Page 1

Prostar

Archive Processor 220-240 V

Prostar

Archive Processor 120 V

Operator’s Manual

A-62051

Part No. 2E8257

Page 2

Safety

User Precautions

• Place the processor on a sturdy, level work surface capable of supporting 63.5 kg (140 lbs) and a table height between 53 cm

(21 in.) and 68 cm (27 in.).

• Make sure the electrical power outlet is located within 1.52 meters (5 feet) of the processor and is easily accessible.

• Use only the power cord(s) that was provided with the processor. Using any other power cord may cause electrical shock

and/or damage the product.

• Be sure the power cord is securely plugged into the wall outlet. Failure to do so may cause electrical shock or fire.

• Do not damage, knot, cut or modify the power cord. This may cause electrical shock or fire.

• The scanner requires a dedicated power outlet. Do not use an extension cord or power strip with the scanner.

• Do not connect the processor to an extension cord of multi-plug power strip. Use a dedicated power outlet.

• Leave sufficient space around the power outlet so it can be easily unplugged in case of an emergency.

• Do not use the processor if it becomes inordinately hot, has a strange odor, emits smoke, or makes unfamiliar noises.

Immediately stop the processor and disconnect the power cord from the power outlet. Contact Kodak Service.

• Follow the Kodak recommended maintenance and cleaning procedures.

• Material Safety Data Sheets (MSDS) are available on the Kodak website at: www.kodak.com/go/msds. When accessing the

MSDSs from the website, you will be required to provide the catalog number of the consumable you want the Material Safety

Data Sheet for. See the section entitled, “Supplies and consumables” later in this guide for supplies and catalog numbers.

• For disposal or recycling information, contact your local authorities, or in the USA, visit the Electronics Industry Alliance

website: www.eiae.org.

CAUTION: Moving parts, avoid contact.

CAUTION: Hot surface, avoid contact

Acoustic emission

Maschinenlärminformationsverordnung – 3, GSGV

Der arbeitsplatzbezogene Emissionswert beträgt <70 db(A).

[Machine Noise Information Ordinance — 3, GSGV

The operator-position noise emission value is <70 dB(A).]

EMC statements

United States: This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part

15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

European Union: WARNING: This is a Class A product. In a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

Japan: This is a Class A product based on the standard of the V oluntary Control Council for interference by information

Technology Equipment (VCCI). If this is used in a domestic environment, radio disturbance may arise. When such trouble

occurs, the user may be required to take corrective actions.

Page 3

Taiwan: WARNING: This is a Class A product. In a domestic environment this product may cause radio interference in which

声明,该产

此为A级产品,在生活环境中品可能会造成无线电干扰。在这种情况下,可能需要

用户对其干扰采取切实可行的措施

case the user may be required to take adequate measures.

Peoples Republic of China: WARNING: This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

Korean: Please note that this equipment has obtained EMC registration for commercial use. In the event that it has been

mistakenly sold or purchased, please exchange it for equipment certified for home use.

Page 4

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Archive Processor Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Start-up Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Daily start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Uncovering the processing section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Filling the fixer tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Filling the developer tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing the processing racks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing the dryer rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Adjusting the inlet water temperature . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Adjusting the developer temperature control. . . . . . . . . . . . . . . . . . . . . .11

Checking the dryer temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Checking the film transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operating the Archive Processor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Attaching film to a take-up reel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Using a trailer holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Looping the film . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

When to start processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Single-strand processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Dual-strand processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Replenishing the Archive Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Replenishment tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Mixed film sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Changing chemicals during processing . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Replenishment unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cleaning the Archive Processor (daily) . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cleaning the Archive Processor (periodic cleaning). . . . . . . . . . . . . . . . . . 31

Cleaning the developer racks and tank . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cleaning the fixer racks, wash racks, and fixer tanks. . . . . . . . . . . . . . . . . 33

Cleaning the air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Clearing a film jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Troubleshooting chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Accessories and Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

New Equipment Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

For installations in the United States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

For installations outside the United States . . . . . . . . . . . . . . . . . . . . . . . . . 41

A-62051 May 2008 i

Page 5

Introduction

The Kodak Prostar Archive Processor 220-240 V and the Kodak

Prostar Archive Processor 120 V are room-light-loading processors that

process 16 mm and 35 mm silver halide microfilms with Kodak Prostar

Chemicals (or equivalent).

The Archive Processors are self-threading, tabletop units with roller

transport.

The Archive Processors feature an energy conservation package that

automatically turns off the film transport, rinse water, and film drying

system after processing is complete.

Kodak Prostar Archive Processor with dual-strand take-up spindles

A-62051 May 2008 1

Page 6

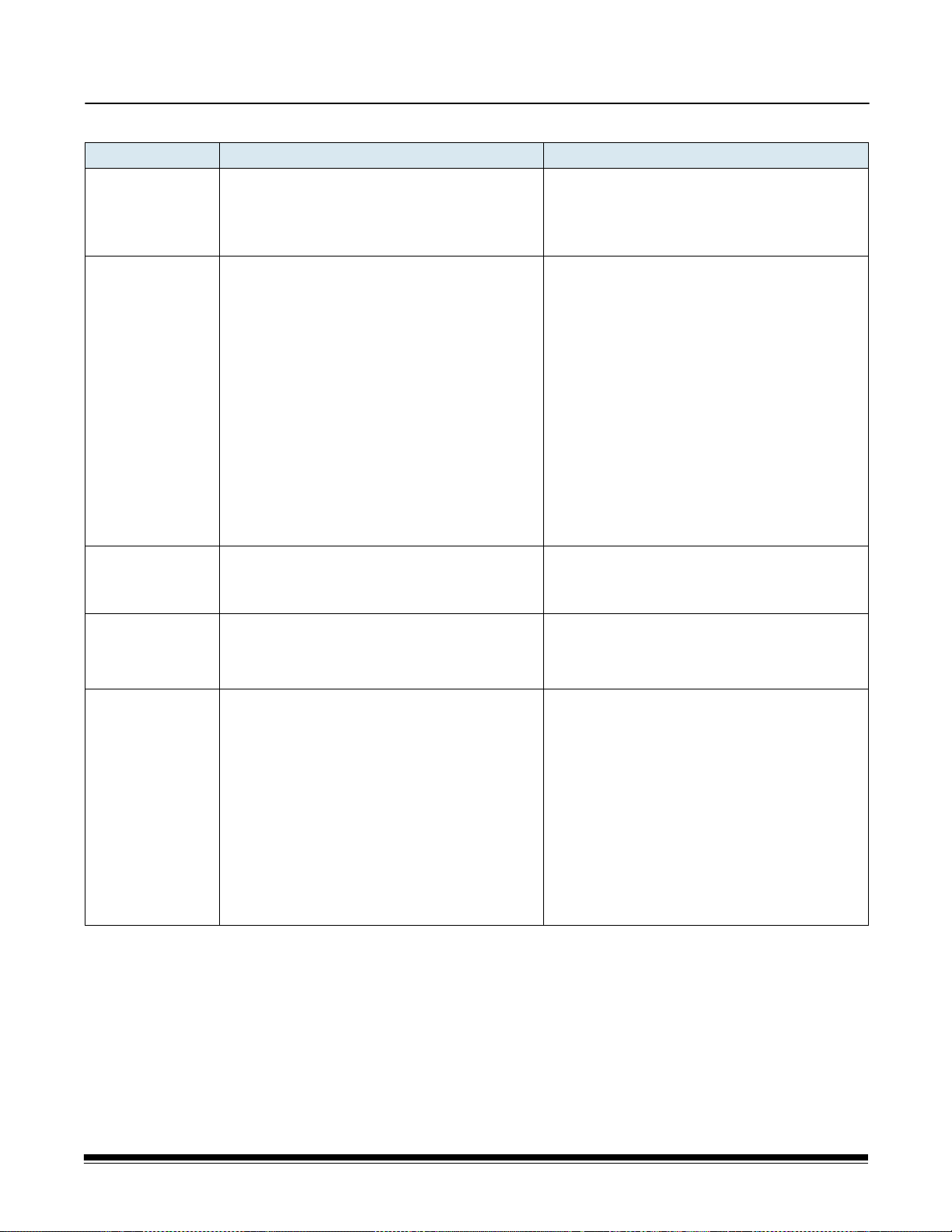

Specifications

Archive Processor 220-240 V Archive Processor 120 V

Power

requirements

Dimensions and

weight

220 to 240 VAC, 50 Hz, single phase,

7.5 amp

Two-prong electrical plug with ground

connection

Height: 91 cm (36 in.) with the cover open

Length: 110 cm (43 in.) with reel on take-up

spindle

120 VAC, 50 Hz, single phase, 12 amp

120 VAC, 60 Hz, single phase, 12 amp

Three-prong electrical plug with ground

connection

Height: 91 cm (36 in.) with the cover open

Length: 99 cm (39 in.) without reel on

take-up spindle

Operating

environment

Heat emissions

Noise emission

Depth: 56 cm (22 in.) with the cover open

Weight: 52.2 kg (1 15 Ib) empty

63.5 kg (140 Ib) with chemicals,

water, and processing racks

Support: Table or stand between

53 and 68 cm (21 and 27 in.) high

Ambient Temperature: 18.5 to 30°C

(65 to 86°F)

