Page 1

Competitive BenChmarking

©Kodak, 2009. Kodak is a trademark of Kodak.

All testing conducted in quality assurance labs at Kodak’s Document Imaging headquarters facility, 2600 Manitou Road, Rochester, NY from November 18th, 2008–December 11th, 2008.

Kodak i780 Scanner vs. Canon DR-X10C Scanner

Kodak i780 Scanner

Table of Contents

Speed and throughput

Speed and throughput appendix

Image and data integrity

Image and data integrity appendix

Sensor durability

➡

➡

➡

➡

➡

Canon DR-X10C Scanner

Misfeed management

Misfeed management appendix

Real-world environment

Real-world environment appendix

➡

➡

➡

➡

Count on Kodak for consistent and true performance.

Count out Canon.

Page 2

The test results report the actual throughput of each scanner using real-world scanner configurations.

1)

200 dpi, Bitonal, Duplex*

124.8 ppm

84.6 ppm

51.7 ppm

47%

141%

2)

300 dpi, Bitonal, Duplex*

126 ppm

39.8 ppm

52.4 ppm

217%

140%

3)

300 dpi, Bitonal, Simplex*

124.9 ppm

89.9 ppm

97.2 ppm

38%

28%

4) 200 dpi, Color, Duplex**

121.4 ppm

58 ppm

42.1 ppm

109%

188%

5) 300 dpi, Color, Duplex**

125.2 ppm

28.7 ppm

38.2 ppm

336%

227%

DR-X10C Scanner.

DR-X10C Scanner’s speed with the

DR-X10C Scanner productivity

Scanner.

i780 Scanner outperforms the

continues to have a detrimental eect on

Speed and throughput

i780 Scanner delivers speed, throughput

DR-X10C Scanner

Kodak i780 Scanner vs. Canon DR-X10C Scanner

Test 1 through 6 Settings Kodak i780 ISIS Results DR-X10C VRS Results DR-X10C ISIS Results

Testing observations and conclusions

i780 % performance

increase over

DR-X10C VRS

Competitive knockouts

i780 % performance

increase over

DR-X10C ISIS

Competitive BenChmarking

•

Kodak i780 Scanner

Canon DR-X10C Scanner

Count on Kodak for consistent and true performance.

Methodology

➡

➡

Count out Canon.

Page 3

Appendices

0

1000

2000

3000

4000

5000

6000

7000

8000

1 2 3 4 5 6

i780 ISIS

DR X10C VRS

DR X10C ISIS

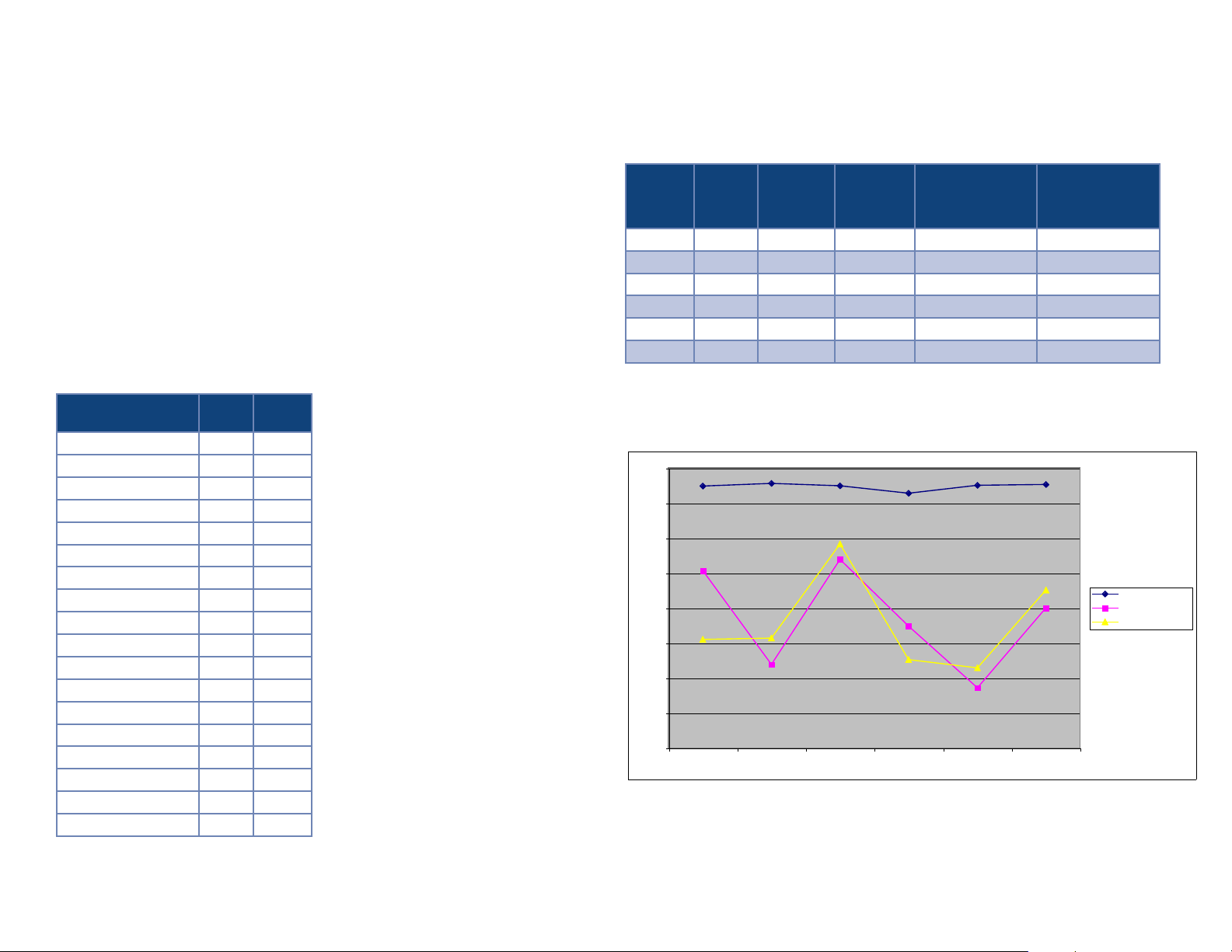

Appendix 1—Testing methodology and results for speed and throughput

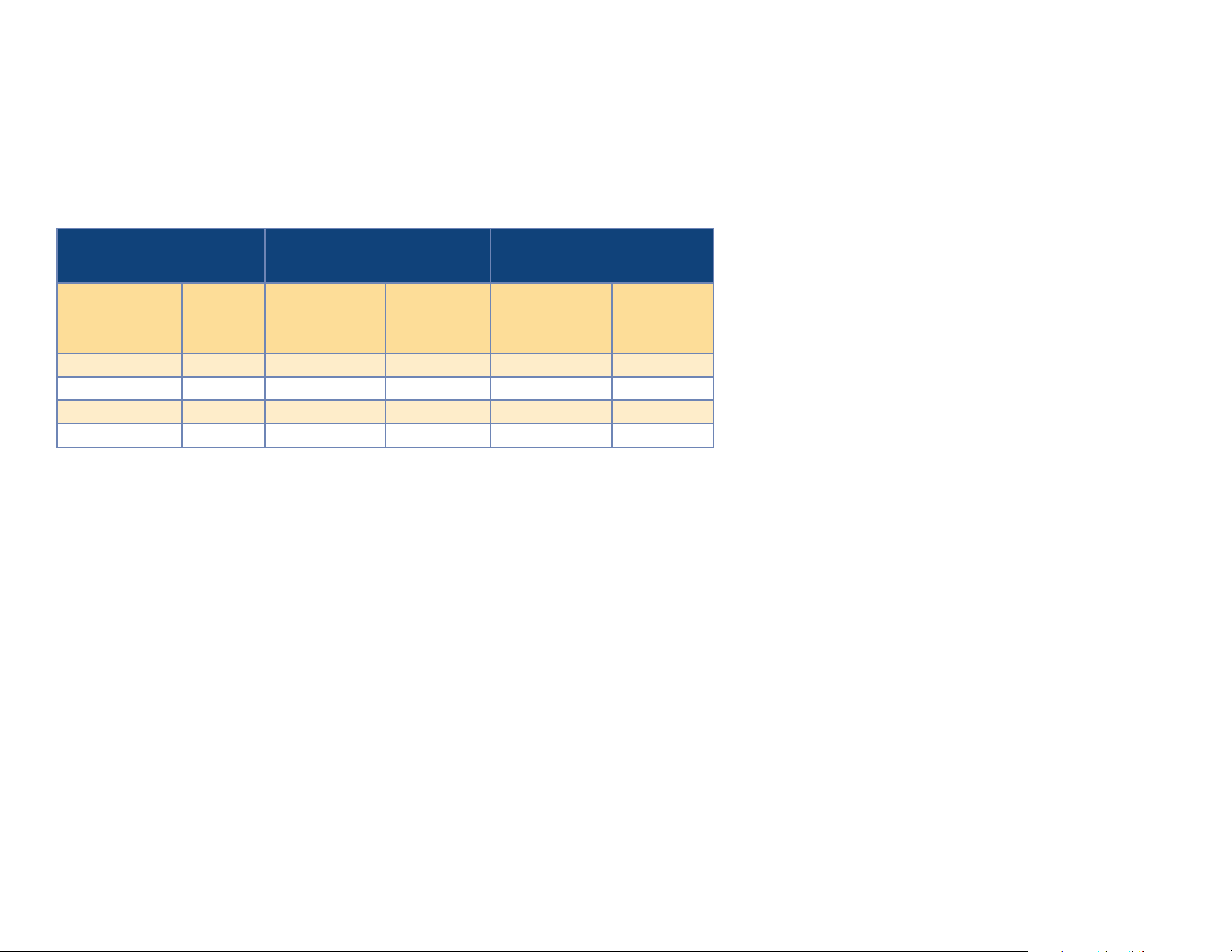

Kodak’s Quality Assurance Team conducted a series of comprehensive, competitive benchmark

tests comparing the Kodak i780 Scanner with ISIS to the Canon DR-X10C Scanner with VRS.

Throughput tests

The intent of these tests was to determine the throughput of each scanner using typical scanner

configurations. All scanners were configured with similar settings and all tests were conducted

with EMC QuickScan Pro v6.5.1 and run on the same PC host. EMC QuickScan Pro was chosen

because of its popularity as a third party application. The EMC QuickScan Pro demonstration

version was used so it would be easier for interested parties to validate results. (See Reference

A for configuration details.) The operator prepared documents prior to testing and fed them into

each scanner as quickly as possible. Five new sets of documents were used for each scanner

during testing. Each test was run for one hour with the total number of pages recorded.

