Page 1

Operation

Residential/Light Commercial Generator Sets

Model:

24RCL

Controller:

RDC2

TP-6905 6/14

Page 2

California Proposition 65

WARNING

Engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth

defects, or other reproductive harm.

Product Identification Information

Product identification numbers determine service parts.

Record the product identification numbers in the spaces

below immediately after unpacking the products so that

the numbers are readily available for future reference.

Record field-installed kit numbers after installing the

kits.

Generator Set Identification Numbers

Record the product identification numbers from the

generator set nameplate(s).

Model Designation

Specification Number

Serial Number

Accessory Number Accessory Description

Controller Identification

Record the controller description from the generator set

operation manual, spec sheet, or sales invoice.

Controller Description

Engine Identification

Record the product identification information from the

engine nameplate.

Manufacturer

Model Designation

Serial Number

TP-6905 6/142

Page 3

Table of Contents

Product Identification Information 2.............................................................

Safety Precautions and Instructions 5.........................................................

Introduction 9...............................................................................

Service Assistance 11.........................................................................

Section 1 Service Views 13....................................................................

Section 2 Generator Set Operation 15..........................................................

2.1 Operating Area 15........................................................

2.2 Prestart Checklist 15......................................................

2.3 Exercising the Generator Set 16............................................

2.4 Generator Set Operation 16................................................

2.4.1 Local Starting and Stopping 16.....................................

2.4.2 Automatic Starting and Stopping 16.................................

2.4.3 Remote Starting and Stopping 16...................................

2.4.4 Engine Start Crank Cycle 16.......................................

2.4.5 Engine Cooldown 16..............................................

2.4.6 Automatic Operation with Model RXT Transfer Switch 16..............

2.4.7 Automatic Operation with Model RDT or RSB Transfer Switches 17.....

2.5 Exercise 17..............................................................

2.5.1 Unloaded Cycle Exercise with Complete System Diagnostics 17........

2.5.2 Unloaded Full-Speed Exercise 18..................................

2.5.3 Loaded Full-Speed Exercise (with RXT only) 18......................

2.5.4 Shutdown During Exercise 18......................................

2.5.5 Power Failure During Exercise 18..................................

2.5.6 Exerciser Reset 18...............................................

2.5.7 Setting the Exerciser at Power-up 18................................

2.5.8 Changing the Exercise Setting 19...................................

2.6 Faults 22................................................................

2.6.1 Warnings 22.....................................................

2.6.2 Shutdowns 22....................................................

2.6.3 ATS Communication Errors 22.....................................

2.6.4 Resetting the Controller after a Fault Shutdown 22....................

2.6.5 Event Log 27....................................................

2.7 Model RXT Transfer Switch Operation 27....................................

2.7.1 Source Availability 27.............................................

2.7.2 ATS Control Sequence of Operation 28..............................

2.7.3 Time Delays 28..................................................

2.7.4 ATS Load Control Relay Time Delay 28.............................

Section 3 RDC2 Controller Operation 29.......................................................

3.1 RDC2 Generator Set / Transfer Switch Controller 29...........................

3.2 Controls and Indicators 29.................................................

3.2.1 Controller Keypad 30.............................................

3.2.2 LED Indicators 30................................................

3.2.3 LCD Display 31..................................................

3.3 Controller Power 32.......................................................

3.4 Battery Charging 32......................................................

3.5 Changing Settings 32.....................................................

3.6 Controller Menus 34

3.7 Main Menu 34............................................................

3.8 Overview Menu 35........................................................

3.9 Engine Metering Menu 35.................................................

3.10 Generator Metering Menu 36...............................................

3.11 Generator Set Information Menu 37.........................................

......................................................

TP-6905 6/14 Table of Contents 3

Page 4

Table of Contents, continued

3.12 Genset Run Time Menu 37................................................

3.13 Genset System Menu 38..................................................

3.14 ATS Status Menu 39......................................................

3.15 ATS Configuration Menu 40................................................

3.16 Date and Time Menu 41...................................................

3.17 Networking Information Menus 42..........................................

3.17.1 Networking Status Submenu 43....................................

3.17.2 Networking Configuration Submenu (OnCue Plus Password) 44........

3.17.3 RBUS Information Submenu 45....................................

3.17.4 Remote Devices Submenu 46......................................

3.18 Programmable Interface Module (PIM) Menus 47.............................

3.19 Load Control Menus 48...................................................

Section 4 Scheduled Maintenance 49..........................................................

4.1 General Maintenance 49..................................................

4.2 Service Schedule 51......................................................

4.3 Lubrication System 52....................................................

4.3.1 Oil Specifications 52..............................................

4.3.2 Oil Check 52.....................................................

4.3.3 Oil Additions 52..................................................

4.3.4 Oil and Filter Change 52...........................................

4.4 Air Cleaner 54...........................................................

4.5 Exhaust System 54.......................................................

4.6 Cooling System 55.......................................................

4.6.1 Checking and Filling Coolant 55....................................

4.6.2 Cooling System Inspection 56......................................

4.6.3 Draining Cooling System 56.......................................

4.6.4 Flushing and Cleaning 56..........................................

4.6.5 Filling Cooling System 56..........................................

4.7 Ignition System 57........................................................

4.8 Battery 59...............................................................

4.9 Storage Procedure 60.....................................................

Section 5 Troubleshooting 61.................................................................

5.1 Introduction 61...........................................................

5.2 USB Port 61.............................................................

5.3 Fault Messages 61.......................................................

5.4 Circuit Protection 61......................................................

5.4.1 Load Circuit Breaker 61...........................................

5.4.2 Fuses 61........................................................

5.4.3 Controller Internal Circuit Protection 61..............................

5.5 Generator Set Troubleshooting 62..........................................

5.6 Controller Troubleshooting 63..............................................

Appendix A Abbreviations 65................................................................

TP-6905 6/14Table of Contents4

Page 5

Safety Precautions and Instructions

IMPORTANT SAFETY INSTRUCTIONS.

Electromechanical equipment,

including generator sets, transfer

switches, switchgear, and accessories,

can cause bodily harm and pose

life-threatening danger when

improperly installed, operated, or

maintained. To prevent accidents be

aware of potential dangers and act

safely. Read and follow all safety

precautions and instructions. SAVE

THESE INSTRUCTIONS.

This manual has several types of safety

precautions and instructions: Danger,

Warning, Caution, and Notice.

DANGER

Danger indicates the presence of a

hazard that will cause severe

personal injury, death,orsubstantial

property damage.

WARNING

Warning indicates the presence of a

hazard that can cause severe

personal injury, death, or substantial

property damage.

CAUTION

Caution indicates the presence of a

hazard that will or can cause minor

personal injury or property damage.

NOTICE

Notice communicates installation,

operation, or maintenance information

that is safety related but not hazard

related.

Safety decals affixed to the equipment

in prominent places alert the operator

or service technician to potential

hazards and explain how to act safely.

The decals are shown throughout this

publication to improve operator

recognition. Replace missing or

damaged decals.

Accidental Starting

WARNING

Accidental starting.

Can cause severe injury or death.

Disconnect the battery cables before

working on the generator set.

Remove the negative (--) lead first

when disconnecting the battery.

Reconnect the negative (--) lead last

when reconnecting the battery.

Disabling the generator set.

Accidental starting can cause

severe injury or death. Before

working on the generator set or

equipment connected to the set,

disable the generator set as follows:

(1) Press the generator set off/reset

button to shut down the generator set.

(2) Disconnect the power to the battery

charger, if equipped. (3) Remove the

battery cables, negative (--) lead first.

Reconnect the negative (--) lead last

when reconnecting the battery. Follow

these precautions to prevent the

starting of the generator set by the

remote start/stop switch.

Battery

WARNING

Sulfuric acid in batteries.

Can cause severe injury or death.

Wear protective goggles and

clothing. Battery acid may cause

blindness and burn skin.

WARNING

Explosion.

Can cause severe injury or death.

Relays in the battery charger

cause arcs or sparks.

Locate the battery in a well-ventilated

area. Isolate the battery charger from

explosive fumes.

Battery electrolyte is a diluted

sulfuric acid. Battery acid can cause

severe injury or death. Battery acid

can cause blindness and burn skin.

Always wear splashproof safety

goggles, rubber gloves, and boots

when servicing the battery. Do not

open a sealed battery or mutilate the

battery case. Ifbattery acid splashes in

the eyes or on the skin, immediately

flush the affected area for 15 minutes

with large quantities of clean water.

Seek immediate medical aid in the case

of eye contact. Never add acid to a

battery after placing the battery in

service, as this may result in hazardous

spattering of battery acid.

Battery acid cleanup. Battery acid

can cause severe injury or death.

Battery acid is electrically conductive

and corrosive. Add 500 g (1 lb.) of

bicarbonate of soda (baking soda) to a

container with 4 L (1 gal.) of water and

mix the neutralizing solution. Pour the

neutralizing solution on the spilled

battery acid and continue to add the

neutralizing solution to the spilled

battery acid until all evidence of a

chemical reaction (foaming) has

ceased. Flush the resulting liquid with

water and dry the area.

Battery gases. Explosion can cause

severe injury or death. Battery gases

can cause an explosion. Do not smoke

or permit flames or sparks to occur near

a battery at any time, particularly when

it is charging. Do not dispose of a

battery in a fire. To prevent burns and

sparks that could cause an explosion,

avoid touching the battery terminals

with tools or other metal objects.

