Page 1

TECHNICAL DATA /

COLOR PAPER

K OD AK PR OFESSIONAL ENDURA

Metallic P aper

p.o.p. that pops

April 2003 • E-4028

KODAK PROFESSIONAL ENDURA Metallic Paper is a

color negative paper with a u nique metallic appearance. It is

coated on a patented multi-laminate base that provides

durable, tear-resistant prints.

This paper is ideal for a variety of portrait/social

applications—for example, glamour, wedding, prom, and

special-events photography and for many commercial

applications. It can be exposed both digitally and optically,

providing consistency and efficiency in the lab.

Like other KODAK PROFESSIONAL ENDURA Papers

and Materials, ENDURA Metallic Paper features

significantly improved image stability. Other improvements

include process robustness and a dramatic increase in D-max

in digital applications. The new paper is easily distinquished

from KODAK PROFESSIONAL Color Metallic Paper by

its unique watermark on the back. ENDURA Metallic Paper

has a single gray dot under "PAPER", while Color Metallic

Paper has two dots separating "PAPER", "PAPIER" and

"PAPEL".

ENDURA Metallic Paper is available in a variety of roll

and sheet sizes. It can be intermixed with other KODAK

PROFESSIONAL Papers in KODAK EKTACOLOR

Chemicals for Process RA-4.

FEATURES BENEFITS

• New emulsion tech nol ogy

for digital and optical

performance

• Patent-pending dual layer

coupler blending

technology

• State-of-the-art image

stability

©Eastman Kodak Company, 2003

• One paper for all expos in g

devices from digital (CRT,

LED) exposing devices to

optical enlargers and

automatic printers

• Excellent latent ima ge

keeping from 5 second s to 24

hours means improved

consistency, especially in

digital devices

• Excellent print quali ty in bo th

high quality and high

productivity modes of

bi-directional printe rs

• Excellent color accuracy and

brightness

• Striking prints and flattering

portraits

• Improved color saturation fo r

blues, cyans and purpl es

• Improved light stability - over

100 years before noti ce abl e

fading in typical home display

• Significantly improv ed dark

stability - over 200 years

before noticeable fading under

most common stor age

conditions

• Superior performance in

professional applications

creating new standar ds for

image permanence

FEATURES BENEFITS

• Metallic look combined

with a smooth glossy

surface

• Patented high intensi t y

reciprocity char act eristics

• More robust proces si ng

capability in KODAK

EKTACOLOR RA

Chemicals

• Reduced develop er

replenishment rates

• 50% less calcium • Significantly reduced

• Exceptional durability and

tear resistance

• Minimum curl with humidity

changes

• Pencil writeability on the

back

• Improved raw stock color—

patented technology

• Reduced sensitom et r ic

variability

• Distinctive, cutting-edge

appearance

• Exposure range of 32 stops from 50 nanoseconds to 10

minutes

• Can be used for all types of

exposing devices, from op tical

enlargers and automatic

printers to digital exposing

devices (CRT, LED, Laser)

• Broad print engine

applicability for CRT, LED,

Laser device s

• Optimized text and fringing

characteristics in all digital

devices

• Rapid access and convenient

process i ng with other pa pers

and materi als for Proces s

RA-4

• Less sensitive to process

chemical activity variations

• Reduced sensitivity to process

fluctuations caused by:

– Image density content (low

key/high key)

– Inadvertent low level of

bleach-fix contaminat i on

– Utilization changes

– Product mix

• More complete paper

development for improv ed

consistency

• Lower process RA-4

processing costs

• Lower environmental impact

propensity for calcium buildup

• Reduced maintenanc e and

cleaner running paper

processors

• Long print life

• Improved print appe arance

and handling

• Convenience in marking prints

for identi fication

• Lighter, more neutral raw

stock color for easie r dodging

and burnin g

• Easier printer setup and focus

• More consistent quality within

an emulsion blend

Page 2

STORAGE AND HANDLING

Store unprocessed paper at 13°C (55°F) or lower in the

original sealed package. High temperatures or high humidity

may produce unwanted print quality changes.

