Operation

Industrial Generator Sets

Models:

10-1000 kW

Controller:

APM402/Decision-Makerr 3000

TP-6694 7/18j

W ARNING: This product can expose you

to chemicals, including carbon monoxide

and benzene, which are known to the State

of California to cause cancer and birth

defects or other reproductive harm.

For more information go to

www.P65warnings.ca.gov

Product Identification Information

W ARNING: Breathing diesel engine

exhaust exposes you to chemicals known to

the State of California to cause cancer and

birth defects or other reproductive harm.

S Always start and operate the engine in

a well-ventilated area.

S If in an enclosed area, vent the exhaust

to the outside.

S Do not modify or tamper with the

exhaust system.

S Do not idle the engine except as

necessary.

For more information go to

www.P65warnings.ca.gov/diesel

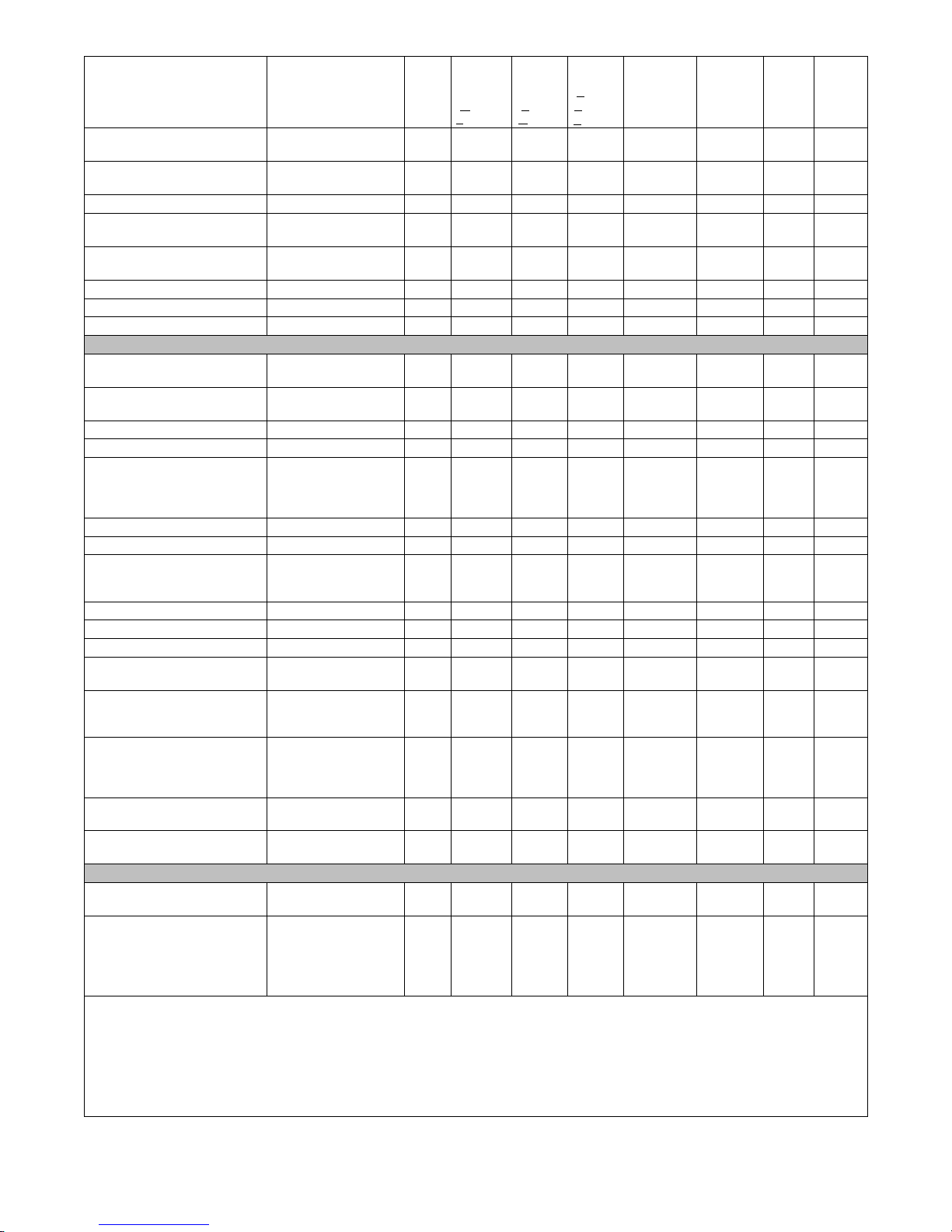

Product identification numbers determine service parts.

Record the product identification numbers in the spaces

below immediately after unpacking the products so that

the numbers are readily available for future reference.

Record field-installed kit numbers after installing the

kits.

Generator Set Identification Numbers

Record the product identification numbers from the

generator set nameplate(s).

Model Designation

Specification Number

Serial Number

Accessory Number Accessory Description

Engine Identification

Record the product identification information from the

engine nameplate.

Manufacturer

Model Designation

Serial Number

Controller Identification

Record the controller description from the generator set

operation manual, spec sheet, or sales invoice. Record

the Controller Serial Number from the controller

nameplate.

Controller DescriptionAPM402/Decision-Maker

Controller Serial Number

r 3000

Firmware/Software Version Numbers

Record the version and reference numbers as shipped

from the manufacturer. Determine the Application

Program Version Number as shown in Menu 20.

Determine the Personality Profile Reference Number

from the disk supplied with the literature packet.

Application Program Version Number

Personality Profile Reference Number

User Parameter File Reference Number

Version Number Upgrades/Updates

Record the version number upgrade/updates when

installed.

Version No./Date Installed

Software Options

Record the software options.

Number and Description

Table of Contents

Product Identification Information 2...........................................................

Safety Precautions and Instructions 7.........................................................

Introduction 13...............................................................................

Abbreviations 13...............................................................

SiteTech Software 13...........................................................

List of Related Materials 13......................................................

Service Assistance 14.........................................................................

Section 1 Specifications and Features 15......................................................

1.1 Introduction 15...........................................................

1.2 Controller Features 15....................................................

1.2.1 Switches and Controls 16..........................................

1.2.2 Annunciator Lamps 16............................................

1.2.3 Digital Display 18.................................................

1.2.4 Controller Fault Diagnostics 23.....................................

1.2.5 Digital Display Circuit Board and Connections 25.....................

1.2.6 Main Logic Circuit Board 25........................................

1.2.7 Terminal Jumper 26...............................................

1.2.8 Communication Ports 26..........................................

1.2.9 Fuses 26........................................................

1.3 Controller Logic Specifications 27...........................................

1.3.1 Status Event and Fault Specifications 27............................

1.3.2 Voltage Regulator and Calibration Specifications 33...................

1.3.3 Voltage Regulator Adjustments 33..................................

Section 2 Operation 35........................................................................

2.1 Prestart Checklist 35......................................................

2.2 Exercising Generator Set 35...............................................

2.3 Operation in Cold Weather Climates 36.....................................

2.4 Controller Operation 36...................................................

2.4.1 Starting 36.......................................................

2.4.2 Stopping (User Stopping and Fault Shutdown) 37.....................

2.4.3 Emergency Stop Switch Resetting 37...............................

2.4.4 System Status Lamps 38..........................................

2.4.5 System Fault Warning Lamp with Digital Displays 38..................

2.4.6 System Fault Shutdown Lamp With Digital Displays 40................

2.4.7 Status and Notice Digital Displays 43...............................

2.4.8 Controller Resetting (Following System Shutdown or Warning) 45.......

2.4.9 Powering Up the Engine Control Module (ECM) 45...................

2.5 Menu Displays 46........................................................

2.6 Monitoring and Programming Setup 49......................................

2.6.1 PC Communications 49...........................................

2.6.2 Modbus Communications 49.......................................

2.7 Reviewing Menu Displays 50...............................................

2.7.1 Error Messages 51...............................................

2.7.2 Overview 52.....................................................

2.7.3 Engine Metering 52...............................................

2.7.4 Generator Metering (and Calibration) 53

2.7.5 GenSet Information 54............................................

2.7.6 GenSet Run Time 54.............................................

2.7.7 GenSet System 54...............................................

2.7.8 GenSet Calibration 56.............................................

.............................

TP-6694 7/18 Table of Contents 3

Table of Contents, continued

2.7.9 Voltage Regulator 57..............................................

2.7.10 Digital Inputs 58..................................................

2.7.11 Digital Outputs 59................................................

2.7.12 Analog Inputs 60.................................................

2.7.13 Battery Charger 1 and 2 61........................................

2.7.14 Event Log 62....................................................

2.7.15 Volt Select 62....................................................

Section 3 Scheduled Maintenance 63..........................................................

3.1 Alternator Service 63......................................................

3.2 Engine Service 63........................................................

3.3 Service Schedule 64......................................................

3.4 Alternator Bearing Service 66..............................................

3.4.1 20--300 kW Models 66............................................

3.4.2 300--1000 kW Models with 4M/5M/7M Single-Bearing Alternator 66.....

3.5 Diesel Fuel Systems 66...................................................

3.5.1 Bleeding Air from Fuel System 66..................................

3.6 Gaseous Fuel Systems 67.................................................

3.6.1 Gaseous Fuel System Concept (Single Fuel) 67......................

3.6.2 LPG Liquid Withdrawal Fuel System Concept 67.....................

3.6.3 Natural Gas and LPG Conversion 67................................

3.6.4 Fuel System Changeover Kits (Dual Fuel) 68.........................

3.7 Crankcase Ventilation (CCV) Heater Kit GM78171-KP1 68.....................

3.8 Air Cleaner Restrictor Indicator (if equipped) 70..............................

3.9 Cooling System 70.......................................................

3.9.1 Coolant Level Check 70...........................................

3.9.2 Cooling System Component Inspection 70...........................

3.9.3 Procedure to Drain Cooling System 71..............................

3.9.4 Procedure to Flush and Clean Cooling System 71....................

3.9.5 Procedure to Refill Cooling System 71..............................

3.10 Battery 72...............................................................

3.10.1 Clean Battery 73.................................................

3.10.2 Electrolyte Level Inspection 73.....................................

3.10.3 Specific Gravity Check 73.........................................

3.10.4 Charge Battery 74................................................

3.11 Storage Procedure 74.....................................................

3.11.1 Lubricating System 75............................................

3.1 1.2 Cooling System 75...............................................

3.11.3 Fuel System 75..................................................

3.1 1.4 Internal Engine Components (Gaseous-Fueled Engines) 75............

3.11.5 Exterior 75.......................................................

3.11.6 Battery 76.......................................................

Section 4 General Troubleshooting 77.........................................................

4.1 General Troubleshooting Chart 78..........................................

4.2 Controller Display and Voltage Regulation Troubleshooting Chart 81............

Section 5 Voltage Reconnection 83............................................................

5.1 Introduction 83...........................................................

5.2 Voltage Reconnection Procedure 83........................................

5.3 Voltage Reconnection Procedure 84........................................

TP-6694 7/18Table of Contents4

Table of Contents, continued

Section 6 Accessories 89.....................................................................

