Page 1

BEFORE YOU BEGINBEFORE YOU BEGIN

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

Please read these instructions carefully to

familiarize yourself with the required tools, materials,

and installation sequences. Follow the sections that

pertain to your particular installation. This will help

you avoid costly mistakes. In addition to proper

installation, read all operating and safety instructions.

Do not lift

the whirlpool by the piping or pump, or use the

piping or pump for structural support of the

whirlpool.

All information is based on the latest product

information available at the time of publication.

Kohler China Ltd. reserves the right to make

changes in product characteristics, packaging, or

availability at any time without notice.

These instructions contain important care, cleaning,

and warranty information-

CAUTION: Risk of product damage.

please leave these

instructions for the consumer.

·

·

We recommend this whirlpool for corner, drop-in, or

flush installations. An undermount kit is also

available.

Inspect the whirlpool for damage before you begin

installation.

You must install this whirlpool to an adequately

supported, level subfloor.

Confirm adequate support for a rim-mounted faucet,

if used; large faucets that may be inadvertently used

as a means of support are not appropriate or safe

for this installation.

Consult local and national codes.

Kohler Co. reserves the right to make revisions in

the design of products without notice, as specified in

the Price Book.

1036303-T01-A

INSTALLATION INSTRUCTIONS

WHIRLPOOL

K-1111-VLN

1

ã

, 2011

Copyright Kohler China Ltd., 2011

C

1141609-T01-A

Page 2

2

IMPORTANT INFORMATIONIMPORTANT INFORMATION

(GFCI) (ELCB)

WARNING: When using electrical products,

basic precautions should always be followed,

including the following:

DANGER: Risk of electric shock.

WARNING: Risk of electric shock.

WARNING: Risk of electric shock.

WARNING: Risk of injury or property damage.

Connect only

to circuits protected by Ground-Fault CircuitInterrupters (GFCI s) or Earth-Leakage CircuitBreakers (ELCB s).

A licensed

electrician should make all electrical connections.

Disconnect

power before servicing.

Please read all instructions thoroughly before

beginning installation, including the following

requirements.

'

'

·

·

·

·

·

· Building materials and wiring should be routed away

from the pump bodies and other heat-producing

components of the unit.

Install to permit access for servicing.

Pressure wire connectors marked Earth/Ground

are provided within the wiring compartments. To

reduce the risk of electric shock, connect these

connectors to the grounding terminals of your

electric service or supply panel with copper wire

equivalent in size to the circuit conductors supplying

this equipment.

Pressure wire connectors are provided on the

exterior of the junction boxes or controls within this

unit to permit connection of bonding conductors

between this unit and all other exposed metal in the

vicinity, as needed to comply with local

requirements.

The unit should be installed

by a qualified service representative, and grounded.

Grounding is required.

NOTICE: Follow all local plumbing and electrical

codes.

·

·

·

·

""

A.

2226

20 8 4

22 2

A. Features

Components include two pumps, two controls, two

heaters, 6 Flexjets, 20 Bodyssage backjets, 8

effervescence ports, 4 chromatherapy lights, 2 pillows,

and two illuminated keypads with two remote controls.

PRODUCT INFORMATIONPRODUCT INFORMATION

1141609-T01-A

Page 3

3

B. Electrical Requirements

'

'''

The installation must have two Class A Ground-Fault

Circuit-Interrupters (GFCI s) or Earth-Leakage CircuitBreakers (ELCB s). The GFCI s or ELCB s protect

against line-to-ground shock hazard.

Do not relocate

the whirlpool pumps, or make other modifications

to the whirlpool system, as this could adversely

affect the performance and safe operation of the

whirlpool. Kohler Co. shall not be liable under its

warranty or otherwise for personal injury or

damage caused by any such unauthorized

modification.

Use two 220-240

V, 20 A, 50/60 Hz dedicated services; one for each

pump/control/heater system.

WARNING: Unauthorized modification may

cause unsafe operation and poor

performance of the whirlpool.

Product Notices

B.

A (GFCI)

(ELCB) GFCI ELCB

2 220/240 20 50/60

//

C. Connections and Service Access

Before installation, ensure proper access to the final

connections.

You must provide a minimum of

three 864mm wide x 381mm high access panels for

servicing the pumps and controls. The access must be

located immediately next to the pumps. Study the

roughing-in information packed with the whirlpool.

NOTICE: Provide generous, unrestricted service

access to the pumps.

C.

3

864mm 381mm

TOOLS AND MATERIALSTOOLS AND MATERIALS

Plus:

·

·

·

·

·

·

·

·

Conventional woodworking tools and materials

Drop Cloth

Cement, mortar or construction adhesive

2x4 wood boards

2x4

Silicone Sealant

Measuring Tape

Pencil

Tin Snips

Safety Glasses

Pipe Wrench

Level

1141609-T01-A

Page 4

4

·

·

·

·

·

·

·

·

·

·

1/16

(2 )

CAUTION: Risk of product damage.

NOTICE:

Do not

support the whirlpool by the rim.

Adequate floor support must be provided.

Consult the roughing-in sheet packed with your

whirlpool for specific floor loading requirements.

·

·

·

·

·

·

·

·

·

·

If you have not already done so, carefully remove

the protective tape from the whirlpool rim.

Apply mortar and tile to the wall, deck and surround

material as needed.

