Page 1

Publication No. 7C8772

SERVICE MANUAL

for the

Kodak X-Omat 2000 PROCESSOR

Service Code: 3554

and the

Kodak X-Omat 2000A PROCESSOR

Service Code: 3555

12JAN99

HEALTH IMAGING

© Eastman Kodak Company

H172_0500AC

Page 2

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be

liable for any loss or damage, including consequential or special damages, resulting from any

use of this information, even if loss or damage is caused by Kodak’s negligence or other fault.

Warning

To avoid hazardous conditions, keep floors and floor coverings around your Kodak X-Omat Processor and associated

drains clean and dry at all times. Any accumulation of fluids from mixing tanks, drain lines, etc., should be cleaned

up immediately. In the event of an accumulation of liquid duetobackup,overflow,orother malfunctions of the drain

associated with your X-Omat Processor, call a plumber or other contractor to correct any problem with the drain.

Kodak accepts no responsibility or liability whatsoever for the serviceability of any drain connected to or associated

with a Kodak X-Omat Processor. Such drains are the sole responsibility of the customer.

Radio Interference

Caution

This equipment generates, uses, and can radiate radio-frequency energy. If the equipment is not installed and used

according to the instructions, it may cause interference to radio communications. The equipment has been tested and

found to comply with the limits for a Class A computing device pursuant to Subpart J of Part 15 of the FCC Rules,

which are designed to provide reasonable protection against such interference when the equipment is operated in a

commercial environment. Operation of this equipment in a residential area is likely to cause interference, in which

case the user at the user's own expense will be required to take whatever measures may be required to correct the

interference.

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in

the Radio Interference Regulations of the Canadian Department of Communications.

2 12JAN99 – 7C8772

Page 3

Table of Contents

Description Page

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Special Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Adjustments and Replacements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

FEED SHELF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

DETECTOR SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CROSSOVER AY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

RACK Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

RACK Replacements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

DRYER RACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TURNAROUND AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

MAIN DRIVE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

DRYER HEATER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

PLUMBING System Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

PLUMBING System Replacements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Procedure and Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Monthly Maintenance Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Lubrication Procedure and Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Correcting Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Adjustment for Squareness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installing a new GUIDE SHOE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Adjustment for Squareness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Tension of the DRIVE CHAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

DRIVE CHAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

RESILIENT DRIVE ROLLER in the DEVELOPER and FIXER RACKS . . . 12

RESILIENT DRIVE ROLLERS in the WASH RACK . . . . . . . . . . . . . . . . . . . 13

Adjustment for Squareness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installing a new DRIVE ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Disassembling the TURNAROUND AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installing a new B ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installing new A ROLLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Checking the GUIDE SHOES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Adjusting the MAIN DRIVE CHAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Aligning the MAIN DRIVE MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installing a new MAIN DRIVE SHAFT, WORM GEARS

or BEARING BLOCKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Adjusting the Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Installing a new BLOWER AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Installing a new DRYER HEATER or HEATER CORE . . . . . . . . . . . . . . . . . 27

Adjusting the Developer Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Checking the Replenishment Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Adjusting the REPLENISHMENT PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

DEVELOPER HEATER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

DEVELOPER THERMISTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

DEVELOPER OVER-TEMPERATURE THERMOSTAT . . . . . . . . . . . . . . . 36

HEAT EXCHANGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

RECIRCULATION PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

O-RING in the RECIRCULATION PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

REPLENISHMENT PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7C8772 – 12JAN99 3

Page 4

SERVICE MANUAL

Section 1: Introduction

Electrostatic Discharge

ESD - Electrostatic discharge - is a primary source of:

• product downtime

• low productivity

• costly repairs

While one cannot feel a static charge of less than 3,500 volts, as few as 30 volts can damage or destroy essential

components in electronic equipment.

Preventive Measures

• Always look for an ESD warning label before doing any procedure involving static-sensitive components such

as CIRCUIT BOARDS. All static-sensitive components are marked with bright graphic labels which frequently

include instructions. Follow all label instructions.

• Wear a GROUNDING STRAP when handling static-sensitive components. Always be sure that the CLIP

remains attached to a properly grounded, unpainted, clean surface.

• Repair static-sensitive components atanESD-protectedwork station or use a portable GROUNDING MAT. For

help in setting up an ESD-protected work station, contact your Kodak representative.

• When moving static-sensitive componentsfromonearea to another, insert and transport the components in ESDprotective packaging.

Special Tools

• SEALANT TL-3230

• MOTOR OIL, 1 oz TUBE TL-2244

• MOTOR OIL, 12 oz TUBE TL-2324

• POTENTIOMETER ADJUSTING TOOL TL-1481

• THERMOMETER 716217

4 12JAN99 – 7C8772

Page 5

Section 2: Adjustments and Replacements

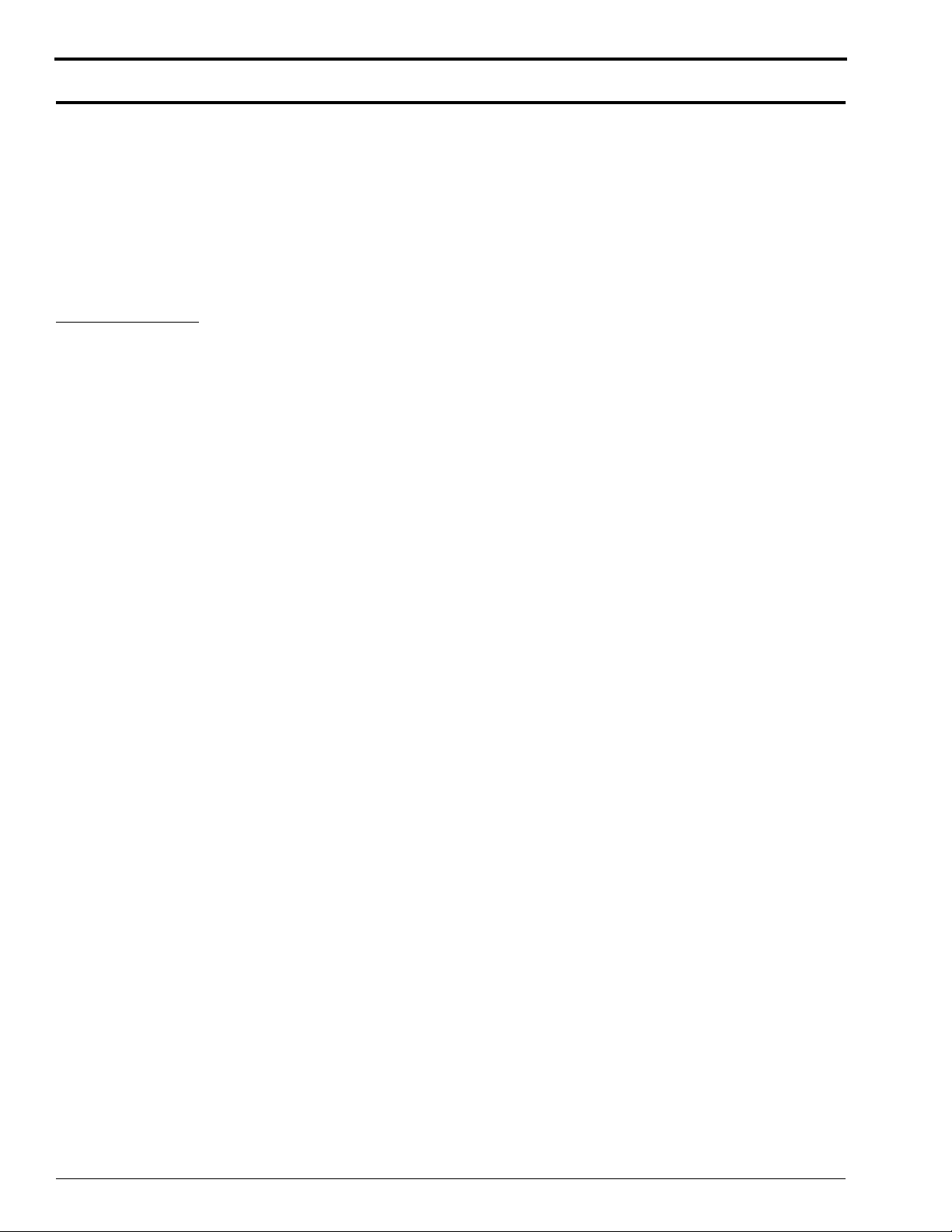

FEED SHELF

Adjustment

[1] Loosen the 4 SCREWS.

[2] Adjust the height of the FEED SHELF to 1.5 mm

1

⁄16 in.) below the NIP of the DETECTOR

1.5 mm

(0.06 in.)

NIP

film entry path

(

CROSSOVER ROLLERS.

[3] Insert a 35 x 43 cm sheet of film into the NIP of

the DETECTOR CROSSOVER ROLLERS.

[4] To adjust for squareness, use the film to align the

FILM GUIDE with the DETECTOR

CROSSOVER ROLLERS.

Adjustments and Replacements

FILM

GUIDE

FEED

SHELF

H172_1017ACA

H172_1017AC

SCREW (4)

DETECTOR SWITCH

Adjustment

DETECTOR

CROSSOVER

ROLLERS

DETECTOR ROLLER

2 SCREWS

2 DETECTOR

SWITCHES

SCREW

ROCKER ARM

[5] Tighten the 4 SCREWS.

1.6 mm

(0.06 in.)

ROCKER

ARM

2 MAGNETS

2 DETECTOR SWITCHES

H172_1036BCA

H172_1036BA

Warning

Moving Parts

[1] Remove the TOP COVER.

[2] Check for squareness:

• DEVELOPER RACK, See Page 9

• DETECTOR CROSSOVER AY, See Page 7

7C8772 – 12JAN99 5

Page 6

SERVICE MANUAL

[3] Install:

• DEVELOPER RACK

• DETECTOR CROSSOVER AY

[4] Loosen the 2 SCREWS on the DETECTOR SWITCHES.

[5] Move the 2 DETECTOR SWITCHES up to the top position.

[6] Set the distance between the MAGNET and the DETECTOR SWITCH on the drive side to 1.6 mm (0.06 in.):

(a) Loosen the SCREW.

(b) Move the ROCKER ARM.

(c) Tighten the SCREW.

Warning

Dangerous Voltage

[7] Energize the PROCESSOR.

[8] Lift the top DETECTOR ROLLER.

[9] Insert a 2.54 cm (1 in.) piece of film into the drive side of the DETECTOR ROLLER.

[10] Slowly move the DETECTOR SWITCH on the drive side down until the REPLENISHMENT PUMP actuates.

[11] Tighten the 2 SCREWS on the DETECTOR SWITCH.

[12] Check that the REPLENISHMENT PUMP stops in 3 seconds after you remove the film.

Note

The feed signal will emit a beep.

[13] Repeat Steps 8-12 for the DETECTOR SWITCH on the non-drive side.

[14] Install the TOP COVER.

[15] Check that the REPLENISHMENT PUMP does not operate unless you feed film.