Remove all jewelry before servicing the

equipment. Discharge static electricity

from your body before touching

batteries by first touching a grounded

TP-6905 6/14 5Safety Precautions and Instructions

Page 6

metal surface away from the battery. To

avoid sparks, do not disturb the battery

charger connections while the battery

is charging. Always turn the battery

charger off before disconnecting the

battery connections. Ventilate the

compartments containing batteries to

prevent accumulation of explosive

gases.

Battery short circuits. Explosion

can cause severe injury or death.

Short circuits can cause bodily injury

and/or equipment damage.

Disconnect the battery before

generator set installation or

maintenance. Remove all jewelry

before servicing the equipment. Use

tools with insulated handles. Remove

the negative (--) lead first when

disconnecting the battery. Reconnect

the negative (--) lead last when

reconnecting the battery. Never

connect the negative (--) battery cable

to the positive (+) connection terminal

of the starter solenoid. Do not test the

battery condition by shorting the

terminals together.

Engine Backfire/Flash

Fire

WARNING

Fire.

Can cause severe injury or death.

Do not smoke or permit flames or

sparks near fuels or the fuel system.

Servicing the fuel system. A flash

fire can cause severe injury or death.

Do not smoke or permit flames or

sparks near the carburetor, fuel line,

fuel filter, fuel pump, or other potential

sources of spilled fuels or fuel vapors.

Catch fuels in an approved container

when removing the fuel line or

carburetor.

Servicing the air cleaner. A sudden

backfire can cause severe injury or

death. Do not operate the generator

set with the air cleaner removed.

Combustible materials. A fire can

cause severe injury or death.

Generator set engine fuels and fuel

vapors are flammable and explosive.

Handle these materials carefully to

minimize the risk of fire or explosion.

Equip the compartment or nearby area

with a fully charged fire extinguisher.

Select a fire extinguisher rated ABC or

BC for electrical fires or as

recommended by the local fire code or

an authorized agency. Train all

personnel on fire extinguisher

operation and fire prevention

procedures.

Exhaust System

WARNING

Carbon monoxide.

Can cause severe nausea,

fainting, or death.

The exhaust system must be

leakproof and routinely inspected.

Generator set operation. Carbon

monoxide can cause severe nausea,

fainting, or death. Carbon monoxide

is an odorless, colorless, tasteless,

nonirritating gas that can cause death if

inhaled for even a short time. Avoid

breathing exhaust fumes when working

on or near the generator set. Never

operate the generator set inside a

building. Never operate the generator

set where exhaust gas could seep

inside or be drawn into a potentially

occupied building through windows, air

intake vents, or other openings.

Carbon monoxide symptoms.

Carbon monoxide can cause severe

nausea, fainting, or death. Carbon

monoxide is a poisonous gas present in

exhaust gases. Carbon monoxide is an

odorless, colorless, tasteless,

nonirritating gas that can cause death if

inhaled for even a short time. Carbon

monoxide poisoning symptoms include

but are not limited to the following:

D Light-headedness, dizziness

D Physical fatigue, weakness in

joints and muscles

D Sleepiness, mental fatigue,

inability to concentrate

or speak clearly, blurred vision

D Stomachache, vomiting, nausea

If experiencing any of these symptoms

and carbon monoxide poisoning is

possible, seek fresh air immediately

and remain active. Do not sit, lie down,

or fall asleep. Alert others to the

possibility of carbon monoxide

poisoning. Seek medical attention if

the condition of affected persons does

not improve within minutes of breathing

fresh air.

Carbon monoxide detectors.

Carbon monoxide can cause severe

nausea, fainting, or death. Install

carbon monoxide detectors on each

level of any building adjacent to the

generator set. Locate the detectors to

adequately warn the building’s

occupants of the presence of carbon

monoxide. Keep the detectors

operational at all times. Periodically

test and replace the carbon monoxide

detectors according to the

manufacturer’s instructions.

Fuel System

WARNING

Explosive fuel vapors.

Can cause severe injury or death.

Use extreme care when handling,

storing, and using fuels.

The fuel system. Explosive fuel

vapors can cause severe injury or

death. Vaporized fuels are highly

explosive. Use extreme care when

handling and storing fuels. Store fuels

in a well-ventilated area away from

spark-producing equipment and out of

the reach of children. Never add fuel to

the tank while the engine is running

because spilled fuel may ignite on

contact with hot parts or from sparks.

Do not smoke or permit flames or

sparks to occur near sources of spilled

fuel or fuel vapors. Keep the fuel lines

and connections tight and in good

condition. Do not replace flexible fuel

lines with rigid lines. Use flexible

sections to avoid fuel line breakage

caused by vibration. Do not operate the

generator set in the presence of fuel

leaks, fuel accumulation, or sparks.

Repair fuel systems before resuming

generator set operation.

Explosive fuel vapors can cause

severe injury or death. Tak e

additional precautions when using the

following fuels:

TP-6905 6/146 Safety Precautions and Instructions

Page 7

Propane (LP)—Adequate ventilation

is mandatory. Because propane is

heavier than air, install propane gas

detectors low in a room. Inspect the

detectors per the manufacturer’s

instructions.

Hazardous Voltage/

Moving Parts

DANGER

CAUTION

Natural Gas—Adequate ventilation is

mandatory. Because natural gas rises,

install natural gas detectors high in a

room. Inspect the detectors per the

manufacturer’s instructions.

Gas fuel leaks. Explosive fuel

vapors can cause severe injury or

death. Fuel leakage can cause an

explosion. Check the LP vapor gas or

natural gas fuel system for leakage by

using a soap and water solution with

the fuel system test pressurized to

6--8 ounces per square inch

(10--14 inches water column). Do not

use a soap solution containing either

ammonia or chlorine because both

prevent bubble formation. A successful

test depends on the ability of the

solution to bubble.

Hazardous Noise

CAUTION

Hazardous noise.

Can cause hearing loss.

Never operate the generator set

without a muffler or with a faulty

exhaust system.

Engine noise. Hazardous noise can

cause hearing loss. Generator sets

not equipped with sound enclosures

can produce noise levels greater than

105 dBA. Prolonged exposure to noise

levels greater than 85 dBA can cause

permanent hearing loss. Wear hearing

protection when near an operating

generator set.

Hazardous voltage.

Will cause severe injury or death.

Disconnect all power sources before

opening the enclosure.

WARNING

Hazardous voltage.

Can cause severe injury or death.

Operate the generator set only when

all guards and electrical enclosures

areinplace.

Moving parts.

WARNING

Hazardous voltage.

Backfeed to the utility system can

cause property damage, severe

injury, or death.

If the generator set is used for

standby power, install an automatic

transfer switch to prevent inadvertent

interconnection of standby and

normal sources of supply.

DANGER

Hazardous voltage.

Will cause severe injury or death.

This equipment must be installed and

serviced by qualified electrical

personnel.

Welding the generator set.

Can cause severe electrical

equipment damage.

Never weld components of the

generator set without first

disconnecting the battery, controller

wiring harness, and engine electronic

control module (ECM).

WARNING

Airborne particles.

Can cause severe injury or blindness.

Wear protective goggles and clothing

when using power tools, hand tools,

or compressed air.

Grounding electrical equipment.

Hazardous voltage can cause

severe injury or death. Electrocution

is possible whenever electricity is

present. Ensure you comply with all

applicable codes and standards.

Electrically ground the generator set,

transfer switch, and related equipment

and electrical circuits. Turn off the main

circuit breakers of all power sources

before servicing the equipment. Never

contact electrical leads or appliances

when standing in water or on wet

ground because these conditions

increase the risk of electrocution.

Disconnecting the electrical load.

Hazardous voltage can cause

severe injury or death. Disconnect

the generator set from the load by

turning off the line circuit breaker or by

disconnecting the generator set output

leads from the transfer switch and

heavily taping the ends of the leads.

High voltage transferred to the load

during testing may cause personal

injury and equipment damage. Do not

use the safeguard circuit breaker in

place of the line circuit breaker. The

safeguard circuit breaker does not

disconnect the generator set from the

load.

TP-6905 6/14 7Safety Precautions and Instructions

Page 8

Welding on the generator set. Can

cause severe electrical equipment

damage. Before welding on the

generator set perform the following

steps: (1) Remove the battery cables,

negative (--) lead first. (2) Disconnect

all engine electronic control module

(ECM) connectors. (3) Disconnect all

generator set controller and voltage

regulator circuit board connectors.

(4) Disconnect the engine batterycharging alternator connections.

(5) Attach the weld ground connection

close to the weld location.

Connecting the battery and the

battery charger. Hazardous voltage

can cause severe injury or death.

Reconnect the battery correctly,

positive to positive and negative to

negative, to avoid electrical shock and

damage to the battery charger and

battery(ies). Have a qualified

electrician install the battery(ies).

Short circuits. Hazardous

voltage/current can cause severe

injury or death. Short circuits can

cause bodily injury and/or equipment

damage. Do not contact electrical

connections with tools or jewelry while

making adjustments or repairs.

Remove all jewelry before servicing the

equipment.

Engine oil pan heater. Hazardous

voltage can cause severe injury or

death. The engine oil pan heater can

cause electrical shock. Disconnect

power to the engine oil pan heater and

allow to cool before working on the oil

pan heater electrical connections.

Electrical backfeed to the utility.

Hazardous backfeed voltage can

cause severe injury or death. Install

a transfer switch in standby power

installations to prevent the connection

of standby and other sources of power.

Electrical backfeed into a utility

electrical system can cause s evere

injury or death to utility personnel

working on power lines.

