Kodak I810 - Scanner Firmware - PC, Scanners i800 Series, I820, I830, I840 User Manual

...

i800 Series Scanners

A-61169

Part No. 9E3959

CAT No. 129 5237

User’s

Guide

Safety and Installation Information for the Kodak i800 Series Scanners

IMPORTANT: Equipment shall be installed by qualified personnel.

WARNING: Dangerous voltage. Disconnect the main power before installation.

WARNING: Before changing a lamp, always power down the scanner and let it cool a minimum

of 10 minutes before proceeding (see Warning Labels below).

CAUTION:

POZOR: Horký povrch -- nedotýkat se

DIKKAT:

CAUTION

POZOR:

DIKKAT: Sicak yüzey, dokunmayin

Hot surface, avoid contact

Hareketli parçalar, dokunmayin

: Moving parts, avoid contact

Pohybující sečástie -- nedotýkat se

User Precautions

Users and their employer need to observe the common sense precautions applicable to the operation of

any machinery. These include, but are not limited to, the following:

• Do not wear loose clothing, unbuttoned sleeves, etc.

• Do not wear loose jewelry, bracelets, bulky rings, long necklaces, etc.

• Hair length should be kept short, using a hair net if needed, or tying long hair up in a bundle.

• Remove all other loose objects from the area that could be drawn into the machine.

• Take sufficient breaks to maintain mental alertness.

• Follow the recommended Kodak cleaning procedures. Do not use air, liquid or gas spray cleaners.

These cleaners only displace the dust, dirt or debris to another location within the scanner, which

could cause the scanner to malfunction.

Supervisors should review their practices and make compliance with these precautions a part of the job

description for operation of the Kodak i800 Series Scanners or any mechanical device.

ElectroMagnetic Compatibility Statements

European Union

This is a Class A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

United States

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to

correct the interference at their own expense.

January 2005 1

Taiwan

Japan Class A

This equipment is in the Class A category (Information Technology Equipment to be used in commercial

and/or industrial areas) and conforms to the standards set by the Voluntary Control Council for Interference

by Information Technology Equipment aimed at preventing radio interference in commercial and/or

industrial areas.

Consequently, when used in a residential area or in an adjacent area thereto, radio interference may be

caused to radio and TV receivers, etc.

Read the instructions for correct handling.

Peoples Republic of China Class A

January 2005 2

Table of Contents

1 Introduction ......................................................................1-1

Product description ............................................................ 1-2

Standard features ..............................................................1-2

Standard configurations..................................................... 1-3

Transport speed................................................................. 1-3

Speeds and resolutions .....................................................1-3

Scanner specifications....................................................... 1-4

Dimensions ..................................................................1-4

Minimum clearances .................................................... 1-4

Acoustic noise.............................................................. 1-4

Electrical ......................................................................1-4

Power system connection ............................................ 1-4

Environmental .............................................................. 1-4

External components ......................................................... 1-5

Back of scanner ................................................................. 1-5

Environmental information and equipment disposal ..........1-6

2 Using the Scanner ...........................................................2-1

Turning on the scanner...................................................... 2-1

Document preparation .......................................................2-2

Acceptable document materials.........................................2-3

Recommended paper weights ...........................................2-3

Acceptable document sizes ............................................... 2-3

Maximum document batch height for automatic feeding ...2-4

Downward and upward curl documents.............................2-4

Adjusting the side guides on the input tray ........................ 2-4

Adjusting the output tray .................................................... 2-5

Scanning documents .........................................................2-6

Loading long documents in the feeder............................... 2-7

Continuous and manual feeding ........................................ 2-7

Feeding thick documents................................................... 2-8

A-61169 January 2005 i

3 Operator Control Panel Functions .................................3-1

Enabling and disabling the scanner................................... 3-2

Enabling the scanner ...................................................3-2

Disabling the scanner ..................................................3-3

Navigating through the functions on the control

panel menu ..................................................................3-4

Accessing information........................................................ 3-5

Lowering the elevator tray..................................................3-5

Using the Diagnostics Settings menu ................................ 3-5

Performing a self-test or extended self-test .................3-6

Running in count-only mode ........................................3-6

Performing a print test.................................................. 3-7

Performing a patch test................................................ 3-8

Using the Settings menu....................................................3-9

Changing the alarm volume ......................................... 3-9

Changing the display contrast.................................... 3-10

Changing the SCSI ID................................................ 3-10

Changing the SCSI termination .................................3-11

Setting the elevator tray position................................ 3-12

Calibrating the scanner.................................................... 3-13

Jogging the transport ....................................................... 3-14

Programmable key assignments......................................3-14

4 Document Printer and Patch Reader .............................4-1

The Document Printer........................................................4-1

Printing information ...................................................... 4-1

Horizontal print position ...............................................4-3

Purging the ink cartridge ..............................................4-4

Replacing the ink cartridge ..........................................4-5

Replacing the ink blotter strips..................................... 4-7

Setting the printer position ...........................................4-9

The Patch Reader............................................................4-10

Patch types ................................................................4-10

Patch code placement ...............................................4-11

Setting the Patch Reader position .............................4-12

ii A-61169 January 2005

5 Maintenance ..................................................................... 5-1

Cleaning the paper path.....................................................5-1

Cleaning the upper transport area ..................................... 5-2

Cleaning the vertical transport area ................................... 5-5

Cleaning the transport area ...............................................5-6

Cleaning the printer and patch head.................................. 5-9

Cleaning the imaging guides............................................5-10

Maintenance and replacement procedures......................5-11

Replacing the feed module and feed module tires...........5-12

Replacing the feed module ........................................5-13

Replacing the feed module tires ................................5-13

Separation roller and tires................................................5-15

Replacing the separation roller ..................................5-15

Replacing the separation roller tires ..........................5-16

Changing the separation pad........................................... 5-16

Cleaning the feed module tires and separation roller

roller tires ...................................................................5-17

Replacing lamps ..............................................................5-17

Replacing the imaging guides..........................................5-20

Customizing the side guides for self-centering feeding ...5-21

Changing the output tray side guides ..............................5-23

Ordering supplies.............................................................5-25

6 Troubleshooting/Messages ............................................ 6-1

Clearing the document path...............................................6-1

Message Listing................................................................. 6-5

Document sensor location ...............................................6-10

Problem solving chart ......................................................6-11

A-61169 January 2005 iii

1 Introduction

This User’s Guide provides information and operator procedures for the

Kodak i800 Series Scanners. The information in this guide is for use with

all of the i800 Series Scanners unless otherwise noted.

