Page 1

DIAGNOSTICS

for the

Publication No. 5B6342

January 1996

Supersedes October 1995

Kodak X-Omat

5000 RA PROCESSOR

© Eastman Kodak Company

H148_0004GA

Page 2

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be liable

for any loss or damage, including consequential or special damages, resulting from any use of

this information, even if loss or damage is caused by Kodak’s negligence or other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

Table of Contents

Description Page

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

All Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fatal Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Non-Fatal Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mechanical Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Transport Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Artifacts and Wrong Film Densities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wet Films . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Solution Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Internal Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Accessing the Internal Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

D1 Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

D2 Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

D3 Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Diagnostic Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

D1 Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

D2 Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

D3 Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Flowcharts for the Internal Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Printing Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

SOLID STATE RELAYS (SSR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Possible Malfunctions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Checking the LOAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Checking the SSR and the 5000 BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Publication History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2 January 1996 – 5B6342

Page 3

Error Codes

Section 1: Error Codes

Introduction

Overview The software on the 5000 MICROPROCESSOR BOARD controls and monitors the operation

of the PROCESSOR and continually checks for errors. Whenanerror occurs, a description of

the error is displayed on the DISPLAY PANEL.

When 2 or moreerrors occur together, allthe errors are displayed, butonly 1 error isvisible on

the DISPLAY PANEL at a time. The error with the highest priority is displayed first. You can

scroll through the list to view the other errors.

An error log on the 5000 BOARD records the last 100 errors that have occurred and the

number of times each error has occurred.

3 types of errors can occur:

• Fatal

• Non-Fatal

• Warning

Fatal and

Non-Fatal Errors

Only qualified service personnel should repair both fatal and non-fatal errors.

• Most fatal errors prevent optimum film processing.

• Most non-fatal errors do not prevent optimum film processing.

Important

When you service a PROCESSOR with a fatal or non-fatal error and you check an electrical

component or BOARD, also check all the:

• connections and CABLES for the component or BOARD

• voltages from the POWER SUPPLY for the component or BOARD

Warning Errors Operators can repair warning errors. Normally,you can feed filminto a PROCESSOR when a

warning error is displayed.

READY LED If any error prevents optimum film processing, the READY LED will de-energize. When the

LED de-energizes, you can feed film into the PROCESSOR but the image quality may not be

correct. Kodak recommends that you do not process film when the LED is de-energized.

5B6342 – January 1996 3

Page 4

DIAGNOSTICS

All Errors

Important

When you check an electrical component or BOARD, also check all the:

• connections and CABLES for the component or BOARD

• voltages from the POWER SUPPLY for the component or BOARD

When you check a SOLID STATE RELAY, usethe tests inthe Appendix to determine the source of themalfunction.

ESD

Possible damage from electrostatic discharge.

