Page 1

Page 2

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Scanner models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Scanner features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Speed/capacity (throughput) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Supporting documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

MSDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

User precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Gas springs warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Environmental information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

EMC statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

United States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Japan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Taiwan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Peoples Republic of China . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Acoustic emission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Power system connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Site specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

System requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Registering your scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Making connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installing the IEEE-1394 card in the host computer . . . . . . . . . . . . . . 2-2

Installing the Kodak Driver software . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installing the FireWire cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Attaching the power cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Powering up the host computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Scanner components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

3 Using the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Turning the scanner on and off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Starting and stopping scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Manually pausing and resuming the scanner . . . . . . . . . . . . . . . . . . . . . . 3-2

Automatically pausing and resuming the scanner . . . . . . . . . . . . . . . . . . . 3-2

Manually ending scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Document preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Adjusting the side guides and end stop . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Locking the side guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Adjusting the back of the output tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Adjusting the front of the output tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Adjusting the output tray for long documents up to 43 cm (17 in.) . . . . . . 3-6

Adjusting the output tray for documents from 43 cm (17 in.) to

86 cm (34 in.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Exit deflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Adjusting the optional short document tray . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Feeding documents using multi-feed detection . . . . . . . . . . . . . . . . . . . . . 3-9

Automatic feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Continuous feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Manual feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Feeding documents that require special handling . . . . . . . . . . . . . . . . . . 3-10

A-61500 April 2007 i

Page 3

Calibrating the scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Image calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Ultrasonics calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

4 The Enhanced Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Printer specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Changing print positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Changing the front horizontal print positions . . . . . . . . . . . . . . . . . . . 4-3

Installing an ink cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Replacing the blotter strips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Cleaning frequency chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Cleaning tools and materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Supplies and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Ordering parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Cleaning procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Replacement procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Replacing the feed module or feed module tires . . . . . . . . . . . . . . . 5-12

Replacing the separation roller or separation roller tires . . . . . . . . . 5-16

Replacing the pre-separation pad . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Replacing the imaging guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Indicator lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Accessing the Operator Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Message listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Numerical message listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Problem solving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Appendix A Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Ultra-Lightweight Paper Feed Module . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

White Background Accessory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Appendix B Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

ii A-61500 April 2007

Page 4

1 Introduction

This User’s Guide provides information and procedures for the Kodak

i600 Series Scanners. The information in this guide is for use with all of

the i600 Series Scanners unless otherwise noted.

Chapter 1, Introduction — provides general information about the

i600 Series Scanners including a product description, scanner features,

safety information and user precautions.

Chapter 2, Getting Started — includes specifications and instructions

on how to install the Kodak i600 Series Scanner. Also provides an

overview of internal and external scanner components.

Chapter 3, Using the Scanner — includes information on how to

prepare your documents for scanning, document feeder and output tray

adjustments, scanner calibration and how to scan documents.

Chapter 4, Using the Enhanced Printer — provides procedures for

using and maintaining the Enhanced Printer.

Chapter 5, Maintenance — provides maintenance procedures for the

i600 Series Scanners, including replacement procedures for the feed

module, separation roller and imaging guides.

Chapter 6, Troubleshooting — provides a description of the LED

indicators, a problem solving chart, procedures for clearing a document

jam and a listing of error messages.

Appendix A, Accessories — provides a description of the optional

accessories that can be purchased to support the Kodak i600 Series

Scanners. Instructions for using these accessories are included with

the accessory.

Appendix B, Specifications — provides a listing of the specifications

for the Kodak i600 Series Scanners.

A-61500 April 2007 1-1

Page 5

Scanner models • Kodak i610 Scanner is a desktop duplex black and white and

grayscale scanner with an automatic document feeder that runs at 80

pages per minute which includes an enhanced printer.

• Kodak i620 Scanner is a desktop duplex color scanner with an

automatic document feeder that runs at 80 pages per minute which

includes an enhanced printer.

• Kodak i640 Scanner is a desktop duplex color scanner with an

automatic document feeder that runs at 100 pages per minute which

includes an enhanced printer.

• Kodak i660 Scanner is a desktop duplex color scanner with an

automatic document feeder that runs at 120 pages per minute which

includes an enhanced printer.

Optional accessories Kodak Feeder Kit for Ultra-Lightweight Paper — allows you to feed

2

lightweight paper from a paper weight range of 25 to 75 g/m

(7 to 20 lbs).

Kodak White Background Accessory — if you are scanning

translucent documents, this accessory will reduce black background

bleed-through which produces whiter images.

See Appendix A, Accessories for more information.

Scanner features • Excellent paper handling, image quality, and reliability.

• Color or grayscale at the same speed as black and white.*

• Includes the Brightness and Contrast Control which allows you to

create custom color tables.*

• Simultaneous black and white and color image output.*

• Simultaneous black and white and grayscale image output.

• Handles a broad range of paper weights and sizes.

• Easy installation.

• ISIS and TWAIN device drivers are included on a CD that is packed

with each scanner.

• International language support.

• Ergonomic design.

• 500-sheet elevator tray.

• Energy Star compliant (also known as “sleep” mode).

• Document printing capabilities.

• Electronic red, green and blue color dropout.

• Output resolutions include:

- black and white: 200, 240, 300, 400

- Color:* 100, 150, 200, 240, 300

- Grayscale: 100, 150, 200, 240, 300

• Multi-feed detection by multiple ultrasonic sensors as well as by

length detection.

* Not applicable to the Kodak i610 Scanner.

1-2 A-61500 April 2007

Page 6

• Automatic and manual feeding.

• JPEG compression allows color and grayscale images to be viewed

in most image viewers.

• Image processing features include: iThresholding, Adaptive

Threshold Processing, orthogonal rotation, color, black and white and

grayscale deskew, auto-crop, automatic color detection, aggressive

cropping, error diffusion, toggle patch, auto-color balancing (autowhite balancing) to ensure good color balance after calibration, and

more.

• Easily replaceable feed module and separation roller.

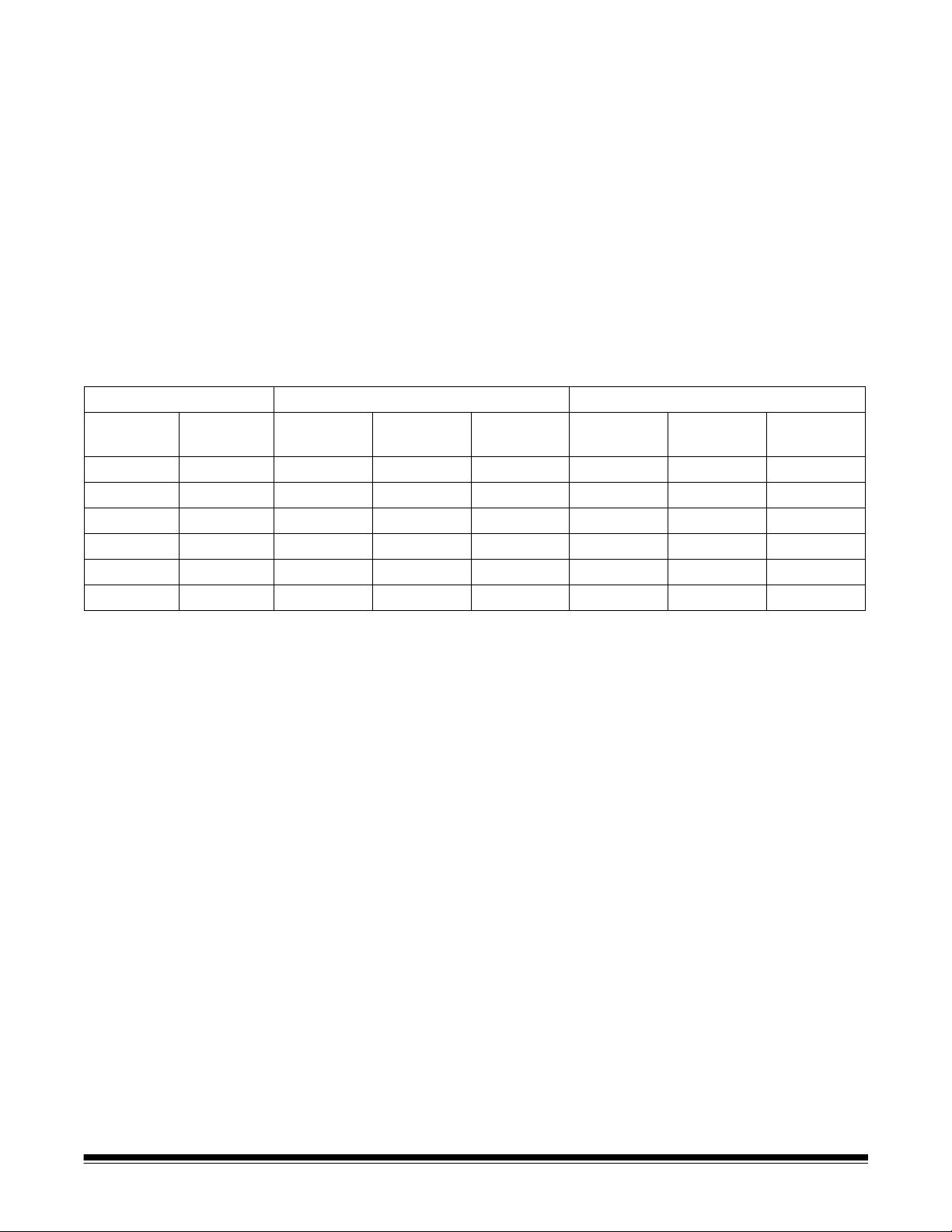

Speed/capacity

(throughput)

Resolution (dpi) Landscape Letter Portrait Letter

Color/Gray Black and

White

100 - 80 100 120 69 83 96

150 - 80 100 120 69 83 96

200 200 80 100 120 69 83 96

240 240 53 66 80 46 55 64

300 300 53 66 80 46 55 64

-400<53 <66 <80 <46 <55 <64

Supporting documentation

The following speeds (pages per minute) are for color/grayscale and

black and white output.

i610/i620 i640 i660 i610/i620 i640 i660

The following documentation is available to support the Kodak i600

Series Scanners:

• Image Processing Guide, A-61504 — available in PDF format on

the Installation CD.

