Page 1

Installation Guide

Bath Whirlpool

K-1106, K-1112, K-1114,

K-1126, K-1131, K-1139,

K-1144, K-1154, K-1157,

K-1160, K-1192, K-1194,

K-1209, K-1224, K-1239,

K-1244, K-1257

M product numbers are for Mexico (i.e. K-12345M)

Los números de productos seguidos de M corresponden a México

(Ej. K-12345M)

Français, page “Français-1”

Español, página “Español-1”

1011092-2-F

Page 2

Important Information

WARNING: When using electrical products, basic precautions should always be followed,

including the following:

Building materials and wiring should be routed away from the pump body and other heat-producing

components of the unit.

Install to permit access for servicing.

Grounding is required. The unit should be installed by a qualified service representative, and grounded.

WARNING: Risk of electric shock. A qualified electrician should make all electrical connections.

WARNING: Risk of electric shock. Disconnect power before servicing.

WARNING: Risk of injury or property damage. Please read all instructions thoroughly before

beginning installation, including the following requirements.

NOTICE: Follow all local plumbing and electrical codes.

Product Information

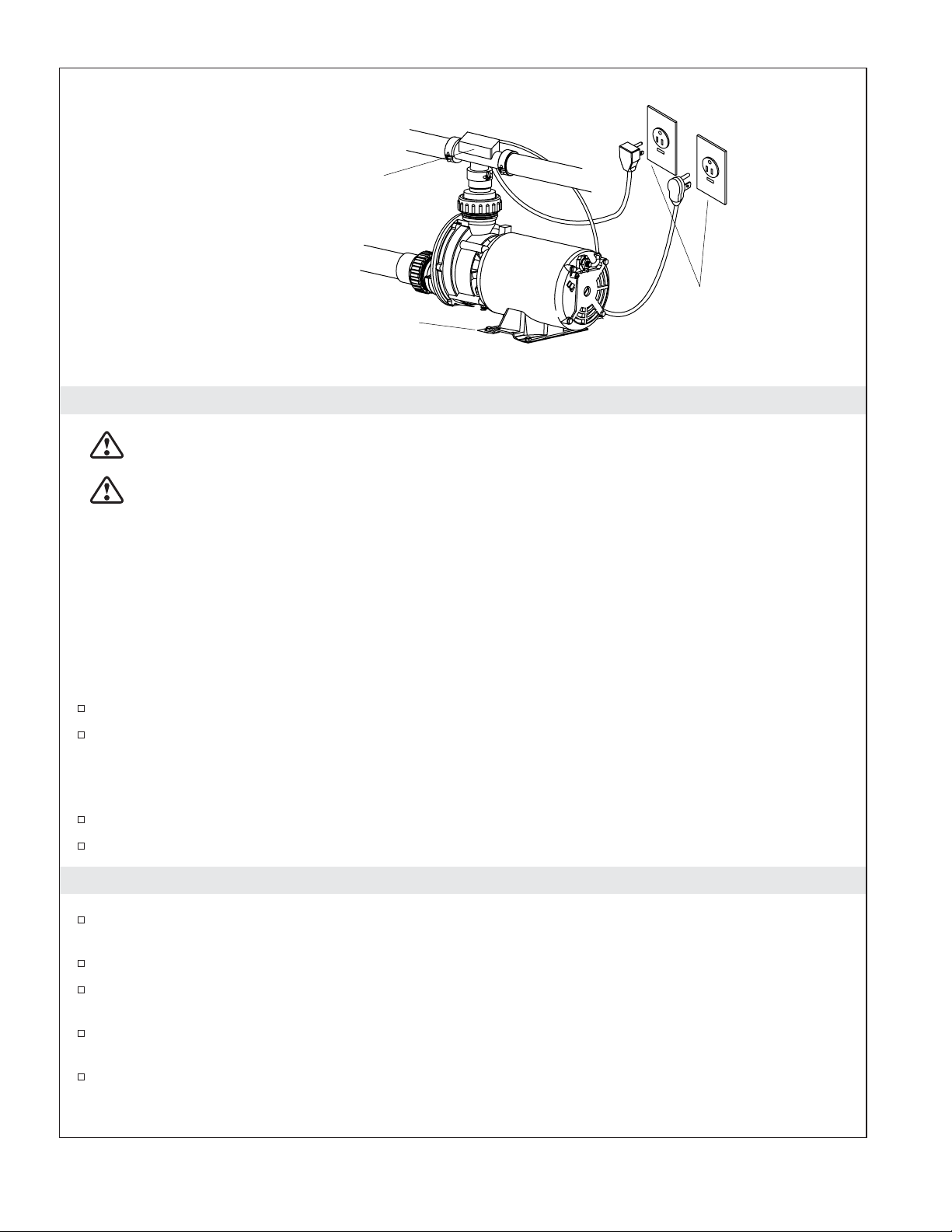

Electrical Requirements

The installation must have a Class A Ground-Fault Circuit-Interrupter (GFCI) or Residual Current Device

(RCD). The GFCI or RCD protects against line-to-ground shock hazard. Use a 120 V, 15 A, 60 Hz dedicated

service for the whirlpool.

″H″ models require a separate 120 V, 15 A, 60 Hz dedicated service for the heater.

NOTE: If the pump supply cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualified persons in order to avoid a hazard. The heater supply cord cannot be replaced. If the

cord is damaged the heater should be replaced.

Product Notices

WARNING: Unauthorized modification may cause unsafe operation and poor performance of the

whirlpool. Do not relocate the whirlpool pump, or make other modifications to the whirlpool

system, as this could adversely affect the performance and safe operation of the whirlpool. Kohler

Co. shall not be liable under its warranty or otherwise for personal injury or damage caused by any

such unauthorized modification.

WARNING: Risk of electrical shock. Disconnect power before servicing.

WARNING: Risk of electrical shock. A qualified electrician should make all electrical connections.

WARNING: Risk of injury or property damage. Please read all instructions thoroughly before

beginning installation.

NOTICE: Follow all local plumbing and electrical codes.

Factory-Assembled Features

Factory installed components include pump with power supply cord and air switch transmitter. No

installation is needed.

″H″ models are also supplied with a factory assembled heater.

The whirlpool pump and piping are factory-assembled.

Connections and Service Access

Before installation, ensure proper access to the final connections.

1011092-2-F 2 Kohler Co.

Page 3

Product Information (cont.)

NOTICE: Provide unrestricted service access to the pump. You must provide access for servicing the

pump and controls. The access must be located immediately next to the pump. Study the Roughing-In

Guide packed with the whirlpool.

Table of Contents

Important Information .............................................................. 2

Product Information ............................................................... 2

Tools and Materials ............................................................... 3

Before You Begin ................................................................. 4

Prepare the Site ................................................................. 5

Prepare the Whirlpool ............................................................. 5

Secure the Unit — Models With Support Blocks .......................................... 6

Secure the Unit — Models With Whirlpool Base .......................................... 7

Secure the Whirlpool to the Stud Framing ............................................... 8

Cut the Pump Banding Straps — Models With Support Blocks ............................... 8

Install the Plumbing ............................................................... 8

Make Electrical Connections ......................................................... 9

Test Run the Whirlpool ............................................................. 9

Complete the Finished Wall ........................................................ 10

Removing the Apron .............................................................. 10

Clean-Up After Installation ......................................................... 10

Confirm Proper Operation .......................................................... 11

Troubleshooting ................................................................. 12

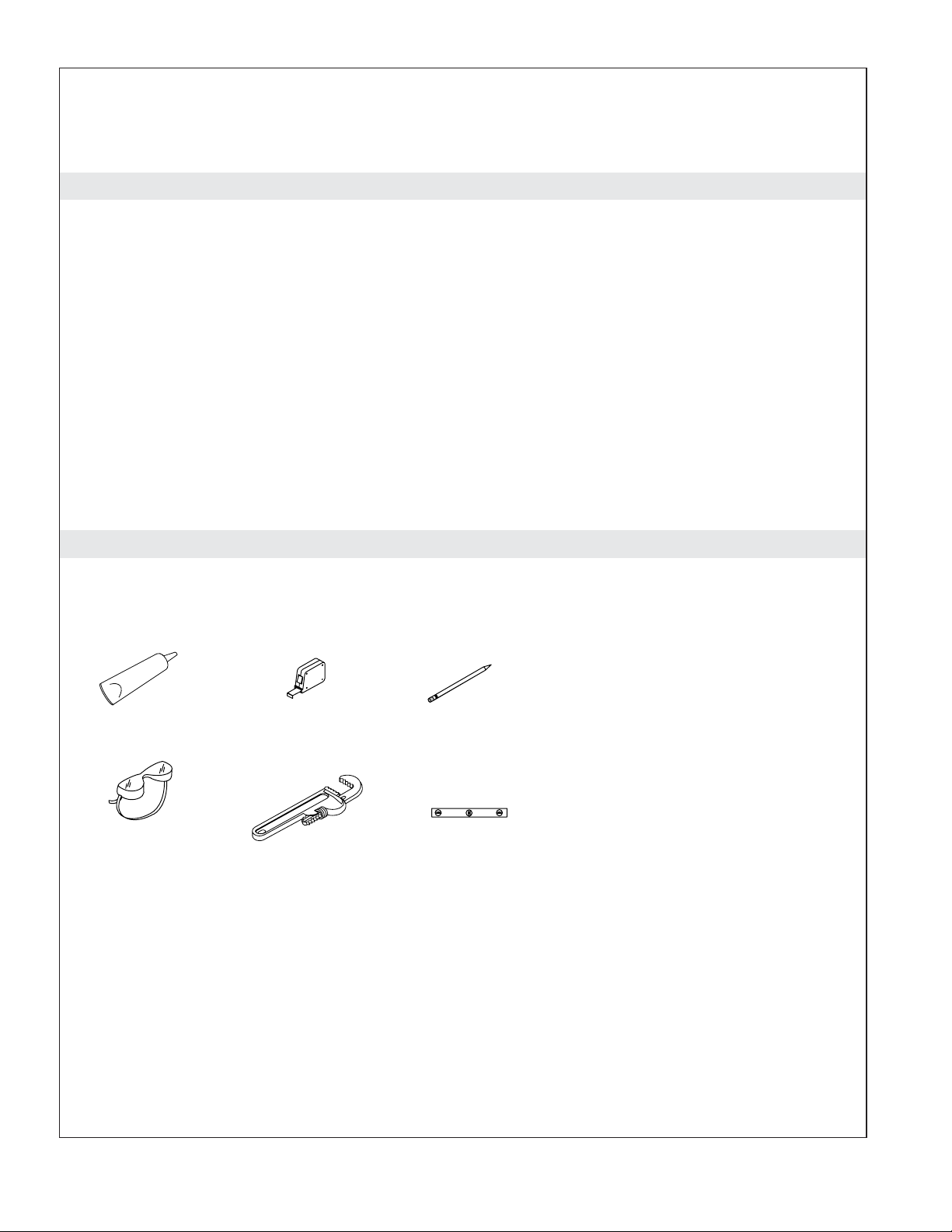

Tools and Materials

Silicone Sealant

Safety Glasses

Tape Measure

Pipe Wrench

Pencil

Level

Plus:

• Conventional woodworking tools

and materials

• Drop Cloth

• Construction adhesive (optional)

• Cement or mortar (optional)

• 2x4s or 2x6s

• Screws or Lag Bolts

Kohler Co. 3 1011092-2-F

Page 4

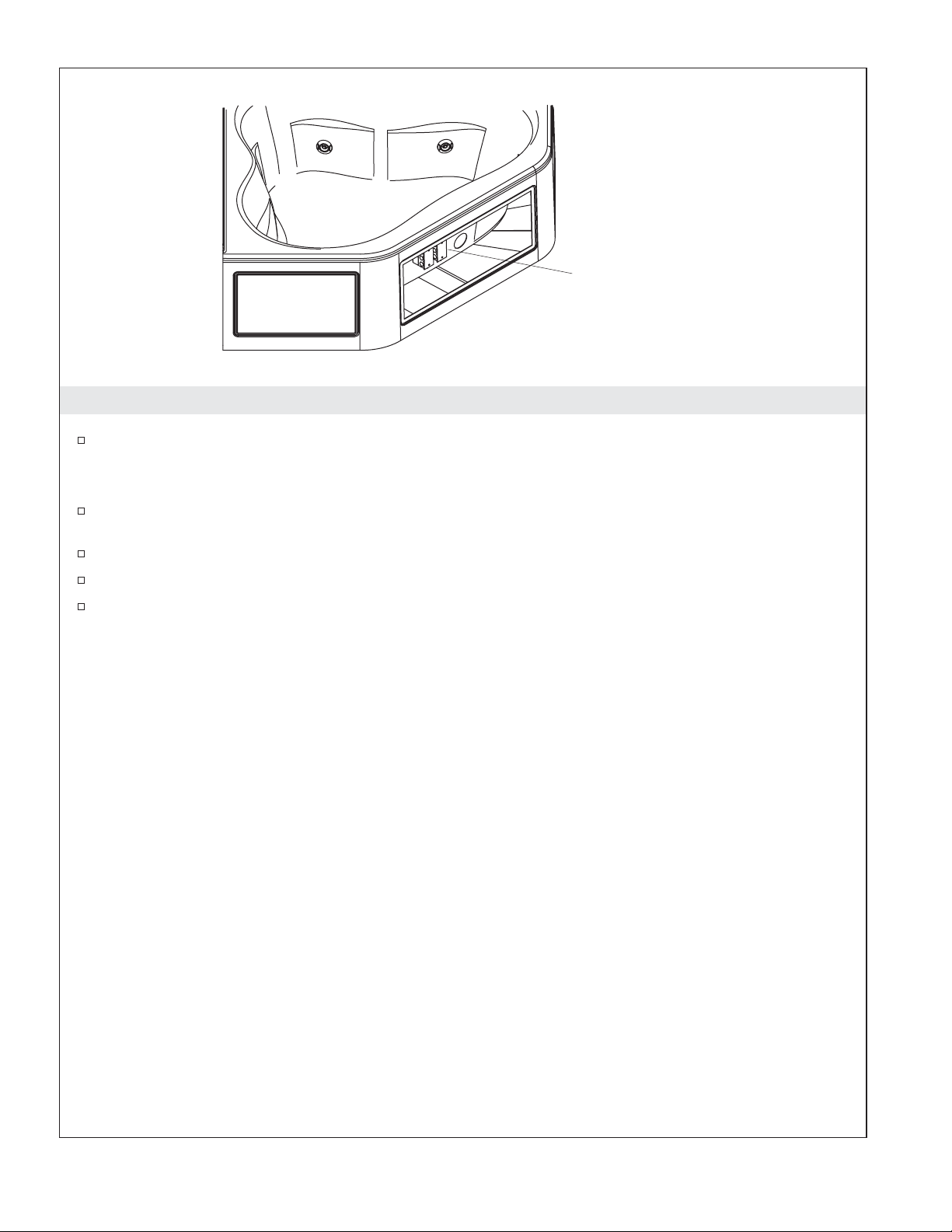

Install the outlets for

the pump and heater

(if used) to the

mounting plate.

