Page 1

VEIL WALL FACED

INSTALLATION INSTRUCTIONS

INTELLIGENT TOILET

K-8423A-0

• We appreciate your commitment to Kohler quality. Please take a few minutes before you begin installation to review

this manual to become familiar with tools, materials and installation methods. If you encounter any installation or

performance problems, please don't hesitate to contact us. Thanks again for choosing Kohler Co.

• Please follow instructions closely to avoid costly mistakes caused by improper installation. Cover and protect the

components and fittings at all times during installation. Flush the plumbing lines before initial use.

• All information in this manual is based upon the latest product information available at the time of publication. Kohler

Co. reserves the rights to make changes in product characteristics, packaging or availability at any time without notice.

• Before continuing, please ensure there is no existing damage to the toilet and that there is suitable space for installation

with no interference with other bathroom fixtures such as shower door openings. Before proceeding with installation,

ensure there is ample room (approx 600mm) down each side of the pan to allow for servicing.

• To prevent serious damage, do not use corrosive solutions (see back page for care and cleaning information).

Any use of non-recommended products could void the Kohler warranty.

• This manual includes important care and cleaning information - please save these instructions.

COMPLIANCE: Ensure installation adheres to local building code & applicable plumbing/electrical standards.

• The Kohler Veil Intelligent Toilet - Wall Faced (

Technical Specification for Plumbing and Drainage Products - Bidet Douche Seats.

• Installation must comply with AS/NZS 3500.1 Plumbing and Drainage - Water Services and AS/NZS 6400 Water

Efficient Products - Rating and Labelling.

K-8423A-0) is WaterMark certified according to ATS 5200.051

Backflow Prevention

• The supplied Dual Check Valve is WaterMark certified according to AS 2845.1 Water Supply - Backflow Prevention

Devices - Materials, Design and Performance Requirements.

• Each site must have High Hazard Backflow Prevention installed upstream of the installation.

• For domestic installations, consult with a Licensed Practitioner (Plumber) before installation.

• For commercial applications, refer to a Hydraulic Consultant before specification or installation.

WARNING: Risk of electric shock. Disconnect power before servicing.

WARNING: Risk of electric shock. Connect only to a properly-grounded, grounding-type receptacle which is

protected by a Ground-Fault Circuit-Interrupter (GFCI) or Residual Current Device (RCD)

WARNING: Risk of electric shock. This product must be grounded. Connect only to a dedicated 220~240V AC,

50/60Hz circuit protected with grounded circuit-breaker or grounded electric leak circuit breaker

WARNING: 10A power supply is required.

Product Functions

• Hands-free flushing

• Manual dual-flush option

• Backflow prevention

• Pre-set water inlet level & flush volume

• Suitable for either S-trap or P-trap installations

Advantages for the In-wall Water Tank

• Anti-impact, rust-proof, macromolecule water tank reduces the possibility of leakages.

• Advanced water tank system is able to adjust 4.5/3 litre water discharge. To maintain the 4-star WELS rating, switch

off the Auto-flush option.

• No influence on wall structure, superb sound-proof effectiveness.

• Easy and quick installation saves time and labour.

• Easy servicing, wall reconstruction is not required.

• Sanitary system with no residual waste.

• Super thin tank body saves installation space and is applicable for all thin mounting walls.

Kohler Co. Jan 2018 1 1345889-A02-A

Page 2

The concept of in-wall tank design & installation

• Compared to traditional setups, the in-wall tank provides an easier and faster installation method, which gives a

more artistic and complete finish.

• The greatest advantage of the in-wall tank is that the toilet installation is not limited to certain locations. It can be

hung almost anywhere which affords a far greater use of bathroom space.

Component information

• Pan with faceplate .......... 20313A-0

• Remote assembly ........... 1235953

• Hydro-Tower 500 in-wall tank .. 18647A-NA

• Faceplate .................................. 1268687

Required tools and materials

• 19mm spanner or adjustable wrench

• Blade

• File

• Hacksaw

• Hex key

• Impact drill

• Level

• Electrical tape + thread sealing tape

• Electrical insulation conduits

• Grease

• Plug for bidet water supply

• Screws/bolts to affix in-wall tank to wall

frame and bottom plate (not supplied). Recommended

to use M6x40 coach screws with appropriate washers.

• Screwdriver

• Rulers/measuring tape

1mm - 2.5mm hard cord should be reserved as power input during the wall construction. In the circuit, a 220V, 50Hz,

10A minimum Ground-Fault Circuit Interrupter (GFCI) or Earth Leakage Circuit-Breaker (ELCB) is required. For