• Quick Tips Guide, A-61501— intended to be used as a quick

reference for basic scanner use.

• FireWire Installation Information, A-61511 — this installation

information is packed with the FireWire cable and should be used to

make the required FireWire cable connections.

• White Background Accessory Instructions, A-61503 — when you

purchase the White Background Accessory these instructions are

included and provide a description of how to install the accessory.

• Ultra-Lightweight Feeder Accessory Instructions, A-61190 —

when you purchase the Ultra-Lightweight Feeder Accessory these

instructions are included and provide a description of how to use the

Ultra-Lightweight Feed Module.

• Brightness and Contrast Control Reference Guide, A-61506 —

provides information and procedures for using the Brightness and

Contrast Control which allows you to create your own custom color

tables.

A-61500 April 2007 1-3

Page 7

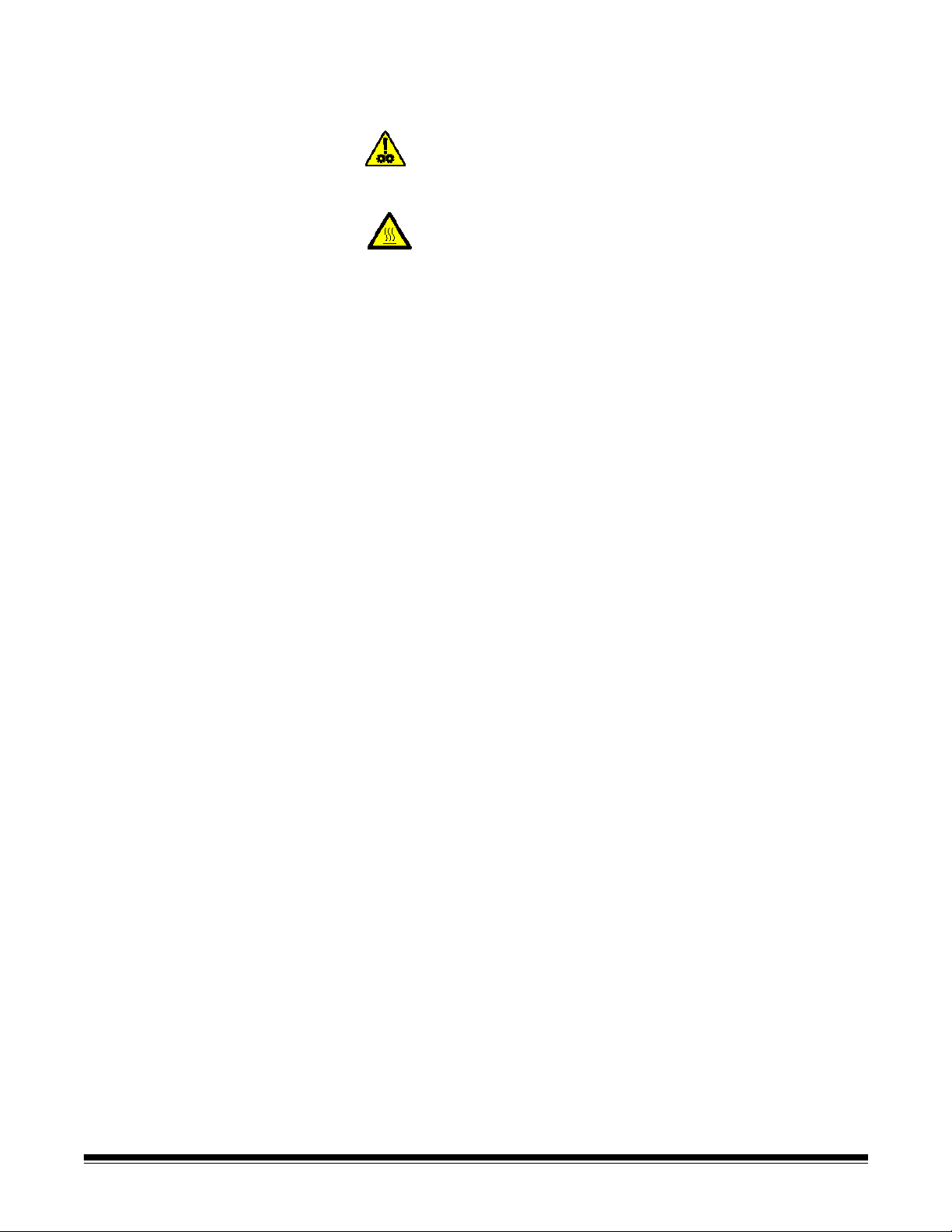

Safety information Warning labels

CAUTION: Moving parts, avoid contact.

CAUTION: Hot surface, avoid contact.

MSDS Material Safety Data Sheets (MSDS) are available on the Kodak

website at: www.kodak.com/go/msds. When accessing the MSDSs

from the website, you will be required to provide the catalog number of

the consumable you want the Material Safety Data Sheet for. See

Chapter 5, “Supplies and accessories” for consumables and catalog

numbers.

User precautions Users and their employer need to observe the common sense

precautions applicable to the operation of any machinery. These

include, but are not limited to, the following:

• Do not wear loose clothing, unbuttoned sleeves, etc.

• Do not wear loose jewelry, bracelets, bulky rings, long necklaces, etc.

• Hair length should be kept short, using a hair net if needed, or tying

long hair up in a bundle.

• Remove all other loose objects from the area that could be drawn into

the machine.

• Take sufficient breaks to maintain mental alertness.

Supervisors should review their practices and make compliance with

these precautions a part of the job description for operation of the

scanner or any mechanical device.

Gas springs warning If the gas springs exhibit a sign of decayed performance, call Service

for replacement. Do not attempt to repair.

Environmental information

• The Kodak i600 Series Scanners contain lead in the circuit board

solder. Disposal of this material may be regulated due to

environmental considerations. For disposal or recycling information,

please contact your local authorities or, in the USA, visit the

Electronics Industry Alliance website: www.eiae.org.

• The product packaging is recyclable.

• The i600 Series Scanners are Energy Star compliant and are shipped

from the factory with the default time set to 15 minutes.

1-4 A-61500 April 2007

Page 8

EMC statements

United States This equipment has been tested and found to comply with the limits for

a Class A digital device pursuant to Part 15 of the FCC rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequently energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Japan This is a Class A product based on the standard of the Voluntary

Control Council for interference by information Technology Equipment

(VCCI). If this equipment is used in a domestic environment, radio

disturbance may arise. When such trouble occurs, the user may be

required to take corrective action.

Taiwa n WARNING: This is a Class A product. In a domestic environment this

product may cause radio interference in which case the user may be

required to take adequate measures.

Peoples Republic of China

此为A级产品,在生活环境中品可能会造成无线电干扰。

用户对其干扰采取切实可行的措施

WARNING: This is a Class A product. In a domestic environment this

product may cause radio interference in which case the user may be

required to take adequate measures.

声明,该产

在这种情况下,可能需要

Acoustic emission Maschinenlärminformationsverordnung – 3, GSGV

Der arbeitsplatzbezogene Emissionswert beträgt <70 db(A).

[Machine Noise Information Ordinance — 3, GSGV

The operator-position noise emission value is <70 dB(A).]

Power system connection

A-61500 April 2007 1-5

This product is also designed for Norwegian IT power system with

phase-to-phase voltage 230V.

Page 9

2 Getting Started

Site specifications Place the scanner:

• In a clean area with temperature and relative humidity typical of an

office environment,

• on a stable, level work surface,

• within 1.52 metres (5 feet) of an electrical power outlet.

IMPORTANT: Only use the scanner indoors in a dry location.

For more information about the scanner specifications, refer to

Appendix B, Specifications.

System requirements Following is the minimum recommended system configuration to run

Kodak i600 Series Scanners.

NOTE: The actual performance of the system depends on the scanning

application, choice of scanning parameters, and the host

computer configuration. If the scanner is not performing at the

optimal speed, a faster computer and/or more RAM may be

necessary to obtain the rated throughput.

Registering your scanner

• Intel PC (or compatible) with a Pentium IV 2 GHz processor

•PCI slot

• Microsoft Windows 2000 Professional, Windows XP (Professional/

Home)

• 512 MB RAM

• Monitor

• Mouse

It is very important that you register your scanner so Kodak can provide

you with the best possible service and support that helps maintain your

continuous scanning. Registering your scanner will help us provide you

with firmware and hardware updates as they become available.

The scanner must be registered before any service support can be

provided.

You can register your scanner’s new equipment warranty online at

www.kodak.com/go/DIwarrantyregistration.

For more information about Kodak’s service and support options,

contact your reseller of Kodak Document Imaging products or visit us

on the web at www.kodak.com/go/DIserviceandsupport.

A-61500 April 2007 2-1

Page 10

Making connections Follow the instructions for installing the IEEE-1394 (FireWire) card and

the Kodak driver software before you plug the scanner into the host

computer.

IMPORTANT: You must install the software on the host computer

before you connect the scanner.

Installing the IEEE-1394 card in the host computer

Installing the Kodak Driver software

Installing the FireWire cable

Install the IEEE-1394 (FireWire) card according to the directions

supplied with the IEEE-1394 card.

IMPORTANT: Use proper precautions to avoid static when you install

the IEEE-1394 card in your computer. Make sure the

computer power cord is disconnected.

1. Insert the Kodak i600 Series Scanners installation CD in the CD-

ROM drive. The installation program starts automatically.

2. Follow the on-screen instructions to install the TWAIN Datasource,

ISIS Driver and the Kodak Scan Validation Tool.

3. Shut down the host computer.

An IEEE-1394 six-pin connector is provided on the rear panel of the

scanner for IEEE-1394 connectivity.

1. Plug the end of the cable with the right angle into the scanner.

2. Connect the other end of the cable into the IEEE-1394 card outlet in

the host computer. Be sure that it is installed correctly and properly

seated.

CAUTION: DO NOT FORCE THE CONNECTOR. If the cable is not

properly connected, it could cause damage to the

scanner.

2-2 A-61500 April 2007

Page 11

Attaching the power cord The Kodak i600 Series Scanner is packed with a set of power cords.

1. Select the power cord which complies with your electrical

requirements and attach it.

2. Turn on the scanner and wait until the top green LED is lit indicating

the scanner has completed power-up self-test and is idle.