Chart 1—Throughput testing

Test Number

i780 ISIS Test #1 74 87 124.8

i780 ISIS Test #2 7557 126.0

i780 ISIS Test #3 749 1 124.9

i780 ISIS Test #4 7283 121.4

i780 ISIS Test #5 7510 125.2

i780 ISIS Test #6 7528 125.5

DR-X10C VRS Test #1 5075 84.6

DR-X10C VRS Test #2 2390 39.8

DR-X10C VRS Test #3 5391 89.9

DR-X10C VRS Test #4 3477 58.0

DR-X10C VRS Test #5 1719 28.7

DR-X10C VRS Test #6 4009 66.8

DR-X10C ISIS Test #1 3102 51.7

DR-X10C ISIS Test #2 3142 52.4

DR-X10C ISIS Test #3 5829 9 7. 2

DR-X10C ISIS Test #4 2527 42.1

DR-X10C ISIS Test #5 2293 38.2

DR-X10C ISIS Test #6 4516 75.3

# Pgs

in 1 hr

Average

ppm

Chart 2—Data and dierences on number of pages scanned in one hour

i780

Test #1 7487 5075 3102 2412 (47%) 4385 (141%)

Test #2 7557 2390 3142 5167 (217%) 4415 (140%)

Test #3 7491 5391 5829 2100 (38%) 1662 (28%)

Test #4 7283 3477 2527 3806 (109%) 4756 (188%)

Test #5 7510 1719 2293 5791 (336%) 5217 (227%)

Test #6 7528 4009 4516 3519 (88%) 3012 (67%)

See Reference A for configuration details.

DR-X10C

VRS

DR-X10C

ISIS

i780 Increase

Over

DR-X10C VRS

Performance

i780 Increase

Over

DR-X10C ISIS

Performance

Chart 3—Graphic representation of data and dierences on number of pages scanned

in one hour

Pages in One Hour

Test #

For more information about testing methodology and laboratory test results, click here

Return to Speed and throughput

Table of Contents

➡

➡

-

-

➡

Page 4

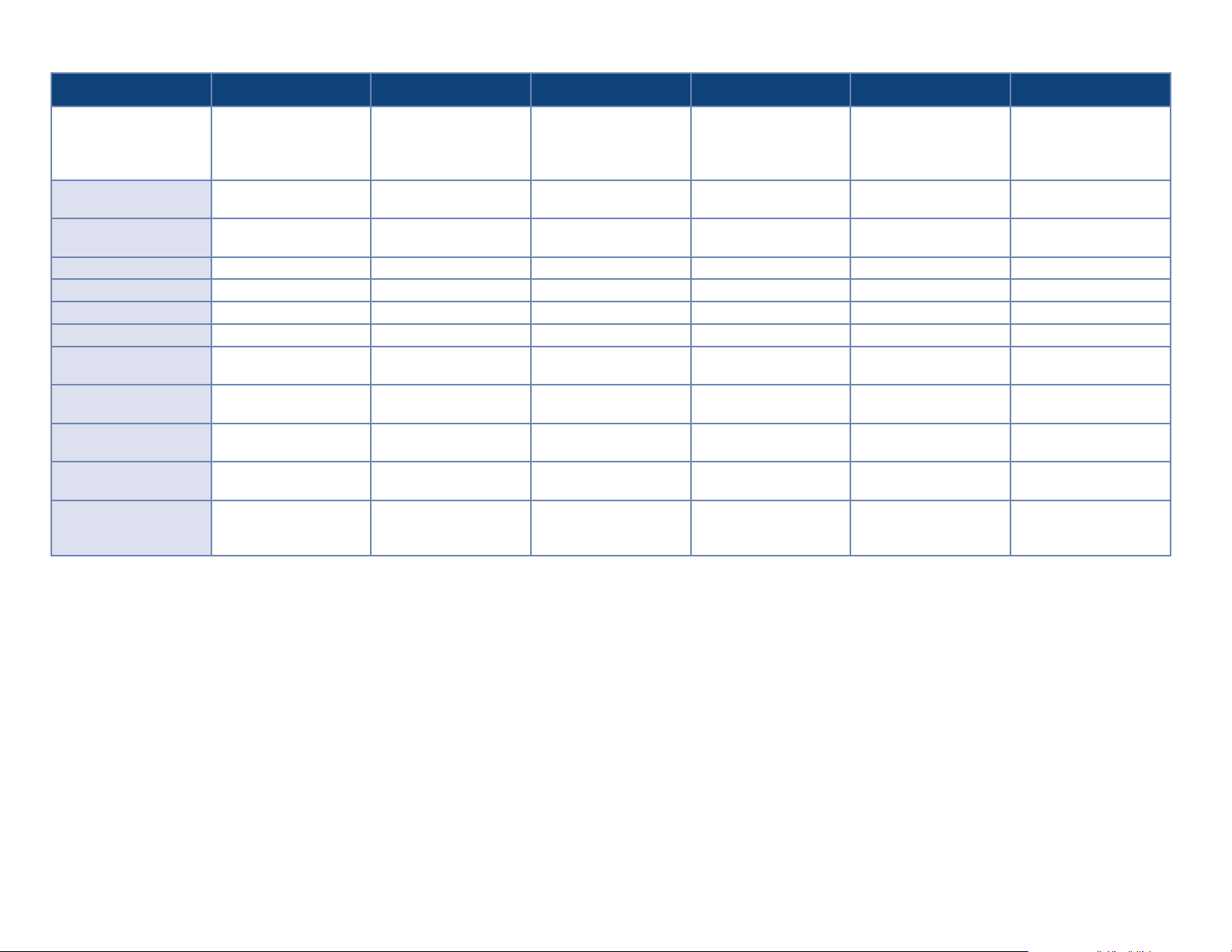

Reference A—Testing configuration details*

Test Job 1 Test Job 2 Test Job 3 Test Job 4 Test Job 5 Test Job 6

EMC QuickScan Settings

QuickScan scan

profile name

Scan—show continue dialog

after scan

Scan—scan mode

Scan—scan type

Scan—dpi

Scan—page size

Image format and naming—

enter file name at…

Image format and naming—

file type

Image format and naming—

color format

Image format and naming—

compression

Image format and

naming— append standard

extension …

200 dpi, bitonal, duplex,

AO, auto thresholding,

multifeed detection,

multipage TIFF output

i780 Test job 01 i780 Test job 02 i780 Test job 03 i780 Test job 04 i780 Test job 05 i780 Test job 06

Checked Checked Checked Checked Checked Checked

Duplex Duplex Simplex Duplex Duplex Simplex

Black and white Black and white Black and white 24-Bit color 24-Bit color 24-Bit color

200 300 300 200 300 300

Scanner max Scanner max Scanner max Scanner max Scanner max Scanner max

Checked Checked Checked Checked Checked Checked

TIFF TIFF TIFF JPEG (*.jpg) JPEG (*.jpg) JPEG (*.jpg)

Binary Binary Binary 24-Bit color 24-Bit color 24-Bit color

Group 4 Group 4 Group 4 Sequential JPEG Sequential JPEG Sequential JPEG

Checked Checked Checked Checked Checked Checked

300 dpi, bitonal, duplex,

AO, auto thresholding,

multifeed detection,

multipage TIFF output

300 dpi, bitonal, simplex,

AO, auto thresholding,

multifeed detection,

multipage TIFF output

200 dpi, color, duplex,

AO, multifeed detection,

multipage TIFF output

300 dpi, color, duplex,

AO, multifeed detection,

multipage TIFF output

300 dpi, color, simplex,

AO, multifeed detection,

multipage TIFF output

For more information about testing methodology and

laboratory test results, click here

Return to Speed and throughput

Table of Contents

➡

➡

➡

Page 5

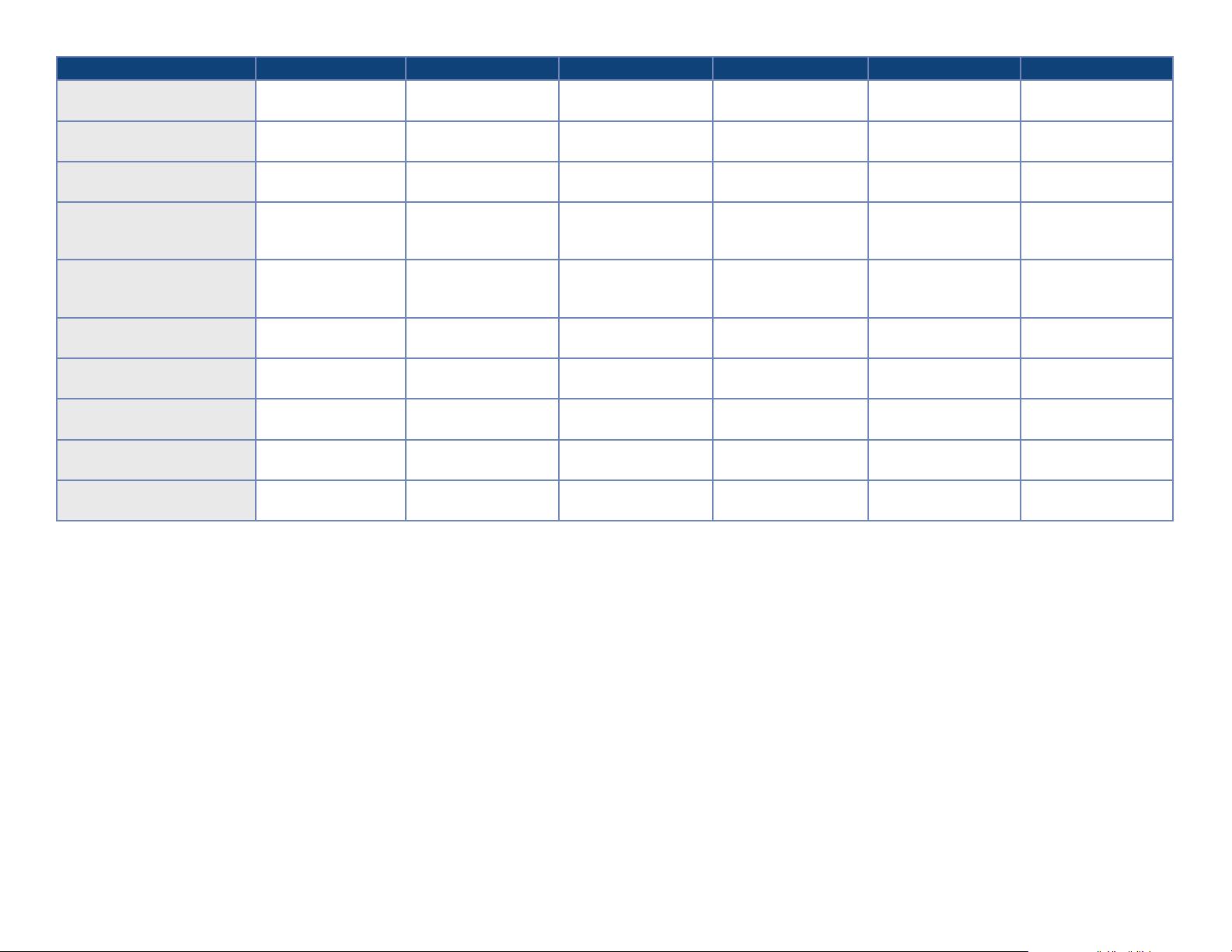

i780 ISIS driver, main,

cropping

i780 ISIS driver, main,

thresholding

i780 ISIS driver, main,

contrast

i780 ISIS driver, layout,

image orientation (both front

and back image #1)

i780 ISIS driver, layout, page

orientation (both front and

back image #1)

i780 ISIS driver, scanner,

document feeder

i780 ISIS driver, scanner,

ultrasonic detection

i780 ISIS driver, dropout,

blank image detection

i780 ISIS driver, image

processing, JPEG quality

i780 ISIS driver, image

processing, color correction

Test Job 1 Test Job 2 Test Job 3 Test Job 4 Test Job 5 Test Job 6

Aggressive Aggressive Aggressive Aggressive Aggressive Aggressive

iThresholding iThresholding iThresholding iThresholding iThresholding iThresholding