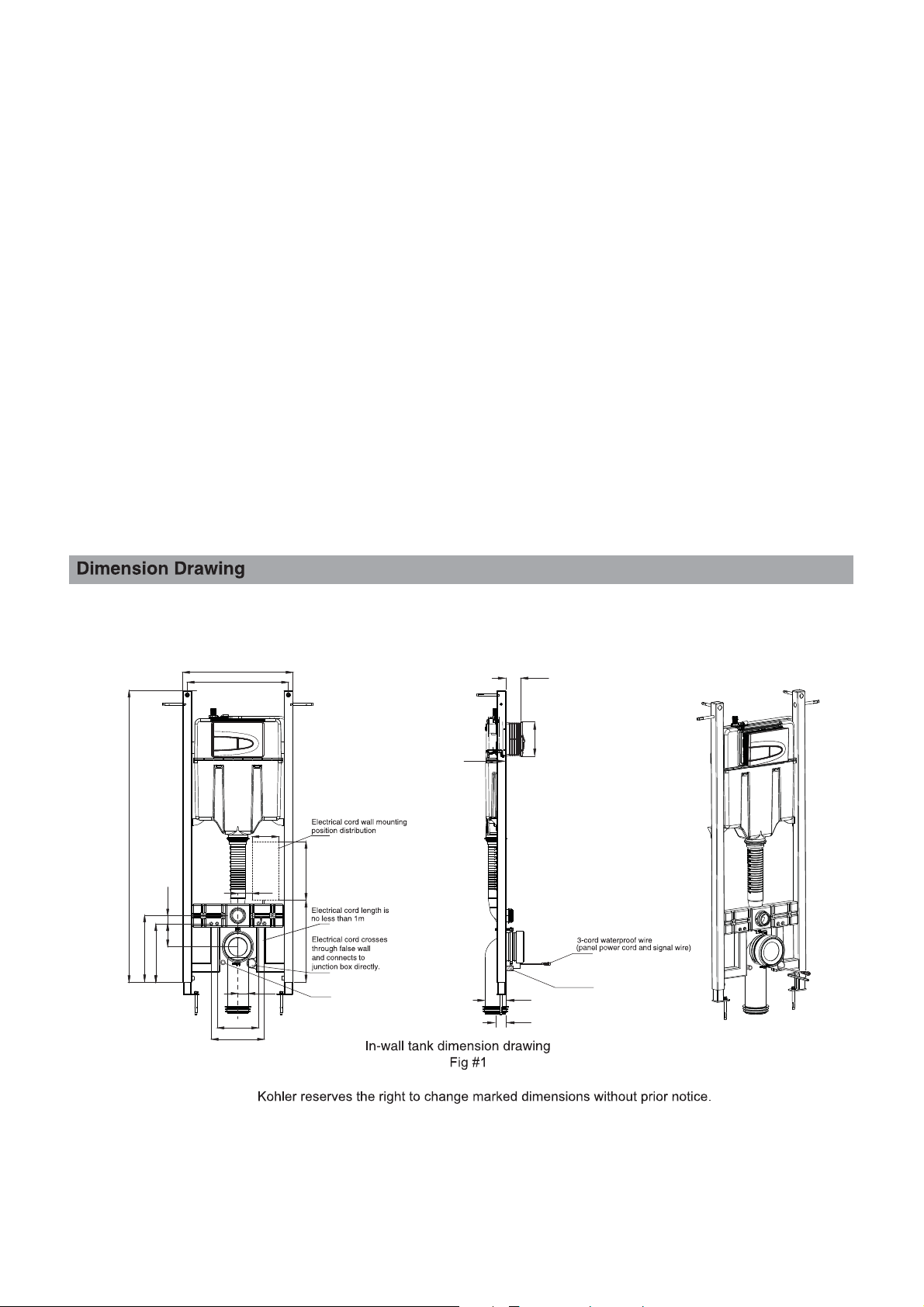

detailed positioning of the hard cord, see diagram below.

478±3

438±3

13~62

88±2

110

150±1

Unit:mm

1265±4

345 ±2

35±2

60

100±3

254±3

45±3

230±3

255

355

Bidet water supply pipe

Bidet water supply connector

90

45

NOTE: S-trap installation shown as default. P-trap configuration is achievable by using a DN80 waste pipe connector.

Kohler Co. Jan 2018 2 1345889-A02-A

Page 3

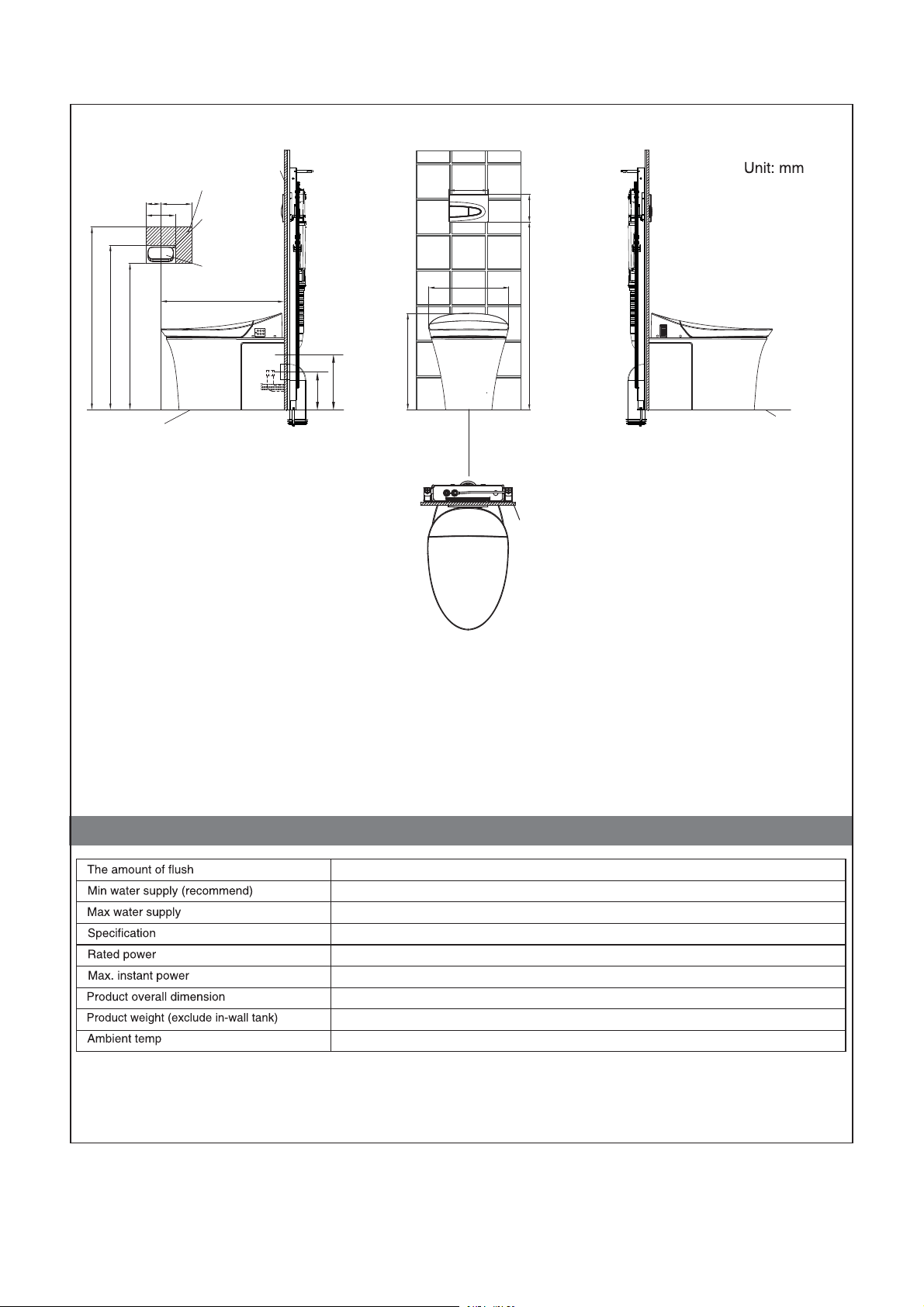

1000

900

Finished floor

800

160

Finished wall

Reference area

170

for installation

Reference area

80

215

150

for application

Remote control

675

(208)

(308)

From floor to

fixing hole centre

533

438

1027

Finished floor

Finished wall

Toilet dimension drawing

Kohler reserves the right to change marked dimensions without prior notice.

SPECIFICATION(8423A-0)

4.5L/3L

70kPa (Dynamic pressure)

740kPa (Static pressure)

220V~ , 50Hz

1000W

1600W

675mm x 438mm x 533mm (Height shall be calculated from floor to the top of the product)

About 48.5Kg.

1- 40 °C

Note: Refer to the User Guide for intelligent bidet specification.

