Page 1

Operation

Industrial Generator Sets

Models:

20-3250 kW

Controllers:

Decision-Makerr 550

Software (Code) Version 2.10 or higher

TP-6200 10/12i

Page 2

California Proposition 65

WARNING

Engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth

defects, or other reproductive harm.

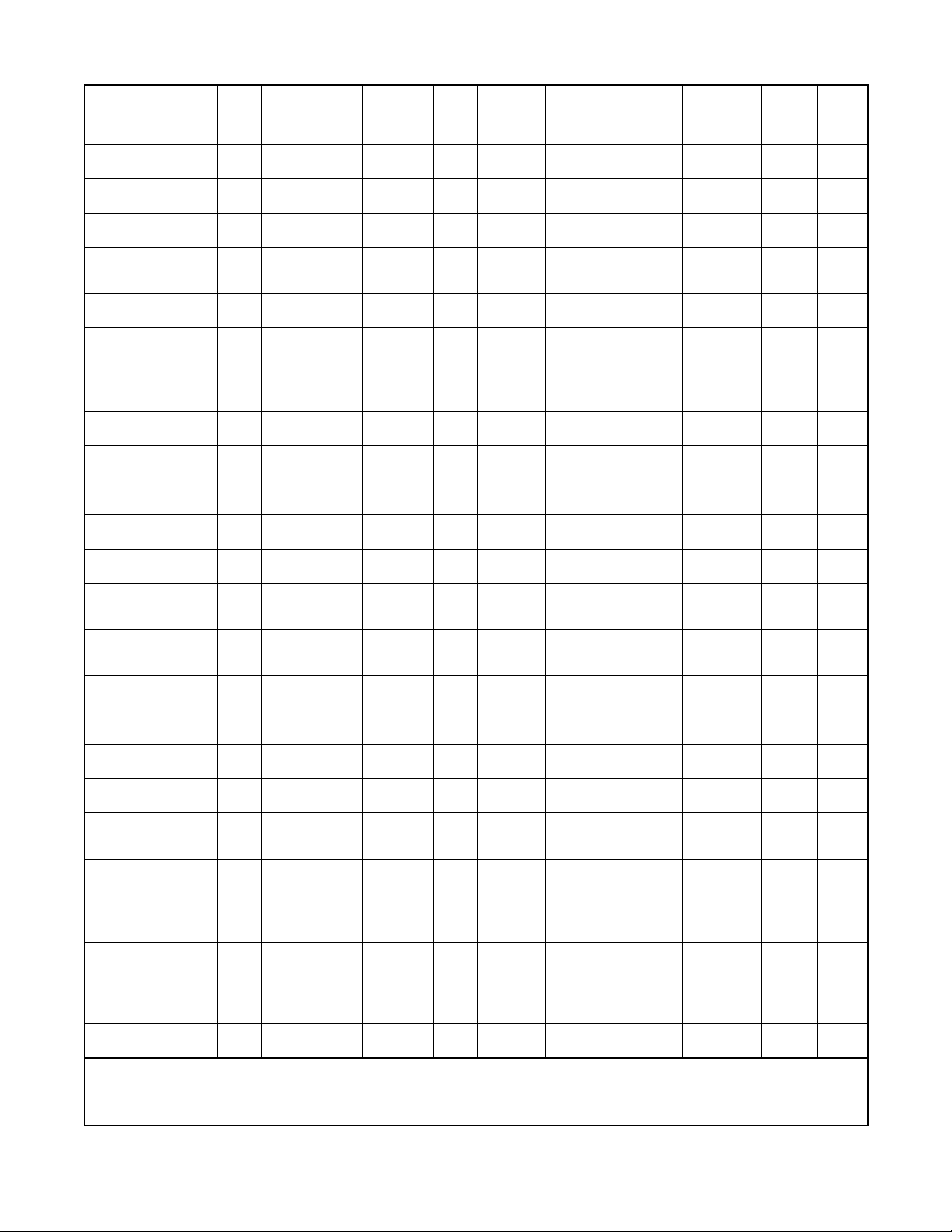

Product Identification Information

Product identification numbers determine service parts.

Record the product identification numbers in the spaces

below immediately after unpacking the products so that

the numbers are readily available for future reference.

Record field-installed kit numbers after installing the kits.

Generator Set Identification Numbers

Record the product identification numbers from the

generator set nameplate(s).

Model Designation

Specification Number

Serial Number

Accessory Number Accessory Description

Controller Identification

Record the controller description from the generator set

operation manual, spec sheet, or sales invoice. Record

the Controller Serial Number from the controller

nameplate.

Controller Description

Controller Serial Number

Decision-Makerr 550

Firmware/Software Version Numbers

Record the version and reference numbers as shipped

from the manufacturer. Determine the Application

Program Version Number as shown in Menu 20.

Determine the Personality Profile Reference Number

from the disk supplied with the literature packet.

Application Program Version Number

Personality Profile Reference Number

User Parameter File Reference Number

Version Number Upgrades/Updates

Record the version number upgrade/updates when

installed.

Engine Identification

Record the product identification information from the

engine nameplate.

Manufacturer

Model Designation

Serial Number

Version No./Date Installed

Version No./Date Installed

Version No./Date Installed

Version No./Date Installed

Version No./Date Installed

Version No./Date Installed

Version No./Date Installed

Version No./Date Installed

Software Options

Record the software options.

Number and Description

Number and Description

Number and Description

Page 3

Table of Contents

Product Identification Information 2............................................................

Safety Precautions and Instructions 7........................................................

Introduction 13...............................................................................

Abbreviations 13..............................................................

List of Related Materials 13.....................................................

Service Assistance 14........................................................................

Section 1 Specifications and Features 15......................................................

1.1 Introduction 15..........................................................

1.2 Controller Features 15....................................................

1.2.1 Annunciator Lamps 16............................................

1.2.2 Digital Display and Keypad 18.....................................

1.2.3 Switches and Controls 20.........................................

1.2.4 Controller Circuit Boards 21.......................................

1.2.5 Fuses 21.......................................................

1.2.6 Terminal Strips and Connectors 21.................................

1.2.7 Circuit Board Interconnections for Calibration Procedure 22............

1.2.8 Communication Ports 23..........................................

1.3 Controller Logic Specifications 23..........................................

1.3.1 Status Event and Fault Specifications 23............................

1.3.2 Voltage Regulator and Calibration Specifications 30..................

1.3.3 Voltage Regulator Adjustments 30..................................

Section 2 Operation 33.......................................................................

2.1 Prestart Checklist 33.....................................................

2.2 Exercising Generator Set 33...............................................

2.3 Controller Operation 33...................................................

2.3.1 Starting 33......................................................

2.3.2 Stopping (User Stopping and Fault Shutdown) 35....................

2.3.3 Emergency Stop Switch Resetting 35...............................

2.3.4 Status Lamps 35.................................................

2.3.5 System Warning Lamp 35.........................................

2.3.6 System Shutdown Lamp 38.......................................

2.3.7 Controller Resetting (Following System Shutdown or Warning) 41......

2.4 Menu List Summary 41...................................................

2.5 Reviewing Digital Display 47..............................................

2.5.1 Keypad Operation 47.............................................

2.5.2 Auto-Scroll Function 48...........................................

2.5.3 Request and Error Messages 48...................................

2.6 Monitoring and Programming Setup 49......................................

2.6.1 PC Communications 50...........................................

2.6.2 Modbus Communications 51.......................................

2.7 Reviewing Menu Displays 52..............................................

2.7.1 Menu 1—Generator Monitoring 53..................................

2.7.2 Menu 2—Engine Monitoring 55....................................

2.7.3 Menu 3—Analog Monitoring 57....................................

2.7.4 Menu 4—Operational Records 58..................................

2.7.5 Menu 5—Event History 59.........................................

2.7.6 Menu 6—Time and Date 59.......................................

2.7.7 Menu 7—Generator System 59....................................

2.7.8 Menu 8—Time Delays 61

2.7.9 Menu 9—Input Setup 62..........................................

2.7.10 Menu 10—Output Setup 64........................................

2.7.11 Menu 11—Voltage Regulator 66....................................

2.7.12 Menu 12—Calibration 67..........................................

.........................................

TP-6200 10/12 Table of Contents 3

Page 4

Table of Contents, continued

2.7.13 Menu 13—Communications 68....................................

2.7.14 Menu 14—Programming Mode 69..................................

2.7.15 Menu 15—Protective Relays (PR) 70...............................

2.7.16 Menu 20—Factory Setup (Version 2.10) 71..........................

2.7.17 Menu 20—Factory Setup (Version 2.21) 72..........................

2.8 Local Programming Mode On 74...........................................

2.8.1 Menu 1—Generator Monitoring 75..................................

2.8.2 Menu 2—Engine Monitoring 79....................................

2.8.3 Menu 3—Analog Monitoring 83....................................

2.8.4 Menu 4—Operational Records 86..................................

2.8.5 Menu 5—Event History 88.........................................

2.8.6 Menu 6—Time and Date 89.......................................

2.8.7 Menu 7—Generator System 90....................................

2.8.8 Menu 8—Time Delays 96.........................................

2.8.9 Menu 9—Input Setup 98..........................................

2.8.10 Menu 10—Output Setup 104........................................

2.8.11 Menu 11—Voltage Regulator 114....................................

2.8.12 Menu 12—Calibration 120..........................................

2.8.13 Menu 13—Communications 125....................................

2.8.14 Menu 14—Programming Mode 129..................................

2.8.15 Menu 15—Protective Relays (PR) 131...............................

2.8.16 Menu 20—Factory Setup 135.......................................

Section 3 Scheduled Maintenance 137..........................................................

3.1 Alternator Service 137.....................................................

3.2 Engine Service 137.......................................................

3.3 Service Schedule 138.....................................................

3.4 Alternator Bearing Service 140..............................................

3.4.1 20--300 kW Models 140............................................

3.4.2 300--2250 kW Models with Single-Bearing Alternator 140...............

3.4.3 1250 kW and Larger Models with Two-Bearing Alternator 140...........

3.5 Diesel Fuel Systems 140...................................................

3.5.1 Bleeding Air from Fuel System 140..................................

3.5.2 Subbase Fuel Day Tank Electronic Control Module (ECM) 141..........

3.5.3 Subbase Inner Fuel Tank Alarm 142.................................

3.6 Gas Fuel Systems (REZG_ and REZX_/RZX_ models) 142.....................

3.6.1 Gas Fuel System Concept (Single Fuel) 142..........................

3.6.2 LPG Liquid Withdrawal Fuel System Concept 142.....................

3.6.3 Natural Gas and LPG Conversion 143...............................

3.6.4 Fuel System Changeover Kits (Dual Fuel) 143........................

3.6.5 Crankcase Ventilation (CCV) Heater Kit GM78171-KP1

(125/150REZG models) 145........................................

3.7 Cooling System 145.......................................................

3.7.1 Coolant Level Check 145...........................................

3.7.2 Cooling System Component Inspection 146...........................

3.7.3 Procedure to Drain Cooling System 146..............................

3.7.4 Procedure to Flush and Clean Cooling System 146....................

3.7.5 Procedure to Refill Cooling System 146..............................

3.8 Radiator Fan Bolt Retorque 147.............................................

3.9 Radiator Expansion Joint Loosening—Initial Setup Only 148....................

3.10 Radiator Fan Bearing Lubrication 148........................................

3.11 Battery 149

3.11.1 Clean Battery 149.................................................

3.11.2 Electrolyte Level Inspection 150.....................................

3.11.3 Specific Gravity Check 151.........................................

3.11.4 Charge Battery 151................................................

...............................................................

TP-6200 10/12Table of Contents4

Page 5

Table of Contents, continued

3.12 Detroit Diesel Engine Control Systems 152...................................

3.12.1 Features 152.....................................................

3.12.2 DDEC Engine Diagnostics 152......................................

3.13 Engine Control Systems 153................................................

3.14 Storage Procedure 153....................................................

3.14.1 Lubricating System 153............................................

3.14.2 Cooling System 153...............................................

3.14.3 Fuel System 154..................................................

3.14.4 Internal Engine Components (Gas-Fueled Engines) 154................

3.14.5 Exterior 154......................................................

3.14.6 Battery 154.......................................................

Section 4 General Troubleshooting 155.........................................................

4.1 General Troubleshooting Chart 156..........................................

4.2 Controller Display and Voltage Regulation Troubleshooting Chart 159............

Section 5 Generator Set Reconnection 161.....................................................

5.1 Introduction 161..........................................................

5.2 Voltage Reconnection Procedure 162........................................

Section 6 Accessories 167.....................................................................

6.1 Accessories and Connections 167...........................................

6.1.1 Audiovisual Alarm Kit 167..........................................

6.1.2 Common Failure Relay Kit 168......................................

6.1.3 Controller (Customer) Connection Kit 168............................

6.1.4 Float/Equalize Battery Charger Kit with Alarm Option 168...............

6.1.5 Ground Fault Annunciation 170.....................................

6.1.6 Idle (Speed) Mode Feature 171.....................................

6.1.7 Low Fuel (Level/Pressure) Switch 172...............................

6.1.8 Prime Power Switch Kit 172........................................

6.1.9 Remote Emergency Stop Kit 173....................................

6.1.10 Remote Reset Feature 173.........................................

6.1.11 Remote Serial Annunciator 174.....................................

6.1.12 Remote Speed Adjustment Potentiometer Kit (Non-ECM Models) 181....

6.1.13 Run Relay Kit 181.................................................

6.1.14 Shunt-Trip Line Circuit Breaker 181..................................

6.1.15 Single-Relay Dry Contact Kit 182....................................

6.1.16 Ten-Relay Dry Contact Kit 182......................................

6.1.17 Twenty-Relay Dry Contact Kit 184...................................

6.1.18 Wireless Monitor 185..............................................

6.2 Accessory Connections 186................................................

Appendix A Abbreviations 193................................................................

