Kohler PA-320751, PA-320743, PA-320742, PA-320748, PA-320747 Operation And Installation Instructions Manual

...Page 1

Operation and

Installation Instructions

Automatic Battery Chargers

Kits:

PA-320741

P

A-320741-SD through P

through P

A-320764 and

A-320764-SD

TT-855 12/93b

Page 2

Table of Contents

SUBJECT PAGE SUBJECT PAGE

Safety Precautions and Instructions 1.

Introduction 4

Specifications 5

Installing Charger 8.

Mount Charger 9.

Ouput Connections 9.

Input Connections 9.

Disconnecting Charger 11.

Battery Charger Operation 12.

Charging Lead-Acid Batteries 12.

Checking Specific Gravity 14.

Charging Nickel-Cadmium Batteries 14.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . .

Charger Voltage Adjustment 15.

Charger and Battery Maintenance 15.

Troubleshooting 16

Standard Accessories 17.

Current Limiting 17.

Reverse Polarity Protection 17.

Automatic Float Operation 17.

Temperature Compensation 17.

AC Input Fuse 17.

DC Output Fuse 17.

Power On Lamp 17.

Wiring Diagrams 18.

Parts Lists 24.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

-855 12/93

T

able of Contents

iTT

Page 3

Safety Precautions and Instructions

A generator set, like any other electro-mechanical

device, can pose potential dangers to life and limb if

improperly maintained or imprudently operated. The

best way to prevent accidents is to be aware of the

potential dangers and to always use good common

sense. In the interest of safety, some general

precautions

follow. Keep these in mind. This manual contains

several

below.

relating the to operating of a generator set

types of safety precautions

which are explained

CAUTION

Caution

will

damage if the warning is ignored.

Note

maintenance information that is important but not

hazard-related.

is

used to indicate the presence of a hazard that

or

can

is used

cause

to notify people of installation, operation, or

minor

personal injury or property

NOTE

DANGER

Danger is used to indicate the presence of a hazard that

will

cause

property damage if the warning is ignored.

Warning is used to indicate the presence of a hazard

that

substantial property damage if the warning is ignored.

severe

WARNING

can

cause

personal injury, death, or substantial

severe

personal injury, death, or

Accidental Starting

WARNING

Accidental starting.

Can cause severe injury or death.

Disconnect battery cables before working on

generator set (negative lead first and reconnect it

last).

Safety decals are affixed to the generator set in

prominent places to advise the operator or service

technician of potentially hazardous situations. The

decals are reproduced here to improve operator

recognition and thereby increase decal effectiveness.

For

a further

the accompanying safety precautions. Before

operating or servicing the generator set, be sure you

understand the message of these decals. Replace

decals if missing or damaged.

Accidental starting can cause severe injury or

death. Turn generator master switch to OFF position,

disconnect power to battery charger, and remove

battery cables (remove negative lead first and

reconnect

on any equipment connected to generator. The

generator set can be started by automatic transfer

switch or remote start/stop switch unless these

precautions are followed.

explanation of decal information, reference

it last) to disable generator set before working

-855 12/93

Safety Precautions

1TT

Page 4

Hazardous Voltage/Electrical Shock

WARNING

Hazardous voltage.

Can cause severe injury or death.

Do not operate generator set without all guards

and electrical enclosures in place.

Hazardous voltage can cause severe injury or

death. De-energize both normal and emergency power

sources before proceeding. Move generator master

switch on controller to OFF position and disconnect

battery negative (–) before working on transfer switch!

Turn the transfer switch selector switch to the OFF

position.

Hazardous voltage can cause severe injury or

death. Keep everyone away from the set and take

precautions to prevent unqualified personnel from

tampering.

only by qualified technicians. Wiring should be

inspected at the recommended interval shown in the

service schedule—replace leads that are frayed or in

poor condition. Do not operate electrical equipment

when standing in water, on wet ground, or when your

hands are wet.

Have the set and electrical circuits serviced

Moving rotor.

Hazardous voltage can cause severe injury or

death. Electrical shock may occur if battery charger is

not properly grounded. Connect battery charger

enclosure

an alternative, run an equipment-grounding conductor

with circuit conductors and connect to

equipment-grounding terminal or lead on battery

charger. Battery charger installation should be

performed

comply with all local codes and ordinances.

to ground of a permanent wiring

as prescribed in equipment manual and must

system. As

(Applies to Optional Battery Charger.)

Hazardous voltage can cause severe injury or

death. Improper reconnection may damage charger

and

battery(ies), and

Installation must be done by a qualified electrician.

create an electrical shock hazard.

(Applies to Optional Battery Charger.)

Hazardous voltage can cause severe injury or

death. Short circuits can cause bodily injury and/or

equipment damage. Do not contact electrical

connections

made.

cause short circuits.

with tools or jewelry while adjustments are

Remove wristwatch, rings, and jewelry that can

2 TT

Safety Precautions

-855 12/93

Page 5

Battery

WARNING

Sulfuric acid in batteries.

Can cause severe injury or death.

Use protective goggles and clothes. Can cause

permanent

in clothing.

Sulfuric

death. Sulfuric acid in battery can cause permanent

damage to eyes, burn skin, and eat holes in clothing.

Always

around the battery. If battery electrolyte

the

eyes or

for

15 minutes with large quantities of clean water

case of eye contact, seek immediate medical aid. Never

add acid to a battery once

service.

electrolyte.

damage to eyes, burn skin, and eat holes

acid in batteries

wear splash-proof safety goggles when working

on skin, immediately flush the af

Doing so may result in

can cause severe injury or

is splashed in

fected area

. In

the

battery has been placed in

hazardous spattering of

the

Explosion can cause severe injury or death. Battery

gases

can cause an explosion. Do not smoke or permit

flame or spark to occur near a battery at any time,

particularly

terminals

sparks that could cause an explosion. Remove

wristwatch,

battery. Never connect negative (–) battery cable to

positive (+) connection terminal of starter solenoid. Do

not

test battery condition by shorting terminals together

or sparks could ignite battery gases or fuel vapors. Any

compartment containing batteries must be well

ventilated to prevent accumulation of explosive gases.

To avoid sparks, do not disturb battery charger

connections

turn charger off before disconnecting battery

connections. When disconnecting battery, remove

negative lead first and reconnect it last.

when it is being charged. A

with tools,

rings, and any other jewelry before handling

while battery is being charged and always

etc. to prevent burns and to prevent

void contacting

NOTES

NOTE

Charge only LEAD-ACID or NICKEL-CADMIUM

batteries with battery charger.

NOTE

Split lock washers may be supplied with some kits. If

split lock washers are supplied with kit, their use is

optional.

(use with kits only)

NOTE

HARDWARE DAMAGE! Engine and generator may

make use of both American Standard and metric

hardware. Be sure to use the correct size tools to

prevent rounding of bolt heads and nuts.

-855 12/93

Safety Precautions

3TT

Page 6

Introduction

This TT includes the following kits:

PA-320741 through P

PA-320741-SD through PA-320764-SD

This manual contains important safety and operating

instructions for automatic 2-amp battery chargers.

Before using the battery charger, read all instructions

and cautionary instructions on (1) battery charger, (2)

battery, and (3) product using battery. Keep these

instructions

The battery chargers are designed for various AC

voltage,

follows:

in mind when operating the battery charger

50- or 60-Hz input, and capable of charging as

A-320764 and

12-Volt Charger Lead-Acid Battery (6-cell)

24-Volt Charger Lead-Acid Battery (12-cell)

Determine input voltage and type of battery(ies) to be

charged. Make any necessary modifications before

using charger.

Grounding Instructions—Connect the battery

charger

or an equipment-grounding conductor with circuit

.

conductors and connect it to equipment-grounding

terminal or lead on battery charger. Connections to

battery charger should comply with all local codes and

ordinances.

to a

grounded, metal, permanent wiring system

4 TT

Introduction

-855 12/93

Page 7

Specifications

The automatic battery charger is designed to charge

and maintain lead-acid and nickel-cadmium

automotive-type batteries in a fully charged state

without any manual intervention. The charger output

provided by the power transformer is controlled by the

circuit board. The control board provides the charger

with current-limiting, AC line compensation,

reverse-polarity protection, ambient-temperature

compensation, and constant voltage charging mode.