Apply a bead of sealant where the tile meets the

whirlpool surface.

Install the faucet trim according to the instructions

packed with the trim.

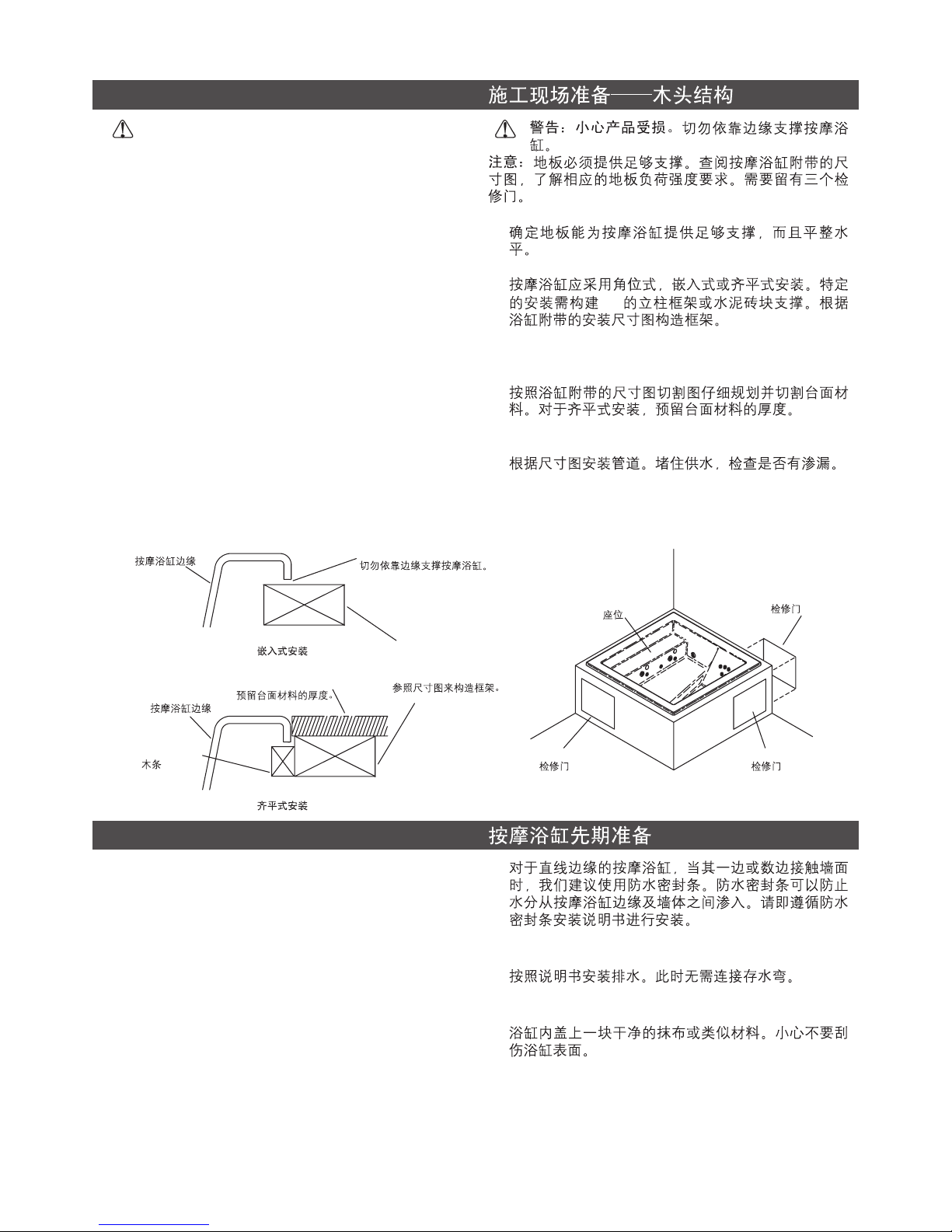

Make sure the flooring offers adequate support for

your whirlpool, and verify that the subfloor is flat and

level.

The whirlpool may be installed as next to the wall or

in an island installation. An island installation

requires a four side surround. In both instances,

make sure the deck is supported by brick or

concrete.

Install an access panel to allow the pump to be

serviced.

Construct brick or concrete supports.

Provide a 2mm gap between the whirlpool rim and

the concrete or brick framing. Frame the floor or

construct a frame for a raised installation in

accordance with the roughing-in information packed

with the whirlpool.

Position the plumbing according to the roughing-in

information packed. Cap the supplies, and check for

leaks.

PREPARE THE SITE - CONCRETE CONSTRUCTIONPREPARE THE SITE - CONCRETE CONSTRUCTION

Bath

Brick

Approved Tile

Backing

Install an access panel to

allow the pump to be serviced.

Whirlpool may be installed next

to the wall or as an island installation.

Approved Tile Backing

2mm

Tile

Typical

Access

Panel

Brick

Tile

1141609-T01-A

Page 5

5

·

·

·

·

2x4

CAUTION: Risk of product damage.

NOTICE:

Do not

support the whirlpool by the rim.

Adequate floor support must be provided.

Consult the roughing-in sheet packed with your

whirlpool for specific floor loading requirements. Three

access panels are required.

·

·

·

·

Make sure the flooring offers adequate support for

your whirlpool, and verify that the subfloor is flat and

level.