Appendix B User-Defined Settings 195........................................................

Appendix C Voltage Regulator Definitions and Adjustments 202.................................

Appendix D Alternator Protection 208.........................................................

Appendix E Inputs and System Events by Application 209......................................

TP-6200 10/12 Table of Contents 5

Page 6

Notes

6 TP-6200 10/12

Page 7

Safety Precautions and Instructions

IMPORTANT SAFETY INSTRUCTIONS.

Electromechanical equipment,

including generator sets, transfer

switches, switchgear, and

accessories, can cause bodily harm

and pose life-threatening danger when

improperly installed, operated, or

maintained. To prevent accidents be

aware of potential dangers and act

safely. Read and follow all safety

precautions and instructions. SAVE

THESE INSTRUCTIONS.

This manual has several types of

safety precautions and instructions:

Danger, Warning, Caution, and Notice.

DANGER

Danger indicates the presence of a

hazard that will cause severe

personal injury, death,or

substantial property damage.

WARNING

Warning indicates the presence of a

hazard that can cause severe

personal injury, death, or

substantial property damage.

CAUTION

Caution indicates the presence of a

hazard that will or can cause minor

personal injury or property damage.

NOTICE

Notice communicates installation,

operation, or maintenance information

that is safety related but not hazard

related.

Safety decals affixed to the equipment

in prominent places alert the operator

or service technician to potential

hazards and explain how to act safely.

The decals are shown throughout this

publication to improve operator

recognition. Replace missing or

damaged decals.

Accidental Starting

WARNING

Accidental starting.

Can cause severe injury or death.

Disconnect the battery cables before

working on the generator set.

Remove the negative (--) lead first

when disconnecting the battery.

Reconnect the negative (--) lead last

when reconnecting the battery.

Disabling the generator set.

Accidental starting can cause

severe injury or death. Before

working on the generator set or

connected equipment, disable the

generator set as follows: (1) Move the

generator set master switch to the OFF

position. (2) Disconnect the power to

the battery charger. (3) Remove the

battery cables, negative (--) lead first.

Reconnect the negative (--) lead last

when reconnecting the battery. Follow

these precautions to prevent starting of

the generator set by an automatic

transfer switch, remote start/stop

switch, or engine start command from a

remote computer.

Battery

WARNING

Sulfuric acid in batteries.

Can cause severe injury or death.

Wear protective goggles and

clothing. Battery acid may cause

blindness and burn skin.

WARNING

Explosion.

Can cause severe injury or death.

Relays in the battery charger

cause arcs or sparks.

Locate the battery in a well-ventilated

area. Isolate the battery charger from

explosive fumes.

Battery electrolyte is a diluted

sulfuric acid. Battery acid can

cause severe injury or death. Battery

acid can cause blindness and burn

skin. Always wear splashproof safety

goggles, rubber gloves, and boots

when servicing the battery. Do not

open a sealed battery or mutilate the

battery case. If battery acid splashes in

the eyes or on the skin, immediately

flush the affected area for 15 minutes

with large quantities of clean water.

Seek immediate medical aid in the

case of eye contact. Never add acid to

a battery after placing the battery in

service, as this may result in

hazardous spattering of battery acid.

Battery acid cleanup. Battery acid

can cause severe injury or death.

Battery acid is electrically conductive

and corrosive. Add 500 g (1 lb.) of

bicarbonate of soda (baking soda) to a

containerwith4L(1gal.)ofwaterand

mix the neutralizing solution. Pour the

neutralizing solution on the spilled

battery acid and continue to add the

neutralizing solution to the spilled

battery acid until all evidence of a

chemical reaction (foaming) has

ceased. Flush the resulting liquid with

water and dry the area.

7Safety Precautions and InstructionsTP-6200 10/12

Page 8

Battery gases. Explosion can cause

severe injury or death. Battery gases

can cause an explosion. Do not smoke

or permit flames or sparks to occur

near a battery at any time, particularly

when it is charging. Do not dispose of a

battery in a fire. To prevent burns and

sparks that could cause an explosion,

avoid touching the battery terminals

with tools or other metal objects.

Remove all jewelry before servicing

the equipment. Discharge static

electricity from your body before

touching batteries by first touching a

grounded metal surface away from the

battery. To avoid sparks, do not disturb

the battery charger connections while

the battery is charging. Always turn the

battery charger off before

disconnecting the battery connections.

Ventilate the compartments containing

batteries to prevent accumulation of

explosive gases.

Battery short circuits. Explosion

can cause severe injury or death.

Short circuits can cause bodily injury

and/or equipment damage.

Disconnect the battery before

generator set installation or

maintenance. Remove all jewelry

before servicing the equipment. Use

tools with insulated handles. Remove

the negative (--) lead first when

disconnecting the battery. Reconnect

the negative (--) lead last when

reconnecting the battery. Never

connect the negative (--) battery cable

to the positive (+) connection terminal

of the starter solenoid. Do not test the

battery condition by shorting the

terminals together.

Engine Backfire/Flash

Fire

Servicing the fuel system. A flash

fire can cause severe injury or

death. Do not smoke or permit flames

or sparks near the carburetor, fuel line,

fuel filter, fuel pump, or other potential

sources of spilled fuels or fuel vapors.

Catch fuels in an approved container

when removing the fuel line or

carburetor.

Servicing the air cleaner. A sudden

backfire can cause severe injury or

death. Do not operate the generator

set with the air cleaner removed.

Combustible materials. A fire can

cause severe injury or death.

Generator set engine fuels and fuel

vapors are flammable and explosive.

Handle these materials carefully to

minimize the risk of fire or explosion.

Equip the compartment or nearby area

with a fully charged fire extinguisher.

Select a fire extinguisher rated ABC or

BC for electrical fires or as

recommended by the local fire code or

an authorized agency. Train all

personnel on fire extinguisher

operation and fire prevention

procedures.

Exhaust System

WARNING

Carbon monoxide.

Can cause severe nausea,

fainting, or death.

The exhaust system must be

leakproof and routinely inspected.

Carbon monoxide symptoms.

Carbon monoxide can cause severe

nausea, fainting, or death. Carbon

monoxide is a poisonous gas present

in exhaust gases. Carbon monoxide is

an odorless, colorless, tasteless,

nonirritating gas that can cause death if

inhaled for even a short time. Carbon

monoxide poisoning symptoms

include but are not limited to the

following:

D Light-headedness, dizziness

D Physical fatigue, weakness in

joints and muscles

D Sleepiness, mental fatigue,

inability to concentrate

or speak clearly, blurred vision

D Stomachache, vomiting, nausea

If experiencing any of these symptoms

and carbon monoxide poisoning is

possible, seek fresh air immediately

and remain active. Do not sit, lie down,

or fall asleep. Alert others to the

possibility of carbon monoxide

poisoning. Seek medical attention if

the condition of affected persons does

not improve within minutes of breathing

fresh air.

Fuel System

WARNING

Explosive fuel vapors.

Can cause severe injury or death.

Use extreme care when handling,

storing, and using fuels.

WARNING

Fire.

Can cause severe injury or death.

Do not smoke or permit flames or

sparks near fuels or the fuel system.

8 Safety Precautions and Instructions TP-6200 10/12

Generator set operation. Carbon

monoxide can cause severe

nausea, fainting, or death. Carbon

monoxide is an odorless, colorless,

tasteless, nonirritating gas that can

cause death if inhaled for even a short

time. Avoid breathing exhaust fumes

when working on or near the generator

set. Never operate the generator set

inside a building unless the exhaust

gas is piped safely outside. Never

operate the generator set where

exhaust gas could accumulate and

seep back inside a potentially occupied

building.

Page 9

The fuel system. Explosive fuel

vapors can cause severe injury or

death. Vaporized fuels are highly

explosive. Use extreme care when

handling and storing fuels. Store fuels

inawell-ventilatedareaawayfrom

spark-producing equipment and out of

the reach of children. Never add fuel to

the tank while the engine is running

because spilled fuel may ignite on

contact with hot parts or from sparks.

Do not smoke or permit flames or

sparks to occur near sources of spilled

fuel or fuel vapors. Keep the fuel lines

and connections tight and in good

condition. Do not replace flexible fuel

lines with rigid lines. Use flexible

sections to avoid fuel line breakage

caused by vibration. Do not operate

the generator set in the presence of

fuel leaks, fuel accumulation, or

sparks. Repair fuel systems before

resuming generator set operation.

Explosive fuel vapors can cause

severe injury or death. Ta k e

additional precautions when using the

following fuels:

Gasoline—Store gasoline only in

approved red containers clearly

marked GASOLINE.

Propane (LP)—Adequate ventilation

is mandatory. Because propane is

heavier than air, install propane gas

detectors low in a room. Inspect the

detectors per the manufacturer’s

instructions.

Natural Gas—Adequate ventilation is

mandatory. Because natural gas rises,

install natural gas detectors high in a

room. Inspect the detectors per the

manufacturer’s instructions.

Fuel tanks. Explosive fuel vapors

can cause severe injury or death.

Gasoline and other volatile fuels stored

in day tanks or subbase fuel tanks can

cause an explosion. Store only diesel

fuel in tanks.

Draining the fuel system. Explosive

fuel vapors can cause severe injury

or death. Spilled fuel can cause an

explosion. Use a container to catch

fuel when draining the fuel system.

Wipe up spilled fuel after draining the

system.

Gas fuel leaks. Explosive fuel

vapors can cause severe injury or

death. Fuel leakage can cause an

explosion. Check the LP vapor gas or

natural gas fuel system for leakage by

using a soap and water solution with

the fuel system test pressurized to

6--8 ounces per square inch

(10--14 inches water column). Do not

use a soap solution containing either

ammonia or chlorine because both

prevent bubble formation. A

successful test depends on the ability

of the solution to bubble.

LP liquid withdrawal fuel leaks.

Explosive fuel vapors can cause

severe injury or death. Fuel leakage

can cause an explosion. Check the LP

liquid withdrawal gas fuel system for

leakage by using a soap and water

solution with the fuel system test

pressurized to at least 90 psi

(621 kPa). Do not use a soap solution

containing either ammonia or chlorine

because both prevent bubble

formation. A successful test depends

on the ability of the solution to bubble.

Hazardous Noise

CAUTION

Hazardous noise.

Can cause hearing loss.

Never operate the generator set

without a muffler or with a faulty

exhaust system.

Engine noise. Hazardous noise can

cause hearing loss. Generator sets

not equipped with sound enclosures

can produce noise levels greater than

105 dBA. Prolonged exposure to

noise levels greater than 85 dBA can

cause permanent hearing loss. Wear

hearing protection when near an

operating generator set.

Hazardous Voltage/

Moving Parts

DANGER

Hazardous voltage.

Will cause severe injury or death.

Disconnect all power sources before

opening the enclosure.

WARNING

Hazardous voltage.

Can cause severe injury or death.

Operate the generator set only when

all guards and electrical enclosures

areinplace.

WARNING

Hazardous voltage.

Backfeed to the utility system can

cause property damage, severe

injury, or death.

If the generator set is used for

standby power, install an automatic

transfer switch to prevent inadvertent

interconnection of standby and

normal sources of supply.

Grounding electrical equipment.

Hazardous voltage can cause

severe injury or death. Electrocution

is possible whenever electricity is

present. Ensure you comply with all

applicable codes and standards.

Electrically ground the generator set,

transfer switch, and related equipment

and electrical circuits. Turn off the

main circuit breakers of all power

sources before servicing the

equipment. Never contact electrical

leads or appliances when standing in

water or on wet ground because these

conditions increase the risk of

electrocution.

Moving parts.

9Safety Precautions and InstructionsTP-6200 10/12

Page 10

High voltage test. Hazardous

voltage can cause severe injury or

death. Follow the instructions of the

test equipment manufacturer when

performing high-voltage tests on the

rotor or stator. An improper test

procedure can damage equipment or

lead to generator set failure.

Testing the photo transistor circuit

board. Hazardous voltage can

cause severe injury or death. When

the end cover is removed, do not

expose the photo transistor circuit

board mounted on the generator set

end bracket to any external light

source, as exposure to light causes

high voltage. Keep foreign sources of

light away from the photo transistor

circuit board during testing. Place

black electrical tape over the LED on

the circuit board before starting the

generator set.

Installing the photo transistor

circuit board. Hazardous voltage

can cause severe injury or death.

Ensure that the foil side of the photo

transistor circuit board, the end of the

shaft, and the threaded holes are clean

and free of metal particles and chips.

Metal debris may short-circuit the

photo transistor circuit board and

cause hazardous voltage in the

generator set. Do not reconnect the

generator set to the load until the AC

voltmeter shows the correct output.

Installing the battery charger.

Hazardous voltage can cause

severe injury or death. An

ungrounded battery charger may

cause electrical shock. Connect the

battery charger enclosure to the

ground of a permanent wiring system.

As an alternative, install an equipment

grounding conductor with circuit

conductors and connect it to the

equipment grounding terminal or the

lead on the battery charger. Install the

battery charger as prescribed in the

equipment manual. Install the battery

charger in compliance with local codes

and ordinances.

Servicing the day tank. Hazardous

voltage can cause severe injury or

death. Service the day tank electrical

control module (ECM) as prescribed in

the equipment manual. Disconnect the

power to the day tank before servicing.

Press the day tank ECM OFF

pushbutton to disconnect the power.

Notice that line voltage is still present

within the ECM when the POWER ON

light is lit. Ensure that the generator set

and day tank are electrically grounded.

Do not operate the day tank when

standing in water or on wet ground

because these conditions increase the

risk of electrocution.

Short circuits. Hazardous

voltage/current can cause severe

injury or death. Short circuits can

cause bodily injury and/or equipment

damage. Do not contact electrical

connections with tools or jewelry while

making adjustments or repairs.

Remove all jewelry before servicing

the equipment.