1 2 3 4

DC

AMPERES

0

AC INPUT

120V 50/60HZ .68A

DC OUTPUT

12V 2A

321

POWER

ON

DC

OUTPUT

6A

VOLT.

ADJ.

AC

INPUT

1A

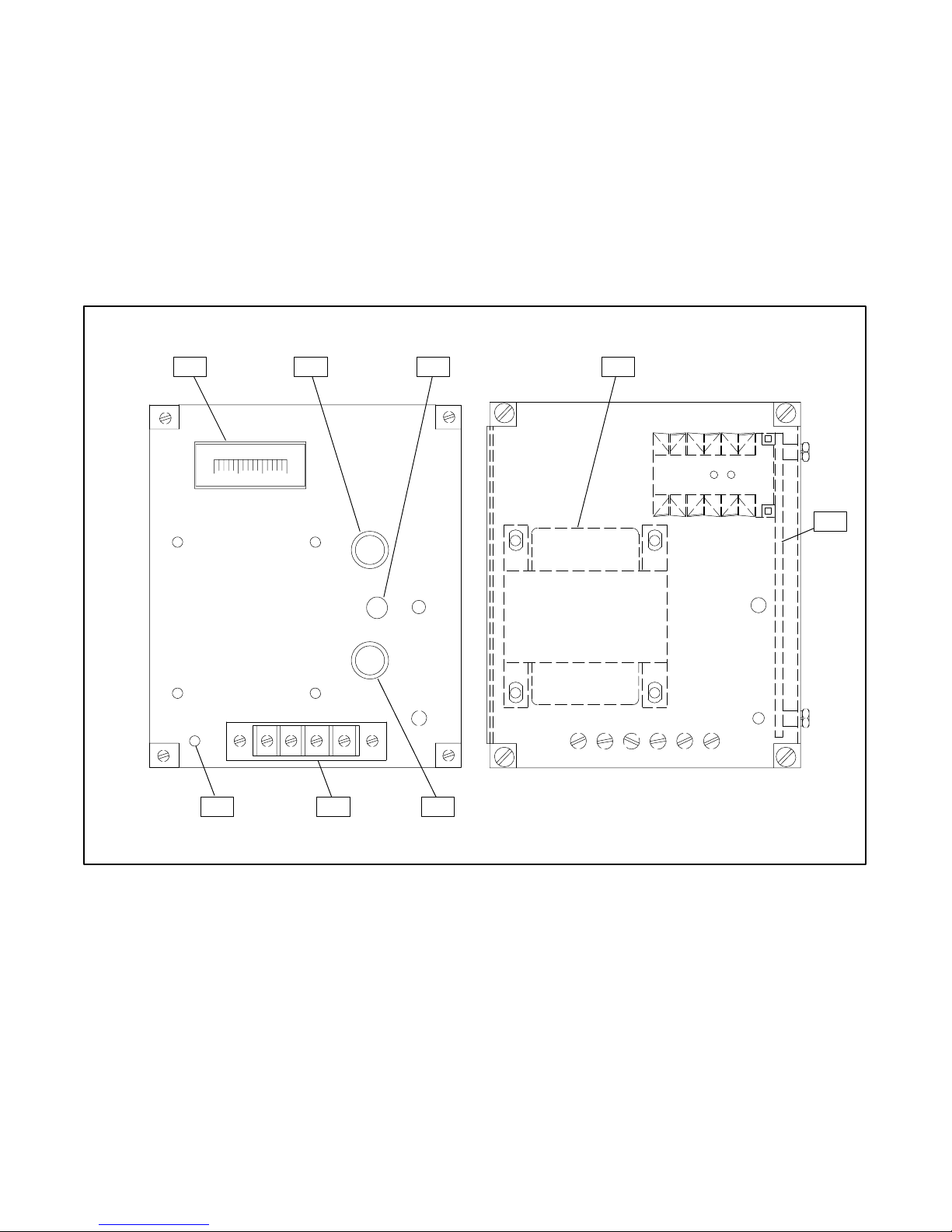

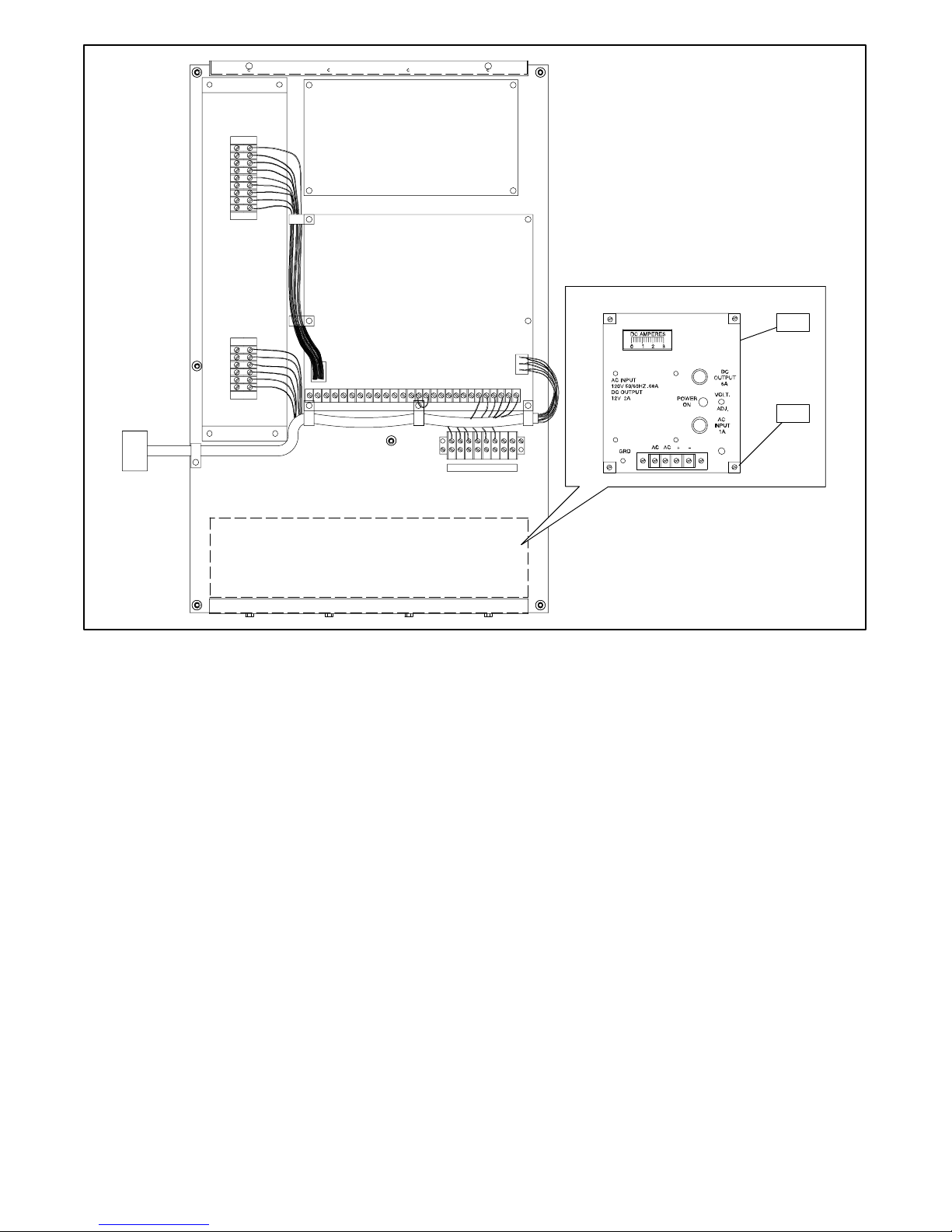

The control circuit board continuously monitors the

battery and load conditions to maintain the battery’s

proper

state of charge. Refer to Figure 1 for component

identification. The chargers are factory adjusted to

maintain the battery at the proper float voltages. The

12-volt

charger will

maintain a lead-acid (6-cell) battery

with no adjustment required. The 24-volt charger will

maintain

a lead-acid (12-cell) battery with no adjustment

required.