To avoid moisture conden sation on unexposed paper that

has been refrigerated, allow the paper to warm up to room

temperature before opening the package. For best results,

remove the paper from cold storage the day before you use

it, or allow the paper to warm up for the appropriate time

from the following table:

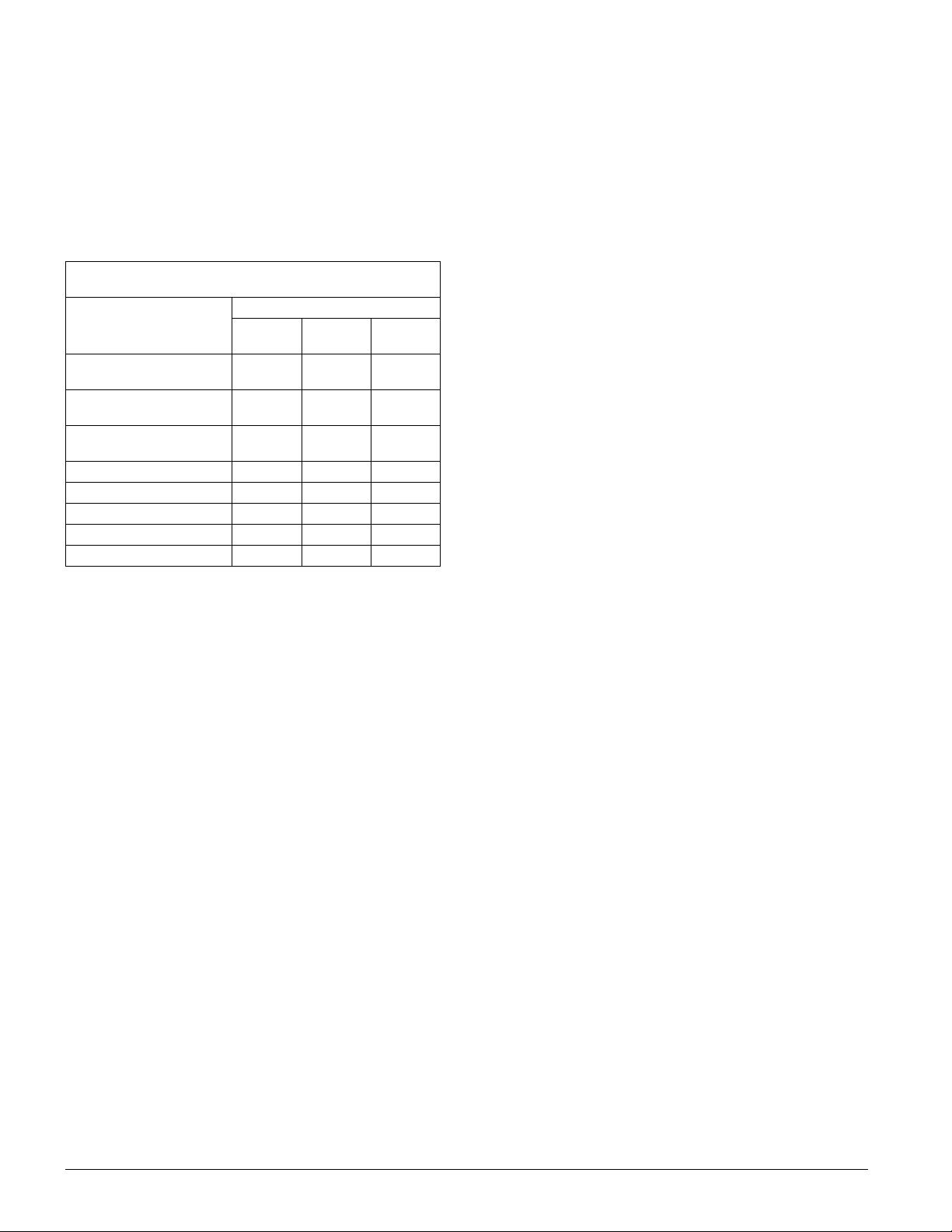

Warm-Up Times (Hours) to Reach

Room Temperature of 21°C (70°F)

