Page 1

User’s Manual A-61408

Part Number 693625

September 1995

KODAK

TM

IMAGELINK

Scanner 500

BUSINESS IMAGING SYSTEMS

Page 2

Declaration of Conformance

The

Kodak Imagelink

Scanner 500S (CAT No. 111 7746) with the following accessories:

• Patch Reader 500

• Bar Code Reader 500

• Controller 500

• Document Printer 500

• Footswitch

Conforms with the following standards and bears a CE mark:

EN 55022 Klasse B/1987, EN 50082-1/1992 and EN 60950/1993 following the

provisions of the applicable directives:

89/336/EEC and amendments

73/23/EEC and amendments

™ Scanner 500D (CAT No. 125 8755) and

Kodak Imagelink

Page 3

Table of Contents

1 Introduction

Scanner Features ..................................................................... 1-1

Scanner Overview .................................................................... 1-2

Control Panel ............................................................................ 1-5

Status Display .................................................................... 1-5

Operation Keys/Indicators .................................................. 1-6

2 Getting Started

Scanner Operation Overview.................................................... 2-1

Power-up Process .................................................................... 2-1

Calibrating the Scanner ............................................................ 2-2

Unsuccessful Calibration.................................................... 2-3

Adjusting the Feed Roller

and Separator Roller................................................................. 2-4

Adjusting the Separator Roller

to Scan Thick Documents .................................................. 2-6

Adjusting the Self-Centering

Feed Shelf ................................................................................ 2-7

Adjusting the Exit Hopper ......................................................... 2-8

3 Operating the Scanner

Scanning Process..................................................................... 3-1

Function Codes......................................................................... 3-2

Using Function Codes ........................................................ 3-2

Function Code Summary.................................................... 3-3

Function Code Listing......................................................... 3-4

Setting Image Levels .............................................................. 3-10

Setting Application Modes ...................................................... 3-10

Preparing Documents ..............................................................3-11

Document Sizes ................................................................3-11

Document Orientation .......................................................3-11

Scanning Documents.............................................................. 3-12

Automatic Feed Method ................................................... 3-12

Manual Feed Method ....................................................... 3-13

4 Error Messages

User Actions.............................................................................. 4-1

System Administrator Actions ................................................... 4-2

Controlled Power-down Sequence..................................... 4-2

Message Listings ...................................................................... 4-3

5 Scanner Maintenance

Cleaning Materials .................................................................... 5-1

Daily (or as required) ................................................................ 5-2

Cleaning the Imaging Guides ............................................. 5-2

Weekly (or as required)............................................................. 5-6

Cleaning the Feed Roller and Separator Roller ................. 5-6

Cleaning the Exterior of the Scanner........................................ 5-8

Vacuuming Inside the Scanner........................................... 5-8

Changing the Lamps............................................................... 5-12

A-61408 September 1995 i

Page 4

6 Troubleshooting

Clearing the Document Path..................................................... 6-2

Document Path................................................................... 6-2

Removing Documents ........................................................ 6-3

Clearing a Jam in Area A.................................................... 6-3

Clearing a Jam in Area B.................................................... 6-4

Clearing a Jam in Area C ................................................... 6-6

Clearing a Jam in Area D ................................................... 6-7

Removing Non-Jammed

Documents................................................................................ 6-8

Appendix A

Kodak Imagelink

Footswitch 500

Function Codes......................................................................... A-1

Appendix B

Kodak Imagelink

Patch Reader 500

Available Patches .....................................................................B-1

Patch Location on Documents..................................................B-2

Printing Patches........................................................................ B-2

Changing the Horizontal Read Position....................................B-3

Cleaning the Patch Reader....................................................... B-4

Function Codes......................................................................... B-4

Performing the Patch Test Function (Future Function) .............B-5

Appendix C

Kodak Imagelink

Bar Code Reader 500

Use of Bar Code Information ....................................................C-1

Bar Code Types ........................................................................C-1

Printing Bar Codes on Documents ...........................................C-2

Function Codes.........................................................................C-3

Performing a Bar Code Test......................................................C-3

Bar Code Test Option 1 – Evaluate ....................................C-5

Fields Displayed ...............................................................C-15

Dimensional Field Values .................................................C-16

Low Bar Code Ratings .....................................................C-17

Bar Code Test Option 2 – Display ....................................C-18

Bar Code Test Option 3 – Read Rate ...............................C-19

Bar Code Specifications ......................................................... C-20

Appendix D

Kodak Imagelink

Document Printer 500

Information Printed ...................................................................D-1

ii A-61408 September 1995

Page 5

1 Introduction

The

Kodak Imagelink

™ Scanner 500 is a high-speed, highresolution rotary scanner designed for medium- to high-volume

digital capture of documents. The Scanner 500 captures printed

characters, handwritten text and graphics from documents of

various sizes and thicknesses in an electronic format for indexing

and database storage.

This manual explains how to setup, operate, maintain and

troubleshoot the Scanner 500.

Scanner Features

This section describes the basic features of the scanner, shows

the basic scanner component locations and lists the Control

Panel component operations.

High Speed Scanning and Image Resolution

Accounting Principles

The accompanying financial

statements include accounts of

the Company and all of its subsidiaries excepts its three finance

sudsidiaries. The finance subsidiaries are accounted for by the

equity method, and their profit

is included in the consolidated

results of operations as a separate item. The consolidated financialposition describes the cost

of the Company’s investments

in its financial subsidiaries in

addition to the degree of profit

retained by them.

Portrait

Accounting Principles

The accompanying financial statements

include accounts of the Company and all

of its subsidiaries excepts its three finance

sudsidiaries. The finance subsidiaries are

accounted for by the equity method, and

their profit is included in the consolidated

results of operations as a separate item.

The consolidated financialposition describes

the cost of the Company’s investments in

its financial subsidiaries in addition to the

degree of profit retained by them.

Landscape

• Scans 85 landscape-style or 60 portrait-style documents

(8.5 x 11 inch or 216 x 279 mm) per minute at 200 dpi.

• Scans 42 landscape-style or 30 portrait-style documents

(8.5 x 11 inch or 216 x 279 mm) per minute at 300 dpi.

Manual or Automatic Feeding

• For manual feeding, documents can be hand-fed one at a time.

• For automatic feeding, documents can be stacked up to

1.5 inches (38 mm) or approximately 350 documents of

20-pound stock.

Front and Rear Side Scanning

• Scans one or two sides of a document in a single pass.

Easy to Operate

• Documents enter and exit the scanner in the same order.

• Document image addresses, current application modes, and

error messages are displayed in the Status Display located on

the Control Panel.