5

294241-B

1. DC

Ammeter

2.

DC Output Fuse

3.

“Power On” Lamp

4. Transformer

GRD

AC

AC + –

678

5.

6.

7. T

8.

Figure 1. Battery Charger Components

Main Circuit Board Assembly

AC Input Fuse

erminal Block

Ground T

erminal (AC)

A-294226-A

P1

-855 12/93

Specifications

5TT

Page 8

Battery Charger Kits Selection Table

e

e

e

e

Volts Input Voltage

led

e

12 24

Descriptions

T

ransfer Switch Accessory No.

Battery Charger Kit No. *

T

ransfer Switch Accessory No.

Battery Charger Kit No. *

* SA

TS model transfer switches have an -SD suffix. EXAMPLE: P

Descriptions

T

ransfer Switch Accessory No.

Battery Charger Kit No. *

T

ransfer Switch Accessory No.

Battery Charger Kit No. *

* SA

TS+ model transfer switches have an -SD suf

Loos

Install

X X KA-24-62A KA-24-64A KA-24-63A KA-24-60A KA-24-68A KA-24-71A

X X PA-320741 PA-320747 PA-320745 PA-320751 PA-320743 PA-320749

X X KA-24-62B KA-24-64B KA-24-63B KA-24-60B KA-24-68B KA-24-71B

X X PA-320742 PA-320748 PA-320746 PA-320752 PA-320744 PA-320750

Figure 2. Battery Chargers for S340 Model Transfer Switch

Volts Input Voltage

led

e

Loos

12 24

Install

X X DA-24-62A DA-24-64A DA-24-63A DA-24-60A DA-24-68A DA-24-71A

X X PA-320741 PA-320747 PA-320745 PA-320751 PA-320743 PA-320749

X X DA-24-62B DA-24-64B DA-24-63B DA-24-60B DA-24-68B DA-24-71B

X X PA-320742 PA-320748 PA-320746 PA-320752 PA-320744 PA-320750

fix. EXAMPLE: P

120 V

50/60 Hz

120 V

50/60 Hz

240 V

50/60 Hz

A-320741-SD

240 V

50/60 Hz

A-320741-SD

220 V

50/60 Hz

220 V

50/60 Hz

480/600 V

50/60 Hz

480/600 V

50/60 Hz

208 V

50/60 Hz

208 V

50/60 Hz

380/416 V

50/60 Hz

380/416 V

50/60 Hz

Figure 3. Battery Chargers for S340+ Model Transfer Switch

Volts Input Voltage

led

e

Loos

12 24

Descriptions

T

ransfer Switch Accessory No.

Battery Charger Kit No. *

T

ransfer Switch Accessory No.

Battery Charger Kit No. *

* MA

TS model transfer switches have an -SD suffix. EXAMPLE: P

Install

X X KD-24-62A KD-24-64A KD-24-63A KD-24-60A KD-24-68A KD-24-71A

X X PA-320753 PA-320759 PA-320757 PA-320763 PA-320755 PA-320755

X X KD-24-62B KD-24-64B KD-24-63B KD-24-60B KD-24-68B KD-24-71B

X X PA-320754 PA-320760 PA-320758 PA-320764 PA-320756 PA-320756

Figure 4. Battery Chargers for M340 Model Transfer Switch

120 V

50/60 Hz

240 V

50/60 Hz

A-320741-SD

220 V

50/60 Hz

480/600 V

50/60 Hz

208 V

50/60 Hz

380/416 V

50/60 Hz

6 TT

Specifications

-855 12/93

Page 9

e

e

e

e

Descriptions

T

ransfer Switch Accessory No.

Battery Charger Kit No. *

T

ransfer Switch Accessory No.

Battery Charger Kit No. *

* MA

TS+ model transfer switches have an -SD suf

Loos

X X PA-320753 PA-320759 PA-320757 PA-320763 PA-320755 PA-320761

X X PA-320754 PA-320760 PA-320758 PA-320764 PA-320756 PA-320762

Figure 5. Battery Chargers for M340+ Model Transfer Switch

e

Descriptions

T

ransfer Switch Accessory No.

Battery Charger Kit No.

T

ransfer Switch Accessory No.

Battery Charger Kit No.

Loos

X X ––– ––– ––– ––– ––– –––

X X ––– ––– ––– ––– ––– –––

Figure 6. Battery Chargers for R33 Model Transfer Switch

Volts Input Voltage

led

12 24

Install

X X DD-24-62A DD-24-64A DD-24-63A DD-24-60A DD-24-68A DD-24-71A

X X DD-24-62B DD-24-64B DD-24-63B DD-24-60B DD-24-68B DD-24-71B

fix. EXAMPLE: P

Volts Input Voltage

led

12 24

Install

X X ––– KD-24-64A KD-24-63A ––– ––– –––

X X ––– KD-24-64B KD-24-63B ––– ––– –––

120 V

50/60 Hz

120 V

50/60 Hz

240 V

50/60 Hz

A-320741-SD

240 V

50/60 Hz

220 V

50/60 Hz

220 V

50/60 Hz

480/600 V

50/60 Hz

480/600 V

50/60 Hz

208 V

50/60 Hz

208 V

50/60 Hz

380/416 V

50/60 Hz

380/416 V

50/60 Hz

Descriptions

Primary Circuit

Protection

Secondary Circuit

Protection

Output Level

Preset at Factory

120 V

50/60 Hz

1 Amp 12 V

1.5 Amp 24 V

Figure 7. Battery Charger Specifications

240 V

50/60 Hz

0.5 Amp 12 V

1 Amp 24 V

12-V

olt Charger—13.2 V

24- V

olt Charger—26.4 V

Input Voltage

220 V

50/60 Hz

0.5 Amp 12 V

1 Amp 24 V

6 Amp Slo-Blo

480/600 V

50/60 Hz

0.2 Amp 12 V

0.4 Amp 24 V

208 V

50/60 Hz

0.5 Amp 12 V

1 Amp 24 V

olt, 2 Amp Current Limiting

olt, 2 Amp Current Limiting

380/416 V

50/60 Hz

0.3 Amp 12 V

0.5 Amp 24 V

-855 12/93

Specifications

7TT

Page 10

Installing Charger

WARNING

Sulfuric acid in batteries.

Can cause severe injury or death.

Use protective goggles and clothes. Can cause

permanent

in clothing.

damage to eyes, burn skin, and eat holes

NOTE

CHARGER

a battery with the same DC voltage as the battery

charger output rating.

DAMAGE!

Connect battery

charger only to

WARNING

Sulfuric

death. Sulfuric acid in battery can cause permanent

damage to eyes, burn skin, and eat holes in clothing.

Always

around the battery. If battery electrolyte

the

for

case of eye contact, seek immediate medical aid. Never

add acid to a battery once

service.

electrolyte.

Accidental starting.

Can cause severe injury or death.

Disconnect battery cables before working on

generator set (negative lead first and reconnect it

last).

Accidental starting can cause severe injury or

death. Turn generator master switch to OFF position,

disconnect power to battery charger, and remove

battery cables (remove negative lead first and

reconnect

on any equipment connected to generator. The

generator set can be started by automatic transfer

switch or remote start/stop switch unless these

precautions are followed.

acid in batteries

wear splash-proof safety goggles when working

eyes or

15 minutes with large quantities of clean water

on skin, immediately flush the af

Doing so may result in

WARNING

it last) to disable generator set before working

can cause severe injury or

is splashed in

fected area

. In

the

battery has been placed in

hazardous spattering of

the

Explosion.

Can cause severe injury or death. Relays in

battery charger cause arcs or sparks.

Locate in a well ventilated area. Keep explosive

fumes away.

Explosion

gases

flame or spark to occur near a battery at any time,

particularly

terminals

sparks that could cause an explosion. Remove

wristwatch,

battery. Never connect negative (–) battery cable to

positive (+) connection terminal of starter solenoid. Do

not

test battery condition by shorting terminals together

or sparks could ignite battery gases or fuel vapors. Any

compartment containing batteries must be well

ventilated to prevent accumulation of explosive gases.