From a Storage Temperat ure of

Size

8 x 10-inch

(100-sheet box)

16 x 20-inch

(50-sheet box)

20 x 24-inch

(50-sheet box)

3 1/2-inch x 775-foot roll 8 hours 6 hours 4 hours

8-inch x 575-foot roll 10 hours 7 hours 4 hours

20-inch x 50-foot roll 6 hours 5 hours 3 hours

30-inch x 100-foot roll 8 hours 6 hours 4 hours

40-inch x 100-foot roll 9 hours 7 hours 5 hours

-18°C

(0°F)

4 hours 3 hours 2 hours

3 hours 2 hours 2 hours

3 hours 2 hours 2 hours

2°C

(35°F)

13°C

(55°F)

Handle the paper carefully by the edges. The paper is

packaged with the emulsion side of all sheets facing in the

same direction. For complete light and moisture protection,

use the inner bag and the two-part card board box t o store the

paper.

Note: Be sure to use sharpened cutting equipment. The

effects of dull cutting blades will be more noticeable with

this paper than with traditional papers because of its

tear-resistant characteristics.

DARKROOM RECOMMENDATIONS

Handle unprocessed paper in total darkness. Be sure that

your darkroom is light tight. Eliminate stray light from

enlarger heads, timers, LEDs, etc.

Note: Using a sa felight will affect your res ults. If absolutely

necessary, you can use a safelight equipped with a KODAK

13 Safelight Filter (amber) with a 7 1/2-watt bulb. Keep the

safelight at least 1.2 metres (4 feet) from the paper. Keep

safelight exposure as short as possible. Run tests to

determine that safelight use gives acceptable results fo r your

application.

EXPOSURE

Digital Printing

You can expose KODAK PROFESSIONAL ENDURA

Metallic Paper with many types of digital printers. It

performs well with the following Kodak digital printers:

• KODAK PROFESSIONAL LED Color Printer

• KODAK PROFESSIONAL LED II Printer 20P/20R

• KODAK PROFESSIONAL Digital Multiprinter

• KODAK PROFESSIONAL Digital Multiprinter II

• KODAK PROFESSIONAL LF CRT Color Printer

• KODAK PROFESSIONAL RP 30 Laser Printer*

• KODAK PROFESSIONAL RR 30 Laser Printer

• KODAK PROFESSIONAL SRP 30 Laser Printer*

• KODAK PROFESSIONAL RP 50 LED Printer

* Calibration routines will become available in June 2003.

Because new digital printers are being developed and

introduced rapidly, any comprehensive list of appropriate

equipment becomes outdated quickly.

Starting values for Kodak digital printers and other

manufacturers’ equipment will be added to at

www.kodak.com/go/endura as they become available.

Look for KODAK Publication CIS-241, Digital Printer

Aims for KODAK PROFESSIONAL ENDURA Metallic

Paper, in April 2003.

Device Calibration

Manufacturers of digital printing equipment nor mally

provide specific calibration procedures with their equipment.

Note: The unique reflective characteristics of KODAK

PROFESSIONAL ENDURA Metallic Paper may require

one or two extra calibration runs.

Optical Printing

Expose KODAK PROFESSIONAL ENDURA Metallic

Paper in automatic printers or enlargers equipped with

tungsten or tungsten-halogen light sour ces or pho to enlarge r

lamps. Set up and balance the printer or enlarger according

to the manufacturer's instructions.

Do not use fluorescent lamps to expose this paper. Use a

heat-absorbing glass to remove infrared radiation. Because

voltage changes affect light output and color quality, use a

voltage regulator.

Keep negatives and the equipment optical system clean.