Relative Humidity: 20 to 76%

Maximum: 5100 BTU (5380 Kjoules)

Standby: 350 BTU (366 Kjoules)

Processing Film: 4100 BTU (4325 Kjoules)

Operator Position Standby Mode

• Sound Pressure Level (L

Operator Position Full System

Operating Mode

• Sound Pressure Level (L

• Instantaneous Peak Values 130 dB(C):

None

• Sound Power Level (L

• Standby: 63.4 dB(A)

• Full System: 69.6 dB(A)

): 51.2 dB(A)

A

): 59.3 dB(A)

A

)

WA

110 cm (43 in.) with large reel on

take-up spindle

Depth 61 cm (24 in.) with the cover open

Weight: 52.2 kg (115 Ib) empty

63.5 kg (140 Ib) with chemicals,

water, and processing racks

Support: Table or stand between

53 and 68 cm (21 and 27 in.) high

Ambient Temperature: 18.5 to 30°C

(65 to 86°F)

Relative Humidity: 20 to 76%

Maximum: 5100 BTU (5380 Kjoules)

Standby: 350 BTU (366 Kjoules)

Processing Film: 4100 BTU (4325 Kjoules)

Operator Position Standby Mode

• Sound Pressure Level (L

Operator Position Full System

Operating Mode

• Sound Pressure Level (L

• Instantaneous Peak Values 130 dB(C):

None

Sound Power Level (L

• Standby: 63.4 dB(A)

• Full System: 69.6 dB(A)

): 51.2 dB(A)

A

): 59.3 dB(A)

A

)

WA

2 A-62051 May 2008

Page 7

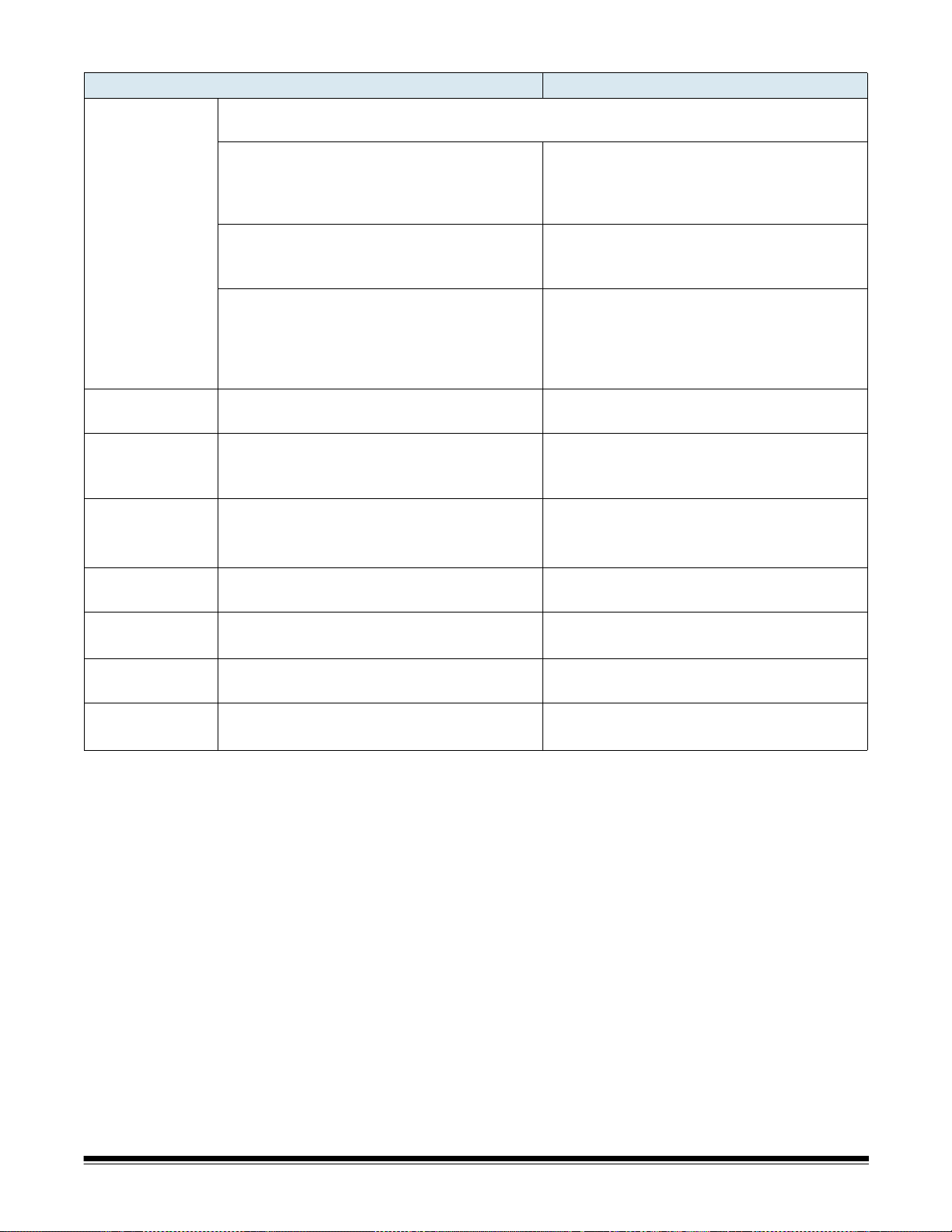

Water supply

Archive Processor 220-240 V Archive Processor 120 V

NOTE: An auxiliary hot water heater should be located within 6 m (20 ft) of the

Archive Processor to provide consistent water temperature.

Film Widths

Film Lengths and

Thicknesses

Film Transport

Speed

Film Processing

Time

Process

Duration

Film Loading

To Mixing Valve:

• Hot Water 46°C (114°F) minimum

• Cold Water 24°C (75°F) maximum

Pressure 276 to 621 kPa (40 to 90 psi)

From Mixing Valve:

• Mixed Water 34.5 to 36.5°C (94 to 98°F)

• Pressure 207 kPa (30 psi) minimum

Drain: Minimum 22.7 L/min (6 gal/min)

capacity floor drain or wall drain located a

minimum of 20 cm (8 in.) lower than the

Archive Processor to prevent wash water from

backing up

Water Consumption: 1.9 L/min (0.5 gal/min)

while processing

16 mm or 35 mm single strand

16 mm dual strand in lengths up to 65.5 m

(215 ft)

30.5 m (100 ft) of 0.14 mm/5.2 mil-thick film

38.1 m (125 ft) of 0.11 mm/4.2 mil-thick film

65.5 m (215 ft) of 0.07 mm/2.7 mil-thick film

3 m/min. (10 ft/min) 3 m/min. (10 ft/min)

30.5 m (100 ft): 11 minutes

65.5 m (215 ft): 22.5 minutes

Approximately 55 seconds for the selfthreader to exit from the Archive Processor

Room-light conditions with camera film spools

only

To Mixing Valve:

• Hot Water 46°C (114°F) minimum

• Cold Water 24°C (75°F) maximum

• Pressure 276 to 621 kPa (40 to 90 psi)

From Mixing Valve:

• Mixed Water 34.5 to 36.5°C (94 to 98°F)

• Pressure 207 kPa (30 psi) minimum

Drain: Minimum 22.7 L/min (6 gal/min)

capacity floor drain or wall drain located a

minimum of 20 cm (8 in.) lower than the

Archive Processor to prevent wash water from

backing up

Water Consumption: 1.9 L/min (0.5 gal/min)

while processing

16 mm or 35 mm single strand

16 mm dual strand in lengths up to 65.5 m

(215 ft)

30.5 m (100 ft) of 0.14 mm/5.2 mil-thick film

38.1 m (125 ft) of 0.11 mm/4.2 mil-thick film

65.5 m (215 ft) of 0.07 mm/2.7 mil-thick film

30.5 m (100 ft): 11 minutes

65.5 m (215 ft): 22.5 minutes

Approximately 55 seconds for the selfthreader to exit from the Archive Processor

Room-light conditions with camera film spools

A-62051 May 2008 3

Page 8

Archive Processor Overview

A

BC DE

G

F

Front Shown throughout this manual is an Archive Processor equipped with

Dual-Strand Take-up Spindles

A Processing Section Cover — light-tight cover for the film

processing section.

