Page 1

Service and Parts

Automatic Transfer Switches

Models:

M340+

Logic:

Microprocessor

U.S.A. Plant ISO Registered

TP-5672 11/95d

Page 2

Table of Contents

SUBJECT PAGE SUBJECT PAGE

Safety Precautions and Instructions I. . . . . . . . . . .

Introduction i. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of Related Manuals i. . . . . . . . . . . . . . . . . . . . . . . .

Service Assistance i. . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 1. Specifications 1-1. . . . . . . . . . . . . . . . . . .

Purpose of Switch 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Components of Switch 1-1. . . . . . . . . . . . . . . . . . . . . . .

Ratings 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interpreting a Transfer Switch Part Number 1-3. . . . .

Specifications 1-4.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Features 1-4. . . . . . . . . . . . . . . . . . . . . . .

Shunt-Jumper-Controlled Accessories 1-5. . . . . .

Optional Features 1-5. . . . . . . . . . . . . . . . . . . . . . . .

Section 2. Operation 2-1. . . . . . . . . . . . . . . . . . . . . . .

LED Indicators 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Switches and Indicators 2-2. . . . . . . . . . . . . . .

Sequence of Operation 2-3. . . . . . . . . . . . . . . . . . . . . . .

Normal Source Failure 2-3. . . . . . . . . . . . . . . . . . . .

Normal Source Restoration 2-4. . . . . . . . . . . . . . .

Sequence of Operation Programmed Transition 2-6.

Normal Source Failure 2-6. . . . . . . . . . . . . . . . . . . .

Normal Source Restoration 2-7. . . . . . . . . . . . . . .

To Disconnect The P1 Plug 2-9. . . . . . . . . . . . . . . . . . .

Electrical Operation Test 2-9. . . . . . . . . . . . . . . . . . . . .

Section 3. Troubleshooting Guide 3-1. . . . . . . . . .

Section 4. Controller Troubleshooting 4-1. . . . . .

Power to the System 4-2. . . . . . . . . . . . . . . . . . . . . . . . .

Keypad And Status Panel 4-3. . . . . . . . . . . . . . . . . . . .

Normal Source Voltage and Frequency 4-6.. . . . . . . .

Emergency Source Voltage and Frequency 4-9.. . . .

System-Status, Not-In-Automatic Error 4-11.. . . . . . .

System-Status, System-Alert 4-12. . . . . . . . . . . . . . . .

Contactor Position Fault Error Messages 4-12. . . . . .

Transfer Hang Error Message 4-12. . . . . . . . . . . . . . . .

Power-Down Error Message 4-12. . . . . . . . . . . . . . . . .

RAM Or Memory Error Message 4-13. . . . . . . . . . . . .

Manual Transfer Message 4-13. . . . . . . . . . . . . . . . . . .

Manual-to-Off Transfer Message 4-13.. . . . . . . . . . . .

Fault #1 Or Fault #2 Message 4-14.. . . . . . . . . . . . . . .

Programming Mode Not-In-Off 4-15. . . . . . . . . . . . . . .

Engine Operates When it Should Not 4-16. . . . . . . . .

Engine Will Not Start 4-18.. . . . . . . . . . . . . . . . . . . . . . .

Area Protection 4-20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shunt Jumper-Controlled Options 4-21. . . . . . . . . . . . .

Inphase Monitor 4-23. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Source Monitors 4-24. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plant Exerciser 4-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time Delays 4-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Override 4-33. . . . . . . . . . . . . . . . . . . . . . . . . . .

Off Delays 4-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 5. Accessory Troubleshooting 5-1. . . . . .

Optional Accessories 5-2. . . . . . . . . . . . . . . . . . . . . . . .

Emergency Source Three-Phase Phase Option 5-2.

Test Switches 5-4.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time Delay Override Option 5-10. . . . . . . . . . . . . . . . .

Preferred Source Switch 5-14.. . . . . . . . . . . . . . . . . . .

Relay Auxiliary Dry Contacts 5-15. . . . . . . . . . . . . . . . .

Main Shaft Auxiliary Dry Contacts 5-22. . . . . . . . . . . .

Meters 5-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Charger 5-47. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Operation Switches 5-54. . . . . . . . . . . . . . . . . .

Load Shedding Contacts 5-63. . . . . . . . . . . . . . . . . . . .

Remote Communication—RS/232 Or RS/485 5-65. .

Section 6. Service Parts 6-1. . . . . . . . . . . . . . . . . . . .

Introduction 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inner Panel 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time Delay 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Source monitors 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Switches 6-5.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time Delay Override Switches 6-5.. . . . . . . . . . . . . . .

Preferred-Source Switches 6-5. . . . . . . . . . . . . . . . . . .

Auxiliary Contacts—Relay 6-5. . . . . . . . . . . . . . . . . . . .

Auxiliary Contacts—Main Shaft 6-5. . . . . . . . . . . . . . . .

Meters 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plant Exercisers 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Chargers 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Source Monitors—Normal and Emergency 6-12. . . .

Load-Shed Contacts 6-12.. . . . . . . . . . . . . . . . . . . . . . .

Time Delays 6-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A. Glossary of Abbreviations A-1.. . . .

Appendix B. General Controller Information B-1.

Appendix C. Commonly Used Accessories C-1. .

Page 3

Safety Precautions and Instructions

A transfer switch, like any other electromechanical

device, can pose potential dangers to life and limb if

improperly maintained or imprudently operated. The

best way to prevent accidents is to be aware of the

potential dangers and to always use good common

sense. Below are some general precautions relating to

theoperation ofa transfer switch. This manual contains

several types of safety precautions which are explained

below. SAVE THESE INSTRUCTIONS.

DANGER

Danger indicates the presence of a hazard that will

cause severe personal injury, death, or substantial

property damage if the danger is ignored.

WARNING

Warning indicates the presence of a hazard that can

cause severe personal injury, death, or substantial

property damage if the warning is ignored.

NOTE

Note communicates installation, operation, or

maintenance information that is important but not

hazard related.

Safety decals are affixed to the generator set in

prominent places to advise the operator or service

technician of potential hazards. The decals are

reproduced here to improve operator recognition. For a

further explanation of decal information, refer to the

safety precautions throughout this manual. Before

operating or servicing the generator set, be sure you

understand the messages of these decals. Replace

decals if missing or damaged.

Safety decals are affixed to the transfer switch in

prominent places to advise the operator or service

technician of potential hazards. The decals are

reproduced here to improve operator recognition. For a

further explanation of decal information, refer to the

safety precautions throughout this manual. Before

operating or servicing the transfer switch, be sure you

understand the messages of these decals. Replace

decals if missing or damaged.

CAUTION

Caution indicates the presence of a hazard that will or

can cause minor personal injury or property damage if

the caution is ignored.

TP-5672 11/95

Safety Precautions and Instructions I

Page 4

Accidental Starting

WARNING

Accidental starting.

Can cause severe injury or death.

Disconnect battery cables before working on

generator set (negative lead first and reconnect it

last).

Accidental starting can cause severe injury or

death. Turn generator set master switch to OFF

position, disconnect power to battery charger, and

remove battery cables (remove negative lead first and

reconnectitlast)to disable generator setbeforeworking

on any equipment connected to generator set. The

generator set can be started by automatic transfer

switch or remote start/stop switch unless these

precautions are followed.

II Safety Precautions and Instructions TP-5672 11/95

Page 5

Battery

WARNING

Sulfuric acid in batteries.

Can cause severe injury or death.

Use protective goggles and clothes. Battery acid can

cause permanent damage to eyes, burn skin, and eat

holes in clothing.

WARNING

Explosion.

Can cause severe injury or death. Relays in

battery charger cause arcs or sparks.

Locate in a well-ventilated area. Keep explosive

fumes away.

Sulfuric acid in batteries can cause severe injury or

death. Sulfuric acid in battery can cause permanent

damage to eyes, burn skin, and eat holes in clothing.

Alwayswear splash-proofsafety goggleswhen working

around the battery. If battery electrolyte is splashed in

the eyes or on skin, immediately flush the affected area

for15 minutes withlargequantities of cleanwater. Seek

immediatemedicalaidin the caseofeyecontact. Never

addacidtoa battery once thebatteryhasbeen placed in

service. This may result in hazardous spattering of

electrolyte.

Sulfuric acid in batteries can cause severe injury or

death. Sulfuric acid in battery can cause permanent

damage to eyes, burn skin, and eat holes in clothing.

Alwayswear splash-proofsafety goggleswhen working

around the battery. If battery electrolyte is splashed in

the eyes or on skin, immediately flush the affected area

with large quantities of clean water. Continue flushing

with water until emergency help arrives Seek

immediatemedicalaidin the caseofeyecontact. Never

addacidtoa battery once thebatteryhasbeen placed in

service. This may result in hazardous spattering of

electrolyte.

Explosioncancause severe injury or death. Battery

gases can cause an explosion. Do not smoke or permit

flame or spark to occur near a battery at any time,

particularly when it is being charged. Avoid contacting

terminals with tools, etc., to prevent burns and sparks

that could cause an explosion. Remove wristwatch,

rings, and any other jewelry before handling battery.

Never connect negative (--) battery cable to positive (+)

connection terminal of starter solenoid. Do not test

batterycondition by shortingterminals together. Sparks

could ignite battery gases or fuel vapors. Ventilate any

compartment containing batteries to prevent

accumulation of explosive gases. To avoid sparks, do

not disturb battery charger connections while battery is

being changed. Always turn battery charger off before

disconnecting battery connections. Remove negative

lead first and reconnect it last when disconnecting

battery.

TP-5672 11/95

Safety Precautions and Instructions III

Page 6

Hazardous Voltage/

Electrical Shock

DANGER

Hazardous voltage.

Will cause severe injury or death.

Do not open enclosure until all power sources are

disconnected.

(600 Volt and above)

DANGER

Hazardous voltage.

Will cause severe injury or death.

Disconnect power sources before servicing.

Barrier must be installed after adjustments,

maintenance, or servicing.

(600 Volt and above)

WARNING

WARNING

Hazardous voltage.

Can cause severe injury or death.

Do not open enclosure until all power sources are

disconnected.

(under 600 Volt)

Hazardous voltage can cause severe injury or

death. Whenever electricity is present, there is the

hazardofelectrocution. Openmaincircuitbreaker on all

power sources before servicing equipment. Electrically

ground the generator set and electrical circuits when in

use. Never come into contact with electrical leads or

appliances when standing in water oron wet ground, as

the chance of electrocution is increased under such

conditions.

Hazardous voltage can cause severe injury or

death. Short circuits can cause bodily injury and/or

equipment damage. Do not contact electrical

connections with tools or jewelry while adjustments are

made. Remove wristwatch, rings, and jewelry that can

cause short circuits.

Hazardous voltage can cause severe injury or

death. To prevent the possibility of electrical shock,

disconnect harness plug before installing any

accessories involving connection to transformer

assembly primary terminals 76, 77, 78, and 79.

Terminals are at line voltage!

(S340, R340, and R33 models only.)

Hazardous voltage can cause severe injury or

Hazardous voltage.

Can cause severe injury or death.

Disconnect power sources before servicing.

Barrier must be installed after adjustments,

maintenance, or servicing.

(under 600 Volt)

IV Safety Precautions and Instructions TP-5672 11/95

death. To prevent the possibility of electrical shock,

disconnect harness plug before installing any

accessories involving connection to transformer

assembly primary terminals on microprocessor logic

models. Terminals are at line voltage!

Page 7

Hazardous voltage can cause severe injury or

death. To prevent the possibility of electrical shock,

de-energize the normal power source to be connected

to the transfer switch before makingany line or auxiliary

connections.

Hazardous voltage can cause severe injury or

death. De-energize bothnormal and emergencypower

sourcesbefore proceeding. Movegenerator set master

switch on controller to OFF position and disconnect

battery negative (--) before working on transfer switch!