6.1 Accessories and Connections 89...........................................

6.1.1 Battery Charger Kit with Alarm Option 89............................

6.1.2 Common Fault/Failure (32A) Relay Kit 90............................

6.1.3 Fifteen-Relay Dry Contact Kit 91....................................

6.1.4 Gas Fuel Valve Kit 94.............................................

6.1.5 Input/Output (I/O) Module Board 95.................................

6.1.6 Key Switch 96....................................................

6.1.7 Low Fuel (Level/Pressure) Switch 96................................

6.1.8 Manual Speed Adjust (Engine RPM Menu) 97........................

6.1.9 Prime Power Switch Kit 97.........................................

6.1.10 Remote Emergency Stop Kit 98....................................

6.1.11 Remote Reset Feature 98.........................................

6.1.12 Remote Serial Annunciator 99......................................

6.1.13 Run Relay Kit 101.................................................

6.1.14 Shunt-Trip Line Circuit Breaker 101..................................

6.2 Accessory Connections 102.................................................

Appendix A Abbreviations 107................................................................

Appendix B Programmer-Defined Settings 109.................................................

Appendix C Voltage Regulator Definitions and Adjustments 115.................................

Appendix D Alternator Protection 119..........................................................

Appendix E Controller Displays from the Engine ECM 121.......................................

TP-6694 7/18 Table of Contents 5

Notes

TP-6694 7/186

Safety Precautions and Instructions

IMPORTANTSAFETY INSTRUCTIONS.

Electromechanical equipment,

including generator sets, transfer

switches, switchgear, and accessories,

can cause bodily harm and pose

life-threatening danger when

improperly installed, operated, or

maintained. To prevent accidents be

aware of potential dangers and act

safely. Read and follow all safety

precautions and instructions. SAVE

THESE INSTRUCTIONS.

This manual has several types of safety

precautions and instructions: Danger,

Warning, Caution, and Notice.

DANGER

Danger indicates the presence of a

hazard that will cause severe

personal injury, death,orsubstantial

property damage.

WARNING

Warning indicates the presence of a

hazard that can cause severe

personal injury, death, or substantial

property damage.

CAUTION

Caution indicates the presence of a

hazard that will or can cause minor

personal injury or property damage.

NOTICE

Notice communicates installation,

operation, or maintenance information

that is safety related but not hazard

related.

Safety decals affixed to the equipment

in prominent places alert the operator

or service technician to potential

hazards and explain how to act safely.

The decals are shown throughout this

publication to improve operator

recognition. Replace missing or

damaged decals.

Accidental Starting

WARNING

Accidental starting.

Can cause severe injury or death.

Disconnect the battery cables before

working on the generator set.

Remove the negative (--) lead first

when disconnecting the battery.

Reconnect the negative (--) lead last

when reconnecting the battery.

Disabling the generator set.

Accidental starting can cause

severe injury or death. Before

working on the generator set or

equipment connected to the set,

disable the generator set as follows:

(1) Press the generator set off/reset

button to shut down the generator set.

(2) Disconnect the power to the battery

charger, if equipped. (3) Remove the

battery cables, negative (--) lead first.

Reconnect the negative (--) lead last

when reconnecting the battery. Follow

these precautions to prevent the

starting of the generator set by the

remote start/stop switch.

Battery

WARNING

Sulfuric acid in batteries.

Can cause severe injury or death.

Wear protective goggles and

clothing. Battery acid may cause

blindness and burn skin.

WARNING

Explosion.

Can cause severe injury or death.

Relays in the battery charger

cause arcs or sparks.

Locate the battery in a well-ventilated

area. Isolate the battery charger from

explosive fumes.

Battery electrolyte is a diluted

sulfuric acid. Battery acid can cause

severe injury or death. Battery acid

can cause blindness and burn skin.

Always wear splashproof safety

goggles, rubber gloves, and boots

when servicing the battery. Do not

open a sealed battery or mutilate the

battery case. If battery acid splashes in

the eyes or on the skin, immediately

flush the affected area for 15 minutes

with large quantities of clean water.

Seek immediate medical aid in the case

of eye contact. Never add acid to a

battery after placing the battery in

service, as this may result in hazardous

spattering of battery acid.

Battery acid cleanup. Battery acid

can cause severe injury or death.

Battery acid is electrically conductive

and corrosive. Add 500 g (1 lb.) of

bicarbonate of soda (baking soda) to a

container with 4 L (1 gal.) of water and

mix the neutralizing solution. Pour the

neutralizing solution on the spilled

battery acid and continue to add the

neutralizing solution to the spilled

battery acid until all evidence of a

chemical reaction (foaming) has

ceased. Flush the resulting liquid with

water and dry the area.

7Safety Precautions and InstructionsTP-6694 7/18

Battery gases. Explosion can cause

severe injury or death. Battery gases

can cause an explosion. Do not smoke

or permit flames or sparks to occur near

a battery at any time, particularly when

it is charging. Do not dispose of a

battery in a fire. To prevent burns and

sparks that could cause an explosion,

avoid touching the battery terminals

with tools or other metal objects.

Remove all jewelry before servicing the

equipment. Discharge static electricity

from your body before touching

batteries by first touching a grounded

metal surface away from thebattery. To

avoid sparks, do not disturb the battery

charger connections while the battery

is charging. Always turn the battery

charger off before disconnecting the

battery connections. Ventilate the

compartments containing batteries to

prevent accumulation of explosive

gases.

Battery short circuits. Explosion

can cause severe injury or death.

Short circuits can cause bodily injury

and/or equipment damage.

Disconnect the battery before

generator set installation or

maintenance. Remove all jewelry

before servicing the equipment. Use

tools with insulated handles. Remove

the negative (--) lead first when

disconnecting the battery. Reconnect

the negative (--) lead last when

reconnecting the battery. Never

connect the negative (--) battery cable

to the positive (+) connection terminal

of the starter solenoid. Do not test the

battery condition by shorting the

terminals together.

Battery gases. Explosion can cause

severe injury or death. Incorrect use

of the equalize charge state may leadto

hazardous situations. Equalization is

ONLY applicable for flooded lead acid

(FLA) type batteries and will damage

gel, absorbed glass mat (AGM), or

nickel-cadmium (NiCad) type batteries.

In the controller menu or SiteTecht

settings, verify that the battery topology

is set correctly for the battery typeused.

Do not smoke or permit flames, sparks,

or other sources of ignition to occur

near a battery at any time.

Engine Backfire/Flash

Fire

WARNING

Risk of fire.

Can cause severe injury or death.

Do not smoke or permit flames or

sparks near fuels or the fuel system.

Servicing the fuel system. A flash

fire can cause severe injury or death.

Do not smoke or permit flames or

sparks near the carburetor, fuel line,

fuel filter, fuel pump, or other potential

sources of spilled fuels or fuel vapors.

Catch fuels in an approved container

when removing the fuel line or

carburetor.

Servicing the air cleaner. A sudden

backfire can cause severe injury or

death. Do not operate the generator

set with the air cleaner removed.

Combustible materials. A fire can

cause severe injury or death.

Generator set engine fuels and fuel

vapors are flammable and explosive.

Handle these materials carefully to

minimize the risk of fire or explosion.

Equip the compartment or nearby area

with a fully charged fire extinguisher.

Select a fire extinguisher rated ABC or

BC for electrical fires or as

recommended by the local fire code or

an authorized agency. Train all

personnel on fire extinguisher

operation and fire prevention

procedures.

Exhaust System

WARNING

Carbon monoxide.

Can cause severe nausea,

fainting, or death.

The exhaust system must be

leakproof and routinely inspected.

Generator set operation. Carbon

monoxide can cause severe nausea,

fainting, or death. Carbon monoxide

is an odorless, colorless, tasteless,

nonirritating gas that can cause death if

inhaled for even a short time. Avoid

breathing exhaust fumes when working

on or near the generator set. Never

operate the generator set inside a

building unless the exhaust gas is

piped safely outside. Never operate

the generator set where exhaust gas

could accumulate and seep back inside

a potentially occupied building.

Carbon monoxide symptoms.

Carbon monoxide can cause severe

nausea, fainting, or death. Carbon

monoxide is a poisonous gas present in

exhaust gases. Carbon monoxide is an

odorless, colorless, tasteless,

nonirritating gas that can cause death if

inhaled for even a short time. Carbon

monoxide poisoning symptoms include

but are not limited to the following:

D Light-headedness, dizziness

D Physical fatigue, weakness in

joints and muscles

D Sleepiness, mental fatigue,

inability to concentrate

or speak clearly, blurred vision

D Stomachache, vomiting, nausea

If experiencing any of these symptoms

and carbon monoxide poisoning is

possible, seek fresh air immediately

and remain active. Do not sit, lie down,

or fall asleep. Alert others to the

possibility of carbon monoxide

poisoning. Seek medical attention if

the condition of affected persons does

not improve within minutes of breathing

fresh air.

8 Safety Precautions and Instructions TP-6694 7/18

Fuel System

WARNING

Explosive fuel vapors.

Can cause severe injury or death.

Use extreme care when handling,

storing, and using fuels.

The fuel system. Explosive fuel

vapors can cause severe injury or

death. Vaporized fuels are highly

explosive. Use extreme care when

handling and storing fuels. Store fuels

in a well-ventilated area away from

spark-producing equipment and out of

the reach of children. Never add fuel to

the tank while the engine is running

because spilled fuel may ignite on

contact with hot parts or from sparks.

Do not smoke or permit flames or

sparks to occur near sources of spilled

fuel or fuel vapors. Keep the fuel lines

and connections tight and in good

condition. Do not replace flexible fuel

lines with rigid lines. Use flexible

sections to avoid fuel line breakage

caused by vibration. Do not operatethe

generator set in the presence of fuel

leaks, fuel accumulation, or sparks.

Repair fuel systems before resuming

generator set operation.

Explosive fuel vapors can cause

severe injury or death. Take

additional precautions when using the

following fuels:

Propane (LPG)—Adequate ventilation

is mandatory. Because propane is

heavier than air, install propane gas

detectors low in a room. Inspect the

detectors per the manufacturer’s

instructions.

Natural Gas—Adequate ventilation is

mandatory. Because natural gas rises,

install natural gas detectors high in a

room. Inspect the detectors per the

manufacturer’s instructions.

Fuel tanks. Explosive fuel vapors

can cause severe injury or death.

Gasoline and other volatile fuels stored

in day tanks or subbase fuel tanks can

cause an explosion. Store only diesel

fuel in tanks.

Draining the fuel system. Explosive

fuel vapors can cause severe injury

or death. Spilled fuel can cause an

explosion. Use a container to catch fuel

when draining the fuel system. Wipe up

spilled fuel after draining the system.

Gas fuel leaks. Explosive fuel

vapors can cause severe injury or

death. Fuel leakage can cause an

explosion. Check the LPG vapor or

natural gas fuel system for leakage by

using a soap and water solution with

the fuel system test pressurized to

6--8 ounces per square inch

(10--14 inches water column). Do not

use a soap solution containing either

ammonia or chlorine because both

prevent bubble formation. A successful

test depends on the ability of the

solution to bubble.

LPG liquid withdrawal fuel leaks.

Explosive fuel vapors can cause

severe injury or death. Fuel leakage

can cause an explosion. Check the

LPG liquid withdrawal fuel system for

leakage by using a soap and water

solution with the fuel system test

pressurized to at least 90 psi

(621 kPa). Do not use a soap solution

containing either ammonia or chlorine

because both prevent bubble

formation. A successful test depends

on the ability of the solution to bubble.

Hazardous Noise

CAUTION

Hazardous noise.

Can cause hearing loss.

Never operate the generator set

without a muffler or with a faulty

exhaust system.

