Page 1

Original Issue Date: 5/04

Model: 4--32 kW

Market: Marine

Subject: Three-Inch (J1939) Remote Digital Gauge Kits

GM32337-KP1 and GM100956-KP1

TT-1379 5/16d

INSTALLATION INSTRUCTIONS

Introduction

The digital gauge allows remote starting/stopping and

monitoring of certain generator set functions. The

three-inch remote digital gauge can be used with the

marine generator set models/controllers shown in

Figure 1. See Figure 2 for the remote digital gauge.

Model Controller Kit Number

EGD, EFGD, and EGZD

EOD and EFOD

EOZD and EFOZD

EKD and EFKD ADC II

EKOD and EFKOD

EKOZD and EFKOZD

EKOZD and EFKOZD

Figure 1 Kit Number for Model with Controller Type

ADC 2100

ADC IId

Decision-

Makerr 3500

GM32337-KP1

GM100956-KP1

1

Note: For generator sets with an ADC 2100

controller and with serial numbers below

2051416: These units used an earlier version of

the ADC 2100controller that was equipped witha

removeable power mode jumper at P7.

Operation of the remote digital gauge’s start/stop

function requires that the jumper is enabled on

the Advanced Digital Control (ADC) (generator

sets shipped from the factory already have the

jumper enabled). Refer to the wiring diagram in

the generator set operation manual if the jumper

was disconnected from terminals 1 and 2 on the

P7 connector (continuous power mode).

Note: For generator sets with an ADC 2100

controller: ADC application program version

3.32 or higher is required for complete digital

gauge operation. If your application program

version is lower than 3.32, use your SecurID to

access Kohler Power Resource Center, click on

the TechTools button, and follow the instructions

to download the files.

Note: For generator sets with a Decision-Makerr

3500 controller: Firmware version 1.14.3 or

higher is required for complete digital gauge

operation. If your firmware version is lower than

1.14.3, visit the Kohler Power Resource Center

website using the TechTools button.

