Page 1

Section 5: Plumbing

Table of Contents

Description Page

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

Recirculation System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Removing the RECIRCULATION PUMP B5 . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Removing the IMPELLER HOUSING or the IMPELLER . . . . . . . . . . . . . . . . . . 5–3

Removing the THERMOWELL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–5

Removing the DEVELOPER or FIXER HEATER . . . . . . . . . . . . . . . . . . . . . . . 5–6

Removing the DEVELOPER or FIXER THERMISTOR . . . . . . . . . . . . . . . . . . . 5–7

Removing the DEVELOPER FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–8

Removing the LEVEL SENSOR HOUSING and LEVEL SENSORPROBES . . 5–9

Removing the DEVELOPER COOLING SOLENOID L2 . . . . . . . . . . . . . . . . . . 5–10

Removing the HEAT EXCHANGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–11

Wash System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–14

Removing the WATER SOLENOID VALVE L1 . . . . . . . . . . . . . . . . . . . . . . . . . 5–14

Replenishment System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–15

Removing the REPLENISHER STRAINER ASSEMBLIES and SCREENS. . . . 5–15

Removing the DEVELOPER or FIXER REPLENISHMENT PUMP . . . . . . . . . . 5–16

Removing the POPPET VALVES for the REPLENISHMENT PUMPS . . . . . . . 5–17

Plumbing

1C7837 – February 1996 5–1

Page 2

ADJUSTMENTS AND REPLACEMENTS

Recirculation System

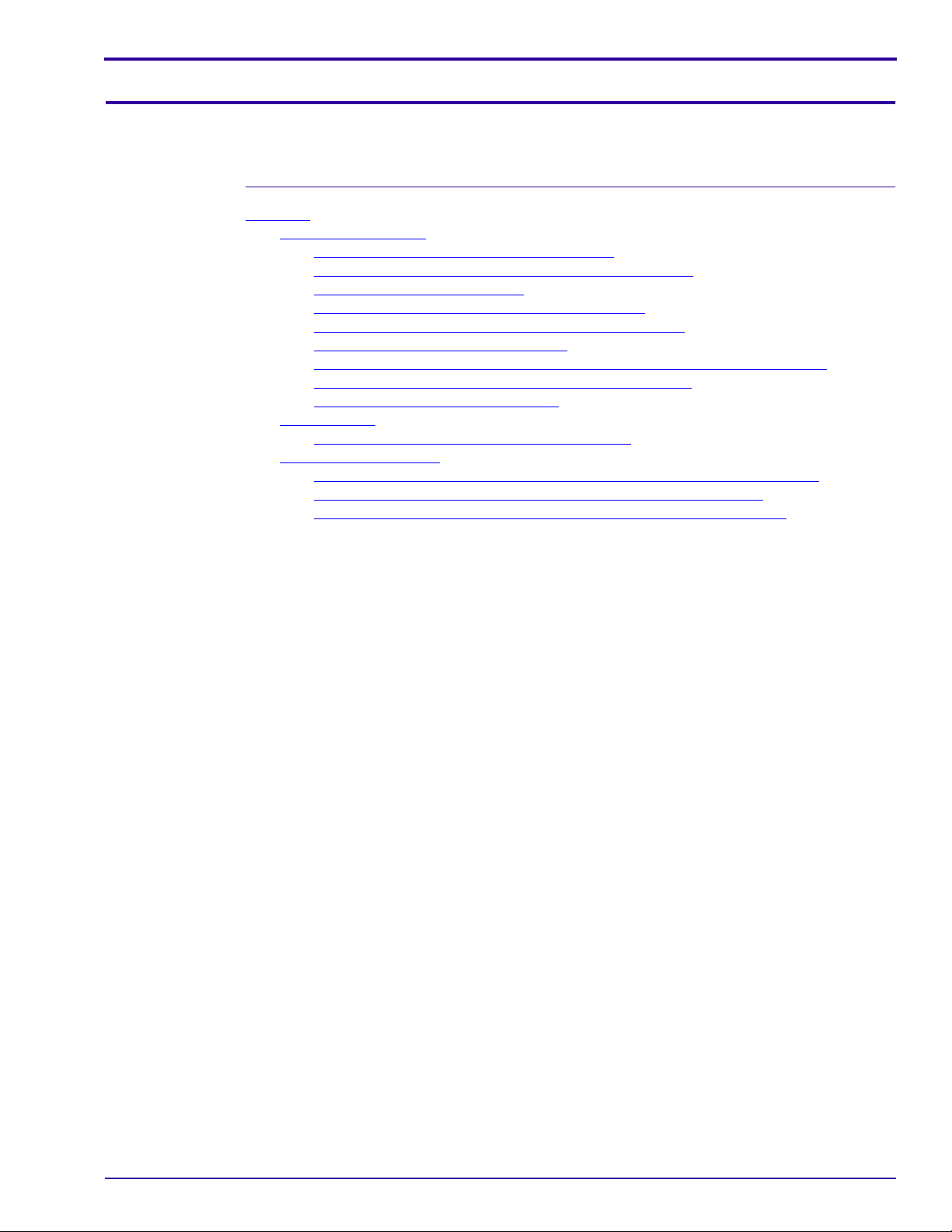

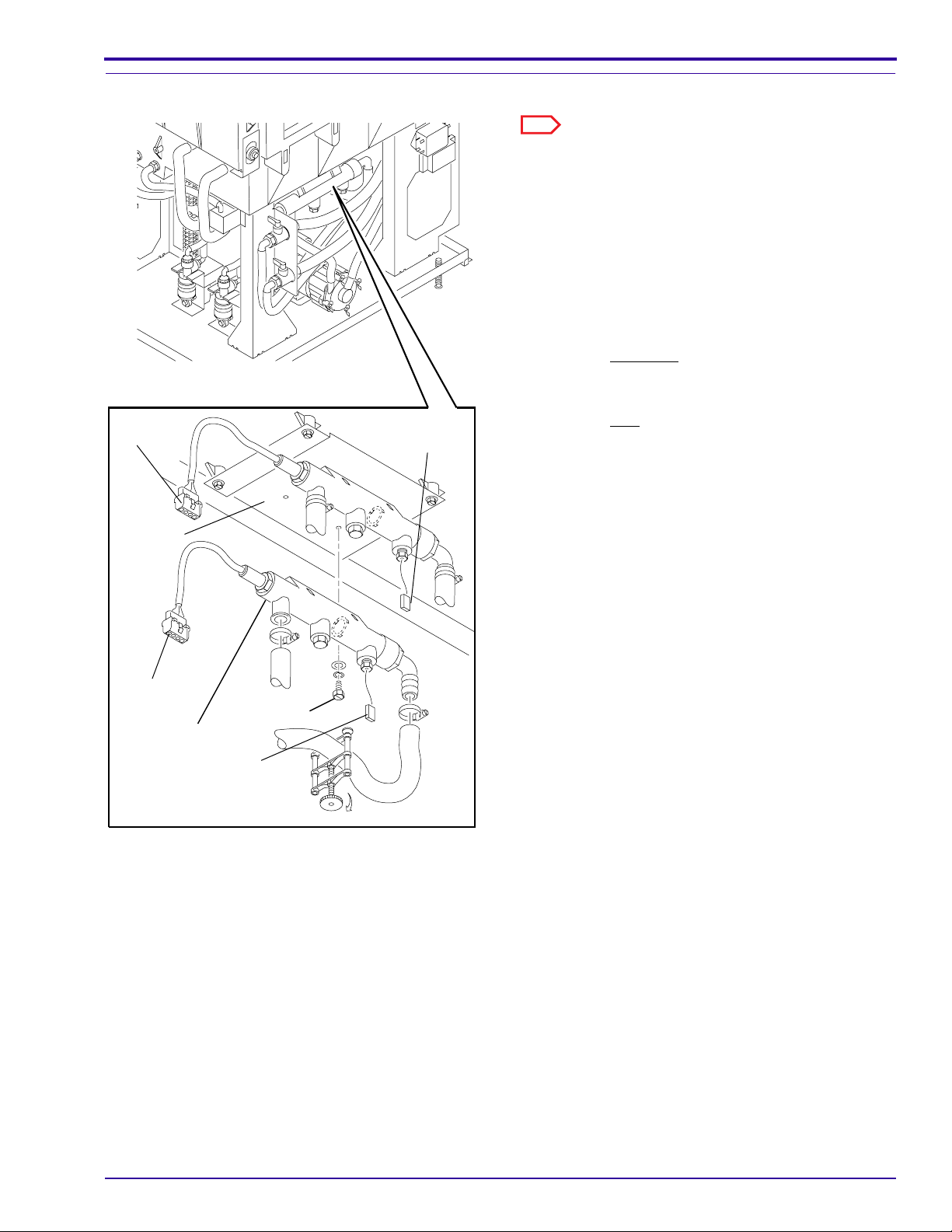

Removing the RECIRCULATION PUMP B5

[1] Move the main wall CIRCUIT BREAKER to “OFF”and CB1 on the PROCESSOR to the “O” position.

[2] Lift the TOP COVER.

[3] Remove:

• DRYER SIDE PANEL

• DRIVE SIDE PANEL

• SPLASH COVER

[4] Open the ELECTRICAL BOX.

[5] Use 4 CLAMPS TL-2170 on the 2 DEVELOPER HOSES and the2 FIXER HOSES to the RECIRCULATION

PUMP.

[6] Loosen the 4 HOSE CLAMPS. Remove the 2 DEVELOPER HOSESand the 2 FIXER HOSES from the

RECIRCULATION PUMP.

Note

The 2 FIXER HOSES are not in the figure.

[7] Remove the 2 SCREWS that hold the RECIRCULATION PUMPto the BASE PLATE of the PROCESSOR.

[8] Disconnect CONNECTOR P/J12 for the RECIRCULATION PUMP.

[9] Remove the RECIRCULATION PUMP.

[10] Reverse the procedure to assemble.

