Page 1

ROUGH DRAFT

THEORY GUIDE

for the

Publication No. Preliminary

10/8/90

Kodak X-Omat

M6RA PROCESSOR

H108_0003DA

Page 2

PLEASE NOTE

The information contained herein is based on the experience and knowledge relating to the subject matter gained by

Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and makes no warranty, express

or implied, with respect to this information. Kodak shall not be liable for any loss or damage, including consequential or

special damages, resulting from the use of this information, even if loss or damage is caused by Kodak’s negligence or

other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic discharge. Use

caution to prevent damage during all service procedures.

Table of Contents

Description Page

2 Preliminary

Page 3

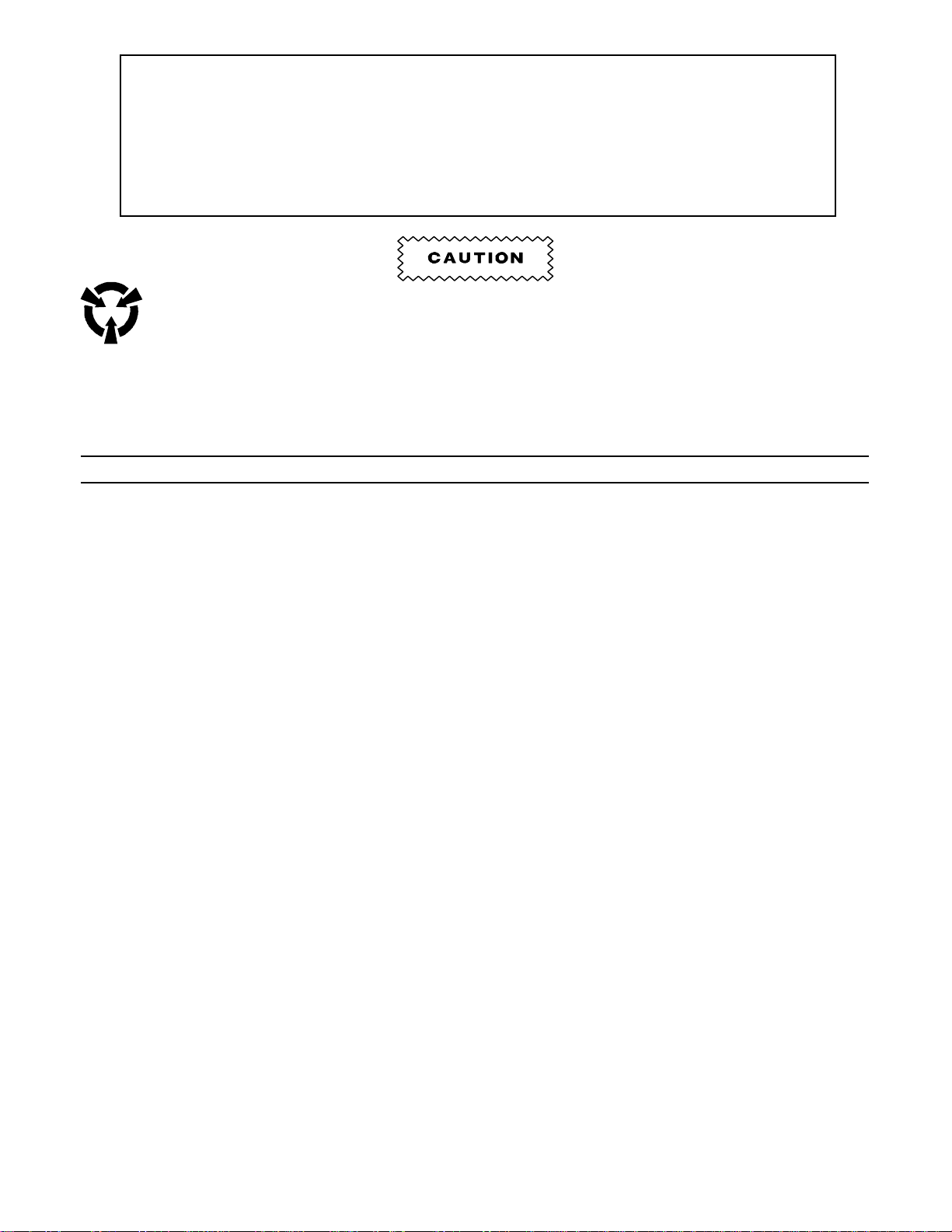

Developer Temperature Control R3, has an internal overtemperature THERMOSTAT.