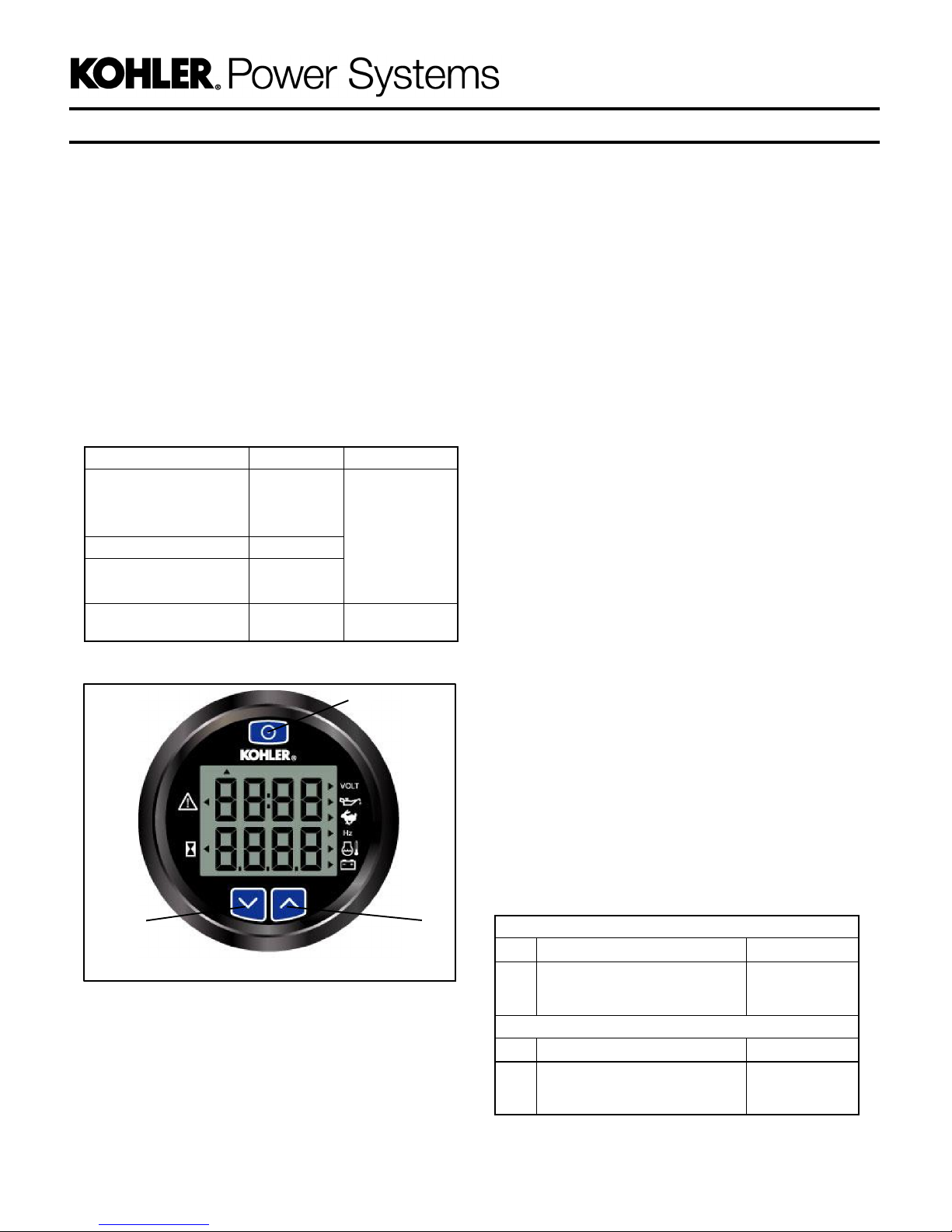

1. SELECT button

2. UP arrow button

3. DOWN arrow button

Figure 2 Remote Digital Gauge

Parts List

Remote Digital Gauge Kits

23

Kit: GM32337-KP1

Qty. Description Part Number

1 Gauge GM100649

1 Harness, gauge GM32325

1 Decal, warning 249494

Kit: GM100956-KP1

Qty. Description Part Number

1 Gauge GM100649

1 Harness, gauge GM100955

1 Decal, warning 249494

Page 2

Safety Precautions

WARNING

Accidental starting.

Can cause severe injury or death.

Disconnect the battery cables before

working on the generator set.

Remove the negative (--) lead first

when disconnecting the battery.

Reconnect the negative (--) lead last

when reconnecting the battery.

Disabling the generator set. Accidental starting can

cause severe injury or death. Before working on the

generator set or connected equipment, disable the generator

set as follows: (1) Move the generator set master switch to the

OFF position. (2) Disconnect the power to the battery charger.

(3) Remove the battery cables, negative (--) lead first.

Reconnect the negative (--) lead last when reconnecting the

battery. Follow these precautions to prevent starting of the

generator set by an automatic transfer switch, remote

start/stop switch, or engine start command from a remote

computer.

Carbon monoxide symptoms. Carbon monoxide can

cause severe nausea, fainting, or death. Carbon monoxide

is a poisonous gas present in exhaust gases. Carbon

monoxide is an odorless, colorless, tasteless, nonirritating gas

that can cause death if inhaled for even a short time. Carbon

monoxide poisoning symptoms include but are not limited to

the following:

D Light-headedness, dizziness

D Physical fatigue, weakness in

joints and muscles

D Sleepiness, mental fatigue,

inability to concentrate

or speak clearly, blurred vision

D Stomachache, vomiting, nausea

If experiencing any of these symptoms and carbon monoxide

poisoning is possible, seek fresh air immediately and remain

active. Do not sit, lie down, or fall asleep. Alert others to the

possibility of carbon monoxide poisoning. Seek medical

attention if the condition of affected persons does not improve

within minutes of breathing fresh air.