Chapter 1, Introduction provides general information about the i800

Series Scanners including a product description, features and benefits,

specifications, an overview of external components and user precautions.

Chapter 2, Using the Scanner includes information on how to

prepare your documents for scanning, elevator tray and output tray

adjustments, turning the scanner on and off and how to scan documents.

Chapter 3, Operator Control Panel Functions provides a list of the

icons found on the Operator Control Panel and what functions can be

performed using the Operator Control Panel.

Chapter 4, Document Printer and Patch Reader provides

instructions for using and changing the location of the Document Printer 1

and the Patch Reader. This chapter also instructs how to change and

purge the ink cartridge.

Chapter 5, Maintenance provides complete maintenance procedures

for the i800 Scanner, including replacement procedures for the feeder

module and tires, separation roller and tires, exposure lamps and imaging

guides.

Chapter 6, Troubleshooting/Messages provides a message listing, a

problem solving chart and how to clear a document jam.

A-61169 January 2005 1-1

Product description

Standard features

The Kodak i800 Series Scanners are ideal for operation with bi-tonal

and/or color/grayscale documents, documents with shaded backgrounds

or foregrounds, and mixed document sets. These scanners offer a new,

user interface and Kodak-patented technologies that produce high quality

production images.

The following features are standard on the Kodak i800 Series Scanners.

• Simultaneous output of color/grayscale and bi-tonal images (i820 and

i840 scanners only)

• SurePath paper handling, featuring:

– 1,000-sheet QuickSet elevator that automatically returns to the

batch level you set

– Automatic feeder with single-sheet feeding and operator-assisted

document stacks. Allows you to set the elevator level to

accommodate 25-, 250- 500-, 750- 1000-document stacks

– 3D Multi-feed Detection, using ultrasonic technology, offering

outstanding reliability

– Flexible document feeding center- and edge-aligned

– An adjustable output tray that handles documents of varying sizes

• The Tri-Color Plus Array provides, in one pass, true color and bi-tonal

images

• Zone Processing allows operator selection of a fixed subsection or

zone (i820 and i840 scanners only)

• PerfectPage, now with iThresholding (color/grayscale and bi-tonal)

• Built-in iThresholding, Adaptive Threshold Processing (ATP), image

compression, despeckle, error diffusion, and dithering for bi-tonal

scanning

• Electronic Color Dropout

• Color on-the-fly

• Accepts custom color tables

• A wide variety of image output resolutions in bi-tonal and

color/grayscale are available

• Easily upgradeable models, at your site, with minimal downtime

• Bundled ISIS and TWAIN drivers

• Friendly operator interface only seven operator control buttons

• Ease-of-use easy replacement of consumables

• Illumination tracking with calibration alert

• Diagnostics and modular design simplify service and minimize

downtime

• Image address with Patch Reader support

• Document Printer 1 imprinting on scanned documents

1-2 A-61169 January 2005

Standard

configurations

Transport speed

Four models of the Kodak i800 Series Scanners are available:

• Kodak i810 Scanner (bi-tonal) provides bi-tonal scanning with

throughput speeds up to 120 ppm

• Kodak i820 Scanner provides color/grayscale and bi-tonal

scanning simultaneously with throughput speeds up to 120 ppm

• Kodak i830 Scanner (bi-tonal) provides bi-tonal scanning with

throughput speeds up to 160 ppm

• Kodak i840 Scanner provides color/grayscale and bi-tonal

scanning simultaneously with throughput speeds up to 160 ppm

Following is the minimum and maximum paper transport speed and

capacity of the scanner:

Dimension Minimum Maximum Operational Mode

Length 6.4 cm (2.5 in.) 27.9 cm (11 in.) Auto-feed

Length 27.9 cm (11 in.) 43.2 cm (17 in.) Auto-feed with extensions

Length 43.2 cm (17 in.) 76.1 cm (30 in.) Operator assistance

Width 6.4 cm (2.5 in.) 8.9 cm (3.5 in.) Operator assistance

Speeds and

resolutions

Scanner Throughput

Width 8.9 cm (3.6 in.) 30.5 cm (12 in.)* Auto-feed

* The scanner transport will allow feeding a 30.5 cm (12-inch)-wide

document but will only scan an area of 29.7 cm (11.7 inches) in width.

The chart below provides speeds and resolutions for the i800 Series

Scanners:

Speed (ips) Bi-tonal

(ppm)

i810 120

80

45

i820 120

80

45*

i830 160

106

60

i840 160

106

60*

21

14

14

21

14

14

28

18.67

18.67

28

18.67

18.67

Resolution (dpi)

200

300, 240

400

200

300, 240

400

200

300, 240

400

200

300, 240

400

Color/Grayscale

Resolution (dpi)

N/A

200, 150, 100

200, 150

200

N/A

N/A

N/A

200, 150, 100

300*, 200, 150, 100

300, 200

* Throughput at these settings may vary based on system limitations.

A-61169 January 2005 1-3

Scanner specifications

Dimensions

Minimum clearances

Front Rear Right Side Left Side Top

Normal

Operation

Maintenance

N/A 4 in.

40 in.