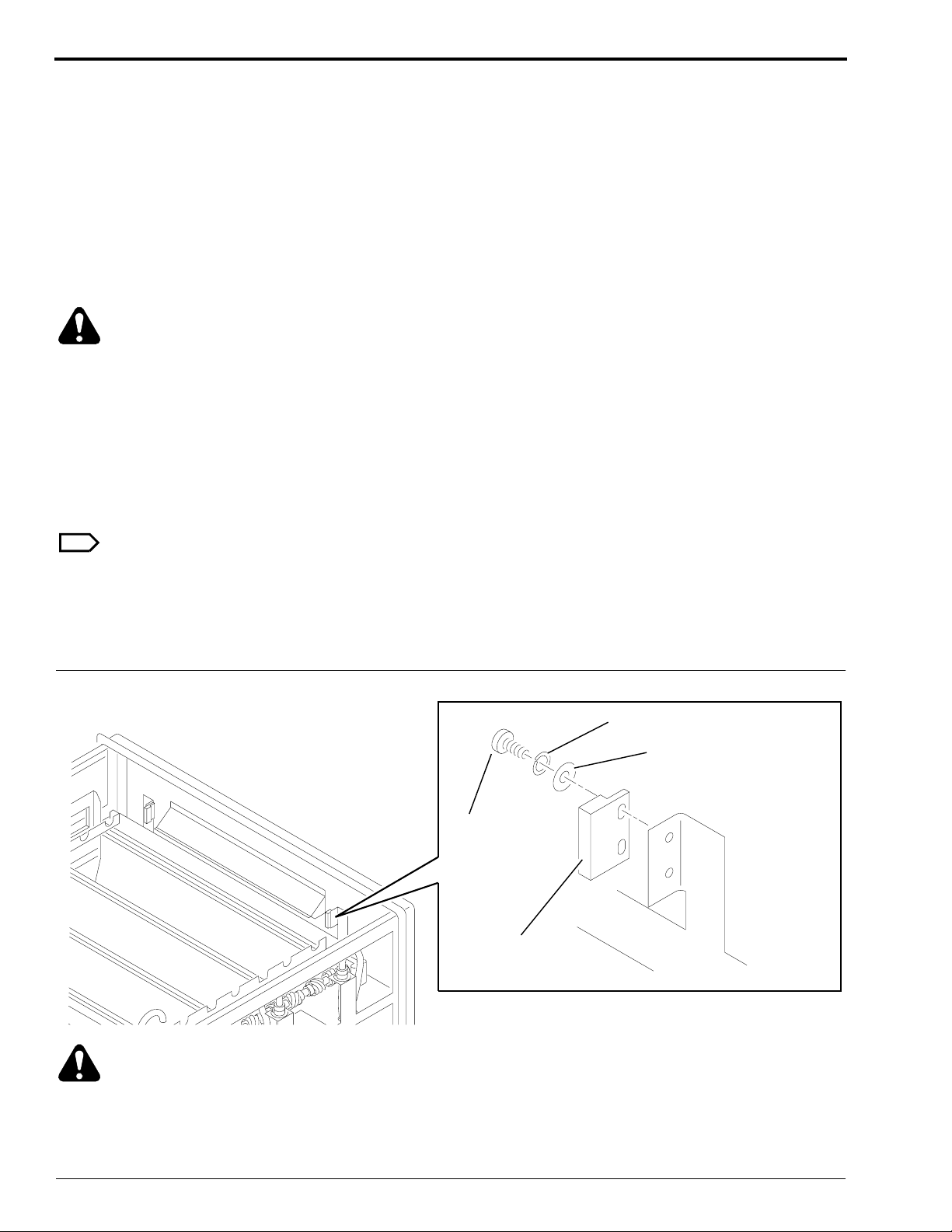

Replacement

2 LOCK WASHERS

2 SCREWS

DETECTOR

SWITCH

2 WASHERS

H172_1037BCA

H172_1037BA

Warning

Dangerous Voltage

[1] Disconnect the PROCESSOR from the main power.

6 12JAN99 – 7C8772

Page 7

[2] Remove:

• TOP COVER

• 2 SCREWS

• 2 LOCK WASHERS

• 2 WASHERS

• DETECTOR SWITCHES

• WIRE TIES, not visible in graphic

ESD

Possible damage from electrostatic discharge.

[3] Disconnect the SWITCH CABLE from the ELECTRICAL BOX.

[4] Connect the new SWITCH CABLE to the ELECTRICAL BOX.

[5] Install:

• DETECTOR SWITCHES

• 2 WASHERS

• 2 LOCK WASHERS

• 2 SCREWS

• new WIRE TIES

• TOP COVER

Adjustments and Replacements

Warning

Dangerous Voltage

[6] Connect the PROCESSOR to the main power.

[7] Do the adjustment procedure for the DETECTOR SWITCHES. See Page 5.

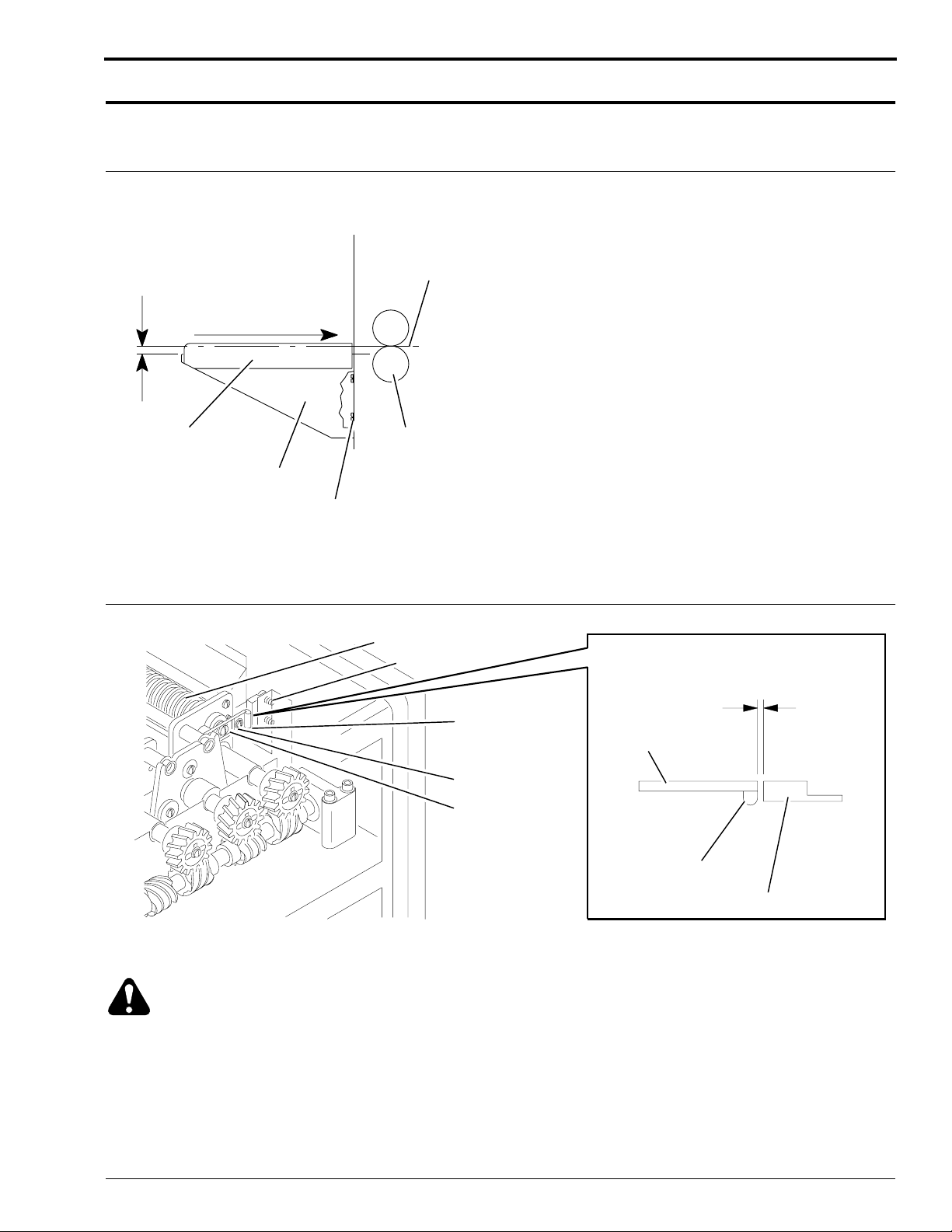

CROSSOVER AY

Adjustment for Squareness

[1] Remove the CROSSOVER AY from the PROCESSOR.

[2] Place the CROSSOVER AY on a smooth, flat surface with the GUIDE SHOES up.

TIE ROD

SIDE

PLATE

2 GUIDE SHOE

SCREWS

TIE ROD

LONG TIP

NUT

SIDE PLATE

NUT

7C8772 – 12JAN99 7

H172_1038BCA

H172_1038BA

Page 8

SERVICE MANUAL

[3] Loosen the 4 NUTS on the TIE RODS.

[4] Press down on the SIDE PLATES so that the SIDE PLATES make uniform contact with the flat surface.

[5] Tighten the 4 NUTS.

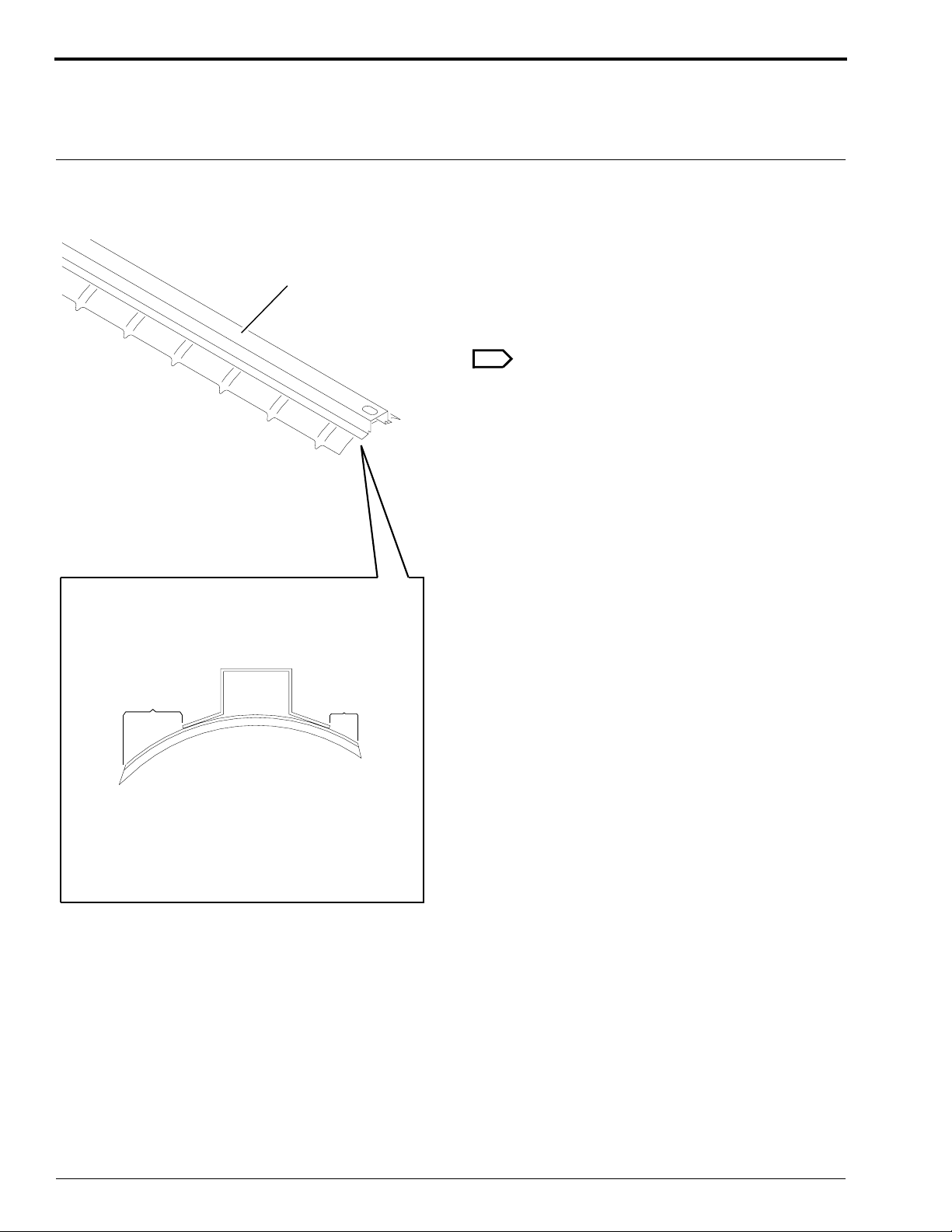

Installing a new GUIDE SHOE

[1] Remove:

• SCREWS

• GUIDE SHOE

GUIDE SHOE

[2] Install the new GUIDE SHOE with the LONG

TIPS in the direction of film transport.

[3] Install the SCREWS.

Note

There are no adjustment procedures for GUIDE

SHOES.

LONG

TIP

SHORT

TIP

H172_1045CCA

H172_1045CA

8 12JAN99 – 7C8772

Page 9

RACK Adjustments

Adjustment for Squareness

Purpose: Use this procedure for the DEVELOPER, FIXER and WASH RACKS.

To adjust the squareness of a DRYER RACK, use the procedure on Page 14.

[1] Remove the RACK from the PROCESSOR.

[2] Place the RACK on a smooth, flat surface.

smooth, flat surface

Adjustments and Replacements

H172_1040ACA

H172_1040AC

SIDE PLATE

TIE ROD

6 SCREWS

H172_1039AA

SIDE PLATE

[3] Loosen the 6 SCREWS on the TIE RODS.