Engine block heater. Hazardous

voltage can cause severe injury or

death. The engine block heater can

cause electrical shock. Remove the

engine block heater plug from the

electrical outlet before working on the

block heater electrical connections.

Handling the capacitor. Hazardous

voltage can cause severe injury or

death. Electrical shock results from

touching the charged capacitor

terminals. Discharge the capacitor by

shorting the terminals together.

(Capacitor-excited models only)

Electrical backfeed to the utility.

Hazardous backfeed voltage can

cause severe injury or death. Install

a transfer switch in standby power

installations to prevent the connection

of standby and other sources of power.

Electrical backfeed into a utility

electrical system can cause severe

injury or death to utility personnel

working on power lines.

Testing live electrical circuits.

Hazardous voltage or current can

cause severe injury or death. Have

trained and qualified personnel take

diagnostic measurements of live

circuits. Use adequately rated test

equipment with electrically insulated

probes and follow the instructions of

the test equipment manufacturer when

performing voltage tests. Observe the

following precautions when performing

voltage tests: (1) Remove all jewelry.

(2) Stand on a dry, approved

electrically insulated mat. (3) Do not

touch the enclosure or components

inside the enclosure. (4) Be prepared

for the system to operate automatically.

(600 volts and under)

WARNING

Airborne particles.

Can cause severe injury or

blindness.

Wear protective goggles and clothing

when using power tools, hand tools,

or compressed air.

Servicing the generator set when it

is operating. Exposed moving parts

can cause severe injury or death.

Keep hands, feet, hair, clothing, and

test leads away from the belts and

pulleys when the generator set is

running. Replace guards, screens,

and covers before operating the

generator set.

Heavy Equipment

WARNING

Connecting the battery and the

battery charger. Hazardous voltage

can cause severe injury or death.

Reconnect the battery correctly,

positive to positive and negative to

negative, to avoid electrical shock and

damage to the battery charger and

battery(ies). Have a qualified

electrician install the battery(ies).

10 Safety Precautions and Instructions TP-6200 10/12

Unbalanced weight.

Improper lifting can cause severe

injury or death and equipment

damage.

Do not use lifting eyes.

Lift the generator set using lifting bars

inserted through the lifting holes on

the skid.

Page 11

Hot Parts

Notice

WARNING

Hot coolant and steam.

Can cause severe injury or death.

Before removing the pressure cap,

stop the generator set and allow it to

cool. Then loosen the pressure cap

to relieve pressure.

WARNING

Hot engine and exhaust system.

Can cause severe injury or death.

Do not work on the generator set until

it cools.

Servicing the alternator. Hot parts

can cause severe injury or death.

Avoid touching the alternator field or

exciter armature. When shorted, the

alternator field and exciter armature

become hot enough to cause severe

burns.

NOTICE

This generator set has been

rewired from its nameplate voltage

to

246242

NOTICE

Voltage reconnection. Affix a notice

to the generator set after reconnecting

the set to a voltage different from the

voltage on the nameplate. Order

voltage reconnection decal 246242

from an authorized service

distributor/dealer.

NOTICE

Canadian installations only.For

standby service connect the output of

the generator set to a suitably rated

transfer switch in accordance with

Canadian Electrical Code, Part 1.

Servicing the exhaust system. Hot

parts can cause severe injury or

death. Do not touch hot engine parts.

The engine and exhaust system

components become extremely hot

during operation.

11Safety Precautions and InstructionsTP-6200 10/12

Page 12

Notes

12 Safety Precautions and Instructions TP-6200 10/12

Page 13

Introduction

This manual provides operation instructions for 20 kW

and larger generator sets equipped with the following

controller:

D Decisionr 550, Software (Code) Version 2.10 or

higher

Version2.10 refers to the controller application software.

To determine the generator set controller software

version, go to Menu 20—Factory Setup and scroll down

to Code Version. The code version is the controller

software version.

Wiring diagram manuals are available separately. Refer

to the engine operation manual for generator set engine

scheduled maintenance information.

Information in this publication represents data available

at the time of print. Kohler Co. reserves the right to

change this publication and the products represented

without notice and without any obligation or liability

whatsoever.

Read this manual and carefully follow all procedures and

safety precautions to ensure proper equipment

operation and to avoid bodily injury. Read and follow the

Safety Precautions and Instructions section at the

beginning of this manual. Keep this manual with the

equipment for future reference.

The equipment service requirements are very important

to safe and efficient operation. Inspect the parts often

and perform required service at the prescribed intervals.

Maintenance work must be performed by appropriately

skilled and suitably trained maintenance personnel

familiar with generator set operation and service.

The disk supplied with this generator set is a backup

copy of the generator set personality program

containing data specific to the engine and alternator.

The engine and alternator data was preprogrammed in

the controller at the factory and no further use of the disk

should be necessary. Typically, your authorized

distributor stores this disk for possible future use such as

controller replacement or other circumstances requiring

a backup.

Abbreviations

This publication makes use of numerous abbreviations.

Typically, the word(s) are spelled out along with the

abbreviation in parentheses when shown for the first

time in a section. Appendix A, Abbreviations, also

includes many abbreviation definitions.

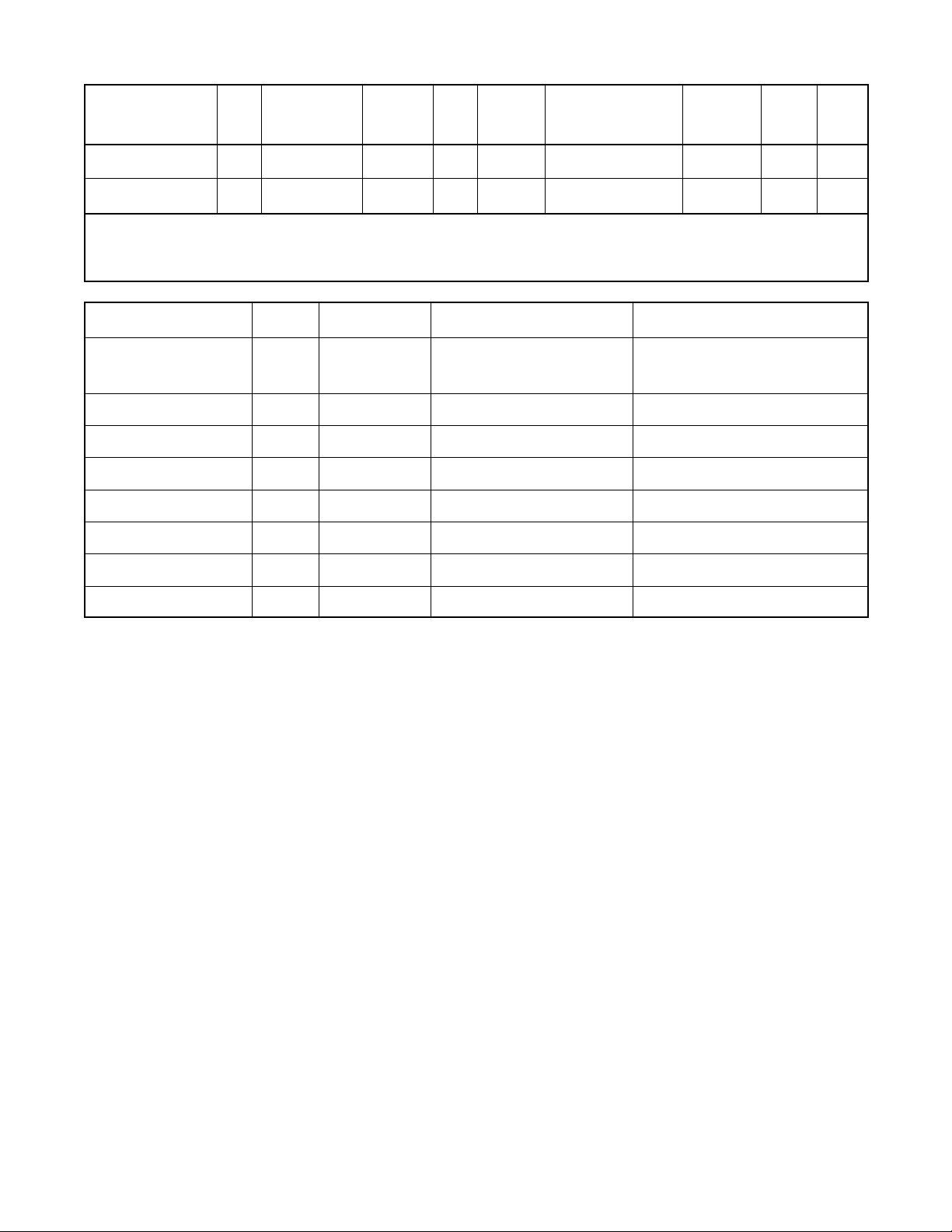

List of Related Materials

Separate literature contains communication and

software information not provided in this manual.

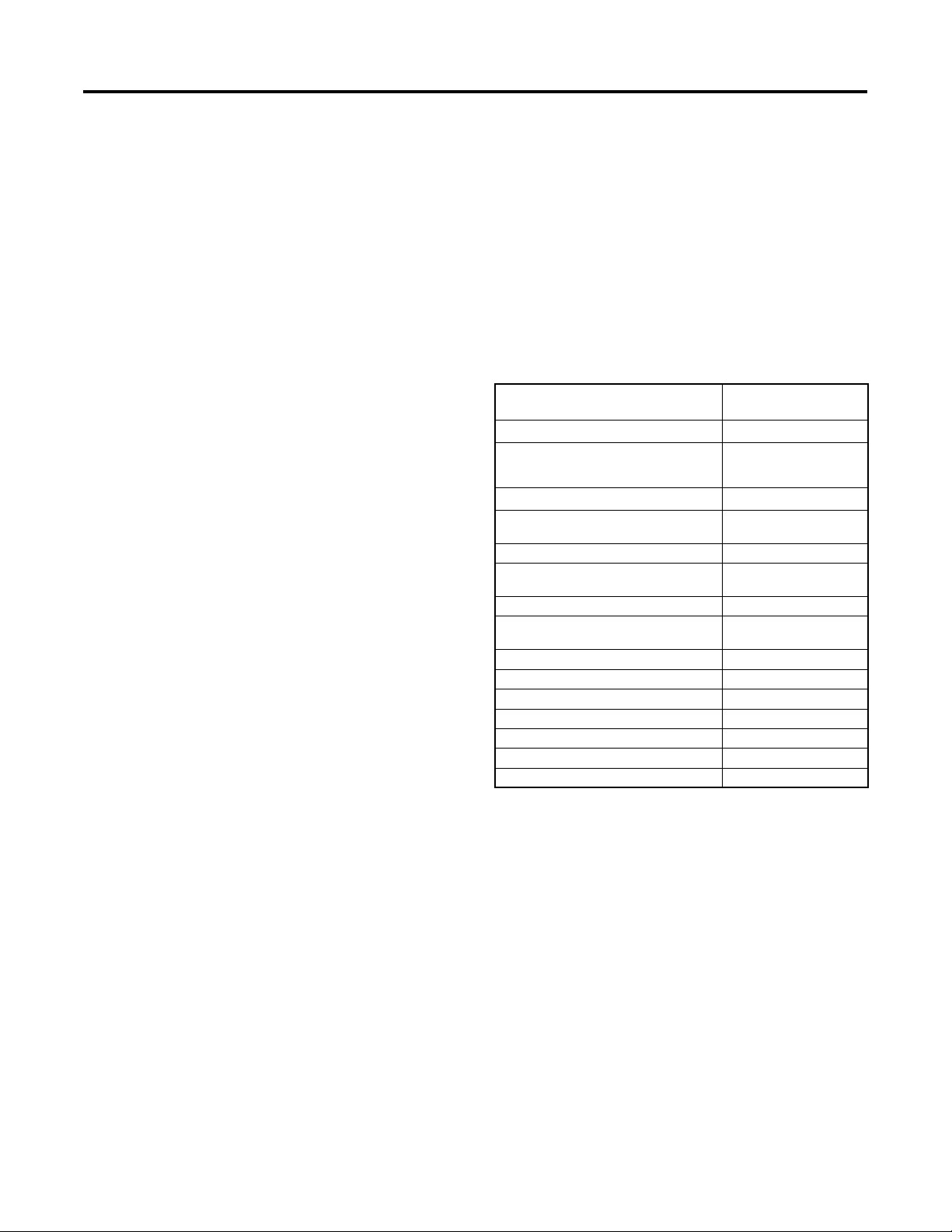

Figure 1 lists the available literature part numbers.

Communication and Software

Manual Description

550 Controller Spec Sheet

Generator Set/Controller

Wiring Diagram Manual

550 Communications Spec Sheet

Monitor III Converters, Connections,

and Controller Setup

Monitor III Software Spec Sheet G6-76

Monitor III Converter,

Modbusr/Ethernet Spec Sheet

Monitor III Software Operation Manual TP-6347

Modbusr Communications Protocol

Operation Manual

Setup and Application Manual TP-6140

Service Parts Controllers TP-6780

Program Loader Software Installation TT-1285

SiteTecht Software Operation Manual

Remote Serial Annunciator (RSA) TT-1377

Remote Serial Annunciator (RSA II) TT-1485

Controller Service Replacement TT-1310

Figure 1 Related Literature

Literature Part No.

G6-46

Multiple Part Numbers

Contact your

Distributor/Dealer

G6-50

TT-1405

G6-79

TP-6113

TP-6701

Modbusr is a registered trademark of Schneider Electric.

13IntroductionTP-6200 10/12

Page 14

Service Assistance

For professional advice on generator set power

requirements and conscientious service, please contact

your nearest Kohler distributor or dealer.

D Consult the Yellow Pages under the heading

Generators—Electric.

D Visit the Kohler Power Systems website at

KohlerPower.com.

D Look at the labels and stickers on your Kohler product

or review the appropriate literature or documents

included with the product.

D Call toll free in the US and Canada 1-800-544-2444.