102 cm

Following are the dimensions and clearances for the Kodak i800 Series

Scanners:

Height: 124 cm (49 in.)

Width: 66 cm (26 in.)

Depth: 127 cm (50 in.)

Weight: 204 kg (450 lbs) including packaging

188 kg (414 lbs) without packaging

The table below provides the minimum clearances for normal operation

and maintenance of the i800 Series Scanners:

10 cm

4 in.

10 cm

4 in.

10 cm

24 in.

61 cm

4 in.

10 cm

4 in.

10 cm

10 in.

25 cm

24 in.

61 cm

Acoustic noise

Electrical

Power system

connection

Environmental

• Operator position standby mode:

– Sound Pressure Level (L

): 39.8 dB(A)

A

• Operator position full system operating mode:

– Sound Pressure Level (L

– Instantaneous Peak Values >

• Sound Power Level (L

WA

): 65.4 dB(A)

A

):

130 dB(C) None

– Standby 56.4 dB(A)

– Full System 72.0 dB(A)

NOTE: All data was measured in accordance with DIN 45635, ANSI

S12.10-1985, and ISO 7779 in a hemi-anechoic chamber.

100 – 127 V, 6.5 A, 50/60 Hz

200 – 240 V, 3.5 A, 50/60 Hz

This product is also designed for Norwegian IT power system with phaseto-phase voltage 230V.

Temperature: 15 to 35°C (59 to 95°F)

Humidity: 15 to 76% (dry bulb)

Altitude: up to 8000 feet (2438 meters)

1-4 A-61169 January 2005

External components

Operator control panel

Side guides

Elevator tray

See the illustration below for the location of the external components of

the scanner.

Top cover

Swing out door

Output tray

Feed module

Feeder extensions

Bi-fold door

Power switch

Gap release lever

Back of scanner

SCSI Connector

Power cord

connector

A-61169 January 2005 1-5

Environmental

information and

equipment disposal

• The Kodak i800 Series Scanners are designed to meet worldwide

environmental requirements.

• Guidelines are available for the disposal of consumable items that are

replaced during maintenance or service; follow local regulations or

contact Kodak locally for more information

• The product packaging is recyclable.

• Parts are designed for reuse or recycling.

• The Kodak i800 Series Scanners contain lead in the circuit boards

and mercury in the lamps. Disposal of these materials may be

regulated due to environmental considerations. For disposal or

recycling information, please contact your local authorities or visit the

Electronics Industry Alliance website: www.eiae.org.

1-6 A-61169 January 2005

2 Using the Scanner

This chapter provides the following operational procedures:

• Turning on the scanner

• Document preparation

• Adjusting the input tray, side guides and output tray

• Scanning documents

• Feeding long documents

• Continuous and manual feeding

Other functions, such as calibration, using the programmable keys, using

multi-feed detection, setting the elevator level, etc. can be performed

using the Operator Control Panel. See Chapter 3, Operator Control Panel

Functions for procedures.

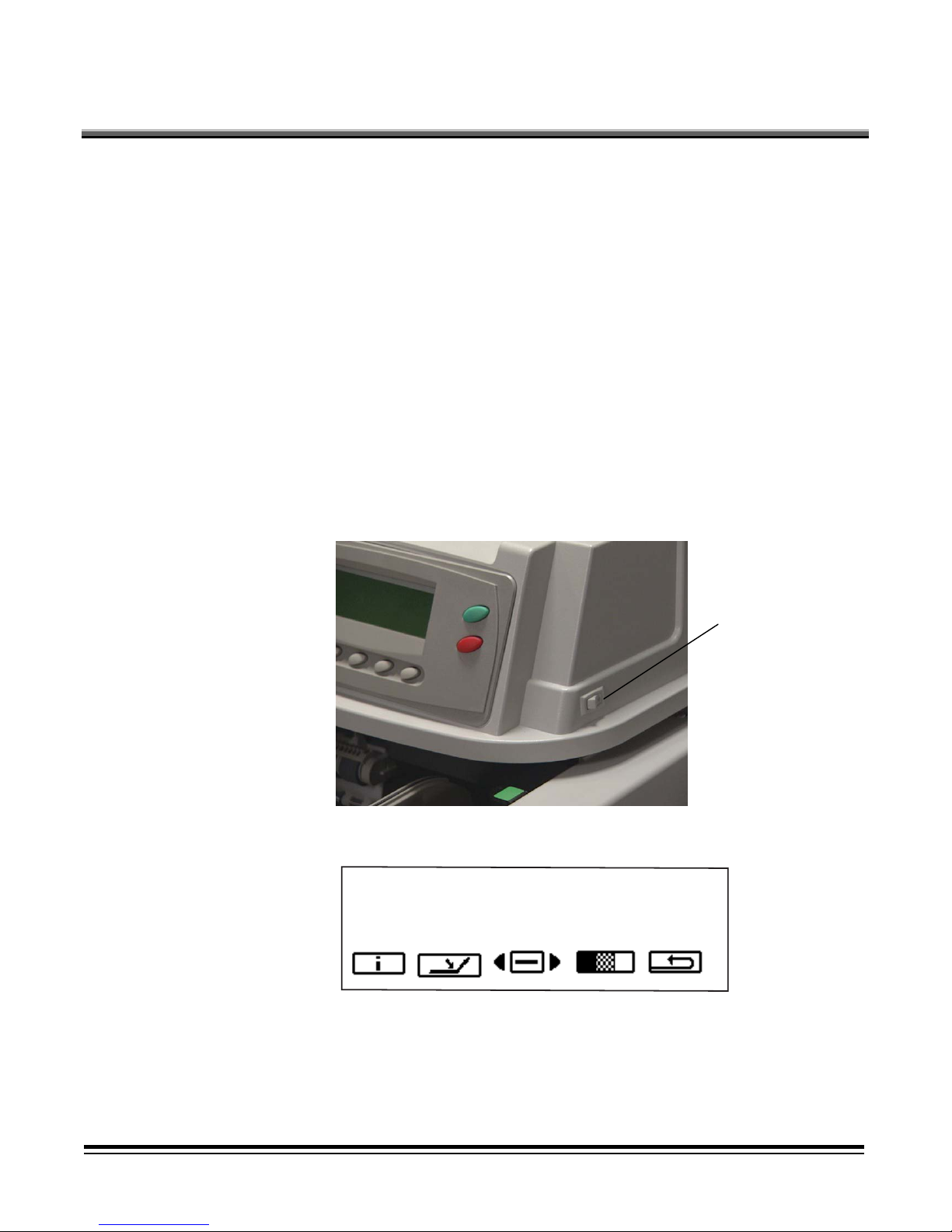

Turning on the scanner

To turn on the scanner:

• Toggle the power switch to the On position.

On/Off switch

When the menu bar is displayed on the Operator Control Panel, the

scanner is Ready.

IMPORTANT: Always power-up the scanner to its Ready state before

A-61169 January 2005 2-1

powering-up the host computer.

Document preparation

Kodak scanners have been tested with a range of documents that

represent the broad spectrum of document types found in the most

common business applications. Optimal scanner performance is

achieved when you scan documents within the recommended document

specifications listed below. Scanning documents that are outside of these

specifications may lead to undesirable results in terms of scanner

reliability, image quality, and/or consumable life.

Before you start scanning, make sure the documents can be fed through

the scanner easily. Best performance is obtained by feeding a good,

clean lead edge. This means the side of the paper which enters the

feeder first should be in the best possible condition.

Use the guidelines below when preparing your documents for scanning.

• Remove staples, rubber bands, loose mending tape or paper clips.

• Straighten wrinkled edges and tape any torn documents.

• Trim ragged edges (steno paper, perforated edges, tractor feed

edges). If ragged edges cannot be trimmed, it is suggested that you

try different feeding orientations to determine which orientation feeds

best.

• A batch of documents to be fed into the scanner must be arranged to

have a common leading edge. Documents may be left-, right-, or

center-aligned in the elevator tray allowing the documents to be fed

into the scanner one at a time.

IMPORTANT: Proper alignment of documents is very important.

Documents must be fed under both feed module tires.

Gap release lever

Feed module tires

• Torn, damaged, or crushed pages can be transported successfully

through the scanner. However, no scanner can transport every

possible type of damaged paper. If damaged documents do not feed

through the transport automatically, feed the documents manually.

Use of the gap release lever may be required.

2-2 A-61169 January 2005

• For heavily damaged documents, a clear document protector can be

used with the following limitations:

– Manual feeding is recommended when using a clear document

protector.

– The document in the clear document protector must be fed under

both feed module tires.

– Multi-feed detection must be disabled when manually feeding a

document in a clear document protector.

NOTE: When using a document protector, feed the fold of the

document protector first rather than the open end.

The correct document preparation when using a document protector

is illustrated below:

Small or damaged

Clear

Document

Protector

document

Acceptable document

materials

Recommended paper

weights

Acceptable document

sizes

• Original and recycled papers

• Photographic papers

• Bond (i.e., laser, inkjet, etc.)

• Carbonless paper (some types of carbonless papers contain

chemicals that may react with feed module and separation tires

possibly requiring more frequent tire changes)

• Offset printing papers (i.e., newspapers, magazine pages)

The elevator tray handles a broad range of paper weights, from 50g

(13 lb.) bond paper to 200g (110 lb.) index paper. Heavier documents

may be fed up to 0.76 mm (0.030 in.). Manual feeding mode, using the

gap release lever, may be required to feed heavier paper weights.

• Length:

– Maximum of 76.2 cm (30 in.) with operator-assisted document

feeding and stacking. 43.2 cm (17 in.) is the maximum length for

unattended document feeding.

– Minimum of 6.4 cm (2.5 in.).

• Width:

A-61169 January 2005 2-3

– Maximum of 29.7 cm (11.7 in./image capture – 12 in./transport)

(A3 width)

– Minimum for automatic feeding of 8.9 cm (3.5 in.)

– Minimum for manual feeding of 6.4 cm (2.5 in.)

Maximum document

batch height for

automatic feeding

Downward and upward

curl documents

Adjusting the side

guides on the input

tray

When feeding batched documents, the maximum height of the batched

documents is 10.2 cm (4 in.), approximately 1000 sheets of 75g (20 lb.)

paper. The elevator tray can be set to accommodate 25-, 250- 500-, 7501000-document stacks.

The elevator tray can handle some amount of lead edge curl, but to

ensure reliable feeding the curl should be at a minimum. It is suggested

that you try and minimize the curl before scanning by stacking the

documents on a flat surface for a period of time to help flatten the

documents.

To accommodate multiple applications with variable feeding

requirements, the side guides can be adjusted for center- or edgefeeding. Center-feeding is recommended for best paper handling

performance. The side guides can be moved together or independently.

1. Pull the guides all the way out and then push them together (toward

the center) to reset.

2. Open the side guides slightly wider than the documents you will be

feeding.

3. Place the documents in the elevator tray.

4. Adjust the side guides to fit the documents.

2-4 A-61169 January 2005

Adjusting the output

tray

Different paper types stack differently. The output tray can be set with

either the front or the rear higher for best stacking.

To angle the output tray so the back of the output tray is higher:

1. Lift the output tray up and pull it out of its current slot.

2. Reset it in the slot that matches the desired height.

To angle the output tray so the front of the output tray is higher:

• Lift the front of the output tray up, swing the height adjustment leg out

and insert it into the groove below the output tray.

NOTE: Short side guides are standard on the output tray. However, tall

side guides and self-centering parts are included and can be

changed by you. See Chapter 5, Maintenance for procedures.