A-61408 September 1995 1-1

Page 6

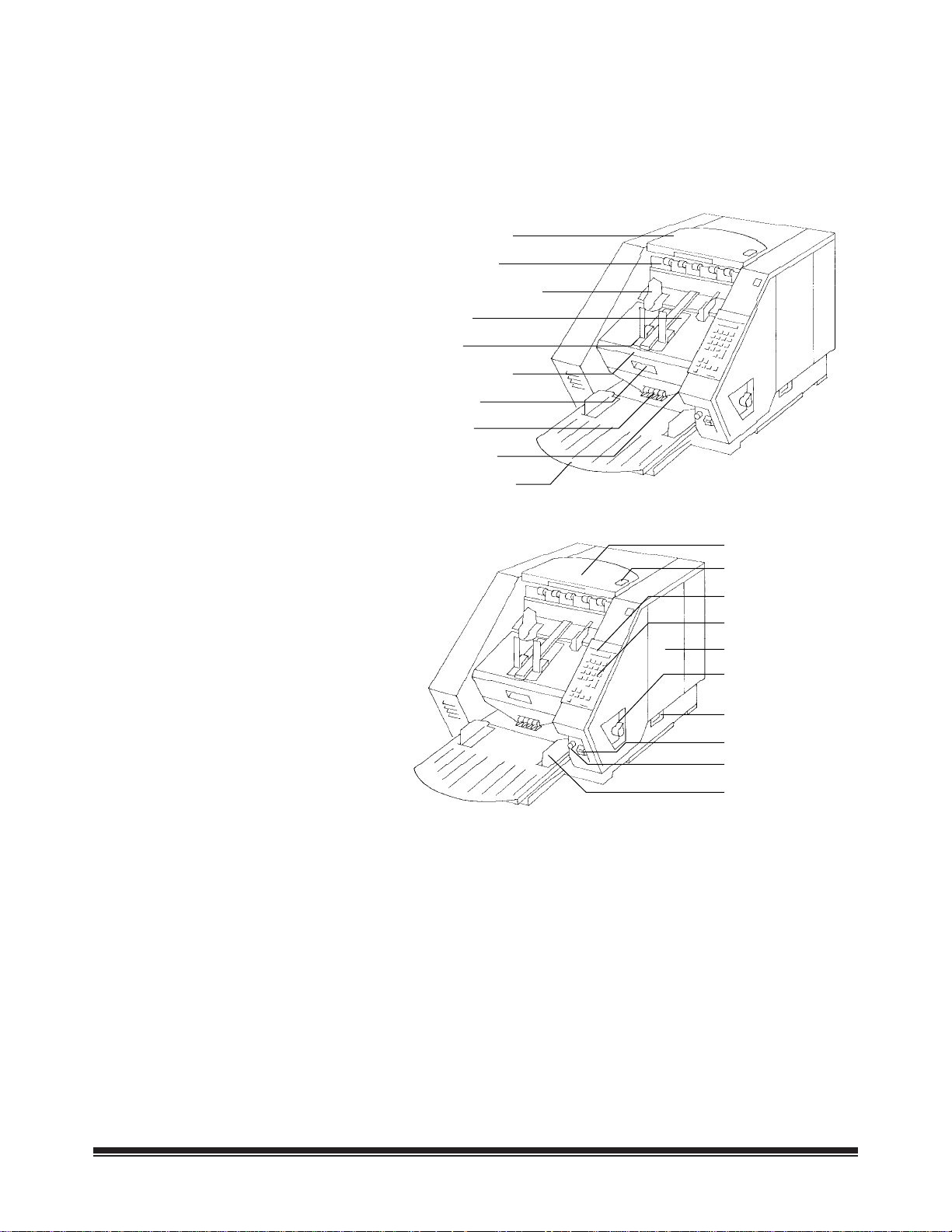

Scanner Overview

The scanner consists of a single tabletop unit with a Feed Shelf

and Exit Hopper. Use the following illustrations and descriptions to

locate and become familiar with the scanner components.

Upper Access Door

Anti-Static Brush

Exit Hopper Side Guides

Exit Hopper

End Stops

Lower Access Door

Door Handle

Feed Roller

Separator Roller

Self-Centering Tray

Door Handle

Door Release Button

Status Display

Control Panel

Side Access Door

Feed Roller Cover

Release Lever

Door Handle

Gap Release Lever

Gap Adjustment Knob

Feed Tray Side Guides

Kodak Imagelink

™ Scanner 500 Front Views

1-2 A-61408 September 1995

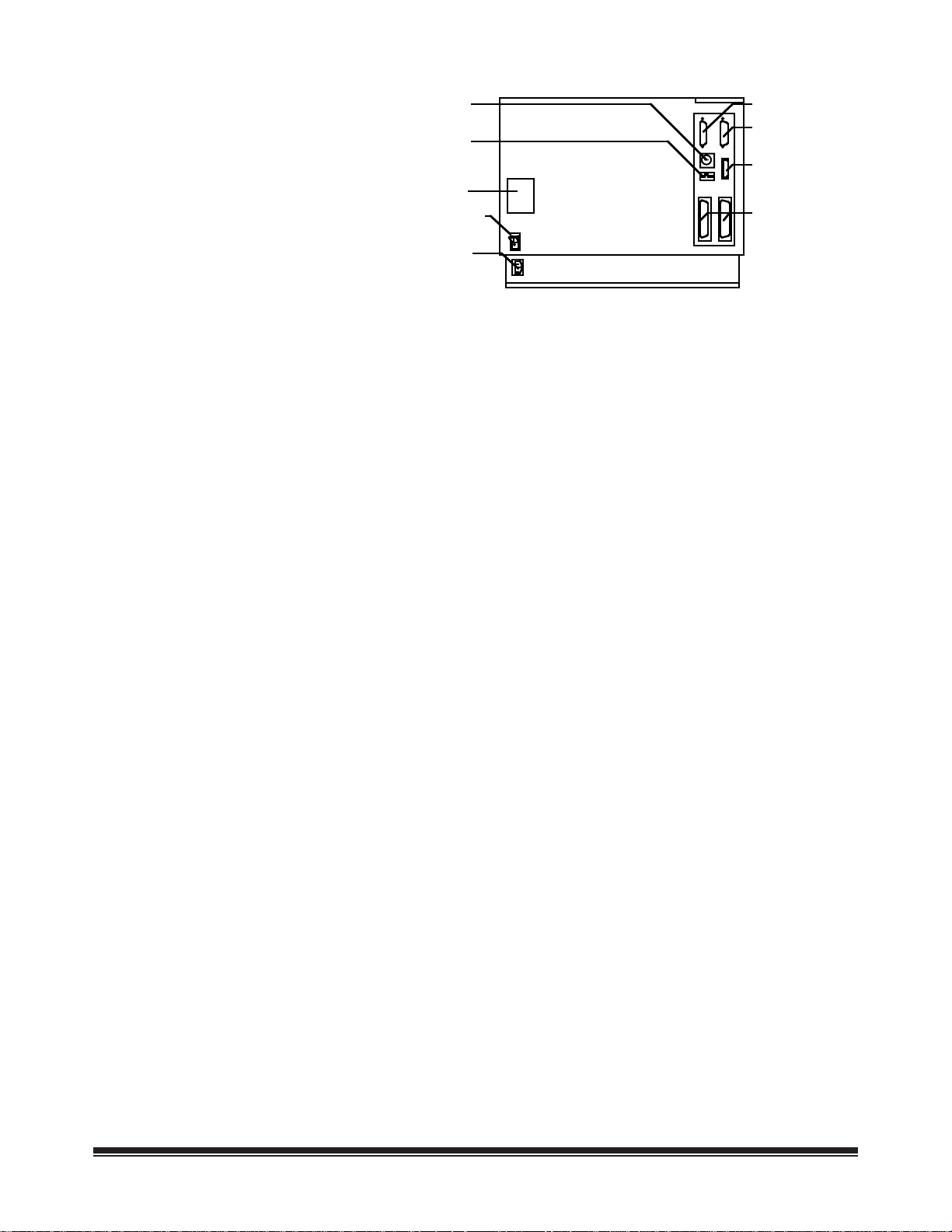

Page 7

Kodak Imagelink

A-61408 September 1995 1-3

™ Scanner 500 Side Views

Page 8

Footswitch

Connector

Dip Switch

Data Plate

Power Switch

(I=On, 0=Off)

Power Cord

Connector

Coin 1/3

Coin 2 (Not for

customer use)

OCS/Video

Connection (Not

for customer use)

SCSI Connectors

Kodak Imagelink

™ Scanner 500 Back View

NOTE: For European units only:

WARNING:

Between the Scanner 500 and the host computer /

the other SCSI device, standard accessory SCSI

cables with ferrite cores (TDK: HF70RH26X29X13)

must be used for radio frequency interference

suppression.

Between the Scanner 500 and the host computer /

the other RS-232C device, standard accessory

RS-232C cable with ferrite core (TDK:

HF70RH12X15X7.3) must be used for radio

frequency interference suppression.

1-4 A-61408 September 1995

Page 9

Control Panel

The Control Panel consists of operation keys, operation indicators

and the Status Display. Use the following illustration and descriptions to locate and become familiar with the Control Panel components.

Status Display

Image Buffer Status

Front Rear

7 8 9 C

4 5 6

1 2 3 +

0 • F

Cal End

Jog

Run Stop

Contrast

Two-line Status Display

Next

Enter

///• // • / •

The Status Display indicates the Image Address, current Application Modes, and Error messages. Use the following illustration and

descriptions to become familiar with the Status Display output.