Fig.#2

Kohler Co. Jan 2018 3 1345889-A02-A

Page 4

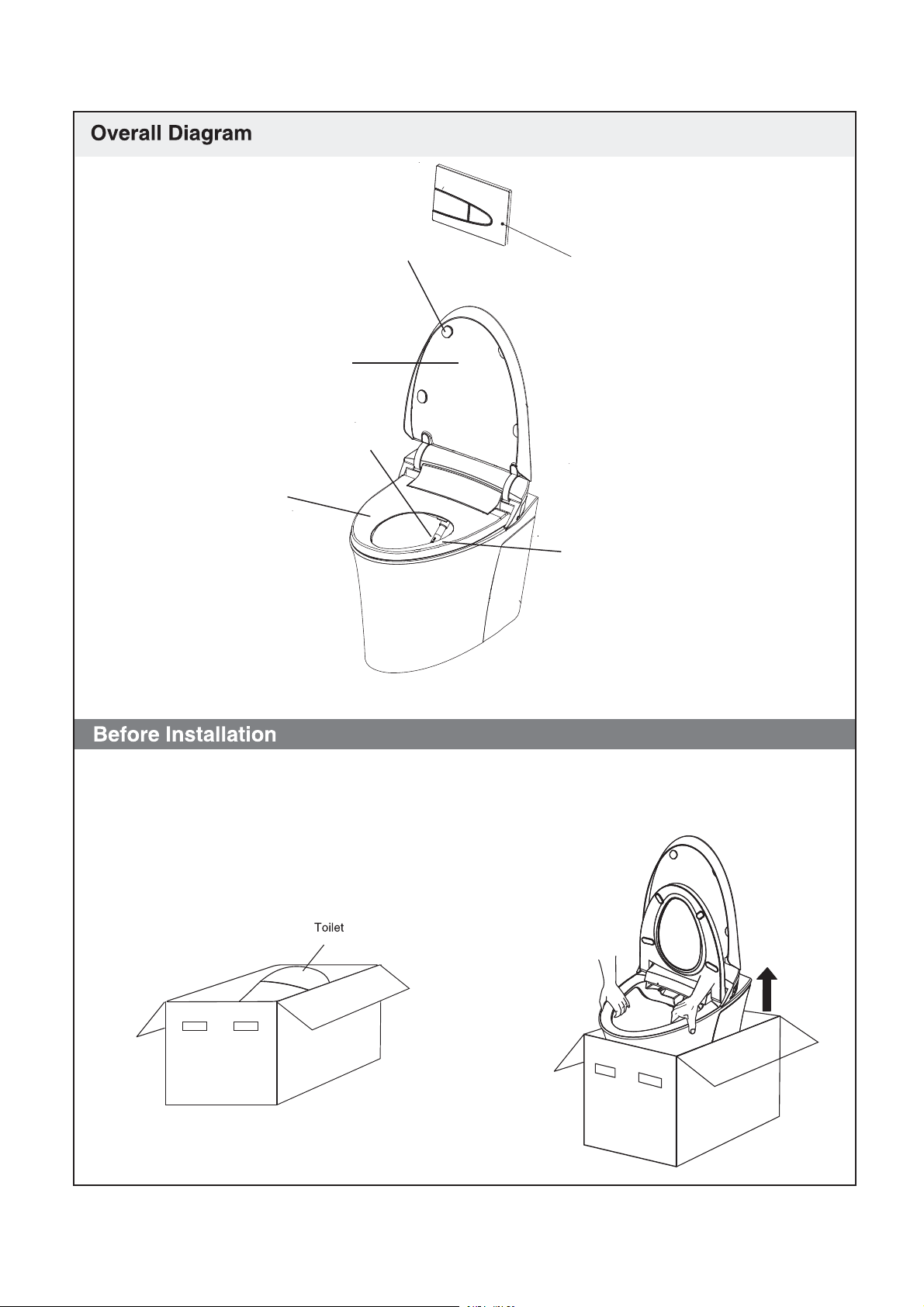

Antibacterial cover

Antibacterial seat

Seat bumpers x4 Flush control panel

(touchless flush detection zone)

Bidet nozzle

Bidet function detection zone

Fig.#3

A. Hold the edge of toilet bowl and slide out from packaging box.

WARNING: Risk of product damage or personal injury. When lifting up the toilet, please hold it by the rim.

Product is heavy, please employ a two-person lift.