Outlet

Before You Begin

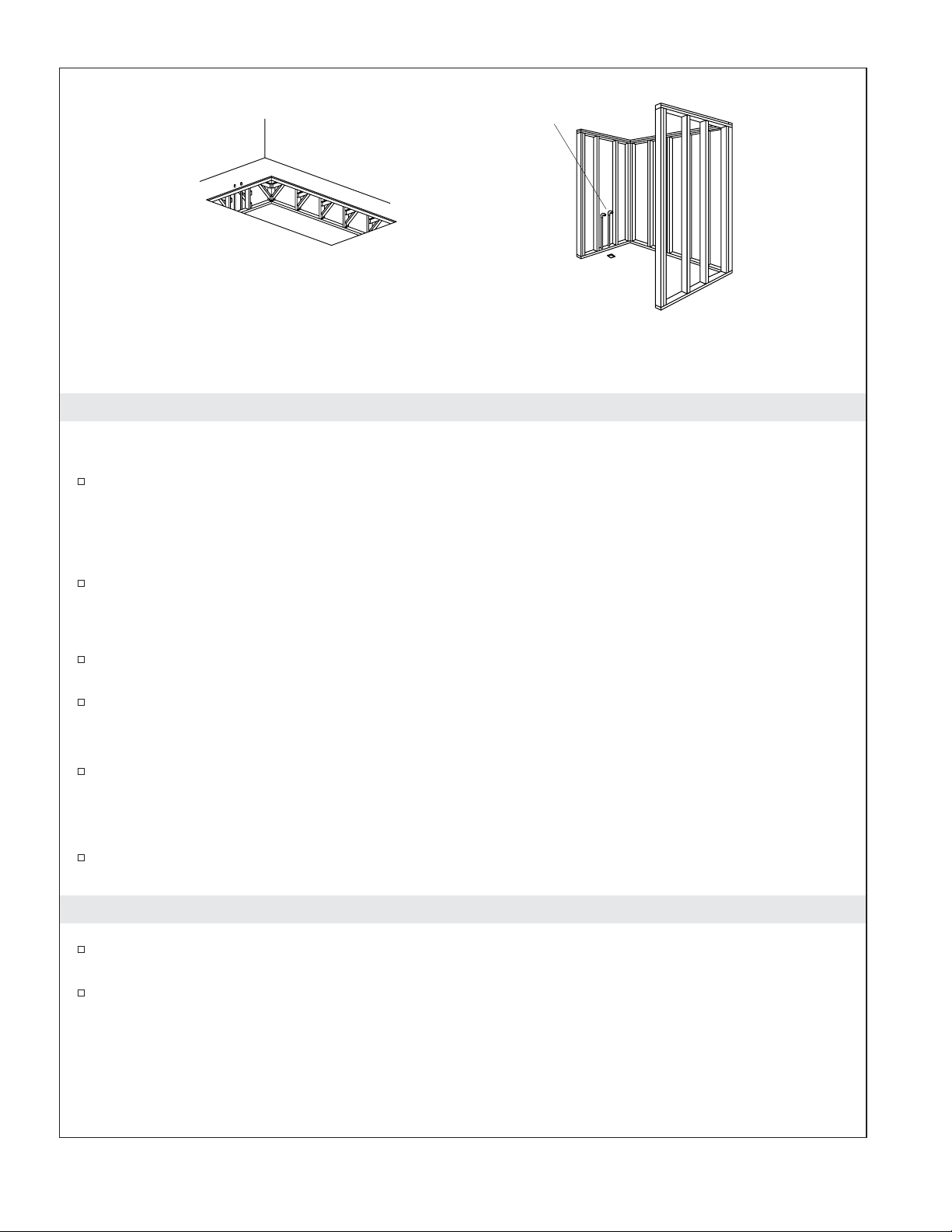

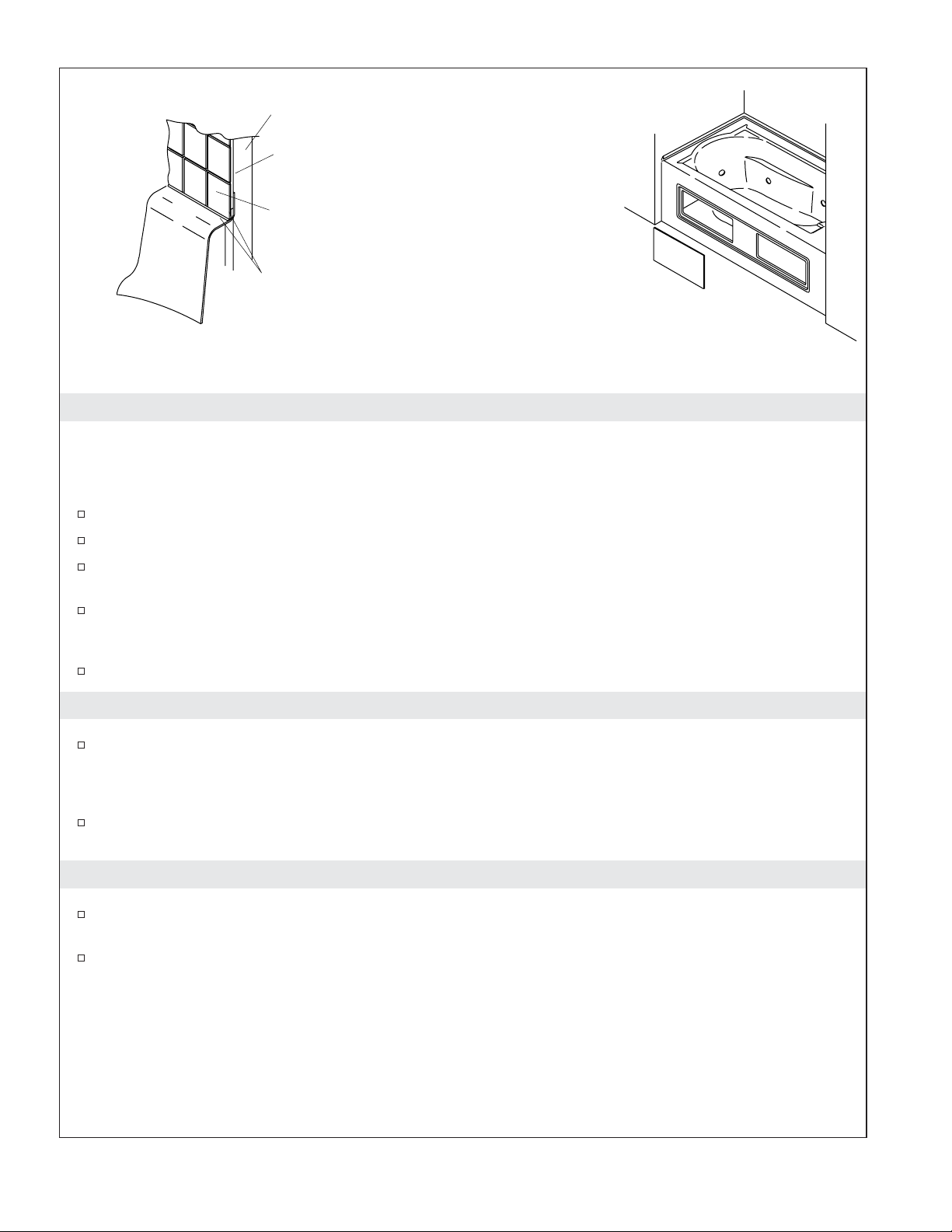

For whirlpools without an apron: A drop-in installation is necessary. For whirlpools with integral

or optional apron: An alcove or corner installation is recommended, depending upon the model

chosen.

For corner units with integral apron: Have a qualified electrician install the outlets for the pump

and heater (if used) at the specified location on the whirlpool. Refer to the above illustration.

Inspect the whirlpool for damage before you begin installation.

Confirm adequate mounting and connection space for the faucet specified for your installation.

Kohler Co. reserves the right to make revisions in the design of products without notice, as specified

in the Price Book.

1011092-2-F 4 Kohler Co.

Page 5

Position the

rough plumbing.

Construct 2x4 or

2x6 stud framing

according to the

roughing-in

information.

Verify that the subfloor

offers adequate support,

and is flat and level.

Position the rough

plumbing.

Construct 2x4 or 2x6

stud framing according

to the roughing-in

information.

Frame the floor

according to the

roughing-in information.

Verify that the subfloor

offers adequate support,

and is flat and level.

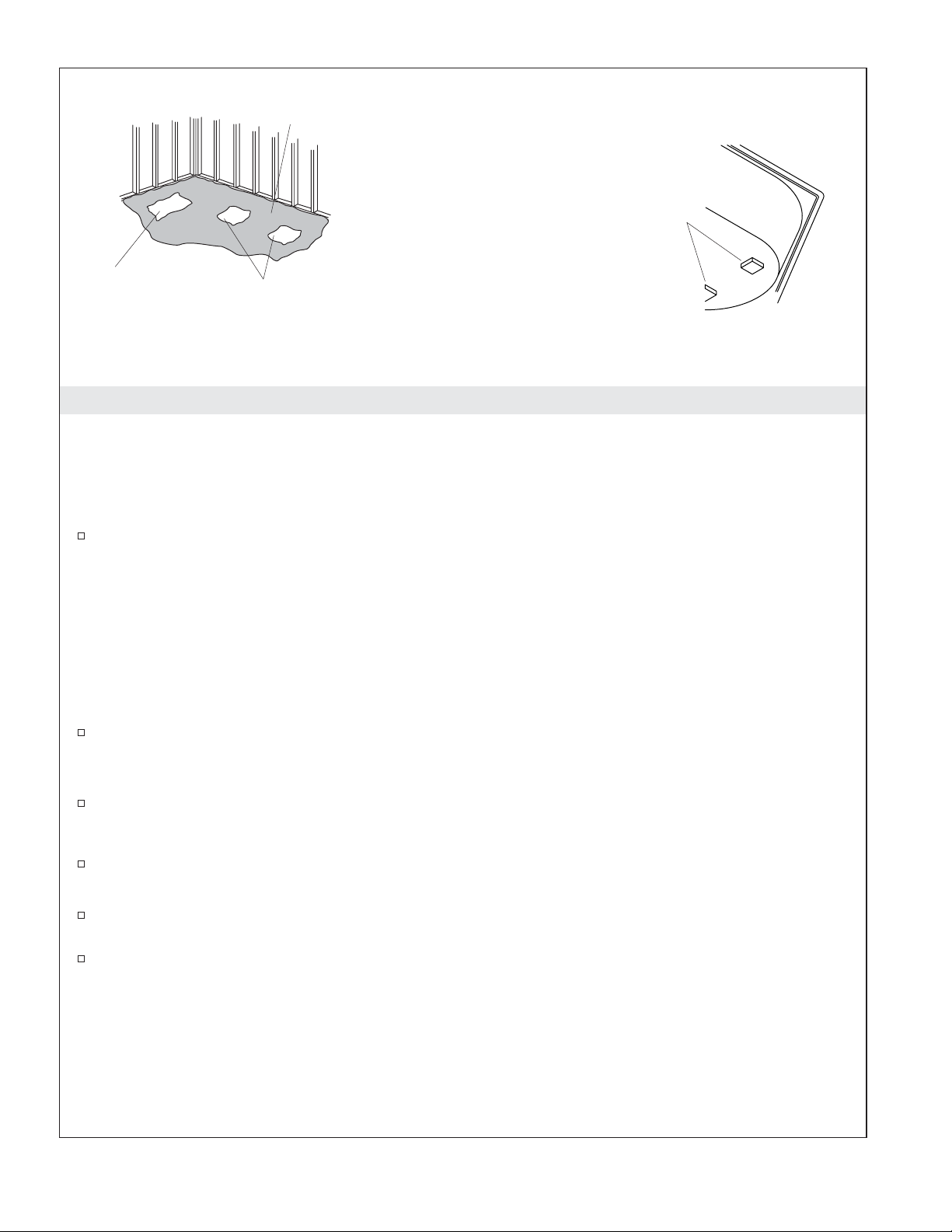

1. Prepare the Site

NOTICE: Refer to the Roughing-in Guide packed with your whirlpool for the required minimum

lb/square foot (kg/square meter) floor support loading.