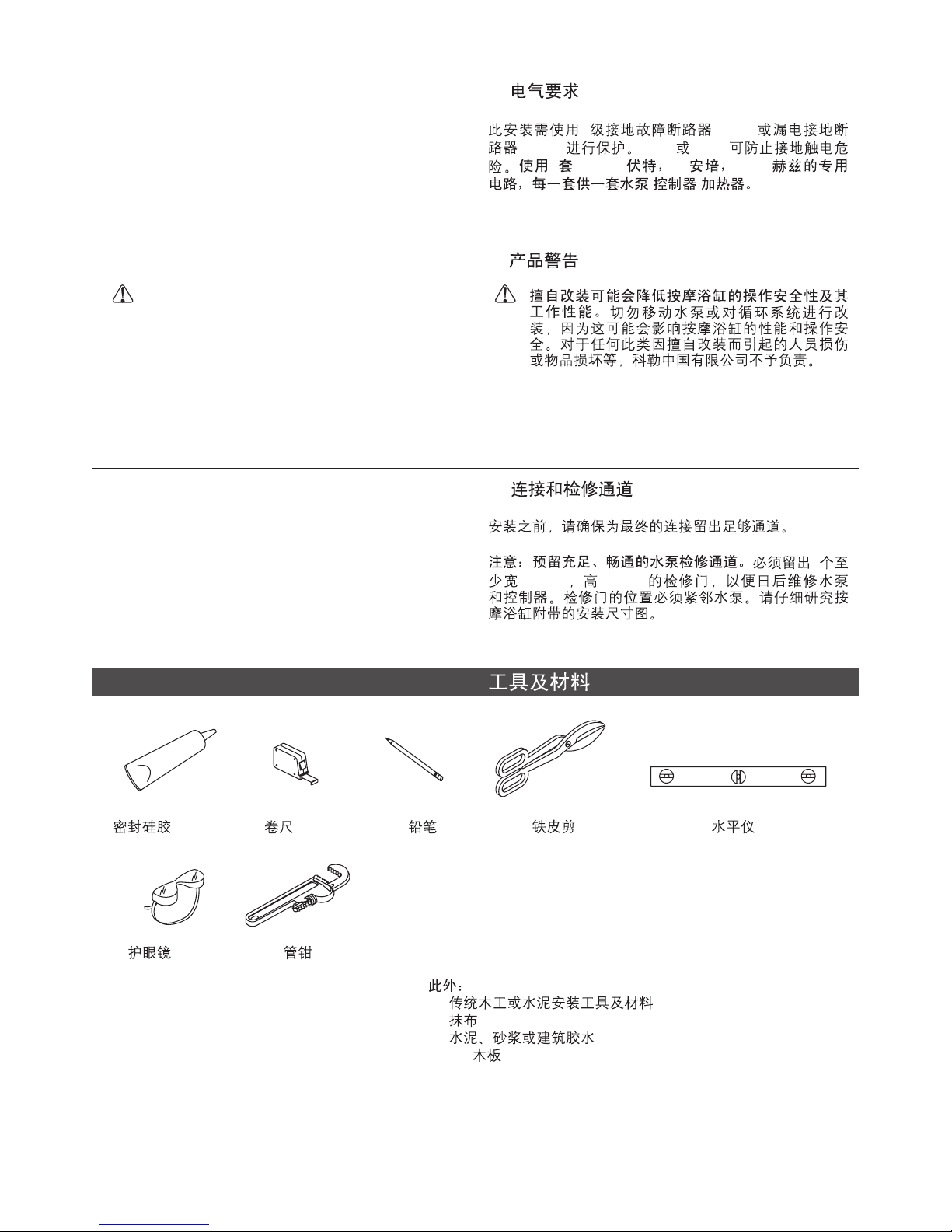

The whirlpool should be installed as a corner, dropin, or flush installation. Construct 2x4 stud framing

designed for your particular installation. Frame the

floor, or construct a frame for a raised installation in

accordance with the roughing-in information packed

with the whirlpool.

Use the roughing-in cut-out information to carefully

lay out and cut the rough deck material. For flushmount installation, allow for the thickness of the

planned deck material.

Position the plumbing according to the roughing-in

information packed. Cap the supplies, and check for

leaks.

PREPARE THE SITE - WOOD CONSTRUCTIONPREPARE THE SITE - WOOD CONSTRUCTION

·

·

·

We recommend a tiling-in bead for straight-rimmed

whirlpools if one or more sides of the whirlpool

contact a wall. This bead prevents water from

seeping between the whirlpool rim and the wall.

Follow the instructions packed with the tiling-in bead

to install the bead now.

Install the drain to the whirlpool according to the

drain manufacturer s instructions. Do not connect

the trap at this time.

Position a clean drop cloth or similar material in the

bottom of the whirlpool. Be careful not to scratch the

surface of the whirlpool.

'

Whirlpool Rim

Do not support the

whirlpool by the rim.

Use the roughing-in

information to construct

the stud framing.

Allow for the thickness of

the planned deck material.

Drop-In Installation

Whirlpool Rim

Wood Batten

Flush Installation

Access Panel 1

1

Seat

Access Panel 3

3

Access Panel 2

2

PREPARE THE WHIRLPOOLPREPARE THE WHIRLPOOL

·

·

·

1141609-T01-A

Page 6

CAUTION: Risk of product damage.