[4] Check that the SIDE PLATES are flat on the flat

surface.

[5] If necessary, applypressureto the SIDEPLATES.

See the figure.

[6] Tighten the SCREWS.

7C8772 – 12JAN99 9

Page 10

SERVICE MANUAL

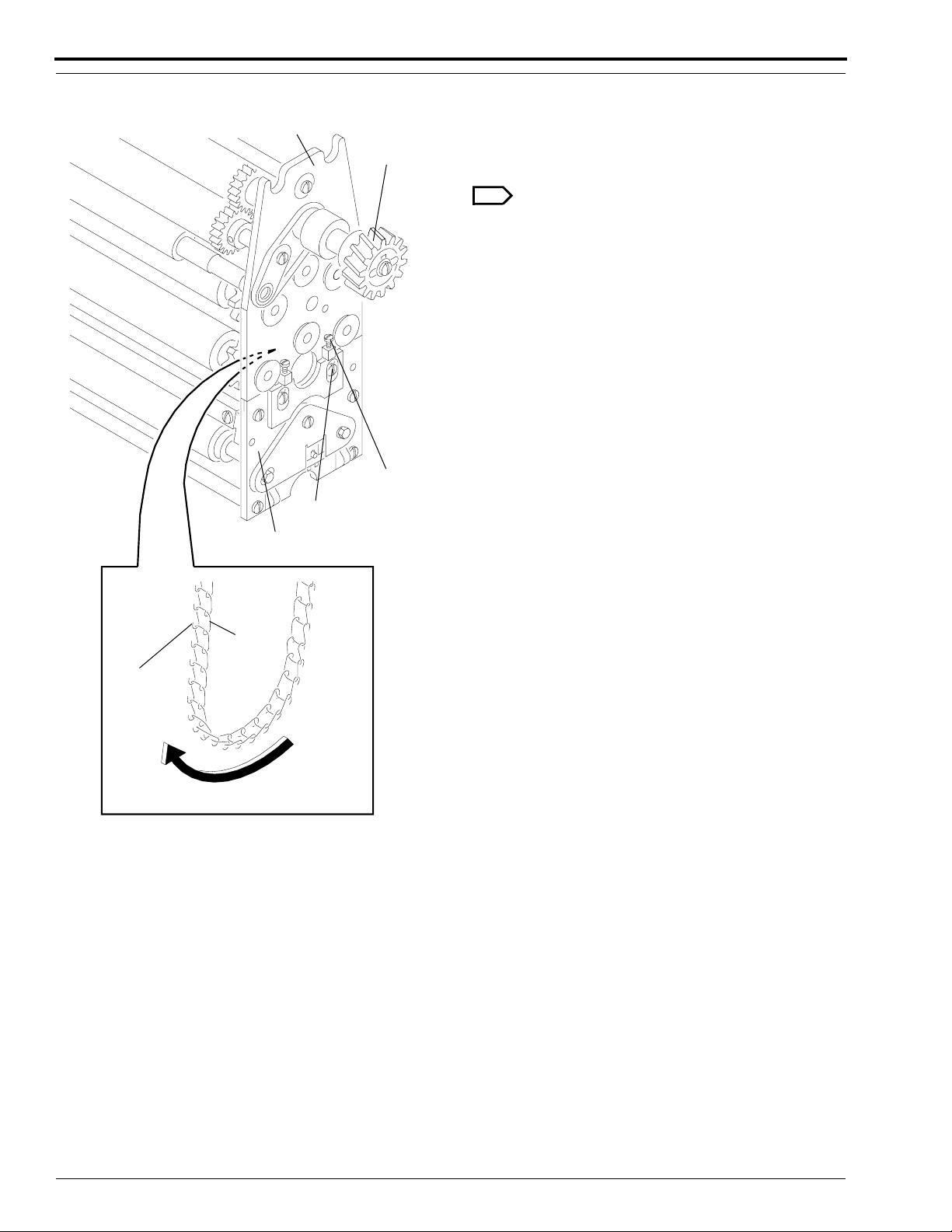

Tension of the DRIVE CHAIN

HOOK

SIDE PLATE

4

TURNAROUND

ASSEMBLY

LINK

ADJUSTING

4

SCREWS

HOLDING

SCREWS

DRIVE

GEAR

[1] Check that the CHAIN is wet with solution.

[2] Check that the RACK is approximately the same

temperature as the solution.

Note

[3] Remove the RACK from the PROCESSOR.

[4] Place the RACK on a smooth, flat surface.

[5] Loosen the 4 HOLDING SCREWS.

[6] On the drive side, loosen the 2 ADJUSTING

SCREWS until the SCREWS do not touch the

SIDE PLATE of the TURNAROUND AY.

[7] Lift the RACK off of the surface and allow the

weight of the TURNAROUND AY to tighten the

CHAIN.

[8] Manually rotate the DRIVE GEAR one full

rotation.

[9] Tighten the 2 HOLDING SCREWS on the

DRIVE side.

[10] Tighten the 2 ADJUSTING SCREWS on the

DRIVE side until the SCREWS touch the SIDE

PLATE of the TURNAROUND AY.

[11] Observe the distance between the RACK SIDE

PLATE and TURNAROUND SIDE PLATE on

the DRIVE side.

[12] Rotate the 2 ADJUSTING SCREWS on the

NON-DRIVE side until the distance between the

SIDE PLATES is the same as the DRIVE side.

[13] Tighten the 2 HOLDING SCREWS on the NON-

DRIVE side.

DRIVE CHAIN

H172_1041CCA

H172_1041CA

10 12JAN99 – 7C8772

Page 11

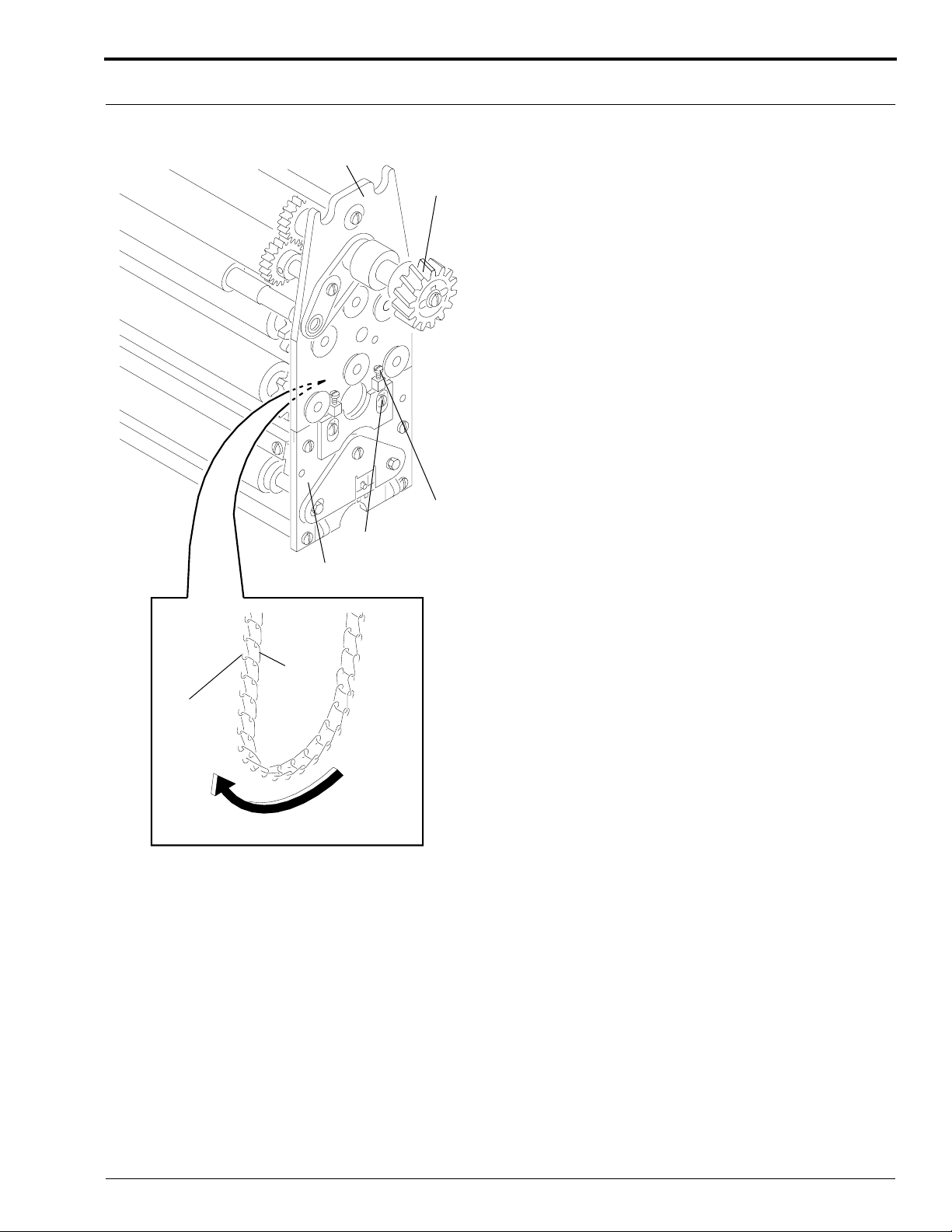

RACK Replacements

DRIVE CHAIN

Adjustments and Replacements

SIDE PLATE

4

TURNAROUND

ASSEMBLY

ADJUSTING

4

SCREWS

HOLDING

SCREWS

DRIVE

GEAR

[1] Use a SCREWDRIVER to pry open the HOOKS

of a LINK.

[2] Connect the new DRIVE CHAIN to the old

DRIVE CHAIN. Make sure the HOOKS and the

openings of the LINKS are in the correct

direction.

[3] Pull the old DRIVE CHAIN through the RACK

AY until the new DRIVE CHAIN is in thecorrect

position.

[4] Remove the old DRIVE CHAIN.

[5] Connect the ends of the new DRIVE CHAIN.

[6] Use the procedure on Page 10 toadjustthetension

of the DRIVE CHAIN.