Scanner Status

(Enabled/Disabled)

Mode Number

(or Name)

Enab l e d M O DE Ø1

ABC/ØØ2 91 .Ø 25.Ø

Fixed Field

Fixed Field

Deliminator

(Backslash)

Field C

Field A

Deliminator

(Period)

Field B

Deliminator

(Period)

A-61408 September 1995 1-5

Page 10

Operation Keys/Indicators

Image Buffer Status

Front Rear

7 8 9 C

4 5 6

1 2 3 +

0 • F

Cal End

Jog

///• // • / •

Contrast

Next

Enter

Run Stop

Image Buffer Status LEDs

Front: Green indicates the buffer is available for scanning; red

indicates the buffer is not available and the feeder is off

(for simplex- and duplex-defined applications modes).

Rear: Same as

only).

Contrast Thumb Wheel

Used to adjust the display contrast between the characters and

the background in the display.

Numeric Keys (0–9)

Used with the Enter key to enter numeric data such as an Image

Address or Function Code.

Decimal Key

Used to insert a field separator in an Image Address. Also used to

designate the front and/or rear document printer vertical start print

position.

Front

(for duplex-defined applications modes

1-6 A-61408 September 1995

Page 11

F (Function) Key

Used with numeric data and the Enter key to enter a function

code.

C (Clear, Cancel) Key

Used to clear error messages from the display. Also used to

cancel a function without changing the preset value(s).

Next

Allows operator to enter the next document Image Address.

Plus (+) Key

Used when inputting a new value for the Image Address. When

pressed, it allows a field to remain unchanged.

Enter

Used to enter numeric data for a Function Code or an Image

Address change.

Back (Backspace)

Used to move the cursor back one space during numeric data

input; the last data input is erased.

Cal

Used to start the calibration function.

End

Used at the end of a batch or job to stop the feeder and transport

system and to alert the host computer that the batch or job has

ended. When pressed, the documents in the transport system will

be scanned and stacked face down in the exit hopper before the

transport is disabled.

Jog

Used to momentarily turn on (jog) the transport system.

Level 3

Used to identify the next document fed into the scanner as a Level 3

document. This key includes an internal LED that illuminates green

when the next document image level to be assigned is Level 3.

Level 2

Used to identify the next document fed into the scanner as a Level 2

document. This key includes an internal LED that illuminates green

when the next document image level to be assigned is Level 2.

A-61408 September 1995 1-7

Page 12

Level 1

Used to identify the next document fed into the scanner as a Level 1

document. This key includes an internal LED that illuminates green

when the next document image level to be assigned is Level 1.

Run

Used to turn on the feeder and transport system.

Stop

Used to stop the feeder and transport system. Documents in the

transport system, when the Stop key is pressed, will be scanned

and placed in the exit hopper before the transport system stops.

Confirmation Tone/Alarm (located under the Control Panel)

The confirmation tone/alarm sounds when one of the following

conditions occur:

• Run key is pressed (one long tone).

• Stop or End key is pressed (many short tones followed by one

long tone).

• Feeder clutch engages/disengages (one short tone).

• Incorrect key input (three short tones).

• Document skew is greater than allowed skew parameter, or

when a document is shorter or longer than specified length

parameters (one short tone).

• Footswitch is pressed (one short tone).

• Bar Code detected (if accessory is enabled and option is setup

to alarm).

• Patch Code detected (if accessory is enabled and option is

setup to alarm).

1-8 A-61408 September 1995

Page 13

2 Getting Started

The

Kodak Imagelink

section describes the power-up process, the calibration function,

and the feeder, feeder shelf and exit hopper adjustments.

Scanner 500 is easy to set up and use. This

Scanner Operation Overview

The following steps are recommended to prepare the scanner for

operation.

1. Turn on the power to the scanner.

2. Calibrate the scanner.

3. Prepare the documents for scanning.

4. Adjust the gap between the feed roller and separator roller,

the height of the feed shelf, the width of the feed shelf side

guides, the height of the exit tray, the width of the exit tray

side guides, and the length of the exit tray end stop.

5. Select the appropriate application mode and image level, or

the count only function.

6. Start the scanner from the host computer.

NOTE: This step is not necessary for the Count Only function.

7. Press Run.

8. Feed the documents into the scanner.

9. Press Stop or End, depending on whether the batch or job

has been completed.

NOTE: After pressing Stop, Run can be pressed again and more

documents can be fed into the scanner. After pressing

End, you must enable the scanner from the host computer before scanning again.

Power-up Process

A-61408 September 1995 2-1

The following steps are required to power up the scanner:

1. Turn the power switch (located on the rear of the scanner) to

the on (I) position.

NOTE: Several initialization messages will appear in the Status

Display. If you cannot see any messages, try adjusting the

contrast.

2. Send the SCAN command from the host computer to the

scanner. The message

Display, as well as the current application mode number and

the next image address. The scanner is ready for operation.

IMPORTANT:

Do not use the Operation keys located on the

Control Panel until the “Warming Up

Completed” message has been displayed in

the Status Display. Entries made before this

message is displayed will not be recognized by

the scanner.

Enabled

will appear in the Status

Page 14

Calibrating the Scanner

You should calibrate the scanner:

• Once a day

• If image quality is poor

• After changing the lamps

NOTE: The Calibration function compensates for the varying

intensity of the scanner lamps which contribute to the

image quality of the scanned document.

Calibrate the scanner with a sheet of paper (calibration target) that

is:

• Blank

• Clean

• Matte (non-glossy finish)

• White or the same color as the background color of the documents you are going to scan

NOTE: When you are using a duplex-defined application mode,

make sure that both front and rear colors of the calibration

target correspond with the front and rear colors of the

documents to be scanned. If you are scanning a variety of

colored documents, use a white sheet of paper to calibrate the scanner.

• Wider than the documents you are going to scan. To scan 8.5 x

11 inch (216 x 279 mm) documents, the calibration paper should

be wider than 8.5 inches (216 mm).

To scan 11 x 17 inch (280 x 432 mm) documents, the calibration

paper should be wider than 11 inches (279 mm) but no wider

than 12 inches (305 mm).

• Between 12 inch (305 mm) and 25.5-inch (648 mm) long.

NOTE: For your convenience, 12" x 12" calibration targets are

supplied with the scanner and are also available from

Parts Services. (Refer to the Appendices in this manual

for ordering details.)

To calibrate the scanner:

1. Be sure the power switch is on, and initialization has completed.

2. Press the Cal key on the Control Panel. A message will

appear in the Status Display prompting you to feed the

calibration target.

3. Insert the calibration target into the feeder.

4. When the scanner calibration is successful, the Status

Display will return to its normal operating display (either

“Disabled” or “Enabled,” depending on the status of the

scanner prior to calibration).

2-2 A-61408 September 1995

Page 15

Unsuccessful Calibration

If calibration fails, perform the following steps:

1. Verify that you are using a clean, matte (non-glossy), blank

sheet of paper to calibrate the scanner.

2. Make sure that length of calibration target is ≥ 12".

3. Make sure no paper is in the document path. Refer to the

section entitled,

4. Clean the imaging guides. Refer to the section entitled,

Cleaning the Imaging Guides

5. Calibrate the scanner again. If this calibration fails, change

the lamps. Refer to the section entitled

Be sure to calibrate the scanner after changing lamps.

If calibration still fails, contact your local service representative.

Clearing the Document Path

.

Changing the Lamps

.

.

A-61408 September 1995 2-3

Page 16

Adjusting the Feed Roller and Separator Roller

The Gap Adjustment Knob on the front panel increases or decreases the space between the feed roller and separator roller.

The gap must be adjusted properly so that documents feed

smoothly without overlapping. When documents of different

thicknesses are fed in a group, adjust the gap using the thinnest

document in the group.

The feed rollers might have to be adjusted to compensate for:

• Very thin documents (onion skin, tracing paper, etc.)

• Very thick documents (card stock, punch cards, cover stock)

• Some coated documents (photographic paper, plastic coated

paper)

If the gap is not adjusted properly:

• More than one document at a time might be drawn into the

transport; not all of the documents will be scanned.

• Documents may be drawn into the transport too quickly; documents may overlap or be spaced too closely (causing an error

display).