Make sure the flooring offers adequate support for your whirlpool, and verify that the subfloor is

flat and level.

For Whirlpools without Apron:

NOTICE: The whirlpool should be installed in a drop-in installation.

Construct 2x4 or 2x6 stud framing for your installation.

NOTICE: The whirlpool must be supported by its feet or base. Do not support the load weight of the

whirlpool by the perimeter of the rim.

For a raised installation: Frame the floor or construct a frame in accordance with the roughing-in

information packed with the whirlpool.

Carefully lay out and cut the rough deck material. Use the cut-out template, if one is provided, or

refer to the Roughing-In Guide for cutout information.

For Whirlpools with Integral or Optional Apron:

The whirlpool should be installed in an alcove or corner installation, depending upon the model

chosen. Construct 2x4 or 2x6 stud framing designed for your particular installation. Construct a

frame in accordance with the roughing-in information packed with the whirlpool.

For All Installations:

Position the plumbing according to the roughing-in information packed. Cap the supplies, and

check for leaks.

2. Prepare the Whirlpool

Install the drain to the whirlpool according to the drain manufacturer’s instructions. Do not connect

the trap at this time.

Position a clean drop cloth or similar material in the bottom of the whirlpool. Be careful not to

scratch the surface of the whirlpool.

Kohler Co. 5 1011092-2-F

Page 6

Spread a 2" (5.1 cm) layer of

cement or mortar bed material.

Apply construction adhesive

to the support blocks.

Clear space for pump.

Clear spaces for

support blocks.

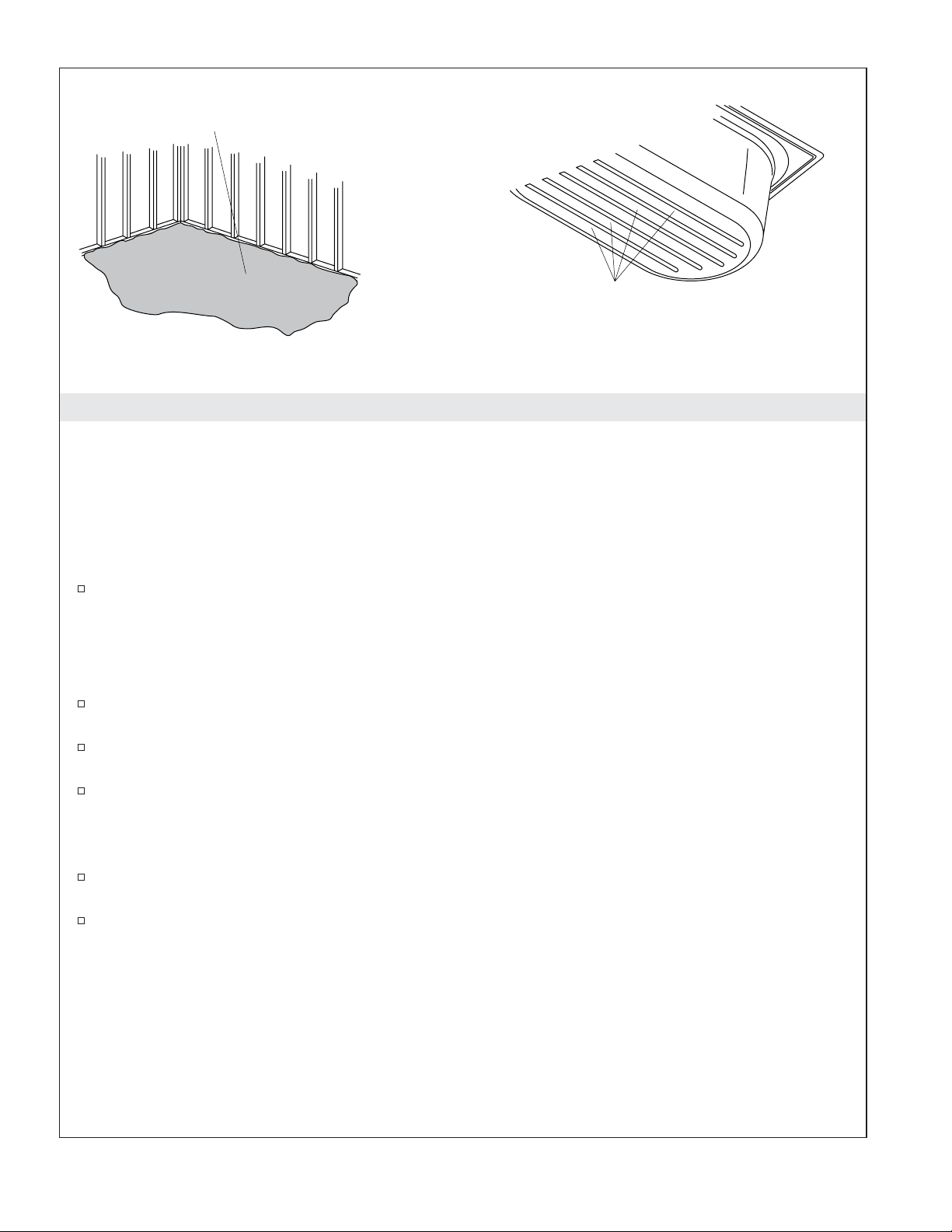

3. Secure the Unit — Models With Support Blocks

NOTICE: Do not lift the whirlpool by the piping or pump, or use the piping or pump for structural

support of the whirlpool. To avoid damage to the whirlpool, lift at the sides of the whirlpool.

NOTICE: Do not support the load weight of the whirlpool by the perimeter of the rim. The rim perimeter

must be adequately supported, but must not support the load weight of the whirlpool.

If the subfloor is not level, shim the whirlpool support blocks as necessary.

Choose the installation option that best applies to your particular installation. Follow the appropriate

instructions.

Option Using a Cement or Mortar Bed

NOTE: Do not use gypsum cement or drywall compound for this application, as they will not provide an

acceptable, durable bond.

NOTE: The pump support bracket (when the pump banding straps are cut) and support blocks must

rest directly on the subfloor.

Spread a 2″ (5.1 cm) thick layer of cement or mortar on the subfloor where the whirlpool will be set.

This will help secure, level, and support the unit. Clear all the material away from the pump

support bracket and support block locations.

Position a piece of plastic drop cloth material on top of the cement or mortar bed. With help,

carefully lift the whirlpool into place, and make sure the pump support bracket and support blocks

do not rest in the bed material.

Secure the drain tailpiece to the trap. Ensure the whirlpool is level and resting on all support blocks.

Option Using Construction Adhesive

Apply a generous amount of high-quality construction adhesive to the bottom of the support blocks.

With help, carefully lift the whirlpool into position.

Insert the drain tailpiece into the trap. Ensure the whirlpool is level and resting on all support

blocks.

1011092-2-F 6 Kohler Co.

Page 7

Spread a 2" (5.1 cm) layer of

cement or mortar bed material.

Apply construction adhesive

to the whirlpool base.

4. Secure the Unit — Models With Whirlpool Base

NOTICE: Do not lift the whirlpool by the piping or pump, or use the piping or pump for structural

support of the whirlpool. To avoid damage to the whirlpool, lift at the sides of the whirlpool.

NOTICE: Do not support the load weight of the whirlpool by the perimeter of the rim. The rim perimeter

must be adequately supported, but must not support the load weight of the whirlpool.

Choose the installation option that best applies to your particular installation. Follow the appropriate

instructions.

If the subfloor is not level, shim the whirlpool base as necessary.

Option Using a Cement or Mortar Bed

NOTE: Do not use gypsum cement or drywall compound for this application, as they will not provide an

acceptable, durable bond.

Spread a 2″ (5.1 cm) thick layer of cement or mortar on the subfloor where the whirlpool will be set.

This will help secure, level, and support the unit.

Position a piece of plastic drop cloth material on top of the cement or mortar bed. With help,

carefully lift the whirlpool into place.

Insert the drain tailpiece into the trap. Make sure the whirlpool is level. Use screws or lag bolts (not

provided) to secure the whirlpool base to the floor. Drill small pilot holes through the whirlpool

base as needed.

Option Using Construction Adhesive

Apply a generous amount of high-quality construction adhesive to the bottom of the whirlpool base.

With help, carefully lift the whirlpool into position.

Insert the drain tailpiece into the trap. Make sure the whirlpool is level. Use screws or lag bolts (not

provided) to secure the whirlpool base to the floor. Drill small pilot holes through the whirlpool

base as needed.

Kohler Co. 7 1011092-2-F

Page 8

Nail 1/4" (6 mm)

thick furring strips

to the studs.

Stud

Use #6 large-head

galvanized nails to secure

the nailing-in flange to the

studs.

Drill a small hole

through the nailing-in

flange at each stud.

Drainage

NOTE:

Pump

Cut the pump

banding straps.

Suction Line

Pump model illustrated may differ from your

actual product.

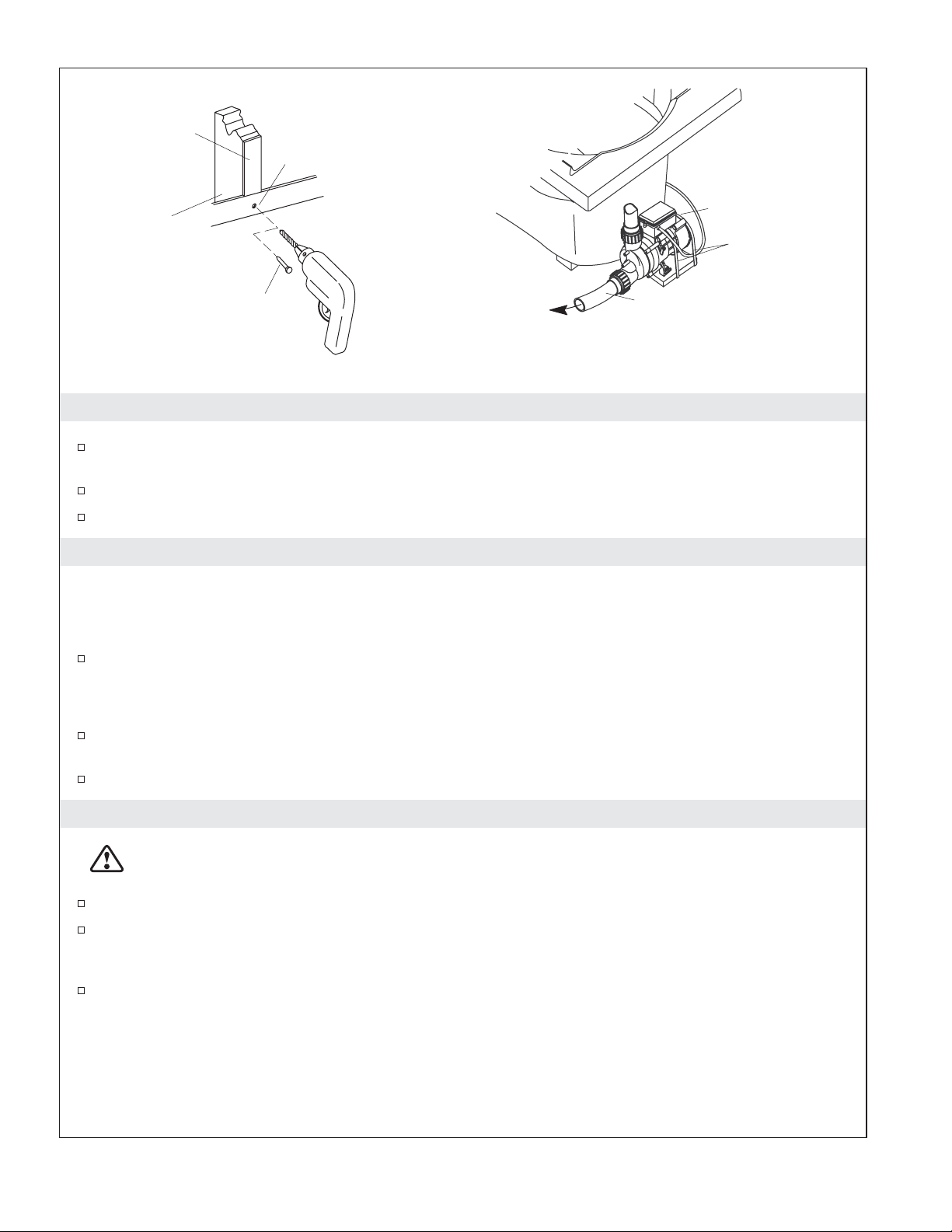

5. Secure the Whirlpool to the Stud Framing

Drill a small pilot hole through the nailing-in flange at each stud. Add shims between the nailing-in

flange and the studs as needed to eliminate gaps.

Nail 1/4″ (6 mm) thick furring strips to the studs to shim out to the edge of the nailing-in flange.

Use #6 large-head galvanized nails to secure the nailing-in flange to the studs.

