Page 1

EASTMAN Fine Grain Duplicating

Positive Film 2366 / 3366

TECHNICAL DATA /

EASTMAN Fine Grain Duplicating Positive Film 2366

(35mm) and 3366 (16mm)is a low-speed duplicating film

intended for making master positives from

black-and-white camera negatives which, when printed

onto EASTMAN Fine Grain Duplicating Panchromatic

Negative Film 5234 and 7234, produces duplicate

negatives that are only distinguishable from the originals

by skilled observers. This blue-sensitive black-and-white

film has very high resolution and incorporates a yellow dye,

which is removed during processing, to provide very high

acutance.

BLACK-AND-WHITE INTERMEDIATE FILM

BASE

2366 and 3366 Films have a clear ESTAR safety base. The

back side of the base contains an anti-static layer with a

carnauba wax lubricant.

DARKROOM RECOMMENDATIONS

Handle unprocessed film in total darkness. If necessary,

you can examine the film for less than one minute, using the

following safelight combination: a 15-watt bulb and

KODAK OC Safelight Filter (greenish-yellow), no closer

than 1.2 metres (4 feet) to the film.

February 2013 • H-1-2366

STORAGE

Store unexposed film at 55°F (13°C) or lower. For extended

storage, store it at 0°F (-18°C) or below. Process exposed

film promptly. Store processed film at 70°F (21°C) or lower

at a relative humidity of 40 to 50 percent for normal

commercial storage; for long-term storage, store it at 35 to

50°F (2 to 10°C) at 15 to 30% relative humidity. For more

information on long-term storage, see KODAK

Publications No. H-845, The Essential Reference Guide for

Filmmakers.

EXPOSURE

For laboratories with subtractive printers, such as a Bell &

Howell Model D Printer, these recommendations should be

helpful as a starting point. Use a 500-watt tungsten lamp

operating with a diffuser at a lamp setting of 75 volts. With

a printer speed of 90 feet per minute and a diaphragm

setting of 15, satisfactory master positives should be

produced from original negatives of average density. (The

maximum density of the negative image should produce a

density of about 0.6 to 0.8 in the master positive, i.e., just

above the lower end of the straight-line portion of the

characteristic curve.)

Recommended Control Gamma

2/3366 Film should be developed to a recommended

control gamma of 1.20 to 1.60 (Status M Densitometry

with a blue filter).

IDENTIFICATION

After processing, the product code number 2/3366,

emulsion and roll number identification, and internal

product symbol (D) are visible along the length of the film.

