Kodak i620, i640, i660 User Manual

P/N 3E9836

A-61500

CAT No. 875 9755

KODAK iNnovation Series Scanners

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Scanner models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Scanner features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Speed/capacity (throughput) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Supporting documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

MSDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

User precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Gas springs warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Safety and regulatory agency approvals . . . . . . . . . . . . . . . . . . . . . . 1-5

Environmental information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

EMC statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Acoustic emission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Power system connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Site specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

System requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Registering your scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Making connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installing the IEEE-1394 card in the host computer . . . . . . . . . . . . . . 2-2

Installing the Kodak Driver software . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installing the FireWire cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Attaching the power cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Powering up the host computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Scanner components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

3 Using the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Turning the scanner on and off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Starting and stopping scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Manually pausing and resuming the scanner . . . . . . . . . . . . . . . . . . . . . . 3-2

Automatically pausing and resuming the scanner . . . . . . . . . . . . . . . . . . . 3-2

Document preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Adjusting the side guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Adjusting the back of the output tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Adjusting the front of the output tray . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Adjusting the output tray for long documents from 37 cm (14.5 in.)

to 43 cm (17 in.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Adjusting the output tray for long documents from 43 cm (17 in.)

to 66 cm (26 in.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Exit deflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Automatic feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Continuous feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Manual feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Feeding documents that require special handling . . . . . . . . . . . . . . . . . .3-11

Calibrating the scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Image calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Ultrasonics calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

A-61500 January 2004 i

4 The Document Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Dynamic print field options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Printer specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Purging an ink cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Accessing the document printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Installing an ink cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Setting the printer position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Document printing problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Document printer maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Expected life of document printer components . . . . . . . . . . . . . . . . . 4-8

Replacing an ink cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Replacing the ink blotter strips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Replacing the ink cartridge carrier . . . . . . . . . . . . . . . . . . . . . . . . .4-11

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Supplies and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Cleaning tools and materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Opening the pod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Cleaning the paper path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Cleaning the drive rollers, feed module and separation roller tires . . . . . . 5-5

Cleaning the drive rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Cleaning the separation roller tires. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Cleaning the feed module tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Cleaning the imaging guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Replacement procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Replacing the feed module or feed module tires . . . . . . . . . . . . . . . . . . .5-11

Replacing the separation roller or separation roller tires . . . . . . . . .5-14

Replacing the pre-separation pad . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Replacing the imaging guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Indicator lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Accessing the Operator Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Clearing a document jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Problem solving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Message listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Appendix A Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Ultra-Lightweight Paper Feed Module . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

White Background Accessory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Appendix B Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

i600 Series Scanners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

ii A-61500 January 2004

1 Introduction

This User’s Guide provides information and procedures for the Kodak

i600 Series Scanners. The information in this guide is for use with all of

the i600 Series Scanners unless otherwise noted.

Chapter 1, Introduction — provides general information about the

i600 Series Scanners including a product description, scanner features,

safety information and user precautions.

Chapter 2, Getting Started — includes specifications and instructions

on how to install the Kodak i600 Series Scanner. Also provides an

overview of internal and external scanner components.

Chapter 3, Using the Scanner — includes information on how to

prepare your documents for scanning, document feeder and output tray

adjustments, scanner calibration and how to scan documents.

Chapter 4, Using the Document Printer — provides procedures for

using and maintaining the Document Printer.

Chapter 5, Maintenance — provides maintenance procedures for the

i600 Series Scanners, including replacement procedures for the feed

module, separation roller and imaging guides.

Chapter 6, Troubleshooting — provides a description of the LED

indicators, a problem solving chart, procedures for clearing a document

jam and a listing of error messages.

Appendix A, Accessories — provides a description of the optional

accessories that can be purchased to support the Kodak i600 Series

Scanners. Instructions for using these accessories are included with

the accessory.

Appendix B, Specifications — provides a listing of the specifications

for the Kodak i600 Series Scanners.

A-61500 January 2004 1-1

Scanner models • Kodak i620 Scanner is a desktop duplex color scanner with an

automatic document feeder that runs at 80 pages per minute which

includes a document printer.

• Kodak i640 Scanner is a desktop duplex color scanner with an

automatic document feeder that runs at 100 pages per minute which

includes a document printer.

• Kodak i660 Scanner is a desktop duplex color scanner with an

automatic document feeder that runs at 120 pages per minute which

includes a document printer.

Optional accessories Kodak Feeder Kit for Ultra-Lightweight Paper — allows you to feed

lightweight paper from a paper weight range of 3 to 9 kg (7 to 20 lbs).

Kodak White Background Accessory — if you are scanning

translucent documents, this accessory will reduce black background

bleed-through which produces whiter images.

See Appendix A, Accessories for more information.

Scanner features • Excellent paper handling, image quality, and reliability.

• Color or grayscale at the same speed as bi-tonal.

• Includes the Brightness and Contrast Control which allows you to

create custom color tables.

• Simultaneous bi-tonal and color image output.

• Simultaneous bi-tonal and grayscale image output.

• Handles a broad range of paper weights and sizes.

• Easy installation.

• ISIS and TWAIN device drivers are included on a CD that is packed

with each scanner.

• International language support.

• Ergonomic design.

• 500-sheet elevator tray.

• Energy Star compliant (also known as “sleep” mode).

• Document printing capabilities.

• Electronic red, green and blue color dropout.

• Output resolutions include:

- Bi-tonal: 200, 240, 300, 400 dpi

- Grayscale and Color: 100, 150, 200, 240, 300 dpi

1-2 A-61500 January 2004

• Multi-feed detection by multiple ultrasonic sensors as well as by

length detection.

• Automatic and manual feeding.

• JPEG compression allows color and grayscale images to be viewed

in most image viewers.

• Image processing features include: iThresholding, Adaptive

Threshold Processing, orthogonal rotation, color, bi-tonal and

grayscale deskew, auto-crop, aggressive cropping, error diffusion,

toggle patch, auto-color balancing (auto-white balancing) to ensure

good color balance after calibration, and more.

• Easily replaceable feed module and separation roller.