6. Cut the Pump Banding Straps — Models With Support Blocks

IMPORTANT! This step is necessary to make your Kohler whirlpool operate more quietly.

NOTE: Do not raise the pump higher than it was before you cut the pump banding straps. If the pump is

raised too high, it will not prime properly.

Use tin snips to cut the two pump banding straps. When the banding straps are cut, the pump

support bracket and pump will drop about 1/2″ (1.3 cm) until they rest on the subfloor. If the pump

drops more than 1/2″ (1.3 cm), shim under the pump support bracket so there is a 1/2″ (1.3 cm)

gap between the pump and bracket to allow for proper drainage.

To minimize whirlpool noise and vibration, be sure the pump is not in direct contact with the

shipping bracket after the pump banding straps are cut.

Secure the pump support bracket to the subfloor with screws or lag bolts (not provided).

7. Install the Plumbing

CAUTION: Risk of property damage. A watertight seal must exist on the whirlpool drain. The

watertight seal will prevent property damage.

Connect the drain to the trap according to the drain manufacturer’s instructions.

Install the faucet valving according to the faucet manufacturer’s instructions. Do not install the

faucet trim until instructed. Open the hot and cold water supplies, and check the supply

connections for leakage.

Run water into the whirlpool, and check the drain connections for leakage.

1011092-2-F 8 Kohler Co.

Page 9

Install a GFCI- or RCD-protected 120 V, 15 A grounded outlet. Install

a second GFCI- or RCD-protected outlet for "H" models for the heater.

Optional Heater

either T-style (shown) or water intake

(not shown).

Make sure air actuator tubing

is securely attached to the pump.

Bond in accordance with applicable codes.

(models may vary)

NOTE:

Pump model illustrated may differ from your actual product.

Plug pump and heater

into these outlets.

8. Make Electrical Connections

WARNING: Risk of electric shock. Make sure the power has been disconnected before performing

the following procedures.

WARNING: Risk of electric shock. Connect the pump and in-line heater (if included) to properly

grounded, grounding-type receptacles protected by Ground-Fault Circuit-Interrupters (GFCI’s) or

Residual Current Devices (RCD’s). Do not remove the grounding pins from the plug. Do not use

grounding adapters.

NOTE: A label identifying the model number and electrical rating of the whirlpool is located near the

whirlpool pump.

NOTICE: The pump (supplied) and heater (if supplied) are equipped with a cord and plug. All wiring for

the heater has been completed at the factory. A qualified electrician must install a GFCI- or RCD-protected,

120 V, 15 A, grounded outlet. No other load should be on this circuit.

Pump Wiring

Locate the outlet behind the whirlpool, and within 24″ (61 cm) of the pump.

Plug the pump into this outlet.

NOTE: Make sure the air actuator tubing is securely attached to the pump, and is not kinked or damaged.

Heater Wiring – “H” Models

Locate the outlet behind the whirlpool, and within 24″ (61 cm) of the heater.

Plug the heater into this outlet.

9. Test Run the Whirlpool

Check all electrical connections, and make sure the electrical power to the whirlpool and heater (if

equipped) is on.

Make sure all union connections to the pump and heater are securely hand tightened.

Verify that the pump banding straps have been cut (if applicable), and that the pump is resting

directly on the subfloor or whirlpool base.

Fill the whirlpool to a level at least 2″ (5.1 cm) above the top of the highest jet. Refer to ″Confirm

Proper Operation″ section for additional information.

Operate the whirlpool for 5 minutes, and check all whirlpool piping connections for leaks.

Kohler Co. 9 1011092-2-F

Page 10

Framing

Water-Resistant

Wall Material

Finished Wall

Whirlpool

Apply silicone sealant to the

joint between the whirlpool

and the finished wall.

On models with an integral apron,

access the pump by gently prying

at the apron edge with a

screwdriver or dull knife to remove.

10. Complete the Finished Wall

NOTE: If your whirlpool has an integral apron, it is designed so the finished wall material (1-1/2″ [3.8 cm]

maximum) will overlap the apron columns. The finished floor material (2″ [5.1 cm] maximum) should butt

against the apron.

If you have not already done so, carefully remove the protective tape from the whirlpool rim.

If necessary allow for deck-mounted valves and spout.

Cover the framing with water-resistant wall material. Seal the joints between the whirlpool rim edge

and the water-resistant wall material with silicone sealant.

Tape and mud the water-resistant wall material. Install the finished wall to the water-resistant wall

material. Seal the joints between the whirlpool rim and the finished wall material with silicone

sealant.

Install the faucet trim according to the trim manufacturer’s instructions.

11. Removing the Apron

Your whirlpool may be equipped with an integral apron which allows you convenient access to

your whirlpool controls. To remove the apron, insert the edge of a flat blade screwdriver or dull

knife under the edge of the apron panel. Be careful not to scratch the visible surfaces. Gently pry up

at one end. Carefully pull the apron panel off.

To reinstall, bow the apron slightly so both ends can be inserted at the same time. Gently press in

the center of the panel to secure the apron in place.

12. Clean-Up After Installation

When cleaning up after installation, do not use abrasive cleansers, as they may scratch and dull the

whirlpool surface. Use warm water and a liquid detergent to clean the surface.

Remove stubborn stains, paint, or tar with turpentine or paint thinner. Do not allow cleaners

containing petroleum distillates to remain in contact with any whirlpool surfaces for long periods

of time. Remove plaster by carefully scraping with a wood edge. Do not use metal scrapers, wire

brushes, or other metal tools. Use a powder-type detergent on a damp cloth to provide mild

abrasive action to any residual plaster.

1011092-2-F 10 Kohler Co.

Page 11

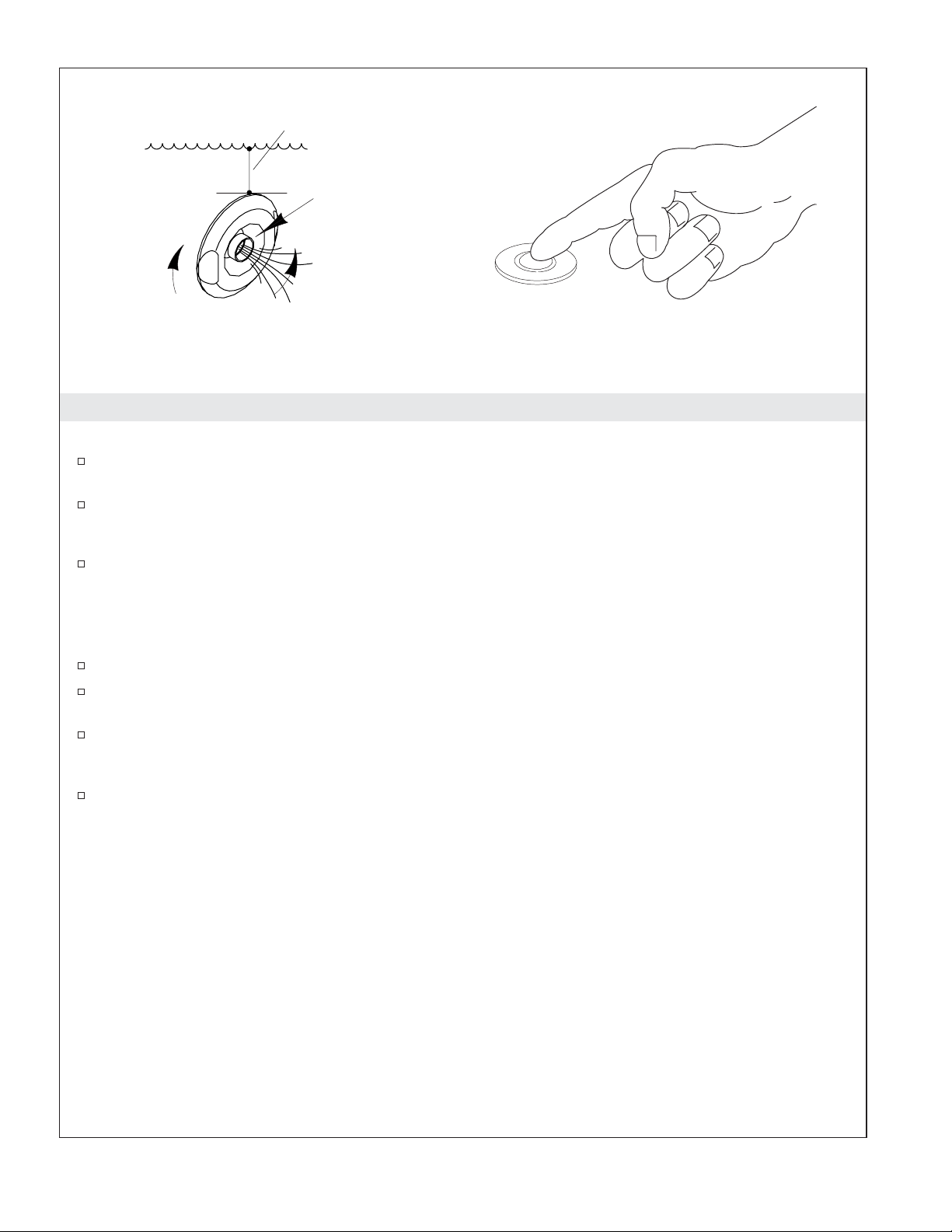

Turn the jet trim ring

clockwise to

decrease the flow.

Fill with water at least 2" (5.1 cm)

above the highest jet.

Position the jet

nozzles to direct

the water flow as

desired.

Turn the jet trim ring counterclockwise

to increase the flow.

Press the air actuator to turn

on and off the whirlpool.

13. Confirm Proper Operation

Fill the Whirlpool

Position the jet nozzles so they face down toward the basin. Turn the jet trim rings fully

counterclockwise.

Fill the whirlpool to a water level at least 2″ (5.1 cm) above the top of the highest jet.

NOTE: The water temperature in the whirlpool should not exceed 104°F (40°C).

To service orifices insert a pencil into the end of the jet nozzle and push the orifice out. After

removing any blockage, check the orifice to make sure it is clear and press it into the jet housing.

NOTE: Orifices are only installed in whirlpool jets when there are six or more jets in the whirlpool system.

Operating Sequence

Press the air actuator to turn on the whirlpool jets.

Adjust each jet for optimum air/water mixture. Turn the trim ring clockwise to reduce the air flow,

and counterclockwise to increase the air flow.

If equipped with a heater, the heater will engage automatically when the pump is turned on and

will disengage when the pump is turned off. The heater will not turn on if the water temperature

exceeds 104°F (40°C).

Press the air actuator a second time to turn off the whirlpool.

Kohler Co. 11 1011092-2-F

Page 12

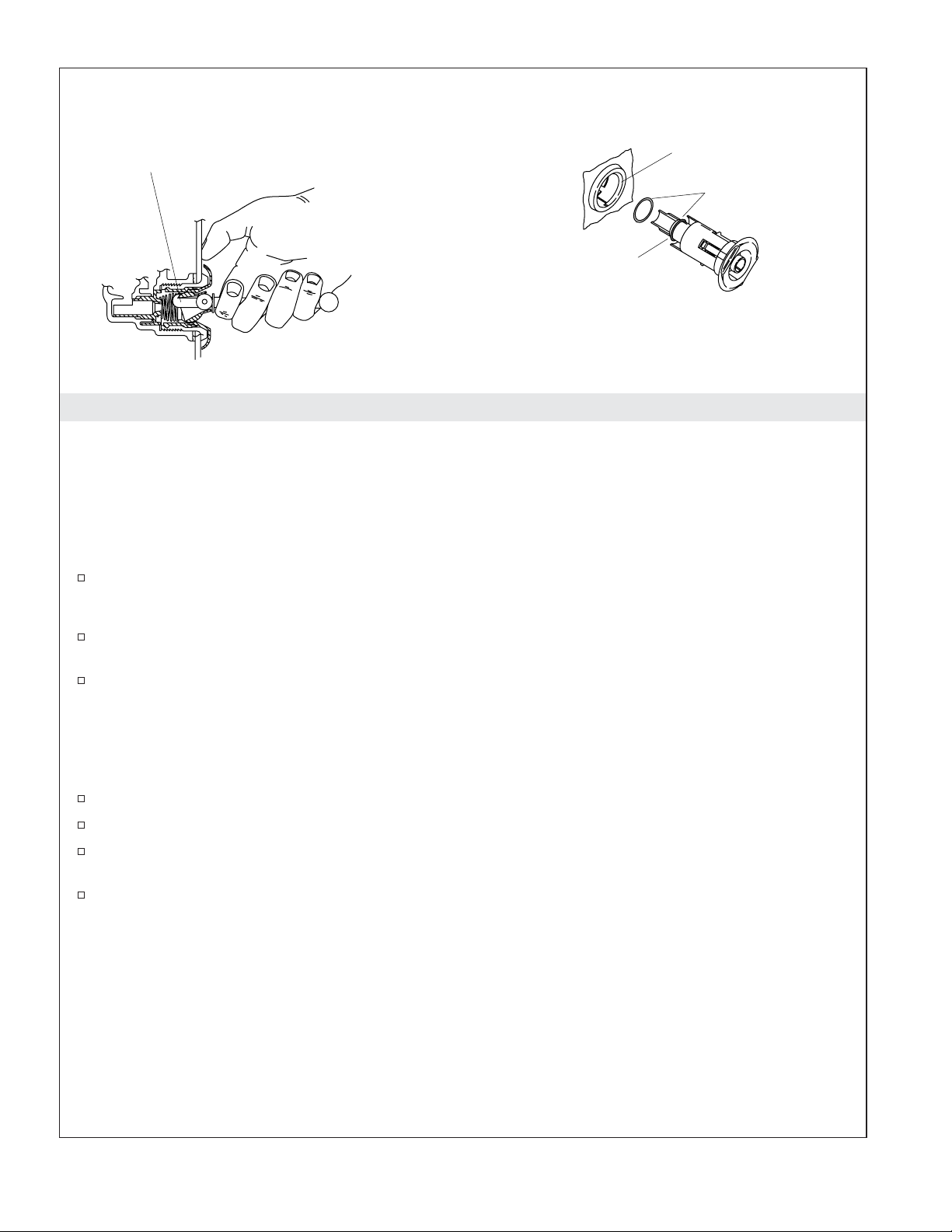

Remove the Jets

Reinstall the Jets

Insert the tool hook as shown and pull the jet out of the

housing. The jet should be facing up when this is done.