To avoid sparks, do not disturb battery charger

connections

turn charger off before disconnecting battery

connections. When disconnecting battery, remove

negative lead first and reconnect it last.

can cause severe injury or death. Battery

can cause an explosion. Do not smoke or permit

when it is being charged. A

with tools,

rings, and any other jewelry before handling

while battery is being charged and always

etc. to prevent burns and to prevent

void contacting

8 TT

Installation

-855 12/93

Page 11

Mount Charger

1. Move generator master switch to OFF position.

Disconnect battery cables, negative lead first.

Open circuit breaker of AC power source to be

applied.

2. Turn automatic transfer switch selector to OFF

position.

3. Open automatic transfer switch enclosure.

Output Connections

NOTE

For

DC

connections use stranded copper wire, 600 V

105_C vinyl plastic insulation UL style 1015, CSA

TEW.

1. Due to the variety of generator installations,

battery cables are not provided. To make battery

connections, cut red (+) 10-gauge stranded wire

to proper length and strip insulation from both

ends. To one end of wire attach a post-type

connector. Route other end of battery cable and

connect

DC terminal block. See

block lock screw to secure battery cable. Repeat

to output positive (+) terminal on

Figure 8. T

ighten terminal

charger

olt,

type

4. Install four captive nuts (298811) in the transfer

switch

inner panel and install battery charger

Figure 8.

5. The battery charger is factory set to maintain the

proper

output for the battery voltage for which it is

rated. No customer adjustments are required.

procedure

connect black wire to output negative (–)

on DC terminal

2. Connect

terminal and black charger lead(s) to battery

negative (–) terminal.

Grounding Instructions—This

be connected to a grounded, metal, permanent wiring

system.

be run with circuit conductors and connected to

equipment-grounding terminal on battery charger.

Connections to battery charger should comply with all

local codes and ordinances.

An equipment-grounding conductor could

with black (–) 10-gauge stranded wire;

block

and secure with lock screw

red charger lead(s) to battery positive

battery charger should

. See

terminal

(+)

also

.

Input Connections

1. Connect

source as indicated by nameplate or transfer

switch wiring diagram.

the correct voltage, 50/60 Hz, AC power

2. Turn AC power on. Power On lamp will light and

ammeter will show charging current.

-855 12/93

Installation

9TT

Page 12

1. Battery

Charger Assembly (see parts lists)

Figure 8. Battery Charger Installation—Solid-State Transfer Switch

2.

Captive Nuts (29881

1) qty

1

2

BW-29500-B294241-B

. 4

10 TT

Installation

-855 12/93

Page 13

Disconnecting Charger

(When Replacing or Servicing Battery)

WARNING

Explosion.

Can cause severe injury or death. Relays in

battery charger cause arcs or sparks.

Locate in a well ventilated area. Keep explosive

fumes away.

Explosion

gases

flame or spark to occur near a battery at any time,

particularly

terminals

sparks that could cause an explosion. Remove

wristwatch,

battery. Never connect negative (–) battery cable to

positive (+) connection terminal of starter solenoid. Do

not

test battery condition by shorting terminals together

or sparks could ignite battery gases or fuel vapors. Any

compartment containing batteries must be well

ventilated to prevent accumulation of explosive gases.

To avoid sparks, do not disturb battery charger

connections

turn charger off before disconnecting battery

connections. When disconnecting battery, remove

negative lead first and reconnect it last.

can cause severe injury or death. Battery

can cause an explosion. Do not smoke or permit

when it is being charged. A

with tools,

rings, and any other jewelry before handling

while battery is being charged and always

etc. to prevent burns and to prevent

void contacting

Sulfuric

death. Sulfuric acid in battery can cause permanent

damage to eyes, burn skin, and eat holes in clothing.

Always

around the battery. If battery electrolyte

the

for

case of eye contact, seek immediate medical aid. Never

add acid to a battery once

service.

electrolyte.

Accidental starting.

Can cause severe injury or death.

Disconnect battery cables before working on

generator set (negative lead first and reconnect it

last).

Accidental starting can cause severe injury or

death. Turn generator master switch to OFF position,

disconnect power to battery charger, and remove

battery cables (remove negative lead first and

reconnect

on any equipment connected to generator. The

generator set can be started by automatic transfer

switch or remote start/stop switch unless these

precautions are followed.

acid in batteries

wear splash-proof safety goggles when working

eyes or

15 minutes with large quantities of clean water

on skin, immediately flush the af

Doing so may result in

WARNING

it last) to disable generator set before working

can cause severe injury or

is splashed in

fected area

. In

the

battery has been placed in

hazardous spattering of

the

WARNING

Sulfuric acid in batteries.

Can cause severe injury or death.

Use protective goggles and clothes. Can cause

permanent

in clothing.

-855 12/93

damage to eyes, burn skin, and eat holes

1. Move generator master switch to OFF position.

2. Remove AC power supply from battery charger.

3. Remove charger connectors from battery,

negative lead first.

Disconnection

11TT

Page 14

Battery Charger Operation

Charging Lead-Acid Batteries

WARNING

Sulfuric acid in batteries.

Can cause severe injury or death.

WARNING

Use protective goggles and clothes. Can cause

permanent

in clothing.

Sulfuric

death. Sulfuric acid in battery can cause permanent

damage to eyes, burn skin, and eat holes in clothing.

Always

around the battery. If battery electrolyte

the

eyes or

for

15 minutes with large quantities of clean water

case of eye contact, seek immediate medical aid. Never

add acid to a battery once

service.

electrolyte.

damage to eyes, burn skin, and eat holes

acid in batteries

wear splash-proof safety goggles when working

on skin, immediately flush the af

Doing so may result in

can cause severe injury or

is splashed in

fected area

. In

the

battery has been placed in

hazardous spattering of

the

WARNING

Explosion.

Can cause severe injury or death. Relays in

battery charger cause arcs or sparks.

Locate in a well ventilated area. Keep explosive

fumes away.

Explosion

gases

flame or spark to occur near a battery at any time,

particularly

terminals

sparks that could cause an explosion. Remove

wristwatch,

battery. Never connect negative (–) battery cable to

positive (+) connection terminal of starter solenoid. Do

not

test battery condition by shorting terminals together

or sparks could ignite battery gases or fuel vapors. Any

compartment containing batteries must be well

ventilated to prevent accumulation of explosive gases.

To avoid sparks, do not disturb battery charger

connections

turn charger off before disconnecting battery

connections. When disconnecting battery, remove

negative lead first and reconnect it last.

can cause severe injury or death. Battery

can cause an explosion. Do not smoke or permit

when it is being charged. A

with tools,

rings, and any other jewelry before handling

while battery is being charged and always

etc. to prevent burns and to prevent

void contacting

Hazardous voltage.

Can cause severe injury or death.

Do not operate generator set without all guards

and electrical enclosures in place.

Hazardous voltage can cause severe injury or

death. Electrical shock may occur if battery charger is

not properly grounded. Connect battery charger

enclosure

an alternative, run an equipment-grounding conductor

with circuit conductors and connect to

equipment-grounding terminal or lead on battery

charger. Battery charger installation should be

performed

comply with all local codes and ordinances.

(Applies to Optional Battery Charger.)

12 TT

to ground of a permanent wiring

as prescribed in equipment manual and must

Operation

Moving rotor.

system. As

Charge

following procedure.

6- or 12-cell lead-acid batteries according to the

1. Inspect battery for defective cables, loose posts,

or loose terminals. Battery terminals and battery

charger clips must be tight and cleaned of all

corrosion for efficient charging.

2. Check

the fluid level in each cell. If fluid

add

distilled water until fluid is at proper level. (No

maintenance is required for sealed batteries.)

When

using a dry-charge battery

be

given a conditioning charge immediately after

the

electrolyte fluid

charger will not operate properly on this type of

battery unless it has been given a conditioning

charge. Follow the battery manufacturer’s

recommendations for length of charge.

has been added. An automatic

level is low

, the battery must

-855 12/93

,

Page 15

3. The charge rate the charger is delivering to the

battery

is indicated on the ammeter

. The charger

control circuit limits the maximum charging

current to 2 amps. No cranking disconnect is

required due to the current-limit protection

feature. A battery is almost fully charged when

one of the following occurs:

Charging

rate will taper to zero.