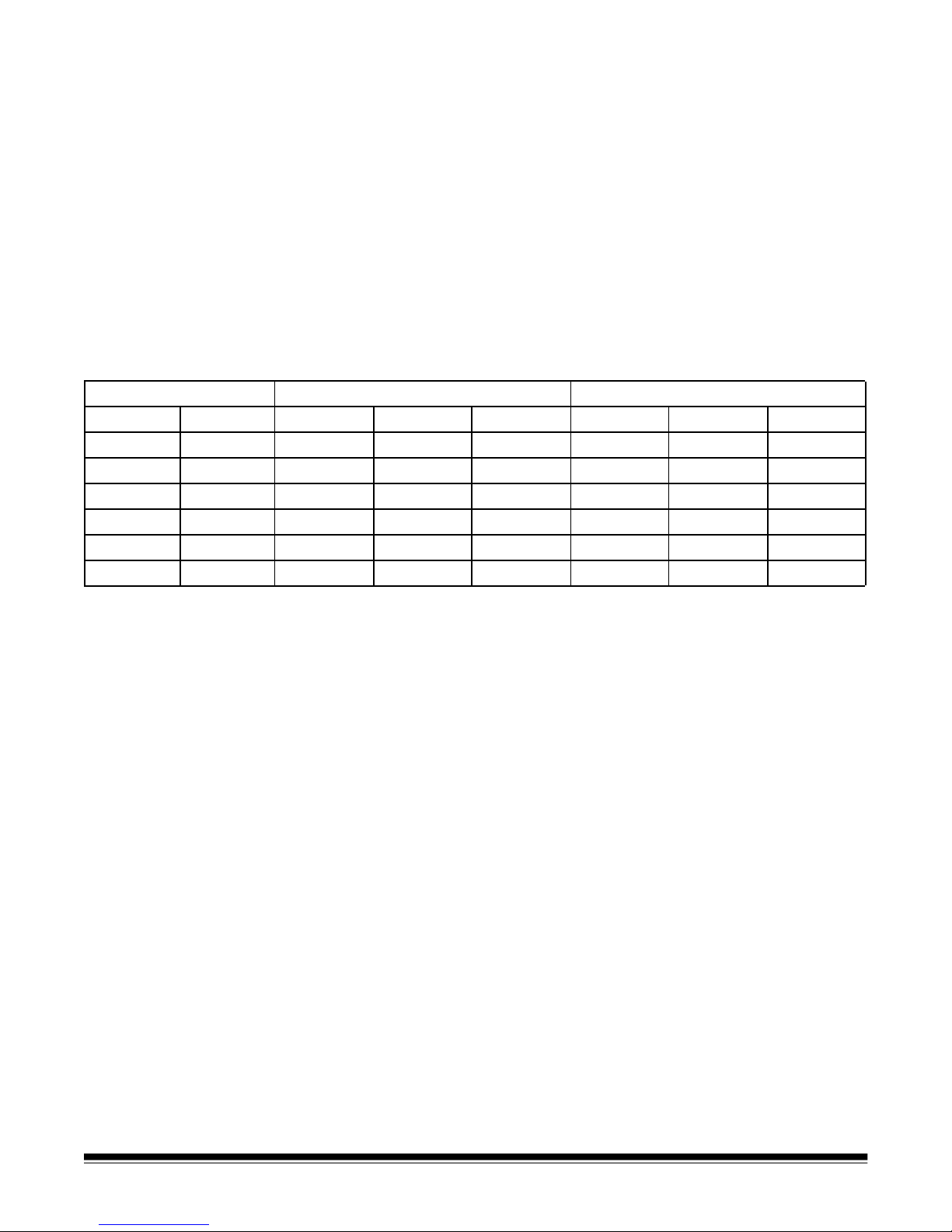

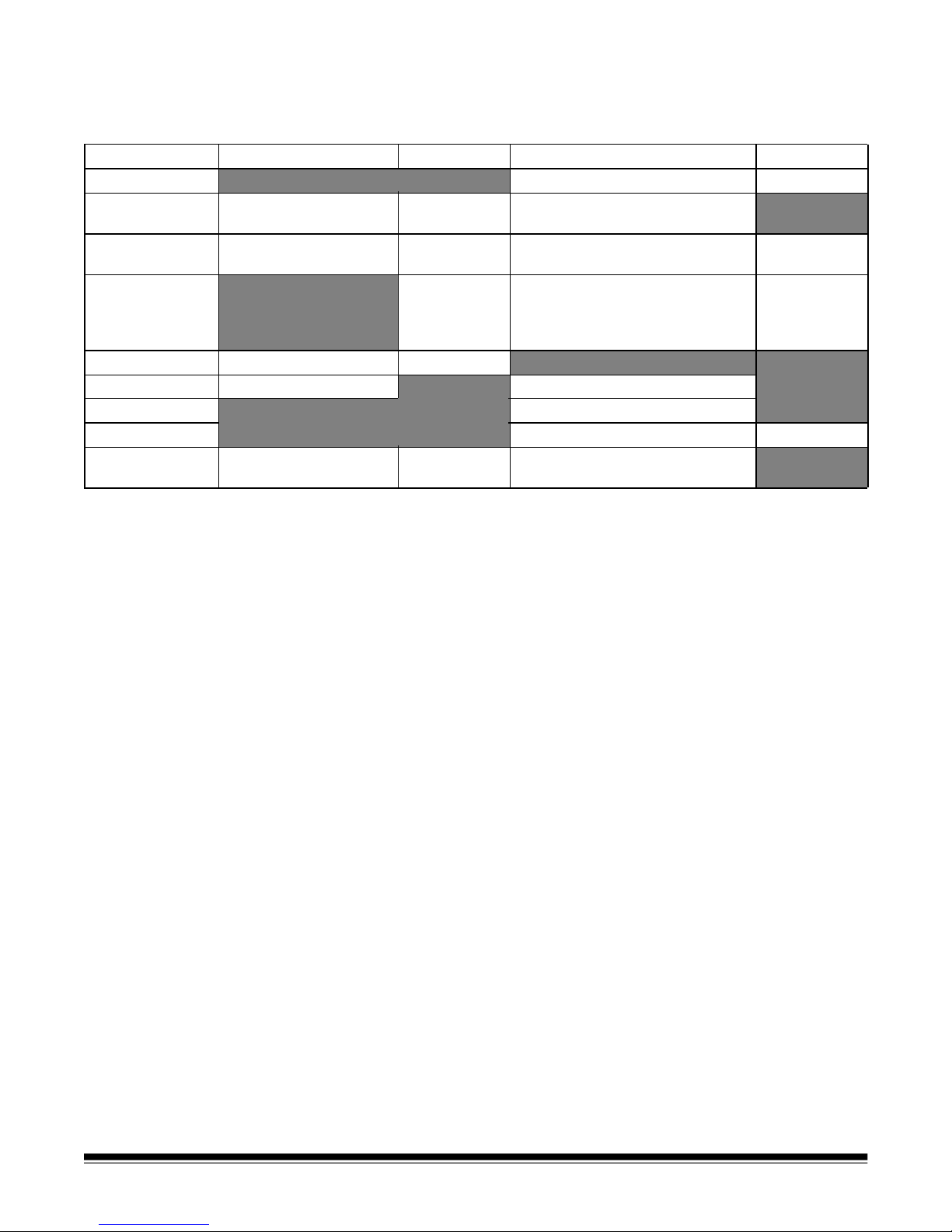

Speed/capacity

(throughput)

Resolution (dpi) Landscape Letter Portrait Letter

Color/Gray Bi-tonal i620 i640 i660 i620 i640 i660

100 - 80 100 120 69 83 96

150 - 80 100 120 69 83 96

200 200 80 100 120 69 83 96

240 240 53 66 80 46 55 64

300 300 53 66 80 46 55 64

- 400 53 66 80 46 55 64

Supporting

documentation

The following speeds (pages per minute) are for color and grayscale

output.