If recirculation is lost, the internal THERMOSTAT in

When the GPMC (500 Board) senses that both the

DEVELOPER and FIXER PROBES are submerged

in solution (reduced resistance), RELAY K503 is

energized, thus applying line AC voltage across B5,

the RECIRCULATION PUMP. Both the DEVELOPER

LEVEL PROBE and the DEVELOPER

THERMISTOR, R3, are looked at by the 500 Board.

K504 is used as an enable for the DEVELOPER

HEATER. K503 turns on the RECIRCULATION

PUMP. Due to the changes in resistance of R3,

SSRU2 is turned on and off at varying rates to

R3 will open. The 500 Board also controls the

WASH WATER SOLENOID, L1, and the

DEVELOPER COOLING SOLENOID, L2. In the

event that developer temperature goes .5°F above

set temperature, it opens the DEVELOPER

COOLING SOLENOID which is in the DRAIN of the

WASH TANK. It also turns on WASH WATER

SOLENOID, L1. The rate of L1 is 1.5 gallons per

minute; the rate of L2 is 1.2 gallons per minute; and

the DRAIN is routed through the cooling loop at the

bottom of the DEVELOPER TANK.

control the temperature. The DEVELOPER HEATER,

BLOCK DIAGRAM

DEVELOPER TEMPERATURE CONTROL

R6

DEVELOPER

THERMISTER

DEV.

LEVEL

PROBE

FIXER

LEVEL

PROBE

500

BOARD

MICROPROCESSOR

K503

(DS3)

K504

(DS4)

