Page 1

Publication

No.

981791

6/92

er

テー

wy,

MODIFICATION

Kodak

X-Omat

Service

|

Modification

and

Kodak

X-Omat

Service

Modification

INSTRUCTIONS

Multiloader

Code:

for

270

Code:

3058

ーー

가

N

に

ει

. x .

^

Ropes

tes

ET

rs

DO

děla

sodné

the

RA

3059

No.

u

лак

иное

Processor

8

300

ve

a

ИС"

|

>

Ds

ο

Purpose:

To

To

overtemperature

Service

Special

Serial

Installation

Special

Effects:

Requirements:

Numbers:

Time:

Tools:

eliminate

protect

the

possible

processor

failure

thermostat.

Use

None.

None.

MULTILOADER

270

RA

Approximately

3/8-inch

3/16-inch

Needle

Type

of

connector

if a failure

qualified

PROCESSOR:

Electric

Drill

Nose

personnel

300:

1‘

Drill,

Bit,

Pliers.

1:

J502

causes

IMPORTANT

101 - 415

101 - 404

hours.

TL-1466

TL-9212

Required

by

installing a relay

the

dryer

to

to

install

this

with

|

in

overheat

modification.

exceptions.

by

the

dryer.

circuit.

installing a dryer

See

page 2 for

the

exceptions.

Parts

Status:

Parts

Requirements:

©

Eastman

Kodak

Company,

Available

See

1992

through

Parts

List.

Service

Parts

Management

in

June

1992.

Page 2

The

information

Eastman

No

patent

Eastman

or

implied,

special

damages,

other

This

caution

List:

No.

165627

187213

523016

191097

575822

191098

480820

852959

852799

853086

182950

918381

fault.

Modification

we

\

J

Parts

Part

—

—

853621

—

981791

981888

748023

748024

981875

748125

955741

981890

981891

869623

contained

Kodak

Company

license

is

Kodak

Company

with

respect

resulting

equipment

to

prevent

Modification

Packing

Over-Temperature

Over-Temperature

Relay

Relay

Over-Temperature

Wire/Ident

Washer

Lock

Nut

Screw

Washer

Lock

Screw

Screw

Washer

Lock

Nut

Wire

Electrical

|

Extraction

Modification

herein

prior

granted

reserves

to

this

from

includes

damage

Kit,

List

K1

Plate

K1

Washer

Washer

Washer

Tie

Box

is

based

to

publication.

by

this

information.

the

information.

981876,

Instructions

Assembly

Too!

Sticker

right

the

use

of

parts

during

Includes:

Thermistor

Plate

Thermostat

Label

/5

on

the

to

change

Kodak

this

information,

and

assemblies

all

|

50°

7(_

PLEASE

experience

this

shall

service

information

not

be

even

procedures.

Description

Plate

NOTE

and

knowledge

if

for

loss

without

any

or

liable

sensitive

relating

notice,

loss

damage

to

damage

or

damage,

is

to

the

and

caused

from

subject

matter

makes

no

including

warranty,

by

consequential

Kodak’s

electrostatic

gained

by

express

negligence

discharge.

or

or

Use

Quantity

4-

=

=

=

==

ANNVNNVNNN=

ANA

AOA

AA

Any

not

Kodak

need

141

158

188

192

202

224

229

X-Omat

this

kit

installed:

Multiloader

,

235

237

244

245

250

255

266

—

300

having a serial

284

285

287

289

290

293

294

number

295

296

297

299

303

304

308

listed

below

318

362

364

366

370

387

389

has

already

been

391

392

393

394

395

396

397

modified,

and

does

398

399

400

401

402

403

404

981791

Page 3

Description

Table

of

Contents

Page

PART A -

PART B -

Electrical

Checking

Deenergizing

Deenergizing

RN

Reversing

Checking

installing

InstallingtheRelayK1....................................

Connecting

Securing

LabelingtheNewiy

installingaWireTleMount............................................

installing

Finishing

Dryer

Installing

Installing

Σε ο αμ

Installing

Bracket

Connecting

Installing

Finishing

Box

Modifications

the

Label

on

Terminal

the

МиНоадег

the

270

RA

A

the

Identification

the

Label

on

Terminal

the

NewRelayKiintothebDryerCircult.................................................

.ee

Block

300...............

TB5...............

иене

Processor...

IA

Tag

on

Terminal

Block

TB4............................................................

Block

TB5

een

the

Relay

Into

the

Dryer

Circuit...

the

Newly

the

New

the

and

Tank

the

Dryer

the

Over-Temperature

the

Over-Temperature

.……… せ ….… せ μμ

Wires

the

New

the

JOD..................oooooooonooooconooccccncccnnonanononononananonnoncconocnnonoconennnononana

Installed

installed

Component

μμ

μμ

Modifications

Over-Temperature

to

the

Developer

Wires.................oooroomoccncccooncnnnonccnnnncanacnnoranannnonocnnnnnnonnnnananancnnonannanccanonsnonos

Wires...................................................

Locator

ο

μμ

ο

Dryer

and

Label...

Thermostat...

Thermostat

Thermostat

ϱϱϱ

μμ

Air

Flow

Switch.........

Fixer

Level

in a Processor

in a Processor

μμ.

sees

Sensing

sneen

nens

Probe

ии

DSE

SELE

ини

ee

With

an

Old

with a New

Se

es

ss

esse

eee

Screws

4

et

5

5

5

6

ns

nn

ини

ee

n

nete

ELLE

teen

ὕωωὕῥυυυς

ss

ss

ss

Type

Dryer

Thermistor

Type

Dryer

Thermistor

NL

een eee

seen

enes

Le

enes

and

Washers..........................

non

ana

nenencnncnnnnnnnnonrnnnnnancnnnananas

НЫ

enes

ans

Kn

sneen

Ken

LEE

nene

sene

И

7

8

9

9

10

12

13

14

15

15

16

17

20

22

26

34

36

981791

3

Page 4

PART

A - Electrical

Box

Modifications

a

λος

981791

Page 5

Checking

the

SECTION

Label

on

Terminal

1

Block

TBS

There

on

is a possibility

incorrectly

TERMINAL

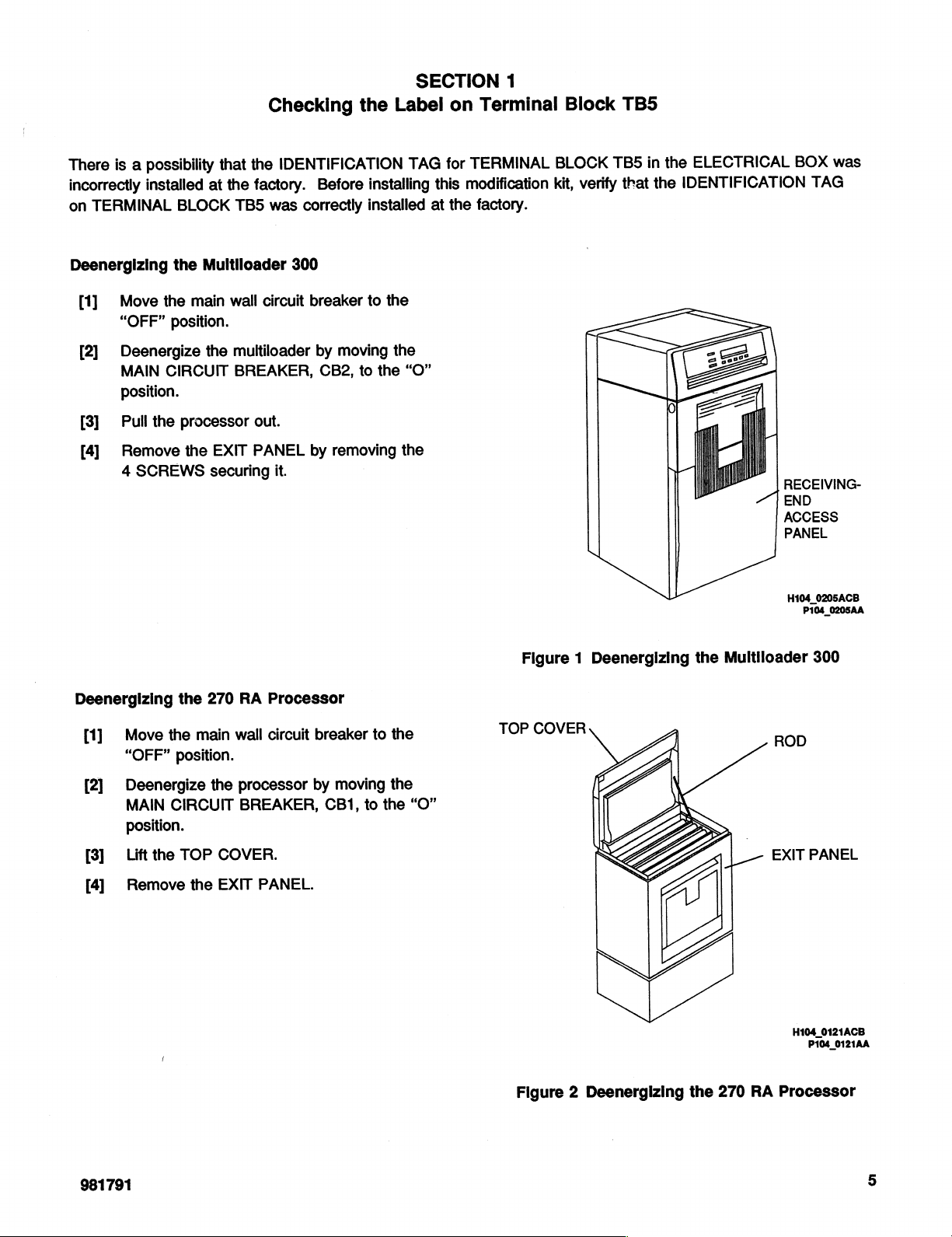

Deenergizing

[1]

[2]

[3]

[4]

installed

Move

“OFF”

Deenergize

MAIN

position.