The following documentation is available to support the Kodak i600

Series Scanners:

• Image Processing Guide, A-61504 — available in PDF format on

the Installation CD. This guide provides information for

• Quick Tips Guide, A-61501— intended to be used as a quick

reference for basic scanner use.

A-61500 January 2004 1-3

• FireWire Installation Information, A-61511 — this installation

information is packed with the FireWire cable and should be used to

make the required FireWire cable connections.

• White Background Accessory Instructions, A-61503 — when you

purchase the White Background Accessory these instructions are

included and provide a description of how to install the accessory.

• Ultra-Lightweight Feeder Accessory Instructions, A-61190 —

when you purchase the Ultra-Lightweight Feeder Accessory these

instructions are included and provide a description of how to use the

Ultra-Lightweight Feed Module.

Safety information Warning labels

CAUTION: Moving parts, avoid contact.

CAUTION: Hot surface, avoid contact.

MSDS Material Safety Data Sheets (MSDS) are available on the Kodak

website at: www.kodak.com/go/msds. When accessing the MSDSs

from the website, you will be required to provide the catalog number of

the consumable you want the Material Safety Data Sheet for. See

Chapter 5, “Supplies and accessories” for consumables and catalog

numbers.

User precautions Users and their employer need to observe the common sense

precautions applicable to the operation of any machinery. These

include, but are not limited to, the following:

• Do not wear loose clothing, unbuttoned sleeves, etc.

• Do not wear loose jewelry, bracelets, bulky rings, long necklaces, etc.

• Hair length should be kept short, using a hair net if needed, or tying

long hair up in a bundle.

• Remove all other loose objects from the area that could be drawn into

the machine.

• Take sufficient breaks to maintain mental alertness.

Supervisors should review their practices and make compliance with

these precautions a part of the job description for operation of the

scanner or any mechanical device.

Gas springs warning If the gas springs exhibit a sign of decayed performance, call Service

for replacement. Do not attempt to repair.

1-4 A-61500 January 2004

Safety and regulatory

agency approvals

The Kodak i600 Series Scanners conform to all applicable national and

international product safety and electronic emission regulatory

requirements. This includes, but is not limited to, the following:

Country or Region Safety Approval Safety Mark Electromagnetic Compatibility EMC Mark

Australia AS/NZS 3548(Class A) C-Tick

Canada CAN/CSA-C22.2 No. 60950

Standard

China GB4943-1995 CCC

European Union CE EN 55022 ITE Emissions (Class B)

Germany EN 60950 TUV GS

International CISPR 22 Class B

Japan VCCI (Class A)

Taiwan CNS 13438 (Class A) BSMI

United States UL 60950 UL CFR 47 Part 15 Subpart B

C - UL Canada ICES - 003 Issue 3 (Class A)

GB 9254 (Class A)

“S&E”

EN61000-3-2 Powerline harmonics

GB 17625.1

EN 61000-3-3 Flicker

EN 55024 ITE Immunity

(FCC Class A)

CCC

“S&E”

CE

Environmental

information

• The Kodak i600 Series Scanners contain lead in the circuit board

solder. Disposal of this material may be regulated due to

environmental considerations. For disposal or recycling information,

please contact your local authorities or, in the USA, visit the

Electronics Industry Alliance website: www.eiae.org.

• The product packaging is recyclable.

• The i600 Series Scanners are Energy Star compliant.

EMC statements

United States This equipment has been tested and found to comply with the limits for

a Class A digital device pursuant to Part 15 of the FCC rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequently energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

A-61500 January 2004 1-5

Japan This is a Class A product based on the standard of the Voluntary

Control Council for interference by information Technology Equipment

(VCCI). If this equipment is used in a domestic environment, radio

disturbance may arise. When such trouble occurs, the user may be

required to take corrective action.

Taiwan WARNING: This is a Class A product. In a domestic environment this

product may cause radio interference in which case the user may be

required to take adequate measures.

Peoples Republic of

China

WARNING: This is a Class A product. In a domestic environment this

product may cause radio interference in which case the user may be

required to take adequate measures.

??,??

??A???,????????????????????????,????

???????????????

Acoustic emission Maschinenlärminformationsverordnung – 3, GSGV

Der arbeitsplatzbezogene Emissionswert beträgt <70 db(A).

[Machine Noise Information Ordinance — 3, GSGV

The operator-position noise emission value is <70 dB(A).]

Power system

connection

This product is also designed for Norwegian IT power system with

phase-to-phase voltage 230V.

1-6 A-61500 January 2004

2 Getting Started

Site specifications Place the scanner:

• In a clean area with temperature and relative humidity typical of an

office environment,

• on a stable, level work surface,

• within 1.52 metres (5 feet) of an electrical power outlet.

IMPORTANT: Only use the scanner indoors in a dry location.

For more information about the scanner specifications, refer to

Appendix B, Specifications .

System requirements Following is the minimum recommended system configuration to run

Kodak i600 Series Scanners.

NOTE:The actual performance of the system depends on the scanning

application, choice of scanning parameters, and the host

computer configuration. If the scanner is not performing at the

optimal speed, a faster computer and/or more RAM may be

necessary to obtain the rated throughput.

Registering your

scanner

• Intel PC (or compatible) with a Pentium IV 2 GHz processor

• PCI slot

• Microsoft Windows 2000 Professional, Windows Me, Windows 98SE,

Windows XP (Professional/Home)

• 512 MB RAM

• Monitor

• Mouse

It is very important that you register your scanner so Kodak can provide

you with the best possible service and support that helps maintain your

continuous scanning. Registering your scanner will help us provide you

with firmware and hardware updates as they become available.

The scanner must be registered before any service support can be

provided.

You can register your scanner’s new equipment warranty online at

www.kodak.com/go/DIwarrantyregistration.