D Outside the US and Canada, call the nearest regional

office.

Headquarters Europe, Middle East, Africa

(EMEA)

Kohler Power Systems

3 rue de Brennus

93200 Saint Denis

France

Phone: (33) 1 49 178300

Fax: (33) 1 49 178301

Asia Pacific

Power Systems Asia Pacific Regional Office

Singapore, Republic of Singapore

Phone: (65) 6264-6422

Fax: (65) 6264-6455

China

North China Regional Office, Beijing

Phone: (86) 10 6518 7950

(86) 10 6518 7951

(86) 10 6518 7952

Fax: (86) 10 6518 7955

East China Regional Office, Shanghai

Phone: (86) 21 6288 0500

Fax: (86) 21 6288 0550

India, Bangladesh, Sri Lanka

India Regional Office

Bangalore, India

Phone: (91) 80 3366208

(91) 80 3366231

Fax: (91) 80 3315972

Japan, Korea

North Asia Regional Office

Tokyo, Japan

Phone: (813) 3440-4515

Fax: (813) 3440-2727

Latin America

Latin America Regional Office

Lakeland, Florida, USA

Phone: (863) 619-7568

Fax: (863) 701-7131

14 Service Assistance TP-6200 10/12

Page 15

Section 1 Specifications and Features

1.1 Introduction

The spec sheets for each generator set provide modelspecific generator and engine information. The

controller spec sheet provides specifications for this

controller. Refer to the respective spec sheet for data

not supplied in this manual. Consult the generator set

service manual, installation manual, engine operation

manual, and engine service manual for additional

specifications.

1.2 Controller Features

The controller features include the annunciator lamps,

digital display and keypad, switches and controls, and

fuses and terminal strip. The following paragraphs detail

the features by general topics.

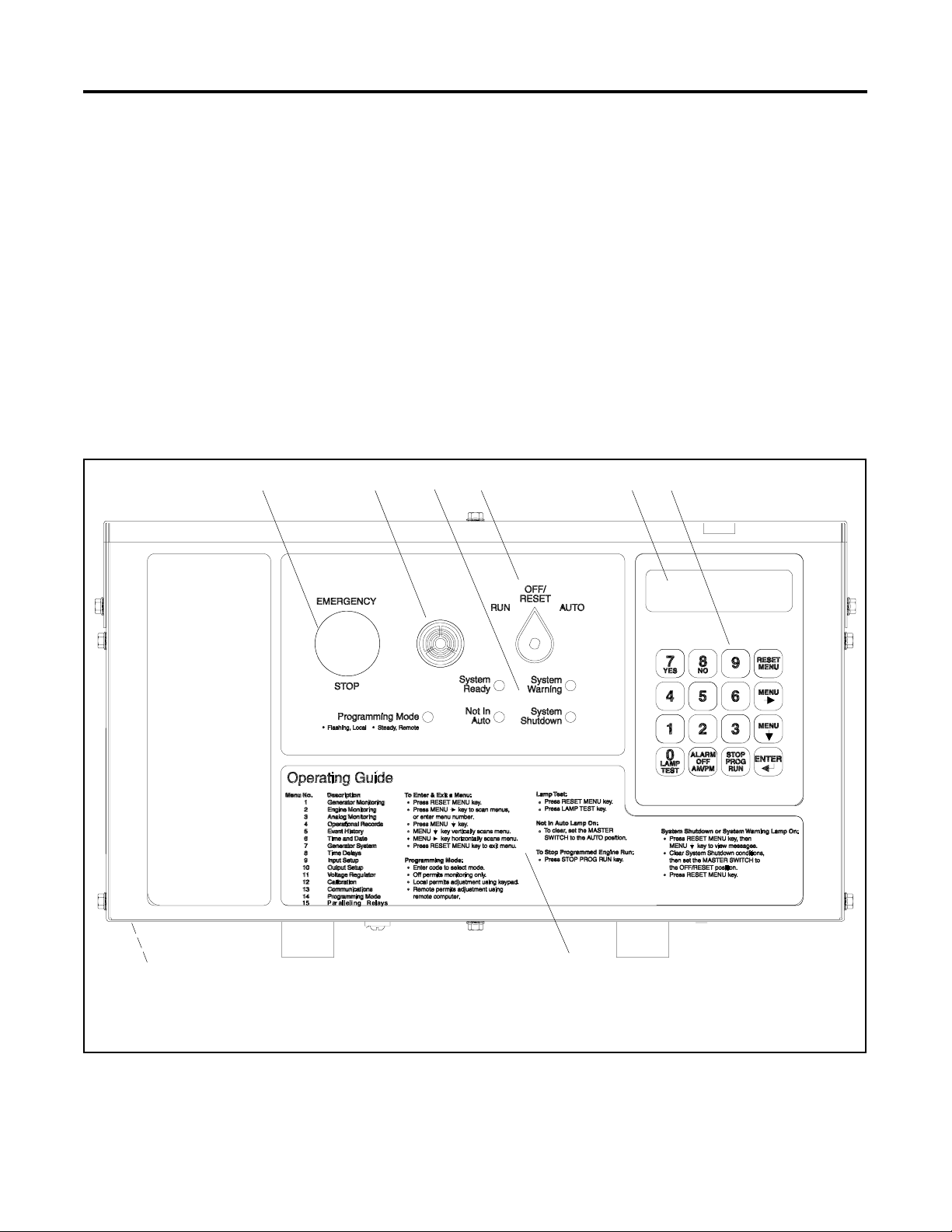

124 5

3

The controller features, accessories, and menu displays

depend upon the engine electronic control module

(ECM) setup and features. Controller features apply to

generator set models with ECM and non-ECM engines

unless otherwise noted.

Note: Press any key on the keypad to turn on the

controller lights and display. The lights and

display turn off 5 minutes after the last keypad

entry.

Note: Measurements display in metric or English. Use

Menu 7—Generator System to change the

measurement display.

See Figure 1-1 for an illustration of the controller front

panel. See Figure 1-2 for an illustration of the controller

with the keyswitch option.

6

8

1. Emergency stop switch

2. Alarm horn (see keypad for alarm silence)

3. Annunciator lamps (see keypad for lamp test)

4. Generator set master switch, run/off-reset/auto positions

5. Digital display

6. Keypad

7. Operating guide

8. Controller terminal strips (on circuit board)

7

Figure 1-1 550 Controller with Three-Position Selector Switch

TP-6200 10/12 15Section 1 Specifications and Features

TP-6083-2

Page 16

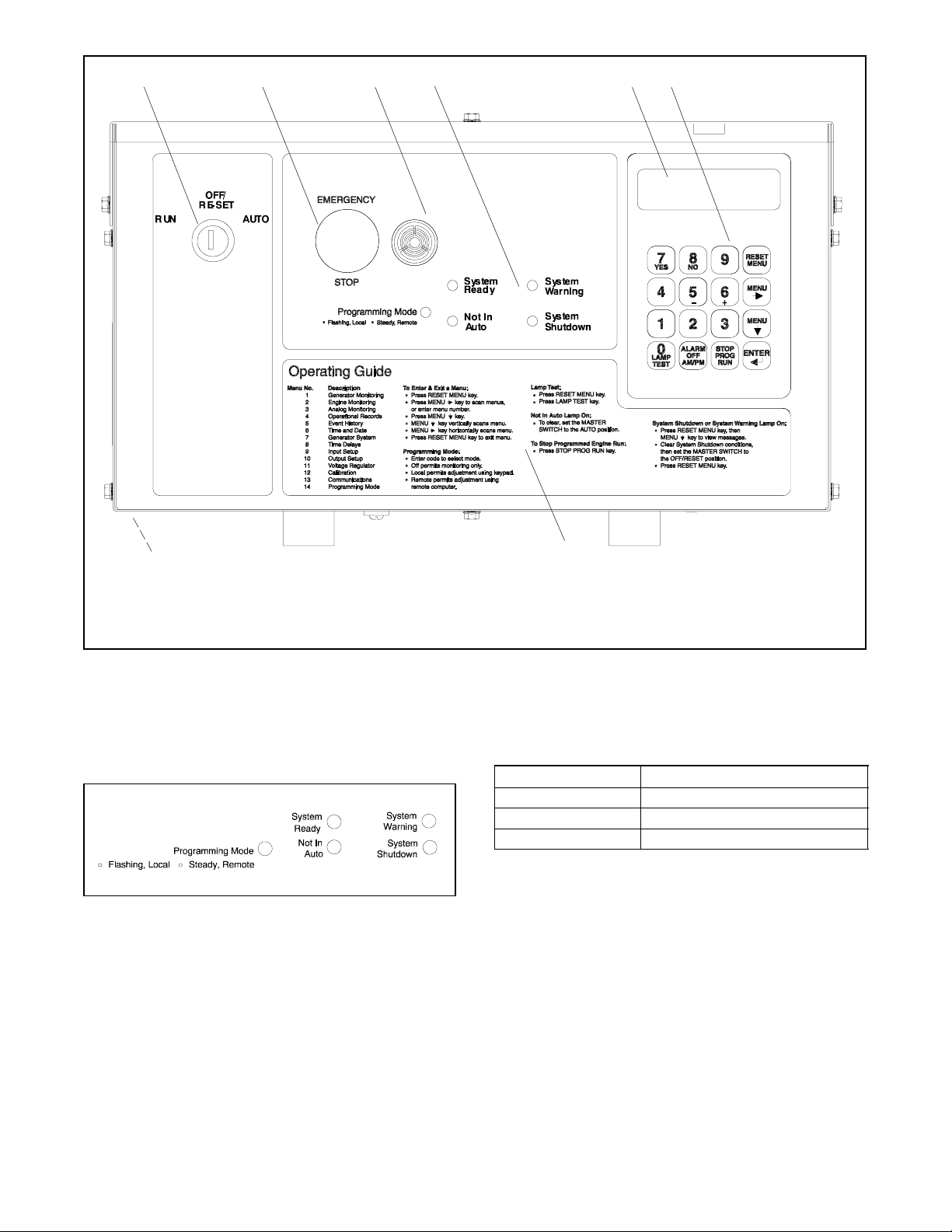

12 4 5

3

6

8

1. Generator set master switch, run/off-reset/auto positions

(keyswitch option)

2. Emergency stop switch

3. Alarm horn (see keypad for alarm silence)

4. Annunciator lamps (see keypad for lamp test)

Figure 1-2 550 Controller with Keyswitch Option

1.2.1 Annunciator Lamps

Five annunciator lamps provide visual generator set

status. See Figure 1-3.

TP-6083-2

Figure 1-3 Annunciator Lamps

System Ready. Green lamp illuminates when the

generator set master switch is in the AUTO (automatic

start) position and the system senses no faults. The unit

is ready to start.

TP-6083-2

7

5. Digital display

6. Keypad

7. Operating guide

8. Controller terminal strips (on circuit board)

Programming Mode. Yellow programming lamp

indicates the user selected programming mode. See

Figure 1-4.

Programming Lamp Programming Mode Selection

Lamp Flashing Local Programming

Lamp Steady On Remote Programming

Lamp Off Programming Disabled

Figure 1-4 Programming Lamp Mode

Note: Find additional information for the programming

mode lamp function and access to the local or

remote programming modes in Section 2.8, Local

Programming Mode On, Menu 14—Programming

Mode.

Not in Auto (NIA). Yellow lamp illuminates when the

generator set master switch is not in the AUTO

(automatic start) position.

TP-6200 10/1216 Section 1 Specifications and Features

Page 17

System Warning. Yellow lamp identifies an existing

fault condition that does not shut down the generator set.

A continuing system warning fault condition may cause

a system shutdown. Correct all system warnings as

soon as practical.

System Shutdown. Red lamp indicates that the

generator set has shut down because of a fault

condition. The unit will not start without resetting the

controller, see Section 2.3.7, Controller Reset

Procedure.

See Section 2.3.5, System Warning Lamp, for

definitions of the items listed.

The following conditions cause a system warning:

D Engine functions:

d ECM yellow alarm

(DDC/MTU engine with MDEC/ADEC)

d High battery voltage

d High coolant temperature

d Low battery voltage

d Low coolant temperature

d Low fuel (level or pressure)*

d Low oil pressure

d Speed sensor fault

d Starting aid (system status)

d Weak battery

D General functions:

d Auxiliary—Analog up to 7 user-selectable inputs

each with a high and low programmable warning

level

d Auxiliary—Digital up to 21 user-selectable

warnings

d Battery charger fault*

d Emergency power system (EPS) supplying load

d Engine cooldown delay

d Engine start delay

d Load shed kW overload

d Load shed underfrequency

d Master switch not in AUTO (automatic start)

position

d NFPA 110 fault (National Fire Protection

Association)

d System ready (system status)

D Alternator functions:

d AC sensing loss

d Ground fault*

d Overcurrent

* Requires optional input sensors.

Note: See Figure 2-8 in User Inputs for factory-

reserved analog and digital inputs that are not

user-selectable.

See Section 2.3.6, System Shutdown Lamp, for

definitions of the items listed.

The following conditions cause a system shutdown:

D Engine functions:

d Air damper closed (status), if equipped

d Coolant temperature signal loss

d ECM red alarm

(DDC/MTU engine with MDEC/ADEC)

d Engine stalled (ECM only)

d High coolant temperature

d High oil temperature

d Low coolant level

d Low oil pressure

d Oil pressure signal loss

d Overcrank

d Overspeed

D General functions:

d Auxiliary—Analog up to 7 user-selectable inputs

each with a high and low programmable

shutdown level

d Auxiliary—Digital up to 21 user-selectable

shutdowns

d ECM communications loss (ECM models only)

d Emergency stop

d Internal fault

d Master switch in OFF/RESET position

d Master switch error

d Master switch open

d NFPA 110 fault

D Alternator functions:

d AC output overvoltage

d AC output undervoltage

d Alternator protection against overload and short

circuits

d Field overvoltage

(M4, M5, M7, or M10 alternator only)

d Locked rotor (failed to crank)

d Overfrequency

d Underfrequency

Note: See Figure 2-8 in User Inputs for factory-

reserved analog and digital inputs which are

not user-selectable.