Pull

the

Remove

4

SCREWS

that

at

BLOCK

the

Multiloader

the

main

position.

the

CIRCUIT

processor

the

EXIT

securing

the

IDENTIFICATION

the

factory.

TB5

was

300

wall

circuit

multiloader

BREAKER,

out.

PANEL

it.

Before

correctly

breaker

by

CB2,

by

installed

to

moving

to

removing

|

TAG

installing

the

the

this

at

the

“O”

the

for

TERMINAL

modification

the

factory.

BLOCK

kit,

verify

R

TB5

that

in

|

the

ELECTRICAL

the

IDENTIFICATION

|

BOX

TAG

RECEIVING-

+

END

ACCESS

PANEL

H104_0205ACB

P104_0205AA

was

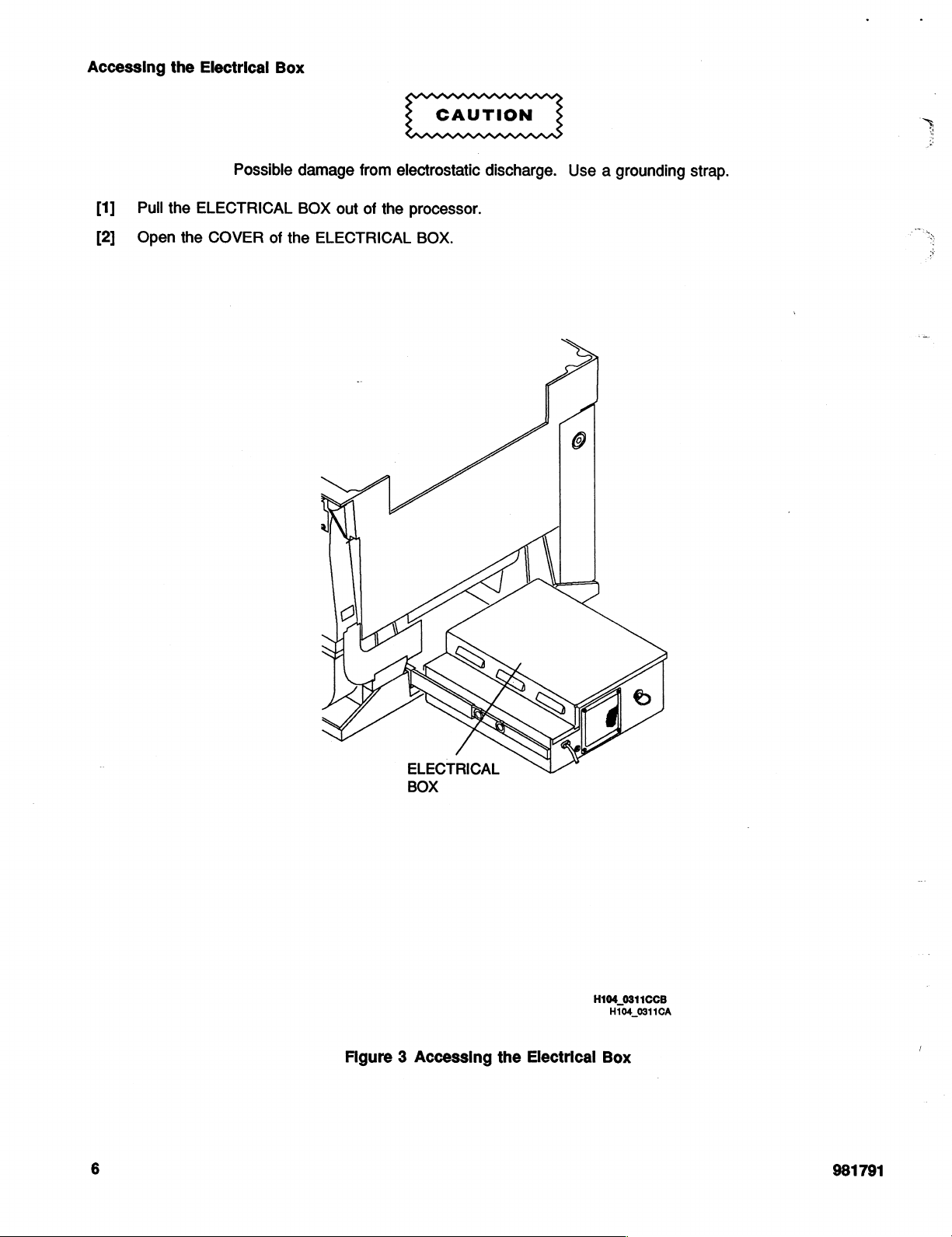

Deenergizing

Move

[1]

“OFF"

[2]

Deenergize

MAIN

position.

[3]

Lift

the

[4]

Remove

the

270

the

main

position.

the

CIRCUIT

TOP

COVER.

the

EXIT

RA

Processor

wall

circuit

processor

BREAKER,

PANEL.

breaker

by

moving

CB1,

to

to

the

the

the

“O”

Figure 1 Deenergizing

TOP

COVER

|

Figure 2 Deenergizing

the

Multiloader

_—

the

270

ROD

EXIT

RA

Processor

300

PANEL

H104_0121ACB

P104_0121AA

981791

Page 6

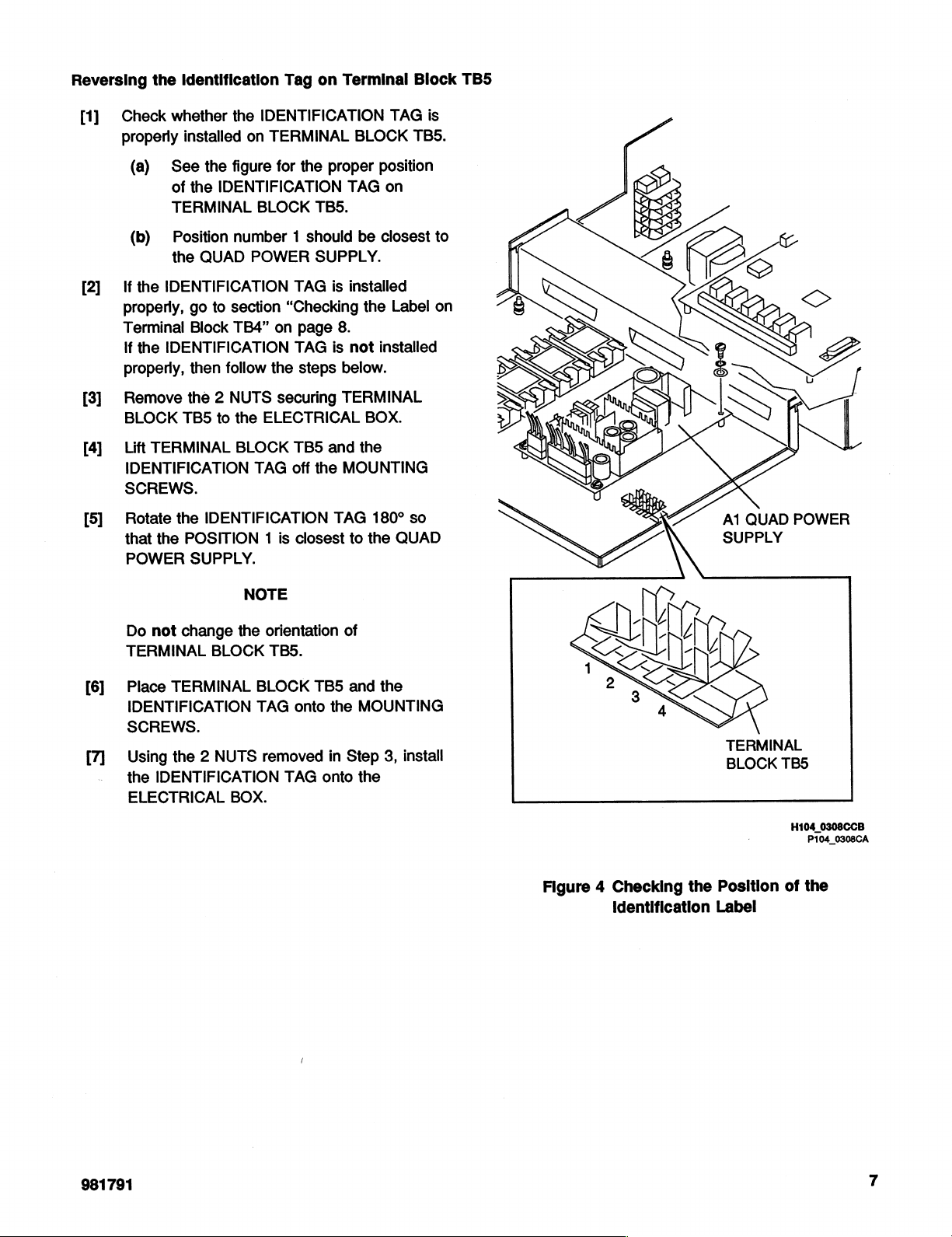

Accessing

the

Electrical

Box

sr

[1]

[2]

Pull

Open

the

ELECTRICAL

the

COVER

Possible

of

the

damage

BOX

out

ELECTRICAL

from

electrostatic

of

the

processor.