0 0 0 0 0 0

Automatic Automatic Automatic Automatic Automatic Automatic

Top edge first Top edge first Top edge first Top edge first Top edge first Top edge first

250—Automatically

start transport

Medium—

3 sensors—end job

Black and White

(back only)—2KB

N/A N/A N/A Good Good Good

N/A N/A N/A Text with pictures Text with pictures Text with pictures

250—Automatically

start transport

Medium—

3 sensors—end job

Black and White

(back only)—2KB

250—Automatically

start transport

Medium—

3 sensors—end job

Black and White

(back only)—2KB

250—Automatically

start transport

Medium—

3 sensors—end job

Color (back only)—

125KB

250—Automatically

start transport

Medium—

3 sensors—end job

Color (back only)—

125KB

250—Automatically

start transport

Medium—

3 sensors—end job

Color (back only)—

125KB

* Note: The Canon DR-X10C Scanner configurations were modeled as closely as possible to the Kodak i780 Scanner set-ups.

Return to Speed and throughput

Table of Contents

➡

➡

Page 6

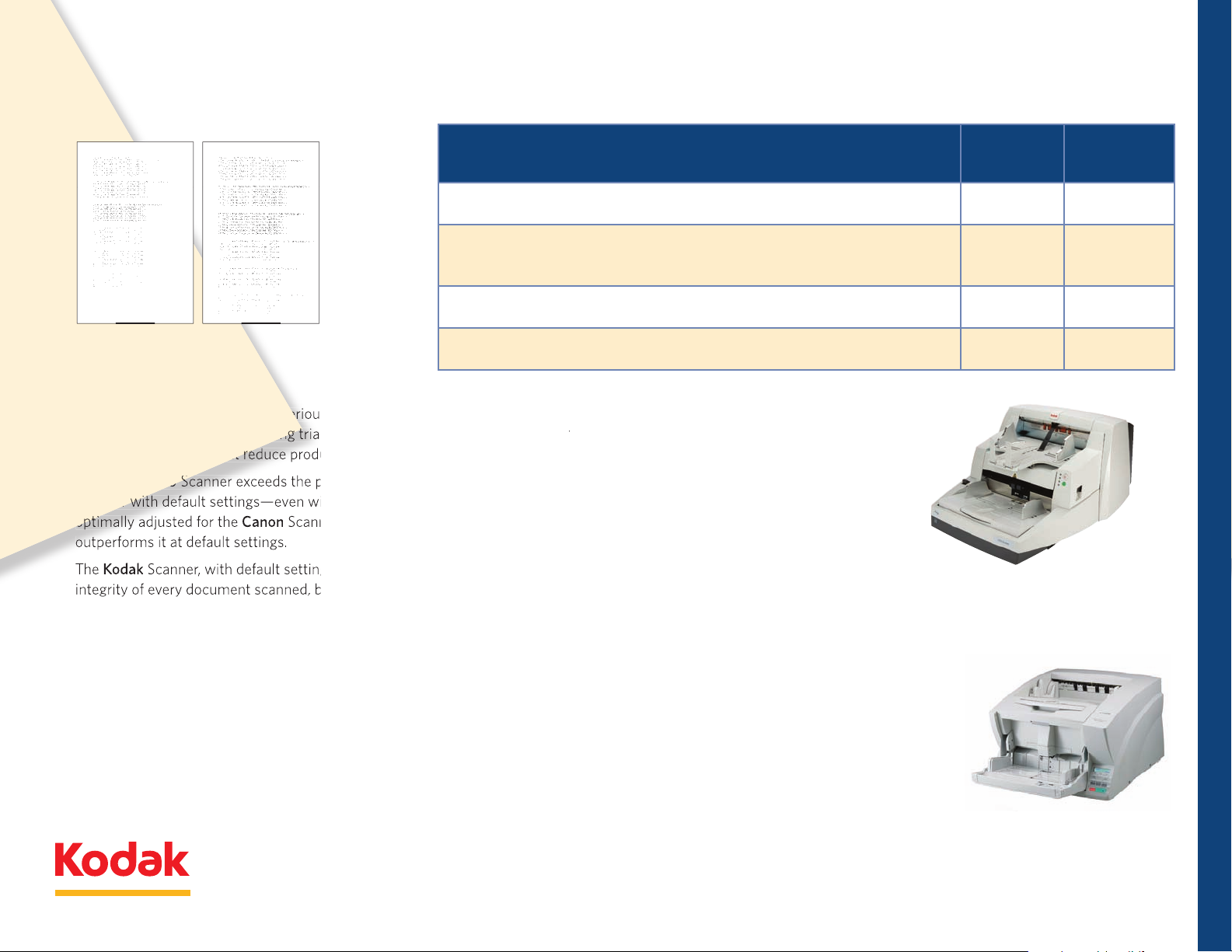

Image and data integrity

i780 Scanner exceeds the performance of the

Scanner, the

Scanner

Scanner, with default settings, maximizes the

i780 Scanner provides outstanding image and data

DR-X10C Scanner does not perform nearly as well.

i780 Scanner while the

DR-X10C

Scanner can only

DR-X10C Scanner delivers

Kodak i780 Scanner vs. Canon DR-X10C Scanner

Test: Light Document Challenge

OCR Read Rate

for Canon

DR-X10C

2

Scanner

OCR Read Rate

for Kodak i780

Scanner

2

Testing observations and conclusions

Competitive knockouts

Methodology

➡

Kodak i780 Scanner

Canon DR-X10C Scanner

Competitive BenChmarking

➡

Count on Kodak for consistent and true performance.

Count out Canon.

Page 7

Appendices

Appendix 2—Testing methodology and results for image and data integrity (OCR read rates)

Kodak’s Quality Assurance Team conducted a series of comprehensive, competitive benchmark tests comparing the Kodak i780

Scanner with VRS to the Canon DR-X10C Scanner ISIS.

Image and data integrity—complete testing results

Canon DR-X10C Scanner—

optimized brightness and

contrast settings

Percent

Font and dpi

variations*

L102 81.7918 L102 0.0000 L102 95.2331

L082 67.1692 L082 0.0000 L082 93.9025

L083 98.9587 L083 0.0000 L083 88.3379

Average Score = 82.6399 Average Score = 0.0000 Average Score = 92.4912

*Font and dpi variations: L = Light; 08 or 10 = Font Size; 2 or 3 = 200 or 300 dpi

from font

and dpi

variations

Canon DR-X10C Scanner—

Default configuration settings

Font and dpi

variations

Percent from

font and dpi

variations

Kodak i780 Scanner—

Default configuration settings

Font and dpi

variations

Percent from

font and dpi

variations

Return to Image and data integrity

Table of Contents

➡

➡

Page 8

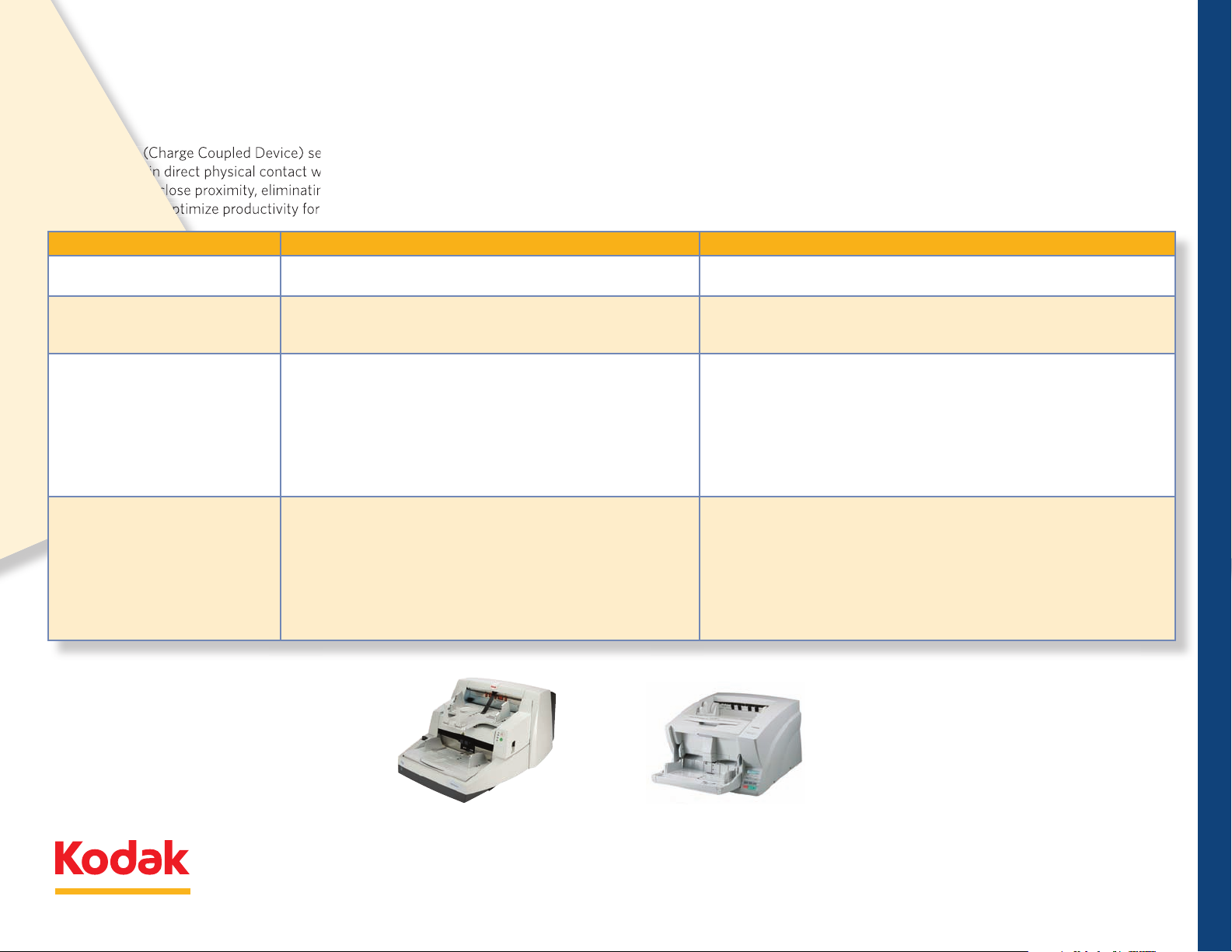

DR-X10C Scanner

i780 Scanner

Contact Image Sensor during the scanning process.