Choose the installation option that best applies

to your particular installation. Follow the

appropriate instructions.

Do not lift

the whirlpool by the piping or pumps, or use the

piping or pumps for structural support of the

whirlpool.

If the subfloor is not level, shim the whirlpool support

blocks as necessary.

·

·

! 2 (50

)

!

!

Option for Using a Cement or Mortar Bed

!

!

!

2" (Spread a 50mm) thick layer of cement or mortar

on the subfloor where the whirlpool will be set.

This will help secure, level, and support the unit.

Clear all the material away from the pump controls

and support block locations.

Do not use gypsum cement or drywall

compound for this application, as they will not provide

an acceptable, durable bond.

Position a piece of plastic drop cloth material on top

of the cement or mortar bed. With help, carefully lift

the whirlpool into place, and make sure the pump

controls and support blocks do not rest in the bed

material.

Insert the drain tailpiece into the trap. Make sure the

whirlpool is level and resting on all support blocks.

NOTE:

NOTE: The pump controls (when the pump banding

straps are cut) and support blocks must rest

directly on the subfloor.

·

·

6

SECURE THE WHIRLPOOL TO THE SUBFLOORSECURE THE WHIRLPOOL TO THE SUBFLOOR

Option for Using Construction Adhesive

Apply a generous amount of high-quality

construction adhesive to the bottom of the support

blocks. With help, carefully lift the whirlpool into

position.

Insert the drain tailpiece into the trap. Make sure the

whirlpool is level and resting on all support blocks.

·

·

Option for Using Silicone Sealant

With help, carefully lift the whirlpool into position.

Insert the drain tailpiece into the trap. Make sure the

whirlpool is level and resting on all support blocks.

Apply a continuous bead of high-quality silicone

sealant around the entire rim of the whirlpool.

·

·

·

!

!

!

!

!

Apply construction adhesive

to the support blocks

Apply a bead of silicone

sealant around the entire rim

Or

Clear spaces for

support blocks

Clear space for pump.

Spread A 2" (51mm)

layer of cement or

mortar bed material.

2 (51 )

1141609-T01-A

Page 7

CAUTION: Risk of property damage.

NOTICE:

NOTE:

Ensure a

watertight seal on the whirlpool drain.

Connect the drain to the trap according to the drain

manufacturer s instructions.

An access panel will simplify future

maintenance.

Check for the required clearance under the rim

of the bath before drilling the hole for the faucet.

Install the faucet valving according to the

manufacturer s instructions. Do not install the faucet

trim until instructed.

Open the hot and cold water supplies.

Check the supply connection for leakage.

Run water into the whirlpool, and check the drain

connections for leakage.

·

·

·

·

·

'

'

·

·

·

·

·

CUT THE PUMP BANDING STRAPSCUT THE PUMP BANDING STRAPS

IMPORTANT! This step is necessary to make your

Kohler whirlpool operate more quietly.

NOTE:

Use tin snips to cut the two pump banding straps

from each whirlpool pump.

Do not raise the pumps higher than they were

before you cut the pump banding straps. If the pumps

are raised too high, they will not prime properly. Make

sure the rubber isolation feet are in place.

To minimize whirlpool noise and vibration, be sure

the pumps are not in direct contact with the

whirlpool after the pump banding straps are cut. The

pump controls contain rubber isolation feet to

reduce pump noise.

·

·

·

·

Pump

Wiring Harness

Rubber Isolation Feet

Control

Cut the pump

banding straps

7

Junction Box

INSTALL THE PLUMBINGINSTALL THE PLUMBING

MAKE ELECTRICAL CONNECTIONSMAKE ELECTRICAL CONNECTIONS

NOTE:

WARNING: Risk of electrical shock.

The product model number is printed on a label

on the pump side of the whirlpool bath. This label also

identifies the electrical rating of the product. All

whirlpools come equipped with a wiring junction box

and are designed to operate between 208 VAC and

240 VAC at either 50 Hz or 60 Hz.

Make

sure the power has been disconnected before

performing the following procedures. Refer to the

"Important Information" section.

208~240 50 60

1141609-T01-A

Page 8

8

WARNING: Risk of electrical shock.

IMPORTANT! load neutral

load neutral

equipment ground

To reduce

the risk of electrical shock, connect the pump to

a properly grounded Ground-Fault CircuitInterrupter (GFCI) or Earth-Leakage CircuitBreaker (ELCB). This will provide additional

protection against line-to-ground shock hazard. A

208-240 V, 20 A, 50/60 Hz dedicated circuit is

required.

The is not used. There

should be no connection to the terminal

on the Ground-Fault Circuit-Interrupter (GFCI) breaker.

The green wire with the yellow stripes is the

and needs to be connected to the

neutral bus in the main circuit breaker box.

(GFCI)

(ELCB)

208-240 20 50/60

(GFCI)

·

·

·

·

The whirlpool bath control and system have been

pre-wired at the factory. A licensed electrician should

make a routine service connection to the junction box.

Connect service to the junction box. The junction box

contains blue, brown, and green with a yellow stripe

colored wires.

Follow local electrical codes. Bond in accordance

with national and local codes.

A wiring harness has been pre-wired at the factory,

allowing communication between the keypad, all

features, and the control. No additional wiring is

required, but ensure that all wires are securely

fastened.

Your wiring harness included an antenna for the

optional remote control. Do not alter or damage this

antenna during installation.