Mask negatives to eliminate stray light. You can use the

white-light or tricolor exposure method.

2 KODAK PROFESSIONAL ENDURA Metallic Paper • E-4028

Page 3

Printer Setup

KODAK PROFESSIONAL ENDURA Metallic Paper is

slightly slower than KODAK PROFESSIONAL PORTRA

and SUPRA ENDURA Papers. As a starting point, use the

same printing times and include a density series to determine

your preferred exposure.

Initial conversion to this paper from KODAK

PROFESSIONAL Color Metallic Paper involves

rebalancing your printers. Since the green speed is about a

1/2 stop faster than Color Metallic Paper, increase your

magenta filtration by approximately 15CC.

White-Light Exposure Method

Control color balance with dichroic filters built into the

printer or enlarger, or with KODAK Color Printing (CP)

Filters (Acetate) placed between the lamp and the negative.

You can use any number of filters between the light source

and the negative. If you use cyan filtration, use filters with

the suffix “-2,” (e.g. “CP10C-2”).

1. Start with a filter pack of 60M + 45Y to make a test

print.

2. Evaluate the test print under light of the same color and

brightness that you will use to display the final print.

(See “Viewing.”)

3. Judge print density first. If necessary, make another

print by adjusting the exposure as recommended in the

following table:

If your

print is

TOO LIGHT Open the lens

TOO DARK Close the lens

Do this OR Do this

aperture to increase

the light level

aperture to

decrease the l ight

level

Increase the

exposure time

Decrease the

exposure time

4. Then judge the color balance. You can use the KODAK

Color Print Viewing Filter Kit, KODAK Publication

No. R-25, to evaluate your test print. The kit contains

18 color-print viewing filters and instructions to help

you determine filter adjustments for the white-light

exposure method.

If your

print is

CY AN Magenta + Yello w

MAGENTA Cyan + Yellow

YELLOW Magenta + C yan

Subtract these

filters

(Red)

(Green)

(Blue)

OR Add these filters

Cyan

Magenta

Yellow

If your

print is

RED Cyan Magenta + Yellow

GREEN Magenta Cyan + Yellow

BLUE Yellow Cyan + Magenta

Subtract these

filters

OR Add these filters

5. Remove neutral density from your filter pack. For

example, if you determine that a filter pack of

40R + 10Y + 10C will give you a pleasing print:

a. Convert any primary filters (R, G, B) to their

subtractive equivalents (C, M, Y):

40R = 40M + 40Y.

b. Add filters of the same color: 10Y + 40Y = 50Y.

c. If the new filter pack has all three subtractive colors,

cancel the neutral density by subtracting the

smallest density value from all three densities:

10C 40M 50Y

-10 -10 -10

30M 40Y =

filtration without

neutral density

6. Adjust the exposure for the new filter pack. An

exposure time that produced a print of satisfactory

density may not produce an acceptable density when

you change the filter pack. The following table gives

filter factors for calculating exposure adjustments when

you use KODAK Color Printing (CP) Filters.

Filter Factors for CP Filters

Filter Factor Filter Factor

05Y

10Y

20Y

30Y

40Y

50Y

05M

10M

20M

30M

40M

50M

05C

10C

20C

30C

40C

50C

1.1

1.1

1.1

1.1

1.1

1.1

1.2

1.3

1.5

1.7

1.9

2.1

1.1

1.2

1.3

1.4

1.5

1.6

05R

10R

20R

30R

40R

50R

05G

10G

20G

30G

40G

50G

05B

10B

20B

30B

40B

50B

1.2

1.3

1.5

1.7

1.9

2.2

1.1

1.2

1.3

1.4

1.5

1.7

1.1

1.3

1.6

2.0

2.4

2.9

Note: The filter factors listed in the table take into account

the effects of filter surfaces.

To use the factors, divide the old exposure time by the

factor for any filter you remove. If you add a filter, multiply

the time by the factor. If you add or remove two or more

filters, multiply the individual factors and use the result as

your factor. You may need to modify these factors for your

equipment.

