Page 1

KODAK MIN-R EV Mammography Film Conversion Guide and Processing Recommendations

KODAK MIN-R EV Mammography Film Conversion Guide

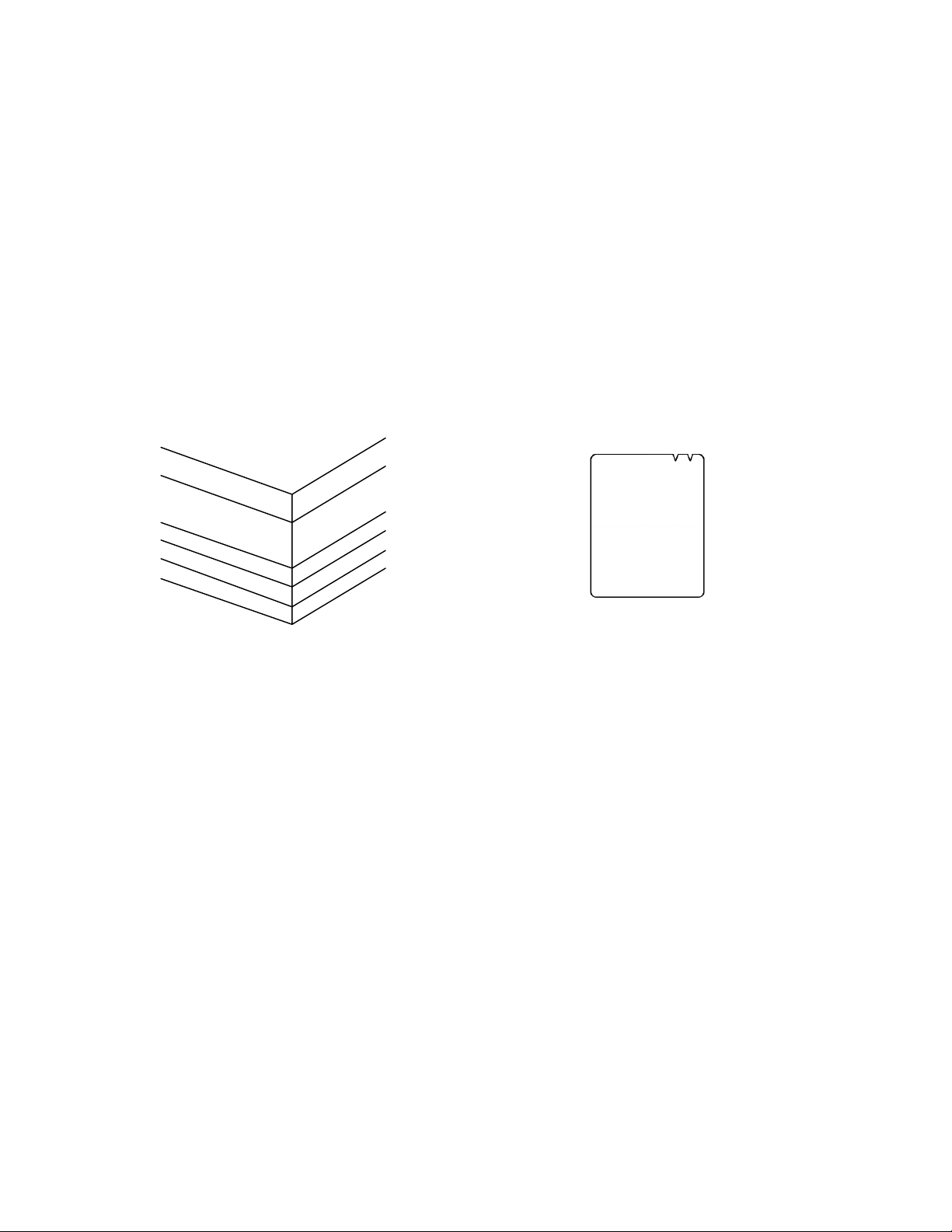

• MIN-R EV has a novel double emulsion design, for use with standard, green-emitting single

screen cassettes.

• MIN-R EV is identified by a spaced double V-notch. The primary emulsion is up when the

notch is on the right hand side at the top edge of the film. The primary emulsion must be in

contact with the screen during imaging.

• Kodak has added an orientation layer to the film to aid in the identification of the primary

emulsion side; the dull side identifies the primary emulsion side of the film (the side which is

to be placed against the screen during imaging).

• KODAK MIN-R EV Film is designed for optimal results in standard cycle processing

o The film may be processed in Rapid cycle when used with KODAK X-OMAT EX II or

KODAK RP X-OMAT Developer and KODAK RP X-OMAT LO Fixer.

•

In documentation that refers to the emulsion side of the film, this should be considered a

reference to the primary emulsion of MIN-R EV film.

prima ry emulsio n

sup p ort : blue

secondary emulsion

antihalation layer

not to scale

orientation layer

OBJECTIVES OF THE CONVERSION GUIDE

• Establish/verify correct processing parameters for KODAK MIN-R EV Film

• Establish quality control aims

• Establish initial image quality parameters

• Verify other Quality Control tests

Tools Required:

• Sensitometer capable of producing 21 steps

• Densitometer capable of spot reading greater than optical density of 4.5

• Thermometer

• Curve plotting paper (KODAK Publication # M3-58, Cat # 841 2843) or scanning

densitometer

• 4-5 cm Lucite or BR 12 tissue equivalent phantom (RMI 156, Nuclear Associates 18-220)

Reference Material:

• KODAK MIN-R EV Film System User Guide (KODAK Publication #, Cat #)

• MIN-R EV Film Demonstration Guidelines

• MIN-R EV Film Q&A Guide

• Service Bulletin No. 30, revised 2003

• Mammography Quality Control Manual 1999, American College of Radiology

Not to scale

0. Before you begin

Benchmark the facility using the mammography benchmarking form.

o Compare sensitometry (current film versus MIN-R EV)

o Compare accreditation phantom (current film versus MIN-R EV)

© Eastman Kodak Company 9/03 Page 1

Page 2

KODAK MIN-R EV Mammography Film Conversion Guide and Processing Recommendations

o Perform the optical density and kVp series with MIN-R EV

1. Processors

KODAK MIN-R EV Film is designed for optimal results in standard cycle processing. All KODAK

X-OMAT Processors should be adjusted to comply with the standard cycle processing

parameters listed in the film processing instructions for that specific processor. If using KODAK

X-OMAT EX II or KODAK RP X-OMAT Developer and KODAK RP X-OMAT LO Fixer, the film

may be processed in the Rapid cycle. If using the rapid cycle, all KODAK X-OMAT Processors

should be adjusted to comply with the rapid cycle processing parameters listed in the film

processing instructions for that specific processor.

KODAK MIN-R EV Film should be processed primary emulsion side down in the KODAK

MIN-R Mammography and KODAK X-OMAT M35A-M / M35-M processors. Best results will be

obtained using the KODAK MIN-R Mammography processor.