Servicing the generator set when it

is operating. Exposed moving parts

can cause severe injury or death.

Keep hands, feet, hair, clothing, and

test leads away from the belts and

pulleys when the generator set is

running. Replace guards, screens, and

covers before operating the generator

set.

Hot Parts

WARNING

Hot coolant and steam.

Can cause severe injury or death.

Before removing the pressure cap,

stop the generator set and allow it to

cool. Then loosen the pressure cap

to relieve pressure.

WARNING

Hot engine and exhaust system.

Can cause severe injury or death.

Do not work on the generator set until

it cools.

Servicing the alternator. Hot parts

can cause severe injury or death.

Avoid touching the alternator field or

exciter armature. When shorted, the

alternator field and exciter armature

become hot enough to cause severe

burns.

Servicing the exhaust system. Hot

parts can cause severe injury or

death. Do not touch hot engine parts.

The engine and exhaust system

components become extremely hot

during operation.

Servicing the engine oil pan heater.

Heated components can cause

severe injury. The oil pan heater will

rapidly become hot when energized.

Do not touch the oil pan heater while it is

hot. Disconnect power to the engine oil

pan heater and allow to cool before

servicing it or nearby parts.

Notice

NOTICE

Canadian installations only.For

standby service connect the output of

the generator set to a suitably rated

transfer switch in accordance with

Canadian Electrical Code, Part 1.

NOTICE

Electrostatic discharge damage.

Electrostatic discharge (ESD)

damages electronic circuit boards.

Prevent electrostatic discharge

damage by wearing an approved

grounding wrist strap when handling

electronic circuit boards or integrated

circuits. An approved grounding wrist

strap provides a high resistance (about

1 megohm), not a direct short,to

ground.

TP-6905 6/148 Safety Precautions and Instructions

Page 9

Introduction

This manual provides operation instructions for Model

24RCL and 30RCLH residential/light commercial

generator sets equipped with the RDC2 generator

set/transfer switch controller.

This generator set is approved for use in stationary

applications in locations served by a reliable utility

power source. Have the generator set installed by an

authorized Kohler distributor/dealer or service

technician. Refer to the Installation Manual for

installation instructions.

Information in this publication represents data available

at the time of print. Kohler Co. reserves the right to

change this publication and the p roducts represented

without notice and without any obligation or liability

whatsoever.

Read this manual and carefully follow all procedures

and safety precautions to ensure proper equipment

operation and to avoid bodily injury. Read and follow the

Safety Precautions and Instructions section at the

beginning of this manual. Keep this manual with the

equipment for future reference.

The equipment maintenance requirements are very

important for safe and efficient operation. Inspect the

parts often and perform required maintenance at the

prescribed intervals. Obtain service from an authorized

Kohler distributor/ dealer or service technician to keep

equipment in top condition.

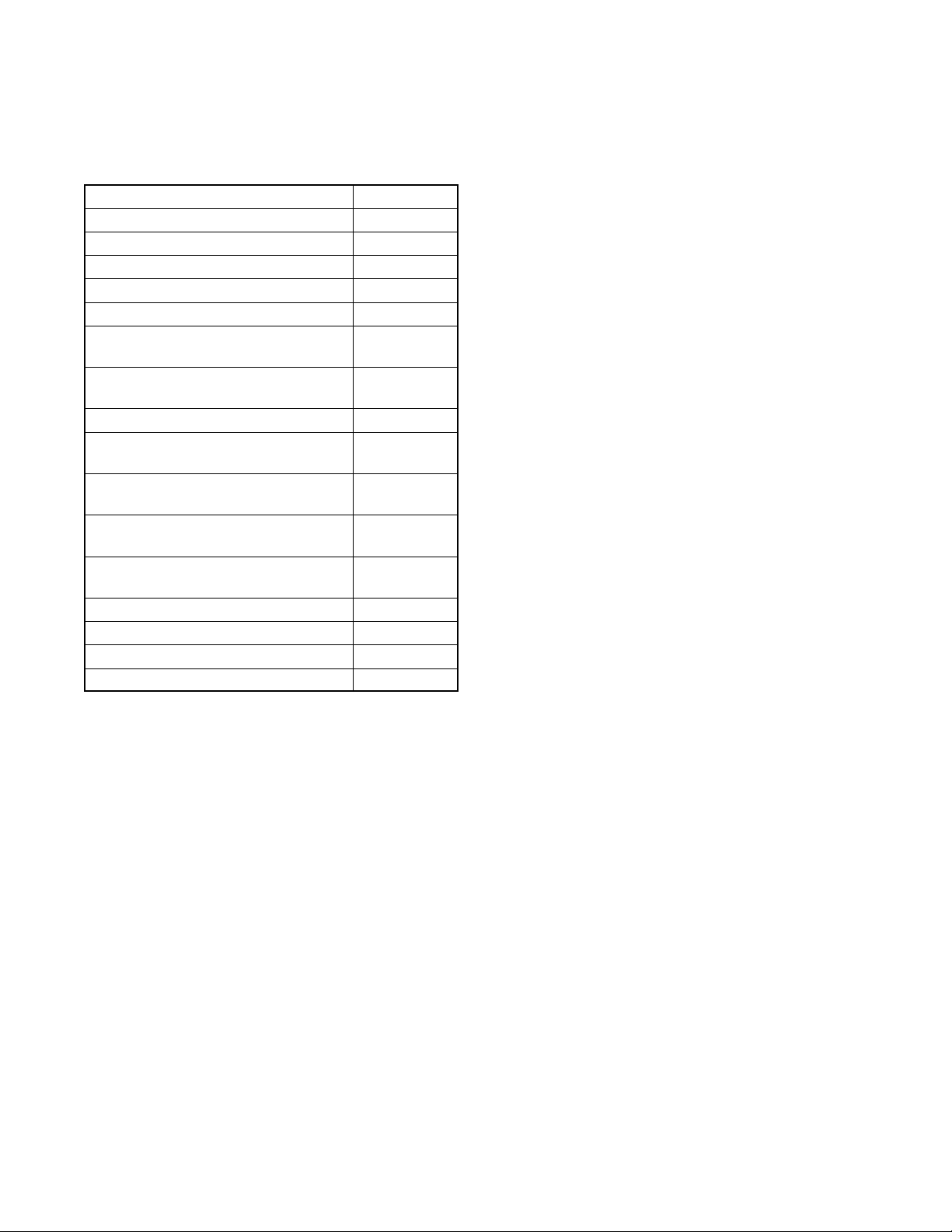

Nameplate

Figure 2 shows a typical generator set nameplate. Copy

the model, serial, and specification numbers from the

nameplate into the spaces provided in the product

information section on the inside front cover of this

manual. See the service view in Section 1 for the

nameplate location.

GM12070

Figure 2 Nameplate, Typical

GM91044--MA2

Figure 1 Model 24RCL Generator Set

TP-6905 6/14 9Introduction

Page 10

List of Related Literature

Figure 3 identifies related literature available for the

generator sets covered in this manual. Only trained and

qualified personnel should install or service the

generator set.

Literature Type Part Number

Specification Sheet, 24RCL G4-228

Specification Sheet, 30RCLH G4-230

Installation Manual, Generator Set TP-6906

Operation Manual, KG2204 Engine TP-6901

Service Manual, Generator Set TP-6907

Service Manual, KG2204 Engine

Mechanical

Service Manual, Engine ECM

Diagnostics

Parts Catalog, KG2204 Engine TP-6904

Parts Catalog, 24RCL and 30RCLH

Generator Set

Installation Instructions, Load Control

Module (LCM)

Installation Instructions, Programmable

Interface Module (PIM)

Operation Manual, OnCuet Plus

Software

Operation/Installation Manual, RXT ATS TP-6807

Operation/Installation Manual, RDT ATS TP-6345

Installation Manual, RSB Transfer Switch TP-6486

Operation Manual, RSB Transfer Switch TP-6487

Figure 3 Related Literature

TP-6902

TP-6903

TP-6908

TT-1574

TT-1584

TP-6928

TP-6905 6/1410 Introduction

Page 11

Service Assistance

For professional advice on generator set power

requirements and conscientious service, please contact

your nearest authorized Kohler distributor or dealer.

D Consult the Yellow Pages under the heading

Generators—Electric.

D Visit the Kohler Power Systems website at

KohlerPower.com.

D Look at the labels and stickers on your Kohler product

or review the appropriate literature or documents

included with the product.

D Call toll free in the US and Canada 1-800-544-2444.

D Outside the US and Canada, call the nearest regional

office.

Headquarters Europe, Middle East, Africa

(EMEA)

Kohler Power Systems Netherlands B.V.