Figure 5–1 Replacement of the RECIRCULATION PUMP

BASE

PLATE

2 SCREWS

CONNECTOR

P/J12

DEVELOPER

HOSES

RECIRCULATION PUMP

SPLASH

COVER

TL-2170

H127_0029BCA

H127_0029BA

5–2 February 1996 – 1C7837

Page 3

Plumbing

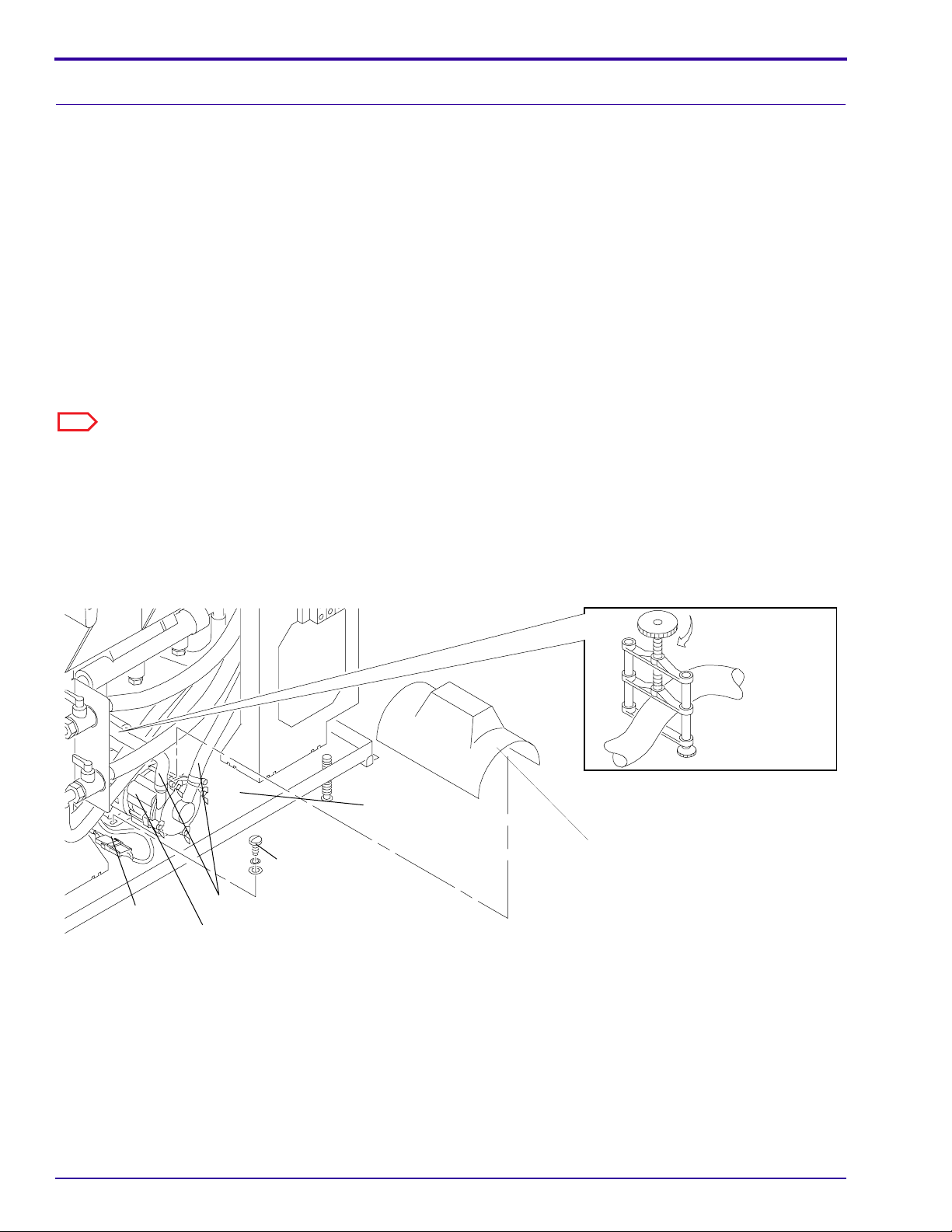

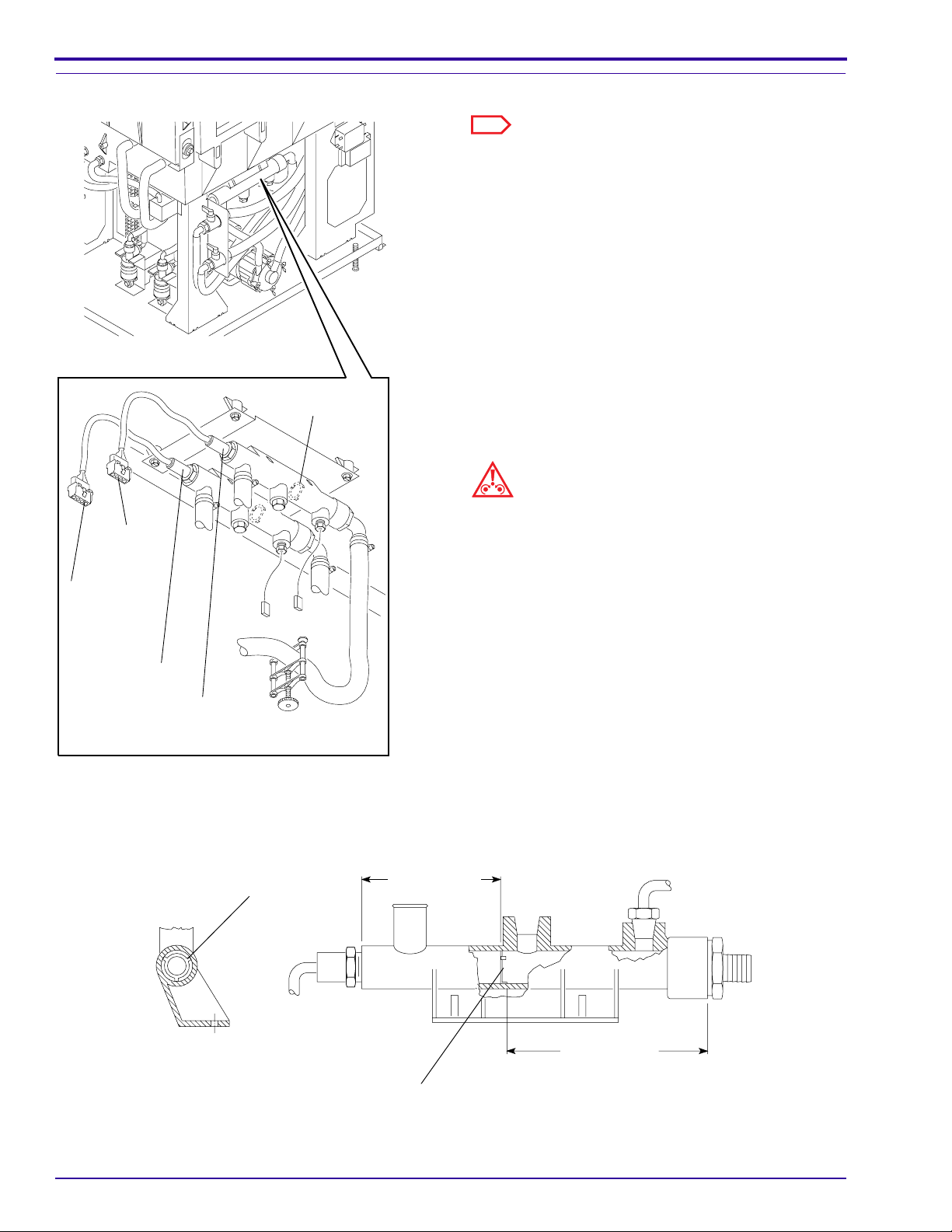

Removing the IMPELLER HOUSING or the IMPELLER

Note

Use this procedure for either the developer IMPELLERHOUSING or the fixer IMPELLER HOUSING.

[1] Move the main wall CIRCUIT BREAKER to “OFF”and CB1 on the PROCESSOR to the “O” position.

[2] Lift the TOP COVER.

[3] Remove the DRIVE SIDE PANEL.

Note

For improved access, remove the FEED SIDE PANELto remove the developer IMPELLER or the DRYER SIDE

PANEL to removethe fixer IMPELLER.

[4] Use 2 CLAMPS TL-2170 on the 2 DEVELOPER HOSES or the2 FIXER HOSES to the RECIRCULATION

PUMP.

Note

The 2 FIXER HOSES are not in the figure.

[5] Loosen the 2 HOSE CLAMPS and remove the 2 DEVELOPER HOSESor the 2 FIXER HOSES from the

IMPELLER HOUSING.

Figure 5–2 Installing CLAMPS on the HOSES tothe RECIRCULATION PUMP

CONNECTOR

P/J-12

IMPELLER

HOUSING

DEVELOPER

HOSES

TL-2170

H127_0029BCB

H127_0029BA

1C7837 – February 1996 5–3

Page 4

ADJUSTMENTS AND REPLACEMENTS

Figure 5–3 Replacement of the IMPELLERHOUSING

or the IMPELLER

RECIRCULATION

PUMP

O-RING

INNER

HOUSING

IMPELLER

WASHER

SCREW

IMPELLER

HOUSING

WING

NUT (4)

H104_0033ACB

H104_0033AA

[6] Remove:

• 4 WING NUTS from the IMPELLER

HOUSING

• IMPELLER HOUSING

Caution

To prevent chemical contamination, keep

theDEVELOPER and FIXER IMPELLERS and

IMPELLER HOUSINGS separate.

[7] Remove the INNER HOUSING from the

RECIRCULATION PUMP.

[8] To remove the IMPELLER from the INNER

HOUSING:

a. Remove the SCREW and WASHER from the

IMPELLER.

b. Remove the IMPELLER.

[9] Check the O-RING for wear. If necessary, install

a newO-RING.

Caution

To prevent leakage, the O-RING must be inthe correct

position.

[10] Check that the O-RING is correctly seated.

[11] Reverse the procedure to assemble.

[12] Tighten the SCREW.

[13] Check that the IMPELLER moves freely.

5–4 February 1996 – 1C7837

Page 5

Removing the THERMOWELL

CONNECTOR

P/J20

MOUNTING

BASE

CONNECTOR

P/J26

Plumbing

Note

Use this procedure for either the developer orfixer

THERMOWELL.

[1] Move the main wall CIRCUIT BREAKER to

“OFF”and CB1 on the PROCESSOR to the “O”

position.

[2] Lift the TOP COVER.

[3] Remove the DRYER SIDE PANEL.

[4] Use 2 HOSE CLAMPS TL-2170 on the HOSES to

the THERMOWELL.

[5] For the developer, disconnectCONNECTORS P/

J20 and P/J26.for the developer or P/J19 for the

fixer.

[6] For the fixer, disconnect CONNECTORSP/J19

and P/J27.

[7] Loosen the 2 HOSE CLAMPS and remove the

HOSES.

[8] Remove the 2 SCREWS holding the

THERMOWELL to the MOUNTINGBASE.

[9] Remove the THERMOWELL.

[10] Reverse the procedure to assemble.