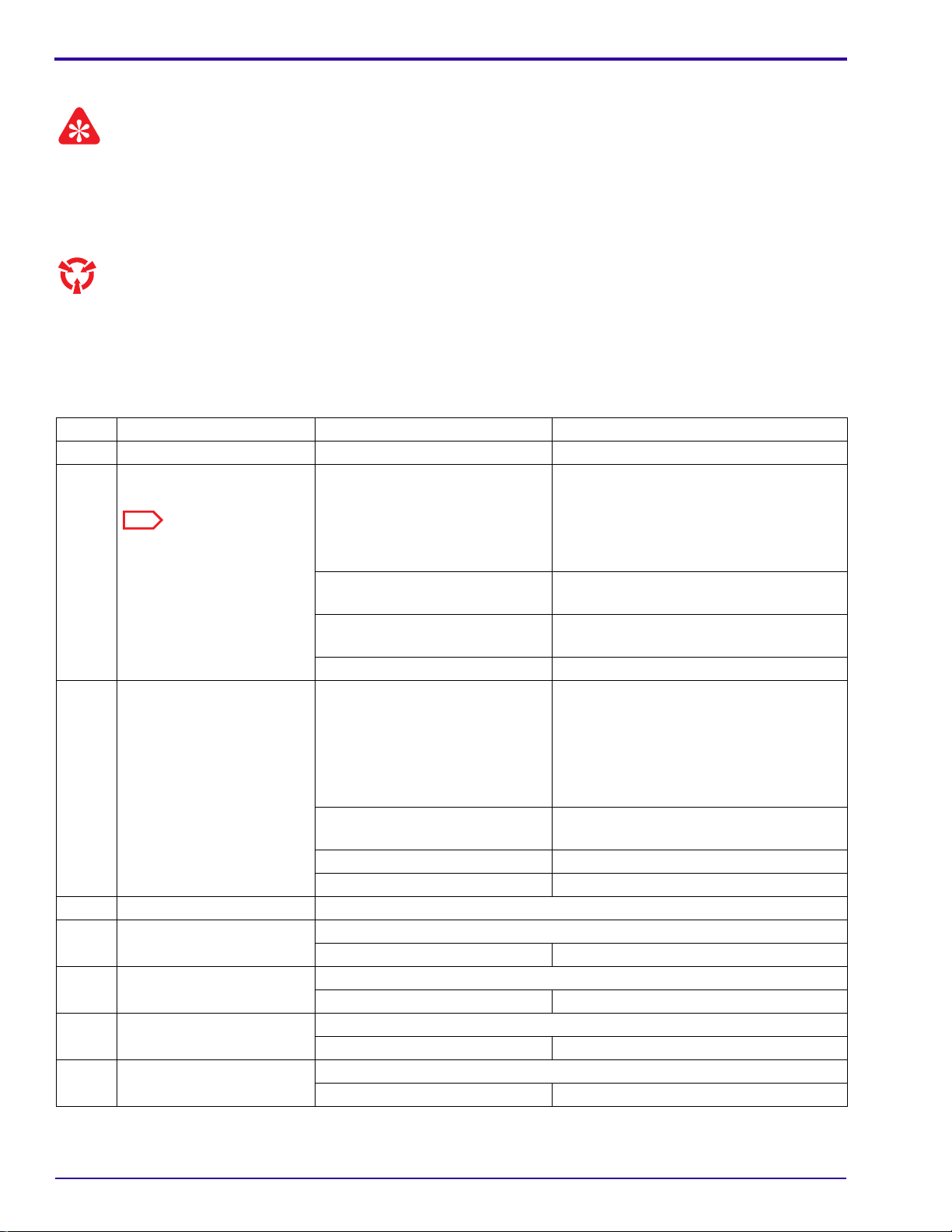

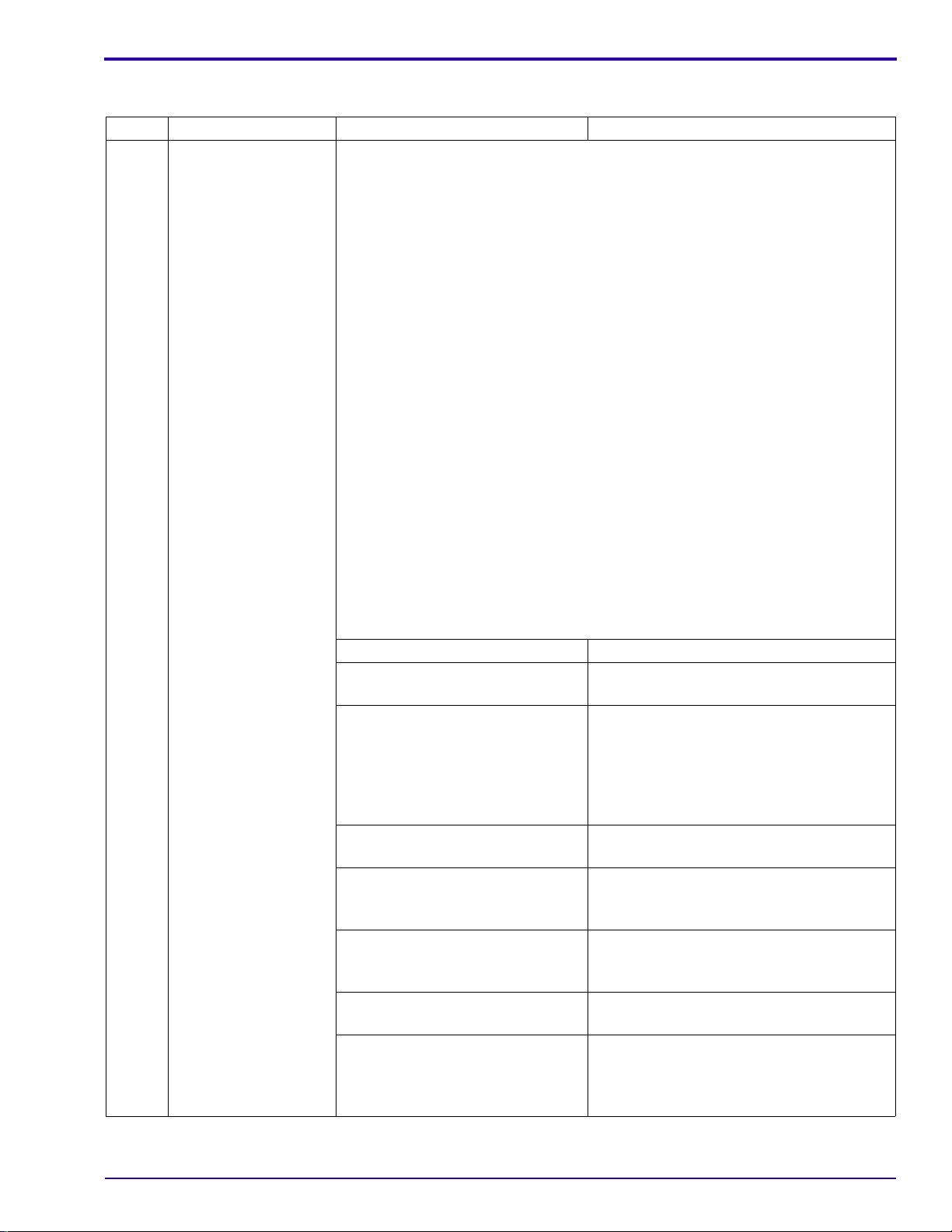

Fatal Errors

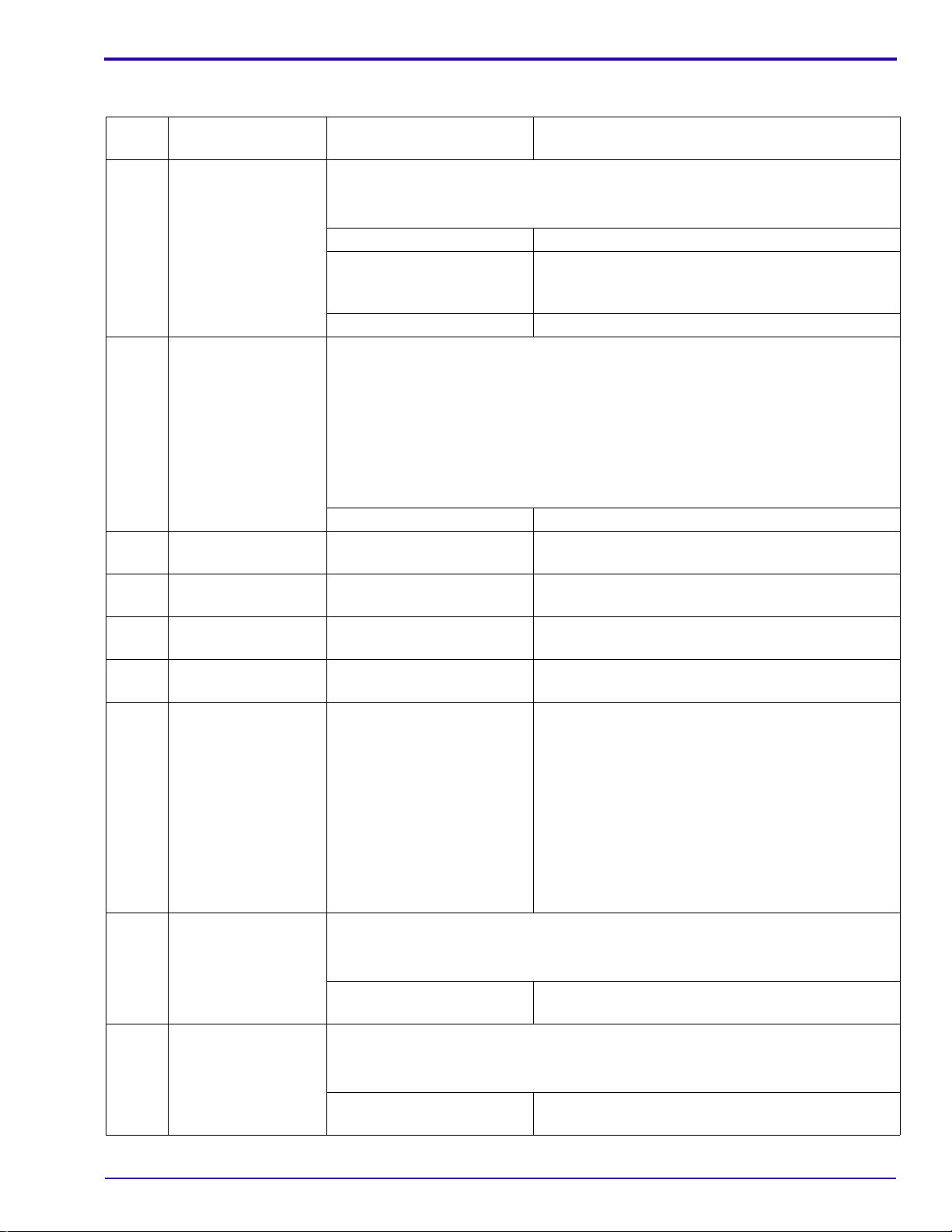

Code Description Possible Malfunction Action

E001 Microcontroller error 5000 BOARD Install a new BOARD.

E002 Dryer over maximum

temperature

Note

The maximum temperature

is 79°C (175°F).

Normally, the DRYER AC

OVERTEMPERATURE

THERMOSTAT opens

before the DRYER reaches

this temperature.

E003 Loss of film accumulator

data link

E004 Inoperative transport See E041.

E007 Developer thermistor

failure

E008 Fixer thermistor failure The FIXER HEATER is disabled when this error occurs.

E009 Dryer thermistor failure The DRYER HEATER is disabled when this error occurs.

E010 Analog-to-digital converter

failure

DRYER BLOWER When the DRYER HEATER energizes,

the DRYER BLOWER should energize.

Check:

• RELAY K1

• DRYER BLOWER

DRYER THERMISTOR Check that the resistance at 25°C (77°F)

is approximately 10 KW.

SOLID STATE RELAY U1 that

controls the DRYER HEATER

5000 BOARD Install a new BOARD.

No communication withthe 6000

BOARD

BOOT PROM U6018 on the

6000 BOARD

6000 BOARD Install a new BOARD.

5000 BOARD Install a new BOARD.

The DEVELOPER HEATER is disabled when this error occurs.

DEVELOPER THERMISTOR Install a new THERMISTOR.

FIXER THERMISTOR Install a new THERMISTOR.

DRYER THERMISTOR Install a new THERMISTOR.

All 3 HEATERS are disabled when this error occurs.

5000 BOARD Install a new BOARD.

Check U1.

De-energize and energize the

PROCESSOR to automatically reset the:

• MICROPROCESSOR on the 5000

BOARD

• MICROPROCESSOR on the 6000

BOARD

Install a new U6018.