HOOK

LINK

DRIVE CHAIN

H172_1041CCA

H172_1041CA

7C8772 – 12JAN99 11

Page 12

SERVICE MANUAL

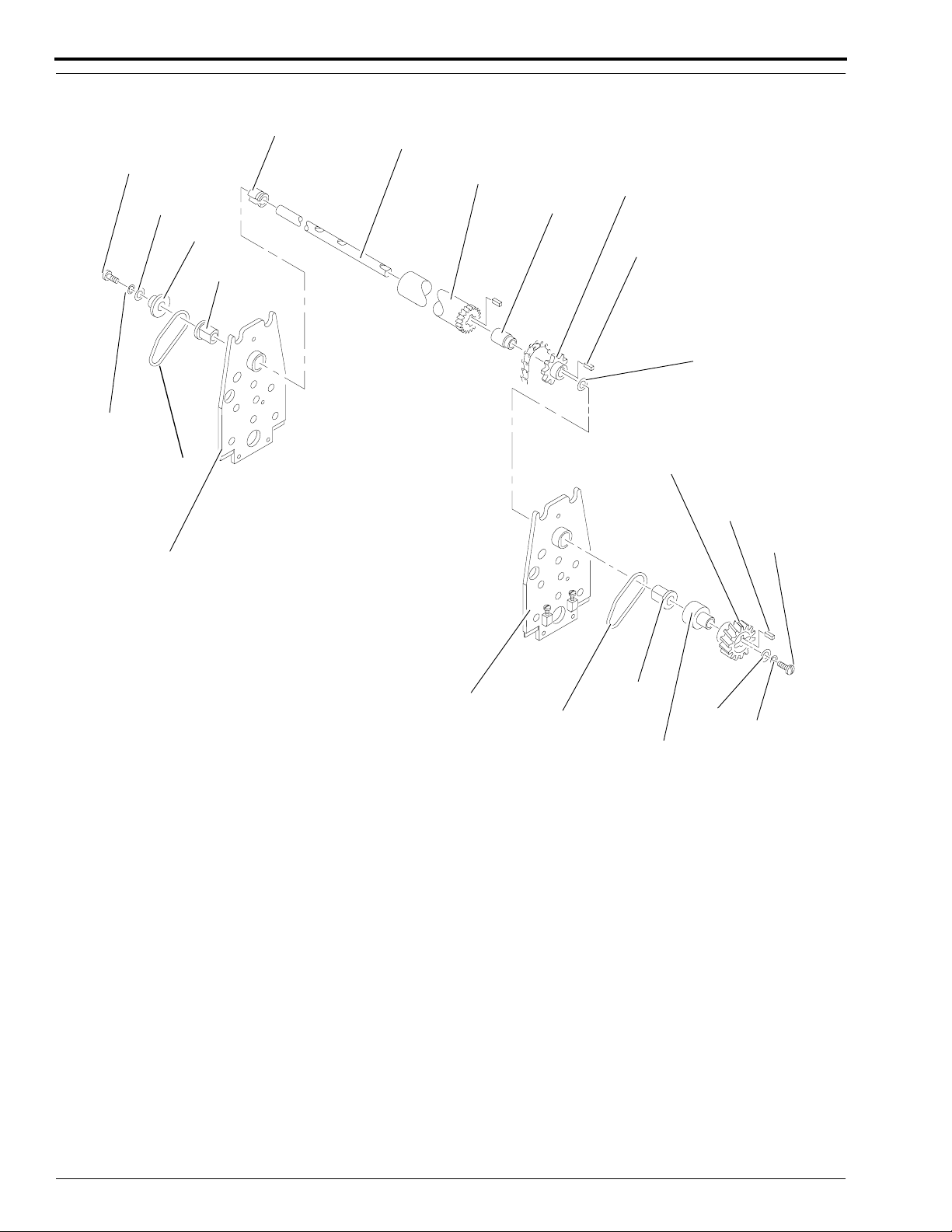

RESILIENT DRIVE ROLLER in the DEVELOPER and FIXER RACKS

SCREW

WASHER

LOCK

WASHER

SPRING

non-drive

SIDE PLATE

SPACER

BEARING

SPACER

SHAFT

RESILIENT

DRIVE

ROLLER

SPROCKET

SPACER

KEY

THRUST

WASHER

DRIVE

GEAR

KEY

SCREW

drive

SIDE PLATE

SPRING

BEARING

SPACER

WASHER

LOCK

WASHER

H172_0631DCA

H172_0631DA

[1] Remove the 2 SPRINGS from the top of the RACK.

[2] Remove from the ends of RESILIENT DRIVE ROLLER outside of the SIDE PLATES:

• SCREWS

• WASHERS

• LOCK WASHERS

• GEAR

• SPACERS

• BEARINGS

[3] Rotate the flat part of the SHAFT to the up position.

[4] Move the DRIVE ROLLER toward the non-drive side and remove the KEY from the DRIVE GEAR.

[5] Move the SHAFT of the DRIVE ROLLER towards the drive side.

[6] Remove:

• THRUST WASHER

• SPROCKET

• SPACER

12 12JAN99 – 7C8772

Page 13

[7] Remove the DRIVE ROLLER.

[8] Reverse the steps to install a new DRIVE ROLLER.

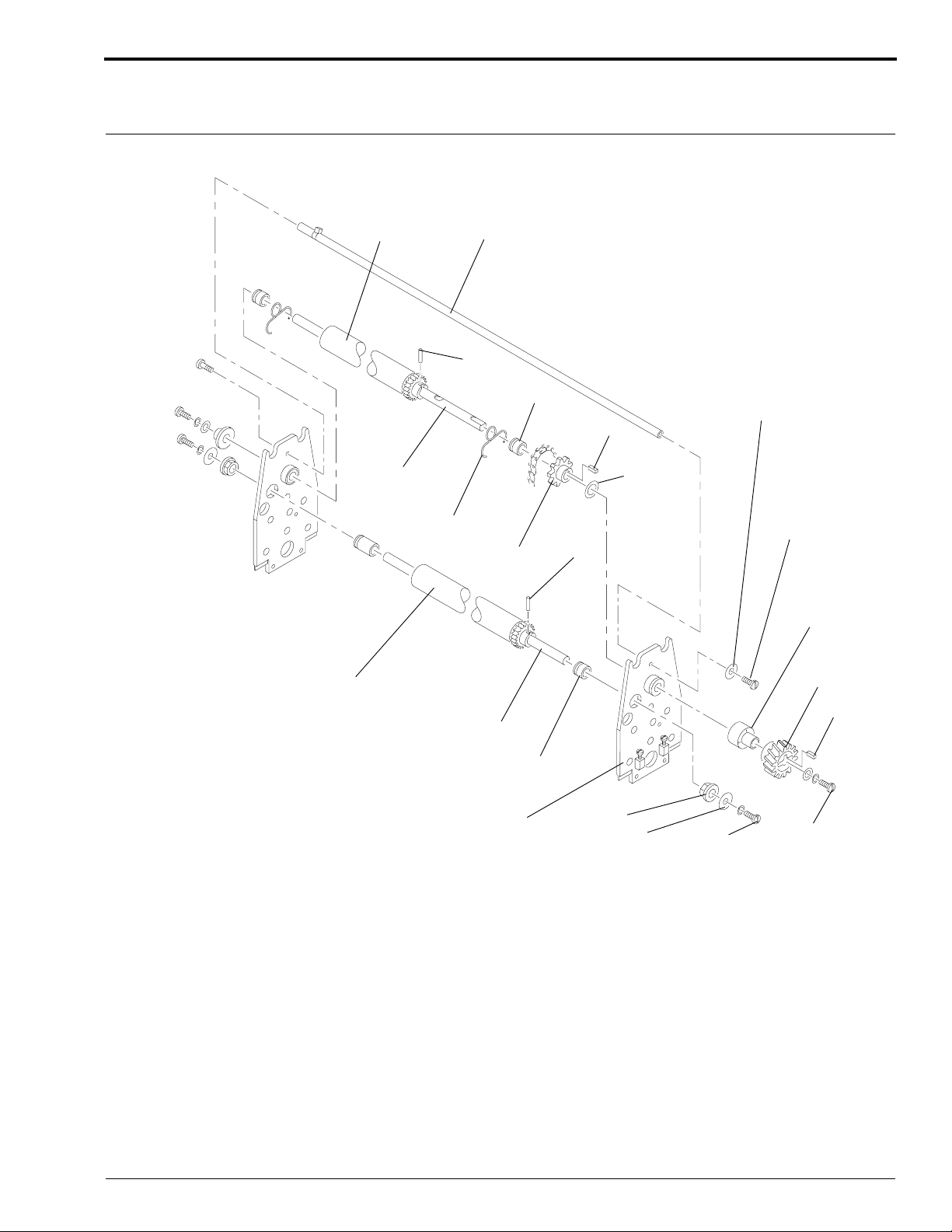

RESILIENT DRIVE ROLLERS in the WASH RACK

RESILIENT

DRIVE

ROLLER

TIE

ROD

PIN

SPACER

Adjustments and Replacements

ID WASHER

KEY

THRUST

WASHER

WASHER

SCREW

2 SCREWS

SPACER

DRIVE

GEAR

KEY

SCREW

H172_0632DCA

H172_0632DA

DRIVEN

ROLLER

SHAFT

2 SPRINGS

SPROCKET

SHAFT

SIDE PLATE

PIN

SPACER

BEARING

[1] Remove from the TIE ROD:

• 2 SCREWS

• ID WASHER

[2] Remove from the ends of DRIVE ROLLER and DRIVEN ROLLER outside of the SIDE PLATES:

• SCREWS

• WASHERS

• DRIVE GEAR

• SPACERS

• BEARINGS

[3] Rotate the flat part of the SHAFT to the up position.

[4] Remove the 2 SPRINGS.

[5] Move the 2 SHAFTS of the DRIVE ROLLER and the DRIVEN ROLLER towards the non-drive SIDE PLATE.

[6] Bend the SIDE PLATE a small distance and remove the ends of the 2 SHAFTS.

7C8772 – 12JAN99 13

Page 14

SERVICE MANUAL

[7] Remove:

• THRUST WASHER

• SPROCKET

• SPACER

[8] Reverse the steps to install a new DRIVE ROLLER and DRIVEN ROLLER.

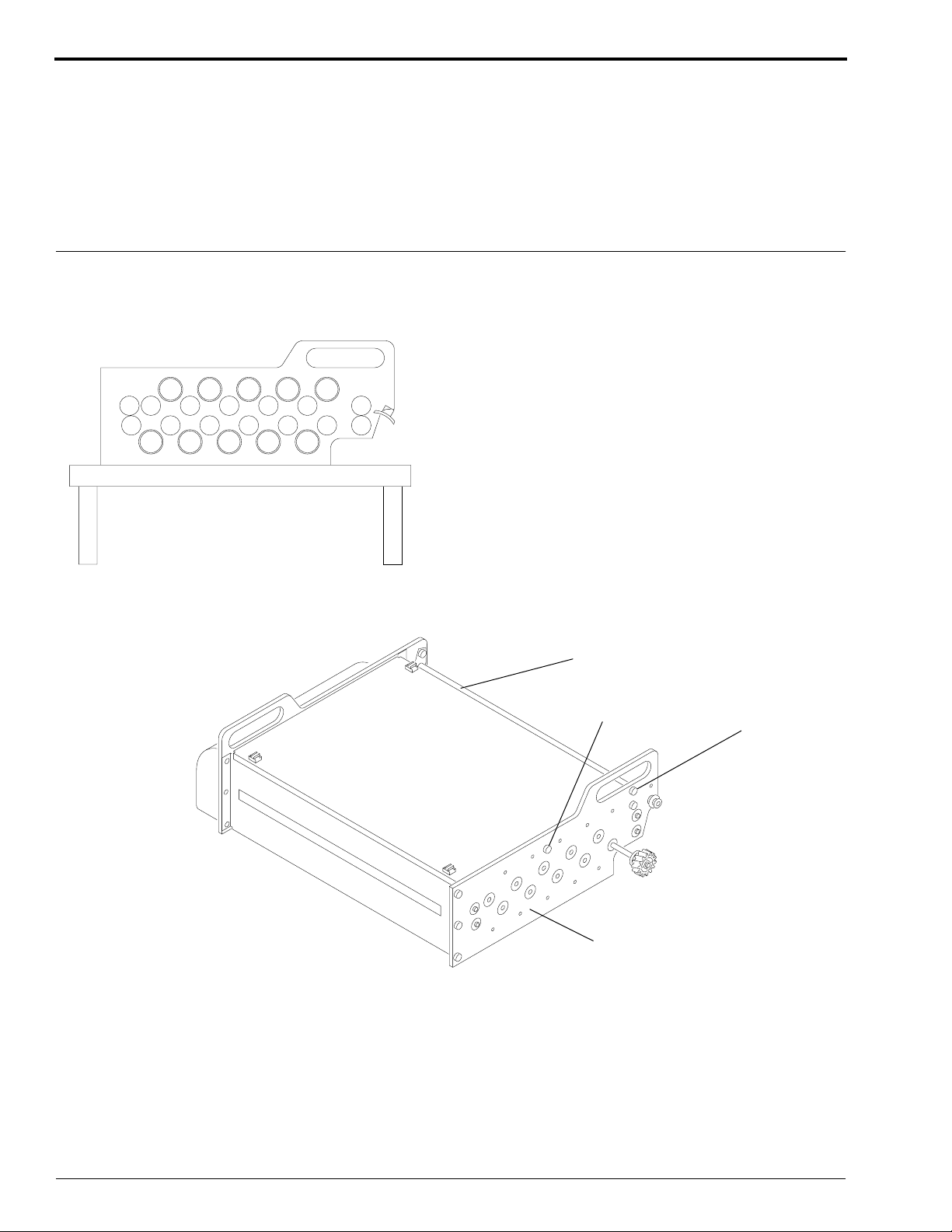

DRYER RACK

Adjustment for Squareness

[1] Remove the RACK from the PROCESSOR.

[2] Place the CROSSOVER AY on a smooth, flat

surface.

smooth, flat surface

H172_1042AA

TIE ROD

2 TIE ROD

SCREWS

2 NUTS

2 SIDE PLATES

H172_1043BCA

H172_1043BA

[3] Loosen the TIE ROD SCREWS and NUTS.

[4] Press down on the SIDE PLATES so that the SIDE PLATES make uniform contact with the flat surface.

[5] Tighten the TIE ROD SCREWS and NUTS.

14 12JAN99 – 7C8772

Page 15

Installing a new DRIVE ROLLER

O-RING

Adjustments and Replacements

PIN

COLLAR

PLENUM

AIR TUBE

O-RING

DRIVE

ROLLER

COVER

SHAFT

PIN

O-RING

COVER

[1] Remove the DRYER RACK from the PROCESSOR.