Kristallaan 1

4761 ZC Zevenbergen

The Netherlands

Phone: (31) 168 331630

Fax: (31) 168 331631

Asia Pacific

Power Systems Asia Pacific Regional Office

Singapore, Republic of Singapore

Phone: (65) 6264-6422

Fax: (65) 6264-6455

China

North China Regional Office, Beijing

Phone: (86) 10 6518 7950

(86) 10 6518 7951

(86) 10 6518 7952

Fax: (86) 10 6518 7955

East China Regional Office, Shanghai

Phone: (86) 21 6288 0500

Fax: (86) 21 6288 0550

India, Bangladesh, Sri Lanka

India Regional Office

Bangalore, India

Phone: (91) 80 3366208

(91) 80 3366231

Fax: (91) 80 3315972

Japan, Korea

North Asia Regional Office

Tokyo, Japan

Phone: (813) 3440-4515

Fax: (813) 3440-2727

Latin America

Latin America Regional Office

Lakeland, Florida, USA

Phone: (863) 619-7568

Fax: (863) 701-7131

TP-6905 6/14 11Service Assistance

Page 12

Notes

TP-6905 6/1412 Service Assistance

Page 13

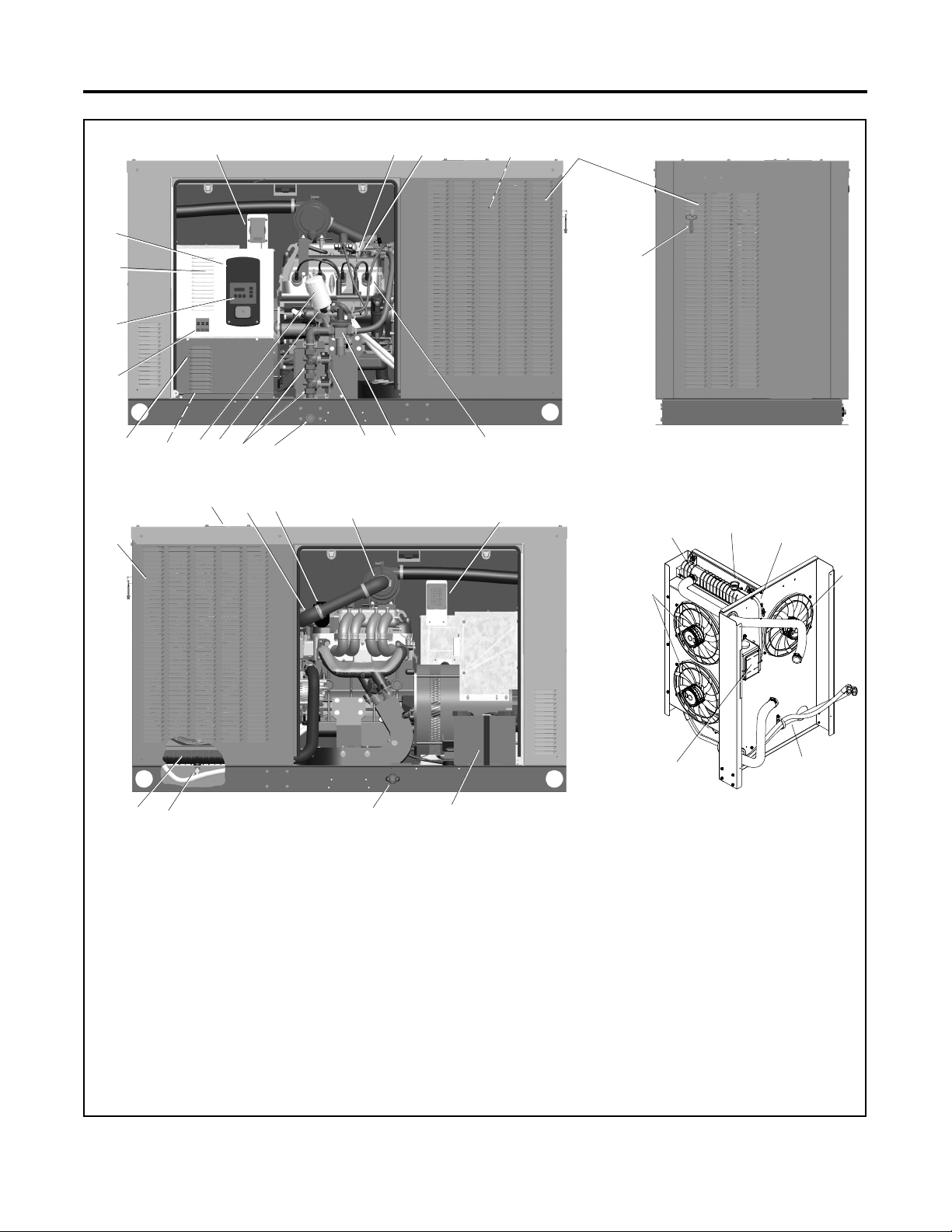

Section 1 Service Views

18

16

17

15

20

14

13

12

21

19

11

10

22

9

23

1

8

SERVICE SIDE

24

2

3

4

5

7

6

19

30

31

32

29

29

33

GM90230

28

27

26

25

34

ADV-8641

Cooling System Detail

NON-SERVICE SIDE

1. Oil check (dipstick)

2. Oil fill location (on valve cover)

3. See cooling system detail

4. Exhaust outlet

5. Enclosure locking tool (shipping location only)

6. Spark plugs

7. EPR (electronic fuel pressure regulator)

8. Engine ECM

9. Fuel inlet (1 in. NPT)

10. Fuel solenoid valves (qty. 2 shown)

11. Oil cooler adapter (model 30RCLH only)

12. Lube oil filter

13. Customer load lead access

14. Customer connection access panel

15. Line circuit breaker

16. Generator set master control buttons (on RDC2 controller)

17. Nameplate location

18. RDC2 controller

19. Fan fuses

20. Cooling air inlet (remove this panel to access coolant drain)

21. Access to coolant fill

22. Air-fuel mixer

23. Throttle body

24. Air cleaner

25. Battery

26. Oil Drain

27. Coolant drain

28. Oil cooler (model 30RCLH only)

29. Fans (qty. 3)

30. Radiator

31. Pressure cap (engine coolant fill)

32. Coolant overflow tube

33. Oil cooler hoses (model 30RCLH only)

34. Coolant overflow bottle

Figure 1-1 24RCL and 30RCLH Service Views for Maintenance

TP-6905 6/14 13Section 1 Service Views

Page 14

Notes

TP-6905 6/1414 Section 1 Service Views

Page 15

Section 2 Generator Set Operation

2.1 Operating Area

WARNING

Carbon monoxide.

Can cause severe nausea,

fainting, or death.

The exhaust system must be

leakproof and routinely inspected.

Carbon monoxide symptoms. Carbon monoxide can

cause severe nausea, fainting, or death. Carbon monoxide

is a poisonous gas present in exhaust gases. Carbon

monoxide is an odorless, colorless, tasteless, nonirritating gas

that can cause death if inhaled for even a short time. Carbon

monoxide poisoning symptoms include but are not limited to

the following:

D Light-headedness, dizziness

D Physical fatigue, weakness in

joints and muscles

D Sleepiness, mental fatigue,

inability to concentrate

or speak clearly, blurred vision

D Stomachache, vomiting, nausea

If experiencing any of these symptoms and carbon monoxide

poisoning is possible, seek fresh air immediately and remain

active. Do not sit, lie down, or fall asleep. Alert others to the

possibility of carbon monoxide poisoning. Seek medical

attention if the condition of affected persons does not improve

within minutes of breathing fresh air.

Generator set operation. Carbon monoxide can cause

severe nausea, fainting, or death. Carbon monoxide is an

odorless, colorless, tasteless, nonirritating gas that can cause

death if inhaled for even a short time. Avoid breathing exhaust

fumes when working on or near the generator set. Never

operate the generator set inside a building. Never operate the

generator set where exhaust gas could seep inside or be

drawn into a potentially occupied building through windows, air

intake vents, or other openings.

Keep the generator set area clear. Maintain at least

0.9 m (3 ft.) of clearance on all sides of the generator

set. Verify that there are no windows, air vents, or other

openings in the building within 1.5 m (5 ft.) of the

generator set exhaust outlet in any direction.

Notice

Do not locate patios, decks, play areas, or animal

shelters near the generator set. Keep items such as

lawn furniture, toys, sports equipment, and all

combustible materials away from the generator set

exhaust outlet. Remind family members, children,

and visitors to use caution near the generator set.

Generator sets connected to automatic transfer

switches start automatically during exercise periods

and power outages. Some generator set components

become hot when the generator set is running and

remain hot for a time after the generator set shuts

down.

2.2 Prestart Checklist

To ensure continued satisfactory operation perform the

following checks or inspections before or at each

startup, as designated, and at the intervals specified in

the service schedule. In addition, some checks require

verification after the unit starts.

Air Cleaner. Check for a clean and installed air cleaner

element to prevent unfiltered air from entering the

engine.

Air Inlets. Check for obstructions that could block the

flow of cooling air. Keep the air intake area clean. Do not

leave rags, tools, or debris on or near the generator set.

Battery. Check for tight battery connections. Consult

the battery manufacturer’s instructions regarding

battery care and maintenance.

Coolant Level. Check the coolant level according to the

cooling system maintenance information.

Drive Belt. Check the belt condition of the water pump

and battery charging alternator belt.

Carbon Monoxide Detectors. Check for the

installation and operation of carbon monoxide (CO)

detectors on each level of any building near the

generator set.

Oil Level. Maintain the oil level at or near, not over, the

full mark on the dipstick.

TP-6905 6/14 15Section 2 Generator Set Operation

Page 16

2.3 Exercising the Generator Set

2.4.5 Engine Cooldown

Operate the generator set without load every week or

every other week for 20 minutes. Perform all of the

prestart checks before starting the exercise procedure.

See Section 2.5 for instructions to set the automatic

exerciser.

2.4 Generator Set Operation

2.4.1 Local Starting and Stopping

Start: Press the RUN button to immediately start the

generator set.

Stop: Press the OFF button. The engine stops.

Run the generator set with no load for at least 2 minutes

to ensure adequate engine cooldown.