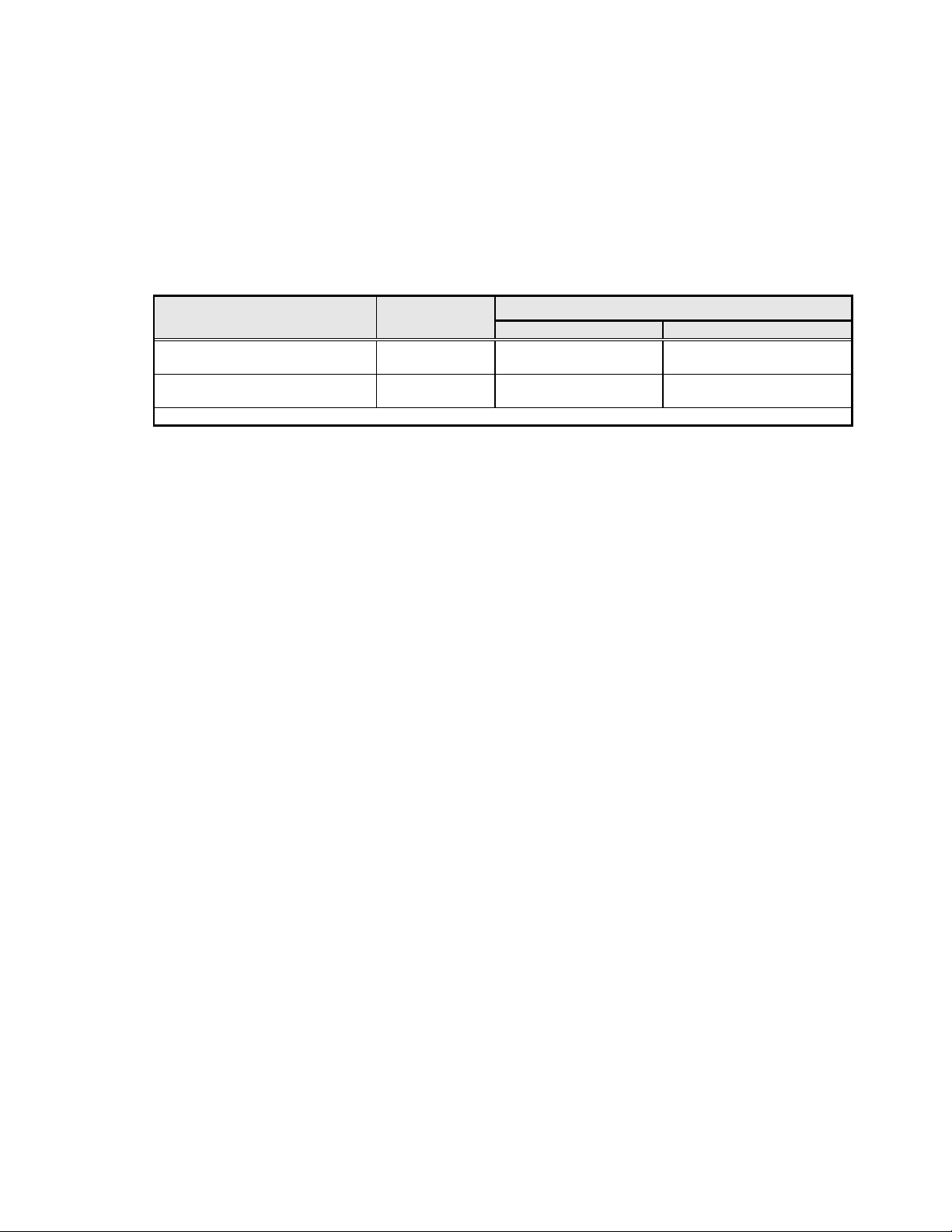

Processor Process Min-R EV Primary Emulsion

Up/Down

Min-R Mammography, M35A-M, M35M Down

3000 RA, 270 RA, M7 series Up

M6 B, M6R, 5000 RA, 480 RA, 460 RA Up

Note: The KODAK Medical X-Ray, X-OMAT M43, M43A, Clinic 1, X-OMAT 1000, M35A, M35

and X-OMAT 2000 and 2000 A Processors are not recommended for processing KODAK

MIN-R EV Film (or other KODAK Mammography Films). Other manufacturers’ processors

with shallow developer tanks or short developer racks may not produce optimum results if

used to process KODAK MIN-R EV Film. Consult the processor manufacturer

recommendations for standard/rapid cycle processing set-up.

2. Chemicals

• Drain, clean, and refill the Developer and Fixer Tanks.

• If using an automated specific gravity based mixer and converting to KODAK X-OMAT

EX II Developer and Replenisher (or KODAK RP X-OMAT Developer and Replenisher)

and KODAK RP X-OMAT LO Fixer and Replenisher, ensure that the specific gravity is

set as follows:

Processing Chemistry Specific Gravity

Range*

KODAK X-OMAT EX II Developer and Replenisher 1.070 to 1.080

KODAK RP X-OMAT Developer and Replenisher 1.081 to 1.091

KODAK RP X-OMAT LO Fixer and Replenisher 1.080 to 1.100

*Specific Gravity measured at 77º F.

KODAK MIN-R EV Film requires 25 ml/l (3 fluid ounces per gallon) of KODAK RP

•

X-OMAT Developer Starter. See the attached General Processor Information for

recommended starter volumes for a specific KODAK processor

Optimum results are obtained using KODAK X-OMAT EX II and RP X-OMAT Developer

Replenishers. Kodak does not recommend the use of KODAK Medical X-ray Developer

Replenisher with KODAK MIN-R EV Film. The United States Food and Drug Administration (FDA)

Mammography Quality Standards Act (MQSA) Final Regulations, effective April 28, 1999, states

that processing solutions be capable of developing films in a manner equivalent to the minimum

requirements specified by the film manufacturer. To determine if another manufacturer's

developer is within Kodak's acceptable range for KODAK MIN-R EV Film, please refer to the

.

© Eastman Kodak Company 9/03 Page 2

Page 3

KODAK MIN-R EV Mammography Film Conversion Guide and Processing Recommendations

KODAK MIN-R EV Film System Mammography User Guide. If attempting to use another

manufacturer’s developer, contact the developer manufacturer for recommended replenishment

rates.

Optimum results are obtained using KODAK RP X-OMAT LO Fixer and Replenisher.

For best results, processing solutions should be mixed with 70°F to 80°F (21.1°C to 26.6°C)

water.

Warning: KODAK Medical X-ray Developer and Replenisher is not recommended for

KODAK Mammography Film. KODAK Medical X-ray Fixer is not optimized for KODAK

Mammography Film.