Fig.#4

Kohler Co. Jan 2018 4 1345889-A02-A

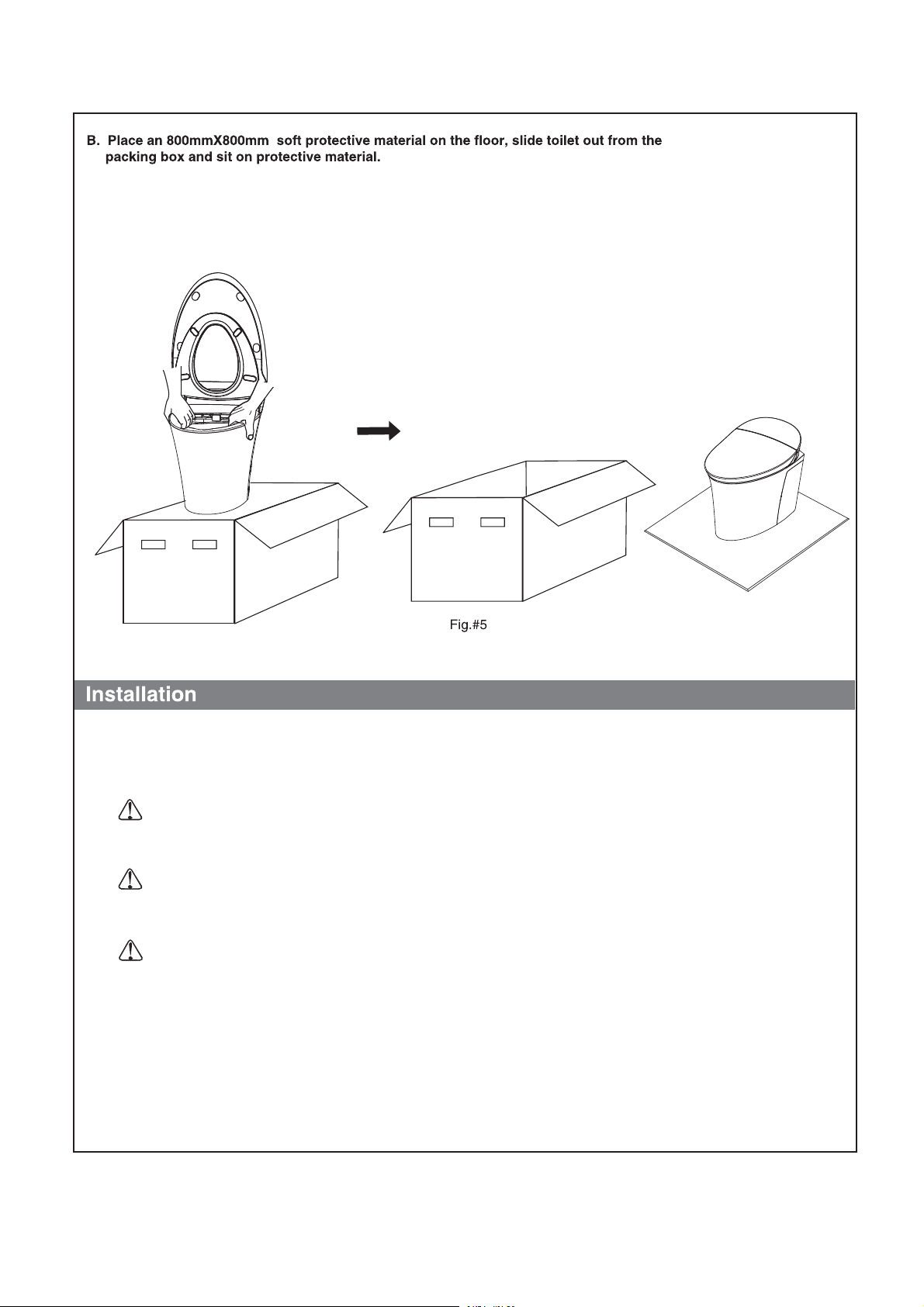

Page 5

A. Where applicable, remove the old toilet

B. Warning for installation

WARNING: Risk of electric shock. Disconnect power before servicing.

Note: The power supply and water pipe of this product is designed for wall face style . Installation

method is marked in dimension drawing.

WARNING: Risk of electric shock. For plug-in installation/wall-mounted electrical supply: Connect only

to a properly-grounded, grounding-type circuit which is protected by a Ground-Fault Circuit-Interrupter

(GFCI) or Earth Leakage Circuit Breaker (ELCB).

WARNING: Bathtub and sprinkler head shall be far away from electrical parts (e.g. remote controller,

power receptacle etc.) if it is wall-hung style, water proof or splash proof receptacle is required. If

wall-mounting power supply is adopted, require anti-water and anti-splash power receptacle.

Kohler Co. Jan 2018 5 1345889-A02-A

Page 6

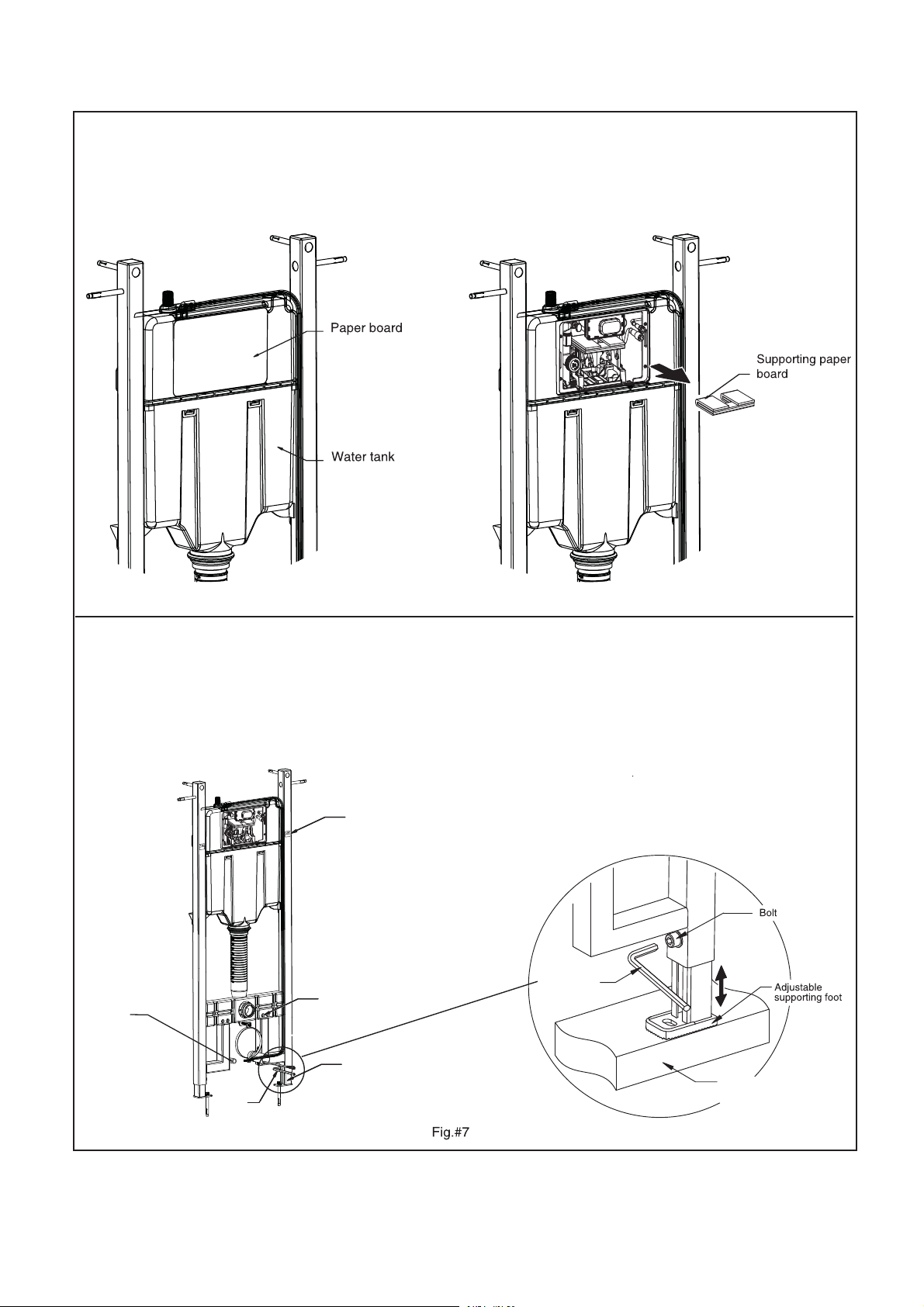

C. In-Wall tank installation

1. Remove the in-wall tank from packing box. Remove paper board from cistern access opening.

Then remove the support paper board under the motor assembly.

Fig.#6

2. Adjust the supporting feet height by loosening the bolts with hex key.

Slide the feet up or down to attain the ideal measurement of 308mm from the floor to the centre of the

bowl fixing holes. The frame should be installed on top of the bottom plate (usually 45mm high). Please allow

for this height when adjusting the feet.

Ensure the adjustment is even by using a level, and tighten the bolts to set the height.

IMPORTANT: Protect electronic connection point and wires from accidental damage.

1 metre height label

(treat 1m as minimum).

Recommended to install frame with

1m mark at 1020mm from floor.