Turn the transfer switch selector switch to the OFF

position.

Hazardous voltage can cause severe injury or

death. Disconnect inner panel harness at in-line

connector. This will de-energize circuit board and logic

circuitry, but allow transfer switch to continue to supply

utility power to necessary lighting and equipment.

Hazardousvoltage will exist ifanyaccessories mounted

to inner panel are NOT wired through the inner panel

harness and de-energized by in-line connector

separation. Such accessories are at line voltage.

TP-5672 11/95

Safety Precautions and Instructions V

Page 8

Heavy Equipment

WARNING

Unbalanced weight.

Improper lift can cause severe injury or death

and/or equipment damage.

Use adequate lifting capacity.

Never leave transfer switch standing upright

unless it is securely bolted in place or stabilized.

VI Safety Precautions and Instructions TP-5672 11/95

Page 9

Notes

NOTE

Hardware Damage! Transfer switch may use both

American standard and metric hardware. Use the

correct size tools to prevent rounding of bolt heads and

nuts.

NOTE

When replacing hardware, do not substitute with

inferior grade hardware. Screws and nuts are

available in different hardness ratings. American

Standard hardware uses a series of markings and

metric hardware uses a numeric system to indicate

hardness. Check markings on bolt head and nuts for

identification.

NOTE

A manual operator handle is provided on the transfer

switch for maintenance purposes only. Return the

transfer switch to the normal position. Remove manual

operator handle (if used) and store it on the transfer

switch in the placeprovided when service is completed.

NOTE

Perform voltage checks in the order given to avoid

damaging the switch.

NOTE

These battery chargers are designed strictly for use in

thistransfer switch andconform with ULand CSAlisting

requirements where specified. Do not use battery

charger before reading instructions.

NOTE

Connect source and load phases as indicated by the

markings and drawings. Improper connections may

causeshortcircuitsand can causephase-sensitiveload

devices to run in reverse or prevent load devices from

functioning.

NOTE

Charger Damage! Connect battery charger only to a

batterywith thesame DC voltage as the battery charger

output rating.

NOTE

Covertransferswitchduring installation to keepdirt,grit,

metal drill chips, etc., out of components. Cover

solenoid mechanism during installation. After

installation, use manual operating handle to position

contactor to ensure that it operates freely. Do not use a

screwdriver to force contactor mechanism.

TP-5672 11/95

Safety Precautions and Instructions VII

Page 10

Introduction

This manual covers the operation, troubleshooting,

repair,and service parts for the M340+ microprocessor

logic controller.

Read through this manual and carefully follow all

procedures and safety precautions to ensure proper

transferswitchoperationandtoavoidbodilyinjury.Keep

this manual with the transfer switchfor futurereference.

Service requirements are minimal but are very

important to the safe and reliable operation of the

transfer switch; therefore, inspect associated parts

often. It is recommended that an authorized service

distributor perform required servicing to keep the switch

in top condition.

All information found in this publication isbased on data

availableat timeof printing. The manufacturerreserves

the right to make changes to this literature and the

products represented at any time without notice and

without incurring obligation.

List of Related Manuals

The logic controller covered in this manual is part of a

family of related devices. Separate service and parts

manuals are available for each group within the overall

family. Be sure this manual is the correct manual for the

automatic transfer switch.

A power conversion unit is included in each automatic

transfer switch. There are three types of power

conversion units and each type is covered in a separate

service and parts manual. Available power conversion

units and the related manual numbers are as follows:

Service/

Power Switch Device

Mechanically held or

electrically held contactors

Molded-case circuit breakers

or switch

Standard contactor,

programmed transition, and

Bypass-Isolation

Parts Manual

TP-5667

TP-5666

TP-5668

Service Assistance

For sales and service in the U.S.A. and Canada check

the yellow pages of the telephone directory under the

headingGENERATORS—ELECTRICfor anauthorized

service distributor/dealer or call 1-800-544-2444.

KOHLER CO., Kohler, Wisconsin 53044 U.S.A.

Phone: 920-565-3381

Fax: 920-459-1646 (U.S.A. Sales)

920-459-1614 (International)

To ensure supply of correct parts or information, make

note of the following identification numbers in the

spaces provided:

PART NUMBER AND SERIAL NUMBER

Part and serial numbers are provided on the nameplate

attached to the transfer switch.

Part No.

Serial No.

TP-5672 11/95 Introduction i

Page 11

Notes

TP-5672 11/95Introduction ii

Page 12

Section 1. Specifications

Purpose of Switch

An automatic transfer switch (ATS)is a device used for

transferring critical electrical loads from a normal

(preferred) source of electrical power to an emergency

(standby) source. This transfer occurs automatically

when the normal source voltage fails, or is substantially

reduced, and the emergency source’s voltage has

reached an acceptable level.

Upon normal source failure, the automatic transfer

switchcontrollersignalsthe generator set(s)tostartand

Components of Switch

A typical automatic transfer switch includes the actual

power switching device and the logic controller to

perform power monitoring and transfer sequencing

tasks. See Figure 1-1. An interface board is also

included to match the controller inputs/outputs to the

levels required by a specific switching device.

The three functional units that make up the automatic

transfer switch are mounted in an enclosure with a

hinged front door. The controller mounts on the back of

thefront doorso its controls and indicatorsare available

to an operator. A signal cable with in-line connectors to

facilitate component replacement and door removal

connects the controller to the interface board and the

switching devices.

transfer to the emergency source. The automatic

transfer switch controller continuously senses for an

acceptable normal source and will retransfer the load to

the normal source after it has been restored to an

acceptable level. After retransfer of the load, the

generator set start signal is removed and the generator

set(s) is allowed to shut down.

1

2

TP-5672 11/95

3

1. Power Conversion Unit

2. Interface Panel

3. Logic Controller

Figure 1-1. Transfer Switch Components

Specifications 1-1

567111

Page 13

Normal

(Utility)

Power

Emergency (Generator) Power

Generator

Start

Generator

Power

Switching

Device

To Load

Figure 1-2. Basic Transfer Switch Block Diagram

Ratings

Anameplate is attachedtotheautomatic transfer switch

enclosure. See Figure 1-3. The nameplate label

includes a factory part number coded to provide

characteristic and rating information that affects

installationandoperation. Copy the partnumberinto the

blank spaces provided in the introduction and then use

the charts in Figure 1-4 to interpret the part number.

NOTE

Also copy the part number and serial number from the

nameplate into the spaces provided in the Service

Assistance Section of the Introduction for use when

requesting service or parts.

Interface

Logic

Controller

Automatic Transfer Switch

AUTOMATICTRANSFER SWITCH

PARTNO. ZCS-160341-0800

SERIAL NO.

VOLTS

PHASE

HERTZ

KOHLER CO. KOHLER WISCONSIN 53044

567112

KOHLER

AMPS

WIRES

POLES

295232

Figure 1-3. Transfer Switch Nameplate

1-2 Specifications TP-5672 11/95

Page 14

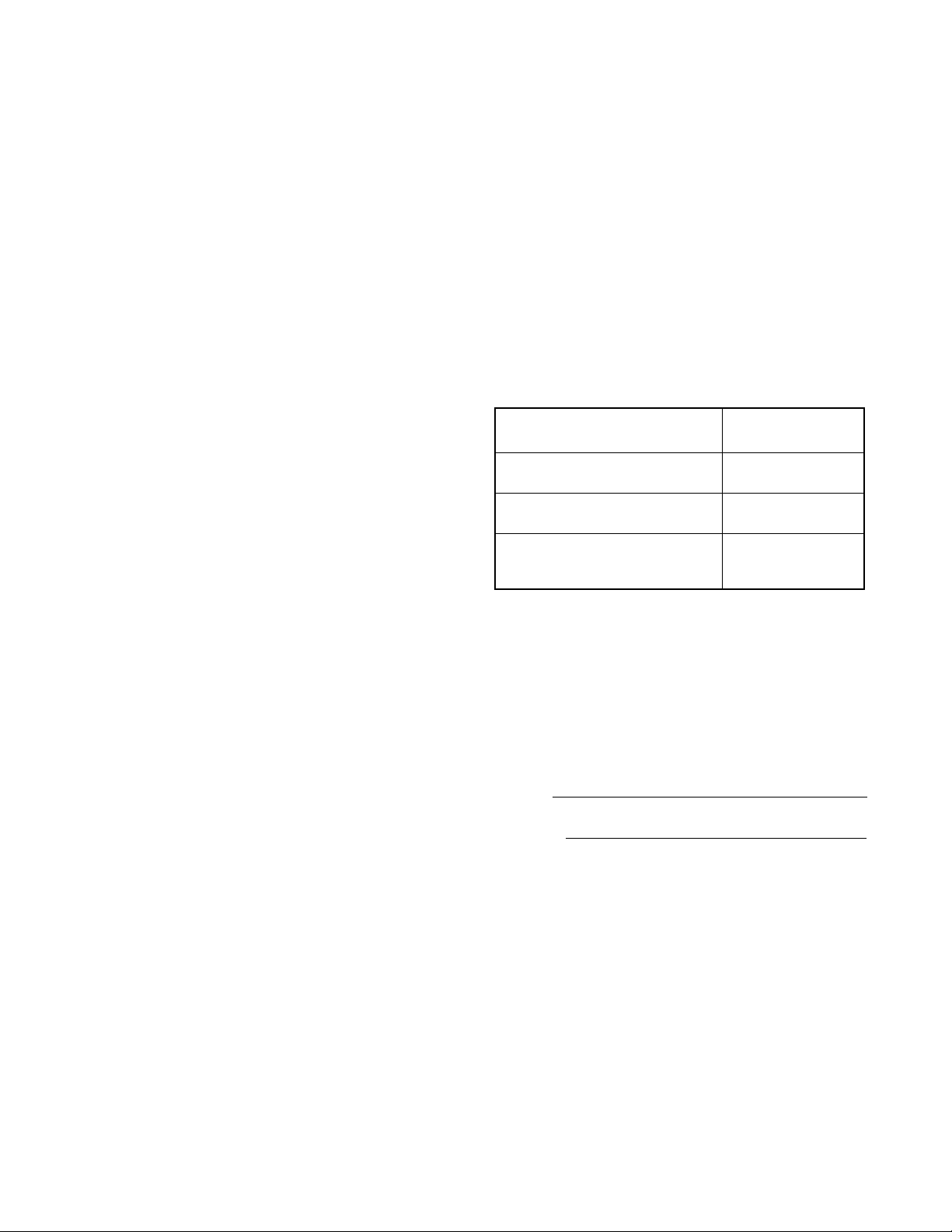

Interpreting a Transfer Switch Part Number

Record the transfer switch part number in the boxes below. The transfer switch part number defines

characteristics and ratings as explained in the accompanying chart.

Type of Switch Type of Logic Voltage & Frequency

Number of

Poles

Number of

Wires

Type of

Enclosure Amperage Rating Code

Kohler Part Number Key

This chart explains the Kohler transfer switch part numbering code system. The

sample part number shown is for a standard molded-case switch with M340+ logic

rated at 480 volts, 60 hertz, 3-phase, 3-pole, and 4 wires in a NEMA 1 enclosure with

an amperage rating of 80 amperes.