B Developer Temperature Control and Display — controls the

developer temperature and displays a value relative to the water

temperature surrounding the developer tank.

C Power Switch — turns the power on (l) and off (O).

D Mode Switch — the standby position (O) maintains the developer

temperature. The run position (l) activates the film transport, rinse

water, and film dryer blower.

E Film Dryer Temperature Control and Display — controls the

dryer air temperature and displays the air temperature in the drying

chamber.

F Tension Roller — loss of film tension after processing causes the

tension roller to be released, initiating a time delay prior to

activating energy conservation mode. Once energy conservation is

activated, the film transport, rinse water, and film dryer blower will

all turn off.

G Take-Up Spindles — mechanisms that wind the processed film

onto the take-up reel.

4 A-62051 May 2008

Page 9

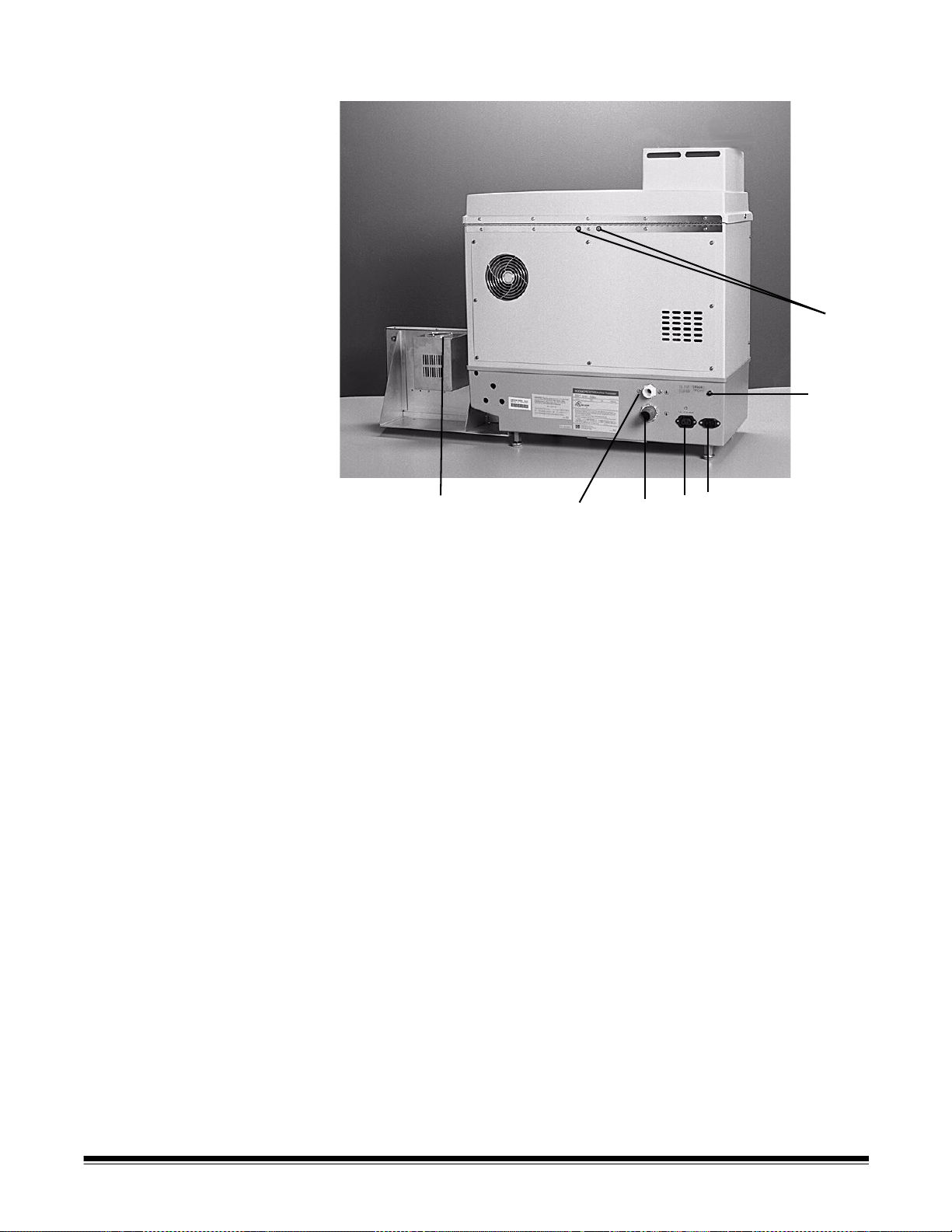

Rear

G

F

E

D

CB

A

A Usage Meter — displays the total number of hours the film

transport motors have been operating. You can use the usage

meter to determine when to change the processing chemicals.

B Water Inlet — connection to thermostatic mixing valve.

C Water Outlet — connection to drain line.

D Accessory Receptacle — supplies power to the optional

automatic Replenishment Unit accessory.

E Power Receptacle — connection for main power cord.

F Circuit Breaker — safety feature in case of electrical overload.

G Hose Input — connectors for the optional automatic

Replenishment Unit accessory hoses.

A-62051 May 2008 5

Page 10

Start-up Procedures

Dryer Section

(Rack #7)

Wash (Rack #6)

Fixer Tanks

(Racks #4 and 5)

Wash (Rack #3)

Developer Tank

(Racks #1 and 2)

Daily start-up Follow these procedures when starting up the Archive Processor at the

beginning of the day, assuming that the Archive Processor was

properly shut down.

Uncovering the processing section

• Lift the processing section cover until it is in an upright position.

The inside of the Archive Processor is shown below without racks.

6 A-62051 May 2008

Page 11

Filling the fixer tanks If the Archive Processor is powered up, shut it off before you

remove the fixer tanks or turn off the water. This reduces the

possibility of water overflowing the water jacket later when you reinsert

the tanks.

NOTE: Use proper precautions when using fixer. Review the MSDS for

the fixer.

1. Pull the gear cover back and lift the fixer tanks out of the

Archive Processor. Each fixer tank is labeled with an F.

2. Fill the fixer tanks with Kodak Prostar Plus Fixer, or equivalent, until

the level reaches the fill line (approximately ¼ gallon or 0.65 liters

per tank).

3. Hold the gear cover back and slowly and carefully lower the fixer

tanks into the fourth and fifth position in the Archive Processor.

NOTE: Make sure that the tanks are fully seated and level with the

fill lines toward the rear of the Archive Processor.

A-62051 May 2008 7

Page 12

Filling the developer tank If the Archive Processor is powered up, shut it off before you remove

the developer tank or turn off the water. This prevents water from

overflowing the water jacket later when you reinsert the tank.

NOTE: Use proper precautions when using developer. Review the

MSDS for the developer.

1. Pull the gear cover back and lift the developer tank out of the

Archive Processor. The developer tank is labeled with a D.

2. Fill the developer tank with Kodak Prostar Plus Developer, or

equivalent, until the level reaches the fill line (approximately

½ gallon or 1.3 liters).

3. Wrap the overflow tubing closely around the right side of the

developer tank.

4. Hold the gear cover back and slowly and carefully lower the

developer tank into the first position in the Archive Processor.

NOTE: Make sure the tank is fully seated and level with the fill line

toward the rear of the Archive Processor.

5. Fill the squeeze bottle with developer.

The squeeze bottle will be needed later to top off the developer t ank

between processing rolls of film.