When you adjust the filtration in equipment that has

built-in dichroic filters, any noticeable differences in density

KODAK PROFESSIONAL ENDURA Metallic Paper • E-4028 3

Page 4

are due to differences in the color density of the print. For

example, you have a print with acceptable density, but a

magenta balance. When you add magenta filtration to correct

the color balance, the print will become too light, so you

must use a longer exposure time.

A rule of thumb for magenta dichroic filtration is to

change the exposure time by one percent for every unit of

change in filtration. For example, if you increase the

magenta filtration by 20M, increase the exposure time by

20 percent. Changes in yellow dichroic filtration do not

usually affect the apparent print density. If yo u use cyan

dichroic filtration, use the filter factors in the table abo ve as

starting points for adjusting exposure.

Tricolor Exposure Method

Use KODAK WRATTEN Gelatin Filters No. 25 (red),

No. 99 (green), and No. 47B (blue) to give the paper three

separate exposures. Do no t move the paper or the enlarger

until you have made all three exposures. Typical exposure

times for making an enlargement from a normally exposed

negative are given in the table below.

Filter

Red 0.7 seconds

Green 0.9 seconds

Blue 1.2 seconds

*

For an enlarger equipped with a Photo Enlarger Lamp No. 212 or

No. 302; the setting may vary with other types of lamps.

Times for an Aperture Setting of f/8

8 X 10 Enlargement of a 120 size KODAK

PROFESSIONAL PORTRA Film Negative)

*

for

Evaluate the test print under light of the same color and

brightness that you will use to display the final print.

(See “Viewing.”)

Judge the print density first. If necessary, make another

print by adjusting the exposure as recommended in the table

below:

If your

print is

TOO LIGHT Open the l ens

TOO DARK Close the lens

Do this OR Do this

aperture to increase

the light level

aperture to

decrease the light

level

OR

OR

Increase all

exposure

times

proportionally

Decrease all

exposure

times

proportionally

LATENT-IMAGE KEEPING

Under normal conditions, you should not notice shifts in the

latent image with keeping times from 5 seconds to 24 hours.

Therefore, you do not need to change your printing

procedures to compensate for latent-image shifts under

normal temperature and handling conditions. (If shifts do

occur, minimize them by keeping the interval between

exposure and processing as consistent as possible.)

PROCESSING

Use KODAK EKTACOLOR RA Chemicals for Process

RA-4, and use KODAK PROFESSIONAL Pro Srips Color

Negative Paper Control Strips for Process RA-4 (see

"Process Control").

When fully converted to this paper, your developer

replenishment rate should be approximately 10% lower than

with KODAK PROFESSIONAL PORTRA III and SUPRA

III Papers or KODAK PROFESSIONAL Color Metallic

Paper. Review your process control charts and make

adjustments as needed to stay in control.

Bleach-fix replenishment rates will stay the same for

Process RA-4. When using KODAK EKTACOLOR PRIME

Bleach-Fix Replenisher, replenishment rates will need to

increase.

For detailed information on replenishment rates and

processing this paper in continuous or roller-transport

processors, see KODAK Publication No. Z-130, Using

KODAK EKTACOLOR RA Chemicals. For information on

processing this paper in trays or rotary-tube and drum

processors, see KODAK Publication No. J-39, Tray, Drum,

and Rotary-Tube Processing with KODAK EKTACOLOR

RA Chemicals. Both publications are available through our

website at www.kodak.com/go/photochemicals.

Do not use drying temperatures above 93°C (200°F) to

avoid damaging prints. Underdrying can produce tackiness

that tends to make paper stick when it is wound into rolls

before cutting. Overdrying can cause curl and complicate

transport in print finishing.

Do not ferrotype this paper-its surface dries to a natural

gloss without ferrotyping.

