 8.8 OHM

12.0 AMPS

10.0 AMPS

24.0 AMPS

20.0 AMPS

50.0 AMPS

42.0 AMPS

325 VDC

1.1 AMPS RMS

20.0 AMPS

16.0 AMPS

40.0 AMPS

32.0 AMPS

80.0 AMPS

64.0 AMPS

325 VDC

1.1 AMPS RMS

Shunt Regulator Current (PK) 44.3 AMPS 44.3 AMPS

Power Dissipation (Cont.) 400 WATTS 400 WATTS

Power Dissipation (PK) 17.3 KW 17.3 KW

Soft Start Surge Current (Max) 150 AMPS 150 AMPS

Charge Time (Max) 25 MSEC 25 MSEC

1-11

Page 32

HAPTER

C

YSTEM DESCRIPTION

1 - S

BDS5

Table 1.5. Environmental Specifications

Operating Temperature*:

3, 6, & 10 AMP Units (Convection Cooled)

20 Amp Units (Internal Fan Cooled)

Storage Temperature -20o C to 70o C

Humidity (Non-Condensing) 10% to 90%

* For operation ambients above 45°C, consult the Applications Group at Industrial Drives.

Table 1.6. Mechanical Specifications

o

C to 45o C

0

o

C to 45o C

0

MODEL WIDTH HEIGHT DEPTH

NUMBER MM IN. MM IN. MM IN.

BDS5-X03- 56 2.20 340 13.49 280 11

BDS5-X06- 76 2.99 340 13.49 280 11

BDS5-X10- 98 3.86 340 13.49 280 11

BDS5-X20- 98 3.90 340 13.49 280 11

PSR4/5-

X12 & X20-

1.6 THEORY OF OPERATION

76 3.00 340 13.49 280 11

DISCRETE INPUTS

•

Drawing D-93030 shows a system overview.

MICROPROCESSOR SYSTEM

•

The BDS5 is a digital positioner and servo drive

combined into one unit. The velocity loop is 100%

digital. The BDS5 has battery backup RAM to

remember your p rogram and most variables through

power-down.

RESOLVER-TO-DIGITAL CONVERTER

•

The BDS5 is based on a Resolver-to-Digital (R/D)

converter. The R/D generates a tachometer signal for

your convenience. However, the BDS5 does not use

the analog tach signal.

SERIAL PORT

•

The BDS5 has a serial port for communications. This

port allows you to monitor the operation, issue

commands, and transmit a program.

The BDS5 has 23 discrete inputs, including REMOTE

ENABLE which is on Connector C2 only. Note that

two signals, HOME and CYCLE, can be input to the

BDS5 on two connectors, C2 and C7. Connector C2

provides these three signals with optical isolation.

Connector C7 expects non-isolated TTL signals on a

26-pin ribbon cable connector. Optional Connector

C8 expects non-isolated TTL signals on a 50-pin

ribbon cable connector.

DISCRETE OUTPUTS

•

The BDS5 has 10 discrete outputs. Notice that O1

appears both on Connector C2 with optical isolation

and on Connector C8.

ENCODER INPUT

•

The BDS5 accepts external inputs in encoder format.

This can come from a master motor in a master/slave

system. Note that you must use a resolver, even if you

use a feedback encoder with the BDS5.

1-12

Page 33

BDS5 C

HAPTER

YSTEM DESCRIPTION

1 - S

ENCODER EQUIVALENT OUTPUT

•

The BDS5 provides encoder format output derived

from the R/D converter.

ANALOG INPUT (O PT1 CARD)

•

As an option, the BDS5 can accept a ±10 volt analog

input. This input is converted to digital format by the

BDS5. Gain and offset adjustments are made digitally

inside the BDS5, not with potentiometers.

PULSE INPUT (OPT2 CARD)

•

The BDS5 can accept special pulse inputs. The

standard BDS5 can accept signals directly from

encoders or encoder-like devices. As an option, the

BDS5 can accept other pulse formats, such as

count/direction or up/down.