4 January 1996 – 5B6342

Page 5

Error Codes

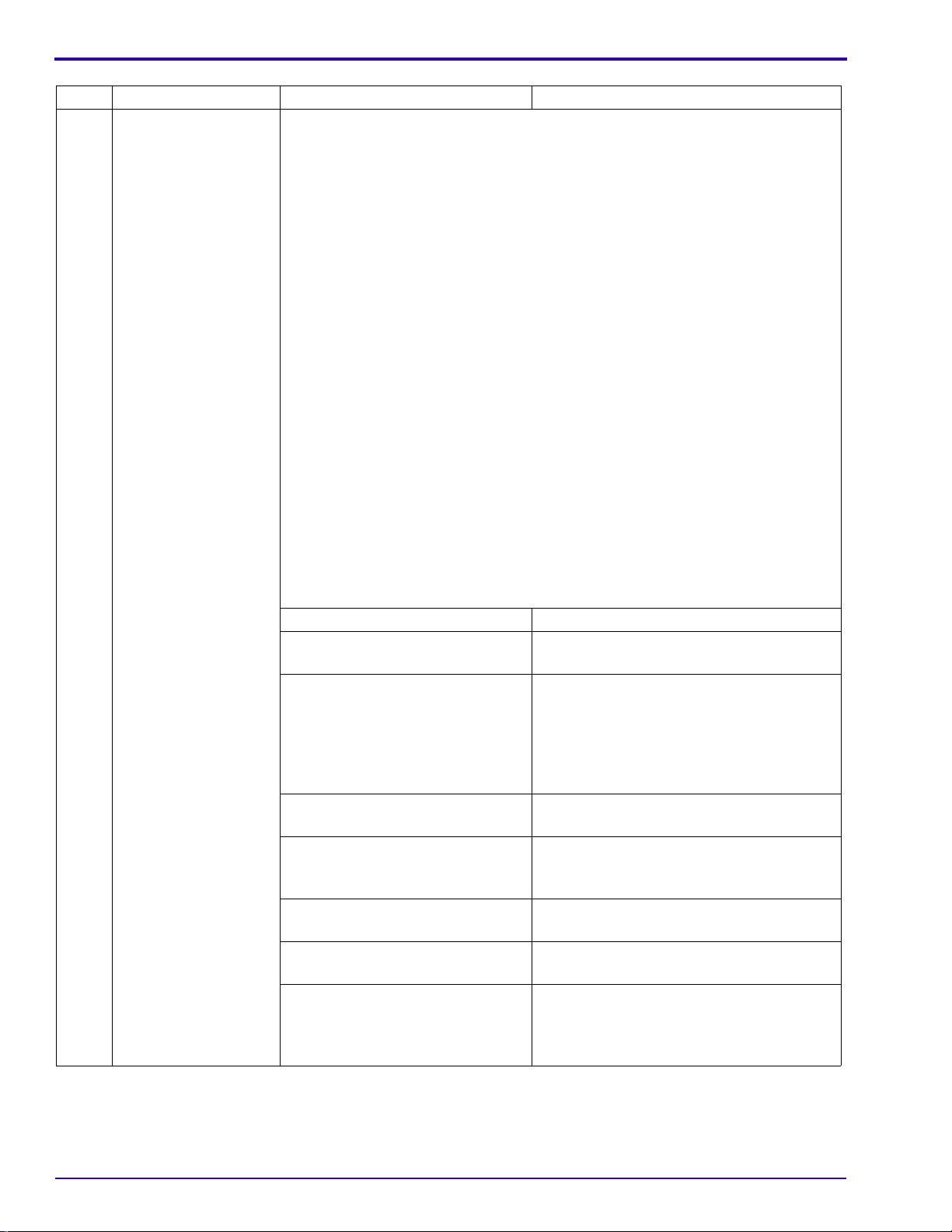

Code Description Possible Malfunction Action

E011 Developer heater failure This error occurs when the 8000 CURRENT SENSE BOARD detects no

current through the DEVELOPER HEATER.

When the temperature of the

developer solution is too high,

the DEVELOPER HEATER

Determine the cause for the high

developer temperature, and repair the

problem.

OVERTEMPERATURE

THERMOSTAT will open. The

THERMOSTAT will reset

automatically when the solution

cools.

No continuity for the

DEVELOPER HEATER

After the HEATER cools, check the

continuity. If necessary, install a new

HEATER.

The 5000 BOARD does not

energize the RELAY K5004 on

Check that the LED DS9 on the 5000

BOARD is energized.

the 5000 BOARD.

If necessary, install a new BOARD.

SOLID STATE RELAY U2 that

Check U2.

controls the DEVELOPER

HEATER

The 5000 BOARD does not

energize the SOLID STATE

Check that LED DS4 on the 5000

BOARD is energized.

RELAY U2.

If necessary, install a new BOARD.

8000 BOARD Install a new BOARD.

E012 Fixer heater failure This error occurs when the 8000 CURRENT SENSE BOARD detects no

current through the FIXER HEATER.

When the temperature of the

fixer solution is too high, the

Determine the cause for the high fixer

temperature, and repair the problem.

FIXER HEATER

OVERTEMPERATURE

THERMOSTAT will open. The

THERMOSTAT will reset

automatically when the solution

cools.

No continuity for the FIXER

HEATER

After the HEATER cools, check the

continuity. If necessary, install a new

HEATER.

SOLID STATE RELAY U5 that

Install a new U5.

controls the FIXER HEATER

The 5000 BOARD does not

energize the RELAY K5004 on

Check that the LED DS9 on the 5000

BOARD is energized.

the 5000 BOARD.

If necessary, install a new BOARD.

The 5000 BOARD does not

energize the SOLID STATE

Check that LED DS1 on the 5000

BOARD is energized.

RELAY U5.

If necessary, install a new BOARD.

8000 BOARD Install a new BOARD.

5B6342 – January 1996 5

Page 6

DIAGNOSTICS

Code Description Possible Malfunction Action

E013 Level sensor circuit failure This error occurs when the level sensor circuit on the 5000 BOARD

malfunctions. The following parts are disabled:

• DEVELOPER and FIXER REPLENISHMENT PUMPS

• RECIRCULATION PUMP

The temperature control for the fixer and developer is disabled.

5000 BOARD Install a new BOARD.

E014 Invalid program software E014 is displayed on the DEVELOPER TEMPERATURE DISPLAY. This

error disables all subsystems, except communications.

The main program software in

Download new software.

the EEPROM on the 5000

BOARD

E015 Invalid bootstrap software The bootstrap software for the

Install a new U5006.

PROM U5006 on the 5000

BOARD

E016 Invalid film accumulator

software

This error does not disable any subsystems. The PROCESSOR will remain

in the standby modeuntil the FILM DETECTOR SWITCHESactuate. These

SWITCHES provide information about the length of the film. Because the

6000 BOARD does not operate correctly, the PROCESSOR uses the

information from the SWITCHES to determine the replenishment rate.

The main program software in

Download new software.

the EEPROM on the 6000

BOARD

6 January 1996 – 5B6342

Page 7

Non-Fatal Errors

Code Description Possible Malfunction Action

E032 Developer tank fill

error

This error will occur if the:

• DEVELOPER TANK:

– does not fill in 2 minutes in normal operation

– does not fill in 10 minutes in the Tank Fill Mode

– is empty and the operator does not select the Tank Fill Mode

• REPLENISHER TANK is empty.

• REPLENISHMENT HOSE has:

– an obstruction

– a kink

– an air bubble

• TANKS of thePROCESSOR are filledwith water during the initial installation

.

The following parts will be disabled:

• DEVELOPER REPLENISHMENT PUMP

• RECIRCULATION PUMP

• temperature control for the fixer and developer

To prevent the error from occurring during the initial installation:

• Add 240 mL (8 fl oz) of developer to the DEVELOPER TANK before you fill

the PROCESSOR with water.

• Energize the RECIRCULATION PUMP to move the developer and remove

any air bubbles. Use the diagnostics to energize the PUMP.

LEVEL PROBES Clean and check the PROBES.

The solution level in the

REPLENISHER TANK is low.

Solution does not flow through the

HOSES between the

REPLENISHMENT TANK and the

REPLENISHMENT PUMP.

The DEVELOPER DRAIN VALVE

is opened.

SOLID STATE RELAY U3 that

controls the DEVELOPER

REPLENISHMENT PUMP

POPPET VALVES in the

DEVELOPER REPLENISHMENT

PUMP

DEVELOPER REPLENISHMENT

PUMP

The 5000 BOARD does not

energize the SOLID STATE

RELAY U3.

Mix new developer solution.

Check that the:

• HOSE CLAMPS are tight.

• HOSES:

– are round and opened

– have no obstructions or air bubbles

Close the VALVE.

Check U3.

Clean and check the VALVES.

Check the REPLENISHMENT PUMP

MOTOR B3.

Check that LED DS3 on the 5000 BOARD

is energized.

If necessary, install a new BOARD.

Error Codes

5B6342 – January 1996 7

Page 8

DIAGNOSTICS

Code Description Possible Malfunction Action

E033 Fixer tank fill error This error will occur if the:

• FIXER TANK

– does not fill in 2 minutes in normal operation

– does not fill in 10 minutes in the Tank Fill Mode

– is empty and the operator does not select the Tank Fill Mode

• REPLENISHMENT TANK is empty.

• REPLENISHMENT HOSE has:

– an obstruction

– a kink

– an air bubble

• TANKS of the PROCESSOR are filled with water during the initial installation

.

The following parts will be disabled:

• FIXER REPLENISHMENT PUMP

• RECIRCULATION PUMP

• temperature control for the fixer and developer

To prevent the error from occuring during the initial installation:

• Add 240 mL (8 fl oz) of fixer to the FIXER TANK before you fill the

PROCESSOR with water.

• Energize the RECIRCULATIONPUMP to movethe fixer andremove any air

bubbles. Use the diagnostics to energize the PUMP.

LEVEL PROBES Clean and check the PROBES.

The solution level in the

Mix new fixer solution.

REPLENISHER TANK is low.

Solution does not flow through the

HOSES between the

REPLENISHMENT TANK and the

Check that the:

• HOSE CLAMPS are tight.