Engine noise. Hazardous noise can

cause hearing loss. Generator sets

not equipped with sound enclosures

can produce noise levels greater than

105 dBA. Prolonged exposure to noise

levels greater than 85 dBA can cause

permanent hearing loss. Wear hearing

protection when near an operating

generator set.

Hazardous Voltage/

Moving Parts

DANGER

Hazardous voltage.

Will cause severe injury or death.

Disconnect all power sources before

opening the enclosure.

DANGER

Hazardous voltage. Moving parts.

Will cause severe injury or death.

Operate the generator set only when

all guards and electrical enclosures

areinplace.

WARNING

Hazardous voltage.

Backfeed to the utility system can

cause property damage, severe

injury, or death.

If the generator set is used for

standby power, install an automatic

transfer switch to prevent inadvertent

interconnection of standby and

normal sources of supply.

Grounding electrical equipment.

Hazardous voltage will cause severe

injury or death. Electrocution is

possible whenever electricity is

present. Ensure you comply with all

applicable codes and standards.

Electrically ground the generator set,

transfer switch, and related equipment

and electrical circuits. Turn off the main

circuit breakers of all power sources

before servicing the equipment. Never

contact electrical leads or appliances

when standing in water or on wet

ground because these conditions

increase the risk of electrocution.

9Safety Precautions and InstructionsTP-6694 7/18

High voltage test. Hazardous

voltage will cause severe injury or

death. Follow the instructions of the

test equipment manufacturer when

performing high-voltage tests on the

rotor or stator. An improper test

procedure can damage equipment or

lead to generator set failure.

Installing the battery charger.

Hazardous voltage will cause severe

injury or death. An ungrounded

battery charger may cause electrical

shock. Connect the battery charger

enclosure to the ground of a permanent

wiring system. As an alternative, install

an equipment grounding conductor

with circuit conductors and connect it to

the equipment grounding terminal or

the lead on the battery charger . Install

the battery charger as prescribed in the

equipment manual. Install the battery

charger in compliance with local codes

and ordinances.

Connecting the battery and the

battery charger. Hazardous voltage

will cause severe injury or death.

Reconnect the battery correctly,

positive to positive and negative to

negative, to avoid electrical shock and

damage to the battery charger and

battery(ies). Have a qualified

electrician install the battery(ies).

Short circuits. Hazardous

voltage/current will cause severe

injury or death. Short circuits can

cause bodily injury and/or equipment

damage. Do not contact electrical

connections with tools or jewelry while

making adjustments or repairs.

Remove all jewelry before servicing the

equipment.

Engine block heater. Hazardous

voltage will cause severe injury or

death. The engine block heater can

cause electrical shock. Remove the

engine block heater plug from the

electrical outlet before working on the

block heater electrical connections.

Testing live electrical circuits.

Hazardous voltage or current will

cause severe injury or death. Have

trained and qualified personnel take

diagnostic measurements of live

circuits. Use adequately rated test

equipment with electrically insulated

probes and follow the instructions of the

test equipment manufacturer when

performing voltage tests. Observe the

following precautions when performing

voltage tests: (1) Remove all jewelry.

(2) Stand on a dry, approved electrically

insulated mat. (3) Do not touch the

enclosure or components inside the

enclosure. (4) Be prepared for the

system to operate automatically.

(600 volts and under)

Servicing the generator set when it

is operating. Exposed moving parts

will cause severe injury or death.

Keep hands, feet, hair, clothing, and

test leads away from the belts and

pulleys when the generator set is

running. Replace guards, screens, and

covers before operating the generator

set.

Heavy Equipment

WARNING

Unbalanced weight.

Improper lifting can cause severe

injury or death and equipment

damage.

Do not use lifting eyes.

Lift the generator set using lifting bars

inserted through the lifting holes on

the skid.

Hot Parts

WARNING

Hot coolant and steam.

Can cause severe injury or death.

Before removing the pressure cap,

stop the generator set and allow it to

cool. Then loosen the pressure cap

to relieve pressure.

WARNING

Hot engine and exhaust system.

Can cause severe injury or death.

Do not work on the generator set until

it cools.

Servicing the alternator. Hot parts

can cause severe injury or death.

Avoid touching the alternator field or

exciter armature. When shorted, the

alternator field and exciter armature

become hot enough to cause severe

burns.

Servicing the exhaust system. Hot

parts can cause severe injury or

death. Do not touch hot engine parts.

The engine and exhaust system

components become extremely hot

during operation.

Electrical backfeed to the utility.

Hazardous backfeed voltage can

cause severe injury or death. Install

a transfer switch in standby power

installations to prevent the connection

of standby and other sources of power.

Electrical backfeed into a utility

electrical system can cause severe

injury or death to utility personnel

working on power lines.

10 Safety Precautions and Instructions TP-6694 7/18

Notice

NOTICE

This generator set has been

rewired from its nameplate voltage

to

246242

NOTICE

Voltage reconnection. Affix a notice

to the generator set after reconnecting

the set to a voltage different from the

voltage on the nameplate. Order

voltage reconnection decal 246242

from an authorized service

distributor/dealer.

NOTICE

Canadian installations only.For

standby service connect the output of

the generator set to a suitably rated

transfer switch in accordance with

Canadian Electrical Code, Part 1.

11Safety Precautions and InstructionsTP-6694 7/18

Notes

12 Safety Precautions and Instructions TP-6694 7/18

Introduction

This manual provides operation instructions for 10 kW

and larger generator sets equipped with the following

controllers:

D APM402 generator set controller

D Decision-Makerr 3000 generator set controller

Note: In 2018, Kohler adopted a global controller

naming convention. To support this, the name of

the Decision-Makerr 3000 controller has

transitioned to APM402. The APM402 has the

same form, fit and function as the

Decision-Makerr 3000 and supports the same

accessories.

Wiring diagram manuals are availableseparately. Refer

to the engine operation manual for generator set engine

scheduled maintenance information.

Information in this publication represents data available

at the time of print. Kohler Co. reserves the right to

change this publication and the products represented

without notice and without any obligation or liability

whatsoever.

SiteTecht Software

Several instances in this manual refer to SiteTecht

software, which can be used for programming the

APM402 or Decision-Makerr 3000 controller.

SiteTecht software is required for updating the

controller application code (firmware), loading

personality profiles, and saving or loading controller

configuration files. Contact your local distributor/dealer

for assistance.

Note: The APM402 controller uses different firmware

than the Decision-Makerr 3000 controller. Do

not attempt to load Decision-Makerr 3000

firmware on an APM402 controller, or vice-versa.

To determine the generator set controller software

version, go to the Overview menu.

List of Related Materials

Separate literature contains communication and

software information not provided in this manual.

Figure 1 lists the available literature part numbers.

Read this manual and carefully follow all procedures

and safety precautions to ensure proper equipment

operation andto avoid bodily injury. Read and follow the

Safety Precautions and Instructions section at the

beginning of this manual. Keep this manual with the

equipment for future reference.

The equipmentservice requirements are very important

to safe and efficient operation. Inspect the parts often

and perform required service atthe prescribedintervals.

Maintenance work must be performed by appropriately

skilled and suitably trained maintenance personnel

familiar with generator set operation and service.

Abbreviations

This publication makes use of numerous abbreviations.

Typically, the word(s) are spelled out along with the

abbreviation in parentheses when shown for the first

time in a section. Appendix A, Abbreviations, also

includes many abbreviation definitions.