CONTROL

L2 L1

SSR

U2

RECIRC

PUMP

B5

WASH

WATER

SOLENOID

L1

COOLING

DUMP

SOLENOID

L2

DEVELOPER

HEATER

HR-3

L1

L1

L2

AC

DC

QUAD

POWER

SUPPLY

H108_9003DC

Preliminary 3

Page 4

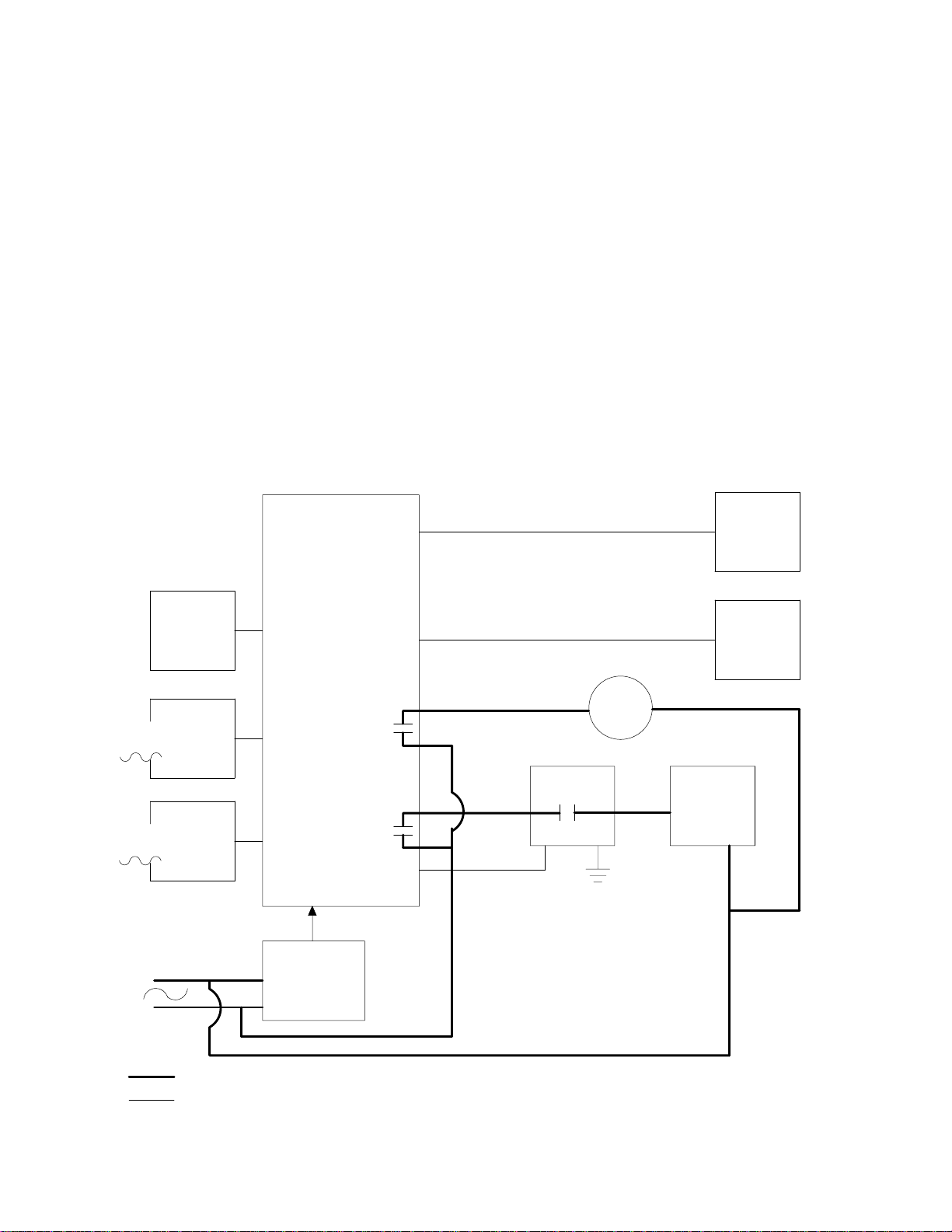

Fixer Temperature Control thermistor is R4. The 500 Board senses the

variations in resistance. K503 is the enable. The

Resistance, or R4, is sensed by the GPMC (500

Board) and is used to control SSRU2. K504 enables

the DEVELOPER HEATER. SSRU2 controls the

DEVELOPER HEATER. K503 turns on the

RECIRCULATING PUMP, B5. So we have a very

large swing — plus 15°F, minus 10°F — and is

variations are used to control SOLID STATE RELAY

U5. The FIXER HEATER is R4. FIXER HEATER

R4 has an internal overtemperature THERMOSTAT

that in the event of loss of recirculation, it will open.

The 500 Board also turns on K503 which turns on

the RECIRCULATION PUMP, B5.

normally controlled at 90°for all cycles. The

BLOCK DIAGRAM

FIXER TEMPERATURE CONTROL

500

R-4

FIXER

THERMISTER

BOARD

MICROPROCESSOR

K503

(DS3)

L2 L1

RECIRC

PUMP

B5

L1

L2

FIXER

LEVEL

PROBE

DEV.

LEVEL

PROBE

AC

DC

QUAD

POWER

SUPPLY

K504

(DS4)

L2

CONTROL

FIXER

SSR

U5

FIXER

HEATER

R-4

L1

H108_9004DC

4 Preliminary

Page 5

Dryer Temperature Control HEATER SOLID STATE RELAY, U1. The DRYER

OVERTEMPERATURE THERMOSTAT should

The DRYER THERMISTOR is R5. Variations in

resistance of R5 are sensed by the 500 Board

(GPMC). This controls the DRYER HEATER

normally be closed unless the HEATERS are turned

on with no air movement. K502 which is on the 500

Board turns on the DRYER BLOWER MOTOR.

RELAY, an enable which is K501; The DRYER

BLOCK DIAGRAM

DRYER TEMPERATURE CONTROL

500 BOARD

L1

L2

DRYER

THERMIS-

TOR

R5

L1

L2

K501

(DS1)

K502

(DS2)

QUAD

POWER

SUPPLY

SSR U1

CONTROL

DRYER

O.T.