[2] Remove:

• top and bottom COVERS

• PLENUM

• first 3 AIR TUBES

• O-RING from the DRIVE GEAR

• PIN

• DRIVE GEAR

[3] From the NON-DRIVE side, remove:

• O-RING from the COLLAR

• PIN

• COLLAR

PIN

DRIVE GEAR

H172_1044DCA

H172_1044DA

7C8772 – 12JAN99 15

Page 16

SERVICE MANUAL

[4] Remove the O-RING from the DRIVE COLLAR on the drive side.

[5] Remove from the DRIVE ROLLER:

• PIN

• SHAFT

[6] Reverse the steps to install a new DRIVE ROLLER.

16 12JAN99 – 7C8772

Page 17

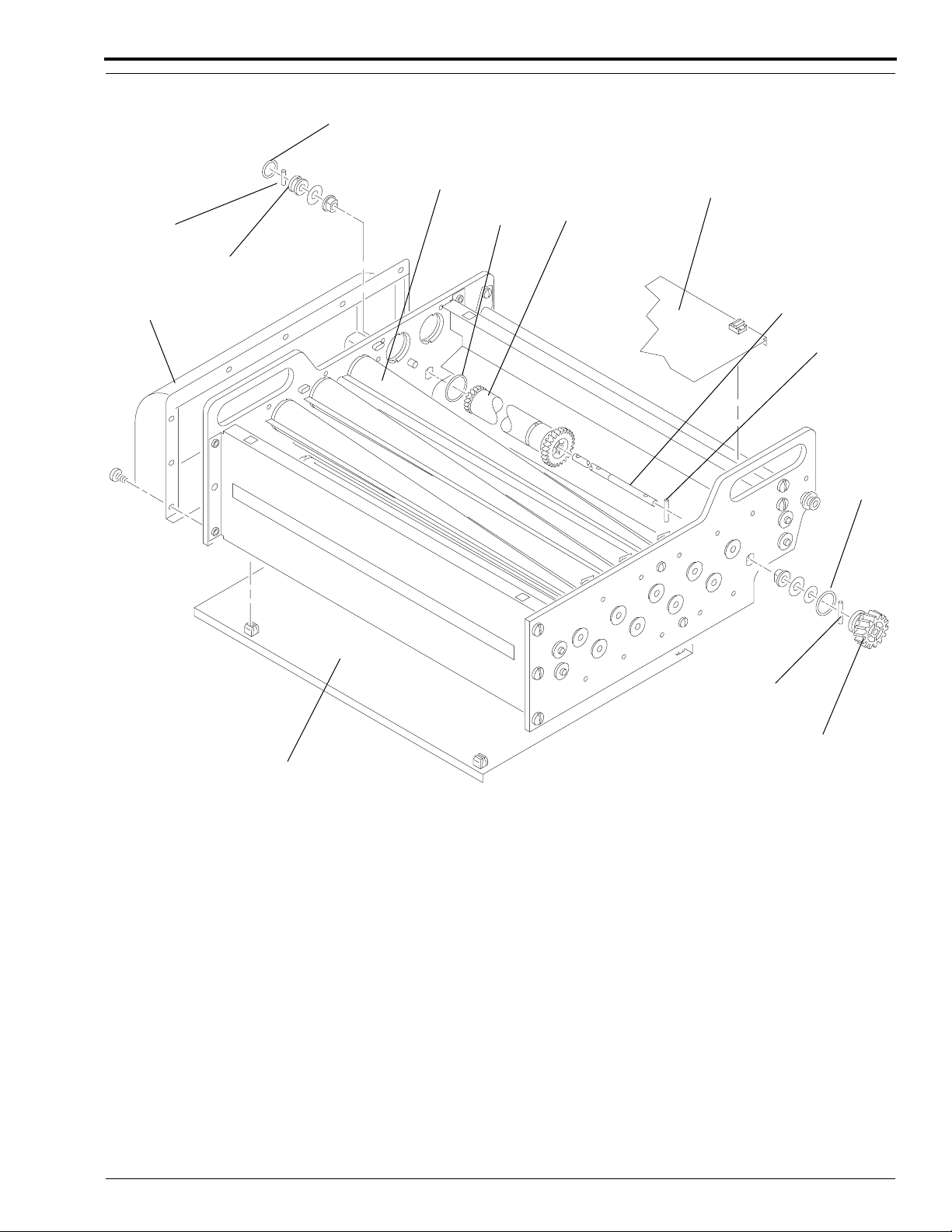

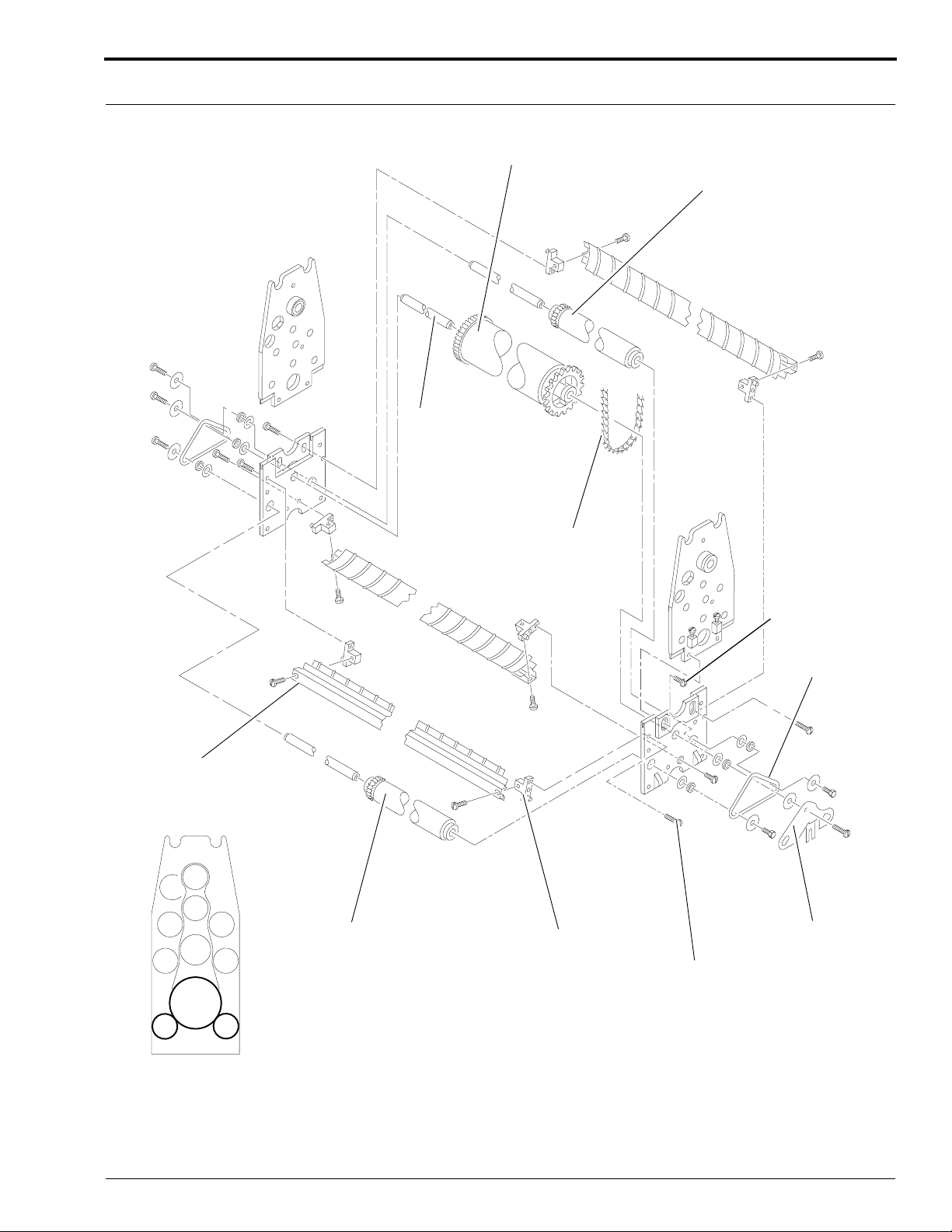

TURNAROUND AY

Disassembling the TURNAROUND AY

SHAFT

Adjustments and Replacements

B ROLLER

A ROLLER

EXIT

GUIDE

SHOE

A ROLLER

CHAIN

2 BRACKETS

4 HOLDING

SCREWS

2 SPRINGS

LOCKING

PLATE

2 SCREWS

H172_0633ECA

H172_0633EA

7C8772 – 12JAN99 17

Page 18

SERVICE MANUAL

[1] Remove:

• EXIT GUIDE SHOE and 2 BRACKETS

• ROLLER above the GUIDE SHOE

• 2 SPRINGS and LOCKING PLATE

• 2 A ROLLERS

[2] Pull the SHAFT from the B ROLLER from the non-drive side.

[3] Remove:

• 4 HOLDING SCREWS

• CHAIN from the B ROLLER

• TURNAROUND AY

Installing a new B ROLLER

See the Figure on Page 17.

[1] Remove:

• TURNOVER AY from the RACK

• 2 SPRINGS

• LOCKING PLATE

• 2 A ROLLERS

• 2 SCREWS

• 2 BRACKETS

• EXIT GUIDE SHOE

• SHAFT, THRUST WASHERS and the BEARING from the B ROLLER

[2] Install:

• new B ROLLER, THRUST WASHERS and the BEARING on the SHAFT

• EXIT GUIDE SHOE

• 2 BRACKETS

• 2 SCREWS

• 2 A ROLLERS

• LOCKING PLATE

• 2 SPRINGS

• TURNOVER AY in the RACK

[3] Use the procedure on Page 10 to adjust the tension on the DRIVE CHAIN, if necessary.

18 12JAN99 – 7C8772

Page 19

Installing new A ROLLERS

Adjustments and Replacements

B ROLLER

A ROLLER

SHAFT

EXIT

GUIDE

SHOE

A ROLLER

CHAIN

2 BRACKETS

4 HOLDING

SCREWS

2 SPRINGS

LOCKING

PLATE

2 SCREWS

H172_0633ECA

H172_0633EA

[1] Remove:

• 2 SPRINGS

• LOCKING PLATE

• SCREW

• A ROLLER from the SHAFT

7C8772 – 12JAN99 19

Page 20

SERVICE MANUAL

[2] Install:

• new A ROLLER on the SHAFT

• A ROLLER in the TURNAROUND AY

• LOCKING PLATE

• SCREW

• 2 SPRINGS

[3] Check that all the GEARS in the TURNAROUND AY engage.

Checking the GUIDE SHOES

[1] Check thatthe LONG TIPS are in the direction of

GUIDE SHOE

film transport.

LONG

TIP

20 12JAN99 – 7C8772

SHORT

TIP

H172_1045CCA

H172_1045CA

Page 21

MAIN DRIVE

Adjusting the MAIN DRIVE CHAIN

Adjustments and Replacements

4 MOUNTING

SCREWS

DRIVE

CHAIN

CHAIN

GUARD

2 GUARD

SCREWS

Warning

• Dangerous Voltage

• Moving Parts

[1] Disconnect the PROCESSOR from the main power.

[2] Remove:

• DRIVE SIDE PANEL

• 2 GUARD SCREWS

• CHAIN GUARD

• 2 SCREWS

• MOTOR CAGE

[3] Loosen the 4 MOUNTING SCREWS.

MOTOR

MOTOR

CAGE

2 SCREWS

H172_1046BCA

H172_1046BA

Caution

Do not tighten the DRIVE CHAIN excessively.

[4] Move the DRIVE MOTOR to tighten the DRIVE CHAIN.

[5] Tighten the 4 MOUNTING SCREWS.

[6] Install:

• MOTOR CAGE

• 2 SCREWS

• CHAIN GUARD

• 2 GUARD SCREWS

• DRIVE SIDE PANEL

7C8772 – 12JAN99 21

Page 22

SERVICE MANUAL

Aligning the MAIN DRIVE MOTOR

3 SETSCREWS

2 SPROCKETS

DRIVE

SHAFT

Warning

• Dangerous Voltage

• Moving Parts

[1] Disconnect the PROCESSOR from the main

power.

[2] Remove:

• DRIVE SIDE PANEL

• 2 GUARD SCREWS

• CHAIN GUARD

[3] Loosen the 3 SETSCREWS.