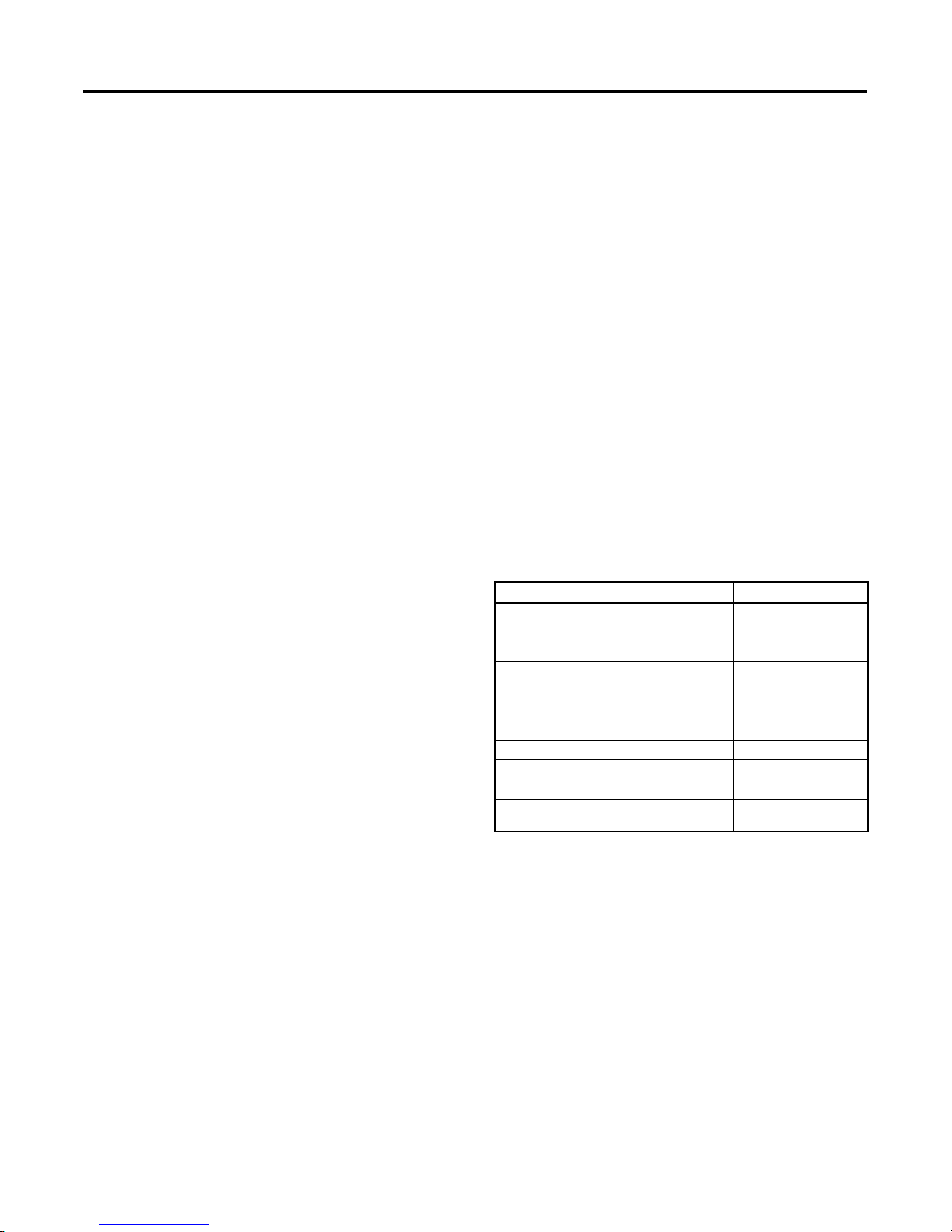

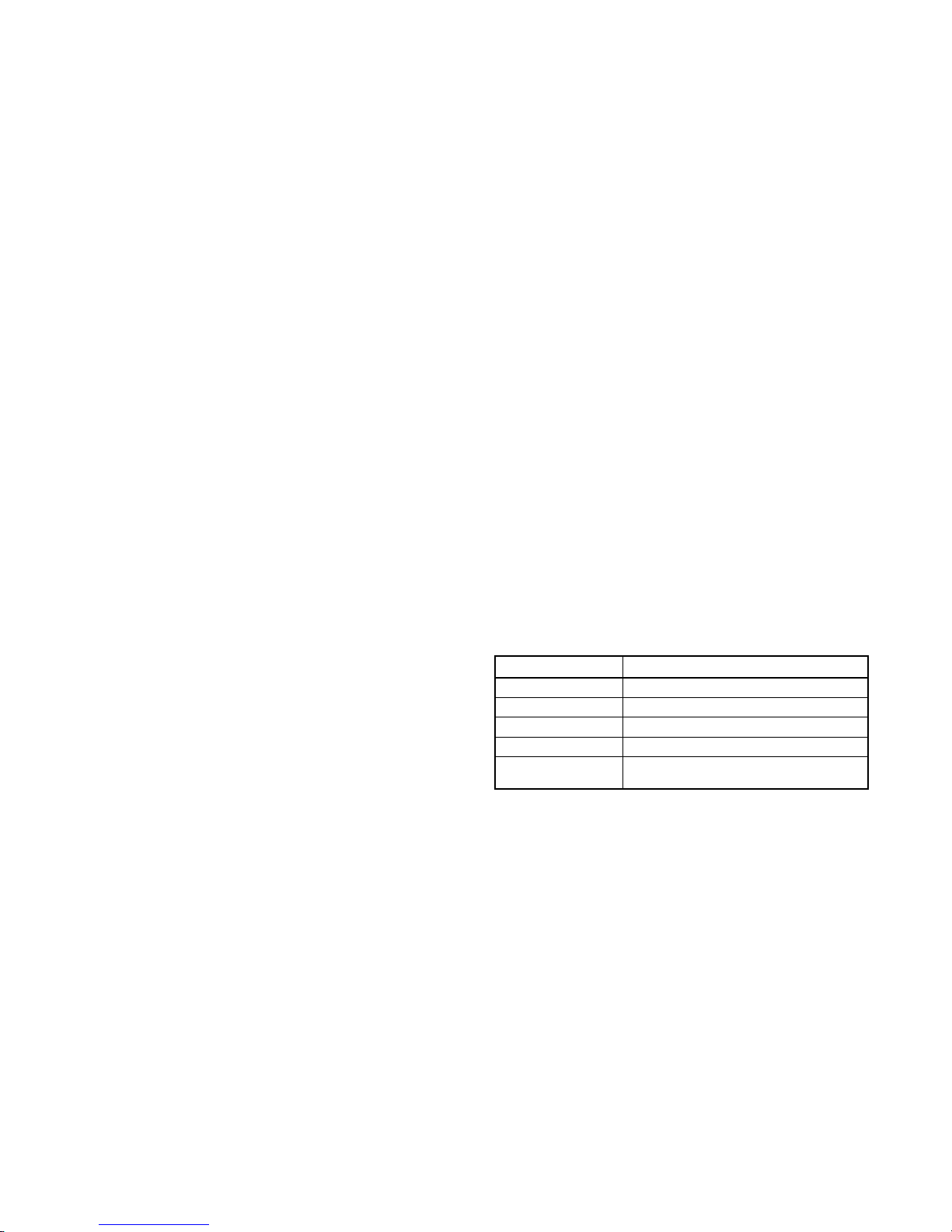

Literature Description Literature Part No.

APM402 Controller Spec Sheet

Decision-Makerr 3000 Controller Spec

Sheet

Generator Set/Controller

Wiring Diagram Manual

Modbusr Communications Protocol

Operation Manual

SiteTecht Software Operation Manual

Remote Serial Annunciator (RSA III) TT-1625

Remote Serial Annunciator (RSA II) TT-1485

Converters, Connections, and Controller

Setup for Network Communication

G6-161

G6-100

Multiple Part Numbers

Contact your

Distributor/Dealer

TP-6113

TP-6701

TT-1405

Figure 1 Related Literature

Several engine manufacturers provide engines with

electronic controls. These electronic controls indicate

engine fault codes in addition to the generator set

controller. The engine operation and service literature

provide information for identifying engine fault codes.

For the latest literature part numbers,see therespective

Parts Catalog.

Modbusr is a registered trademark of Schneider Electric.

13IntroductionTP-6694 7/18

Service Assistance

For professional advice on generator set power

requirements and conscientiousservice, please contact

your nearest Kohler distributor or dealer.

D Visit the Kohler Co. website at KOHLERPower.com.

D Look at the labels and decals on your Kohler product

or review the appropriate literature or documents

included with the product.

D Call toll free in the US and Canada 1-800-544-2444.

D Outside the US and Canada,call the nearest regional

office.

Headquarters Europe, Middle East, Africa

(EMEA)

Kohler EMEA Headquarters

Netherlands B.V.

Kristallaan 1

4761 ZC Zevenbergen

The Netherlands

Phone: (31) 168 331630

Fax: (31) 168 331631

Asia Pacific

Kohler Asia Pacific Headquarters

Singapore, Republic of Singapore

Phone: (65) 6264-6422

Fax: (65) 6264-6455

China

North China Regional Office, Beijing

Phone: (86) 10 6518 7950

(86) 10 6518 7951

(86) 10 6518 7952

Fax: (86) 10 6518 7955

East China Regional Office, Shanghai

Phone: (86) 21 6288 0500

Fax: (86) 21 6288 0550

India, Bangladesh, Sri Lanka

India Regional Office

Bangalore, India

Phone: (91) 80 3366208

(91) 80 3366231

Fax: (91) 80 3315972

Japan, Korea

North Asia Regional Office

Tokyo, Japan

Phone: (813) 3440-4515

Fax: (813) 3440-2727

14 Service Assistance TP-6694 7/18

Section 1 Specifications and Features

1.1 Introduction

The spec sheets for each generator set provide modelspecific generator and engine information. The

controller spec sheet provides specifications for this

controller. Refer to the respective spec sheet for data

not supplied in this manual. Refer to the generator set

service manual, installation manual, engine operation

manual, and engine service manual for additional

specifications.