A-61169 January 2005 2-5

Scanning documents

Before you scan documents, be sure the menu bar is displayed on the

Operator Control Panel.

Operator Control

panel

Documents must be fed under both feed module tires. For faster

throughput, feed documents into the elevator tray in landscape orientation

(longer side as the leading edge).

To start scanning:

1. Enable the scanner from the host.

2. Place the documents to be fed in the elevator tray.

3. Press Start/Resume.

Start/Resume

Stop/Pause

NOTES:

• Documents must be fed under both feed module tires.

• Do not lean on the elevator tray and/or document extenders while the

scanner is running. If this happens, the elevator tray may make some

noise and stop in position. See the Problem Solving Chart in Chapter

6, Troubleshooting/Messages for procedures on recovery from this

situation.

• Use caution when feeding small documents; small documents may fall

through the slots of the elevator tray and cannot be easily retrieved.

To stop scanning:

• Press Stop/Pause.

2-6 A-61169 January 2005

Loading long

documents in the

feeder

Continuous and

manual feeding

The feeder accommodates documents up to 76.2 cm (30 in.) in length. To

feed documents longer than 30.5 cm (12 inches):

1. Pull out the document extenders.

Document

extenders

2. Place the documents in the elevator tray.

NOTE: Operator assistance is required when feeding documents longer

than 43.2 cm (17 in.).

Continuous feeding allows you to place additional batches of documents in

the elevator tray (with operator assistance). Any time during continuous

scanning, additional documents can be added at the bottom of the input

stack. The elevator position must be set to 25 for continuous and manual

feed operations.

To add to a batch of documents:

• Add a small stack of documents to the bottom of the batch in the

elevator tray, by gently lifting the corner of the stack and adding the

documents underneath the last document.

Manual feeding is recommended when you have a heavily damaged

document, envelope or other thick documents, which may require

additional clearance. Follow the guidelines for document size, weight,

quantity, etc. outlined in the section entitled, “Document preparation”

earlier in this chapter.

A-61169 January 2005 2-7

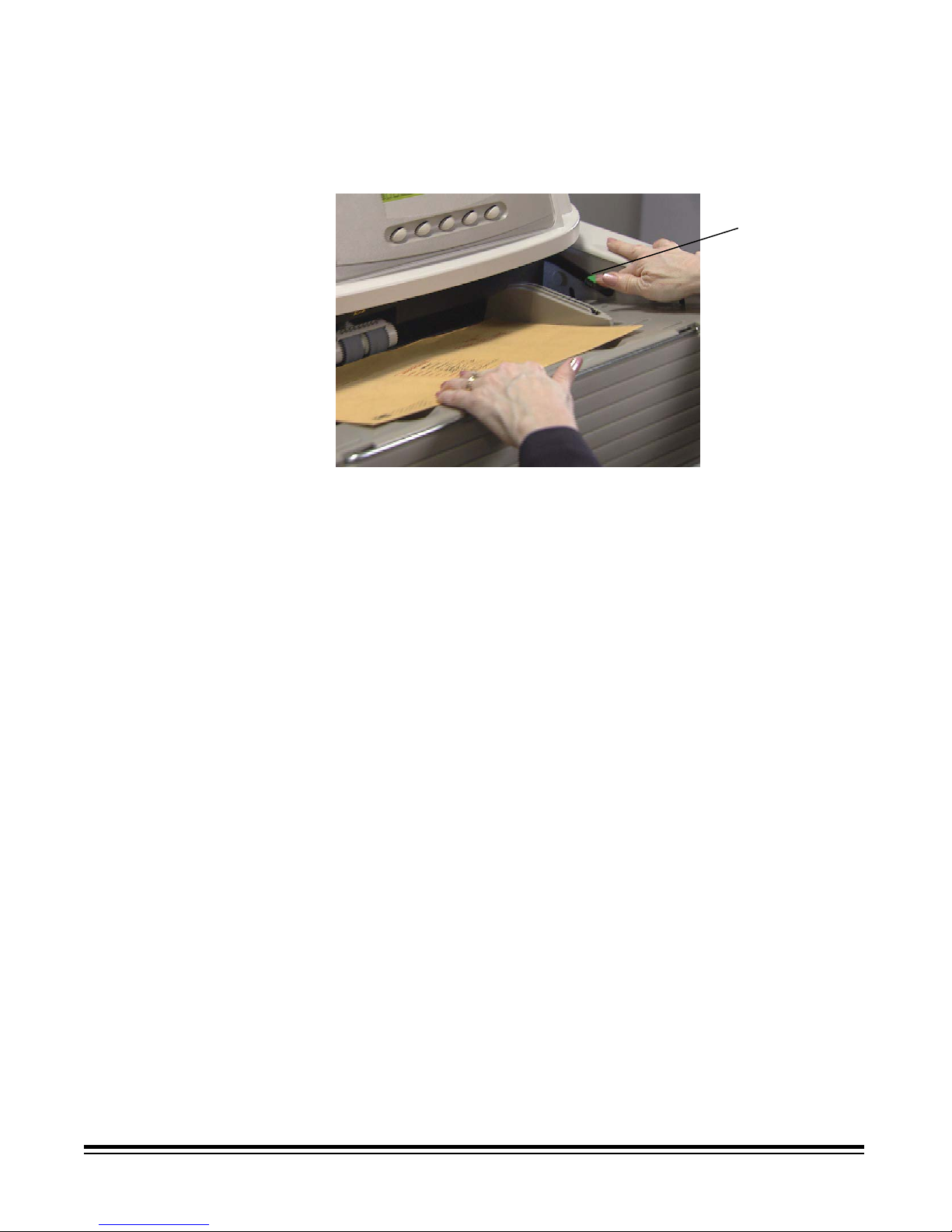

Feeding thick

documents

To feed thick documents:

1. Press and hold the gap release lever this provides more clearance

to ease document feeding.