LED'S

•

The BDS5 provides LED's for diagnostics. These

LED's are on the front panel of the BDS5. The LED's

are listed below:

ACTIVE

SYS OK

CPU

FAULT

RELAY

CURRENT LOOP COMPENSATION

•

The BDS5 has analog current loops. The current loop

compensation components are all contained in the

compensation module located on the front of the

BDS5. The current loop compensation changes when

you change the motor model. You must install the

correct compensation module when changing motor

models.

YOU MUST HAVE THE

PROPER COMPENSATION

MODULE INSTALLED FOR

YOUR MOTOR

CAUTION

Failure to install the proper

compensation module can

cause damage to the BDS5,

the motor, or both.

1.7 SIMPLIFIED SCHEMATIC

DIAGRAM AND SYSTEM DIAGRAM

Drawings D-93030 and A-84847 illustrate a BDS5

servo system with all of the major components.

1-13

Page 34

HAPTER

C

24 VOLT DC

CUSTOMER

SUPPLIED

-

+

IN COMMON

YSTEM DESCRIPTION

1 - S

I/O DC

COMMON

REMOTE

HOME

CYCLE

HOME

CYCLE

LIMIT

MOTION

GATE

MANUAL

I1

I2

I3

I4

I5

I6

I7

I8

I9

I10

I11

I12

I13

I14

I15

I16

C2-PIN 5

C2-PIN 15

C2-PIN 9

C2-PIN 19

C2-PIN 8

C2-PIN 18

C7-PIN 9

C7-PIN 13

C7-PIN 11

C7-PIN 15

C7-PIN 17

C7 (EVEN PINS)

C7 STANDARD I/O

C8 (EVEN PINS)

C8-PIN 33

C8-PIN 31

C8-PIN 29

C8-PIN 27

C8-PIN 25

C8-PIN 23

C8-PIN 21

C8-PIN 19

C8-PIN 17

C8-PIN 15

C8-PIN 13

C8-PIN 11

C8-PIN 9

C8-PIN 7

C8-PIN 5

C8-PIN 3

C8-PIN 1

C8 OPTIONAL I/O

ALTERNATE POWER SOURCE

FOR REMOTE, HOME, AND

CYCLE ONLY !

OPTICAL

ISOLATOR

OPTICAL

ISOLATOR

OPTICAL

ISOLATOR

INPUT BUFFERS

AND PULL-UP

74HC14

INPUT BUFFERS

AND PULL-UP

74LS540

RS-232

RS-485

TXD

RXD

TD+

TD-

RD+

RD-

C5-PIN 3

C5-PIN 2

120 OHM

C5-PIN 6

C5-PIN 7

120 OHM

C5-PIN 8

C5-PIN 9

MICROCOMPUTER SYSTEM

MICROPROCESSOR

BATTERY

BACK-UP

RAM

3

J1

452

7

J1

8

ROM

BDS5

1

1K

6 1K

+5

1-14

DIFF CMD HI

DIFF CMD LO

IN A

IN A

IN B

IN B

C2-PIN 11

C2-PIN 1

C1-PIN 5

C1-PIN 10

C1-PIN 4

C1-PIN 9

ANALOG

TO PULSE

CONVERTER

OPTIONAL

SN75175

SN75175

CH A

CH B

ENCODER

TO

DIGITAL

BDS5 SYSTEM OVERVIEW

Page 35

BDS5 C

75155

75156

75156

RD TD

HARDWARE

WATCHDOG

HAPTER

24 VOLT

OPTICAL

ISOLATOR

1 - S

"RELAY"

( N. O. )

YSTEM DESCRIPTION

"ACTIVE"

LED

"SYS OK"

LED

"CPU"

LED

"FAULT"

LED

"RELAY"