CONNECTOR

P/J19

THERMOWELL

CONNECTOR

P/J27

2 SCREWS

TL-2170

H127_0045CCA

H127_0045CA

1C7837 – February 1996 5–5

Page 6

ADJUSTMENTS AND REPLACEMENTS

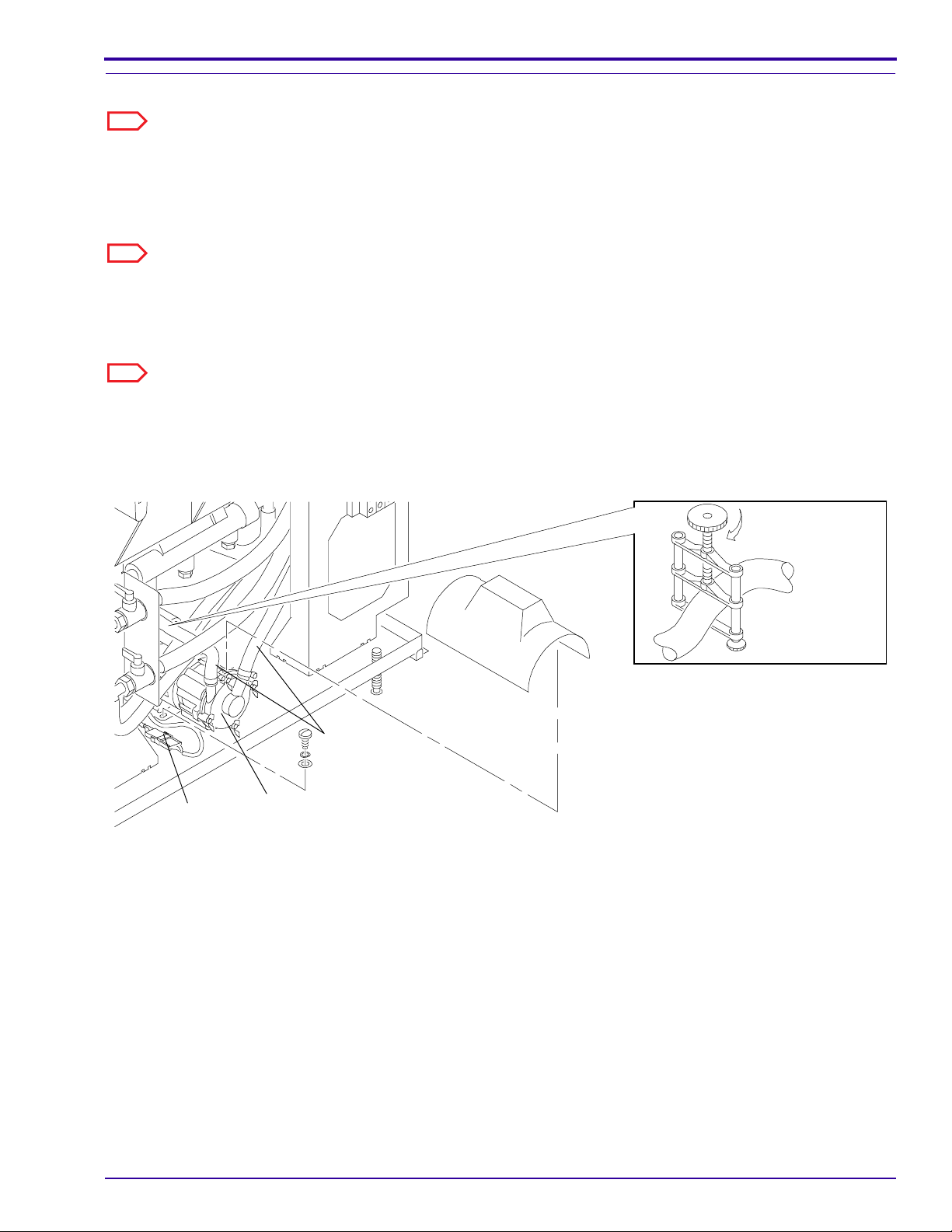

Removing the DEVELOPER or FIXER HEATER

LOCATING

RING

Note

Use this procedure for either the DEVELOPER

orFIXER HEATER.

[1] Move the main wall CIRCUIT BREAKER to

“OFF”and CB1 on the PROCESSOR to the “O”

position.

[2] Lift the TOP COVER.

[3] Remove the DRYER SIDE PANEL and the DRIVE

SIDE PANEL.

[4] Use 2 CLAMPS TL-2170 on the HOSES to the

THERMOWELL.

[5] Disconnect CONNECTOR P/J20 for the

developer or CONNECTORP/J19 for the fixer.

[6] Remove the DEVELOPER or FIXER HEATER

from the THERMOWELL.

Caution

CONNECTOR

P/J-20

CONNECTOR

P/J-19

FIXER

HEATER

DEVELOPER

HEATER

Figure 5–4 Replacement of the DEVELOPER or FIXERHEATER

TL-2170

HEATER

LOCATOR

H127_0050CCA

H127_0050CA

+

8.38 0.25 cm

+

(3.3 0.1 in)

-

[7] Check that the HEATER LOCATOR is in the

[8] Reverse the procedure to assemble.

[9] Check for leakage at the THERMOWELL.

• The internal HEATER LOCATOR must be in

thecorrect position in the THERMOWELL.

• Do not overtighten the parts during the

installation of theHEATER.

• Use SEALANT 1C8022 on the threads during

the installationof the HEATER into the

THERMOWELL. See the instructions

providedwith the SEALANT.

correct positionin the THERMOWELL.

+

13.9 0.25 cm

+

(5.5 0.1 in)

-

HEATER

LOCATOR

H104_0444BCA

H104_0444BA

5–6 February 1996 – 1C7837

Page 7

Removing the DEVELOPER or FIXER THERMISTOR

Use this procedure for either the DEVELOPER

orFIXER THERMISTOR.

[1] Move the main wall CIRCUIT BREAKER to

[2] Lift the TOP COVER.

[3] Remove the DRYER SIDE PANEL.