This occurs as

battery becomes charged and the battery voltage

approaches the control voltage setting. The

ammeter needle may fluctuate, indicating a

continuous supply of pulsating current that

automatically keeps the battery in a charged

condition.

Specific gravity reading (using a hydrometer)

should be between 1.250 and 1.285 at an

electrolyte temperature of 80_F (26.7_C). This

hydrometer reading indicates a battery that is in

good condition.

a

Bubbles appear at the surface of the battery

fluid. This indicates a battery that is 80 to 85%

charged. Vigorous bubbling occurs when the

battery is near full charge.

D As

a battery becomes charged

and the battery

voltage approaches the control voltage

setting,

the charging rate will taper to zero. The

ammeter needle may fluctuate, indicating a

continuous supply of pulsating current that

automatically keeps the battery in a charged

condition.

D A battery in good condition should have a

specific gravity reading (using a hydrometer)

between 1.250 and 1.285 at an electrolyte

temperature

of 80_F (26.7_C). See “Checking

Specific Gravity.”

D When

a battery reaches 80-85% of full charge,

bubbles appear on the surface of fluid.

Vigorous bubbling occurs when the battery is

near full charge.

-855 12/93

Operation

13TT

Page 16

Checking Specific Gravity (Lead-Acid Batteries)

Use

a battery hydrometer to check the specific gravity of

the electrolyte in each battery cell. While holding the

hydrometer

at the top of the electrolyte level. The battery is fully

charged if the specific gravity is 1.260 at an electrolyte

temperature

specific gravities of each cell should not exceed 0.01.

The battery should be charged if the specific gravity is

below 1.215 at an electrolyte temperature of 80_F

(26.7_C). The temperature of the battery electrolyte

will affect the specific gravity reading and

taken into consideration when checking battery

specific gravity. If the hydrometer used does not

have a temperature correction table, use the one

shown in Figure 9.

vertically

of 80

_F (26.7_

, read the number on the glass bulb

C). The dif

ference between

must be

_C _F

71.1

65.6

60.0

54.4

48.9

43.3

37.8

32.2

26.7

21.1

15.6

10

4.4

1.1

6.7

12.2

160

150

140

130

120

110

100

90

80

70

60

50

40

30

20

10

Correction

+ .032

+ .030

+ .028

+ .026

+ .024

+ .022

+ .020

+ .018

+ .016

+ .014

+ .012

+ .010

+ .008

+ .006

+ .004

+ .002

0

.002

.004

. 006

.008

.010

.012

.014

.016

.018

.020

.022

.024

.026

.028

EXAMPLE

T

(26.7_C)

Hydrometer Reading 1.250

Acid T

20_

Subtract .024 Sp. Gravity

Corrected Sp. Gravity is 1.226

EXAMPLE NO

T

(26.7_C)

Hydrometer Reading 1.235

Acid T

(37.8_C)

Add .008 Sp. Gravity

Corrected Sp. Gravity is 1.243

NO

. 1

emperature below 80

emperature

F (6.7

_C)

. 2

emperature above 80

emperature 100_F

_F

_F

Charging Nickel-Cadmium Batteries

Since charging recommendations vary between

manufacturers of nickel-cadmium batteries, specific

nickel-cadmium battery charging instructions are not

provided

nickel-cadmium battery for specific charging and

14 TT

in this manual. Contact the manufacturer of

Operation

the

The Temperature correction amounts to about .004 (4

“points”)

of specific gravity for each 10_F (5.5_C) change in

temperature.

Figure 9. Specific Gravity Temperature Correction

maintenance instructions. If the voltage setting

recommended by the battery manufacturer is different

from the battery charger’s factory setting, call battery

charger manufacturer for the procedure for properly

adjusting the battery charger.

-855 12/93

Page 17

Charger Voltage Adjustment

The

battery charger’s output settings are factory set and

normally

is

required, contact

or service literature. The factory settings are listed

below.

require no customer

an authorized distributor for service

adjustment. If adjustment

Charger and Battery Maintenance

WARNING

Hazardous voltage.

Can cause severe injury or death.

Do not operate generator set without all guards

and electrical enclosures in place.

Hazardous voltage can cause severe injury or

death. Electrical shock may occur if battery charger is

not properly grounded. Connect battery charger

enclosure

an alternative, run an equipment-grounding conductor

with circuit conductors and connect to

equipment-grounding terminal or lead on battery

charger. Battery charger installation should be

performed

comply with all local codes and ordinances.

to ground of a permanent wiring

as prescribed in equipment manual and must

(Applies to Optional Battery Charger.)

Hazardous voltage can cause severe injury or

death. Improper reconnection may damage charger

and

battery(ies), and

Installation must be done by a qualified electrician.

create an electrical shock hazard.

(Applies to Optional Battery Charger.)

Hazardous voltage can cause severe injury or

death. Short circuits can cause bodily injury and/or

equipment damage. Do not contact electrical

connections

made.

cause short circuits.

with tools or jewelry while adjustments are

Remove wristwatch, rings, and jewelry that can

Moving rotor.

system. As

Factory Output Settings

Charger

Voltage

12 V 13.2 V 2 A

24 V 26.4 V 2 A

WARNING

Sulfuric acid in batteries.

Can cause severe injury or death.

Use protective goggles and clothes. Can cause

permanent

in clothing.

Sulfuric

death. Sulfuric acid in battery can cause permanent

damage to eyes, burn skin, and eat holes in clothing.

Always

around the battery. If battery electrolyte

the

eyes or

for

15 minutes with large quantities of clean water

case of eye contact, seek immediate medical aid. Never

add acid to a battery once

service.

electrolyte.

Warranty repairs must be made through an

dealer.

1. Check battery terminals and charger connectors

2. Check battery fluid level regularly; maintain

damage to eyes, burn skin, and eat holes

acid in batteries

wear splash-proof safety goggles when working

on skin, immediately flush the af

Doing so may result in

for clean contact surfaces. Clean battery

terminals and charger connectors as necessary

with a mild baking soda/water solution. If battery

charger does not work, see Troubleshooting

section.

battery fluid at proper level.

Float

Voltage

can cause severe injury or

the

battery has been placed in

hazardous spattering of

NOTE

Current

Limit

is splashed in

fected area

authorized

. In

the

-855 12/93

Operation

15TT

Page 18

Troubleshooting

Problem Remedy

No Ammeter Reading 1. Check charger connections to battery for correct polarity.

2. Turn off AC supply prior to rechecking the battery charger for clean, tight

connections.

3. Check for AC at the charger terminal strip.

4. Check AC input and DC output fuses.

5. Check

6. With AC supply disconnected, check DC output lead connections from

secondary voltage at transformer: 24 volts across

volts to center tap.

circuit board to DC output terminal block.

secondary

, with 12

Needle Remains at 2 Amps

Indefinitely

1. Battery charger not matched to battery voltage.

2. Battery may be severely discharged or have shorted cells.

16 TT

Troubleshooting

-855 12/93

Page 19

Standard Accessories

Current Limiting

The charger is protected from overload by its

current-limiting circuitry. This circuitry continuously

monitors

the charger output current and is set to limit the

Reverse Polarity Protection

When the charger is connected to the battery, the

reverse polarity protection circuit determines if the

connection is of the proper polarity. If the polarity is

Automatic Float Operation

When the charger is properly connected to the battery

and AC power is applied to the charger, the charger

operates in the constant-current mode until the battery

voltage

level, the charger will switch to the constant-voltage

rises to the preset float level. At the preset float

Temperature Compensation

current to 2 amps from full load to short circuit.