LED

C2-PIN 17

C2-PIN 16

C2-PIN 10

C2-PIN 20

RELAY

01 HI

01 LO

ISSUE

D-93030

SHULER

2

12-17-92

COPY CODEI

8

9

7

5

6

4

2

3

1

COMPENSATION

CARD

PIN 10

PIN 5

PIN 9

PIN 4

PIN 8

PIN 3

RESOLVER

TO

DIGITAL

CONVERTER

A-PHASE

CURRENT

LOOP

B-PHASE

CURRENT

LOOP

C-PHASE

CURRENT

LOOP

C3-PIN 4

C3-PIN 10

C3-PIN 1

C3-PIN 9

C3-PIN 3

BUS +

REF HI

REF LO

SIN HIC3-PIN 7

SIN LO

COS HI

COS LO

PWM

POWER

STAGE

BUS -

ABSOLUTE

VALUE

CIRCUIT

CURRENT

SAMPLE

CURRENT

SAMPLE

CURRENT

SAMPLE

TACH SCALING = 1000 RPM/V

DIGITAL

TO

ENCODER

OUTPUT BUFFERS

5 VOLTS = FULL SCALE

CH A

CH B

CH Z

WITH OPEN

COLLECTORS

ULN2803A

Ma

Mb

Mc

GND

1.0K

4700pf

75174

75174

75174

3.01K

C8 OPTIONAL I/O

C7 STANDARD I/O

MOTOR

RESOLVER

C2-PIN 2

C2-PIN 12

C1-PIN 1

C1-PIN 6

C1-PIN 2

C1-PIN 7

C1-PIN 3

C1-PIN 8

C8-PIN 35

C8-PIN 47

C8-PIN 45

C8-PIN 43

C8-PIN 41

C8-PIN 39

C8-PIN 37

C7-PIN 21

C7-PIN 19

C7-PIN 23

C2-PIN 4

C2-PIN 14

STATUS

01

02

03

04

05

06

07

08

CYCLE

READY

I MONITOR

COMMON

TACH

MONITOR

COMMON

OUT A

OUT A

OUT B

OUT B

OUT Z

OUT Z

1-15

Page 36

HAPTER

C

YSTEM DESCRIPTION

1 - S

BDS5

4

ISSUE

MASTER

ENCODER

A-84847

TERMINAL

OR

PC COMPATIBLE

ACTIVE

SYS OK

FAULT

RELAY

MODEL No

SERIAL No

BUS+

BUS-

CPU

T

1

J1

Ma

Mb

Mc

MODEL No.

REV No.

C5

INDUSTRIAL

DRIVES

GND

C1

C2

C3

C4

BDS5

EXTERNAL REGEN RESISTOR

D.C. BUS

REGEN

OVERLOAD

BLOWN FUSE

C1

MODEL No

C2

SERIAL No

INDUSTRIAL

DRIVES

PSR

BUS+

BUS-

La

Lb

Lc

GND

CUSTOMER I/O

(OPTO-22 COMPATIBLE)

CYCLE READY

O7

O8

GATE

MOTION

CYCLE

LIMIT

HOME

STATUS

MANUAL

115 VAC,

1 PHASE

O1

O2

O3

O4

O5

O6

I1

I2

I3

I4

I5

I6

I7

I8

I9

I10

I1

I2

I3

I4

I5

I6

4

ISSUE

A-84847

R. FURR

1-14-91

1-16

230 VAC,

3 PHASE

OR

115 VAC,

1 PHASE

GOLDLINE

MOTOR

TYPICAL BDS5 SYSTEM INTERCONNECT

COPY CODE

I

Page 37

BDS5 C

HAPTER

C

NSTALLATION

I

2.1 INTRODUCTION

2

HAPTER

NSTALLATION

2 - I

The information in this chapter will familiarize you

with safety information, unpacking and inspection,

installation requirements, mounting procedures and

wiring for installing the BDS5, PSR4/5 and/or

External Regen Resistors. Read the entire chapter

carefully. The chapter contains an extensive checkout

procedure because most installation problems are

caused by incorrect wiring or poor wiring practices.

Complete the entire checkout procedure before

attempting to put your BDS5 system into operation.

2.2 SAFETY INFORMATION

The purpose of this section is to alert you to possible

safety hazards associated with this equipment and the

precautions you can take to reduce the risk of personal

injury and damage to the equipment.