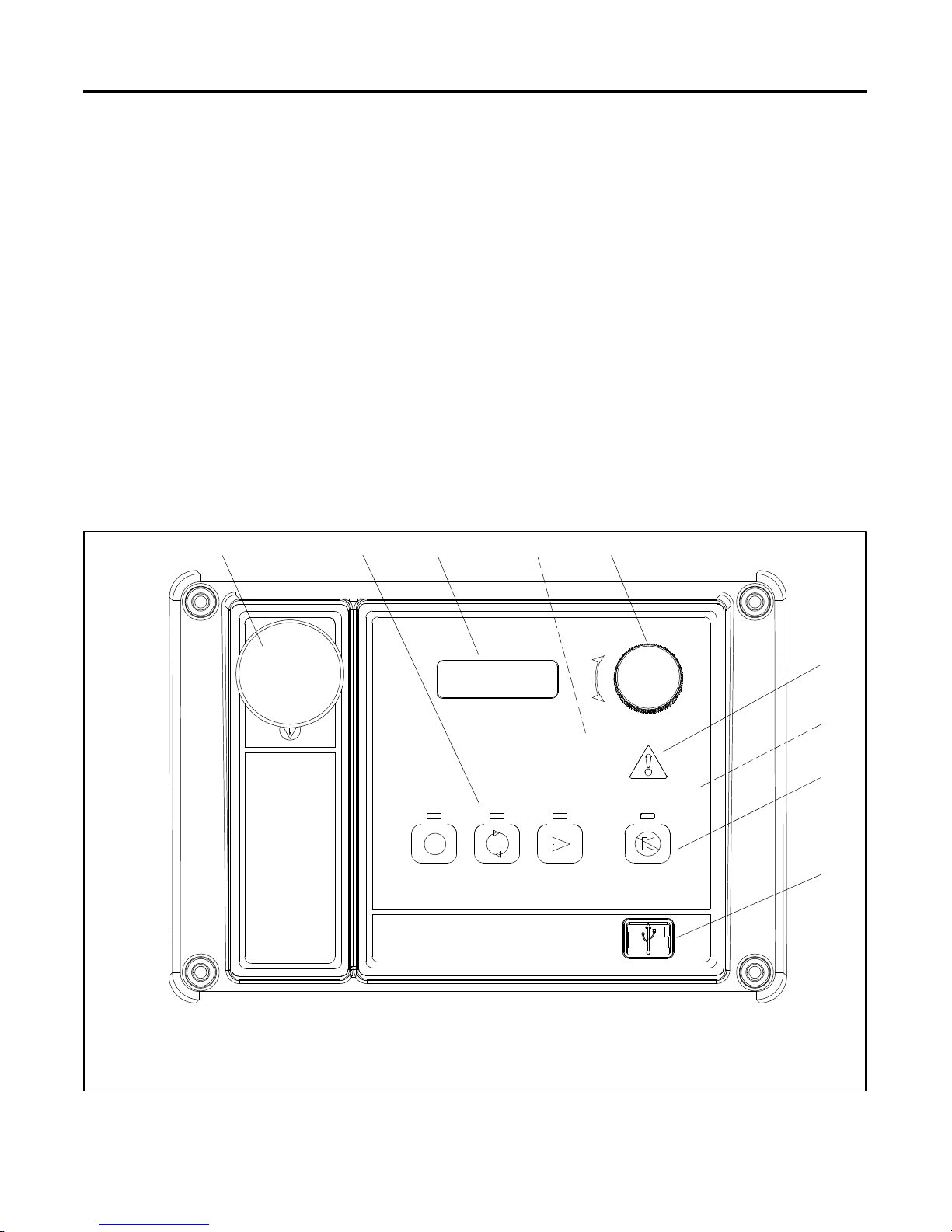

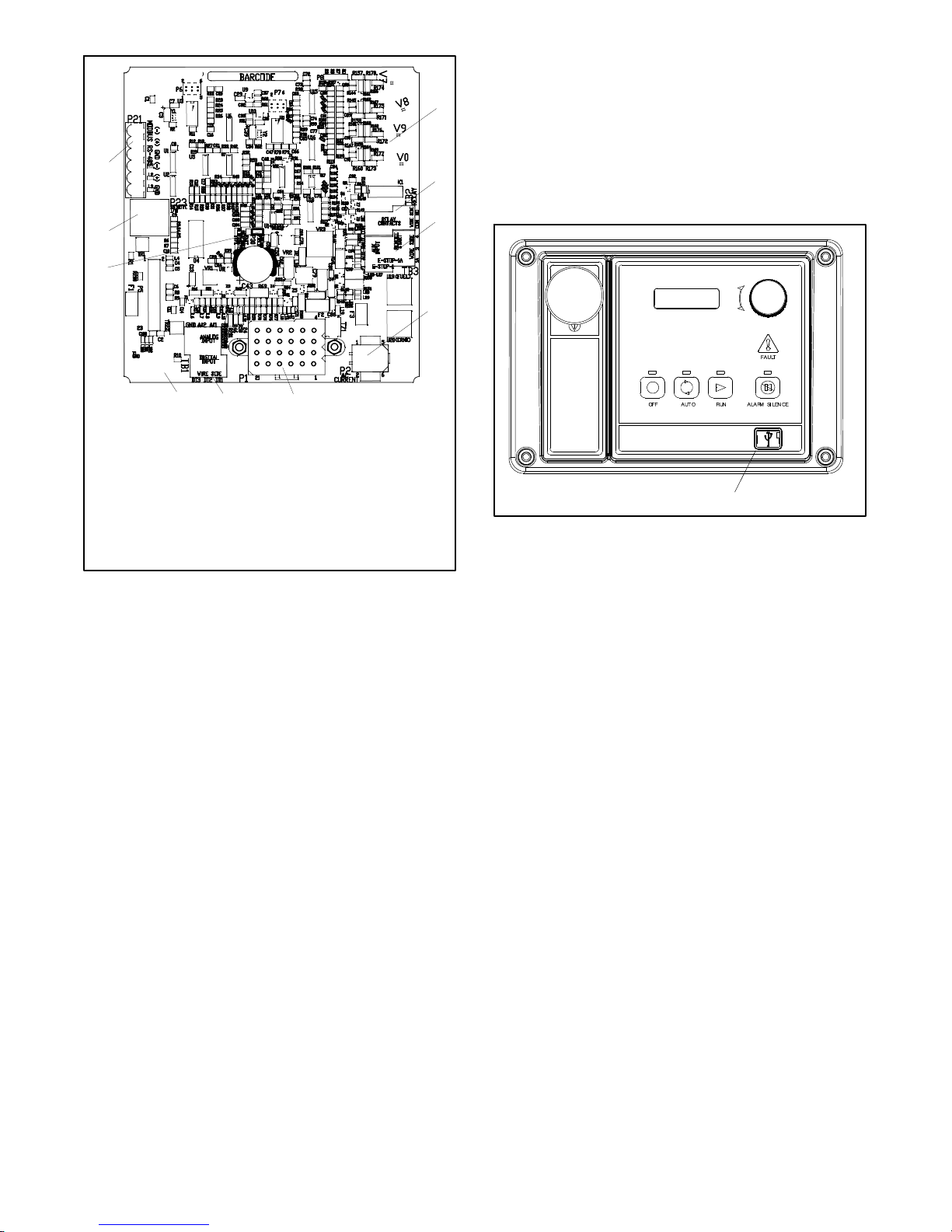

1.2 Controller Features

The controller features include the annunciator lamp,

digital display and pushbutton/rotary selector dial,

switches and controls, and fuses and terminal strip. The

following paragraphs detail the features by general

topics.

See Figure 1-1 for an illustration of the controller front

panel.

12 45

3

The controller features,accessories, and menudisplays

depend upon the engine electronic control module

(ECM) setup and features. Controller features apply to

generator set models with ECM and non-ECM engines

unless otherwise noted.

Note: Press the pushbutton/rotary selector dial to turn

on the controller lights and display. The lights and

display turn off 60 minutes after the last entry

when in the AUTO mode.

Note: After about 5 minutes of no user input

(pushbutton/rotary selector dial or buttons), the

menu is reset to the top of the main menus and

auto-paging activates for the Overview

submenus.

Note: Measurements display in metric or English units.

Use the Generator Set System menu to change

the measurement display.

OFF/RESET AUTO RUN ALARM SILENCE/

1. Emergency stop switch

2. Generator set master control switches,

OFF/RESET-- AUTO--RUN buttons with lamps

3. Digital display

4. Alarm horn (behind panel)

5. Pushbutton/rotary selector dial

6. Annunciator fault lamp

7. Controller terminal strips (on circuit board)

8. Alarm silence/lamp test button with lamp

9. Mini USB connection

Figure 1-1 Controller with Digital Display and Pushbutton/Rotary Selector Dial

FAU LT

LAMP TEST

6

7

8

9

GM65741-

TP-6694 7/18 15Section 1 Specifications and Features

1.2.1 Switches and Controls

Note: US/Metric Display is selectable in Section

1.2.3—Digital Display—Generator Set System

Menu.

Alarm Horn. The alarm horn alerts theoperator or other

attendants that a shutdown or warning condition exists.

Alarm (Horn) Silence. The alarm silence/lamp test

switch silences the alarm horn at the operator’s

discretion. Press the master control switch AUTO

button before pressing the alarm silence/lamp test

button. The alarm horn cannot be silenced unless the

master control switch AUTO button is pressed.

Note: Additional alarm silencing options are shown in

Section 1.2.3—Digital Display—Generator Set

System Menu.

Restore alarm horn switches at all locations including

those on remote annunciator kits after correcting the

fault shutdown to avoidreactivating the alarm horn. See

Section 2—Operation, 2.4.8 Controller Resetting for

resetting the controller.

Emergency Stop. The operator-activated pushbutton

immediately shuts down the generator set inemergency

situations. Reset the emergency stop switch after

shutdown by pulling the emergency stop switch

outward. Usethe emergency stopswitch for emergency

shutdowns only. Use the master control switch

OFF/RESET button for normal shutdowns.

The pushbutton/rotary selector dial hasseveral features

and functions:

D Momentarily press the dial to activate the digital

display if dark.

D Rotate the dial to navigate through the main

menus—turn clockwise to go forward (down) and

counterclockwise to go back (up). The menus do not

wrap to the beginning.

D Press the dial at a given main menu to access the

submenus within the selected main menu.

D When in the submenu, rotate the dial to navigate

through the submenu—clockwise to go forward

(down) and counterclockwise to go back (up). The

menus do not wrap to the beginning.

D Momentarily press the dial when in the submenu to

make a user selection choice (if available) or to go

back to the respective main menu.

D Press the dial forat least3 seconds to return tothe top

of the main menus (Overview) regardless if you are in

the main menus or submenus.

D After about 5 minutes of no user input (pushbutton/

rotary selector dial or buttons), the menu resets to the

top of the main menus and auto-paging activates for

the Overview submenus.

1.2.2 Annunciator Lamps

The controller has a single annunciator fault lamp

providing visual generator set status. In addition, each

button has a corresponding lamp. See Figure 1-2.

Generator Set Master Control Switches

(OFF/RESET--AUTO--RUN). These switches reset the

controller fault lamps and start/stops the generator set.

Additional information in shown in Section 2—

Operation.

Lamp Test. Press and hold the Alarm Silence/Lamp

Test button for two seconds to test the controller

indicator lamps, alarm horn, and digital display.

Manual Speed Adjust (Engine RPM). The control

allows varying the engine speed for applications using

closed transition ATS. The user can set the nominal

running frequency slightly above or below the utility

frequency to ensure that synchronization occurs.

Additional information is shown in 2.7.7 GenSet

System. Available as a factory-installed option o r

requires a new factory personality profile.

Pushbutton/Rotary Selector Dial. This control

provides access to the menus for monitoring. Press the

selector dial to activate the digital display and to select

choices shown on the display. Rotate the dial to

navigate through the menus.

Lamp/Button Lamp Color

Alarm (Fault) Lamp Yellow (Warning) or Red (Shutdown)

Off/Reset Button Red

Auto Button Green (System Ready)

Run Button Yellow

Alarm Silence/Lamp

Test Button

Yellow

Figure 1-2 Annunciator Lamps

System Status Lamps (Master Control Switches)

The green lamp illuminates on the master controlswitch

AUTO (automatic start) button indicating the system

senses no faults and the unit is ready to start by remote

command.

The red lamp illuminates on the master control switch

OFF/RESET button indicating the generator set is

stopped.

The yellow lamp illuminates onthe master control switch

RUN button indicating the generator set is cranking or

running from a local command.

Only one of the three master control switch lamps will

illuminate at any given time.

TP-6694 7/1816 Section 1 Specifications and Features

Alarm Silence Lamp. Yellow lamp illuminates

indicating the alarm horn was silenced.

(System) Fault Lamp. Yellow lamp illuminates

indicating a warning condition or red lamp illuminates

indicating a shutdown condition. See System Warning

Fault Lamp and System Shutdown Fault Lamp following

for system fault conditions.

System Warning Fault Lamp. Yellow lamp identifies

an existing fault condition that does not shut down the

generator set. A continuing system warning fault

condition may cause a system shutdown. Correct all

system warnings as soon as practical.

See Section 2.4.5, System Fault Warning Lamp with

Digital Displays, for definitions of the items listed. The

following conditions cause a system warning:

D AC sensing loss

D Auxiliary input (analog or digital)

D Battery charger communication loss

D Battery charger fault *

Note: Optional input sensors not required with charger

GM87448.

D Battery charger identity conflict

D Battery charger parameter mismatch

D Battery fault

D Common warning

D Critical high fuel level (diesel-powered models only) *

D Default parameters loaded

D ECM diagnostics (multiple engine inputs)

D Fuel tank leak (diesel-powered models only) *

D Ground fault *

D High battery voltage

D High coolant temperature

D High fuel level (diesel-powered models only) *

D Input/output communication loss

D Low battery voltage

D Low coolant temperature

D Low cranking voltage

D Low engine oil level *

D Low fuel (level for diesel-powered models) *

D Low fuel (pressure for gas-powered models) *

D Low oil pressure

D Not-in-auto (master control switch)

D Speed sensor fault

* Requires optional input sensors with all battery chargers except

battery charger GM87448.

System Shutdown Fault Lamp. Red lamp indicates

that the generator set has shut down because of a fault

condition. The unit will not start without resetting the

controller, see Section 2.4.8, Controller Resetting

procedure.

See Section 2.4.6, System Fault Shutdown Lamp with

Digital Displays, for definitions of the items listed. The

following conditions cause a system shutdown:

D AC sensing loss

D Alternator protection

D Auxiliary input (analog or digital)

D Common fault

D ECM address conflict

D ECM communications loss

D ECM diagnostics (multiple engine inputs)

D ECM model mismatch

D Emergency stop

D Enclosure temperature: high shutdown (available on

select Telecom units only)

D Engine over speed

D Engine under speed

D File system error (controller firmware fault)

D Fuel tank leak (diesel-powered models only) *

D High coolant temperature

D Internal failure

D kW overload

D Locked rotor (failed to crank)

D Loss of fuel

D Low coolant level *

D Low engine oil level *

D Low fuel level (diesel-powered models only) *

D Low oil pressure

D Megajector communications loss

(GM/PSI and Doosan gas-powered models only)

D Metering communication loss

D No coolant temperature signal

D No oil pressure signal

D Overcrank

D Overfrequency

D Overvoltage (each phase)

D Run relay overload

D Underfrequency

D Undervoltage (each phase)

D (Voltage) regulator communication loss

* Requires optional input sensors.

TP-6694 7/18 17Section 1 Specifications and Features

1.2.3 Digital Display

Overview Menu

Press the pushbutton/rotary selector dial to turn on the

controller lamps and display. The lamps and display

turn off 60 minutes after the last entry.

Note: The APM402 controller takes about 5--10

seconds to power on.

The generator set must be running for some displays to

indicate values. If the generator set is not running some

values will display zero or N/A (not available).

Some displays are engine dependent, refer to the

Appendix, Controller Displays from the Engine ECM.

The 12-character, 2-line backlit heated display provides

generator set and engine data, system status, and fault

information. See Figure 1-1. The digital display shows

abbreviations in some instances, refer to 1.3.1 Status

Event and Fault Specifications for theabbreviations and

their full descriptions.

Note: US/Metric Unit Display is selectable in

Generator Set System.

Note: Display Contrast is selectable in Generator Set

System. The contrast display adjustment allows

user selected resolution values to improve digital

display clarity.

Note: After about 5 minutes of no user input

(pushbutton/rotary selector dial or buttons), the

menu resets to the top of the main menus and

auto-paging activates for the Overview

submenus.

The main menus are listed below. Within each main

menu are multiple submenus with descriptions

following.