For more information about Kodak’s service and support options,

contact your reseller of Kodak Document Imaging products or visit us

on the web at www.kodak.com/go/DIserviceandsupport.

A-61500 January 2004 2-1

Making connections Follow the instructions for installing the IEEE-1394 (FireWire) card and

the Kodak driver software before you plug the scanner into the host

computer.

IMPORTANT:You must install the software on the host computer

before you connect the scanner.

Installing the IEEE-1394

card in the host

computer

Installing the Kodak

Driver software

Installing the FireWire

cable

Install the IEEE-1394 (FireWire) card according to the directions

supplied with the IEEE-1394 card.

IMPORTANT: Use proper precautions to avoid static when you install

the IEEE-1394 card in your computer. Make sure the

computer power cord is disconnected.

1. Insert the Kodak i600 Series Scanners installation CD in the CD-

ROM drive. The installation program starts automatically.

2. Follow the on-screen instructions to install the TWAIN Data Source,

ISIS Driver and the Kodak Scan Validation Tool.

3. Shut down the host computer.

An IEEE-1394 six-pin connector is provided on the rear panel of the

scanner for IEEE-1394 connectivity.

1. Plug the end of the cable with the right angle into the scanner (see

the following illustration).

2-2 A-61500 January 2004

2. Connect the other end of the cable into the IEEE-1394 card outlet in

the host computer. Be sure that it is installed correctly and properly

seated.

CAUTION: DO NOT FORCE THE CONNECTOR. If the cable is not

properly connected, it could cause damage to the

scanner.

Attaching the power cord The Kodak i600 Series Scanner is packed with a set of power cords.

1. Select the power cord which complies with your electrical

requirements and attach it.

2. Turn on the scanner and wait until the top green LED is lit indicating

the scanner has completed power-up self-test and is idle.

Powering up the host

• Turn the power on to the host computer.

computer

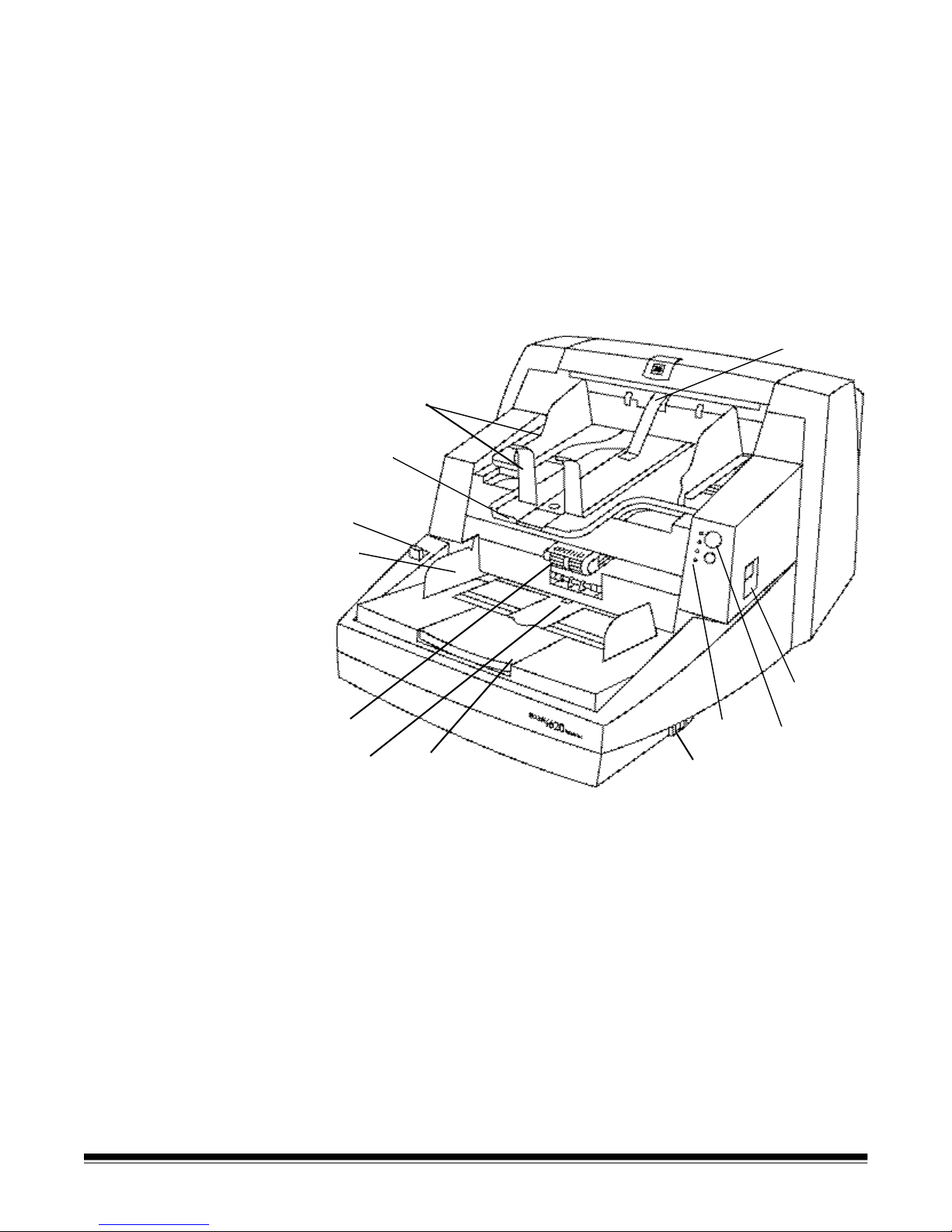

Scanner components Front view

5

12

4

3

10

6

2

11

1

8

9

7

1 Elevator tray extender — open the elevator tray extender to

accommodate long documents.

2 Feed module — provides smooth document feeding of various

sizes, thicknesses and textures.

CAUTION: Moving parts, avoid contact.

3 Elevator tray side guides — slide the guides in or out to

accommodate the document size you want to scan.

Side guides can be left-, center- and right-adjusted to

accommodate documents of various widths.

4 Gap Release lever — allows you to manually adjust the space

between the feed module and separation roller for documents that

require special handling.

5 Output tray and End stop — collects the scanned documents.

The output tray width and end stop length can be adjusted.

A-61500 January 2004 2-3

6 POD release latch — push up the POD release latch when you

need to access the inside of the scanner.

7 Stop/Pause and Start/Resume buttons —

Pause (white with red triangle) button: to

temporarily stop scanning.

Resume (green) button: to start scanning.

8 LEDs— illuminate or flash from top to bottom as follows:

Illuminates when the power is turned on and the scanner is idle.