©Eastman Kodak Company, 2013

Page 2

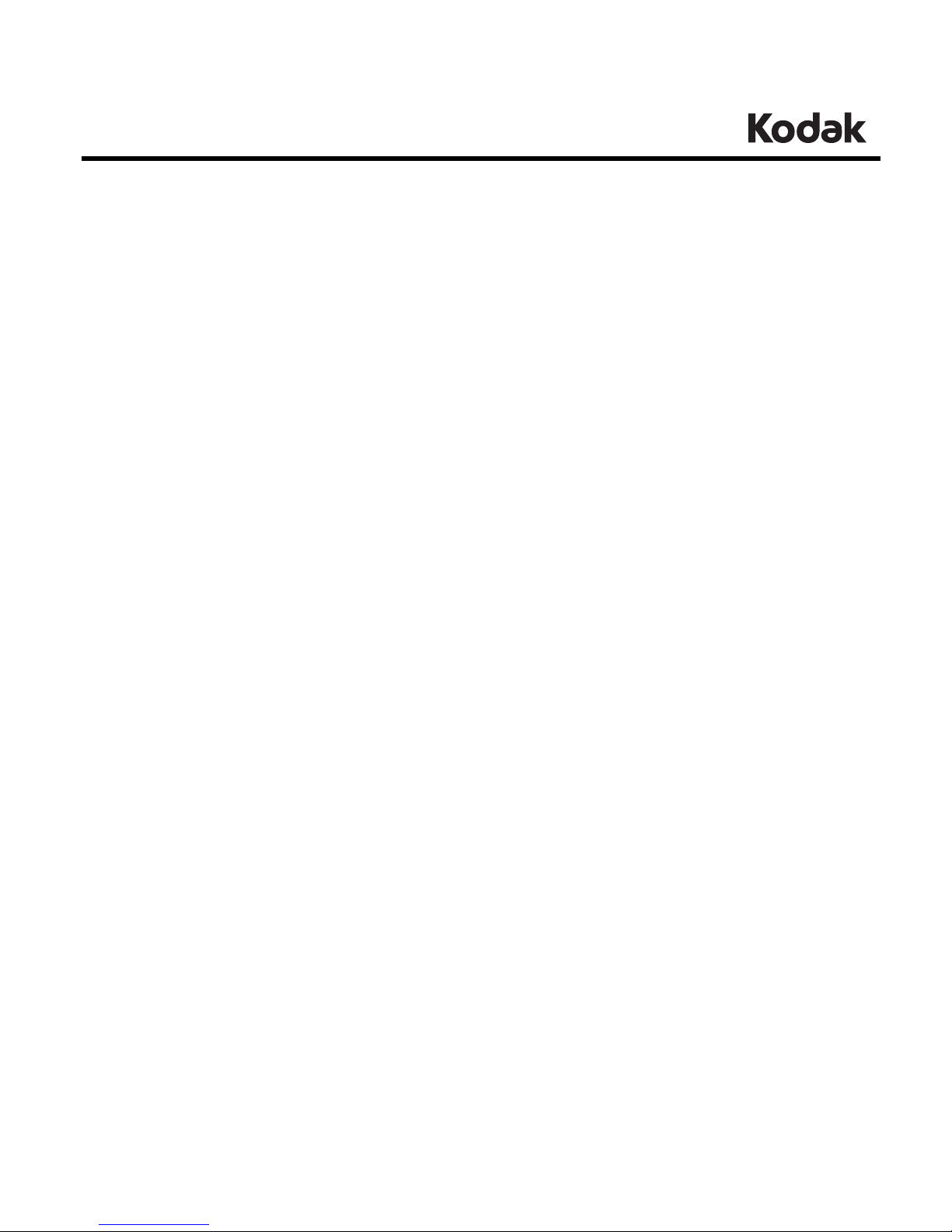

PROCESSING

The following process recommendations should be used as starting points for a typical continuous-immersion processing

machine using formulas presented in KODAK Publication No.H-24.15, Manual for Processing EASTMAN Motion Picture Films,

Module 15. The processing times may require modification for a particular machine.

Processing Step Te m p e r a t u r e Time Replenishment Rate

(mL per 100 min)

35 mm 16 mm

KODAK Developer D-96

‡

Stop Rinse

70 +-2°F

*

70 +-1/2°F

(21 +-0.3°C)

†

1,250

(D-96R)

625

(D-96R)

50 sec 12,000 6,000

(21 +-1°C)

KODAK Fixi ng Bath F-5

*

70 +-2°F

11 min 850 425

(21 +-1°C)

Wash (counter - current) 70 +-2°F

10 min 12,000 6,000

(21 +-1°C)

Dry 95°F(

*

Agitation in the developer and fixing bath should be by recirculation through submerged spray jets that impinge on the film strands.

†

Develop to recommended control gamma of 1.2 to 1.6.

‡

Countercurrent flow of fixer-laden water overflow from the wash tank, pH about 6.

§

Many factors affect the drying: air temperature, relative humidity (RH); volume, rate and distribution of the air flow; final squeegeeing, etc.

35°C)

§

In a conventional convection-type drying cabinet with air at about 95°F (35°C) and 40 to 50 percent RH, drying will take 15

to 20 minutes. With an impingement-type drying cabinet, however, with a higher temperature and lower RH, drying time is

greatly reduced. With either type of dryer, the film should be dry without tackiness 1/2 to 2/3 of the way through. Upon

cooling to room temperature after leaving the dryer, the film should be in equilibrium with the room air at approximately 50

percent RH.