[4] Use 2 CLAMPS TL-2170 on the HOSES to the

[5] Disconnect CONNECTOR P/J26 for the

[6] Remove the THERMISTOR from the

DEVELOPER

THERMISTOR

Use SEALANT 1C8022 on the threads of

theTHERMISTOR for the installation of the

THERMISTOR into the THERMOWELL. See the

instructions provided with the SEALANT. Do not

overtightenthe parts during the installation of the

THERMISTOR.

FIXER THERMISTOR

CONNECTOR P/J-26

[7] Reverse the procedure to assemble.

[8] Check for leakage at the THERMOWELL.

Plumbing

Note

“OFF”and CB1 on the PROCESSOR to the “O”

position.

THERMOWELL.

developer or CONNECTORP/J27 for the fixer.

THERMOWELL.

Important

CONNECTOR P/J-27

TL-2170

H127_0050CCB

H127_0050CA

1C7837 – February 1996 5–7

Page 8

ADJUSTMENTS AND REPLACEMENTS

Removing the DEVELOPER FILTER

REPLENISHER

HOSE

[1] Move the main wall CIRCUIT BREAKER to

“OFF”and CB1 on the PROCESSOR to the “O”

position.

[2] Lift the TOP COVER.

[3] Remove the WET SECTION COVER and the

REPLENISHER HOSEfrom the MANDREL

ASSEMBLY.

MANDREL

ASSEMBLY

DEVELOPER

FILTER

WING NUT

LEVEL

SENSOR

HOUSING

Important

When removing the MANDREL ASSEMBLY, placea

DRIP TRAY under it to prevent contamination of the

FIXER.

[4] Rotate the MANDREL ASSEMBLY until the notch

in the topof the ASSEMBLY aligns with the LEVEL

SENSOR HOUSING CLIP on theLEVEL

SENSOR HOUSING.

[5] Remove the MANDREL ASSEMBLY by pulling

straight up.

[6] Remove:

• WING NUT from the MANDREL ASSEMBLY

• DEVELOPER FILTER from the MANDREL

ASSEMBLY

[7] Reverse the procedure to assemble.

[8] Install the MANDREL ASSEMBLY.

[9] Rotate the MANDREL ASSEMBLY until the

LEVEL SENSOR HOUSINGCLIP is in the locked

position.

H127_0135CCA

H127_0135CA

Figure 5–5 Replacement of the DEVELOPER FILTER

LEVEL SENSOR

HOUSING CLIP

H127_0061BCA

H127_0061BA

5–8 February 1996 – 1C7837

UNLOCKED

MANDREL

HOUSING

LOCKED

Page 9

Removing the LEVEL SENSOR HOUSING and LEVEL SENSORPROBES

H127_0153AA

H127_0153ACA

WASHER

GASKET SIDE

SCREW

TANK

PROBE

WIRE

Plumbing

MANDREL

ASSEMBLY

SCREW (2)

WASHER

REPLENISHER

HOSE

Note

Use this procedure for either the developer,red, or fixer,

blue, LEVEL SENSOR PROBES.

[1] Move the main wall CIRCUIT BREAKER to

“OFF”and CB1 on the PROCESSOR to the “O”

position.

[2] Lift the TOP COVER.

[3] Remove the WET SECTION COVER and the

NON-DRIVE SIDE PANEL.

[4] Remove the 2 SCREWS and the WASHER

located on the outsideof the TANK.

[5] Lift the LEVEL SENSOR HOUSING out.

[6] Remove the LEVEL SENSOR PROBE from the

LEVEL SENSOR HOUSING.

[7] Reverse the procedure to assemble.

[8] Check that the PROBE WIRE is correctly attached

to theSCREW and WASHER.

[9] Check that the WASHER is in the correct position

withthe GASKET SIDE of the WASHER against

the TANK. See Figure .

PROBE

WIRE

LEVEL SENSOR

HOUSING

LEVEL

SENSOR

PROBE

H127_0134CCA

H127_0134CA

Figure 5–6 Replacement of theLEVEL SENSOR

HOUSING and PROBES

1C7837 – February 1996 5–9

Page 10

ADJUSTMENTS AND REPLACEMENTS

Removing the DEVELOPER COOLING SOLENOID L2

[1] Move the main wall CIRCUIT BREAKER to “OFF”and CB1 on the PROCESSOR to the “O” position.

[2] Lift the TOP COVER.

[3] Remove the DRIVE SIDE PANEL.

[4] Move the ELECTRICAL BOX out.

[5] Use 2 CLAMPS TL-2170 on the 2 HOSES to the COOLING SOLENOID.

[6] Loosen the HOSE CLAMPS and remove the HOSES.

[7] Disconnect CONNECTOR P/J23 at the COOLING SOLENOID.

[8] Remove:

• 2 SCREWS holding the COOLING SOLENOID tothe MOUNTING BRACKET

• COOLING SOLENOID

Important

• When installing the COOLING SOLENOID, the“A” must be on the top and the “C”on the bottom.

• Use SEALANT 1C8022 on the threads of the FITTINGS during theinstallation of the FITTINGS into the new

COOLING SOLENOID. Seethe instructions provided with the SEALANT.

• Do not overtighten the parts during the installation of thefittings in the COOLING SOLENOID.

[9] Reverse the procedure to assemble.

[10] Check for leakage at the COOLING SOLENOID.

