Page 1

{OperatorsManual}{Product io n}{HealthImaging}

Publication No. 3E0815

29SEP99

HEALTH IMAGING

OPERATOR MANUAL

for the

Kodak Min-R MAMMOGRAPHY PROCESSOR

H176_0001AC

© Eastman Kodak Company, 1999

Page 2

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be liable

for any loss or damage, including consequential or special damages, resulting from any use of

this information, even if loss or damage is caused by Kodak’s negligence or other fault.

Warning

To avoid hazardous conditions, keep floors and floor coverings around your Processor and associated drains clean

and dry at all times. Any accumulation of fluids from mixing tanks, drain lines, etc., should be cleaned up immediately.

In the event of an accumulation of liquid due to backup, overflow, or other malfunctions of the drain associated with

your Processor, call a plumber or other contractor to correct any problem with the drain. Kodak accepts no

responsibility or liability whatsoever for the serviceability of any drain connected to or associated with a Processor.

Such drains are the sole responsibility of the customer.

Table of Contents

Description Page

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Overview

Processing Film

Processing Solutions

Correcting Difficulties

Cleaning and Periodic Maintenance

New Equipment Warranty

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Start Up

Feeding Sheet Film

Shutdown

Preparing the Solutions

Draining the Tanks

Filling the Tanks

Daily Procedure

Every Two Week s

Warranty Coverage

How to Obtain Service

Limitations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2 29SEP99 – 3E0815

Page 3

Safety

Section 1: Safety

Chemical Hazard

Warning

Gloves and protective eyewear must be worn when working with chemistry, especially fixer solutions. If chemicals

get into the eyes, flush them thoroughly with large volumes of water. If irritation persists, see a doctor.

Besides being a potential cause of falls, the chemistry can contaminate waste water and irritate the skin and eyes.

Chemistry spills must be cleaned up immediately. You must:

• prevent the spilled chemistry from entering a waste water drain.

• clean up the spill with a moist mop or rag.

• dispose of cleaning material s and was te water col lecte d duri ng the clean up acc ordi ng to envi r onm ent

regulations.

• ensure that the air exhaust pipe is always connected to a ventilation system, because inhalation of chemicals is

dangerous to health and should be avoided.

• observe all environmental regulation for storage and disposal of waste chemicals.

• use these instructions in conjunction with the chemical instructions.

Operator Precaution

Warning

The operator must:

• only be allowed to remove the Top Cover to avoid electrical and mechanical hazard.

• not exchange any internal parts.

• call service personnel to perform any repairs.

• not operate equipment with a damaged power cord.

• not use an extension cord to power this equipment.

• position the power cord so it will not be tripped over or pulled.

Equipment Damage

Caution

The equipment is not contained in a sealed cabinet. Therefore, it must not be used in locations where it can come in

contact with liquids, including bodily fluids.

This equipment generates, uses, and can radiate radio frequency energy. If not installed by qualified service

personnel and used in accordance with the User Guide, may cause interference to radio communications and other

electronic devices. Operation of this equipment in a residential area may cause interference, in which case the user,

at their own expense, will be required to take whatever measures may be required to correct the interference.