TP-6200 10/12 17Section 1 Specifications and Features

Page 18

1.2.2 Digital Display and Keypad

Figure 1-5 illustrates the digital display and keypad.

Note: Press any key on the keypad to turn on the

controller lights and display. The lights and

display turn off 5 minutes after the last keypad

entry.

The 2-line vacuum fluorescent display provides

generator set and engine condition information.

The 16-button keypad gives the user information access

and local programming capability.

Keypad Functions

Alarm (Horn) Off key silences the alarm horn at the

operator’s discretion. Place the generator set master

switch in the AUTO position before silencing the alarm

horn. See Section 2.3.7, Controller Reset Procedure,

and Section 1.2.3, Switches and Controls.

TP-5829-2

Figure 1-5 Digital Display and Keypad

AM/PM key provides time of day data entries when

programming.

Enter ↵ key provides confirmation entry when selecting

menu or programming.

Lamp Test key tests the controller indicator lamps,

horn, and digital display. See Section 1.2.3, Switches

and Controls.

Menu down ↓ key provides navigation within menus

when necessary.

Menu right → key provides navigation within menus

when necessary.

Numeric 0--9 keys provide numeric data entries when

selecting menus or programming.

Reset Menu key exits a menu, clears incorrect entries,

and cancels the auto-scroll feature.

Stop Prog (Program) Run key allowstheusertostop

any previously programmed generator set run

sequence. See Section 1.2.3, Switches and Controls.

Yes/No keys provides data answer entries when

programming.

Alternator Output Displays (Menu 1)

AC Amps displays the alternator output current. The

display shows each line of 3-phase models.

AC Volts displays the alternator output voltages. The

display shows all line-to-neutral and line-to-line voltage

combinations.

Alternator Duty Level displays the actual load kW

divided by the nameplate kW rating as a percentage.

Frequency displays the frequency (Hz) of alternator

output voltage.

Hourmeter displays the generator set operating hours

loaded and unloaded for reference in scheduling

maintenance.

KVA displays the total and individual L1, L2, and L3 kVA.

KVAR displays the total and individual L1, L2, and L3

kVAR.

Power Factor displays the kW/kVA and the individual

line power factor values.

Watts displays the total and individual L1, L2, and L3

kilowatts.

TP-6200 10/1218 Section 1 Specifications and Features

Page 19

Engine Displays (Menu 2)

Some engine displays are available with selected

generator set engines using engine ECMs only. The

controller display shows N/A (not available) for items

that are unavailable. See the controller spec sheet for

applicable generator set models.

Ambient Temperature displays the generator set area

ambient temperature.

Charge Air Pressure displays the engine turbocharger

boost air pressure.

Charge Air Temperature displays the engine

turbocharger boost air temperature.

Coolant Level displays the engine coolant level.

Coolant Pressure displays the engine coolant

pressure.

Coolant Temperature displays the engine coolant

temperature.

Event History displays up to 100 stored system events

including status, warnings, and shutdowns.

Last Start Date displays the date when the generator

set last operated.

Number of Starts displays the total number of

generator set startup events.

Number of Starts (Since) Last Maintenance displays

the total number of generator set startup events since

the last maintenance date.

Operating Days (Since) Last Maintenance displays

the total number of days of operation since the last

maintenance date. A counted day of operation can be

1--24 hours.

Run Time displays the total loaded hours, total

unloaded hours, and total kW hours.

Run Time Since Maintenance displays the total loaded

hours, total unloaded hours, and total kW hours.

Crankcase Pressure displays the engine crankcase

pressure.

DC Volts displays the voltage of starting battery(ies).

Fuel Pressure displays the fuel supply pressure.

Fuel Rate displays the calculated fuel consumption rate

based on fuel injector outputs.

Fuel Temperature displays the fuel supply

temperature.

Oil Level displays the engine oil level as a percent of full

capacity.

Oil Pressure displays the engine oil pressure.

Oil Temperature displays the engine oil temperature.

RPM (Tachometer) displays the engine speed.

Used Last Run displays the accumulated amount of

fuel used since last reset by the engine DDEC reader.

Operational Record Displays (Menus 4 and 5)

The operational record displays events since last reset.

See Section 2.8.4, Menu 4—Operational Records, for

resetting procedure.

Time Delay Displays (Menu 8)

The time delays are user adjustable. See Section 2.8.8,

Menu 8—TIme Delays, for time delay adjustments. See

Section 1.3.1, Status Event and Fault Specifications, for

range and default settings.

Crank On/Crank Pause displays the time allocated for

generator set crank on and crank pause in

minutes:seconds.

Engine Cooldown displays the time delay for engine

cooldown while the master switch is in the AUTO or RUN

positions and not in the idle mode.

Engine Start displays the time delay before the

generator set starts while the master switch is in AUTO

or RUN positions.

Overcrank Shutdown (Number of) Crank Cycles

displays the number of unsuccessful crank cycles

(crank on/crank pause) before the generator set shuts

down on an overcrank fault.

Overvoltage displays the time delay before the

generator set shuts down because of an overvoltage

condition.

Starting Aid displays the engine starting aid activation

time.

Engine Start Countdown displays the time remaining

before the next generator set startup.

TP-6200 10/12 19Section 1 Specifications and Features

Undervoltage displays the time delay before the

generator set shuts down because of an undervoltage

condition.

Page 20

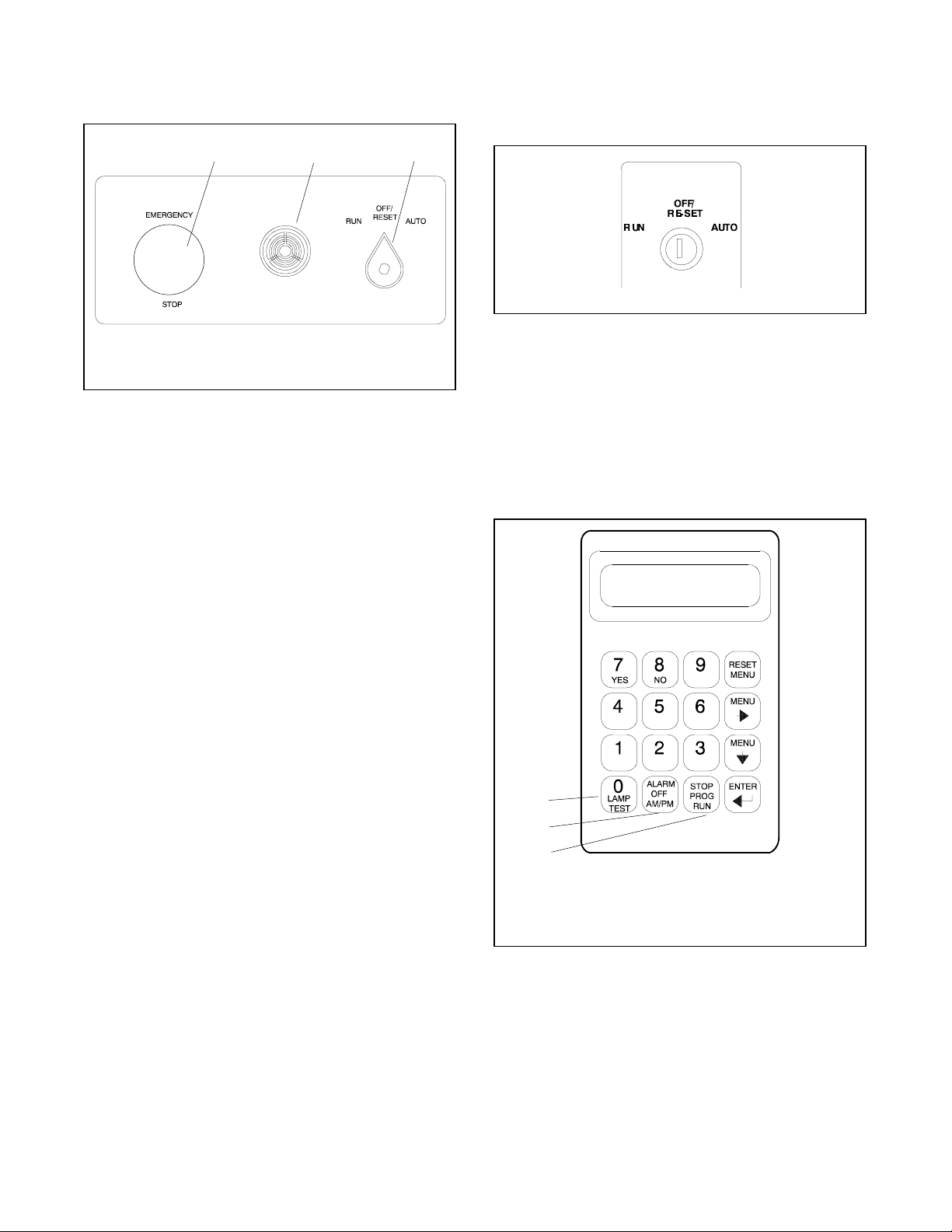

1.2.3 Switches and Controls

See Figure 1-6 and Figure 1-8 for switches and controls.

123

TP-6083-2

1. Emergency stop switch

2. Alarm horn

3. Generator set master switch

Figure 1-6 Switches and Alarm Horn

Note: Find additional switches and controls in

Section 2.5.1, Keypad Operation.

Alarm Horn. The alarm horn alerts the operator or other

attendants that a shutdown or warning condition exists.

See Section 1.3, Controller Logic Specifications, for

conditions. Place the generator set master switch in the

AUTO position before silencing the alarm horn. The

alarm horn cannot be silenced unless the generator set

master switch is in the AUTO position. See

Section 2.3.7, Controller Reset Procedure.

The generator set master switch with the keyswitch

option (Figure 1-7) is available to meet appropriate local

code requirements. The key is removable in the AUTO

position only.

TP-6083-2

Figure 1-7 Generator Set Master Switch with

Keyswitch Option

Lamp Test. The keypad switch tests the controller

indicator lamps, horn, and digital display. Press the

reset menu key before pressing the lamp test key.

Stop Prog (Program) Run. Keypad switch allows the

user to stop any previously programmed generator set

run sequence.

Alarm (Horn) Off. The keypad switch silences the

alarm horn at the operator’s discretion. Place the

generator set master switch in the AUTO position before

silencing the alarm horn. Restore alarm horn switches

at all locations including those on remote annunciator

and audiovisual alarm kits to the normal position after

correcting the fault shutdown to avoid reactivating the

alarm horn. See Section 2.3.7, Controller Reset

Procedure.

AM/PM. This keypad switch provides time of day data

entries when programming.

Emergency Stop. The operator-activated pushbutton

immediately shuts down the generator set in emergency

situations. Reset the emergency stop switch after

shutdown by pulling the switch knob outward. Use the

emergency stop switch for emergency shutdowns only.

Use the generator set master switch for normal

shutdowns.

Generator Set Master Switch (Run/Off-Reset/Auto).

This switch resets the controller fault lamps and

start/stops the generator set. Refer to Section 2.3.1,

Starting, Section 2.3.2, Stopping, and Section 2.3.3,

Emergency Stop Switch Reset Procedure.

1

2

3

1. Lamp test

2. Alarm horn silence

3. Stop program run

Figure 1-8 Keypad Switches

TP-5829-2

TP-6200 10/1220 Section 1 Specifications and Features

Page 21

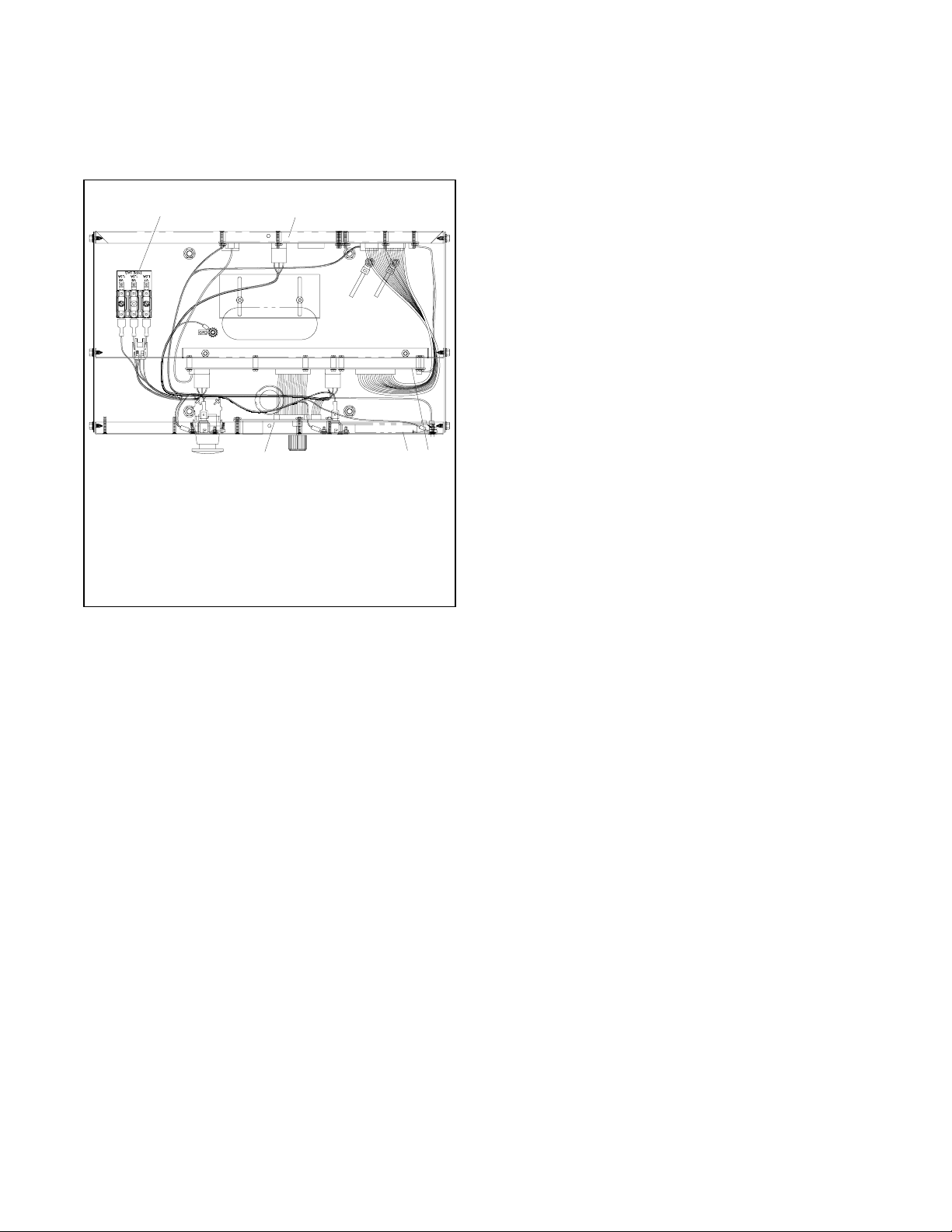

1.2.4 Controller Circuit Boards

1.2.5 Fuses

The controller has five circuit boards—indicator,

interconnection, keypad, digital display, and main logic/

communication. See Figure 1-9 for circuit board

locations.