3. Adjust the Developer and Fixer Replenishment Rates.

Dedicated Processing: KODAK MIN-R EV Film requires specific replenishment rates for

developer and fixer. These recommendations are guidelines for KODAK X-OMAT EX II

Developer and Replenisher, KODAK RP X-OMAT Developer and Replenisher and KODAK RP

X-OMAT LO Fixer and

adjustment for specific processing environments.

If attempting to use other manufacturer’s developers and fixers, contact the manufacturer for

recommended replenishment rates.

Replenisher. Developer and fixer replenishment rates may require

Recommended Replenishment Rates

Dedicated Mammography

A processor is considered dedicated if only mammography or single-emulsion film such as

ultrasound is processed.

General purpose (non-dedicated) processors should use the replenishment rates listed for

general radiography.

Note: These guidelines should be used as initial starting points only. If adjustments are made

from these it is recommended that only 10% change be made at any one time.

For Area Processors with Smart Replenishment

KODAK X-OMAT Processor Models 270 RA, 3000 RA, M6RA, 460 RA, 480 RA, 5000 RA

KODAK X-OMAT Multiloader 7000, KODAK X-OMAT Multiloader 300/300 Plus

• Smart Replenishment is enabled by default. It is recommended that smart

replenishment be disabled for Min-R EV film. Consult service.

• The equivalent area of a 35 x 43 cm (14 x 17 in.) film is 1505 cm sq. (238 sq. in.).

• Replenishment takes place after the equivalent area of a 35 x 43 cm (14 x 17 in.) film

has been fed; therefore, replenishment rates must be set for a 35 x 43 cm (14 x 17

in.) film feed.

• Additional replenishment occurs automatically during low film usage. This feature

can be overridden by using software version 3.0 or higher. Note: X-OMAT 3000 RA

and X-OMAT 5000 RA Processors have the ability to override this feature without

installing new software.

© Eastman Kodak Company 9/03 Page 3

Page 4

KODAK MIN-R EV Mammography Film Conversion Guide and Processing Recommendations

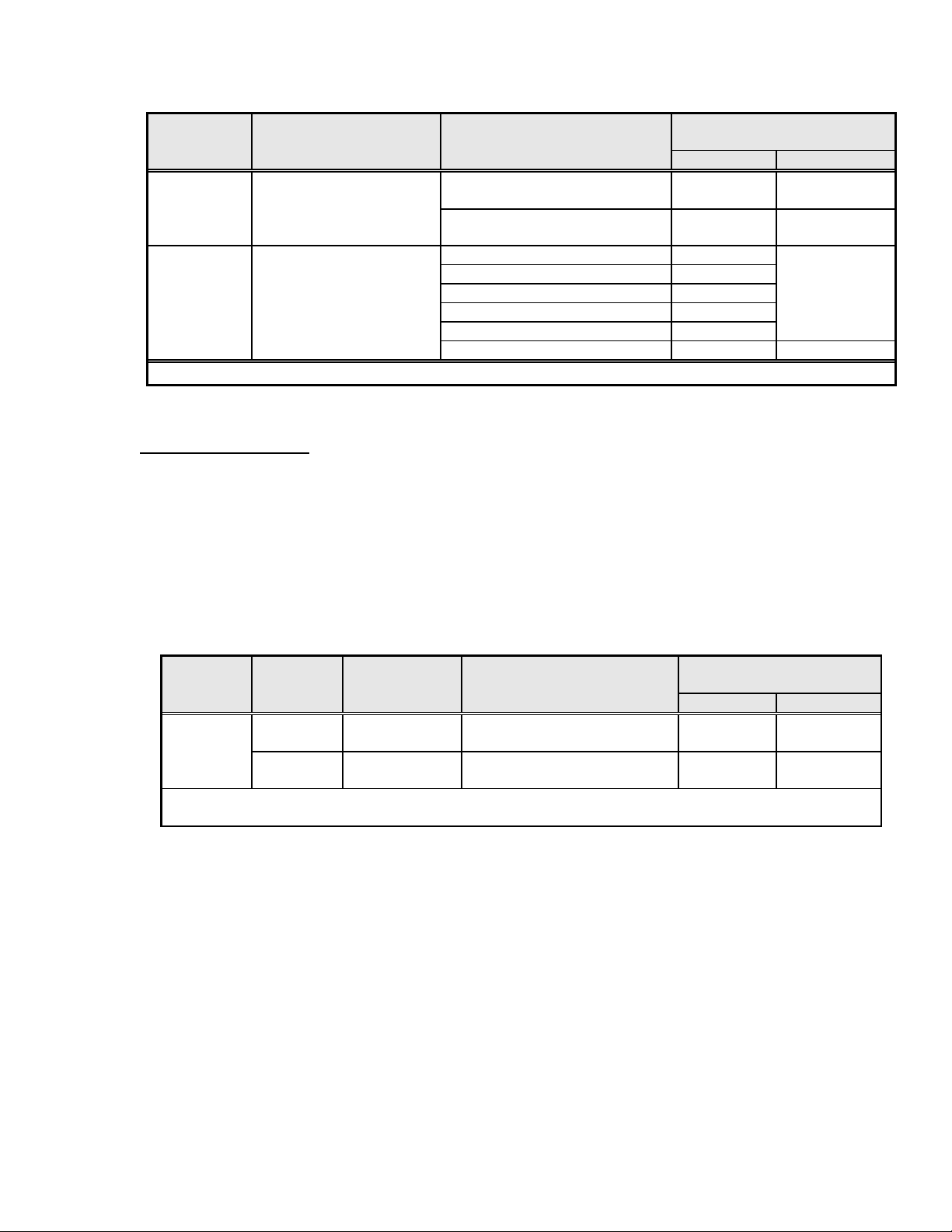

Average Number of Replenishment Rates*

Film Use Films per 8 hrs (ml per 35 x 43 cm)

Processed Condition Of Processor Operation Developer Fixer

MIN-R EV Smart Replenishment

60 sheets or more 90 105

disabled (recommended)

Less than 60 sheets Flooded Flooded

MIN-R EV Smart Replenishment

enabled

260 sheets or more 90

200 sheets 80

150 sheets 70

100 sheets 65

70 sheets 60

Less than 60 sheets Flooded Flooded

* Flooded replenishment is available if needed to maintain sensitometry for very low use conditions.

Smart replenishment should be turned off (refer to Service Bulletin No. 30)

For Length Processors

KODAK X-OMAT Processor Models M35-M, M35A-M, M7B, M7B-E, M6A-N, M6AW , M6B,

M6R

KODAK MIN-R Mammography Processor

• Replenishment takes place whenever film is in the entrance rollers.

• Replenishment rates must be set according to usage and film size(s) fed.

• MIN-R EV Film is fed primary emulsion side down in M35-M, M35A-M, and MIN-R

Mammography Processors.

• For the KODAK Multiloader 700 docked to length replenished processors, mammography

rates are set using 18 cm film travel.