NOTE:

·

·

·

·

120/240 VAC

Source

* Connections to be Made

at the Circuit Breaker

Field Wiring

(From Junction Box

to GFCI Breaker)

No Connection

(Load Neutral)

* Equipment Ground

Neutral Bus

(In Breaker Box)

* Line Neutral

(White Curly

Wire)

Typical Two-Pole

Circuit Breaker

with GFCI

Breaker Box

Heater (models may vary) T-style (shown)

or In-line (not shown)

()T()

()

Bond in accordance with national and local codes.

Open bonding lugs are located at the top of the

junction box.

Typical Wiring Connection for North America

Wire Connector

Ground (Green with

Yellow Stripes)

()

From Control

Brown (L2)

Wire Connectors

Electrician to provide suitable

strain relief cable.

Blue (L1)

S/N

240 V

120 V

120 V

NL1L2

*L2

240 V

*L1

Heater Electrical Cord

Pump Electrical Cord

Wiring Harness

Junction Box

Control

1141609-T01-A

Page 9

9

INSTALL THE WHIRLPOOL TRIM KITINSTALL THE WHIRLPOOL TRIM KIT

·

·

·

·

Install the whirlpool trim kit according to the

instructions packed with the trim kit. Pay particular

attention to the jet installation steps below - they are

very important and are included here to help you

obtain smooth, trouble-free jet operation. When

installed correctly, the jet should turn smoothly both

clockwise and counterclockwise.

The jet O-ring must be carefully positioned,

lubricated, and be in good condition to permit easy

rotation and proper operation of the jet.

Lubricate the O-ring with silicone lubricant to

prevent noisy operation of the jet.

Install the O-ring onto of the jet.

Carefully insert the jet into the housing, and lightly

push and rotate the jet until it snaps into position.

NOTE:

the first shoulder

Do not force the jet into place.

·

·

·

·

O

O

O

Housing

Slide the o-ring onto

the first shoulder of the jet

O

Inspect and lubricate

the o-ring

O

Insert the jet into the

housing, and lightly push

and rotate until it snaps

in position

TEST RUN THE WHIRLPOOLTEST RUN THE WHIRLPOOL

·

·

·

·

·

·

·

Check all electrical connections, then make sure all

union connections to the pumps and heaters are

securely hand tightened.

Verify both sets of pump banding straps have been

cut and the pump controls are resting directly on the

subfloor. Ensure the rubber isolation feet are in

place.

Turn electrical power to both pumps on.

Fill the whirlpool with water until the water level is

above the highest backjet.

Operate the whirlpool for 5 minutes (refer to the

"Operating Sequence" section). Three small lights

near the whirlpool floor will illuminate as long as the

keypad remains lit. The keypad controls the

chromatherapy feature.

Check for leaks coming from the piping connections

on the back side of the whirlpool unit.

Turn on the each of the whirlpool features and verify

proper function. Check for any water leakage on the

whirlpool's back side.

·

·

·

·

·

·

·

5( )

1141609-T01-A

Page 10

·

·

Turn on the chromatherapy cycle and allow it to

sequence through all eight colors; white, violet,

indigo blue, aqua blue, green, yellow, orange and

red. It takes approximately 1 minute to cycle through

all eight colors.

Verify functions using the remote controls. Refer to

the Remote Control Operation section of this guide

and supplemental instruction sheet, Programming

Your Remote Controls , packed with your literature.

For additional information on whirlpool

operation, see the Confirm Proper Operation section

of this guide.

NOTE:

""

"

"

""

·

·

8

81

10

·

·

·

·

If you have not already done so, carefully remove

the protective tape from the whirlpool rim.

Cover the framing with water-resistant wall material.

Seal the joints between the whirlpool rim edge and

the water-resistant wall material with silicone sealant.

Tape and mud the water-resistant wall material.

Install the finished wall to the water-resistant wall

material so it is 2mm above the bath surface. Seal

the joints between the whirlpool rim and the finished

wall material with silicone sealant.

Install the faucet trim according to the instructions

packed with the trim.

·

·

·

·

/

/

/

/

//

2mm

COMPLETE THE FINISHED WALL/DECKCOMPLETE THE FINISHED WALL/DECK

Apply silicone sealant to the water-resistant

wall material and the finished wall.

Apply silicone sealant to the water-resistant

wall material and the finished wall.

Install the finished

wall material.

First install water-resistant

wall material.

Drop-In Installation

Install the finished wall

material.

First install water-resistant

wall material.

Flush Installation

Whirlpool

Whirlpool

1141609-T01-A

Page 11

11

CLEAN-UP AFTER INSTALLATIONCLEAN-UP AFTER INSTALLATION

·

·

·

·

·

·

When cleaning up after installation, do not use

abrasive cleansers, as they may scratch and dull the

whirlpool surface. If necessary, use warm water and

a liquid detergent to clean the surface of the

whirlpool, user keypad and remote control.

Remove stubborn stains, paint, or tar with turpentine

or paint thinner.

Remove plaster by carefully scraping with a wood

edge. Do not use metal scrapers, wire brushes, or

other metal tools. Use a powder-type detergent on a

damp cloth to provide mild abrasive action to any

residual plaster.

Do not allow cleaners containing

petroleum distillates to remain in contact with

any whirlpool surfaces for long periods of time.

CAUTION: Risk of product damage.