8 A-62051 May 2008

Page 13

Installing the processing

Rack #6

Gear Cover

Gear Cover

Dryer Rack (#7)

Dryer Section Cover

racks

1. Make sure that the rollers of each rack turn freely when you rotate

the drive gear.

2. Drain off any e xcess water if the ra cks were lef t submerged in water

since the last time film was processed.

3. Hold the gear cover back and lower the processing racks into the

processor (#6 rack first, then #5, #4, #3, #2, and #1).

The rack number is located just above the drive gear.

CAUTION: Lower the racks slowly and carefully into the

Archive Processor to avoid splashing any chemicals.

Installing the dryer rack 1. Lift off the dryer section cover.

2. Make sure that the rollers of the dryer rack turn freely when rotating

the drive gear.

3. Pull the gear cover back and lower the dryer rack into the dryer

section.

4. Replace the dryer section cover.

A-62051 May 2008 9

Page 14

Adjusting the inlet water

Thermometer

Thermometer

Sleeve

Standpipe

temperature

1. Turn on the water supply using the thermostatic mixing valve.

2. Turn the power switch to the On position.

3. Insert the thermometer in the thermometer fixed measuring point

sleeve located in the front right corner of the #1 rack.

4. Install the standpipe in the Archive Processor tank after the water

temperature, indicated on the mixing valve, reaches 34.5 to 36.5°C

(94 to 98°F).

Installing the standpipe after the water reaches the proper

temperature at the mixing valve enables the developer solution to

reach operating temperature sooner.

5. Route the tubing from the developer tank through the notch in the

partition.

6. Insert the tubing into the standpipe.

7. Allow the water jacket to fill up.

8. A float switch automatically turns off the water flow when the water

level is just below the top of the standpipe.

9. Close the processing section cover.

10.Allow approximately 25 minutes for the developer temperature to

stabilize before adjusting the temperature control setting.

10 A-62051 May 2008

Page 15

Adjusting the developer

Thermometer

temperature control

The Archive Processor’s developer temperature control is factory set to

a value of 88.0 to control the developer temperature at 37.8°C ±0.3°C

(100°F ±0.5°F). The display values and setpoint value are arbitrary

numbers and do not represent the temperature in degrees; they are

values relative to the developer temperature.

Reading the developer temperature

The developer temperature must be read on the dial thermometer.

1. Lift the processing section cover.

2. Locate the dial thermometer in the front right corner of the #1 rack.

3. Read the value on the thermometer.

If the developer temperature thermometer value is not 37.8°C

±0.3°C (100°F ±0.5°F), you must make an adjustment. Adjust the

developer temperature control setpoint value only if necessary.

Refer to the next section, “Changing the developer temperature

control setpoint value.”

4. Close the processing section cover.

A-62051 May 2008 11

Page 16

Changing the developer temperature control setpoint value

The developer temperature control is located on the left side of the

control panel.

1. Press and release the PGM button on the developer temperature

control.

The light to the left of the SP (setpoint) illuminates. The control is

now in the setpoint mode.

2. Change the developer temperature:

• Push and release the down arrow to lower the temperature.

• Push and release the up arrow to raise the temperature.

The amount of change to the setpoint is equal to the amount of

change to the developer temperature in degrees Celsius. For

example, increasing the developer temperature setpoint by 1.2 will

increase the developer temperature by approximately 1.2°C

(2.2°F).

To increase or decrease the developer temperature by 1°F,

increase or decrease the developer temperature setpoint by 0.56.

For each degree Fahrenheit (°F) of desired change, multiply by 0.56

and round to the nearest tenth.

For example, if the dial thermometer reads 98.5°F, an increase of

1.5°F is required to obtain 100°F. Multiply 1.5°F by 0.56 and you get

0.84

(1.5 x 0.56 = 0.84). Round 0.84 to the nearest tenth to get 0.8.

Therefore, to increase the developer temperature 1.5°F, you must

increase the developer temperature setpoint by 0.8.

3.Press and release the PGM button on the developer temperature

control to return to display mode.

The green light indicator to the left of the SP is no longer

illuminated. The current temperature is displayed.

The green light indictor illuminates when the temperature is at

the setpoint and flashes when the temperature is above the

setpoint. The light does not illuminate when the temperature

is below the setpoint.

This light can be used to determine when the temperature has

stabilized at the setpoint.

4. Wait 20 minutes between adjustments.

5. Lift up the processing section cover.

6. Read the developer temperature. If the temperature is not 37.8°C

±0.3°C (100°F ±0.5°F), repeat steps 1 through 6 until the

temperature stabilizes at the setpoint.

7. Close the processing section cover.

12 A-62051 May 2008

Page 17

Checking the dryer temperature

1. Turn on the drying heater and blower:

• If the water jacket is not full, fill the water jacket and press and

release the Mode switch to the Run position.

• If the water jacket is full, press and release the Mode switch to

the Run position.

2. Check the temperature reading on the dryer contr ol after it stab ilizes

(approximately 5 minutes).

If the drying temperature stabilizes (the displayed value stops

climbing) before it reaches the setpoint, the room temperature may

be too low or the specified setpoint is too high for the

Archive Processor to obtain. The green light will be off. (See

Operating Environment in the “Specifications” section.)

The Archive Processor is stabilized at the setpoint when the display

temperature cycles (decreasing, then increasing) and the indicator

light cycles (on, flashing, off).

3. Adjust the dryer temperature control (if necessary) so the dryer

temperature falls within the acceptable temperature range of 38 to

52°C (100 to 125°F).

Under most operating environments, a setting of 48°C (118°F) is

sufficient for proper drying. If the processor is operated in a high

temperature and high humidity environment, a setting as high as

52°C (125°F) may be required.

Adjusting the dryer temperature

1. Press and release the PGM button on the dryer control (located on

the right side of the control panel).

The light to the left of the SP (setpoint) illuminates. The control is

now in the setpoint mode.

2. Change the dryer temperature:

• Push and release the down arrow to lower the temperature.

• Push and release the up arrow to raise the temperature.

3. The amount of change to the setpoint is equal to the amount of

change to the dryer temperature.

For example, increasing the dryer temperature setpoint by 5 will

increase the dryer temperature by 5°C on the Archive Processor

220-240 V or 5°F on the Archive Processor 120 V.

NOTE: The Field Engineer can change the control readout to either

Fahrenheit (°F) or Celsius (°C).

A-62051 May 2008 13

Page 18

4. Press and release the PGM button on the dryer control to return to

display mode. The light to the left of the SP (setpoint) is no longer

illuminated. The current temperature is displayed.

5. Allow some time for the dryer chamber temperature to st abilize af ter

each adjustment (approximately 5 minutes).

NOTE: Film must feel dry to the touch. If the dryer temperature is too

high, film could stick to the rollers and cause a film jam. Also, a

temperature setting that is too high can cause the film to stick

together on the reel (bricking).

If the dryer temperature is too low, the film will not dry

completely, causing it to feel tacky when it exits and stick

together on the take-up reel.

Image quality defects will occur if the temperature setting is

too low or too high.

6. Turn the dryer and the transport off by lifting and releasing the

tension roller.

The dryer and transport will stop after a preset time delay has

elapsed. (The factory preset is 60 seconds. The Field Engineer can

change the time delay.)

Checking the film transport 1. Press and release the Mode switch to the Run position.

2. Feed a self-threader into the feed chute on the #1 rack to make sure

that all racks are fully seated and working properly. Allow the selfthreader to exit the processor.

3. Lift and release the tension roller to shut off the processor. The

processor will stop 60 seconds after the tension roller is released.

14 A-62051 May 2008

Page 19

Operating the Archive Processor

Film

Film Reel

Trailer Holder

Slot

Attaching film to a take-up reel

Using a trailer holder 1. Wrap the film counterclockwise around a trailer holder (snubber).

As processed film exits the Archive Processor, you must attach it to a

take-up reel. There are different ways to attach film to a take-up reel,

depending on the type of reel you are using. One way is to use a trailer

holder (snubber). Another way is to wrap the film around the center of

the reel. Both ways are described in this section.

NOTE: Kodak no longer supplies this reel with a separate trailer hold.

Kodak supplies only the integral film cinch pin as shown below.