Classification of Power Switch

M: Switch or Circuit Breaker

T: Electrically & Mechanically Held

Z: Contactor Style

Type of Power Switch

C: Contactor

E: Electrically Held Contactor

L: Mechanically Held Contactor

M: Molded-Case Circuit Breaker

N: Molded-Case Switch (no protection)

Type of Switch

S: Standard

B: Bypass

Type of Logic

5: M340+

6: M340+ with programmed transition

Voltage Code

60:600 Volt, 60 Hz 66: 480 Volt, 60 Hz

62:120 Volt, 60 Hz 68: 208 Volt, 60 Hz

63:220 Volt, 50 Hz 71: 380 Volt, 50/60 Hz

64:240 Volt, 60 Hz

SAMPLE PART NUMBER

MNS-566341-0080

Number of Poles

2: 2 pole, 1 phase (MM_, MN_, TE_, TL_, devices

will be supplied with 3 poles)

3: 3 pole, 3 phase

6: 4 pole, fully rated switched poles

(no overlapping neutral)

Number of Wires

2: 2 wire

3: 3 wire

4: 4 wire

Enclosure

1: NEMA type 1

Amperes

Available sizes vary with the type of switch.

Figure 1-4. Transfer Switch Model Description

TP-5672 11/95

Specifications 1-3

Page 15

Specifications

The specifications listed below are for the M340+ logic

controller. See the respective power switching device

manual for its specifications.

Standard Features

D Normal source voltage sensing adjustable from

75% to 130% of normal for pickup and from 70% to

135% for dropout; provides monitoring line-to-line

for all phases of 3-phase switches.

D TDNE (Time Delay Normal-to-Emergency)

adjustable 0 to 5 minutes.

D TDES (Time Delay Engine Start) adjustable from

0 to 6 seconds.

D TDEN (Time Delay Emergency-to-Normal)

adjustable 0 to 30 minutes.

D Program Transition (Center off)—time delay

during transfer with neither source connected to

the load. Adjustable 0 to 2 minutes.

D LCD digital voltmeter.

D LCD digital running time meter.

D LCD digital transfer counter.

D LCD digital frequency meter.

D Status panel with keypad data entry.

D Area protection with override.

D TDEC (Time Delay Engine Cooldown) adjustable

from 0 to 30 minutes.

D Generator engine start contacts.

D Indicators for switch position—normal and

emergency.

D Indicators for source available—normal and

emergency.

D Lamp test switch, momentary.

D Underfrequency sensing—one phase emergency

source only.

1-4 Specifications TP-5672 11/95

Page 16

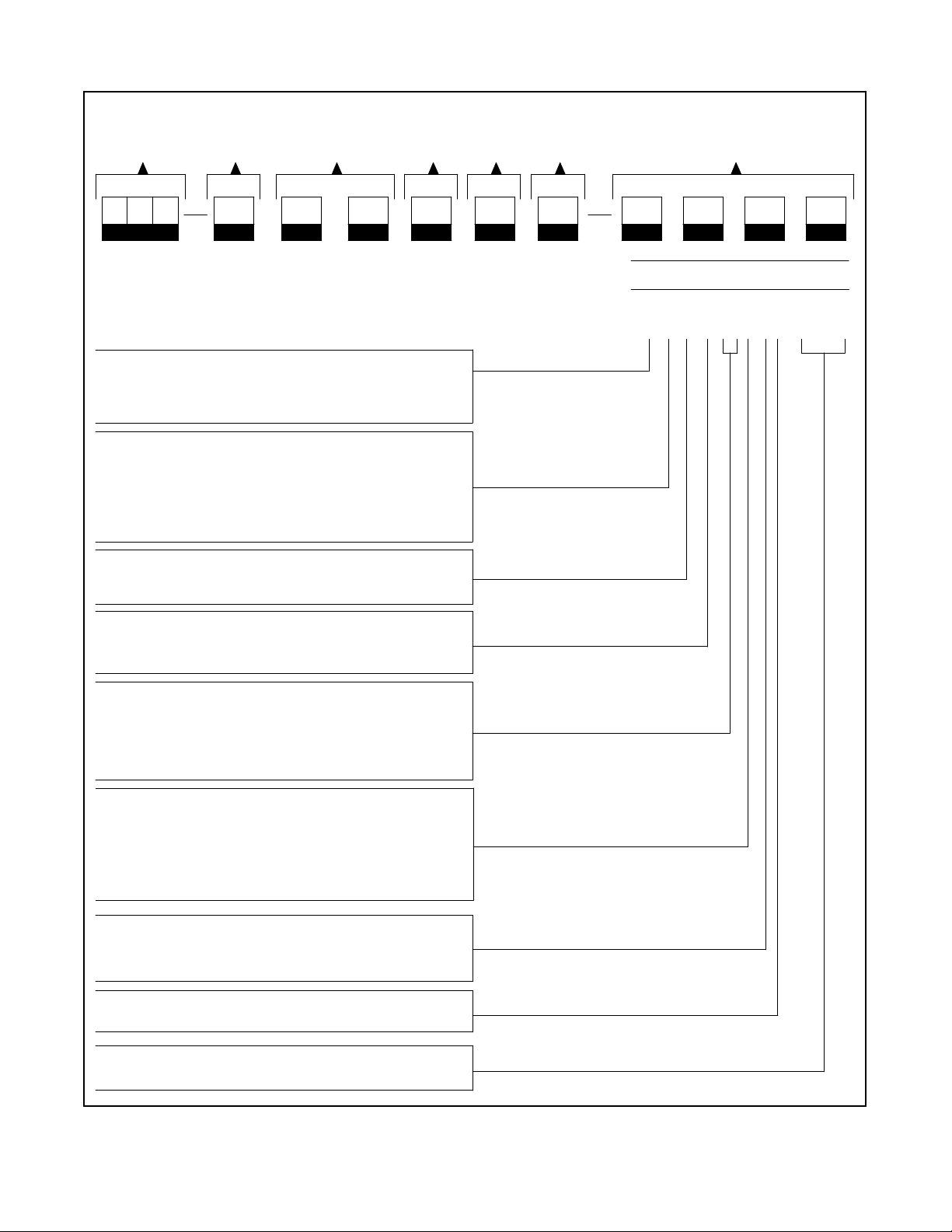

Shunt-Jumper-Controlled Accessories

Enable or disable shunt-jumper-controlled accessories

by altering socket JP1 on the main logic board. See

Figure 1-5. All shunt-jumper features are disabled from

thefactoryunlessthe function was ordered atthetimeof

purchase. But features can be enabled after factory

delivery by adding jumpers to the JP1 socket.

Main Logic Board

JP1

MANUAL

TIME

PLANT

VOLT/

PHASE

OFF

Figure 1-5. Logic Board Accessory Programming

Shunts

D Manual Override. Enabling manual override

allows automatic transfer to an available source

when the connected source fails. Transfer time

delays will be bypassed. Disabling manual

override causes the logic board to wait for manual

operation. The logic board will not automatically

seek the available source.

D Inphase Monitor. Abnormal inrush currents from

switching between two live power sources can

damage motors and related equipment. The

purpose of the inphase monitor is to minimize

abnormal inrush currents to equipment when the

ATS transfers from one source to a new power

source. The inphase monitor samples a single

phase of one source and compares it to a single

phase of the other source. When the two voltages

are within the desired phase angle and

approaching a zero phase angle difference, the

inphase monitor signals the transfer switch to

OVRIDE

DELAY

EXER

FREQ

SEQUENCER

MONITORIN-PHASE

DELAYS

567215

operate. The transfer may be from utility to

generator,from generator to generator,or utility to

utility.

NOTE

This option is available only on contactor type,

nonprogrammed transition switches. If the

contactor is not of this type, then the controller will

not allow this option to be enabled. Enable this

accessory by installing the INPHASE MONITOR

jumper on the controller’s main logic board.

D Phase Rotation and Anti-Single Phasing. This

function provides source monitoring for both the

normal and emergency sources. The feature

includesphaserotation(A B C only)andanti-single

phase protection. This option must be used in

conjunction with accessory DD-05-K in order to

provide source monitoring on the emergency side.

Enable this accessory by installing the PHASE

SEQUENCER jumper on the controller’s main

logic board.

D Normal and Emergency Source Sensing. This

function provides overvoltage sensing on all

phasesof the normalsource,over/underfrequency

sensing on one phase of the normal source,

overvoltage sensing on one phase of the

emergency source, and overfrequency sensing on

one phase of the emergency source. Enable this

accessory by installing theVOLT/FREQjumper on

the controller’s main logic board.

D Plant Exerciser. This function enables a no-load

plantexerciser.Userhasachoice of 7-day,14-day,

or calendar-based exercise modes. Enable this

accessory by installing the PLANT EXER jumper

on the controller’s main logic board.

D Extended Time Delay. This function extends the

time delay to 99 minutes for TDNE, TDES, TDEN,

TDOE, TDON, and TDEC. Enable this accessory

by installing the TIME DELAY jumper on the

controller’s main logic board.

D Off Position Time Delay. This function enables

the time delay during transfer when neither source

is connected to the load. Enable this accessory by

installing the OFF DELAYS jumper on the

controller’s main logic board.

Optional Accessories

See Appendix C for details of optional accessories. The

nameplate includes a list of the accessories selected.

See Figure 1-3.

TP-5672 11/95

Specifications 1-5

Page 17

Section 2. Operation

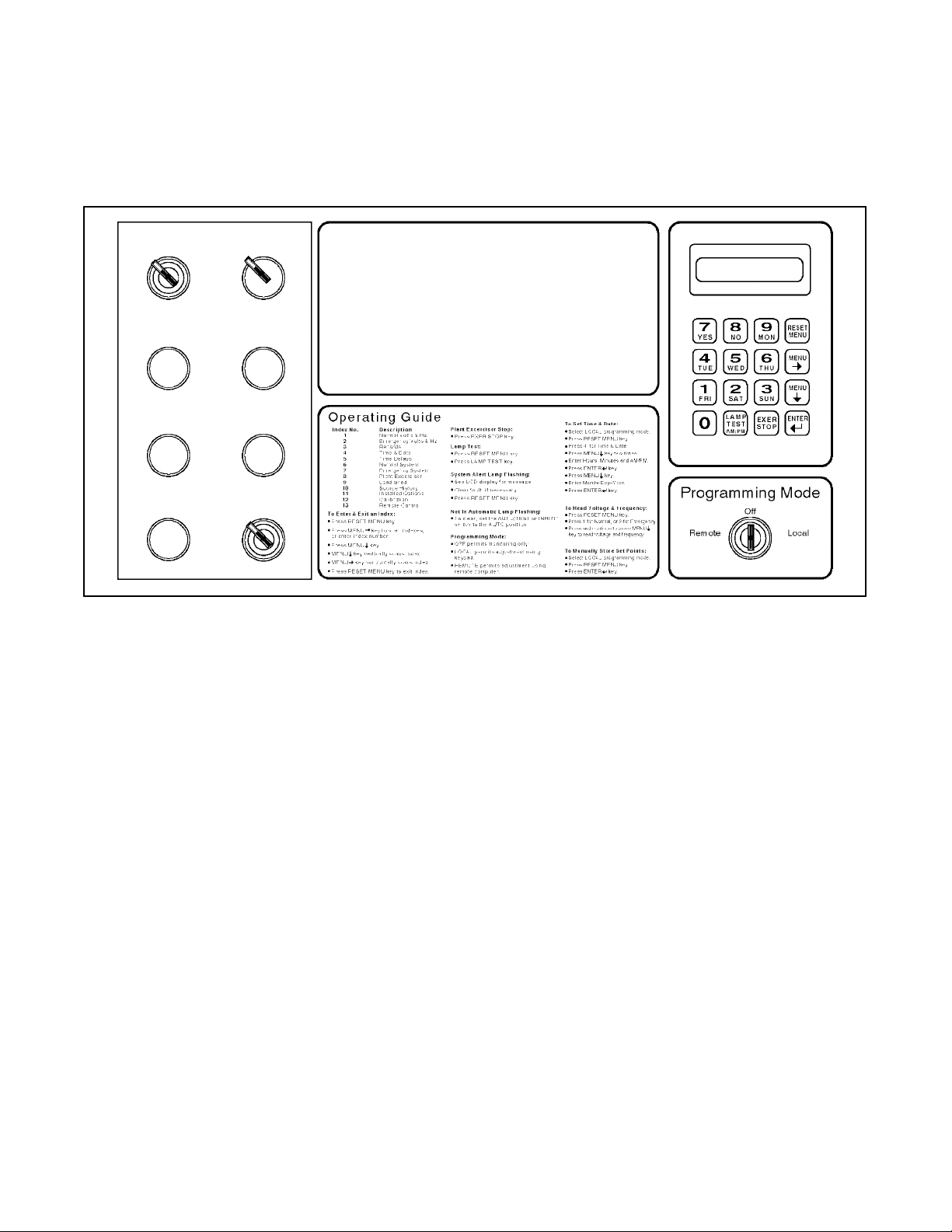

Control Switches and Indicators

Various optional control switches and indicator lamps

may be present on the transfer switch door depending

AUTO

TRANSFER

MANUAL

TRANSFER TO

EMERGENCY

MANUAL

TRANSFER TO

OFF

MANUAL

TRANSFER TO

NORMAL

MANUAL

TRANSFER

TEST SWITCH

NORMAL TEST

BYPASS

EMERGENCY TO

NORMAL TIME DELAY

BYPASS NORMAL

TO EMERGENCY

TIME DELAY

AUTO INHIBIT

Contactor Position Time Delays

Normal On EndEmergency

·

Source Available

Normal Emergency

· ·

System Status

Not In Automatic

· ·

Programming Mode Not in Off

·

Flashing, Local Steady,Remote

· ·

Plant Exerciser Load Shed Inphase Monitor Area Protection

· · · ·

Off

·

·

System Alert

Accessory Active

on the options chosen. See Figure 2-1 for LED, Switch,

and Key locations.