• HOSES:

REPLENISHMENT PUMP.

– are round and opened

– have no obstructions or air bubbles

The FIXER DRAIN VALVE is

Close the VALVE.

opened.

SOLID STATE RELAY U4 that

Check U4.

controls the FIXER

REPLENISHMENT PUMP

POPPET VALVES in the FIXER

Clean and check the VALVES.

REPLENISHMENT PUMP

FIXER REPLENISHMENT PUMP Check the REPLENISHMENT PUMP

MOTOR B4.

The 5000 BOARD does not

energize the SOLID STATE

Check that LED DS2 on the 5000 BOARD

is energized.

RELAY U4.

If necessary, install a new BOARD.

8 January 1996 – 5B6342

Page 9

Code Description Possible Malfunction Action

E038 Loss of developer

cooling ability

Water does not enter the WASH

TANK.

Check:

• that water is supplied to the

PROCESSOR

– The water supply is turned on.

– The FILTER is clean.

• WASH WATER SOLENOID L1

– The operation is correct.

– The SCREEN has no obstructions.

• COOLING/DRAIN SOLENOID L2

The temperature of the water

entering the WASH TANK is too

hot.

Decrease the temperature of the water

supply. The wash water must be a

minimum of 5.5°C (10°F) below the setpoint

of the developer.

HEAT EXCHANGER in the

DEVELOPER TANK

The 5000 BOARD does not

energize the SOLENOID L1 or

Remove any obstructions from the

EXCHANGER.

Check for 24 V DC at TERMINALS1 and 2

on the WASH WATER SOLENOID L1.

de-energize the SOLENOID L2.

Check that 24 V DC is not present at

TERMINALS 1 and 2 for the

COOLING/DRAIN SOLENOID L2.

Error Codes

E040 Loss of dryer heating

ability

If necessary, install a new BOARD.

RECIRCULATION PUMP Check the RECIRCULATION PUMP

MOTOR B5. If necessary, install a new

PUMP.

A PANEL is not installed. Install the PANEL.

DRYER OVERTEMPERATURE

THERMOSTAT

Reset the THERMOSTAT. If the

THERMOSTATopensagain,determinethe

cause of the high temperature. If you

cannot determine the cause of theproblem,

install a new THERMOSTAT.

SOLID STATE RELAY U1 that

Check U1.

controls the DRYER HEATER

No continuity for the DRYER

HEATER

The 5000 BOARD does not

energize the SOLID STATE

Check that the resistance at 25°C (77°F) is

approximately 18 W.

Check that LED DS5 on the 5000 BOARD

is energized.

RELAY U1.

If necessary, install a new BOARD.

5B6342 – January 1996 9

Page 10

DIAGNOSTICS

Code Description Possible Malfunction Action

E041 Loss of transport speed control

When the PROCESSOR operates normally:

• The supply voltage from the +24 V POWER SUPPLY PS3 to the

PCOM and +24 V TERMINALS of the DRIVE MOTOR

Note

This error occurs when the

transport speed is adjusted for

10 seconds and the speed is

not within 7.6 cm/min (3 in./min)

of the setpoint.

CONTROLLER A4 is 24 V DC.

• The control voltage to TERMINALS 4 and 6 on the DRIVE MOTOR

CONTROLLER A4 is approximately:

– 0.85 V DC for the Extended Speed

– 1.55 V DC for the Standard Speed

– 2.25 V DC for the Rapid Speed

– 3.00 V DC for the K/RA Speed

• Feedback pulses from the DRIVE MOTOR CONTROLLER A4 at

Test Point MOTFB on the 5000 BOARD indicate the speed of the

DRIVE MOTOR.

If the transport operates slower than the set speed, the

MICROPROCESSOR increases the control voltage approximately

25 mV every second at TERMINALS 4 and 6 on the DRIVE MOTOR

CONTROLLER A4. If the voltage reaches 5 V DC, the

MICROPROCESSOR stops increasing the voltage. When you check

the voltage, if it is:

• 5 V DC, check for mechanical malfunctions.

• 0, check the wiring and the CONNECTOR.

5000 BOARD If the control voltage is not correct at

TERMINALS 4 and 6of the DRIVE MOTOR

CONTROLLER A4, install a new BOARD.

DC DRIVE MOTOR B6 or

DRIVE MOTOR

CONTROLLER A4

If B6 operates, but no pulses occur at Test

Point MOTFB on the 5000 BOARD or if the

supply voltage and the control voltagetothe

CONTROLLER are not correct, check:

• B6

•A4

E042 Loss of accessory data link Loose connections Check all connections between any

accessory and the PROCESSOR.

5000 BOARD Install a new BOARD.

2000 BOARD Install a new BOARD.

E045 Display data link error CABLES between the

Check the CABLES.

3000 and 5000 BOARD

10 January 1996 – 5B6342

Page 11

Warnings

Error Codes

Error

Code

E128 Top cover not in

place

E129 Tanks currentlybeing

filled

E130 Replenish pumps

disabled

E132 Developer under set

temperature

E133 Developer over set

temperature

E134 Dryer under set

temperature

E137 Film accumulator

LED error

Error

Description

Possible

Malfunction Action

When this error occurs, the following functions are disabled:

• film transport

• film accumulation

The TOP COVER is opened. Close the TOP COVER.

INTERLOCKSWITCHESS3

and S4

• MAGNETS

7000 BOARD Install a new BOARD.

When this error occurs,

• the following functions are disabled:

– film transport

– film accumulation

• the following parts are disabled:

– RECIRCULATION PUMP

– 3 HEATERS

None None. This message will clear automatically.

None Use the KEYPAD to select either Automatic or

None None. This message will clear automatically when

None None. This message will clear automatically when

None None. This message will clear automatically when

6000 BOARD Check that no chemical deposits are on the

Check S3 and S4. If necessary, install a new

SWITCH or MAGNET.

Flooded Replenishment to enable the PUMPS.

the developer reaches the setpoint temperature.

the developer reaches the setpoint temperature.

the DRYER reaches the setpoint temperature.

PROTECTIVE COVER for the BOARD.

De-energize and energize the PROCESSOR to

reset the:

• MICROPROCESSOR on the 5000 BOARD

• MICROPROCESSOR on the 6000 BOARD

Check the BOARD. Use the internaldiagnostics. If

necessary, install a new BOARD.

E141 Low developer tank

level

E142 Low fixer tank level When this error occurs, the:

5B6342 – January 1996 11

When this error occurs, the:

• RECIRCULATION PUMP is disabled

• temperature control for the fixer and developer is disabled

None None. This error will clear automatically when the

developer solution reaches the correct level.

• RECIRCULATION PUMP is disabled

• temperature control for the fixer and developer is disabled

None None. This error will clear automatically when the

fixer solution reaches the correct level.

Page 12

DIAGNOSTICS

12 January 1996 – 5B6342

Page 13

Section 2: Mechanical Diagnostics

Transport Malfunction

Possible Cause Check

RACK and CROSSOVER

ASSEMBLIES

ROLLER ASSEMBLIES ROLLERS

DRYER AIR TUBE BAFFLES

TOP COVER TOP COVER

RACK and CROSSOVER ASSEMBLIES:

correct positions

seated correctly

• squareness

– SeetheAdjustments and Replacements,PublicationNo.5B6340,

RACKS and CROSSOVERS.

Adjusting the Squareness of the CROSSOVERS

Adjusting the Squareness of the RACKS

• cleaned completely

– See the Preventive Maintenance, Publication No. 5B6747.

CROSSOVER TROUGHS

• correct positions

• correct positions

• rotate freely

• GUDGEONS

– no damage

– If necessary, install new ROLLERS.

GEARS, SPROCKETS, and IDLERS

• engage correctly

• not broken or worn

BEARINGS

• no wear

SPRINGS and E-RINGS

• not broken or missing

RACK ASSEMBLY

• DRIVE CHAIN

– tension

• installed

Temperature setting of the DRYER

lowest possible setting to provide the best image quality

•

DRYER ROLLERS and AIR TUBES

• seated correctly

DRYER BELT

• moves correctly

• closed

Mechanical Diagnostics

5B6342 – January 1996 13

Page 14

DIAGNOSTICS

Artifacts and Wrong Film Densities

Possible Cause Check

Replenishment system Replenishment rates

• correct setting

HOSES

• opened and round

• no obstructions or air bubbles

HOSE CLAMPS

• tight

REPLENISHMENT PUMP

• operation

• calibration

Replenishment chemicals

• Change any chemicals that are:

– not mixed correctly

– exhausted

– contaminated

Note

When you mix chemicals:

• Mix a maximum of a 2-week supply of the DEVELOPER

RELENISHER.