This indicator will flash if the scanner is in “sleep” or lamp saver

mode.

illuminates when the scanner is enabled and/or scanning, and

flashes when the scanner is powering up.

flashes when a document has jammed in the transport or

when a multi-feed has been detected. Illuminates when a usercorrectable error has been detected.

Illuminates when you need to call Service.

Refer to Chapter 6, Troubleshooting, for complete descriptions of

the LED indicators.

9 Power switch — press the power switch on (I) or off (O) as

required.

10 Exit deflector (optional) — aids in document stacking.

11 Paper Present Sensor — detects the presence of documents in

the elevator tray.

12 Height Adjustment Wire — located underneath the output tray

(not shown in illustration), this wire can be pulled out to raise the

front of the output tray.

2-4 A-61500 January 2004

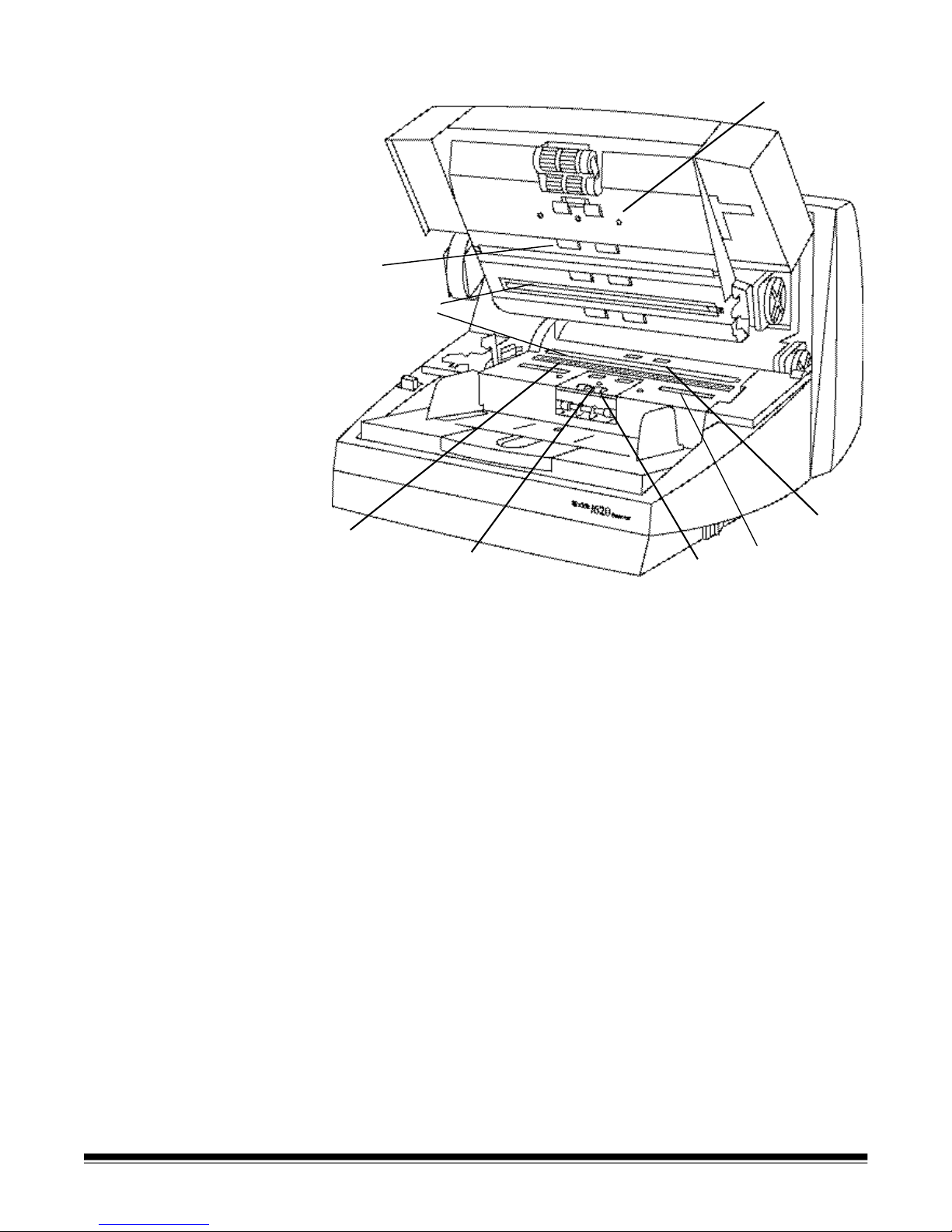

Internal components

7

4

3

2

1

6

5

2

1 Separation roller — provides smooth document feeding of various

sizes and textures one document at a time.

2 Ink blotter strips — collects residue from the Document Printer.

3 Imaging guides — the scanner has an upper and lower imaging

guide. It is important to keep the imaging guides clean to obtain

optimum image quality.

CAUTION: Hot surface, avoid contact.

4 NFR rollers — transports the documents through the paper path.

5 Pre-separation pad — provides smooth document feeding of

various sizes and textures one document at a time.

6 Drive rollers — transports documents through the paper path.

A-61500 January 2004 2-5

7 Paper path sensors — the scanner has 3 (ultrasonic) multi-feed

detection sensors, 1 (optical) paper path sensor and 1 (optical)

paper present sensor. These sensors detect the presence of

documents in the elevator tray and documents in the paper path

during feeding and imaging.