Engine Start

·

·

Normal To Emergency

·

·

Emergency To Normal

·

·

Engine Cooldown

·

·

Off Position

·

·

Figure 2-1. Front Panel

LED Indicators

Contactor Position. LEDs indicate transfer switch

position—NORMAL (green), EMERGENCY (red), or

OFF (yellow).

Source Available. LEDs indicate source with

acceptable voltage and frequency—Normal (green)

and/or Emergency (red).

System Status

Not in Automatic (red). LED flashes to indicate that

Test switch is actuated, or Auto/Manual switch is in the

Manual position.

System Alert (red). LED flashes to indicate possible

problem with contactor or logic operation. System alert

will also flash if any fault signals are received from the

generator set.

Programming Mode Not in Off (yellow). LED flashes

to indicate that programming switch is in the LOCAL

position. A steady, nonflashing light indicates that the

programming switch is in the REMOTE position.

Operation 2-1TP-5672 11/95

Page 18

Time Delays

Engine Start (If emergency source is a generator set).

ON LED indicates that engine-start time delay is timing.

ENDLED indicates thattheengine has been signaledto

start.

Normal to Emergency. ON LED indicates that the

normal-to-emergency time delay is timing. END LED

indicates that the time delay has completed timing.

Emergency to Normal. ON LED indicates that the

emergency to normal time delay is timing. END LED

indicates that the time delay has completed timing.

transfer from emergency to normal and normal to

emergency when sources are near synchronization.

NOTE

When a programmed transition switch is ordered, the

inphase monitor option is disabled by the

microprocessor.

Area Protection. Area protection LED indicates that

the controller is in the area protection mode. The

generator will be signaled to START and the contactor

will transfer to the emergency positionand remain there

while in area protection.

Engine Cooldown. ON LED indicates that the

generator set engine cooldown timer is timing. END

LED illuminates until the engine has shut down.

Off Position. ON LED indicates that the time delay off

positionistiming. ENDLEDindicatesthatthetimedelay

has completed timing.

Accessory Active

Plant Exerciser. Plant excerciser LED indicates that

the system is in the exerciser mode.

LoadShed. LoadshedLEDindicates that programmed

load shedding is active.

Inphase Monitor (availableon ZCtype powerswitches

only). Inphase monitor LED indicates that the sources

are being monitored for phase relationship to allow

inphase transfer. The inphase monitor will permit

Control Switches

Test Switch (Standard). Move the test switch to the

TEST position to simulate a normal source outage.

Not-in-Automatic system status light will flash.

Bypass N-E Time Delay Pushbutton Switch

(Option). If the bypass normal-to-emergency time

delay pushbutton is pressed when

normal-to-emergency time delay is on, time delay will

end.

Bypass E-N Time Delay Pushbutton Switch

(Option). If the bypass normal-to-emergency time

delay pushbutton is pressed, when

emergency-to-normal time delay is on, time delay will

end.

Manual Transfer to Emergency Switch (Option).

When the transfer switch control is in the manual mode

of operation and manual to emergency is required,

press the manual transfer-to-emergency pushbutton to

Programming Mode Switch

NOTE

Theprogramming modeswitch keysshould bekept ina

safe place to prevent unwanted tampering with the

transfer switch control. Do not leave the programming

switch in the LOCAL position with the transfer switch

unattended.

Remote. Allows both status monitoring and setting of

the transfer switch controls by a connected personal

computer.

Off. Transfer switch status settings and power source

may be monitored from the local LCD display or

connected computers.

Local. Allows both status monitoring and setting of

transfer switch control from the microprocessor’s LCD

display and keypad.

cause the transfer switch to transfer to the emergency

position.

Manual Transfer to Off Switch (Option). When the

transfer switch control is in the manual mode of

operation and manual to off is required, press the

manual transfer-to-emergency pushbutton to cause the

transfer switch to transfer to the off position.

Manual Transfer to Normal Switch (Option). When

the transfer switch control is in the manual mode of

operation and manual to normal is required, press the

manual transfer-to-emergency pushbutton to cause the

transfer switch to transfer to the normal position.

Auto/Inhibit Switch (Option). If the auto/inhibit switch

is in the AUTO position, the transfer switch will operate

normally. If the switch is in the Inhibit position, the

transfer switch will not transfer under any conditions.

2-2 Operation TP-5672 11/95

Page 19

Sequence of Operation

This section describes the correct operation of a

microprocessor-controlled transfer switch.

Sequence of Operation Standard Switch

When the Normal Source Fails

1. The source-available normal LED turns off.

2. The time-delay-engine-start ON LED illuminates

to indicate the engine-start-time-delay is timing.

3. The time-delay-engine-start END LED illuminates

to indicate the engine has been signaled to start.

4. The source-available emergency LED

illuminates.

5. The time-delay normal-to-emergency ON LED

illuminates to indicate the normal-to-emergency

time delay is timing.

6. The time-delay normal-to-emergency END LED

illuminates to indicate the time delay has

completed timing.

7. The load-shed LED illuminates at the same time

all loads to be shed are disconnected from the

switch (if equipped with load-shed option).

8. The inphase monitor LED illuminates (if equipped

with inphase monitor option on ZC type power

switches only). The controller monitors the two

voltagesto makesure theyare ata desiredphase

angle and approaching zero phase angle

difference.

9. The contactortransfers tothe emergency position

after the load-shed time-before-transfer timer has

completed timing. The contactor-position normal

LED turns off and the contactor-position

emergency LED illuminates. The inphase monitor

LED turns off.

10. After the load-shed time-after-transfer timer has

completed timing, the selected loads for the

emergencysource are nowreturnedto the switch.

The load-shed LED turns off (if equipped with

load-shed option).

Operation 2-3TP-5672 11/95

Page 20

When the Normal Source Returns

1. The source-available, normal LED illuminates.

completed timing. The contactor-position

emergency LED turns off and the

contactor-position normal LED illuminates.

2. The time-delay emergency-to-normal ON LED

illuminates to indicate the emergency-to-normal

time delay is timing.

3. The time-delay emergency-to-normal END LED

illuminates to indicate the time delay has

completed timing.

4. The load-shed LED illuminates at the same time

all loads to be shed are disconnected from the

switch (if equipped with load-shed option).

5. The inphase monitor LED illuminates (if equipped

with load-shed option).

6. The contactor transfers to the normal position

after the load-shed time-before-transfer timer has

7. After the load-shed time-after-transfer timer has

completed timing, the selected loads for the

normal source are returned to the switch. The

load-shed LED turns off (if equipped with

load-shed options).

8. The time-delay engine-cooldown ON LED

illuminates to indicate the generator set engine

cooldown timer is timing.

9. The time-delay engine-cooldown END LED stays

illuminated until the generator has shut down.

10. The source-available, emergency LED turns off.

2-4 Operation TP-5672 11/95

Page 21

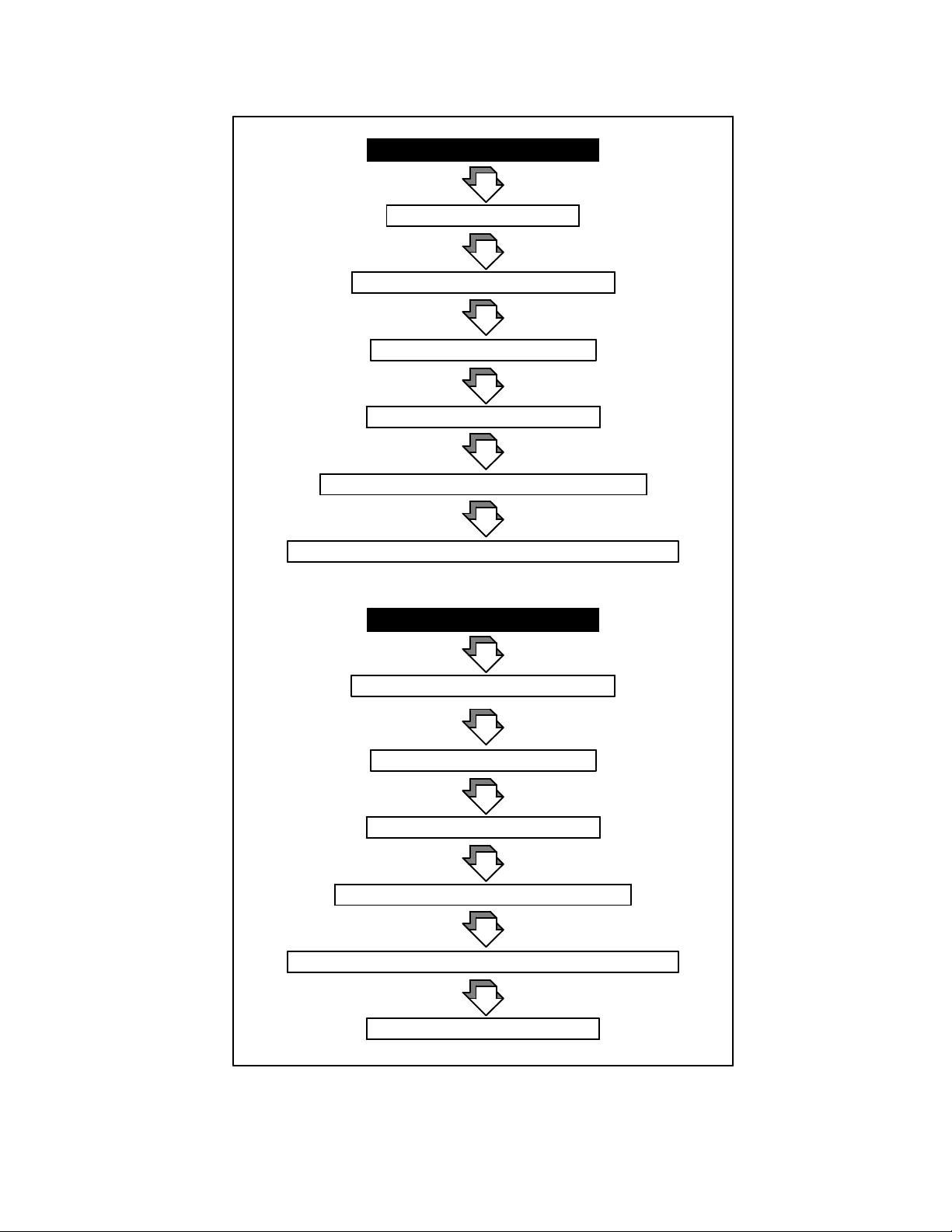

Microprocessor-Controlled Transfer Logic

Standard Switch

Normal Source Failure

Time Delay Engine Start

Time Delay Normal-to-Emergency

Load Shed (all)—if equipped

Inphase Monitor—if equipped

Contactor Transfer to Emergency Position

Load Return (programmed sequence)—if equipped

Normal Source Return

Time Delay Emergency-to-Normal

Load Shed (all)—if equipped

Inphase Monitor—if equipped

Contactor Transfer to Normal Position

Load Return (programmed sequence)—if equipped

Time Delay Engine Cooldown

Operation 2-5TP-5672 11/95

Page 22

Sequence of Operation Programmed Transition Switch

When the Normal Source Fails

NOTE

When a programmed transition switch is ordered, the

inphase monitor option is disabled by the

microprocessor.