Scanner design, the sensor is encased in glass that

CCD sensor design means it is not placed in the

i780 Scanner

Sensor durability

i780 Scanner is designed to maximize uptime, reduce

Kodak i780 Scanner vs. Canon DR-X10C Scanner

Competitive BenChmarking

Kodak i780 Scanner Canon DR-X10C Scanner

Count on Kodak for consistent and true performance.

Count out Canon.

Page 9

Conclusions

Scanner, because of its Contact Image Sensor, requires documents

Scanner, thanks to its CCD (Charged Coupled Device) sensor’s

i780 Scanner is not at risk of sensor damage due to physical contact with

i780 Scanner, using CCD technology, is designed to maximize uptime,

DR-X10C Scanner may be vulnerable to damage, and since sensor glass replacement

Scanner requires a service call, there is a potential negative impact to uptime

i780 Scanner handles occasional staples and common dust

Kodak

i780 Scanner’s sensor and scanner design easily tackles common real-

DR-X10C Scanner utilizes sensor technology that may be vulnerable to

i780 Scanner’s sensor design, including CCD technology, sensor

Competitive knockouts

Competitive BenChmarking

➡

Count on Kodak for consistent and true performance.

Count out Canon.

Page 10

DR-X10C Scanner Performance

i780 Scanner Performance

DR-X10C Scanner to re-feed

Scanner experiences

Scanner

DR-X10C Scanner’s retry

i780 Scanner’s misfeed detection feature settings,

Optimized operator control: “beep and stop”—alerts operator

job.

Optimized operator productivity: “beep and pause”—alerts

Optimized throughput: “beep and continue”—alerts operator

i780

Scanner by as much as 50%.

These results demonstrate

i780 Scanner design and architecture, outperform those

Misfeed management

misfeed detection/retry mechanism and required operator

Scanner with this challenge document set is

i780 Scanner’s performance with the same set of challenge documents.

The lack of flexible options for the operator to eectively manage misfeeds,

misfeed

Kodak i780 Scanner vs. Canon DR-X10C Scanner

Kodak i780 Scanner

Canon DR-X10C Scanner

Competitive BenChmarking

Count on Kodak for consistent and true performance.

Count out Canon.

Page 11

Testing observations and conclusions

DR-X10C Scanner does not oer flexible options for the operator to

i780 Scanner’s throughput performance and productivity exceeds

DR-X10C Scanner by as much as 50% with a challenge set

i780 Scanner provides far more elegant and flexible misfeed

i780 Scanner delivers far greater flexibility, customization and practical

DR-X10C Scanner’s options for handling misfeeds may at first

i780 Scanner). The

model does not oer this possibility.

i780 Scanner will eectively

Competitive knockouts

Methodology

➡

Competitive BenChmarking

➡

Count on Kodak for consistent and true performance.

Count out Canon.

Page 12

Appendices

Appendix 3—Part A—Misfeed management—Testing methodology and results

Kodak’s Quality Assurance Team conducted a series of comprehensive, competitive benchmark tests comparing the Kodak i780 Scanner/ISIS to the Canon DR-X10C Scanner ISIS/

Canon DR-X10C Scanner with VRS.

Misfeed management—test results

Multifeed productivity test

This test is intended to simulate a job set with pages that create real multifeeds where

two pages feed at the same time through the scanner and cannot be separated with

retry feeding.

The job stream consisted of 100 pages with induced multifeeds placed every 10 pages

in the document stack starting at page 5. The document stack was used for all multifeed

tests described.

Scanner features and settings profile used for multifeed productivity test:

300 dpi bitonal, duplex, auto orientation ON, auto thresholding ON, multifeed detection ON,

all zones ON, set to disable scanner on multifeed detect. Multipage TIFF output selected.

Canon “retry” count set to one attempt.

General test steps:

• Operatorscannedveprepared100-pagemultifeedstacks.

• Thestackswereloadedseparately,onefollowinganother.

• Eachmultifeedpagewasrescannedasquicklyaspossiblebyremovingthesticky

note and placing the document back in the feeder.

• Whentheimagesofthemultifeeddocumentweresenttothehosttheywereremoved

(deleted) from the batch before the rescan.

Multifeed Productivity Test

Time to scan batch of five sets of

100 pages with 10 induced multifeeds

in each set

Demonstrated performance in ppm 26.1 21.5

Kodak i780

Scanner ISIS

19 min 11 sec 23 min 15.75 sec

Canon DR-X10C

Scanner VRS

Challenging document productivity test

This test was intended to simulate a very challenging document including a wide range of sizes,

thicknesses and finishes.

General test steps:

•

Operator scanned five prepared challenge stacks.

• The stacks were loaded separately, one following another.

• Each real multifeed was rescanned.

• Images of real multifeeds were not included in the batch.

Scanner features and settings profile for challenge document productivity test:

200 dpi bitonal, duplex, auto orientation ON, auto thresholding ON, multifeed detection ON,

multifeed retry ON, all zones ON, set to disable scanner on multifeed. Multipage TIFF output.

Canon “retry” count set to one attempt.

Challenge Document

Productivity Test

Results

Product Tested # of Pages Total time Average ppm # Multifeeds

Kodak

i780 Scanner ISIS

Canon

DR-X10C Scanner ISIS

250 5:18:03 47. 2 25

250 11:36:63 21.5 25

Duration

For more information about testing methodology and

laboratory test results, click here

Return to Misfeed management

Table of Contents

➡

➡

➡

Page 13

Appendix 3—Part B—Misfeed management—Job stream configurations

This appendix defines the job streams used in the multifeed productivity test and the

challenge document productivity test.

Multifeed productivity test

This is a set of 100 pages of 20# 8.5in x 11in copier paper. Sticky notes (3in x 3in) were

placed on the documents as defined below.

Page # Sticky note

5 False multifeed

15 True multifeed

25 True multifeed (recovered)

35 False multifeed

45 True multifeed

55 False multifeed

65 False multifeed

75 True multifeed (recovered)

85 True multifeed

95 False multifeed

Challenge document productivity test

This document set was intended to be a collection of extremely dicult to scan documents.

Doc # Qty Description Orientation

1–5 5 Duplex printed copier paper (Pendleton) Portrait

6 1 Bank-sized check Landscape

7 1 Business card Portrait

8 1 Shipment air way bill Landscape

9 1 Personal check Landscape

10 1 W3 form (letter size) Portrait

11 1 Dark gray iThresholding document (Perfect Page set) Portrait

12 1 W2 form (letter size) Portrait

13 1 Empty business-sized envelope Landscape

14 1 Onionskin iThresholding document (Perfect Page set) Portrait

15 1 Kodak’s blue reseller questionnaire (Perfect Page set) Portrait

16 1 Value-added tax return (Perfect Page set) Portrait

17 1 5" x 7" Glossy color photo Landscape

18 1 8.5" x 17" Glossy chart Portrait

Challenge document productivity test, continued

Doc # Qty Description Orientation

19 1 8.125" x 17" Photo Portrait

20, 21 2 Personal checks (Perfect Page set) Landscape

22 1 Toggle patch 8.5" x 11" with 2 corners cut o Landscape

23 1 USPS Express Mail multipart mailing label (Label 11-B) Landscape

24, 25 2 Steno pad, torn from spiral but not cleaned Portrait

26 1 USPS PS Form 3811, 3½" x 11" card stock Landscape

3

/

16

27, 28 2 USPS Certified Mail receipt, PS Form 3800, 3

" x 5 ½" Landscape

29 1 USPS envelope EP14H w/large window, 5" x 10" Landscape

30–33 3 Duplex printed copier paper (Pendleton) Portrait

34 1 Gloss personal identification card, 3¾" x 6 ¾" Landscape

7

1

/

/

8

" x 8

8

35 1 Textured invitation card 3

36 1

37 1

Duplex printed copier paper, wrinkled and

torn corner (Pendleton)

Scissor-cut black card stock, edges not straight

(approx 3¾" x 4½")

" Landscape

Portrait

Landscape

38 1 Tri-folded Kodak i1200/i1300 Scanner Quick Tips Portrait

39 1 Order form photocopy, 11" x 17" Portrait

40 1 Extended warranty application (Perfect Page set) Portrait

41–47 6 Duplex printed copier paper (Pendleton) Portrait

48 1

49 1 Blue Extremely Urgent USPS mailing envelope, 11½" x 15

50 1 NexPress Press sample document, glossy, 8

Red Domestic/International USPS mailing envelope,

11 ½" x 15

1

/

8

"

1

1

/

/

8

" x 10

Portrait

1

/

8

" Portrait

8

" Portrait

For more information about testing

methodology and laboratory test

results, click here

Return to Misfeed management

Table of Contents

➡

➡

➡

Page 14

Appendix 3—Part C—Misfeedmanagement—Workstationcongurations

Workstation Components Version

OptiPlex 755 Minitower:

Operating system(s):

Memory: 2GB DDR2 Non-ECC SDRAM, 667MHz, (2 DIMM)

Boot Hard Drives: 250GB SATA 3.0Gb/s and 8MB DataBurst Cache

Video Card: Integrated Video, Intel GMA3100

Intel Core 2 Duo Processor E6850 (3.0GHz, 4M, VT,

1333MHz FSB)