Housing

Inspect and

lubricate the O-ring.

Slide the O-ring

onto the first

shoulder of the jet.

Insert the jet into the housing, and lightly

push and rotate until it snaps in position.

Troubleshooting

NOTICE: This section is for general aid only. A Kohler Authorized Service Representative or qualified

electrician should correct any electrical problems. For warranty service, contact your dealer or wholesale

distributor.

Remove the Jets

NOTE: A special tool is provided with the replacement jets that will allow you to remove the jets from the

whirlpool. This tool is also supplied with each trim kit.

Position the jet ball nozzle so it is pointing upward.

NOTE: The nozzle must remain pointed up or the tool will slip off.

Insert the removal tool, hooked end up, into the opening of the jet and hook the inside top of the

nozzle.

Grasp the tool firmly and place your thumb against the whirlpool wall. Pull steadily on the tool

until the jet assembly pulls free of the hole. Be careful not to lose the O-ring.

Reinstall the Jets

NOTE: To allow easy rotation and proper operation of the jet, the O-ring must be: (1) correctly positioned,

(2) lubricated, and (3) in good condition.

Install the O-ring onto the first shoulder of the jet.

Using the silicone lube packet (provided), lubricate the O-ring to prevent noisy operation of the jet.

Carefully insert the jet into the housing, then lightly push and rotate the jet until it snaps into

position. Do not force the jet.

Verify the jet is installed correctly. The jet should turn smoothly both clockwise and

counterclockwise. Remove and reinstall, if necessary.

1011092-2-F 12 Kohler Co.

Page 13

Troubleshooting (cont.)

Symptoms Probable Causes Recommended Action

1. Whirlpool does not start

or stop.

2. Motor starts, not all jets

are functioning.

3. Whirlpool stops

automatically before 18

minutes.

4. Pump does not prime.

(Models with support

blocks only.)

5. Noisy operation. A. Pump banding straps have not

6. Heater does not operate.

(“H” models only)

A. No power to motor. A. Check that the pump and heater

B. Air hose is loose or disconnected. B. Check that the hose is connected

C. Air hose is pinched or kinked. C. Adjust hose to clear the

D. Part(s) of the push button

assembly is/are damaged.

E. Push button has grease in the

bleed area.

F. Air hose is damaged. F. Replace the air hose.

G. Motor/pump does not work. G. Rebuild or replace motor/pump.

A. Jet is closed. A. Rotate jet trim ring

B. Jet not installed correctly. B. Reinstall jet; check for O-ring

C. Jets are blocked. C. Remove blockage.

A. The GFCI or RCD trips. A. Identify source of fault, and

B. Suction blocked. B. Remove obstruction.

C. Jets are blocked. C. Remove blockage.

D. Motor overheated and protection

device activated.

A. Pump shimmed too high. A. Lower pump support bracket.

been cut. (Models with support

blocks only.)

B. Jet O-ring dislodged. B. Remove jet, replace and lubricate

A. No power to heater. A. Reset the GFCI or RCD.

B. Water temperature exceeds 104°F

(40°C).

C. Heater does not work. C. Replace heater.

are plugged in and that the GFCI

or RCD is switched to the correct

position. Plug in or reset the

GFCI/RCD as needed.

at both the receiver/pump end

and to the air switch. Reconnect

if needed.

pinched/kinked area. If the

tubing is pinched/kinked and

cannot be readjusted, or no

noticeable pinch/kink is

apparent, poke a small hole in

the tubing with a tack and try

the system again.

D. Replace the push button

assembly.

E. Disassemble the push button

assembly and wipe away any

excess grease. Reassemble the

button and retry the system.

counterclockwise to open.

damage.

correct.

D. Check for blockage at motor

vents. Remove blockage and

allow motor to cool.

Check for suction blockage.

Remove blockage and allow

motor to cool.

Check for jet blockage. Remove

blockage and allow motor to

cool.

A. Cut pump banding straps with

tin snips.

O-ring, and reinstall jet.

B. Allow water to cool and heater

will reengage.

Kohler Co. 13 1011092-2-F

Page 14

Guide d’installation

Baignoire à hydromassage

Informations importantes

AVERTISSEMENT : Lors de l’utilisation des produits électriques, des précautions de base

doivent toujours être observées, incluant ce qui suit :

Les matériaux de construction et le câblage devraient être acheminés loin du corps de la pompe et des autres

composants qui dégagent de la chaleur de l’unité.

Installer de façon à permettre l’accès pour l’entretien.

Une mise à la terre est requise. L’unité doit être installée par un représentant qualifié, et mise à la terre.

AVERTISSEMENT : Risque d’électrocution. Un électricien qualifié devrait effectuer toutes les

connexions électriques.

AVERTISSEMENT : Risque d’électrocution. Débrancher l’alimentation avant de procéder à

l’entretien.

AVERTISSEMENT : Risque de blessures ou d’endommagement du matériel. Veuillez s’il vous

plaît lire avec attention toutes les instructions avant de commencer l’installation, y compris les

conditions suivantes:

AVIS : Respecter tous les codes de plomberie et électriques locaux.

Information sur le produit

Branchements électriques requis

L’installation électrique doit avoir un Disjoncteur de Fuite de Terre (GFCI) ou un appareil de courant

résiduel (RCD) de classe A. Le GFCI ou le RCD protège contre une électrocution par la mise à la terre.

Utiliser une alimentation de 120 V, 15 A, 60 Hz dédiée à la baignoire à hydromassage.

Les modèles«H»nécessitent une alimentation dédiée de 120 V, 15 A, 60 Hz pour le chauffe-eau.

REMARQUE : Si le câble d’alimentation de la pompe est endommagé, il doit être remplacé par le

fabricant, son représentant ou autre personnel similaire qualifié pour éviter tout danger. Le cordon

d’alimentation du chauffe-eau ne peut pas être remplacé. Si le cordon est endommagé, le chauffe-eau

devrait être remplacé.

Notices du produit

AVERTISSEMENT : Des modifications non approuvées pourraient provoquer un fonctionnement

dangereux ou un mauvais fonctionnement de la baignoire à hydromassage. Ne pas déplacer la

pompe d’hydromassage ou effectuer d’autres modifications au système d’hydromassage car cela

pourrait affecter les performances et la sécurité de la baignoire à hydromassage. Kohler Co. décline

toute responsabilité sous ses garanties quant à toutes blessures ou dommages causés par des

modifications non autorisées.

AVERTISSEMENT : Risque d’électrocution. Débrancher l’alimentation avant de procéder à

l’entretien.

AVERTISSEMENT : Risque d’électrocution. Un électricien qualifié devrait effectuer toutes les

connexions électriques.

Kohler Co. Français-1 1011092-2-F

Page 15

Information sur le produit (cont.)

AVERTISSEMENT : Risque de blessures ou d’endommagement du matériel. Veuillez lire toutes

les instructions avant de commencer l’installation.

AVIS : Respecter tous les codes de plomberie et électriques locaux.

Pièces assemblées en usine

Les composants installés en usine comprennent la pompe avec câble d’alimentation électrique et

l’interrupteur d’air. Aucune installation n’est nécessaire.

Les modèles«H»sont aussi fournis avec un chauffe-eau assemblé en usine.

La pompe et la tuyauterie de la baignoire à hydromassage ont été assemblées en usine.

Connexions et accès pour l’entretien

S’assurer d’avoir suffisamment d’accès pour les connexions finales avant l’installation.

Kohler Co. Français-2 1011092-2-F

Page 16

Information sur le produit (cont.)

AVIS : Fournir un panneau d’accès libre à la pompe. Il faut prévoir un accès pour l’entretien de la pompe

et des contrôles. L’accès doit être situé tout près de la pompe. Étudier le guide de raccordement

accompagnant la baignoire à hydromassage.

Sommaire

Informations importantes ........................................................... 1

Information sur le produit ........................................................... 1

Outils et matériels ................................................................ 3

Avant de commencer .............................................................. 4

Préparer le site .................................................................. 5

Préparer la baignoire à hydromassage ................................................. 5

Sécuriser les modèles d’unités avec blocs de support ...................................... 6

Sécuriser les modèles d’unité avec base de baignoire à hydromassage ......................... 7

Sécuriser la baignoire à hydromassage au cadrage du montant .............................. 8

Couper les sangles de la pompe—Modèles avec blocs de renfort ............................. 8

Installer la plomberie .............................................................. 8

Faire les connexions électriques ...................................................... 9

Tester la baignoire à hydromassage ................................................... 9

Compléter le mur fini ............................................................. 11

Retirer le bandeau ............................................................... 11

Nettoyage après installation ........................................................ 11

Confirmer le bon fonctionnement .................................................... 12

Dépannage .................................................................... 13

Outils et matériels

Mastic à la silicone

Lunettes de protection

Mètre ruban

Clé à tuyau

Crayon

Niveau à bulle

Plus:

• Outils conventionnels de menuiserie et

matériaux

• Toile de protection

• Adhésif de construction (optionnel)

• Ciment ou mortier (optionnel)

• 2x4 ou 2x6

• Vis ou tire-fonds

1011092-2-F Français-3 Kohler Co.

Page 17

Installer les sorties de

la pompe et chaffeau

(si utilisé) sur la

plaque de montage.

Sortie

Avant de commencer

Pour les baignoires à hydromassage sans bandeau : Une installation encastrée est nécessaire. Pour

des baignoires à hydromassage avec bandeau intégral ou optionnel: Une installation en alcôve ou

en coin est recommandée, selon le modèle choisi.

Pour des unités en angle avec bandeau intégré: Laisser un électricien qualifié installer les prises

pour la pompe et le chauffe-eau (si utilisé) à l’emplacement spécifié sur la baignoire à

hydromassage. Se référer à l’illustration ci-dessus.

Avant de commencer l’installation, examiner la baignoire à hydromassage pour y déceler tout

dommage.

S’assurer que l’espace de montage et de raccordement du robinet soit adéquat pour l’installation.

Kohler se réserve le droit d’apporter des modifications à la conception de ses produits sans préavis

comme cela est indiqué dans le catalogue des prix.

Kohler Co. Français-4 1011092-2-F

Page 18

Positionner

la plomberie.

S'assurer que le sousplancher puisse supporter

suffisamment de poids et

qu'il soit de niveau.

Construire le

cadrage de

montants de 2x4

ou de 2x6

suivant

l'information du

plan de

raccordement.

Positionner la

plomberie.

Construire un cadrage de

montants de 2 x 4 ou de

2 x 6 suivant l'instruction

du plan de raccordement.

Cadrer le sol selon

l'instruction du plan

de raccordement.

Vérifier que le sousplancher offére un

support adquat et

qu'il soit plat et nivelé.

1. Préparer le site

AVIS : Se référer au guide de raccordement emballé avec la baignoire à hydromassage pour la charge de

support de sol minimum requis lb/pied carré (kg/mètre carré).

S’assurer que le sol constitue un support adéquat pour la baignoire à hydromassage et que le

plancher soit plat et nivelé.

Pour des baignoires à hydromassage sans bandeau:

AVIS : La baignoire à hydromassage devrait être installée dans un espace encastré.

Construire un cadre de support de 2x4 ou de 2x6 pour votre installation.

AVIS : La baignoire à hydromassage doit être supportée par ses pieds ou la base. Ne pas supporter le

poids de charge de la baignoire à hydromassage par le périmètre du rebord.

Pour une installation surélevée : Encadrer le plancher ou construire un cadre conforme aux

informations du plan de raccordement qui accompagne la baignoire à hydromassage.

Disposer et découper soigneusement le matériau du comptoir brut. Employer le gabarit s’il est

fourni, ou se référer au guide de raccordement pour l’information de découpe.

Pour des baignoires à hydromassage avec bandeau intégral ou optionnel:

Selon le modèle choisi, la baignoire à hydromassage devrait être installée dans une alcôve ou en

angle. Construire un cadre avec des montants de 2x4 ou de 2x6 pour votre installation particulière.

Construire un cadre selon l’information du plan de raccordement qui accompagnent la baignoire à

hydromassage.

Pour toutes les installations:

Déterminer l’emplacement de la plomberie selon le plan de raccordement fourni. Boucher les

alimentations et vérifier s’il y a des fuites.

2. Préparer la baignoire à hydromassage

Installer le drain sur la baignoire à hydromassage selon les instructions du fabricant. Ne pas

connecter le siphon à ce moment.

Placer un chiffon propre ou matière similaire à la base de la baignoire à hydromassage. S’assurer de

ne pas rayer la surface de la baignoire à hydromassage.