Safety notices in this manual provide important

information. Read and be familiar with these

instructions before attempting installation, operation,

or maintenance. Failure to observe these precautions

could result in serious bodily injury, damage to the

equipment, or operational difficulty.

WARNING

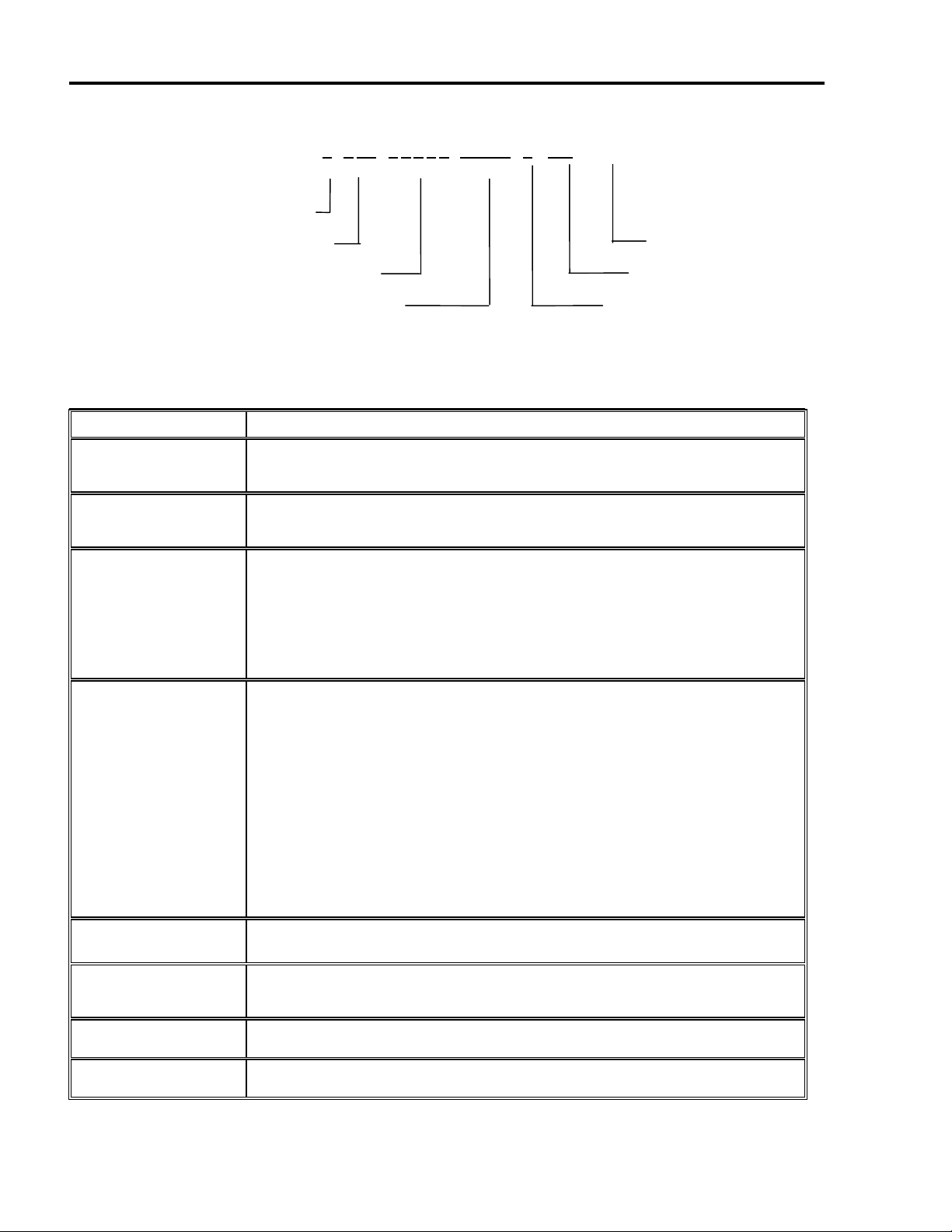

Figure 2.1. Safety-Alert Symbols

The safety-alert symbols are illustrated in Figure 2.1.