[4] Align the SPROCKETS with eachother.

[5] Tighten the 3 SETSCREWS.

[6] Check:

• DRIVE CHAIN does not touch the

MOUNTING PLATE

• SPROCKET on the DRIVE SHAFT does not

touch the DRYER RACK

[7] Install:

• DRIVE SIDE PANEL

• 2 GUARD SCREWS

• CHAIN GUARD

MOTOR

SHAFT

DRIVE

CHAIN

MOUNTING

PLATE

H172_1047CCA

H172_1047CC

22 12JAN99 – 7C8772

Page 23

Adjustments and Replacements

Installing a new MAIN DRIVE SHAFT, WORM GEARS or BEARING BLOCKS

WORM

GEAR

DRIVE

SHAFT

SPACER

4 SCREWS

2 BEARING

BLOCKS

2 SHIMS

SETSCREW

DRIVE

CHAIN

CHAIN

GUARD

PIN

4 MOUNTING

SCREWS

H172_0634DCA

H172_0634DA

[1] Remove the CHAIN GUARD.

[2] Loosen the 4 MOUNTING SCREWS.

[3] Remove:

• DRIVE CHAIN

• 4 SCREWS from the 2 BEARING BLOCKS

• SHIMS

• DRIVE SHAFT

[4] Install the new WORM GEAR or BEARING BLOCKS.

[5] Place the SHIMS under the BEARING BLOCKS.

[6] Install, but do not tighten, the 4 SCREWS in the BEARING BLOCKS.

[7] Adjust the position of the BEARING BLOCKS until the DRIVE SHAFT moves freely.

7C8772 – 12JAN99 23

Page 24

SERVICE MANUAL

Caution

Do not tighten the SCREWS excessively.

[8] Tighten the 4 SCREWS.

[9] Use the procedure on Page 21 to adjust the tension of the MAIN DRIVE CHAIN.

[10] Tighten the 4 MOUNTING SCREWS.

[11] Install the CHAIN GUARD.

DRYER HEATER

Adjusting the Temperature

DRYER

TEMPERATURE

CONTROL

KNOB

Factors which determine the correct temperature are:

Use the lowest temperature necessary to dry the film.

Important

• condition of the air

• amount and type of the film

[1] Rotate the DRYER TEMPERATURE

CONTROL KNOB to adjust the temperature:

• clockwise to increase the temperature

• counterclockwise to decrease the temperature

H172_1065ACA

H172_1065AC

24 12JAN99 – 7C8772

Page 25

Installing a new BLOWER AY

Warning

Dangerous Voltage

[1] Disconnect the main power.

4 MOUNTING

SCREWS

ELECTRICAL

BOX

Adjustments and Replacements

RECEIVING

END

COVER

BLOWER

MOTOR

800

CIRCUIT

BOARD

DRYER

HEATER

H172_1048DCA

H172_1048DA

[2] Remove:

• TOP COVER

• DRYER RACK

• RECEIVING END COVER

• SIDE PANELS

ESD

Possible damage from electrostatic discharge.

7C8772 – 12JAN99 25

Page 26

SERVICE MANUAL

[3] Disconnect from the 800 CIRCUIT BOARD:

(Not visible in the graphic)

• CONNECTOR 801

• CONNECTOR 802

[4] Disconnect the CABLE ASSEMBLY from the ELECTRICAL BOX.

[5] Remove:

• MOUNTING SCREWS

• BLOWER MOTOR

[6] Reverse the steps to install the new BLOWER MOTOR.

26 12JAN99 – 7C8772

Page 27

Installing a new DRYER HEATER or HEATER CORE

Warning

Dangerous Voltage

[1] Disconnect the main power.

RECEIVING

4 MOUNTING

SCREWS

ELECTRICAL

BOX

END

COVER

800

CIRCUIT

BOARD

HEATER

TOP COVER

Adjustments and Replacements

[2] Remove:

• TOP COVER

• DRYER RACK

• RECEIVING END COVER

• SIDE PANELS

2 SCREWS

EXHAUST

HOSE

2 SCREWS

HEATER

CORE

H172_1048DCB

H172_1048DA

ESD

Possible damage from electrostatic discharge.

7C8772 – 12JAN99 27

Page 28

SERVICE MANUAL

[3] Disconnect from the 800 CIRCUIT BOARD:

(Not visible in the graphic)

• CONNECTOR 801

• CONNECTOR 802

[4] Disconnect from the ELECTRICAL BOX:

• TB2-1

• TB2-3

• TB2-5

• GROUND WIRE

[5] Remove:

• EXHAUST HOSE

• 6 MOUNTING SCREWS

• 4 SCREWS

• DRYER HEATER

[6] To install a new DRYER HEATER, reverse the steps above.

To install a new HEATER CORE, continue with Step 7.

[7] Loosen the 2 SCREWS.

[8] Remove the HEATER TOP COVER.

[9] Remove from inside the DRYER HEATER:

(Not visible in the graphic)

• 4 HEX NUTS

• 4 MOUNTING SCREWS

• HEATER CORE

[10] Reverse the steps to install the new HEATER CORE.

28 12JAN99 – 7C8772

Page 29

PLUMBING System Adjustments

Adjusting the Developer Temperature

[1] Remove the TOP COVER.

Adjustments and Replacements

Insert THERMOMETER

here

H172_1006BCB

H172_1006BC

[2] Wait until the TEMPERATURE READY LIGHT blinks slowly or does not illuminate.

[3] Insert a THERMOMETER into the DEVELOPER TANK on the non-drive side of the PROCESSOR between

the SIDE PLATE of the DEVELOPER RACK and the RACK SUPPORT.

[4] Check that the temperature of the developer is correct for the operating cycle of the PROCESSOR.

Cycle Temperature

Standard

Rapid

100 CIRCUIT BOARD

33.3

± 0.3°C (92.0 ± 0.5°F)

± 0.3°C (94.0 ± 0.5°F)

34.4

ELECTRICAL

R2

BOX

H172_1031BCB

H172_1031BC

[5] If the developer temperature is correct, advance to Step 9.

7C8772 – 12JAN99 29

Page 30

SERVICE MANUAL

Warning

• Dangerous Voltage

• Possible damage from electrostatic discharge

[6] If the developer temperature is not correct:

(a) Remove the DRIVE SIDE PANEL.

(b) Open the DOOR on the ELECTRICAL BOX.

(c) Use the POTENTIOMETER ADJUSTING TOOL TL-1481 to adjust R2 on the 100 CIRCUIT BOARD:

• Rotate R2 clockwise to increase the temperature

• Rotate R2 counterclockwise to decrease the temperature

[7] Allow the developer solution to reach a stable temperature.

[8] Do Step 4.

[9] Close the DOOR on the ELECTRICAL BOX.

[10] Install the DRIVE SIDE PANEL and TOP COVER.

30 12JAN99 – 7C8772

Page 31

Checking the Replenishment Rates

UPPER ROLLER

DETECTOR CROSSOVER

ASSEMBLY

Adjustments and Replacements

2 DETECTOR

SWITCHES

H172_1006BCA

H172_1006BC

DEVELOPER TUBING

METAL LATCH

QUICK

DISCONNECT

GRADUATED

CYLINDER

FIXER TUBING

Warning

Wear protective eyewear. The replenishment solutions

are pumped quickly and might splash.

[1] Remove the TOP COVER.

[2] Lift the UPPER ROLLER of the DETECTOR

CROSSOVER AY.

[3] Check that the replenishment solutions flow

freely through the TUBING located along the

DRIVE SIDE RACKS.

[4] Disconnect the DEVELOPER TUBING by

pressing the METAL LATCH.

Note

H172_1005ACA

H172_1005AC

[5] Pull the DEVELOPER TUBING slightly and rotate it over the edge of the FRAME and into a GRADUATED

CYLINDER.

[6] Lift the UPPER ROLLER of the DETECTOR CROSSOVER AY for the correct time:

Cycle Time

Standard 34 seconds

Rapid 25 seconds

The DEVELOPER TUBINGmightbeidentifiedwitha

red WIRE TIE.

[7] When the REPLENISHMENT PUMP stops, check that the amount of solution in the GRADUATED

CYLINDER is correct for the film size and use condition. See the table on Page 32.

[8] If the replenishment rate is not correct, do the procedure “Adjusting the REPLENISHMENT PUMP” on Page

32.

[9] Connect the DEVELOPER TUBING by pushing it into theMETALLATCHuntiltheDEVELOPERTUBING

snaps in place.

[10] Check the replenishment flow rate of the fixer solution by doing Steps 4 - 9 with the FIXER TUBING.

[11] Install the TOP COVER.

7C8772 – 12JAN99 31

Page 32

SERVICE MANUAL

Replenishment Flow Rate,

mL per 35 x 43 cm

34 seconds for Standard Cycle

25 seconds for Rapid Cycle

Developer Fixer

Film Size Processed Use Condition

Average Amount of Film

per 8 Hours of

PROCESSOR Operation

Only roll films 35 cm wide High 105 Linear feet or more 50 70

Medium 35 - 105 linear feet 65 85

Low 35 linear feet or less* 80 100

Only 35 x 35 cm film High 90 sheets or more 50 70

Medium 30 - 90 sheets 65 85

Low 30 sheets or less* 80 100

Average size intermix film High 115 sheets or more 50 70

Medium 40 - 115 sheets 65 85

Low 40 sheets or less* 80 100

Only 35 x 43 cm film High 75 sheets or more 60 85

Medium 25 - 75 sheets 80 100

Low 25 sheets or less* 100 120

* If sensitometry does not stay within control limits, flooded replenishment may be needed. Order and install

FLOODED REPLENISHMENT KIT 419779.

Note

For more information and for new recommended processing instructions, see SERVICE BULLETIN 30, Pub. No.

632661.

Adjusting the REPLENISHMENT PUMP

BRACKET

TOP COVER

[1] Remove:

• TOP COVER

• RECEIVING BIN

• 2 SCREWS

• PUMP COVER

PUMP COVER

2 SCREWS

32 12JAN99 – 7C8772

H172_1028ACA

H172_1028AC

Page 33

SETSCREW

Adjustments and Replacements

REPLENISHMENT PUMP

ADJUSTMENT

SCREW

Do not

adjust!

LOCKNUT

H172_1029BCA

H172_1029BC

BRACKET

HOLE

ADJUSTMENT SCREW

DECREASE

[2] Check to see if the ADJUSTMENT SCREW is visible through the BRACKET HOLE.

[3] If the ADJUSTMENT SCREW is visible, advance to Step 5.

UPPER ROLLER

DETECTOR CROSSOVER

ASSEMBLY

2 DETECTOR

SWITCHES

INCREASE

OUTPUT

H172_1006BCA

H172_1006BC

[4] If the ADJUSTMENT SCREW is notvisible,operatetheREPLENISHMENTPUMP until the ADJUSTMENT

SCREW is visible by lifting the UPPER ROLLER of the DETECTOR CROSSOVER AY.

Caution

Do not adjust the LOCKNUT.

[5] Loosen the SETSCREW.

[6] Rotate the ADJUSTMENT SCREW to change the flow rate:

• clockwise to increase the flow rate.

• counterclockwise to decrease the flow rate.

[7] Tighten the SETSCREW.

[8] Check the Replenishment Rates. See Page 31

[9] If the flow rate is not correct, do Steps 3 - 8 again

7C8772 – 12JAN99 33

Page 34

SERVICE MANUAL

[10] Install:

• PUMP COVER

• 2 SCREWS

• TOP COVER

• RECEIVING BIN

PLUMBING System Replacements

DEVELOPER HEATER

Warning

Dangerous Voltage

[1] Disconnect the main power.

DEVELOPER

TANK

TUBE

2 SCREWS

TUBE

DEVELOPER

HEATER

H172_1049BCA

H172_1049BC

[2] Drain the DEVELOPER TANK or apply CLAMPS to the 2 TUBES on the THERMOWELL.

ESD

Possible damage from electrostatic discharge.

[3] Open the ELECTRICAL BOX.

[4] Disconnect the wires of the DEVELOPER HEATER at TB2-9 and TB2-10.

Warning

When you remove the DEVELOPER HEATER from the THERMOWELL, there might be a leakage of solution.

Clean all spills.

[5] Remove:

• 2 SCREWS

• THERMOWELL

• DEVELOPER HEATER from the THERMOWELL

[6] Apply SEALANT TL-3230 to the THREADS on the new DEVELOPER HEATER.