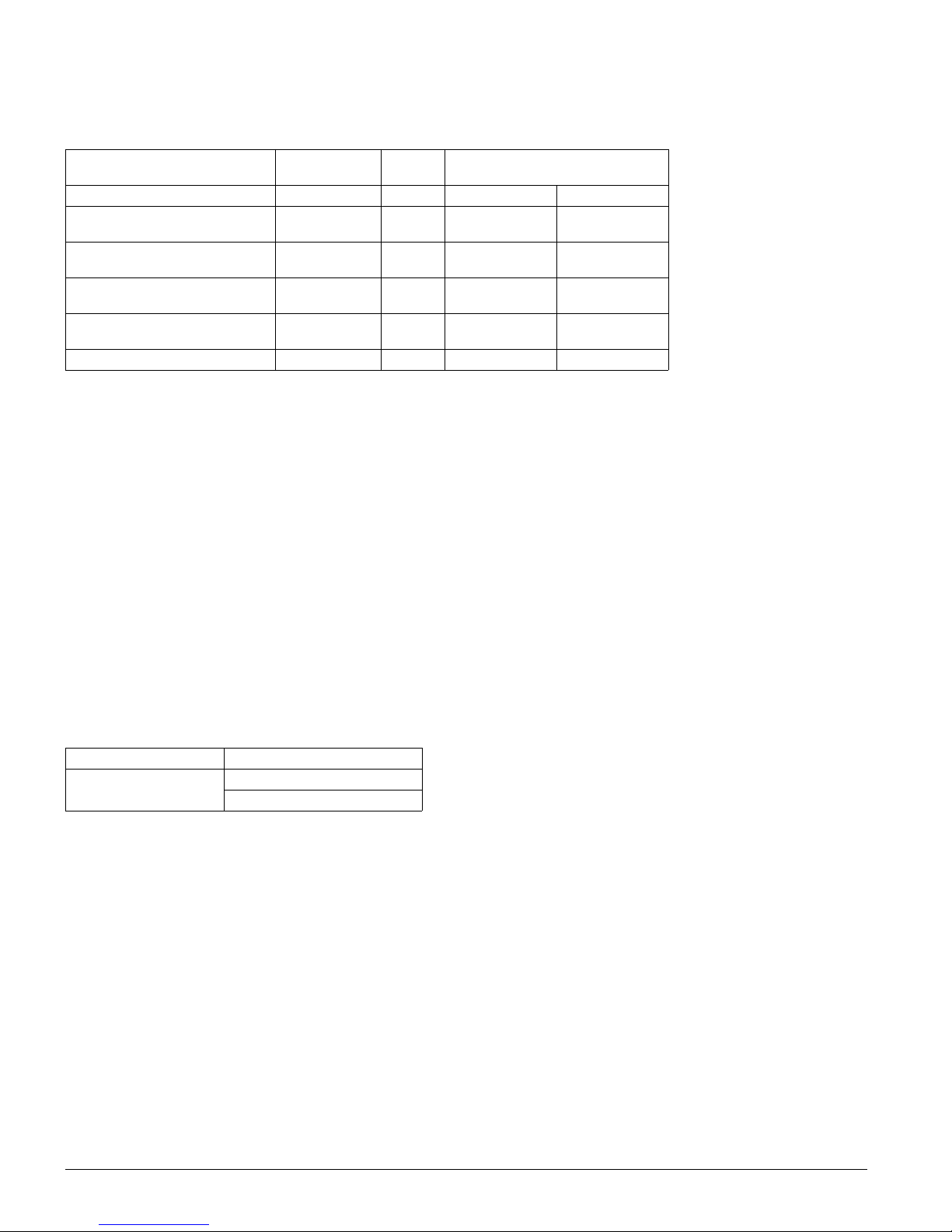

IMAGE STRUCTURE

The modulation-transfer curves, the diffuse rms

granularity, and the resolving-power data were generated

from samples of 2/3366 Film exposed with tungsten light

and processed as recommended in Process D-96 at 70°F

(21°C) to the recommended control gamma. For more

information on image-structure characteristics, see

KODAK Publication No H-845, The Essential Reference

Guide for Filmmakers.