BOX.

discharge.

Use a grounding

strap.

Figure 3 Accessing

ELECTRICAL

BOX

the

Electrical

H104

0311CCB

H104_0311CA

Box

6

981791

Page 7

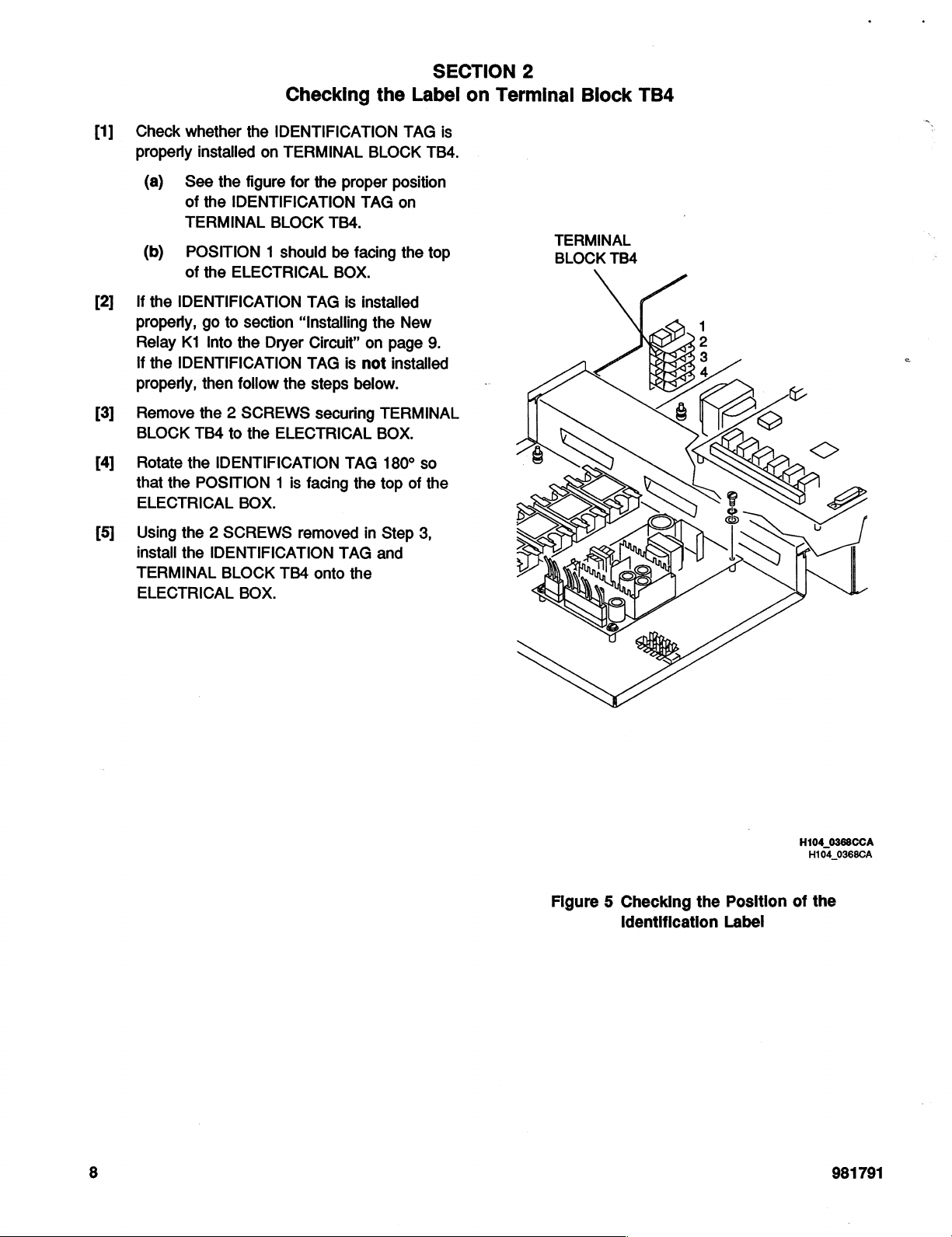

Reversing

the

Identification

Tag

on

Terminal

Block

TB5

Check

[1]

properly

(a)

(b)

If

[2]

[3]

[4]

[5]

the

properly,

Terminal

If

the

properly,

Remove

BLOCK

Lift

IDENTIFICATION

SCREWS.

Rotate

that

POWER

whether

installed

See

of

TERMINAL

Position

the

IDENTIFICATION

IDENTIFICATION

TB5

TERMINAL

the

the

POSITION 1 is

the

the

figure

the

IDENTIFICATION

number 1 should

QUAD

go

to

section

Block

TB4”

then

follow

the 2 NUTS

to

the

BLOCK

IDENTIFICATION

SUPPLY.

IDENTIFICATION

on

TERMINAL

for

the

BLOCK

POWER

ELECTRICAL

TAG

NOTE

TB5.

SUPPLY.

TAG

“Checking

on

page

TAG

the

steps

securing

TB5

off

the

closest

BLOCK

proper

TAG

be

is

installed

the

8.

is

not

below.

TERMINAL

BOX.

and

the

MOUNTING

TAG

180*

to

the

TAG

is

TBS.

position

on

closest

installed

Label

so

QUAD

to

on

A1

QUAD

SUPPLY

POWER

Do

TERMINAL

Place

[6]

IDENTIFICATION

SCREWS.

Using

[7]

the

ELECTRICAL

not

change

TERMINAL

the 2 NUTS

IDENTIFICATION

the

BLOCK

BLOCK

TAG

removed

BOX.

orientation

TBS.

onto

TAG

of

TB5

the

in

onto

and

the

MOUNTING

Step

3,

the

install

Figure 4 Checking

TERMINAL

BLOCK

the

Position

identification

Label

TB5

H104

0308CCB

P104_0308CA

of

the

981791

Page 8

Checking

the

SECTION

Label

on

Terminal

2

Block

TB4

[1]

[2]

[3]

[4]

[5]

Check

properly

If

properly,

Relay

If

properly,

Remove

BLOCK

Rotate

that

ELECTRICAL

Using

install

TERMINAL

ELECTRICAL

whether

installed

(a)

See

of

the

TERMINAL

(b)

POSITION 1 should

of

the

the

IDENTIFICATION

go

K1

Into

the

IDENTIFICATION

then

the 2 SCREWS

TB4

the

the

POSITION 1 is

the 2 SCREWS

the

the

IDENTIFICATION

on

TERMINAL

the

figure

for

the

IDENTIFICATION

BLOCK

ELECTRICAL

TAG

to

section

the

follow

to

the

IDENTIFICATION

BOX.

IDENTIFICATION

BLOCK

BOX.

“Installing

Dryer

Circuit”

TAG

the

steps

ELECTRICAL

facing

removed

TB4

onto

BLOCK

proper

TAG

TB4.

be

facing

BOX.

is

installed

the

on

is

not

below.

securing

TAG

the

in

TAG

the

TAG

TB4.

position

on

the

top

New

page

9.

installed

TERMINAL

BOX.