1011092-2-F Français-5 Kohler Co.

Page 19

Étendre une couche

de béton ou mortier

de 2" (5,1 cm).

Appliquer du

mastic adhésif de

construction aux

blocs de support.

Dégagement

pour la pompe.

Dégagement pour

les blocs de support.

3. Sécuriser les modèles d’unités avec blocs de support

AVIS : Ne pas soulever la baignoire à hydromassage par la tuyauterie ou par la pompe ou utiliser la

tuyauterie ou la pompe pour supporter la baignoire à hydromassage. Afin d’éviter d’endommager la

baignoire à hydromassage, soulever sur les côtés de la baignoire.

AVIS : Ne pas supporter le poids de charge de la baignoire à hydromassage par le périmètre du rebord. Le

périmètre du rebord doit être soutenu de manière adéquate, mais il ne doit pas supporter le poids de

charge de la baignoire à hydromassage.

Si le sous-plancher n’est pas à niveau, placer des blocs de renfort sous la baignoire à hydromassage,

si nécessaire.

Choisir l’option d’installation qui s’applique le mieux à votre installation. Suivre les instructions

correspondantes.

Option pour utilisation de lit de ciment ou de mortier

REMARQUE : Ne pas utiliser de plâtre dur ou un mélange pour cloison sèche pour cette installation, car

ces produits ne fourniront pas un scellement acceptable et durable.

REMARQUE : Le support de pompe (une fois les sangles de retenue coupées) et les blocs de support

doivent reposer directement sur le sol.

Étendre une couche de ciment ou mortier de 2″ (5,1 cm) d’épaisseur sur le sous-plancher à l’endroit

d’installation de la baignoire. Ceci aidera à sécuriser, niveler et supporter l’unité. Écarter tout

matériau de l’emplacement du montant de la pompe et des blocs de support.

Positionner une bâche en plastique sur le lit de ciment ou de mortier. Avec de l’assistance, soulever

et mettre soigneusement la baignoire à hydromassage en place et s’assurer que le support de pompe

et les blocs de renfort ne reposent pas sur le matériau de l’embase.

Fixer l’about du drain sur le siphon. S’assurer que la baignoire à hydromassage soit nivelée et

qu’elle s’appuie sur tous les blocs de renfort.

Option pour l’utilisation de mastic adhésif de construction

Appliquer un adhésif de construction de haute qualité à la base des blocs de renfort. Avec de

l’assistance, soulever et mettre la baignoire à hydromassage en place avec précaution.

Insérer la pièce de raccordement du drain dans le siphon. S’assurer que la baignoire à

hydromassage soit nivelée et qu’elle s’appuie sur tous les blocs de renfort.

Kohler Co. Français-6 1011092-2-F

Page 20

Etaler une couche de ciment de 2"

(5,1 cm) ou un matériau de mortier.

Appliquer du mastic adhésif

de construction à la base de

la baignoire d'hydromassage.

4. Sécuriser les modèles d’unité avec base de baignoire à hydromassage

AVIS : Ne pas soulever la baignoire à hydromassage par la tuyauterie ou par la pompe ou utiliser la

tuyauterie ou la pompe pour supporter la baignoire à hydromassage. Afin d’éviter d’endommager la

baignoire à hydromassage, soulever sur les côtés de la baignoire.

AVIS : Ne pas supporter le poids de charge de la baignoire à hydromassage par le périmètre du rebord. Le

périmètre du rebord doit être soutenu de manière adéquate, mais il ne doit pas supporter le poids de

charge de la baignoire à hydromassage.

Choisir l’option d’installation qui s’applique le mieux à votre installation. Suivre les instructions

correspondantes.

Si le sol n’est pas nivelé, placer des cales sous la baignoire si nécessaire.

Option pour utilisation de lit de ciment ou de mortier

REMARQUE : Ne pas utiliser de plâtre dur ou un mélange pour cloison sèche pour cette installation, car

ces produits ne fourniront pas un scellement acceptable et durable.

Étendre une couche de ciment ou mortier de 2″ (5,1 cm) d’épaisseur sur le sous-plancher à l’endroit

d’installation de la baignoire. Ceci aidera à sécuriser, niveler et supporter l’unité.

Positionner une bâche en plastique sur le lit de ciment ou de mortier. Avec de l’aide, positionner la

baignoire à hydromassage.

Insérer la pièce de raccordement du drain dans le siphon. Vérifier que la baignoire soit nivelée.

Utiliser des vis ou des tire-fonds (non fournis) pour fixer la base de la baignoire au plancher. Percer

des petits trous-pilotes dans la base de la baignoire à hydromassage selon le besoin.

Option pour l’utilisation de mastic adhésif de construction

Appliquer du mastic adhésif de construction de haute qualité à la base de la baignoire à

hydromassage. Avec de l’assistance, soulever et mettre la baignoire à hydromassage en place avec

précaution.

Insérer la pièce de raccordement du drain dans le siphon. Vérifier que la baignoire soit nivelée.

Utiliser des vis ou des tire-fonds (non fournis) pour fixer la base de la baignoire au plancher. Percer

des petits trous-pilotes dans la base de la baignoire à hydromassage selon le besoin.

1011092-2-F Français-7 Kohler Co.

Page 21

Clouer des

planchettes de 1/4"

(6 mm) d'épaisseur

sur les montants.

Percer un trou

pilote sur la

collerette à

chaque montant.

Montant

Utiliser des clous

galvanisés # 6 à large tête

pour fixer la collerette de

cloutage aux montants.

Drainage

REMARQUE:

Ligne d'aspiration

Le modèle de pompe illustré peut varier

du produit actuel.

Pompe

Couper les

sangles de

retenue de la

pompe.

5. Sécuriser la baignoire à hydromassage au cadrage du montant

Percer un petit trou-pilote dans la bride cloutage de chaque montant. Placer des cales entre la bride

de cloutage et les montants, au besoin, pour éliminer les espaces.

Clouer des planchettes de 1/4″ (6 mm) sur les montants de façon à se caler contre le rebord de la

bride.

Utiliser des clous galvanisés #6 à tête large pour sécuriser la bride aux montants.

6. Couper les sangles de la pompe—Modèles avec blocs de renfort

IMPORTANT ! Cette étape est nécessaire pour que votre baignoire à hydromassage Kohler fonctionne

plus silencieusement.

REMARQUE : Ne pas soulever la pompe à un niveau supérieur à celui d’avant avoir coupé les sangles de

retenue. Si la pompe est trop élevée, elle ne s’amorcera pas correctement.

Couper les sangles de retenue de la pompe avec une cisaille de ferblantier. Lorsque les sangles de

retenue sont sectionnées, le support de pompe et la pompe s’abaisseront d’environ 1/2″ (1,3 cm)

jusqu’à reposer sur le sol. Si la pompe s’abaisse de plus de 1/2″ (1,3 cm), placer des cales

au-dessous du support de pompe, pour qu’il y ait un dégagement de 1/2″ (1,3 cm) entre la pompe

et le support afin de permettre la bonne évacuation de l’eau.

Pour réduire les bruits et vibrations émanant de la baignoire à hydromassage, s’assurer que la

pompe ne soit pas en contact direct des supports d’expédition après que les sangles aient été

sectionnées.

Sécuriser le support de baignoire au plancher avec des vis ou des tire-fonds (non inclus).

7. Installer la plomberie

ATTENTION : Risque d’endommagement du matériel. Un joint d’étanchéité doit être présent sur

le drain de la baignoire à hydromassage. Le joint étanche doit prévenir tout dommage.

Connecter le drain au siphon selon les instructions du fabricant.

Installer les valves du robinet conformément aux instructions du fabricant. Ne pas installer la

garniture du robinet avant l’instruction de le faire. Ouvrir les alimentations d’eau chaude et froide et

vérifier qu’il n’y ait pas de fuites.

Laisser couler l’eau dans la baignoire à hydromassage et vérifier s’il y a des fuites dans les

connexions du drain.

Kohler Co. Français-8 1011092-2-F

Page 22

Installer une prise de terre 120V, 15A GFCI ou RCD. Installer une

seconde prise de terre protégée GFCI ou RCD pour les

modèles de chauffe-eau "H".

Chauffe-eau optionnel

de style en T (illustré) ou admission d'eau (non illustré).

S'assurer que la tuyauterie de l'interrupteur

d'air soit bien attachée à la pompe.

Sceller en fonction des codes en vigueur.

REMARQUE:

(les modèles peuvent varier)

Brancher la pompe

et le chauffe-eau sur

ces prises.

Le modèle de pompe illustré peut varier du produit actuel.

8. Faire les connexions électriques

AVERTISSEMENT : Risque d’électrocution. S’assurer que l’alimentation ait été débranchée avant

d’effectuer les procédures suivantes.

AVERTISSEMENT : Risque d’électrocution. Connecter la pompe et le chauffe-eau en ligne (si

inclus) à des prises de terre correctement mises à la terre et protégées par des disjoncteurs

différentiels (GFCI) ou des appareils de courant résiduel (RCD). Ne pas retirer les broches de mise à

la terre de la fiche. Ne pas utiliser d’adaptateurs de mise à la terre.

REMARQUE : Une étiquette qui identifie le numéro de modèle et les caractéristiques électriques de la

baignoire à hydromassage est située à proximité de la pompe de la baignoire à hydromassage.

AVIS : La pompe (fournie) et le chauffe-eau (si fourni) sont munis d’un cordon et d’une fiche. Tous les

câblages du dispositif de chauffage ont été effectués en usine. Un électricien qualifié doit installer une prise

mise à la terre de 120 V et 15 A protégée par un GFCI ou un RCD. Aucune autre charge ne doit être

montée sur ce circuit.

Câblage de pompe

Localiser la prise de courant derrière la baignoire à hydromassage, dans les 24″ (61 cm) de la

pompe.

Brancher le cordon d’alimentation de la pompe à cette prise.

REMARQUE : S’assurer d’attacher fermement l’interrupteur d’air à la pompe, et qu’il ne soit ni pincé ou

endommagé.

Câblage de chauffe-eau – Modèles « H” »

Localiser la prise de courant derrière la baignoire à hydromassage, à [24″ (61 cm)] de distance du

chauffe-eau.

Brancher le chauffe-eau sur cette prise.

9. Tester la baignoire à hydromassage

Contrôler toutes les connexions électriques et s’assurer que la baignoire à hydromassage et que le

chauffe-eau soient alimentés.

S’assurer que tous les raccords à la pompe et au chauffe-eau soient fermement serrés à la main.

S’assurer également que les sangles de retenue des pompes ont été sectionnés (si applicable) et que

la pompe repose directement sur le sol ou sur la base de baignoire.

1011092-2-F Français-9 Kohler Co.

Page 23

Tester la baignoire à hydromassage (cont.)

Remplir la baignoire à hydromassage à au moins 2″ (5,1 cm) au-dessus du jet le plus élevé. Se

référer à la section « Confirmer le bon fonctionnement » pour obtenir de l’information

supplémentaire.

Faire fonctionner la baignoire à hydromassage pendant 5 minutes et, vérifier que tous les raccords

des tuyaux de la baignoire à hydromassage n’aient pas de fuites.

Kohler Co. Français-10 1011092-2-F

Page 24

Cadrage

Matériau hydrorésistant

du mur

Mur fini

Baignoire à

hydromassage

Poser un joint d'étanchéité

entre le bord de la

baignoire à hydromassage

et le mur fini.

Pour les modèles avec

bandeau intégré, accéder à

la pompe en soulevant

délicatement le bord du

bandeau à l'aide d'un

tournevis plat pour le retirer.

10. Compléter le mur fini

REMARQUE : Si la baignoire à hydromassage a un bandeau intégré, elle est conçue de manière à ce que le

matériau du mur fini 1-1/2″ (3,8 cm) max. dépasse les colonnes du bandeau. Le matériau du sol fini 2″

(5,1 cm) max. devrait se terminer contre le bandeau.

Retirer soigneusement la pellicule de protection recouvrant la surface de la baignoire à

hydromassage si cela n’a pas déjà été fait.

Si nécessaire prévoir de l’espace pour la pose des valves et du bec sur le comptoir.

Recouvrir le cadrage avec du matériau hydrorésistant. Sceller les joints entre le rebord de la

baignoire à hydromassage et le matériau hydrorésistant du mur à l’aide de mastic à la silicone.

Poser et appliquer le matériau hydrorésistant du mur. Installer le mur fini sur le matériau

hydrorésistant. Sceller les joints d’étanchéité entre le bord de la baignoire à hydromassage et le

matériau du mur fini avec du mastic à la silicone.

Installer la garniture du robinet conformément aux instructions du fabricant.

11. Retirer le bandeau

Cette baignoire à hydromassage peut être dotée d’un bandeau intégré permettant l’accès aux

commandes d’hydromassage. Pour retirer le bandeau, insérer un tournevis à tête plate ou un

couteau sous le rebord du panneau du bandeau. Travailler soigneusement pour ne pas égratigner les

surfaces visibles. Soulever doucement une extrémité. Retirer soigneusement le panneau du bandeau.

Pour réinstaller, tordre légèrement le bandeau, de façon à pouvoir insérer les deux extrémités au

même moment. Appuyer doucement sur le centre du panneau pour mettre en place le bandeau.

12. Nettoyage après installation

Lors du nettoyage après installation, ne pas utiliser de nettoyant abrasif, car il pourrait rayer et

abîmer la surface de la baignoire à hydromassage. Utiliser de l’eau tiède et un détergent liquide

pour nettoyer la surface.