Operating thegenerator set. Carbon monoxidecan cause

severe nausea, fainting, or death. Be especially careful if

operating the generator set when moored or anchored under

calm conditions because gases may accumulate. If operating

the generator set dockside, moor the craft so that the exhaust

discharges on the lee side (the side sheltered from the wind).

Always be aware of others, making sure your exhaust is

directed away from other boats and buildings.

WARNING

Disabling the generator set. Accidental starting can

cause severe injury or death. Before working on the

generator set or equipment connected to the set, disable the

generator set as follows: (1) Press the generator set off/reset

button to shut down the generator set. (2) Disconnect the

power to the battery charger, if equipped. (3) Remove the

battery cables, negative (--) lead first. Reconnect the negative

(--) lead last when reconnecting the battery. Follow these

precautions to prevent the starting of the generator set by the

remote start/stop switch.

WARNING

Carbon monoxide.

Can cause severe nausea,

fainting, or death.

The exhaust system must be

leakproof and routinely inspected.

Explosion.

Gasoline vapors can cause

explosion and severe injury or

death.

Before starting the generator set,

operate the blower 4 minutes and

check the engine compartment for

gasoline vapors.

Ignition-protected equipment. Explosive fuel vapors can

cause severe injury or death. Gasoline vapors can cause an

explosion. USCG Regulation 33CFR183 requires that all

electrical devices (ship-to-shore transfer switch, remote start

panel, etc.) must be ignition protected when used in a gasoline

and gaseous-fueled environment.

2 TT-1379 5/16

Page 3

Installation Procedure

1. Remove the generator set from service.

1.1 For generator sets with an ADC 2100

controller: Place the generator set master

switch in the OFF position.

For generator sets with an ADC II or ADC IId

controller: Press the start/stop button to stop

the generator set. Then, press the power button

to turn off the controller.

For generator sets with a Decision-Makerr

3500 controller: Press the OFF/RESET button

to shut down the generator set.

1.2 Disconnect the generator set engine starting

battery, negative (--) lead first.

