Page 1

SWOP® Off-Press Proof Application Data Sheet

Matchprint ProofPro 2610 Proofer with

DirectWorks Suite or Matchprint ProofPro RIP

The SWOP Review Committee has approved the use of off-press proofs as input material to publications. SWOP specifications recommend

that: “The appearance of an off-press proof used in this application must closely simulate a SWOP Certified Press Proof.” See other

explanations and recommendations as outlined on pages 21 and 47 of the 2001 Ninth Edition of the

SWOP Specifications for Web Offset Publications.

I. Manufacturer

Kodak Polychrome Graphics

401 Merritt 7

Norwalk, CT 06851

II. Product

Kodak Polychrome Graphics (KPG) Matchprint ProofPro Model 2610

III. Introduction

The history of Matchprint proofing products designed to meet the needs of the printing industry began in the 1960’s when proofing films

were introduced. Throughout this time, we have viewed color reproduction as a process rather than a series of independent events. We

base this on the premise that an advertiser's major commitment to expense and image is determined at the print production site. For this

reason, a Proof, when made to the following guidelines, is intended to simulate the characteristics of a production press operating within

the SWOP guidelines for production printing.

IV. Control Guide

SWOP specifies that a control guide such as a GATF/SWOP Proofing Bar be supplied on every off-press proof. As a minimum, this guide

should contain solids for the primary process colors and two-color overprints, as well as a 25%, 50%, and 75% tint in of each of the

process colors. A control guide containing these imaging characteristics must be present on every proof. All control guides should be

checked for accuracy of the original values. Use and interpretation of a control guide is the responsibility of the user.

V. System Components

For a KPG Matchprint ProofPro 2610 inkjet printer proof to be considered a "SWOP" proof, the following components must be used:

• Matchprint ProofPro RIP or DirectWorks Suite

• KPG Matchprint ProofPro 2610 inkjet printer

• Matchprint ProofPro Inkjet Media Publication/Dye

• X-Rite AutoScan Spectrophotometer DTP-41 or equivalent

Page 2

VI. System/Software Setup

Refer to the Matchprint ProofPro or the DirectWorks Suite User’s Guide for the following procedures:

Reference Profile: = US_Web_SWOP.icc

Paper Profile in MPPP RIP v1.0: = MPPP2610_600x600_MPDye_MPPPDyePub_v1r1.icc

Paper Profile in MPPP RIP v2.0: = K_13_5533_0N003_031_XRD41_1.icc

Set Kodak Polychrome Graphics CFM to Rendering Intent: = Perceptual, Black Generation: = Retain Integrity if CMYK to CMYK is left

unchecked, use GCR , Total ink: = 310, Black Ink Limit: = 100, Black Generation: = Medium.

Calibrate the KPG Matchprint ProofPro 2610 inkjet printer for use with Matchprint ProofPro Inkjet Media Publication/Dye paper utilizing the file:

In MPPP RIP v1.0: = MPPP2610_600x600_MPDye_MPPPDyePub_v1r1.bpl

In MPPP RIP v2.0: = K_13_5533_0N003_031_XRD41_1.epl

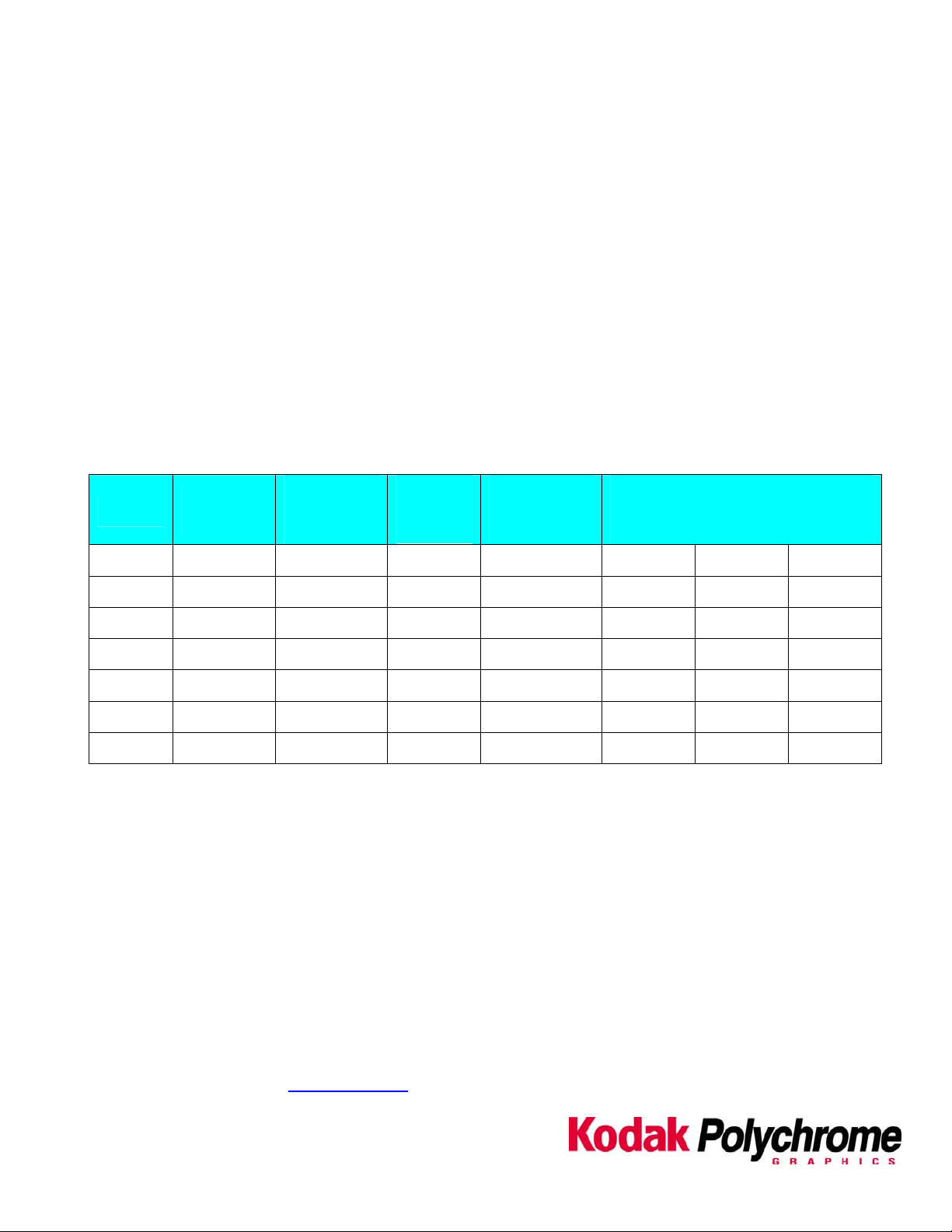

VII. Finished Proof Characteristics

A properly made proof using the Matchprint ProofPro 2610 inkjet printer with Matchprint ProofPro RIP or DirectWorks Suite, printed on

Matchprint ProofPro Inkjet Media Publication/Dye should have the following color characteristics:

Color

Density

Absolute

Density

Hi-Lo Ink

References

TVI @ 50%

(Dot Gain)

(± 3)

Print Contrast@

75% Tone

( ± 3)

Color (per CGATS.5)*

L* C* h(ab)*

(± 3) (± 3) ( ± 3)

Yellow .89(± 0.05) 0.90 – 1.05 17 24 83.92 75.15 92.27

Magenta 1.32(± 0.05) 1.30 – 1.46 21 32 47.10 67.97 355.56

Cyan 1.29(±0.05) 1.22 – 1.36 24 27 56.64 55.69 225.51

Black 1.73((± 0.06) 1.53 – 1.68 24 40 14.80 4.49 -

Red 46.58 76.52 34.12

Green 52.28 67.25 159.47

Blue 21.65 58.68 307.40

Background Density (+/-0.02): Dc = 0.11 Dm = 0.12 Dy = 0.15

*CIELCh values represent measurements at target density.

Note: All measurements were made using a calibrated Gretag™ SPM50 spectrophotometer (D50 illuminant, 2° observer, non-polarized).

The density (Status T) and colorimetric values are absolute, base included, measured over a black backup. TVI’s were calculated using the

Murray-Davies equation (CGATS.4). All tolerances reflect normal systems variability and assume the use of a calibrated measurement

device.

To establish comparison values for finished proofs and determine any offset in instrumentation used, measure each pair of ink reference

patches from a current SWOP Ink Hi-Lo Color Reference. Compare them to the values shown in the table above for each color. The SWOP

Hi-Lo Color Reference used to calculate the offset values had a December 2002 expiration date.

VIII. Sample Proofs

Kodak Polychrome Graphics has supplied two proofs that conform to this Application Data Sheet to SWOP

CALL TOLL-FREE 1-877-KPGraphics (1-877-574-7274) FOR ADDITIONAL INFORMATION

OR VISIT US ON THE WEB AT www.kpgraphics.com

© 2005 Eastman Kodak Company. All rights reserved. Kodak, Matchprint and ProofPro are

trademarks of Eastman Kodak Company. All trademarks and registered trademarks used

herein are the property of their respective owners.

ADS 0024-050504

for their analysis and retention.

Loading...

Loading...