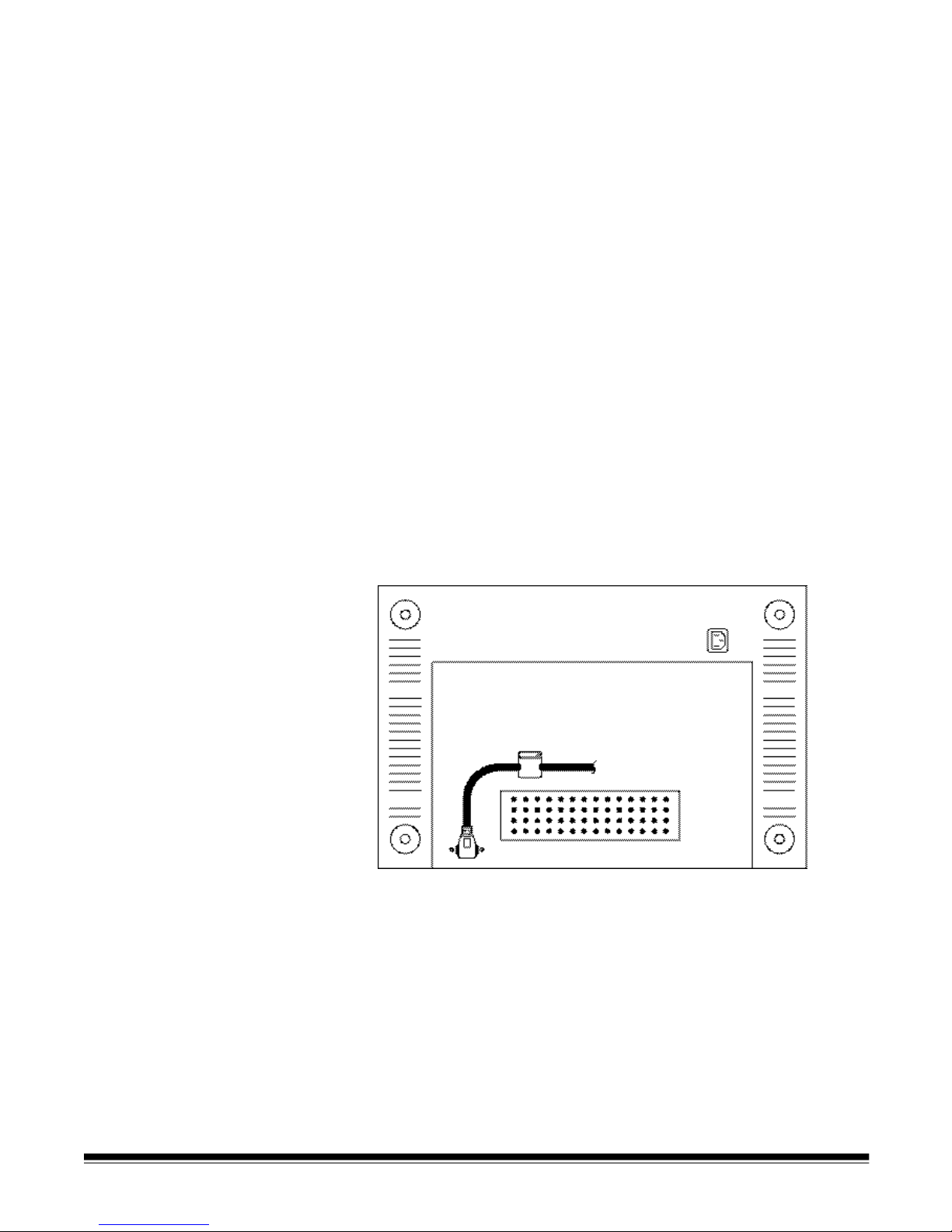

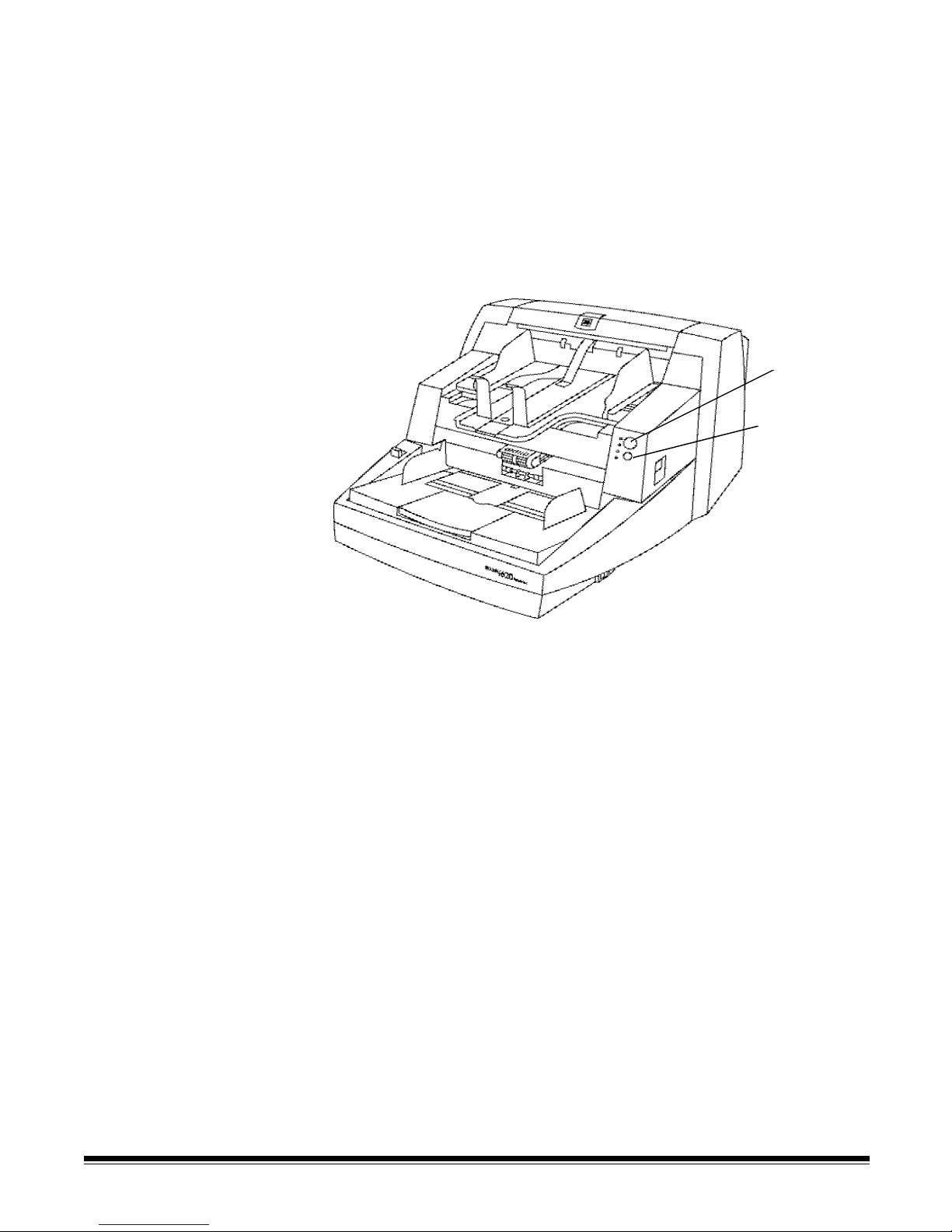

Rear view

Power Cord

Connection

FireWire Connection

Retainer clip

Power Cord Connection — provides power to the scanner. The

scanner is packed with six power cords. Choose the power cord

appropriate for your location and connect it accordingly. Connect the

power cord first to the scanner, then to the wall outlet.