Genuine Windows XP Professional, SP2, x32, with

Media, English

Scanner Related Components Version

PC Scanning Software EMC QuickScan Pro 6.5.1 demo (build 8372)

Created with QuickDriver Version

1.0.10710.10002

Canon DR-X10C Scanner ISIS Driver Canon DR-X10C version 1.1.10807.03001

Canon DR-X10C Scanner Firmware Version 2.10

Canon DR-X10C Scanner Driver Version 4.20.148

Interface Used (ISIS configuration) USB interface was used

Canon DR-X10C Kofax Card CGA Firmware Version 3.10.011

Interface Used (Canon VRS configuration) USB interface was used

Interface Used (Kodak) IEEE 1394—FireWire 400

Kodak i780 Scanner ISIS Drivers eki700 Version 2.0.10809.29001

Kodak i780 Scanner Firmware Version 2.00.21

PixTools 32-Bit Runtime Libraries Version 7.0 build 2124

For more information about testing

methodology and laboratory test

results, click here

Return to Misfeed management

Table of Contents

➡

➡

➡

Page 15

Appendix 3—Part D—Misfeed management—Scanner features and settings profile

Kodak i780 Scanner configuration EMC Captiva QuickScan Pro v6.5.1 demo settings

Kodak i780 Scanner ISIS Multifeed Productivity Test Challenge Document Productivity Test

200 dpi, bitonal, duplex, AO, auto thresholding,

multifeed detection, multipage TIFF output

QuickScan scan profile name i780 Test job 01 i780 Test job 02

General—save images to this folder

Scan—show continue dialog after scan Checked Checked

Scan—scan mode Duplex Duplex

Scan—scan type Black and white Black and white

Scan—dpi 200 300

Scan—page size Scanner max Scanner max

Image format and naming—enter file name at … Checked Checked

Image format and naming—file type TIFF TIFF

Image format and naming—color format Binary Binary

Image format and naming—compression Group 4 Group 4

Image format and naming—append standard extension … Checked Checked

i780 ISIS driver, main, cropping Aggressive Aggressive

i780 ISIS driver, main, thresholding iThresholding iThresholding

i780 ISIS driver, main, contrast 0 0

i780 ISIS driver, layout, image orientation

(both front and back image #1)

i780 ISIS driver, layout, page orientation

(both front and back image #1)

i780 ISIS driver, scanner, document feeder 250—Automatically start transport 250—Automatically start transport

i780 ISIS driver, scanner, ultrasonic detection Medium—3 sensors—end job Medium—3 sensors—end job

i780 ISIS driver, dropout, blank image detection Black and white (back only)—2KB Black and white (back only)—2KB

i780 ISIS driver, image processing, JPEG quality N /A N/A

C:\Program Files\EMC Captiva\QuickScan\

My Images\i780\Job01

Automatic Automatic

Top edge first Top edge first

300 dpi, bitonal, duplex, AO, auto thresholding,

multifeed detection, multipage TIFF output

C:\Program Files\EMC Captiva\QuickScan\

My Images\i780\Job02

i780 ISIS driver, image processing, color correction N /A N/A

For more information about testing methodology and

laboratory test results, click here

Return to Misfeed management

Table of Contents

➡

➡

➡

Page 16

Appendix 3—Part D— Misfeed management—Scanner features and settings profile, continued

Canon DR-X10C Scanner, VRS configuration EMC Captiva QuickScan Pro v6.5.1 demo settings

Canon DR-X10C with VRS Option Multifeed Productivity Test Challenge Document Productivity Test

200 dpi, bitonal, duplex, AO, auto thresholding,

multifeed detection, multipage TIFF output

QuickScan scan profile name DR-X10C VRS test job 01 DR-X10C VRS test job 02

General—save images to this folder

Scan—show continue dialog after scan Checked Checked

Scan—scan mode Duplex Duplex

Scan—scan type Black and white Black and white

Scan—dpi 200 300

Scan—page size Scanner max Scanner max

Image format and naming—enter file name at … Checked Checked

Image format and naming—file type TIFF TIFF

Image format and naming—color format Binary Binary

Image format and naming—compression Group 4 Group 4

Image format and naming—

append standard extension …

PixKofax, main tab, paper source Feeder Feeder

PixKofax, main tab, dpi 200 300

PixKofax, main tab, mode Black and white Black and white

PixKofax, main tab, page size Scanner’s maximum Scanner’s maximum

PixKofax, main tab, orientation Portrait Portrait

PixKofax, main tab, simplex/duplex Duplex Duplex

PixKofax, more, detect page size Checked Checked

PixKofax, main tab, (scanner preset) {preset

names are retained so you can use dierent

names as needed}

PixKofax, advanced (VRS adjustments), clarity,

auto brightness

PixKofax, advanced (VRS adjustments), clarity,

brightness

C:\Program Files\EMC Captiva\QuickScan\My Images\

x10c-VRS\Job01

Checked Checked

Test01 Test02

Checked Checked

N/A N/A

300 dpi, bitonal, duplex, AO, auto thresholding,

multifeed detection, multipage TIFF output

C:\Program Files\EMC Captiva\QuickScan\My Images\

x10c-VRS\Job02

For more information about testing methodology and

laboratory test results, click here

Return to Misfeed management

Table of Contents

➡

➡

➡

Page 17

Appendix 3—Part D— Misfeed management—Scanner features and settings profile, continued

Canon DR-X10C Scanner, VRS configuration, continued

Canon DR-X10C with VRS Option Multifeed Productivity Test Challenge Document Productivity Test

PixKofax, advanced (VRS adjustments), clarity, contrast 50 50

PixKofax, advanced (VRS adjustments), clarity,

advanced clarity

PixKofax, advanced (VRS adjustments), clarity, gamma 17 17

PixKofax, advanced (VRS adjustments), noise, line filter Normal Normal

PixKofax, advanced (VRS adjustments), noise, speckle removal Small Small

PixKofax, advanced (VRS adjustments), noise, fill holes Not checked Not checked

PixKofax, advanced (VRS adjustments), skew, deskew Deskew, auto crop, auto orientation Deskew, auto crop, auto orientation

PixKofax, advanced (VRS adjustments), color,

enable detection

PixKofax, advanced (VRS adjustments), background,

enable smoothing

PixKofax, advanced (VRS adjustments), blank page

PixKofax, advanced (VRS adjustments), (profile name) {profile

names are not retained in PixKofax so only use one}

PixKofax, VRS Admin, warnings, brightness out of range 35—Ignore error 35—Ignore error

PixKofax, VRS Admin, warnings, contrast out of range 40—Ignore error 40—Ignore error

PixKofax, VRS Admin, warnings, color confidence out of range 50—Ignore error 50—Ignore error

PixKofax, VRS Admin, errors, paper jam Auto resolve Auto resolve

PixKofax, VRS Admin, errors, multifeed Auto resolve Auto resolve

PixKofax, VRS Admin, errors, out of paper Auto resolve Auto resolve

PixKofax, VRS Admin, errors, cover open Auto resolve Auto resolve

PixKofax, VRS Admin, errors, auto crop failure boundary

note detected

PixKofax, VRS Admin, errors, auto deskew failure Ignore error Ignore error

PixKofax, VRS Admin, errors, staple detection Auto resolve Auto resolve

PixKofax, VRS Admin, errors, excessive skew Auto resolve Auto resolve

PixKofax, VRS Admin, accelerated scanning Best Best

PixKofax, advanced (VRS adjustments),

Canon ISIS, endorser

PixKofax, advanced (VRS adjustments), Canon ISIS,

color—front/rear color dropout

Enabled detection, delete, context @ 50,

Enabled @ level 2 Enabled @ level 2

N/A N/A

N/A N/A

Enabled detection, delete, context @ 50,

ignore holes

Test Test

Ignore error Ignore error

No endorser No endorser

None None

ignore holes

For more information about testing methodology and laboratory test results, click here

Return to Misfeed management

➡

Table of Contents

➡

➡

Page 18

Appendix 3—Part D— Misfeed management—Scanner features and settings profile, continued

Canon DR-X10C Scanner, VRS configuration, continued

Canon DR-X10C with VRS Option Multifeed Productivity Test Challenge Document Productivity Test

PixKofax, advanced (VRS Adjustments), Canon ISIS, color, JPEG compression Good Good

PixKofax, advanced (VRS Adjustments), Canon ISIS, picking rectangle Not checked Not checked

PixKofax, advanced (VRS Adjustments), Canon ISIS, rotation (front/rear) 0 0

PixKofax, advanced (VRS Adjustments), Canon ISIS, multifeed Enabled with 3 zones Enabled with 3 zones

PixKofax, advanced (VRS Adjustments), Canon ISIS, other (speed/quality) High speed scanning enabled High speed scanning enabled

PixKofax, advanced (VRS Adjustments), Canon ISIS, other, moire removal Checked Checked

PixKofax, advanced (VRS Adjustments), Canon ISIS, other, staple detection Checked Checked

PixKofax, advanced (VRS Adjustments), Canon ISIS, other, error recovery Checked Checked

Canon DR-X10C Operator control panel settings

Canon DR-X10C OCP—buzzer control (ON2 ON1 OFF) ON2 ON2

Canon DR-X10C OCP—double feed control (

Canon DR-X10C OCP—double feed retry (3-2-1-OFF) 1 1

Canon DR-X10C OCP—staple detection (ON/OFF) ON ON

Canon DR-X10C OCP—staple control (2/1/0) 0 0

Canon DR-X10C OCP—long document (ON/OFF)

Canon DR-X10C OCP—manual feed mode (ON/OFF) OFF OFF

Canon DR-X10C OCP—stand by mode (240-60-10) 240 240

Canon DR-X10C OCP—Japanese (ON/OFF) OFF OFF

Canon DR-X10C OCP—display contrast — —

Canon DR-X10C OCP—SCSI speed (20-10-5) 20 20

Canon DR-X10C OCP—USB short packet (ON/OFF) ON ON

Canon DR-X10C OCP—dust detection mode (ON/OFF) ON2 ON2

Canon DR-X10C OCP—tray position (2-1-0) 1 1

Canon DR-X10C OCP—torque control (5-4-3-2-1) 3 3

Canon DR-X10C OCP—auto USB power o (

Canon DR-X10C OCP—total counter (display only) N/A N/A

Canon DR-X10C OCP—roller counter (reset to 0) N/A N/A

Canon DR-X10C OCP—imprinter test N/A N/A

Canon DR-X10C OCP—cleaning mode N/A N/A

ON/OFF) ON ON

OFF OFF

ON/OFF) OFF OFF

For more information about testing methodology and laboratory test results, click here

Return to Misfeed management

➡

Table of Contents

➡

➡

Page 19

Appendix 3—Part D— Misfeed management—Scanner features and settings profile, continued