2. Wrap the film around the trailer holder one more time.

3. Insert the trailer holder (snubber) in the core of the take-up reel.

4. Insert the film in the slot of the take-up reel.

A-62051 May 2008 15

Page 20

Looping the film 1. Make a loop of film about four inches long.

Pin

Slot

Film

Film Reel

2. Insert the film loop in the slot of the take-up reel.

3. Push the film around core of the take-up reel and wrap the loop

around the pin in the center of the take-up reel.

4. Pull the film gently to tighten it around the take-up reel.

16 A-62051 May 2008

Page 21

When to start processing

When the developer, film dryer, and water have reached their

acceptable operating temperatures, you may begin processing film.

Leave the dial thermometer in the developer tank; this makes it easier

to check the developer temperature before processing the next roll.

NOTE: When the Archive Processor is idle for an extended period, the

solutions may evaporate. Check the solution levels and

replenish the developer and fixer tanks as necessary.

Use the usage meter as a guide to changing chemicals. It displays the

number of hours the film drive system has run. Replace the developer

and fixer with fresh chemicals according to the frequency listed in

“Replenishing the Archive Processor,” or every two weeks, whichever

interval comes first.

NOTE: Do not restrict the movement of the tension roller. The tension

roller must be allowed to pivot freely for proper operation of the

Archive Processor.

Single-strand processing

Make sure that you have completed all of the procedures in the “Daily

start-up” section and that you have familiarized yourself with the

information in the “When to start processing” section before beginning

processing.

NOTE: To prevent film jams, remove as much curl from the self-

threader as possible by winding the self-threader in the opposite

direction from the existing curl.

1. Press and release the Mode switch to the Run position to pre-heat

the film dryer.

IMPORTANT: Always press and release the Mode switch to the Run

position, even if the transport is running. This prevents

the film transport from stopping during processing.

2. Lift the processing section cover.

3. Verify that the developer is at the proper level and add developer, if

necessary.

A-62051 May 2008 17

Page 22

To replenish the developer, place the neck of the squeeze bottle in

the developer tank and squeeze the bottle until the solution level

reaches above the middle of the first white roller located below the

feed chute.

4. Open the film box and remove the roll of exposed film.

NOTE: Do not let the film unwind.

IMPORTANT: Follow the next steps carefully to avoid film jams.

5. Using the reel flanges to guide you, line up a 16 mm self-threader (a

special leader that helps prevent film jams) with the film edges.

6. Slide the self-threader, with the black side up, under the leading

edge of the film and hold it in place with your index finger.

The film should overlap the self-threader by a minimum of 51 mm

(2 in.) with the emulsion (light-colored) side of the film contacting

the black side of the self-threader.

7. Fasten the leading end of the film to the self-threader using a

minimum of 76 mm (3 in.) of Kodak Prostar Tape, or equivalent.

NOTE: For 35 mm film, place several pieces of tape side-by-side to

fasten the leading edge of the film to the self-threader.

18 A-62051 May 2008

Page 23

8. Wind the self-threader onto the film reel.

Feed Chute

NOTE: Make sure the tape does not extend over the edges of the

film or self-threader. Avoid leaving fingerprints on the

adhesive side of the tape.

9. Verify that the temperatures of the developer, film dryer, and water

are all within specification.

NOTE: Under normal operating conditions, the dryer will have

reached the operating temperature by the time you have

attached the self-threader.

If there is high humidity, low temperature, or low line

voltage, the dryer may take longer to reach the acceptable

operating temperature. In these situations, you may want to

wait until all three operating temperatures are acceptable

before you attach the self-threader.

10.Place the roll of film on the supply spindle of the #1 rack so the film

unwinds off the right side of the reel (when you are facing the front

of the Archive Processor).

The emulsion (dull) side of the film and the gray side of the selfthreader both must face the left side of the Archive Processor.

11.Feed the self-threader down into the feed chute in the first

developer rack until the #1 rack starts to draw the self-threader into

the Archive Processor.

12.After the rollers draw the approximately 36 cm (14 in.) of the selfthreader into the rack, close the processing section cover.

After approximately 50 seconds, the self-threader exits below the

tension roller on the take-up (right) side of the Archive Processor.

IMPORTANT: As the self-threader exits the dryer, make sure

that it does not catch on anything that will cause

the film to back up and jam in the processor.

13.Grasp and keep a slight tension on the self-threader while drawing it

out until the film appears.

A-62051 May 2008 19

Page 24

14.Cut the film from the self-threader with a pair of scissors.

Take up Reel

Film

Tension Roller

15.Attach the film to a reel using one of the methods described in

“Attaching film to a take-up reel.”

16.Place the take-up reel on the spindle.

NOTE: If you pull on the self-threader or when you remove the self-

threader from the film, you may unintentionally raise and lower

the tension roller. Raising and lowering the tension roller

activates the time delay for energy conservation mode, which

causes the film transport to stop after 60 seconds (3 m or 10 ft

of film).

If approximately 2.5 m (8 ft) of film has exited from the

Archive Processor but has not yet been tensioned, lift and

release the tension roller to reset the time delay for an

additional 60 seconds.

If the film transport stops before the film is tensioned,

immediately press and release the Mode switch to the Run

position or lift and release the tension roller bracket. This will

restart the film transport. If film is left stopped in the processing

chemicals, image quality problems will result.

Remove all film ends and tape before reusing the selfthreaders. Do not use self-threaders that have been folded,

curled or shortened. Store the self-threaders by hanging them

from the prepunched hole in the end.

When the trailing end of the film leaves the dryer rack, tension is

lost and the tension roller automatically lowers. The loss of tension

activates the 60-second time delay for the energy conservation

mode. Once energy conservation mode is activated, the film

transport, rinse water, and dryer blower will all turn off.

17.Add developer to the developer tank if the Archive Processor

operates in manual replenishment mode.

Add developer after 61 m (200 ft) of 0.14 mm/5.2 mil-thick film or

65.5 m (215 ft) of 0.07 mm/2.7 mil-thick film has been processed.

20 A-62051 May 2008

Page 25

Dual-strand processing

If your Archive Processor is equipped with Dual-Strand Take-up

Spindles, follow the steps below to process two reels of film

simultaneously. Before processing, complete all of the procedures in

the “Daily start-up” section and familiarize yourself with the information

in the “When to start processing” section.

NOTE: To prevent film jams, remove as much curl from the self-

threader as possible by winding the self-threader in the opposite

direction from the existing curl.

1. Press and release the Mode switch to the Run position to pre-heat

the film dryer.

IMPORTANT: Always press and release the Mode switch to the Run

position, even if the transport is running. This prevents

the film transport from stopping during processing.

2. Lift the processing section cover.

3. Verify that the developer is at the proper level and add developer, if

necessary.

To replenish the developer, place the neck of the squeeze bottle in

the developer tank and squeeze the bottle until the solution level

reaches above the middle of the first white roller located below the

feed chute.

4. Open the film box and remove the roll of unexposed film.

NOTE: Do not let the film unwind.

IMPORTANT: Follow the next steps carefully to avoid film jams.

5. Using the reel flanges to guide yo u, line up the nar row end of a dualstrand self-threader (a special leader that helps prevent film jams)

with the film edges.

6. Slide the self-threader, with the black side up, under the leading

edge of the film and hold it in place with your index finger.

The film should overlap the self-threader by a minimum of 51 mm

(2 in.) with the emulsion (light-colored) side of the film contacting the

black side of the self-threader.

A-62051 May 2008 21

Page 26

7. Fasten the leading end of the film to the dual-strand self-threader

Self-threader

with a minimum of 76 mm (3 in.) of Kodak Prostar Tape, or

equivalent.

8. Wind the self-threader onto the film reel.

NOTE: Make sure the tape does not extend over the edges of the

film or self-threader. Avoid leaving fingerprints on the

adhesive side of the tape.

9. Verify that the temperatures of the developer, film dryer, and water

are all within specification.

NOTE: Under normal operating conditions, the dryer will have

reached the operating temperature by the time you have

attached the self-threader.

If there is high humidity, low temperature, or low line

voltage, the dryer may take longer to reach the acceptable

operating temperature. In these situations, you may want to

wait until all three operating temperatures are acceptable

before you attach the self-threader.

10.Place the roll of film on the supply spindle of the #1 rack so the film

unwinds off the right side of the reel (when you are facing the front

of the Archive Processor).