3E0815 – 29SEP99 3

Page 4

OPERATORS MANUAL

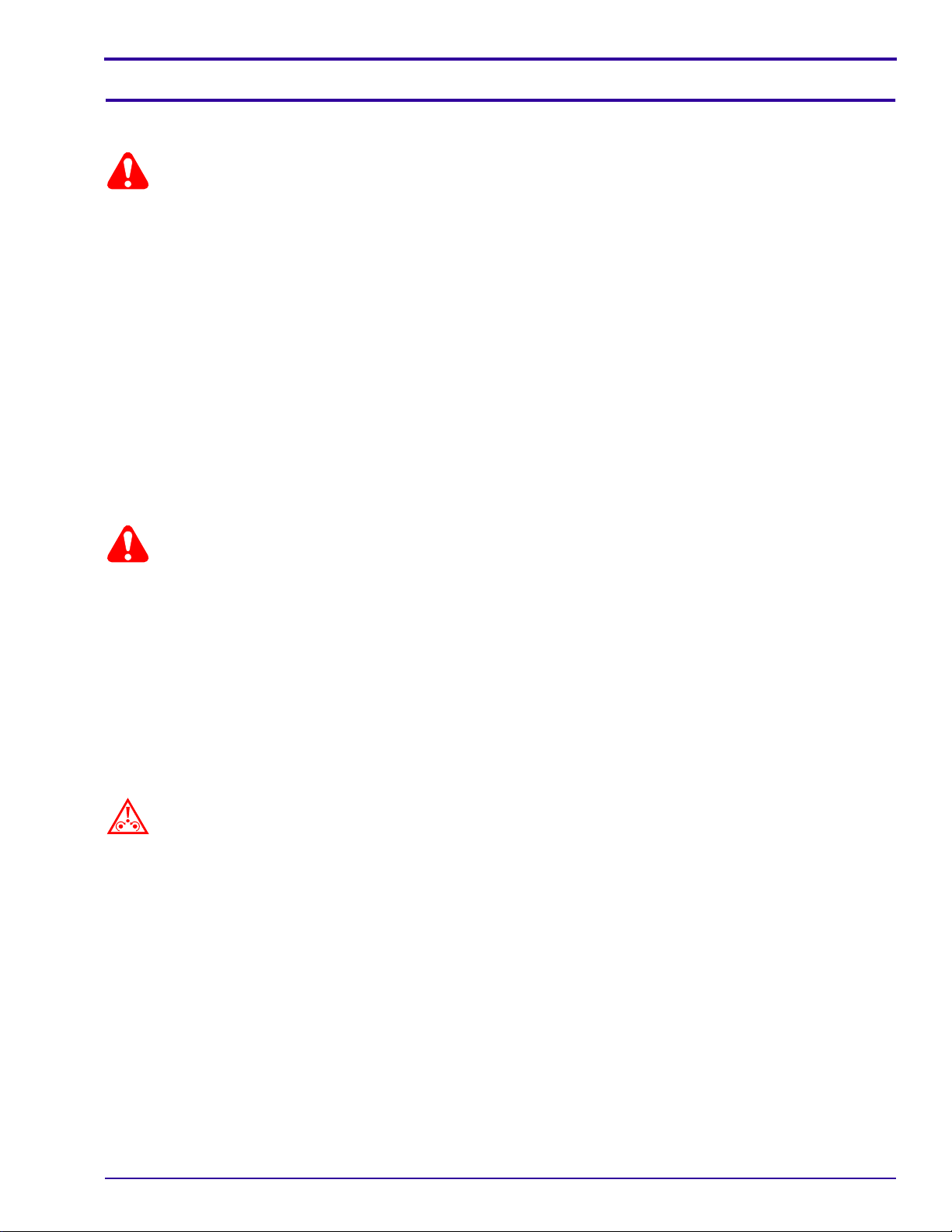

Nonpatient Contact Equipment

1.83 m

2.5 m

1.83 m1.83 m

H176_0034HC

Warning

This device is not medical equipment according to EN 60 601-1 and must not enter the patient environment as

defined by EN 60 601-1. The following requirements have to be met:

• Distance from the device to Nonpatient Contact Equipment:

Horizontal = 1.83 meters

Vertical = 2.5 meters above the floor under the patient

• Contact of the patient and the device simultaneously by the caregiver is not allowed.

• No direct electrical connection is allowed between the device and the Nonpatient Contact Equipment.

4 29SEP99 – 3E0815

Page 5

Overview

Section 2: Overview

The Processor is designed to process medical x-ray sheet film that can be processed in the Kodak RP X-Omat

Developer and Replenisher, the Kodak RP X-Omat Fixer and Replenisher, and the Kodak RP X-Omat EX Developer

and Replenisher.

The self-threading roller transport system has:

• a film-length detection system

• a replenishment system

• a developer solution filter

• a recirculation system for the developer and fixer solutions

• an automatic standby feature

The Processor can operate at 2 different transport speed cycles:

• Standard Cycle has a transport speed of 76.2

dry to dry, for a 43 cm (17 in.) sheet of film. The developer temperature is 33.3

• Rapid Cycle has a transport speed of 101.6 ±

dry to dry, for a 43 cm (17 in.) sheet of film. The developer temperature is 34.4 ±

Note

The transport speed and the developer solution filter can only be changed by qualified service personnel.

A film feed signal sounds 3 seconds after the film being processed has cleared the Rollers of the Detector Crossover

Assembly. This indicates that the Processor is ready to accept another piece of film.

± 1.5 cm (30.4 ± 0.6 in.) per minute or 157 ± 5 seconds drop time,

± 0.3°C (92.0 ± 0.5°F).