When you see these symbols in this manual, be alert to

the potential for personal injury. Follow the

recommended precautions and safe operating practices

included with the alert symbols.

"

Warning

to potential danger or harm. Failure to follow warning

notices could result in personal injury or death.

"

Caution

which if not followed, could result in personal injury

and/or equipment damage.

"

Note

understanding or use of these products.

" refers to personal safety. They alert you

" directs attention to general precautions,

" highlights information critical to your

CAUTION

NOTE

2-1

Page 38

HAPTER

C

NSTALLATION

2 - I

BDS5

2.3 UNPACKING AND INSPECTION

Electronic components in

this amplifier are static

sensitive. Use proper

CAUTION

Upon receipt of the equipment, closely inspect

components to ensure that no damage has occurred in

shipment. If damage is detected, notify the carrier

immediately.

Carefully remove packing material and remove the

equipment from the shi pping container. Do not

dispose of shipping materials until the packing list has

been checked. Parts that are contained within the

shipment, but not physically attached to the

equipment, should be verified against the packing list.

If any parts are missing, notify Industrial Drives at

once.

procedures when handling

component boards.

2.4 INSTALLATION REQUIREMENTS

from physical and environmental damage. Refer to

specifications for complete system dimensions.

Allow sufficient clearance for

the large "regenerative" heat

producing resistor(s)

mounted at the upper edge

CAUTION

of the PSR4/5 unit and the

externally mounted regen

(shunt regulator) power

resistor(s).

2.5 MOUNTING

The BDS5 and PSR4/5 should be mounted in a cabinet

or other suitable enclosure to protect them from

physical and environmental damage.

The PSR4/5 and the BDS5 are provided with

protective guards over the power terminal blocks.

After wiring is complete, ALWAYS REPLACE THE

PROTECTIVE GUARDS TO REDUCE SHOCK

HAZARD.

Proper installation and field wiring are of prime

importance when considering the application of servo

amplifiers. Many problems may be avoided if

installation of the equipment is done properly. Users

should familiarize themselves with and follow

installation and wiring instruction in addition to all

applicable codes, laws, and standards. Pay special

attention to the following topics when installing

Industrial Drives' equipment.

2.4.1 Environmental Considerations

The environment that this equipment is placed in can

have dramatic effects on its operation. Industrial

Drives recommends that the BDS5 and PSR4/5 be

operated and stored under the following conditions:

Operating Temperature: 0° C to 45° C

•

Storage Temperature: -20° C to 70° C

•

Humidity: 10% to 90% (Non Condensing)

•

2.4.2 Enclosures

It is suggested that the BDS5 and PSR4/ 5 be mounted

in a cabinet or other suitable enclosure to protect them

REPLACE THE POWER

TERMINAL GUARDS AFTER

WARNING

WIRING THE SYSTEM!

2.5.1 Mounting the BDS5

Refer to drawing A-93703 in Appendix B for

mounting dimensions. The BDS5 and PSR4/5 should

be mounted in the vertical position. Since these units

are convection cooled, there should be a minimum of

25 millimeters (1 inch) of unobstructed space above

and below the units. In addition, there should be a

minimum of 20 millimeters (0.8 inch) between units to

ensure proper airflow for these convection-cooled

units.

2.5.2 Mounting the PSR4/5

The PSR4/5 Power Supply module may be mounted

on either side of the BDS5. However, a 20 millimeter

(0.8 inch) space is required between units.

Some PSR4/5's have resistors which dissipa te the

energy returned to the PSR4/5 during regenerative

braking. These are referred to as regen resistors.

Some applications require externally mounted regen

2-2

Page 39

BDS5 C

HAPTER

NSTALLATION

2 - I

resistors, while others may require none at all. To

determine if your PSR4/5 has internal regen resistors,

check its model number.

REGEN RESISTORS GET

HOT!