Canon DR-X10C Scanner, ISIS configuration EMC Captiva QuickScan Pro v6.5.1 demo settings

Canon DR-X10C ISIS Multifeed Productivity Test Challenge Document Productivity Test

200 dpi, bitonal, duplex, AO, auto thresholding,

multifeed detection, multipage TIFF output

QuickScan scan profile name DR-X10C ISIS test job 01 DR-X10

General—save images to this folder

Scan—show continue dialog after scan Checked Checked

Scan—scan mode Duplex Duplex

Scan—scan type Black and white Black and white

Scan—dpi 200 300

Scan—page size Scanner max Scanner max

Image format and naming—enter file name at… Checked Checked

Image format and naming—file type TIFF TIFF

Image format and naming—color format Binary Binary

Image format and naming—compression Group 4 Group 4

Image format and naming—append standard extension … Checked Checked

DR-X10C ISIS Driver, basic, user preference

DR-X10C ISIS Driver, basic, mode Black and white Black and white

DR-X10C ISIS Driver, basic, page size Auto detection Auto detection

DR-X10C ISIS Driver, basic, dpi 200 300

DR-X10C ISIS Driver, basic, scanning mode Duplex Duplex

DR-X10C ISIS Driver, basic, deskew Checked Checked

DR-X10C ISIS Driver, brightness, auto Checked Checked

DR-X10C ISIS Driver, brightness, gamma, custom Not checked Not checked

DR-X10C ISIS Driver, image processing, text orientation Checked Checked

DR-X10C ISIS Driver, other, rapid recovery system Checked Checked

DR-X10C ISIS Driver, other, JPEG transfer N/A N/A

DR-X10C ISIS Driver, other, staple detection Checked Checked

DR-X10C ISIS Driver, other, feeding option Standard feeding Standard feeding

DR-X10C ISIS Driver, other, double feed detection Ultrasonic Ultrasonic

DR-X10C ISIS Driver, other, double feed detection, setting 3 Sensors 3 Sensors

C:\Program Files\EMC Captiva\QuickScan\

My Images\x10c-ISIS\Job01

300 dpi, bitonal, duplex, AO, auto thresholding,

multifeed detection, multipage TIFF output

C ISIS test job 02

C:\Program Files\EMC Captiva\QuickScan\

My Images\x10c-ISIS\Job02

For more information about testing methodology and laboratory test results, click here

Return to Misfeed management

➡

Table of Contents

➡

➡

Page 20

Appendix 3—Part D— Misfeed management—Scanner features and settings profile, continued

Canon DR-X10C Scanner, ISIS configuration, continued

Canon DR-X10C ISIS Multifeed Productivity Test Challenge Document Productivity Test

Canon DR-X10C Operator control panel settings

Canon DR-X10C OCP—buzzer control (ON2 ON1 OFF) ON2 ON2

Canon DR-X10C OCP—double feed control (

Canon DR-X10C OCP—double feed retry (3-2-1-OFF) 1 1

Canon DR-X10C OCP—staple detection (

Canon DR-X10C OCP—staple control (2/1/0) 0 0

Canon DR-X10C OCP—long document (ON/OFF)

Canon DR-X10C OCP—manual feed mode (ON/OFF) OFF OFF

Canon DR-X10C OCP—stand by mode (240-60-10) 240 240

Canon DR-X10C OCP—Japanese (ON/OFF)

Canon DR-X10C OCP—display contrast N/A N/A

Canon DR-X10C OCP—SCSI speed (20-10-5) 20 20

Canon DR-X10C OCP—USB short packet (

Canon DR-X10C OCP—dust detection mode (ON/OFF) ON2 ON2

Canon DR-X10C OCP—tray position (2-1-0) 1 1

Canon DR-X10C OCP—torque control (5-4-3-2-1) 3 3

Canon DR-X10C OCP—auto USB power o (

Canon DR-X10C OCP—total counter (display only) N/A N/A

Canon DR-X10C OCP—roller counter (reset to 0) N/A N/A

Canon DR-X10C OCP—imprinter test N/A N/A

Canon DR-X10C OCP—cleaning mode N/A N/A

ON/OFF) ON ON

ON/OFF) ON ON

OFF OFF

OFF OFF

ON/OFF) ON ON

ON/OFF) OFF OFF

Return to Misfeed management

Table of Contents

➡

➡

Page 21

DR-X10C Scanner performance in real-world scanning scenarios

i780 Scanner performance in real-world scenarios

i780 Scanner’s design focuses on keeping dust away

Real-world environment

(Mixed Batches/Transport/Reliability/

SurePath/Dust Detection)

Kodak i780 Scanner vs. Canon DR-X10C Scanner

A variety of real-world scanning scenarios were created and tested with documents scanned by the Kodak i780 Scanner and Canon DR-X10C Scanner.

Kodak i780 Scanner

Canon DR-X10C Scanner

4, 5

Competitive BenChmarking

Count on Kodak for consistent and true performance.

Count out Canon.

Page 22

Testing observations and conclusions

DR-X10C Scanner must be constantly vigilant when

DR-X10C Scanner creates potential confusion because with misfeed

DR-X10C Scanner during

i780 Scanner delivers reliable productivity

i780 Scanner seamlessly

DR-X10C Scanner. The

Scanner arrives with a variety of

DR-X10C Scanner. Envelopes,

Scanner into misfeed detect/rapid recovery mode, which

DR-X10C Scanner side-by-side

i780 Scanner, the

Scanner’s retry feeding mechanism

i780 Scanner is not fooled by adhesive labels or varying paper

Scanner, as a questionable design for detecting and clearing dust may

Competitive knockouts

Methodology

➡

➡

➡

Competitive BenChmarking

Count on Kodak for consistent and true performance.

Count out Canon.

Page 23

Appendices

Appendix 4—Part A—Real-world environment—Testing methodology and results

Kodak’s Quality Assurance Team conducted a series of comprehensive, competitive benchmark tests comparing the Kodak i780 Scanner/ISIS to the Canon DR-X10C Scanner ISIS/

Canon DR-X10C Scanner with VRS.

Misfeed management—test results

Multifeed productivity test

This test is intended to simulate a job set with pages that create real multifeeds where

two pages feed at the same time through the scanner and cannot be separated with

retry feeding.

The job stream consisted of 100 pages with induced multifeeds placed every 10 pages

in the document stack starting at page 5. The document stack was used for all multifeed

tests described.

Scanner features and settings profile used for multifeed productivity test:

300 dpi bitonal, duplex, auto orientation ON, auto thresholding ON, multifeed detection ON,

all zones ON, set to disable scanner on multifeed detect. Multipage TIFF output selected.

Canon “retry” count set to one attempt.

General test steps:

• Operatorscannedveprepared100-pagemultifeedstacks.

• Thestackswereloadedseparately,onefollowinganother.

• Eachmultifeedpagewasrescannedasquicklyaspossiblebyremovingthesticky

note and placing the document back in the feeder.

• Whentheimagesofthemultifeeddocumentweresenttothehosttheywereremoved

(deleted) from the batch before the rescan.

Multifeed Productivity Test

Time to scan batch of five sets of

100 pages with 10 induced multifeeds

in each set

Demonstrated performance in ppm 26.1 21.5

Kodak i780

Scanner ISIS

19 min 11 sec 23 min 15.75 sec

Canon DR-X10C

Scanner VRS

Challenging document productivity test

This test was intended to simulate a very challenging document including a wide range of sizes,

thicknesses and finishes.

General test steps:

•

Operator scanned five prepared challenge stacks.

• The stacks were loaded separately, one following another.

• Each real multifeed was rescanned.

• Images of real multifeeds were not included in the batch.

Scanner features and settings profile for challenge document productivity test:

200 dpi bitonal, duplex, auto orientation ON, auto thresholding ON, multifeed detection ON,

multifeed retry ON, all zones ON, set to disable scanner on multifeed. Multipage TIFF output.

Canon “retry” count set to one attempt.

Challenge Document

Productivity Test

Results

Product Tested # of Pages Total time Average ppm # Multifeeds

Kodak

i780 Scanner ISIS

Canon

DR-X10C Scanner ISIS

250 5:18:03 47. 2 25

250 11:36:63 21.5 25

Duration

For more information about testing methodology and

laboratory test results, click here

Return to Real-world environment

Table of Contents

➡

➡

➡

Page 24

Appendix 4—Part B—Real-world environment—Job stream configurations

This appendix defines the job streams used in the multifeed productivity test and the

challenge document productivity test.

Multifeed productivity test

This is a set of 100 pages of 20# 8.5in x 11in copier paper. Sticky notes (3in x 3in) were

placed on the documents as defined below.

Page # Sticky note

5 False multifeed

15 True multifeed

25 True multifeed (recovered)

35 False multifeed

45 True multifeed

55 False multifeed

65 False multifeed

75 True multifeed (recovered)

85 True multifeed

95 False multifeed

Challenge document productivity test

This document set was intended to be a collection of extremely dicult to scan documents.

Doc # Qty Description Orientation

1–5 5 Duplex printed copier paper (Pendleton) Portrait

6 1 Bank-sized check Landscape

7 1 Business card Portrait

8 1 Shipment air way bill Landscape

9 1 Personal check Landscape

10 1 W3 form (letter size) Portrait

11 1 Dark gray iThresholding document (Perfect Page set) Portrait

12 1 W2 form (letter size) Portrait

13 1 Empty business-sized envelope Landscape

14 1 Onionskin iThresholding document (Perfect Page set) Portrait

15 1 Kodak’s blue reseller questionnaire (Perfect Page set) Portrait

16 1 Value-added tax return (Perfect Page set) Portrait

17 1 5" x 7" Glossy color photo Landscape

18 1 8.5" x 17" Glossy chart Portrait

Challenge document productivity test, continued

Doc # Qty Description Orientation

19 1 8.125" x 17" Photo Portrait

20, 21 2 Personal checks (Perfect Page set) Landscape

22 1 Toggle patch 8.5" x 11" with 2 corners cut o Landscape

23 1 USPS Express Mail multipart mailing label (Label 11-B) Landscape

24, 25 2 Steno pad, torn from spiral but not cleaned Portrait

26 1 USPS PS Form 3811, 3½" x 11" card stock Landscape

3

/

16

27, 28 2 USPS Certified Mail receipt, PS Form 3800, 3

" x 5 ½" Landscape

29 1 USPS envelope EP14H w/large window, 5" x 10" Landscape

30–33 3 Duplex printed copier paper (Pendleton) Portrait

34 1 Gloss personal identification card, 3¾" x 6 ¾" Landscape

7

1

/

/

8

" x 8

8

35 1 Textured invitation card 3

36 1

37 1

Duplex printed copier paper, wrinkled and

torn corner (Pendleton)