Average Number of Replenishment Rates

Film Film Use Films per 8 hrs (ml per 18 x 24 cm)**

Processed Feeding Condition Of Processor Operation Developer Fixer

MIN-R EV

Single Medium - High

Low

Double Medium - High

Low

60 sheets or more

60 sheets or less*

60 sheets or more

60 sheets or less *

25

Flooded

50

Flooded

Flooded

Flooded

* If flooded replenishment is not used, sensitometry may not stay within control limits.

** Use a single 18 x 24 cm film to set the replenishment rates listed.

Recommended Replenishment Rates

Non-Dedicated Mammography

Non-Dedicated Processing: KODAK MIN-R EV Film can be processed with most current

traditional medical x-ray film. Kodak does not recommend processing Helium Neon and IR films

with KODAK MIN-R EV Film. Use 25 ml/l (3 fl oz per gallon) of KODAK RP X-OMAT Developer

Starter for non-dedicated processing environments. KODAK MIN-R EV Film requires specific

replenishment rates for developer and fixer. These recommendations are guidelines for KODAK

X-OMAT EX II Developer and Replenisher, KODAK RP X-OMAT Developer and Replenisher,

and KODAK RP X-OMAT LO Fixer and Replenisher. Developer and fixer replenishment rates

may require adjustment for specific processing environments. If attempting to use other

manufacturers’ developers and fixers, contact the manufacturer for recommended replenishment

rates.

105

30

60

© Eastman Kodak Company 9/03 Page 4

Page 5

KODAK MIN-R EV Mammography Film Conversion Guide and Processing Recommendations

For Area Processors with Smart Replenishment

KODAK X-OMAT Processor Models 270 RA, 3000 RA, M6RA, 460 RA, 480 RA, 5000 RA

KODAK X-OMAT Multiloader 7000, KODAK X-OMAT Multiloader 300/300 Plus

• Smart Replenishment is enabled by default.

• Replenishment takes place after the equivalent area of a 35 x 43 cm (14 x 17 in.) film has

been fed; therefore, replenishment rates must be set for a 35 x 43 cm (14 x 17 in.) film feed.

•

Additional replenishment occurs automatically during low film usage.

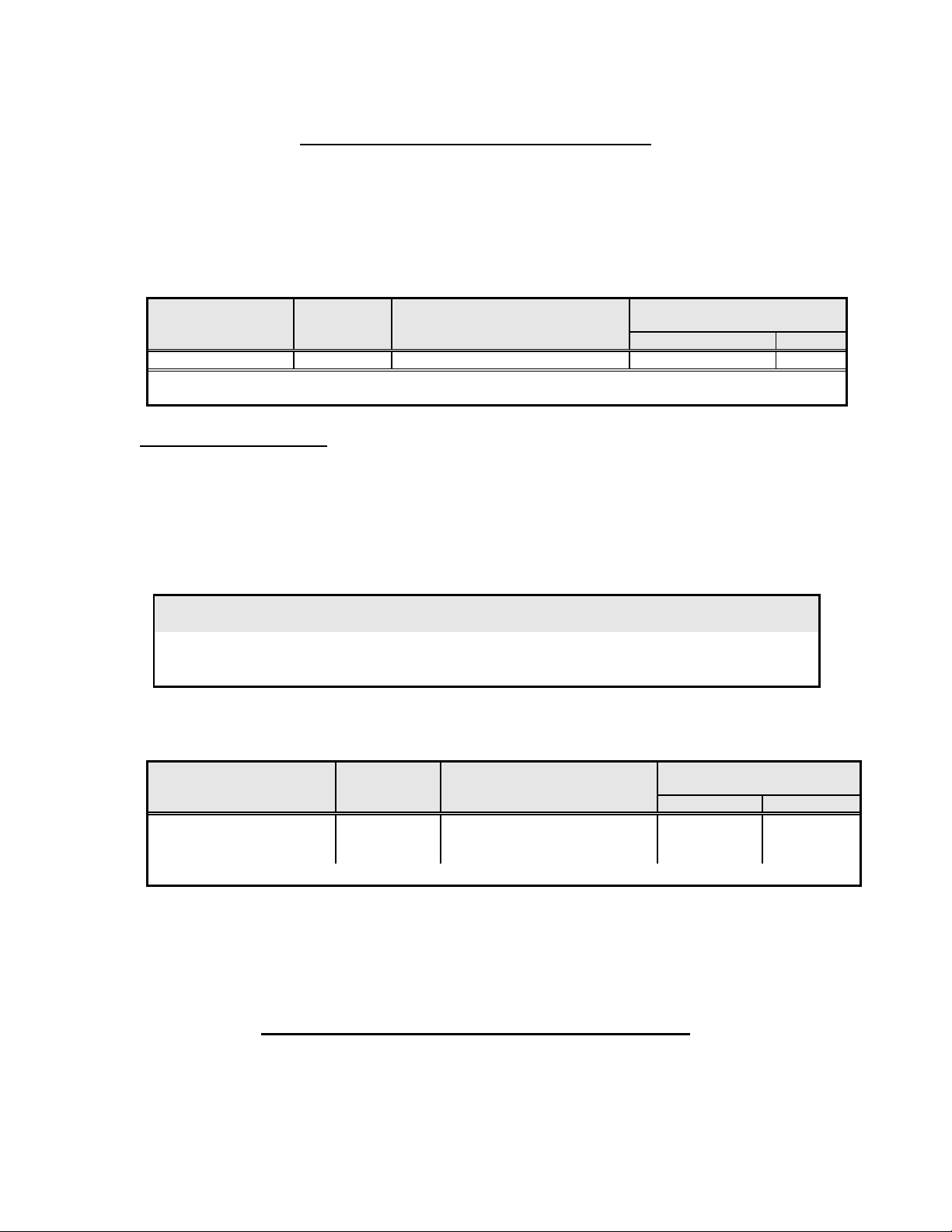

Average Amount of 35 x 43 cm Replenishment Rates

Film Size Use Equivalent Films per (ml per 35 x 43 cm)

Processed Condition 8 hrs of Processor Operation Developer Fixer

All Any Any number * 60 85

* Flooded replenishment should not be needed due to the automatic compensation for use, but it is available if

needed to maintain sensitometry for very low use conditions (fewer than the equivalent of 25 35x43 cm films).

For Length Processors

KODAK X-OMAT Processor Models M35-M, M35A-M, M7B, M7B-E, M6A-N, M6AW , M6B,

M6R

KODAK MIN-R Mammography Processor

• Replenishment takes place whenever film is in the entrance rollers.

• Replenishment rates must be set according to usage and film size(s) fed.

• Film should be fed as recommended in the processor Operator Manual/User Guide.