If your PSR4/5 has internal

CAUTION

NOTE

Refer to appropriate outline and dimension drawings

in Appendix B for more information:

A-93569BDS5 3 and 6 Amp Unit

A-93571BDS5 10 Amp Unit

A-93570BDS5 20 Amp Unit

A-93880BDS5 30 and 40 Amp Unit

A-93010BDS5 55 Amp Unit

A-93581PSR4/5 12 and 20 Amp Unit

A-93031PSR4/5 50 and 75 Amp Unit

regen resistors, allow

sufficient clearance above the

PSR4/5.

Refer to Drawing A-93703 for

more information concerning

mounting.

2.5.3 Mounting the External Regen Resistor

External mounting of regen resistors is an option on

PSR4/5's. To determine if your unit uses external

regen resistors, check its model number. Also, the

model number indicates the standard resistor value.

These resistors should be enclosed to reduce shock

hazard. Regen resistors get hot! They are a burn

hazard and they are a fire hazard. They can produce

enough heat to melt insulation. Enclos e these

resistors! The enclosure must provide ventilation and

withstand high temperatures. Do not mount the

resistors underneath the BDS5 or PSR4/5.

EXTERNAL REGEN

RESISTORS ARE A SHOCK

HAZARD!

Mount these resistors

WARNING

CAUTION

properly! Enclose these

resistors to protect personnel

and equipment!

EXTERNAL REGEN

RESISTORS GET HOT!

If you are using external regen

resistors, allow sufficient

clearance around the

resistors. Enclosures must

provide ventilation.

2.6 WIRING

The customer is responsible for providing proper

circuit breaker or fuse protection. The customer is

responsible for providing proper wire gauge and

insulation rating for all wiring, including motor, AC

line, DC bus, and External Regen Resistor

connections. The customer is responsible for making

sure that all system wiring and electrical protection

comply with all applicable national and local electric

codes.

Drawing A-93103 is the System Wiring Diagram. It is

a seven-sheet drawing. Carefully read all of Drawing

A-93103 before wiring your BDS5 system, including

all of the notes on the last sheet. Refer to BDS5

Connectors Diagram A-96372M, provided at the end

of this chapter, for connector locations.

Carefully read all seven

sheets of Drawing A-93103

before wiring your BDS5

WARNING

system, including ALL of the

notes on the last sheet.

When wiring your BDS5 system, obse rve the

following guidelines:

1. Twist all AC leads to minimize electromagnetic

emissions (noise).

2-3

Page 40

HAPTER

C

NSTALLATION

2 - I

BDS5

2. Avoid running signal l eads in close proximity to

power leads, motor stator leads, or other sources

of electromagnetic noise. Run signal leads in

separate conduit from power leads. Shields are

recommended for signal leads.

3. Minimize lead lengths.

4. Connect the BDS5 system according to the

System Wiring Diagram, A-93103; pay close

attention to the grounding scheme and notes.

2.6.1 Wiring the Ground

Ground terminals are provided on the front of BDS4's,

BDS5's, and PSR4/5's. These ground screws are

directly below the Power Terminal Block of each unit.

To prevent shock hazard and to ensure proper

operation of the system, the BDS5, PSR4/5, and the

motor must be grounded. Each BDS5 and PSR4/5 has

two ground screws on the front of its chassis.

GROUND YOUR BDS5,

PSR4/5, and motor

PROPERLY! Failure to

WARNING

One of the ground screws on the PSR4/5 should be

connected to Earth Ground or Machine Ground. The

other should be connected to the adjacent BDS5

ground screw, along with the ground wire fro m the

motor. The ot her ground screw on the B DS5 chassis

should then be connected to the next BDS5, etc. Use

10 AWG or larger wire for grounding between BDS5's

and PSR4/5's and from PSR4/5 to Earth Ground or

Machine Ground.

provide proper grounding can

result in a shock hazard.

2.6.2 Wiring the Power Connections

This section discusses how to wire the PSR4/5 and

BDS5 power connections.

To prevent equipment

damage, the AC Line and the

DC bus must be connected as

CAUTION

indicated by the System

Wiring Diagram, A-93103.

for operation from either a 115 volt or a 230 volt AC

Line. The PSR4/5 and the BDS5 must both have the

same voltage rating. Operating a PSR4/5 or a BDS5

with incorrect voltage can damage the units.