Scissor-cut black card stock, edges not straight

(approx 3¾" x 4½")

" Landscape

Portrait

Landscape

38 1 Tri-folded Kodak i1200/i1300 Scanner Quick Tips Portrait

39 1 Order form photocopy, 11" x 17" Portrait

40 1 Extended warranty application (Perfect Page set) Portrait

41–47 6 Duplex printed copier paper (Pendleton) Portrait

48 1

49 1 Blue Extremely Urgent USPS mailing envelope, 11½" x 15

50 1 NexPress Press sample document, glossy, 8

Red Domestic/International USPS mailing envelope,

11 ½" x 15

1

/

8

"

1

1

/

/

8

" x 10

Portrait

1

/

8

" Portrait

8

" Portrait

For more information about testing methodology and laboratory

test results, click here

Return to Real-world environment

Table of Contents

➡

➡

➡

Page 25

Appendix 4—Part C—Real-worldenvironment—Workstationcongurations

Workstation Components Version

OptiPlex 755 Minitower:

Operating system(s):

Memory: 2GB DDR2 Non-ECC SDRAM, 667MHz, (2 DIMM)

Boot Hard Drives: 250GB SATA 3.0Gb/s and 8MB DataBurst Cache

Video Card: Integrated Video, Intel GMA3100

Intel Core 2 Duo Processor E6850 (3.0GHz, 4M, VT,

1333MHz FSB)

Genuine Windows XP Professional, SP2, x32, with

Media, English

Scanner Related Components Version

PC Scanning Software EMC QuickScan Pro 6.5.1 demo (build 8372)

Created with QuickDriver Version

1.0.10710.10002

Canon DR-X10C Scanner ISIS Driver Canon DR-X10C version 1.1.10807.03001

Canon DR-X10C Scanner Firmware Version 2.10

Canon DR-X10C Scanner Driver Version 4.20.148

Interface Used (ISIS configuration) USB interface was used

Canon DR-X10C Kofax Card CGA Firmware Version 3.10.011

Interface Used (Canon VRS configuration) USB interface was used

Interface Used (Kodak) IEEE 1394—FireWire 400

Kodak i780 Scanner ISIS Drivers eki700 Version 2.0.10809.29001

Kodak i780 Scanner Firmware Version 2.00.21

PixTools 32-Bit Runtime Libraries Version 7.0 build 2124

For more information about testing methodology and

laboratory test results, click here

Return to Real-world environment

Table of Contents

➡

➡

➡

Page 26

Appendix 4—Part D—Real-world environment—Scanner features and settings profile

Kodak i780 Scanner configuration EMC Captiva QuickScan Pro v6.5.1 demo settings

Kodak i780 Scanner ISIS Multifeed Productivity Test Challenge Document Productivity Test

200 dpi, bitonal, duplex, AO, auto thresholding,

multifeed detection, multipage TIFF output

QuickScan scan profile name i780 Test job 01 i780 Test job 02

General—save images to this folder

Scan—show continue dialog after scan Checked Checked

Scan—scan mode Duplex Duplex

Scan—scan type Black and white Black and white

Scan—dpi 200 300

Scan—page size Scanner max Scanner max

Image format and naming—enter file name at … Checked Checked

Image format and naming—file type TIFF TIFF

Image format and naming—color format Binary Binary

Image format and naming—compression Group 4 Group 4

Image format and naming—append standard extension … Checked Checked

i780 ISIS driver, main, cropping Aggressive Aggressive

i780 ISIS driver, main, thresholding iThresholding iThresholding

i780 ISIS driver, main, contrast 0 0

i780 ISIS driver, layout, image orientation

(both front and back image #1)

i780 ISIS driver, layout, page orientation

(both front and back image #1)

i780 ISIS driver, scanner, document feeder 250—Automatically start transport 250—Automatically start transport

i780 ISIS driver, scanner, ultrasonic detection Medium—3 sensors—end job Medium—3 sensors—end job

i780 ISIS driver, dropout, blank image detection Black and white (back only)—2KB Black and white (back only)—2KB

i780 ISIS driver, image processing, JPEG quality N /A N/A

C:\Program Files\EMC Captiva\QuickScan\

My Images\i780\Job01

Automatic Automatic

Top edge first Top edge first

300 dpi, bitonal, duplex, AO, auto thresholding,

multifeed detection, multipage TIFF output

C:\Program Files\EMC Captiva\QuickScan\

My Images\i780\Job02

i780 ISIS driver, image processing, color correction N /A N/A

For more information about testing methodology and

laboratory test results, click here

Return to Real-world environment

Table of Contents

➡

➡

➡

Page 27

Appendix 4—Part D—Real-world environment—Scanner features and settings profile, continued

Canon DR-X10C Scanner, VRS configuration EMC Captiva QuickScan Pro v6.5.1 demo settings

Canon DR-X10C with VRS Option Multifeed Productivity Test Challenge Document Productivity Test

200 dpi, bitonal, duplex, AO, auto thresholding,

multifeed detection, multipage TIFF output

QuickScan scan profile name DR-X10C VRS test job 01 DR-X10C VRS test job 02

General—save images to this folder

Scan—show continue dialog after scan Checked Checked

Scan—scan mode Duplex Duplex

Scan—scan type Black and white Black and white

Scan—dpi 200 300

Scan—page size Scanner max Scanner max

Image format and naming—enter file name at … Checked Checked

Image format and naming—file type TIFF TIFF

Image format and naming—color format Binary Binary

Image format and naming—compression Group 4 Group 4

Image format and naming—

append standard extension …

PixKofax, main tab, paper source Feeder Feeder

PixKofax, main tab, dpi 200 300

PixKofax, main tab, mode Black and white Black and white

PixKofax, main tab, page size Scanner’s maximum Scanner’s maximum

PixKofax, main tab, orientation Portrait Portrait

PixKofax, main tab, simplex/duplex Duplex Duplex

PixKofax, more, detect page size Checked Checked

PixKofax, main tab, (scanner preset) {preset

names are retained so you can use dierent

names as needed}

PixKofax, advanced (VRS adjustments), clarity,

auto brightness

PixKofax, advanced (VRS adjustments), clarity,

brightness

C:\Program Files\EMC Captiva\QuickScan\My Images\

x10c-VRS\Job01

Checked Checked

Test01 Test02

Checked Checked

N/A N/A

300 dpi, bitonal, duplex, AO, auto thresholding,

multifeed detection, multipage TIFF output

C:\Program Files\EMC Captiva\QuickScan\My Images\

x10c-VRS\Job02

For more information about testing methodology and laboratory test results, click here

Return to Real-world environment

➡

Table of Contents

➡

➡

Page 28

Appendix 4—Part D—Real-world environment—Scanner features and settings profile, continued

Canon DR-X10C Scanner, VRS configuration, continued

Canon DR-X10C with VRS Option Multifeed Productivity Test Challenge Document Productivity Test

PixKofax, advanced (VRS adjustments), clarity, contrast 50 50

PixKofax, advanced (VRS adjustments), clarity,

advanced clarity

PixKofax, advanced (VRS adjustments), clarity, gamma 17 17

PixKofax, advanced (VRS adjustments), noise, line filter Normal Normal

PixKofax, advanced (VRS adjustments), noise, speckle removal Small Small

PixKofax, advanced (VRS adjustments), noise, fill holes Not checked Not checked

PixKofax, advanced (VRS adjustments), skew, deskew Deskew, auto crop, auto orientation Deskew, auto crop, auto orientation

PixKofax, advanced (VRS adjustments), color,

enable detection

PixKofax, advanced (VRS adjustments), background,

enable smoothing

PixKofax, advanced (VRS adjustments), blank page

PixKofax, advanced (VRS adjustments), (profile name) {profile

names are not retained in PixKofax so only use one}

PixKofax, VRS Admin, warnings, brightness out of range 35—Ignore error 35—Ignore error

PixKofax, VRS Admin, warnings, contrast out of range 40—Ignore error 40—Ignore error

PixKofax, VRS Admin, warnings, color confidence out of range 50—Ignore error 50—Ignore error

PixKofax, VRS Admin, errors, paper jam Auto resolve Auto resolve

PixKofax, VRS Admin, errors, multifeed Auto resolve Auto resolve

PixKofax, VRS Admin, errors, out of paper Auto resolve Auto resolve

PixKofax, VRS Admin, errors, cover open Auto resolve Auto resolve

PixKofax, VRS Admin, errors, auto crop failure boundary

note detected

PixKofax, VRS Admin, errors, auto deskew failure Ignore error Ignore error

PixKofax, VRS Admin, errors, staple detection Auto resolve Auto resolve

PixKofax, VRS Admin, errors, excessive skew Auto resolve Auto resolve

PixKofax, VRS Admin, accelerated scanning Best Best

PixKofax, advanced (VRS adjustments),

Canon ISIS, endorser

PixKofax, advanced (VRS adjustments), Canon ISIS,

color—front/rear color dropout

Enabled detection, delete, context @ 50,

Enabled @ level 2 Enabled @ level 2

N/A N/A

N/A N/A

Enabled detection, delete, context @ 50,

ignore holes

Test Test

Ignore error Ignore error

No endorser No endorser

None None

ignore holes

For more information about testing methodology and laboratory test results, click here

Return to Real-world environment

➡

Table of Contents

➡

➡

Page 29

Appendix 4—Part D—Real-world environment—Scanner features and settings profile, continued

Canon DR-X10C Scanner, VRS configuration, continued

Canon DR-X10C with VRS Option Multifeed Productivity Test Challenge Document Productivity Test

PixKofax, advanced (VRS Adjustments), Canon ISIS, color, JPEG compression Good Good

PixKofax, advanced (VRS Adjustments), Canon ISIS, picking rectangle Not checked Not checked

PixKofax, advanced (VRS Adjustments), Canon ISIS, rotation (front/rear) 0 0

PixKofax, advanced (VRS Adjustments), Canon ISIS, multifeed Enabled with 3 zones Enabled with 3 zones

PixKofax, advanced (VRS Adjustments), Canon ISIS, other (speed/quality) High speed scanning enabled High speed scanning enabled

PixKofax, advanced (VRS Adjustments), Canon ISIS, other, moire removal Checked Checked

PixKofax, advanced (VRS Adjustments), Canon ISIS, other, staple detection Checked Checked

PixKofax, advanced (VRS Adjustments), Canon ISIS, other, error recovery Checked Checked