• Documents may become skewed during transport; jamming may

occur.

To adjust the feed roller and separator roller gap:

1. Check to see that the power switch is on.

2. Turn the Gap Adjustment Knob clockwise three complete

turns to open the gap between the feed roller and the separator roller.

3. Use Function Code F04 to start the Count Only function.

4. Press Run.

5. Select two documents of similar size, texture, and thickness

to the types of documents you will be scanning.

2-4 A-61408 September 1995

Page 17

6. Place one document on top of the other, hold them firmly by

their trailing edges (the edge opposite the side to be inserted

into the scanner), and insert them approximately 1/8-inch

(3 mm) into the gap.

7. If the documents do not separate, proceed to step 8. If the

documents separate, remove the documents from the feeder

and turn the Gap Adjustment Knob clockwise 1/2 turn and

insert the documents again. Repeat this step until the documents do not separate. Proceed to step 8.

8. Rotate the Gap Adjustment Knob counterclockwise 1/4 turn.

IMPORTANT:

Do not adjust the gap while documents are in

the feeder or transport systems; an inaccurate

adjustment will result.

9. Firmly hold the trailing edges of the documents and reinsert

the leading edges into the gap.

10. If the bottom document is not separating from the top document, remove the documents from the feeder and repeat

steps 7 and 8 until the bottom document separates from the

top document.

11. When you have adjusted the gap so that the bottom document separates from the top document consistently, rotate the

Gap Adjustment Knob counterclockwise another 3/4 to 1 turn

to complete the adjustment.

12. Feed a stack of 50 or 100 documents through the scanner

two times. Make sure the Count Only value on the status

display reflects the total number of documents that were fed

and that the Count Only value shows the same amount each

time the documents are fed into the scanner. This shows that

the gap is adjusted correctly.

13. Use Function Code F04 to turn off the Count Only function.

A-61408 September 1995 2-5

Page 18

Adjusting the Separator Roller to Scan Thick Documents

To scan very thick documents (card or cover stock), use the Gap

Release Lever to increase the gap between the feed roller and

separator roller to allow documents to be fed into the transport.

The Gap Release Lever is located on the front panel of the

scanner to the right of the Gap Adjustment Knob.

1. Press down and hold the Gap Release Lever. This opens the

gap between the feed and separator rollers and allows thick

documents to pass between them.

2. Manually feed the thick documents while holding down the

Gap Release Lever.

2-6 A-61408 September 1995

Page 19

Adjusting the Self-Centering Feed Shelf

Before you begin scanning, adjust the width of the Feed Shelf

Side Guides and the height of the Feed Shelf.

1. Adjust the width of the Feed Shelf Side Guides to hold the

widest document you will be scanning. Leave approximately

1

/16-inch (2 mm) clearance on each side of the largest docu-

ment to allow for proper feeding.

NOTE: Ensure that documents are center-fed so that each

document covers the 2 1/2 inch—required width as

indicated by the label on the feed tray.

2.5"

A3

11 X 17"

A4

8.5 X 11"

A5

2. For manual feeding, the Feed Shelf can be in the 0°, 30°, or

40° position. For automatic feeding, raise the Feed Shelf to

the 30° or 40° position.

40° Position

30° Position

A-61408 September 1995 2-7

Page 20

Adjusting the Exit Hopper

The Exit Hopper must be adjusted properly so documents will

stack correctly.

1. Adjust the width of the Exit Hopper Side Guides to hold the

widest document you will be scanning. Leave 1/4-inch (5 mm)

clearance on each side of the document.

2. Adjust the length of the Exit Hopper End Stop to hold the

longest document you will be scanning.

NOTE: An End Stop Extension is included to accommodate

documents up to 17 inches in length. To attach the

End Stop Extension, fold the spring-loaded Exit

Hopper End Stops down and slide the extension’s

tabs into the slits just above the Exit Hopper End

Stops. To remove the extension, slightly press the

spring-loaded Exit Hopper End Stops and pull the

extension out from the Exit Hopper.

End Stop Extension Tabs Slits

Exit Hopper

End Stops

2-8 A-61408 September 1995

Page 21

3. Adjust the height of the Exit Hopper so the scanned documents naturally fall between the Exit Hopper Side Guides and

the Exit Hopper End Stop. The Exit Hopper has three height

positions: standard, 10° from standard, and 20° from standard.

NOTE: The 20° position is specifically for A4 size, onion skin

documents.

A-61408 September 1995 2-9

Page 22

3 Operating the Scanner

This section describes the scanning process, application modes,

image level settings and function key operation. Function Codes

and their descriptions are also listed.

Scanning Process

To scan documents, follow the steps below:

1. Prepare the scanner for operation (refer to Section 2).

2. Select the application mode.

3. Select the appropriate operating values and conditions

required for the application on the host computer.

4. Press the Run key.

5. Feed the documents into the transport.

The scanner assigns a sequential ID number, document

image level, and image address to the electronic image.

As the document is scanned, the sequential ID number,

document image level, and the image address become part

of the image header file associated with the electronic image;

this information is transferred to the host computer.

NOTE: When a duplex-defined application mode is used, each

document has a front and rear image, each having

independent image headers. These image headers are

stored in the front and rear image buffers, respectively.

The host computer initiates a transfer of the image header

and electronic image information to a magnetic or optical

disk media for fast and easy retrieval of the documents.

When finished scanning, the documents are deposited in

the Exit Hopper face down in the same order in which

they were fed.

6. Press Stop to disable the transport system after the last

document has been scanned or press End to alert the host

computer the batch or job has ended and to disable the

transport system after scanning the last document.

NOTE: If Stop or End is pressed while scanning a stack of

documents, the feeder will stop, but documents in the

transport system will be scanned and deposited face

down in the exit tray before the transport system is

disabled.

A-61408 September 1995 3-1

Page 23

Function Codes

There are a number of functions available for use in the scanner

which can be used to temporarily change scanner operating

conditions and values, and to obtain system and accessory status

and information. These functions are selected using the function

keys on the Control Panel.

Using Function Codes

To use the available functions:

1. Press the F key.

2. Press the numeric key(s) which correspond to the desired

Function Code.

3. Press Enter.

4. If the Function Code is used to enable/disable an option (turn

an option On/Off):

– Press the numeric key 1 to turn the option On (enable) or

press the numeric key 0 to turn the option Off (disable).

– Press Enter.

– or –

If the Function Code requires numeric input:

– Press numeric key(s) to enter the required value.

– Press Enter.

NOTE: The C key can be used to cancel a function before Enter

pressed in step 4.

3-2 A-61408 September 1995

Page 24

Function Code Summary

Listed below is a summary of each function code. Following this

list, is a detailed description of each function code.

Application Modes

Select Application Mode ........................................................... F01

Restore Application Mode.........................................................F02

Index/Image Address

Level 0 ......................................................................................F07

Last Image Address .................................................................. F08

Status

Accessory Status ...................................................................... F05

Transport System Operation Time............................................F17

Date and Time ..........................................................................F23

Counters

Count Only................................................................................F04

Total Document Counter ........................................................... F09

Level 0 Counter ........................................................................ F10

Level 1 Counter ........................................................................ F11

Level 2 Counter ........................................................................ F12

Level 3 Counter ........................................................................ F13

Reset Level Counters ...............................................................F14

Setup

Display Language ..................................................................... F19

Measurement System...............................................................F20

Set Time.................................................................................... F21

Set Date....................................................................................F22

Controls

Length Monitor..........................................................................F70

Omit Length Monitor on Next Document .................................. F71

Skew Monitor ............................................................................ F72

Host

Latch Flag ................................................................................. F73

Momentary Flag........................................................................F74

Patch Reader Accessory

Patch Reader............................................................................F50

Confirmation Tone..................................................................... F53

Omit Patch Read on Next Document........................................ F54

Patch Test .................................................................................F55

Bar Code Reader Accessory

Bar Code Reader......................................................................F60

Confirmation Tone..................................................................... F63

Omit Bar Code Read on Next Document.................................. F64

Bar Code Test ...........................................................................F65

Document Printer Accessories

Front and Rear Document Printers...........................................F40

Front Document Printer ............................................................ F41

Rear Document Printer .............................................................F42

Omit Printing on Next Document ..............................................F44

Print Test................................................................................... F45

Vertical Start Print Position (Front) ...........................................F46

Vertical Start Print Position (Rear) ............................................ F47

Purge Print Heads ....................................................................F48

Footswitch Accessory

Confirmation Tone..................................................................... F75

A-61408 September 1995 3-3

Page 25

Function Code Listing

F01 Select Application Mode

Allows you to select one of the scanner's predefined application

modes. Enter a value from 1–18.