[7] Insert the new DEVELOPER HEATER into the THERMOWELL.

34 12JAN99 – 7C8772

Page 35

Adjustments and Replacements

5 mm

(13/64 in.)

13.9 cm

(5.500 .060 in.)

THERMOWELL

HEATER LOCATOR

DEVELOPER

HEATER

60

HEATER

LOCATOR

H172_1050BCA

H172_1050BA

[8] Use the HEATER LOCATOR on the THERMOWELL to check the correct location of the DEVELOPER

HEATER.

Caution

Do not tighten the DEVELOPER HEATER excessively or you will cause damage to the THERMOWELL.

[9] Use your hand to tighten the DEVELOPER HEATER, then tighten the DEVELOPER HEATER an additional

1/2 rotation.

[10] Install the THERMOWELL using 2 SCREWS.

[11] Connect the wires of the DEVELOPER HEATER at TB2-9 and TB2-10.

[12] Close the ELECTRICAL BOX.

[13] Fill the DEVELOPER TANK or remove the CLAMPS from the TUBES on the THERMOWELL.

DEVELOPER THERMISTOR

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Drain the DEVELOPER TANK or apply CLAMPS to the 2 TUBES on the THERMOWELL. See the Figure

on Page 34.

ESD

Possible damage from electrostatic discharge.

[3] Open the ELECTRICAL BOX.

[4] Disconnect the wires of the DEVELOPER THERMISTOR at TB4-13 and TB4-14.

Warning

When you remove the DEVELOPER THERMISTOR from the THERMOWELL, there might be a leakage of

solution. Clean all spills.

[5] Remove the DEVELOPER THERMISTOR from the THERMOWELL.

[6] Apply SEALANT TL-3230 to the THREADS on the new DEVELOPER THERMISTOR.

7C8772 – 12JAN99 35

Page 36

SERVICE MANUAL

DEVELOPER

THERMISTOR

4 mm

(5/32 in.)

THERMOWELL

Caution

You must install the DEVELOPER THERMISTOR at the correct distance from the THERMOWELL.

[7] Install the new DEVELOPER THERMISTOR 4 mm (5/32 in.) from the THERMOWELL.

[8] Connect the wires of the new DEVELOPER THERMISTOR at TB4-13 and TB4-14.

[9] Close the ELECTRICAL BOX.

[10] Fill the DEVELOPER TANK or remove the CLAMPS from the TUBES on the THERMOWELL.

H172_1051BCA

H172_1051BA

DEVELOPER OVER-TEMPERATURE THERMOSTAT

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Drain the DEVELOPER TANK or apply CLAMPS to the 2 TUBES on the THERMOWELL. See the Figure

on Page 34.

ESD

Possible damage from electrostatic discharge.

[3] Open the ELECTRICAL BOX.

[4] Disconnect the wires of the DEVELOPER OVER-TEMPERATURE THERMOSTAT at:

• TB4-8

• TB4-9

• TB4-15

• TB4-16

Warning

When you remove the DEVELOPER OVER-TEMPERATURE THERMOSTAT from the THERMOWELL, there

might be a leakage of solution. Clean all spills.

[5] Remove the DEVELOPER OVER-TEMPERATURE THERMOSTAT from the THERMOWELL.

36 12JAN99 – 7C8772

Page 37

Adjustments and Replacements

[6] Apply SEALANT TL-3230 to the THREADS on the new DEVELOPER OVER-TEMPERATURE

THERMOSTAT.

DEVELOPER

THERMISTOR

5 mm

(13/64 in.)

13.9 cm

(5.500 + .060 in.)

−

THERMOWELL

DEVELOPER

OVER-TEMPERATURE

THERMOSTAT

H172_1052BCA

H172_1052BA

Caution

You must install the DEVELOPER OVER-TEMPERATURE THERMOSTAT at the correct distance from the

THERMOWELL.

[7] Install the new DEVELOPER OVER-TEMPERATURE THERMOSTAT 5 mm (13/64 in.) from the

THERMOWELL.

[8] Connect the wires of the new DEVELOPER OVER-TEMPERATURE THERMOSTAT to:

• TB4-8

• TB4-9

• TB4-15

• TB4-16

[9] Close the ELECTRICAL BOX.

[10] Fill the DEVELOPER TANK or remove the CLAMPS from the TUBES on the THERMOWELL.

7C8772 – 12JAN99 37

Page 38

SERVICE MANUAL

HEAT EXCHANGER

Purpose: Use this procedure for the replacement of the HEAT EXCHANGER for the FIXER TANK or the

WASH TANK.

Warning

RACK

SUPPORT

2 SCREWS

2 TANK

CLIPS

Dangerous Voltage

[1] Disconnect the main power.

[2] Disconnect thewatersupply to the PROCESSOR.

[3] Remove:

• TOP COVER

• 2 SIDE PANELS

[4] Drain the 3 TANKS.

[5] Remove:

• 2 SCREWS

• RACK SUPPORT

• TANK SEALS

• TANK CLIP

[6] Disconnect all TUBING from the TANK.

2 TANK

SEALS

H172_1053CCA

H173_1053CA

38 12JAN99 – 7C8772

Page 39

Adjustments and Replacements

2 GASKETS

2 FITTINGS

WATER INLET

TUBE

TANK

HEATER

EXCHANGER

2 O-RINGS

2 WASHERS

2 GLAND NUTS

[7] Remove if necessary:

• 2 FITTINGS

• WATER INLET TUBE

[8] To remove the TANK, lift the non-drive side of

the TANK first.

[9] Remove from the TANK:

• 2 GLAND NUTS

• 2 O-RINGS

• 2 WASHERS

• HEAT EXCHANGER

Important

Use new GASKETS if you are installing a FIXER

TANK.

[10] Install:

• new HEAT EXCHANGER

• 2 O-RINGS

• 2 WASHERS

• 2 GLAND NUTS

• TANK

• 2 FITTINGS

• 2 GASKETS

• WATER INLET TUBE

• TANK SEALS

• TANK CLIP

• TUBING

• RACK SUPPORT

H172_1054CCA

H172_1054CA

[11] Move the RACK SUPPORT toward the non-drive side of the PROCESSOR.

[12] Install the 2 SCREWS.

[13] Fill the TANKS with water.

[14] Check for leakage.

[15] Drain the water from the DEVELOPER TANK and the FIXER TANK.

[16] Fill the DEVELOPER TANK and the FIXER TANK with the correct solution.

[17] Connect the water supply.

Warning

Dangerous Voltage

[18] Connect the main power.

7C8772 – 12JAN99 39

Page 40

SERVICE MANUAL

RECIRCULATION PUMP

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Disconnect the water supply to the PROCESSOR.

[3] Remove:

• TOP COVER

• 2 SIDE PANELS

[4] Drain the 3 TANKS.

[5] Install PINCH CLAMPS on the TUBING to the RECIRCULATION PUMP to prevent leakage of solution.

[6] Disconnect the TUBING to the RECIRCULATION PUMP.

[7] Remove:

• MOUNTING SCREWS

• RECIRCULATION PUMP

• MOTOR LEADS (not visible in figure)

[8] Install:

• new RECIRCULATION PUMP

• MOTOR LEADS (not visible in figure)

• MOUNTING SCREWS

[9] Connect the TUBING to the RECIRCULATION PUMP.

[10] Connect the water supply.

[11] Remove the PINCH CLAMPS from the TUBING.

[12] Fill the 3 TANKS with water.

MOUNTING

SCREW

RECIRCULATION PUMP

H172_1055BCA

H172_1055BA

Warning

Dangerous Voltage

[13] Connect the main power.

40 12JAN99 – 7C8772

Page 41

Adjustments and Replacements

Caution

Do not operate the RECIRCULATION PUMP if the TANKS are empty.

[14] Actuate the RECIRCULATION PUMP.

[15] Check for:

• agitation of the water in the TANK

• leakage

[16] Drain the water from the DEVELOPER TANK and the FIXER TANK.

[17] Fill the DEVELOPER TANK and the FIXER TANK with the correct solution.

O-RING in the RECIRCULATION PUMP

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Disconnect the water supply to the PROCESSOR.

[3] Remove:

• TOP COVER

• 2 SIDE PANELS

[4] Install PINCH CLAMPS on the TUBING to the RECIRCULATION PUMP to prevent leakage of solution.

7C8772 – 12JAN99 41

Page 42

SERVICE MANUAL

O-RING

4 WING

NUTS

OUTER

PUMP

HOUSING

SCREW

[5] Remove:

• 4 WING NUTS

• OUTER PUMP HOUSING

• O-RING

Important

The new O-RING must seat correctly.

[6] Install:

• O-RING

• OUTER PUMP HOUSING

• 4 WING NUTS

[7] Remove the PINCH CLAMPS from the TUBING.

WASHER

IMPELLER

SHAFT

H172_1056DCA

H172_1056DA

42 12JAN99 – 7C8772

Page 43

Warning

Dangerous Voltage

[8] Connect the main power.

Caution

Do not operate the RECIRCULATION PUMP if the TANKS are empty.

[9] Actuate the RECIRCULATION PUMP.

[10] Check for:

• agitation of the solution in the TANK

• leakage

REPLENISHMENT PUMP

Adjustments and Replacements

EXIT

PANEL

PUMP

COVER

DRYER TEMPERATURE CONTROL

KNOB

2 REPLENISHMENT PUMPS

2 WASHERS

TOP COVER

2 SIDE PANELS

H172_1028ACB

H172_1028AC

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Disconnect thewatersupply to the PROCESSOR.

[3] Remove:

• TOP COVER

• 2 SIDE PANELS

• RECEIVING BIN

• DRYER TEMPERATURE CONTROL

KNOB

• PUMP COVER

• EXIT PANEL

REPLENISHER TUBE LINES

2 LOCK WASHERS

2 SCREWS

H172_1057BCA

H172_1057BC

[4] Disconnect:

• MOTOR LEAD TB3-6

• MOTOR LEAD TB3-2

• GROUND WIRE

[5] Install PINCH CLAMPS on the TUBING to the REPLENISHMENT PUMP.

7C8772 – 12JAN99 43

Page 44

SERVICE MANUAL

[6] Disconnect the REPLENISHER TUBE LINES.

[7] Remove:

• 2 SCREWS

• 2 LOCK WASHERS

• 2 WASHERS

• REPLENISHMENT PUMP

[8] Reverse the steps to install a new REPLENISHMENT PUMP.

44 12JAN99 – 7C8772

Page 45

Periodic Maintenance

Section 3: Periodic Maintenance

Procedure and Schedule

Important

The Periodic Maintenance procedures include additional procedures which are not in the OPERATOR MANUAL,

Publication No. 7C8770. For optimum operation of the PROCESSOR, it is important to do these procedures.

[1] Process 5 sheets of unprocessed film.

[2] Check the film for artifacts.

[3] Do all of the Monthly Maintenance Procedures first.

[4] Do the procedure for lubrication on Page 53.

[5] Check the specifications of the site.

[6] Process 5 sheets of film.

[7] Check the film for artifacts.

Monthly Maintenance Procedures

DETECTOR SWITCHES

[1] Check that the DETECTOR SWITCHES operate the REPLENISHMENT PUMP.

[2] Adjust the DETECTOR SWITCHES if necessary. Use the procedure on Page 5.

DETECTOR CROSSOVER AY

[1] Use a damp, lint-free CLOTH or a SPONGE to clean the DETECTOR ROLLERS.

[2] Check:

• ROCKER ARM moves freely

• ROCKER ARM does not have corrosion

• DETECTOR CROSSOVER AY for squareness

[3] Clean the ROCKER ARM if it does not move freely.

[4] Install a new ROCKER ARM if it has corrosion.

[5] Check the DETECTOR CROSSOVER AY for squareness. Use the procedure on Page 7.

[6] Check that the DETECTOR CROSSOVER AY is correctly seated.

CROSSOVER AYs

[1] Remove the CROSSOVER AYs from the PROCESSOR.

[2] Rinse the CROSSOVER AYs with water.