Powering up the host

• Turn the power on to the host computer.

computer

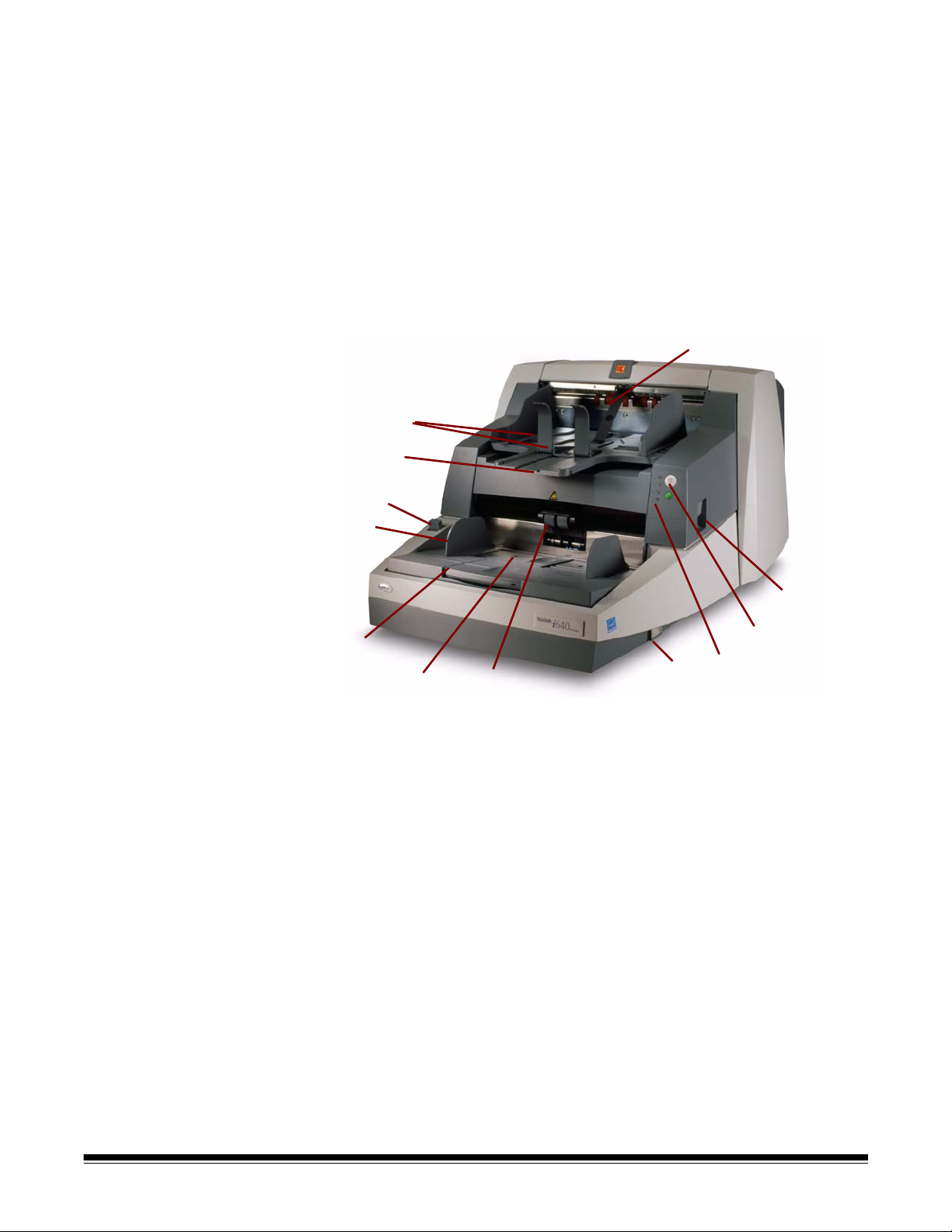

Scanner components Front view

5

12*

4

3

1

11 2

10

6

7

8

9

1 Elevator tray extender — open the elevator tray extender to

accommodate long documents.

2 Feed module — provides smooth document feeding of various

sizes, thicknesses and textures.

CAUTION:Moving parts, avoid contact.

3 Elevator tray side guides — slide the guides in or out to

accommodate the document size you want to scan. Side guides

can be left-, center- and right-adjusted to accommodate

documents of various widths. The side guides can also be locked

into position if desired.

4 Gap Release lever — allows you to manually adjust the space

between the feed module and separation roller for documents that

require special handling.

5 Output tray and End stop — collects the scanned documents.

The output tray width and end stop length can be adjusted.

6 POD release latch — push up the POD release latch when you

need to access the inside of the scanner.

A-61500 April 2007 2-3

Page 12

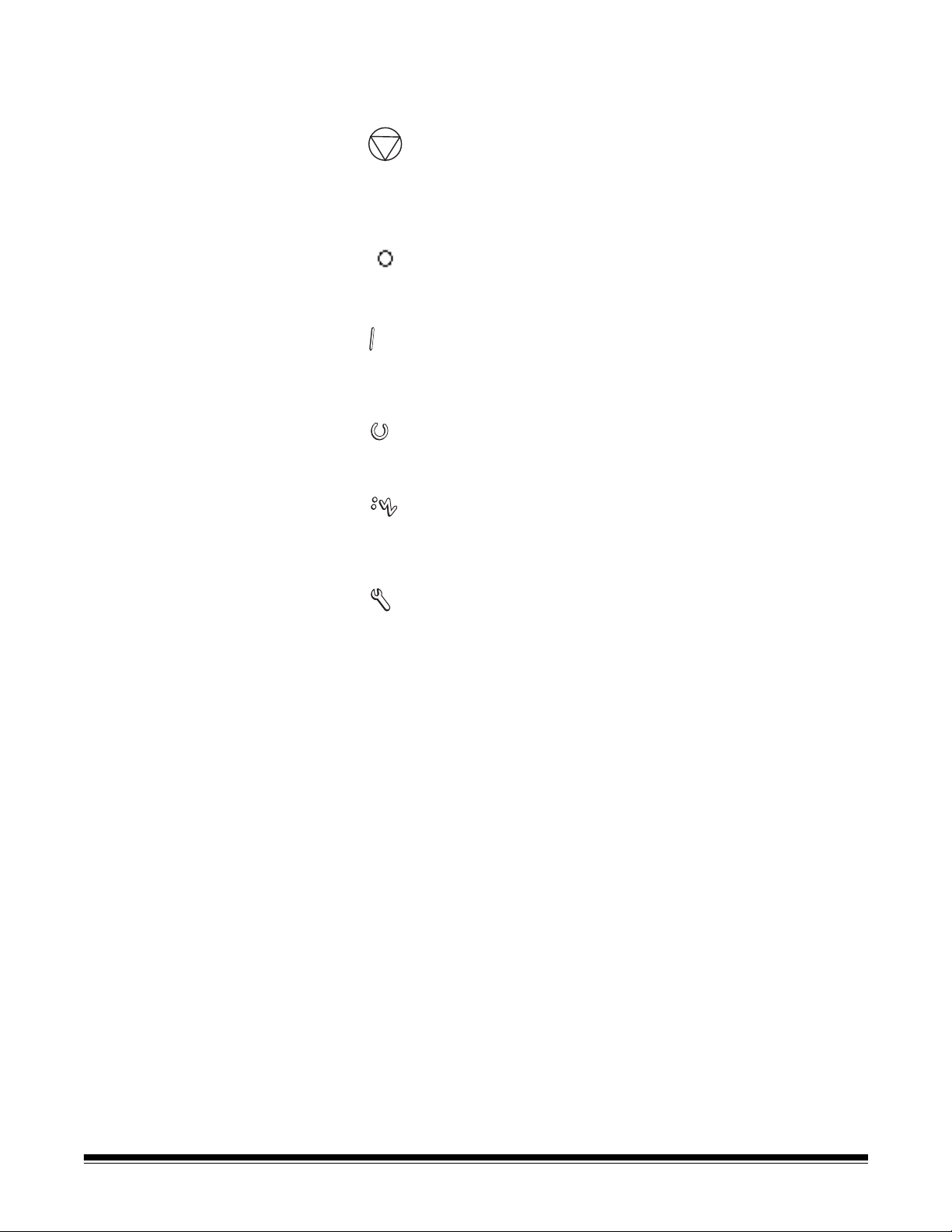

7 Stop/Pause and Start/Resume buttons —

Stop/Pause (white with red triangle) button:

press once to temporarily pause scanning (the

green button can then use used to resume

scanning). Press twice to stop scanning

(end of job).

Start/Resume (green) button: to start scanning.

8LEDs— illuminate or flash from top to bottom as follows:

Illuminates when the power is turned on and the scanner is idle.

This indicator will flash if the scanner is in “sleep” or lamp saver

mode.

illuminates when the scanner is enabled and/or scanning, and

flashes when the scanner is powering up.

flashes when a document has jammed in the transport or

when a multi-feed has been detected. Illuminates when a usercorrectable error has been detected.

Illuminates when you need to call Service.

Refer to Chapter 6, Troubleshooting, for complete descriptions of

the LED indicators.

9 Power switch — press the power switch on (I) or off (O) as

required.

10 Exit deflector (optional) — aids in document stacking.

11 Paper Present Sensor — detects the presence of documents in

the elevator tray.

12* Height Adjustment Wire — located underneath the output tray

(not shown in photo), this wire can be pulled out to raise the front of

the output tray.