180°

so

top

of

the

Step

3,

and

is

TERMINAL

BLOCK

TB4

Figure 5 Checking

Identification

the

Position

Label

H104

0368CCA

H104_0368CA

of

the

981791

Page 9

Installing

the

New

SECTION

Relay

K1

3

Into

the

Dryer

Circuit

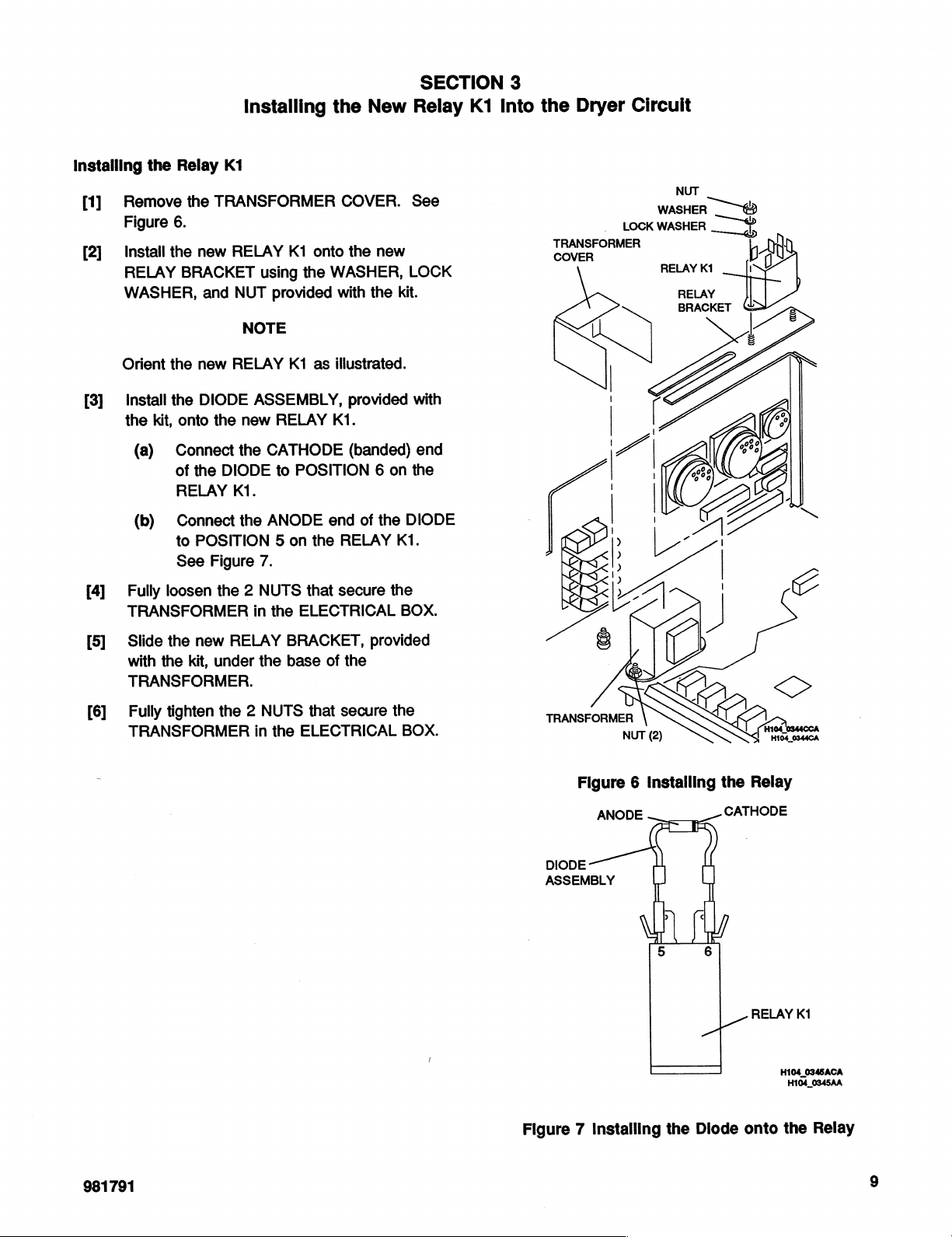

Installing

Remove

[1]

Figure

Install

[2]

RELAY

WASHER,

Orient

Install

[3]

the

(a)

(b)

Fully

[4]

TRANSFORMER

the

kit,

loosen

Relay

6.

the

the

the

onto

Connect

of

RELAY

Connect

to

See

K1

the

TRANSFORMER

new

RELAY

BRACKET

and

NUT

NOTE

new

RELAY

DIODE

the

new

the

the

DIODE

KI.

the

POSITION 5 on

Figure

the 2 NUTS

K1

onto

using

the

provided

K1

as

ASSEMBLY,

RELAY

CATHODE

to

POSITION 6 on

ANODE

the

7.

that

in

the

ELECTRICAL

COVER.

the

new

WASHER,

with

the

kit.

illustrated.

provided

KI.

(banded)

end

of

the

RELAY

secure

KI.

the

See

LOCK

with

end

the

DIODE

BOX.

NUT

LOCK

TRANSFORMER

COVER

C

WASHER

WASHER

RELAY

RELAY

BRACKET

GP

K1

RD

「

|

M

û

[5]

[6]

Slide

with

TRANSFORMER.

the

new

the

kit,

Fully

tighten

TRANSFORMER

RELAY

under

the

the 2 NUTS

in

the

BRACKET,

base

of

the

that

secure

ELECTRICAL

provided

the

BOX.

Figure 6 Installing

ANODE

DIODE

ASSEMBLY

u

5

the

6

AT

Relay

CATHODE

RELAY

K1

H104_0345ACA

H104_0345AA

981791

Figure 7 Installing

the

Diode

onto

the

Relay

Page 10

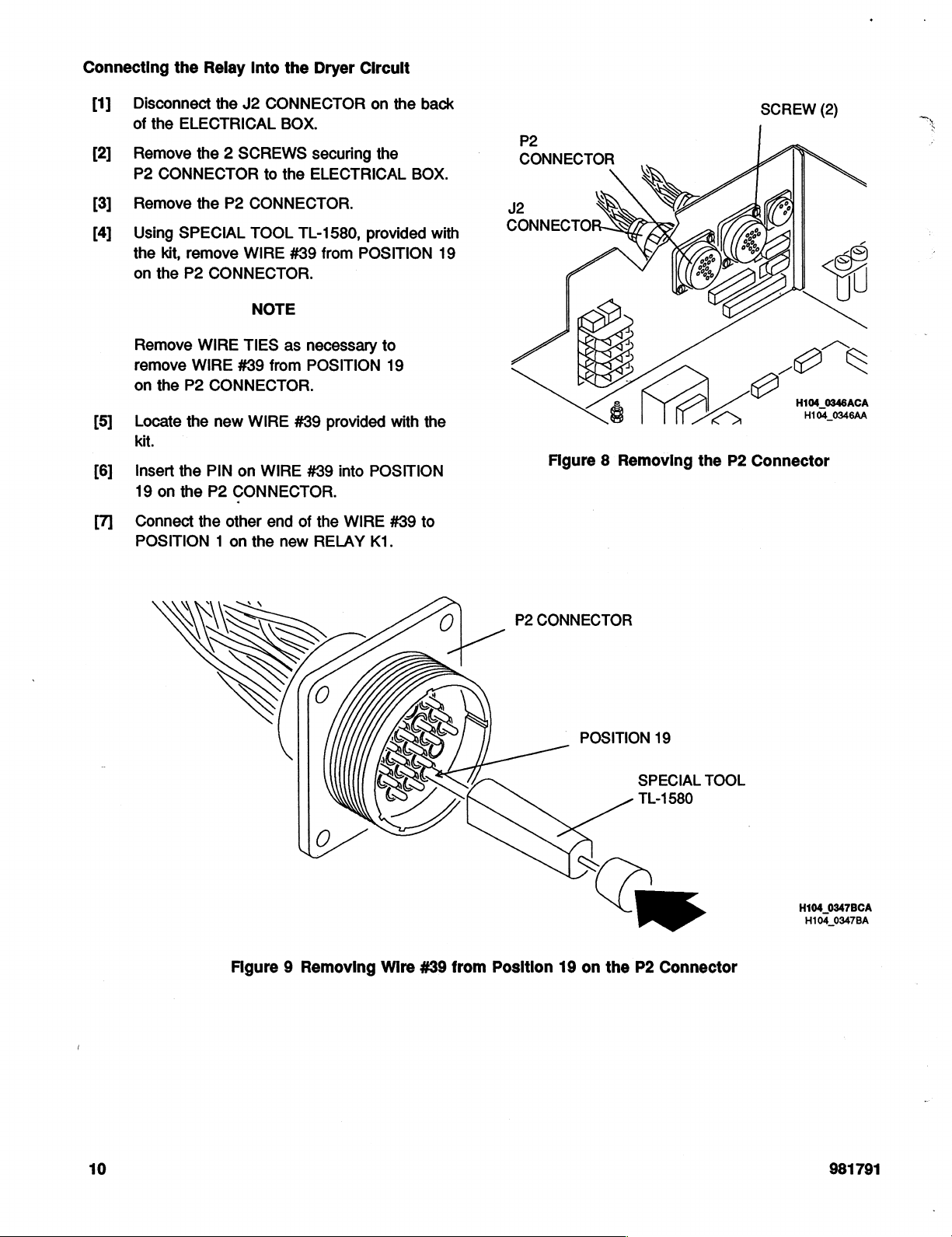

Connecting

the

Relay

Into

the

Dryer

Circult

Disconnect

[1]

of

Remove

[2]

P2

Remove

[3]

Using

[4]

the

on

Remove

remove

on

Locate

[5]

kit,

Insert

[6]

19

Connect

POSITION 1 on

the

ELECTRICAL

the 2 SCREWS

CONNECTOR

the

SPECIAL

kit,

remove

the

P2

CONNECTOR.

WIRE

WIRE

the

P2

CONNECTOR.

the

the

PIN

on

the

P2

the

the

J2

P2

CONNECTOR.