Gap release lever

2. Push the envelope/thick document into the transport. If more than one

document is to be scanned, feed them into the transport one at a time.

3. After the documents have been fed into the transport, release the gap

release lever.

NOTE: Before feeding envelopes:

− Disable multi-feed detection via the host or programmable

button (if the scanner is set up for multi-feed detection.)

− Be sure the envelope is empty and unsealed.

− When using the gap release lever, the maximum thickness

allowed for a document is 0.76 mm (.030 inches).

2-8 A-61169 January 2005

3 Operator Control Panel Functions

There are a variety of functions available from the Operator Control

Panel. This chapter provides procedures and information for:

• Enabling and disabling the scanner

• Control Panel functions overview

• Navigating through the functions on the Control Panel menu

• Accessing information

• Lowering the elevator tray

• Using the Diagnostics Settings menu

• Performing Diagnostic functions:

− Performing a self-test or extended self-test

− Running in count-only mode

− Performing a print test

− Performing a patch test

• Using the Setting menu:

− Changing the alarm volume

− Changing the display contrast

− Changing the SCSI ID

− Changing the SCSI termination

− Setting the elevator tray position

• Calibrating the scanner

• Jogging the transport

• Programmable key assignments

A-61169 January 2005 3-1

Enabling and disabling

the scanner

Enabling the scanner

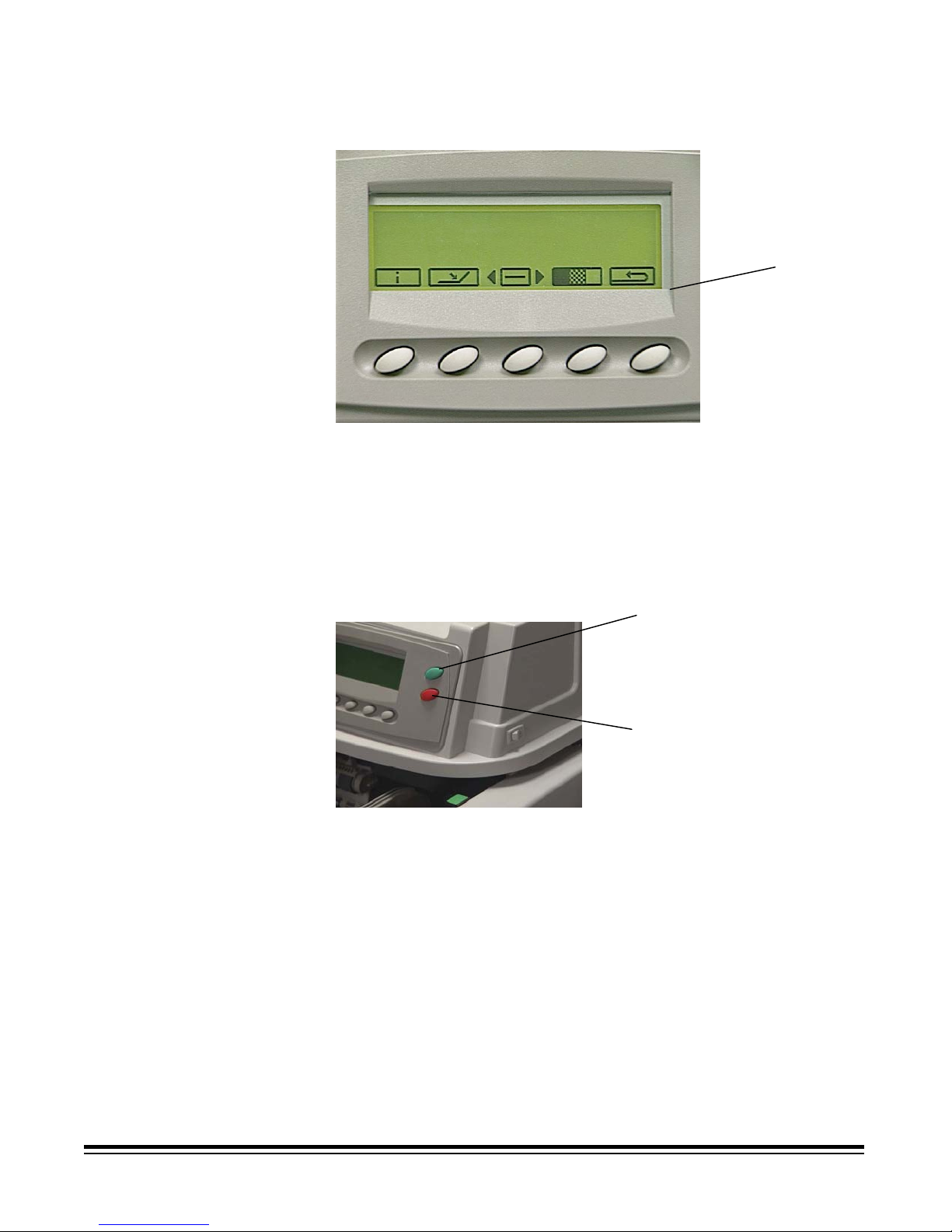

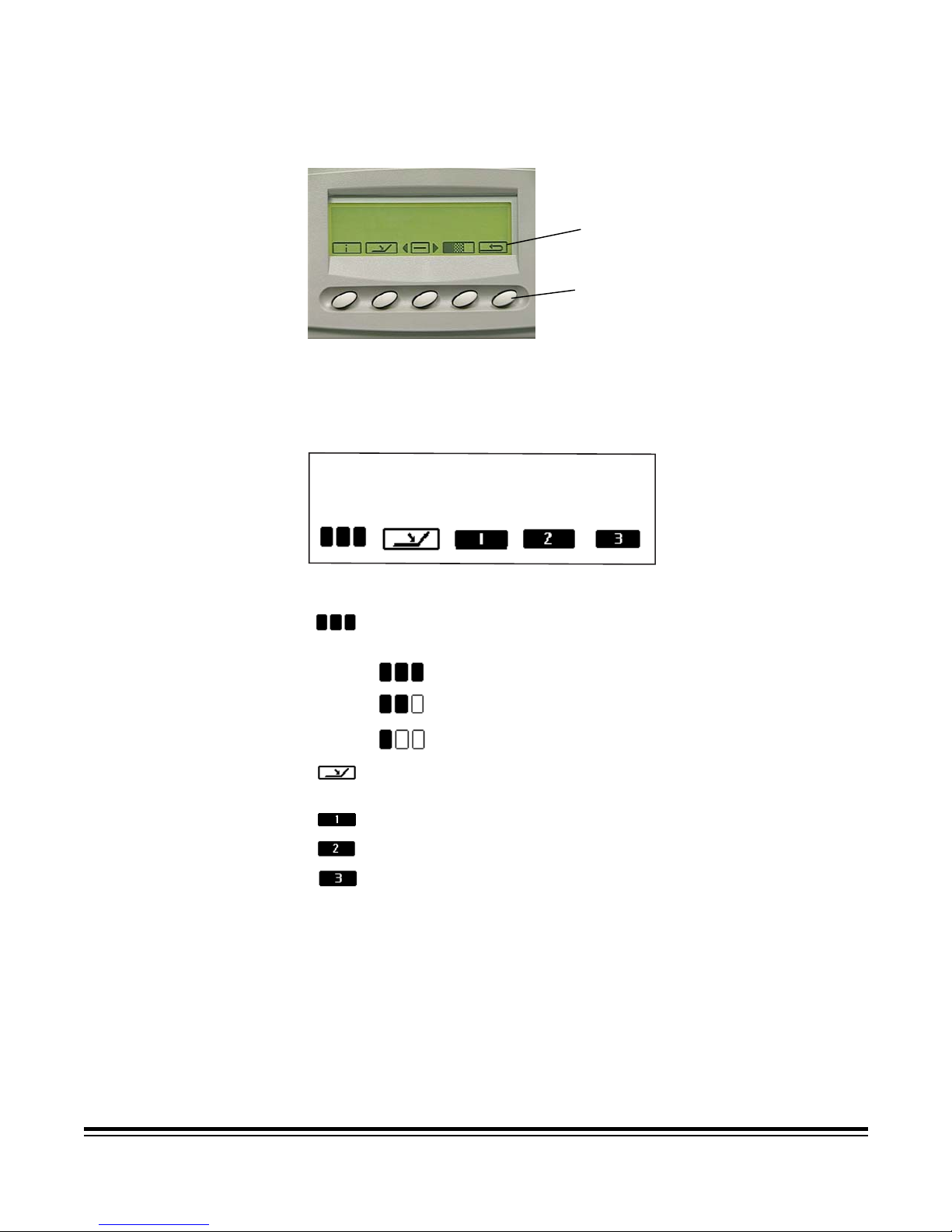

The five buttons at the bottom of the Control Panel correspond to the

icons above the buttons To activate the icons, press the corresponding

button.

Icons

Control panel

buttons

The scanner can only be enabled from the host computer. When the

scanner is enabled, you can change the image address level, override

the elevator setting and use the programmable keys. When enabled, the

icons on the Operator Control Panel will look like this:

These functions can be performed when the scanner is enabled:

Increments the image address level. Depending on the image

address level the icon may appear as follows:

Lowers the elevator tray if it is not already in the lowest

indicating the next image address is level 3

indicating the next image address is level 2

indicating the next image address is level 1

position.

Performs the first programmable function.

Performs the second programmable function.

Performs the third programmable function.

NOTE: Programmable keys are set-up during application setup. Check

with your system administrator for the function of each

programmable key. Possible programmable key assignments

are as follows:

• No scanner functionality (default)