. Processor Process Min-R EV Primary Emulsion

Up/Down

Min-R Mammography, M35A-M, M35M Down

3000 RA, 270 RA, M7 series Up

M6 B, M6R, 5000 RA, 480 RA, 460 RA Up

• X-OMAT M35M, M35A-M and MIN-R Mammography Processors are not recommended for

roll film

Average Number of Replenishment Rates

Film Size Use Films per 8 hrs (ml per 35 x 43 cm)

Processed Condition Of Processor Operation Developer Fixer

Average size intermix High

Medium

Low

115 sheets or more

40 - 115 sheets

40 sheets or less *

50

65

80

70

85

100

* If flooded replenishment is not used, sensitometry may not stay within control limits.

Flooded Replenishment:

processor quality control with low volume processing. For KODAK MIN-R EV Film, it requires

25 ml/l (3 fl oz per gallon) of KODAK RP X-OMAT Developer Starter in the external

developer replenishment tank.

Flooded replenishment can be used to help maintain stable

Flooded Replenishment Rate Recommendations

• For low use rates, if sensitometry does not stay within control limits, flooded replenishment

may be needed to maintain the developer solution at a continuously fresh chemical activity.

This is accomplished by replenishing not only when film is fed or area accumulated, but also

© Eastman Kodak Company 9/03 Page 5

Page 6

KODAK MIN-R EV Mammography Film Conversion Guide and Processing Recommendations

on the basis of additional replenishment added during the processor on time with an

automatic replenishment timing system.

• When in the flooded mode, developer starter is added to the replenishment tanks at a rate of

89 ml per gallon or 25 ml per liter (3 fl oz per gallon) for MIN-R EV film.

• For detailed information on how to set up each processor for flooded replenishment, see the

appropriate service publication for that processor.

• Qualified service personnel should do the processor setup.

• When filling the developer replenishment or processor tank, add starter according to the table

below.

KODAK Flooded Add Starter?

Developer Mode Replenishment Tank Processor Tank

X-OMAT EX II

RP X-OMAT No No Yes

Yes Yes No*

* Fill the processor tank with chemistry that was mixed in the replenishment tank.

No

Yes

No

Yes

Yes

No*

4. Dryer

Dedicated processors converted to Min-R EV film may be able to reduce the dryer temperature.

An uneven density pattern may be noted if the dryer temperature is too high. Please refer to

Section 7.

• Set the Dryer temperature to the minimum required to produce dry film. Tacky or wet films

occurring even with adjusted Dryer temperatures may indicate that additional service is

required.

• Check that the Dryer Air Tubes are in the correct positions. Remove any dirt from the Dryer

Rollers and Air Tubes, especially the slots.

• Check the settings for correct replenishment.

• Check the replenishment system for kinks in the Tubing, the operation of the Recirculation

and Replenishment Pumps, and the Detector Switches. Change any chemicals that were not

mixed correctly, are exhausted, or are contaminated.

• Check that the Dryer air exhaust is free from any obstructions and is installed correctly

according to the specifications in the installation instructions.

• You may be able to decrease the dryer temperature.

• Should uneven density be noticed, refer to Section 7, evaluating the Imaging Chain for

Uniformity.

© Eastman Kodak Company 9/03 Page 6

Page 7

KODAK MIN-R EV Mammography Film Conversion Guide and Processing Recommendations

General Processor Information

NC = Not Controlled (temperature)

NR = Process Not Recommended for this film type

Processor

Model

gal

M35-M

M35A-M

MIN-R

Mammo

M7B

M7B-E

3000 RA

270 RA

XML300

XML300+

XML7000

M6A-N

M6AW

M6B

M6R

M6RA

460 RA

480 RA

5000 RA

* Fixer temperature may exceed value listed due to internal ambient temperatures in the processor.

** Drop Time is defined as the time from the Lead Edge In (LEI) to the Trail Edge Out (TEO) for a 35 x 43 cm film. (Represents 18 x 24 cm

LEI/TEO)

Approx

Cycle

S 2.25

S 92° F

R

S 2.25

S 94° F

R

S 2.8

S 95° F

R

Devl

Tank

Volume

(L)

(8.3)

2.25

(8.3)

(8.3)

2.25

(8.3)

(10.7)

2.8

(10.7)

Starter

Volume

MIN-R EV

fl oz

(ml)

6.5

(190)

6.5

(190)

6.5

(190)

6.5

(190)

Molded:

8.5 (250)

Stainless

8 (237)

:

8.5

(250)

Dev

°F

(°C)

92° F

(33.3°

C)

(33.3°

C)

94°F

(34.4°

C)

94° F

(34.4°

C)

(34.4°

C)

99° F

37.2°

C

95° F

(35°

C)

(35°

C)

101°

F

(38.3°

C)

Temperature

Fixer*

°F

(°C)

NC 40° - 85° F

NC 40° - 85° F

NC 40° - 85° F

90° F

(32° C)

95° F

(35° C)

NC M6A-N

95° F

(35° C)

Water

°F

(°C)

(4° - 29.4°

C)

(4° - 29.4°

C)

(4° - 29.4°

C)

40° - 85° F

(4° - 29.4°

C)

85° - 90° F

(30°-32.2°C)

M6AW,

:

M6B

40° - 90° F

(4° - 32.2°

C)

40° - 85° F

(4° - 29.4°

C)

:

Transport

Speed

in./min

(cm/min) films/hr seconds seconds

30

(76.2)

30

(76.2)

42

(106.7)

42

(106.7)

57

(144.8)

66

(167.6)

66

(167.6)

99

(251.5)

Capacity

35 x 43

cm (18 x

24 cm)

94

(145)

(145)

146

(250)

148

(250)

201 19 82

229

(393)

233

(393)

351 16 60

Approx

Devl

Time

33 150

33 150

25 112

27 120

26 111

25 90

24 95

Approx

Drop Time**

35cm length

(24cm

length)

(135)

(135)

(101)

(116)

(104)

(86)

(89)

5. Processor Quality Control Operating Levels

The following instructions are recommendations for the control of the processor quality. Different

sensitometric parameters will be monitored (MD: mid-density/speed, DD: density

difference/contrast, B+F: base+fog/gross fog). You can modify these different parameters based

on local regulations or guidelines.

Processor Control Aims

a. Using a Sensitometer, expose and process a Sensitometric strip. Repeat this exposure

and processing once each day for five consecutive days. For large volume processing

tanks or very low film volume a 10 day average may be used. For the

Control Sensitometer and X-rite models 394 and 396, the following Dip Switch settings

are recommended for KODAK MIN-R EV Film:

• SINGLE and GREEN settings at Exposure Setting No. 4

• 1-down, 2-down, 3-up, 4-down

© Eastman Kodak Company 9/03 Page 7

KODAK Process

Page 8

KODAK MIN-R EV Mammography Film Conversion Guide and Processing Recommendations

− Using a lower exposure setting will decrease the optical density, using a

higher exposure setting will increase the optical density.