± 2.0 cm (40.0 ± 0.8 in.) per minute or 118 ± 4 seconds drop time,

± 0.3°C (94.0 ± 0.5°F).

3E0815 – 29SEP99 5

Page 6

OPERATORS MANUAL

Section 3: Processing Film

Start Up

H176_0001ACB

H176_0001AC

TOP COVER

MAIN POWER SWITCH

[1] Check that the Processor is off.

[2] Remove the Top Cover.

6 29SEP99 – 3E0815

Page 7

Processing Film

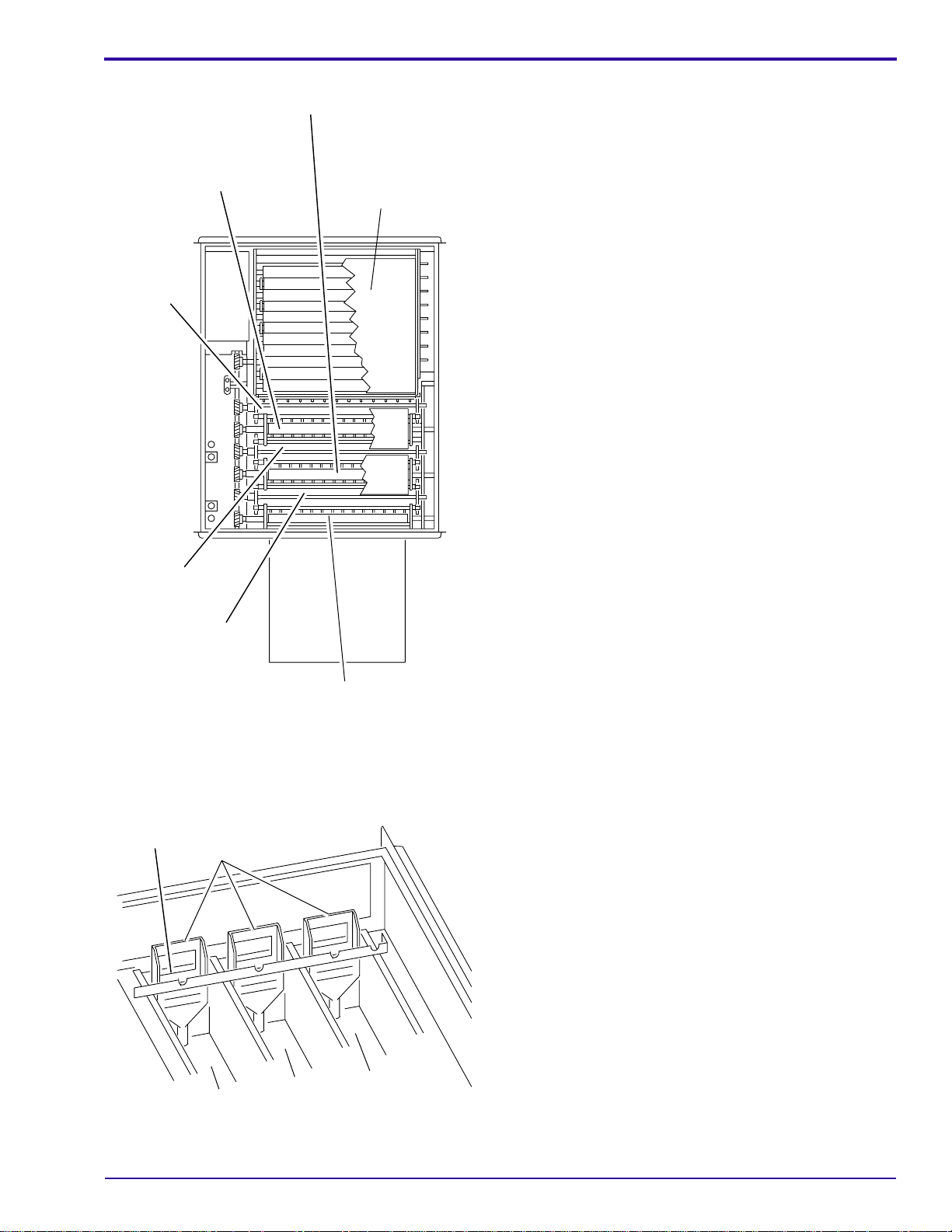

FIXER/WASH

CROSSOVER

ASSEMBLY

WASH

RACK

DEVELOPER/FIXER

CROSSOVER ASSEMBLY

DRYER

ASSEMBLY

[3] Check that the following are seated correctly:

• Developer Rack

•Fixer Rack

• Wash Rack

• Fixer/Wash Crossover Assembly

• Developer/Fixer Crossover Assembly

• Detector Crossover Assembly

•Dryer Assembly

FIXER

RACK

DEVELOPER

RACK

OVERFLOW

LEVEL

WEIRS

DETECTOR

DETECTOR

CROSSOVER

CROSSOVER

ASSEMBLY

ASSEMBLY

H172_1001CCD

H172_1001CC

[4] Check that the solutions in the Developer, Fixer,

and Wash Tanks are at the Overflow Level.

[5] Turn on the water supply.

H172_1004ACE

H172_1004AC

3E0815 – 29SEP99 7

WASH

TANK

FIXER

TANK

DEVELOPER

TANK

Page 8

OPERATORS MANUAL

2 EVAPORATION

COVERS

WATER

INLET TUBE

TOP

COVER

H172_1000ACB

H172_1000AC

DRYER TEMPERATURE

CONTROL KNOB

[6] Check:

• water is flowing from the Water Inlet Tube of

the Wash Tank

• 2 Evaporation Covers are installed

[7] Install the Top Cover .

Warning

Dangerous Voltage

[8] Energize the Processor.

[9] Wait until the Digital T emperature Display displays

the correct temperature of the developer solution:

Cycle Temperature

Standard 33.3 ± 0.3°C (92.0 ± 0.5°F)

Rapid 34.4 ± 0.3°C (94.0 ± 0.5°F)

H176_0001ACA

H176_0001AC

DIGITAL

TEMPERATURE

DISPLAY

RUN / STANDBY SWITCH

[10] Press the Run/Standby Switch.

[11] F eed a sheet of Kodak Roller Transport Cleanup

Film into the Processor.

[12] Adjust the Dryer T emperature Control Knob to the

lowest possible temperature that will still allow the

film to dry.

8 29SEP99 – 3E0815

Page 9

Feeding Sheet Film

Processing Film

1 each

35 x 43 cm

or

14 x 17 in.

1 each

24 x 30 cm

or

10 x 12 in.

1 each

1 each

35 x 35 cm

or

14 x 14 in.

1 each

24 x 24 cm

1 each

[1] Press the Run/Standby Switch. The Motors will

begin to operate.

Important

• Feed Mammography film with the emulsion side

down.

• Feed General Radiography film with the emulsion

side up.

• A film feed signal will sound when it is safe to feed

another sheet of film.

[2] Check that the developer solution is at the correct

temperature. See the table on Page 8

, Step 9.

[3] Feed a sheet of film into the Processor.

Note

The Processor will automatically return to the “Standby”

mode after the last film exits the Processor.

18 x 24 cm

2 each

10 x 10 cm

or

4 x 4 in.

1 each

11 x 14 in.

18 x 43 cm

H172_1002CC

3E0815 – 29SEP99 9

Page 10

OPERATORS MANUAL

Shutdown

TOP COVER

MAIN

POWER

SWITCH

H172_0502ACA

H172_0502AC

[1] Turn off:

• Main Power Switch

• water supply

Warning

Dangerous Voltage

[2] Disconnect the main power.

[3] Do the “Daily Procedure” on Page 18

.

[4] Install the T op Cover with a 5 cm (2 in.) opening for

venting purposes.

Note

The optimum time to do daily cleaning is at shutdown.

10 29SEP99 – 3E0815

Page 11

Processing Solutions

Section 4: Processing Solutions

Preparing the Solutions

Warning

• Use eye protection and rubber gloves.

• Wash the mixing equipment thoroughly between solutions to prevent contamination of the processing solutions.

• Do not mix more than a 2-week supply of chemicals.

[1] Mix the volume of processing solution required. Use the instructions packed with the chemicals.

Draining the Tanks

Warning

Dangerous Voltage

[1] De-energize and disconnect the main power.

SILVER RECOVERY UNIT

FIXER DRAIN

TUBE

H172_1007ACB

H172_1007AC

FIXER TANK

Warning

Use eye protection and rubber gloves.

[2] Remove the Top Cover.

[3] If the Processor has a Silver Recovery Unit

connected, disconnect the Fixer Drain Tube at the

input side of the Silver Recovery Unit.