1. The source-available, normal LED turns off.

2. The time-delay-engine-start ON LED illuminates

to indicate the engine-start-time-delay is timing.

3. The time-delay-engine-start END LED illuminates

to indicate the engine has been signaled to start.

4. The source-available emergency LED illuminates

after the generator is at rated voltage and

frequency.

5. The time-delay normal-to-emergency ON LED

illuminates to indicate the normal-to-emergency

time delay is timing.

6. The time-delay normal-to-emergency END LED

illuminates to indicate the time delay has

completed timing.

7. The load-shed LED illuminates at the same time

all loads to be shed are disconnected from the

switch (if equipped with load-shed option).

8. After the load-shed time-before-transfer timerhas

completed timing, the contactor transfers to the

Off position. The contactor-position normal LED

turns off and the contactor-position Off LED

illuminates.

9. The time-delay-off-position ON LED illuminates to

indicate the Off position time delay is timing.

10. The time-delay-off-position END LED illuminates

to indicate the time delay has completed timing.

11. The contactor transfers to the emergency

position. The contactor-position Off LED turns off

and the contactor-position emergency LED

illuminates.

12. After the load-shed time-after-transfer timer

completes timing, the selected loads for the

emergencysource arereturned to the switch. The

load-shed LED turns off (if equipped with

load-shed option).

2-6 Operation TP-5672 11/95

Page 23

When the Normal Source Returns

1. The source-available, normal LED illuminates.

2. The time-delay emergency-to-normal ON LED

illuminates to indicate the emergency-to-normal

time delay is timing.

3. The time-delay emergency-to-normal END LED

illuminates to indicate the time delay has

completed timing.

4. The load-shed LED illuminates at the same time

all loads to be shed are disconnected from the

switch (if equipped with load-shed option).

5. After the load-shed time-before-transfer timerhas

completed timing, the contactor transfers to the

Off position. The contactor-position emergency

LED turns off and the contactor-position Off LED

illuminates.

6. The time-delay off-position ON LED illuminates to

indicate the off-position-time-delay is timing.

7. The time-delay off-position END LED illuminates

to indicate the time delay has completed timing.

8. The contactor transfers to the normal position.

The contactor-position OFF LED turns off and the

contactor-position normal LED illuminates.

9. After the load-shed time-after-transfer timer has

completed timing, the selected loads for the

normal source are returned to the switch. The

load-shed LED turns off (if equipped with

load-shed option).

10. The time-delay-engine-cooldown ON LED

illuminates to indicate the generator set engine

cooldown timer is timing.

11. The time-delay-engine-cooldown END LED stays

illuminated until the generator has shut down.

12. The source-available emergency LED turns off.

Operation 2-7TP-5672 11/95

Page 24

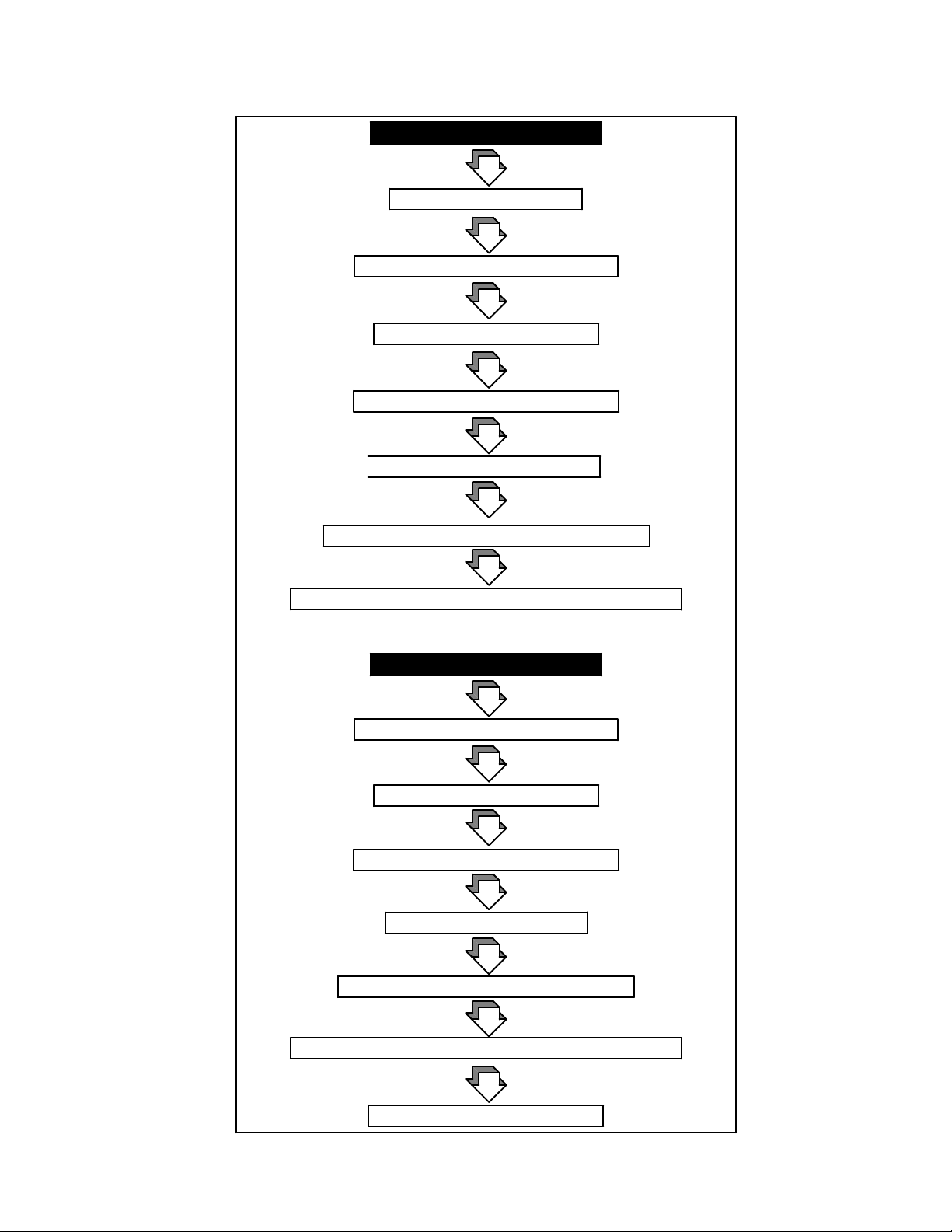

Microprocessor-Controlled Transfer Logic

Programmed Transition Switch

Normal Source Failure

Time Delay Engine Start

Time Delay Normal-to-Emergency

Load Shed (all)—if equipped

Contactor Transfer to Off Position

Time Delay Off-to-Emergency

Contactor Transfer to Emergency Position

Load Return (programmed sequence)—if equipped

Normal Source Return

Time Delay Emergency-to-Normal

Load Shed (all)—if equipped

Contactor Transfer to Off Position

Time Delay Off-to-Normal

Contactor Transfer to Normal Position

Load Return (programmed sequence)—if equipped

Time-Delay-Engine-Cooldown

2-8 Operation TP-5672 11/95

Page 25

To Disconnect The P1 Plug

1. If the transfer switch isin the normal position, open

the emergency-source circuit breaker.

it is available, after a time delay. For immediate

retransfer, open and then reclose the

emergency-source circuit breaker. Place the

generator set start switch in the AUTO position.

2. If the transfer switch is in the emergency position,

open the normal-source circuit breaker.

3. Separate the in-line disconnect plug by grasping

and squeezing the plug. Do NOT pull on the wires.

560423

Electrical Operation Test

Place the transfer switch in the NORMAL position. Use

thefollowing procedureto check theelectrical operation

of the automatic transfer switch:

1. Press andhold the testpushbutton for 15seconds.

See Figure 2-1.

2. The generator set should start and run after the

time delay engine start (TDES) completed timing.

3. The transfer switch will transfer to the emergency

position. The transfer occurs after the

normal-to-emergency time delay (TDNE) has

completed timing.

4. Release the test pushbutton. The transfer switch

retransfers to normal after the

emergency-to-normal time delay.

5. Time delay engine cooldown (TDEC) allows the

engineto continue running foranunloaded running

time. The transfer switch TDEC will complete

timing before any TDEC function in the generator

set controller begins timing.

6. Close load circuit breaker(s) when loads may be

safely energized.

Figure 2-2. In-Line Disconnect Plug

To Reconnect The P1 Plug

1 Engage the in-line disconnect plugby grasping the

connectors and pressing them together. See

Figure 2-2.

2 If thetransfer switch isin the normalposition, place

thegenerator set startswitchin the AUTOposition.

Then close the emergency-source circuit breaker.

3. If the transfer switch is in the emergency position,

close the normal-source circuit breaker. The load

willautomatically retransferto the normalsource, if

NOTE

Connecting the transfer switch in-line disconnect

plugs(P1)togetherwhen the generator controller’s

master switch is in the AUTO position causes the

generator set to IMMEDIATELY start and run until

the generator set controller’s cooldown timer

completes timing.

This completes functional tests of the transfer switch.

Leave the AUTO/MANUAL switch in the AUTO

TRANSFER position.

Operation 2-9TP-5672 11/95

Page 26

Section 3. Troubleshooting Guide

For location of pushbuttons, switches, LEDs, and keys

referred to in this section, see Figure 2-1. Refer to

Figure 3-1 as a guide to troubleshooting problems with

Problem Refer to Section 4—Controller Troubleshooting

None of the LEDs are on and the LCD is blank Power to the system

Pressing a key on the keypad does not supply the appropriate

response

Every LED does not turn on and every character block on the LCD

does not blacken

The normal source should be available but the Source-Available,

Normal LED is not on

The emergency source should be available but the

Source-Available, Emergency LED is not on

The Automatic/Test pushbutton is pressed, the Automatic/Inhibit

switch (option DD-09) is set to Inhibit, or the Automatic-Transfer key

switch (option DD-29) is set to manual, but the System-Status,

Not-In-Automatic LED is not flashing

The System-Status, System-Alert LED is flashing; check the LCD

for a message

The LCD displays Auxiliary-Switch Fault or Double Auxiliary--Switch

fault message

The LCD displays Transfer Hang error message Transfer hang error message

The LCD displays Power-Down error message Power-down error message

The LCD displays RAM or Memory error message RAM or memory error message

The Programming-Mode-Not-In-Off LED is flashing Programming-mode-not-in-off

The engine operates when it should not be operating Engine operates when it should not

The engine should start Engine will not start

One of the control options is not working (the control options

include the inphase monitor, source-phase-sequence,

normal/emergency voltage/frequency sensing, plant exerciser,

extended time delay,and manual override)

the microprocessor logic controller. Refer to Figure 3-2

as guide to troubleshooting problems with the

microprocessor accessories.