• Scanner End-of-Job

• Terminate Batch

• Omit Multi-feed Detection on Next Document

• Omit Printing on Next Document

• Omit Patch Reading on Next Document

3-2 A-61169 January 2005

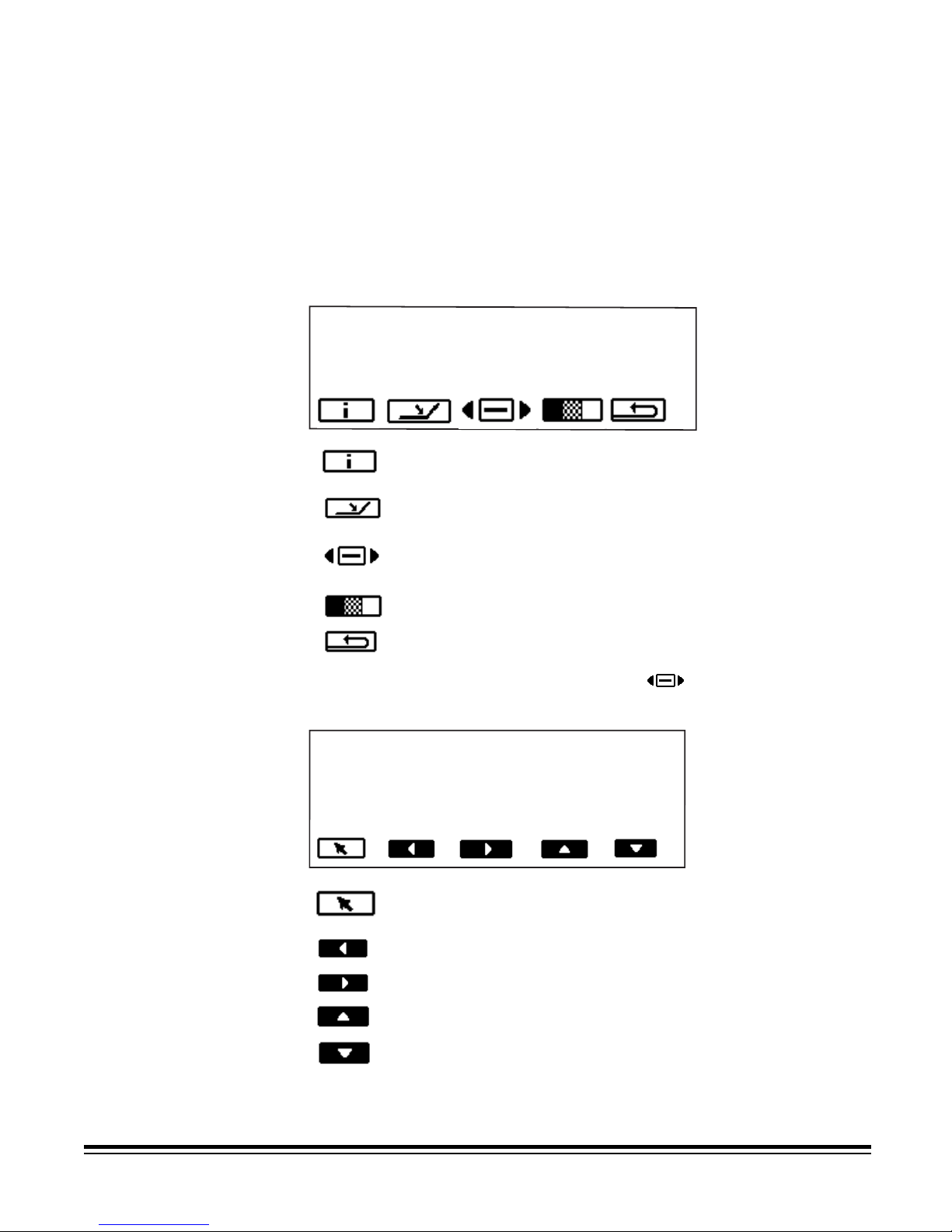

Disabling the scanner

The scanner can be disabled from the host computer or the scanner, if

the end-of-job function is assigned to one of the programmable keys.

When the scanner is disabled, you can display scanner information, lower

the elevator tray, use the Diagnostics Settings menu, calibrate the

scanner and jog the transport.

Disabled scanner functions

When the scanner is first powered on and disabled, the following icons

will be displayed. These functions can only be performed when the

scanner is disabled.

Displays information: including the last image address,

meter values, scanner serial number.

Lowers the elevator tray if it is not already in the lowest

position.

Displays the Diagnostics Settings menu, which allows

you to perform additional functions.

Calibrates the scanner.

Temporarily turns on the transport to help clear a

document jam.

When the Diagnostics Settings menu button

is selected, these

functions are available:

Exit Diagnostics Settings

Performs the selected function. This button is referred

to as Return.

Moves left to the next selectable item (left arrow).

Moves right to the next selectable item (right arrow).

Moves up to the next selectable item (up arrow).

Moves down to the next selectable item (down arrow).

A-61169 January 2005 3-3

Navigating through the

functions on the

control panel menu

The left and right arrows navigate along the top of the menu bar.

In this example, the left and/or right arrow will rotate through the options

of Exit, Diagnostics and Settings.

Exit Diagnostics Settings

Run self test

Run extended self test

Run count only

Run print test

The up and down arrows navigate through the menu selections.

In this example, the up and/or down arrow will rotate through the options

of Run self test, Run extended self test, Run count only, Run print test,

Run patch test.

NOTE: Only four options can be displayed at a time. Selecting the down

arrow will display additional options.

Exit Diagnostics Settings

Run self test

Run extended self test

Run count only

Run print test

• The Return arrow performs the selected function. In the

example above, after you select Run print test, select the Return

arrow to perform a print test.

3-4 A-61169 January 2005

Accessing information

Lowering the elevator

tray

Using the Diagnostics

Settings menu

The information icon will display information including the last image

address, meter values, and scanner serial number.

• Select this icon

to display information.

0.0.0.1

Pages: 22453

Hours on: 447

Hours feeding: 32

S/N: 76858463

The level of the elevator tray can be set to accommodate various sizes of

document batches.

• Select this icon

NOTE: This will temporarily override the setting, which is configured for

elevator position from the Settings menu. The next time the

scanner is enabled from the host the menu setting will resume.

The Menu icon displays the Diagnostics Settings menu.

to lower the elevator tray to its lowest position.

Exit Diagnostics Settings

The following Diagnostics functions are available:

• Performing a self-test

• Performing an extended self-test

• Running in count-only mode

• Performing a print test

• Performing a patch test

A-61169 January 2005 3-5

Performing a self-test or

extended self-test

Running in count-only

mode

You can perform a self-test or an extended self-test on the scanner. The

self-test is the same test performed when the scanner is powered-up; the

extended self-test is a more thorough test.

To perform a self-test or extended self-test:

1. Select the Diagnostics Settings menu

2. Use the right or left arrow to navigate to the Diagnostics function.

3. Use the down arrow to select Run self-test or Run extended self-

test.

icon.

Exit Diagnostics Settings

Run self-test

Run extended self-test

Run count only

Run print test

4. Select Return. The scanner will run the self-test and report the

results on the display.

You may want to count the number of documents entering the scanner

without actually scanning.

To run in count-only mode:

1. Select the Diagnostics Settings menu

2. Use the right or left arrow to navigate to the Diagnostics function.

3. Use the down arrow to select Run count only.

icon.

Exit Diagnostics Settings

Run self-test

Run extended self-test

Run count only

Run Print test

4. Place the documents in the elevator tray.

5. Select Return. The message Counting Pages will be displayed.

6. Press Start/Resume. The page count will be displayed.

3-6 A-61169 January 2005

Loading...

Loading...