F02 Restore Application Mode

Allows you to restore the current application mode to its original

user-defined preprogrammed status.

F04 Count Only On/Off

Allows you to count the number of documents entering the scanner without scanning the documents. The Count Only counter will

be reset to 0 when this function is selected and displayed in the

Status Display. All accessories are inhibited when the Count Only

function is selected.

F05 Accessory Status

Displays the current statuses of the system’s optional accessories

(except Footswitch), software functions (Skew Monitor function

and Length Monitor function), and confirmation tone selections.

The status of the first accessory/function is indicated in the Status

Display; press Enter to display, one at a time, the status of the

next and subsequent accessories and functions.

“On Via Fnc Code” and “Off Via Fnc Code’ indicate the optional

accessory, software function, or confirmation tone has been

enabled or disabled with the appropriate function code. “Not

Machine Set” indicates the optional accessory has not been

software enabled for the scanner.

F07 Level 0

Allows you to define the next document scanned a Level 0 document.

F08 Last Image Address

Allows you to display the image address of the last document

scanned.

F09 Total Document Counter

Allows you to display the total number of documents that have

entered the feeder as Level 3, Level 2, Level 1 and Level 0

documents. By entering 0, or any valid number, the Total Document Counter can be reset or preset. The Document Counter also

resets to 0 when 999,999,999 is reached. Reset and preset will

not affect the individual level counters.

3-4 A-61408 September 1995

Page 26

F10 Level 0 Counter

Allows you to display the total number of documents that have

entered the feeder as Level 0 documents. The counter is automatically incremented whenever Level 0 is requested and

scanned. By entering 0, or any valid number, the Level 0 Counter

can be reset or preset. The counter also resets to 0 when

999,999,999 is reached, or when the Reset Level Counters

function (Function Code 14) is performed. Reset and preset will

not affect the Total Document Counter.

F11 Level 1 Counter

Allows you to display the total number of documents that have

entered the feeder as Level 1 documents. The counter is automatically incremented whenever Level 1 is requested and

scanned. By entering 0, or any valid number, the Level 1 Counter

can be reset or preset. The counter also resets to 0 when

999,999,999 is reached, or when the Reset Level Counters

function (Function Code 14) is performed. Reset and preset will

not affect the Total Document Counter.

F12 Level 2 Counter

Allows you to display the total number of documents that have

entered the feeder as Level 2 documents. The counter is automatically incremented whenever Level 2 is requested and

scanned. By entering 0, or any valid number, the Level 2 Counter

can be reset or preset. The counter also resets to 0 when

999,999,999 is reached, or when the Reset Level Counters

function (Function Code 14) is performed. Reset and preset will

not affect the Total Document Counter.

F13 Level 3 Counter

Allows you to display the total number of documents that have

entered the feeder as Level 3 documents. The counter is automatically incremented whenever Level 3 is requested and

scanned. By entering 0, or any valid number, the Level 3 Counter

can be reset or preset. The counter also resets to 0 when

999,999,999 is reached, or when the Reset Level Counters

function (Function Code 14) is performed. Reset and preset will

not affect the Total Document Counter.

F14 Reset Level Counters

Allows you to reset the four level counters (Level Counters 0, 1,

2, 3) to 0. All previous level counter values will be lost and cannot

be restored. The Reset Level Counters function will not affect the

Total Document Counter.

A-61408 September 1995 3-5

Page 27

F17 Transport System Operation Time

Allows you to display elapsed time of operation of the transport

system.

NOTE: This elapsed time is recorded in the scanner’s software

and will be reset if a ROM replacement is performed.

Therefore, this software time display can vary from the

elapsed time indicated in the transport system operation

meter located inside the side access door.

F19 Display Language

Allows you to choose your preferred language. Enter 1 for Japanese, 0 for English.

F20 Measurement System

Allows you to choose the measurement system to be used. Enter

1 for inches, 0 for millimeters.

F21 Set Time

Allows you to set the time on the Status Display. The format is

HH:MM. HH equals the hour using the 24-hour clock. MM equals

the minutes, valid entries are from 00 to 59.

NOTE: The HH:MM format is the default setting. However, one of

various display formats can be selected at installation or

upon request.

F22 Set Date

Allows you to set the date on the Status Display. The format is

YYYY/MM/DD. YYYY equals the four-digit year. MM equals the

month; valid entries are from 01 to 12. DD equals the day; valid

entries are from 01 to 31.

NOTE: The YYYY/MM/DD format is the default setting. However,

one of various display formats can be selected at installation or upon request.

F23 Display Date ant Time

Allows you to view the time and date in the Status Display in the

selected display formats.

3-6 A-61408 September 1995

Page 28

The following function codes can be used when the optional

Document Printer Accessory is installed.

F40 Front and Rear Document Printers On/Off*

Allows you to enable/disable the Front and Rear Document

Printers.

Enter 1 to enable or 0 to disable.

F41 Front Document Printer On/Off*

Allows you to enable/disable the Front Document.

Enter 1 to enable or 0 to disable.

F42 Rear Document Printer On/Off*

Allows you to enable/disable the Rear Document Printer.

Enter 1 to enable or 0 to disable.

F44 Omit Printing on Next Document On/Off*

Allows you to specify that no information be printed on the next

document scanned. Normal printing resumes with subsequent

documents. Enter 1 to enable or 0 to disable.

F45 Print Test*

Allows you to test for print position, print quality and print message

contents. The Document Printer(s) can be tested on any number

of documents until you press Stop.

F46 Front Document Printer Vertical Start Print Position*

Allows you to specify how far printed information will appear

vertically from the leading edge of the documents. Use the numeric keys to input values between 0.125 and 20 inches (3 to 508

mm) in increments of 0.125 inches (3 mm).

NOTE: The value will correspond to the selected measurement

system. The value should not exceed the document

length. The horizontal start print position is changed

manually.

F47 Rear Document Printer Vertical Start Print Position*

Allows you to specify how far printed information will appear

vertically from the leading edge of the documents. Use the numeric keys to input values between 0.125 and 20 inches (3 to 508

mm) in increments of 0.125 inches (3 mm).

NOTE: The value will correspond to the selected measurement

system. The value should not exceed the document

length. The horizontal start print position is changed

manually.

F48 Purge Print Heads*

Allows you to purge and clean slightly hardened ink from each

Document Printer’s print head(s). Feed a single blank document

after the Feeder Clutch engages.

* The Document Printer is an optional accessory.

A-61408 September 1995 3-7

Page 29

F50 Patch Reader On/Off*

Allows you to enable/disable the Patch Reader. Enter 1 to enable

or 0 to disable.

F53 Patch Reader Confirmation Tone On/Off*

Allows you to enable/disable the confirmation tone that informs

you if the Patch Reader has successfully read a patched document. Enter 1 to enable or 0 to disable.

F54 Omit Patch Reading on Next Document On/Off*

Allows you to inhibit patch reading on the next document scanned.

Normal patch reading resumes with subsequent documents. Enter

1 to enable or 0 to disable.

F55 Patch Test*

Allows you to test for patch position and patch quality. The test

result will indicate: T-Patch, 2-Patch, 3-Patch, or Patch Not Read.

F60 Bar Code Reader On/Off†

Allows you to enable/disable the Bar Code Reader. Enter 1 to

enable or 0 to disable.

F63 Bar Code Reader Confirmation Tone On/Off†

Allows you to enable/disable the confirmation tone that informs

you if the Bar Code Reader has successfully read a bar code

document. Enter 1 to enable or 0 to disable.