For other manufacturers, follow the recommendations for optimum mammographic results

(optimized green, single emulsion).

b. Read and record the densities of each step of the sensitometric strip using the

densitometer, including an area of processed film that has not been exposed.

c. From the five strips, determine the average of the densities for each step using the

respective densities for each step.

d. Determine which step has an average density closest to 1.20 but above 1.0. Designate

this step as the mid-density (MD)/speed step. Tolerance +/- 0.10-0.15

e. Determine which step has a density closest to 2.20 and which step has a density closest

to but not less than 0.45. The difference in densities between these two steps should be

designated as the density difference (DD)/contrast. Tolerance +/- 0.10-0.15

f. Determine the average of the densities from the unexposed area of the five strips. This

density will be designated as the base-plus-fog level (B+F)/gross fog of the film.

Tolerance < 0.25

g. Start a new Processor quality control chart and record the numerical values of the MD

(speed), DD (contrast) and B+F (gross fog) on the centerline of the appropriate areas of

the control chart.

Baseline Operating Level (on the day of conversion)

a. Using a Sensitometer, expose and process five (5) sensitometric strips at the same time

and on the same side of the processor.

b. Read and record the densities of each step of the sensitometric strip using the

densitometer, including an area of processed film that has not been exposed.

c. Determine the average of the densities for each step using the densities for that step

from the five strips.

c. Determine which step has an average density closest to 1.20. Designate this step as the

mid-density (MD)/speed step.

e. Determine which step has a density closest to 2.20 and which step has a density closest

to but not less than 0.45. The difference in densities between these two steps should be

designated as the density difference (DD)/contrast.

f. Determine the average of the densities from the unexposed area of the five strips. This

density will be designated as the base-plus-fog level (B+F) of the film.

g. Start a new Processor quality control chart and record the numerical values of the MD

(speed), DD (contrast) and B+F on the centerline of the appropriate areas of the control

chart.

These can be used as the baseline operating aims until the five-day averaging has been

completed.

6. Automatic Exposure Control (AEC)

The desired optical density and operating kVp preference should be established. Refer to the

KODAK MIN-R EV Film System Mammography User Guide (KODAK Publication # , Cat # )

for a procedure to establish kVp and optical density for MIN-R EV Film.

Auto AEC/Phototimer recalibration is recommended after processing has stabilized

Customers should consult their x-ray equipment manufacturer to ensure proper recalibration. If

this is not performed at the time of conversion, then an interim AEC photo-timer adjustment

should be determined. Using the appropriate tissue equivalent phantom, adjust the density

control setting to achieve the desired optical density for the new screen/film system.

significant difference in the curve shape of Min-R EV film, optimum results for all breast

types may not be achieved if the mammography x-ray unit is NOT calibrated for Min-R EV.

.

Due to the

Note: aims of the phantom QC should be adjusted once the calibration is performed if optical

density or density difference change

.

© Eastman Kodak Company 9/03 Page 8

Page 9

KODAK MIN-R EV Mammography Film Conversion Guide and Processing Recommendations

The following table shows system speeds for KODAK MIN-R EV Film with KODAK MIN-R EV

Screens, and may be useful in determining an interim AEC adjustment.

Speed Contrast Comparisons for KODAK Mammography Film

Relative

Cycle

MIN-R EV EV 150 Standard/Rapid 150 4.5 4.7 >4.5

MIN-R EV EV 190 Standard/Rapid 190 4.5 4.7 >4.5

MIN-R 2000 2000 Standard 150 3.60 3.80 >4.0

MIN-R 2000 2190 Standard 190 3.60 3.80 >4.0

MIN-R 2000 MIN-R Standard 100 3.60 3.80 >4.0

MIN-R L 2000 Standard 150 3.40 3.60 >4.0

MIN-R L 2190 Standard 190 3.40 3.60 >4.0

MIN-R L MIN-R Standard 100 3.40 3.60 >4.0

1 Relative speed determined from matched-density radiographs of a mammography phantom. KODAK MIN-R M Film and

MIN-R Screen arbitrarily assigned a relative speed of 100.

2 Contrast was measured as the average gradient between densities 0.25 and 2.00 above gross fog using inverse square

sensitometry

Speed

Contrast Film Screen Processing

RP EX II

D-Max

While system speeds may be similar, screen absorptions are different. Equipment

adjustment will be necessary.

7. Evaluating the Imaging Chain for Uniformity

Description:

• Pattern of plus or minus density

• May appear either as a band or a diffuse region

• Readily seen on a flat field or phantom, rarely in the clinical image

• Can appear across the image, but seen most often in a uniform phantom along the chest

wall side of the image

Picture:

Probable Cause or Causes:

The density pattern may be caused by a combination of factors in the exposing and processing of

the film.

• Grid/cassette holder

o Grid motor

o Grid artifact/defect

o Carbon fiber top damage

• Dryer

© Eastman Kodak Company 9/03 Page 9

Page 10

KODAK MIN-R EV Mammography Film Conversion Guide and Processing Recommendations

o Dryer temperature too high

o Air tubes blocked or obstructed

o Buildup on dryer rollers

o Squeegee rollers

o Dryer venting

• Processor

o Hesitation in developer rack

o Stubbing in developer rack

o Processor type

Some processors have a better path through the developer, wash and

dryer (e.g. Min-R Mammography or X-OMAT 5000 RA processor)

Note: In deep tank processors, test films should be processed emulsion

up and down to determine best orientation for uniformity.

Films must be processed emulsion down in X-OMAT M35M, M35A-M

and Min-R Mammography processors.

• Chemistry

o Type and/or quality of the chemistry

Mixed and replenished properly

Note: High contrast developers may increase the visualization of breast structure.

Consequently, they may also enhance the visualization of any anomalies present in

the imaging chain. The visualization of grid and dryer patterns may be more

pronounced with these developers.

Isolating Non-Uniformity

Step 1. Determine if the artifact is coming from the processor or the X-ray exposure

equipment

Equipment Needed

• 1 inch (2cm) thick uniform sheet of acrylic or Lucite

• Cassette with known good screen-film contact

The following procedure may be used to make this evaluation:

• Expose films to an optical density of 1.10 to 1.50, using the same cassette and the uniform

sheet of acrylic.

—The exposure time used should be at least 0.5 seconds or longer to eliminate grid

artifacts caused by too short an exposure time.

—The cassette must be known to have good screen-film contact.

• Process one film so that the narrowest dimension of the film is the leading edge; process

a second film so that the widest dimension of the film is the leading edge.

• Once processed, view the film pairs (or single films) in the same orientation as

processed.

• Artifacts that are parallel to each other on a film pair occurred in the processor

(artifacts may be parallel or perpendicular to film travel).

Artifacts that are perpendicular to each other on a film pair occurred during exposure from the

x-ray unit.

© Eastman Kodak Company 9/03 Page 10

Page 11

KODAK MIN-R EV Mammography Film Conversion Guide and Processing Recommendations

Artifacts that are parallel to each other are caused by

the processor; artifacts that are perpendicular are

caused during exposure.