THERMOSTAT

S7

RELAY K8

DRYER

HEATER

R1 + R2

DRYER

BLOWER

MOTOR

B1

AC

DC

H108_9005DC

Preliminary 5

Page 6

Developer/Fixer Replenishment Control equivalent of a 14 x 17 sheet of film, it tells the

DEVELOPER SOLID STATE RELAY, U3, and the

The COVER INTERLOCK SWITCH, F6, must be

closed. The UFD (300 Board) senses film is going

through. DETECTOR SWITCHES S1 and S2 detect

the end of the film. The timing takes place on the

300 Board and the 500 Board decides when the

alarm within the UFD (5500 5600 Board) will sound

off to let the operator know when the next film can

FIXER SOLID STATE RELAY, U4, to turn on the

DEVELOPER REPLENISHMENT PUMP, B3, and the

FIXER REPLENISHMENT PUMP, B4, for times that

are set up in the software. To check replenishment

rates there is a replenishment calibrate switch, S5,

and it feeds directly through the 500 Board to both

PUMPS.

be fed into the PROCESSOR. When the UFD (300)

Board signals the 500 Board that it has detected the

BLOCK DIAGRAM

DEVELOPER/FIXER REPLENISHMENT CONTROL

COVER

INTERLOCK

S6

DRIVESIDE

FILM DET.

NON-DRIVE

SIDE FILM

DET.

REPLENISH

CALIBRATE

SWITCH

300

BOARD

S1

OR

S2

S5

5600

BOARD

FILM

ACCUMULATOR

L1

L2

AC

DC

500

BOARD

MICRO-

PROCESSOR

POWER

SUPPLY

DC

A1

CONTROL

L2

CONTROL

L2

L1

DEVELOPER

SSR-U3

FIXER

SSR-U4

DEV-

REPLENISH

PUMP

B3

FIXER

REPLENISH

PUMP

B4

H108_9006DC

6 Preliminary

Page 7

D.C. Drive Motor Control BOARD 400, and through RELAY K506. The control

is a varying DC voltage that goes to A2 from the 500

INTERLOCK SWITCH F6 must be closed.

Instructions are given to the 500 Board via the 200

Board (Interface Board) KEYPAD display to tell the

500 Board in which cycle to operate. This

information is passed to the DRIVE MOTOR SPEED

Board. The DRIVE MOTOR SPEED CONTROLLER

uses this as a control voltage and provides power to

the D.C. DRIVE MOTOR. The D.C. DRIVE MOTOR

produces feedback pulses which are fed back to the

500 Board.

CONTROLLER, A2, through the CURRENT LIMITER

BLOCK DIAGRAM

D.C. DRIVE MOTOR CONTROL

COVER

INTERLOCK

SW S4

L1

L2

PCB 200

INTERFACE

5600

BOARD

FILM

ACCUMULATOR

AC

DC

500

BOARD

MICRO-

PROCESSOR

POWER

SUPPLY

DC

A1

24 V dc

FUSE

F2

DRIVE

MOTOR

SPEED

CONTROLLER

A2

DC

DRIVE

MOTOR

B6

H108_9007DC

Preliminary 7

Page 8

p108_9008ec

Figure 1 All Systems Block Diagram

8 Preliminary

Page 9

BLANK PAGE

Preliminary 9

Page 10

3056tg_a.txt

EASTMAN KODAK COMPANY • ROCHESTER, N.Y. 14650Printed in USA

Kodak

and

X-Omat

are trademarks.

Health Sciences Division

Page 11

Datalogics, Inc. PAGER Typesetting System

Job Completion Statistics

There were 3 errors in this job. Please check your .LOG file to resolve errors. If you encounter

problems that you can’t resolve yourself, please contact your support staff as soon as possible. Keep

this sheet along with the rest of the output so that we can determine the cause of this problem.

Thank you.

CAPS Support

Filename:

Composition Procedure: PRINT

Output Device: POSTSCRIPT V6.008

User: HSD_JUNK

Date: 4-JUN-98

Time: 19:25

Total Pages: 10

Processing Info Used: None!

_$1$DIA3:[HSD.COMMON.TRAD.3056.MKTG]3056TG_A.TXT;14

Loading...

Loading...