Then judge color balance:

If your

print is

CYAN Red Blue + Green

MAGENTA Gr een Red + Blue

YELLOW Blue Red + Green

RED Blue + Green Red

GREEN Red + Blue Green

BLUE Red + Green Blue

Subtract these

filters

OR

Add these

filters

4 KODAK PROFESSIONAL ENDURA Metallic Paper • E-4028

Page 5

PROCESS CONTROL

T o produce high-quality color prints consistently and with a

minimum of waste, you need to match your process to a

standard for density, color, and contrast each time you

process paper. In addition to monitoring process parameters

such as solution times, temperature, replenishment rates,

solution concentrations, etc., you should regularly run

control strips to ensure best results.

KODAK PROFESSIONAL Pro Strips Color Negative

Paper Control Strips / for Proces s RA-4 (CAT 12 9 8587) are

designed specifically for use with KODAK

PROFESSIONAL Papers and KODAK PROFESSIONAL

Print and Display Materials in professional labs. These

control strips are designed to detect process conditions that

can degrade the quality of your finished prints. They are

better able to track the papers that are processed in

professional finishing laboratories.

For more information, see KODAK Publication No.

CIS-202, Using KODAK PROFESSIONAL Pro Strips

Color Negative Paper Control Strips / for Process RA-4.

SCANNER TOOLS

The KODAK Q-60 Color Input Targets are available on

KOD AK EKTACHROME Professional Film in both 35 mm

and 4 x 5 inch formats and on KOD AK EKT A COLOR Paper .

Developed primarily for use by prepress houses in the

printing industry, this target can also be used by professional

photographers, desktop publishers, and in the emerging

hybrid imaging area.

The target is designed for use in the commercial and

desktop arenas as a comparative control tool to help

customers calibrate their input product to the final outpu t.

This target maps the gamut of color space that KODAK

EKTACHROME Film and EKTACOLOR Paper can

reproduce.

When used properly, customers will be able to compare

their output—whether it is separations for the printed page

and four-color prin ting, or secon d-generation or iginals fro m

a film recorder to the originals. This will help customers

optimize the capabilities of their system for color

reproduction of an extreme range of color gamut.

Scanner color characterization targets produced in

accordance with ANSI IT8.7/1 (transmission) and IT8.7/2

(reflection) Standards (or ISO 12641) are available from

Kodak.

The KODAK PROFESSIONAL Q-60 Color Input

Target ⁄ Q-60R2 is manufactured on KODAK

PROFESSIONAL ENDURA Paper, and is likewise

identified by a watermark with a single grey dot under

PAPER. This target can be used with both the newer

ENDURA Papers and older papers. The older Q-60R1

target, which has the same two-dot watermark as the older

papers, can be used with the newer papers.

ILLUMINATION FOR EVALUATION OF

PRINTS

Evaluation of prints for color and density requires higher

illumination levels than those used in normal display

conditions. A good av er age cond i tio n is a light source with

a color temperature of 5000 K ± 1000, a Color Rendering

Index of 85 to 100, and an illuminance of at least 50

footcandles (538 lux). Fluorescent lamps such as cool white

deluxe (made by several manufacturers) meet these

conditions.

You can also use a mixture of incandescent and

fluorescent lamps. For each pair of 40-watt cool white

deluxe fluorescent lamps, use a 75-watt frosted, tungsten

bulb.

Viewing conditions should meet ANSI Standard

PH2.30-1989.

RETOUCHING

If possible, do any required retouching on color negatives

before you make prints —especially if you plan to make more

than one print from each negative. For information on

retouching negatives, see KODAK Publication No. E-71,

Retouching Color Negatives.

If the negative image is small, you can make corrections

much more easily by applying dry or liquid dyes to small or

large areas of the enlarged print. Although you’ll probably

do most retouching with dyes, you may sometimes want to

use black lead, colored pencils, or opaque. Because color

prints have separate dye layers, you can’t use an etching

knife to reduce density as you can with black-and-white

materials. For information on retouching prints, see

KODAK Publication No. E-70, Retouching Prints on

KODAK EKTACOLOR and EKTACHROME Papers.