Keypad and status panel

Keypad and status panel

Source-available, normal error

Source-available, emergency error

System-status, not-in-automatic error

System-status, system-Alert error

Auxiliary-switch fault or double auxiliary-switch fault error

message

Shunt-jumpered controlled options

TP-5672 11/95

Figure 3-1. Microprocessor logic controller troubleshooting chart

TroubleshootingGuide

3-1

Page 27

Problem Refer to Section 5—Accessory Troubleshooting

Controller will not sense three-phase emergency voltage Phase sequencer,accessory DD-05

The generator set does not start when the test switch is in the

Test switch, accessory DD-06 and DD-07

engine start position

The generator set does not start when the test switch is in the test

Test switch, accessory DD-06 and DD-07

position

The normal-to-emergency time delay pushbutton does not work Time delay override, accessory DD-08

The emergency-to-normal time delay pushbutton does not work Time delay override, accessory DD-08

The auxiliary dry contacts relay boards do not operate Relay auxiliary dry contacts, accessory DD-14

The analog meters are not working Meters, accessory DD-18

The battery charger is not working Battery charger, accessory DD-24

The manual transfer to emergency source does not work Manual operation switches, accessory DD-29

The manual transfer to normal source does not work Manual operation switches, accessory DD-29

The manual transfer to off does not work Manual operation switches, accessory DD-29

The auto/manual switch does not work in the manual position Manual operation switches, accessory DD-29

The auto/manual switch does not work in the auto position Manual operation switches, accessory DD-29

The load shed contacts do not work Load-shed contacts, accessory DD-35

Problems with remote communication exist Remote communication—RS/232 or RS/485, accessory

DD-51

Figure 3-2. Accessory troubleshooting chart

3-2 TroubleshootingGuide

TP-5672 11/95

Page 28

Section 4. Controller Troubleshooting

The following section will assist in solving common

problems with the M340+ controller. Note any optional

accessoriesthatmayhavebeenfurnishedonthisswitch

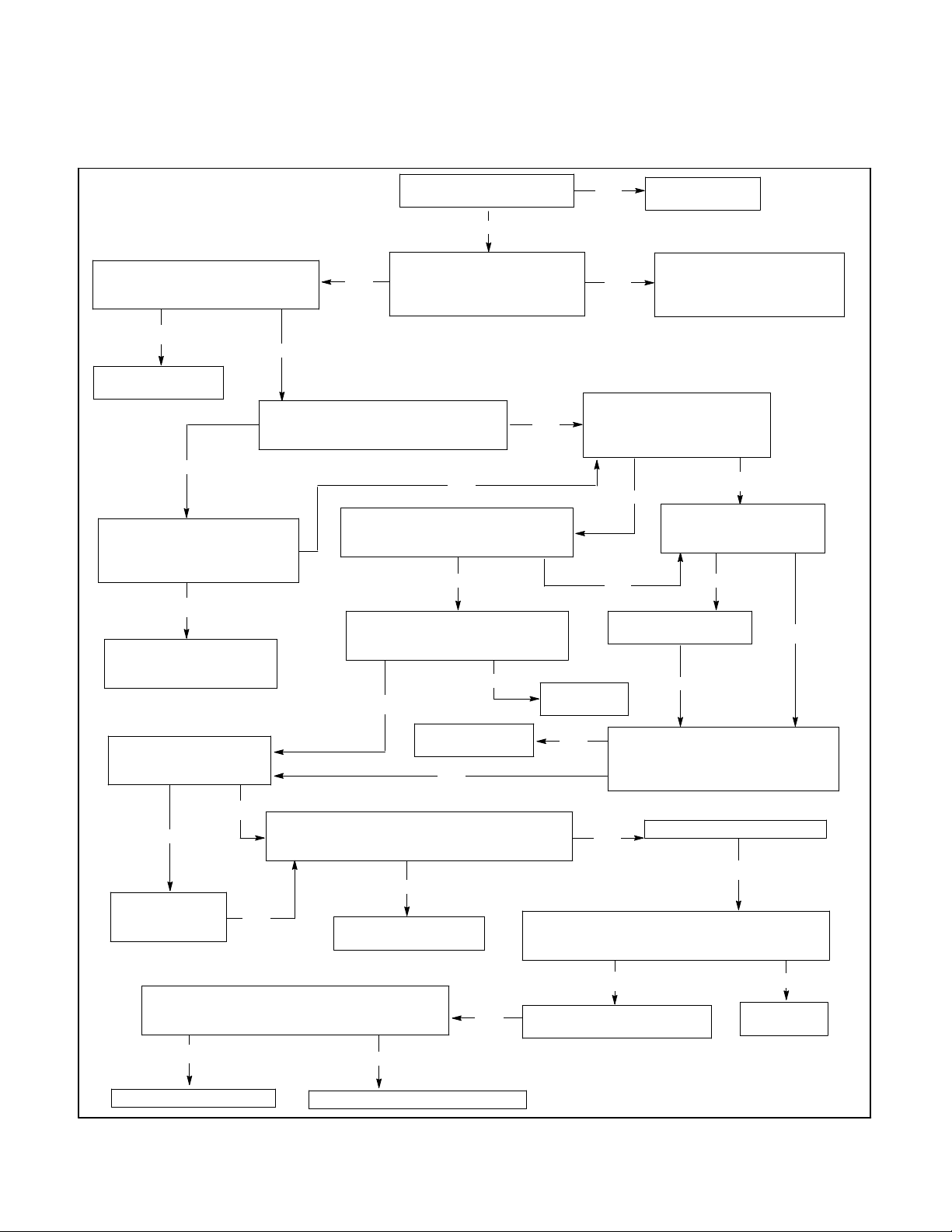

Is the LCD screen blank

and no LEDs illuminated?

Is there 19 vac between terminals

TB-AC1-NAS and TB-AC1-NCS of

the power supply board?

No

Yes

Replace the power

supply board.

Is a battery connected to terminals

TB-DC1-29 and TB-DC1-34 of the

power supply board?

Yes

Is there rated battery voltage

between terminals TB-DC1-29

and TB-DC1-34 of the power

supply board?

No

Check battery and wiring

from battery to assembly

for open of shorted leads.

Is an optional remote

communications board

installed?

Yes No

Is there 10 vdc between pin P2-13

of plug 2 and terminals TB-DC1-34

of the power supply board?

Is there normal source

voltage between terminals

TB-AC1-NA and TB-AC1-NC

of the power supply board?

Is there 10 vdc between terminals

TB-DC1-30 and TB-DC1-34 of

the power supply board?

No

Replace the

load-shed board.

No

and review their operation in section 5—Accessory

Troubleshooting.

No

Yes

Is there from 12 to 30 vdc

No

Yes

Yes Yes

Yes

between terminals

TB-DC1-23 and TD-DC1-34

of the power supply board?

Replace the

logic board.

Yes

Troubleshooting

complete.

Check the normal source

and contactor-to-power

supply board wiring harness

for open or shorted leads.

Yes

Is there an optional

load-shed board

installed?

No

Disconnect the

load-shed board.

Yes

Recheck the voltage at terminals

TB-DC1-23 and TB-DC1-30 of the

power supply board, and pin P2-13

of plug 2. Are the voltages correct?

No

No

Yes

Disconnect the

communications

board.

Recheck the voltage at terminals TB-DC1-23

and TB-DC1-30 of the power supply board, and

pin P2-13 of plug 2. Are the voltages correct?

No

Replace the logic board.

TP-5672 11/95

No

Recheck the voltage at terminals TB-DC1-23

and TB-DC1-30 of the power supply board, and

pin P2-13 of plug 2. Are the voltages correct?

Yes

Yes

Replace the remote

communication board.

Yes

Replace the power supply board.

Figure 4-1. Troubleshooting—Power to the system

Yes

No

Recheck the voltage at terminals TB-DC1-23

and TB-DC1-30 of the power supply board, and

pin P2-13 of plug 2. Are the voltages correct?

Disconnect the status panel

board.

Disconnect the logic board.

No

Controller Troubleshooting

No

Yes

Replace the

logic board.

4-1

Page 29

Power to the System

Ifthereisaproblemwiththelogicboard,thefirststepisto

check the status panel. If no LEDs on the status panel

are illuminated and the liquid crystal display (LCD) is

blank, check the power to the system by performingthe

following steps. See Figure 4-1 for the Power to the

System troubleshooting flowchart. See Appendix B

Figure B-4 for location of power supply board

components referred to in this section. See Appendix B

FigureB-6forlocationanddescriptionofP2ribboncable

pins. See Appendix B Figure B-9 for location of main

logic board components referred to in this section.

1. Using a voltmeter, connect one test lead to

TB-AC1-NA. Connect the other test lead to

TB-AC1-NC. If the voltmeter does not read the

expected normal source voltage,check the normal

sourceandthecontactor-to-assemblyharness,P1.

2. If thenormalsourcevoltageispresent,connectone

test leadto TB-AC1-NAS and the other test leadto

TB-AC1-NCS. If the voltmeter does not read

approximately 19 volts AC, the secondary normal

source voltage, check that the transformer is wired

correctly. If the transformer is wired correctly and

the voltmeter still does not read 19 volts AC,

disconnect transformer secondary wires andretest

transformer secondary voltage to determine if the

transformer or the logic board assembly is at fault.

3. If boththenormalsourcevoltageandthesecondary

normal source voltage are present, connect one

test lead to TB-AC1-EA and the other test lead to

TB-AC1-EC. If the voltmeter does not read the

expected emergency source voltage, check the

emergency source and the contactor-to-assembly

harness, P1.

4. If theemergencysourcevoltageispresent,connect

one test lead to TB-AC1-EAS and the other test

leadtoTB-AC1-ECS.If thevoltmeterdoesnot read

approximately19voltsAC,theexpectedsecondary

emergency source voltage, check that the

transformer is wired correctly. If the transformer is

wiredcorrectly andthe voltmeter still doesnot read

19 volts AC, disconnect transformer secondary

wires and retest transformer secondary voltage to

determine if the transformer or the logic board

assembly is at fault.

5. If the emergency source, normal source, and

transformers are all working properly, and the

batteryback-upoptionisused,connectthe positive

testleadtoTB-DC1-29andthe negativetestleadto

TB-DC1-34.If thevoltmeterdoesnot read between

12and30voltsDC,expectedbatteryvoltage,check

the battery-to-assembly wires and the battery.

6. Connect the positive test lead to TB-DC1-23, and

the negative test lead to TB-DC1-34. If the

voltmeter does not read betweenapproximately12

and30voltsDC,checkifanaccessoryisconnected

toTB-DC1-23.Ifthereisanaccessoryconnectedto

TB-DC1-23,disconnectit. If the voltmeter stilldoes

notread between12and30 voltsDC, performstep

9.

NOTE

When taking a voltage or resistance measurement

at a ribbon cable pin, do not disconnect the ribbon

cable from the board. Use a needle point probe to

take the readings from the holes on the top side of

the ribbon cable connector.

7. Connect the positive test lead to P2-13, and the

negative test lead to TB-DC1-34. If the voltmeter

does not read approximately 10 volts DC, perform

step 9. See Appendix B Figure 6 for location of P2

ribbon cable pins.

8. Connect the positive test lead to TB-DC1-30 and

the negative test lead to TB-DC1-34. If the

voltmeterdoesnotreadapproximately10voltsDC,

perform step 9.