Canon DR-X10C Operator control panel settings

Canon DR-X10C OCP—buzzer control (ON2 ON1 OFF) ON2 ON2

Canon DR-X10C OCP—double feed control (

Canon DR-X10C OCP—double feed retry (3-2-1-OFF) 1 1

Canon DR-X10C OCP—staple detection (ON/OFF) ON ON

Canon DR-X10C OCP—staple control (2/1/0) 0 0

Canon DR-X10C OCP—long document (ON/OFF)

Canon DR-X10C OCP—manual feed mode (ON/OFF) OFF OFF

Canon DR-X10C OCP—stand by mode (240-60-10) 240 240

Canon DR-X10C OCP—Japanese (ON/OFF) OFF OFF

Canon DR-X10C OCP—display contrast — —

Canon DR-X10C OCP—SCSI speed (20-10-5) 20 20

Canon DR-X10C OCP—USB short packet (ON/OFF) ON ON

Canon DR-X10C OCP—dust detection mode (ON/OFF) ON2 ON2

Canon DR-X10C OCP—tray position (2-1-0) 1 1

Canon DR-X10C OCP—torque control (5-4-3-2-1) 3 3

Canon DR-X10C OCP—auto USB power o (

Canon DR-X10C OCP—total counter (display only) N/A N/A

Canon DR-X10C OCP—roller counter (reset to 0) N/A N/A

Canon DR-X10C OCP—imprinter test N/A N/A

Canon DR-X10C OCP—cleaning mode N/A N/A

ON/OFF) ON ON

OFF OFF

ON/OFF) OFF OFF

For more information about testing methodology and laboratory test results, click here

Return to Real-world environment

➡

Table of Contents

➡

➡

Page 30

Appendix 4—Part D—Real-world environment—Scanner features and settings profile, continued

Canon DR-X10C Scanner, ISIS configuration EMC Captiva QuickScan Pro v6.5.1 demo settings

Canon DR-X10C ISIS Multifeed Productivity Test Challenge Document Productivity Test

200 dpi, bitonal, duplex, AO, auto thresholding,

multifeed detection, multipage TIFF output

QuickScan scan profile name DR-X10C ISIS test job 01 DR-X10

General—save images to this folder

Scan—show continue dialog after scan Checked Checked

Scan—scan mode Duplex Duplex

Scan—scan type Black and white Black and white

Scan—dpi 200 300

Scan—page size Scanner max Scanner max

Image format and naming—enter file name at… Checked Checked

Image format and naming—file type TIFF TIFF

Image format and naming—color format Binary Binary

Image format and naming—compression Group 4 Group 4

Image format and naming—append standard extension … Checked Checked

DR-X10C ISIS Driver, basic, user preference

DR-X10C ISIS Driver, basic, mode Black and white Black and white

DR-X10C ISIS Driver, basic, page size Auto detection Auto detection

DR-X10C ISIS Driver, basic, dpi 200 300

DR-X10C ISIS Driver, basic, scanning mode Duplex Duplex

DR-X10C ISIS Driver, basic, deskew Checked Checked

DR-X10C ISIS Driver, brightness, auto Checked Checked

DR-X10C ISIS Driver, brightness, gamma, custom Not checked Not checked

DR-X10C ISIS Driver, image processing, text orientation Checked Checked

DR-X10C ISIS Driver, other, rapid recovery system Checked Checked

DR-X10C ISIS Driver, other, JPEG transfer N/A N/A

DR-X10C ISIS Driver, other, staple detection Checked Checked

DR-X10C ISIS Driver, other, feeding option Standard feeding Standard feeding

DR-X10C ISIS Driver, other, double feed detection Ultrasonic Ultrasonic

DR-X10C ISIS Driver, other, double feed detection, setting 3 Sensors 3 Sensors

C:\Program Files\EMC Captiva\QuickScan\

My Images\x10c-ISIS\Job01

300 dpi, bitonal, duplex, AO, auto thresholding,

multifeed detection, multipage TIFF output

C ISIS test job 02

C:\Program Files\EMC Captiva\QuickScan\

My Images\x10c-ISIS\Job02

For more information about testing methodology and

laboratory test results, click here

Return to Real-world environment

Table of Contents

➡

➡

➡

Page 31

Appendix 4—Part D—Real-world environment—Scanner features and settings profile, continued

Canon DR-X10C Scanner, ISIS configuration, continued

Canon DR-X10C ISIS Multifeed Productivity Test Challenge Document Productivity Test

Canon DR-X10C Operator control panel settings

Canon DR-X10C OCP—buzzer control (ON2 ON1 OFF) ON2 ON2

Canon DR-X10C OCP—double feed control (

Canon DR-X10C OCP—double feed retry (3-2-1-OFF) 1 1

Canon DR-X10C OCP—staple detection (

Canon DR-X10C OCP—staple control (2/1/0) 0 0

Canon DR-X10C OCP—long document (ON/OFF)

Canon DR-X10C OCP—manual feed mode (ON/OFF) OFF OFF

Canon DR-X10C OCP—stand by mode (240-60-10) 240 240

Canon DR-X10C OCP—Japanese (ON/OFF)

Canon DR-X10C OCP—display contrast N/A N/A

Canon DR-X10C OCP—SCSI speed (20-10-5) 20 20

Canon DR-X10C OCP—USB short packet (

Canon DR-X10C OCP—dust detection mode (ON/OFF) ON2 ON2

Canon DR-X10C OCP—tray position (2-1-0) 1 1

Canon DR-X10C OCP—torque control (5-4-3-2-1) 3 3

Canon DR-X10C OCP—auto USB power o (

Canon DR-X10C OCP—total counter (display only) N/A N/A

Canon DR-X10C OCP—roller counter (reset to 0) N/A N/A

Canon DR-X10C OCP—imprinter test N/A N/A

Canon DR-X10C OCP—cleaning mode N/A N/A

ON/OFF) ON ON

ON/OFF) ON ON

OFF OFF

OFF OFF

ON/OFF) ON ON

ON/OFF) OFF OFF

For more information about testing methodology and

laboratory test results, click here

Return to Real-world environment

Table of Contents

➡

➡

➡

Page 32

Appendix 5—Real-world environment—Testing methodology and results (dust and contaminants)

Kodak’s Quality Assurance Team conducted a series of comprehensive, competitive benchmark

tests comparing the Kodak i780 Scanner with VRS to the Canon DR-X10C Scanner ISIS. Testing

parameters exceeded normal benchmark tests.

Real-world results: testing results (for dust and contaminants)

Tests performed:

1) Performance of Dust Evasion System

Result—This test was halted when we could not get the Dust Detection System to detect

dust in the scanner during normal operation.

2)

Determine the Dust Particle size needed to trigger the Canon DR-X10C Scanner Dust

Detection System

Result—This test was halted. We could not get dust to trigger the detection system.

Canon DR-X10C Scanner Streak Detection Software

Testing was performed using Dust Detect Modes ON1 and ON2.

Test 1—Description and detailed results

The intent of this test was to seed the imaging area of the Canon DR-X10C Scanner with

a large quantity of naturally made paper dust. Dust was collected from Kodak Scanners

normally used for testing purposes in the QA Lab. Dust was placed on the upper and lower

image paths.

This is a photo of the dust that was seeded in the scanner at the beginning of the test. The

dust was collected from several scanners in the QA Lab. This was not “manufactured” dust.

This photo was taken after the first sheet was scanned. Notice there is little sign of the piles

of dust that had been placed in the scanner.

Note: Dust Detection occurs prior to scanning the first image.

Canon DR-X10C Scanner Sleep Mode

The scanner has a configurable sleep mode. The settings are 10, 60, and 240 min.

We did not find a way to turn this o.

When the scanner is enabled after waking up from Stand-by Mode, the cleaning

system activates.

For more information about testing methodology and

laboratory test results, click here

Return to Real-world environment

Table of Contents

➡

➡

➡

Page 33

Appendix 5—Real-world environment—Testing methodology and results (dust and contaminants), continued

Performance of Dust Evasion System Test—detailed results, continued

This is a portion of the first image taken. There were streaks both in the image and in the

background.

s Streak on the document

s Streaks seen in the background

Conclusion

The scanner’s ability to remove large amounts of dust from the imaging area was observed.

However, there was still a noticeable streak in the image after the dust was removed.

Dust particle size to trigger Canon DR-X10C Dust Detection System

The intent of this test was to run the scanner until there was a visible streak in the image and

disable the scanner. When the scanner was re-enabled the dust detection system was to

detect the dust, clean the imaging area and continue scanning. This test would be repeated

until the Dust Detection System could no longer correct for the dust on the guides.

To speed up the creation of dust, the Dust Creator Tool was used.

Photo of Dust Creation Tool

During our testing we noticed that there were very visible streaks in the images. When the

scanner was disabled and re-enabled, the Dust Detection System did not detect the dust.

The dust streak grew from 1 pixel wide to about 49 pixels wide. Dust was not detected by the

Dust Detection System using either the ON1 or ON2 settings.

Conclusion

The Dust Detection System did not detect dust that was clearly visible in the image.

For more information about testing methodology

and laboratory test results, click here

Return to Real-world environment

Table of Contents

➡

➡

➡

Page 34

Appendix 5—Real-world environment—Testing methodology and results (dust and contaminants), continued

Test #2—Determine dust particle size to trigger DR-X10C Dust Detection System—

detailed results

The intent of this test was to determine under what conditions the Dust Detection System

would detect dust.

Using a “Dust Creation Tool” to create dust quickly, we also needed a way to prevent the dust

brush from cleaning the imaging area. We taped a piece of plastic document protector over

the brush mechanism.

To determine if the Dust Detection System was operating, we placed a sticky note over the

image guide. This action triggered a dust detection “event.”

We then cut the sticky notes into smaller and smaller width strips and placed them on the

image guides. This also triggered a dust event. We were able to create a sliver at about 1/16th

inch wide. This also triggered a dust detection event. We concluded that the Dust Detection

System was functioning.

We scanned for several days using the Dust Creation Tool. We were disabling and re-enabling

every 10 documents. The Dust Detection System did not detect dust.

We placed a pile of dust just before the image guide and allowed the document to spread dust

throughout the scanner. The dust was visible in the image, but the Dust Detection System did

not detect a dust error.

We scanned in bitonal image capture mode and got the same results.

As a last test we taped a human hair across the imaging area. This was immediately detected

when the scanner was enabled.

Overall testing conclusion

The Dust Detection System did not detect dust but could detect more dense or solid objects.

We concluded that if the test was run long enough, the dust would have built up to the point

were the Dust Detection System would have triggered an event. However, streaks caused by

dust would have been noticeable in images long before then.

Return to Real-world environment

Table of Contents

➡

➡

Loading...

Loading...