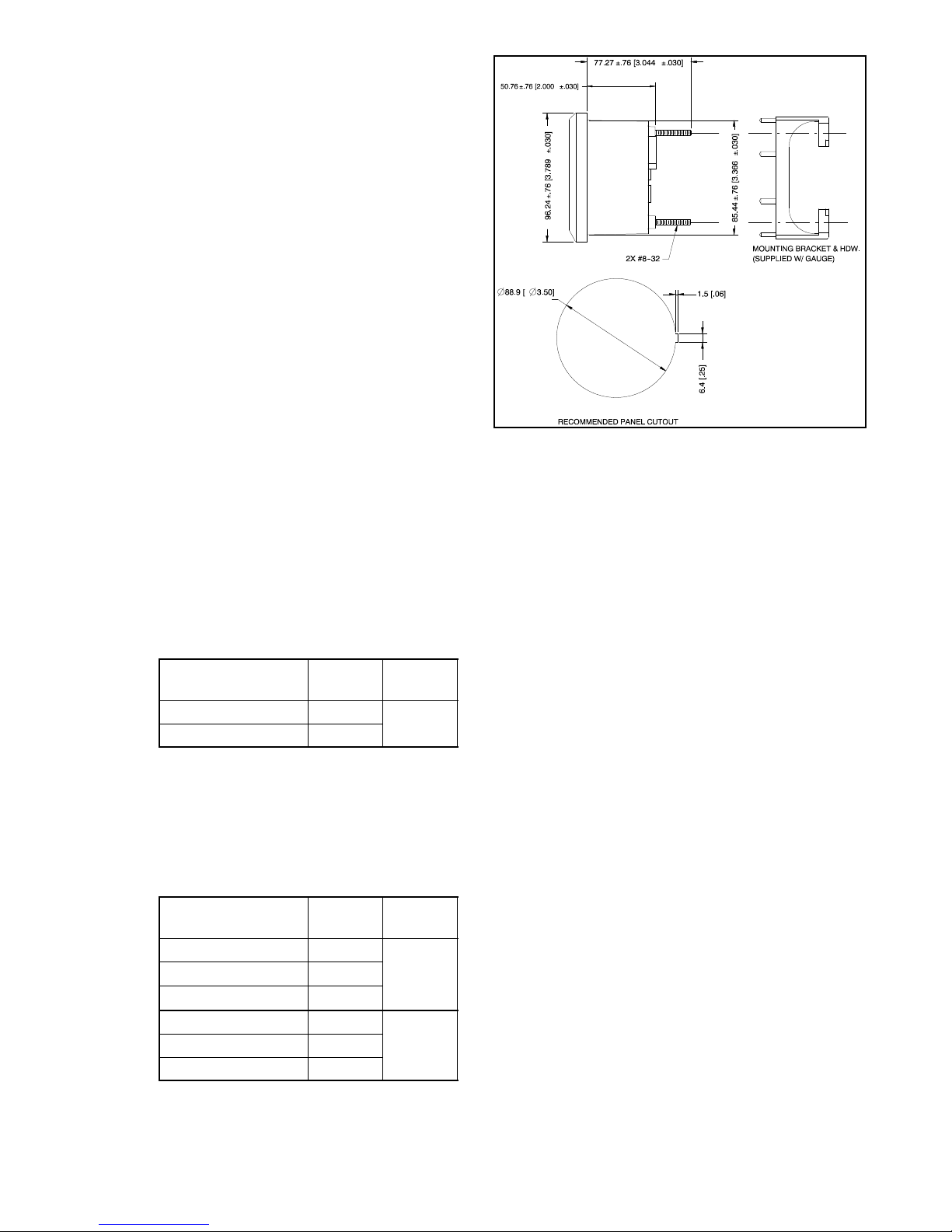

2. Install the remote digital gauge.

2.1 Select a dry location to mount the remote digital

gauge. Consider the length of the wiring

harness and the gauge’s mounting depth and

size when selecting a location. See Figure 5 for

the mounting dimensions.

2.2 For unitswith an ADCcontroller, ordera remote

extension harness kit. See Figure 3 for kit

selection. Do not use more than 3 remote

harness kits and do not exceed 23 m (75 ft.) in

harness length.

Remote Extension

Harness Kit Number

GM32333-KP1 4.6 (15)

GM32333-KP2 7.6 (25)

Figure 3 Remote Extension Harness Kits (For Units

with an ADC Controller)

For units with a Decision-Makerr 3500

controller, order a remote extension harness

kit. See Figure 4 for kit selection. DO NOT

exceed 91.4 m (300 ft.) CAN network length.

Length

m (ft.)AsShown In

Figure 8

NOTE: Dimensions in brackets

are inch equivalents.