9. If eachofthemeasurementstakeninsteps6,7,and

8 was correct, this step may be skipped.

a. Disconnect the main logic board ribbon cable

from P2, and recheck the voltages in steps 6, 7,

and8. If thevoltagereadings in steps 6,7, and8

are now correct, the main logic board is

defective. Replace the logic board assembly.

b. If the logic board is equipped with a load shed

board, disconnect the load shed ribbon cable

from P10 on the main logic board, and recheck

the voltages in steps 6, 7, and 8. If the voltage

readings in steps 6, 7, and 8 are now correct,

replace the Load Shed board.

c. If the logic board is equipped with a remote

communications board, disconnect the remote

communications ribbon cable from P12 on the

main logic board, and recheck the voltages in

steps6, 7, and 8. If thevoltagereadings in steps

6, 7, and 8 are now correct, replace the remote

communications board.

d. Disconnect the status panel ribbon cable from

P4,andrecheckthevoltagesinsteps6,7, and8.

If the voltage readings in steps 6, 7, and 8 are

now correct, the status panel is defective.

Replace the logic board assembly.

e. If the voltages measured in steps 6, 7, and 8

were never correct, replace the power supply

board.

4-2 Controller Troubleshooting

TP-5672 11/95

Page 30

Keypad And Status Panel

For location of pushbuttons, switches, LEDs, and keys

referred to in this section, see Figure 2-1.

1. Testthe keypadby pressinga keyandcheckingthe

response.If theresponseiscorrect,repeatthisstep

until satisfied that there is not a problem with the

keypad. If the response is ever incorrect, the

keypad is defective. Replace the logic board

assembly.

2. Press the LAMP TEST key on the keypad.

3. If afterpressingtheLAMPTEST keysomeLEDson

thedisplaypanelareon, butat leastoneLED isnot

on, the status panel is defective. Replace the logic

board assembly.

4. If after pressing the LAMP TEST key some of the

character blocks on the LCD appear black, but at

least one character block is not black, the status

panel is defective. Replace the logic board

assembly.

5. If after pressing the LAMP TEST key no LEDs are

on, and the character blocks in the LCD are black,

verify that there is power to the system by

performing the steps outlinedin Section 4—Power

To The System. Check the P2 and P4 ribboncable

connections by performingthefollowingsteps. See

Appendix B FigureB-9 for locationof ribboncables

andotherpowersupplyboardcomponentsreferred

to in this section.

a. Disconnect all power sources.

b. Wait 30 seconds.

c. Being careful not to bend or break any of the

pins, remove both P2 and P4 ribbon cable

connectors.

d. Inspect the pins on the P2 and P4 ribbon cable

connectors.

e. If pinsarebent,carefullybendthemback. Ifpins

are broken, replace the ribbon cable connector.

f. Carefully reconnect P2 and P4 ribbon cable

connector.

g. If the problem still exists,replacethe logic board

assembly.

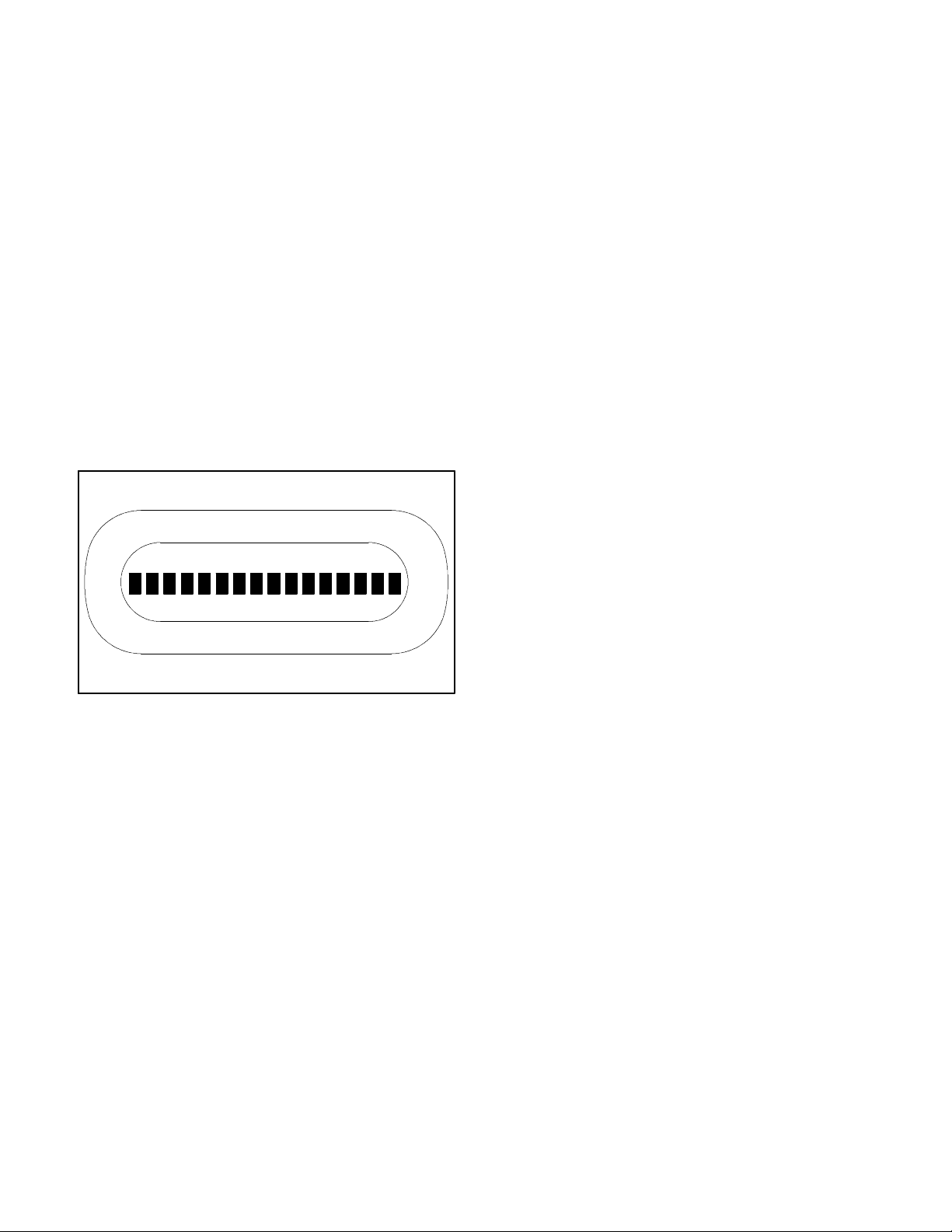

560442

Figure 4-2. The M340+ LCD display during a lamp

test

TP-5672 11/95

Controller Troubleshooting

4-3

Page 31

If the normal source is available, but the source available normal LED

is not illuminated. Check the trip point settings in index 6. See TP-5664

for programming information. Are the trip points programmed correctly?

Yes

Does the microprocessor display,in index 1, rated normal source voltages and frequency?

No

Correct the trip point settings

in index 6. See TP-5664 for

programming information.

Is the transfer switch

wire with a phase

Yes

rotation of ABC?

Yes

No

Replace the

logic board.

Calibrate the normal source

voltage.

Yes

Does the voltage between terminals TB-AC1-NA

and TB-AC1-NB and terminals TB-AC1-NB and

TB-AC1-NC of the power supply board equal the

rated voltage for the transfer switch?

No

Check the normal source voltage

and the wiring harness from the

contactor to power supply board

for open or shorted leads.

Yes

Is the inphase

sequence option

installed?

Yes

Does the voltage between terminals

TB-AC1-NC and TB-AC1-NA of the

power supply board equal the rated

voltage for the transfer switch?

No

Is 3-phase

sensing used?

No

Check the normal source voltage

and the wiring harness from the

contactor to power supply board

for open or shorted leads.

Is the voltage between pin P2-15 of

Yes

plug 2 and terminal TB-DC1-34 of the

power supply board 1/25 of line

voltage? See Appendix B Figure B-5.

Yes

Turn the generator set off. Jumper terminal

TB-DC1-24 to TB-DC1-34 of the power

supply board . Is the voltage between pin

P2-15 of plug 2 and terminal TB-DC1-34 of

the power supply board equal to 0 vac?

No

No

Replace the power

supply board.

No

Replace the power

supply board.

No

Yes

Is 3-phase

sensing used?

Yes

No

Calibrate the controller’s

normal source voltage.

Is the voltage between pin P2-18 of

plug 2 and terminal TB-DC1-34 of the

power supply board 1/25 of line

voltage? See Appendix B Figure B-5.

Yes

Replace the power

supply board.

Rewire the source for

ABC phase rotation.

Figure 4-3. Troubleshooting—Source-available, normal error

Yes

Is the voltage between pin P2-16 of plug 2 and

terminal TB-DC1-34 of the power supply board

1/25 of line voltage? See Appendix B Figure

B-5.

No

Is the voltage between pin P2-17 of

plug 2 and terminals TB-DC1-34 of

the power supply board 1/25 of line

voltage? See Appendix B Figure B-5.

No

No

Replace the power

supply board.

No

Replace the power

supply board.

Yes

Calibrate the controller’s

normal source voltage.

4-4 Controller Troubleshooting

TP-5672 11/95

Page 32

For location of pushbuttons, switches, LEDs, and keys

referred to in this section, see Figure 2-1.

This section covers the condition in which the normal

source is available but the Source-Available, Normal

LED is not on.

The first item to check is the trip-point settings. The

trip-pointsettingscan be foundinIndex 6 inthe program

menu. See Figure 4-4 for recommended trip-point

settings.Thetrip-pointsdonotneedtoexactlymatchthe

recommended trip-point settings for proper operation.

However, if the trip-point settings in Index 6 are too high

ortoo low,problemscouldoccur. Ifthe trip-pointsettings

are too high or too low, correct them. Then enter normal

source voltage and normal source frequency, and store

the set points.

Next check Index 1 in the program menu for correct

normal source voltage and frequency reading. If the

voltage and frequency values in Index 1 match the

voltage and frequency values in Index 6, perform the

following steps.

1. Check if the phase sequence option is installed. If

thereisa jumperacrossJP1-5,thephasesequence

option is installed.

2. If the phase sequence option is installed, press the

MENU arrow down key to check the phase

sequence in Index 1. Utility power must be

phased ABC.

3. If the normal source is single-phase,verify inMenu

Index 6 that single-phase sensing was selected. A

single-phase source must be sensed as a

single-phase source.