2-4 A-61500 April 2007

Page 13

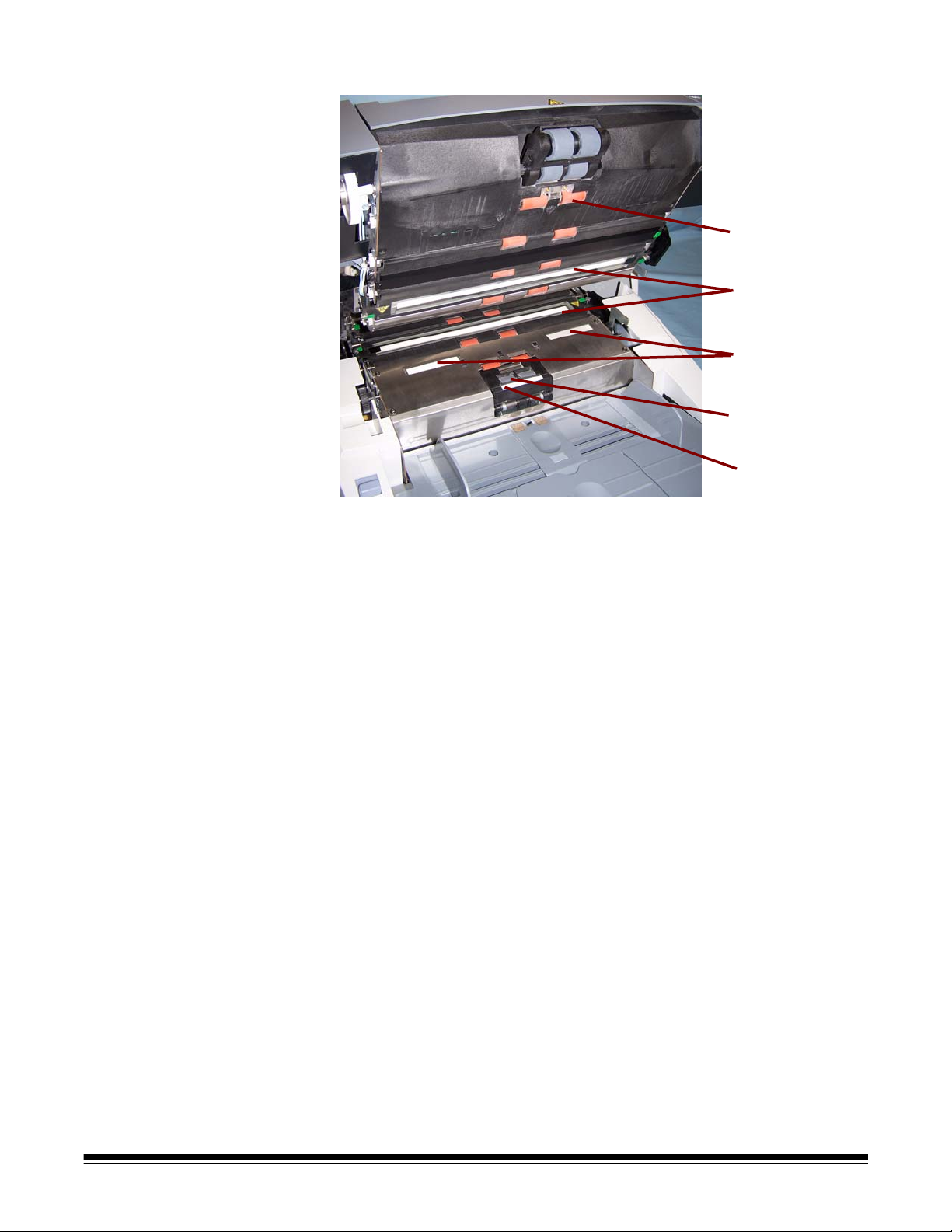

Internal components

Rollers

Imaging guides

Ink blotter strips

Separation roller

Pre-separation pad

Separation roller — provides smooth document feeding of various

sizes and textures one document at a time.

Ink blotter strips — collects residue from the Enhanced Printer.

Imaging guides — the scanner has an upper and lower imaging guide.

It is important to keep the imaging guides clean to obtain optimum

image quality.

CAUTION:Hot surface, avoid contact.

Rollers — drive rollers and NFR rollers transport the documents

through the paper path.

Pre-separation pad — provides smooth document feeding of various

sizes and textures one document at a time.

A-61500 April 2007 2-5

Page 14

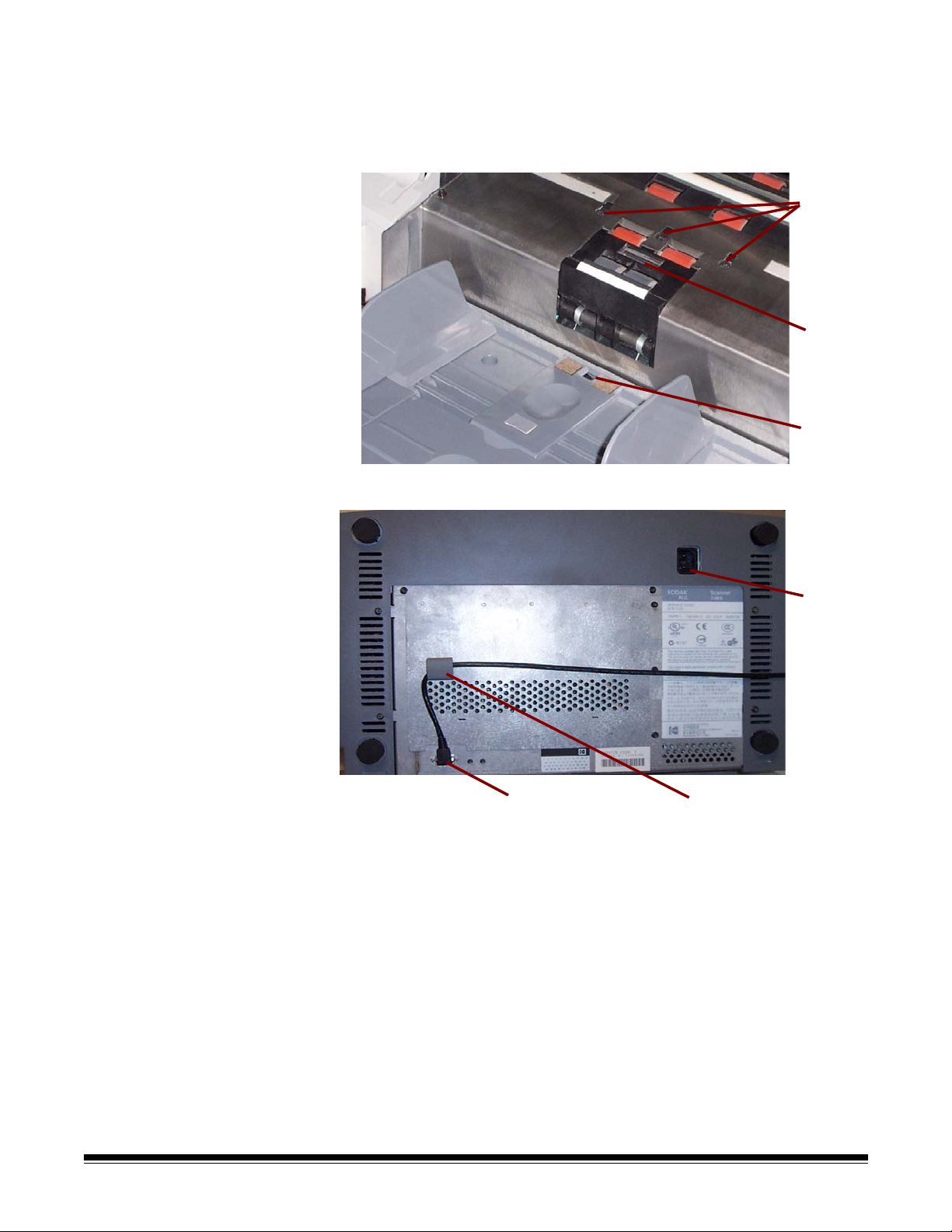

Sensors — the scanner has 3 (ultrasonic) multi-feed detection

sensors, 1 (optical) paper path sensor and 1 (optical) paper present

sensor. These sensors detect the presence of documents in the

elevator tray and documents in the paper path during feeding and

imaging.

Ultrasonic

sensors

Paper

Path

sensor

Paper

Present

sensor

Rear view

Power

cord

connection

IEEE-1394 connection

Retainer clip

Power Cord Connection — provides power to the scanner. The

scanner is packed with six power cords. Choose the power cord

appropriate for your location and connect it accordingly. Connect the

power cord first to the scanner, then to the wall outlet.

FireWire (IEEE-1394) Connection — before connecting the FireWire

cable, be sure that power to the scanner is off. See the FireWire

instructions packed with the scanner for connection instructions. After

connection, place the cable in the retainer clip located above the

connector.

2-6 A-61500 April 2007

Page 15

3 Using the Scanner

This chapter provides the following operational procedures:

• Turning on/off the scanner

• Starting, stopping, pausing and resuming the scanner

• Document preparation

• Adjusting the side guides and output tray

• Scanning documents

• Feeding long documents

• Automatic, continuous and manual feeding

• Calibration

Turning the scanner on and off

Starting and stopping scanning

• Press the button on the scanner’s lower right-side (I) to power it up.

• Press the button on the scanner’s lower right-side (O) to power it

down.

After you power up the scanner, wait until for it to complete self-test.

When completed, the top green indicator light will remain on and

constant. If this does not occur, refer to Chapter 6, “Indicator lights” for

more information.

IMPORTANT: Always power up the scanner to its ready state before

powering up or restarting the host computer.

Scanning is controlled by integration software developed for your

application. To start and stop scanning, refer to the documentation

provided with your integration software.

If your application does not automatically start the scanner transport,

begin the scanning process by pressing the Start/Resume button on

the scanner.

NOTE: Before you start scanning, make sure the scanner is ready for

operation, which is indicated by the top green indicator light

being on and constant.

A-61500 April 2007 3-1

Page 16

Manually pausing

While scanning documents:

and resuming the

scanner

• Press the Stop/Pause button on the scanner once to pause

scanning.

NOTE: Your application may configure the scanner with a transport

timeout function which signals an End of Job. If you do not start/

resume scanning before the timeout expires, you cannot

continue scanning without restarting the job from the host

application.

• Press the Start/Resume button on the scanner to restart scanning

after it has been paused.

Stop/Pause

button

Start /Resume

button

Automatically pausing and resuming the scanner

Manually ending scanning

During scanning the scanner monitors its own internal image buffer

memory. In order to prevent overwriting images before the host

computer can retrieve them, the scanner will automatically pause the

feeder while waiting for the host computer to read existing images.

The scanner automatically resumes scanning by restarting the feeder

once image buffer memory is cleared. To avoid this situation be sure

your host computer meets the minimum system requirements as

referred to in Chapter 2.

After feeding the last document to be scanned, you can end scanning

by pressing the Stop/Pause button on the scanner twice. An end of job

message will be sent to your host application.

You cannot continue scanning without restarting the job from the host

application.

3-2 A-61500 April 2007

Page 17

Document preparation

Before you begin scanning documents, make certain the documents

can be fed through the scanner easily.