D Overview

D Engine Metering

D Generator Metering

D GenSet Information

D GenSet Run Time

D GenSet System

D GenSet Calibration (Decision-Makerr 3000

controllers before Version 3.0.25)

D Voltage Regulation

D Digital Inputs

D Digital Outputs

D Analog Inputs

D Event Log

D Volt Select

When a new shutdown or warning fault occurs, the

auto-paging display feature activates.

Active Shutdowns display if any are present. This

alerts the user to single or multiple shutdown fault

conditions. See 1.2.2—Annunciator Lamps—System

Shutdown Fault Lamp for a list of possible shutdown

faults.

Active Warnings display if any are present. This alerts

the user to single or multiple warning fault conditions.

See 1.2.2—Annunciator Lamps—System Warning

Fault Lamp for a list of possible warning faults.

Generator Set State displays the generator set status:

D Off

D Standby

D Running

D Cooldown

D Stopping

Average Volts Line-to-Line value displays. For

three-phase configurations the average line-to-line

voltage of L1, L2, and L3 is displayed. Single-phase

configurations show the L1-L2 voltage.

Frequency (Hz) value displays for the output AC

voltage.

Current value displays as the average for three-phase

configurations or the current value for L1-L2 with

single-phase configurations.

Average kW displays. For three-phase configurations

the average line-to-line kilowatts of L1, L2, and L3 is

displayed. Single-phase configurations show the L1-L2

kilowatts.

Coolant Temperature diplays for the engine coolant

temperature.

Oil Pressure displays the engine oil pressure.

Fuel Level % displays the fuel tank level for diesel-

powered models when so equipped.

Fuel Pressure displays fuel pressurefor someengines.

Refer to the Appendix, Controller Displays from the

Engine ECM.

Battery displays the DC voltage of the engine starting

battery(ies).

CHG1 and CHG2 display battery charger voltage and

current (amps) if one or two CAN-enabled 10 Amp

battery chargers (GM87448 only) have been

connected. Shows N/A if charger GM87448 was

TP-6694 7/1818 Section 1 Specifications and Features

connected and then removed. (DEC3000 version 4.11

or higher, and APM402)

Engine Run Time displays the total run time hours.

The calibration values are r eviewable at all times and

provide the calibration of the voltage and current

sensing logic. Changing the systemvoltage or replacing

the circuit board requires a calibration adjustment.

Software Version displays in the Overview menu. Use

the version number to determine if an upgrade is

needed and/or when troubleshooting the controller.

Engine Metering Menu

Note: The Engine Metering Menu may vary depending

upon if the selector dial is rotated clockwise or

counterclockwise.

Engine Speed (Tachometer) displays the engine

speed in RPM.

Oil Pressure displays the engine oil pressure. This

value also shows in the Overview Menu.

Coolant Temperature displays the engine coolant

temperature. This value also shows in the Overview

Menu.

Fuel Level % displays the fuel tank level for dieselpowered models if so equipped. This value also shows

in the Overview Menu.

Battery displays the DC voltage of the engine starting

battery(ies). This value also shows in the Overview

Menu.

Fuel Pressure displays fuel pressurefor someengines.

Refer to the Appendix, Controller Displays from the

Engine ECM. This value also shows in the Overview

Menu.

Generator Metering Menu

Total Power kVA and kW displays alternator output as

actual output values.

To enable calibration

, start the generator set and select

the Volts L1-L2 display. Then push and hold the

pushbutton/rotary selector dial until the Calibration

Enabled popup appears. Calibration of each display is

now available. The display will show the following

values for three-phase generator sets. Single-phase

generator sets will only display items marked (*).

D Volts L1-L2 *

D Volts L2-L3

D Volts L3-L1

D Volts L1-N *

D Volts L2-N *

D Volts L3-N

D Current L1 *

D Current L2 *

D Current L3

The user can change individual values or can select

Reset Calib?--Yes to reset all values. The Reset Calib?

display will only show if calibration is enabled. Refer to

the requirements shown with Generator Set Calibration

in 2.4.7 Status and Notice Digital Displays.

To disable calibration

, Rotate the pushbutton/rotary

selector dial until the <-- Return popup appears.

Momentarily press the pushbutton/rotary selector dial.

Stop the generator set if not already done.

Generator Set Information Menu

GenSet M/N displays the generator set model number.

GenSet S/N displays the generator set serial number.

Controller S/N displays the controller serial number.

Rated Power displays alternator output as a

percentage of the entered data value.

Volt s displays the alternator output AC voltages. The

display shows all line-to-line and line-to-neutral voltage

combinations for three-phase or single-phase

configurations.

Current displays the alternator output AC amps. The

display shows each line (L1-L2-L3) of three-phase

models or L1-L2 current for single-phase models.

Frequency (Hz) value displays for the output AC

voltage. This value also shows in the Overview Menu.

Reset Calibration providing the means to reset the

configuration values is available in this menu.

TP-6694 7/18 19Section 1 Specifications and Features

Generator Set Run Time Menu

Engine Run Time displays the total run time hours.

This value also shows in the Overview Menu.

Engine Loaded displays the total loaded hours.

Engine Starts displays the total number of generator

set startup events.

Total Ene rgy displays the total kW hours.

Generator Set System Menu

Generator Set (Reset) Calibration Menu

The values in this menus are user-entered for the

generator set configuration and are NOT measured

values of the generator set.

Changes to the Generator Set System menu require the

use of SiteTecht software except for Measure System

and Contrast selections.

System Frequency displays the programmer-entered

L1-L2-L3 output voltage frequency for three-phase or

the L1-L2 output voltage frequency for single-phase.

System Phase displays the programmer-entered

configuration as Single Phase, Single Phase Dog Leg,

Three Phase Wye, or Three Phase Delta.

System Voltage displays the programmer-entered

L1-L2-L3 output voltage for three-phase or the L1-L2

output voltage for single-phase.

Power Rating displays the programmer entered kW

value for the generator set.

Amp Rating displays the programmer entered current

value for the generator set.

Power Type displays the programmer entered

generator set application configuration as Standby or

Prime.

Battery Voltage displays the engine electrical system

12 or 24 volts.

Measurement System displays the user selected unit

of measure as Metric or English.

Contrast displays user selected resolution values to

improve digital display clarity.

Alarm (Horn) Silence displays the programmer

selected alarm silence method as Always or Auto Only

using SiteTecht software. TheAlways selectionallows

the alarm to be silenced in any of the

OFF/RESET--AUTO--RUN modes. The Auto Only

selection allows silencing of the alarm only while in the

Auto mode.

This menu is only available in Decision-Makerr 3000

controller firmware versions before 3.0.25. On

Decision-Makerr 3000 controllers with later firmware

versions, or on APM402 controllers, go to Generator

Metering Menu—Reset Calibration.

The calibration values are r eviewable at all times and

provide the calibration of the voltage and current

sensing logic. Changing the systemvoltage or replacing

the circuit board requires a calibration adjustment. In

order to review the values when the generator set is

NOT running, enter Yes when the Enter Calib? is

displayed. The user can review the values but

attempting to change the values will cause a Cannot

calibrate error message.

If the unit is NOT running and No is entered when the

Enter Calib? is shown, the display returns to the

Generator Set Calibration main menu and entry to the

Generator Set Calibration menu is denied.

If the unit is running and Yes is entered when the Enter

Calib? is shown, the display will show the following

values for three-phase generator sets. Single-phase

generator sets will only display items marked (*).

D Volts L1-L2 *

D Volts L2-L3

D Volts L3-L1

D Volts L1-N *

D Volts L2-N *

D Volts L3-N

D Current L1 *

D Current L2 *

D Current L3

The user can change individual values or can enter Yes

when Reset all Calib? is displayed. At the end of the

Generator Set Calibration menu, Exit calibration is

shown. Press the pushbutton/rotary selector dial to exit

this menu. Refer to the requirements shown with

Generator Set Calibration in 2.4.7 Status and Notice

Digital Displays.

Note: Press the Alarm Silence/Lamp Test button to

silence the alarm horn.

Manual Speed Adjust (Engine RPM) is available as a

user selectable adjustment. The user can set the

nominal running frequency slightly above or below the

utility frequency to ensure that synchronization occurs.

Refer to 2.7.7 GenSet System for more information.

Available as a factory-installed option or requires a new

factory personality profile.

TP-6694 7/1820 Section 1 Specifications and Features

Voltage Regulator Menu

Digital Inputs Menu

Decision-Makerr 3000 Controller firmware before

3.0.25:

The voltage regulator value is reviewable at all times. In

order to review the value when the generator set is NOT

running, enter Yes when the Enter volt reg? is displayed.

The user can review the value but attempting to change

the value will cause a Cannot edit when stopped error

message.

If the unit is NOT running and No is entered when the

Enter volt reg? is shown, the display returns to the

Voltage Regulator main menu and entry to the Voltage

Regulator menu is denied.

If the unit is running and Yes is entered when the Enter

volt reg? is shown, the display will show the value.

The usercan change the value at this time. At the endof

the Voltage Regulator menu, Exit voltage reg is

shown----press the pushbutton/rotary selector dial to exit

this menu.

Decision-Makerr 3000 Controller firmware 3.0.25 and

higher, or APM402 Controller:

The voltage regulator value is reviewable at all times

and provides the ability to fine adjust voltage. Changing

the system voltage or replacing the circuit board

typically requires a voltage adjustment.

To enable calibration

, start the generator set and select

the VR Volt Adj display. Then push and hold the

pushbutton/rotary selector dial until the Editing Enabled

popup appears. Editing of thevoltage adjustment isnow

available.

This menu allows the user to review the settings. There

are up to three digital inputs that are programmer

selectable if not reserved by factory options.

The displays for digital inputs appear as shown below

with Values true or false. Items shown in the digital

displayasTrueareactive.

D DIn A1 (digital input A1) standard

D DIn A2 (digital input A2) standard

D DIn A3 (digital input A3) standard (see note below)

D DIn B1 (digital input B1) with I/O module board

D DIn B2 (digital input B2) with I/O module board

Changes to the Digital Inputs menu requires the use of

SiteTecht software. The digitalinput caneither openor

close the circuit to activate.

Note: DIn A3 digital input is factory reserved for

Enclosure Temperature: High Shutdown on

select Telecom units.

Digital Outputs Menu

This menu allows the user to review the settings. There

is one digital output standard with the controller that is

programmer selectable. The one SPDT switch has

2 amp. contacts at 32 VDC or 0.5 amp. contacts at

120 VAC max.

There is an optional 2 input/5 output (I/O) module board

available that can provide five digital outputs. The

standard digital output on the controller is used to drive

the optional I/O Module board and becomes factory

reserved and no longer available as programmer

selectable.

The user can change the individual value or can select

Reset VR?--Yes to reset to the default value. The Reset

VR Settings display will only show if editing is enabled.

To disable calibration

, Rotate the pushbutton/rotary

selector dial until the <-- Return popup appears.

Momentarily press the pushbutton/rotary selector dial.

Stop the generator set if not already done.

The displays for digital outputs appear as shown in the

following list with Values as True or False. Items shown

in the digital display as True are active.

D DOut A1 (digital output A1) standard

D DOut B1 (digital output B1) with I/O module board

D DOut B2 (digital output B2) with I/O module board

D DOut B3 (digital output B3) with I/O module board

D DOut B4 (digital output B4) with I/O module board

D DOut B5 (digital output B5) with I/O module board

Changes to the Digital Outputs menu requires the use of

SiteTecht software. The digital output can either open

or close the circuit to activate.