NOTE:

Do not

submerge the pillows underwater or use them as

seat cushions.

For best attachment to the whirlpool surface,

moisten the back surface of the pillows at the suction

cup locations.

Clean the whirlpool surface of any soap film or oils.

Moisten the suction cups located on the back side of

the pillows. Position the small pillows above the

backjets and above the waterline by pressing down

firmly with the heel of your hand. Check to make

sure that the pillows are attached firmly to the

whirlpool.

Detach the pillows by lifting them off the whirlpool

surface.

·

·

INSTALL THE REMOVABLE PILLOWSINSTALL THE REMOVABLE PILLOWS

Position the small pillows as

desired above the waterline

and above the backjets.

1141609-T01-A

Page 12

Fill the Whirlpool

NOTE:

NOTE:

Please read these steps carefully before you

operate your whirlpool.

Turn the jet trim rings fully counterclockwise.

Position the jet nozzles so they face down toward

the basin.

Fill the whirlpool with water until the water level is

above the highest backjet.

The water temperature in the whirlpool should

not exceed 104 F (40 C). The heater will automatically

turn off as the water temperature approaches 104 F

(40 C) and will remain off until the water cools.

oo

o

o

·

·

40 40

·

·

12

CONFIRM PROPER OPERATIONCONFIRM PROPER OPERATION

Your whirlpool is equipped with two keypads, each

controlled by its own operating system. Follow the

steps below to confirm the keypads are operating

correctly.

A built-in heater automatically helps to maintain

the water temperature when the whirlpool is running, as

long as the water temperature does not exceed 104 F

(40 C). The heater will disengage at higher

temperatures.

Please refer to your Homeowners Guide

for detailed instructions on the user keypad and remote

control.

The keypad controls the chromatherapy feature.

Press the Power On/Off button on the keypad to

turn the whirlpool on. The whirlpool will start at

medium flow and three small lights near the

whirlpool floor will illuminate as long as the keypad

remains lit.

Increase or decrease the water flow by pressing

either the up or down arrow buttons on the keypad.

An indicator bar in the center of the keypad shows

the water flow volume.

Adjust each Flexjet for optimum air/water mixture.

Turn the Flexjet trim clockwise to reduce the air flow

and counterclockwise to increase the airflow.

NOTE:

IMPORTANT!

NOTE:

o

o

·

·

·

Water-Level Sensors - To use all functions (including

backjets), fill to a level above both water-level sensors.

()

Flexjet - Turn the jet trim ring fully

counterclockwise and position the

jet nozzle downward.

Suction Cover

2

/

3

40 40

/

·

·

·

OPERATING SEQUENCEOPERATING SEQUENCE

1141609-T01-A

Page 13

· Rotate the outer ring until the heater button is

flashing. Press OK to turn the heater off. Press

OK again to turn the heater back on. The heater

will help to maintain the water temperature up to

104 F (40 C).

Press the Power On/Off button a second time to turn

the whirlpool off. The lights near the whirlpool floor

will remain illuminated until the keypad enters the

sleep mode.

Repeat the steps above to verify the operation of the

second keypad.

A built-in timer automatically stops the pump

and motor after approximately 20 minutes of operation.

oo

NOTE:

""

""

·

·

·

·

·

OK OK

40

20

/

Flexjet Flow Mode

Increases Flow

or Pulse Rate

Effervescence Mode

Indicator Bar - Shows

water flow volume or

pulse rate

Chromatherapy Cycle

Decreases Flow

Heater On/Off

Power On/Off

ChromatherapySpecific Color

Rotate outer ring to

access desired mode.

Backjet ModeAdjust Pulse

Activates Mode

Selected

Lighted User Keypad

Turn the Flexjet

trim clockwise to

decrease the flow.

Turn the Flexjet trim

counterclockwise

to increase the flow.

Backjet Operation

NOTE:

Rotate the outer ring until the backjet mode is

flashing and press OK . The backjet pulsing action

will start at medium speed. The backjet pulsing

action will start at medium speed. The backjets

pulse from the bottom of the whirlpool toward the

top, with water flow and pulse action occuring

from two backjets at a time.

If the water level falls below the water level

sensors, the backjets will stop. The backjet icon and

indicator bar on the user keypad will flash. The backjets

will automatically restart when the water level covers

the sensors.

·

""

· To increase or decrease the backjet pulsing action,

press either the up or down arrow buttons on the

keypad, while the backjet mode is active.

To increase or decrease the flow volume to the

backjets, rotate the outer ring to the Flexjet mode,

press OK to activate the mode, and press either

the up or down arrows on the keypad. This also

increases or decreases the flow to all modes.

To activate or deactivate different modes while

the backjets are operating, rotate the outer ring until the

disired mode is flashing and press OK . (Example: To

turn the heater off, rotate the ring until the heater icon is

flashing and press OK ).

Press OK while the backjet mode is flashing to

turn off the backjets.

Repeat the above steps for the second keypad.

NOTE:

·

·

·

""

""

""

""

OK·

·

·

·

·

OK

OK

(

OK )

OK

MODES OF OPERATIONMODES OF OPERATION

13

1141609-T01-A

Page 14

14

Effervescence Operation

NOTE:

·

·

·

·

·

With the whirlpool operating, rotate the outer ring of

the keypad until the effervescence icon is flashing.