GM30565-B

Figure 5 Mounting Dimensions

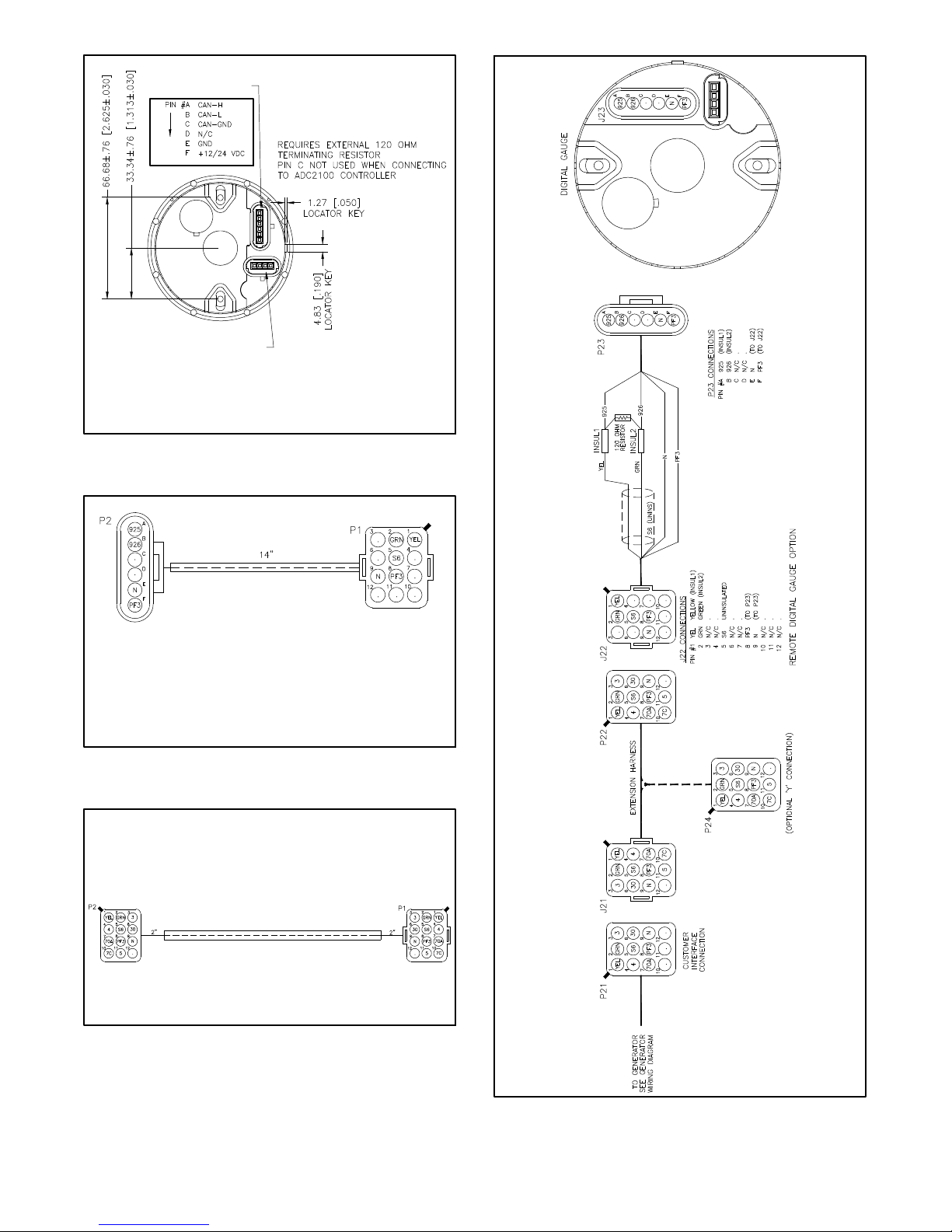

2.3 Connect the 6-pin inline connector of the gauge

harness (GM32325 or GM100955) to the 6-pin

inline connector on the digital gauge. See

Figure 6 and Figure 7 or Figure 10.

2.4 For Kit GM32337-KP1: Connect the 12-pin

connector end of the gauge harness or a remote

extension harness to the generator set’s

customer-interface 12-pin connector. See

Figure 7, Figure 8, and Figure 9.

2.5 For Kit GM100956-KP1: Connect the 6-pin

connector end of the gauge harness to a remote

extension harness. See Figure 10, Figure 11,

Figure 12, Figure 13, Figure 14, and Figure 15.

Connect the lead ends of the extension harness

to the TB12 terminal strip. The TB12 terminal

strip is located inside the junction box. See

Figure 15 for TB12 connections.

Remote Extension

Harness Kit Number*

GM91774-KP1 7.6 (25)

GM91774-KP2 15.2 (50)

GM91774-KP3 30.5 (100)

GM92053-KP1 7.6 (25)

GM92053-KP3 30.5 (100)

* Y Harness shown in Figure 13

Figure 4 Remote Extension Harness Kits (For Units

with a Decision-Makerr 3500 Controller)

TT-1379 5/16 3

Length

m (ft.)AsShown In

Figure 11

Figure 12GM92053-KP2 15.2 (50)

Page 4

Connects to the

remote harness.