12

5

1. AC fuse block (TB5)

2. Interconnection circuit board TB1, TB2, TB3, and TB4

terminal strips and F1, F2, and F3 fuses

3. Main logic (microprocessor)/communication circuit board

4. Keypad and digital display circuit boards

5. Indicator circuit board (LED and alarm horn)

34

GM10193B-A

Figure 1-9 Controller Circuit Boards and Fuses

(Controller Top View)

Indicator (Status) Circuit Board includes the LED

status lamps, alarm horn, and generator set master

switch.

Interconnection Circuit Board provides the terminal

strips to connect the controller (customer) connection

board and/or dry contact kits and three DC fuses (F1, F2,

and F3). See 6.1.3 for more information.

Keypad (Switch Membrane) Circuit Board provides

the keypad to navigate the generator set displays and

enter data.

Digital Display Circuit Board provides the vacuum

fluorescent display (VFD) for monitoring the generator

set functions and output values.

Main Logic (Microprocessor)/Communication

Circuit Board provides the controller operation logic

and provides PC communication locally (direct) or

remotely (via modem) using RS-232 or RS-485

connectors.

AC Circuit Fuses (TB5). Fuses are located inside the

controller. See Figure 1-9.

D 1.5-Amp (V7) fuse protects L1 sensing input to

interconnection circuit board.

D 1.5-Amp (V8) fuse protects L2 sensing input to

interconnection circuit board.

D 1.5-Amp (V9) fuse protects L3 sensing input to

interconnection circuit board.

DC Circuit Fuses fuses are located on the controller

interconnection circuit board.

D 5-Amp Remote Annunciator (F1) fuse protects the

dry contact kit if equipped and the controller panel

lamps.

D 5-Amp Controller (F2) fuse protects the controller

circuitry.

D 15-Amp Engine and Accessories (F3) fuse protects

the engine/starting circuitry and accessories.

1.2.6 Terminal Strips and Connectors

Terminal strips and connectors for inputs and outputs

are located on the interconnection circuit board. See

Section 6, Accessories.

TB1 Input Connection Terminal Strip provides input

connections for remote start and emergency stop

(E-Stop).

TB2 Analog Input Connection Terminal Strip

provides analog input connections, including non-ECM

sensor connections.

TB3 Accessory Power Output Connection Terminal

Strips provides a generator set power supply for factory

use.

TB4 Digital Input Connection Terminal Strips

connect external devices (engine ECM and user

supplied) to the generator set digital inputs.

P23 Connector connects the interconnection circuit

board to the controller (customer) connection terminal

strip (connector P25) inside the junction box. See 6.1.3

for more information.

TP-6200 10/12 21Section 1 Specifications and Features

Page 22

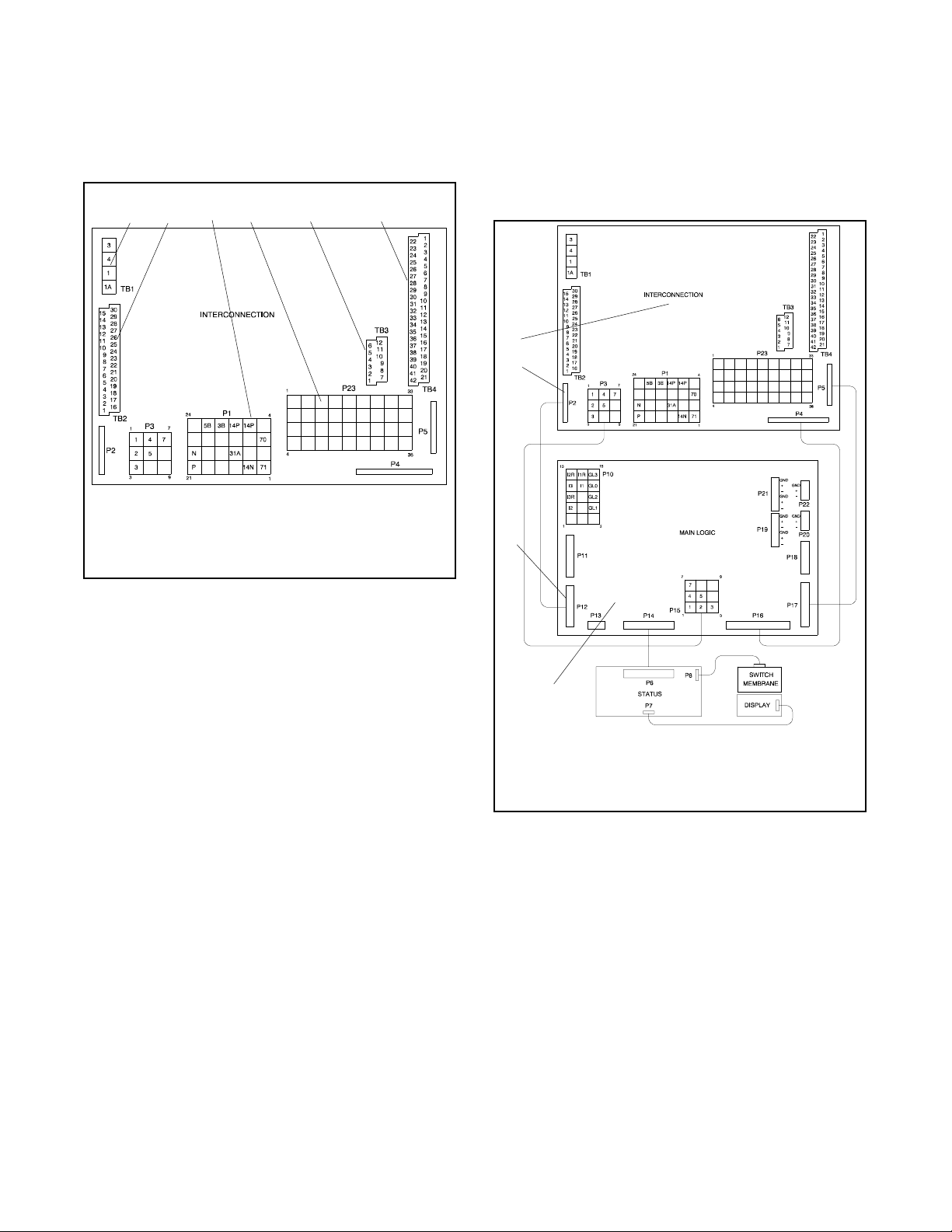

Figure 1-10 shows locations of the terminal strips on the

controller interconnection circuit board. See Section 6.2,

Accessory and Connections, for specific terminal

identification information. Refer to the wiring diagrams

for additional information on connecting accessories to

the terminal strips.

2

1

3

4

56

ADV-6533-A

1.2.7 Circuit Board Interconnections for

Calibration Procedure

The interconnection circuit board shown in Figure 1-11

contains a ribbon connector that requires disconnection

during the calibration procedure in Menu 12—

Calibration. Disconnect ribbon connector P2 prior to

zeroing out (resetting) the auxiliary analog inputs.

1

2

1. TB1 terminal strip

2. TB2 terminal strip

3. P1 Connector

4. P23 Connector

5. TB3 terminal strip

6. TB4 terminal strip

Figure 1-10 Interconnection Circuit Board Terminal

Strips and Connectors

4

4

ADV-6533-A

1. Interconnection circuit board

2. P2 ribbon connector

3. P12 ribbon connector

4. Main logic circuit board

Figure 1-11 Interconnection Circuit Board Ribbon

Connector P2 (Top View of Circuit Board)

TP-6200 10/1222 Section 1 Specifications and Features

Page 23

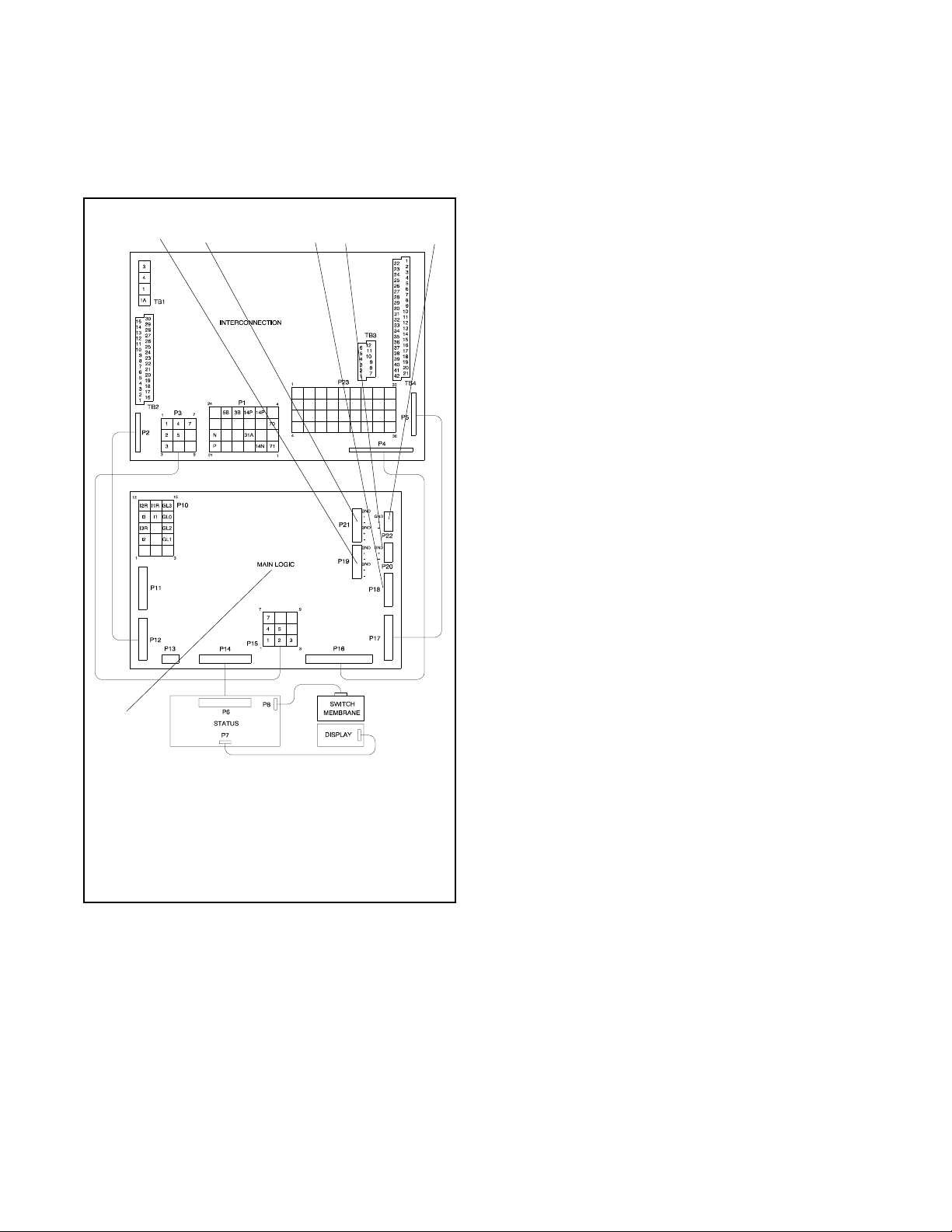

1.2.8 Communication Ports

1.3 Controller Logic Specifications

The main logic circuit board contains several

communication ports for Modbusr and KBUS

connections. See Figure 1-12. Refer to the List of

Related Materials in the Introduction for corresponding

communication installation information.

12 34 5

The controller logic specifications section is an overview

of the various features and functions of the controller.

Certain features function only when optional

accessories are connected. See Section 2, Operation,

for details.

The default selection time delays and relay driver

outputs (RDOs) are factory set and adjustable with the

programming mode on (Menu 14). Some data entries

require using a PC in the Remote Programming mode.

See the monitor software operation manual for details.

Inhibit Time Delay. The inhibit time delay is the time

period following crank disconnect during which the

generator set stabilizes and the controller does not

detect a fault or status event. Select the desired inhibit

time delay from 0 to 60 seconds.

TIme Delay (Shutdown or Warning). The time delay

follows the inhibit time delay. The time delay is the time

period between when the controller first detects a fault or

status event and the controller warning or shutdown

lamp illuminates. The delay prevents any nuisance

alarms. Select the desired time delay from 0 to

60 seconds.