[4] Place the Fixer Drain Tube in the Floor Drain or a

compatible collection container. Check the local

codes for the correct collection procedures.

WASH TANK

red WEIR

H176_0026BCA

H176_0026BC

3E0815 – 29SEP99 11

DEVELOPER

TANK

blue WEIR

beige WEIR

Page 12

OPERATORS MANUAL

Caution

Drain only 1 Tank at a time.

Check the local codes for the correct collection procedures.

Do not interchange the Weirs:

Weir Tank

red Developer

blue Fixer

beige Wash

[5] Remove the blue Weir.

[6] Drain the Fixer Tank.

[7] Install the blue Weir.

[8] Remove the red Weir.

[9] Drain the Developer Tank.

[10] Install the red Weir.

[11] Remove the beige Weir.

[12] Drain the Wash Tank.

[13] Install:

• beige Weir

• Top Cover

12 29SEP99 – 3E0815

Page 13

Filling the Tanks

Processing Solutions

FIXER/WASH

CROSSOVER

ASSEMBLY

WASH

RACK

DEVELOPER/FIXER

CROSSOVER ASSEMBLY

Warning

Dangerous Voltage

[1] De-energize and disconnect the main power.

Warning

Use eye protection and rubber gloves.

[2] Remove the Top Cover.

[3] Carefully and slowly remove the correct

Crossover Assembly and Rack from the Tank that

is to be filled.

FIXER

RACK

DEVELOPER

RACK

DETECTOR

DETECTOR

CROSSOVER

CROSSOVER

ASSEMBLY

ASSEMBLY

H172_1001CCE

H172_1001CC

3E0815 – 29SEP99 13

Page 14

OPERATORS MANUAL

DRIP TRAY

DEVELOPER

TANK

FIXER

TANK

H172_1004ACA

H172_1004AC

WEIRS

WASH

TANK

FIXER

TANK

SPLASH GUARD

H172_1003ACB

H172_1003AC

FILL

LINES

DEVELOPER

TANK

[4] Install the Splash Guard between the Developer

Tank and the Fixer Tank.

Caution

• Small amounts of fixer will cause excessive

developer contamination.

• Use the Drip Tray.

• If solutions are changed in both Tanks, fill the Fixer

Tank first so any solution that spills into the

Developer Tank can be completely cleaned.

[5] T o fill the Fixer Tank, add fixer replenisher until the

solution is at the higher Fill Line on the blue Weir.

[6] Remove and rinse the Splash Guard.

[7] Install the Splash Guard over the Fixer Tank.

[8] To fill the Developer Tank:

(a) Fill the Developer T ank half full of dev eloper

replenisher from the Replenisher Tank.

(b) Add the Kodak RP X-Omat Developer

Starter:

• for Mammography, 380 mL

(13 fl oz)

• for General Radiography,

190 mL (6.5 fl oz)

(c) Fill the Developer Tank to the lower Fill Line

on the red Weir with developer replenisher.

14 29SEP99 – 3E0815

Page 15

DEVELOPER/FIXER

CROSSOVER ASSEMBLY

FIXER/WASH

CROSSOVER

ASSEMBLY

DEVELOPER RACK

red WIRE TIE

FIXER RACK

blue WIRE TIE

WASH RACK

white WIRE TIE

DRYER

ASSEMBLY

DETECTOR

CROSSOVER

ASSEMBLY

ROLLERS

"D"

WASHER

"F"

WASHER

"W"

WASHER

Processing Solutions

Caution

• Prevent contamination and spills.

• The Racks are identified with a letter on the Washer

and a color on the Wire Tie:

“D” for the Developer Rack - red

“F” for the Fixer Rack - blue

“W” for the Wash Rack - white

[9] Slowly and carefully install the Racks. Use:

• Drip Tray

• Splash Guard

[10] Remove the Splash Guard and rinse thoroughly

with water.

[11] Install:

• Crossover Assemblies

• 2 Evaporation Covers

• Dryer Assembly, if removed

[12] Check that the developer solution is at the correct

temperature. See the table on Page 8

[13] Install the Top Cover.

, Step 9.