2.4.2 Automatic Starting and Stopping

An automatic transfer switch monitors the utility power

and signals the generator set to start when utility power

is lost. The ATS then transfers the load to the generator

set.

When utility power is restored, the transfer switch

transfers the load back to utility, runs the generator set

with no load to cool down the engine, and then stops the

generator set engine. The electric fans continue to run

for two minutes after the engine shuts down to evacuate

the engine compartment.

The engine cooldown time delay allows the engine to

run after the loads have been removed.

The engine cooldown time delay is set to 5 minutes. The

engine stops before the cooldown time delay expires if

the temperature drops below the cooled-down

temperature level, or if the temperature rises above the

high limit during the cooldown cycle.

The electric fans continue to run for two minutes after the

engine shuts down to evacuate the engine

compartment.

If a transfer switch other than the Model RXT is used, an

additional engine cooldown time delay may be

programmed on the transfer switch. To allow the smart

engine cooldown on the RDC2 controller to operate

most efficiently, set the cooldown time on the transfer

switch controller to zero or the minimum time allowed.

Refer to the instructions provided with the transfer

switch for more information.

2.4.6 Automatic Operation with Model

RXT Transfer Switch

The Model RXT transfer switch connects to the RDC2

controller through the ATS interface board on the

transfer switch. Also see Section 2.7, Model RXT

Transfer Switch Operation.

The RDC2 controller must be in AUTO mode for

automatic transfer switch operation.

2.4.3 Remote Starting and Stopping

A remote switch connected to terminals 3 and 4 can be

used to start and stop the generator set. Close the

switch to start and run the generator set. Open the

switch to stop the generator set.

Run the generator set with no load for at least 2 minutes

to ensure adequate engine cooldown.

2.4.4 Engine Start Crank Cycle

The controller attempts to start the generator set three

times (three crank cycles, 15 seconds crank and

15 seconds off). If the generator set does not start in

three attempts, the system shuts down on an overcrank

fault. See Section 2.6.

Pressing the OFF button during the crank cycle stops

the cranking. No other buttons are acknowledged during

the crank cycle.

Automatic Start

The RDC2 controller receives utility source voltage

sensing data from the Model RXT transfer switch.

1. If the utility source voltage falls below an

acceptable level, the controller starts the engine

start time delay.

2. If the utility source is not restored before the time

delay expires, the generator set starts.

3. After the Normal-to-Emergency time delay, the

ATS is signaled to transfer the load to the

emergency source.

TP-6905 6/1416 Section 2 Generator Set Operation

Page 17

Automatic Stop

1. When the utility source is restored, the

Emergency-to-Normal time delay starts.

If a Model RDT or RSB transfer switch is used, refer to

the instructions provided with the transfer switch to set a

loaded exercise at the ATS, if desired.

2. When the Emergency-to-Normal time delay

expires, the load is transferred to the utility.

3. The generator set stops.

2.4.7 Automatic Operation with Model

RDT or RSB Transfer Switches

If a Kohler Model RDT or RSB transfer switch is used,

the engine start contacts from the ATS must be

connected to engine start leads 3 and 4 on the generator

set.

The RDC2 generator set controller must be in AUTO

mode to respond to remote start/stop signals from an

ATS or remote switch. Press the AUTO button on the

RDC2 controller to put the generator set into automatic

mode.

Automatic Start

The engine start contacts on the ATS close to signal the

generator set to start, and remain closed while the

generator set is running.

Automatic Stop

The engine start contacts on the ATS open to signal the

generator set to stop.

2.5.1 Unload ed Cycle Exercise with

Complete System Diagnostics

An unloaded cycle exercise runs the generator set

without signalling the transfer switch to transfer the

electrical load from the utility source to the generator set.

The Unloaded Cycle exercise with diagnostics is the

recommended exercise mode and is the factory-default

exercise setting.

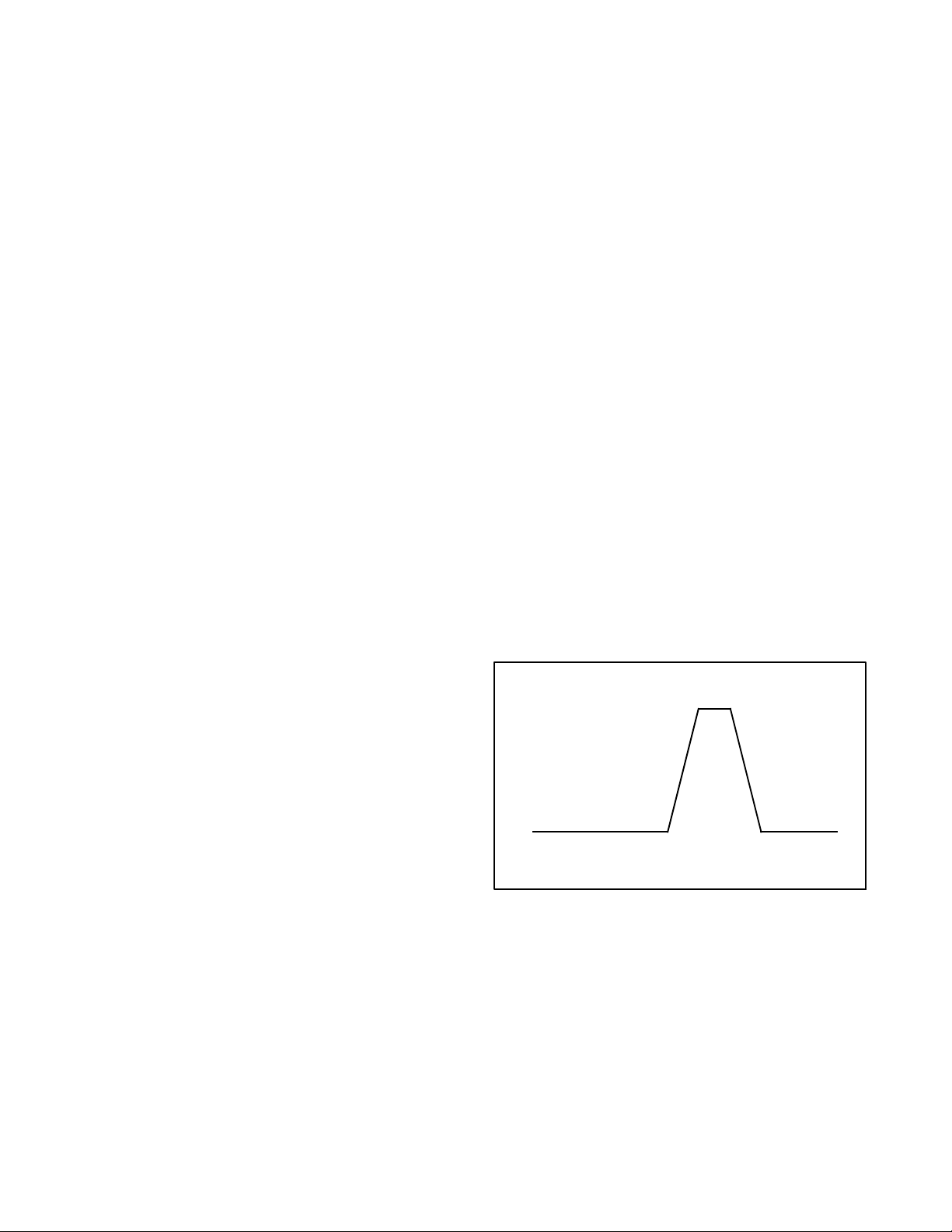

The Unloaded Cycle exercise runs the engine for

20 minutes in the cycle shown in Figure 2-1 and

described below.

D Runs at reduced speed for 10 minutes to warm up

and exercise the engine.

D Ramps up and runs at full speed for 3 minutes.

Engine diagnostics are performed during this

full-speed portion of the cycle, which provides the

best test of engine and alternator power backup

capability. Diagnostic tests at full speed can identify

potential problems with the power output and alert the

operator before an emergency event.

D Ramps down and runs at reduced speed for

5 minutes to cool down the engine before shutting

down automatically.

2.5 Exercise

The RDC2 controller can be set to automatically run the

generator set at the same time and day every week or

every other week. Exercising the generator set every

week or every two weeks is required in order to keep the

engine and alternator in good operating condition.

Three exercise modes are available: unloaded cycle,

unloaded full speed, and loaded full speed. See

Sections 2.5.1 through 2.5.3 for information about the

exercise modes. A loaded exercise can be set at the

RDC2 controller only if a Model RXT transfer switch is

connected.

Note: With the RDT and RSB transfer switches, it is

possible to have two exercise settings (one

unloaded exercise set at the generator set

controller, and another exercise set at the ATS

controller). If the exercise times overlap, the ATS

exercise setting takes priority.

3min.

1min.

Engine Speed, RPM

10 min. 5 min.

Engine

Exercise

Full-Speed

Diagnostics

1min.

Cooldown

Figure 2-1 Unloaded Exercise Cycle

System Diagnostics

During the unloaded cycle exercise, the controller

monitors the following data. The controller display

indicates an unloaded exercise run during the

diagnostics, unless a fault is detected as described

below.

TP-6905 6/14 17Section 2 Generator Set Operation

Page 18

D ATS connection. The controller verifies that the

Model RXT ATS interface board is connected.

D Battery voltage. Battery voltage is checked before

exercise to verify engine starting capability. Battery

voltage provides a measurement of battery health. If

the controller detects low battery voltage, low battery

or low charging battery is displayed and the exercise

does not start.

generator set. To set a loaded exercise, follow the

procedure in Section 2.5.8 and select Exercise Type:

Loaded.