If the artifact is processor caused:

• Lay the film on the film feed tray in the

darkroom, and mark an arrow (↑) on

the corner of the film with a lead pencil

immediately before processing to

indicate the direction of film travel.

• It is also helpful to mark the emulsion

orientation (up [U] or down [D]), as

well as which side of the processor

feed tray (right [R] or left [L]) is being

used, when feeding the film into the

processor, e.g., ↑UR (emulsion up,

Note that processors in which MIN-R EV Mammography film will be processed should be

evaluated initially to determine whether films should be processed emulsion side up or emulsion

side down--which orientation provides the best uniformity and the fewest artifacts--before

processing clinical and quality control films.

• To thoroughly evaluate the entire processor, up to ten films should be exposed and

processed as described above: one pair emulsion side up on the right side of the film

right side feed tray)

© Eastman Kodak Company 9/03 Page 11

Page 12

KODAK MIN-R EV Mammography Film Conversion Guide and Processing Recommendations

feed tray, one pair emulsion up on the left side of the feed tray, one pair emulsion side

down on the right side of the film feed tray, and one pair emulsion side down on the left

side of the film feed tray.

• Expose the first two film pairs that will be processed as described above (emulsion side

up on right, emulsion side up on left) using the small moving grid device (18 x 24 cm

bucky) and use to evaluate whether artifacts are being generated by the x-ray unit in

conjunction with the small bucky.

• Careful analysis of all of the films will indicate whether emulsion side up or down gives the best

overall processing results.

• the protocol should subsequently be posted in the darkroom so all films are processed

consistently.

• All clinical images, sensitometric strips, and phantom images emulsion side

up or all emulsion side down.

• Determine which side of the processor and which orientation (emulsion up or down)

gives the best uniformity.

Film must be processed emulsion side down in the MIN-R Mammography, X-OMAT M-35AM,

and X-OMAT M-35M Processors. (Multiloaders may be excluded as film orientation during

processing is fixed.)

• Quality control films (phantom images and sensitometric strips) should also be

processed in a specific location with respect to the film feed tray (right side or left side,

with the edge of the film butted against the guide of the film feed tray).

Determine how much of the non-uniformity pattern is coming from the grid. Changes made to

the processor will not be able to improve upon this.

• Expose with and without the grid.

o Expose one film as normal and process emulsion side down on the non-gear

side of the processor.

o Make a table top exposure (set the loaded cassette on top of the table, place the

Lucite on top and make the exposure) and process emulsion side down on the

non-gear side of the processor.

Please contact the equipment manufacturer if the pattern is noticeable.

© Eastman Kodak Company 9/03 Page 12

Page 13

KODAK MIN-R EV Mammography Film Conversion Guide and Processing Recommendations

With grid—note non-uniform

pattern

Without grid

Please record your results in Section 1 of the Troubleshooting Non-Uniformity worksheet.

Step 2. Test the ventilation of the processor by following the procedure outlined below

Failure to properly vent the processor or multiloader exhaust can cause corrosion inside the

equipment (and any interfaced equipment) and can increase the probability of film artifacts.

Venting according to the specifications outlined in this bulletin will help minimize these problems.

Some equipment (like the KODAK X-OMAT 5000 RA Processor) may have different procedures

and specifications for exhaust measurement. Service documentation for a particular piece of

equipment always takes precedence over these recommendations.

Items Needed

1. Air Meter (TL-2431).

The above item can be ordered through Service Parts Management at 800-431-7278 (U.S.) or

585-724-7278 (Outside U.S.).

STEP ACTION

Make sure the processor/multiloader exhaust hose is connected to the building

1

exhaust system. Disposal of effluent air must comply with prevailing environmental

codes.

2 Power down the processor/multiloader.

3 Disconnect the exhaust hose from the rear of the equipment.

4

Connect the rubber hose on the Air Meter’s center connector.

5 Connect the L Tube to the rubber hose.

6

7

Make a 6.4 mm (1/4 in.) hole approximately 30.5 cm (12 in.) from the end of the

exhaust hose that will be connected to the processor.

Insert the L Tube into the hole (Step 6) so the end of the L Tube is flush with the

inside of the exhaust hose and perpendicular to the wall of the exhaust hose.

Important: Do not connect the exhaust hose to the processor when checking negative static

pressure.

© Eastman Kodak Company 9/03 Page 13

Page 14

KODAK MIN-R EV Mammography Film Conversion Guide and Processing Recommendations

Procedure: Measuring the Static Pressure

Step Action

1 Hold the air meter vertically to assure the greatest accuracy. Make sure the meter tubing

is not kinked.

2 Record the average of several readings.

3 Compare the average reading with the information in the table below (Measuring the

Static Pressure).

Important: The negative airflow in the processor exhaust duct must remain constant

when the processor is in the run, standby, and shut-down mode; therefore, the building

exhaust system must be on 24 hours a day and have the same negative airflow

throughout the day.

4 If the average reading is not within the tolerances specified in the table, adjust the Air Gap

Assembly to obtain the tolerances. If the tolerances still cannot be obtained and you must

exceed the maximum in order to obtain the correct negative static pressure, contact site

management personnel to have the building exhaust corrected.

Important: There must be an adequate air gap (maximum 5.08 cm / 2 inches) between

the processor exhaust hose and the building exhaust to prevent positive airflow from

flowing back into the processor. If the building exhaust venting system cannot meet

specifications, an Auxiliary Ventilation Fan Kit can be ordered through Service Parts

Management.

5 Reconnect the exhaust hose to the processor.

Measuring the Static Pressure

Negative Static Pressure of Water Head Duct Diameter

Minimum Maximum

76 mm (3 in) 0.76 mm (0.03 in.) 1.02 mm (0.04 in.)

102 mm (4 in.) 0.25 mm (0.01 in.) 0.51 mm (0.o02 in.)

© Eastman Kodak Company 9/03 Page 14

Page 15

KODAK MIN-R EV Mammography Film Conversion Guide and Processing Recommendations

(

Additional Notes

If the processor/multiloader is installed in a darkroom wall opening, the darkroom air pressure

must exceed the air pressure of the area outside the darkroom. This will:

• Prevent air from cascading through the processor and into the darkroom area.

• Assure correct dryer venting.

• Minimize chemical fume and vapor containment inside the processor and its dryer exhausting

system.

• Reduce film artifacts in the out-of-solution transport roller sections.

• Reduce corrosion of the processor/multiloader.

Room Ventilation

The room must have a minimum of 10 air exchanges each hour

Record your results in Section 2 of the Troubleshooting Non-Uniformity worksheet.

Step 3. Having ruled out the x-ray unit and grid and the ventilation as causes of the uneven

density, look at the films by reflected light to see if the uneven density pattern is visible.