• A batch of documents to be fed into the scanner must be arranged so

the leading edges of all documents are aligned and centered under

the feed module; this allows the feeder to introduce documents into

the scanner one at a time.

• Staples and paper clips in documents may damage the scanner and

documents. Remove all staples and paper clips before scanning.

• Documents with missing corners, perforated edges, hole punches in

the margins, irregular and curled edges, torn, damaged, or crushed

pages can be transported successfully through the scanner.

However, no scanner can transport every possible type of damaged

paper. If in doubt about whether a specific damaged document can

be transported through the scanner, place the document in a clear

protective sleeve with the lead edge of the document aligned with the

folded edge of the sleeve. Sleeves should be manually fed, one at a

time, folded edge first, while using the gap release lever. Ultrasonic

multi-feed detection is not recommended when using plastic sleeves.

NOTE: When scanning documents in a clear protective sleeve, the

elevator tray side guides must be aligned to accommodate the

width of the sleeve.

Kodak scanners have been tested with a range of documents that

represent the broad spectrum of document types found in the most

common business applications. Optimal scanner performance is

achieved when scanning documents within the recommended

document specifications listed below. Scanning documents outside of

these specifications may lead to undesirable results in terms of scanner

reliability, image quality, and/or consumable life.

Materials:

• Virgin, recycled and photographic papers

• Clear protective sleeves meeting the size and thickness

requirements in this section

Paper Types: Bond, Laser, Inkjet, Offset

Paper Weights: The elevator tray handles a broad range of paper

weights from 45 to 200 g/m

Ultra Lightweight Paper can handle paper weights from 25 to 75 g/m

(7 to 20 lbs).

Minimum Document Size: 6.4 x 6.4 cm (2.5 x 2.5 in.). Documents as

small as 5 cm (2 in.) (i.e. business cards) can be center-fed, in portrait

orientation one at a time.

2

(12 to 110 lb.). The Kodak Feeder Kit for

2

A-61500 April 2007 3-3

Page 18

Maximum Document Size: 30.5 x 86 cm (12 x 34 in.). Documents

larger than 43 cm (17 in.) require operator assistance.

Paper inks: All inks on the paper must be dry before scanning is

started. This includes: Standard offset printing, Inkjet printer, Thermal

transfer, Handwriting inks.

Correction Fluids: Liquid Paper®, Tipp-Ex®, Wite-out®, and other

similar correction fluids.

Feeder Capacity: The elevator tray can hold up to 500 sheets of

2

75 g/m

(20 lb.) paper.

Adjusting the side guides and end stop

To accommodate multiple applications with variable feeding

requirements, the side guides can be adjusted for right-, left- or centeredge feeding. The side guides can be moved together or independently

to achieve offset feeding.

1. Pull the side guides all the way out and then push them together

(toward the center) to reset or center them.

End stop

Side guides

2. Open the side guides slightly wider than the documents you will be

feeding.

3. Adjust the output tray end stop to slightly longer than the longest

document being fed in a batch.

4. Place the documents in the elevator tray.

5. Adjust the side guides to fit the documents.

3-4 A-61500 April 2007

Page 19

Locking the side guides Side guides may be locked into position after they are adjusted. This

may be helpful when the placement of print strings is important.

If you want to lock the side guides into position, move any documents

which may be in the input tray and move the locking switch into the

locked position.

Adjusting the back of the output tray

Different paper types stack differently. The output tray can be set in

either one of two positions. In addition, you can raise the front of the

output tray to lift the front edge of the documents.

To raise or lower the back of the output tray:

1. Lift the front of the output tray and pull it out of the detent position.

2. Set the back of the tray either in the upper position or lower position

as desired.

A-61500 April 2007 3-5

Page 20

Adjusting the front of

To raise the front of the output tray:

the output tray

Adjusting the output

tray for long

documents up to 43

1. Lift the front of the output tray.

2. Swing the height adjustment wire out from underneath the output

tray and insert it into the groove on the printer access cover.

3. When finished using the output tray in this position, tuck the height

adjustment wire back into position and lower the output tray.

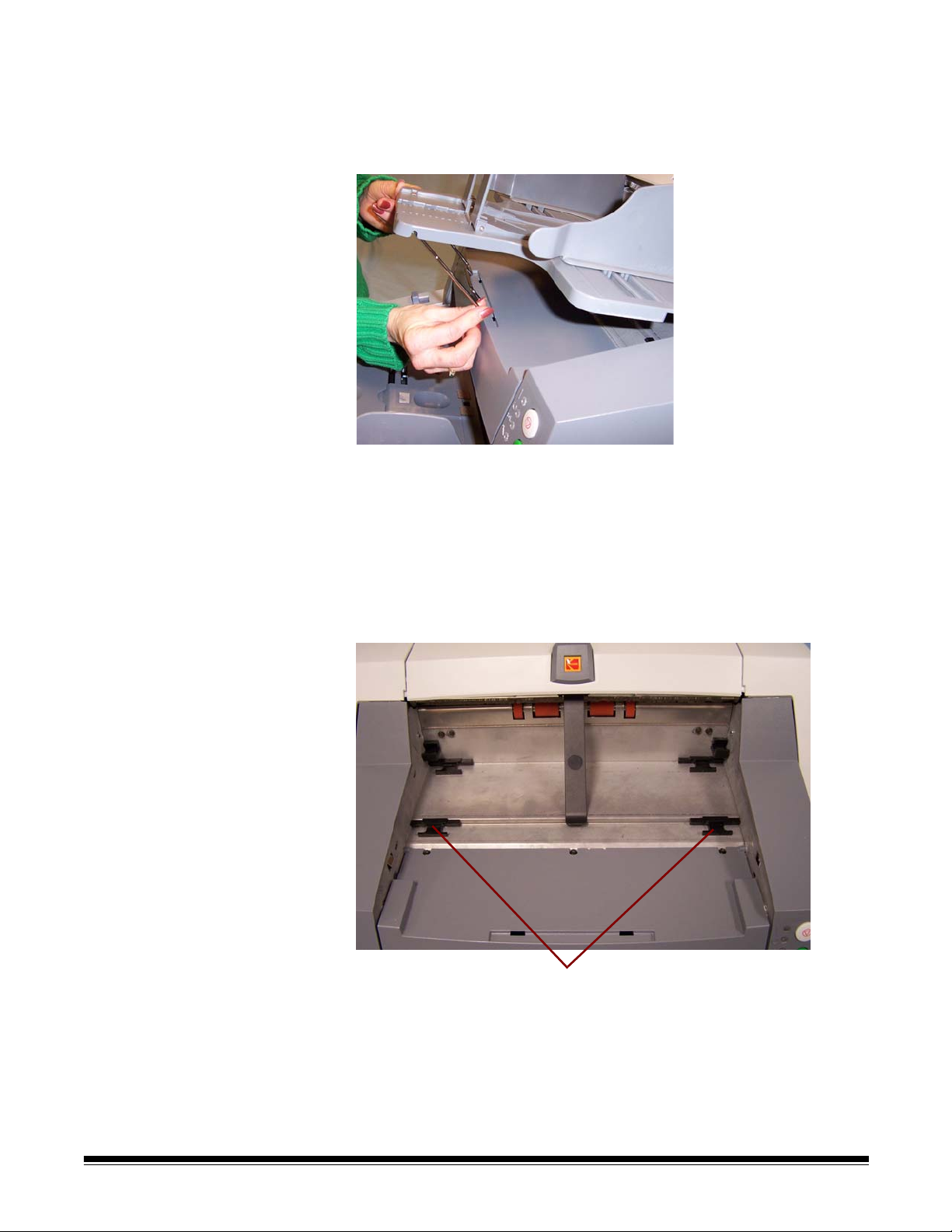

To adjust the output tray to accommodate long documents from 37 cm

14.5 in.) to 43 cm (17 in.):

1. Lift the front of the output tray and pull it out of the detent position.

cm (17 in.)

2. Place the output tray in the forward detent position.

Forward detent positions

3. Gently push down on the left side of the output tray until in snaps

into place.

4. Adjust the output tray end stop to accommodate long (or short)

documents by pulling the end stop forward (or backward).

5. Remove the exit deflector.

3-6 A-61500 April 2007

Page 21

Adjusting the output tray for documents from 43 cm (17 in.) to 86 cm (34 in.)

An output tray document extender is available for scanning documents

from 43 cm (17 in.) to 86 cm (34 in.). Contact your Kodak Field

Engineer (1-800-3KODAK3) to order the document extender (Part No.

5E4754).

1. Lift the front of the output tray and pull it out of the detent position.

2. Place the output tray in the forward detent position.

3. Gently push down on the left side of the output tray until in snaps

into place.

4. Remove the end stop.

5. Remove the exit deflector.

6. Install the output tray document extender.

Exit deflector The optional exit deflector aids in document stacking. When feeding

long documents, it is suggested that the exit deflector be removed.

The exit deflector can be pulled out of place or pushed into place as

required.

A-61500 April 2007 3-7

Page 22

Adjusting the optional short document tray

A short document tray is available for scanning smaller documents.

This tray can be ordered from Parts Services. See Chapter 5, “Supplies

and Consumables” for ordering information.

1. Remove the end stop on the output tray.

2. Slide the short document tray on the rail of the output tray and push

it up to the desired position to accommodate your documents.

3. Adjust the side guides as necessary.

3-8 A-61500 April 2007

Page 23

Feeding documents using multi-feed detection

The scanner has three multi-feed detection sensors. When Multi-feed

detection is enabled, adjust the side guides so the documents fully

cover at least one sensor. If the document partially covers a sensor,

false multi-feeds may occur.

Automatic feeding To scan a batch of documents follow the guidelines for size, type,

quantity, etc., outlined in the “Document preparation” section.

For faster throughput, place documents into the elevator tray in

landscape orientation (longer side as the leading edge).

IMPORTANT: Staples and paper clips on documents may damage the

scanner. Remove all staples and paper clips before

scanning.

1. Align the leading edges of the stacked documents.

2. Position the stack of the documents, face up in the elevator tray so it

covers the paper present sensor.

3. Adjust the elevator tray side guides.

4. Adjust the output tray position, if necessary.

5. Adjust the output tray end stop, if necessary.

Depending on how your scanner is set up, your documents will

automatically start scanning, or you may need to press the Start/

Resume button to begin scanning.

Continuous feeding Continuous feeding can be used when you want to scan small batches

of documents (less than 25).