The emulsion (dull) side of the film and the gray side of the selfthreader both must face the left side of the Archive Processor.

11.Place the self-threader on top of the racks.

12.Load the second roll of microfilm on the spindle of the #2 developer

rack so that it unwinds from the right. Hold the film in place with your

index finger to prevent the film from unwinding.

22 A-62051 May 2008

Page 27

13.Place the film on top of the self-threader, overlapping it by 51 mm

Self-threader

Reel loaded

on second

spindle

Reel loaded

on first

spindle

(2 in.), and fasten the end of the film to the black side of the dualstrand self-threader with a minimum of 76 mm (3 in.) of Kodak

Prostar Tape, or equivalent.

14.Loop the leading edge of the self-threader to the left and beneath

the reels.

NOTE: Make sure the tape does not extend over the edges of the

film or self-threader.

15.Feed the self-threader down into the feed chute in the first

developer rack until the rack starts to draw the self-threa der into the

Archive Processor.

16.After the rollers draw all of the self-threader into the rack, close the

processing section cover.

After approximately 35 seconds, the self-threader exits below the

tension roller on the take-up (right) side of the Archive Processor.

IMPORTANT: As the self-threader exits the dryer, make sure that it

does not catch on anything that will cause the film to back

up and jam in the processor.

A-62051 May 2008 23

Page 28

17.Grasp and keep a slight tension on the self-threader while drawing it

The first film goes

on the reel closest

to the processor

out until the first film appears.

18.Cut the first film from the self-threader with a pair of scissors.

19.Attach the first film to a reel using one of the methods described in

“Attaching film to a take-up reel.”

20.Place the take-up reel on the spindle closest to the processor.

NOTE: If you pull on the self-threader or when you remove the self-

threader from the film, you may unintentionally raise and

lower the tension roller. Raising and lowering the tension

roller activates the time delay for energy conservation

mode, which causes the film transport to stop after 60

seconds (3 m or 10 ft of film).

If approximately 2.5 m (8 ft) of film has exited from the

Archive Processor but has not yet been tensioned, lift and

release the tension roller to reset the time delay for an

additional 60 seconds.

If the film transport stops before the film is tensioned,

immediately press and release the Mode switch to the run

position or lift and release the tension roller bracket. This

will restart the film transport. If film is left stopped in the

processing chemicals, image quality problems will result.

Remove all film ends and tape before reusing the selfthreaders. Do not use self-threaders that have been folded,

curled or shortened. Store the self-threaders by hanging

them from the prepunched hole in the end.

21.Continue to keep tension on the self-threader to keep the film

moving until the second film appears.

22.Cut the second film from the self-threader with a pair of scissors.

23.Attach the second film to a reel using one of the methods described

in “Attaching film to a take-up reel.”

24 A-62051 May 2008

Page 29

24.Insert the take-up reel onto the spindle farthest from the processor.

The second film goes

on the reel farthest

from the processor

When the trailing end of the film leaves the dryer rack, tension is

lost and the tension roller automatically lowers. The loss of tension

activates the 60-second time delay for the energy conservation

mode. Once energy conservation mode is activated, the film

transport, rinse water, and dryer blower will all turn off.

25.Add developer to the developer tank if the Archive Processor

operates in manual replenishment mode.

Add developer after 61 m (200 ft) of 0.14 mm/5.2 mil-thick film or

131 m (430 ft) of 0.07 mm/2.7 mil-thick film has been processed

while in dual-strand operation.

A-62051 May 2008 25

Page 30

Replenishing the Archive Processor

Replenishment tables Replace the developer and fixer with fresh chemicals according to the

frequency listed in the table below, or every two weeks, whichever

interval comes first.

NOTE: Change the developer and fixer at least every two weeks.

Film Manual Replenishment Automatic Replenishment

16 mm

single strand

16 mm

dual strand

35 mm

single strand

Mixed film sizes If you are processing both 16 mm and 35 mm film, use a combination of

the chemical replenishment guidelines. The chemical usage ratio for

35 mm to 16 mm film is 1:2.

5 hours

900 m (3000 ft)

2.5 hours

two strands of 450 m

(1500 ft) each

2.5 hours

450 m (1500 ft)

30 hours

5500 m (18,000 ft)

15 hours

two strands of 2750 m

(9000 ft) each

15 hours

2750 m (9000 ft)

Changing chemicals during processing

For example, with manual replenishment, you can process 457 m

(1500 ft) of 16 mm film and 230 m (750 ft) of 35 mm film before you

need to change the chemicals.

Use proper precautions when using processing chemicals. Review the

MSDS for the developer and fixer.

1. Power down the Archive Processor or turn off the water. This

reduces the possibility of the water jacket overflowing later when

you reinsert the tanks.

2. Hold the gear cover back and remove the processing racks from the

processor (#1 rack first, then #2, #3, #4, and #5).

The rack number is located just above the drive gear. Hold a

sponge under the racks when transferring them to the sink. This

avoids chemicals dripping on surrounding work areas or the floor

and possible cross-contamination of chemicals.

3. Pull the gear cover back and lift the fixer tanks out of the

Archive Processor. Each fixer tank is labeled with an F.

26 A-62051 May 2008

Page 31

4. Pull the gear cover back and lift the developer tank out of the

Archive Processor. The developer tank is labeled with a D.

5. Empty the developer tank.

6. Fill the developer tank with Kodak Prostar Plus Developer, or

equivalent, until the level reaches the fill line (approximately

½ gallon or 1.3 liters).

7. Wrap the overflow tubing closely around the right side of the

developer tank.

8. Hold the gear cover back and slowly and carefully lower the

developer tank into the first position in the Archive Processor.

NOTE: Make sure that the tank is fully seated and level with the fill

line toward the rear of the Archive Processor.

9. Route the tubing from the developer tank through the notch in the

partition.

10.Insert the tubing into the standpipe.

11.Empty the fixer tanks.

12.Fill the fixer tanks with Kodak Prostar Plus Fixer, or equivalent, until

the level reaches the fill line (approximately ¼ gallon or 0.65 liters

per tank).

13.Hold the gear cover back and slowly and carefully lower the fixer

tanks into the fourth and fifth position in the Archive Processor.

NOTE: Make sure the tanks are fully seated and level with the fill

line toward the rear of the Archive Processor.

14.Hold the gear cover back and lower the processing racks back into

the processor (#5 rack first, then #4, #3, #2, and #1).

The rack number is located just above the drive gear. Hold a

sponge under the racks when transferring them from the sink.

This avoids chemicals dripping on surrounding work areas or

the floor and possible cross-contamination of chemicals.

CAUTION: Lower the racks slowly and carefully into the

Archive Processor to avoid splashing any chemicals.

15.Close the processing section cover.

16.Power up the Archive Processor or turn the water on, depending on

the action that you performed in Step 1.

17.Allow approximately 25 minutes for the developer temperature to

stabilize before attempting to adjust the temperature control setting.

18.Press and release the Mode switch to the Run position.

19.Feed a self-threader into the feed chute on the #1 rack to make sure

that all racks are fully seated and working properly. Allow the selfthreader to exit the processor.

20.Lift and release the tension roller to shut off the processor. The

processor will stop 60 seconds after the tension roller is released.

A-62051 May 2008 27

Page 32

Replenishment unit If you prefer to use automatic replenishment rather than manual, you

must use the optional Kodak Prostar Replenishment Unit.

When using freshly mixed chemicals in the replenishment unit:

• 1300 ml (43.9 oz.) fills the tanks.

• The balance of the gallon (approximately 2400 ml) allows you to

process 915 m (3000 ft) of 16 mm microfilm.

• Each additional gallon (3785 ml) allows you to process 1525 m

(5000 ft) of 16 mm microfilm.

To avoid low film density resulting from low developer levels, change

the replenisher bottles when the solution level reaches the level

indicated in the operator's manual for the replenisher unit.

28 A-62051 May 2008

Page 33

Maintenance

Follow the recommended cleaning procedures to provide continued

quality film processing and reliable operation, and to extend the life of

the Archive Processor.