Connects to

additional serial

gauges, if equipped.

NOTE: Dimensions in brackets are inch equivalents.

Figure 6 Remote Digital Gauge Connections

(Back View)

Connects to the

remote digital gauge

connector.

Connects to the

generator set

customer-interface

connector or

a remote harness

connector.

Figure 7 Remote Gauge Harness GM32325

(Included with Kit GM32337-KP1)

15 ft. Extension Harness Kit GM32333-KP1

25 ft. Extension Harness Kit GM32333-KP2

GM30565A-B

GM32325-F

Figure 8 Remote Extension Harness Kits

(For Use With Kit GM32337-KP1)

4 TT-1379 5/16

GM30248-

GM33846A-D

Figure 9 Harness Connection Diagram

For Kit GM32337-KP1

Page 5

25 ft. Extension Harness Kit GM92053-KP1

50 ft. Extension Harness Kit GM92053-KP2

100 ft. Extension Harness Kit GM92053-KP3

Connects to the

remote digital gauge

connector.

Connects to the

remote extension

harness connector.

Figure 10 Remote Gauge Harness GM100955

(Included with Kit GM100956-KP1)

25 ft. Extension Harness Kit GM91774-KP1

50 ft. Extension Harness Kit GM91774-KP2

100 ft. Extension Harness Kit GM91774-KP3

Figure 11 Remote Extension Harness Kits

(For Use With Kit GM100956-KP1)

GM100955-

GM100990-

GM100997

Figure 12 Remote Extension Harness Kits

(For Use With Kit GM100956-KP1)

Y Harness Kit GM92054-KP1

GM100996-

Figure 13 Y Harness Kit

(For Use With Kit GM100956-KP1)

Figure 14 Remote System Diagram For Kit GM100956-KP1

TT-1379 5/16 5

GM92060-A

Page 6

Sheet 1 of 2

Sheet 2 of 2

Figure 15 Interconnection Diagram For Kit GM100956-KP1

6 TT-1379 5/16

GM88254-B

Page 7

2.6 Use rubber grommets and cable ties as

necessary to protect and secure the wiring from

sharp objects, exhaust system, water, and any

moving parts.

2.7 For gasoline-powered marine generator

sets, select a location as near as practical to the

generator remote digital gauge for mounting the

warning decal. The decal should be visible when

starting the generator set from the remote digital

gauge. Before applying the decal, ensure that

the surface is clean and dry.

3. Restore the generator set to service.

3.1 Check that the generator set is off and stopped.

3.2 Reconnect the generator set engine starting

battery, negative (--) lead last.

4. Set the controller parameter for J1939

communications.

4.1 For generator sets with an ADC 2100

controller: Set the ADC 2100 controller’s

communication parameter to Cn01 or Cn06.

Consult TT-1364 for instructions to change the

controller’s parameter settings.

For generator sets with a Decision-Makerr

3500 controller: Using SiteTecht, under the

Genset System Configuration menu, select

J1939 for the Public CAN Protocol parameter.

See Figure 16.

Note: For more information on SiteTecht,see

TP-6701t SiteTech Software Operation

Manual.

Note: ADC 2100 controllers: When the

master switch is in the AUTO position,

the controller may automatically power

down and go into Sleep Mode to

conserve battery power. This will occur,

after one hour of inactivity, only when the

CAN parameter is set to Cn06. If the

CAN parameter is set to Cn01, the

controller will remain powered and will

draw battery power. See TT-1364 for

more information.