For a loaded exercise with a transfer switch other than a

Kohlerr Model RXT, program the exercise at the

transfer switch controller. Refer to the transfer switch

operation manual for instructions.

D Coolant level check. The coolant level is checked.

D Communication integrity tests. J1939, RBUS,

Ethernet, and USB are monitored for messages

indicating that the controller and wiring are reliable.

D Engine speed. Engine speed is measured at low

speed and full speed. An overspeed or underspeed

condition will result in a fault condition and shutdown.

D Generator output frequency and voltage.

Operating the generator at full speed allows the

RDC2 controller to check the output power for correct

voltage, frequency, and stability. When the engine is

running at full speed, the controller verifies that the

voltage and frequency are within acceptable limits. A

fault message is displayed if the voltage or frequency

is out of range.

D Oil pressure. Oil pressure is verified to ensure

proper lubrication of critical engine components.

Pressure is monitored at both low and full speeds. If

the oil pressure is low, low oil pressure is displayed

and the generator set shuts down.

2.5.2 Unloaded Full-Speed Exercise

The unloaded full speed exercise runs the generator set

at full speed for 20 minutes without transferring the load.

To set an unloaded full speed exercise, follow the

procedure in Figure 2-3 and select Exercise Mode:

Unloaded Full.

2.5.4 Shutdown During Exercise

The following advanced diagnostic operation applies to

RDC2 controllers with firmware versions 5.04 and

higher.

If the generator set shuts down on a fault during an

exercise, the controller will try to restart the engine. If the

engine starts, the generator set will run at full speed for

two minutes and then stop. The event history will show

Advanced Diagnostic Active. The exercise schedule is

maintained.

If the engine does not start, the shutdown message will

be displayed. Correct the fault condition and reset the

fault as described in Section 2.6.

2.5.5 Power Failure During Exercise

If the utility power is lost during an unloaded exercise,

the ATS transfers to the emergency source, the exercise

is ended and the control remains in the AUTO mode.

If the utility power is lost during a loaded exercise, the

exercise is ended. The ATS remains in the emergency

position and the control goes into the AUTO mode.

The generator set continues to run and supply power to

the load for the duration of the utility power outage.

When Utility power is restored, the ATSwill re-transfer to

the utility source through normal timing sequences.

2.5.6 Exerciser Reset

2.5.3 Loaded Full-Speed Exercise (with

RXT only)

A loaded exercise starts the generator set, ramps u p to

full speed, and then transfers the electrical load from the

utility source to the generator set. The load is transferred

back to the utility source before the generator set shuts

down.

Note: With a loaded exercise, power to the building is

lost for up to 10 seconds during load transfer.

For a loaded exercise controlled by the RDC2 controller,

a Model RXT transfer switch must be connected to the

To reset the exerciser to run at a different day and/or

time or to change the exercise mode, follow the

procedure in Section 2.5.7 to change the exerciser

settings.

2.5.7 Setting the Exerciser at Power-up

When power is connected to the controller, you will be

prompted to set the date, time, and exercise schedule.

1. At power--up, the date is displayed with the year

flashing. Use the up or down arrow key to step to

the current year.

TP-6905 6/1418 Section 2 Generator Set Operation

Page 19

2. Press Select button to save the year and move to

the month.

2. Press the Select button to go to the main menu.

SeeFigure2-2.

3. Use the arrow and select buttons to set the month

and the day.

4. The time is displayed with the hour flashing. Use

the up or down arrow key to step to the current hour

and am or pm setting.

Note: Check the am/pm setting displayed. If pm is

displayed and you need to change it to am,

use the down arrow button to step down in

time until the correct hour and am are

displayed.

5. Press the Select button to save the hour and move

to minutes.

6. Use the up or down arrow button to change the

minutes.

7. Press Select to save the time and move to the next

screen.

8. Next Exercise is displayed. Use the up, down, and

select buttons to set the exercise time and date. Be

sure to set a time and date in the future.

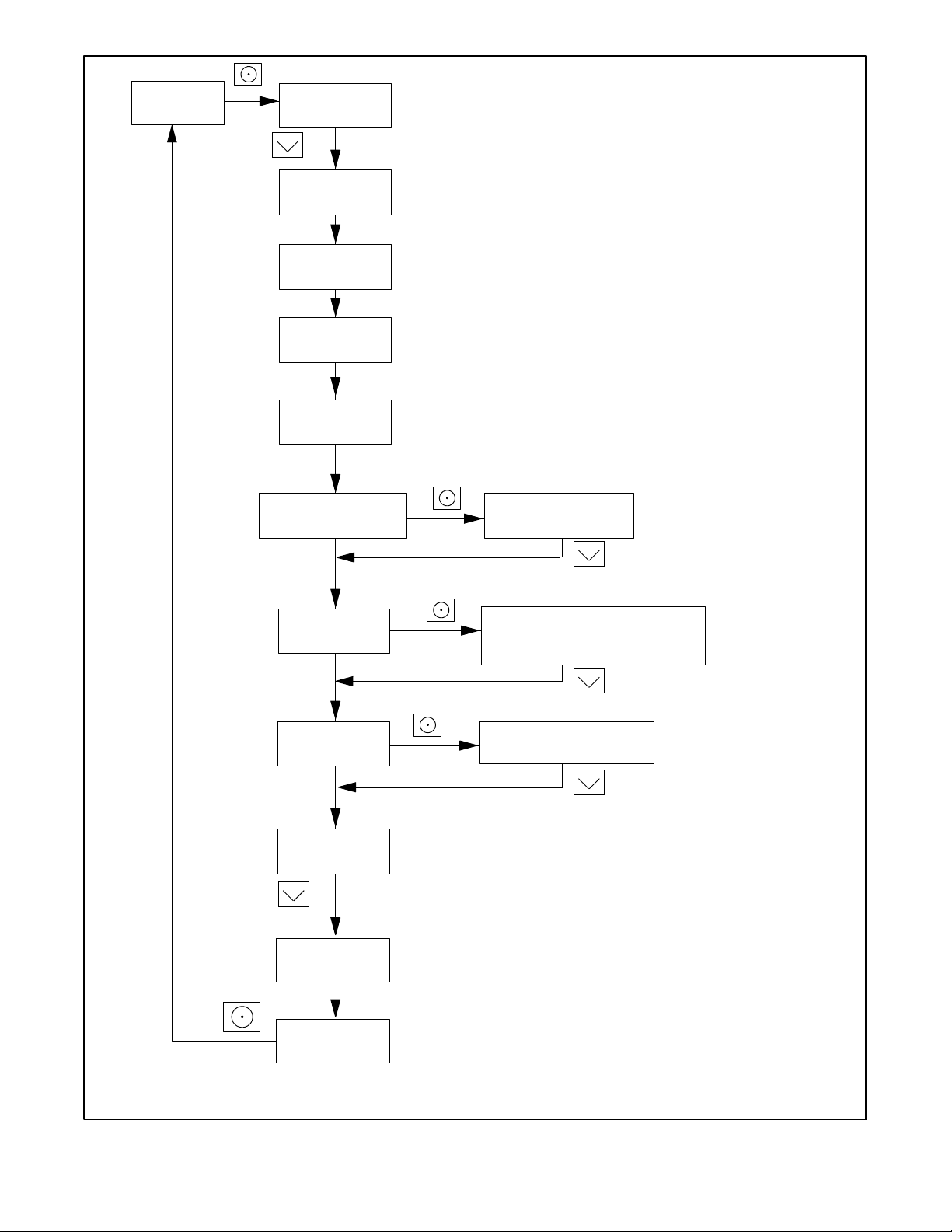

3. Press the down arrow button to step to the Genset

System menu.

4. Press the Select button to enter the Genset system

menu. See Figure 2-3.

5. Use the down arrow button to step to the next

Exercise menu.

6. Press the Select button. The setting flashes to

show that it can be changed. For example, the hour

flashes to show that the hour can be changed.

7. Press the UP or Down arrow buttons to change the

setting.

8. Press the Select button to save the setting and

move to the next. For example, save the hour

setting and move to minutes.

9. Repeat steps 5 through 8 to change the next item

on the line until the desired settings are displayed.

10. Press Select to save after all settings have been

selected. Settings will stop flashing.

9. Press Select. The controller exits the exercise

menu.

10. Press the Auto button and verify that the AUTO

LED is lit. The generator set must be in automatic

mode for the exercise to run as scheduled.

Theexercisewillrunevery7daysatthesametime,

starting on the date set. To change the exerciser to run

every other week or on a different day and time, use the

following procedure.

2.5.8 Changing the Exercise Setting

Set the date and time on the controller before setting the

exercise schedule. Set the exerciser to automatically

run the generator set for 20 minutes every week or every

two weeks. Follow the procedure below and see the

flowchart in Figure 2-3 to set the exercise time and date,

mode, and frequency.

Procedure to Change the Exercise Setting

1. Press the AUTO button on the controller.

11. If the generator set is connected to a Kohlerr Model

RXT transfer switch, the exercise can be changed

to a loaded exercise. Set the Exercise Mode to

loaded full speed, unloaded full speed, or unloaded

cycle as shown in Figure 2-3.

12. Set the exercise frequency (weekly or every two

weeks). Weekly exercises are recommended.

13. Press the down arrow button to step to the Return

menu. Press the Select button to return to the main

menu.

14. Check that the AUTO LED is lit. The generator set

must be in automatic mode for the exercise to run

as scheduled.