Cleaning the Archive Processor (daily)

At the end of each day's processing, clean the Archive Processor as

follows:

1. Turn off the water at the thermostatic mixing valve.

2. Turn the power switch to the Off position (O).

3. Lift the processing section cover.

4. Pull the standpipe out to drain the water jacket.

5. Hold the gear cover back and remove the processing racks from the

processor (#1 rack first, then #2, #3, #4, #5, and #6). The rack

number is located just above the drive gear. Hold a sponge under

the racks when transferring them to the sink. This avoids chemicals

dripping on surrounding work areas or the floor and possible crosscontamination of chemicals.

A-62051 May 2008 29

Page 34

6. Rinse the racks thoroughly in water while turning the drive gear.

7. Lightly rub the rollers with a clean cloth while rinsing to remove any

deposits from processing.

To remove difficult stains, use a nonabrasive cloth that will not

scratch the roller surface. Discoloration of the rollers is normal and

causes no harm.

8. Clean the developer racks (#1 and #2) thoroughly.

9. Leave the developer racks (#1 and #2) submerged in clean water

until they are needed.

Do not store the developer racks (#1 and #2) in the same water as

the fixer racks (#4 and #5).

CAUTION: When removing and rinsing the fixer racks (#4 and #5),

do not splash the developer racks with fixer or drip

fixer into the developer tanks.

Hold a sponge under the racks when transferring them

to the sink.

10.After thoroughly cleaning the remaining four processing racks, leave

them submerged in water until they are needed.

NOTE: Do not let the racks sit in water containing minerals that can

form a coating on the racks.

11.If the chemicals are exhausted, remove the developer and fixer

tanks, empty and rinse them out with water.

12.If the chemicals are not exhausted, the tanks can be left in the

Archive Processor.

13.Remove the dryer section cover and the dryer rack (#7).

14.Clean the dryer rack rollers with a clean, damp cloth. Do not rinse

the dryer rack with water.

15.Clean the recirculator cover, the area around the recirculator

assembly, and the drip tray with a damp sponge. Do not remove

the probe or pull out the wire from the recirculator.

16.Close the processing section cover and let the Archive Processor

stand as is until it is time to start it up again.

30 A-62051 May 2008

Page 35

Cleaning the Archive Processor (periodic cleaning)

Clean the developer racks with Kodak Developer System Cleaner and

Neutralizer, or equivalent, every time the chemical tanks are changed

using automatic replenishment (every third time with manual

replenishment) to remove silver and chemical deposits.

NOTE:Discharge, treatment, or disposal of spent solutions may

be subject to local, state, or federal laws. Contact

appropriate authorities to determine the requirements that

apply to the use of this product.

Cleaning the developer racks and tank

CAUTION: Follow the safe-handling instructions printed on the

bottle label.

1. Mix the Kodak System Cleaner.

• Start with 750 ml of water and add 125 ml of cleaner part “A”

concentrate and add 125 ml of cleaner part “B” concentrate then

mix until the solution is uniform.

or

• 6 parts of water add 1 p art of cleaner “A” and 1 part of clean er “B”

then mix until the solution is uniform.

NOTES:

• Do not mix developer system cleaner directly with neutralizer.

• Improper mixing and handling, such as allowing the cleaner to come

in contact with residual developer or the other processing solutions,

can form irritating sulfur dioxide fumes. Use adequate ventilation.

2. Mix neutralizer

• Start with 875 ml of water, add 125 ml of neutralizer concentrate

then mix until the solution is uniform

or

• 7 parts of water, add 1 part of neutralizer concentrate then mix

until uniform

3. Disconnect the power from the wall outlet.

4. Lift the processing section cover.

A-62051 May 2008 31

Page 36

5. Lift out the developer racks (#1 and #2).

6. Rinse the developer racks thoroughly with warm water.

7. Empty the developer tank and rinse the with warm water.

8. Fill the developer tank with mixed Kodak De veloper System Cleaner

“A” and “B” or equivalent, until the developer racks are covered,

then rotate the drive gears until the deposits are removed.

9. Allow a maximum of 30 minutes to clean heavily coated racks.

NOTE: Do not soak the racks longer than 30 minutes or at

temperatures above 32°C (90°F).

10.Remove the developer racks and rinse them thoroughly while

rotating the drive gears with warm water. There may be some

discoloration on the rollers; this is normal.

11.Empty the solution from the developer tank and rinse it with warm

water.

12.Pour the mixed neutralizer solution into the developer tank.

13.Place the developer racks into the neutralizer for 2 minutes.

14.Lift the developer racks out of neutralizer and wash them with warm

water.

Cleaning the fixer racks, wash racks, and fixer tanks

15.Empty the neutralizer from the developer tank and rinse it with warm

water.

NOTE: Do not use Kodak Developer System Cleaner and

Neutralizer on the fixer racks (#4 and #5) and wash racks

(#3 and #6) or on the dryer rack (#7). The daily

maintenance procedure is usually sufficient for these racks

(refer to “Cleaning the Archive Processor (daily)”). If

deposits have formed, refer to “Cleaning the fixer racks,

wash racks, and fixer tanks.”)

16.Close the processing section cover and let the Archive Processor

stand as is until it is time to start it up again.

1. Mix the Kodak Fixer/W ash System Cleaner , or equivalent, according

to the instructions on the bottle.

NOTE: If a smaller volume is needed, mix proportional amounts of

chemicals and water.

CAUTION: Follow the safe-handling instructions printed

on the label.

2. Lift out the fixer racks (#4 and #5) and the wash racks (#3 and #6).

3. Rinse the fixer racks and wash racks thoroughly with water and

place them in a plastic container .

4. Fill the plastic container with Kodak Fixer/Wash System Cleaner, or

equivalent, until the fixer racks and wash racks are covered. Soak

the racks until the deposits are removed.

32 A-62051 May 2008

Page 37

NOTE: Do not soak the racks longer than 30 minutes or at

temperatures above 38°C (100°F).

5. Remove the fixer racks and wash racks and rinse them thoroughly.

6. Place the fixer racks and wash racks in a container large enough to

hold them standing up and submerged; rinse them for at least 30

minutes in running water.

7. Soak the racks overnight in clean water.

8. Immerse the fixer tanks in the Kodak Fixer/Wash System Cleaner,

or equivalent.

9. Soak until the deposits have been removed.

10.Rinse the fixer tanks thoroughly with running water.

11.Close the processing section cover and let the Archive Processor

stand as is until it is time to start it up again.

A-62051 May 2008 33

Page 38

Changing the air filter Change the air filter every six months. The air filter is located under the

Air filter

Air filter housing

Archive Processor. It is accessible from the front of the processor.

1. Pull the air filter toward you and out of the air filter housing.

2. Hold a new air filter so that the air flow arrow on the edge of the filter

points up.

3. Slide the new air filter into the air filter housing.

34 A-62051 May 2008

Page 39

Troubleshooting

Clearing a film jam If a jam occurs either before or after the film is tensioned on the t ake-up

reel, follow the procedure below.

1. Turn the power switch to the off (O) position, and unplug the power

cord.

2. Lift the processing section cover.

3. Hold the supply spool to keep the film from unwinding.

4. Cut the film where it enters the first rack.

5. Remove the reel of film and immediately put it in the film box.

6. Lift off the dryer section cover.

7. In sequence, starting with the dryer rack, partially raise each rack

and cut the film where it enters the rack.

NOTE: Do not drip fixer from the fixer racks on the developer racks

or into the developer tank.

8. Lift each rack out of the Archive Processor and carefully pull the film

from the rack.

If film is wrapped around the rollers and cannot easily be pulled

from the rack, use scissors to carefully cut the film free from the

rollers. Remove all pieces of film from the rack.

NOTE: Do not scratch the rollers.

9. Thoroughly rinse all racks except the dryer rack and put them back

in the Archive Processor.

10.Turn the power switch to the On (l) position.

11.Press and release the Mode switch to the Run position.

12.Feed a self-threader through the Archive Processor two times to

check for further jamming problems.

13.If the self-threader exits from the Archive Processor without

problems, resume processing.

14.Lower the processing section cover.

A-62051 May 2008 35

Page 40

Troubleshooting chart

Problem Possible Cause Remedy

Archive Processor

does not power up

Film images are too

light or dark

Film jam

Power switch is set to the

Off (O) position

Main power supply is off Call a qualified electrician to check the power source.