ADC 2100 Controller

CAN

Setting

Cn01 Never/None J1939 gauge with

Cn06 1 Hour J1939 gauge with

Power

Down Time

Application

Notes

no sleep mode

one hour sleep

mode

For generator sets with an ADC II controller:

Set the CAN A parameter to J1939. Consult the

generator set installation manual for full

instructions to set the CAN A parameter.

Figure 16 Genset System Configuration (in SiteT echt)

For generator sets with an ADC IId controller:

Set the CAN A parameter, under the Gen Set

System menu, to J1939. Consult the generator

set operation manual for full instructions to set

the CAN A parameter.

TT-1379 5/16 7

Page 8

Gauge Operation

To Select the Units of Measure:

Note: Data can be displayed in either US or

international units.

1. With no power to the gauge, press and hold the

SELECT button. See Figure 17.

2. Apply power to the gauge.

3. The gauge displays: Adc 2100

Note: The gauge will display Adc 2100 even if

the generator set is equipped with an

ADC II or ADC IId controller.

4. The gauge displays: UnIT SEt

5. Press and hold both the UP and DOWN buttons

until the gauge beeps and the display changes.

6. Use the UP or DOWN buttons to selecteither Int or

USA units.

7. Press and hold both the UP and DOWN buttons

until the gauge beeps and the display changes.

8. Press the DOWN button.

21

!

GM30565-B

10

1. Fault indicator

2. Arrow (if blinking, indicates that the generator set is running)

3. Select button

4. Voltage (volts)

5. Oil pressure (psi or kPa)

6. Engine speed (rpm)

7. Frequency (Hz)

8. Coolant temperature (_For_C)

9. Battery voltage (VDC)

10. Runtime hours

Figure 17 Remote Digital Gauge

3

4

5

6

7

8

9

9. The gauge displays: ESC 08 ?

10. Press and hold both the UP and DOWN buttons

until the gauge switches to the monitor mode.

8 TT-1379 5/16

Page 9

Digital Gauge Modes:

Start/Stop Command Mode

Note: The digital gauge has three normal operating

modes: monitor, start/stop, and backlight adjust.

Use the SELECT button at the top of the gauge to

step through the modes.

Monitor Mode

Press the SELECT button until the display shows

generator set data and indicator arrows. Use the UP or

DOWN arrow to scroll through the data. The

corresponding illuminated arrow indicates which data is

being displayed. See Figure 17. Any faults are

displayed in blinking text. The following generator set

operation data is displayed in this mode:

D Voltage (AC volts)

D Oil pressure (psi or kPa). May require the

installation of an optional oil pressure

sender on the engine. See Figure 18.

D Engine speed (rpm)

D Frequency (Hz)

D Coolant temperature (_For_C)

D Runtime hours

D Battery voltage (VDC)

Note: The maximum battery voltage that the

ADC will display on the remote digital

gauge is 31.5 volts. If the voltage is

higher than 31.5, it will display 31.5 volts.

Model Oil Pressure Sender

EKD and EFKD

EOD and EFOD

EOZD and EFOZD

EGD, EFGD, and EGZD

EKOZD and EFKOZD

Figure 18 Models with Optional or Standard

Oil Pressure Sender

Optional

StandardEKOD and EFKOD

Press the SELECT button until the display shows SEND

RUN or SEND STOP. Use the UP or DOWN arrow to

send a remote start/stop command.

Note: The ADC 2100 must be powered (display active)

and the master switch must be in the AUTO

position for remote start/stop. If the ADC 2100

master switch is in the RUN position, a remote

stop command will not stop the generator set.

The arrow at the top left side of the display blinks

to indicate that the generator set is running (see

Figure 17, item 2).

Note: The ADC II and ADC IId must be powered

(display active) for remote start/stop.

Note: The Decision-Maker 3500 must be powered

(display active) and in the AUTO position for

remote start/stop. If in the RUN position, a

remote stop command will not stop the generator

set. The arrow at the top left side of the display

blinks to indicate that the generator set is running

(see Figure 17, item 2).