Therefore, no crank disconnect is required when the

plant is exercised.

incorrect,

connected.

float

float mode until AC input power is lost or the current

required to maintain the battery at the float voltage

setting exceeds 2 amps.

the charger will not turn on when

mode. The charger will operate in constant-voltage

AC input is

The charger will provide temperature compensation of

–2 mV/_

of –40_C (–40_F) to +60_C (+140_F). This feature will

automatically adjust the float voltage setting

C per cell over the ambient temperature

to

prevent

range

AC Input Fuse

When

AC input is applied, the AC input fuse will open to

protect the power transformer from damage due to a

short circuit condition. The fuse may also open if

DC Output Fuse

The DC output fuse will open and protect the power

transformer

been

from damage if the current limit setting

disabled or set to its maximum. It will also open if

has

Power On Lamp

The Power On lamp is connected across the power

transformer ’s primary winding and indicates when AC

power is present.

the battery from being overcharged at high ambient

temperatures and undercharged at low ambient

temperatures.

subjected to vibration for an extended period of time.

Replace

charts in “Specifications” section for fuse value.

the charger output leads are shorted together for an

extended period of time.

the fuse to return the charger to operation. See

-855 12/93

Standard

Accessories

17TT

Page 20

Wiring Diagrams

WIRING DIAGRAM

AMMETER

ON

B+

AC

CT

AC

B–

ORANGE

VIOLET

ORANGE

YEL

YEL

CONTROL

BOARD

1

1.5

SCHEMATIC

DC

OUTPUT

6

AMP

AC

INPUT

AMP—12 V

AMP—24 V

BLK

POWER

ON

–ACAC+

TERMINAL

BLOCK

RED

BLUE

WHT

RED

BLK

RED

RED

RED/BLUE OR RED/YELLOW

BLK/YEL

+

BLK/RED

TRANSFORMER

BLK

BLK/WHT

B+

WHT

GND.

ORANGE

TRANS.

GND.

RED

BLK

BLK /YEL

VIOLET

RED/BLUE

OR

RED/YELLOW

ORANGE

BLUE

RED

DC

A

AMMETER

POWER

ON

YEL

YEL

BLK

DC OUTPUT

6

AMP

WHT

BLK/

WHT

BLK/

RED

1

AMP—12 V

AC INPUT

, 1.5

WHT

AMP—24 V

BLK

AC AC

RED

+ –

TERMINAL

BLOCK

Figure 10. Wiring Diagram, Schematic—120-Volt Battery Charger

AC

CT

AC

ON

B–

CONTROL

BOARD

294262-A

18 TT

Wiring Diagrams

-855 12/93

Page 21

ON

B+

AC

CT

AC

B–

ORANGE

VIOLET

ORANGE

YEL

YEL

CONTROL

BOARD

WIRING DIAGRAM

OUTPUT

6

AC

INPUT

0.5

AMP—12 V

1

AMP—24 V

BLK

DC

AMP

POWER

ON

–ACAC+

TERMINAL

BLOCK

RED/BLUE OR RED/YELLOW

BLK

RED

WHT

AMMETER

RED

+

RED

BLUE

RED

TRANSFORMER

BLK

GND.

TRANS.

GND.

ORANGE

RED

VIOLET

RED/BLUE

RED/YELLOW

0.5

AMP—12 V

BLK

OR

AC INPUT

ORANGE

BLUE

, 1

AMP—24 V

SCHEMATIC

BLK

RED

DC

WHT

A

AMMETER

DC OUTPUT

6

AMP

AC AC

POWER

ON

RED

+

BLK

–

YEL

YEL

TERMINAL

BLOCK

B+

AC

AC

B–

CT

ON

CONTROL

BOARD

Figure 11. Wiring Diagram, Schematic—208-Volt Battery Charger

-855 12/93

294262-A

Wiring Diagrams

19TT

Page 22

WIRING DIAGRAM

AMMETER

ON

TRANS.

ORANGE

RED

B+

AC

CT

AC

B–

RED/YELLOW

ORANGE

VIOLET

ORANGE

YEL

YEL

CONTROL

BOARD

VIOLET

RED/BLUE

OR

0.5

SCHEMATIC

ORANGE

BLUE

OUTPUT

6

AC

INPUT

AMP—12 V

1

AMP—24 V

BLK

DC

AMP

RED

DC

A

POWER

ON

–ACAC+

TERMINAL

BLOCK

AMMETER

DC OUTPUT

6

AMP

RED/BLUE OR RED/YELLOW

BLK

RED

WHT

POWER

ON

BLK

RED

RED

YEL

YEL

BLK

+

BLUE

RED

TRANSFORMER

B+

AC

CT

AC

CONTROL

BOARD

ON

B–

GND.

GND.

0.5

BLK

AC INPUT

AMP—12 V

, 1

AMP—24 V

Figure 12. Wiring Diagram, Schematic—220-Volt Battery Charger

20 TT

Wiring Diagrams

BLK

WHT

AC AC

RED

+ –

TERMINAL

BLOCK

294262-A

-855 12/93

Page 23

WIRING DIAGRAM

AMMETER

ON

B+

AC

CT

AC

B–

ORANGE

VIOLET

ORANGE

YEL

YEL

CONTROL

BOARD

0.5

AMP—12 V

1

AMP—24 V

BLK

SCHEMATIC

DC

OUTPUT

6

AMP

AC

INPUT

POWER

ON

–ACAC+

TERMINAL

BLOCK

RED/BLUE OR RED/YELLOW

RED

BLK

BLK/WHT

RED

RED

BLK/YEL

BLUE

RED

+

TRANSFORMER

BLK/

RED

WHT

BLK

GND.

TRANS.

GND.

ORANGE

RED

BLK

BLK /YEL

VIOLET

RED/BLUE

OR

RED/YELLOW

WHT

BLK/

RED

0.5

AC INPUT

AMP—12 V

ORANGE

BLUE

, 1

AMP—24 V

RED

DC

A

BLK/WHT

BLK

AMMETER

DC OUTPUT

6

AMP

AC AC

POWER

ON

RED

+ –

BLK

YEL

YEL

TERMINAL

BLOCK

B+

AC

CT

AC

ON

B–

CONTROL

BOARD

294262-A

Figure 13. Wiring Diagram, Schematic—240-Volt Battery Charger

-855 12/93

Wiring Diagrams

21TT

Page 24

WIRING DIAGRAM

AMMETER

ON

TRANS.

ORANGE

RED

B+

AC

CT

AC

B–

RED/YELLOW

ORANGE

VIOLET

ORANGE

YEL

YEL

VIOLET

RED/BLUE

OR

CONTROL

BOARD

ORANGE

0.3

0.5

SCHEMATIC

BLUE

DC

OUTPUT

6

AMP

AC

INPUT

AMP—12 V

AMP—24 V

BLK

RED

DC

A

POWER

ON

TERMINAL

BLOCK

AMMETER

DC OUTPUT

6

AMP

–

RED/BLUE OR RED/YELLOW

RED

+

BLK

416

BLK/WHT

POWER

ON

BLK

RED

RED

+

BLUE

RED

TRANSFORMER

BLK

AC380

WHT

GND.

B+

AC

CT

AC

CONTROL

BOARD

YEL

YEL

ON

B–

BLK/

WHT

AMP—24 V

BLK

GND.

BLK

AC INPUT

0.3

AMP—12 V

WHT

, 0.5

Figure 14. Wiring Diagram, Schematic—380/416-Volt Battery Charger

22 TT

Wiring Diagrams

AC

380 416

RED

+ –

TERMINAL

BLOCK

294262-A

-855 12/93

Page 25

WIRING DIAGRAM

AMMETER

ON

B+

AC

CT

AC

B–

ORANGE

VIOLET

ORANGE

YEL

YEL

CONTROL

BOARD

OUTPUT

INPUT

0.2

AMP—12 V

0.4

AMP—24 V

BLK

SCHEMATIC

6

AC

DC

AMP

TERMINAL

BLOCK

POWER

ON

–AC480+

RED/BLUE OR RED/YELLOW

RED

600

BLK

RED

RED

BLK/WHT

+

BLUE

RED

TRANSFORMER

BLK

WHT

GND.

TRANS.

GND.

