-1-

HYDRO-TOWER 300 300

INSTALLATION INSTRUCTIONS

IN-WALL TANK

K-4179T/K-4178T/K-10611T

K-4177T/K-8857T/K-20341T/K-75890T/K-75891T

KOHLER CHINA INVESTMENT CO., LTD NO.158, JIANG CHANG SAN ROAD,

JING'AN DISTRICT, SHANGHAI, PRC POST CODE: 200436

( ) 158 200436

300 ( )...............................................................................................................................K-4178T

300 3/4.5 .......................................................................................................................................K-4179T

300 3/4.5 ..........................................................................................................................K-10611T

( ).........................................................................................................................................K-4177T

( ).........................................................................................................................................K-8857T

( )..............................................................................................................................................K-20341T

( ) ..........................................................................................................................................K-75890T

( ) .................................................................................................................................................K-75891T

Ordering Information

HYDRO-TOWER 300 In-Wall Tank(With Frame) ..................................................................................................................K-4178T

HYDRO-TOWER 300 3/4.5L In-Wall Tank With Frame.........................................................................................................K-4179T

HYDRO-TOWER 300 3/4.5L In-Wall Tank Without Frame ..................................................................................................K-10611T

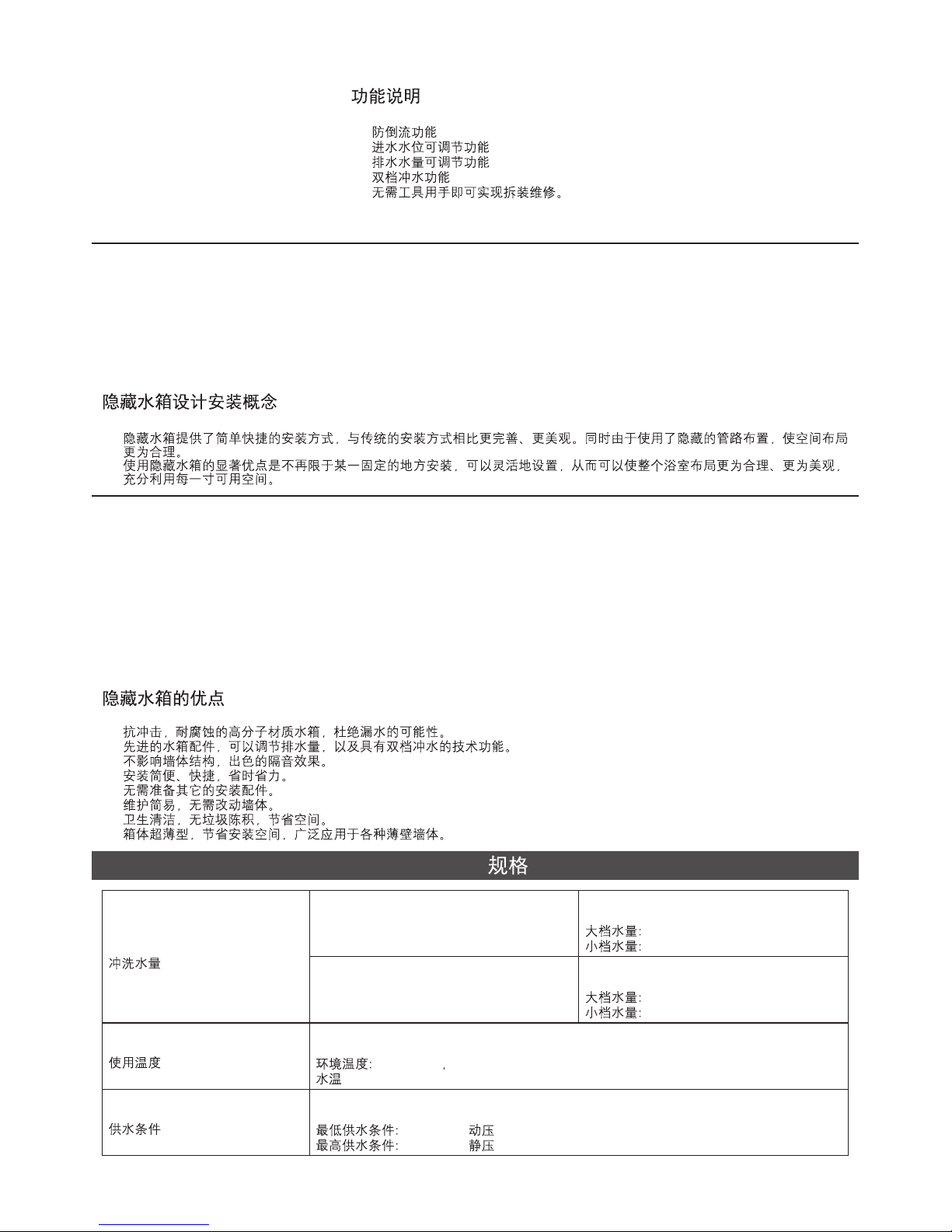

DROPLET In-Wall Tank Faceplate (Not Supplied) ................................................................................................................K-4177T

BEVEL In-Wall Tank Faceplate (Not Supplied)......................................................................................................................K-8857T

PEBBLE In-Wall Tank Faceplate(Not Supplied) ..................................................................................................................K-20341T

LYNK Faceplate (Not Supplied)...........................................................................................................................................K-75890T