• Follow all directions for mixing chemicals and solutions.

• Use a SPLASH GUARD and DRIP TRAY when you remove the

FIXER RACK from thePROCESSOR to prevent contamination ofthe

developer.

DEVELOPER and FIXER TANKS

• DRAIN VALVES

– completely closed

Recirculation system DEVELOPER and RECIRCULATION HOSES

• ORIFICES

– no obstructions

DEVELOPER FILTER

• If necessary, install a new FILTER.

Movement of the solutions at the surface of the PROCESSOR TANKS

when you enrgize the PROCESSOR and the TANKS are full.

• If the solutions do not move, check that the:

– HOSES have no obstructions or air bubbles in the recirculation

system

– RECIRCULATION PUMP operates

– DEVELOPER FILTER is clean and in the correct position

14 January 1996 – 5B6342

Page 15

Possible Cause Check

RACK and CROSSOVER

ASSEMBLIES

RACKS and CROSSOVERS

• correct position

• seated correctly

• cleaned completely

– See the Preventive Maintenance, Publication No. 5B6747.

CROSSOVER TROUGHS and EVAPORATION COVERS

• correct position

• TROUGHS

– clean

• TROUGH DRAINS

– no obstructions

• CROSSOVER YOKE

– correct position

ROLLERS ROLLERS

• clean and not scratched

• correct position

• rotate freely

• GUDGEONS

– no damage

– If necessary, install new ROLLERS.

DETECTOR ROLLERS

• clean

GEARS, SPROCKETS, and IDLERS

• engage correctly

• no wear

BEARINGS

• no wear

SPRINGS

• not broken or missing

DEVELOPER and FIXER RACK ASSEMBLIES

• ROLLER SPROCKETS

– engage correctly

• DRIVE CHAINS

– correct adjustment of the tension

Mechanical Diagnostics

5B6342 – January 1996 15

Page 16

DIAGNOSTICS

Possible Cause Check

Drying system DRYER AIR TUBES

• clean

– If necessary, use a BOTTLE BRUSH and water to clean the

TUBES and SLOTS in the TUBES.

• BAFFLES

– installed

Temperature setting of the DRYER

• lowest possible setting to provide the best image quality

• exhaust for the PROCESSOR

– meets the specifications

– See the Site Specifications, Publication No. 5B6338.

Wrong water temperature Temperature of the water

• 4.5 - 29.5˚C (40 - 85˚F)

Wash water WASH TANK and CROSSOVER TROUGH

• Water flows into these parts

COVERS and PANELS TOP COVER

• closed

ACCESS PANEL

• installed

EVAPORATION COVERS

correct position

•

Ventilation system Exhaust for the PROCESSOR

• meets the specifications

• See the Site Specifications, Publication No. 5B6338.

• Internal EXHAUST FAN operates correctly

External EXHAUST HOSE

• connected from the AIR EXHAUST on the PROCESSOR to the

BUILDING EXHAUST

Internal EXHAUST HOSE

• connected from the internal EXHAUST FAN to the AIR EXHAUST

16 January 1996 – 5B6342

Page 17

Wet Films

Possible Cause Check

Film and chemicals are not

compatible.

Replenishment system Replenishment rates

Film

• compatible with the selected cycle

• correct setting

HOSES

• opened and round

• no obstructions or air bubbles

HOSE CLAMPS

• tight

REPLENISHMENT PUMP

• operation

• calibration

Replenishment chemicals

• Change any chemicals that are:

– not mixed correctly

– exhausted

– contaminated

Mechanical Diagnostics

Note

When you mix chemicals:

• Mix a maximum of a 2-week supply of the DEVELOPER RELENISHER.

• Follow all directions for mixing chemicals and solutions.

• Use a SPLASH GUARD and DRIP TRAY when you remove the FIXER

RACK from the PROCESSOR to prevent contamination of the developer.

REPLENISHMENT TANKS

• quantity of solution

DEVELOPER and FIXER TANKS

• DRAIN VALVES

– completely closed

Recirculation system Movement of the solutions at the surface of the PROCESSOR TANKS when

you energize the PROCESSOR and the TANKS are full.

• If the solutions do not move, check that the:

– HOSES have no obstructions or air bubbles in the recirculation system

– RECIRCULATION PUMP operates

– DEVELOPER FILTER is clean and in the correct position

5B6342 – January 1996 17

Page 18

DIAGNOSTICS

Possible Cause Check

Drying system DRYER AIR TUBES

• clean

– Ifnecessary,useaBOTTLEBRUSHandwatertocleantheTUBESand

SLOTS in the TUBES.

• BAFFLES

– installed

DRYER

• lowest possible temperature to provide the best image quality

DRYER AIR EXHAUST

• no obstructions

• installed correctly

– If necessary, see the Installation Instructions, Publication No. 5B6339.

DRYER HEATER

• operates correctly

DRYER ROLLERS and AIR TUBES

• seated correctly

Wash water Water

• input to the WASH TANK

• temperature

• input to the CROSSOVER TROUGHS

– is connected

RACK and CROSSOVER

ASSEMBLIES

WASH RACK

• SQUEEGEE ROLLERS

– clean

– good condition

SPRINGS

• not broken or missing

SQUEEGEE ASSEMBLY

• operates correctly

• ROLLERS

– clean

– good condition

• SPRINGS

– correct tension

YOKE and CROSSOVER TROUGHS

• installed correctly

CROSSOVER TROUGHS

holes are

• opened

– Ifnecessary,cleantheholes to prevent an overflowofthewaterfromthe

TROUGHS into the DEVELOPER and FIXER TANKS.