TP-6694 7/18 21Section 1 Specifications and Features

Analog Inputs Menu

Volt Select Menu

This menu allows the user to review the settings. There

is one analog input that is programmer selectable if not

reserved by factory options.

There is an optional 2 input/5 output (I/O) module board

available that can provide two additional analog inputs.

The displays for analog inputs appear as shown below

with Values of 0--5 volts.

D AIn A1 (analog input A1) standard

(reserved and not user programmable)

D AIn A2 (analog input A2) standard

D AIn B1 (analog input B1) with I/O module board

D AIn B2 (analog input B2) with I/O module board

Changes to the Analog Inputs menu requires the use of

SiteTecht software.

Event Log Menu

This menu allows the user to reviewup to1000 entries of

system events including shutdown faults, warning

faults, and status events. See 1.2.4 Controller Fault

Diagnostics for a list of the items that appear on the

Event Log.

Note: The generator set must be stopped before

changing the voltage selection.

This menu allows the user to readily change controller

voltage settings. Thevolt select feature is typically used

in towable or temporary applications.

Note: The volt select menu requires initial activation by

SiteTecht software. In SiteTecht software,

select True to activate the volt select menu.

Note: The generator set output leads require voltage

reconnection if the generator set does not have a

voltage selector switch installed.

With the generator set stopped, go to the Volt Select

menu. Then push and hold the pushbutton/rotary

selector dial until the voltage selection starts to flash.

Volt selection is now available. Scroll to the desired

voltage and momentarily press the pushbutton/rotary

selector dial to confirm the voltage selection.

The displays for Volt Select appear as shown in the

following list.

D 120/240 V 1 Ph

D 120/208 V 3 Ph

D 139/240 V 3 Ph

D 277/480 V 3 Ph

D 120/240 V 3 Ph

TP-6694 7/1822 Section 1 Specifications and Features

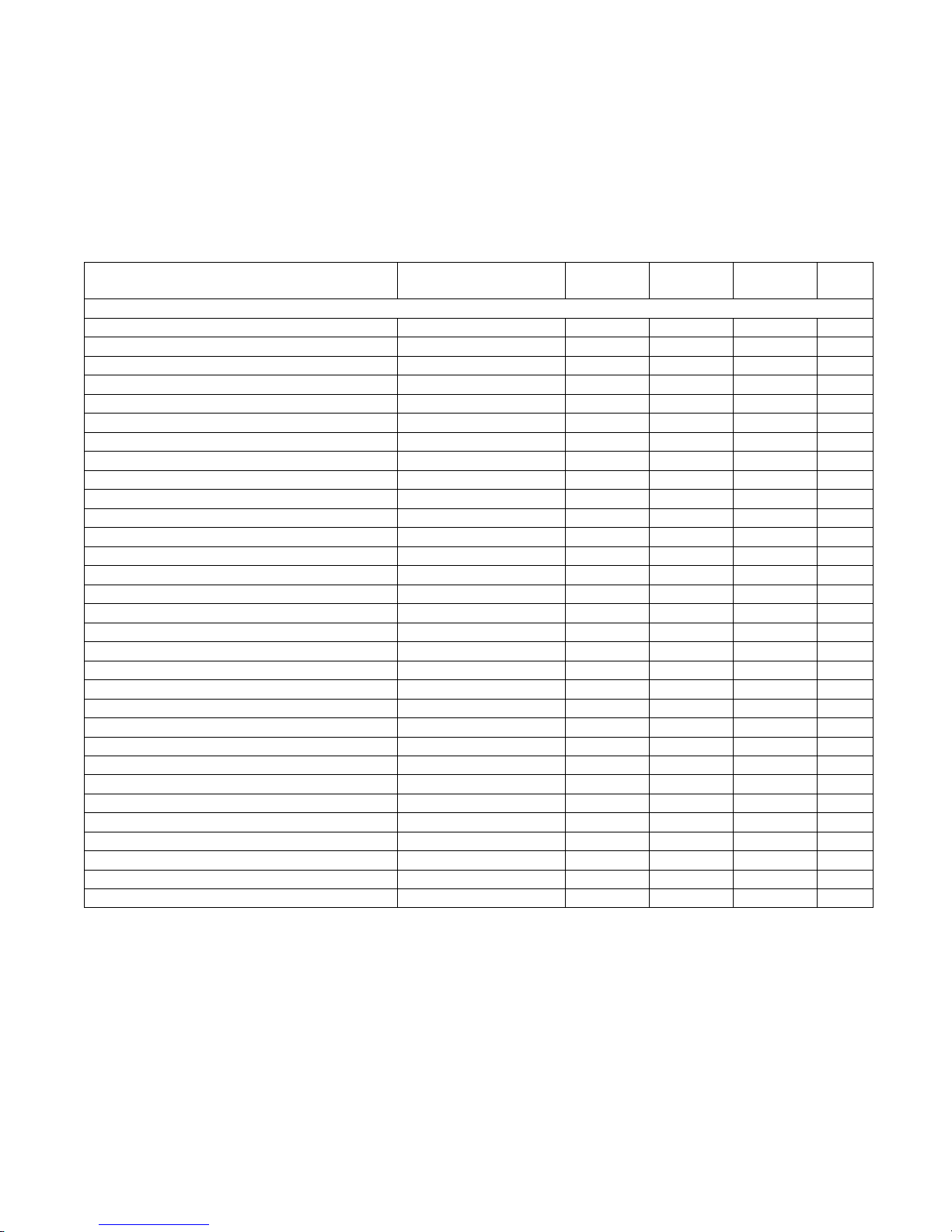

1.2.4 Controller Fault Diagnostics

This table provides descriptions of the system events

and their types—warning, shutdown, status, and notice.

Warnings show yellow fault lamp and signal an

impending problem. Shutdowns show red fault lamp

and stopthe generator set. Status isan event that is not

an alert but is part of the event history. Notice is an alert

System Events Display Message List

that is NOT part of the event history. System events are

available as a Relay Output as shown.

Throughout this manual there are examples of the

display text. In some cases, the message words and

phrases are abbreviated or shortened to accommodate

the number of characters in the 12 x 2 digital display.

See the following table fora full description of thesystem

event display messages.

Warning

Description Display Message

Engine Functions

Critically high fuel level (diesel-powered models only) * Fuel Level Critically High X X

ECM communications loss ECM Comm Err Shutdwn X X

ECM diagnostics (multiple inputs) [

ECM diagnostics (multiple inputs) [

ECM faults (address conflict) ECM Addr Err Shutdwn X X

ECM faults (model mismatch) ECM Mismatch Shutdwn X X

Engine over speed Eng Speed High Shutdwn X] X

Engine start aid active Starting Aid Notice N X

Engine under speed Eng Speed Low Shutdwn X X

Fuel tank leak * Fuel Leak Warning X X

Fuel tank leak * Fuel Leak Shutdwn X X

High battery voltage Battery High Warning X X

High coolant (engine) temperature Coolnt Temp High Warning X X

High coolant (engine) temperature Coolnt Temp High Shutdwn X] X

High fuel level (diesel-powered models only) * Fuel Level High Warning X X

Loss of fuel Loss of fuel X X

Low battery voltage Battery Low Warning X X

Low coolant level * Coolant Lvl Low Shutdwn X X

Low coolant temperature Coolant Temp Low Warning X X

Low cranking voltage Lo Crank Vlt Warning X X

Low engine oil level * Oil Level Low Warning X X

Low engine oil level * Oil Level Low Shutdwn X X

Low fuel level (diesel models) * Fuel Level Low Warning X X

Low fuel level (diesel models) * Fuel Level Low Shutdwn X X

Low fuel pressure (gas models) * Fuel Press Low Warning X X

Low oil pressure Oil Press Low Warning X X

Low oil pressure Oil Press Low Shutdwn X] X

No coolant temperature signal Temp Sig Loss Shutdwn X X

No oil pressure signal Press Sig Loss Shutdwn X X

Overcrank Over Crank Shutdwn X] X

Speed sensor fault Spd Sens Flt Warning X X

ECM xxxxxx Warning X X

ECM xxxxxx Shutdwn X X

Function

Shutdown

Function

Status/

Notice

Relay

Output

TP-6694 7/18 23Section 1 Specifications and Features

Warning

Description

General Functions

Alarm horn silenced (Alarm Silence LED only) X

Alarm silence, auto only (NFPA 110) or always AlrmSilence: Auto Only or

Aux. inputs 0--5 VDC, 1 analog

(2 additional inputs available with I/O module option)

Aux. inputs 0--5 VDC, 1 analog

(2 additional inputs available with I/O module option)

Auxiliary inputs, up to 3 digital

(2 additional inputs available with I/O module option)

Auxiliary inputs, up to 3 digital

(2 additional inputs available with I/O module option)

Backup parameters loaded Backup Pars Status S No

Battery charger 1 communication loss Bat1CommLoss X

Battery charger 2 communication loss Bat2CommLoss X

Battery charger fault * (* does not apply to charger

GM87448)

Battery charger identity conflict BatIdErr X

Battery charger parameter mismatch Param Mismatch X

Battery Fault Battery Flt X

Chicago code active Auto Locked Notice N X

Common fault (includes ])

Common warning fault Common Warng X N X

Default parameters loaded Default Pars Warning X X

Emergency stop Emerg Stop Shutdwn X] X

Enclosure temperature: high shutdown Enclsr Temp: High Shutdwn X X

Engine cooldown (delay) active Eng Cooldown Notice N X

Engine start delay active Start Delay Notice N X

Engine started Engine Start Status S X

Engine stopped Engine Stop Status S X

EPS supplying load Emerg Pwr On Notice N X

File system error (controller fault) File Error Shutdwn X X

Generator running Gen Running Notice N X

Input/output (module option board) communication loss OB1 Com Loss X X

Internal failure Intern Error Shutdwn X X

Metering communication loss MeterCommLos Shutdwn X X

NFPA 110 alarm active NFPA Alarm Notice N X

Not in auto (master switch) Not In Auto Warning X X

Remote start Remote Start Status S X

System ready System Ready Status S X

System timer failed TimerErrorNotice N X

Generator Functions

AC sensing loss AC Sens Loss Warning X X

AC sensing loss AC Sens Loss Shutdwn X X

Alternator protection Alt Protect Shutdwn X X

Ground fault input * Ground Fault Warning X X

kW overload Total Power High Shutdwn X X

Locked rotor (failed to crank) Locked Rotor Shutdwn X X

Overfrequency Freq High Shutdwn X X

Overvoltage (each phase) Volts xx--xx High Shutdwn X X

Underfrequency Frequency Low Shutdwn X X

Undervoltage (each phase) Volts xx--xx Low Shutdwn X X

(Voltage) regulator communication loss RegCommLoss Shutdwn X X

* Function requires optional input sensors or kits or is engine ECM dependent on some generator set models.

[ ECM inputs are engine manufacturer dependent.

] The Common Fault Shutdown includes the items marked X] in the Shutdown Function column.