FireWire (IEEE-1394) Connection — before connecting the FireWire

cable, be sure that power to the scanner is off. See the FireWire

instructions packed with the scanner for connection instructions. After

connection, place the cable in the retainer clip located above the

connector.

2-6 A-61500 January 2004

3 Using the Scanner

This chapter provides the following operational procedures:

• Turning on/off the scanner

• Starting, stopping, pausing and resuming the scanner

• Document preparation

• Adjusting the side guides and output tray

• Scanning documents

• Feeding long documents

• Continuous and manual feeding

• Calibration

Turning the scanner

on and off

• Press the button on the scanner’s lower right-side (I) to power it up.

• Press the button on the scanner’s lower right-side (O) to power it

down.

After you power up the scanner, wait until for it to complete self-test.

When completed, the top green indicator light will remain on and

constant. If this does not occur, refer to Chapter 6, “Indicator lights” for

more information.

IMPORTANT: Always power up the scanner to its ready state before

powering up or restarting the host computer.

Starting and stopping

scanning

A-61500 January 2004 3-1

Scanning is controlled by integration software developed for your

application. To start and stop scanning, refer to the documentation

provided with your integration software.

If your application does not automatically start the scanner transport,

begin the scanning process by pressing the Start/Resume button on

the scanner.

NOTE:Before you start scanning, make sure the scanner is ready for

operation, which is indicated by the top green indicator light

being on and constant.

Manually pausing

While scanning documents:

and resuming the

scanner

• Press the Stop/Pause button on the scanner to stop scanning.

NOTE:Your application may configure the scanner with a transport

timeout function which signals an End of Job. If you do not start/

resume scanning before the timeout expires, you cannot

continue scanning without restarting the job from the host

application.

• Press the Start/Resume button on the scanner to restart scanning

after it has been paused.

Stop/Pause

button

Start/Resume

button

Automatically

pausing and

resuming the

scanner

During scanning the scanner monitors its own internal image buffer

memory. In order to prevent overwriting images before the host

computer can retrieve them, the scanner will automatically pause the

feeder while waiting for the host computer to read existing images.

The scanner automatically resumes scanning by restarting the feeder

once image buffer memory is cleared. To avoid this situation be sure

your host computer meets the minimum system requirements as

referred to in Chapter 2.

3-2 A-61500 January 2004

Document

preparation

Before you begin scanning documents, make certain the documents

can be fed through the scanner easily.

• A batch of documents to be fed into the scanner must be arranged so

the leading edges of all documents are aligned and centered under

the feed module; this allows the feeder to introduce documents into

the scanner one at a time.

• Staples and paper clips in documents may damage the scanner and

documents. Remove all staples and paper clips before scanning.

• Documents with missing corners, perforated edges, hole punches in

the margins, irregular and curled edges, torn, damaged, or crushed

pages can be transported successfully through the scanner.

However, no scanner can transport every possible type of damaged

paper. If in doubt about whether a specific damaged document can

be transported through the scanner, place the document in a clear

protective sleeve with the lead edge of the document aligned with the

folded edge of the sleeve. Sleeves should be manually fed, one at a

time, folded edge first, while using the gap release lever. Ultrasonic

multi-feed detection is not recommended when using plastic sleeves.

NOTE:When scanning documents in a clear protective sleeve, the

elevator tray side guides must be aligned to accommodate the

width of the sleeve.

Kodak scanners have been tested with a range of documents that

represent the broad spectrum of document types found in the most

common business applications. Optimal scanner performance is

achieved when scanning documents within the recommended

document specifications listed below. Scanning documents outside of

these specifications may lead to undesirable results in terms of scanner

reliability, image quality, and/or consumable life.

Materials:

• Virgin, recycled and photographic papers

• Clear protective sleeves meeting the size and thickness

requirements in this section

Paper Types: Bond, Laser, Inkjet, Offset

Paper Weights: The elevator tray handles a broad range of paper

weights from 45 to 200 g/m2 (12 to 110 lb.). The Kodak Feeder Kit for

Ultra Lightweight Paper can handle paper weights from 25 to 75 g/m2

(7 to 20 lbs).

Minimum Document Size: 6.4 x 6.4 cm (2.5 x 2.5 in.). Documents as

small as 5 cm (2 in.) (i.e. business cards) can be center-fed, in portrait

orientation one at a time.

A-61500 January 2004 3-3

Maximum Document Size: 30.5 x 66 cm (12 x 26 in.). Documents

larger than 43 cm (17 in.) require operator assistance.

Paper inks: All inks on the paper must be dry before scanning is

started. This includes: Standard offset printing, Inkjet printer, Thermal

transfer, Handwriting inks.

Correction Fluids: Liquid Paper®, Tipp-Ex®, Wite-out®, and other

similar correction fluids.

Feeder Capacity: The elevator tray can hold up to 500 sheets of

75 g/m2 (20 lb.) paper.