18 January 1996 – 5B6342

Page 19

Solution Levels

Possible Cause Check

Replenishment system Replenishment rates

• correct setting

HOSES

• opened and round

• no obstructions or air bubbles

REPLENISHMENT PUMP

• operation

• calibration

REPLENISHMENT TANKS

• quantity of solution

POPPET VALVES

• clean

• no damage

DEVELOPER and FIXER TANKS

• DRAIN VALVES

– no leakage

CROSSOVER TROUGHS

• correct positions

• TROUGHS

– clean

• TROUGH DRAINS

– no obstructions

Mechanical Diagnostics

5B6342 – January 1996 19

Page 20

DIAGNOSTICS

20 January 1996 – 5B6342

Page 21

Section 3: Internal Diagnostics

Accessing the Internal Diagnostics

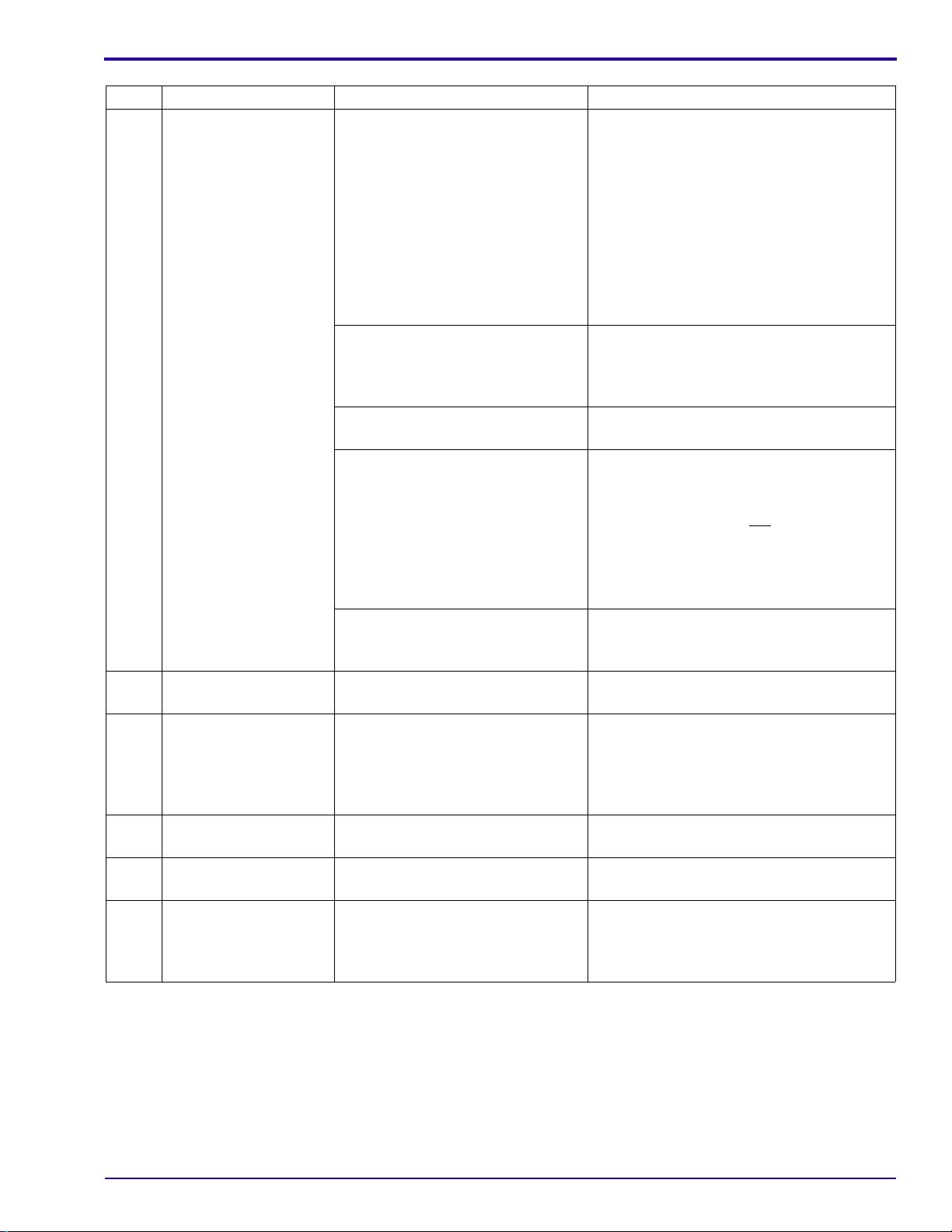

Procedure

Internal Diagnostics

READY

DRYER

TEMP

1 2 3 4 CANCEL

∧∨CYCLE MORE DONE/

INFO SETUP OPTIONS DONE/

USAGE DIAG SW

SLEEP SELECT

CYCLE

VERSION

MORE GO TO

SETUP

REQUEST

RETURN

RETURN

MORE DONE/

RETURN

[1] Press “GO TO SETUP” from the main menu.

[2] Enter the access code. If the customer:

• has not changed the code, it is 4213.

• has changed the code, see the Adjustments

and Replacements, Publication No. 5B6340,

Electrical, Resetting or Bypassing the Access

Code.

[3] Press “MORE”.

[4] Press “INFO”.

[5] Press “DIAG”todisplaythefirstdiagnosticmenu.

Advance to the next page to see the

3 diagnostic menus.

In addition to accessing the first diagnostic menu

from this screen, you can access additional

screens that will enable you to access more

information about the PROCESSOR. Select:

• “USAGE” to access information about the

type and quantity of film and chemicals used

in the PROCESSOR

• “SW VERSION” to access the software

version number for the following programs for

the 5000 and 6000 BOARDS:

– Boot program

– Main program

• “MORE” to access the total number of hours

the:

– PROCESSOR has been energized

– DRIVE MOTOR has been energized

• “DONE/RETURN” repeatedly to return to the

main menu

5B6342 – January 1996 21

Page 22

DIAGNOSTICS

D1 Menu

[6] Press “MORE” to display the D2 Menu.

VIEW

ERRORS

D2 Menu

HEATER

TESTS

D3 Menu

PUMP

TESTS

FILM

DETECT

SOLENOID

TESTS

RECEPT

OUTLET

SENSOR

TESTS

MOTOR

TESTS

FILM

ACCUMUL

MORE DONE/

RETURN

[7] Press “MORE” to display the D3 Menu.

MORE DONE/

RETURN

[8] Press “MORE” to return to the first diagnostic

menu.

MORE DONE/

RETURN

22 January 1996 – 5B6342

Page 23

Diagnostic Menus

Overview

When you enter the diagnostic menu, the software:

• de-energizes the following electrical components:

– all HEATERS

– all PUMPS

– all SOLENOIDS

– the BLOWER and DRIVE MOTORS

• de-energizes the SAFELIGHT OUTLET

• disables the error code detection

You can use the internal diagnostics to energize and de-energize electrical components. When you

energize a component, it will automatically de-energize in 4 minutes.

Details

To view the specific options that are availablefrom the D1, D2, and D3 Menus, see the Flowcharts for

the Internal Diagnostics on the following pages.

Menus

Internal Diagnostics

D1 Menu

VIEW

ERRORS

D2 Menu

HEATER

TESTS

FILM

DETECT

SOLENOID

TESTS

SENSOR

TESTS

MOTOR

TESTS

MORE DONE/

RETURN

MORE DONE/

RETURN

From the first menu, you can:

• access History and Frequency Error Logs

• monitor FILM DETECTOR SWITCHES

• monitor SENSORS

• access the D2 Menu

• return to the main menu

From this menu, you can:

• energize and de-energize:

– HEATERS

– SOLENOIDS

– MOTORS

• access the D3 Menu

• return to the main menu

Note

When you energize the HEATERS, energize the

RECIRCULATION PUMPS, too, to prevent the

OVERTEMPERATURE THERMOSTAT from opening.

5B6342 – January 1996 23

Page 24

DIAGNOSTICS

D3 Menu

PUMP

TESTS

RECEPT

OUTLET

FILM

ACCUMUL

MORE DONE/

RETURN

From this menu, you can:

• energize and de-energize:

– PUMPS

– RECEPTACLE OUTLET

– LEDs

• calibrate LEDs on the 6000 BOARD

• determine film size

• access the D1 Menu

• return to the main menu

24 January 1996 – 5B6342

Page 25

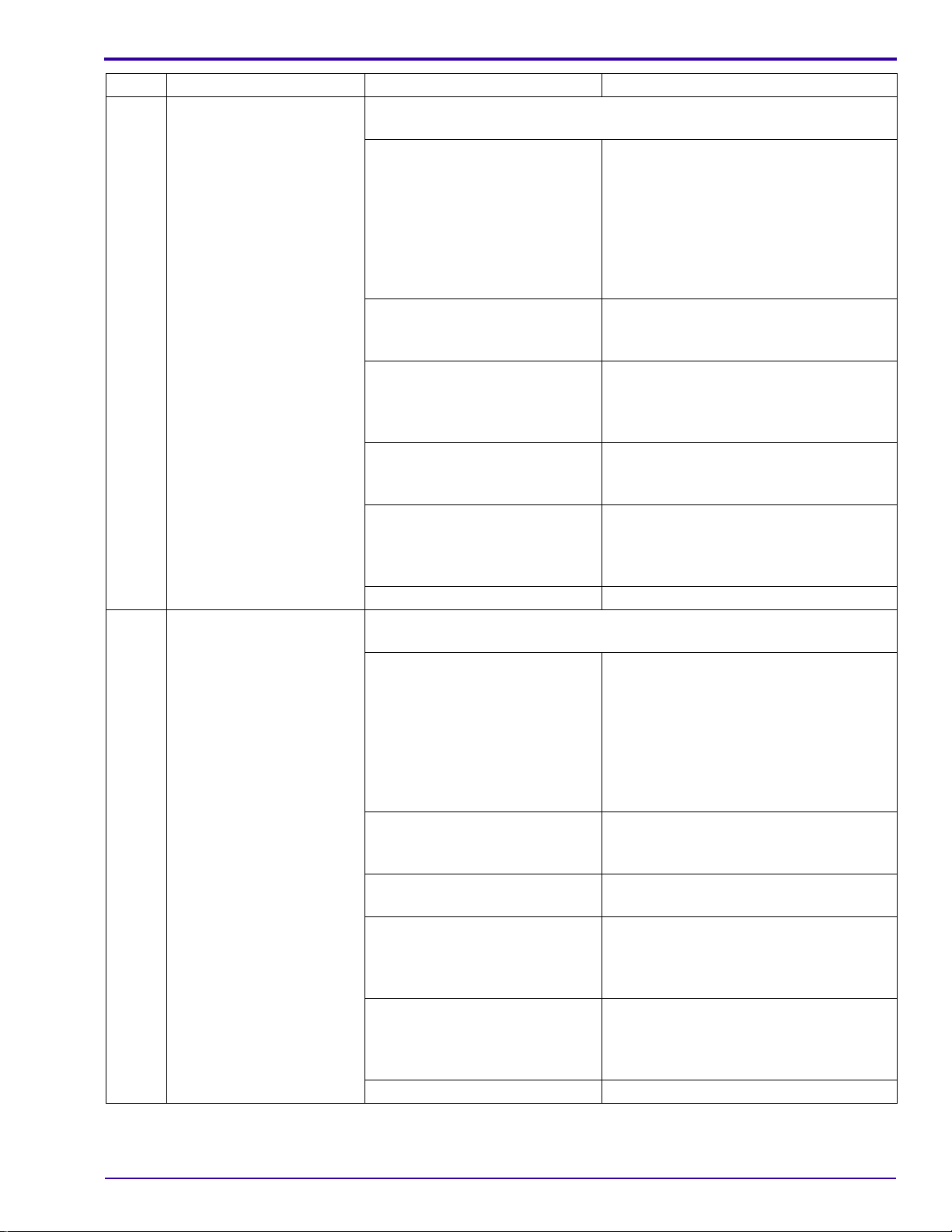

Flowcharts for the Internal Diagnostics

Internal Diagnostics

From DIAG

DONE /

RETURN

MORE

TESTS

SENSOR

To D2 Menu

DONE /

RETURNTANK

MORE

COVER

FIXERDEV

TANK

DEVELOPER TANK : NOT FULL

DONE /

OFF

DRIVE

ROOM LIGHT : LIGHT DETECTED

DONE /

RETURN

MORE

TEMP

FIXER

DEV

TEMP

LIGHT

ROOM

DONE /

RETURN

TYPE

CLEAR

DONE /

RETURN

MORE

TEMP

DRYER

PRESS BUTTON TO SELECT

CANCEL

REQUEST

ALL

D1 Menu

H148_9013EC

FILM

DETECT

VIEW

PRESS BUTTON TO SELECT

ERRORS

ON RETURNDRIVE

DRIVE

NONDRIVE

SIDE

DRIVE SIDE : FILM DETECTED

DONE /

RETURN

LOG

FREQ

LOG

PRESS BUTTON TO SELECT

HISTORY

E129 : 1 3/28/95 10:06:04 AM

1) E002 09/21/94 18:09

2) E014 05/23/94 22:35

CLEAR

ENTRY

V

V V

DONE /

RETURN

V

FATAL

NON

FATAL

SELECT TYPE OF ERROR TO BE CLEARED

WARNING

5B6342 – January 1996 25

Page 26

DIAGNOSTICS

From D1 Menu

DONE /

RETURN

MORE

TESTS

MOTOR

To D3 Menu

DONE /

RETURNBLOWER

BLOWER

EXHAUST

DRYERDRIVE

PRESS BUTTON TO SELECT

MOTOR

DONE /

RETURNSOLENOID

DRYER BLOWER : ON

DONE /

RETURN

OFF

ON

DONE /

RETURN

DONE /

RETURN

SPEED

SELECT

OFF

ON

DRIVE MOTOR : ON

DONE /

RETURN

CANCELDEFAULT

REQUEST

SETTING

V

V

48 IN/MIN = DRIVE MOTOR SPEED

H148_9015EC

TESTS

SOLENOID

TESTS

PRESS BUTTON TO SELECT

D2 Menu

HEATER

DRAINWASH

PRESS BUTTON TO SELECT

WATER

DONE /

RETURN

DRYER

HEATER

FIXER

HEATER

DEV

PRESS BUTTON TO SELECT

HEATER

DRAIN SOLENOID : ON

DEVELOPER HEATER : ON

OFF

ON

DONE /

RETURN

OFF

26 January 1996 – 5B6342

Page 27

Internal Diagnostics

From D2 Menu

DONE /

RETURN

MORE

FILM

ACCUMUL

To D1 Menu

DONE /

RETURN

CALIB

DET

LED/ LED/

PRESS BUTTON TO SELECT

DONE /

RETURN

DONE /

RETURN

DONE /

RETURN

OUTLET

RECEPT

PUMP

TESTS

PRESS BUTTON TO SELECT

D3 Menu

ON OFF

RECEPTACLE OUTLET : OFF

RETURN

PUMP

RECIRC

FIXER DONE /

REPLEN

DEV

PRESS BUTTON TO SELECT

REPLEN

1 ++++?++++++ ++----?----22 OPERATION COMPLETE

RECIRCULATION PUMP : OFF

+ Film is detected.

DONE /

RETURN

ON OFF

- Film is not detected.

? LED does not operate correctly.

DONE /

RETURN

ON OFF

FIXER REPLENISH PUMP : OFF

DONE /

RETURN

ON OFF

DEV REPLENISH PUMP : OFF

H148_9014EC

5B6342 – January 1996 27

Page 28

DIAGNOSTICS

28 January 1996 – 5B6342

Page 29

Section 4: Reports

Overview

Options

The equipment software enables you to use a PRINTER to obtain copies of the following reports.

• A Status Report, which includes information about:

– Processing Parameters

– Options

– Automatic Starting and Stopping Times

– Software Versions

– Miscellaneous Information

• A Usage Report, which includes information about the use of:

– Film

– Chemicals

• A Log Report, which provides information about errors in 2 formats:

– Frequency

– History

Reports

Requirements

You must have the following components to print reports:

• CABLES

• PRINTER with the following specifications:

The

– PRINTER ADAPTER CABLE TL-5004

– INTERFACE CABLE TL-4391

– 9600 baud

– 8 data bits

– no parity

– serial interface

– XON/XOFF protocol

Kodak Diconix

180si PRINTER meets these specifications.