Display Message

AlrmSilence: Always

Aux Input Warning X X

Aux Input Shutdwn X X

Aux Input Warning X X

Aux Input Shutdwn X X

Batt Chg Flt X

Common Fault Shutdwn X N X

Function

Shutdown

Function

Status/

Notice

S No

Relay

Output

X

TP-6694 7/1824 Section 1 Specifications and Features

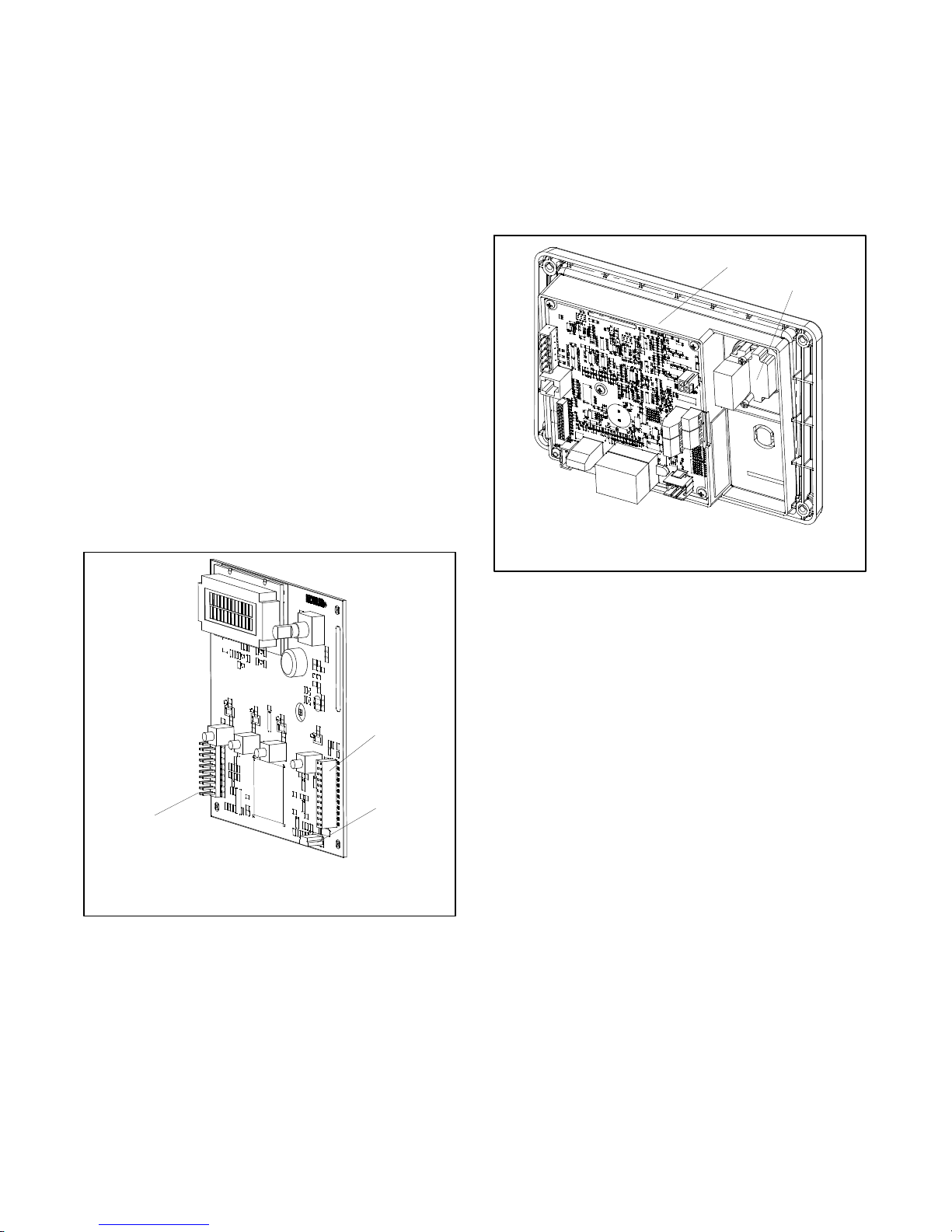

1.2.5 Digital Display Circuit Board and

Connections

The digital display circuit board provides:

D The backlit LCD (liquid crystal display) for monitoring

the generator set functions and output values

D Master control switches with status lights

D Fault lamp

D Pushbutton/rotary selector dial to navigate the

generator set displays

D Alarm horn and alarm silence/lamp test switch/light

D Mini USB connector for PC setup using SiteTecht

software

See Figure 1-3 for the circuit board connections.

Circuit Board Connections

P9 Connector the 24-pin connector attaches directly to

the main logic circuit board.

P10 Connector mini USB for PC upgrades located on

the front panel using SiteTecht software.

1.2.6 Main Logic Circuit Board

The main logic circuit board provides the terminal strips

and connection sockets to connect the controller to the

engine/generator, input/output connections, optional

I/O module kit, and circuit protection fuses. See

Figure 1-4 and Figure 1-5 for the circuit board

connections. See Section 6, Accessories for more

information.

1

2

P11 Connector is a 20-pin connector (not used).

1

2

3

GM65741-

1. P9 24-pin connector (opposite side) connects to main board

2. P10 5-pin mini USB connector

3. P11 20-pin connector (not used)

Figure 1-3 Digital Display Circuit Board Connectors

1. Main logic circuit board

2. Remote emergency stop switch

GM65741-

Figure 1-4 Main Circuit Board and Emergency Stop

Switch

Circuit Board Connections

P1 (24-Pin) Connector for engine/generator wiring

harness.

P2 (6-Pin) Connector for AC current.

(4) Push-on Connectors for V7/V8/V9/V0 for

generator set output voltage connection.

TP-6694 7/18 25Section 1 Specifications and Features

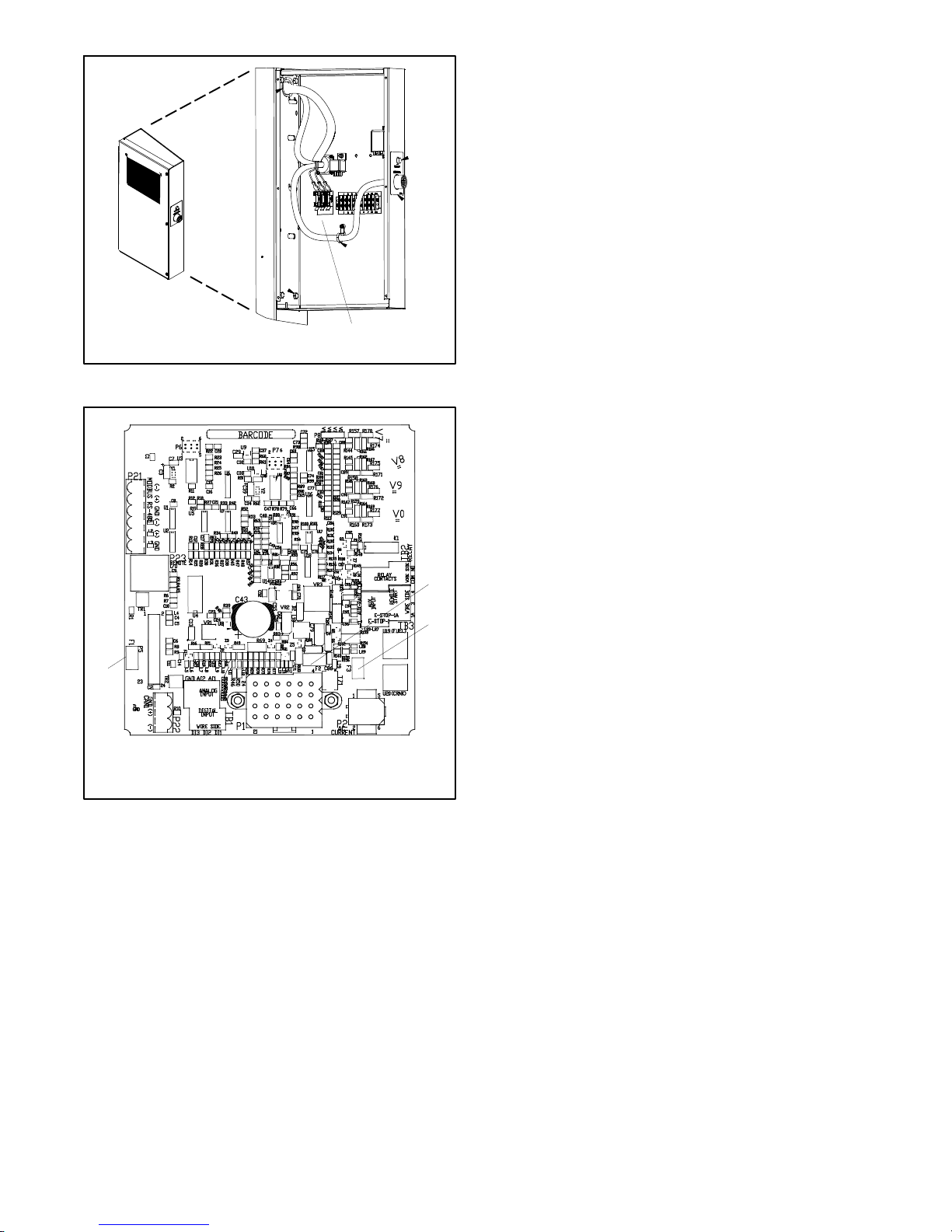

1.2.8 Communication Ports

10

9

8

7

1. (4) push-on terminal connectors

2. TB2 4-position terminal block

3. TB3 6-position terminal block

4. P2 6-pin connector

5. P1 24-pin connector

6. TB1 6-position terminal block

7. P22 3-pin connector

8. P30 jumper (Wound Field or Fast Response)

9. P23 8-pin connector (RJ45)

10. P21 6-pin connector (for RS-485 communication)

6

5

Figure 1-5 Main Circuit Board Connectors

4

GM64345-1-A

1

The main logic circuit board contains a single mini USB

communication port forPC connections, seeFigure 1-6.

For Modbusr communication using RS-485, see

Figure 1-5 (P21). Refer to the List of Related Materials

2

in the Introduction for corresponding SiteTecht

software and/orcommunication installationinformation.

3

GM65741-

1. Mini USB connection

1

Figure 1-6 Communication Port

1.2.9 Fuses

P21 (6-Pin) Connector for (RS-485) connection of

optional RSA or Modbusr communication.

P22 (3-Pin) Connector for engine ECM. Alternate CAN

connection.

P23 (8-Pin) Connector (RJ45) for optional input/output

(I/O) module circuit board.

Refer to Section 6.2, Accessory Connections for

specific connections of the following terminal block

connections.

TB1 (6-Position) Terminal Block for analog and digital

inputs.

TB2 (4-Position) Terminal Block for K1 relay outputs.

TB3 (6-Position) Terminal Block for E-stop, remote

start contacts, and aux. input connections.

1.2.7 Terminal Jumper

A circuit board P30 jumper is set based on alternator

type—Wound Field (300 kW and larger) or

Fast Response (less than 350 kW). The jumper is

factory set and needs no further adjustment. See

Figure 1-5 for location of the P30 jumper.

AC Circuit Fuses (TB5). Fuses are located inside the

generator set control box. See Figure 1-7

D 1.5-Amp (V7) fuse protects L1 sensing input to

interconnection circuit board.

D 1.5-Amp (V8) fuse protects L2 sensing input to

interconnection circuit board.

D 1.5-Amp (V9) fuse protects L3 sensing input to

interconnection circuit board.

DC Circuit Fuses are located on the controller circuit

board. See Figure 1-8.

D 1-Amp (F1) auto-resettable, fuse protects the

controller circuits.

D 1-Amp (F2) auto-resettable fuse protects the