When the scanner is configured for continuous feeding, the elevator

tray is raised to a position where approximately 25 documents can be

loaded. The elevator tray will remain in this position to allow more

documents to be loaded to the bottom of the stack.

To continuously feed documents, follow Steps 1 through 5 above. As

the documents are being scanned, you can continuously add a batch of

documents to the bottom of the stack.

NOTE: Depending on how your scanner is configured, the transport will

stop when the Transport Timeout has been reached.

A-61500 April 2007 3-9

Page 24

Manual feeding To manually feed documents:

1. Position the document you want to feed in the elevator tray so that

the paper present sensor is covered.

2. Press Start/Resume.

Feeding documents that require special handling

The gap release lever allows you to manually adjust the space between

the feed module and separation roller for documents that require

special handling; i.e. documents that are badly torn. If you are in doubt

about whether a damaged document can be transported through the

scanner, use the gap release lever and manually feed the document.

Using the scanner in continuous feed mode is recommended when

handling special documents.

1. Press and hold the gap release lever — this provides clearance to

ease document feeding.

2. Push the document into the elevator tray. If more than one

document is to be scanned, feed them one at a time.

3. After the document(s) has been fed, release the gap release lever.

3-10 A-61500 April 2007

Page 25

Calibrating the scanner

There are two types of calibration that can be performed on the i600

Series Scanners: Image calibration and Ultrasonics calibration.

• Image calibration: optimizes the optical system in your scanner in

order to achieve the best overall quality of scanned images. Frequent

calibration is not needed or recommended.

IMPORTANT: If the White Background Accessory is installed, it must be

replaced with the black background strip, and the

scanner must be rebooted prior to calibration.

• Ultrasonics calibration: ensures that the ultrasonics system that

detects multi-feeds and document edges is properly adjusted for best

performance. Frequent calibration is not needed or recommended.

Image calibration Use the calibration target provided with your scanner. Be sure to use a

good, clean calibration target. Additional calibration targets can be

ordered. See Chapter 5, “Supplies and accessories” for ordering

information.

NOTE: The screens shown in this section are for the TWAIN

Datasource. The screens displayed on your system may be

different.

1. Open the pod and clean the imaging guides. Refer to the

maintenance procedures in Chapter 5.

2. If the lamps have not been on, allow the lamps to warm up for 90

seconds.

3. Center the side guides in the elevator tray and output tray.

4. Place the calibration target in the elevator tray.

5. Open the Scan Validation Tool.

6. Select Kodak Scanner: i600.

A-61500 April 2007 3-11

Page 26

The main Kodak Scanner window will be displayed.

7. Click the Setup icon to access the main Kodak Scanner window.

8. Click Settings. The following screen will be displayed.

9. Click Device.

3-12 A-61500 April 2007

Page 27

The following screen will be displayed.

10.Click Diagnostics. The following screen will be displayed.

11. Click Calibrate.

12.Select Image. Calibration begins. A confirmation box is displayed

when calibration is complete.

13.Click OK.

A-61500 April 2007 3-13

Page 28

NOTE: If calibration fails, check the Operator Log for details. See

Chapter 6, “Accessing the Operator Log” for more

information. You must wait at least 90 seconds before

calibrating again.

Ultrasonics calibration Use only an A4 size / 75-80 g/m

perform an Ultrasonics calibration.

NOTE: The screens shown in this section are for the TWAIN

Datasource. The screens displayed on your system may be

different.

1. Center the side guides in the elevator tray and output tray.

2. Place the paper in the elevator tray in portrait orientation.

3. Follow Steps 5 - 12 above to access the Calibration dialog box.

4. Select Type: UDDS. Calibration begins. A confirmation box is

displayed when calibration is complete

2

or lettersize / 20 lb. bond paper to

5. Click OK.

NOTE: If calibration fails, check the Operator Log for details. See

Chapter 6, “Accessing the Operator Log” for more

information.

3-14 A-61500 April 2007

Page 29

4 The Enhanced Printer

This chapter provides instructions for using the Enhanced Printer. The

following information and procedures can be found in this chapter:

• Overview information about the Enhanced Printer, including

information about print fields and printer specifications.

• Setting horizontal printer positions.

• Replacing the ink cartridge and ink blotter strips.

NOTE: More detailed information on the Enhanced Printer can be found

in the Image Processing Guide, A-61504.

Overview The Kodak i600 Series Scanners include a factory-installed, pre-

configured front printer. The printer operates at full scanner speed. The

printer can add a date, time, document sequential counter, and custom

messages.

The printer is unique in that the document print string can be configured

to include both literal (static) information (i.e., information that stays the

same for each document, such as batch name or operator) and

dynamic information (i.e., information that may change for each page

scanned, such as the document sequential counter). The capture

software application controls static fields; any information that the

software allows you to enter can be sent to the printer.

All printer controls and functions are accessible through the ISIS Driver

or TWAIN Data source. Printing must be enabled or disabled for each

scan session.

NOTES:

• Clean the scanner’s paper path components daily when using the

printer.

• You cannot print on documents that are smaller than 10 cm (4 in.).

• The ink cartridge must be installed prior to powering on the scanner,

or it could result in errors when printing is attempted.

A-61500 April 2007 4-1

Page 30

Printer specifications

Characteristic Description

Maximum lines 1

Maximum characters 40

Print locations (horizontal) 12 front manually set,

Print locations (vertical) Set by capture software application

Print orientation 0, 90, 180 or 270 degrees

Font size 2 selectable, Bold or Normal

NOTE: Not all languages can support a Bold

font based on the complexity of the

characters, such as half-width

Katakana.

Ink cartridge Black: HP-C6602A

Red: HP-C6602R

Green: HP-C6602G

Blue: HP-C6602B

Print side Front (pre-scan)

Minimum printing distance

from document lead edge

Static fields available User-specified messages via capture

Dynamic fields available Up to a nine-digit sequential document

Languages supported Any phonetic language (for example: Dutch,

0.89 cm (0.35 in.)

software application

number, date, four-digit time

English, French, German, Italian,

Portuguese, Spanish, Japanese (half-width

Katakana)

4-2 A-61500 April 2007

Page 31

Changing print positions

The horizontal print position can be changed manually.

Changing the front horizontal print position

1. Remove the output tray.

2. Open the print access cover.

There are 12 horizontal print positions. These positions are visible

by a small detent on the printer rail.

A-61500 April 2007 4-3

Page 32

3. The printer carrier slides easily along the rail. There is a small arrow

on the green printer carrier. Slide the printer carrier to the desired

position aligning the arrow with the detent position on the rail.

4. Close the printer access cover.

5. Reinstall the output tray.

NOTE: Printing automatically stops approximately ½-inch (1.27 cm)

from the trailing edge of the document, even if the information

has not been completely printed.

4-4 A-61500 April 2007

Page 33

Replacing the ink

Replace the ink cartridge when:

cartridge

• printed characters appear light or uneven

• missing characters are evident

• a print test reveals inconsistent character quality

• cleaning has not improved the overall print quality

1. Remove the output tray and lift the printer access cover.

2. Holding the printer carrier as shown, press and hold the release tab

on the bottom of the printer carrier and rotate the printer carrier to

the left until it locks into position.

IMPORTANT: Dispose the empty ink cartridge in accordance with all

federal, state and local laws.

3. Lift the ink cartridge out from the printer carrier.

4. Remove the tab from the new ink cartridge.

5. Slightly angle a new ink cartridge in the print carrier and snap it into

place.

A-61500 April 2007 4-5

Page 34

6. Press and hold the release tab on the bottom of the printer carrier

and rotate the printer carrier back into position.

NOTE: If the ribbon cable should become disconnected, snap it

back into position.

7. Slide the printer carrier into the desired position matching the arrow

on the printer carrier with the detent position.

8. Replace the output tray.

9. Run a print test.

4-6 A-61500 April 2007

Page 35

Replacing the blotter strips

Blotter strips collect ink overflow. They should be replaced when there

is a build-up of ink. Replacement blotter strips may be purchased

through your supplier.

1. Open the pod.

2. Use the green tab to lift and remove the ink blotter strip cover to

access the front blotter strips.

Remove Ink Blotter Strip cover

3. Carefully pull the blotter strip(s) off the transport. You can replace

one or both of the strips as necessary..

4. Discard the soiled strip(s)

5. Peel the backing away from the blotter strip.

A-61500 April 2007 4-7

Page 36

6. Align the blotter strip in the transport channel. Be sure it is properly

aligned before pressing the adhesive side into the channel.

7. Press the blotter strip firmly into the channel.

8. Repeat Steps 5 - 7 for the other blotter strip, if necessary.

9. Replace the ink blotter strip cover.

10.Close the pod.

4-8 A-61500 April 2007

Page 37

5 Maintenance

This chapter provides:

• a cleaning frequency chart

• a list of cleaning tools and materials

• a list of supplies and accessories

• cleaning procedures for the scanner

• replacement procedures for parts that are customer-replaceable

IMPORTANT: Scanner components marked with a green tab indicate

operator-accessible parts.

Cleaning your scanner and preventative maintenance on a regular

basis is required to ensure the best possible image quality. The

following is a preventative maintenance procedure that is

recommended to prevent costly interruptions during production

scanning. Following this procedure as recommended should take

approximately 5 to 10 minutes.

Some document types generate more paper dust and debris and may

require more frequent cleaning than recommended.

NOTES:

• Some debris from the rubber tires on the feed module and separation

roller is normal. Tire debris does not always mean that the tires are

worn or damaged. After cleaning, inspect the tires for wear and

replace the separation roller or feed module if necessary.

• When cleaning rollers/tires, allow the rollers/tires to dry completely

before scanning.

• Using unapproved cleaning fluids or solvents may damage the rubber

tires.

A-61500 April 2007 5-1

Page 38

Cleaning frequency chart

A recommended cleaning sequence includes vacuuming the scanner

transport, cleaning the residue from the feed module, separation roller

or drive rollers and cleaning the imaging guides.

Use the chart below as a guide to how frequently you should clean your

scanner.

Cleaning tools and materials

Procedure Start of

day

Vacuum output tray and input

areas (elevator and transport)

Clean all rollers xx

Vacuum transport area xxx

Remove and vacuum under

background strips

Remove and clean imaging

guides

Vacuum under imaging guides xx

Run transport cleaning sheet xx

Wipe imaging guides with cloth xxx

x

x

xx

Middle of

shift

Start of new

shift

Use only these cleaning tools and materials when performing routine

maintenance on your scanner. Use of any other cleaning materials

could damage your scanner.