To rule out the dryer as a cause, expose several additional flat field films, following the procedure

above. Process the first film in the orientation that gave you the best results in step 1 and catch it

as it exits the wash rack prior to entering the dryer section. Let it air dry.

.

The dryer pattern exhibited on the left is

visible by both reflected and transmitted light.

It may be minimized by following the

recommendations on pages 15-16 of this

document.

Examine the film to see if the non-uniformity changes. If it does, then follow the corrective actions

for dryer pattern. Record your results in Section 3 of the Troubleshooting Non-Uniformity

Worksheet.

Step 4. If the uneven density pattern does not change in step 3, try to isolate which rack in

the processor it may be occurring.

Record your results in Section 4 of the Troubleshooting Non-Uniformity worksheet.

Corrective Action (according to cause):

Symptom Cause Corrective Action

Grid non-uniformity

Shoreline Artifacts

visible in both transmitted

Dryer Temperature too high Turn down dryer temperature as

Contact your x-ray equipment

manufacturer.

low as possible to dry the film.

© Eastman Kodak Company 9/03 Page 15

Page 16

KODAK MIN-R EV Mammography Film Conversion Guide and Processing Recommendations

and reflected light)

Hesitation Marks/stub lines

(visible in transmitted light)

As per the guidance on page 255 of the ACR’s Mammography Quality Control Manual 1999 “If

significant film processor artifacts are detected, contact the person maintaining the processor or

the film processor service organization or dealer. Contact the X-ray equipment service person for

suggestions on additional testing procedures and for help in correcting X-ray equipment artifacts.

Gentle cleaning may be able to eliminate cassette or screen artifacts. Not all artifacts can be

totally eliminated. It may be helpful to use the concept of ALARA (as low as reasonably

achievable) when attacking artifacts. If they can be easily eliminated, they should. If the artifact is

difficult or expensive to eliminate and is subtle (not mimicking or obscuring clinical information), it

Air tubes blocked or obstructed Clean air tubes (Check at each

PM or as needed)

Try rotating several air tubes by

180 degrees

Wash rack squeegee rollers Squeegee rollers must be clean

and in good working order.

(Check imperfections, spring

pressure, smooth rotation, etc.)

Poor ventilation Check the ventilation as per

procedure in Service Bulletin

No. 101.

Improperly mixed, underreplenished developer and fixer

Change in velocity of the film

travel resulting from interference

within the film path

Malfunctioning rack or drive

component (roller, gear, chain,

drive motor or sprocket)

Incorrectly assembled or

damaged guide shoes

Guide Shoes out of adjustment

or out of alignment

Chemical buildup on rollers Inspect all rollers for dirt and

Warped or rough rollers

Worn roller bearings, shafts and

sideplates

Idler rollers not turning Adjust rack chains

Damaged gear or gudgeon

Improperly mixed or depleted

developer and/or fixer

Review mixing procedures

Verify that the replenishment

rates are set appropriately (as

per Service Bulletin No. 30

recommendations).

Repair or replace rollers,

bearings, shafts, sideplates,

gears, gudgeons and guide

shoes

Check that the guide shoes are

not loose and are positioned in

the correct direction

Check that the developer rack

and developer/fixer crossover

are assembled correctly

buildup of dried chemicals.

Clean the rollers according to

manufacturer’s

recommendations.

Check that the sideplates of the

guide shoes are correctly

oriented

Review mixing procedures

Verify that the replenishment

rates are set as per Service

Bulletin No. 30

recommendations.

© Eastman Kodak Company 9/03 Page 16

Page 17

KODAK MIN-R EV Mammography Film Conversion Guide and Processing Recommendations

may be tolerable. The medical physicist should consult with the interpreting physician as to

whether the artifact is tolerable.”

Troubleshooting Non-Uniformity Worksheet

Section 1). Determine if the artifact is coming from the processor or the X-ray exposure

equipment

After completing the tests on pages 10-12, please compare the test films and record your

results below:

Grid versus non bucky comparison: ________________________________________________

Emulsion Up versus Emulsion Down comparison: _____________________________________

Non-gear versus gear side of processor: _____________________________________________

Section 2). Determine the ventilation of the processor

Record your results and compare to Kodak’s recommendations on page 14:

Negative static pressure: _________ Results within Kodak’s recommendations? Y N

Section 3) Ruling out the dryer as a cause of the uneven density pattern

Perform the test as outlined on page 15.

Examine the resulting films to see if the uneven density pattern changes.

Record your results:

Did the dryer pattern change? Yes No

If it does, then follow the corrective action for dryer pattern on page.

Section 4) If the uneven density pattern does not change, try to isolate which rack in the

processor in which it may be occurring.

Results:

Pattern was isolated in the: developer rack fixer rack wash rack

Could not isolate pattern.

If you cannot isolate the cause of the pattern, please send a copy of this form, your test films and

the completed Information Needed by Kodak to Facilitate Troubleshooting form to:

Eastman Kodak Company

Health Imaging Technical Support

343 State Street

Rochester, NY 14650-1131

© Eastman Kodak Company 9/03 Page 17

Page 18

KODAK MIN-R EV Mammography Film Conversion Guide and Processing Recommendations

8. Other Mammography Quality Control Tests

• Emulsion Log

See KODAK MIN-R EV Film System User Guide (KODAK Publication #, Cat #).

• Phantom Image Evaluation

Perform the test as described in the Mammography Quality Control Manual for

Radiologists, Medical Physicists, and Technologists, American College of Radiology

1999 (ACR QC Manual) page 258.

• Note any changes in the number of test objects seen. Re-establish the baseline

numbers.

• The density difference on the phantom may be significantly higher due to the high

contrast of KODAK MIN-R EV Film.

• Darkroom Fog Test

Perform the test as described in the KODAK MIN-R EV Film System User Guide

(KODAK Publication # , Cat # ). Please note that a 7.5 watt bulb is recommended with

KODAK mammography film.

• Analysis of Fixer Retention in Film

Perform the test as described in the KODAK MIN-R EV Film System User Guide

(KODAK Publication # , Cat # ).

The conversion to MIN-R EV Film includes a conversion to new KODAK MIN-R EV

Screens. The following tests should be performed:

• Screen-Film Contact

Perform the test as described in the KODAK MIN-R EV Film System User Guide.

• Uniformity of Screen Speed

Perform the test as described in the KODAK MIN-R EV Film System User Guide

(KODAK Publication #, Cat # ).

For More Information:

Outside U.S. please contact your local Kodak representative.

U.S. Distributors Contact:

Health Imaging

Technical Support

1-800-328-2910 (option 1 for faxback)

CES Personnel Contact:

Film Handling TAC

U.S.: 1-800-328-2910

Canada: 1-800-433-1414

Kodak, MIN-R, and X-OMAT are trademarks.

Eastman Kodak Company, 2003

© Eastman Kodak Company 9/03 Page 18

Loading...

Loading...