ORANGE

RED

BLK

AC INPUT

0.2

AMP—12 V

VIOLET

RED/BLUE

OR

RED/YELLOW

WHT

, 0.4

BLK

ORANGE

BLUE

BLK/

WHT

AMP—24 V

RED

DC

A

AC

AMMETER

DC OUTPUT

6

AMP

480 600

POWER

ON

RED

+ –

BLK

YEL

YEL

TERMINAL

BLOCK

B+

AC

CT

AC

ON

B–

CONTROL

BOARD

294262-A

Figure 15. Wiring Diagram, Schematic—480/600-Volt Battery Charger

-855 12/93

Wiring Diagrams

23TT

Page 26

Parts List

Kits PA-320741 and PAB-320741-SD

Description Qty. Part Number

Charger Assembly, 120/12-volt battery (includes *) 1 A-294226

Circuit Board Assembly, 12-volt ATS battery * 1 A-294239

Lead *

Lead *

Lead *

Lead *

1 LB-1806-15457

1 LR-1806-5757

1 LR-1808-15457

1 LW-1803-15400

Washer, #6 lock * 6 X-22-6

Washer, #8 lock * 2 X-22-7

Insulink Terminal * 1 X-367-3

Insulink Terminal * 1 X-367-4

Terminal * 1 X-431-25

Terminal * 2 X-431-29

Terminal * 3 X-431-30

Screw, 6-32 x 0.875 in. * 2 X-49-3

Screw, 8-32 x 0.500 in. * 4 X-51-15

Screw, 8-32 x 0.625 in. * 1 X-51-53

Spacer, fiber * 4 X-712-13

Fuse * 1 226520

Fuse * 1 226525

Holder, fuse * 2 238426

Ammeter * 1 293278

Transformer * 1 293279

Strip, terminal * 1 293281

Lamp * 1 293655

Cover, terminal block * 1 294214

Box, silkscreen * 1 294241

Decal, barrier * 1 294742

Retainer * 4 294759

Lead 1 T078-1814-1313

Lead 1 T079-1814-1313

Nut, captive 4 298811

* Indicates parts that are included with the charger assembly.

24 TT

Parts Lists

-855 12/93

Page 27

Parts

Kits PA-320742 and PAB-320742-SD

Description Qty. Part Number

Charger Assembly, 120/24-volt battery (includes *) 1 A-294227

Circuit Board Assembly, 24-volt ATS battery * 1 A-294240

List

Lead *

Lead *

Lead *

Lead *

Washer, #6 lock * 6 X-22-6

Washer, #8 lock * 2 X-22-7

Insulink Terminal * 1 X-367-3

Insulink Terminal * 1 X-367-4

Terminal * 1 X-431-25

Terminal * 2 X-431-29

Terminal * 3 X-431-30

Screw, 6-32 x 0.875 in. * 2 X-49-3

Screw, 8-32 x 0.500 in. * 4 X-51-15

Screw, 8-32 x 0.625 in. * 1 X-51-53

Spacer, fiber * 4 X-712-13

Fuse * 1 226520

1 LB-1806-15457

1 LR-1806-5757

1 LR-1808-15457

1 LW-1803-15400

Holder, fuse * 2 238426

Fuse, 1.5 amp * 1 291207

Ammeter * 1 293278

Transformer * 1 293279

Strip, terminal * 1 293281

Lamp * 1 293655

Cover, terminal block * 1 294214

Box, silkscreen * 1 294242

Decal, barrier * 1 294742

Retainer * 4 294759

Lead 1 T078-1814-1313

Lead 1 T079-1814-1313

Nut, captive 4 298811

* Indicates parts that are included with the charger assembly.

-855 12/93

Parts Lists

25TT

Page 28

Parts

Kits PA-320743 and PAB-320743-SD

Description Qty. Part Number

Charger Assembly, 208/12-volt battery (includes *) 1 A-294228

Circuit Board Assembly, 12-volt ATS battery * 1 A-294239

List

Lead *

Lead *

Lead *

Washer, #6 lock * 6 X-22-6

Washer, #8 lock * 2 X-22-7

Terminal * 1 X-431-25

Terminal * 2 X-431-29

Terminal * 3 X-431-30

Terminal * 1 X-431-46

Screw, 6-32 x 0.875 in. * 2 X-49-3

Screw, 8-32 x 0.500 in. * 4 X-51-15

Screw, 8-32 x 0.625 in. * 1 X-51-53

Spacer, fiber * 4 X-712-13

Fuse * 1 226520

Fuse * 1 226521

Holder, fuse * 2 238426

1 LB-1806-15457

1 LR-1806-15457

1 LR-1808-5757

Ammeter * 1 293278

Strip, terminal * 1 293281

Lamp * 1 293655

Transformer * 1 293659

Cover, terminal block * 1 294214

Box, silkscreen * 1 294243

Decal, barrier * 1 294742

Retainer * 4 294759

Lead 1 T078-1814-1313

Lead 1 T079-1814-1313

Nut, captive 4 298811

* Indicates parts that are included with the charger assembly.

26 TT

Parts Lists

-855 12/93

Page 29

Parts

Kits PA-320745 and PAB-320745-SD

Description Qty. Part Number

Charger Assembly, 240/12-volt battery (includes *) 1 A-294230

Circuit Board Assembly, 12-volt ATS battery * 1 A-294239

List

Lead *

Lead *

Lead *

Washer, #6 lock * 6 X-22-6

Washer, #8 lock * 2 X-22-7

Terminal * 1 X-431-25

Terminal * 2 X-431-29

Terminal * 3 X-431-30

Terminal * 1 X-431-46

Screw, 6-32 x 0.875 in. * 2 X-49-3

Screw, 8-32 x 0.500 in. * 4 X-51-15

Screw, 8-32 x 0.625 in. * 1 X-51-53

Spacer, fiber * 4 X-712-13

Fuse * 1 226520

Fuse * 1 226521

Holder, fuse * 2 238426

1 LB-1806-15457

1 LR-1806-15457

1 LR-1808-5757

Ammeter * 1 293278

Strip, terminal * 1 293281

Lamp * 1 293655

Cover, terminal block * 1 294214

Box, silkscreen * 1 294245

Decal, barrier * 1 294742

Retainer * 4 294759

Transformer * 1 295092

Lead 1 T078-1814-1313

Lead 1 T079-1814-1313

Nut, captive 4 298811

* Indicates parts that are included with the charger assembly.

-855 12/93

Parts Lists

27TT

Page 30

Parts

Kits PA-320746 and PAB-320746-SD

Description Qty. Part Number

Charger Assembly, 220/24-volt battery (includes *) 1 A-294231

Circuit Board Assembly, 24-volt ATS battery * 1 A-294240

List

Lead *

Lead *

Lead *

Washer, #6 lock * 6 X-22-6

Washer, #8 lock * 2 X-22-7

Terminal * 1 X-431-25

Terminal * 2 X-431-29

Terminal * 3 X-431-30

Terminal * 1 X-431-46

Screw, 6-32 x 0.875 in. * 2 X-49-3

Screw, 8-32 x 0.500 in. * 4 X-51-15

Screw, 8-32 x 0.625 in. * 1 X-51-53

Spacer, fiber * 4 X-712-13

Fuse * 1 226520

Fuse * 1 226525

Holder, fuse * 1 238426

1 LB-1806-15457

1 LR-1806-15457

1 LR-1808-5757

Ammeter * 1 293278

Strip, terminal * 1 293281

Lamp * 1 293655

Cover, terminal block * 1 294214

Box, silkscreen * 1 294246

Decal, barrier * 1 294742

Retainer * 4 294759

Transformer * 1 295092

Lead 1 T078-1814-1313

Lead 1 T079-1814-1313

Nut, captive 4 298811

* Indicates parts that are included with the charger assembly.