Figure 5–7 Replacement of the DEVELOPER COOLINGSOLENOID

COOLING

SOLENOID

CONNECTOR

P/J23

TL-2170

A

FITTINGS

A

H127_0046BCA

H127_0046BA

2 SCREWS

5–10 February 1996 – 1C7837

Page 11

Removing the HEAT EXCHANGER

Plumbing

EXIT RACK

CONNECTOR

P/J-33

DRYER RACK

[1] Move the main wall CIRCUIT BREAKER to “OFF”and CB1 on the PROCESSOR to the “O” position.

[2] Lift the TOP COVER.

[3] Remove the DRIVE SIDE PANEL and the WET SECTION COVER.

[4] Disconnect CONNECTOR P/J33.

[5] Remove the EXIT RACK and the DRYER RACK.

[6] Use 2 CLAMPS TL-2170 on the HEAT EXCHANGER FORMED TUBING.

[7] Remove the HOSE CLAMPS.

Figure 5–8 Installing the CLAMPS

H127_0136BCA

H127_0136BA

TL-2170

CLAMP (2)

HEAT

EXCHANGER

FORMED

H127_0048BCB

H127_0048BA

1C7837 – February 1996 5–11

TUBING

Page 12

ADJUSTMENTS AND REPLACEMENTS

Figure 5–9 Replacement of the HEAT EXCHANGER

HEAT

EXCHANGER

O-RING SEAL

[8] Remove:

• FORMED TUBING from the ends of the BARBEDFITTINGS

• BARBED FITTINGS from the HEAT EXCHANGER

• O-RING SEALS

• HEAT EXCHANGER from the WASH TANK

BARBED FITTING

HOSE CLAMP

FORMED TUBING

H127_0215HCA

H127_0215HA

5–12 February 1996 – 1C7837

Page 13

Figure 5–10 Aligning the Ends ofthe HEAT EXCHANGER

Plumbing

HEAT

EXCHANGER

O-RING SEAL

BARBED FITTING

HEAT

EXCHANGER

Caution

• Install new O-RING SEALS 532378. Do notuse the existing O-RING SEALS again.

• Do not overtighten the BARBED FITTINGS.

NOTE: Align the ends of

the HEAT EXCHANGER

flush with the ends of

the BARBED FITTINGS.

H127_0214BCA

H127_0214BA

[9] Reverse the procedure to assemble. Align the ends ofthe HEAT EXCHANGER flush with the ends of the

BARBED FITTINGS. See Figure 5–10.

1C7837 – February 1996 5–13

Page 14

ADJUSTMENTS AND REPLACEMENTS

Wash System

Removing the WATER SOLENOID VALVE L1

[1] Move the main wall CIRCUIT BREAKER to “OFF”and CB1 on the PROCESSOR to the “O” position.

[2] Turn off the main water supply.

[3] Lift the TOP COVER.

[4] Remove the DRIVE SIDE PANEL.

[5] Remove the 2 SCREWS from the WATER SOLENOID VALVE.

[6] Disconnect CONNECTOR P/J30 from the WATER SOLENOID VALVE.

Note

Disconnect the HOSES very slowly to release thepressure.

[7] Loosen the HOSE CLAMPS and remove the 2 HOSES from theWATER SOLENOID VALVE.

[8] Remove the WATER SOLENOID VALVE from the PROCESSOR.

[9] Reverse the procedure to assemble.

Important

Check for leakage at the WATER SOLENOIDVALVE.

2 SCREWS

H127_0137BCA

H127_0137BA

CONNECTOR

P/J30

WATER

SOLENOID

VALVE

5–14 February 1996 – 1C7837

Page 15

Plumbing

Replenishment System

Removing the REPLENISHER STRAINER ASSEMBLIES and SCREENS

[1] Move the main wall CIRCUIT BREAKER to “OFF”and CB1 on the PROCESSOR to the “O” position.

[2] Use 2 CLAMPS TL-2170 on the HOSES on either side of theREPLENISHER STRAINER.

[3] To remove the REPLENISHER STRAINER, loosen the 2 HOSECLAMPS and remove the REPLENISHER

STRAINER.

[4] Remove the CAP and the SCREEN from the REPLENISHER STRAINER.

[5] Clean the SCREEN or, if necessary, install a new SCREEN.

[6] Check the O-RING for wear. If necessary, install a newO-RING.

[7] Reverse the procedure to assemble.