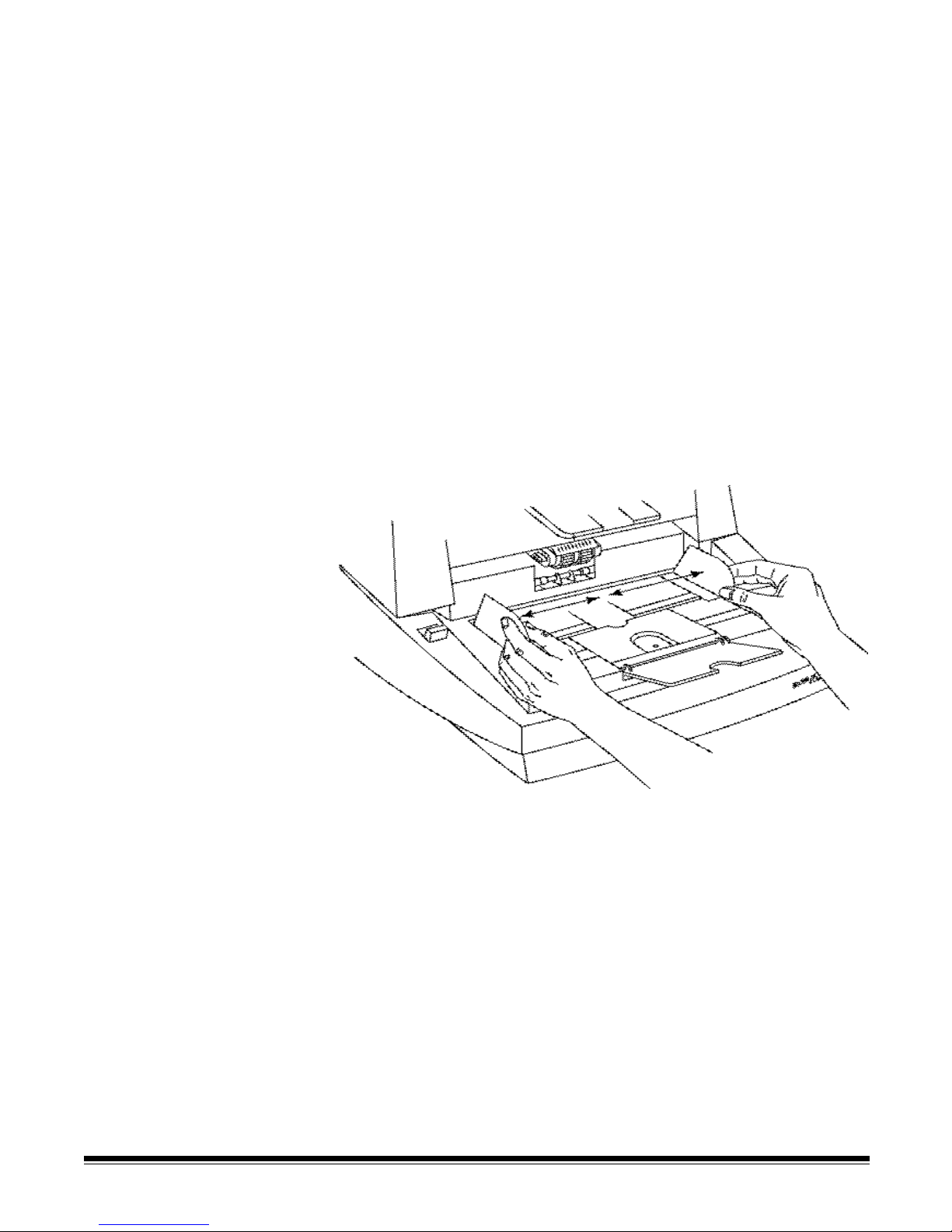

Adjusting the side

guides

To accommodate multiple applications with variable feeding

requirements, the side guides can be adjusted for right-, left- or centeredge feeding. Center-feeding is recommended for best paper handling

performance. The side guides can be moved together or independently

to achieve offset feeding.

1. Pull the side guides all the way out and then push them together

(toward the center) to reset or center them.

3-4 A-61500 January 2004

2. Open the side guides slightly wider than the documents you will be

feeding.

3. Place the documents in the elevator tray.

4. Adjust the side guides to fit the documents.

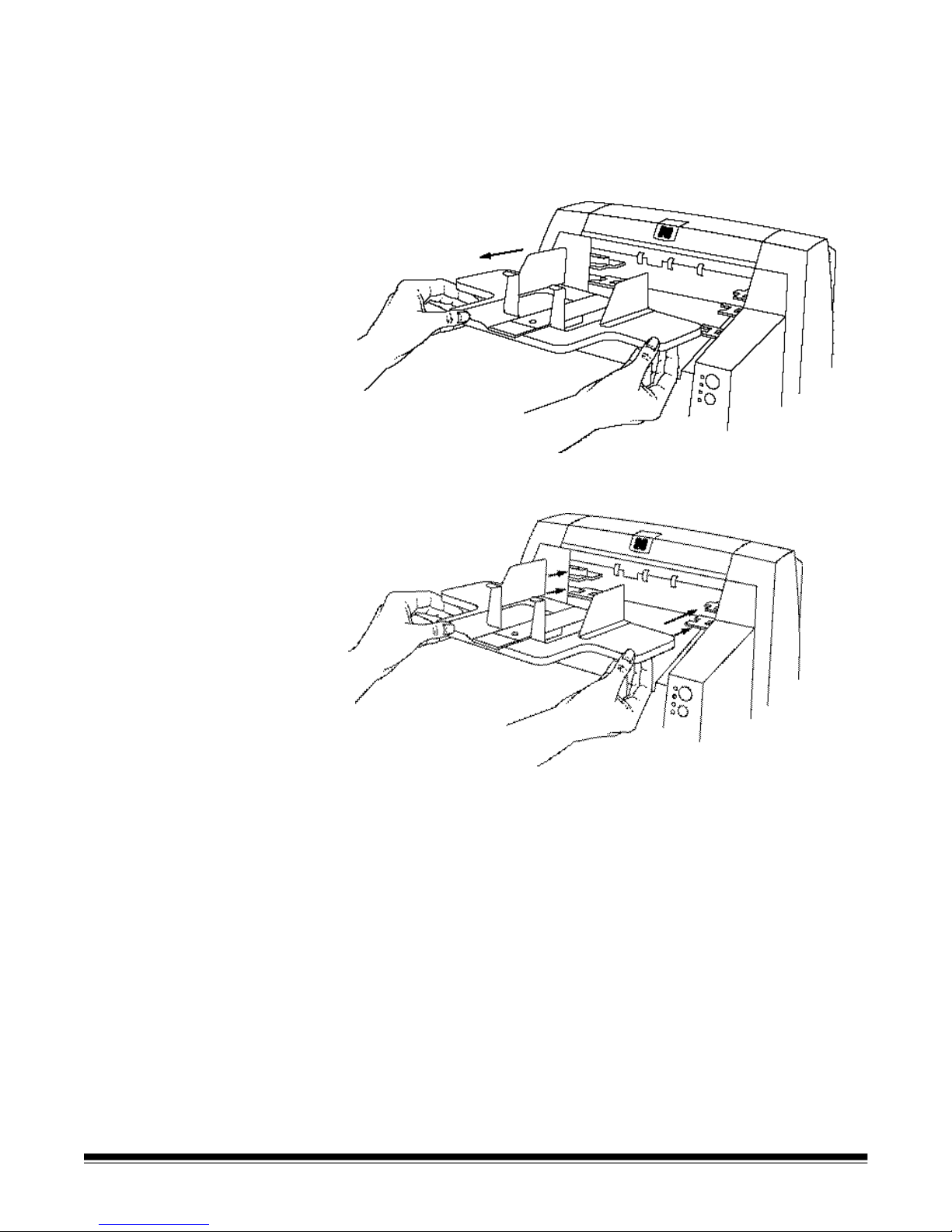

Adjusting the back of

the output tray

Different paper types stack differently. The output tray can be set in

either one of two positions. In addition you can raise the front of the

output tray to lift the front edge of the documents.

To raise or lower the back of the output tray:

1. Lift the front of the output tray and pull it out of the detent position.

2. Set the back of the tray either in the upper position or lower position

as desired.

A-61500 January 2004 3-5

Loading...

Loading...