Refer to the generator set operation manual and follow

the safety precautions when operating the generator

set.

Backlighting Mode

Press the SELECT button until the display shows LEVL.

Use the UP or DOWN arrow to select a lighting level:

D 0 = no backlight

D 3 = brightest backlight.

Note: While in this mode, faults appear on the display,

however no audible alarm is heard.

Once set, the backlight level defaults to the last

selection.

The maximumpower draw of the remote gauge is50 mA

at 12 VDC (or 25 mA at 24 VDC) with the brightest

backlight.

TT-1379 5/16 9

To Silence an Audible Alarm:

Faults are indicated by blinking or solid text and an

audible alarm. To silence an audible alarm, press and

hold the UP and DOWN arrow buttons simultaneously

until the gauge emits a long beep and then release.

Note: For a fault warning, the background lamp is solid.

For a fault shutdown, the background lamp will

flash. Consult your operation manual for more

details on warnings and shutdowns.

Page 10

Note: Always identify and correct the cause of a fault

shutdown before resetting the controller. Consult

the operation manual for guidance and items to

check.

Digital Gauge Fault Codes

Fault codes are displayed on the gauge when a fault

condition is detected.

See Figure 19 for faults displayed on the gauge for units

equipped with an ADC 2100 controller.

See Figure 20 for faults displayed on the gauge for units

equipped with an ADC II or ADC IId controller.

See Figure 21 for faults displayed on the gauge for units

equipped with a Decision-Makerr 3500 controller.

Units with ADC 2100 Controller

Digital Gauge

Display

LOP Low Oil Pressure

OC Over Crank

OS Over Speed

LCL Low Coolant Level

LOC Loss of Coolant

AF Auxiliary Input Fault

HE High Engine Temperature

OU Over Voltage

UU Under Voltage

OF Over Frequency

UF Under Frequency

LB Low Battery Voltage

HB High Battery Voltage

Figure 19 Fault Codes Displayed on the Gauge (for

Units Equipped with an ADC 2100

Controller)

Description

Units with ADC II or ADC IId Controller

Digital Gauge

Display

LOP Low Oil Pressure

OC Over Crank

OS Over Speed

AF Auxiliary Input Fault

HE High Engine Temperature

OU Over Voltage

UU Under Voltage

OF Over Frequency

UF Under Frequency

LB Low Battery Voltage

HB High Battery Voltage

Description

Figure 20 Fault Codes Displayed on the Gauge (for

Units Equipped with an ADC II or ADC IId

Controller)

Units with Decision-Makerr 3500 Controller

Digital Gauge

Display

LOP Low Oil Pressure

OS Over Speed

AF Auxiliary Input Fault

HE High Engine Temperature

OU Over Voltage

UU Under Voltage

OF Over Frequency

UF Under Frequency

For other possible fault codes, the gauge displays:

SHdn (for a Shutdown) or

Alrt (for an Alert/Warning).

Check the interface on the Decision-Makerr 3500 Controller for more

details.

Description

Figure 21 Fault Codes Displayed on the Gauge (for

Units Equipped with an Decision-Makerr

3500 Controller)

10 TT-1379 5/16

Page 11

Notes

TT-1379 5/16 11

Page 12

KOHLER CO., Kohler, Wisconsin 53044 USA

Phone 920-457-4441, Fax 920-459-1646

For the nearest sales and service outlet in the

US and Canada, phone 1-800-544-2444

KOHLERPower.com

Kohler Power Systems

Asia Pacific Headquarters

7 Jurong Pier Road

Singapore 619159

Phone (65) 6264-6422, Fax (65) 6264-6455

Availability is subject to change without notice. Kohler Co. reserves the

right tochange the design or specifications without noticeand withoutany

obligation or liability whatsoever. Contact your local Kohlerr generator

set distributor for availability.

2004, 2006, 2012, and 2016 by Kohler Co. All rights reserved.

12 TT-1379 5/16

Loading...

Loading...