TOOL

WIRE

NOTE

TIES

#39

new

WIRE

on

CONNECTOR.

other

the

CONNECTOR

BOX.

securing

to

the

ELECTRICAL

TL-1580,

#39

as

necessary

from

POSITION

#39

WIRE

#39

end

of

new

from

provided

into

the

WIRE

RELAY

on

the

the

provided

POSITION

to

19

with

POSITION

#39

K1.

back

BOX.

with

the

to

19

P2

CONNECTOR

p

©

Figure 8 Removing

DA

9

の

A

the

P2

SCREW

A

Connector

(2)

ee

s

X

Figure 9 Removing

Wire

#39

from

P2

CONNECTOR

Position

_

POSITION

19

on

(

the

19

SPECIAL

TL-1580

P2

Connector

TOOL

H104_0347BCA

H104_0347BA

10

981791

Page 11

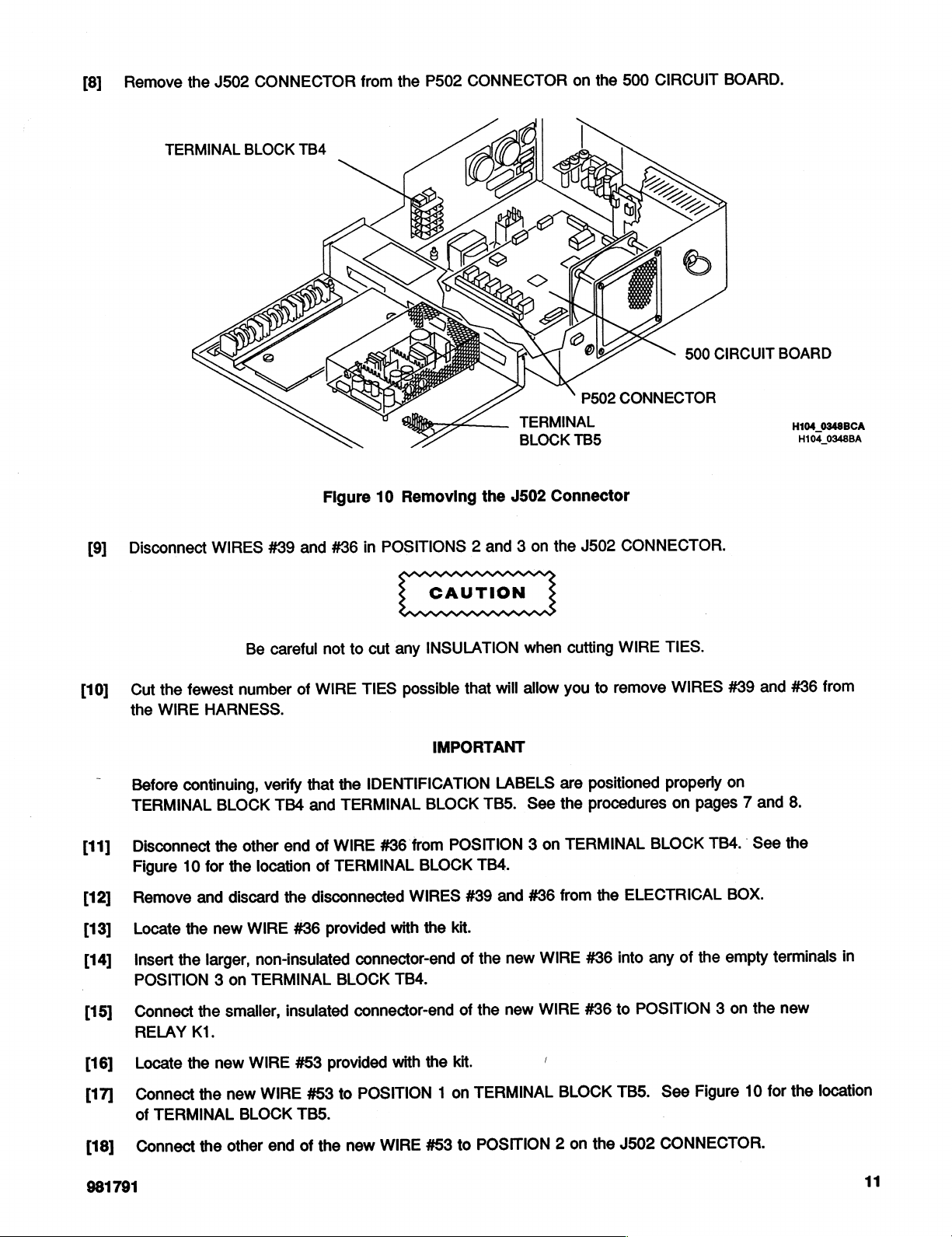

[8]

Remove

the

J502

CONNECTOR

from

the

P502

CONNECTOR

on

the

500

CIRCUIT

BOARD.

[91

TERMINAL

Disconnect

BLOCK

WIRES

#89

TB4

and

Figure

in

#86

10

Removing

POSITIONS

2

the

and

BLOCK

J502

on

3

P502

TB5

Connector

J502

the

500

CONNECTOR

CONNECTOR.

CIRCUIT

BOARD

H104_0348BA

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

the

Cut

|

WIRE

the

Before

TERMINAL

continuing,

Disconnect

Figure

Remove

10

Locate

the

Insert

POSITION

Connect

RELAY

Locate

Connect

of

TERMINAL

fewest

HARNESS.

BLOCK

the

for

and

new

the

larger,

3

smaller,

the

K1.

the

new

the

Be

careful

number

verify

TB4

end

other

location

the

discard

on

new

the

436

WIRE

non-insulated

TERMINAL

insulated

WIRE

WIRE

BLOCK

not

to

TIES

WIRE

of

the

that

TERMINAL

and

WIRE

of

TERMINAL

of

disconnected

provided

connector-end

BLOCK

connector-end

#53

provided

POSITION

to

453

TBS.

cut

any

INSULATION

possible

IDENTIFICATION

from

#36

WIRES

with

TB4.

with

that

IMPORTANT

BLOCK

POSITION

BLOCK

#39

the

kit.

of

of

the

kit.

on

1

when

allow

will

LABELS

See

TB5.

3

TB4.

#36

and

new

the

new

the

TERMINAL

cutting

you

are

the

TERMINAL

on

from

WIRE

WIRE

|

BLOCK

WIRE

remove

to

positioned

procedures

BLOCK

ELECTRICAL

the

any

into

#36

POSITION

to

#36

TB5.

TIES.

WIRES

properly

pages

on

TB4.

the

of

Figure

See

#39

on

BOX.

empty

on

3

and

and

7

See

terminals

the

for

10

#36

8.

the

new

the

from

in

location

[18]

981791

Connect

the

other

end

of

the

new

WIRE

#53

POSITION

to

2

on

the

J502

CONNECTOR.

11

Page 12

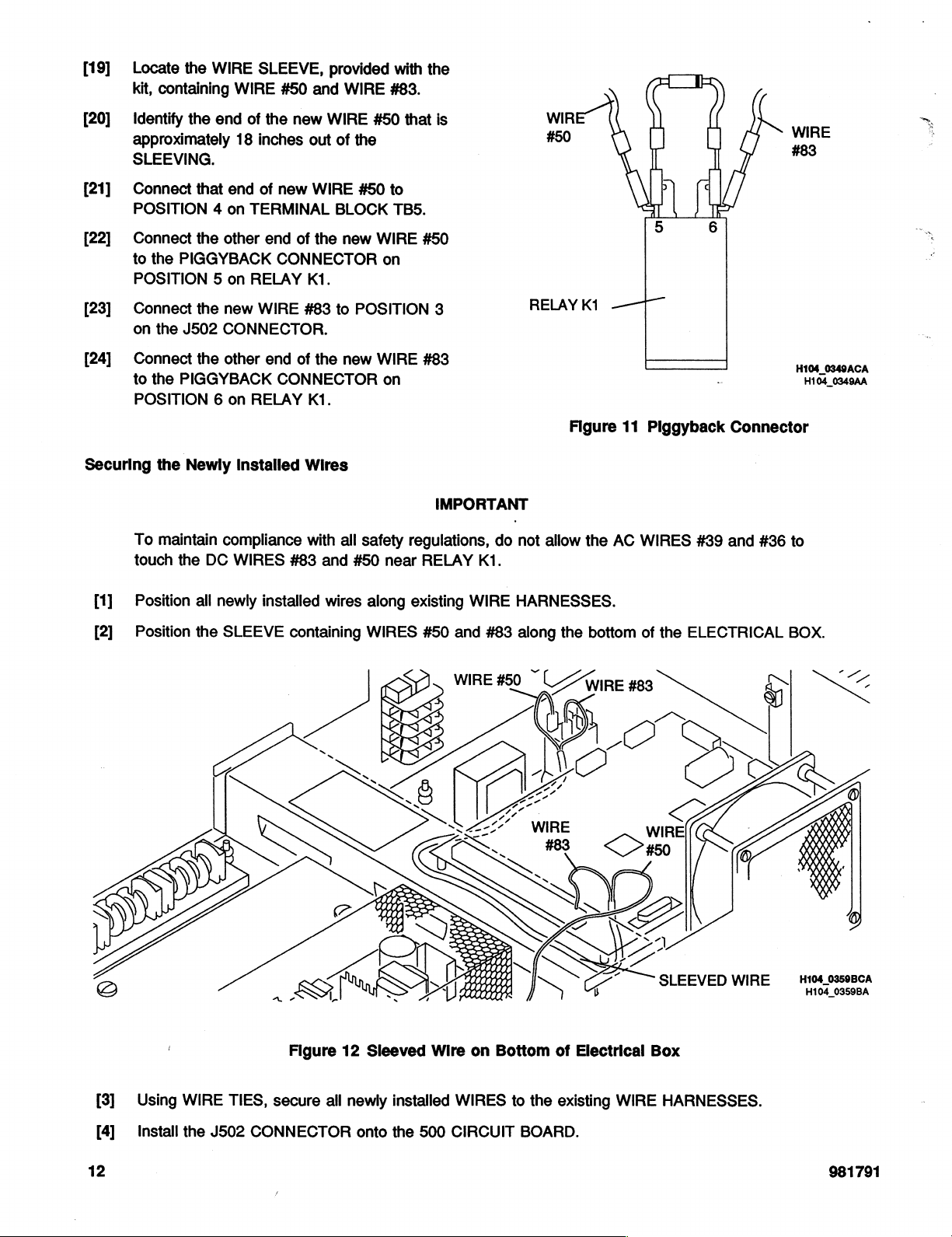

[19]

Locate

kit,

containing

the

WIRE

WIRE

SLEEVE,

#50

provided

and

WIRE

with

#83.

the

[20]

Identify

approximately

SLEEVING.