Use the proper AC Line

voltage. PSR4/5's and BDS5's

are configured at the factory

for 115 volt or 230 volt AC

Line voltage. See the model

CAUTION

number description at the

beginning of this chapter to

determine the required

voltage for your PSR4/5 and

BDS5.

2.6.2.1 Wiring the Motor

Connect Pins A, B, and C of the motor connector

through a motor cable to Ma, Mb, and Mc,

respectively, on the Power Terminal Block located on

the front of the BDS5 amplifier. Connect Pin D of the

motor connector through the same motor cable to the

BDS5 chassis ground screw located directly beneath

the Power Terminal Block.

IT IS VERY IMPORTANT THAT YOU WIRE THE

MOTOR PROPERLY. Brushless permanent magnet

motors are not like induction motors. You cannot

simply interchange two phases to reverse the direction

of rotation.

Standard Industrial Drives motor cable has the color

code as shown in Table 2.1.

Table 2.1. Motor Cable Color Code

Motor

Connector

Pin A M

Pin B M

Pin C M

WARNING

Incorrect motor wiring can

cause erratic or runaway

motor operation. Use of

factory supplied cable sets is

highly recommended.

Wire

Marker

a

b

c

BDS5 Power

Terminal

Terminal M

Terminal M

Terminal M

a

b

c

The PSR4/5 and BDS5 are configured at the factory

2-4

Page 41

BDS5 C

HAPTER

NSTALLATION

2 - I

2.6.2.2 Motor Protection

Under normal conditions, you do not need to add

protection for your motor; the BDS5 is normally

configured to limit the continuous current below the

rating of the motor. However, if the drive is oversized

(that is, it can provide continuous current that greatly

exceeds the motor's continuous current rating), you

may want to add motor overload relays in series with

the motor. Also, you can wire a contactor in series

with the motor leads. ALWAYS BE CAREFUL TO

WIRE THE MOTOR PROPERLY.

2.6.2.3 Motor Thermostat

Industrial Drives brushless motors have a thermostat.

The thermostat contacts are closed during normal

operation and open when the motor overheats. The

BDS5 does not provide a direct input for the motor

thermostat. You should connect the thermostat

contacts to a BDS5 general purpose input, and

program your BDS5 to bring about an orderly

shutdown when the thermostat opens. The thermostat

ratings are:

Rated Voltage: 277 VAC at 60 Hz

250 VAC at 50 Hz

WARNING

NOTE

LATCH THE MOTO R

THERMOSTAT!

DO NOT CONNECT THE

THERMOSTAT DIRECTLY TO

THE BDS5 REMOTE ENABLE

OR LIMIT INPUTS.

The motor thermostat resets

(closes) when the motor

cools. This can allow the

motor to restart operation

unexpectedly after a motor

thermostat fault unless the

thermostat is latched. Always

latch the thermostat.

B series (GOLDLINE) motors

have the thermostat wired to

the resolver connector at the

motor.

BR series motors have the

thermostat wired to the power

connector at the motor.

Rated Current: 2.5 Amps at power factor of 1.0

1.6 Amps at power factor of 0.6

Resistance: 50 m Ohms

The thermostat resets (closes) when the motor cools.

The customer is responsible for making sure that the

motor does no t begin moving unexpecte dly when the

thermostat closes. Do not connect the thermostat

directly in line with the BDS5 REMOTE ENABLE or

LIMIT inputs, as this may allow the system to begin

operatio n unexpectedly. Yo u must la tch the

thermostat switch, either in hardware or software. IT

CAN TAKE SEVERAL MINUTES FOR THE

MOTOR TO COOL ENOUGH TO ALLOW THE

THERMOSTAT TO CLOSE. UNEXPECTE D

OPERATION SEVERAL MINUTES AFTER A

FAULT IS A SAFETY HAZARD!

Some electrical noise from the motor leads will couple

capacitively with the thermostat leads. This

occasionally causes false thermostat trips. That is,

your controller senses that the thermostat opened even