F64 Omit Bar Code Reading on Next Document On/Off†

Allows you to inhibit bar code reading on the next document

scanned. Normal bar code reading resumes with subsequent

documents.

F65 Bar Code Test†

Allows you to test for bar code position, bar code quality and bar

code read rate.

F70 Length Monitor On/Off

Allows you to enable/disable the length monitor which monitors

the length of the document(s) scanned against predefined minimum/maximum allowable lengths. Messages and/or confirmation

tones indicate if the document is shorter/longer than the predefined minimum/maximum.

* The Patch Reader is an accessory.

† The Bar Code Reader is an accessory.

3-8 A-61408 September 1995

Page 30

F71 Omit Length Monitor on Next Document On/Off

Allows you to inhibit the length monitor on the next document

scanned. Normal length monitoring resumes with subsequent

documents. Enter 1 to enable or 0 to disable.

F72 Skew Monitor On/Off

Allows you to enable/disable the Skew Monitor which monitors for

an unacceptable skew. The degree of an unacceptable skew is

preprogrammed at installation. It can be either 5° or 10°.

Messages and/or confirmation tones indicate if the document is

shorter/longer than the predefined minimum/maximum.

F73 Latch Flag On/Off

Allows you to enable/disable the Latch Flag function. When

enabled, the Latch Flag function activates the Latch Flag bit in the

image header of documents entering the feeder to indicate the

scanned documents are of special interest. Enter 1 to enable or 0

to disable.

F74 Momentary Flag On/Off

Allows you to enable/disable the Momentary Flag function. When

enabled, the Momentary Flag function activates the Momentary

Flag bit in the image header of documents entering the feeder to

indicate the scanned documents are of special interest. Enter 1 to

enable or 0 to disable.

NOTE: The Momentary Flag will automatically disable after a

single document has been fed.

F75 Footswitch Confirmation Tone On/Off

‡

Allows you to enable/disable the Confirmation Tone which is

issued whenever the footswitch is pressed and/or released. Enter

1 to enable or 0 to disable.

‡

The Footswitch is an accessory.

A-61408 September 1995 3-9

Page 31

Setting Image Levels

Image levels are document management tools used to identify

specific types of documents or sets of documents for later indexing and retrieval. The image level assigned to each document is

inserted into the image header associated with the document

image. This information is later used to index and retrieve the

scanned image.

There are four document image levels: 3, 2, 1, and 0. There are

three ways to set levels 3, 2, and 1, and two ways to set level 0:

• The operator can press a document Image Level key on the

Control Panel to assign level 3, level 2, or level 1.

• The operator can use the F key and function code F07 to assign

level 0.

• The operator can use the optional

Accessory to assign levels 3, 2, 1, or 0.

• The operator can use the optional Patch Reader to set levels 3,

2, or 1.

Kodak Imagelink

Footswitch

Setting Application Modes

Eighteen application modes are available for use with the scanner.

These application modes can be defined by the user and selected

when a specific combination of functions, scanning conditions and

values are required.

These conditions and values include Display Language, Measurement Format, Index Format, Image Address Rules, Level Rules,

Accessory Status (enabled/disabled), etc. This data is saved in

the scanner until changed by a Kodak representative.

All eighteen application modes contain default values for general

applications, but at installation or upon request, a Kodak representative can be called to program the scanner for specific

applications. To access a specific application mode, utilize the

Select Application Mode function and enter the corresponding

application mode number (1-18) via the numeric keys and press

Enter.

NOTE: In addition to these user-defined conditions and values,

the image processing parameters from the host

computer's image processing parameter list, such as

cropping, noise filter, compression, resolution, and

simplex/duplex are also included in the application modes.

The scanner contains default image processing parameters for general applications. For specific applications the

image processing parameters must be independently set

at the host computer for each of the application modes.

3-10 A-61408 September 1995

Page 32

Preparing Documents

To prepare documents for scanning:

1. Remove any staples, rubber bands, loose mending tape, or

paper clips from the documents.

2. Straighten any badly wrinkled edges.

3. Tape torn documents.

Document Sizes

Document Orientation

The following size documents can be scanned using the

Imagelink

Scanner 500:

Kodak

• Length: 2.5 to 17 inches (64 to 432 mm)

• Width: 2.5 to 12 inches (64 to 305 mm)

• Minimum document thickness:

Onion Skin (0.0015 inch/0.04 mm)

• Maximum document thickness:

– Index Card (0.014 inch/0.36 mm)

– Index Card (0.040 inch/1.00 mm) (with gap release lever held

down)

Before you start scanning, position all documents the way you

would like them to be displayed on the host computer. You should

feed the documents so that the text or graphic appears to be

facing in the same direction.

The accompanying financial statements

include accounts of the Company and all

of its subsidiaries excepts its three finance

sudsidiaries. The finance subsidiaries are

accounted for by the equity method, and

their profit is included in the consolidated

results of operations as a separate item.

The consolidated financialposition describes

the cost of the Company’s investments in

its financial subsidiaries in addition to the

in its financial subsidiaries in

addition to the degree of profit

retained by them.

degree of profit retained by them.

cialposition describes the cost

of the Company’s investments

Accounting Principles

The accompanying financial

statements include accounts of

the Company and all of its sub-

sidiaries excepts its three finance

sudsidiaries. The finance subsid-

iaries are accounted for by the

equity method, and their profit

is included in the consolidated

results of operations as a sepa-

rate item. The consolidated finan-

Accounting Principles

Accounting Principles

The accompanying financial statements

include accounts of the Company and all

of its subsidiaries excepts its three finance

sudsidiaries. The finance subsidiaries are

accounted for by the equity method, and

their profit is included in the consolidated

results of operations as a separate item.

The consolidated financialposition describes

the cost of the Company’s investments in

its financial subsidiaries in addition to the

degree of profit retained by them.

Accounting Principles

The accompanying financial

statements include accounts of

the Company and all of its subsidiaries excepts its three finance

sudsidiaries. The finance subsidiaries are accounted for by the

equity method, and their profit

is included in the consolidated

results of operations as a separate item. The consolidated financialposition describes the cost

of the Company’s investments

in its financial subsidiaries in

addition to the degree of profit

retained by them.

or

NOTE: The Document Feed Shelf can accommodate a single

document or a batch of documents up to 1.5 inches

(38 mm) thick.

A-61408 September 1995 3-11

Page 33

Scanning Documents

After you have prepared the scanner and your documents, you

are ready to begin scanning.

Automatic Feed Method

1. Make sure you select the correct scanning operation conditions and values.

2. Place the feed shelf in the up position.

3. Pick up a stack of documents up to 1.5 inches (38 mm) thick.

Hold the stack with the front sides facing up and the top of the

documents facing toward the scanner. Tap the bottom edge of

the stack against a flat surface so the documents are in an

even bundle.

4. Fan the stack of documents so the leading edge of the top

document sticks out the farthest.

5. Make sure the power switch is on, then press Run.

6. Place the stack of documents into the feeder so the leading

edge of the first document meets the feed roller. Each document will be drawn into the feeder, scanned, and deposited

face down in the exit hopper in the same order it entered the

feeder.

NOTE: Ensure the documents are center-fed so each document

covers the 2.5-inch required width as indicated by the

label on the feed tray.

2.5"

A3

11 X 17"

A4

8.5 X 11"

A5

Feed T ra y Label

NOTE: The scanner is designed so each document automatically

gravitates into the feeder. Depending on the friction

between the documents, the automatic flow of the documents into the feeder may be inhibited. If the document

flow is inhibited, gently push the top document towards

the feeder to re-establish automatic feeding.

3-12 A-61408 September 1995

Page 34

7. As you scan documents:

– Set the image level, as required.

– Periodically remove documents from the exit hopper.

NOTE: When the image buffer is full, the feeder will turn off, the

image buffer status LED illumination color will change to

red, and a short pause in scanning may occur as images

are being transferred to the host computer. The feeder will

turn on, the image buffer status LED illumination color will

change back to green, and scanning will resume automatically.

8. Press Stop to disable the transport system after the last

document has been scanned or press End to alert the host

computer the batch or job has ended and to disable the

transport system after the last document has been scanned.