Press OK to activate the effervescence ports. The

effervescence action will start at the flow volume last

set in the flexjet flow mode.

Increase or decrease the flow volume by pressing

either the up or down arrow buttons on the keypad.

The effervescence mode is intended to be a

relaxing, soothing experience. The Flexjet mode and

backjets will automatically turn off when the

effervescence mode is activated. Chromatherapy may

be used with all modes of operation.

Press OK while the effervescence mode is flashing

to turn off the effervescence ports.

Repeat the above steps for the second keypad.

""

""

Chromatherapy Operation

NOTE:

Chromatherapy Cycle.

Chromatherapy Specific Color Selection.

Chromatherapy may be used with all modes of

operation or when the pump is not operating.

When the pump is not operating, only one of the

keypads will control the chromatherapy operation.

When this mode is

activated, the chromatherapy lights will

automatically and continuously cycle through the

eight colors; white, violet, indigo blue, aqua blue,

green, yellow, orange, and red. One cycle through

all eight colors takes approximately one minute.

Rotate the outer ring to select this mode and press

OK to activate it. Press OK while the

chromatherapy mode is active to end the cycle.

When

this mode is activated, you may choose a specific

color for the bath. Rotate the outer ring to select this

mode and press OK to activate it. Use the

up/down arrows to reach the desired color. Press

OK while the chromatherapy mode is active to end

the Chromatherapy operation.

·

·

"" ""

""

""

·

·

·

·

·

OK

OK

·

·

8

81

OK

OK

OK

OK

NOTE: Refer to your Homeowners Guide for detailed

instructions on your remote control.

Because your unit has two keypads and two remote

controls, you must program both remote controls.

For detailed instructions, refer to the supplemental

instruction sheet, Programming Your Remote

Controls , packed with your literature.

The remote control places the whirlpool functions at

your fingertips. You may access and modify all

modes/features from the remote control. The

waterproof remote control is designed to be used in

the bath and will float in the water. The remote

control uses two AAA batteries.

The mode selector button functions in the same way

as the outer ring. When M is pressed, one of the

modes will flash on the user keypad. If M is

pressed again, the next mode in clockwise order will

flash. When the desired mode is flashing, press

OK to activate it.

·

·

·

"

"

""

""

""

2

M

M

OK

·

·

·

AAA

REMOTE CONTROL OPERATIONREMOTE CONTROL OPERATION

1141609-T01-A

Page 15

· When the Flexjet mode is active, the arrows will

increase or decrease the water flow volume. When

the backjet mode is active, the arrows increase or

decrease the backjet pulse speed.

·

SYMPTOMS

A. Check wiring and connect power.

B. Reset GFCI or ELCB.

C. Check wiring for proper connections.

Replace wiring harness if necessary.

D. Replace user keypad.

E. Replace control.

A. Rotate jet trim counterclockwise to open.

B. Reinstall jet; check for O-ring damage.

C. Remove blockage.

A. Reset GFCI or ELCB.

B. Check wiring for proper connections.

Replace wiring harness if necessary.

C. Replace user keypad.

D. Replace control.

A. Reset GFCI or ELCB.

B. Check wiring for proper connections.

Replace wiring harness if necessary.

C. Replace user keypad.

D. Replace control.

A. Check wiring for proper connections.

B. Replace pump.

C. Replace control.

A. Lower pump/control to subfloor level.

B. Securely tighten nut(s) on intake side of

pump.

C. Replace motor/pump.

D. Replace control.

A. Identify source of fault and correct. Reset

GFCI or ELCB.

B. Remove obstruction.

C. Remove blockage.

D. Check for blockage at suction and/or jets.

Remove blockage and allow motor to cool.

A. See service manual.

A. Replace user keypad.

B. Replace control.

PROBABLE CAUSES

RECOMMENDED ACTION

1. User keypad does

not illuminate when

power button is

pressed or outer ring

is rotated.

2. Motor starts, but all

jets are not

functioning.

3. User keypad is

illuminated, but does

not respond to

buttons or outer ring.

4. User keypad

indicator bar keeps

scanning at power-up.

5. User keypad is

illuminated, but pump

won't start.

6. Motor runs but pump

won't prime

(cavitates).

7. Pump stops before

18 minutes.

8. Pump does not

automatically stop

after 22 minutes.

9. Pump will not turn off

when the power

button on the user

keypad is pressed.

A. No power to control.

B. GFCI or ELCB tripped.

C. Wiring harness from user keypad to

control is loose, disconnected or

damaged.

D. User keypad does not work.

E. Control does not work.

A. Jet is closed.

B. Jet not installed correctly.

C. Jets are blocked.

A. Control program is locked.

B. Wiring harness from user keypad to

control is loose, disconnected or

damaged.

C. User keypad does not work.

D. Control does not work.

A. Control program is locked.

B. Wiring harness from user keypad to

control is loose, disconnected or

damaged.

C. User keypad does not work.

D. Control does not work.

A. Power cord from pump to control is loose,

disconnected or damaged.

B. Pump does not work.

C. Control does not work.

A. Pump is shimmed too high.

B. Small air leak at pump inlet.

C. Motor/pump does not work.

D. Control does not work.

A. GFCI or ELCB tripped.

B. Suction is blocked

C. Jets are blocked.

D. Motor overheated and protection device

activated.