After a scheduled exercise run, the next exercise time

and date will be updated automatically based on the

Exercise Frequency setting.

Other transfer switches: For a loaded exercise with a

transfer switch other than a Kohlerr Model RXT,

program the exercise at the transfer switch controller.

Refer to the transfer switch operation manual for

instructions.

TP-6905 6/14 19Section 2 Generator Set Operation

Page 20

Status

Displays

Overview ---->

1.2 h

Engine ---->

Metering

Generator-- -->

Metering

Genset ---->

Information

Genset ---->

Run Time

Genset ---->

System

ATS -- - ->

Status

ATS -- - ->

Configuration

D a t e -- -- >

and Time

Network -- -->

Information

PIM -- -->

Status

Load ---->

Control

Event Log-- -->

tp6810

Figure 2-2 RDC2 Main Menu

TP-6905 6/1420 Section 2 Generator Set Operation

Page 21

Genset ---->

System

System Voltage:

240 V

System Freq:

60 Hz

VR Voltage Adj:

240.0V

System Phase:

Single

System Battery:

12 V

Next Exercise *

HR:MN PM MM/DD/YY

Exercise Mode:

Unloaded Cycle

Exercise Freq:

Weekly

Meas. System:

English

Next Exercise

HR:MN PM MM/DD/YY

Exercise Mode:

None/Unloaded Full Sp/

Unloaded Cycle/Loaded Full SP

Exercise Freq:

Weekly/Every Other Week

See Section 2.5.8, Changing

the Exercise Setting

Contrast:

50

<-- -- Return

* If the exerciser has not been set, No Exercise Sch will be displayed.

Figure 2-3 Procedure to Set the Exerciser

TP-6905 6/14 21Section 2 Generator Set Operation

tp6809

Page 22

2.6 Faults

2.6.3 ATS Communication Errors

Selected fault conditions are shown in Figure 2-5. Fault

conditions are classified as warnings or shutdowns. If a

fault occurs that is not listed in the table, contact an

authorized distributor/dealer for service.

Note: All ECM faults are grouped under one listing in

Figure 2-5.

If a programmable interface module (PIM) is connected

to the generator set controller, additional faults can be

activated by customer-supplied equipment. See

TT-1584, Installation Instructions for the Programmable

Interface Module, for available inputs and outputs.

2.6.1 Warnings

The controller displays a fault message but the

generator set does not shut down on a warning. The

controller resets automatically after a warning condition

is corrected.

2.6.2 Shutdowns

Under a fault shutdown condition, the generator set

shuts down automatically and the controller displays a

fault message. The OFF LED flashes. See Figure 2-5.

Shutdown switches (such as the low coolant level switch

or high engine temperature switch) on the generator set

will automatically reset when the problem is corrected.

However, the fault condition at the controller does not

clear until the controller is reset.

When a Model RXT transfer switch is used, an ATS fault

indicates that the connection to the interface board on

the transfer switch has been lost. Check the connection

to the ATS interface board.

2.6.4 Resetting the Controller after a

Fault Shutdown

Always identify and correct the cause of a fault

shutdown before resetting the controller.Check the fault

message displayed on the controller and refer to

Figure 2-5 to identify and correct the fault condition

before proceeding. Contact a n authorized

distributor/dealer for service, if necessary.

Press the OFF button to reset the controller,or follow the

procedure below. See Figure 2-4.

Procedure to Reset the Controller after a Fault

Shutdown

1. Press the Select button to go to the Overview

menu.

2. Press Select again. The active fault is displayed.

3. Press Select. Confirm Clear Fault: NO is displayed.

4. Press the Up arrow button. Confirm Clear Fault:

YES is displayed.

5. Press the Select button to enter YES and clear the

fault.

The generator set cannot be restarted until the fault

condition is corrected and the controller is reset. See

Section 2.6.4 to reset the controller after a fault

shutdown.

Fault Message

Overview ---->

1.2 h

Figure 2-4 Clearing a Fault

6. Press the Select Button to return to the overview

menu.

7. Press AUTO to put the generator set into automatic

mode.

Fault Message Confirm Clear

Fault: NO

Press Up

arrow button.

Confirm Clear

Fault: YES

tp6810

TP-6905 6/1422 Section 2 Generator Set Operation

Page 23

Fault (RDC2)

AC Sens Loss

Warning

(1 sec.)

Shutdwn

(3 sec.)

Accy PwrOver

Warning

Alt Protect

Shutdwn

ATS ComError

Warning

ATS PhaseRot

Warning

Aux Input

Shutdwn

Batt Chg Flt

Warning

Battery CrLo

Warning

Battery High

Warning

Battery Low

Warning

Chk DateTime

Warning

Coolant Lvl Low

Shutdwn

Fault (OnCuer

Condition Check

Plus)

AC Sensing

Lost

AC Sensing Lost. In Auto mode, generator

output AC sensing is lost. Detection begins 10

seconds after crank disconnect.

Warning: after 1 second if no output detected

after crank disconnect.

Shutdown: after 3 seconds if voltage was

present and then lost.

Accessory

Power Overload

Accessory Power Overload. An over current

fault (short circuit) on the accessory controller

power output.

Alternator

Protection

High generator current is detected. The

generator set shuts down to protect the

alternator from damage caused by

overheating the windings. (30RCLH only)

ATS

Communication

Error

ATS Phase

Rotation

Mismatch

ATS Communication Error. Warning is

displayed if RXT interface connection is lost.

See Section 2.6.3.

ATS Phase Rotation Mismatch. Transfer

switch phase rotation does not match. ATS

will not transfer.

Auxiliary Input Auxiliary Input. An optional

customer-connected input is closed. (Digital

input from optional PIM.)

Battery Charger

Fault

Engine starting battery voltage rises above

150% (18 Volts) of the battery voltage setting

for more than 10 seconds. Inhibited during the

engine crank cycle.

Clears when the battery voltage returns to an

acceptable level.

Critically Low

Battery Voltage

Engine starting battery voltage falls below 11

V for more than 10 seconds. Inhibited during

the engine crank cycle.

Clears when the battery voltage returns to an

acceptable level.

High Battery

Voltage

Engine starting battery voltage rises above

133% (16 V) of the battery voltage setting for

more than 10 seconds. Inhibited during the

engine crank cycle.

Clears when the battery voltage returns to an

acceptable level.

Low Battery

Voltage

Engine starting battery voltage falls below the

battery voltage setting (typically 12.5 volts) for

more than 90 seconds when the engine is not

running. Inhibited during the engine crank

cycle.

Clears when the battery voltage returns to an

acceptable level.

Verify Date

Time Setting

Low Coolant

Level Shutdown

The time and date have not been set on the

generator controller.

The coolant level switch input has been

activated.

Contact an authorized

distributor/dealer for service.

Contact an authorized

distributor/dealer for service.

Reduce the load by turning off

appliances.

Check communication wiring between

transfer switch interface board and

generator set.

Correct the ATS connection. Refer to

the ATS Installation manual, wiring

diagrams, and labels on the transfer

switch.

Check customer-supplied equipment.

Check external battery charger.

Check the battery rating and

condition.

Check the battery charger operation.

Charge or replace the battery.

Check the battery rating and

condition.

Check the battery charger operation.

Check the battery rating and

condition.

Check the battery charger operation.

Charge or replace the battery.

Enter the date and time using the

RDC2 controller. See Figure 3-8 and

Figure 3-16.

Check coolant level.

Check radiator hoses for leaks.

Contact an authorized

distributor/dealer for service.

TP-6905 6/14 23Section 2 Generator Set Operation

Page 24

Fault (RDC2)

CoolTempHigh

Warning

CoolTemp Vhi

Shutdwn

Fault (OnCuer

Plus)

Ect Higher

Than

Expected 1

Ect Higher

Than

Expected 2

Condition Check

Coolant temperature is too high. Check coolant level.

Check radiator and fans for

obstruction.

Contact an authorized

distributor/dealer for service and

provide the fault code.

Coolant temperature is extremely high. Check coolant level.

Check radiator and fans for

obstruction.

Contact an authorized

distributor/dealer for service and

provide the fault code.

CoolntTemp 0

Shutdwn

CoolntTemp 3

Shutdwn

CoolntTemp 4

Shutdwn

CoolntTemp 5

Shutdwn

Crank Lost

Warning

Crank Noise

Warning

“ECM” warnings

(any warnings

with ECM in the

fault name)

Coolant Temp 0

Shutdown

Coolant Temp 3

Shutdown

Coolant Temp 4

Shutdown

Coolant Temp 5

Shutdown

Crank Signal

Lost

Crank Sync

Noise

“ECM”

warnings (any

warnings with

ECM in the

fault name)

The ECM reported a problem with the coolant

temperature sensor reading: 0 = high

temperature.

The ECM reported a problem with the coolant

temperature sensor reading: 3 = high voltage.

The ECM reported a problem with the coolant

temperature sensor reading: 4 = low voltage.

The ECM reported a problem with the coolant

temperature sensor reading: 5 = open circuit.

Crankshaft Position Sensor (CPS) timeout

error occurred.

Crankshaft Position Sensor (CPS)

synchronization error occurred.

This group of faults includes a wide variety of

faults that originate from the engine ECM

and also contain ECM in the fault name.

Check coolant level.

Check radiator and fans for

obstruction.

Contact an authorized

distributor/dealer for service and

provide the fault code.

Contact an authorized

distributor/dealer for service and

provide the fault code.