6

ADV-6533-A

1. P19—unused isolated connection (ISO2), RS-485 port

2. P21—KBUS isolated connection (ISO1), RS-485 port

3. P18—KBUS or Modbusr, RS-232 port

(Monitor III connection)

4. P20—Modbus, RS-485 port (Monitor III connection)

5. P22—ECM connector

6. Main logic circuit board

Figure 1-12 Main Logic Circuit Board Communication

Ports (Top View of Circuit Board)

1.3.1 Status Event and Fault

Specifications

The table starting on the next page contains all status

events and faults with ranges and time delays including

items that do not have adjustments.

Note: The engine ECM may limit the crank cycle even if

the controller is set to a longer time period.

Modbusr is a registered trademark of Schneider Electric.

TP-6200 10/12 23Section 1 Specifications and Features

Page 24

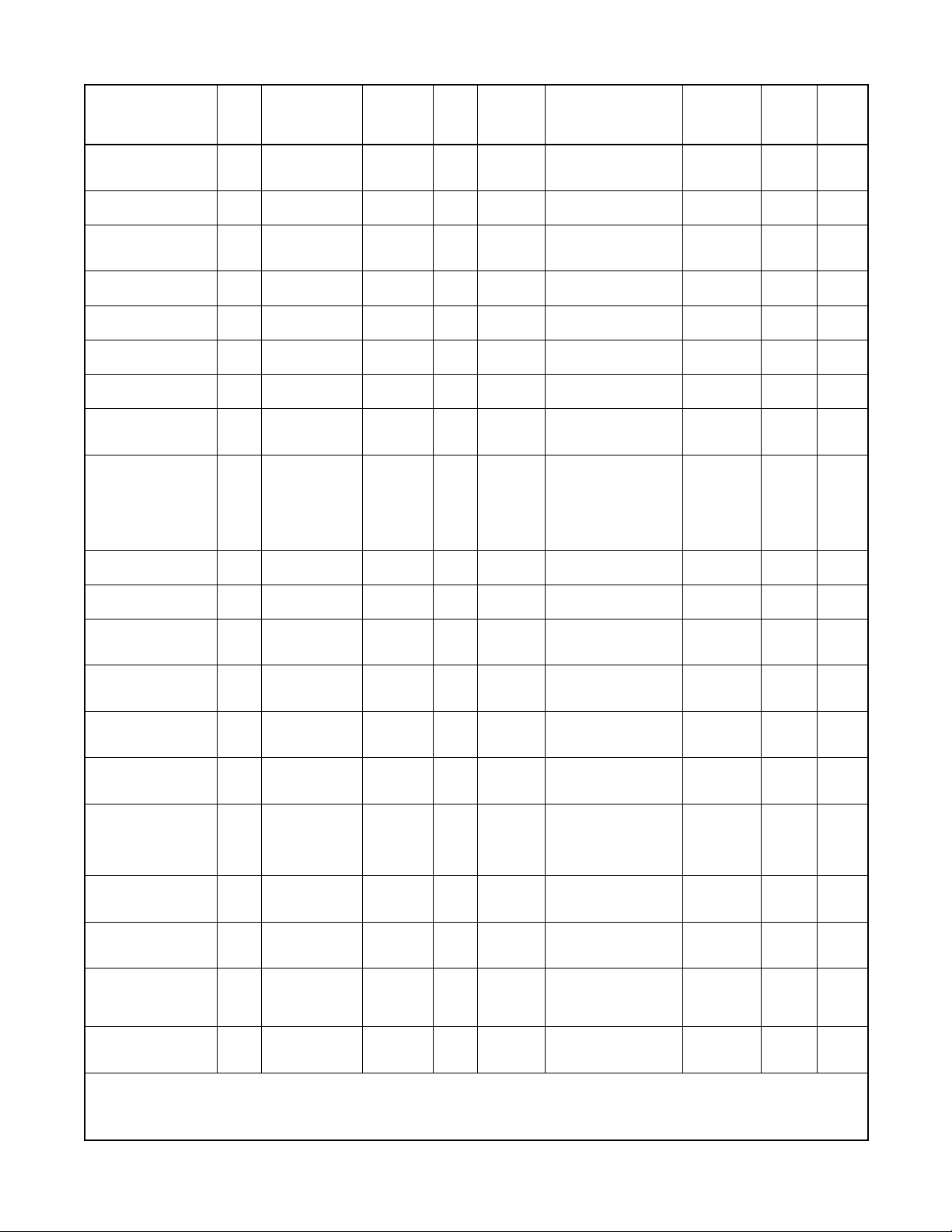

Factory-Defined Settings

Status Event

or Fault

Access Code

(password)

AC Sensing Loss 10 AC SENSING

Air Damper Control

(if used) **

Air Damper Indicator

(if used), see D20 **

Air/Fuel Module

(AFM) Engine Start

Delay ]

Air/Fuel Module

(AFM) Remote

Start]

Air/Fuel Module

(AFM) Shutdown

(see D11) ]

Alternator Protection

Shutdown

Analog Aux. Input 0 9 LOCAL BATT

Analog Aux. Inputs

A01--A07

Analog Aux. Input

A01 (non-ECM only)

Analog Aux. Input

A02 (non-ECM only)

Analog Aux. Input

A03 ]

Analog Aux. Input

A04 *

Analog Aux. Input

A04 ]

Analog Aux. Input

A06 VSG (Volvo,

GM, Doosan only)

* All models, except Waukesha-powered models. ** NFPA applications

[ Non-paralleling applications [[ DDC/MTU engine with MDEC/ADEC

] Waukesha-powered models ]] FAA only

w Paralleling applications

Refer

to

Menu

Digital Display

14 User-Selectable 0(zero)

LOSS

10

10 AFM ENG

START DELAY

10 AFM REMOTE

10 ALTERNATOR

9 USER-DEFINED

9 A01

9 A02

9 A03

9 A04

9 A04

9, 12 A06 ANALOG

START

PROTECTION

VDC

A01--A07

COOLANT

TEMP

OIL

PRESSURE

INTAKE AIR

TEMP

FUEL LEVEL

OIL TEMP

AUXILIARY IN

Relay

Driver

Output

(RDO)

RDO-25 * On Warning

RDO-25 ]

Alarm

Horn

Off

On Shutdown

On Shutdown

On Shutdown

On Shutdown

On Warning Default Values with

Off Vol vo:

Lamp Range Setting

or

Warning

or

Warning

or

Warning

Shutdown

or

Warning

Fixed

Fixed

Default Values with

Warning Enabled:

HI warning 90%

LO warning 10%

HI shutdown 100%

LO shutdown 1%

Default Values with

Warning Enabled:

HI/LO warning and

HI/LO shutdown are

all engine dependent

Default Values with

Warning Enabled:

HI/LO warning and

HI/LO shutdown are

all engine dependent

(255 psi max.)

Default Values with

Warning Enabled:

HI/LO warning and

HI/LO shutdown are

all engine dependent

Default Values with

Warning Enabled:

HI/LO warning are

engine dependent

Warning Enabled:

HI/LO warning are

engine dependent

Default

Selection

30 sec.

inhibit,

5 sec. delay

30 sec.

inhibit,

0 sec. delay

warning,

5 sec. delay

shutdown

30 sec.

inhibit,

0 sec. delay

warning,

5 sec. delay

shutdown

30 sec.

inhibit,

0 sec. delay

warning

30 sec.

inhibit,

0 sec. delay

warning

30 sec.

inhibit,

0 sec. delay

warning

0.5V=1250

4.5V=8750

GM/Doosan

60 Hz:

0.5V=2375

4.5V=2625

50 Hz:

0.5V=2327

4.5V=2624

Inhibit

Time

Delay

(sec.)

0--60 0--60

Time

Delay

(sec.)

TP-6200 10/1224 Section 1 Specifications and Features

Page 25

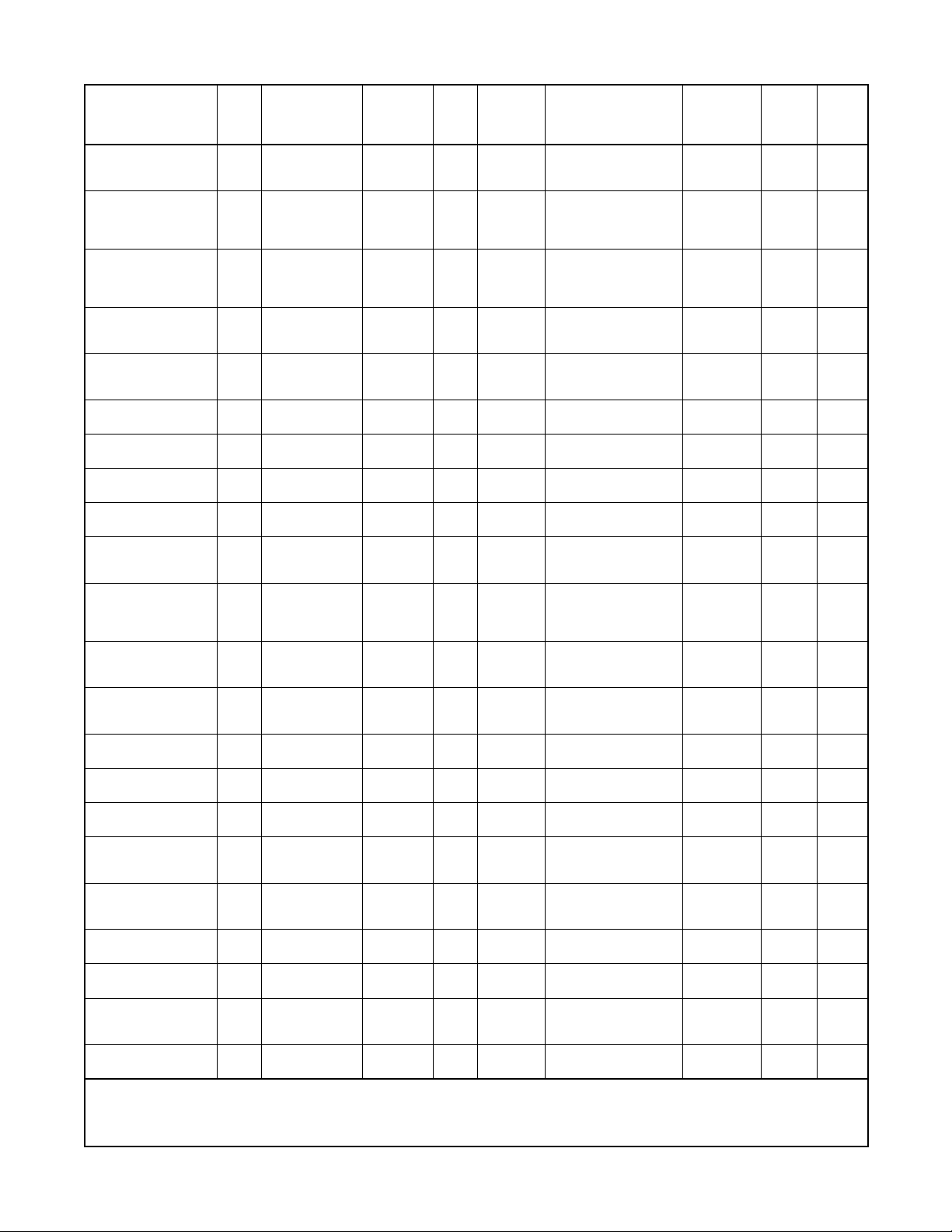

Factory-Defined Settings

Status Event

or Fault

Analog Aux. Input

A07

Battery Charger Fault

(see D01) **

Battle Switch

(Fault Shutdown

Override Switch)

Block Heater

Control [[

Breaker Trip w

Common Protective

Relay Output w

Critical Overvoltage

Shutdown

Cyclic Cranking 8 Off 1--6 crank cycles

Defined Common

Faults

(each input value is

set separately)

Detonation Shutdown

(see D13) ]

Detonation Warning

(see D12) ]

Digital Aux. Input

D01--D21

Digital Aux. Input

D01 Battery Charger

Fault **

Digital Aux. Input

D02 Low Fuel

Warning **

Digital Aux. Input

D03 Low Coolant

Temperature **

Digital Aux. Input

D04 Field

Overvoltage (M4,

M5, M7, or M10 alt.

only)

Digital Aux. Input

D05 Breaker

Closed w

Digital Aux. Input

D06 w

Digital Aux. Input

D09 Low Fuel

Pressure Shutdown

(125RZG only)

Digital Aux. Input

D11 Air/Fuel Module

(AFM) Shutdown ]

* All models, except Waukesha-powered models. ** NFPA applications

[ Non-paralleling applications [[ DDC/MTU engine with MDEC/ADEC

] Waukesha-powered models ]] FAA only

w Paralleling applications

Refer

to

Menu

Digital Display

9 A07

ANALOG VOLT

ADJUST

9 BATTLE

10 BLOCK HEATER

10 BREAKER

10 COMMON PR

10 CRITICAL

10 DEFINED

9, 10 USER-DEFINED

9, 10 D01 BATTERY

9, 10 D02

9, 10 D03 LOW

9, 10 D04

9, 10 D05

9, 10 D06 ENABLE

9, 10 D09

9, 10 D11

SWITCH

CONTROL

TRIP

OUTPUT

OVERVOLTAGE

COMMON

FAULT

D01--D21

CHARGER

FAULT

LOW FUEL

WARNING

COOLANT

TEMP

FIELD

OVERVOLTAGE

BREAKER

CLOSED

SYNCH

LOW FUEL

SHUTDOWN

AFM

SHUTDOWN

Relay

Driver

Output

(RDO)

RDO only

RDO-30 Off Warning

RDO-31 w

RDO-18

(lead 32A)

RDO-11

(lead 61)

RDO-08

(lead 63)

RDO-05

(lead 35)

Alarm

Horn

Off Warning Fixed

Off Warning

On Shutdown Fixed 275 volts

On Shutdown

On Shutdown

On Warning Fixed 0 sec.