28 TT

Parts Lists

-855 12/93

Page 31

Parts

Kits PA-320747 and PAB-320747-SD

Description Qty. Part Number

Charger Assembly, 240/12-volt battery (includes *) 1 A-294232

Circuit Board Assembly, 12-volt ATS battery * 1 A-294239

List

Lead *

Lead *

Lead *

Washer, #6 lock * 6 X-22-6

Washer, #8 lock * 2 X-22-7

Insulink Terminal * 1 X-367-3

Terminal * 1 X-431-25

Terminal * 2 X-431-29

Terminal * 3 X-431-30

Terminal * 1 X-431-46

Screw, 6-32 x 0.875 in. * 2 X-49-3

Screw, 8-32 x 0.500 in. * 4 X-51-15

Screw, 8-32 x 0.625 in. * 1 X-51-53

Spacer, fiber * 4 X-712-13

Fuse * 1 226520

Fuse * 1 226521

1 LB-1806-15457

1 LR-1806-15457

1 LR-1808-5757

Holder, fuse * 2 238426

Ammeter * 1 293278

Transformer * 1 293279

Strip, terminal * 1 293281

Lamp * 1 293655

Cover, terminal block * 1 294214

Box, silkscreen * 1 294247

Decal, barrier * 1 294742

Retainer * 4 294759

Lead 1 T078-1814-1313

Lead 1 T079-1814-1313

Nut, captive 4 298811

* Indicates parts that are included with the charger assembly.

-855 12/93

Parts Lists

29TT

Page 32

Parts

Kits PA-320748 and PAB-320748-SD

Description Qty. Part Number

Charger Assembly, 240/24-volt battery (includes *) 1 A-294233

Circuit Board Assembly, 24-volt ATS battery * 1 A-294240

List

Lead *

Lead *

Lead *

Washer, #6 lock * 6 X-22-6

Washer, #8 lock * 2 X-22-7

Insulink Terminal * 1 X-367-3

Terminal * 1 X-431-25

Terminal * 2 X-431-29

Terminal * 3 X-431-30

Terminal * 1 X-431-46

Screw, 6-32 x 0.875 in. * 2 X-49-3

Screw, 8-32 x 0.500 in. * 4 X-51-15

Screw, 8-32 x 0.625 in. * 1 X-51-53

Spacer, fiber * 4 X-712-13

Fuse * 1 226520

Fuse * 1 226525

1 LB-1806-15457

1 LR-1806-15457

1 LR-1808-5757

Holder, fuse * 2 238426

Ammeter * 1 293278

Transformer * 1 293279

Strip, terminal * 1 293281

Lamp * 1 293655

Cover, terminal block * 1 294214

Box, silkscreen * 1 294248

Decal, barrier * 1 294742

Retainer * 4 294759

Lead 1 T078-1814-1313

Lead 1 T079-1814-1313

Nut, captive 4 298811

* Indicates parts that are included with the charger assembly.

30 TT

Parts Lists

-855 12/93

Page 33

Parts

Kits PA-320749 and PAB-320749-SD

Description Qty. Part Number

Charger Assembly, 380/416/12-volt battery (includes *) 1 A-294234

Circuit Board Assembly, 12-volt ATS battery * 1 A-294239

List

Lead *

Lead *

Lead *

Washer, #6 lock * 6 X-22-6

Washer, #8 lock * 2 X-22-7

Terminal * 1 X-431-25

Terminal * 2 X-431-29

Terminal * 3 X-431-30

Terminal * 2 X-431-46

Screw, 6-32 x 0.875 in. * 2 X-49-3

Screw, 8-32 x 0.500 in. * 4 X-51-15

Screw, 8-32 x 0.625 in. * 1 X-51-53

Spacer, fiber * 4 X-712-13

Fuse * 1 226520

Fuse * 1 226526

Holder, fuse * 1 238426

1 LB-1806-15457

1 LR-1806-15457

1 LR-1808-5757

Ammeter * 1 293278

Holder, fuse * 1 293652

Strip, terminal * 1 293653

Lamp * 1 293655

Cover, terminal block * 1 294215

Box, silkscreen * 1 294249

Decal, barrier * 1 294742

Retainer * 4 294759

Transformer * 1 295089

Lead 1 T078-1814-1313

Lead 1 T079-1814-1313

Nut, captive 4 298811

* Indicates parts that are included with the charger assembly.

-855 12/93

Parts Lists

31TT

Page 34

Parts

Kits PA-320750 and PAB-320750-SD

Description Qty. Part Number

Charger Assembly, 380/416/24-volt battery (includes *) 1 A-294235

Circuit Board Assembly, 24-volt ATS battery * 1 A-294240

List

Lead *

Lead *

Lead *

Washer, #6 lock * 6 X-22-6

Washer, #8 lock * 2 X-22-7

Terminal * 1 X-431-25

Terminal * 2 X-431-29

Terminal * 3 X-431-30

Terminal * 2 X-431-46

Screw, 6-32 x 0.875 in. * 2 X-49-3

Screw, 8-32 x 0.500 in. * 4 X-51-15

Screw, 8-32 x 0.625 in. * 1 X-51-53

Spacer, fiber * 4 X-712-13

Fuse * 1 226520

Holder, fuse * 1 238426

Ammeter * 1 293278

1 LB-1806-15457

1 LR-1806-15457

1 LR-1808-5757

Holder, fuse * 1 293652

Strip, terminal * 1 293653

Lamp * 1 293655

Cover, terminal block * 1 294215

Box, silkscreen * 1 294250

Fuse * 1 294552

Decal, barrier * 1 294742

Retainer * 4 294759

Transformer * 1 295089

Lead 1 T078-1814-1313

Lead 1 T079-1814-1313

Nut, captive 4 298811

* Indicates parts that are included with the charger assembly.

32 TT

Parts Lists

-855 12/93

Page 35

Parts

Kits PA-320751 and PAB-320751-SD

Description Qty. Part Number

Charger Assembly, 480/600/12-volt battery (includes *) 1 A-294236

Circuit Board Assembly, 12-volt ATS battery * 1 A-294239

List

Lead *

Lead *

Lead *

Washer, #6 lock * 6 X-22-6

Washer, #8 lock * 2 X-22-7

Terminal * 1 X-431-25

Terminal * 2 X-431-29

Terminal * 3 X-431-30

Terminal * 2 X-431-46

Screw, 6-32 x 0.875 in. * 2 X-49-3

Screw, 8-32 x 0.500 in. * 4 X-51-15

Screw, 8-32 x 0.625 in. * 1 X-51-53

Spacer, fiber * 4 X-712-13

Fuse * 1 226520

Fuse * 1 226527

Holder, fuse * 1 238426

1 LB-1806-15457

1 LR-1806-15457

1 LR-1808-5757

Ammeter * 1 293278

Transformer * 1 293649

Holder, fuse * 1 293652

Strip, terminal * 1 293653

Lamp * 1 293655

Cover, terminal block * 1 294215

Box, silkscreen * 1 294251

Decal, barrier * 1 294742

Retainer * 4 294759

Lead 1 T078-1814-1313

Lead 1 T079-1814-1313

Nut, captive 4 298811

* Indicates parts that are included with the charger assembly.

-855 12/93

Parts Lists

33TT

Page 36

Parts

Kits PA-320752 and PAB-320752-SD

Description Qty. Part Number

Charger Assembly, 480/600/24-volt battery (includes *) 1 A-294237

Circuit Board Assembly, 24-volt ATS battery * 1 A-294240

List

Lead *

Lead *

Lead *

Washer, #6 lock * 6 X-22-6

Washer, #8 lock * 2 X-22-7

Terminal * 1 X-431-25

Terminal * 2 X-431-29

Terminal * 3 X-431-30

Terminal * 2 X-431-46

Screw, 6-32 x 0.875 in. * 2 X-49-3

Screw, 8-32 x 0.500 in. * 4 X-51-15

Screw, 8-32 x 0.625 in. * 1 X-51-53

Spacer, fiber * 4 X-712-13

Fuse * 1 226520

Fuse * 1 226528

Holder, fuse * 1 238426

1 LB-1806-15457

1 LR-1806-15457

1 LR-1808-5757

Ammeter * 1 293278

Transformer * 1 293649

Holder, fuse * 1 293652

Strip, terminal * 1 293653

Lamp * 1 293655

Cover, terminal block * 1 294215

Box, silkscreen * 1 294252

Decal, barrier * 1 294742

Retainer * 4 294759

Lead 1 T078-1814-1313

Lead 1 T079-1814-1313

Nut, captive 4 298811

* Indicates parts that are included with the charger assembly.

34 TT

Parts Lists

-855 12/93

Page 37

TT-855 12/93b

E

1993. All rights reserved.

Loading...

Loading...