Hex key

Bidet water supply

Bowl fixing holes

Adjustable

Hex

key

support feet

Bottom

plate (nog)

Kohler Co. Jan 2018 6 1345889-A02-A

Page 7

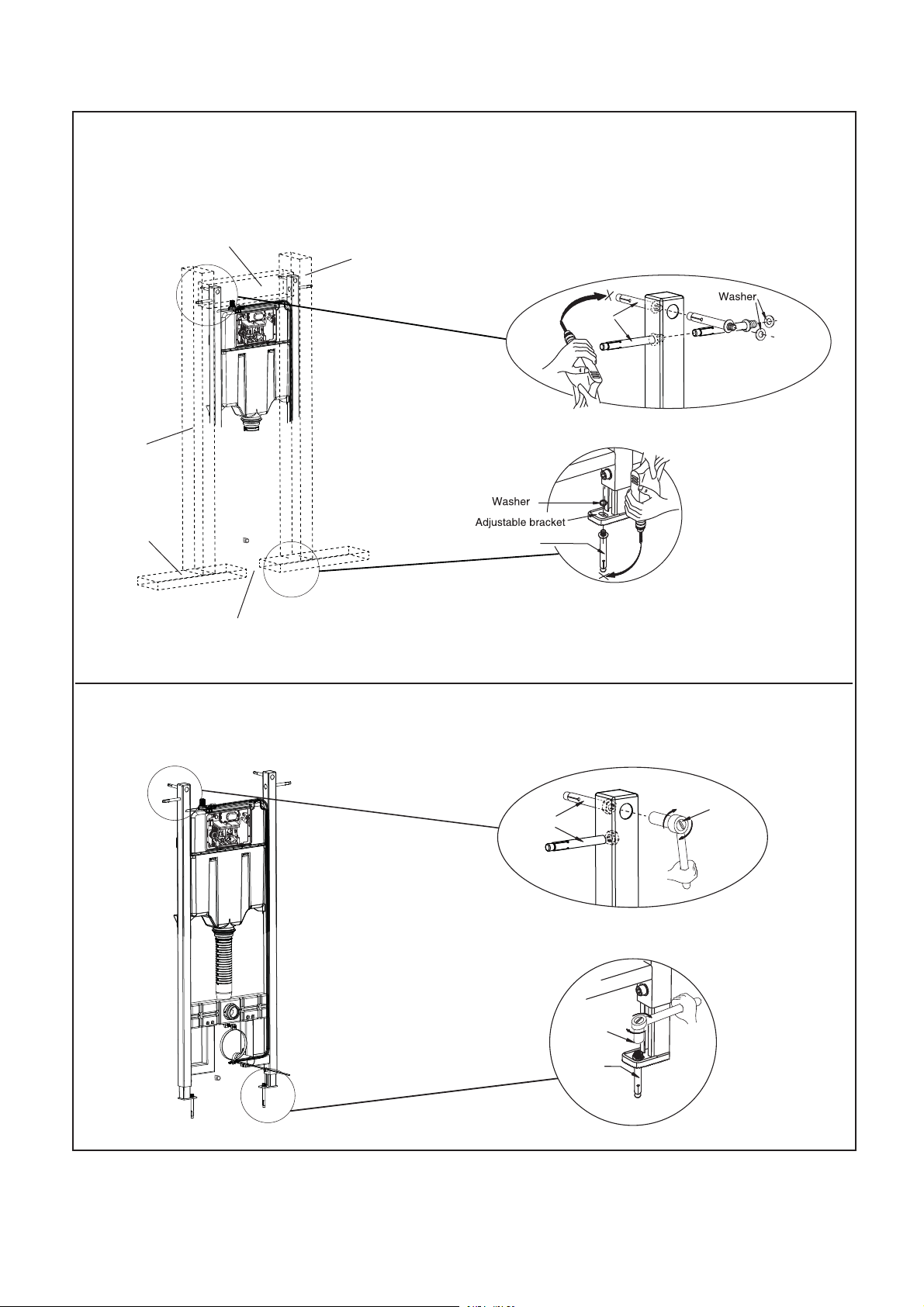

3. Construct a mounting frame to surround the in-wall tank. This should consist of vertical studs and a horizontal

nog,adjacent to the steel supports. If installation is an S-trap configuration, ensure the bottom plate has at least a

100mm cut-out in the centre for the discharge elbow.

If required, drill pilot holes with a drill as shown in Fig A and B.

Insert coach screws with washers into the installation holes in the framework, then tighten.

Repeat for all screws.

Nog

Stud

Coach

screw

Stud

Bottom plate

Gap for

discharge elbow

(S-trap install)

4. Tighten screw by wrench as shown in Fig A.

Tighten screw by wrench as shown in Fig B.

Recommend M6x40 coach

screw with 3mm washer.

Coach screw

Fig.#8

Coach

Screw

A

B

Socket

Wrench

A

Recommend M6x40 coach

screw with 3mm washer.