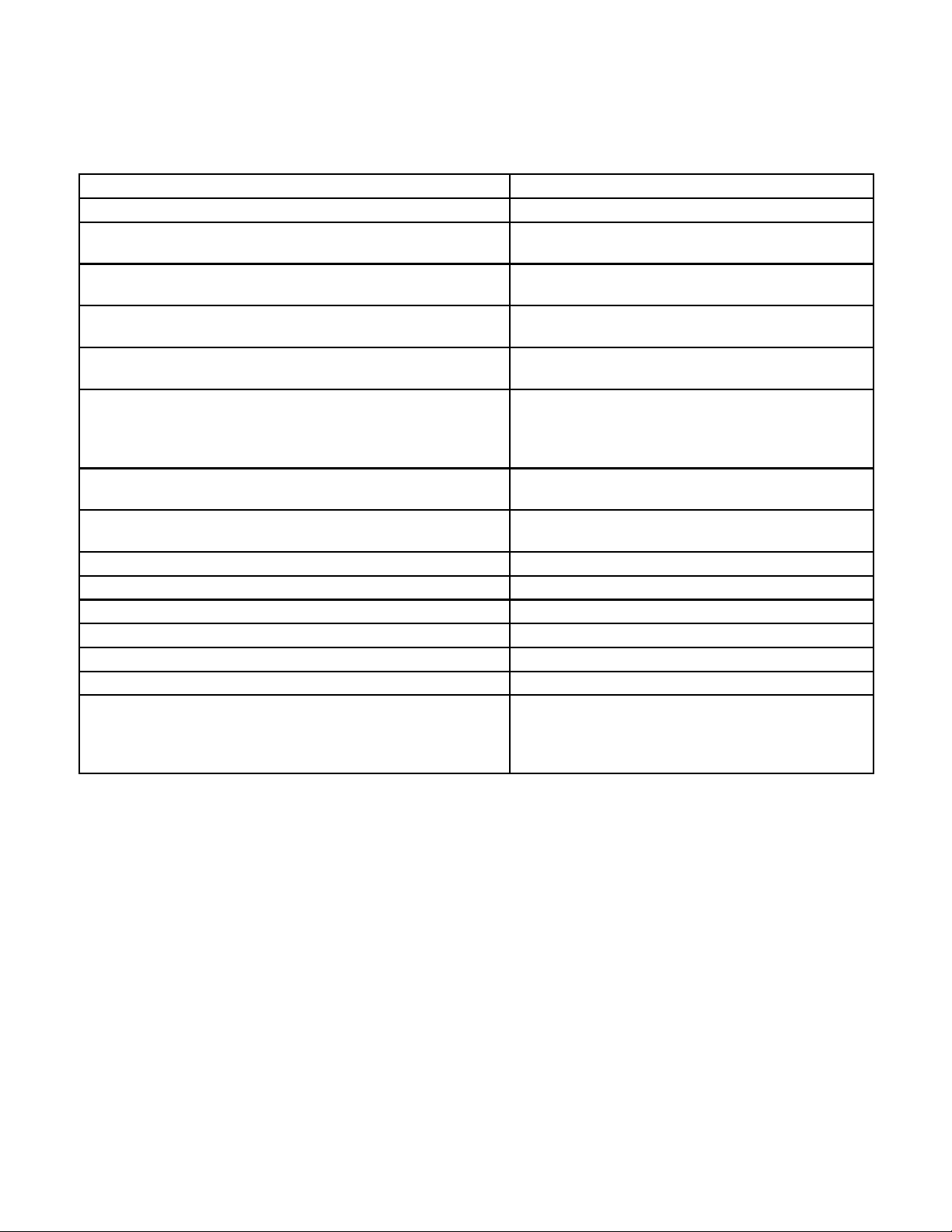

Trip Point Setting Limits

Overvoltage

Dropout

Overvoltage

Pickup

Undervoltage

Pickup

Undervoltage

Dropout

Overfrequency

Dropout

Overfrequency

Pickup

Underfrequency

Pickup

Underfrequency

Dropout

105% -- 135% 115%

100% -- 130% 110%

75% -- 100% 90%

70% -- 95% 85%

105% -- 135% 115%

100% -- 130% 110%

85% -- 100% 90%

80% -- 95% 85%

Normal Source

Factory Setting

Figure 4-4. Normal source voltage trip point

setting limits and factory settings

4. If the source is available, the phase sequencing is

correct, the sensing is correct, and the

Source-Available, NormalLED is still not on, check

the P2 ribbon cable connector.

a. Remove all power sources.

b. Wait for 30 seconds.

c. Makingsurenot to bendor breakanyofthepins,

remove the P2 ribbon cable connector.

d. Inspect the pins on the P2 ribbon cable

connector.

e. If any of the pins are bent, carefully bend them

back. If any of the pins are broken, the ribbon

cableconnectorisdefective.Replacetheribbon

cable connector.

f. Carefully, reconnect P2 ribboncable connector.

5. If the Source-Available, Normal LED is still not

illuminated, the status panel is defective. Replace

the logic board assembly. If a value in Index 1 is

incorrect, see steps below.

TP-5672 11/95

Controller Troubleshooting

4-5

Page 33

Incorrect Normal Source Voltage And Frequency Values

See Appendix B, Figure B-9 for location of TB-AC1 and

other power supply boardcomponents referredto inthis

section.

1. If the system is single-phase, use a voltmeter to

measure the normal source voltage by connecting

onetest leadto TB-AC1-NA and theother test lead

to TB-AC1-NC. Note the voltmeter reading.

2. If the system is three-phase, use a voltmeter to

measure the normal source voltage by connecting

onetest leadto TB-AC1-NA and theother test lead

to TB-AC1-NB. Note the voltmeter reading.

Connectone test leadto TB-AC1-NBand the other

test lead to TB-AC1-NC. Note the voltmeter

reading.

3. If the voltmeter did not display the normal source

voltageinstep 1 or step 2, checkthe normalsource

and the contactor-to-assembly harness, P1.

4. If the voltage reading(s) in step 1 or step 2 did not

match the value(s) displayed in Index 1, check the

powersupplyboardbyperformingthefollowingfour

steps.

NOTE

When taking a voltage or resistance measurement

at a ribbon cable pin, do not disconnect the ribbon

cable from the board. Use a needle point probe to

take the readings from the holes on the top side of

the ribbon cable connector.

a. Check the TestLED onthe powersupplyboard.

IftheTestLEDisnoton,installa jumperbetween

TB-DC1-24 and TB-DC1-34. If the Test LED

comesonwhenthejumperisinstalled,checkthe

Automatic/Test pushbutton and the connected

accessories.

b. Using a voltmeter, connect one test lead to

P2-15andtheothertestleadto TB-DC1-34.See

Appendix B, FigureB-9 for locationof P2ribbon

cable connector. The voltmeter should read

approximately 1/25 of the line voltage. See

Appendix B, Figure B-5 for values. Turn the

generator off. See Appendix B, Figure B-9 for

location of P2 ribbon cable pins.

c. Connect one test lead to P2-16 and the other to

TB-DC1-34. The voltmeter should read

approximately 1/25 of the line voltage. See

Appendix B, Figure B-5.

d. If the system is three-phase, connect one test

lead to P2-17 and the other to TB-DC1-34. The

voltmeter should read approximately 1/25 of the

line voltage. See Appendix B, Figure B-5.

e. If the system is three-phase, connect one test

lead to P2-18 and the other to TB-DC1-34. The

voltmeter should read approximately 1/25 of the

line voltage. See Appendix B, Figure B-5.

f. Removepowerfrom thelogicboard.Disconnect

the P2 ribbon cable connector. Recheck the P2

pointsonthepowersupplyboardinsteps4a,4b,

4c, and 4d. If the voltage readings are now

correct, either an accessory or the logic board

main logic board is bad.

5. If any of the voltage readings in step four were

incorrect, replace the power supply board. If all of

the voltage readings in step four were correct,

calibrate the normal source voltage.

Calibrate Logic Board Normal

Three-Phase Source Voltage

1. Press the Automatic/Test pushbutton to start the

generatorand to transfer the loadto the generator.

2. Disconnect the incoming normal power to the

transfer switch by removing the line fuses, the

in-line disconnect plug, or the incoming circuit

breaker.

3. Verify that the normalsource voltage is zero. Using

a voltmeter connect one test lead to TB-AC1-NA

and one test lead to TB-AC1-NC. The voltmeter

shouldread 0 volts AC. Connect one voltmetertest

lead to TB-AC1-NA and the other test lead to

TB-AC1-NB.The voltmetershouldread0 voltsAC.

Connectonevoltmeter test leadto TB-AC1-NBand

the other test lead to TB-AC1-NC. The voltmeter

should read 0 volts AC.

4. If the normal source is three-phase, it can be

sensed as either single-phase or three-phase

depending on what the application requires. In

Menu Index 6 choose the appropriate sensing

method: single-phase sensing or three-phase

sensing.

NOTE

When calibrating either the normal source or

emergency source, never auto-zero the source

unless it is zero volts. If source voltage is present

and the YES key is pressed and entered at the

AUTO-ZERO message, the logicboard will always

read the system voltage as zero volts.

5. Using the menu in Index 12, arrow down to

N-AUTO-ZERO? and press the YES key and the

ENTER key.

6. Observe the ENTRY ACCEPTED message on the

LCD.

4-6 Controller Troubleshooting

TP-5672 11/95

Page 34

7. When the message on the LCD again reads,

N-AUTO-ZERO?,restorethenormalpowersource.

10. Press the RESET MENU key and then the ENTER

key to store the set points.

8. If single-phase sensing is used, perform this step.

PresstheMENUArrowDownkey so the LCDreads

N-VOLT VAC. If the value displayed on the LCD

after N-VOLT VAC is not between60% and 80% of

the system voltage, replace the logic board

assembly. If the value is between 60% and 80% of

the system voltage, measure the normal system

voltagebyconnectingone test leadofa voltmeterto

TB-AC1-NAand theother test lead toTB-AC1-NC.

Enter the measured value at the LCD message

N-VOLT VAC. Press the ENTER key and observe

the ENTRY ACCEPTED message on the LCD.

9. If three-phase sensing is used, perform this step.

PresstheMENUArrowDownkey so the LCDreads

N-PHA-C VAC. If the values displayedon theLCD

after N-PH A-C VAC, N-PH A-B VAC,or N-PH B-C

VAC are not between 60% and 80% of the system

voltage, replace the logic board assembly. If the

values are between 60% and 80% of the system

voltage, measure and enter the normal system

voltage by performing the next three steps.

a. Connect one test lead of a voltmeter to

TB-AC1-NA. Connect the other test lead to

TB-AC1-NB. Enter the measured value at the

LCD message N-PH A-B VAC. Press the

ENTER key. Observe the ENTRY ACCEPTED

message on the LCD. Press the MENU arrow

down key.

b. Connect one test lead to TB-AC1-NB, and

connecttheothertestleadtoTB-AC1-NC.Enter

the measuredvalue at the LCD message N-PH

B-C VAC. Press the ENTER key. Observe the

ENTRY ACCEPTED message on the LCD.

Press the MENU arrow down key.

NOTE

If the system will not calibrate, replace the logic

board assembly.

Calibrate Logic Board Normal

Single-Phase Source

NOTE

When calibrating either the normal source or

emergency source, never auto-zero the source

unless it is zero volts. If source voltage is present

and the YES key is pressed and entered at the

AUTO-ZERO message, the logicboard will always

read the system voltage as zero volts.

1. Using the menu in Index 12, arrow down to

N-AUTO-ZERO?. Press the YES key and the

ENTER key.

2. Observe the ENTRY ACCEPTED message on the

LCD.

3. When the message on the LCD again reads,

N-AUTO-ZERO?,restorethenormalpowersource.

4. Press the MENUArrowDownkeysotheLCDreads

N-VOLT VAC. If the value displayed on the LCD

after N-VOLT VAC is not between60% and 80% of

the system voltage, replace the logic board

assembly. If the value is between 60% and 80% of

the system voltage, measure the normal system

voltagebyconnectingone test leadofa voltmeterto

TB-AC1-NAand theother test lead toTB-AC1-NC.

Enter the measured value at the LCD message

N-VOLT VAC. Press the ENTER key and observe

the ENTRY ACCEPTED message on the LCD.

c. Connect one test lead to TB-AC1-NA, and

connecttheothertestleadtoTB-AC1-NC.Enter

the measuredvalue at the LCD message N-PH

A-C VAC. Press the ENTER key. Observe the

ENTRY ACCEPTED message on the LCD.

Press the MENU arrow down key.

TP-5672 11/95

5. Press the RESET MENU key and then the ENTER

key to store the set points.

NOTE

If the system will not calibrate, replace the logic

board assembly.

Controller Troubleshooting

4-7

Page 35

Is the phase sequence

option installed?

No

Is the phase

sequence in

index 2 A-B-C?

No

Rewire the source for

a phase sequence of

A-B-C in Index 2.

If the emergency source is available, but

the source available emergency LED is not

illuminated, check the trip point settings in

index 7. Are the settings correct?

Yes

Does the microprocessor display,

in index 2, rated emergency

source voltages and frequency?

Is single-phase

sensing used?

Yes

Are the pickup and

Yes

dropout settings

correct in index 7?

Yes

No

Replace the

logic board.

Correct the trip point

settings in index 7.

No

Correct the setpoints

in Index 7.

NoYes

Measure the voltage between

terminals TB-AC1-EB and

No

TB-AC1-EC of the power

supply board; note results.

Yes

Yes

Does the voltage between