Electrical plug is not firmly

connected in an outlet

or at the rear of the

Archive Processor

Circuit breaker is tripped Reset the circuit br ea ke r ( to lo ca te the circ uit br ea ke r, see

Incorrect developer

temperature

• Developer is exhausted

(light images)

• Developer tanks are not

filled to the correct level

(light images)

Self-threader is incorrectly

taped to the film

Turn the power switch to the On (l) position.

Check the electrical plug connection in the outlet and at

the rear of the Archive Processor.

the illustration at the top of Page 5).

• Adjust the thermostatic-mixing valve so that the incoming

water temperature is between 34 and 37°C

(94 and 98°F).

• Adjust the developer temperature control to a nominal

37.8°C (100°F).

Replenish the developer.

To replenish the developer, place the neck of the squeeze

bottle in the developer tank and squeeze the bottle until

the solution level reaches above the middle of the first

white roller located below the feed chute.

Clear the film jam (refer to “Clearing a film jam”). Reattach

or replace the self-threader (refer to “Operating the

Archive Processor”).

Self-threader is not

full length

Self-threader is damaged Clear the film jam (refer to “Clearing a film jam”). Replace

Self-threader is curled Clear the film jam (refer to “Clearing a film jam”). Reverse

Racks are not fully seated Clear the film jam (refer to “Clearing a film jam”). Check

Self-threader catches on

the table when exiting from

the Archive Processor

Film is loaded backward Clear the film jam (refer to “Clearing a film jam”). Place th e

Dryer chamber is too hot

Film is tacky, sticks to the

dryer rack

Clear the film jam (refer to “Clearing a film jam”). Replace

the self-threader (refer to “Operating the Archive

Processor”).

the self-threader (refer to “Operating the Archive

Processor”).

wind the self-threader until it lies flat (uncurled).

that all racks are properly seated and that all drive gears

are properly engaged.

Clear the film jam (refer to “Clearing a film jam”). Move the

Archive Processor toward the right edge of the t able so the

film clears the table edge.

film on the supply spindle so it unwinds from the right side

with the emulsion side (light color) of the film facing to the

left.

Refer to “Checking the dryer temperatur e.”

Clear the film jam (refer to “Clearing a film jam”).

Lower the dryer temperature.

36 A-62051 May 2008

Page 41

Troubleshooting Chart (continued)

Problem Possible Cause Remedy

Layers of film

(convolutions) stick

together on the

take-up reel

Film is scratched, has

digs or abrasions

Developer

temperature does not

reach 37.8°C in the

required 30 minutes

Self-threader

separates from the

film

Dryer chamber is not hot

enough to dry the film (film

feels damp)

Racks and tanks need

cleaning

Make sure that the trouble

is not caused by the

microfilming equipment in

which the film was exposed

Developer temperature

needs adjusting

Incorrect wash-water

temperature

Fingerprints on the

adhesive side of the

splicing tape

Adhesive tape is too short Reattach or replace the self-threader using a minimum of

Raise the dryer temperature.

Refer to “Maintenance.”

Adjust the developer temperature (refer to “Adjusting the

developer temperature control”).

Adjust the thermostatic mixing valve (refer to “Adjusting

the inlet water temperature”).

Reattach or replace the self-threader (refer to “Operating

the Archive Processor”). Avoid leaving fingerprints on the

adhesive side of the splicing tape.

76 mm (3 in.) of tape (refer to “Operating the

Archive Processor”).

Film quality is poor Chemicals are exhausted Change the chemicals.

Film stops before it is

tensioned on the

take-up reel.

Developer is contaminated

by system cleaner or fixer

The time delay of 60

seconds passed before the

film could be tensioned

Wash the racks and change the chemicals.

Train the operator to tension film in less than 60 seconds.

Lift the tension arm or press and release the Mode switch

to the Run position immediately to reset the 60-second

time delay for energy conservation mode (refer to

“Operating the Archive Processor”).

A-62051 May 2008 37

Page 42

Accessories and Supplies

Kodak Thermostatic Mixing Valve

Designed to control the water temperature to the

Archive Processor at a flowrate of 1.9 to 7.6 liters/

minute (0.5 to 2 gal/min).

Kodak Processor Cabinet

The top of the cabinet has space for the

Archive Processor and a chemical replenishing unit.

There is storage space inside the cabinet. The unit is

107 cm (42 in.) long, 64 cm (25 in.) deep, and 64 cm

(25 in.) high.

Kodak Prostar Replenishment Unit

Automatically replenishes the developer and fixer in

the Archive Processor.

Item Catalog

Number

142 3698

144 4256

809 0755

Supplies Catalog

Kodak Prostar Plus Developer 102 2490

Kodak Prostar Plus Fixer 102 2656

Kodak Developer System Cleaner and Neutralizer 150 0719

Kodak Fixer/Wash System Cleaner 139 5110

Kodak Solid Flange Return Reel (16 mm) case of 300 873 0715

Kodak Solid Flange Return Reel (35 mm) case of 150 144 2433

Microfilm Storage Carton, 16 mm case of 160 849 8966

Microfilm Storage Carton, 35 mm case of 80 841 8741

Kodak Prostar 16 mm Self-Threader 199 0993

Kodak Prostar 16 mm Dual-Strand Self-Threader 146 5194

Kodak Prostar 35 mm Self-Threader 199 1009

Kodak Prostar Tape and Dispenser 199 0977

Supplies Part Number

Kodak Prostar Air Filter 321984

Material Safety Data Sheets (MSDS) are available on the Kodak website at:

www.kodak.com/go/msds. When accessing the MSDSs from the website, you will be

required to provide the catalog number of the consumable you want the Material Safety

Data Sheet for. See the section entitled, “Supplies and consumables” later in this guide

for supplies and catalog numbers

Number

38 A-62051 May 2008

Page 43

New Equipment Warranty

For Installations in the United States

Kodak Prostar Archive Processor 120 V: Kodak warrants the

processor to function properly for three months from date of initial

installation, when installed within one year from date of shipment. This

warranty covers the purchaser of this equipment as well as anyone else

who owns it during the warranty period.

Warranty Repair Coverage: If this equipment does not function

properly during the warranty period, a Kodak Global Customer Service

and Support (GCSS) Field Engineer will provide on-site repair service

during Kodak’s normal working hours. Such repair service will include

any adjustments and/or replacement of parts ne cessary to maintain the

equipment in good working order. Off-hours service is available at

overtime rates.

Days and Hours of Coverage: Warranty coverage is available

Monday through Friday during Kodak’s normal working hours (usually

8:00 a.m. to 5:00 p.m.), excluding holidays celebrated locally.

How to Obtain Service: Call your nearest Kodak GCSS Office.

Limitations: Standard warranty service is limited to the contiguous

United States, the island of Oahu in Hawaii, and certain areas of

Alaska.

This warranty does not cover: circumstances beyond Kodak’s control;

service or parts to correct problems resulting from the use of

attachments, accessories, or alterations not marketed by Kodak;

service required as the result of relocation; unauthorized modifications

or service; misuse; abuse; failure to follow Kodak’s operating

instructions; or supply items (such as glass and lamps).

KODAK MAKES NO OTHER WARRANTIES, EXPRESS, IMPLIED,

OR OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE FOR THIS EQUIPMENT.

Repair or replacement without charge are Kodak’s only obligations

under this warranty . KODAK WILL NOT BE RESPONSIBLE FOR ANY

CONSEQUENTIAL OR INCIDENT AL DAMAGES RESULTING FROM

THE SALE, USE, OR IMPROPER FUNCTIONING OF THIS

EQUIPMENT, REGARDLESS OF THE CAUSE. Such damages for

which Kodak will not be responsible include, but are not limited to, loss

of revenue or profit, downtime costs, loss of use of the equipment, cost

of any substitute equipment, facilities, or services or claims of your

customers for such damages.

This limitation of liability will not apply to claims for injury to persons or

damage to property caused by the sole negligence or fault of Kodak or

by persons under its direction or control.

A-62051 May 2008 39

Page 44

For Installations outside the United States

For installation in countries other than the United States, the terms and

conditions of the new equipment warranty will be provided by the Kodak

company in the country in which the sale is finalized, or by a Kodakappointed distributor in those countries where Kodak does not have

direct sales representation.

40 A-62051 May 2008

Page 45

Eastman Kodak Company

343 State Street

Rochester, NY 14650 U.S.A.

© Kodak, 2008. All rights reserved.

TM: Kodak

Loading...

Loading...