Diffuse RMS Granularity 9

Resolving Power 100 lines/mm (TOC 1.6:1)

200 lines/mm (TOC 1000:1)

*

Read at a net diffuse visual density of 1.0, using a 48-micrometre aperture.

†

Determined according to a method similar to the one described in ISO

6328-1982, Photography—Photographic Materials—Determination of ISO

Resolving Power.

2 EASTMAN Fine Grain Duplicating Positive Film 2366 / 3366 • H-1-2366

Page 3

CURVES

F010_0092AC

Tungsten

Process:

Exposure:

KODAK Developer D-96

Densitometry:

at 21°C (70°F) recommended

control gamma

Diffuse Visual

200

50

70

100

20

30

7

3

5

2

1

10

RESPONSE (%)

SPATIAL FREQUENCY (cycles/mm)

60020050201054321100

Diffuse visual

control gamma

F010_0091AC

Gross Fog

D = 1.0 Above

Gross Fog

D = 0.3 Above

recommended

21°C (70°F) to

1.4 seconds

Developer D-96 at

_

_

_

Densitometry:

KODAK

Effective Exposure:

Process:

1.0

0.0

1.0

2.0

*

3.0

LOG SENSITIVITY

2

WAVELENGTH (nm)

to produce specified density

*Sensitivity = reciprocal of exposure (ergs/cm ) required

250 300 350 400 450 500 550 600 650 750700

NOTICE: The sensitometric curves and data in this publication represent product tested

under the conditions of exposure and processing specified. They are representative of

production coatings, and therefore do not apply directly to a particular box or roll of

photographic material. They do not represent standards or specifications that must be

met by Eastman Kodak Company. The company reserves the right to change and

improve product characteristics at any time.

Modulation Transfer Curve

Note: These photographic modulation-transfer values were

determined by using a method similar to the one described

in ANSI Standard PH2.39-1977 (R1990). The film was

exposed with the specified illuminant to spatially varying

sinusoidal test patterns having an aerial image modulation

of a nominal 60 percent at the image plane, with processing

as indicated. In most cases, these photographic

modulation-transfer values are influenced by

development-adjacency effects and are not equivalent to

the true optical modulation-transfer curve of the emulsion

layer in the particular photographic product.

4.0

Exposure:

Process:

Densitometry:

3.0

GAMMA

2.00

2.0

1.80

1.60

DENSITY

1.40

GAMMA

1.20

1.0

0.0

1.0

F010_0090AC

Characteristic Curves

Tungsten, 1/25 second

KODAK Developer

D-96, at 21 C (70 F)

Diffuse visual

12 min

= 1.15

9 min = 1.67

NET

FOG

0.02

Time-Fog

DEVELOPMENT TIME

(Minutes)

0.01

10864

12

0.0

LOG EXPOSURE (lux-seconds)

1.0

Spectral Sensitivity Curve

6½ min = 1.15

5 min = 1.67

4 min = 1.67

Base Density = 0.04

2.0

3.0

EASTMAN Fine Grain Duplicating Positive Film 2366 / 3366 • H-1-2366 3

Page 4

EASTMAN Fine Grain Duplicating Positive Film 2366 / 3366

AVAILABLE ROLL LENGTHS

For information on film roll lengths, check Kodak's

Professional Motion Imaging Price Catalog or see a Kodak

sales representative in your country.

MORE INFORMATION

Outside the United States and Canada, please contact your

Kodak representative. You can also visit our web site at

www.kodak.com/go/motion for further information. You

may want to bookmark our location so you can find us

easily the next time.

H-2 Cinematographer’s Field Guide

H-845 The Essential Reference Guide for Filmmakers

H-24 Manual for Processing KODAK Motion Picture Films,

H-606 KODAK Telecine Tool Kit and Reference Manual

www.kodak.com/go/fieldguide

www.kodak.com/go/referenceguide

ocess ECP--2D Specifications, Module 9A

Pr

www.kodak.com/go/h24

www.kodak.com/go/telecine

Positive Film 2366 / 3366

Kodak and Eastman are trademarks.

KODAK Publication No. H-1-2366

Revised 2-13EASTMAN Fine Grain Duplicating

Loading...

Loading...