NOTE: If the Stop or End key is pressed while scanning a stack

of documents, the feeder will disable, but documents in

the transport system will be scanned and deposited face

down in the exit tray before the transport system is

disabled.

Manual Feed Method

1. Make sure you select the correct scanning operation conditions and values.

2. Place the feed shelf in the up or down position—whatever is

most convenient.

3. Insert the documents one at a time.

NOTE: Ensure the documents are center-fed so each document

covers the 2.5-inch required width as indicated by the

label on the feed tray.

2.5"

A3

11 X 17"

A4

8.5 X 11"

A5

Feed T ra y Label

A-61408 September 1995 3-13

Page 35

4 Error Messages

User Actions

Error messages are classified into types of errors depending on

the method of recovery from the error. There are three types of

errors: Operator Information and Warnings, Operator Recoverable

Errors or Service Errors.

NOTE: When a + (Plus) mark is displayed between the error code

number and the error message, it indicates that more than

one error message has been generated. Press the +

(Plus) key to view the accompanying error message(s).

Error Numbers 100 through 199

Operator Information And Warnings errors.

When you see an Operator Information and Warning error, you

may be required to verify, or reenter data.

If you cannot solve the problem, call the system administrator. If

the error message persists, the system administrator will call

service personnel.

Error Numbers 200 through 299

Operator Recoverable Errors

When you see a Operator Recoverable Error, perform the action

specified by the error message and error code listing.

If you cannot solve the problem, call the system administrator. If

the error message persists, the system administrator will call

service personnel.

Error Numbers 600 through 999

Service Errors

When you see a Service Error, contact the system administrator

immediately. Initial error recovery may be performed by the

system administrator. If the error message persists, the system

administrator will call service personnel.

NOTE: When an error message is displayed, various keys on the

Control Panel may be temporarily invalid for safety

reasons. However, the Jog key is available at most times

so the documents in the transport system can be removed.

A-61408 September 1995 4-1

Page 36

System Administrator Actions

The system administrator is required to assist the operator when

the E100–299 series error messages and error code listings

indicate that host control is required.

Also, the system administrator is required to perform the actions

suggested by the accompanying error message(s) when the

E600-999 error messages are displayed. Remember to utilize the

+ (Plus) key to display the accompanying error message(s).

Listed below are the accompanying error messages that may be

displayed with the E600-999 error messages:

• When the accompanying error message reads “E234 Press

JOG To Remove Docs,” press the Jog key until all documents in

the transport system are deposited in the exit hopper. Then

perform the controlled power-down sequence.

• When the accompanying error message reads “E235 Controlled

Power-Down Reqrd,” perform the controlled power-down as

described in the section entitled,

quence

• When the accompanying error message reads “E298 Calibration Required,” perform the controlled power-down sequence.

Then press the Cal key to perform the calibration process.

.

Controlled Power-down Se-

Controlled Power-down Sequence

Furthermore, the system administrator is required to contact a

service representative when:

• the initial error recovery has been performed but the error

message persists

• the initial error recovery has no effect on the error message

• an indicated accessory must be replaced

Before performing the controlled power-down sequence, determine whether or not the error can be addressed from the host.

If the error can be addressed from the host, perform the required

host recovery procedures. If the error cannot be addressed from

the host, or if the scanner’s error message is not cleared when the

host recovery procedures are performed, continue with the

following power-down sequence:

1. Verify all images in the image buffer(s) are transferred to the

host.

2. If necessary, prepare the host and corresponding system

components for a scanner power-down.

3. Turn the scanner power off for at least five seconds, then turn

the power back on again.

4. If necessary, determine the last image transferred to the host,

reset the Image Address and Image Level to the correct

values, and re-scan all documents whose images have not

been transferred to the host. If required, calibrate before rescanning.

5. If the error message persists, call service.

4-2 A-61408 September 1995

Page 37

Message Listings

Error Code Description Action

E102 Press STOP

And Try Again

E103 Select

Valid Mode (1-18)

E104 Function

Not Available

E106 Doc Length

Monitor Warning

E107 Doc Skew

Monitor Warning

E112 Invalid

Patch Level

E113 Incorrect

Image Address

E114 Check

Current IA/Level

E116 Accessory

Not Mode Enabled

When error codes are displayed, in most cases, you will need to

press the C key to clear the message. Then proceed with any

additional procedures as indicated in the Action column of the

following chart. If the error persists, contact your system

administrator.

Tried to use a function code that

is not valid while the transport

system is running.

Tried to use an invalid application

mode.

Tried to use an invalid function

code.

Tried to scan a document which is

longer/shorter than the

maximum/minimum length which

has been set for the current

application mode.

Tried to scan a document which is

skewed greater than the

maximum skew angle which has

been set for the current

application mode and less than 30

degrees.

Tried to feed a patch document

that is invalid for the current

application mode. The patch

document is ignored and the

previous image level and image

address remain unchanged.

Tried to use an invalid image

address for the current application

mode. The image address was

not completely input prior to

pressing Enter.

The operator pressed the Level

key and then fed a T-Patch

document. The Level key input is

ignored and the level defined by

the T-Patch of the current

application mode is assigned to

the next document.

Tried to use an accessory that

has not been enabled.

After pressing C, press Stop to stop

the transport, then input the desired

code.

After pressing C, enter function code

F01 and a valid application mode

number (1-18) to select another mode.

After pressing C, press F and input a

valid function code. If this message is

displayed during scanning, the

message can be ignored. It will be

cleared at the end of scanning when

the Stop or End key is pressed.

After pressing C, check the document

length. If longer than actual, change

settings otherwise rescan.

Note the document that was skewed

and press C to clear the message.

Check self-centering feed tray.

After pressing C, feed correct patch.

After pressing C, press Next to input

the correct image address.

After pressing C, verify the current

image level and image address.

After pressing C, press F and enter a

different function code or select a

application mode that is enabled. If the

selected accessory is desired, service

must be called to change the mode

configuration.

A-61408 September 1995 4-3

Page 38

Error Code Description Action

E118 Check

Correct IA/Level

E119 Check

Correct IA/Level

E127 Wait

Image Buffr Full

E128 Doc Interval

Too Narrow

E132 Printer

Not Machine Enabled

E133 Bar Code

Not Machine Enabled

E134 Patch

Not Machine Enabled

E135 Printer

Hardware Error

The operator pressed the Next

key, input a new image address

and fed a patch document that

conflicts with the image level of

the Next key input. The image

address defined by the Next key

will be assigned to the next

document and the patch level will

be ignored.

A T-Patch document has been fed

and then the Next key was

pressed to input a new image

address. The image address of

the T-Patch is ignored and the

Next key input is assigned to the

next document.

The image buffer has become too

full. The feeder stops feeding

documents but the documents in

the transport system continue to

be scanned. When the image

buffer empties, the message will

clear and scanning automatically

continues.

The document interval has

become too narrow. If not

corrected may lead to false

document jams or incorrect

scanning and image addressing.

Tried to use a Document Printer

function code (F40-49) but the

Document Printer accessory is

not enabled.

Tried to use a Bar Code Reader

function code (F60-65) but the

Bar Code Reader accessory is

not enabled.

Tried to use a Patch Reader

function code (F50-55) but the

Patch Reader accessory is not

enabled.

Tried to use a Document Printer

function code (40-49) after the

following two events occurred:

• The message E207 Printer

Hardware Error was displayed

at power on and

• The C key was used to clear

the message (but the error

status was not cleared.

After pressing C, verify the current

image level and image address.

After pressing C, verify the current

image level and image address.

Wait for the error message to clear

and the feeder to automatically

continue scanning. If the feeder does

not automatically start, it is possible

the host is not reading the images

from the image buffer. If this happens,

contact your system administrator.

Adjust the gap adjustment knob to

widen the document interval. See

Adjusting the Feed Roller and

Separator Roller

manual. Press C to clear the

message.

Press C to clear the error condition. If

the printer accessory is desired,

service must be called to change the

mode configuration.

Press C to clear the error condition. If

the bar code reader accessory is

desired, service must be called to

change the mode configuration.