Socket

Wrench

Coach

Screw

Fig.#9

B

Kohler Co. Jan 2018 7 1345889-A02-A

Page 8

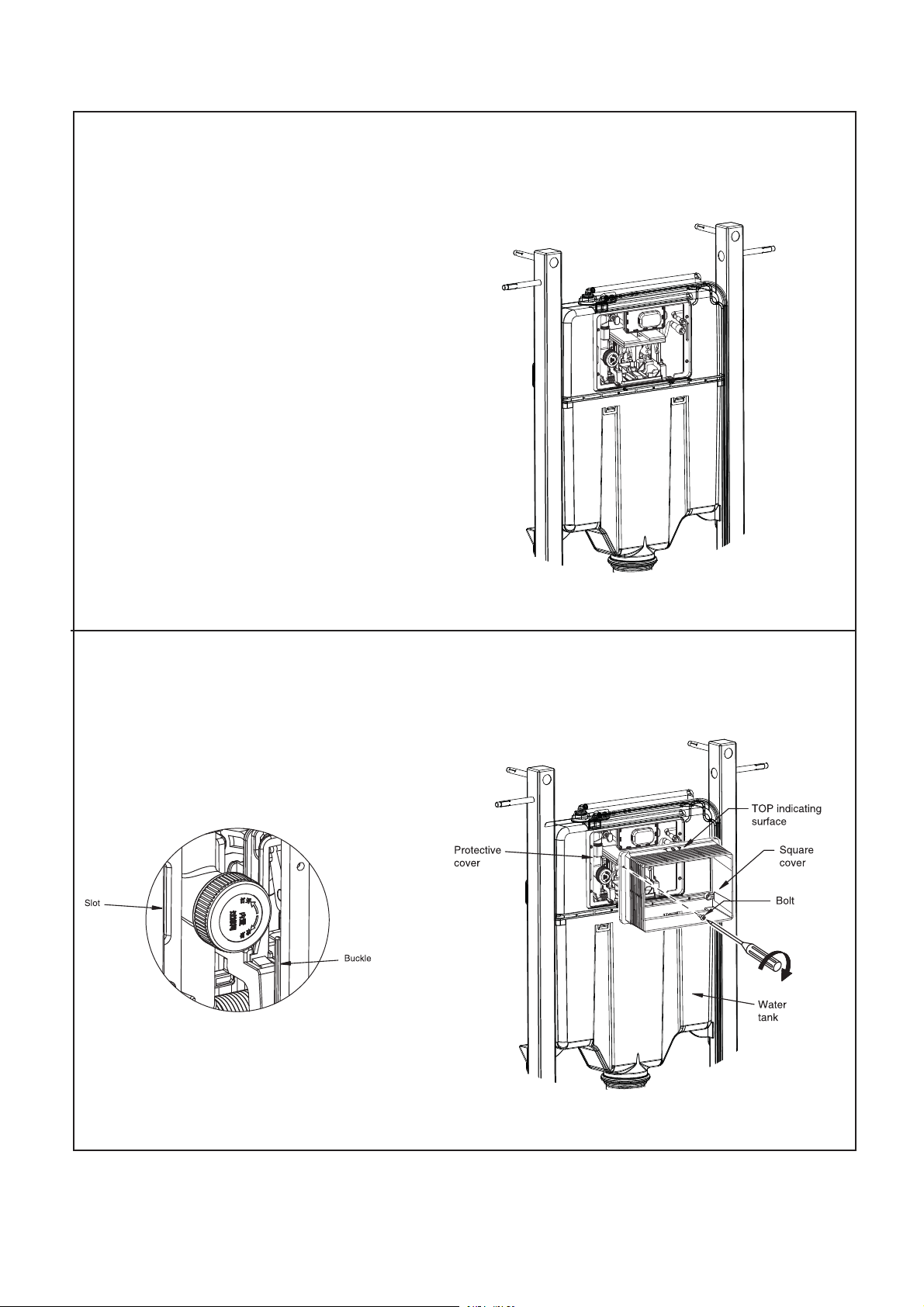

5. Ensure water tank internal valve is OFF.

6. Connect a temporary rubber or plastic hose onto

valve and flush the water supply line. Ensure

water is clean with no residual debris fouling the

inside of the pipeline.

Fig.#10

7. Place square cover within protection cover of water tank.

Snap the buckle into the slot and tighten square cover

bolts on tank.

NOTE: Square cover has the word TOP on it indicating

which surface should face upwards when installed.

Fig.#11

Kohler Co. Jan 2018 8 1345889-A02-A

Page 9

D1. S-trap installation method

Discharge elbow

Water tank bracket

Discharge elbow lower end

Discharge port

Mounting bracket

securing screw

(skip to Step D2 on pg10 for P-trap installation)

1. Loosen the screw on mounting bracket, then insert discharge elbow into the mounting bracket.

Adjust the pipe position and tighten the mounting bracket screw to secure the discharge elbow.

Lastly, insert the discharge elbow lower end into discharge port.

Note: To allow testing of the cistern for

leaks and water level, plug the

water supply for bidet function.

2. Place the bung into the discharge elbow.

Note: Do not lubricate the connection

between pan and waste connector.

Lubricate connection between waste

connector and discharge elbow.

Proceed to Step E on pg10.

Fig.#12

Bowl fixing hole

Discharge elbow

Bidet water supply

Pan waste connector

Bung

Fig.#13

Kohler Co. Jan 2018 9 1345889-A02-A

Page 10

D2. P-trap installation method

Square cover

Finished wall

(refer to Step D1 on pg9 for S-trap installation)

1. Loosen screw on mounting bracket and

insert the waste connector.

Adjust waste connector position and

tighten the mounting bracket to secure.

Mounting bracket

securing screw

Waste connector

for DN80 pipe

Fig.#14

E. Prepare and finish the wall

IMPORTANT: 1. When preparing the wall, the wallboard/tiling cut-out must fit very neatly around the square cover

of flush panel. No large gaps are permitted (tolerance of approx 1mm).

2. There may be significant amounts of dust when preparing the wall - be sure to fit dust cover over

cistern opening and protect the electrical fittings and pipework.

Bowl fixing hole

Cover the

water inlet

Pan waste connector

Bung

Fig.#15

Kohler Co. Jan 2018 10 1345889-A02-A

Page 11

3. Remove the bung from discharge port after finishing the wall preparation, then cut off the excess of square cover

and concealed conduit with a blade.

4. Insert the pan fixing bolts so the washer is hard against the finished wall, notched end outwards for tightening.

NOTE: 1. Ensure the bolt can rotate freely when preparing the wall. The washer should be located outside the wall.

2. When preparing the wall, cross the water inlet hose, control panel signal wire and power cord

through the wall and under the tank.

Finished wall

(shown transparent for clarity)

Water tank

mounting bracket

Square cover

Water inlet

Wall cut-out

Discharge port

Bidet water supply

F. Bowl installation

1. Remove the side panels.

Concealed conduit

Side Panel

Pan fixing bolt hole

Pan fixing bolt

Power supply

cord

Control panel

signal wire

Fig.#16

Blade

Bidet water

supply

Power and data cables

Fixing bolt

Bung

Fig.#17

2. Install the discharge pipe and water inlet pipe as shown. Place a ruler on the rear of the discharge pipe and water

inlet, and use a pencil to mark the position. Adjust the space based on the rear of the toilet to wall discharge port.

Water inlet pipe

Discharge

pipe

Fig.#18

Kohler Co. Jan 2018 11 1345889-A02-A

Page 12

3. Mark the reserved space on the rear end of the discharge and water

inlet pipes.

Cut off the excess and use a file to clean up the edges.

Fig.#19

4. Place the small rubber seal on the water inlet pipe.

Place the big rubber seal on the discharge pipe.

Insert the pipes into the corresponding pipeline.

Small rubber seal

Inlet Pipe

Reserved Space

Drainage Pipe

Water Inlet Pipe

Discharge Pipe

Fig.#20

Big rubber seal

5. Connect bidet water supply hose (straight end onto the water supply fitting on tank frame). Feed hose under the

pan connector (discharge pipe) and attach the MF fitting onto the 90º bend. Attach this end to the pan inlet.

Ensure the pan fixing bolts are tight against the wall, as shown.

Apply grease to the discharge port to ease installation.

CAUTION: Toilet is heavy, use a two person lift.

Bidet water supply

Bidet water

supply hose

Lubricant

Bidet water

supply hose

Fixing bolt

M-F fitting

90º bend

Fig.#21

Kohler Co. Jan 2018 12 1345889-A02-A

Page 13

6. Place lag washer, rubber bush, washer onto the lag bolts, as shown.

Thread on the hex nuts and tighten with a 19mm spanner or wrench.

Place a level across the rim to ensure the toilet is flat.

Spanner

Bush

Fig.#22

7. Remove the two screws on the right-hand side of the toilet

and remove the side panel.

Remove the 3 remaining screws and remove the

junction box cover.

Level

Fig.#23

8. Feed the power cord through the rubber gasket from

the wall and connect to the junction box.