• Kodak Digital Science Transport Cleaning Sheets

• Kodak Digital Science Roller Cleaning Pads

• Staticide Wipes for Kodak Scanners

• A vacuum cleaner and tools

5-2 A-61500 April 2007

Page 39

Supplies and

Contact your scanner supplier to order supplies.

accessories

Item CAT No.

Kodak Feeder Consumables Kit for i600/i1800 Series

Scanners

Kodak Feeder Kit for Ultralightweight Paper for i600/i1800

Series Scanners

Kodak Extra-Large Feeder Consumables Kit for i600/i1800

Series Scanners

Kodak Extra-Extra-Large Feeder Consumables Kit for i600/

i1800 Series Scanners

Kodak Imaging Guide Set / for i600/i1800 Series Scanners 197 6703

Kodak Printer Ink Blotters, Front Side for i600/i1800 Series

Scanners

Enhanced Printer Ink Carrier 113 3842

Enhanced Printer Black Ink Cartridge (qty 3) 818 3386

Enhanced Printer Red Ink Cartridge (qty 3) 159 6832

Enhanced Printer Ink Blotter Kit (qty 60) 140 1728

Kodak Digital Science Transport Cleaning Sheets (qty 50) 169 0783

Kodak Digital Science Roller Cleaning Pads (qty 24) 853 5981

Staticide Wipes for Kodak Scanners (qty 144) 896 5519

Kodak Calibration Targets (qty 5) 127 1436

108 4755

896 5279

842 6157

134 3680

125 7633

NOTE: Items and catalog numbers are subject to change.

Ordering parts The following parts can be ordered from Parts Services.

Parts Part No.

Exit deflector 3E9575

Black Background 9E3357

26 in document extender (qty 1) 5E4754

30 in document extender (qty 1) 9E3216

34 in document extender (qty 1) 9E5277

Short document tray 9E5746

A-61500 April 2007 5-3

Page 40

Cleaning procedure Follow the cleaning procedure below to ensure the best scanner

performance and image quality.

Cleaning the output tray and elevator area

1. Power down the scanner.

2. Remove the output tray.

3. Thoroughly vacuum the output tray area and the input area

(elevator) using a brush attachment of a vacuum cleaner.

Opening the pod

4. Push up on the pod release lever and open the pod.

5-4 A-61500 April 2007

Page 41

Cleaning the drive rollers

5. Manually rotate and wipe the NFR and drive rollers with a roller

cleaning pad.

IMPORTANT: The roller cleaning pad contains sodium lauryl ether

sulfate and sodium silicate which can cause eye

irritation. Refer to the MSDS for more information.

6. Dry the rollers with a lint-free cloth.

Cleaning the separation roller tires

7. Pull the separation pad holder forward and remove the separation

roller.

8. Manually rotate and wipe the separation roller tires with a roller

cleaning pad. For best results wipe parallel to the ribs in order to

remove any residue between the ribs.

9. Inspect the tires. If the tires show signs of wear or damage, replace

the separation roller. See “Replacement procedures” later in this

chapter.

10.Reinstall the separation roller.

A-61500 April 2007 5-5

Page 42

Cleaning the feed module tires

11. Lift up the printer access cover.

12.Push the release lever down (located underneath the printer access

cover) to release and remove the feed module.

13.Manually rotate and wipe the feed module tires with a roller cleaning

pad. For best results wipe parallel to the ribs in order to remove any

residue between the ribs.

14.Inspect the tires. If the tires show signs of wear or damage, replace

the feed module tires. See “Replacement procedures” later in this

chapter.

5-6 A-61500 April 2007

Page 43

15.Reinstall the feed module by aligning the pins, fitting it into position

and pulling up on the release lever to lock it into place. Verify that

the feed module is securely in place and moves freely after you

install it.

Align

these

areas

16.Close the printer access cover.

A-61500 April 2007 5-7

Page 44

Cleaning the scanner transport area

17.Thoroughly vacuum the entire transport area, paying particular

attention to these areas:

• the edges of the transport

• the reflective tape near the front of the transport

• the reflective tape near the front of the pod

reflective

tape near

front of

pod

reflective

tape near

front of

transport

• the three paper path sensors at the base of the transport and the

pod

5-8 A-61500 April 2007

Page 45

Cleaning the background strips

18.Using the green tabs pull off the upper and lower background strips

and set them aside.

Lower strip

Upper strip

19.Vacuum the areas where the background strips are adhered to.

20.Reinstall the upper and lower background strips.

Cleaning the imaging guides

21.Turn the screw on each end of the upper imaging guide, remove it

from its position and set it aside.

Lower imaging guide

22.Turn the screw on each end of the lower imaging guide, remove it

from its position and set it aside.

A-61500 April 2007 5-9

Page 46

23.Carefully vacuum the areas between the lamps (both upper and

lower), then use a Staticide wipe to thoroughly clean the glass dust

plate between the lamps.

24.Clean the imaging guides thoroughly with a Staticide wipe.

IMPORTANT: Staticide wipes contain isopropanol which can cause eye

irritation and dry skin. Wash your hands with soap and

water after performing maintenance procedures. Refer to

the MSDS for more information.

25.Reinstall the upper and lower imaging guides. Handle the imaging

guides carefully as to not put fingerprints on the guides.

26.Close the pod.

27.Reinstall the output tray.

28.Power on the scanner.

5-10 A-61500 April 2007

Page 47

Running a transport cleaning sheet

1. Place a transport cleaning sheet in the elevator tray in landscape

orientation.

2. Open the Scan Validation Tool by selecting Start>Programs>

Kodak>Document Imaging>Scan Validation Tool. The Scan

Validation Tool dialog box will be displayed.

3. Select TWAIN (or ISIS) for the Driver Types and Kodak Scanner

i600 as the Driver and click OK.

The Scan Validation Tool dialog box will be displayed.

4. If Saved images to file is checked, uncheck it.

5. Click Start

6. After the transport sheet is scanned, turn it over and click Start

again.

7. Open the pod and wipe the imaging guides with a lint-free cloth.

8. Close the pod and check your image quality.

A-61500 April 2007 5-11

Page 48

Replacement procedures

This section provides procedures for replacing the following parts. Use

the list below as a guideline for frequency of replacement.

• Feed Module tires and Separation Roller tires — tire life will vary

depending upon paper types, environment and cleanliness. Nominal

tire life will be approximately 250,000 documents; results will vary.

Degradation of feeder performance, multiple feeds, stoppages, etc.

indicate a need to change tires. Change all the tires on the feed

module and separation roller at the same time.

• Feed Module and Separation Roller — it is recommended that you

install a new feed module and separation roller approximately every

4th tire change. Install a new feed module and separation roller at the

same time.

• Pre-separation Pad — it is recommended that you change the pre-

separation pad approximately every 250,000 documents.

• Imaging Guides — replace when the imaging guides are heavily

scratched and defects show in the image.

Replacing the feed module or feed module tires

To replace the feed module or feed module tires:

1. Remove the output tray.

2. Lift up the printer access cover.

3. Open the pod.

5-12 A-61500 April 2007

Page 49

4. Push down on the release lever (located underneath the printer

access cover) to release and remove the feed module.

5. If you are just replacing the feed module:

• Insert the new feed module by aligning the pins, fitting it into

position and pulling up on the release lever to lock it into place.

Verify that the feed module is securely in place and moves freely

after you install it.

• Close the pod and the printer access cover.

• Reinstall the output tray.

A-61500 April 2007 5-13

Page 50

If you want to replace the tires, proceed as follows:

6. With one hand, press the locking tabs (one on each side) while

holding the bottom housing with the other hand, pull the upper

housing up and away from the rollers.

Locking tab

7. Remove one core assembly.

8. Replace each tire by sliding the tire off the core.

Core assembly

9. Install each new tire by gently pulling it over the core.

IMPORTANT:Do not overstretch the tire; it may tear.

10.Replace the core assembly in the feed module.

11. Repeat the replacement procedure outlined above for the other core

assembly.

5-14 A-61500 April 2007

Page 51

12.Align the tabs on the upper housing with the slots on the lower

housing.

Locking tab

Slot

13.Press the upper and lower housings together until they snap into

place.

14.Reinstall the feed module by aligning the pins, fitting it into position

and pulling up on the release lever to lock it into place. Verify that

the feed module is securely in place and moves freely after you

install it.

15.Close the pod.

16.Close the printer access cover.

17.Reinstall the output tray.

Align

these

areas

A-61500 April 2007 5-15

Page 52

Replacing the separation roller or separation roller tires

1. Open the pod.

2. Pull the separation pad holder forward and remove the separation

roller.

If you want to replace the separation roller, do Steps 3 and 4. If you

want to replace the separation roller tires, go to Step 5.

3. Insert the new separation roller. Be sure to line up the slots on the

separation roller with the holders.

4. Push the separation roller holder back in place and close the pod.

To replace the tires:

5. Replace each tire by sliding the tire off the core.

6. Install each new tire by gently pulling it over the core.

IMPORTANT:Do not overstretch the tire; it may tear.

7. Reinstall the separation roller. Be sure to line up the slots on the

separation roller with the holders.

8. Push the separation roller holder back in place and close the pod.

5-16 A-61500 April 2007

Page 53

Replacing the preseparation pad

Change the pre-separation pad when the frequency of double-fed

documents increases.

1. Open the pod.

2. Remove the pre-separation pad.

3. Install the new pre-separation pad. Be sure it snaps into place.

4. Close the pod.

Replacing the imaging guides

The imaging guides should be replaced when they are heavily

scratched and defects show in the image.

NOTE: Handle the imaging guides carefully as to not put fingerprints on

the guides.

1. Open the pod.

2. Turn the screw on each end of the upper imaging guide to remove it

from its position.

3. Install the new imaging guide and turn the screws to secure the

imaging guide.

4. Repeat Steps 2 and 3 to replace the lower imaging guide.

5. Close the pod.

A-61500 April 2007 5-17

Page 54

6 Troubleshooting

This chapter provides:

• A description of the indicator lights located on the front of the

scanner.

• Information about accessing the Operator Log.

• A problem solving chart.

• A message listing of possible errors you may encounter while using

the scanner.