KODAK PROFESSIONAL ENDURA Metallic Paper • E-4028 5

Page 6

POST-PROCESS TREATMENTS

Mounting Prints

You can mount prints with dry mounting tissue. The

temperature across the heating platen should be 82 to 93°C

(180 to 200°F). Preheat the cov er sheet that you use o ver the

face of the print to remove moisture. Apply pressure for 30

seconds, or up to 3 minutes in the case of a thick mount.

Caution

Temperatures above 93°C (200°F) for long peroids of time

can cause physical and color changes in prints. Excessive

moisture can also cause color shifts. To minimize these

changes, mount at the lowest temperature and over the

shortest possible time.

Note: Images on KODAK PROFESSIONAL ENDURA

Metallic Paper may shift towards a pink balance after heated

to excessive temperatures, but will return to normal color

balance when completely cooled to room temperature.

You can also use contact-type adhesive or cement for

cold-mounting.

For information on lacquering and other post-process

treatments, see KODAK Publication No. E-176,

Post-Processing Treatment of Color Prints—Effects on

Image Stability, available through our website at

www.kodak.com/go/professional.

DISPLAY

KODAK PROFESSIONAL ENDURA Metallic Paper has

been formulated to provide imp ro ved dye stability and print

longevity for prints displayed under typical home lighting

conditions (i.e., 120 lux for 12 hours a day) and typical home

dark storage conditions (i.e., 20 to 30°C [68 to 73.4°F] and

50% humidity).

Photographic dyes, like all dyes, can change with time and

exposure to sunlight, ultraviolet radiation, excessive heat,

and high humidity. To h elp prevent changes i n photographic

dyes, follow these guidelines:

• Illuminate prints with tungsten light whenever possible.

• Display prints in the lowest light level consistent with

your viewing needs.

• If a print is exposed to direct or indirect sunlight or

fluorescent light, use an ultraviolet-absorbing filter

(such as glass) between the light source and the print.

• If prints are displayed behind glass, maintain a slight

separation between the prints and the glass.

• Keep the temperature and humidity as low as possible.

• Use album materials described in KODAK Publication

No. E-30, Storage and Care of KODAK Photographic

Materials - Before and After Processing.

PRINTER CONTROL TOOLS

The following tools are manufactured by Kodak for

optimization of printer balance and slope controls of

KODAK PROFESSIONAL PORTRA Films printed on

KODAK PROFESSIONAL Papers.

Product

KODAK PROFESSIONAL

PORTRA

Printer Control

Negative Set / Size 135

KODAK PROFESSIONAL

PORTRA

Printer Control

Negative - Normal

KODAK PROFESSIONAL

PORTRA

Printer Control

Negative - Very Under

KODAK PROFESSIONAL

PORTRA

Printer Control

Negative - Under

KODAK PROFESSIONAL

PORTRA

Printer Control

Negative - Over

KODAK PROFESSIONAL

PORTRA

Printer Control

Negative - Very Over

The following tools are manufactured by Kodak for

optimization of printer balance and slope controls of

KODAK PROFESSIONAL PORTRA Films printed on

KODAK PROFESSIONAL Papers.

Product

KODAK PROFESSIONAL

PORTRA 400BW

Printer Control

Negative Set / Size 135

KODAK PROFESSIONAL

PORTRA 400BW

Printer Control

Negative Set / Size 120

The following tools are manufactured by Kodak for

optimization of printer balance and slope controls of

KODAK PROFESSIONAL T400 CN Film printed on

KODAK PROFESSIONAL Papers.

Product

KODAK T400 CN

Printer Balancing Kit /

Sizes 135 and 120

Features /

Description

Size 135 Film

Includes one of

each: Very Under,

Under, Normal,

Over, Very Over

Size 120 Film

Normal

Size 120 Film

V ery Under

Size 120 Film

Under

Size 120 Film

Over

Size 120 Film

Very Over

Features /

Description

Size 135 Film

Includes one of

each: Very Under,

Under, Normal,

Over, Very Over

Size 135 Film

Includes one of

each: Very Under,

Under, Normal,

Over, Very Over

Features /

Description

Sizes 135, 120 865 3552

CAT No.