[21]

[22]

[23]

[24]

Securing

Connect

POSITION

Connect

to

the

POSITION 5 on

Connect

on

the

Connect

to

the

POSITION 6 on

the

To

maintain

touch

the

end

18

end

that

on

4

the

other

PIGGYBACK

the

new

J502

CONNECTOR.

the

other

PIGGYBACK

Newly

the

Installed

compliance

DC

WIRES

of

the

new

inches

new

of

TERMINAL

end

CONNECTOR

RELAY

WIRE

end

CONNECTOR

RELAY

#83

WIRE

out

WIRE

BLOCK

of

the

K1.

483

of

the

KI.

Wires

with

and

#50

of

the

#50

new

WIRE

on

to

POSITION

new

WIRE

on

all

safety

#50

that

is

to

TB5.

#50

3

#83

IMPORTANT

regulations,

near

RELAY

|

do

K1.

WIR

#50

RELAY

not

allow

Ki 一 一

Figure

the

AC

11

Piggyback

WIRES

|

-

#389

WIRE

Connector

and

#86

to

#83

H104

0349ACA

H104_0349AA

[1]

[2]

2

(の

Position

Position

all

newly

the

installed

SLEEVE

wires

containing

|

|

along

WIRES

existing

BES

Figure

12

Sleeved

WIRE

#50

and

WIRE

D

TARA

Wire

on

HARNESSES.

#83

along

#50

Bottom

~

the

A

/

AIA

of

Electrical

bottom

WIRE

of

the

#83

ELECTRICAL

É

Box

BOX.

5

H104_0359BCA

H104

-一

0359BA

[3]

[4]

12

Using

WIRE

Install

the

|

TIES,

J502

secure

CONNECTOR

all

newly

onto

installed

the

500

WIRES

CIRCUIT

to

the

BOARD.

existing

WIRE

HARNESSES.

981791

Page 13

Labeling

[1]

Install

P2

[2]

Install

J502

the

Newly

the

WIRE

CONNECTOR.

the

WIRE

CONNECTOR.

Installed

TIE

labeled

TIE

labeled

Wires

P2,

provided

J502,

with

provided

the

with

kit,

the

onto

kit,

onto

the

the

WIRE

WIRE

HARNESS

HARNESS

leading

leading

to

the

to

the

981791

13

Page 14

SECTION

Installing a Wire

4

Tie

Mount

Some

BOX

Label”

BUNDLES

is

[1]

Install a WIRE

[2]

Using a WIRE

ELECTRICAL

already

procedure

closed.

has a WIRE

on

secured,

TIE

TIE,

BOXES

page

and

MOUNT,

secure

TIE

15.

will

the

have

the

MOUNT

Installing

help

prevent

provided

WIRE

NOTE

WIRE

with

BUNDLE

TIE

installed,

the

WIRE

the

possibility

the

MOUNT

go

kit,

to

the

TIE

to

to

the

newly

already

the

“Installing

MOUNT

of

WIRES

side

of

installed

installed.

the

will

help

being

the

ELECTRICAL

WIRE

If

your

New

Component

keep

the

pinched

TIE

ELECTRICAL

WIRE

when

BOX.

MOUNT.

WIRE

Locator

the

TIE

人

cover

CUT,

MOUNT

Figure

13

Installing

the

Wire

Tie

Mount

to

the

Electrical

Box

14

981791

Page 15

SECTION

5

Some

of

the

TERMINAL

positions.

[1]

Install

proper

(a)

(b)

existing

BLOCK

the

TB5

new

location

Remove

Place

the

LABEL

COMPONENT.

LOCATOR

LABEL

Installing

COMPONENT

as

being

COMPONENT

of

the

new

the

backing

new

COMPONENT

in

the

ELECTRICAL

the

New

LOCATOR

interchanged.

LOCATOR

COMPONENT

from

the

new

LOCATOR

BOX.

Component

LABELS

The

new

LABEL

LOCATOR

COMPONENT

onto

LABEL

show

the

COMPONENT

the

LABEL.

over

Locator

+24

volt

ELECTRICAL

LOCATOR

the

existing

Label

and

the

LOCATOR

BOX.

LABEL.

COMPONENT

24

LABEL

See

volt

return

position

correctly

the

figure

LOCATOR

on

labels

for

the

all

M

[1]

(2)

[3]

[4]

Install

the

page

10.

Install

the

Close

the

Connect

Figure 8 on

the

Figure

P2

CONNECTOR

TRANSFORMER

ELECTRICAL

J2

CONNECTOR

page

10,

14

to

BOX

BOX

if

necessary.

mia,

ER

Installing

Finishing

the

ELECTRICAL

COVER.

COVER.

to

the

P2

New

the

SECTION

the

BOX

CONNECTOR

Component

6

Job

using

on

the

of

Label

the

Locator

the 2 SCREWS

back

removed

ELECTRICAL

in

Step 2 on

/

BOX.

H104_0348BCB

H104_0348BA

See

[5]

981791

Slide

the

ELECTRICAL

BOX

into

the

processor.

15

Page 16

PART B -

Dryer

and

Tank

Modifications

16

981791

Page 17

0]

[2]

Remove:

+

WET

SECTION

è

TOP

EXIT

è

DRYER

è

NON-DRIVE

If

installing

5

WASHERS,

RACK

this

Installing

COVER

ASSEMBLY

SIDE

PANEL

Modification

and 5 LOCK

the

Dryer

(270

RA

Only)

(270

RA

Only).

on a multiloader,

WASHERS.

SECTION

Over-Temperature

remove

1

the

SAFETY

Thermostat

PANEL

by

removing

the 5 SCREWS,

H104_0356DCA

H104_0366DA

981791

Figure

15

Removing

the

Safety

Panel

17

Page 18

There

type

the

old

page

are 2 types

your

processor

type

bracket

22.

of

DRYER

has

and

begin

THERMISTOR

be

sure

on

page

to

20.

IMPORTANT

BRACKETS.

follow

the

The

instructions

Refer

appropriate

for

the

to

the

illustrations

instructions.

new

type

The

bracket

Gea)

>

XY

to

identify

instructions

begin

Old

Type

THERMISTOR

on

the

for

3

Figure

16

Old

Type

Dryer

Thermistor

Bracket

Η104

0142808

P104_0142BA

18

981791

Page 19

|

©

“New

Type

THERMISTOR

BRACKET

Figure

17

New

|

Type

Dryer

H104_0350CCA

Thermistor

H104_0350CA

Bracket

981791

19

Page 20

Installing

[1]

[2]

|

the

Locate

WRAPS,

insert

BLOWER

Over-Temperature

the

remaining 2 WIRES

are

the

WIRES

end

of

MOTOR

the

on

The

#76

WIRE

Thermostat

and

with

the

side

insulated

provided

#86.

the

of

In a Processor

with

insulated

the

processor.

connector

the

kit.

The 2 WIRES,

connector

NOTE

is

the

bigger

With

through

{

——

an

Old

Type

which

the

ACCESS

of

the 2 connectors.

ACCESS

HOLE

Dryer

are

secured

HOLE

Thermistor

together

above

the

Bracket

with

TIE

DRYER

%

+

[3]

Figure

Pull

the

18

WIRES

Inserting

up

through

the

Wires

the

DRYER

through

VT

^

AIR

ング

the

DUCT

~,

DRYER

MOTOR

|

Access

in

the

BLOWER

Hole

bottom

H104_0357ACA

H104_0357AA

Above

of

the

the

Dryer

DRYER

Blower

TANK.

Motor

INSULATED

CONNECTORS

20

Figure

19

Pulling

the

Wires

Up

Through

E

ン

DRYER

the

DRYER

TANK

Dryer

+

Air

AIR

DUCT

Duct

In

the

|

Bottom

of

the

H104_0364BCA

H104_0354BA

Dryer

Tank

981791

Page 21

Using

[4]

LOCK

the

the

THERMOSTAT

kit.

Connect

[5]

the

DRYER

THERMOSTAT.

Remove

[6]

WASHER

THERMISTOR

page

Place

[Π

THERMOSTAT

DRYER

the 2 SCREWS, 2 WASHERS,

WASHERS,

OVER-TEMPERATURE

appropriate

the

DRYER

(a)

(b)

AIR

OVER-TEMPERATURE

the

securing

18.

Save

LOCK

Do

not

THERMISTOR

the

new

THERMISTOR

provided

OVER-TEMPERATURE

BRACKET,

WIRES

SCREW,

the

WASHER

that

DUCT

WASHER,

the

BRACKET.

SCREW,

remove

BRACKET.