Power switch is OFF

Green light OFF

Valve is OFF

NOTE: Wiring order shall be L, N, Ground from top to bottom.

L - Live wire

N - Neutral wire

- Grounding wire

Fig.#24

Kohler Co. Jan 2018 13 1345889-A02-A

Page 14

9. After completing the wiring work, adjust power

input and lock the junction box cover.

Power switch is OFF

Green light OFF

10. Ensure the in-wall tank water outlet hose

connection is tightened and does not leak.

11.Turn power switch to ON and open water inlet

valve.

Fig.#25

12. Apply silicone sealant around the back edge of the pan

to ensure a clean adhesion to the wall.

Install the left and right side panels.

Valve is ON

In-Wall tank

water outlet hose

Fig.#26Apply silicon gel

Side panel

G. Water Level adjustment

1. Follow the steps 6 to 11 on page 19 and 20 of this document

to remove the water inlet valve.

Water inlet valve

Fig.#27

Kohler Co. Jan 2018 14 1345889-A02-A

Page 15

2. Turn the screw clockwise to increase the water level by +5mm.

Place the water inlet vavle in its original position.

Fig.#28

H. Control panel installation

1. Slide water splash plate into Slot A and B in square cover.

NOTE: After the splash plate is installed, the locators should be under the

surface.

Snap in position

Locators

Fig.#29

I. Top Button installation

1. When locating the four locknuts on supporting board,

adjust to OPEN mark, as shown.

Square cover

Slot B

Water

splash

plate

Slot A

Locknut

Fixing lock

Supporting board

Fig.#30

Kohler Co. Jan 2018 15 1345889-A02-A

Page 16

2. Tighten the four screws to LOCK mark after installing

the supporting board.

Fig.#31

3. Screw two lag bolts into the bracket, as shown. Ensure

the bolts are perpendicular to the wall.

Locknut

Supporting board

Bolt

Supporting bracket

Fig.#32

4. Align control panel in position, the push forward and fasten.

Install motor assembly signal wire and control panel signal

Wire into U type hole of splash plate, as shown below.

U type hole

Supporting

board

Lag Bolt

Cover

board

Control panel signal wire

Motor assembly signal wire

Fig.#33

Kohler Co. Jan 2018 16 1345889-A02-A

Page 17

5. Once connected to the power and water supply, the toilet is ready for use.

Flush FULL button

Flush ECO button

Fig.#34

Dismantle and service discharge valve

1. Dismantle the control panel, as shown.

Hold control panel bottom with both hands and push upward to open the panel. Ope from the bottom up.

Dismantle motor assembly signal wire and control panel signal wire.

Control panel signal wire

Motor assembly signal wire

2. Unscrew two lag bolts as shown

Snap in position

Fig.#35

Supporting

board

Cover board

Bolt

Lag bolt

Bracket

Fig.#36

Kohler Co. Jan 2018 17 1345889-A02-A

Page 18

3. Pay special attention when dismantling supporting board.

All 4 lock nuts should align with the OPEN mark.

Fig.#37

4. Dismantle supporting board as shown.

Locknut

Supporting board

5. Pull water splash plate out

Supporting board

Fig.#38

Square cover

Water splash

plate

Snap in position

Fig.#39

Slot A

Kohler Co. Jan 2018 18 1345889-A02-A

Page 19

6. Dismantle motor assembly snap-in mechanism, remove motor assembly.

Fig.#40

7. Hold bracket top by hand as shown, then lift up to unlock the bracket.

Motor assembly

Snap-in mechanism

Bracket

Fig.#41

8. Take discharge valve lever out from lag washers on both ends as shown.

Lever clip

Lag washer

Fig.#42

Kohler Co. Jan 2018 19 1345889-A02-A

Page 20

9. Open/close water supply.

Rotate valve switch to open/close water supply as shown.

Valve

On

Off

Fig.#43

10. Loosen filter nut, as shown.

Nut

Loose

Filter

Fig.#44

11. Remove the water inlet valve for cleaning or adjusting.

Tighten

Water inlet valve

Fig.#45

Kohler Co. Jan 2018 20 1345889-A02-A

Page 21

12. Hold fastener by hand as shown, pull the top of fastener

along with the direction of arrow .

Then remove fastener.

Fig.#46

13. To remove the discharge valve, rotate valve along

the arrow direction, as shown. It should make a

“click” sound when installing or removing.

Fastener

Fastener

Outlet Valve

Fig.#47

14. Loosen discharge valve as shown and then take valve out

for cleaning or adjusting.

Outlet

Valve

Fig.#48

Kohler Co. Jan 2018 21 1345889-A02-A

Page 22

I. Clean Filter

Loosen filter locknut, as shown.

Clean filter dirt with water and tighten locknut back in

original position.

Filter

Filtration Net

Tighten

Fig.#49

J. Discharge valve adjustment

Adjust water tank flush volumes as shown:

Full Flush: 1. Open adjustment switch

2. Open small hole

Half Flush: 1. Adjust float box position

(water level should be on the bottom of float box)

Adjustment Switch

Loosen

Locknut

Floating Box

Drainage valve

Fig.#50

K. Water inlet valve adjustment

Inlet Valve

Adjusting the control pole will cause the water level to

change within the water tank.

Control Pole

Turn the pole clockwise to increase the water level and

anti-clockwise to reduce it.

Floating Box

Fig.#51

Kohler Co. Jan 2018 22 1345889-A02-A

Page 23

Install Remote Control Docking Station

NOTE: Use suitable mounting methods for the wall construction material. Special fixings may be required for

walls made of plasterboard.

NOTE: Do not install this appliance in positions where it might come in contact with water.

1. Select a proper position for the control docking station to be installed. The position shall be easily operated by

the user when seated on the toilet.

2. Based on the docking station hole positions, drill two 6mm diameter holes, 45mm deep.

3. Insert lag bolt anchors into the holes.

4. Remove the double-sided tape and place docking station over the fixing holes.

5. Fasten docking station with screws and place bushing on the bolts.

Fig.#52

Steps of installation Public anti-loss installation

Screw

Lag bolt

anchor

Lag bolt

Hook

Fig.#53

Hook board

Remove rubber

plug

Remove rubber

plug

Remote control

Docking station

Gasket

Kohler Co. Jan 2018 23 1345889-A02-A

Page 24

TROUBLE SHOOTING

This troubleshooting guide is for general aid only. A Kohler Authorised Service Representative should correct any

electrical problems. For warranty service, contact your dealer or wholesale distributor.

Symptoms Probable Causes Recommended Action

1. Toilet does not work. A. A power failure occurred. A. Wait until the power is restored.

B. Product is under protected status. B. Turn power off at switchbox and then

turn back on.

C. Toilet is OFF. C. Turn on switch on terminal box.

2. Toilet does not flush. A. No water supply. A. Wait for restoration of water supply.

B. The water supply stop is closed. B. Open the water supply stop.

C. A power failure occurred. C. Wait until the power is restored or check

“manual flush” section.