NOTE In-Wall Tank Faceplate(Not Supplied) ......................................................................................................................K-75891T

!

!

!

!

!

Read installation guide in illustration and word file carefully, and install the tank according to instructions in the guide to avoid

product damage and installation inconvenience caused by inappropriate operation.

All data contained is based upon the last product information available at the time of publication. Kohler Company reserves

the right to implement changes of product characteristics, packaging and availability at any time without further notice.

Do not apply erosive cleanser and solvent in the tank, which will damage tank spares and result in leakage in the tank.

Kohler will not be responsible for any damage related to above mentioned cleanser or solvent. Mild detergent can be used.

Do not apply spares that are not provided by Kohler, and please note that glass adhesive tape shall not be applied to the

installation of Kohler spares. Kohler will not be responsible for any damage related to installation with spares not provided by

Kohler.

This product complies with GB26730-2011.

!

!

!

!

!

GB26730-2011

BEFORE YOU BEGINBEFORE YOU BEGIN

©©Copyright Kohler China Investment Co., Ltd. 2017

2017

1263048-T01-C

-2-

!

!

!

!

!

!

!

!

Advantages Of In-wall Tank

!

!

!

!

!

!

!

!

Made of macromolecular materials that prevents corrison andleaking.

Will not affect the structure of the wall and provides excellent sound insulation.

Easy installation and time efficient.

.

.

Clean, garbage free, and space .

Advanced water tank fitting, which makes possible the adjustment of the water discharge and double flush.

Extra-thin shell of the tank helps to save a lot of space and fit for any walls.

Do not need to prepare any other spareparts

Easy maintenance and servicing

saving

!

!

Design And Installation Concept Of In-wall Tank

!

!

Installation of in-wall tank is much easier and nice-looking comparative to that of traditional tank. Meanwhile, the space

layout will be more reasonable due to the application of in-wall tank pipes and connectors.

The most remarkable advantage of in-wall tank is that the installation will never be limited to certain area, and can be

installed wherever as you wish, which will make the bathroom layout more reasonable and nice-looking, and make good use

of every inch of the bathroom space.

SPECIFICATIONS

Liter per flushing

Temperature

Environmental temperature: 1 ~55

Water temperature: 1 ~45

°C °C,

°C °C

°C °C

°C °C

1 ~55

1 ~45

Full flushing volume:

Half flushing volume:

6L

3L

6L

3L

K-4179T

K-10611T

K-4178T

Full flushing volume: 4.5L

Half flushing volume: 3L

4.5L

3L

!