Retirer les taches résistantes, peinture, ou goudron avec de l’essence de térébenthine ou un diluant

pour peinture. Ne pas laisser de nettoyants à base de distillats de pétrole rester en contact avec

les surfaces de la baignoire à hydromassage pendant une longue période. Retirer les résidus de

plâtre en raclant au moyen d’un bord en bois. Ne pas utiliser de grattoirs en métal, une brosse en

fer ou d’autres outils en métal. Utiliser des nettoyants en poudre sur un chiffon humide pour une

action abrasive douce sur les résidus de plâtre.

1011092-2-F Français-11 Kohler Co.

Page 25

Tourner la bague

du jet vers la

droite pour

diminuer le débit.

Remplir d'eau au-moins à 2" (5,1 cm)

au-dessus du jet le plus élevé.

Orienter les jets

pour diriger le

débit d'eau en

position désirée.

Tourner la bague du jet vers la gauche

pour augmenter le débit d'eau.

Appuyer sur l'interrupteur d'air pour activer

ou arrêter la baignoire à hydromassage.

13. Confirmer le bon fonctionnement

Remplir la baignoire à hydromassage

Orienter les buses des jets vers le fond du bassin. Tourner les bagues de garniture du jet

complètement vers la gauche.

Remplir la baignoire à hydromassage au moins à 2″ (5,1 cm) au-dessus du jet le plus élevé.

REMARQUE : La température de la baignoire à hydromassage ne devrait pas excéder 104°F (40° C).

Pour l’entretien des orifices, introduire un crayon dans l’extrémité de la buse du jet et pousser

l’orifice vers l’extérieur. Après avoir retiré tout blocage, inspecter l’orifice pour s’assurer qu’il soit

dégagé et le presser dans le logement du jet.

REMARQUE : Ces orifices ne sont installés dans les jets de baignoire à hydromassage que lorsque le

système contient six jets ou plus.

Séquence d’opération

Appuyer sur l’interrupteur d’air pour activer les jets.

Ajuster chaque jet pour un mélange optimal d’eau et d’air. Tourner l’anneau à droite pour réduire le

débit d’air, ou à gauche pour l’augmenter.

Si équipé d’un chauffe-eau, celui-ci s’activera automatiquement avec la mise en marche de la

pompe, et s’arrêtera quand la pompe est éteinte. Le chauffe-eau ne s’activera pas si la température

de l’eau excède 104°F (40°C).

Appuyer sur l’interrupteur d’air une seconde fois pour arrêter la baignoire à hydromassage.

Kohler Co. Français-12 1011092-2-F

Page 26

Retirer les jets

Réinstaller les jets

Insérer l'outil en crochet comme indiqué, et retirer le

jet hors de son logement. Le gicleur devrait être vers

le haut quand cela sera terminé.

Logement

Inspecter et lubrifier

le joint torique.

Glisser le joint torique

sur le premier

épaulement du jet.

Insérer le jet dans son logement, tourner et pousser

doucement jusqu'à ce qu'il s'enclenche en position.

Dépannage

AVIS : Cette section est seulement destinée à une aide générale. Seul un agent agréé de Kohler ou un

électricien qualifié devrait corriger tous les problèmes électriques. Pour une réparation sous garantie,

contacter le vendeur ou distributeur.

Retirer les jets

REMARQUE : Un outil spécial est fourni avec les jets de remplacement pour permettre de retirer les

anciens jets de la baignoire à hydromassage. Cet outil est aussi fourni avec chaque kit de garniture.

Positionner le jet de façon à ce qu’il pointe vers le haut.

REMARQUE : Le gicleur doit rester pointé vers le haut pour que l’outil ne glisse pas.

Insérer l’outil d’extraction, avec son côté crochet vers le haut dans l’ouverture du jet et accrocher la

partie supérieure du gicleur.

Tenir l’outil fermement et placer le pouce contre le mur de la baignoire à hydromassage. Tirer avec

force sur l’outil jusqu’à ce que l’ensemble du jet sorte du trou. Faire attention à ne pas perdre le

joint torique.

Réinstaller les jets

REMARQUE : Pour permettre une rotation aisée et un fonctionnement correct des jets, le joint torique doit

être : (1) correctement placé, (2) lubrifié, et (3) en bonne condition.

Installer le joint torique sur le premier épaulement du jet.

Lubrifier le joint torique avec le paquet de lubrifiant silicone (fourni), afin d’éviter le fonctionnement

bruyant du jet.

Insérer délicatement le jet dans le logement, puis pousser et pivoter légèrement jusqu’à ce qu’il

s’enclenche en place. Ne pas forcer le jet.

L’appareil n’est pas installé correctement. Le jet devrait pivoter aisément dans les deux sens. Retirer

et réinstaller si nécessaire.

1011092-2-F Français-13 Kohler Co.

Page 27

Dépannage (cont.)

Symptômes Causes probables Action recommandée

1. La baignoire à hydromassage

ne démarre/s’arrête pas.

2. Le moteur démarre, tous les

jets ne fonctionnent pas.

3. La baignoire à hydromassage

s’arrête automatiquement

avant 18 minutes.

4. La pompe ne s’amorce pas.

(Modèles avec des blocs de

support uniquement.)

A. Pas de courant au moteur. A. Vérifier que la pompe et que le

B. Le tuyau d’air est desserré ou

déconnecté.

C. Le tuyau d’air est pincé ou plié. C. Ajuster le tuyau pour dégager

D. Partie(s) du bouton poussoir

est/sont endommagé(e)s.

E. Le bouton poussoir a de la

graisse dans la zone

d’écoulement.

F. Le tuyau d’air est endommagé. F. Remplacer le tuyau d’air.

G. Le moteur/pompe ne fonctionne

pas.

A. Le jet est fermé. A. Tourner la bague du jet vers la

B. Le jet n’est pas installé

correctement.

C. Les jets sont bloqués. C. Retirer le blocage.

A. Le GFCI ou RCD se déclenchent. A. Identifier la source du

B. L’aspiration est bloquée. B. Retirer l’obstruction.

C. Les jets sont bloqués. C. Retirer le blocage.

D. Moteur surchauffé et système de

protection activé.

A. La pompe est en position trop

élevée.

chauffe-eau soient branchés et

que les disjoncteurs GFCI ou

RCD soient en position

correcte. Brancher ou

réinitialiser le GFCI/RCD selon

le besoin.

B. Vérifier que le tuyau est

connecté aux deux extrémités

receveur/pompe et à

l’interrupteur d’air. Reconnecter

si nécessaire.

l’endroit pincé/plié. Si la

tuyauterie est pincée/pliée et

ne peut pas être réajustée, ou

qu’aucune pliure n’est

apparente, faire un petit trou

dans le tube avec un petit clou

et essayer le système à

nouveau.

D. Remplacer l’ensemble du

bouton poussoir.

E. Désassembler le bouton

poussoir et essuyer tout excès

de graisse. Rassembler le

bouton et essayer le système à

nouveau.

G. Reconstruire ou remplacer le

moteur/pompe.

gauche pour l’ouvrir.

B. Réinstaller le jet; s’assurer que

le joint torique ne soit pas

endommagé.

problème, puis y remédier.

D. Vérifier s’il y a blocage aux

prises d’air du moteur. Retirer

l’obstruction et laisser le

moteur refroidir.

Vérifier si la conduite

d’aspiration n’est pas bouchée.

Retirer l’obstruction et laisser le

moteur refroidir.

Vérifier si les jets sont bouchés.

Retirer l’obstruction et laisser le

moteur refroidir.

A. Abaisser le support de pompe.

Kohler Co. Français-14 1011092-2-F

Page 28

Dépannage (cont.)

Symptômes Causes probables Action recommandée

5. Fonctionnement bruyant. A. Les sangles de retenue de la

6. Le chauffe-eau ne fonctionne

pas. (Modèles “H”

uniquement)

pompe n’ont pas été coupées.

(Modèles avec des blocs de

support uniquement.)

B. B.Le joint torique est délogé. B. Retirer le jet, remplacer et

A. Pas de courant au chauffe-eau. A. Réinitialiser le GFCI ou le RCD.

B. La température de l’eau excède

104°F (40°C).

C. Le chauffe-eau ne fonctionne

pas.

A. Couper les sangles de retenue

avec des cisailles de ferblantier.

lubrifier le joint torique, et

réinstaller le jet.

B. Laisser refroidir et le

chauffe-eau redémarrera.

C. Remplacer le chauffe-eau.

1011092-2-F Français-15 Kohler Co.

Page 29

Guía de instalación

Bañera de hidromasaje

Información importante

ADVERTENCIA: Al usar aparatos eléctricos, siga siempre las precauciones básicas, incluyendo

las siguientes:

El material de construcción y el cableado se deben colocar lejos del cuerpo de la bomba y de otros

componentes que produzcan calor.

Instale la unidad de manera que se permita el acceso para darle servicio.

La conexión a tierra es un requisito. Un representante de servicio autorizado debe instalar esta unidad y

conectarla a tierra.

ADVERTENCIA: Riesgo de descarga eléctrica. Un electricista calificado debe realizar todas las

conexiones eléctricas.

ADVERTENCIA: Riesgo de descarga eléctrica. Desconecte el suministro eléctrico antes de dar

servicio.

ADVERTENCIA: Riesgo de lesiones personales o daños a la propiedad. Lea atentamente todas las

instrucciones antes de comenzar la instalación, incluyendo los requisitos detallados a continuación.

AVISO: Cumpla con todos los códigos locales de electricidad y de plomería.

Información sobre el producto

Requisitos eléctricos

La instalación debe contar con un interruptor de circuito con pérdida a tierra (GFCI) de Clase A o dispositivo

de corriente residual (RCD). El GFCI o RCD protege contra el peligro de descarga eléctrica de línea a tierra.

Utilice un circuito dedicado de 120 V, 15 A y 60 Hz para la bañera de hidromasaje.

Los modelos ″H″ requieren un circuito dedicado de 120 V, 15 A y 60 Hz para el calentador.

NOTA: Si el cable eléctrico de la bomba está dañado, debe ser reemplazado por el fabricante, un agente de

servicio autorizado por el fabricante o personas igualmente calificadas para así evitar un peligro. El cable

eléctrico del calentador no se puede reemplazar. Si el cable eléctrico está dañado, el calentador se debe

reemplazar.

Avisos sobre el producto

ADVERTENCIA: Las modificaciones no autorizadas pueden causar un funcionamiento peligroso

y bajo rendimiento de la bañera de hidromasaje. No cambie la ubicación de la bomba de la bañera

de hidromasaje, ni haga otras modificaciones en el sistema de hidromasaje, ya que esto podría tener

un efecto adverso en el rendimiento y en el funcionamiento seguro de la bañera de hidromasaje.

Kohler Co. no se hace responsable bajo esta garantía o de ninguna otra forma, de las lesiones

personales o los daños provocados por modificaciones no autorizadas.

ADVERTENCIA: Riesgo de descarga eléctrica. Desconecte el suministro eléctrico antes de dar

servicio.

ADVERTENCIA: Riesgo de descarga eléctrica. Un electricista calificado debe realizar todas las

conexiones eléctricas.

Kohler Co. Español-1 1011092-2-F

Page 30

Información sobre el producto (cont.)

ADVERTENCIA: Riesgo de lesiones personales o daños a la propiedad. Por favor, lea atentamente

todas las instrucciones antes de comenzar la instalación.

AVISO: Cumpla con todos los códigos locales de electricidad y de plomería.

Componentes ensamblados en fábrica

Los componentes instalados en la fábrica incluyen la bomba con cable de alimentación eléctrica y el

interruptor de aire. No es necesario instalarlos.

Los modelos ″H″ también vienen equipados con un calentador.

La bomba y las tuberías de la bañera de hidromasaje están montadas en fábrica.

Acceso de servicio y a las conexiones

Antes de instalar, asegúrese de proveer el acceso adecuado a las conexiones finales.

1011092-2-F Español-2 Kohler Co.

Page 31

Información sobre el producto (cont.)

AVISO: Provea acceso sin restricciones para dar servicio a la bomba. Se debe proveer acceso para dar

servicio a la bomba y los controles. El panel de acceso se debe ubicar justo al lado de la bomba. Consulte

el diagrama de instalación que viene con la bañera de hidromasaje.

Contenido

Información importante ............................................................. 1

Información sobre el producto ....................................................... 1

Herramientas y materiales .......................................................... 3

Antes de comenzar ............................................................... 4

Prepare el sitio .................................................................. 5

Prepare la bañera de hidromasaje .................................................... 5

Fije la unidad - Modelos con bloques de soporte .......................................... 6

Fije la unidad - Modelos con base de bañera de hidromasaje ................................ 7

Fije la bañera de hidromasaje a la estructura de postes .................................... 8

Corte las cintas de la bomba—Modelos con bloques de soporte .............................. 8

Instale la plomería ................................................................ 8

Realice las conexiones eléctricas ..................................................... 9

Pruebe el funcionamiento de la bañera de hidromasaje ..................................... 9

Termine la pared acabada ......................................................... 11

Cómo desmontar el faldón ......................................................... 11

Limpieza después de la instalación ................................................... 11

Confirme el funcionamiento correcto .................................................. 12

Procedimiento para resolver problemas ............................................... 13

Herramientas y materiales

Sellador de silicona

Lentes de seguridad

Cinta para medir

Llave para tubo

Lápiz

Nivel

Más:

• Materiales y herramientas convencionales

para carpintería

• Lona

• Adhesivo de construcción (opcional)

• Cemento o mortero (opcional)

• Postes de madera de 2x4 ó 2x6

• Tornillos o pernos de fijación

Kohler Co. Español-3 1011092-2-F

Page 32

Instale los tomacorrientes

para la bomba y el

calentador (de utilizarse)

en la placa de montaje.