Figure 5–11 Replacement of the REPENISHER STRAINERASSEMBLIES or the SCREENS

REPLENISHER

STRAINER

TL-2170

O-RING

CAP

SCREEN

H127_0030BCA

H127_0030BA

1C7837 – February 1996 5–15

Page 16

ADJUSTMENTS AND REPLACEMENTS

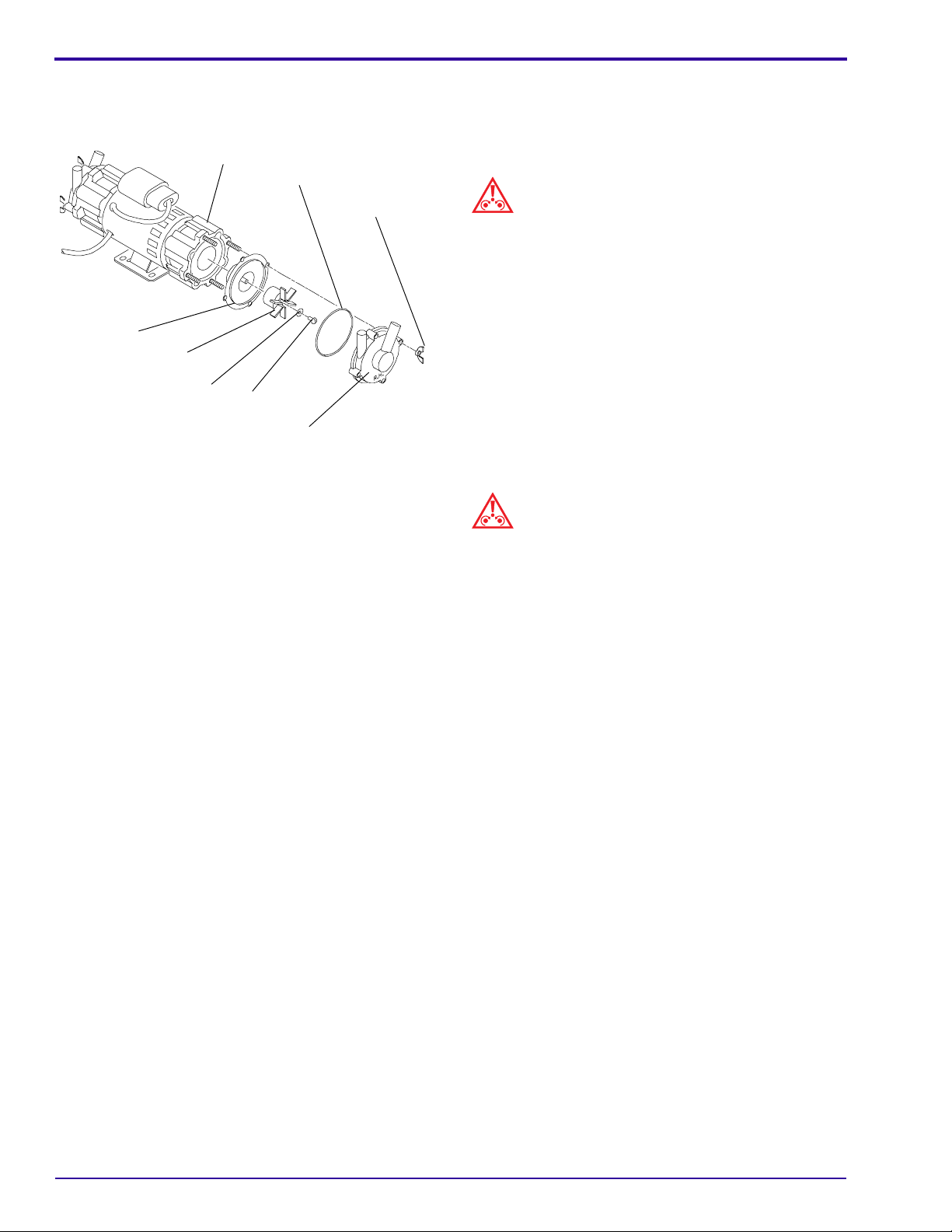

Removing the DEVELOPER or FIXER REPLENISHMENT PUMP

[1] Move the main wall CIRCUIT BREAKER to “OFF”and CB1 on the PROCESSOR to the “O” position.

[2] Lift the TOP COVER.

[3] Remove the DRIVE SIDE PANEL.

[4] Move the ELECTRICAL BOX out.

[5] Use 2 CLAMPS TL-2170 on the 2 HOSES at the FIXERor DEVELOPER REPLENISHMENT PUMP.

[6] Remove:

• 2 HOSES from the REPLENISHMENT PUMP

• 2 SCREWS from the PUMP

[7] Disconnect CONNECTOR P/J15 for the developer or P/J16for the fixer.

[8] Remove the FIXER or DEVELOPER REPLENISHMENT PUMP.

[9] Reverse the procedure to assemble.

[10] Record the J number of the CONNECTORon the tag that is on the new DEVELOPER REPLENISHMENT

PUMP.

Figure 5–12 Replacement of a REPLENISHMENT PUMP

TL-2170

H127_0031BCA

H127_0031BA

ELECTRICAL

BOX

2 SCREWS

FIXER

REPLENISHMENT

PUMP

DEVELOPER

REPLENISHMENT

PUMP

5–16 February 1996 – 1C7837

Page 17

Plumbing

Removing the POPPET VALVES for the REPLENISHMENT PUMPS

[1] Move the main wall CIRCUIT BREAKER to “OFF”and CB1 on the PROCESSOR to the “O” position.

[2] Lift the TOP COVER.

[3] Remove the DRIVE SIDE PANEL.

[4] Move the ELECTRICAL BOX out.

[5] Use 2 CLAMPS TL-2170 on the 2 HOSES at the FIXERor DEVELOPER REPLENISHMENT PUMP.

[6] Remove the 2 HOSES from the FIXER or DEVELOPER REPLENISHMENTPUMP.

[7] Remove the FITTINGS from the VALVE body and the O-RINGS.

Note

Observe the direction of the POPPET VALVES beforeremoving them.

[8] Remove the POPPET VALVES.

[9] Check that the O-RINGS are seated correctly and thatthe POPPET VALVES and FITTINGS are in the correct

positions in theVALVE BODY. See Figure .

[10] Reverse the procedure to assemble.

Figure 5–13 Replacement of thePOPPET VALVES in the REPLENISHMENT PUMPS

FITTINGS

VALVE

BODY

H127_0033BCA

H127_0033BA

O-RINGS

POPPET

VALVES

1C7837 – February 1996 5–17

Page 18

ADJUSTMENTS AND REPLACEMENTS

5–18 February 1996 – 1C7837

Loading...

Loading...