Indicator lights There are four indicator lights on the front of the

scanner. See the table below for LED meanings:

LED indicators

= green, Power

= green, Ready

= yellow, Jam/User correctable

= red, Service/Error

= indicates when an indicator is flashing

Led display Description

Scanner is in sleep or lamp saver mode.

To return to Ready state:

• press the Start/Resume button on the scanner or enable

scanning from the host, or

• add paper to an empty elevator tray, or remove paper from

the elevator tray.

Scanner is powered on and idle.

Scanner is idle and a document jam or multi-feed has been

detected. See Operator Log for details.

Scanner is idle and has detected a user-correctable error.

See Operator Log for details.

Scanner is idle and has detected a hardware/software error.

Cycle power on the scanner. If the condition persists, see the

Operator Log for details. If the condition cannot be cleared,

call Service.

A-61500 April 2007 6-1

Page 55

Led display Description

Scanner is in sleep mode and has detected a hardware error.

Cycle power on the scanner. If the condition persists, see the

Operator Log for details. If the condition cannot be cleared,

call Service.

Scanner warm-up sequence.

Scanner is enabled. Start/Resume and Stop/Pause buttons

are available.

Scanner is enabled and scanning is allowed. Start/Resume

and Stop/Pause buttons are available, however a warning

condition has been detected. See the Operator Log for

details. (e.g., clean the imaging guides, calibrate the scanner,

etc.)

6-2 A-61500 April 2007

Page 56

Accessing the

The Operator Log is accessed through the Scan Validation Tool.

Operator Log

1. Select Start>Programs>Kodak>Document Imaging>Scan

Validation Tool.

2. From the Driver Types box, select TWAIN.

3. Open the Scan Validation Tool.

4. Select Kodak Scanner: i600.

The main Kodak Scanner window will be displayed..

5. Click the Setup icon to access the main Kodak Scanner window..

A-61500 April 2007 6-3

Page 57

6. Click Settings. The following screen will be displayed.

Click Device.The following screen will be displayed.

6-4 A-61500 April 2007

Page 58

7. Click Diagnostics. The following screen will be displayed.

8. Click the Logs tab.

9. From the drop down box, select Operator to display the Operator

log. The most current log entries are displayed at the top of the list.

See the following Message Listing for an explanation of the error

condition.

A-61500 April 2007 6-5

Page 59

Message listing Following is an alphabetic list of messages and corrective actions you

can take if one of the following messages is encountered.

Operator Log Message ID# Description/Action

Background accessory changed

while powered up

Calibration failed 108 • Try to calibrate the scanner again. Be sure you are using the

Calibration is suggested 185, 585,

Calibration succeeded 107 Informational message. The scanner has been successfully

Calibration target is too narrow 331 The calibration target is too small. A 12- x 12-inch calibration

Call Service Many ID

Check document preparation 123 • Make sure the leading edges of the documents are aligned.

Check imaging guides and lamps 149, 549,

Close pod and re-enable scanner 306 The pod may have been opened and not closed properly when

Document too dark to deskew 143, 543,

Document too long to rotate 46, 446,

Elevator too full, feed module

missing or broken

381 Background Accessory was changed while the scanner was

powered on.

• Turn the power off to the scanner, wait a few seconds and

power the scanner back on.

• If you get this message and you did not change the

Background Accessory, clean and calibrate the scanner.

correct calibration target. See Chapter 3, “Calibrating the

scanner”.

• Clean the imaging guides. See Chapter 5, Maintenance for

procedures.

• If the problem persists, call Service.

• It is suggested that you calibrate the scanner when the current

985

numbers

949

943

846

297 • There is too much paper in the elevator tray and it is holding

batch of documents has completed.

calibrated.

target is required for Image calibration.

• Calibrate the scanner again using the correct calibration target.

A condition was detected that may require repair.

• Turn the power off to the scanner, wait a few seconds and

power the scanner back on.

• If the problem persists, call Service.

See Chapter 3, “Document preparation” for more information.

• Verify that the imaging guides are installed correctly. See

Chapter 5, Maintenance.

• Clean both sides of the imaging guides.

• If the pod is closed, and the message persists, call Service.

scanning was attempted.

• Be sure the pod is completely closed.

Informational message. The scanner was unable to find the

document edges to determine the skew angle.

• The document is too dark.

• The image is too large.

The scanned document was too long to rotate. Scanning was

stopped.

• Locate this document and rescan it with a lower resolution or

with Rotation turned off.

the feed module up. The elevator tray capacity is 500 sheets.

Remove some documents from the elevator tray.

• The feed module is not installed properly. See Chapter 5,

Maintenance, for correct installation procedures.

• If the problem persists, call Service.

6-6 A-61500 April 2007

Page 60

Operator Log Message ID# Description/Action

Image buffer exceeded threshold 1, 48 The feeder has stopped and the transport is still running

because the scanner’s internal image buffer is almost full.

Processing will resume after the host computer has successfully

retrieved enough images to allow the scanner to continue.

• Be sure your host computer meets the recommended

specifications to avoid this condition.

Image outside document area 286 Based on relative cropping parameters, the image to be

generated from this document would be outside the document

area.

• Make sure the relative cropping offset, width and length are

correct and that the correct document is being scanned.

Image size exceeds available

memory

Jam in transport 30 A document is lodged in the transport.

301 There is not enough room to store this image in the buffer using

the current settings.

• Lower the resolution setting before scanning the next batch of

documents.

• Select a different compression value.

• Remove the documents that have been scanned from the exit

tray.

• Open the pod.

• Remove any jammed documents from inside the transport.

• Close the pod.

NOTE: The following procedure is a general guideline. Your

procedure may be different depending on how your

application is set up.

• Verify the last document that was scanned correctly.

• Place any documents that were not scanned at the top of the

batch.

• Place the documents in the elevator tray and begin scanning.

One or more documents that passed through the transport were

not scanned.

• Refeed all documents for which images were not obtained.

Lamps not ready for calibration 110 Calibration was attempted before the lamps were warmed up.

• Wait until the lamps have completely warmed (90 seconds)

and try the calibration again.

Lamps not ready for scanning 252 Scanning was attempted before the lamps were warmed up.

• Try to scan again.

Lamps ready for calibration 278 Informational message. The lamps are warmed and the scanner

is ready for calibration.

Lamps ready for scanning 280 Informational message. The lamps are warmed and scanning

can be started.

Lamps timed out 355 • Informational message. The lamps were turned off due to

inactivity.

Lower imaging guide dirty or

document in transport

294, 694,

1094

The lower (rear) imaging guide is dirty or there may be a small

piece of paper in the imaging guide area.

• Follow the cleaning procedures in Chapter 5, Maintenance to

clean the imaging guides.

A-61500 April 2007 6-7

Page 61

Operator Log Message ID# Description/Action

Multi-feed detected 23 A multi-feed document condition has been detected and the

scanner was set to the Display only mode.

• Check the host monitor to see if there are any overlapped

documents that may need to be rescanned.

This condition may be caused by poor document separation.

• Replace the separation roller tires and pre-separation pad.

See Chapter 5, Maintenance for procedures.

Multi-feed detected 334 A multi-feed has been detected, the transport has stopped and

the job has ended.

• Re-enable the scanner. Check the host monitor to see if there

are any overlapped documents that may need to be

rescanned.

This condition may be caused by poor document separation.

• Replace the separation roller tires and pre-separation pad.

See Chapter 5, Maintenance for procedures.

Multi-feed length detected 247 A document was measured which exceeded the configured

maximum allowable length in the Display only mode. This may

be due to a document overlap.

• Check the host monitor to see if there are any overlapped

documents that may need to be rescanned.

This condition may be caused by poor document separation.

• Replace the separation roller tires and pre-separation pad.

See Chapter 5, Maintenance for procedures.

Multi-feed length detected 248 A document was measured which exceeded the configured

maximum allowable length and the transport has stopped. This

may be due to a document overlap.

• Re-enable the scanner. Check the host monitor to see if there

are any overlapped documents that may need to be

rescanned.

This condition may be caused by poor document separation.

• Replace the separation roller tires and pre-separation pad.

See Chapter 5, Maintenance for procedures.

No paper in elevator tray 260 The scanner was started with an empty elevator tray.

• Place the documents you want to scan in the elevator tray and

try again.

Page on demand complete 337 Informational message. The scanner has completed scanning

the requested number of documents.

Parameter settings conflicting 4 The image processing values sent by the host are invalid.

• Check the job settings for illegal combinations. Refer to the

Image Processing Guide for valid parameter values.

Pod door closed 213 Informational message. The pod was closed.

Pod door opened 212 Informational message. The pod is not closed completely.

Power on self-test completed 20 Informational message. The scanner has completed its self-tests

after power-on.

6-8 A-61500 April 2007

Page 62

Operator Log Message ID# Description/Action

Print head not installed 282 An attempt was made to use the Document Printer without a

print head installed.

• Be sure the cable is properly connected to the ink cartridge

carrier and the ink cartridge is installed in the print head

assembly. See Chapter 4, The Document Printer for more

information.

NOTE:The ink cartridge must be installed before turning on the

scanner.

Printer bitmap font in use 132 Informational message. At the time of this message, a bitmap

printer font file was found on the Flash disk and is being used in

lieu of the static font information built in the scanner software.

Printer count exceeded maximum

set value

Refeed document set 52, 137,

Scanner failed to enable 5 • The previous error condition has not been corrected. For

Scanner failed initialization 6 This error could occur during scanner power-up.

Scanner has lost synchronization 131, 531,

Scanner interface cable reset 319 The scanner interface cable has reset. Some device on the

Scanner paused for rotation or

host processing

Transport timeout 336 Informational message. The transport was turned off due to

Ultrasonics calibration failed 333 The Ultrasonics calibration failed.

258 The printer count is larger than the maximum configured value.

• Reconfigure the scanner to allow a larger value for the printer

count. Refeed the document set.

Documents passed through the transport but no images were

created.

• Refeed these documents and verify that the images have been

captured.

Documents passed through the transport but no images were

153, 537,

553, 937,

953

931

63 Informational message. Scanner paused.

created.

• Refeed these documents and verify that the images have been

captured.

example, there could be a document jam that has not been

completely cleared.

• Incomplete or conflicting image processing parameters. For

example, selecting Error Diffusion for binarization and Noise

Filter together.