Salida

Antes de comenzar

Para las bañeras de hidromasaje sin faldón: Se requiere una instalación de sobreponer. Para las

bañeras de hidromasaje con faldón integral u opcional: Se recomienda una instalación encajonada

entre tres paredes o en esquina, dependiendo del modelo elegido.

Para las bañeras en esquina con faldón integral: Pida a un electricista calificado que instale los

tomacorrientes para la bomba y el calentador (de utilizarse) en el lugar especificado de la bañera de

hidromasaje. Consulte la ilustración mostrada arriba.

Verifique que la bañera de hidromasaje no esté dañada antes de iniciar la instalación.

Confirme que haya suficiente espacio para montar y conectar la grifería especificada para su

instalación.

Kohler Co. se reserva el derecho de modificar el diseño de los productos sin previo aviso, tal como

se especifica en la lista de precios.

1011092-2-F Español-4 Kohler Co.

Page 33

Instale las

tuberías de

plomería.

Verifique que el subpiso

proporcione suficiente

soporte, y que esté

plano y nivelado.

Construya una

estructura de

postes de 2x4

o de 2x6 según

el diagrama de

instalación

incluido con el

producto.

Coloque las tuberías

de plomería.

Construya una estructura

de postes de 2x4 o de 2x6,

conforme al diagrama

de instalación.

Encuadre el piso

conforme al diagrama

de instalación.

Verifique que el subpiso

proporcione el soporte

adecuado, y que esté

plano y nivelado.

1. Prepare el sitio

AVISO: Consulte la Guía del diagrama de instalación embalada con su bañera de hidromasaje para el

soporte mínimo requerido del piso en libras/pie cuadrado (kg/metro cuadrado).

Asegúrese de que el piso ofrezca suficiente soporte para su bañera de hidromasaje y que el subpiso

esté plano y nivelado.

Para las bañeras de hidromasaje sin faldón:

AVISO: La bañera de hidromasaje debe instalarse sobrepuesta.

Construya una estructura de postes de 2x4 ó 2x6 para su instalación.

AVISO: Los pies o base de la bañera de hidromasaje deben soportarla. No apoye el peso de la bañera de

hidromasaje por el perímetro del borde.

Para una instalación elevada: Construya una estructura de postes de madera en el piso o construya

una estructura conforme a la información de instalación provista con la bañera de hidromasaje.

Trace y corte con cuidado el material de la cubierta no acabada. Si se ha incluido, utilice la plantilla

de corte, o en su defecto, consulte la información de corte en la Guía del diagrama de instalación.

Para las bañeras de hidromasaje con faldón integral u opcional:

La bañera de hidromasaje debe instalarse encajonada entre tres paredes o en esquina, dependiendo

del modelo elegido. Construya una estructura de postes de 2x4 ó 2x6 diseñada para su instalación

en particular. Construya una estructura conforme a la información de instalación provista con la

bañera de hidromasaje.

Para todas las instalaciones:

Instale las tuberías de plomería según el diagrama de instalación provisto. Tape los suministros y

verifique que no haya fugas.

2. Prepare la bañera de hidromasaje

Instale el desagüe en la bañera de hidromasaje según las instrucciones del fabricante del desagüe.

Aún no conecte la trampa.

Coloque una lona gruesa limpia o un material similar en el fondo de la bañera de hidromasaje.

Tenga cuidado de no rayar la superficie de la bañera de hidromasaje.

Kohler Co. Español-5 1011092-2-F

Page 34

Extienda una capa de

concreto o mortero de

2" (5,1 cm).

Aplique adhesivo de

construcción a los

bloques de soporte.

Limpie el espacio

para la bomba.

Limpie el espacio para

los bloques de soporte.

3. Fije la unidad - Modelos con bloques de soporte

AVISO: No levante la bañera de hidromasaje por los tubos o la bomba, ni use los tubos o la bomba como

soporte estructural de la bañera de hidromasaje. Para evitar daño a la bañera de hidromasaje, levántela por

los lados.

AVISO: No apoye el peso de la bañera de hidromasaje por el perímetro del borde. El perímetro del borde

debe tener el soporte adecuado, pero no debe soportar el peso de la bañera de hidromasaje.

Si el subpiso no está nivelado, acuñe los bloques de soporte de la bañera de hidromasaje según sea

necesario.

Elija la opción de instalación más apropiada para su instalación en particular. Siga las instrucciones

correspondientes.

Opción que utiliza una capa de cemento o mortero

NOTA: No utilice cemento de yeso o pasta para paneles de yeso con esta aplicación, puesto que no

proporcionarán una adherencia aceptable ni duradera.

NOTA: El soporte de la bomba (cuando las cintas metálicas están cortadas) y los bloques de soporte

deben descansar directamente sobre el subpiso.

Extienda una capa de 2″ (5,1 cm) de espesor de cemento o mortero en el subpiso donde se instalará

la bañera de hidromasaje. Esto ayudará a fijar, nivelar y dar soporte a la unidad. Limpie todo el

material de la zona donde se instalarán los soportes de la bomba y los bloques de soporte.

Coloque un pedazo de lona gruesa de plástico sobre el cemento o mortero. Obtenga ayuda para

colocar la bañera de hidromasaje en su lugar y verifique que el soporte de la bomba y los bloques

de soporte no se apoyen sobre la capa de material.

Fije el tubo final del desagüe en la trampa. Asegúrese de que la bañera de hidromasaje esté a nivel y

apoyada en todos los bloques de soporte.

Opción que utiliza adhesivo de construcción

Aplique una cantidad abundante de adhesivo de construcción de alta calidad en la parte inferior de

los bloques de soporte. Obtenga ayuda para colocar con cuidado la bañera de hidromasaje en su

lugar.

Inserte el tubo final en la trampa. Asegúrese de que la bañera de hidromasaje esté a nivel y apoyada

en todos los bloques de soporte.

1011092-2-F Español-6 Kohler Co.

Page 35

Extienda una capa de cemento

o mortero de 2" (5,1 cm).

Aplique adhesivo de

construcción a la base de la

bañera de hidromasaje.

4. Fije la unidad - Modelos con base de bañera de hidromasaje

AVISO: No levante la bañera de hidromasaje por los tubos o la bomba, ni use los tubos o la bomba como

soporte estructural de la bañera de hidromasaje. Para evitar daño a la bañera de hidromasaje, levántela por

los lados.

AVISO: No apoye el peso de la bañera de hidromasaje por el perímetro del borde. El perímetro del borde

debe tener el soporte adecuado, pero no debe soportar el peso de la bañera de hidromasaje.

Elija la opción de instalación más apropiada para su instalación en particular. Siga las instrucciones

correspondientes.

Si el subpiso no está nivelado, será necesario acuñar la base de la bañera.

Opción que utiliza una capa de cemento o mortero

NOTA: No utilice cemento de yeso o pasta para paneles de yeso con esta aplicación, puesto que no

proporcionarán una adherencia aceptable ni duradera.

Extienda una capa de 2″ (5,1 cm) de espesor de cemento o mortero en el subpiso donde se instalará

la bañera de hidromasaje. Esto ayudará a fijar, nivelar y dar soporte a la unidad.

Coloque un pedazo de lona gruesa de plástico sobre el cemento o mortero. Obtenga ayuda para

colocar con cuidado la bañera de hidromasaje en su lugar.

Inserte el tubo final en la trampa. Verifique que la bañera de hidromasaje esté nivelada. Utilice

tornillos o pernos de fijación (no provistos) para fijar la base de la bañera de hidromasaje al piso.

Taladre pequeños orificios guía en la base de la bañera, según sea necesario.

Opción que utiliza adhesivo de construcción

Aplique una cantidad abundante de adhesivo de construcción de alta calidad por debajo de la base

de la bañera de hidromasaje. Obtenga ayuda para colocar con cuidado la bañera de hidromasaje en

su lugar.

Inserte el tubo final en la trampa. Verifique que la bañera de hidromasaje esté nivelada. Utilice

tornillos o pernos de fijación (no provistos) para fijar la base de la bañera de hidromasaje al piso.

Taladre pequeños orificios guía en la base de la bañera, según sea necesario.

Kohler Co. Español-7 1011092-2-F

Page 36

Clave listones

de enrasar de

1/4" (6 mm) en

los postes.

Poste

Utilice clavos

galvanizados de cabeza

grande #6 para fijar el

reborde de clavado a los

postes.

Taladre un

pequeño orificio

a través del

reborde de

clavado en cada

poste.

Desagüe

NOTA:

Bomba

Corte las cintas

metálicas de la

bomba.

Línea de succión

Es posible que el modelo de bomba ilustrado

sea diferente al producto que haya adquirido.

5. Fije la bañera de hidromasaje a la estructura de postes

Taladre un pequeño orificio guía a través del reborde de clavado en cada poste. Añada cuñas entre

el reborde de clavado y los postes según sea necesario para eliminar los huecos.

Clave los listones de enrasar de 1/4″ (6 mm) de espesor en los postes para emparejar el borde con el

reborde de clavado.

Utilice clavos de cabeza grande galvanizados del #6 para fijar el reborde de clavado a los postes de

madera.

6. Corte las cintas de la bomba—Modelos con bloques de soporte

¡IMPORTANTE! Este paso es necesario para que su bañera de hidromasaje Kohler funcione más

silenciosamente.

NOTA: No levante la bomba a mayor altura de la que tenía antes de cortar las cintas metálicas. Si la

bomba está demasiado alta, no cebará correctamente.

Utilice tijeras de chapa para cortar las dos cintas metálicas de la bomba. Después de cortar las cintas

metálicas, el soporte de la bomba y la bomba descenderán una 1/2″ (1,3 cm) hasta apoyarse en el

subpiso. Si la bomba desciende más de 1/2″ (1,3 cm), coloque cuñas debajo del soporte de la

bomba, de manera que haya un espacio de 1/2″ (1,3 cm) entre la bomba y el soporte para un buen

desagüe.

Para minimizar el ruido y la vibración de la bañera de hidromasaje, asegúrese de que la bomba no

esté en contacto directo con el soporte de transporte una vez cortadas las cintas metálicas.

Fije el soporte de la bomba al subpiso con tornillos o pernos de fijación (no provistos).

7. Instale la plomería

PRECAUCIÓN: Riesgo de daños a la propiedad. Debe existir un sello hermético en el desagüe de

la bañera de hidromasaje. Este sello hermético evitará daños a la propiedad.

Conecte el desagüe a la trampa según las instrucciones del fabricante del desagüe.

Instale las válvulas de la grifería según las instrucciones del fabricante de la grifería. No instale la

guarnición de la grifería hasta que se le indique. Abra los suministros del agua caliente y fría, y

compruebe que no haya fugas en las conexiones de suministro.

Haga que el agua circule en la bañera de hidromasaje y compruebe que no haya fugas en las

conexiones del desagüe.

1011092-2-F Español-8 Kohler Co.

Page 37

Instale un tomacorriente con protección GFCI o RCD conectado a tierra, de 120 V y 15 A.

Instale un segundo tomacorriente con protección GFCI o RCD para

el calentador de los modelos "H".

Calentador opcional

bien sea de estilo T (ilustrado) o de toma de agua

(no ilustrado).

(el modelo puede ser diferente)

Verifique que la tubería del accionador

de aire esté bien conectada a la bomba.

Enchufe la bomba y el

Cumpla con los códigos correspondientes.

NOTA:

Es posible que el modelo de bomba ilustrado sea diferente al producto que haya adquirido.

calentador en estos

tomacorrientes.

8. Realice las conexiones eléctricas

ADVERTENCIA: Riesgo de descarga eléctrica. Asegúrese de desconectar la corriente eléctrica antes

de realizar el siguiente procedimiento.

ADVERTENCIA: Riesgo de descarga eléctrica. Conecte la bomba y el calentador en línea (si

provisto) a un tomacorriente con conexión a tierra que tenga protección mediante un interruptor de

circuito con pérdida a tierra (GFCI) o dispositivo de corriente residual (RCD). No retire las clavijas

de conexión a tierra del enchufe. No utilice adaptadores de conexión a tierra.

NOTA: Esta etiqueta identifica el número de modelo y la capacidad nominal eléctrica de la bañera de

hidromasaje que se encuentra cerca de la bomba de hidromasaje.

AVISO: La bomba (provista) y el calentador (si provisto) están equipados con un cable y un enchufe. Todo

el cableado del calentador se ha realizado en fábrica. Un electricista calificado debe instalar un

tomacorriente conectado a tierra, de 120 V, 15 A con protección mediante un interruptor GFCI o RCD. Este

circuito no debe tener ninguna otra carga.

Cableado de la bomba

Coloque el tomacorriente detrás de la bañera de hidromasaje y a menos de 24″ (61 cm) de la bomba.

Enchufe la bomba en este tomacorriente.

NOTA: Asegúrese de que el tubo del accionador de aire esté bien conectado a la bomba y que no esté

doblado o dañado.

Cableado del calentador – Modelos ″H″