!

!

!

!

Function Explanation

!

!

!

!

!

Anti flow-backwards

Adjustment of inlet water level

Adjustment of flushing volume

Single/double gear

Assemble, disassemble and

maintenance can be done without

tools.

flushing

Water Supply

Min water supply: 0.02MPa (dynamic pressure)

Max

water supply: 0.74MPa (static pressure)

0.02MPa ( )

0.74MPa ( )

1263048-T01-C

RECOMMENDES TOOLS AND MATERIALSRECOMMENDES TOOLS AND MATERIALS

!

!

!

!

!

!

!

!

!

!

!

!

!

Open end/adjustable wrenches

Allen wrench

Knife

File

Hacksaw

Masonry

Level

Screw driver

Insulation tape

Tape measure

Seal tape

Bushing

Lubricant

!

!

!

!

!

!

!

!

!

!

!

!

!

/

-3-

ROUGHING-IN

UNIT: mm

Reference Value

K-4179T/K-4178T

478 3

88 2

438 3

681 4

269 5

35 2

100 3

205 3

1048 4

1066 4

1098 4

Finished floor

90~142

18~62

45~95

90 0.5

230 3

180 3

52~230

Height Suggested/ 1150

K-10611T

478 3

88 2

440 3

333 2

Finished floor

722~792

(235~305)

604~674

60 1

Height to floor is decided by bowl

18~62

1263048-T01-C

K-4177T

K-75890T

K-8857T

K-75891T

K-20341T

215 1

225 1

150 1

160 1

150 1

160 1

160 1

215 1

225 1

225 1

Kohler reserves the right to change marked dimensions without prior notice.