Contact an authorized

distributor/dealer for service and

provide the fault code.

Contact an authorized

distributor/dealer for service and

provide the fault code.

Contact an authorized

distributor/dealer for service and

provide the fault code.

Contact an authorized

distributor/dealer for service and

provide the fault code.

Contact an authorized

distributor/dealer for service and

provide the fault code.

Emerg Stop

Shutdwn

Emergency

Stop Shutdown

Eng Derate Engine Derate

Active

Eng Speed High

Shutdwn

Eng Speed Low

Shutdwn

Exer Not Sch

Warning

High Engine

Speed

Low Engine

Speed

ATS Exercis e

Not Scheduled

The emergency stop switch has been

activated, or there has been an open circuit in

the wiring.

The ECM reported a torque limiting error

caused by coolant overheating.

Engine speed exceeds 115% of the normal

running speed for more than 0.3 seconds.

Engine speed drops below 85% of the normal

running speed for more than 3 seconds.

Exercise Not Scheduled. No exercise has

been scheduled on the RDC2 controller.

Contact an authorized

distributor/dealer for service.

Check coolant level.

Contact an authorized

distributor/dealer for service and

provide the fault code.

Contact an authorized

distributor/dealer for service.

Reduce the load by turning off

appliances.

Contact an authorized

distributor/dealer for service.

See Section 2.5 for instructions to set

the exerciser.

TP-6905 6/1424 Section 2 Generator Set Operation

Page 25

Fault (RDC2)

Frequency High

Shutdwn

Frequency Low

Shutdwn

Genset S/N

Unaval Warning

IAT High 1

Warning

IAT Volt Hi

Warning

IAT Volt Lo

Warning

Invalid Csum

Warning

Fault (OnCuer

Condition Check

Plus)

High Frequency Governed frequency exceeds 110% of the

system’s frequency setpoint for more than 10

seconds. Function becomes active 10

seconds after engine start (10 second inhibit).

Low Frequency Governed frequency falls below 90% of the

system frequency setting for more than

10 seconds, or 1 Hz below the system

frequency setting for more than 60 seconds.

Function becomes active 10 seconds after

engine start (10 second inhibit).

Unavailable

Generator set serial number is unavailable. Contact an authorized

Genset Serial

Number

Iat Higher

Engine manifold air temperature is too high. Contact an authorized

Than

Expected 1

Iat High

Voltage

The ECM reported an Engine Air

Temperature/Manifold Absolute Pressure

Sensor (TMAP) error.

Iat Low

Voltage

The ECM reported an Engine Air

Temperature/Manifold Absolute Pressure

Sensor (TMAP) error.

Flash Csum

An ECM error occurred. Contact an authorized

Invalid

Contact an authorized

distributor/dealer for service.

Reduce the load by turning off

appliances and restart the generator

set.

Contact an authorized

distributor/dealer for service.

distributor/dealer for service. See

section 3.11.

distributor/dealer for service and

provide the fault code.

Contact an authorized

distributor/dealer for service and

provide the fault code.

Contact an authorized

distributor/dealer for service and

provide the fault code.

distributor/dealer for service and

provide the fault code.

Lo Crank Vlt

Warning

Locked Rotor

Shutdwn

MainPwrOverL

Shutdwn

Maint Req’d

Warning

Not in Auto

Warning

Oil Pres Low

Shutdwn

Low Cranking

Voltage

Low cranking voltage. Battery voltage falls

below 60% of system battery voltage for more

than 6 seconds while the starter is engaged.

Locked Rotor No engine rotation is sensed during cranking.

Shuts down 3 seconds after the fault is

detected.

Main Power

Overload

Maintenance

Main power overload. An over current fault on

the 70 controller power output (short circuit).

Engine maintenance is due. Check the maintenance schedule in

Required

Warning

Not In Auto The generator set is not in Automatic

(standby) mode. Remote start and stop

commands from a transfer switch or remote

switch will be ignored.

Low Oil

Pressure

The engine ECM indicates low oil pressure.

Note: The low oil pressure shutdown does not

protect against low oil level. Check the engine

oil level regularly as recommended in

Section 4.

Charge or replace the battery.

Check the battery.

Check for loose connections.

Check for obstruction of alternator or

engine.

Contact an authorized

distributor/dealer for service.

Check for shorted run relay. Check

wiring for short circuits.

Contact an authorized

distributor/dealer for service.

the operation manual for tasks such

as changing the oil, spark plugs or the

air filter.

Press AUTO to place the generator

set in Automatic mode, when

appropriate.

Check for leaks in the lubrication

system.

Check the oil level and add oil if the

level is low.

Check the oil pressure switch and

wiring.

TP-6905 6/14 25Section 2 Generator Set Operation

Page 26

Fault (RDC2)

Over Crank

Shutdwn

PrimLoopOpn

Warning

PrimLoopSht

Warning

RAM Failure

Warning

Fault (OnCuer

Plus)

Over Crank Three unsuccessful starting attempts. Check the fuel supply, spark plug,

Primary Loop

Open

Primary Loop

Shorted

Ram Failure An ECM memory error occurred. Contact an authorized

Condition Check

and battery.

Check for loose connections.

Contact an authorized

distributor/dealer for service.

Ignition coil 1 voltage is below normal or

there is an open circuit.

Ignition coil 1 voltage is abnormal. Check the battery voltage.

Check the battery voltage.

Contact an authorized

distributor/dealer for service and

provide the fault code.

Contact an authorized

distributor/dealer for service and

provide the fault code.

distributor/dealer for service and

provide the fault code.

RunRelCoil

Shutdwn

Spd Sens Flt

Shutdwn

Total Power High

Shutdwn

Volts L1-L2 High

Shutdwn

Volts L1-L2 Low

Shutdwn

Volts L2-L3 High

Shutdwn

Volts L2-L3 Low

Shutdwn

Volts L3-L1 High

Shutdwn

Volts L3-L1 Low

Shutdwn

Run Relay Coil

Overload

Speed Sensor

Fault

Total Power

High Shutdown

High Generator

Voltage L1-L2

Low Generator

Voltage L1-L2

High Generator

Voltage L2-L3

Low Generator

Voltage L2-L3

High Generator

Voltage L3-L1

Low Generator

Voltage L3-L1

Excessive current on the run (70) line. Check for shorted relays or shorted

Engine speed sensor has failed or engine

stalled. ECM is no longer reporting valid

speed.

Measured load is greater than 102% of the

generator set power rating for more than 1

minute. (30RCLH only)

Generator Voltage High. Output voltage

exceeds 120% of the system nominal voltage

for more than 2 seconds.

Generator Voltage Low. Output voltage falls

below 80% of the nominal system voltage for

more than 10 seconds.

Generator Voltage High. Output voltage

exceeds 120% of the system nominal voltage

for more than 2 seconds.

Generator Voltage Low. Output voltage falls

below 80% of the nominal system voltage for

more than 10 seconds.

Generator Voltage High. Output voltage

exceeds 120% of the system nominal voltage

for more than 2 seconds.

Generator Voltage Low. Output voltage falls

below 80% of the nominal system voltage for

more than 10 seconds.

wires.

Contact an authorized

distributor/dealer for service.

Reduce the load by turning off

appliances.

Contact an authorized

distributor/dealer for service.

Reduce the load by turning off

appliances and restart the generator

set.

Contact an authorized

distributor/dealer for service.

Contact an authorized

distributor/dealer for service.

Reduce the load by turning off

appliances and restart the generator

set.

Contact an authorized

distributor/dealer for service.

Contact an authorized

distributor/dealer for service.

Reduce the load by turning off

appliances and restart the generator

set.

Contact an authorized

distributor/dealer for service.

Figure 2-5 Controller Fault Messages

TP-6905 6/1426 Section 2 Generator Set Operation

Page 27

2.6.5 Event Log

The event log displays up to 1000 controller faults and

notices, starting with the most recent event. Events are

numbered 1--1000, with 1 being the most recent. Each

event is displayed with the date and time of the event,

the number of the event, a code to indicate whether the

event was a warning ( W ), shutdown (S), or

informational notice (I), the engine hours at the time of

the event, and the event description.

2.7 Model RXT Transfer Switch

Operation

The RDC2 generator set/transfer switch controller

manages automatic transfer switch (ATS) functions

when connected to a Kohlerr Model RXT transfer switch

through the ATS interface board. Refer to the Model

RXT Operation/Installation Manual for information

about the transfer switch operation.

Procedure to View Event History

1. Press Select to enter the main menu.

2. Press the down arrow to step down to the event log.

3. Press Select to display the most recent event.

4. Press the down arrow to step to the next event.

5. Use the up and down arrow buttons to view events.

6. Press the Select button to exit the event log.

To stop viewing the event history before the last event,

press the select button to return to the main menu.

Date MO/DA/YEAR

Event Log ---->

Press UP and Down arrow

buttons to scroll through events

time HR:MN

event number, W/S/I, engine hours

event name

2.7.1 Source Availability

The Model RXT transfer switch supplies voltage

sensing data to the RDC2 controller through the ATS

interface board. If the source voltage falls below the

undervoltage dropout setting, the source is considered

to have failed. See Figure 2-7.

Item Setting

Accuracy ±5%

Undervoltage Dropout 90% of Pickup

Undervoltage Pickup 90% of Nominal

Figure 2-7 Voltage Sensing Parameters

The RDC2 controller also has a set of power system

LEDs below the pushbuttons. The power system LEDs

indicate which power sources are available and which

source is supplying power to the building. See

Figure 3-1.