H176_0033CCA

H176_0033CC

3E0815 – 29SEP99 15

Page 16

OPERATORS MANUAL

Section 5: Correcting Difficulties

1. Transport Failure

2. Surface Artifacts

3. Abnormal Film Densities

4. Wet Films

5. Low Solution Levels

6. Overlapping of Films

123456

• • Film Feeding Error

Feed only single thicknesses of film. Feed the next film only after the

film feed signal sounds If there is no film feed signal, refer the difficulty

to qualified service personnel.

•••• Feed only compatible films.

• • Check that all Racks and Crossovers are seated correctly.

•• Check that the surfaces of all the Roller s are cle an and sm ooth , espe ci al ly in

the Developer Turnaround Assembly.

• • Check that the Dryer Air Tubes are in the correct positions.

• • Remove any dirt from the Dryer Rollers and Air Tubes from the Dryer

Assembly, especially the slots. Use a bottle brush and rinse with water.

• ••• Check that the replenishment rates are correct.

• Adjust the Dryer temperature control setting to the lowest possible

temperature that still allows good drying.

• Clean the Feed Shelf and Detector Rollers.

•• • Clean any biological growth in the Wash Tank with a mild solution of chlorine

bleach. Use 60 mL (2 fl oz) of bleach per 3.8 L (1 gallon) of water. Wipe the

Tanks with a soft sponge.

• • Check that the Weirs are seated correctly. Check that the Tanks are full.

•••• • Change any chemicals that were not mixed correctly, are exhausted, or are

contaminated. Check that the replenishment flow rates are correctly set. Fill

the Replenishment Tanks if necessary.

•• • Check that all Rollers are in place and positioned and rotating correctly.

•• • Check that all Roller Gears, Sprockets, and Idlers are engaged.

•• • Replace any Roller that has a broken or worn Gudgeons.

•• • Replace any Bearings that do not allow the Turnaround Rollers to rotate

correctly.

•• Check the tension on the Rack Chain. Check that the Rollers do not hesitate

and that the Chain moves smoothly.

• With the Processor on, check for movement on the surface of the solutions.

Movement indicates recirculation.

•• If the incoming wash water is dirty, clean the Rack and Tank thoroughly.

Change the incoming Water Filter. Use the correct Water Filter.

• Check that the Dryer Air Exhaust is free from any obstruction.

• • Check that the Turnaround Assembly is adjusted correctly. The Turnaround

Assemblies must be square with the Racks.

• • Check the incoming water temperature. Temperature must be between

°C (40°F) and 29.4°C (85°F).

4.4×

16 29SEP99 – 3E0815

Page 17

Correcting Difficulties

1. Transport Failure

2. Surface Artifacts

3. Abnormal Film Densities

4. Wet Films

5. Low Solution Levels

6. Overlapping of Films

123456

• Check that the correct Bulb and Safelight Filter are in the Safelight and at the

correct distance from the Feed Shelf and work surface.

• • Check that the Top Cover is tight on the Processor. Check that there are no

leaks in the Light Lock Gasket.

• 10 x 10 cm films - feed films diagonally if they fail to transport reliably.

• For all transport speeds, the buzzer should sound once the trailing edge of the

film has advanced 75 mm (3 in.) into the Processor.

••• • Check that the Tank solution levels are at the overflow Weirs.

• Check for solution in the Replenishment Tanks. Fill if necessary.

NOTE: Mix developer replenisher in quantities not to exceed a 2-week

supply.

• With a reliable thermometer, check that the temperature of the developer is

correct. If necessary, have qualified service personnel make adjustments.

NOTE: Check the incoming water temperature. It must be a minimum of 4×

(7

°×F) lower than the desired developer temperature.

°C

3E0815 – 29SEP99 17

Page 18

OPERATORS MANUAL

Section 6: Cleaning and Periodic Maintenance

Daily Procedure

DRYER

ASSEMBLY

ROLLERS

CROSSOVER

ASSEMBLIES

DETECTOR

CROSSOVER

ASSEMBLY

GUIDE

SHOE

2 EVAPORATION

COVERS

H172_1001CCF

H172_1001CC

Important

The optimum time to do daily cleaning is at shutdown.

[1] Identify any change in the operating condition of

the Processor to service personnel.

Warning

Dangerous Voltage

[2] De-energize the Processor. Disconnect the main

power.

[3] Turn off the water supply.

Warning

Use eye protection, rubber gloves, and protective

clothing before doing any maintenance procedures.

[4] Remove the Top Cover.

Caution

Do not touch or move the Guide Shoes.