On Warning Fixed 0 sec.

On Warning Fixed 0 sec.

On Shutdown Fixed 1 sec.

Off Warning Fixed 0 sec.

On Shutdown Fixed 5 sec.

On Shutdown Fixed 0 sec.

or

Warning

or

Warning

Range SettingLamp

±10% of system

voltage over the range

of 0.5--4.5 VDC

10--30 sec. crank on

1--60 sec. pause

Default shutdowns

include:

Emergency stop

High coolant temp

Low oil pressure

Overcrank

Overspeed

Default

Selection

(L1--L2)

15 sec.

15 sec.

30 sec.

inhibit,

5 sec. delay

30 sec.

inhibit,

5 sec. delay

inhibit,

0 sec. delay

inhibit,

0 sec. delay

inhibit,

0 sec. delay

inhibit,

15 sec.

delay

inhibit,

0 sec. delay

20 sec.

inhibit, 0

sec. delay

inhibit,

0 sec. delay

inhibit,

0 sec. delay

Inhibit

Time

Delay

(sec.)

3

0--60 0--60

0--60 0--60

Time

Delay

(sec.)

TP-6200 10/12 25Section 1 Specifications and Features

Page 26

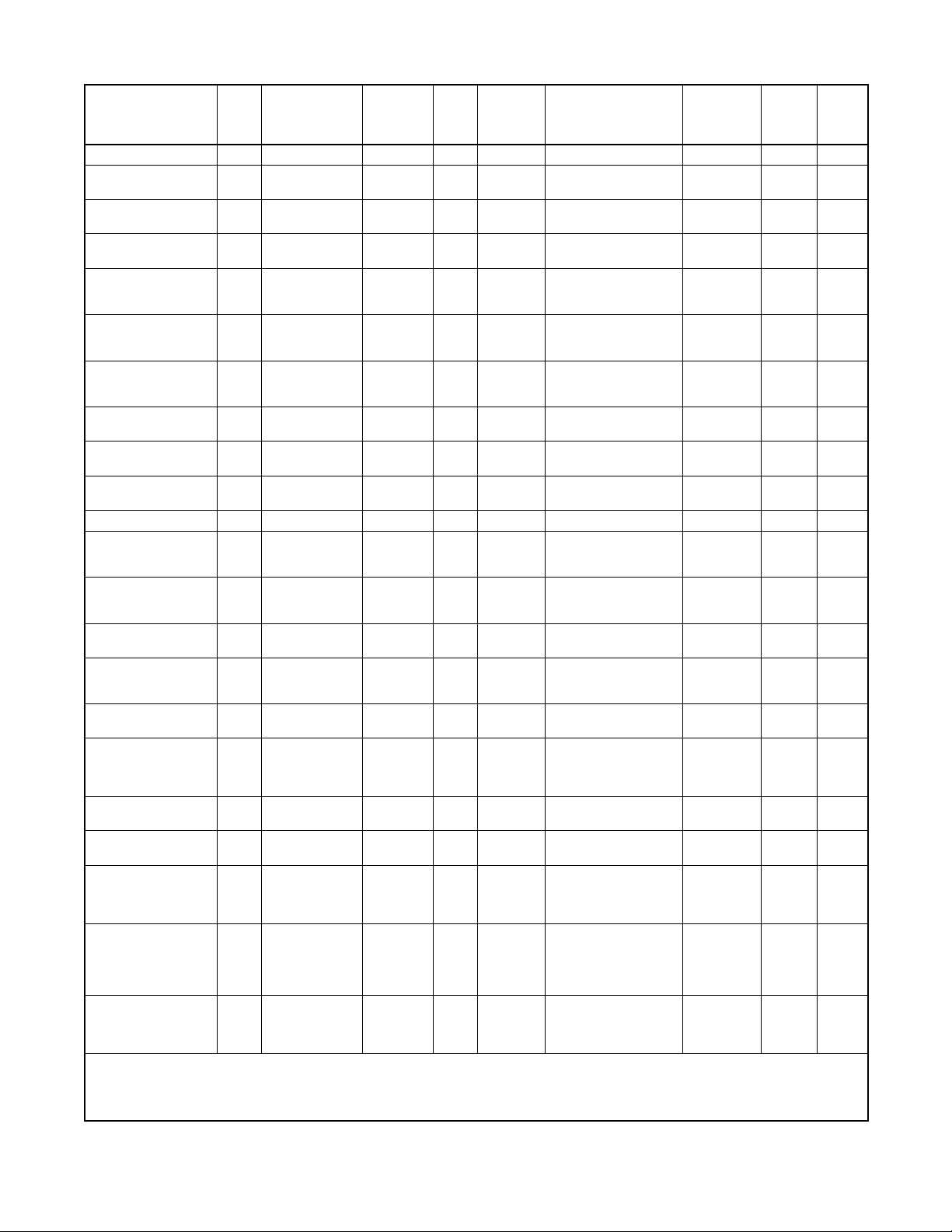

Factory-Defined Settings

Status Event

or Fault

Digital Aux. Input

D12 Detonation

Warning ]

Digital Aux. Input

D13 Detonation

Sensing Module

(DSM) Shutdown ]

Digital Aux. Input

D13 Knock Detection

Module (KDM)

Shutdown ]

Digital Aux. Input D14

Low Coolant Level,

(with LCL switch) **

Digital Aux. Input

D15 Remote

Shutdown

Digital Aux. Input

D16 Remote Reset

Digital Aux. Input

D17 VAR/PF mode

Digital Aux. Input

D18 Voltage Lower

Digital Aux. Input

D19 Voltage Raise

Digital Aux. Input

D20 Air Damper

Indicator (if used) **

Digital Aux. Input

D21 Idle (speed)

Mode Function

ECM Red Alarm

(was MDEC Red

Alarm) [[

ECM Yellow Alarm

(was MDEC Yellow

Alarm) [[

EEPROM Write

Failure

Emergency Stop

Shutdown

Engine Cooldown

(see Time Delay--)

Engine Derate Active 10 ENGINE

(Engine) J1939 CAN

Shutdown

(ECM only)

Engine Stalled

(ECM only)

Engine Start

(see Time Delay--)

EPS (Emergency

Power System)

Supplying Load

Field Overvoltage

(see D04)

* All models, except Waukesha-powered models. ** NFPA applications

[ Non-paralleling applications [[ DDC/MTU engine with MDEC/ADEC

] Waukesha-powered models ]] FAA only

w Paralleling applications

Refer

to

Menu

Digital Display

9, 10 D12

9, 10 D13

9, 10 D13

9, 10 D14 LOW

9, 10 D15 REMOTE

9, 10

9, 10

9, 10

9, 10

9, 10 D20

9, 10 D21

10 ECM RED

10 ECM YELLOW

10 EEPROM WRITE

10 EMERGENCY

10 J1939 CAN

10 ENGINE

10 EPS

DETON

WARNING

DETON

SHUTDOWN

KNOCK

SHUTDOWN

COOLANT LVL

SHUTDOWN

AIR DAMPER

IDLE MODE

ACTIVE

ALARM

ALARM

FAILURE

STOP

DERATE

ACTIVE

SHUTDOWN

STALLED

SUPPLYING

LOAD

Relay

Driver

Output

(RDO)

RDO-19 On Shutdown Fixed 30 sec.

RDO-23 *

(lead 56)

RDO-21 Off Warning Fixed inhibit time 0 sec.

RDO-14

(lead 48)

RDO-22 Off Warning Fixed 1% of rated

Alarm

Horn

On Warning Fixed 2 sec.

On Shutdown Fixed 0 sec.

On Shutdown Fixed 0 sec.

On Shutdown 0 sec.

On Shutdown Fixed 0 sec.

On Shutdown

On Warning

On Shutdown

On Shutdown

On Shutdown

On Shutdown

Range SettingLamp

Default

Selection

inhibit,

0 sec. delay

inhibit,

0 sec. delay

inhibit,

0 sec. delay

inhibit,

5 sec. delay

inhibit,

0 sec. delay

inhibit,

0 sec. delay

inhibit,

60 sec.

delay

line current

Inhibit

Time

Delay

(sec.)

Time

Delay

(sec.)

0--600

or 9:99

for

infinity

TP-6200 10/1226 Section 1 Specifications and Features

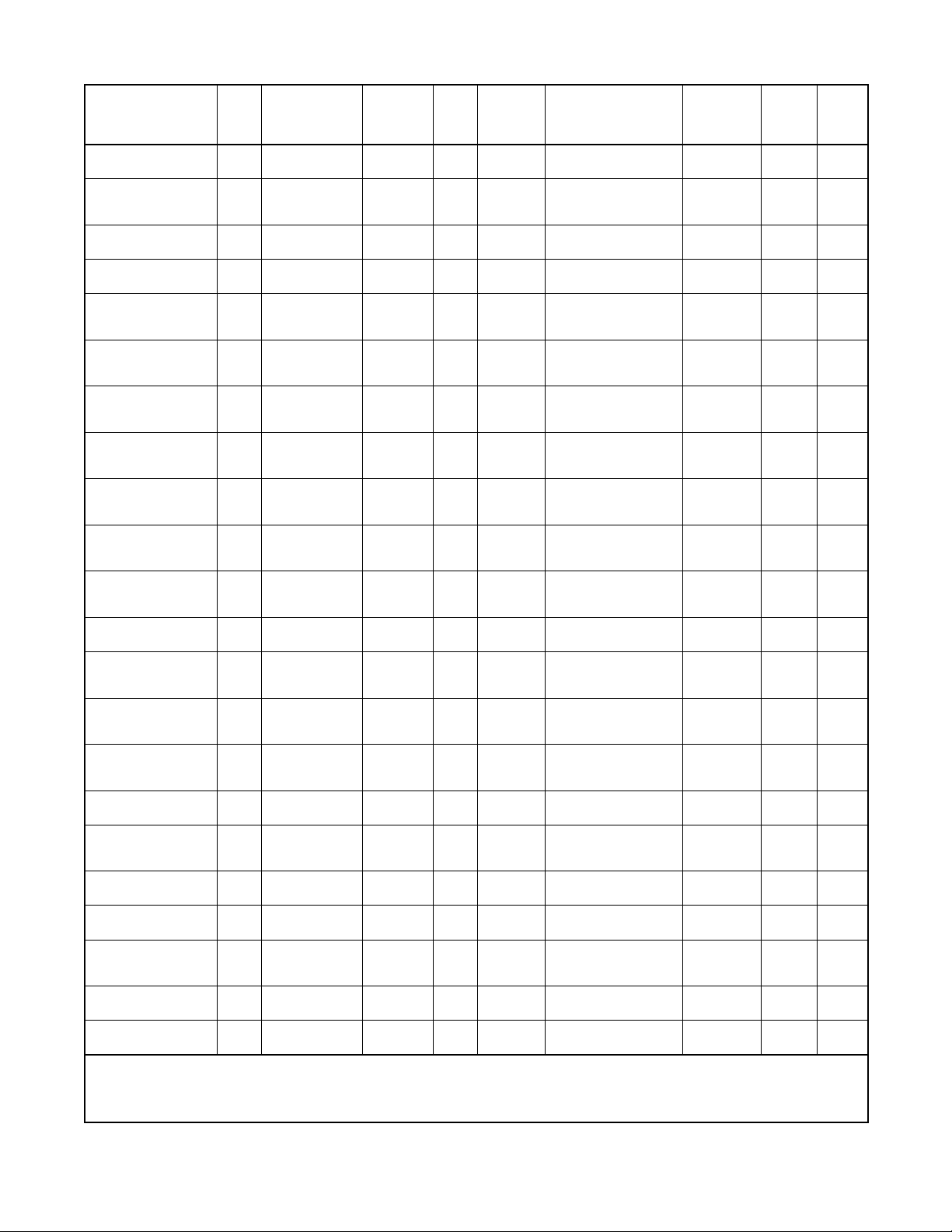

Page 27

Factory-Defined Settings

Status Event

or Fault

Fuel Level (see A04)

Fuel Valve Relay ]

Generator Set

Running

Ground Fault

Detected

High Battery Voltage 10 HIGH

High Coolant

Temperature

Shutdown

High Coolant

Temperature Warning

High Oil Temperature

Shutdown

High Oil Temperature

Warning ][[

Idle (speed) Mode

Function (see D21)

In Synch w

Intake Air

Temperature

Shutdown [[

Intake Air

Temperature Warning

[[

Intake Air Temp

Warning(seeA03)]

Intake Air Temp

Shutdown (see

A03)]

Internal Fault

Shutdown

J1939 CAN

Shutdown (see

Engine J1939 CAN

Shutdown)

Knock Shutdown

(see D13) ]

kW Overload

(see Load Shed)

Load Shed

kW Overload ]]

Load Shed Over

Temperature [[

(Activated by a High

Coolant Temp.

shutdown)

Load Shed

Underfrequency [

* All models, except Waukesha-powered models. ** NFPA applications

[ Non-paralleling applications [[ DDC/MTU engine with MDEC/ADEC

] Waukesha-powered models ]] FAA only

w Paralleling applications

Refer

to

Menu

Digital Display

10 FUEL VALVE

10 RDO-15

10 GROUND

10 HI COOL

10 HI COOL

10 HI OIL TEMP

10 HI OIL TEMP

10 IN SYNCH RDO-29 *

10 INTAKE AIR

10 INTAKE AIR

10 INTERNAL

10 LOAD SHED

10 LOAD SHED

10 LOAD SHED

RELAY

FAULT

BATTERY

VOLTAGE

TEMP

SHUTDOWN

TEMP

WARNING

SHUTDOWN

WARNING

TEMP SDWN

TEMP WARN

FAULT

KW OVER

OVER

TEMPERATURE

UNDER

FREQUENCY

Relay

Driver

Output

(RDO)

RDO-23 ]

(lead 70R)

RDO-13 Off Warning 14.5--16.5 V (12 V)