OVER-TEMPERATURE

BRACKET

with

THERMOSTAT

provided

you

pulled

in

Step 3 to

DRYER

See

WASHER,

for

reassembly.

the

DRYER

over

BRACKET.

and

the

kit,

with

through

the

and

LOCK

Figure

and

the

existing

2

install

to

the

|

16

on

SCREW 一 和

WASHER

Existing

BRACKET

©

İN

|

|

|

<

v

Neat

TS

|

FI

«————

å

SCREW

4

|

>

LOCK

WASHER

New

BRACKET

OVER-

TEMPERATURE

THERMOSTAT

WASHER

R

THERMOSTAT

E,

GS

|

NK

TS

|

-

之

[8]

[9]

Insert

and

tighten

LOCK

the

BRACKET

BRACKET.

Continue

the

WASHER

OVER-TEMPERATURE

into

with

Dryer

Air

the

removed

the

DRYER

section

Flow

Switch”

SCREW,

“Connecting

WASHER

in

Step 6 through

THERMOSTAT

THERMISTOR

on

page

Wires

26.

and

to

Figure

|

20

Installing

Thermistor

<

an

Old

Bracket

Type

H104

0353CCA

H104_0353CA

Dryer

981791

21

Page 22

Installing

[1]

Remove

(a)

(b)

[2]

Remove

the

Over-Temperature

the

SCREW,

Save

the

Discard

the

and discard

WASHER,

WASHER

SCREW.

the

DRYER

Thermostat

and

and

LOCK

THERMISTOR

In a Processor

LOCK

WASHER

WASHER

for

|

BRACKET.

with a New

securing

Type

the

DRYER

reassembly.

See

Figure

Dryer

Thermistor

THERMISTOR

|

17

on

page

19.

Bracket

BRACKET.

3

[3]

[4]

|

The

INSERT

SCREW,

THERMISTOR

Locate

WRAPS,

Insert

BLOWER

the

the

may

also

come

WASHER,

remaining 2 WIRES

are

WIRES

end

and

BRACKET,

#76

of

the

WIRE

MOTOR.

The

insulated

一 二

LOCK

be

and

with

out

when

WASHER.

sure

provided

#86.

the

connector

一

ι

NOTE

you

remove

When

to

follow

the

with

the

insulated

Φ

connector

NOTE

is

the

the

DRYER

you

are

ready

appropriate

kit.

The 2 WIRES,

through

bigger

of

THERMISTOR

to

install

the

instructions.

which

the

ACCESS

the 2 connectors.

are

BRACKET,

DRYER

secured

HOLE

the

together

above

the

with

TIE

DRYER

LT

Figure

21

Inserting

the

Wires

<=

through

/

the

——

DRYER

MOTOR

|

Access

ACCESS

HOLE

Hole

BLOWER

H104

0357ACA

H104_0357AA

Above

the

Dryer

Blower

Motor

22

981791

Page 23

[5]

Pull

the

WIRES

up

through

the

DRYER

ン

ン

ン

DRYER

ZA

EL

AIR

DUCT

Le.

~

TANK

in

the

DRYER

bottom

AIR

DUCT

of

the

DRYER

|

C

TANK.

INSULATED

CONNECTORS

”

H104_0354BCA

H104_0354BA

Figure

[6]

Using

the 2 SCREWS, 2 WASHERS,

OVER-TEMPERATURE

the

kit.

[7]

Connect

OVER-TEMPERATURE

22

Pulling

the

WIRES

the

Wires

THERMOSTAT

that

you

THERMOSTAT.

Up

Through

pulled

the

and 2 LOCK

to

the

through

the

Dryer

Alr

Duct

In

the

WASHERS,

THERMISTOR/THERMOSTAT

DRYER

AIR

provided

DUCT

Bottom

with

in

Step 5 to

of

the

the

kit,

BRACKET,

the

Dryer

install

the

provided

DRYER

Tank

with

981791

23

Page 24

[8]

Place

the

new

THERMISTOR/THERMOSTAT

WASHER

$

ad

BRACKET

SCREW

LOCK

over

WASHER

the

DRYER

THERMISTOR.

OVER-

TEMPERATURE|

THERMOSTAT

©

NS

P<

+、

THERMISTOR/

THERMOSTAT

BRAckET

| ャ ーー

WASHER

LOCK

WASHER

Figure

23

Installing a New

Type

Dryer

Thermistor/Thermostat

H104

0351CCA

H104_0351CA

Bracket

24

981791

Page 25

If

the

INSERT

you

removed

BRACKET,

[1]

[2]

[5]

remained

the

DRYER

follow

Insert

the

new

and

the

WASHER

removed

THERMISTOR/THERMOSTAT

Tighten

Using a SCREWDRIVER,

1/4

turn

in

Step 6 on

the

SCREW

and

In

the

Instructions

SCREW,

and

no

more.

the

THERMISTOR

only

processor

provided

LOCK

page

21

finger

tighten

below:

with

WASHER

into

the

BRACKET.

tight.

the

when

the

SCREW

kit,

WASHER

THERMISTOR

©

<!

No,

er

o

k

NED

|

|

HT

<

一

NUT

|

ーーーーー-

ゅ

<

テーーーー

LOCK

WASHER

THERMISTOR/

THERMOSTAT

BRACKET

OVER-TEMPERATURE

THERMOSTAT

WASHER

WASHER

LOCK

一

-一

SCREW

TS

asso

my,

If

the

INSERT

you

removed

BRACKET,

Position

[1]

WIRES

when

the

Use

THERMISTOR/THERMOSTAT

Using

[2]

3/16

through

INSERT

Thoroughly

[3]

remove

came

the

follow

the

so

you

TANK.

care

an

in.

DRILL

the

all

out

of

the

processor

DRYER

the

THERMISTOR/THERMOSTAT

that

drill

to

not

ELECTRIC

bottom

was

clean

the

THERMISTOR

Instructions

they

will

the

hole

through

drill

through

DRILL,

BIT,

TL-9212,

of

the

located.

the

DRYER

shavings.

not

TANK

be

when

below:

in

the

way

the

bottom

the

WIRES.

TL-1466,

make a hole

AIR

where

DUCT

with

the

of

to

a

Sle

DRILLED

HOLE

| |

|

ἆ

H104

0352CCA

H104_0352CA

[4]

[5]

981791

Install

the

through

Install

the

NUT,

provided

SCREW

SCREW,

the

newly

WASHER,

with

installed

provided

created

LOCK

the

kit,

in

the

previous

with

hole.

WASHER,

to

secure

the

kit,

the

step.

Up

and

Figure

24

Replacing

Hardware

the

Insert

Provided

with

the

25

Page 26

Connecting

[1]

Remove

removing

LOCK

6

If

removing

COVER

need

WASHERS,

Wires

to

to

the

Dryer

the

DRYER

the

6

WASHERS

the

from a multiloader,

remove

and

IMPORTANT

PLENUM

SCREWS,

securing

NOTE

DRYER

only 4 SCREWS,

LOCK

Alr

Flow

COVER

6

WASHERS,

it.

PLENUM

you

WASHERS.

Switch

by

and

will

There

AIR

paddle-like

the

FLOW

protrusion

Refer

type

to

The

Old

page

connecting

Switch

are 2 types

FLOW

SWITCHES.

FLOW

SWITCH.

SWITCH

to

your

follow

instructions

Type

28.

begin

extending

the

processor

the

Air

The

of

DRYER

The

SWITCH

protrusion

illustrations

appropriate

Flow

to

the

on

has a flat,

extending

The

New

has

a

bent,

from

has

for

connecting

Switch

instructions

New

Type

page

31.

AIR

Old

Type

from

Type

AIR

arm-like

the

SWITCH.

to

identify

and

instructions.

begin

for

be

to

Air

the

sure

the

on

Flow

Old

Type

AIR

FLOW

SWITCH

26

H104_0146CCB

P104

0146CA

Figure

|

25

Old

Type

Dryer

Alr

Flow

Switch

981791

Page 27

New

AIR

SWITCH

Type

FLOW

981791

Figure

26

New

Type

Alr

Flow

H104_0355CCA

H104_0355CA

Switch

27

Page 28

Connecting

In

this

section

the

DRYER

The

DRYER

temperature

Wires

AIR

OVER-TEMPERATURE

exceeds a safe

to

of

the

modification,

VANE

an

Old

SWITCH.

Type

you

This

level.

Dryer

Air

will

be

will

protect

THERMOSTAT

Flow

wiring

the

Switch

the

OVER-TEMPERATURE

processor

will

tum

off

if

the

the

DRYER

DRYER

THERMOSTAT

HEATER

HEATER

if

circuit

malfunctions.

the

DRYER

in

series

with

—

[1]

Remove

[2]

If

you

If

you

Using a small

ES

Figure

the

have a Multiloader

have a 270

27

CONNECTOR

SCREW

Wiring

RA

DRIVER,

y

>>

the

HOUSING

300,

remove

Processor,

press

Over-Temperature

from

the

DRYER

WIRE

remove

the

WIRE

CLIP

#50

#53

NOTE

inside

Thermostat

AIR

from

the

from

the

CONNECTOR

oa

to

FLOW

CONNECTOR

the

CONNECTOR

the

Alr

SWITCH.

HOUSING.

HOUSING

Flow

Switch

HOUSING.

to

release

H104_0370BC

the

WIRE.