A. 20-minute timer inadvertently disabled.

A. User keypad does not work.

B. Control does not work.

This troubleshooting guide is for general aid only. A Kohler Authorized Service Representative or qualified electrician

should correct all electrical problems. For warranty service, contact your dealer or wholesale distributor.

Troubleshooting the Whirlpool System

TROUBLESHOOTING PROCEDURESTROUBLESHOOTING PROCEDURES

15

1141609-T01-A

Page 16

A.

B. GFCI ELCB

C.

D.

E.

1.

A.

B. GFCI ELCB

C.

D.

E.

A.

B. O

C.

A. GFCI ELCB

B.

C.

D.

2.

3.

A.

B.

C.

A.

B.

C.

D.

A. GFCI ELCB

B.

C.

D.

4. A.

B.

C.

D.

A.

B.

C.

A. /

B.

C. /

D.

5.

6.

A.

B.

C.

A.

B.

C. /

D.

A. GFCI

ELCB

B.

C.

D. /

A.

7. 18

8. 22

A. GFCI ELCB

B.

C.

D.

A. 20

A.

B.

9. A.

B.

16

1141609-T01-A

Page 17

SYMPTOMS

A. Replace motor/pump.

B. Replace control.

PROBABLE CAUSES

10.Pump operates but

variable speed

feature does not

work.

A. Motor/pump does not work.

B. Control does not work.

A. Allow bath water to cool.

B. Turn heater on.

C. Check wiring for proper connections.

D. Replace heater.

E. Replace control.

11.Bath water cools

while pump is

operating.

A.

oo

Water temperature above 104 F (40 C).

B. Heater is turned off on user keypad.

C. Wiring from heater to control is loose,

disconnected, or damaged.

D. Heater does not work.

E. Control does not work.

A. Cut pump banding straps with tin snips.

B. Remove jet, replace and lubricate O-ring,

then reinstall jet.

12.Noisy operation. A. Pump banding straps have not been cut.

B. Dry or dislodged jet O-ring (squeal).

A. Replace batteries.

B. Replace wiring harness.

C. See homeowners guide or service manual.

D. Replace remote control.

E. Replace control.

A. Check for loose or damaged wires.

Repair or replace as needed.

13.Remote control does

not work or operates

both pumps.

14.Lights near whirlpool

floor do not

illuminate.

A. Batteries improperly installed or dead.

B. Antenna on wiring harness is damaged.

C. Remote control not programmed correctly.

D. Remote control does not work.

E. Control does not work.

A. Wiring damage.

Troubleshooting continued

A. /

B.

10.

A. /

B.

A.

B.

C.

D.

E.

11.

A. 40

B.

C.

D.

E.

A.

B. O

12.

A.

B. O ( )

A.

B.

C.

D.

E.

A.

13.

14.

A.

B.

C.

D.

E.

A.

17

RECOMMENDED ACTION

1141609-T01-A

Page 18

SYMPTOMS

A. Turn on pump.

B. Check for loose connections or wires

leading from backjet pulse canister to

control. Replace backjet pulse canister or

control if necessary.

C. Fill whirlpool so water level sensors are

covered.

D. Replace actuator switch.

E. Check for loose connections or wires

leading from the pump motor to the control.

F. Remove blockage.

G. Reconnect or replace switch wires that

use modular plug.

PROBABLE CAUSES

15.Backjets do not

operate.

A. Whirlpool pump is not operating.

B. Backjet butterfly valve does not open.

C. Not enough water in whirlpool.

D. Actuator switch does not work.

E. Power from pump motor to control is off.

F. Backjet pipe is blocked.

G. Switch wire from switch to control is

disconnected.

A. Check for loose connections or wires

leading from pulse canister to control.

Replace pulse canister or control if

necessary.

B. Replace switch.

C. Reconnect or replace switch wires that

use modular plug.

16.Backjets do not

pulse.

A. Pulse canister does not work.

B. Switch does not work.

C. Switch wire from switch to control is

disconnected.

Troubleshooting the Beckjet Syetem

A.

B.

C.

D.

E.

F.

G.

15.

A.

B.

C.

D.

E.

F.

G.

A.

B.

C.

16.

A.

B.

C.

18

RECOMMENDED ACTION

1141609-T01-A

Page 19

SYMPTOMS

A. Turn on pump.

B. Replace butterfly valve.

C. Refer to the service manual to

troubleshoot the system. Refer to

installer/dealer.

D. Replace control.

PROBABLE CAUSES

17.Effervescence ports

do not work.

A. Whirlpool pump is not operating.

B. Effervescence butterfly valve does not

work.

C. Pump does not work.

D. Control does not work.

A. Remove blockage.

B. Increase water flow.

18.Effervescence ports

do not bubble.

A. Air intake on suction line is blocked.

B. Water flow is too low.

Troubleshooting the Effervescence Jets

A.

B.

C.

/

D.

17. A.

B.

C.

D.

A.

B.

18.

A.

B.

SYMPTOMS

A. Check wiring for proper connections.

Replace wiring if necessary.

B. Replace control.

PROBABLE CAUSES

19.Chromatherapy

lights do not work.

A. Loose, disconnected or damaged

wiring/connections.

B. Control does not work.

Troubleshooting the Chromatherapy Lights - H2 Models Only

A.

B.

19.

A.

B.

H2

19

RECOMMENDED ACTION

RECOMMENDED ACTION

1141609-T01-A

Loading...

Loading...