-4-

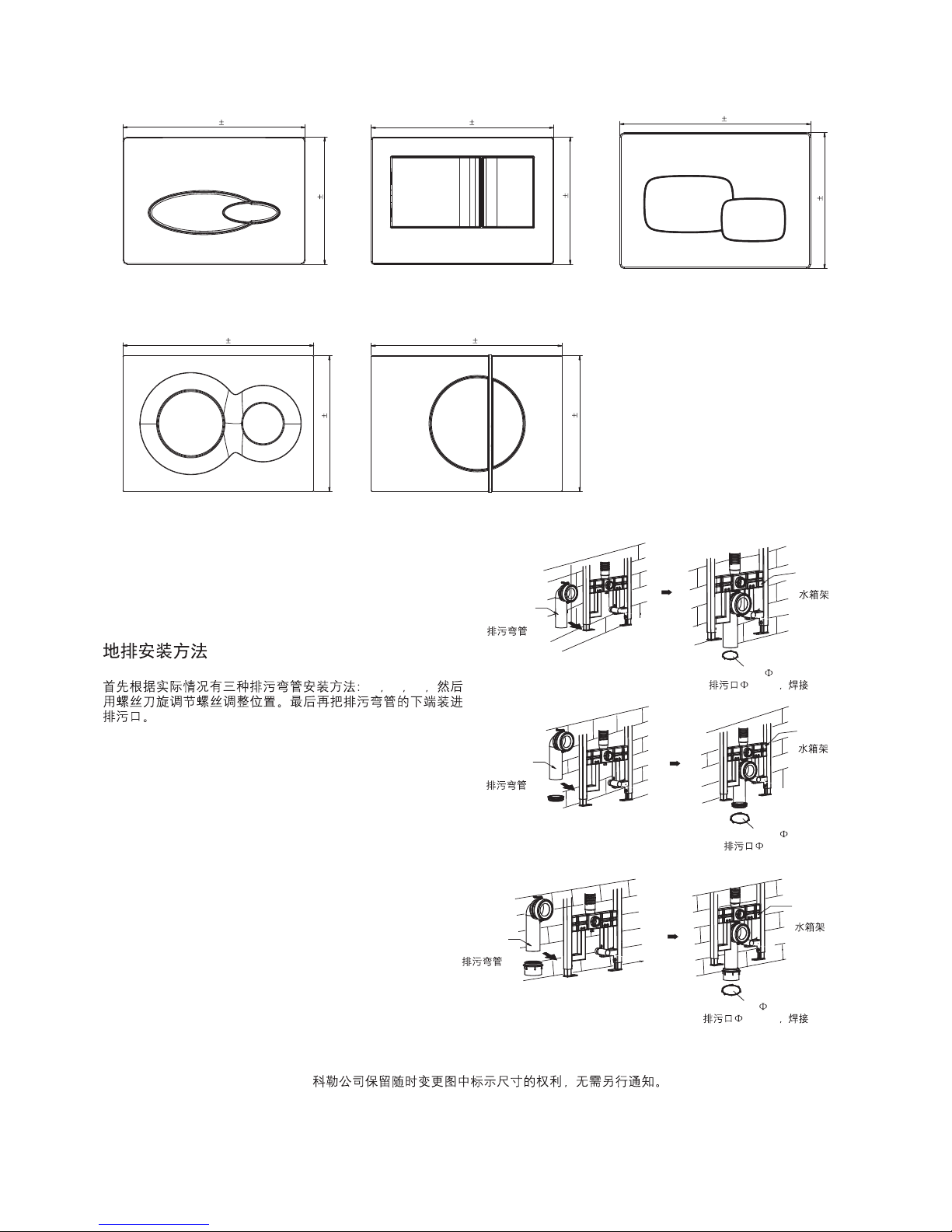

Floor Discharge Installation Method

Three discharge pipe installation methods based on actual

situation: A, B, C, adjust position by screw driver. Snap

discharge pipe lower end into discharge port.