[3] Use warm water and a soft BRUSH to clean the CROSSOVER AYs, or use:

Cleaning Solution Type of CROSSOVER

DEVELOPER SYSTEM CLEANER and

NEUTRALIZER, Catalog No. 843 4615

FIXER/WASH SYSTEM CLEANER,

Catalog No. 139 5110

DEVELOPER/FIXER CROSSOVER

FIXER/WASH CROSSOVER

7C8772 – 12JAN99 45

Page 46

SERVICE MANUAL

BRACKET

ROLLER

ROLLER

GEAR

NUT

SPRING

DRIVE

GEAR

GUIDE

SHOE

BEARING

[4] Check that the surface of the RESILIENT ROLLER is smooth. Install a replacement if necessary.

[5] Check components for wear or broken parts. Install replacements if necessary:

• SPRINGS

• ROLLER GEARS

• BEARING

• BRACKET

• NUTS

• DRIVE GEAR

[6] Check the CROSSOVER AYs for squareness. Use the procedure on Page 7.

RACK AYs

[1] Remove the RACKS from the PROCESSOR.

[2] Rinse the RACKS with warm water.

[3] Use warm water and a soft BRUSH to clean the RACKS, or use:

Cleaning Solution RACK

DEVELOPER SYSTEM CLEANER and

NEUTRALIZER, Catalog No. 843 4615

FIXER/WASH SYSTEM CLEANER,

Catalog No. 139 5110

DEVELOPER

FIXER

WASH

H172_1058BCA

H172_1058BA

46 12JAN99 – 7C8772

Page 47

Note

The ROLLERS might change color with time. This change is normal.

Periodic Maintenance

bottom view

BEARING

ROLLER

top view

LOCKING

PLATE

[4] Check:

• SPRINGS for correct tension and for wear

• ROLLERS and BEARINGS rotate freely

• ROLLERS move freely in the LOCKING PLATES

• surfaces of the ROLLERS are smooth

[5] Install replacement SPRINGS and ROLLERS if necessary.

SHAFT

SPRING

BEARING

H172_1060DCA

H172_1060DA

7C8772 – 12JAN99 47

Page 48

SERVICE MANUAL

DRIVE CHAIN

SPROCKET

GEAR

TURNAROUND

ASSEMBLY

SHAFT

DRIVE

GEAR

SPRING

LOCKING

PLATE

[6] Manually rotate the DRIVE GEAR to check the

LINKS of the DRIVE CHAIN.

Important

The tension of the DRIVE CHAIN must be correct.

• If the DRIVE CHAIN is too tight, the ROLLERS

will bind and cause wear of the BEARING.

• If the DRIVE CHAIN is too loose, the ROLLERS

will not move smoothly.

[7] Check the tension of the DRIVE CHAIN.

[8] If necessary, adjust the tension of the DRIVE

CHAIN using the procedure on Page 10.

LINK

DRIVE CHAIN

H172_1041CCB

H172_1041CA

48 12JAN99 – 7C8772

Page 49

DRYER

Periodic Maintenance

SPRING

GEAR

ROLLER

AIR TUBE

H172_1059BCA

H172_1059BA

[1] Remove the DRYER RACK from the PROCESSOR.

[2] Check for broken GEARS and install new ROLLERS if necessary.

[3] Check the SPRINGS, not visible in the graphic, for correct tension and for wear. Install new SPRINGS if

necessary.

[4] Check and adjust the temperature of the DRYER. Use the procedure on Page 24.

MAIN DRIVE

WORM

GEAR

DRIVE

CHAIN

SPROCKET

[1] Check the DRIVE CHAIN for wear and install a new DRIVE CHAIN if necessary.

[2] Check and adjust the tension of the DRIVE CHAIN. Use the procedure on Page 21.

[3] Lubricate the DRIVE CHAIN if necessary. Use the procedure on Page 53.

[4] Check for wear and install replacements if necessary:

• BEARINGS

• SPROCKETS

• WORM GEARS

[5] Check the TEETH of the SPROCKETS. If the TEETH are sharp, install new SPROCKETS.

[6] Check the WORM GEARS for burrs. Install new WORM GEARS if necessary.

[7] Rinse the WORM GEARS with warm water.

BEARING

H172_1061BCA

H172_1061BA

7C8772 – 12JAN99 49

Page 50

SERVICE MANUAL

PLUMBING

[1] Check components and connections for leakage:

• RECIRCULATION PUMPS

• VALVES

• TUBING

• TANKS

[2] Check that the temperature of the water supply is 4-30

WATER

INLET

TUBE

°C (40-85°F).

[3] Check the flow rate of the water supply:

(a) Drain the TANKS.

(b) Remove:

• FIXER/WASH CROSSOVER

• DRYER RACK

• WASH RACK

(c) Start the water supply.

(d) Measure the flow rate at the WATER INLET TUBE. The rate should be 946 mL/min. (1/4 gal/min.),

+10%, -0%.

H172_1062BCA

H172_1062BC

RECIRCULATION PUMPS

Caution

Do not operate the RECIRCULATION PUMP if the TANKS are empty.

[1] Actuate the RECIRCULATION PUMPS.

[2] Check for:

• leakage

• agitation of the solution in the TANKS

• excessive noise from the RECIRCULATION PUMPS

50 12JAN99 – 7C8772

Page 51

Periodic Maintenance

DEVELOPER FILTER

Important

Install a new DEVELOPER FILTER monthly or after approximately 1000 sheets of film have been processed.

[1] Soak the new DEVELOPER FILTER in warm

water for 30 seconds.

[2] Remove the FILTER AY.

[3] Lift the FILTER AY above the level of the

solutions.

Note

Keep the FILTER AY above the level of the solutions

during the procedure to prevent draining the solutions

from the TANKS.

[4] Disassemble:

• FILTER HOUSING

• DEVELOPER FILTER

• O-RING

CAP

• CAP

O-RING

DEVELOPER

FILTER

FILTER

HOUSING

H172_1026CCA

H172_1026CC

Temperature of the Developer Solution

[1] Do the procedure on Page 29.

Important

The O-RING must be seated correctly.

[5] Assemble:

• FILTER HOUSING

• new DEVELOPER FILTER

• O-RING

• CAP

[6] Install the FILTER HOUSING in the

PROCESSOR.

[7] Check that theTUBINGconnected to theFILTER

HOUSING is not bent.

7C8772 – 12JAN99 51

Page 52

SERVICE MANUAL

Chemical Replenishment

[1] Check the replenishment rates. Use the procedure on Page 31.

[2] Check the STRAINERS for debris:

(a) Place CLAMPS on the TUBING to stop the flow of replenishment solution.

(b) Disassemble the STRAINER AYs.

(c) Use a BRUSH and warm water to clean the STRAINER AYs and the SCREENS.

STRAINER ASSEMBLY

SCREEN

H172_1063BCA

H172_1063BA

INTERLOCK SWITCH

MAGNET

TOP COVER

MAGNET

INTERLOCK

SWITCH

H172_1064BCA

H172_1064BC

[1] Press the RUN/STANDBY SWITCH.

Warning

Moving Parts

[2] Remove the TOP COVER.

[3] Check that the components stop operating:

• MAIN DRIVE MOTOR

• BLOWER MOTOR

• DRYER HEATER

[4] If the components do not stop when the TOP COVER is removed, install a new INTERLOCK SWITCH.

52 12JAN99 – 7C8772

Page 53

Periodic Maintenance

Lubrication Procedure and Schedule

Warning

Dangerous Voltage

[1] Disconnect the main power before applying lubrication to the PROCESSOR.

Caution

Do not allow lubricants to touch the CROSSOVERS or RACK ASSEMBLIES, or to drip into the TANKS.

[2] Apply lubricant to the parts identified in the Table:

Frequency of

Part

MAIN DRIVE CHAIN As necessary,

RECIRCULATION

PUMPS

DRYER BLOWER

BEARINGS

MAIN DRIVE MOTOR No lubrication is necessary

GEAR HOUSING of the

MAIN DRIVE MOTOR

Lubrication Lubricant Procedure

NLGI - No. 2 LITHIUM BALL

check monthly

Every 6 months LIGHT OIL

Every 6 months LIGHT OIL

No lubrication is necessary

AND ROLLER BEARING

GREASE TL-2324

Example: SAE No. 20 MOTOR

OIL TL-2244

Example: SAE No. 20 MOTOR

OIL TL-2244

Apply to the surface of the

CHAIN.

Apply drops of OIL in the

OIL HOLES.

Apply drops of OIL in the

OIL HOLES.

7C8772 – 12JAN99 53

Page 54

SERVICE MANUAL

Section 4: Correcting Problems

1. Transport Failure

2. Surface Artifacts

3. Abnormal Film Densities

4. Wet Films

5. Low Solution Levels

6. Overlapping of Films

123456

• • Film Feeding Error

Feed only single thicknesses of film. Feed the next film only after the

film feed signal sounds If there is no film feed signal, refer the difficulty

to qualified service personnel.

• • • • Feed only compatible films.

• • Check that all RACKS and CROSSOVERS are seated correctly.

• • Check that the surfaces of all the ROLLERS are clean and smooth, especially in

the DEVELOPER TURNAROUND AY.

• • Check that the DRYER AIR TUBES are in the correct positions.

• • Remove any dirt from the DRYER ROLLERS and AIR TUBES, especially the

slots. Use a bottle brush and rinse with water.

• • • • Check that the replenishment settings are correct.

• Adjust the DRYER temperature control setting to the lowest possible

temperature that still allows good drying.

• Clean the FEED SHELF and DETECTOR ROLLERS

• • • Clean any biological growth in the WASH TANK with a mild solution of

chlorine bleach. Use 60 mL (2 fl oz) of bleach per 3.8 L (1 gallon) of water.

Wipe the TANKS with a soft sponge.

• • Check that the WEIRS are seated correctly. Check that the TANKS are full.

• • • • • Change any chemicals that were not mixed correctly, are exhausted, or are

contaminated. Check that the replenishment flow rates are correctly set. Fill the

Replenishment TANKS if necessary.

• • • Check that

• • • Check that

• • • Replace any ROLLER that has a broken or worn GUDGEONS.

• • • Replace any BEARINGS that do not allow the TURNAROUND ROLLERS to

rotate correctly.

• • Check the tension on the RACK CHAIN. Check that the ROLLERS do not

hesitate and that the CHAIN moves smoothly.

• With the PROCESSOR energized, check for movement on the surface of the

solutions. Movement indicates recirculation.

• • If the incoming wash water is dirty, clean the RACK and TANK thoroughly.

Change the incoming WATER FILTER. Make sure to use the correct WATER

FILTER.

• Check that the DRYER AIR EXHAUST is free from any obstruction.

• • Check that the TURNAROUND ASSEMBLY is adjusted correctly. Make sure

that the TURNAROUND ASSEMBLIES are square with the RACKS.

all ROLLERS are in place and positioned and rotating correctly.

all ROLLER GEARS, SPROCKETS, and IDLERS are engaged.

54 12JAN99 – 7C8772

Page 55

Correcting Problems

1. Transport Failure

2. Surface Artifacts

3. Abnormal Film Densities

4. Wet Films

5. Low Solution Levels

6. Overlapping of Films

123456

••

• Check that the correct BULB and SAFELIGHT FILTER are in the

• • Check that the TOP COVER and PANELS are tight on the PROCESSOR.

• 10 x 10 cm films - feed films diagonally if they fail to transport reliably.

• • • • Check that the solution levels of the TANKS are at the overflow WEIRS.

• Check for solution in the REPLENISHMENT TANKS. Fill if necessary.

• With a THERMOMETER of known accuracy, check that the temperature of the

Check the incoming water temperature. Temperature must be between 4.4

°F) and 29.4°C (85°F).

(40

SAFELIGHT and at the correct distance from the FEED SHELF and work

surface.

Check that there are no leaks in the LIGHTTIGHT GASKET.

• Check the time delay. For all transport speeds, the BUZZER should sound once

the trailing edge of the film has advanced 75 mm (3 in.) into the PROCESSOR.

NOTE: Mix developer replenisher in quantities not to exceed a 2-week

supply.

developer is correct. If necessary, have qualified service personnel make

adjustments.

NOTE: Check the incoming water temperature. It must be a minimum of 4

°F) lower than the desired developer temperature.

(7

°C

°C

Publication History

Affected

Print Date Pub No. ECO No.

Jan. 99 7C8772 N/A All sm3554_1_12jan99.fm First Printing

Pages File Name Notes

7C8772 – 12JAN99 55

Page 56

Kodak and X-Omat are trademarks.

sm3554_1_12jan99.fm

Printed In USA

EASTMAN KODAK COMPANY

Health Imaging

● ROCHESTER, N.Y. 14650

Loading...

Loading...