D. Product is under protected status. D. Turn on switch on terminal box.

3. Toilet does not flush A. Filter screen is clogged. A. Refer to “Clean filter screen” section

completely. B. Insufficient manual button travel. B. Dismantle water outlet control panel,

adjust manual flush adjustment rod.

4. Clean function does A. No water supply. A. Wait for restoration of water supply.

not operate properly. B. Water supply valve is not fully open. B. Fully open water supply valve.

C. Toilet is on OFF mode. C. Turn on switch on terminal box

D. Unseated or current sitting position is D. Sit again or adjust sitting position.

unable to detect.

E. Filter screen is clogged. E. Refer to “Clean and Replace Filter

Screen” section.

F. Insufficient water supply pressure. F. Inspect water inlet hose for any sharp

bending. Adjust hose if required.

.

5. Flush function stops A. Auto stops flush function after continuous A. If needed, press flush button again.

during operation. 5 min flushing.

B. The seat does not detect any user. B. Adjust sitting position and sit again.

6. Spray function starts A. The seat is covered by an object or the A. Remove object and wipe the seat.

even when unseated. seat is wet.

7. Dryer stops working A. Dryer auto stops after continuous 4 min. A. If needed, press dryer button again.

during operation. B. The seat does not detect any user. B. Adjust sitting position and sit on again.

8. Deodoriser fan stops A. The seat sensor is not detecting the user. A. Remove object or wipe seat.

working B. Accidental pressing of STOP button. B. If needed, sit on again after 2 seconds.

C. Auto deodorising function is disabled. C. Refer to “Remote setting guide” section.

9. Unable to open or A. The seat sensor is not detecting the user. A. Remove object or wipe seat.

close cover. B. Customer interference during previous B. Use the remote or manually open/close

cover swing process. cover back to normal position.

*Do not block switch during swing process*

10. Unable to auto A. User does not enter/leave detecting zone. A. Enter or leave detecting zone.

open/close cover. B. Remote “auto swing” function is OFF. B. Refer to “Remote setting guide” section.

C. Toilet is flushing. C. Wait until toilet flush process completes.

11. Night light is not A. Night light function is OFF. A. Refer to “Auxiliary side panel function”

Kohler Co. Jan 2018 24 1345889-A02-A

Page 25

TROUBLE SHOOTING (continued)

This troubleshooting guide is for general aid only. A Kohler Authorised Service Representative should correct any

electrical problems. For warranty service, contact your dealer or wholesale distributor.

Symptoms Probable Causes Recommended Action

12. UV sterilisation A. Customer sits on seat. A. Please close cover and reactivate UV

stops. sterilisation and close toilet cover.

B. The seat is wet or covered by an object. B. Remove objects or wipe seat.

13. No display on A. Battery runs out. A. Install new battery.

remote. B. Wrong battery installation. B. Re-install battery correctly.

C. Remote has not been awakened yet. C. Touch remote screen.

Approach or sit on toilet.

Press awaken button on remote.

14. Remote unable to A. Battery runs out. A. Refer to “Remote battery use and

control toilet. replace” section to replace battery.

B. Remote to toilet distance is too far. B. Refer to “Remote - toilet communication”

section and move remote closer to toilet.

C. Toilet power is not ON. C. Connect toilet power supply.

D. Toilet is under OFF mode. D. Turn on switch to terminal box.

E. Toilet and remote are not connected. E. Refer to “Remote - toilet communication”

section, connect toilet to remote.

15. Seat temp is low A. Seat temp is OFF. A. Refer to “Remote guide” section

when seated. for temperature settings.

B. Energy saving mode. B. Refer to “Remote guide” section to exit

energy saving mode.

16. No water supply A. Water inlet valve is not OPEN. A. Open water inlet valve.

from inlet valve. B. Water inlet float is covered by other parts. B. Adjust other parts to avoid any contact

with float during operation.

C. Water inlet valve float blocked by debris. C. Clean float with water.

17. No water when A. Wrong adjusting board and screw rod A. Re-install screw rod.

pressing FLUSH FULL installation.

or FLUSH ECO button. B. Discharge valve lever and barb are not B. Re-install barb on discharge valve lever

connected. and snap in.

18. Water level is high A. Water inlet valve float is not set properly. A. Adjust water level again.

or too low.

19. Toilet leaks. A. Foreign objects are blocking water inlet A. Adjust other parts to avoid any contact

valve float when water enters the tank. float during process.

B. Foreign objects on water sealing piece. B. Remove foreign objects on water sealing

piece.

NOTE: To service the toilet, please observe the following rules:

Turn off switch on terminal box.

If necessary, open the water supply valve.

Please cut off power supply before servicing terminal box.

Kohler Co. Jan 2018 25 1345889-A02-A

Page 26

Customer Obligations

If you live where the water quality is hard, you must keep your discharge hole clean to ensure proper toilet

operation.

Clean your toilet at least once a week, and use a long handle brush to clean discharge hole. Insert the brush in as

much as possibly to prevent mineral matter accumulation.

Most toilet cleaners are not harmful to eh vitreous china surface of the toilet pan. Kohler Co. does not recommend

the use of any cleaning products which are submerged in the cistern as the acids contained within the cleaner will

prematurely deteriorate gaskets and valve parts. Please follow the pan cleaner manufacturer’s instructions carefully.

Please follow manufacturer instructions when using toilet cleaning products. Do not use harsh abrasive cleaners.

Do not use corrosive detergents or solutions on or near the seat.

WARNING: Any damage caused by chlorine (Lime Hypochlorite) shall void the KOHLER warranty.

WARNING: Do not use cement to install toilet. The cement thermal expansion may cause toilet feet to

be damaged and/or burst. KOHLER will not be responsible for any toilet damage caused by

unsuitable installation products or methods.

WARNING: Prevent toilet damage. Do not toss unusual products into toilet which may cause clogging.

Do not apply impact forces to bowl as it may cause damage and water leakages.

Do not use toilet when ambient temperature is lower than 1°C.

Note: Refer to the homeowner’s guide (document #1274372-A05) for bidet cleaning and service information.

Note: Completely flush water supply pipe to eliminate debris and impurities from pipeline before connection.

Use potable tap water for water supply.

CONTACT AND WARRANTY INFORMATION

For warranty information, please visit our website

Australia

www.kohler.com.au

New Zealand

www.kohler.co.nz

CALL US FOR HELP

NEW ZEALAND AUSTRALIA

KOHLER NZ LTD KOHLER CO.

Free Ph: 0800 564 537 (0800 KOHLER) Free Ph: 1 800 KOHLER

Free Fax: 0800 664 488 (1 800 564 537)

www.kohler.co.nz www.kohler.com.au

Kohler Co. Jan 2018 26 1345889-A02-A

Loading...

Loading...