Press C to clear the error condition. If

the patch code accessory is desired,

service must be called to change the

mode configuration.

Press C to clear the error condition.

section in this

4-4 A-61408 September 1995

Page 39

Error Code Description Action

E136 Bar Code

Hardware Error

E137 Footswitch

Not Machine Set

E138 Accessory

Off Via Fnc Code

E139 ConfirmTone

Not Mach Enabled

E150 Buffer Data

Transfer To Host

E151 Buffer Data

Transfer To Host

E152 Scanning

Try Again

E204 Re-Scan

Skew Monitor Err

E205 IA Overflow

Press Next Key

E207 Printer

Hardware Error

E208 Bar Code

Hardware Error

Tried to use a Bar Code Reader

function code (60-65) after the

following two events occurred:

• The message E208 Bar Code

Hardware Error or E640-645

Bar Code Health Check Err was

displayed at power on, and

• The C key was used to clear

the message (but the error

status was not cleared.

Tried to use footswitch function

code but the footswitch accessory

is not enabled.

Tried to use an accessory that is

enabled for the current application

mode during mode configuration,

but the accessory is presently

disabled via a function code.

Tried to use a Confirmation Tone

function code (F53, F63, F75) but

Confirmation Tone is not enabled.

Tried to change function codes

via function code F02. This

function cannot be performed

because scanned images still

remain in the image buffer.

Tried to use the bar code test via

function code F65. This function

cannot be performed because

scanned images still remain in the

image buffer.

Tried to enter a function code

while scanning.

Tried to scan a document that is

skewed greater than the

maximum skew angle which has

been set for the current

application mode and less than 30

degrees.

One of the three image address

fields has been overflowed. For

example, if the level 1 field is set

to two digits, up to 99 level 1

documents may be scanned, the

100th document will cause an

overflow.

At power on, a hardware error has

been detected in the Document

Printer. The E236 Turn Off

Accessory message is also

displayed.

At power on, a hardware error has

been detected in the Bar Code

Reader. The E236 Turn Off

Accessory message is also

displayed.

Press C to clear the error condition.

Press C to clear the error condition. If

the footswitch accessory is desired,

service must be called to change the

mode configuration.

After pressing C, press F and enter

the function code that enables the

desired accessory.

Press C to clear error condition. If

Confirmation Tone is required, contact

your system administrator.

After pressing C enter F02 again. If all

images have not been read by the

host, the error message will be

displayed again. If this cycle

continues, contact your system

administrator.

After pressing C enter F65 again. If all

images have not been read by the

host, the error message will be

displayed again. If this cycle

continues, contact your system

administrator.

Press the STOP/END key to stop

scanning.

Note the document that was skewed

and press C to clear the message.

After pressing C, press the Next key

or one of the three Level keys to

change the image address or image

level so the corresponding field does

not overflow.

Press C to clear the error condition

and contact System Administrator to

disable printer.

Press C to clear the error condition

and contact System Administrator to

disable printer.

A-61408 September 1995 4-5

Page 40

Error Code Description Action

E209 Bar Code

DataOverflow

E214 Re-Scan

Length Monitr Er

E216 Printer

Hardware Error

E217 Bar Code

Hardware Error

E222 Jam–Feed/

Horz Trans Area

E223 Jam–Vert

Trans/Exit Area

E224 Jam Or Dble

Feed–Check Trans

E225 Jam–Check

Entire Transport

E230 Open Door

Entire Transport

E232 Close All

Access Doors

E234 Press JOG,

To Remove Docs

E235 Controlled

Power-Down Reqrd

E236 Turn Off

Accessory

The Bar Code Reader detected

more than the maximum 80

characters. The documents

deposited in the exit hopper must

be rescanned after the error has

been corrected.

Tried to scan a document which is

longer/shorter than maximum/

minimum length defined by the

current application mode.

At power on, a hardware error has

been detected in the Document

Printer. The E236 Turn Off

Accessory message is also

displayed. The Document Printer

was not disabled via function

code F40-42.

At power on, a hardware error has

been detected in the Bar Code

Reader. The E236 Turn Off

Accessory message is also

displayed. The Bar Code Reader

was not disabled via function

code F60.

A document jam has been

detected in the feeder or

horizontal transport area.

A document jam has been

detected in the vertical transport

or exit area.

A document jam or double-feed

has been detected.

A document jam has been

detected.

This message is displayed along

with other document jam

messages.

One or more access doors are

open.

When pressing the Run key, a

document has been detected

under a document sensor.

This message is displayed

accompanying a more detailed

error message.

Disable the accessory that has

been selected via the

corresponding function code so

the current application mode can

be used.

After pressing C, verify the bar code

has more than 80 characters. Disable

the Bar Code Reader (F64) and

rescan the document.

Rescan after checking length.

Disable the Document Printer via

function code F40-42 or select an

application mode that does not use the

Document Printer.

Disable the Bar Code Reader via

function code F60 or select an

application mode that does not use the

Bar Code Reader.

Clear the jam by following the

procedures outlined in Section 6,

Troubleshooting

Clear the jam by following the

procedures outlined in Section 6,

Troubleshooting

Clear the jam by following the

procedures outlined in Section 6,

Troubleshooting

Clear the jam by following the

procedures outlined in Section 6,

Troubleshooting

Open the access door and transport

plate as suggested by the

accompanying messages and proceed

with clearing the jam by following the

procedures outlined in Section 6,

Troubleshooting

Close the door(s) that are open.

Press the Jog key to remove all

documents in the transport system.

Press Run to start the transport

system and rescan any documents

which have not been scanned.

Perform a controlled power-down

sequence.

After pressing C, press the F key and

the corresponding function code to

disable to accessory.

in this manual.

in this manual.

in this manual.

in this manual.

in this manual.

4-6 A-61408 September 1995

Page 41

Error Code Description Action

E241 Enter Cor-

rect IA, Re-Scan

E244 Enter Cor-

rect IA, Re-Scan

E245 Enter Cor-

rect IA, Re-Scan

E246 Enter Cor-

rect IA, Re-Scan

E250 Frnt Illu-

mination Failure

E251 Rear Illu-

mination Failure

E261 Fr Cal Illu-

mination Failure

E262 Rr Cal Illu-

mination Failure

E263 Calibration

Target Too Short

The patch document fed conflicts

with the level key pressed.

A T-patch document was fed then

followed by a 2-patch or 3-patch

document which conflicted with

the level of the T-Patch.

Two T-patch documents were fed

one right after the other.

The T-Patch document fed

conflicts with the level of the

image address entered.

A front lamp failure was detected

while the front lamp was

illuminated.

A rear lamp failure was detected

while the rear lamp was

illuminated.

A front lamp failure was detected

during the calibration process.

A rear lamp failure was detected

during the calibration process.

Tried to use a Calibration Target

shorter than the specified 12

inches.

After pressing C, verify the current

image level and image address and if

necessary alter the image level or

image address via the Level keys,

Next key or press Run and rescan the

patch document.

After pressing C, verify the current

image level and image address and if

necessary alter the image level or

image address via the Level keys,

Next key or press Run and rescan the

T-Patch, 2-patch or 3-patch document.

After pressing C, verify the current

image level and image address and if

necessary alter the image level or

image address via the Level keys or

Next key . Do not scan another TPatch document.

After pressing C, verify the current

image level and image address and if

necessary alter the image level or

image address via the Level keys,

Next key . Do not scan another TPatch.

Press Cal to initiate the calibration

process. If error persists, verify the

front optical path is free of

obstructions, clean the imaging

guides, and replace both the front and

rear (duplex scanners only) lamps.

Press Cal to initiate the calibration

process. If error persists, verify the

front optical path is free of

obstructions, clean the imaging

guides, and replace both the front and

rear (duplex scanners only) lamps.

Press the Jog key to remove the

Calibration Target from the transport

system. Press Cal and try the

calibration process again. If error

persists, verify the front optical path is

free of obstructions, clean the imaging

guides, and replace both the front and

rear (duplex scanners only) lamps.

Press the Jog key to remove the

Calibration Target from the transport

system. Press Cal and try the

calibration process again. If error

persists, verify the front optical path is

free of obstructions, clean the imaging