ABC

B

C

A

Discharge

Elbow

Discharge

Elbow

Discharge

Elbow

Water Tank

Bracket

Water Tank

Bracket

Water Tank

Bracket

Drain outlet 90mm, welding

90mm

Drain outlet 110mm

110mm

Drain outlet 110mm, welding

110mm

1263048-T01-C

-5-

INSTALLATION

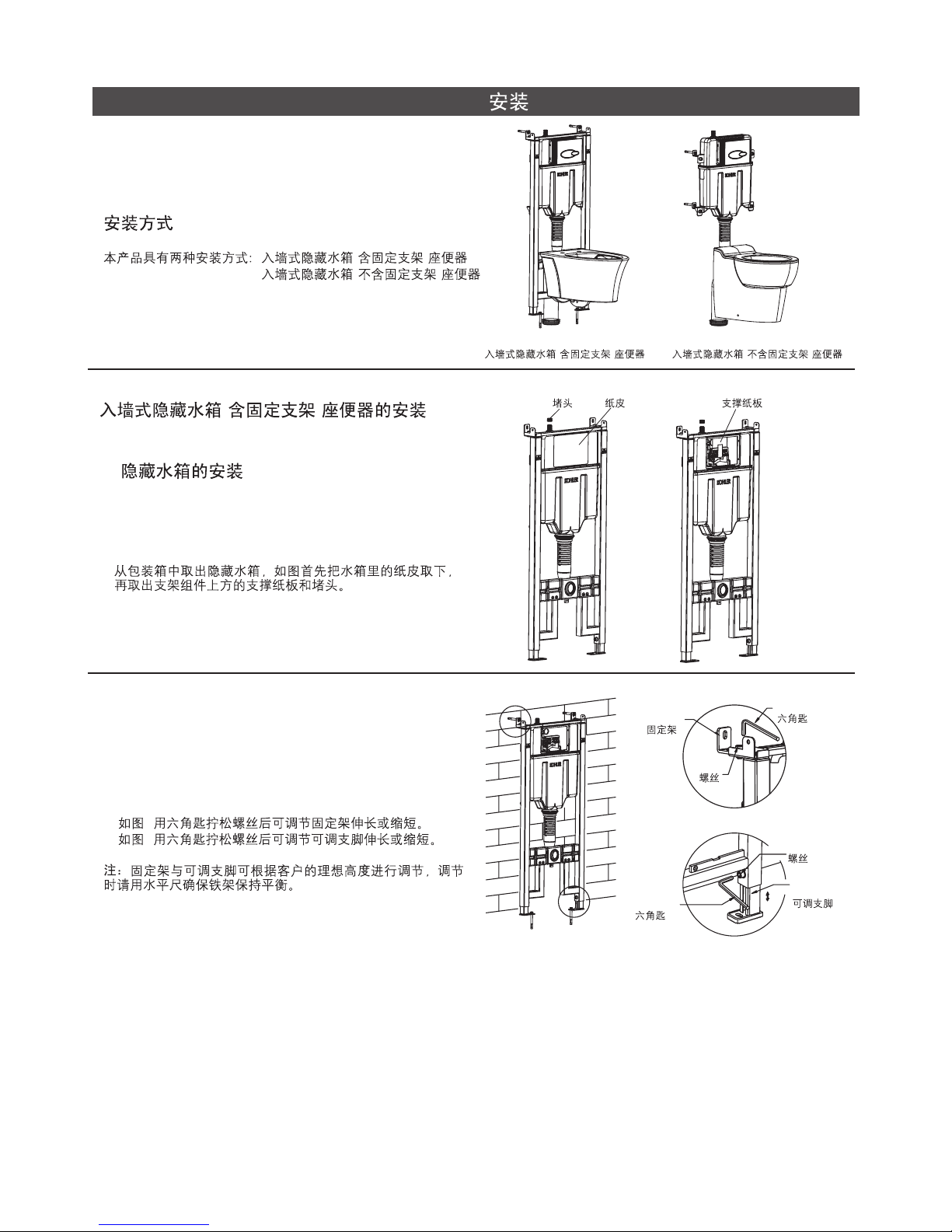

Way of Installation

There are two ways to install this product: in-wall tank with

frame & in-wall tank without frame

()

()

In-wall Tank Without Frame

()

In-wall Tank With Frame

()

Installation For In-wall Tank With Frame

A. Installation of In-wall Tank

()

A.

1. Remove in-wall tank from packing box. Remove paper

board inside water tank first as shown. Then remove board

and plug above bracket assembly.

1.

Plug Paper Board Board

2. Loose hex-head screw and adjust mounting bracket height

as shown in Fig A.

Loose hex-head screw and adjust supporting feet height as

shown in Fig B.

mounting bracket and supporting feet shall be adjusted

per customer ideal height. Use leveler to ensure the balance

of steel bracket.

Note:

2. A

B

Screw

Screw

Hex-head

Wrench

Medium

Allen Key

Adjustable

Bracket

Mounting

Bracket

A

B

1263048-T01-C

-6-

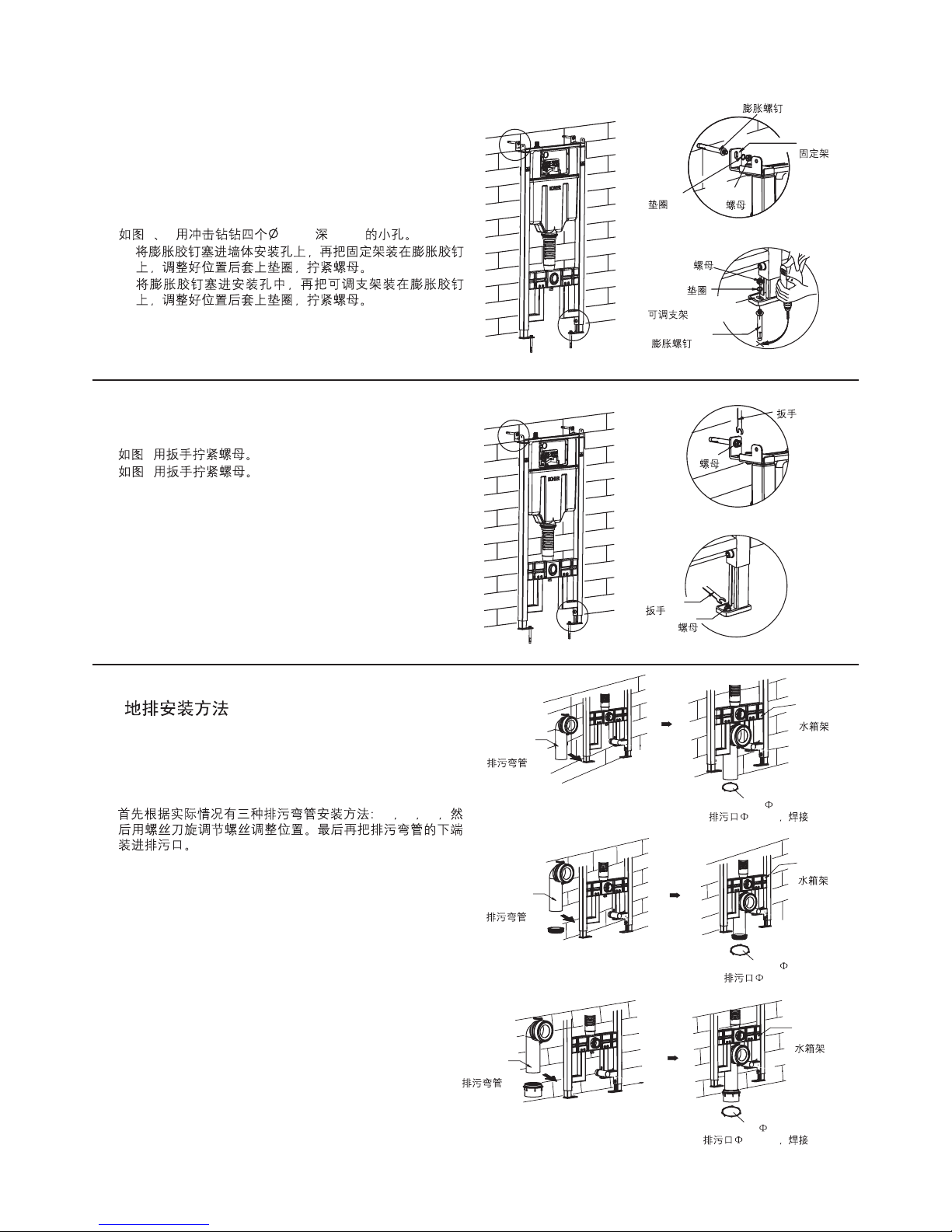

3. Drill four holes with diameter of 10mm and depth of 80mm

with churn drilling as shown.

A. Fill the bulge nail into the instruction hole on the wall, fix

the fixing frame to the bulge nail, adjust the gasket and

tighten the nut.

B. Fill the bulge nail into the instruction hole, fix the

adjustable bracket to the bulge nail, adjust the gasket

and tighten the nut.

3. A B 10mm 80mm

A.

B.

Adjustable Bracket

Mounting

Bracket

A

B

Bulge Screw

Bulge Screw

Gasket

Gasket

Nut

Nut

4. Tighten the nut with the wrench as shown in illustration A.

Tighten the nut with the wrench as shown in illustration B.

4. A

B

A

B

Nut

Nut

Wrench

Wrench

B. Floor Discharge Installation Method

B.

1. Three discharge pipe installation methods based on actual

situation: A, B, C, adjust position by screw driver. Snap

discharge pipe lower end into discharge port.

1. ABC

B

C

A

Discharge

Elbow

Discharge

Elbow

Discharge

Elbow

Water Tank

Bracket

Water Tank

Bracket

Water Tank

Bracket

Drain outlet 90mm, welding

90mm

Drain outlet 110mm

110mm

Drain outlet 110mm, welding

110mm

1263048-T01-C

Loading...

Loading...