[5] Remove and rinse with warm water:

• 2 Evaporation Covers

• Crossover Assemblies

[6] Rotate and clean the Rollers with a soft brush and

warm water.

[7] Use a cloth or synthetic sponge to remove any

water from the Rollers or allow to air dry.

[8] Remove all chemical deposits above the solution

level in the processing section.

[9] Clean off debris or buildup from the dryer area

with a warm, damp sponge or cloth.

[10] Install:

• Crossover Assemblies

• 2 Evaporation Covers

[11] At shutdown for venting purposes, install the Top

Cover with a 5 cm (2 in.) gap.

18 29SEP99 – 3E0815

Page 19

Every Two Weeks

Cleaning and Periodic Maintenance

RACKS

DRYER

ASSEMBLY

[1] Do Step 2 - Step 8 of the “Daily Procedure” on

Page 18

.

[2] Remove the Dryer Assembly.

[3] Clean off debris from the dryer area and Dryer

Assembly with a warm, damp sponge or cloth.

Caution

• Avoid contamination of the processing solutions.

• Use the Drip Tray when moving Racks to or from

the Processor.

[4] Remove the Racks.

[5] Install the Splash Guard between the Developer

Tank and the Fixer Tank. See Page 14

[6] Rinse the Racks and wipe them with a clean soft

cloth.

, Step 4.

H172_1008ACC

H172_1008AC

CHAIN

ROLLER

H172_1001CCG

H172_1001CC

[7] Check:

• Chains move freely

• Rollers rotate smoothly

[8] Install:

• Racks

• Dryer Assembly

• Top Cover

3E0815 – 29SEP99 19

Page 20

OPERATORS MANUAL

SILVER RECOVERY UNIT

BYPASS

H172_1007ACA

H172_1007AC

[9] T o check the operation of the Silver Recovery Unit

if installed:

(a) Check that no solution is flowing through the

Bypass.

(b) If soluti on is present in the Bypass, the Silver

Recovery Unit is not operating. Make a call

to service personnel.

(c) Use the Kodak Silver Estimating Test

Papers, Catalog No. 196 5466, to check the

silver content of the solution flowing into the

drain.

(d) If the test results indicate more than

1 gram/liter of silver, a new Silver Recovery

Unit must be installed. Make a call to service

personnel.

20 29SEP99 – 3E0815

Page 21

New Equipment Warranty

Section 7: New Equipment Warranty

Warranty Coverage

Kodak warrants the Processors to function properly for 1 year from the date of initial installation, when installed within

one year from the date of shipment.

If the equipment does not function correctly during the warranty period, the dealer that sold the equipment will provide

or arrange for repair of the equipment during the dealer's normal working hours. Such repair service will include any

necessary adjustments and/or replacement of parts necessary to maintain your equipment in good working order.

How to Obtain Service

Should equipment require service, see the sales contract for details on whom to call for service, or contact the dealer

that sold you the equipment.

Limitations

• Warranty service is limited to the contiguous United States, the island of Oahu in Hawaii, and certain areas of

Alaska.

• This warranty does not cover circumstances beyond Kodak's control, misuse, or abuse. Any attachments,

accessories, or alterations not marketed by Kodak (including service or parts to correct problems resulting from

the use of such attachments, accessories or alterations), failure to follow Kodak's operating instructions, or

supply items.

• Kodak makes no other warranties, express, implied, or of merchantability for this equipment.

• Repair without charge is Kodak's and the dealer's only obligation under this warranty.

– Kodak will not be responsible for any consequential or incidental damages resulting from the sale,

use, or improper functioning of this equipment even if loss or damage is caused by the negligence

or other fault of Kodak.

– Such damages for which Kodak will not be responsible, include, but are not limited to, loss of revenue or

profit, downtime costs, loss of use of the equipment, cost of any substitute equipment, facilities or services

or claims of your customers for such damages.

• This limitation of liability will not apply to claims for injury to persons or damage to property caused by the sole

negligence or fault of Kodak or by persons under its direction or control.

Publication History

Affected

Print Date Pub No. ECO No.

29SEP99 3E0815 4014-504 All om3752_1_29sep99.fm First Printing

3E0815 – 29SEP99 21

Pages File Name Notes

Page 22

Printed in U.S.A. • om3752_1.fm

EASTMAN KODAK COMPANY

Rochester, NY 14650

Kodak, Min-R and X-Omat are trademarks.

HEALTH IMAGING

Loading...

Loading...