5B6342 – January 1996 29

Page 30

DIAGNOSTICS

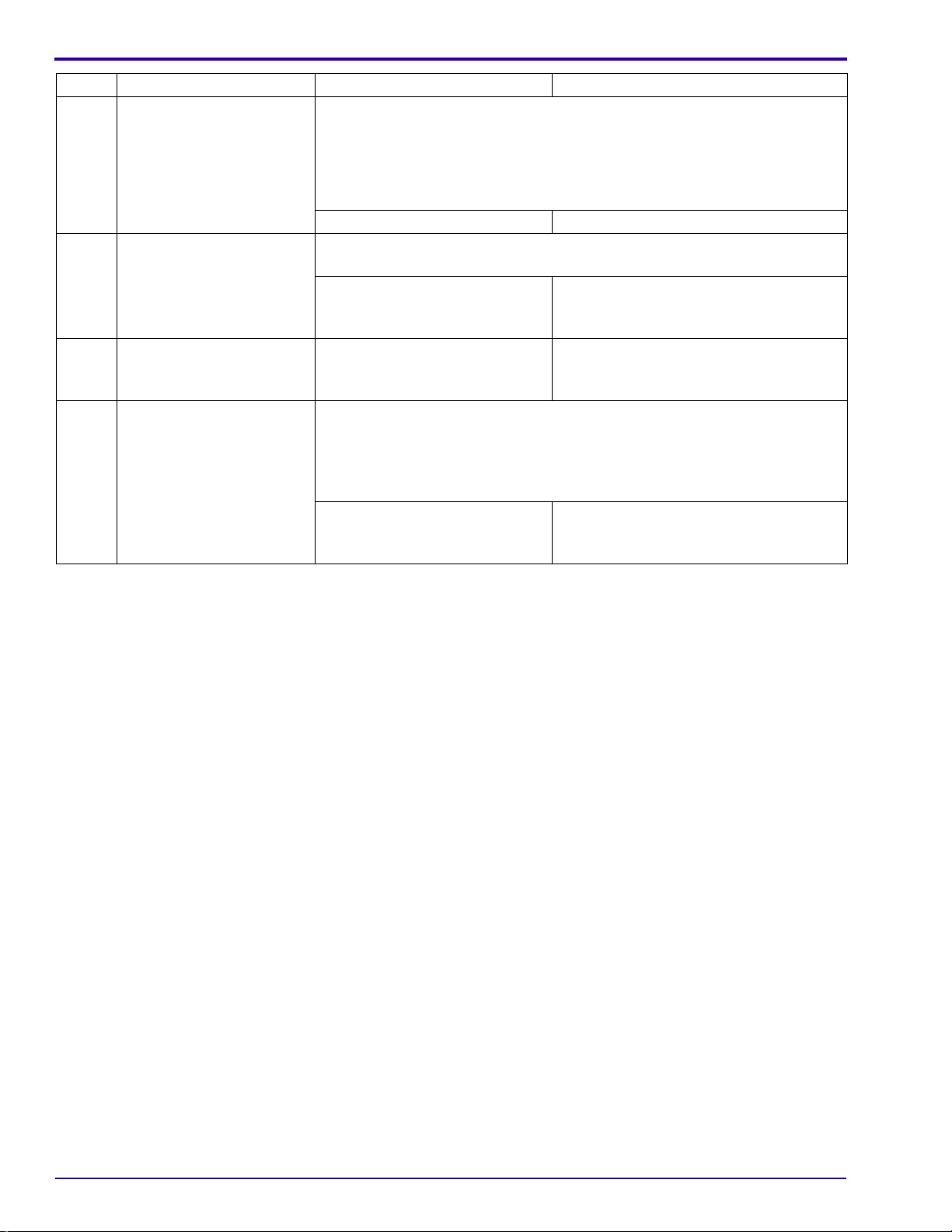

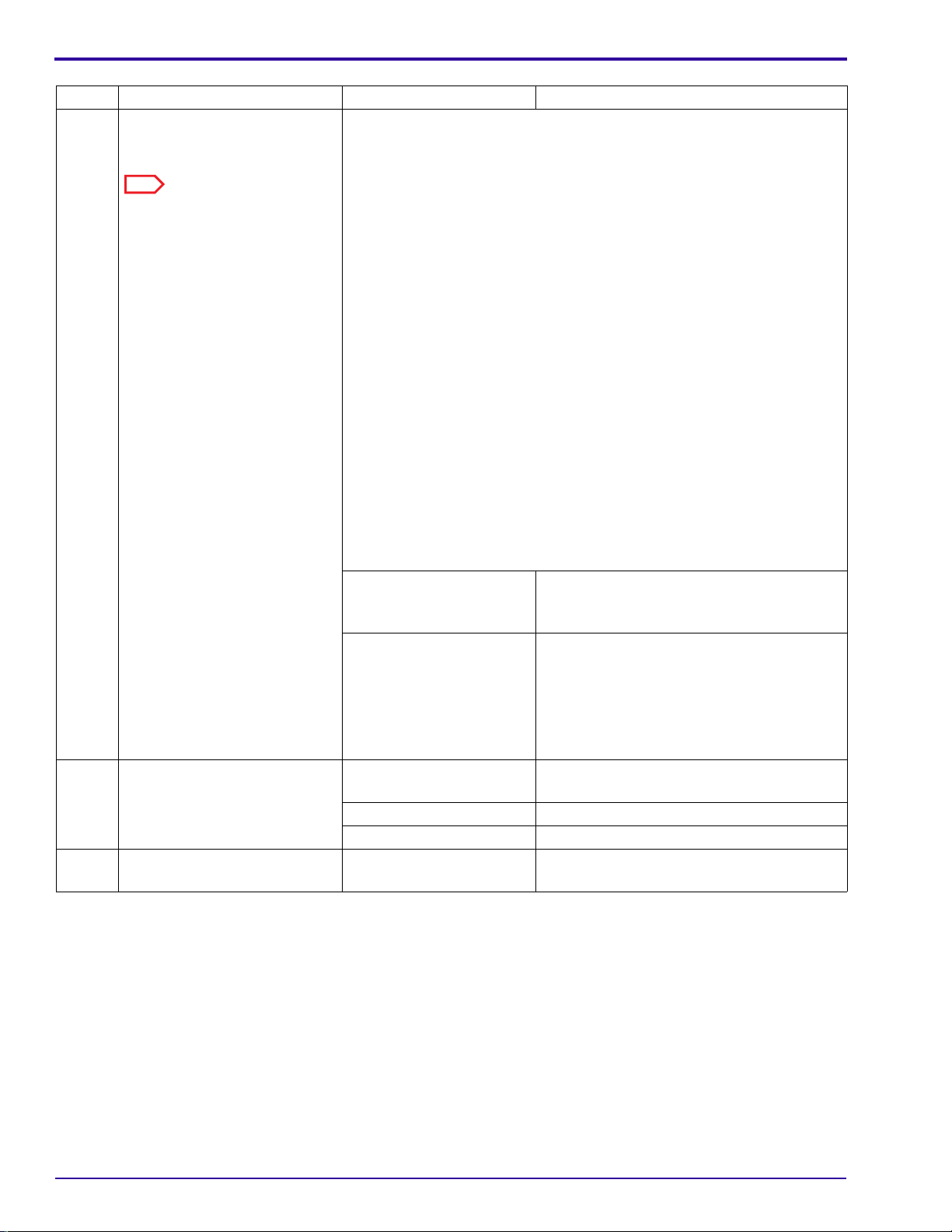

Printing Reports

Procedure

[1] Connect:

• the INTERFACE CABLE TL-4391 to the PROCESSOR INTERFACE CONNECTOR (PIC) on either the

DRYER END or the FEED END of the PROCESSOR

• the PRINTER ADAPTER CABLE TL-5004 to the INTERFACE CABLE TL-4391 and the PRINTER

PROCESSOR

INTERFACE

CONNECTOR

(PIC)

H148_0174BCB

H148_0174BA

READY

DRYER

TEMP

SLEEP SELECT

CYCLE

MORE GO TO

SETUP

1 2 3 4 CANCEL

REQUEST

∧∨CYCLE MORE DONE/

RETURN

INFO SETUP OPTIONS DONE/

RETURN

USAGE DIAG SW

VERSION

PROC

PRINTER MORE DONE/

HOURS

MORE DONE/

RETURN

RETURN

FEED ENDDRYER END

[2] Press “GO TO SETUP” from the main menu.

[3] Enter the access code.

[4] Press “MORE”.

[5] Press “INFO”.

[6] Press “MORE” to access the options for the

printer.

[7] Press “PRINTER” to access the options for the

printer.

30 January 1996 – 5B6342

Page 31

Reports

SELECT

PRINTER

PRINT TO

PIC

SELECT

PRINTER

PRINT

STATUS

PRINT

REPORT

PRINT TO

EBOX

PRINT

REPORT

PRINT

USAGE

PRINT

ALL

PRINT

ALL

PRINT

LOGS

DONE/

RETURN

DONE/

RETURN

DONE/

RETURN

DONE/

RETURN

[8] From this screen, you can:

• Press “SELECT PRINTER” to indicate which

connection you used in Step 1:

– PROCESSOR INTERFACE

CONNECTOR (PIC)

– ELECTRICAL BOX (EBOX)

• Press “PRINT REPORT” to select which

reports you want to print:

– Status

– Usage

– Log

• Press “PRINT ALL” to print all the reports at

once.

• Press “DONE/RETURN” repeatedly to return

to the main menu.

5B6342 – January 1996 31

Page 32

DIAGNOSTICS

32 January 1996 – 5B6342

Page 33

Section 5: Appendix

SOLID STATE RELAYS (SSR)

Possible Malfunctions

3 possible malfunctions can occur:

• The control voltage is supplied, but the LOAD does not operate.

– Result: The LOAD malfunctions.

• The control voltage is supplied, but the SSR does not conduct the voltage.

– Result: The SSR malfunctions.

• The 5000 BOARD does not receive the supply voltage at the correct time.

– Result: The 5000 BOARD malfunctions.

Use the following procedures to determine which component malfunctions.

L1

Connect this wire to energize the load.

L2

LOAD*

Appendix

*for example, a

MOTOR or HEATER

21

+3

4

Apply +5 V DC here

to energize the

SOLID STATE RELAY (SSR)

H148_0001BC_

Checking the LOAD

Warning

Dangerous Voltage

[1] De-energize the PROCESSOR.

[2] Place a CLIP between TERMINALS 1 and 2 on the SSR.

[3] Energize the PROCESSOR

[4] If the LOAD:

• operates, the LOAD is not the problem.

• does not operate, install a new LOAD.

[5] De-energize the PROCESSOR.

[6] Remove the CLIP.

5000 BOARD

5B6342 – January 1996 33

Page 34

DIAGNOSTICS

Checking the SSR and the 5000 BOARD

Warning

Dangerous Voltage

[1] De-energize the PROCESSOR.

[2] Disconnect the wire that connects the 5000 BOARD to TERMINAL 3 on the SSR.

[3] Place a CLIP between:

• +5 V DC on the QUAD POWER SUPPLY

• TERMINAL 3 on the SSR

[4] Energize the PROCESSOR.

[5] If the LOAD:

• operates, install a new 5000 BOARD.

• does not operate, install a new SSR.

[6] De-energize the PROCESSOR.

[7] Remove the CLIP.

34 January 1996 – 5B6342

Page 35

Publication History

Section 6: Publication History

Print Date Pub. No. ECO No. Affected Pages File Name Notes

October 1995 5B6342 2649-029 All dg3425_1_029.doc First printing.

January 1996 5B6342 2649-062 Covers dg3425_1_062.doc Graphic Unification.

January 1998 5B6342 2649-062 All dg342500.fm First CD-ROM printing. Content

is identical to January 1996

version; formatting may vary from

print version.

5B6342 – January 1996 35

Page 36

Kodak, Diconix,

and

X-Omat

are trademarks.

dg342500.fm

Printed In USA

HEALTH IMAGING

EASTMAN KODAK COMPANY ● ROCHESTER, N.Y. 14650

Loading...

Loading...