179 8511

846 0958

107 1398

841 1902

177 1302

144 5741

CAT No.

156 8286

114 4419

CAT No.

6 KODAK PROFESSIONAL ENDURA Metallic Paper • E-4028

Page 7

CURVES

S

)

*

y

4.0

3.0

ITY

2.0

DEN

1.0

0.0

Exposure:

Process:

Densitometry:

3.0

Characteristic Curves

0.5 sec.

RA-4, 95°F (35°C), 45 sec.

Status A

2.0

LOG EXPOSURE (lux-seconds)

4.0

R

G

B

0.01.0

1.0

Spectral-Sensitivity Curves

Spectral-Dye-Density Curves

2.5

Process:

2.0

1.5

1.0

DIFFUSE SPECTRAL DENSITY

0.5

0.0

400

RA-4

Yellow

500

WAVELENGTH (nm

Magenta

600

Cyan

700

3.0

Yellow-

Forming

2.0

LOG SENSITIVITY

1.0

Effective Exposure:

Process:

0.0

250 300 350 400 450 500 550 600 650 750700

RA-4

Layer

0.5 sec.

Magenta-

Forming

Layer

Cyan-

Forming

Layer

WAVELENGTH (nm)

*Sensitivity = reciprocal of exposure (erg/cm ) required

to produce specified densit

2

NOTICE: The sensitometric curves and data in this publication represent product te sted

under the conditions of exposure and processing specified. They are representative of

production coatings, and therefore do not apply directly to a particular box or roll of

photographic material. They do not represent standards or specifications that must be met

by Eastman Kodak Company. The company reserves the right to change and improve

product characteristics at any time.

KODAK PROFESSIONAL ENDURA Metallic Paper • E-4028 7

Page 8

KODAK PROFESSIONAL ENDURA Metallic Paper

MORE INFORMATION

Kodak has many publications to assist you with information

on Kodak products, equipment, and materials.

Additional information is available on the Kodak website

and through the U.S.A./Canada faxback system.

The following publications are available from dealers who

sell Kodak products, or you can contact Kodak in your

country from more information.

E-30 Storage and Care of KODAK Photographic

Materials—Before and Afte r Processing

E-70 Retouching Prints on KODAK EKTACOLOR

and EKTACHROME Papers

E-71 Retouching Color Negatives

E-176 Post-Processing Treatment of Color Prints—

Effects on Image Stability

J-39 Tray, Drum, and Rotary-Tube Processing with

KODAK EKTACOLOR RA Chemicals

K-4 How Safe is Your Safelight?

Z-130 Using KODAK EKTACOLOR RA Chemicals

For the latest version of tech ni cal support publications for

KODAK PROFESSIONAL Products, visit Kodak on-line at:

http://www.kodak.com/go/professional

If you have questions about KODAK PROFESSIONAL

Products, call Kodak.

In the U.S.A.:

1-800-242-2424, Ext. 19, M onday–Friday

9 a.m.–7 p.m. (Eastern time)

In Canada:

1-800-465-6325, Mon day–Friday

8 a.m.–5 p.m. (Eastern time)

Note: The Kodak materials described in this publication for

use with KODAK PROFESSIONAL ENDURA Metallic

Paper are available from dealers who supply KODAK

PROFESSIONAL Products. You can use other materials,

but you may not obtain similar results.

KODAK PROFESSIONAL ENDURA

Metallic Pap er

KODAK Publication No. E-4028

Kodak, Kodak Professional, Ektachrome , Ekta c o lo r, Endura, Portr a, Supra and Wratten

are trademar ks .

New 2-03

Printed in U.S.A.

Loading...

Loading...