28

WIRE

#50/#53

CONNECTOR

Figure

HOUSING

28

Removing

Wire

#50/#53

from

the

Connector

Housing

H104_0314BCB

H104_0314BA

981791

Page 29

[3]

Insert

either

HOUSING.

of

the 2 WIRES

Press

the

WIRE

from

the

CONNECTOR

OVER-TEMPERATURE

completely

into

the

THERMOSTAT

CONNECTOR

into

the

HOUSING.

CONNECTOR

[4]

[5]

[6]

DES

Connect

Using

SPLICE

SPLICE

the

Using

SPLICE

PLIERS,

PLIERS,

the

CONNECTOR

connect

CONNECTOR,

CONNECTOR.

connect

CONNECTOR.

SK

HOUSING

the

remaining

provided

the

wire

Verify

to

the

DRYER

wire

from

with

the

kit.

removed

that

the

in

wire

Step 2 on

SPLICE

CONNECTOR

AIR

the

OVER-TEMPERATURE

Verify

that

page

is

completely

FLOW

the

SWITCH.

wire

is

28

(WIRE

connected

completely

THERMOSTAT

#50

or

to

the

N

connected

#53)

to

SPLICE

to

to

the

other

CONNECTOR.

NF

the

new

the

end

of

H104_0358BCA

H104_0358BA

Figure

Verify

that

29

Connecting

the

SPLICE

the

Wires

CONNECTOR

to

the

IMPORTANT

is

outside

Over-Temperature

of

the

DRYER

Thermostat

PLENUM

COVER.

981791

29

Page 30

[7]

Install

the

DRYER

PLENUM

COVER.

[8]

[9]

[10]

Position

WIRE

Verify

positioned

DRYER

will

Install

PANEL

have.

Go

the

TIES,

that

PLENUM

not

be

the

depending

to

Step 1 on

all

in

pinched.

SAFETY

wires

and

if

necessary.

NOTE

the

wires

the

GROOVE

COVER

PANEL

on

page

secure

are

See

which

34.

the

properly

on

the

so

that

the

figure.

or

the

equipment

wires

they

SIDE

with

you

GROOVE

DRYER

PLENUM

COVER

Figure

30

Routing

Groove

Wires

In

the

H104_0356CCA

Through

Dryer

Plenum

H104_0356CA

the

30

981791

Page 31

Connecting

In

this

section

the

DRYER

The

DRYER

temperature

Wires

AIR

exceeds a safe

to a New

of

the

modification,

VANE

OVER-TEMPERATURE

SWITCH.

Type

you

This

level.

Dryer

Alr

will

be

will

protect

THERMOSTAT

Flow

wiring

Switch

the

OVER-TEMPERATURE

the

processor

will

turn

off

if

the

the

DRYER

DRYER

THERMOSTAT

HEATER

HEATER

circuit

if

the

in

series

malfunctions.

DRYER

with

——a

[1]

Locate

[2]

If

If

>

Figure

the

AIR

FLOW

you

have a Multiloader

you

have a 270

31

RA

Wiring

the

Over-Temperature

SWITCH

300,

Processor,

CONNECTORS

disconnect

WIRE

disconnect

#50

WIRE

Thermostat

in

the

DRYER

from

#53

from

the

to

PLENUM.

AIR

the

AIR

the

FLOW

FLOW

Alr

SWITCH

Flow

SWITCH

a

H104_0369BC

Switch

CONNECTOR.

CONNECTOR.

981791

31

Page 32

[3]

[4]

Using

PLIERS,

Verify

that

Install

either

CONNECTOR,

the

one

connect

wire

is

of

the

provided

WIRE

#50

completely

wires

from

with

the

or

#53

to

connected

the

THERMOSTAT

kit.

the

to

new

the

SPLICE

SPLICE

to

CONNECTOR,

CONNECTOR.

the

other

end

of

provided

the

new

with

SPLICE

the

kit.

NO

A

Figure

32

Installing

SPLICE

CONNECTOR

the

Splice

Connector

to

the

Thermostat

|

δ-/

3

S

|

9

Wire

OA

H104

H104_0358BA

0358BCA

32

981791

Page 33

[5]

Locate

THERMOSTAT.

the

second

wire

from

the

Connect

[6]

the

disconnected

Install

[7]

Position

[8]

WIRE

Verify

positioned

DRYER

will

Install

[9]

PANEL

have.

AIR

FLOW

the

TIES,

that

not

be

the

depending

that

second

in

DRYER

the

wires

if

necessary.

all

the

in

the

PLENUM

pinched.

SAFETY

THERMOSTAT

SWITCH

Step 2 on

PLENUM

and

secure

NOTE

wires

GROOVE

COVER

See

PANEL

on

which

CONNECTOR

page

COVER.

the

are

properly

on

the

so

that

the

figure.

or

the

equipment

31.

wires

they

SIDE

wire

with

you

to

GROOVE

DRYER

PLENUM

COVER

Figure

33

Installing

the

Dryer

Plenum

H104

H104

Cover

0356CCA

0356CA

981791

33

Page 34

In

this

procedure

from

leaking

eliminate

eliminate

[1]

the

the

Remove

you

through

problem

poor

electrical

and

will

seal

the

tank

of

deposits

discard

Installing

Level

contact

the

the

screw

walls

forming

LEVEL

Sensing

onto

and

SECTION

the

New

Probe

holes

in

the

the

LEVEL

on

the

LEVEL

the

malfunctioning

SENSING

PROBE

Developer

Screws

Fixer

and

SENSING

SENSING

of

SCREW

NOTE

2

and

and

Washers

Developer Tank

PROBE

the

SCREWS.

PROBE

LEVEL

on

the

SENSING

Fixer

side

SCREWS,

side

wall

walls

to

This

procedure

and

PROBES.

of

the

prevent

should

therefore

DEVELOPER

chemistry

should

TANK.

-

№

Some

wall

DEVELOPER

SENSING

[2]

Position

the

[3]

Using

CONNECTOR/WIRE

[4]

Repeat

of

of

the

hole

the

the

later

DEVELOPER

PROBE.

the

new

in

the

new

the

procedure

model

TANK,

WASHER,

side

SCREW,

processors

remove

wall

of

provided

to

the

for

TANK.

the

provided

the

side

the

LEVEL

have 2 LEVEL

If

your

processor

SCREW

with

DEVELOPER

with

the

wall

of

the

SENSING

that

secures

the

kit,

TANK.

kit,

secure

DEVELOPER

PROBE

SENSING

has 2 SCREWS

the

CONNECTOR/WIRE

so

that

the

See

Figure

the

LEVEL

TANK.

SCREW

PROBE

GASKET

34

SENSING

in

SCREWS

through

side

on

page

the

side

the

side

of

the

35.

PROBE

wall

through

wall

to

the

WASHER

and

of

the

the

of

the

LEVEL

the

FIXER

side

is

against

TANK.

^

:

34

|

|

981791

Page 35

WASHER

x

SCREW

GASKET

A

À

CONNECTOR/

WIRE

AZ

Figure

34

installing

the

New

Washer

and

Level

Sensing

Probe

Screw

H104_0867DCA

H104

0367DA

|

981791

35

Page 36

SECTION

3

[1]

[2]

install:

*

DRYER

.

ТОР

.

МЕТ

Circle

*

For a Multiloader

*

For a 270

RACK

EXIT

ASSEMBLY

SECTION

the

appropriate

RA

COVER.

number

300,

circle

Processor,

(270

RA

on

number

circle

Finishing

the

Only)

the

Modification

11.

number

8.

Sticker.

MODIFICATION

STICKER

Job

レン

MODIFICATION

STICKER

TS,

ON

_

Figure

[3]

[4]

[5]

[6]

[8]

35

If

you

Install

Close

Energize

Move

Verify

Locating

on a Multiloader

have a multiloader,

the

EXIT

PANEL.

the

TOP

COVER.

the

unit

the

main

wall

proper

operation

the

Modification

300

by

moving

circuit

of

slide

the

the

breaker

the

processor.

H104

H104_0343AC

Sticker

processor

MAIN

CIRCUIT

to

the

0343ACA

“ON”

back

into

BREAKER

position.

Figure

the

|

36

multiloader.

to

the

Locating

on a 270

“I”

position.

ーー

で

レプ

the

Modification

RA

Processor

DRYER

PLENUM

H104

0336ACA

H104

Sticker

0336AA

981791

Page 37

[9]

Locate

the

Diagrams

The

Modification

appropriate

that

do

not

Kit

set

of

new

Wiring

apply

to

your

includes 2 sets

Diagrams,

equipment.

of

new

Wiring

NOTE

provided

Diagrams

with

the

that

illustrate

kit.

Discard

the

new

the

set

of

circuits:

new

Wiring

[10]

* a set

* a set

Insert

*

*

for

for

the

Publication

Publication

the

the

new

Kodak

Kodak

pages

Number

Number

X-Omat

X-Omat

into

their

WD

3058-1

636720

Multiloader

270

RA

Processor

proper

for

for

the

places

the

Kodak

300

in

Kodak

X-Omat

your

X-Omat

Wiring

Multiloader

270

RA

Diagram

Processor.

Package.

300

981791

37

Page 38

22

3058mi_11.bxt

Kodak

EASTMAN

and

X-Omat

KODAK

are

trademarks.

Customer

COMPANY

Equipment

+

ROCHESTER,

Services

N.Y.

Division

14650

Printed

in

USA

Loading...

Loading...